Patents

Literature

32 results about "Mussel adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

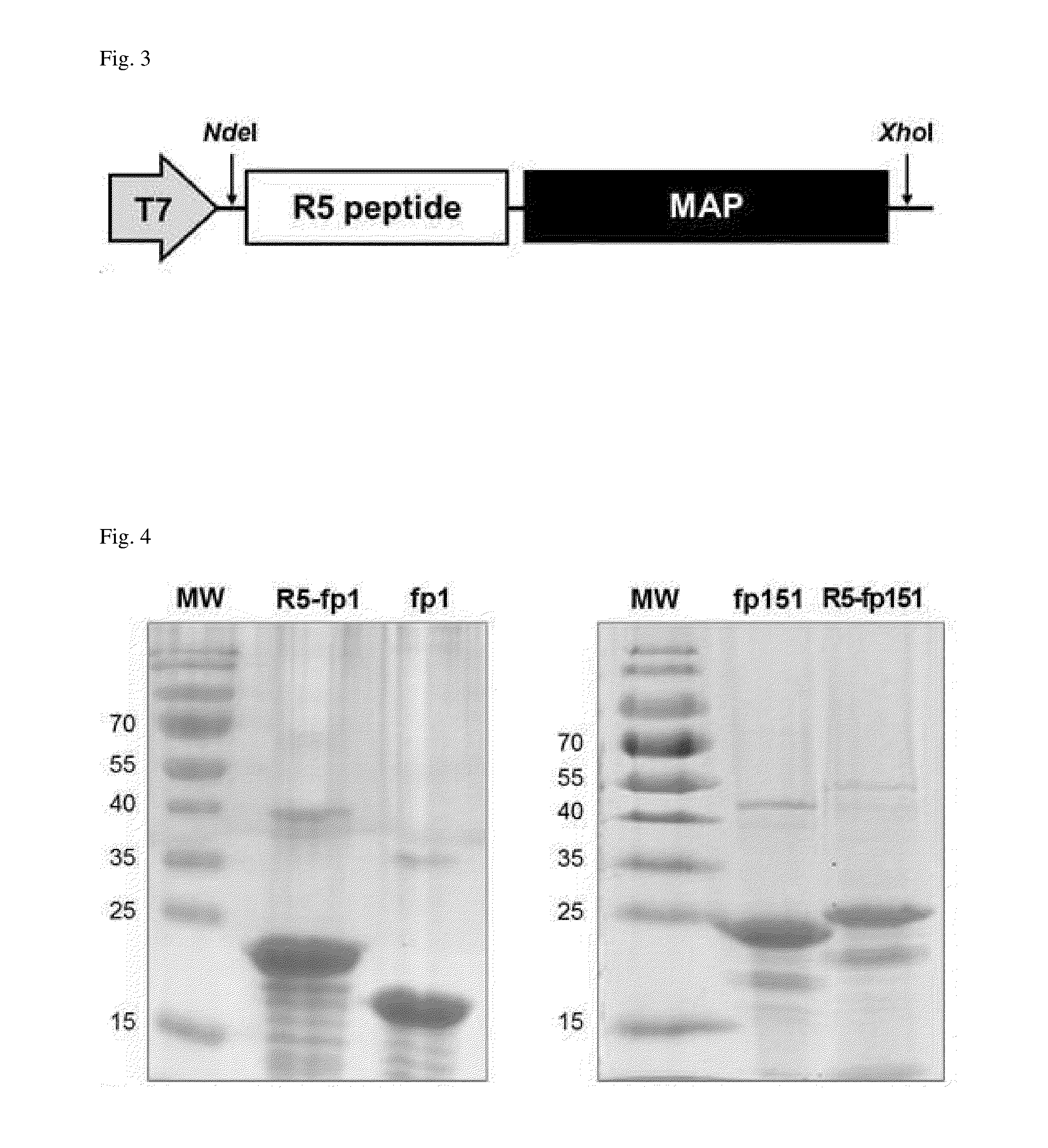

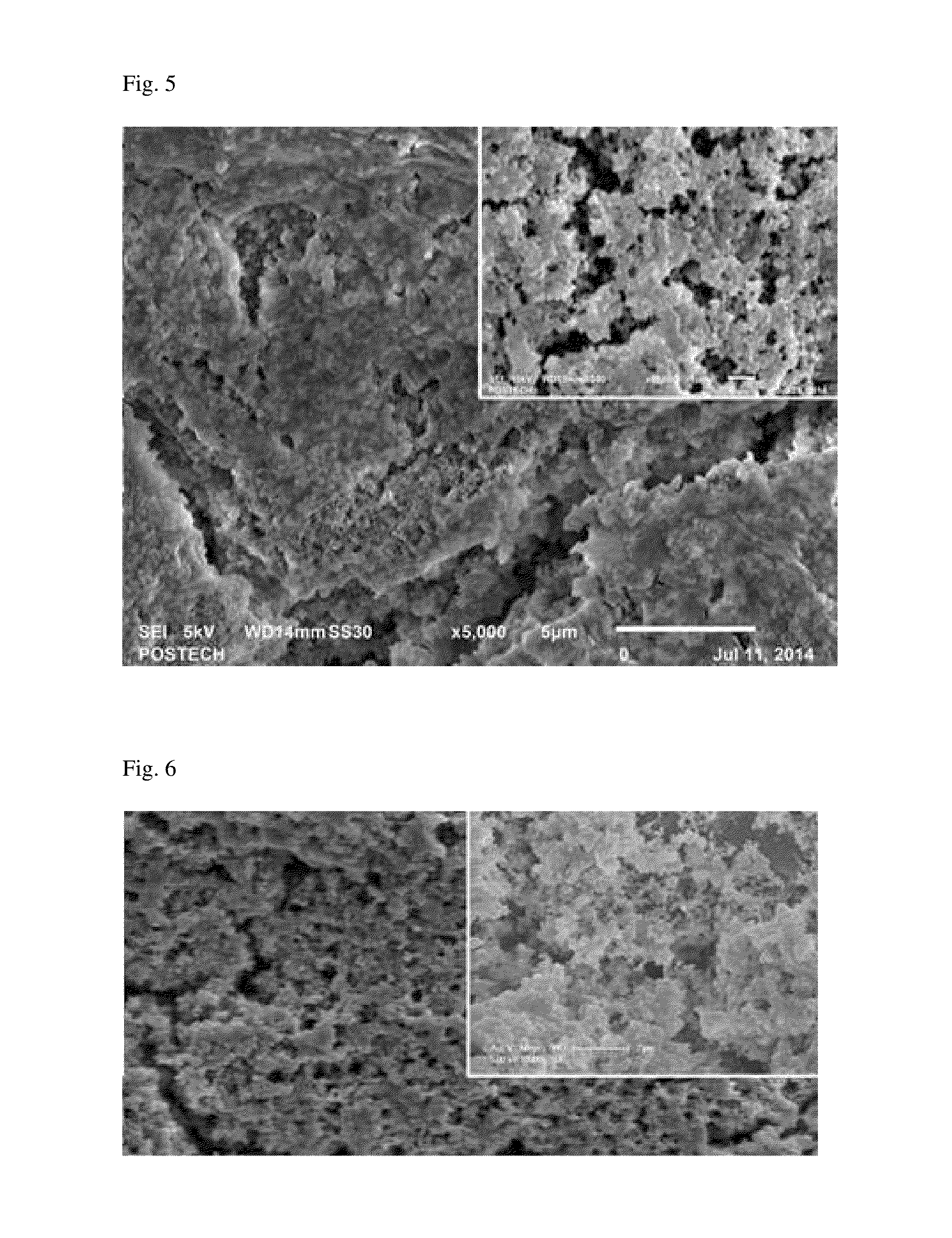

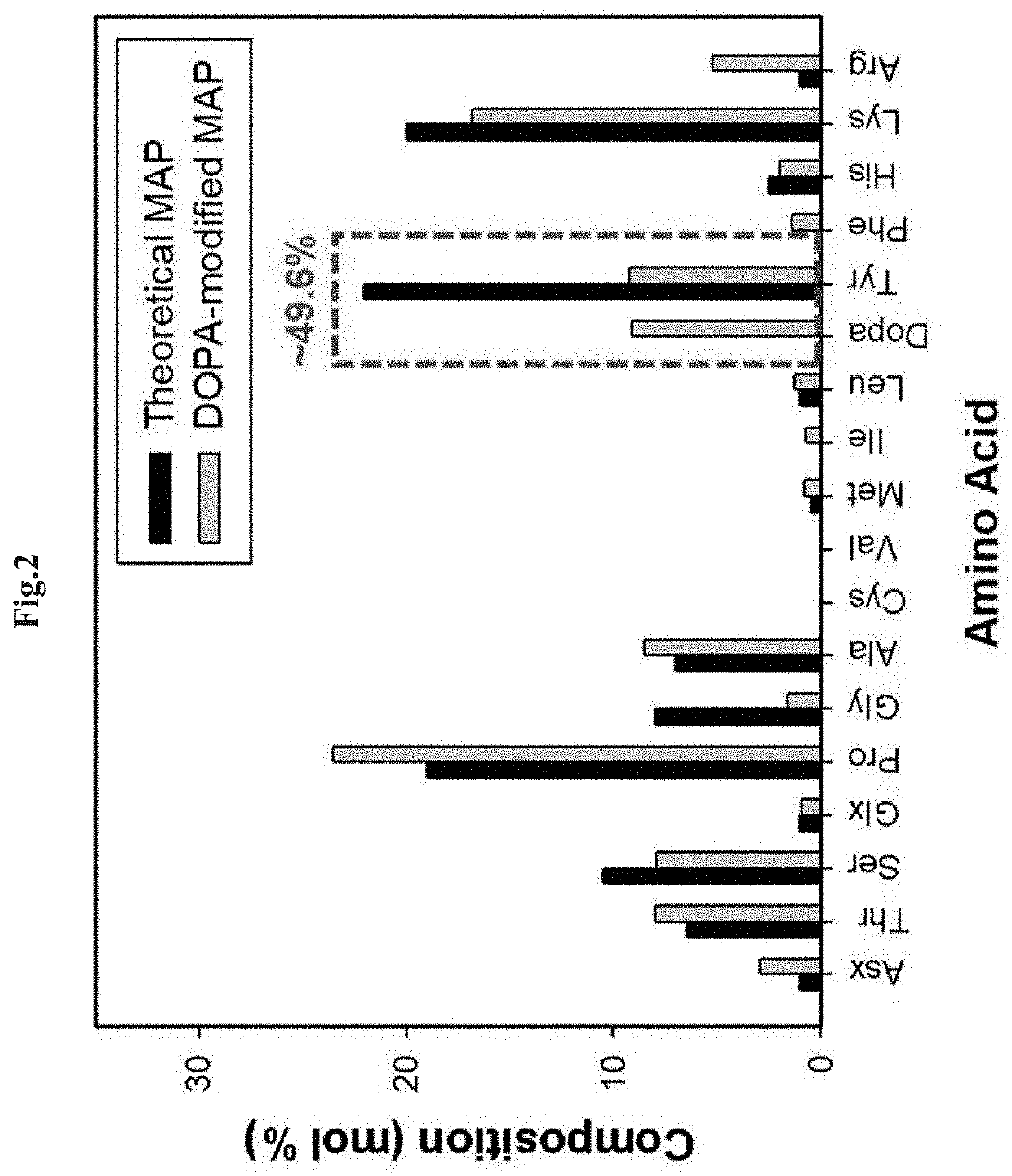

Surface immobilization of various functional biomolecules using mussel adhesive protein

