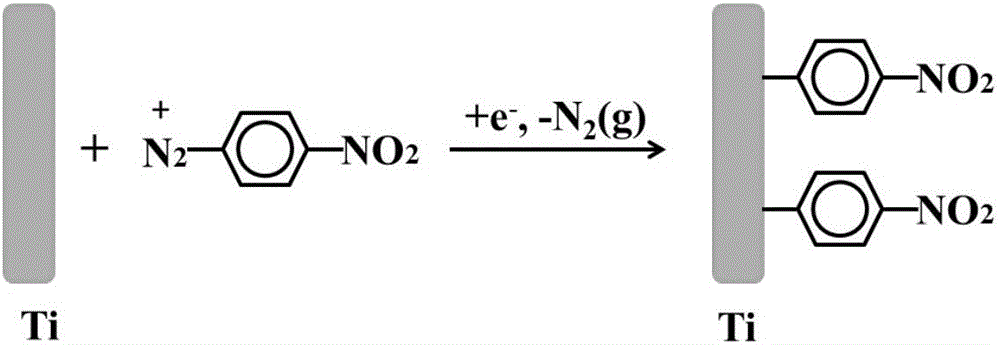

Method for modifying bonding surface of metal by virtue of electric grafting of aryl diazonium salts onto surface of metal

An aryl diazonium salt and electrografting technology, which is applied in the direction of metal layered products, chemical instruments and methods, surface reaction electrolytic coating, etc., can solve the problems of fiber strength loss, easy pollution, high cost, etc., and achieve interface bonding The effect of enhanced effect, low price, and simple and easy surface treatment method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

