Chain Component And Chain

A technology for chains and parts, applied in transmission chains, coatings, metal material coating processes, etc., can solve the problems of poor adhesion and peeling of substrates, and achieve small damage, good wear resistance, and good wear resistance. The effect of elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

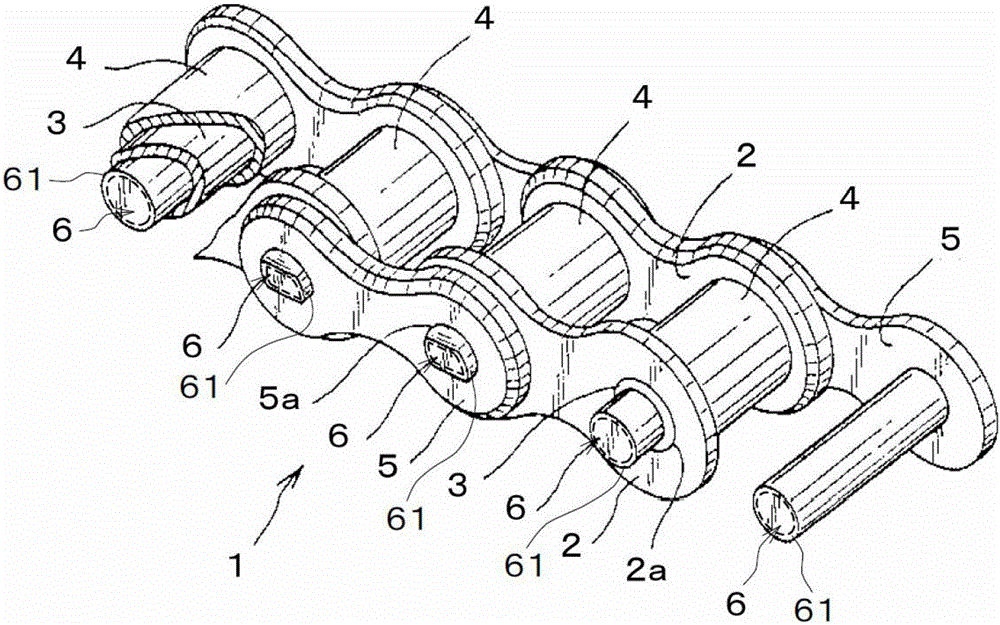

[0082] As the material to be processed in Example 1, the wire rod of SUJ2 was cut to a predetermined length and subjected to grinding treatment to obtain a base of the pin 6 as a steel base.

[0083] To be formulated within the above numerical range, including Cr powder, alumina, and NH 4 The Cl treatment agent and the pin 6 are accommodated in the alumina boat, and the alumina boat is put into the heating furnace. Replace with inert gas (air in the heating furnace), and add gas (NH 3 and N 2 ), the temperature is raised to the above-mentioned temperature, and the temperature is maintained to form a chromium nitride layer 61 on the outside of the pin 6 . Thereafter, the power to the heater was turned off, and the temperature was gradually cooled.

[0084] As described above, the pin 6 having the chromium nitride layer 61 formed on the outer side of the steel substrate was obtained.

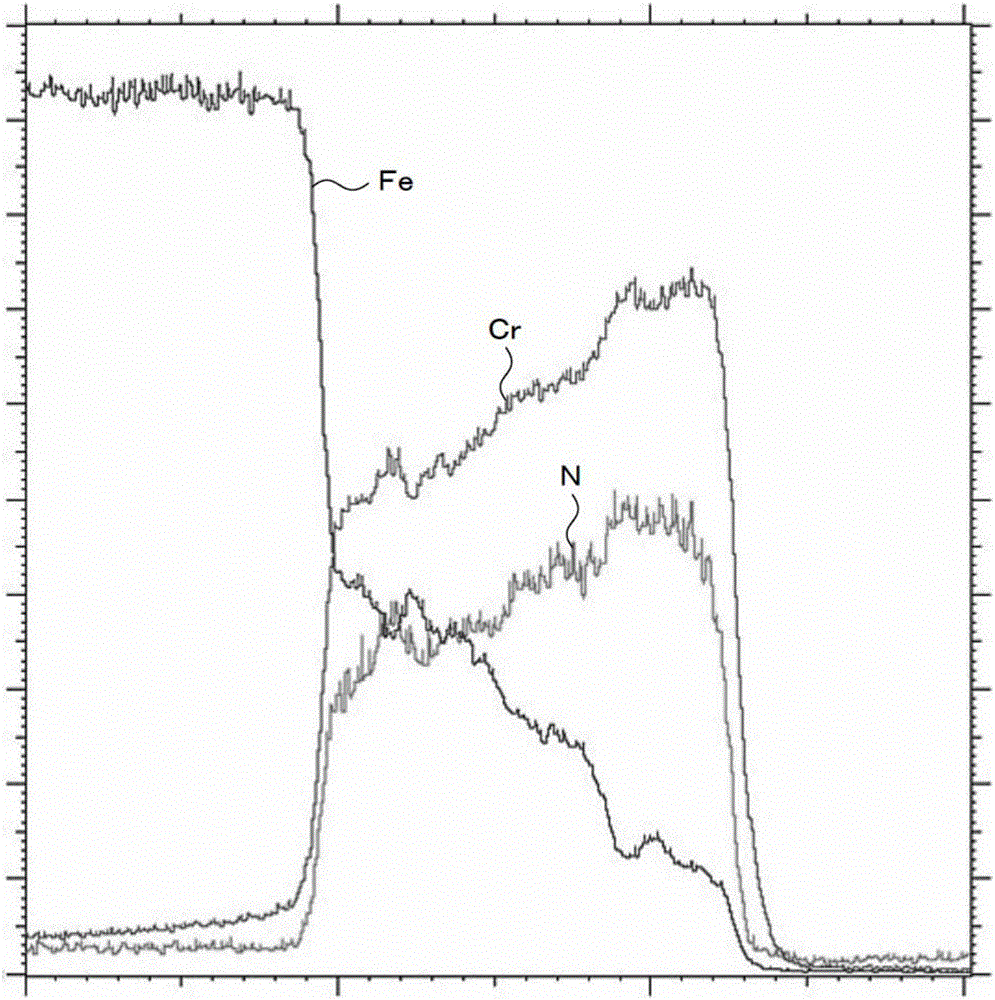

[0085] The Fe content of the chromium nitride layer 61 is 13% by mass, the Cr content is 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com