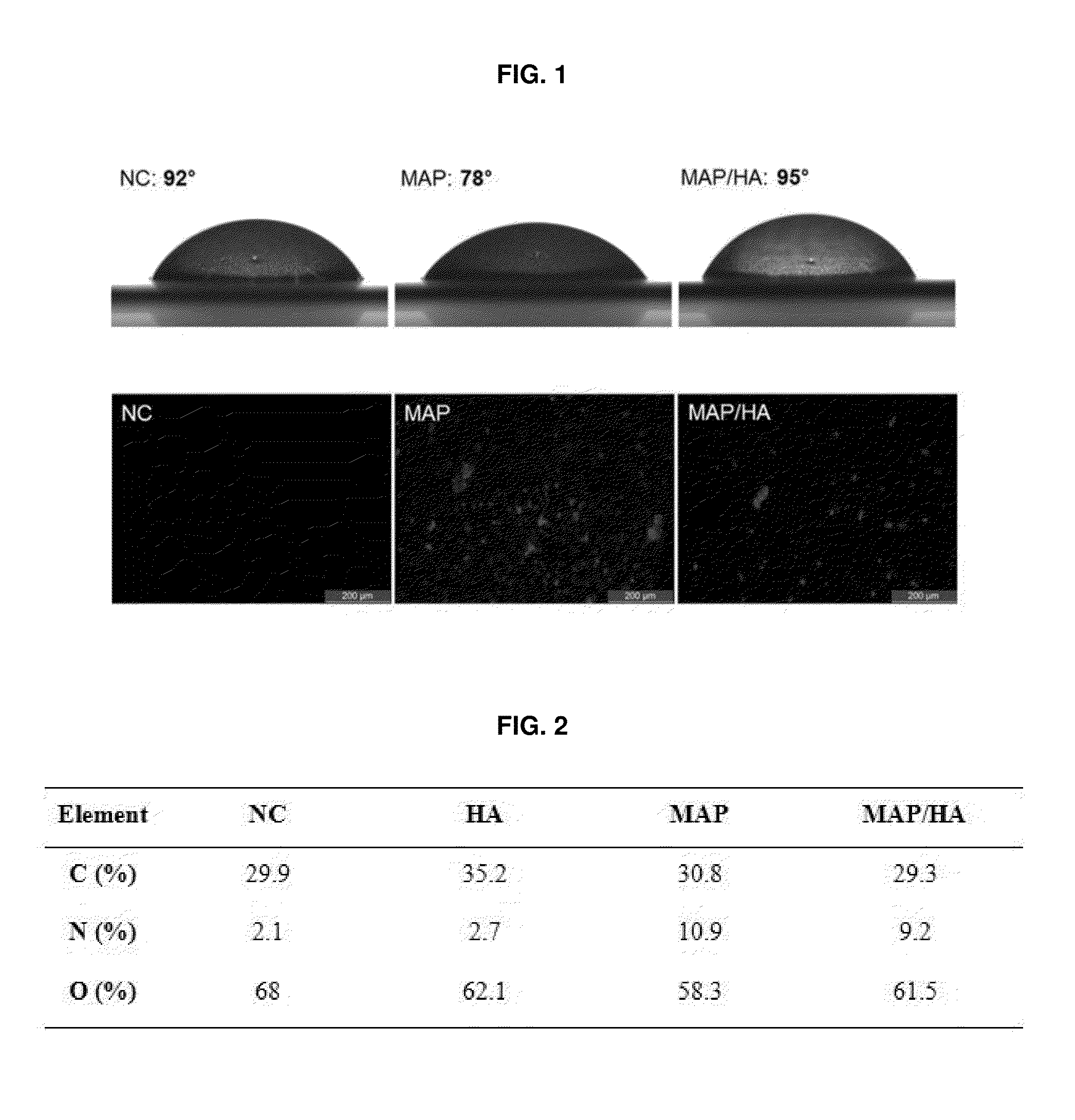

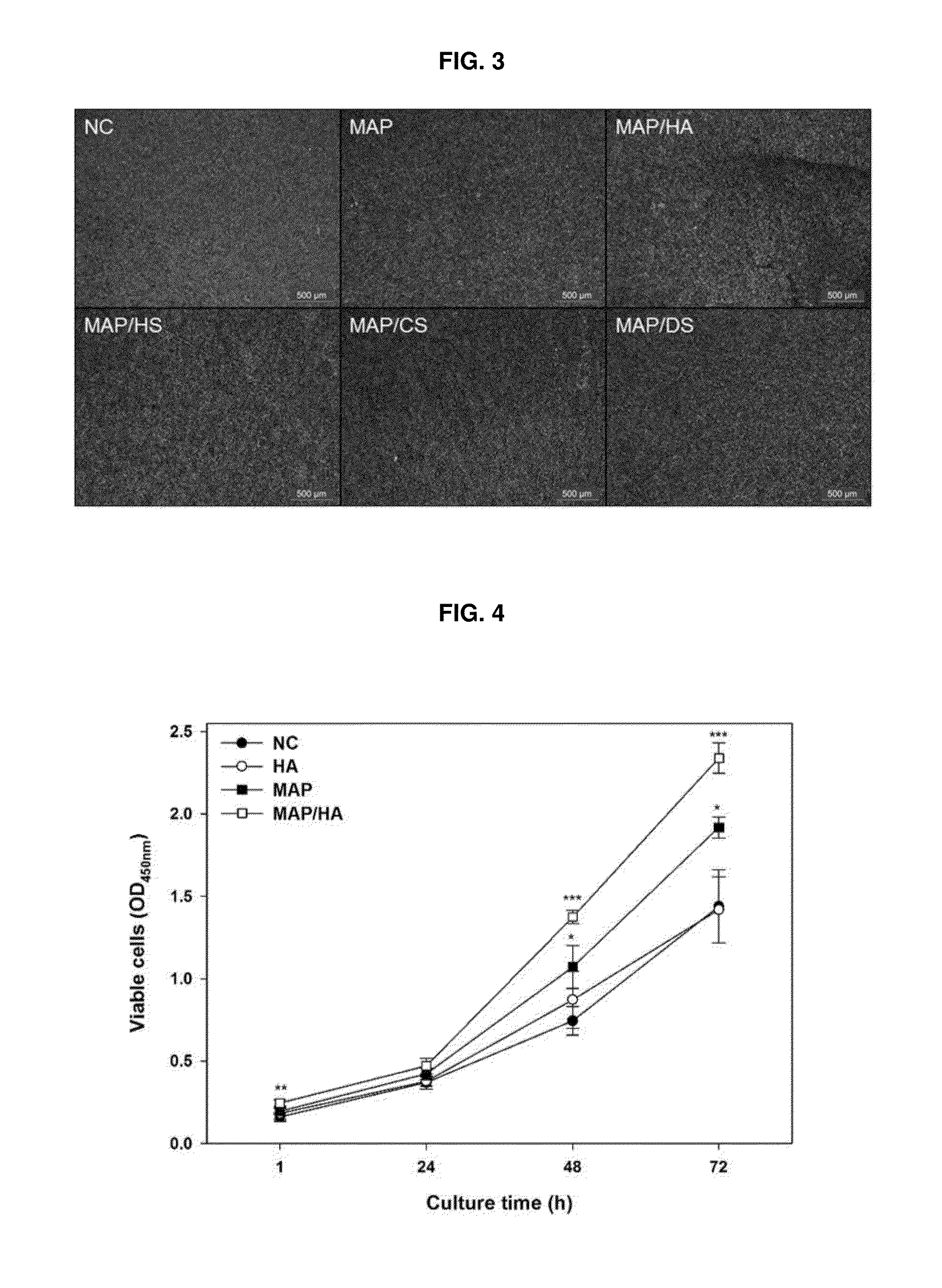

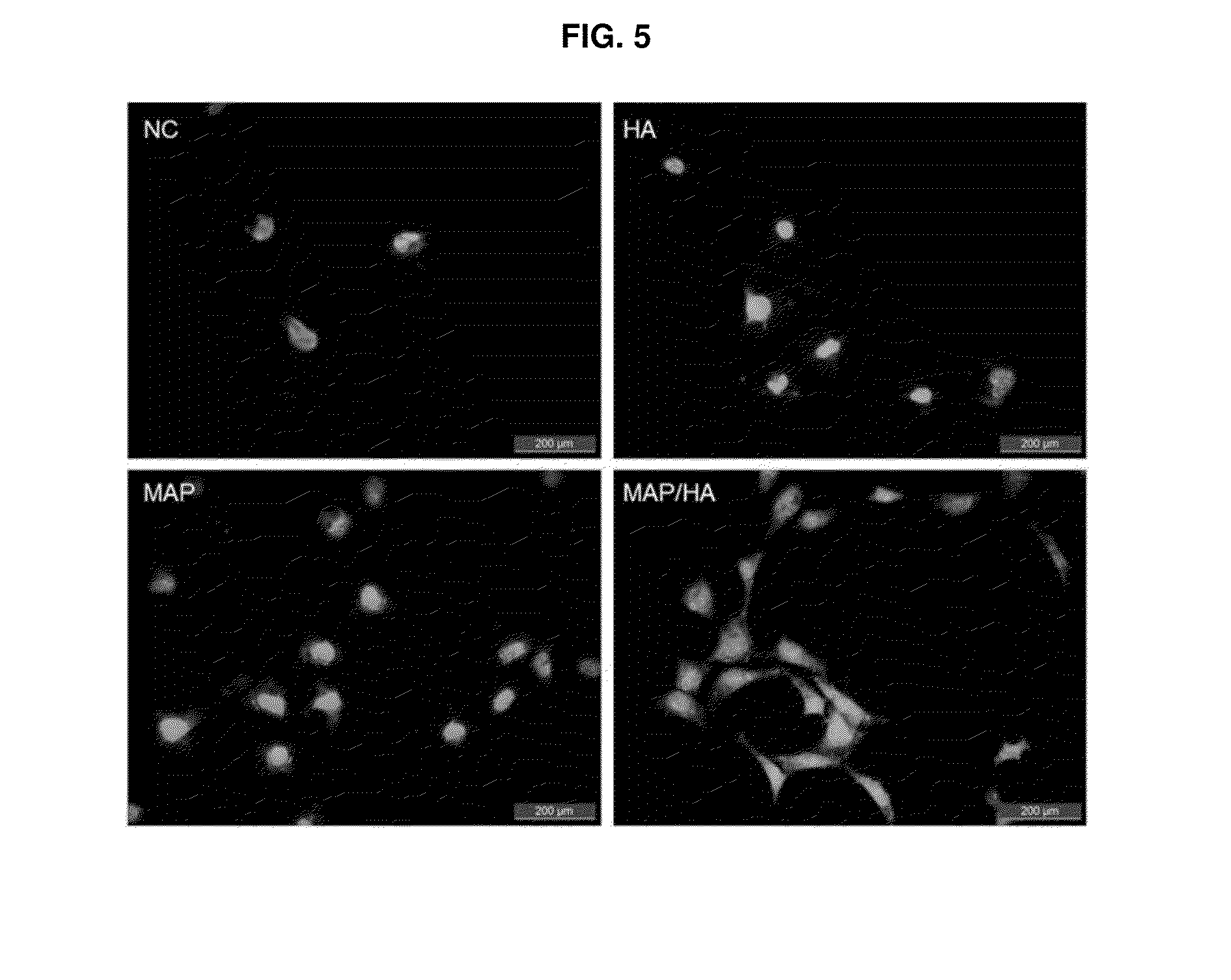

The present invention relates to technology of immobilizing or coating various functional bioactive substances on various surfaces without physical chemical treatment using mussel adhesive protein. More specifically, the present invention relates to a functional scaffold for tissue engineering comprising artificial extracellular matrix, manufactured by coating various functional bioactive substances on the surface of nanofiber and metal scaffold using mussel adhesive protein, and a method of manufacturing the same.

Owner:POSTECH ACAD IND FOUND

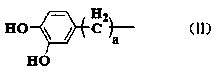

Preparation method for biomimetic mussel adhesive used for adhesion on wet surface and underwater curing

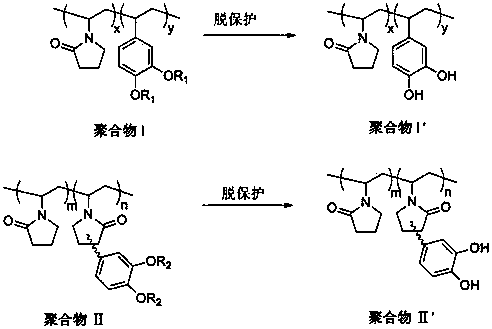

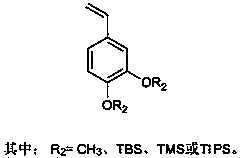

InactiveCN103965810AEfficient synthesisImprove bindingNon-macromolecular adhesive additivesPolymer scienceAttachment protein

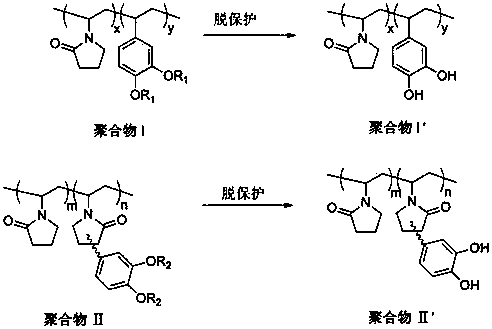

The invention relates to a preparation method for a biomimetic mussel adhesive used for adhesion on a wet surface and underwater curing. The method is characterized in that the biomimetic mussel adhesive is composed of two components including A and B, wherein the component A is a methanol solution of a polymer containing catechol groups; the polymer containing catechol groups is obtained in the manner that N-vinyl pyrrolidone and a polymerizable catechol derivative monomer are subjected to free radical polymerization and further subjected to deprotection; the component B is a crosslinking curing agent. The method has the advantages as follows: 1, the synthetic method is simple and efficient, raw material and reagents used in the reaction process are low in price and easy to get, and amplification in the operation process and industrial production are facilitated; 2, the biomimetic mussel adhesive has certain biocompatibility and initial adhesion performance, can be used for adhesion on the wet surface and underwater curing, and has the bonding strength being over 1 MPa, so as to be applied to adhesion of human tissue and adhesion in the wet environment of commonly-used base material as well as adhesion under the water. According to the invention, perfect combination between synthetic macromolecule and natural mussel attachment proteins is successfully realized, the technical bottleneck about the current biomimetic mussel adhesive is expected to break through, and meanwhile, a new approach for shellfish-based development of biomimetic high polymer material is provided.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

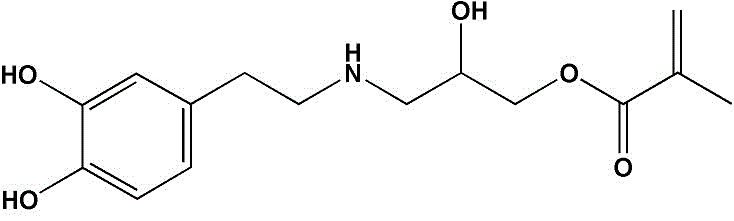

Light-cured adhesive resin used for dental restoration, and preparation method thereof

InactiveCN106691874AThe improvement effect is obviousEasy to prepareImpression capsDentistry preparationsChemical structureGlycidyl methacrylate

The invention discloses a light-cured adhesive resin used for dental restoration, and a preparation method thereof. The light-cured adhesive resin used for dental restoration is invented based on enlightenment from marine mussel adhesion behavior. Oral moist application environment and bonding requirements on multi-material dental restoration materials are taken into consideration, derivative dopamine (DA) of the main chemical structure dopa of mussel adhesive proteins is introduced into an acrylic resin adhesive, and a novel adhesive functional additive dopamine glycidyl methacrylate (DA-GMA) is obtained via synthesis, and functional molecules with light-curable carbon-carbon double bonds and super high adhesive performance pyrocatechol groups are obtained. The functional molecules are added into an oral adhesive formula at a certain ratio so as to obtain the light-cured adhesive resin which possesses excellent adhesive properties and is used for dental restoration.

Owner:BEIJING UNIV OF CHEM TECH +1

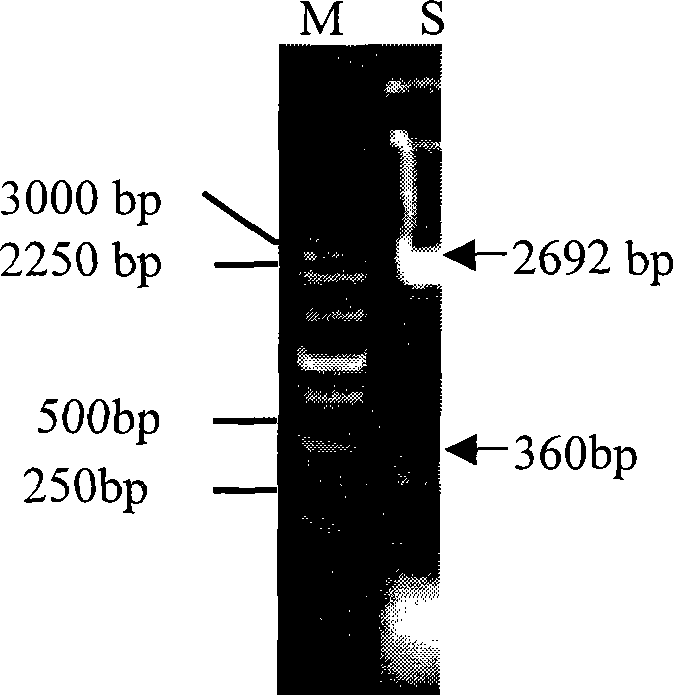

Process for producing ocean mussel adhesion protein water-proof biological adhesive agent

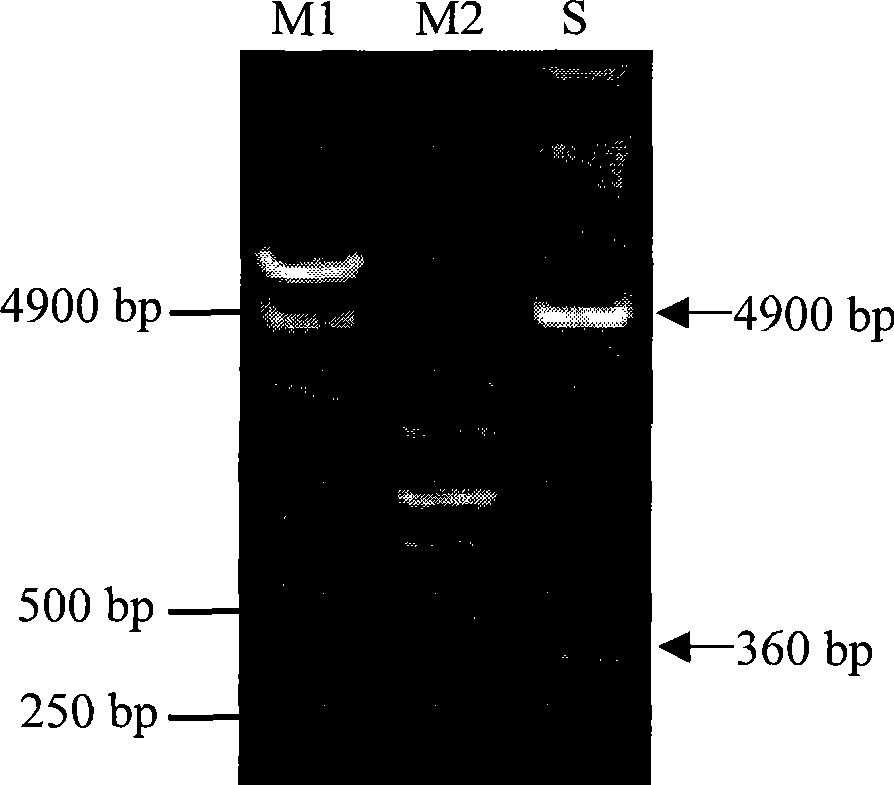

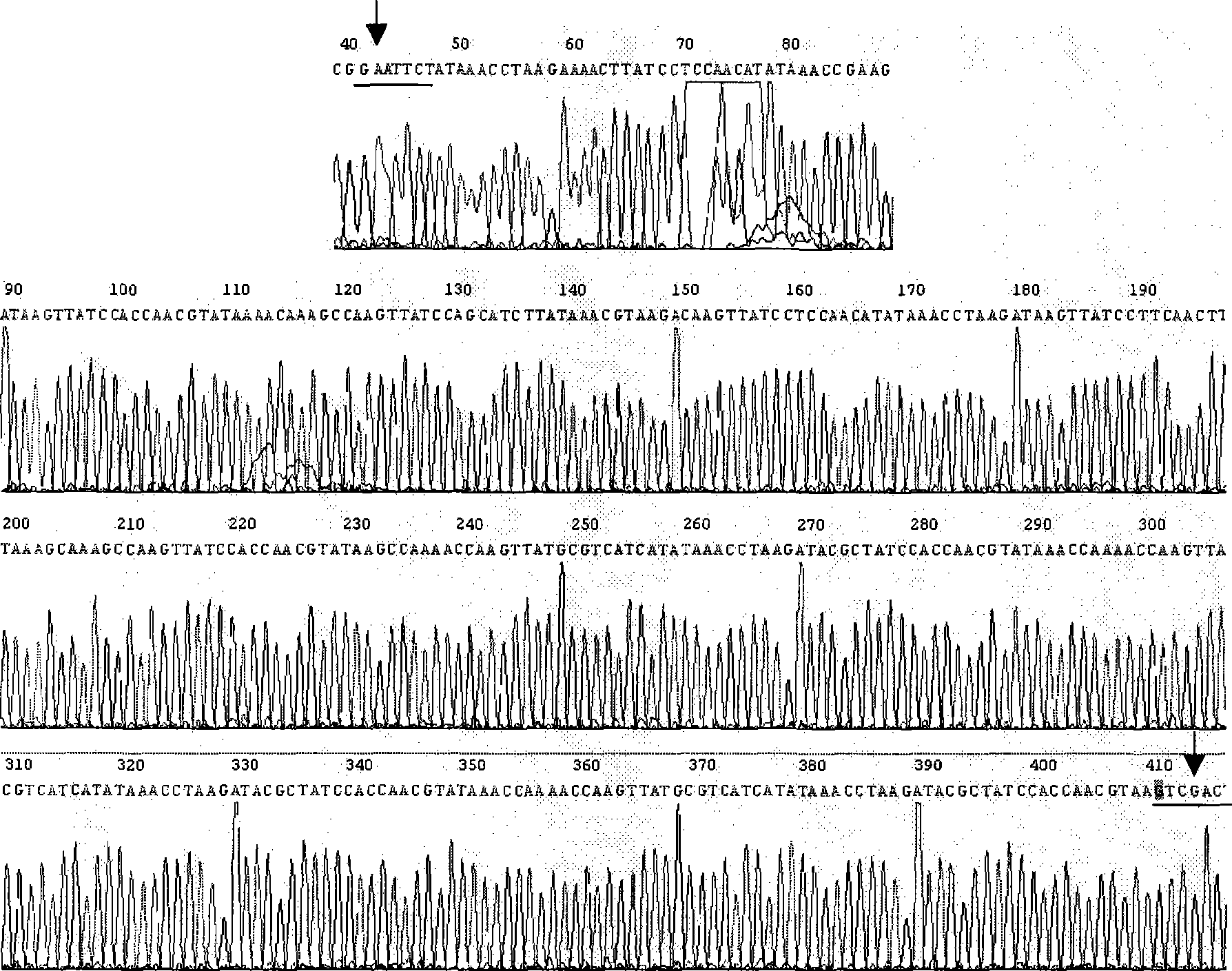

InactiveCN101429508ASimple processNo waste foundProtein adhesivesPeptide preparation methodsTotal rnaBioadhesive