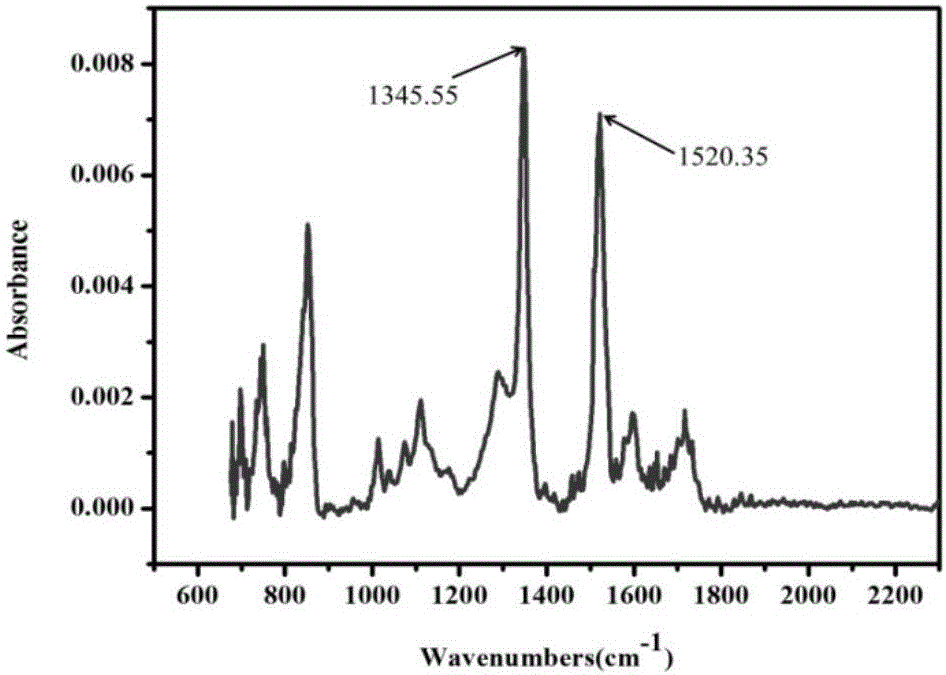

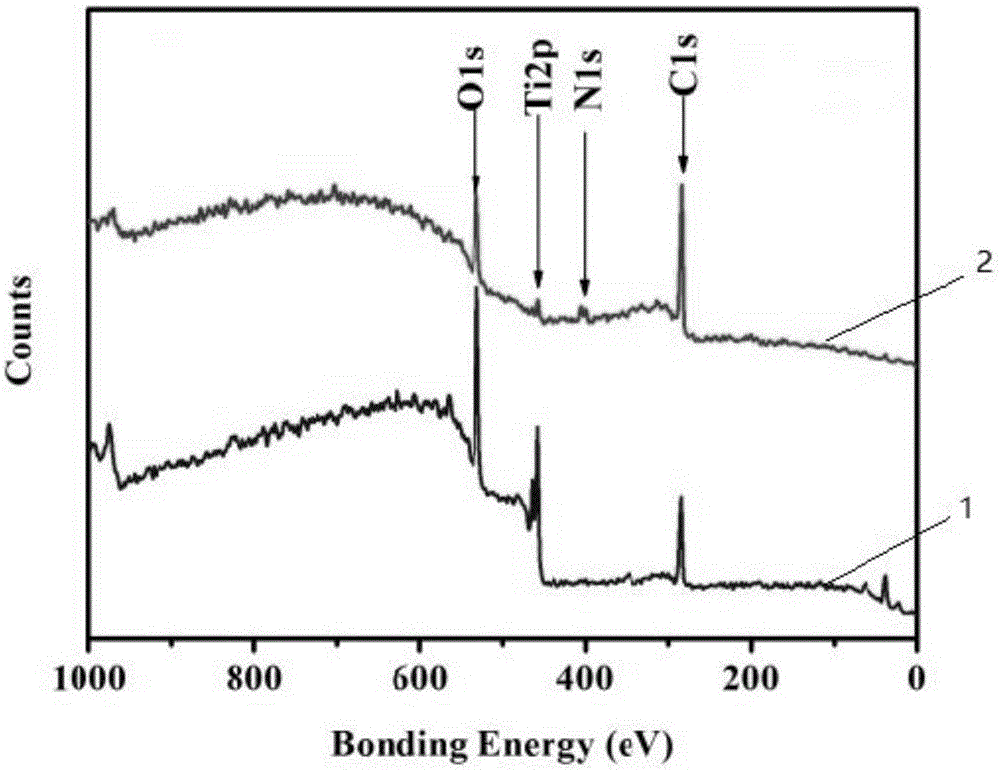

Method used

Image

Examples

Embodiment 1

[0034] (1), TA2 titanium plate surface pickling pretreatment:

[0035] Rinse the surface of the TA2 titanium plate with distilled water to remove surface pollutants; then wipe the surface of the TA2 thin plate with acetone to remove surface grease; then put the TA2 titanium plate into a mixed acid composed of 350g / L nitric acid and 60g / L hydrofluoric acid In the solution, acid wash at 40°C for 40s to remove the surface oxide layer, take it out and dry it at 80°C for 10min to obtain a dried and cleaned TA2 board.

[0036] 2. Preparation of p-nitrophenylaryl diazonium salt:

[0037] Measure 4ml of distilled water and 6.8ml of concentrated hydrochloric acid into a clean 50mL beaker and keep stirring. After cooling to room temperature, move the beaker to an ice-salt bath. Then add 2.76g of p-nitroaniline powder into the beaker and stir for 3 to 5 minutes to completely dissolve it. Stand for several minutes so that the temperature of the solution is maintained at 0-5°C. At the s...

Embodiment 2

[0048] (1), TA2 surface anodic oxidation pretreatment:

[0049] (A), rinse the surface of the TA2 titanium plate with distilled water to remove surface pollutants; then wipe the surface of the TA2 thin plate with acetone to remove surface grease; then put the TA2 titanium plate into the nitric acid of 350g / L and the hydrofluorine of 60g / L In a mixed acid solution composed of acid, pickle at 40°C for 40s to remove the surface oxide layer, take it out and dry it at 80°C for 10min to obtain a dried and cleaned TA2 board.

[0050] (B), the TA2 titanium plate that obtains in the step (A) is put into electrolyzer and carry out anodic oxidation, with TA2 titanium plate as anode, stainless steel plate as negative electrode, by 300g / L sodium hydroxide, 65g / L sodium tartrate , 30g / L ethylenediaminetetraacetic acid, 6g / L sodium silicate in the electrolyte composed of 10V voltage oxidation for 10min, so that the surface of TA2 titanium plate to obtain a layer of uniform and dense oxide fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com