Oil-removing and cleaning process for automobile part

A technology for auto parts and processes, applied in the field of degreasing and cleaning processes for auto parts, can solve problems such as oil residue and achieve the effect of convenient surface treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

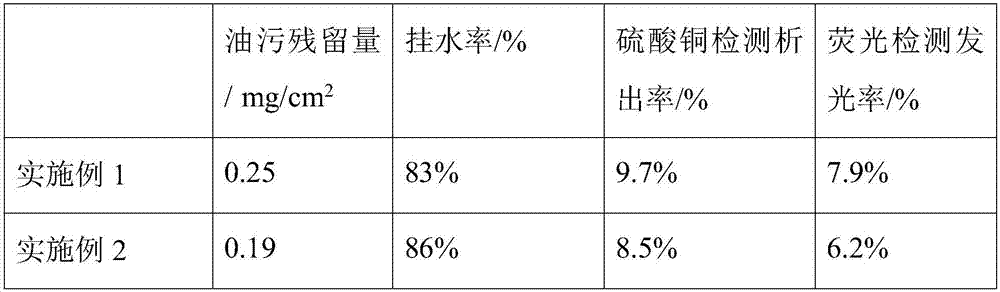

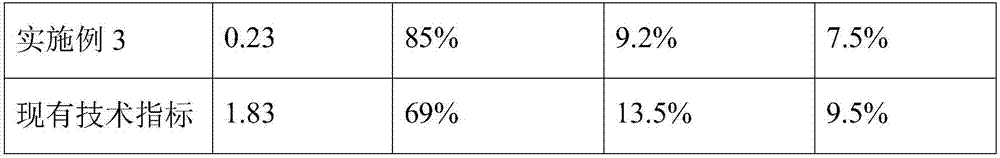

Examples

Embodiment 1

[0025] A degreasing and cleaning process for auto parts, the steps comprising:

[0026] (1) Remove oil slick

[0027] Car parts are washed with an emulsified degreaser, and the composition of the emulsified degreaser includes kerosene, turpentine, lauric acid, triethanolamine, butyl cellosolve, surfactant and sodium metasilicate aqueous solution, and the mass ratio of its components is 61: 22.5:5.4:3.6:1.5:2.4:6.7, pickling after cleaning and drying;

[0028] (2) pickling

[0029] Carry out pickling in 10% (volume) sulfuric acid solution, temperature is 30 ℃;

[0030] (3) Washing

[0031] Wash auto parts in flowing water with a water velocity of 0.5m / s;

[0032] (4) Acid degreasing

[0033] Acid degreasing is carried out in a degreasing liquid composed of phosphoric acid, sulfuric acid, nitric acid and boric acid with a mass ratio of 57.5:35.5:16.3:7.5. The acid degreasing temperature is 75°C and the degreasing time is 1 min;

[0034] (5) Second pickling

[0035] Use th...

Embodiment 2

[0043] A degreasing and cleaning process for auto parts, the steps comprising:

[0044] (1) Remove oil slick

[0045] Car parts are washed with an emulsified degreaser, and the composition of the emulsified degreaser includes kerosene, turpentine, lauric acid, triethanolamine, butyl cellosolve, surfactant and sodium metasilicate aqueous solution, and the mass ratio of its components is 61: 22.5:5.4:3.6:1.5:2.4:6.7, pickling after cleaning and drying;

[0046] (2) pickling

[0047] Carry out pickling in 15% (volume) sulfuric acid solution, temperature is 35 ℃;

[0048] (3) Washing

[0049] Wash auto parts in flowing water with a water velocity of 0.5m / s;

[0050] (4) Acid degreasing

[0051] Acid degreasing is carried out in a degreasing liquid composed of phosphoric acid, sulfuric acid, nitric acid and boric acid with a mass ratio of 57.5:35.5:16.3:7.5. The acid degreasing temperature is 75-100°C, and the degreasing time is 3 minutes;

[0052] (5) Second pickling

[005...

Embodiment 3

[0061] A degreasing and cleaning process for auto parts, the steps comprising:

[0062] (1) Remove oil slick

[0063] Car parts are washed with emulsified degreaser, then pickled after cleaning and drying;

[0064] (2) pickling

[0065] Carry out pickling in 20% (volume) sulfuric acid solution, temperature is 30-40 ℃;

[0066] (3) Washing

[0067] Wash auto parts in flowing water with a water velocity of 0.5m / s;

[0068] (4) Acid degreasing

[0069] Degreasing the acid liquid in a degreasing liquid composed of phosphoric acid, sulfuric acid, nitric acid and boric acid with a mass ratio of 57.5:35.5:16.3:7.5. The degreasing temperature of the acid liquid is 100°C, and the degreasing time is 1 min;

[0070] (5) Second pickling

[0071] Use the mixed acid of concentrated nitric acid and hydrofluoric acid with a mass ratio of 3:1 to pickle the auto parts for 8 seconds;

[0072] (6) Second washing

[0073] Wash the auto parts in flowing water with a water speed of 0.3m / s, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com