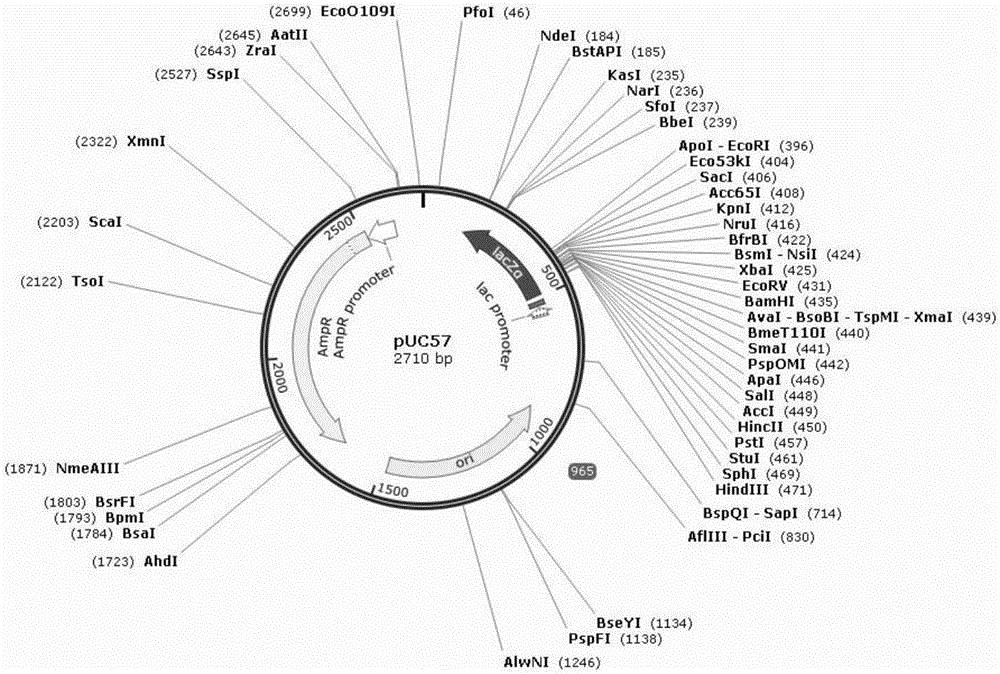

The invention provides a method for preparing a marine mussel adhesive protein waterproof biological adhesive, and relates to a biological adhesive. The invention provides the method for preparing marine mussel-Mytilus coruscus adhesive protein waterproof biological adhesive with degradability, water resistance and good biological compatibility by a method of biological gene engineering. The method comprises the following steps: extracting total RNA from the foot part of alive Mytilus coruscus to be reversely transcribed into cDNA; designing a PCR primer according to an Mcfp-1 gene sequence of the Mytilus coruscus; connecting the obtained DNA fragment in a prokaryotic expression vector pGEX-4T through PCR amplification to construct a recombinant plasmid; then transforming the recombined plasmid in a colon bacillus BL21 bacterial strain; and finally, purifying and modifying the expressed polypeptide product. The preparation method is simple, and the expression product is soluble, can be easily purified with low cost, and has similar or better effect compared with CELL-TAK<TM> cell and tissue adhesive without cytotoxicity. The adhesive accords with the requirement of scientific research, and can be used as a biological medical material.

Owner:XIAMEN UNIV

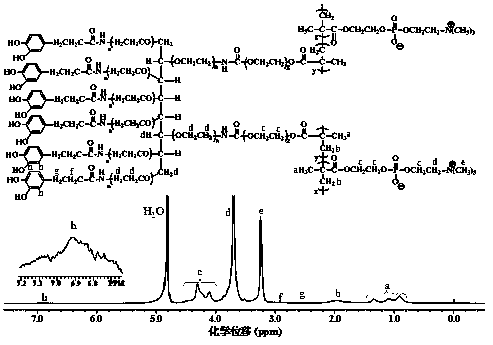

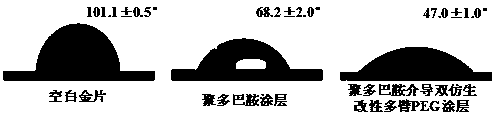

Mussel-adhered and cytomembrane antifouling double-bionic multi-armed PEG and preparation method thereof

ActiveCN104804195AEnhanced inhibitory effectAntifouling/underwater paintsPaints with biocidesMytilopsisPolyethylene glycol

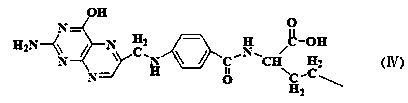

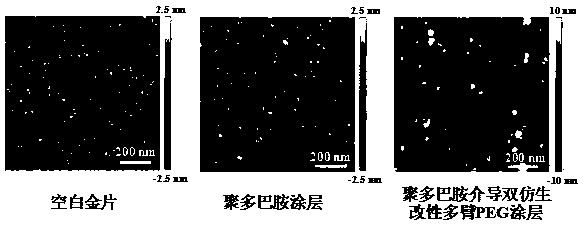

The invention discloses a catechol Mytilopsis-adhered and amphion-like extracellular membrane structured double-bionic modified multi-armed PEG as shown in the general structural formula (I) and a preparation method thereof. By a simple direct coating mode such as dispensing, spraying, dip-coating or spin-coating, etc. of the PEG, a multi-armed polyethylene glycol flexible chain and amphion-like extracellular membrane structured double anti-biopollution surface is constructed on the surface of various polydopamine-mediated base materials. Due to a branching structure and multiple modifiable ends of the bionic modified multi-armed PEG, it brings the possibility to prepare a functional polymer with multiple functional groups and regulable proportion. As the polydopamine with ultrastrong adhesion is used as a mediation layer, a compact and stable double anti-biopollution coating can still be formed on the surface of almost any base materials on the condition that content of catechol in the multifunctional multi-armed PEG is limited.

Owner:NORTHWEST UNIV

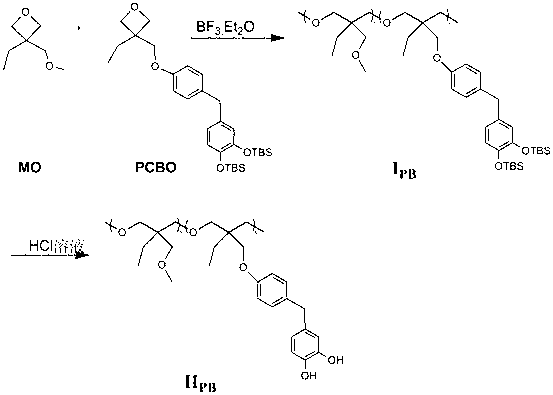

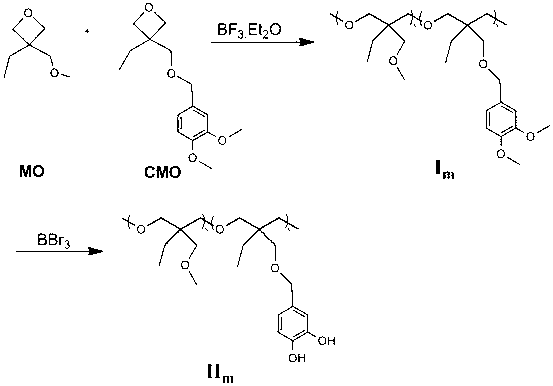

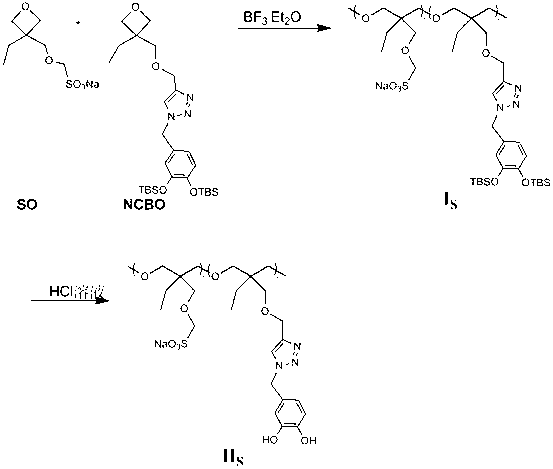

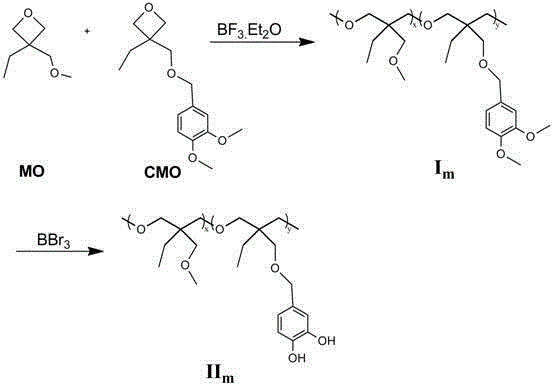

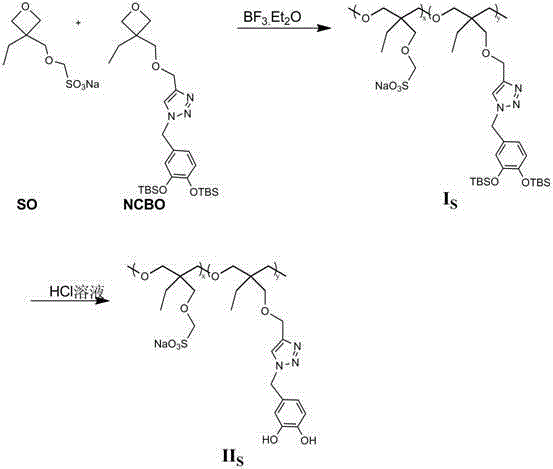

Preparation method of biomimetic mussel adhesive based on synthesis of oxetane derivatives

InactiveCN103289074AEfficient synthesisAchieve the perfect combinationPolyether adhesivesPolymer dissolutionPolymer science

The invention relates to a preparation method of a biomimetic mussel adhesive based on the synthesis of oxetane derivatives. The preparation method comprises the following main steps: preparing a phenolic hydroxy protected polymer with a catechol side-chain structure through ring-opening copolymerization of two oxetane derivative monomers; carrying out deprotection on the polymer so as to obtain a catechol structure containing polymer; and after the catechol structure containing polymer is dissolved, adding a certain amount of a crosslinking agent into the polymer, and uniformly mixing so as to obtain the biomimetic mussel adhesive. The method has the characteristics that: 1) the synthesis method is simple and efficient, and raw materials and reagents used in the process of reaction are cheap and easily available, thereby facilitating the amplification of an operating process and industrial production; and 2) the bonding strength is over 5 MPa, so that an effect that a synthetic polymer simulates the attachment protein properties of natural mussels is successfully achieved, and a purpose of integrating certain biocompatibility and high adhesion strength is reached; therefore, the method provides is a novel synthesis technique of biomimetic mussel adhesives and provides a new way for developing novel bionic polymer materials based on the effective protein components of shellfish.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Body-type high-strength bionic adhesive preparation method

InactiveCN105602481AAchieve the perfect combinationWide applicabilityUnsaturated alcohol polymer adhesivesPolymer sciencePolyvinyl alcohol

The present invention relates to a body-type high-strength bionic adhesive preparation method, which comprises: adding polyvinyl alcohol and a solvent to a reaction kettle, adding a catalyst and a pyrocatechol-containing compound under protection of argon or nitrogen, carrying out a stirring reaction for a certain time at a temperature of 50-100 DEG C, cooling the system to a room temperature, precipitating in water, repeatedly washing the precipitate by using water, and carrying out vacuum drying to obtain the bionic adhesive. According to the present invention, the adhesive is synthesized by using the one-step method, such that the operation scale-up and the industrial production are easily achieved; the adhesive is the body-type adhesive, the curing is rapid, and the strength achieves more than or equal to 6 MPa; the adhesive has the wide substrate universality, and is suitable for adhesion of metals, plastics, glasses, ceramics, bones and the like, and is further suitable for preparation of formaldehyde-free wood-based plates; and the perfect combination of the synthetic polymer and the natural mussel adhesion protein is achieved, the technical bottleneck of the current bionic mussel adhesive is expected to be broken through, and the new approach is provided for the development of the bionic polymer materials based on shellfish.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

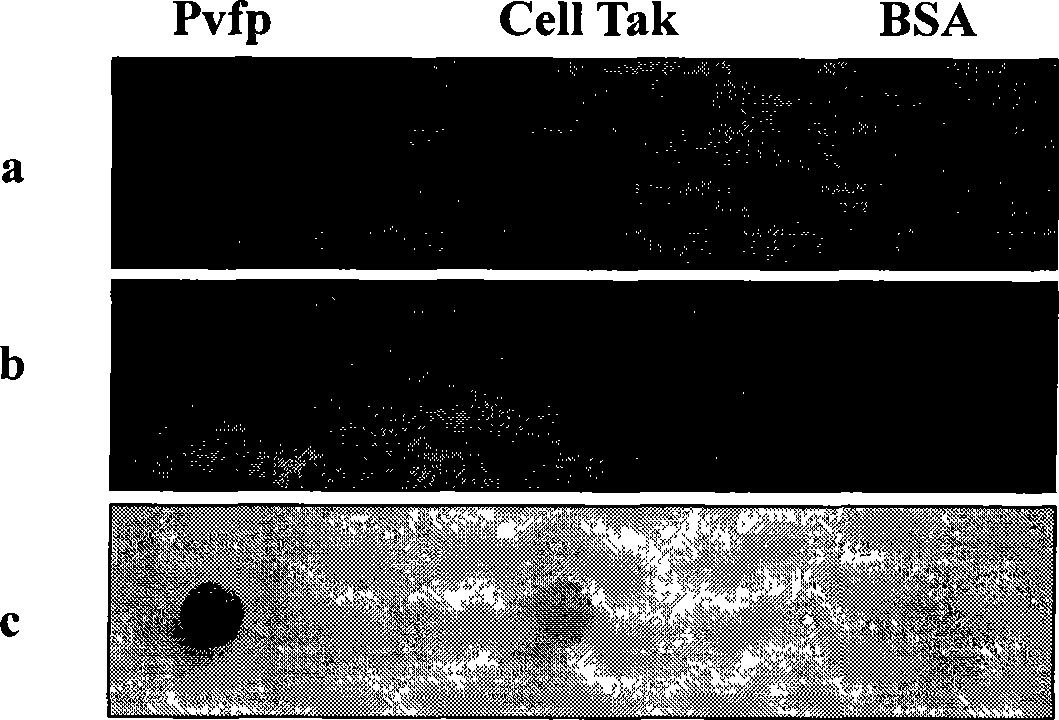

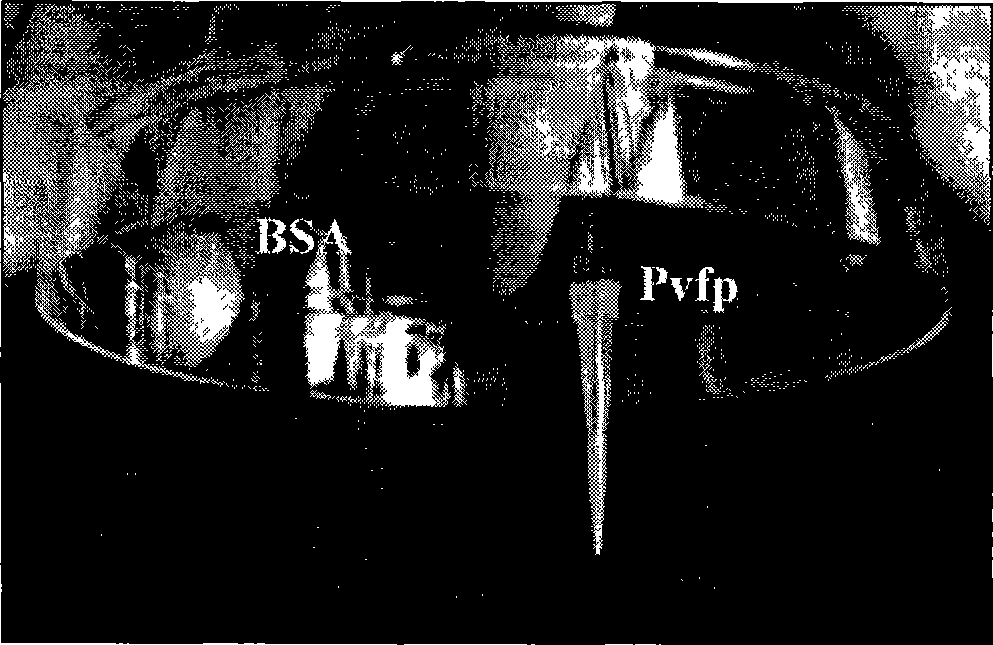

Method for preparing biology adhesive using emerald mussel adhesion protein

The invention provides a method for preparing biological adhesive by using perna viridis to adhere protein, relates to a biological adhesive. The invention provides a method for preparing a waterproof biological adhesive with better biological compatibility and low cost that extracts adhesive protein from perna viridis having wide raw material and low cost. The method includes steps as follows: cutting foot from live perna viridis, then mincing and homogenating, processing protein acidification, acetone protein precipitation, purification, finally, obtaining the waterproof biological adhesive. The adhesive protein waterproof biological adhesive can be obtained rapidly from perna viridis most abundant in China southeast seaside. The perna viridis biological adhesive has characteristics of high production, low cost and better adhesive effect. The prepared adhesive can adhere on surface of glass, metallic titanium and plastic, adheres cell in short time, adheres plastic or mouse thighbone, and has no cell toxicity. The biological adhesive as biological medical material biological adhesive has wide application prospect in clinical use.

Owner:XIAMEN UNIV

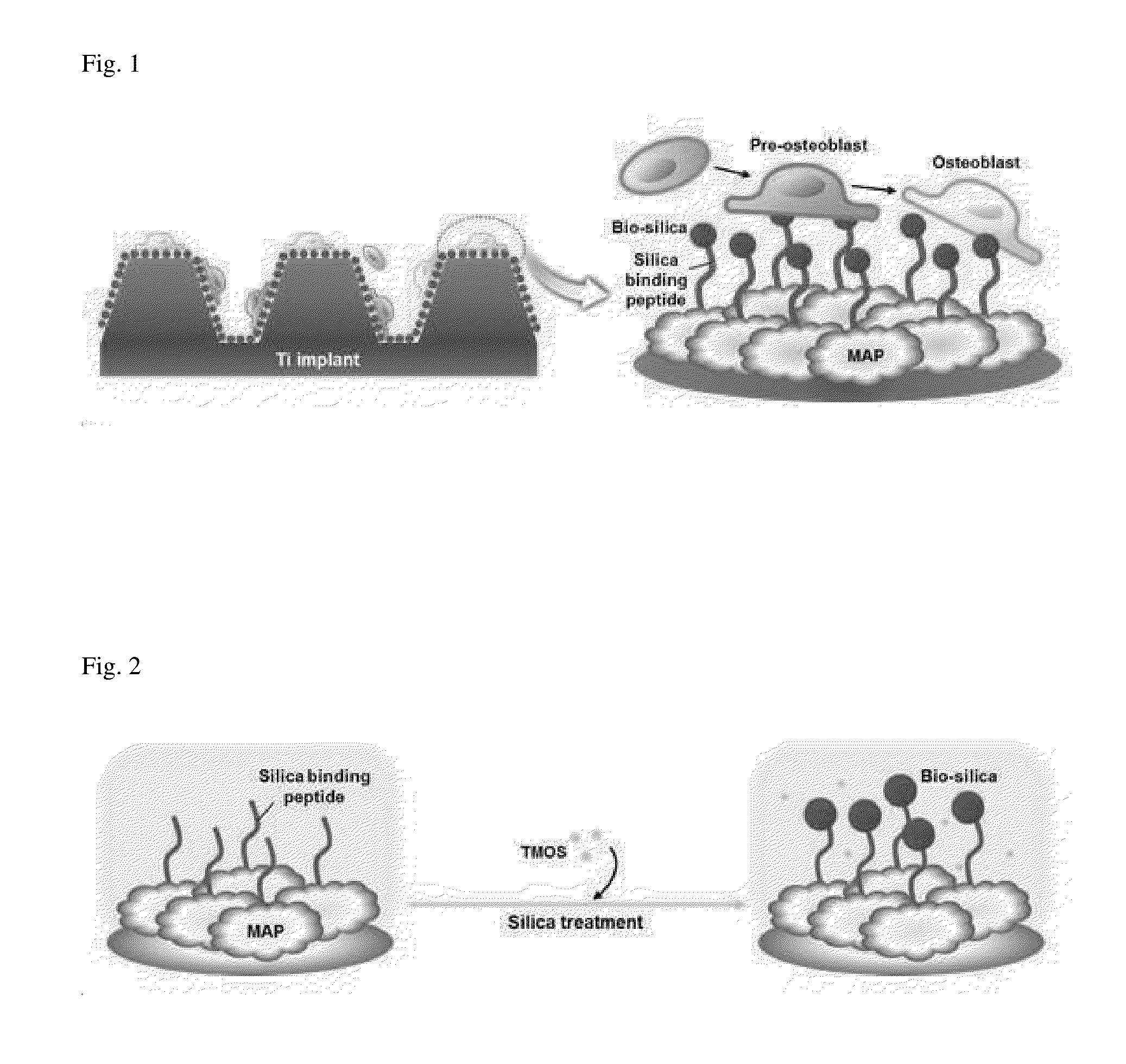

Mussel-inspired bioactive surface coating composition generating silica nanoparticles

ActiveUS20160096868A1Improve adhesion strengthBig ratioPeptide/protein ingredientsAntibody mimetics/scaffoldsSilica nanoparticlesBinding peptide

The present invention relates to a fusion protein comprising a mussel adhesive protein and a silica-binding peptide linked to the mussel adhesive protein, a silica nanoparticle a silica connected to the fusion protein, a fusion protein-silica nanoparticle complex comprising the silica nanoparticle having bioactivity and adhesiveness for cell proliferation and accelerating the differentiation, a surface coating composition including the complex, its use, and a method of coating a surface using the surface coating composition.

Owner:POSTECH ACAD IND FOUND

Preparation method of tissue adhesive

InactiveCN105770979AGood biocompatibilityPromote degradationSurgical adhesivesBiocompatibility TestingMussel adhesion

The invention discloses a preparation method of a tissue adhesive.Dopamine hydrochloride is introduced into a polymerization matrix poly 1,8-octylene glycol-polyethylene oxide-citrate through a fusion copolycondensation method, a catechol containing prepolymer is obtained, and in cooperation with sodium periodate, the synthesized mussel bionic tissue adhesive is obtained.The adhesive has excellent adhesion performance similar to that of mussel adhesion protein and meanwhile has good biocompatibility and biodegradability, and is low in preparation cost.

Owner:GUANGXI UNIV

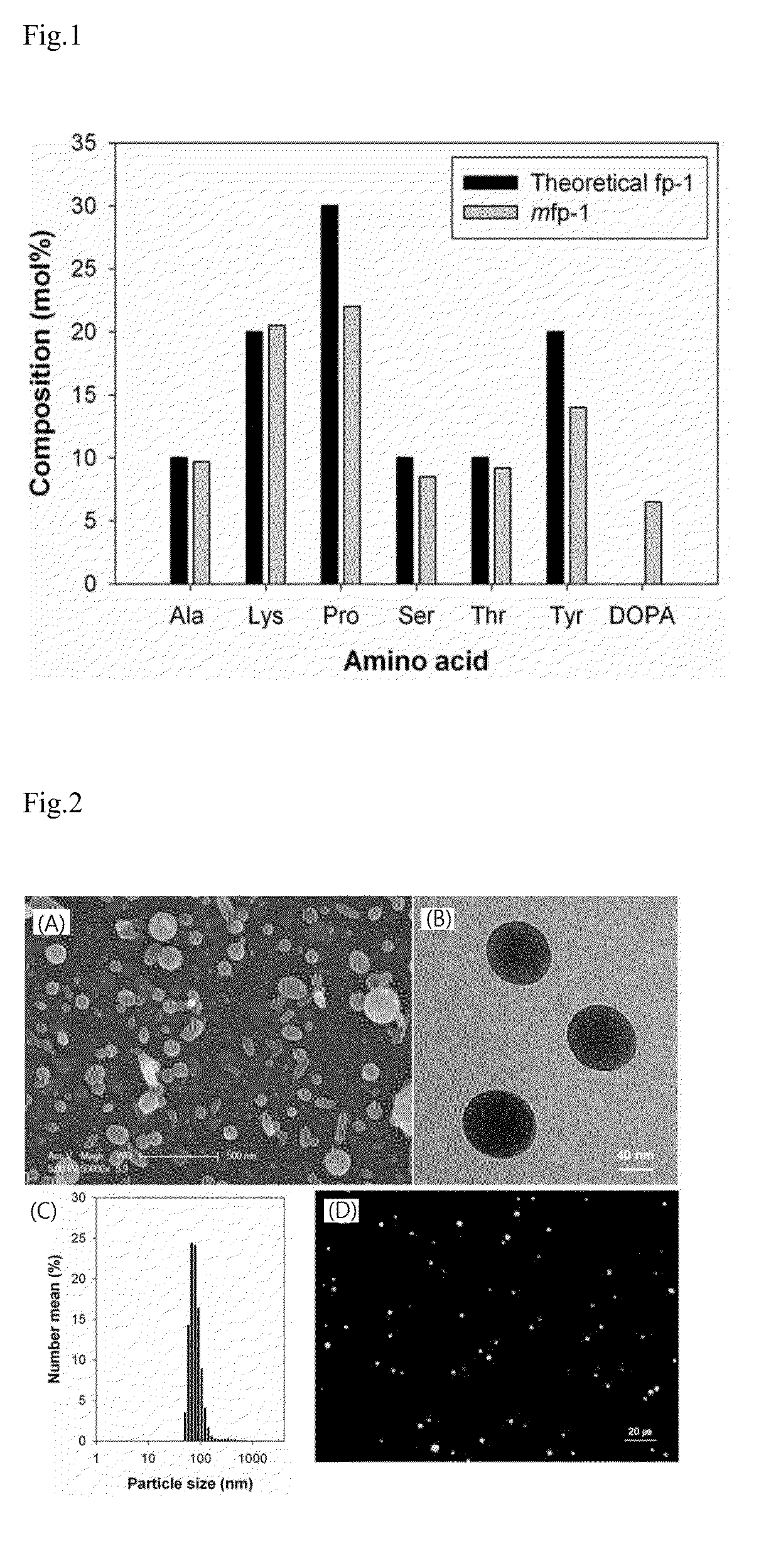

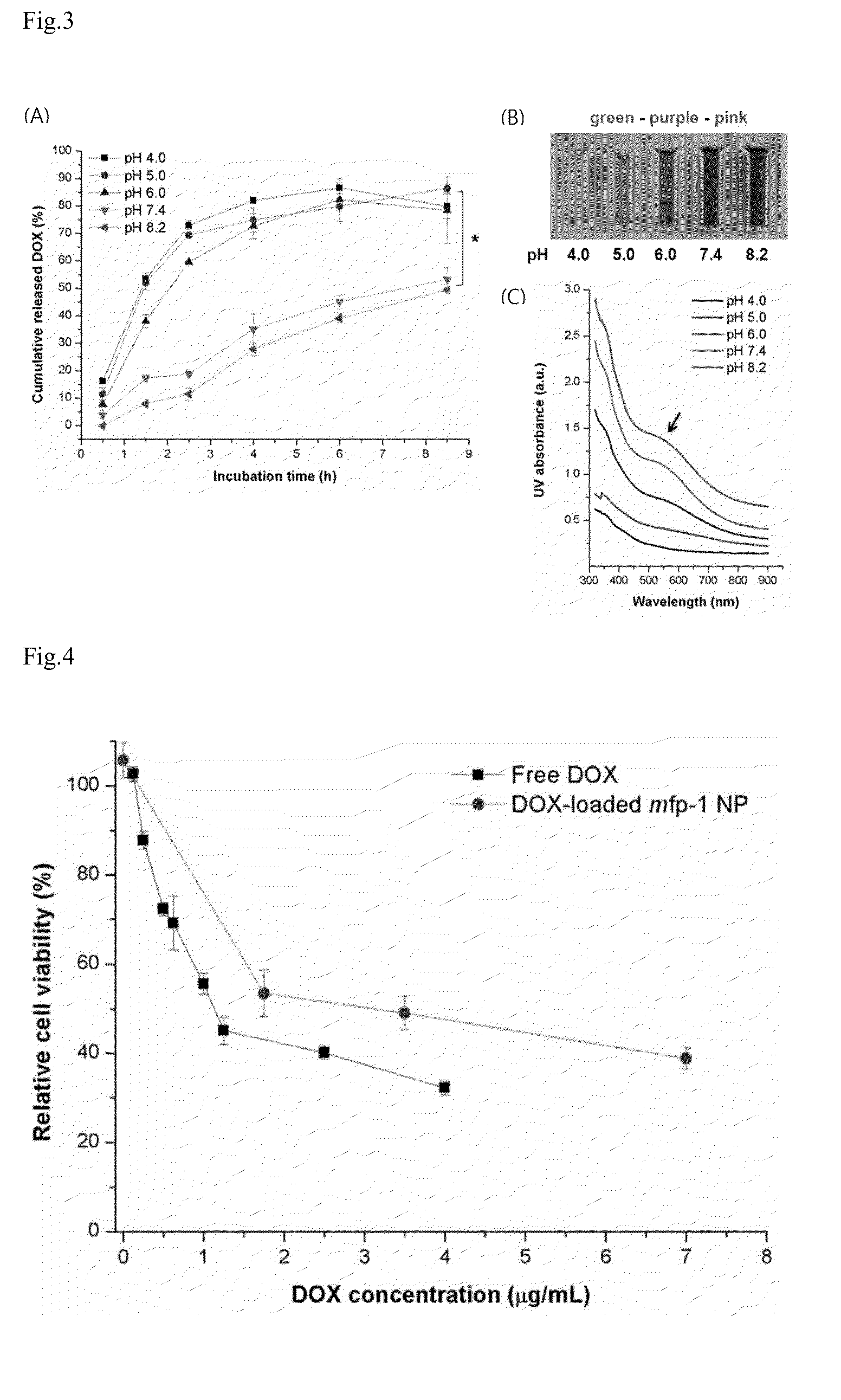

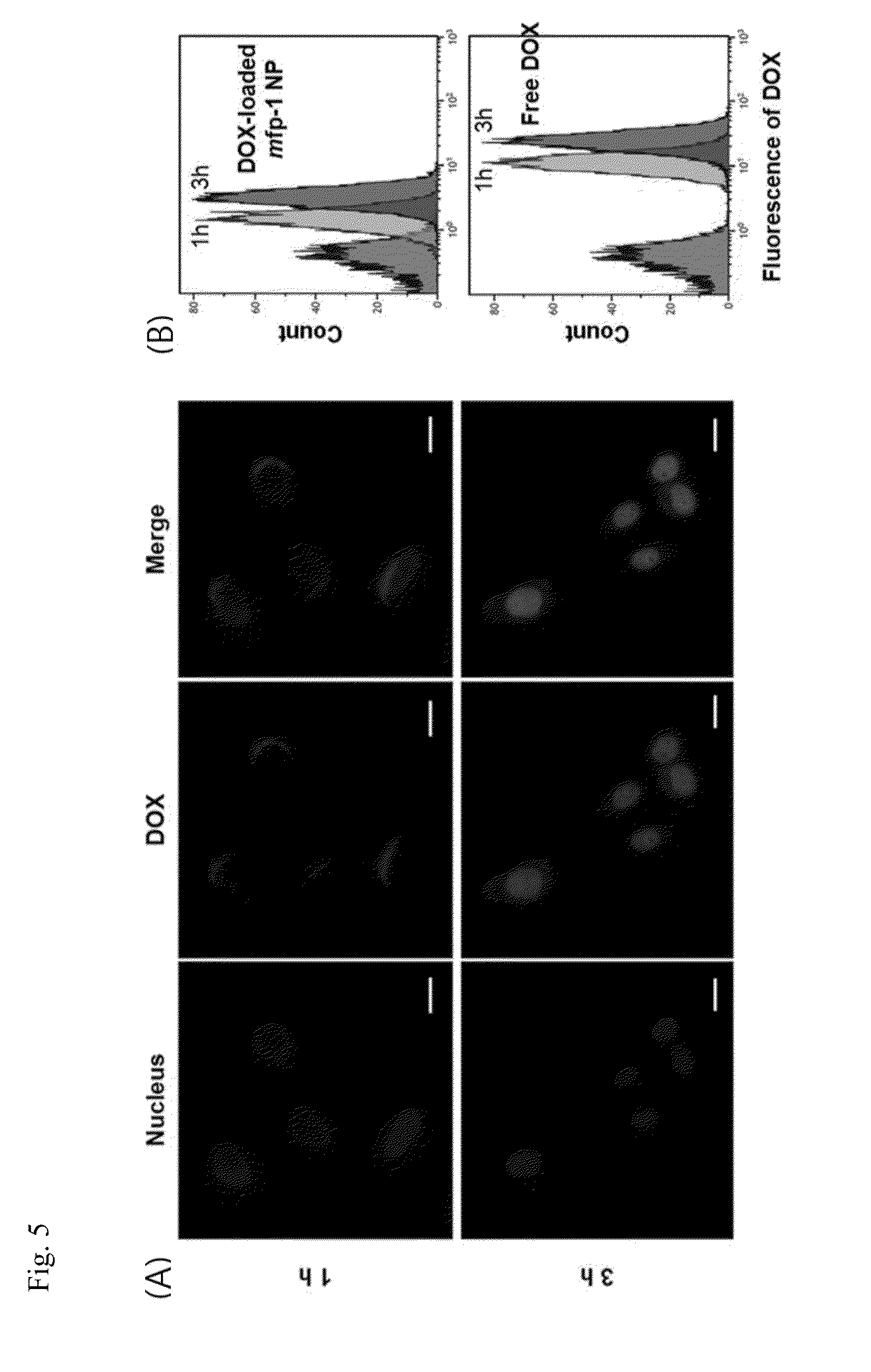

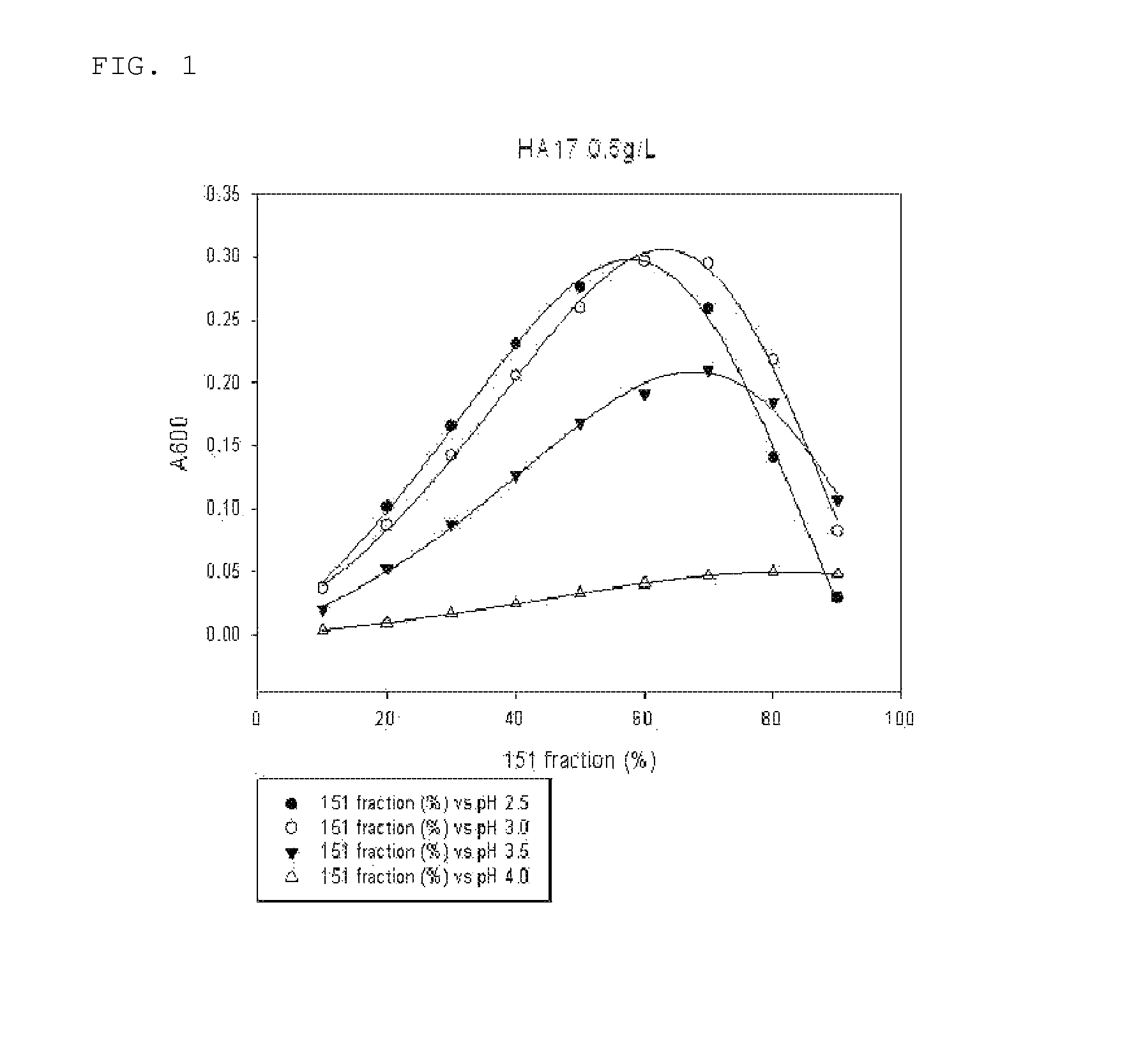

Ph-responsive nanoparticle using mussel adhesive protein for drug delivery and method for preparing the same

ActiveUS20160263136A1Simple processLow toxicityOrganic active ingredientsSaccharide peptide ingredientsDiseaseMedicine

The present invention relates to a pH-responsive metal-catechol derivative nanoparticle for drug delivery based on a mussel adhesive protein, particularly Fe(III)-DOPA nanoparticle, and a method for preparing the same. A nanoparticle for drug delivery according to the present invention is prepared using a pH responsive substance, catechol derivative-metal complex, particularly Fe(III)-DOPA complex, based on a mussel adhesive protein. Thereby, the present invention has excellent biocompatibility, is capable of easily and quickly penetrating into a target cell, and releases a loaded drug under acidic conditions, which enables to selectively deliver a drug to a specific disease having an acidic environment.

Owner:POSTECH ACAD IND FOUND

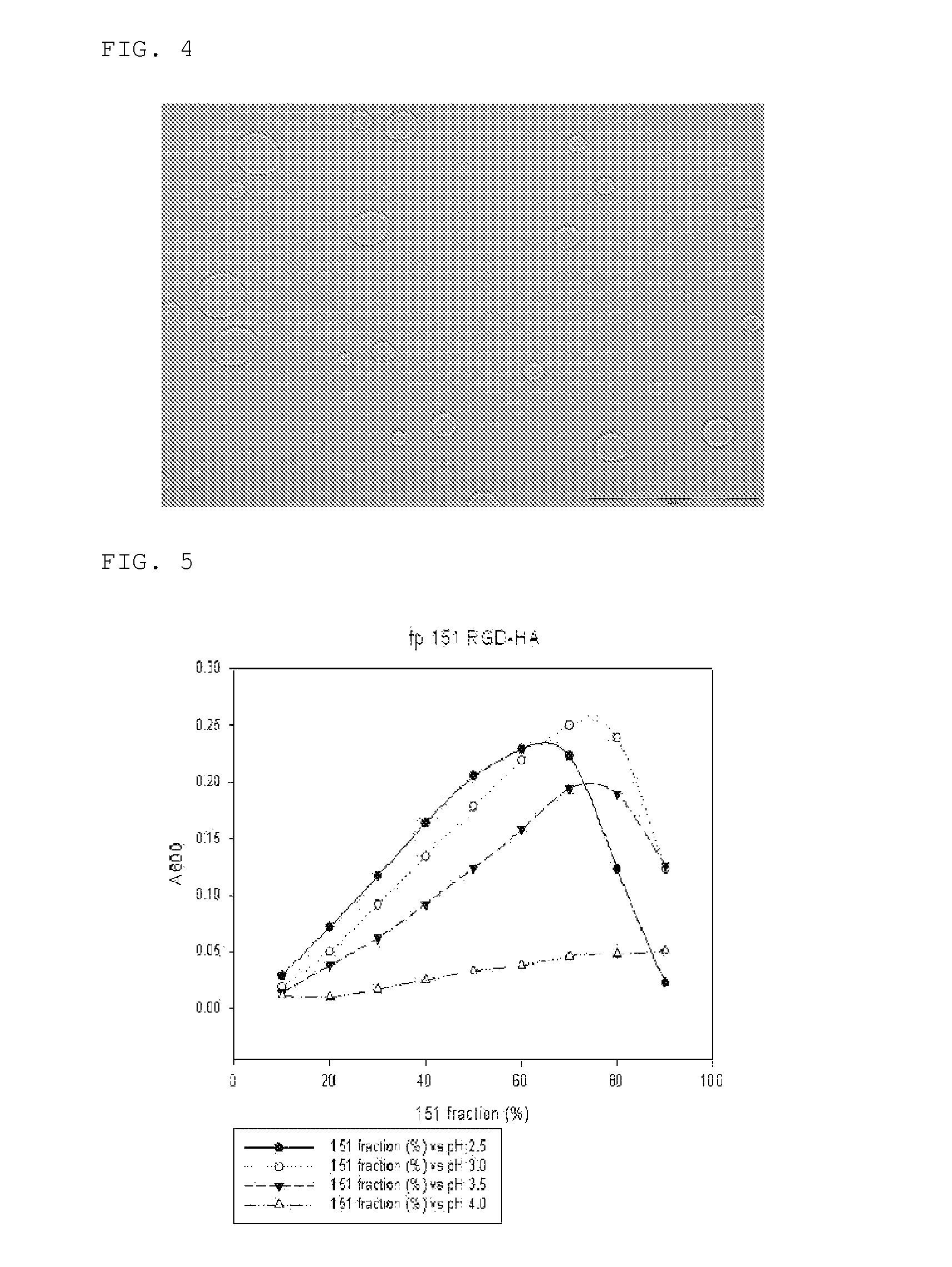

Coacervate having an ionic polymer mixed with the adhesive protein of a mussel or of a species of the variome thereof

ActiveUS20120201748A1Improve adhesion strengthEffectively used as adhesiveAntibacterial agentsOrganic active ingredientsActive componentAnionic polymers

The present invention relates to a coacervate comprising a mussel adhesive protein and an anionic polymer, and more particularly, to a coacervate prepared by mixing a mussel adhesive protein with an anionic polymer, and a novel use thereof. In the present invention, a coacervate prepared by mixing a mussel adhesive protein and an anionic polymer shows a very excellent adhesive strength to various substrates such as cells or metals, and is able to maintain its adhesive strength in the presence of water or under water, thereby being effectively used as an adhesive. Moreover, it has an activity capable of encapsulating bioactive materials, thereby being effectively used as an active component of a composition for delivering bioactive materials.

Owner:POSTECH ACAD IND FOUND

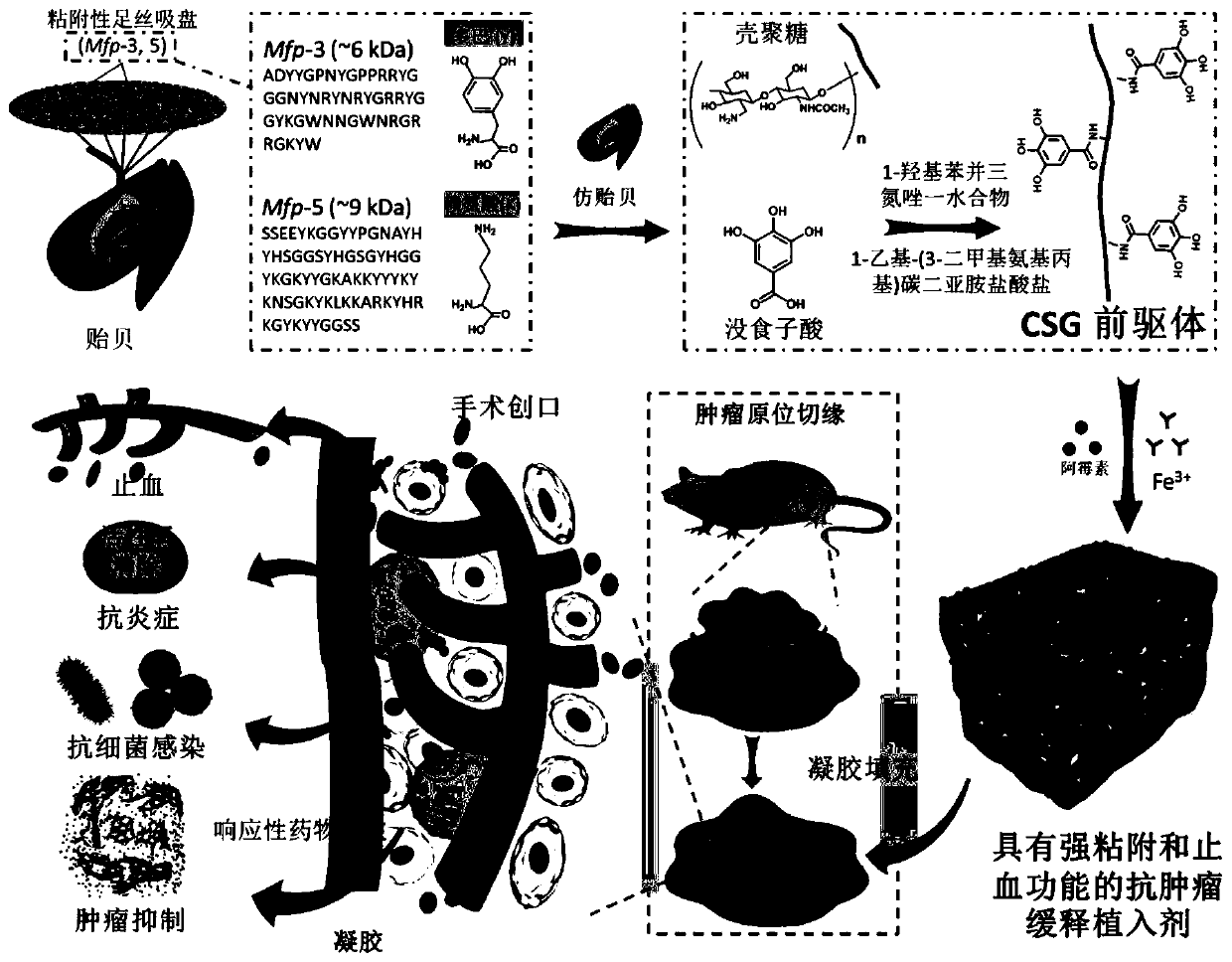

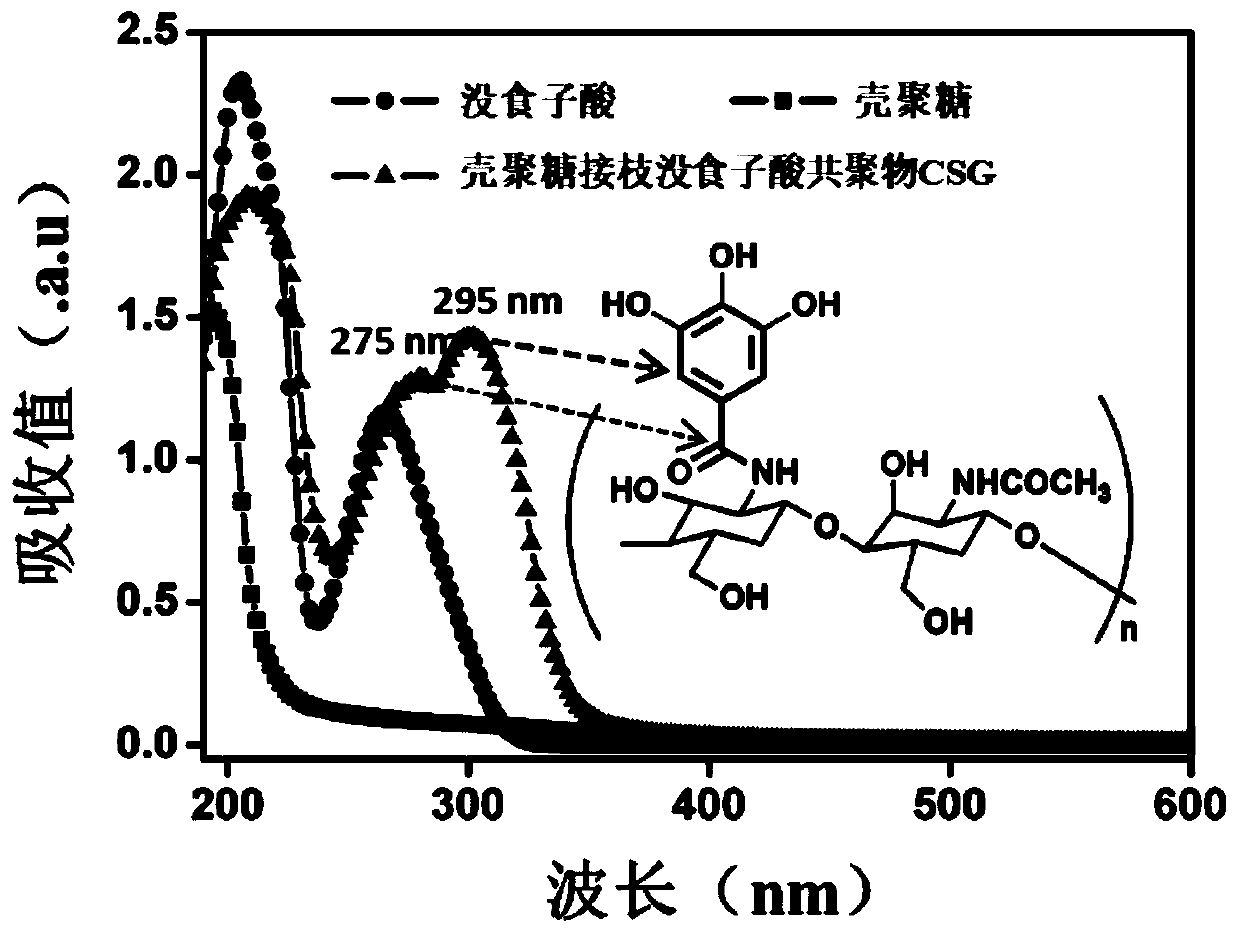

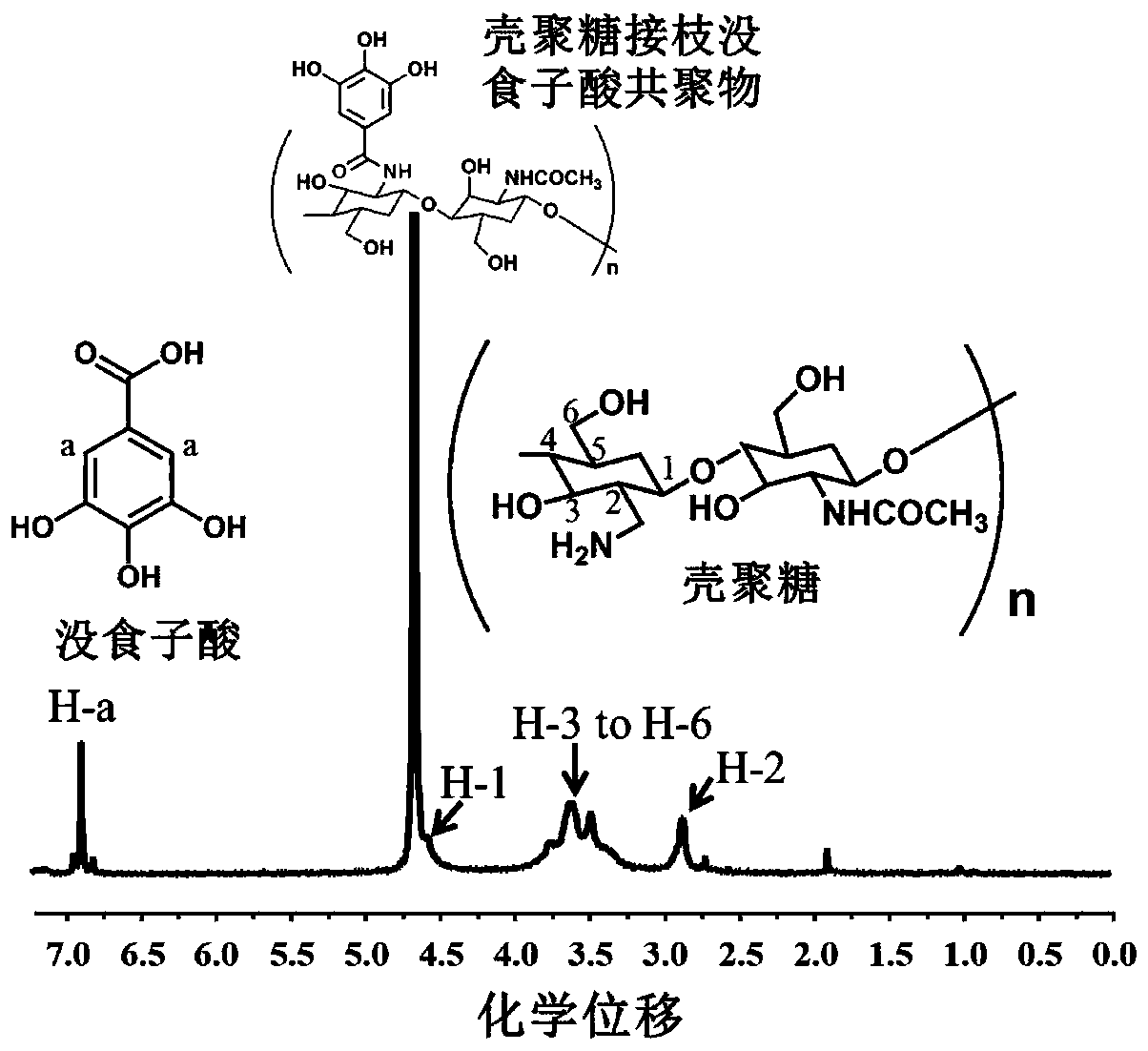

Antitumor slow-release implant having strong adhesion and hemostasis functions and preparation method thereof

ActiveCN110251457AImprove antibacterial propertiesStrong adhesionOrganic active ingredientsEnergy modified materialsGallic acid esterAdditive ingredient

The invention discloses an antitumor slow-release implant having strong adhesion and hemostasis functions and a preparation method thereof. Inspired by mussel adhesion mechanism and catechol and iron ion chelating mechanism, postoperative thermal chemotherapy hydrogel based on mussel adhesion mechanism deriving is developed successfully through bionic design and serves as a multifunctional operative tissue adhesion and treatment agent. Main ingredients of the implant include chitosan, gallic acid, Fe3+ chelating agent and drug. Coating and treating of a wound can be performed by covalently crosslinking and freeze-drying chitosan and gallic acid, dissolving before use, adding antitumor drug, utilizing the Fe3+ chelating agent for crosslinking and ultrasonically mixing well to form gel. The implant has various functions of adhesion, hemostasis, bacteria resisting, inflammation diminishing and thermal chemotherapy of the wound, and postoperative relapse prevention of tumor can be realized by coating an irregular wound of the tumor with the implant and performing mild thermal chemotherapy.

Owner:HEFEI UNIV OF TECH

Method for separating and purifying mussel adhesive protein

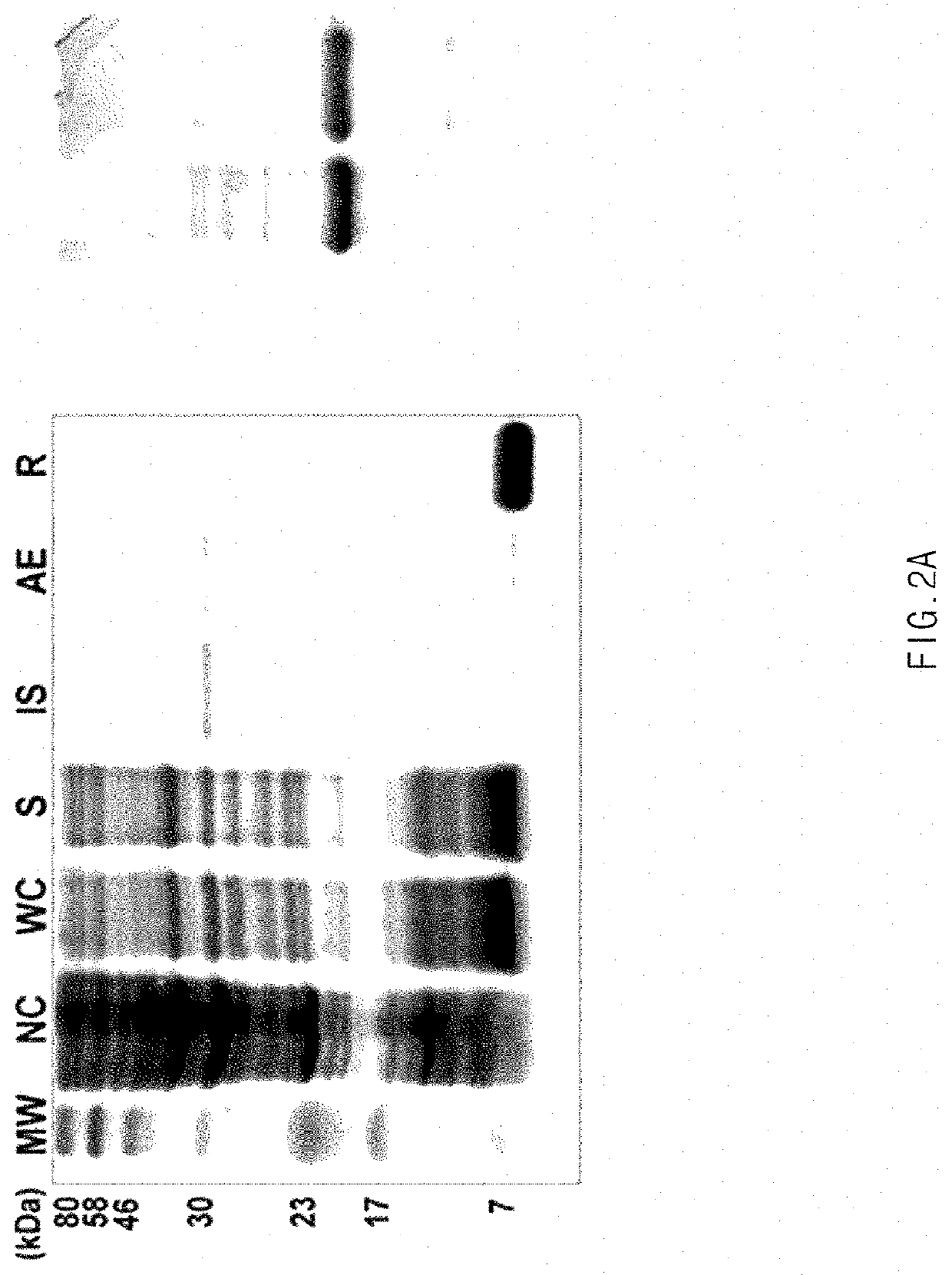

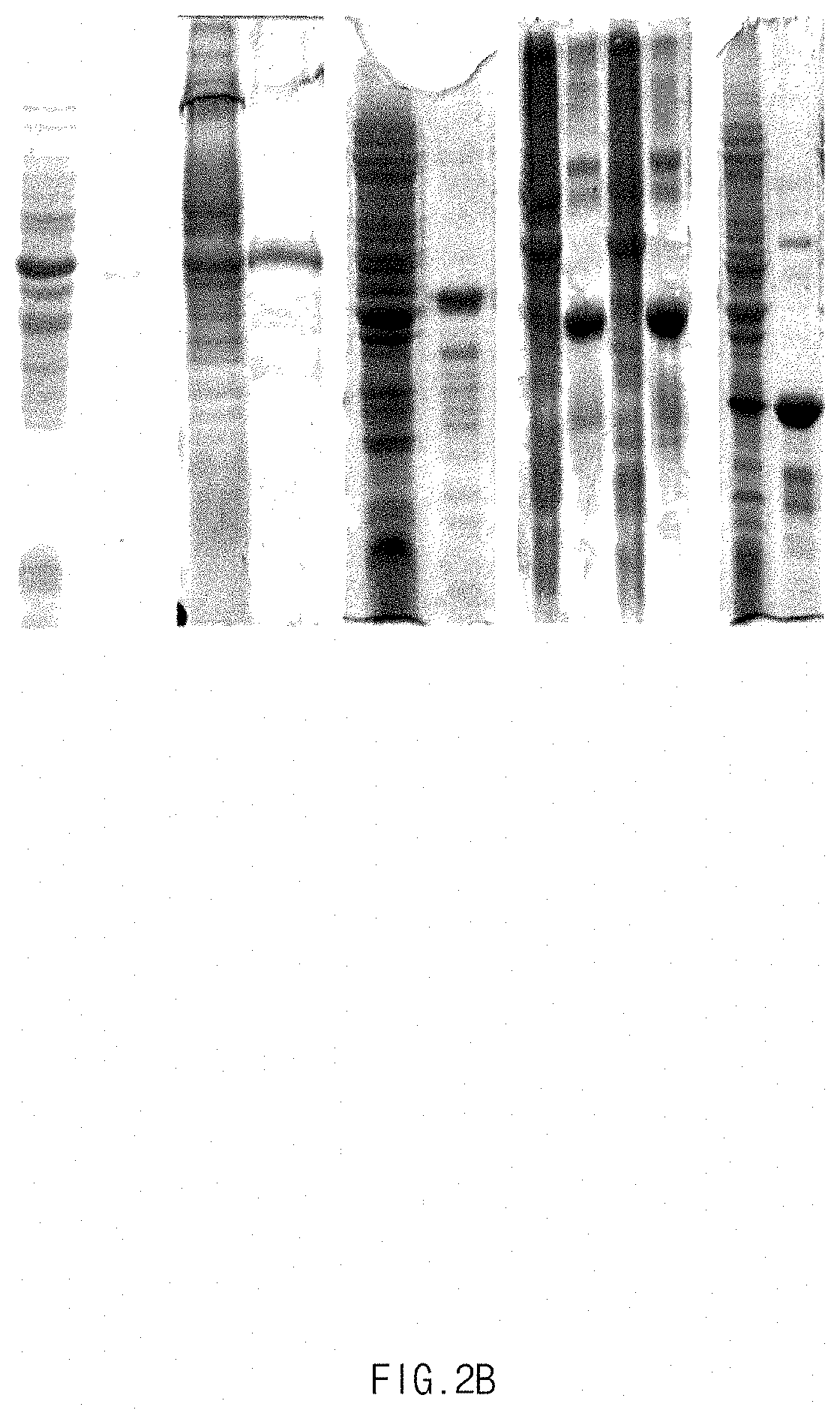

InactiveUS20200062809A1High purityLow production costAntibody mimetics/scaffoldsPeptide preparation methodsInsoluble proteinOrganic solvent

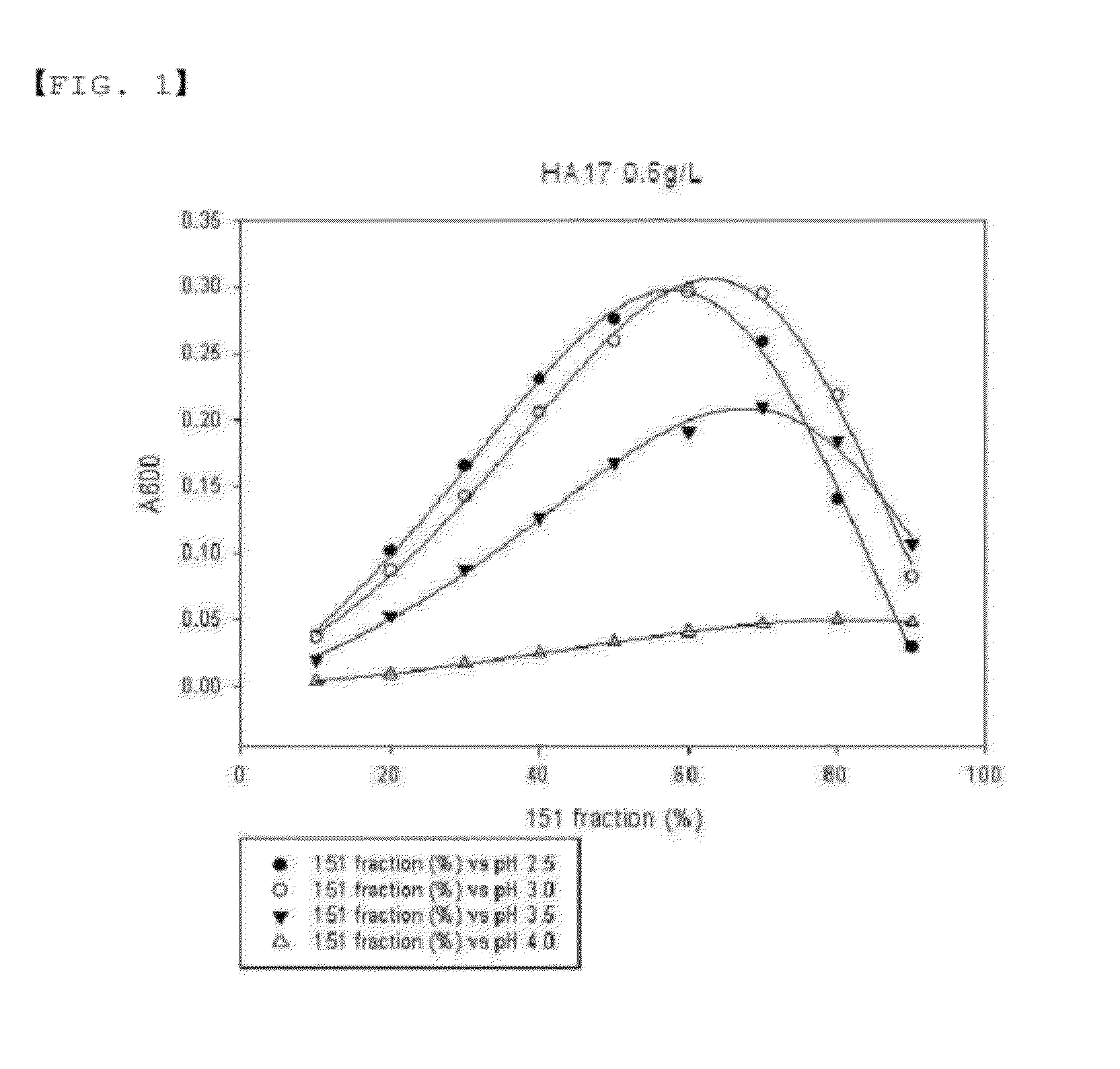

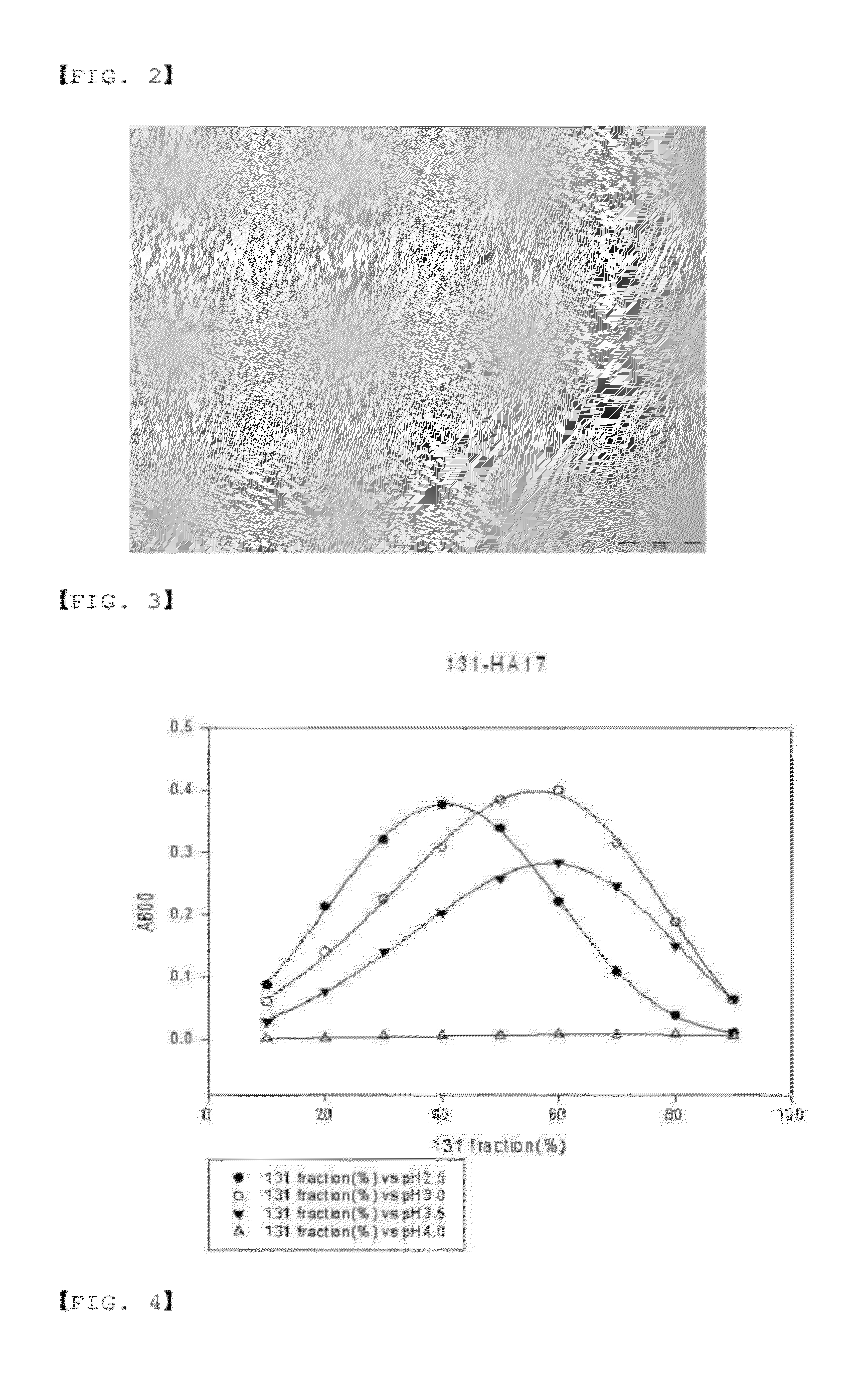

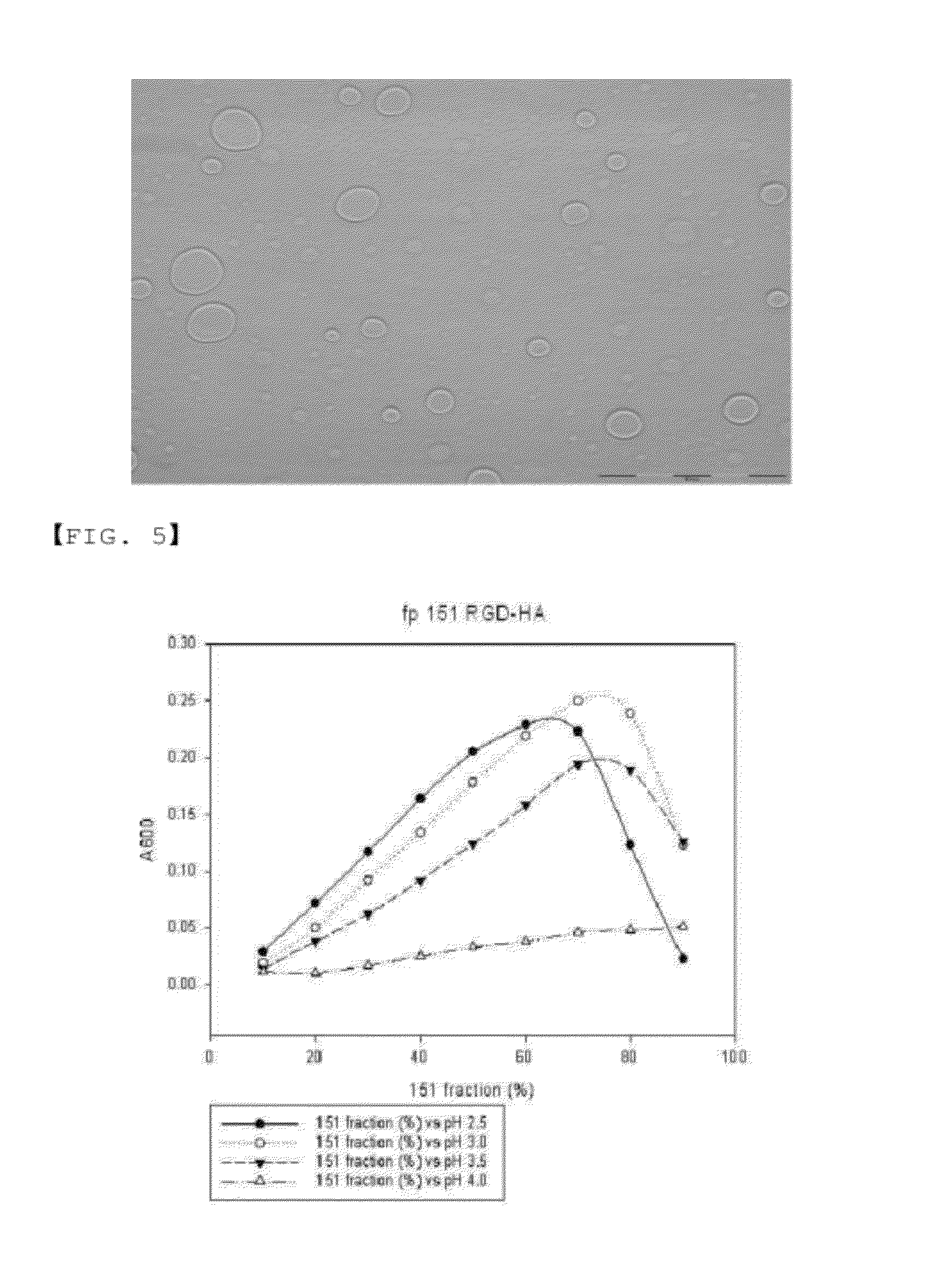

Provided is a method for separating and purifying a mussel adhesive protein, including the steps of: (1) crushing cells containing a mussel adhesive protein; (2) centrifuging the crushed cells to obtain an insoluble protein aggregate including the mussel adhesive protein; (3) treating the insoluble protein aggregate with an acidic organic solvent to obtain a low-purity mussel adhesive protein solution; (4) selectively precipitating the mussel adhesive protein by controlling the acidity of the low-purity mussel adhesive protein solution; and (5) treating the precipitate with a surfactant to remove endotoxins from the mussel adhesive protein. The method of the subject matter can purify a large amount of mussel adhesive proteins of high purity with a simple process. In particular, the subject matter can be applied effectively to the development of novel uses of mussel adhesive proteins by significantly reducing production costs through economical production of the mussel adhesive protein.

Owner:KOLLODIS BIOSCI

Environment-friendly bionic ocean corrosion resisting paint

InactiveCN106147306AReduce coefficient of frictionImprove water repellencyAntifouling/underwater paintsPaints with biocidesAlloySolvent

The invention discloses environment-friendly bionic ocean corrosion resisting paint. The environment-friendly bionic ocean corrosion resisting paint is characterized by being prepared from, by weight, 20-25 parts of fluorinated acrylic ester, 22-24 parts of epoxy phenolic resin, 12-15 parts of silicone rubber, 10-12 parts of silicon-aluminum-barium-calcium alloy powder, 3-4 parts of titanium dioxide, 2-4 parts of biological preservative, 3-4 parts of adhesive force thickener, 5-7 parts of filler and 24-28 parts of solvent. Friction coefficient can be reduced effectively, and hydrophobicity can be improved; through the synergistic effect of the filler and the adhesive force thickener, contamination release performance is improved, so that adhesion of attachments does not occur easily or is not firm; the biological preservative has an effective adhesion inhibition effect and has a quite high mussel adhesion preventing capacity; P-cinnamic acid sulfate has a strong marine bacteria and barnacle adhesion inhibition effect, is purely natural and free of pollution, and has a good environment protection effect; the corrosion resisting paint can be sprayed or brushed, and a coating is resistant to corrosion and suitable for severe marine climate.

Owner:QINGDAO ZHONGTIAN ZHICHENG SERVICE PLATFORM OF SCI & TECH CO LTD

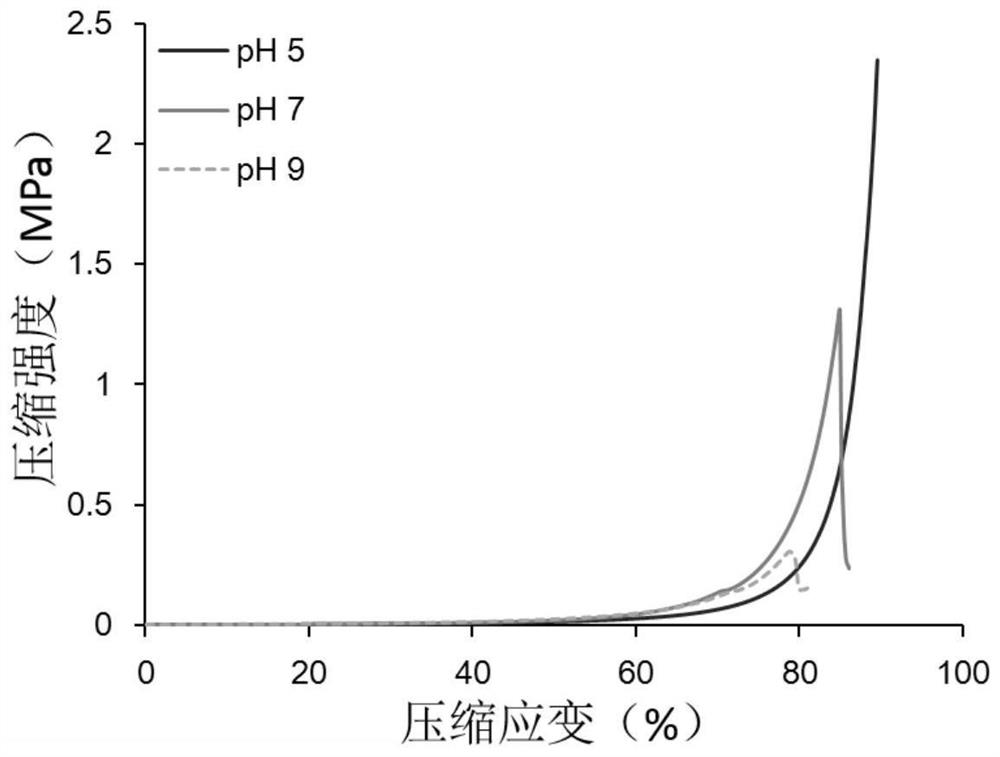

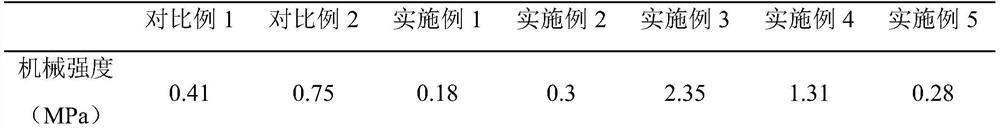

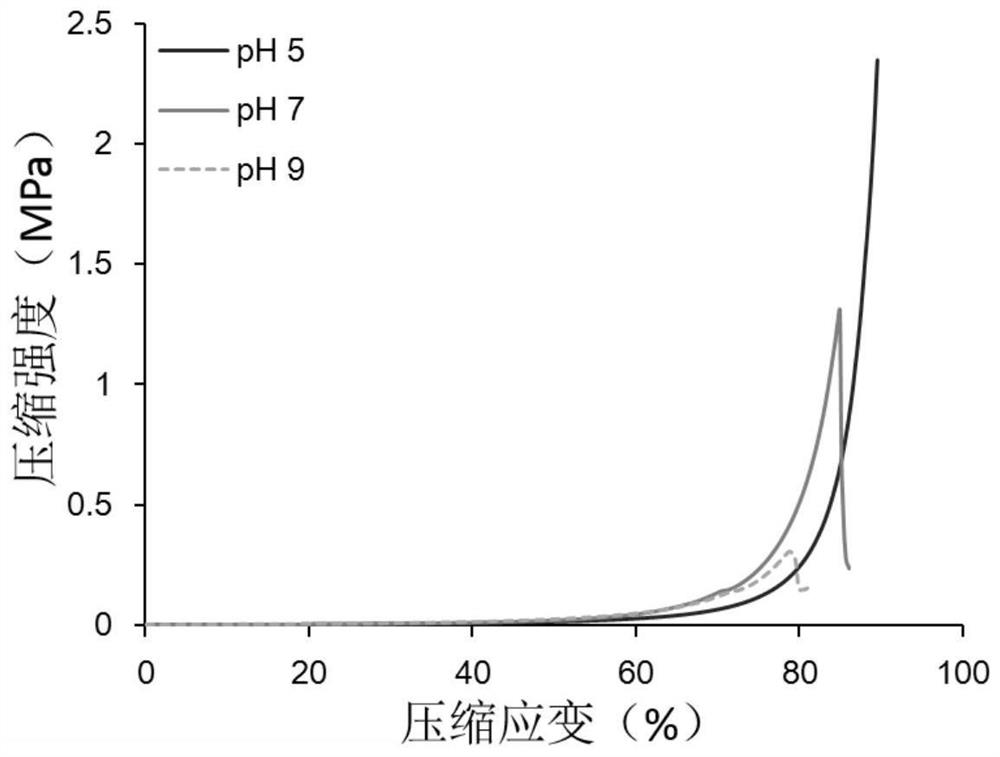

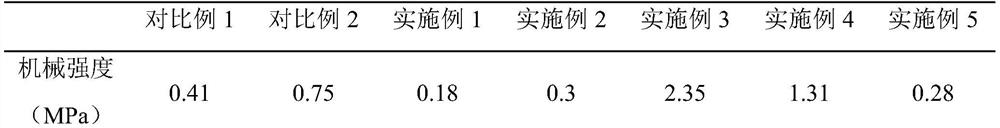

Preparation method of PEGDA-mussel adhesive protein-collagen composite hydrogel with strong adhesion and high mechanical strength

The invention discloses a preparation method of PEGDA-mussel adhesive protein-collagen composite hydrogel with strong adhesion and high mechanical strength, belonging to the technical field of hydrogel. In order to improve the mechanical strength and tissue adhesion of a collagen hydrogel, the invention discloses the preparation method for the PEGDA-mussel adhesive protein-collagen composite hydrogel with strong adhesion and high mechanical strength. The method comprises the following steps: dissolving mussel adhesive protein into an acetic acid solution to obtain an acetic acid solution of the mussel adhesive protein; dissolving a collagen solid in the acetic acid solution of the mussel adhesive protein to obtain a mussel adhesive protein-collagen solution; carrying out alkali neutralization until a pH value is in a range of 5-9, and adding a PEGDA solid until the solid is completely dissolved; and adding a photoinitiation factor, and carrying out ultraviolet crosslinking to form thePEGDA-mussel adhesive protein-collagen composite hydrogel. The preparation method is simple in process and easy to operate, and has wide application prospects in the fields of tissue engineering, medicine and the like.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

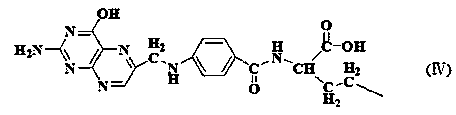

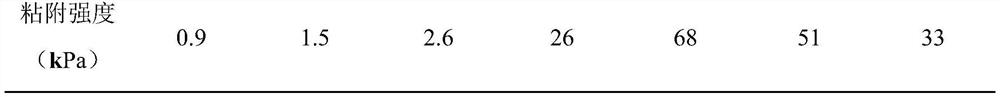

Cloning and expression of recombinant adhesive protein mefp-2 of the blue mussel, mytilus edulis

The present invention includes a Mytilus edulis cDNA having a nucleotide sequence that encodes for the Mytilus edulis foot protein-2 (Mefp-2), an example of a mollusk foot protein. Mefp-2 is an integral component of the blue mussels' adhesive protein complex, which allows the mussel to attach to objects underwater. The isolation, purification and sequencing of the Mefp-2 gene will allow researchers to produce Mefp-2 protein using genetic engineering techniques. The discovery of Mefp-2 gene sequences will also allow scientists to better understand how the blue mussel creates its waterproof adhesive protein complex.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

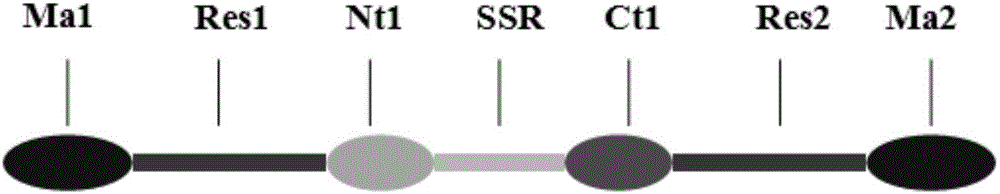

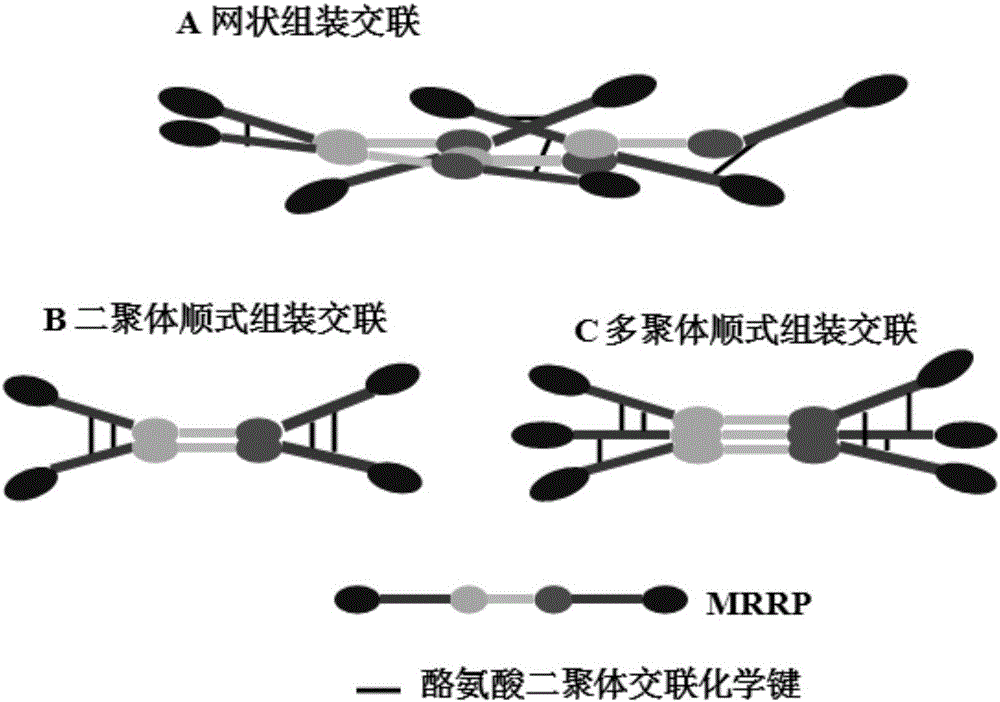

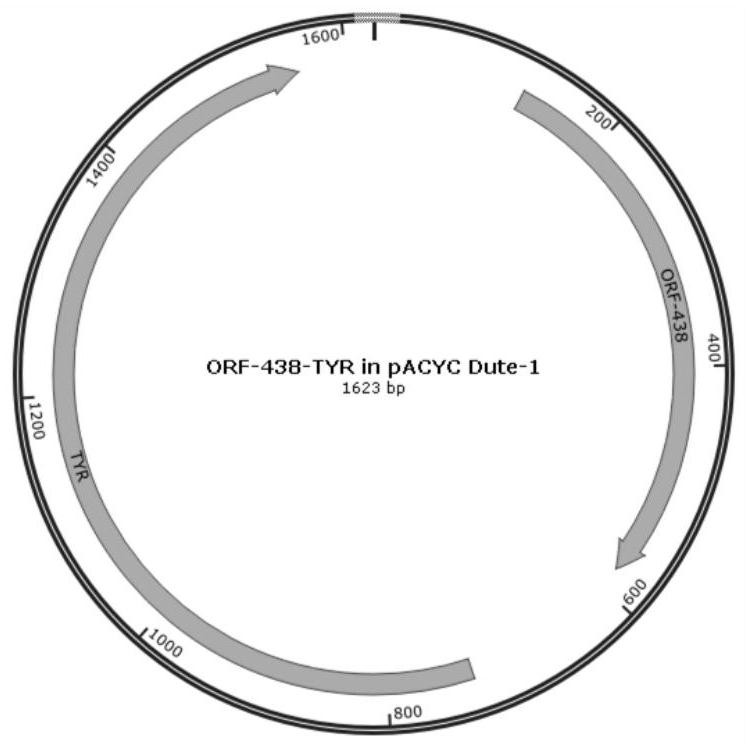

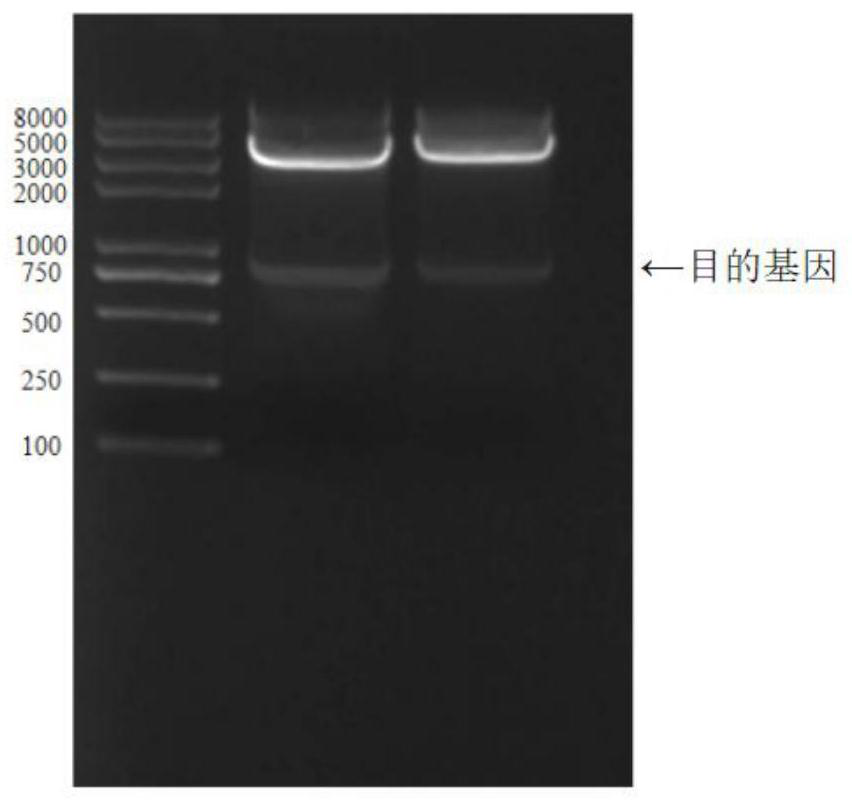

MRRP protein, gene, carrier, engineering bacteria and application thereof

ActiveCN105085685AImprove manufacturing yieldSelf-assembly properties haveBacteriaPeptide/protein ingredientsAttachment proteinBiology

The invention discloses MRRP protein, a gene, a carrier, engineering bacteria and application of the MRRP protein, the gene, the carrier and the engineering bacteria to preparation of wound healing medicine. The MRRP protein is formed by sequentially connecting mussel attachment protein Ma1, elastic drosophila melanogaster protein Res1, a spider silk protein nitrogen end sequence Nt1, a spider silk protein middle-piece repetitive sequence SSR, a spider silk protein carbon end sequence Ct1, elastic drosophila melanogaster protein Res2 and mussel attachment protein Ma2. The MRRP protein integrates self-assembling performance of spider silk protein, high elasticity of the elastic drosophila melanogaster protein and high viscosity of the mussel attachment protein, comprehensive performance is excellent, lengths are uniform, the MRRP protein can be biodegraded completely, the yield is high by adopting a microorganism method for preparing, and chemical pollution is avoided; the MRRP protein has high elasticity, and can bond wounds, so that the wounds are bonded without using lines.

Owner:山东润土节能环保工程有限公司

Coacervate having an ionic polymer mixed with the adhesive protein of a mussel or of a species of the variome thereof

ActiveUS8673986B2Improve adhesion strengthEffectively used as adhesiveBiocideNervous disorderPolymer scienceAnionic polymers

The present invention relates to a coacervate comprising a mussel adhesive protein and an anionic polymer, and more particularly, to a coacervate prepared by mixing a mussel adhesive protein with an anionic polymer, and a novel use thereof. In the present invention, a coacervate prepared by mixing a mussel adhesive protein and an anionic polymer shows a very excellent adhesive strength to various substrates such as cells or metals, and is able to maintain its adhesive strength in the presence of water or under water, thereby being effectively used as an adhesive. Moreover, it has an activity capable of encapsulating bioactive materials, thereby being effectively used as an active component of a composition for delivering bioactive materials.

Owner:POSTECH ACAD IND FOUND

A kind of preparation method of bulk type high-strength bionic adhesive

InactiveCN105602481BAchieve the perfect combinationWide applicabilityUnsaturated alcohol polymer adhesivesPolymer sciencePolyvinyl alcohol

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

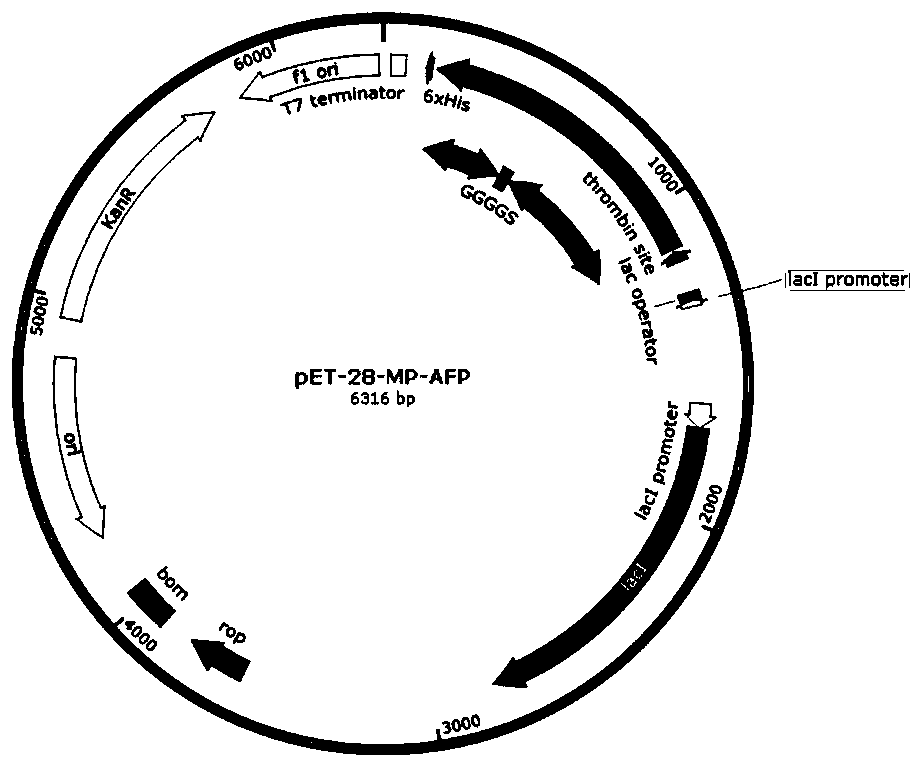

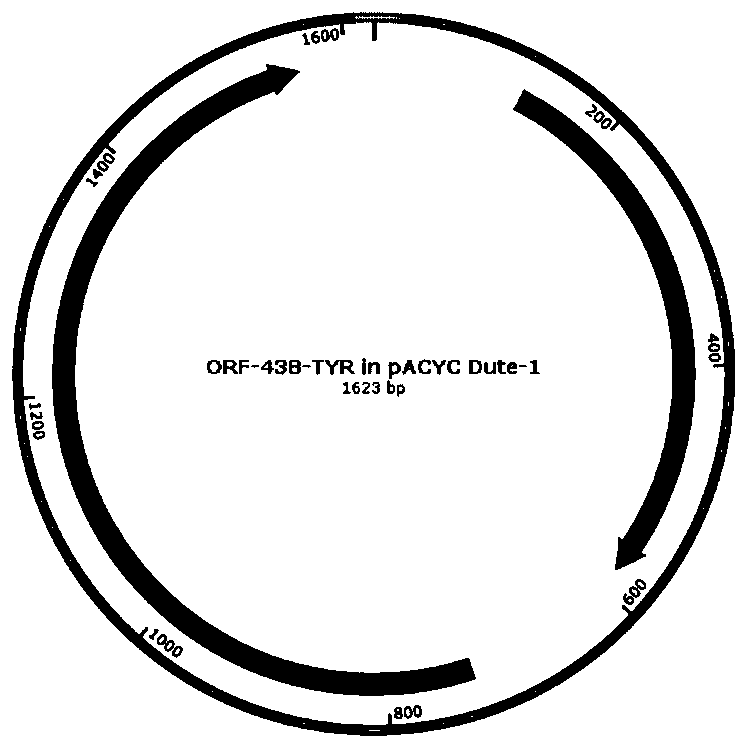

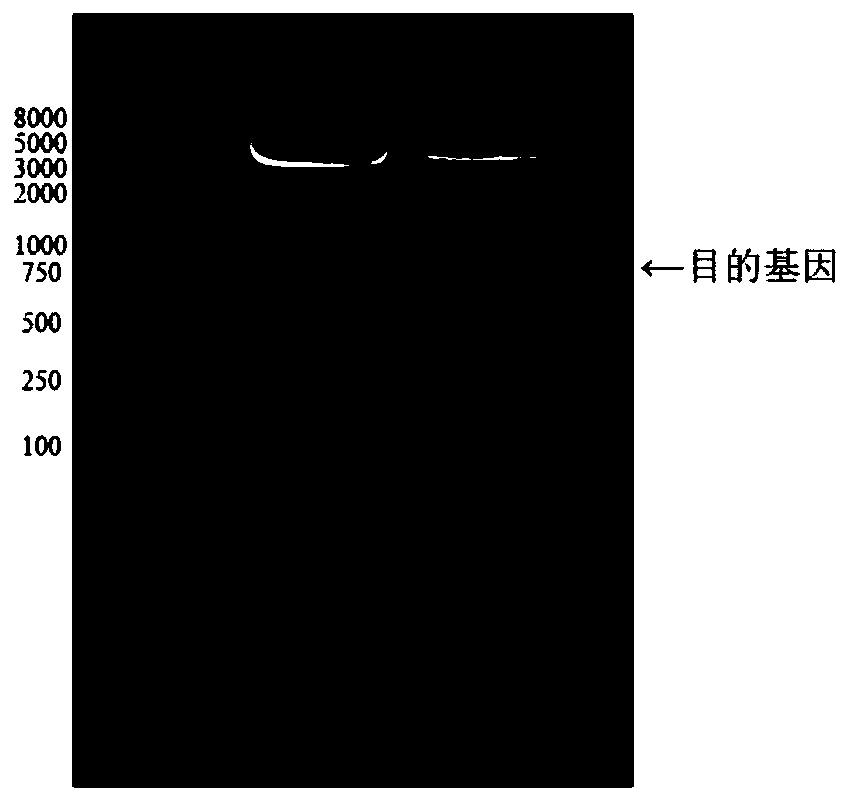

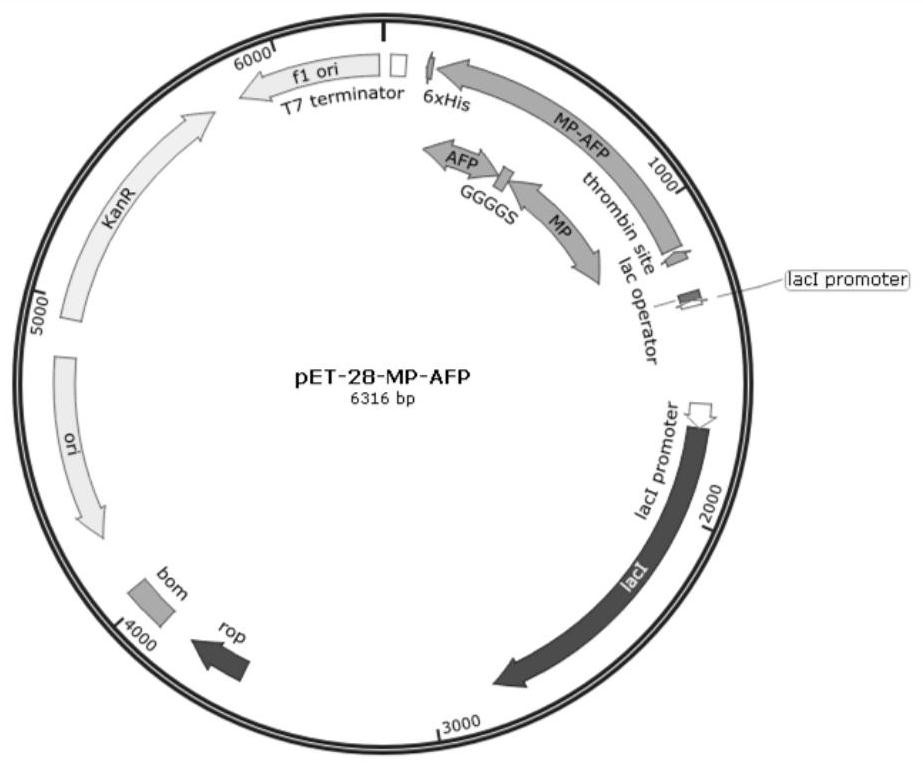

Diblock fusion protein with adhesion-antifreeze dual functions, and synthesis method and application thereof

ActiveCN110776569AGrowth impactGentle and efficient processAntibody mimetics/scaffoldsHybrid peptidesEscherichia coliInclusion bodies

The invention relates to a diblock fusion protein with adhesion-antifreeze dual functions, and a synthesis method and application thereof. By taking genetic engineering as a technological means, a gene expression vector simultaneously containing antifreeze protein genes and adhesion protein genes is prepared and converted into a host cell, through an inducer, the host cell overexpresses the protein, and thus the fusion protein is obtained by separation and purification. The amino acid sequence of the fusion protein is SEQ ID NO.3, and the nucleotide sequence of the fusion protein is SEQ ID NO.4. The mussel adhesion protein and the antifreeze protein are fused on the gene level, and thus the diblock fusion protein with the adhesion-antifreeze dual functions is constructed; and the fusion protein is expressed through fermentation of escherichia coli, supernatant protein is purified through an affinity chromatogram, an inclusion body is purified through acetic acid, a high-purity separation and purification method is constructed, the fusion protein is synthesized through a microbial one-step method, the process is mild and efficient, the cost is low, the equipment requirement degree is low, and expanded production at the later period is easy.

Owner:TIANJIN UNIV

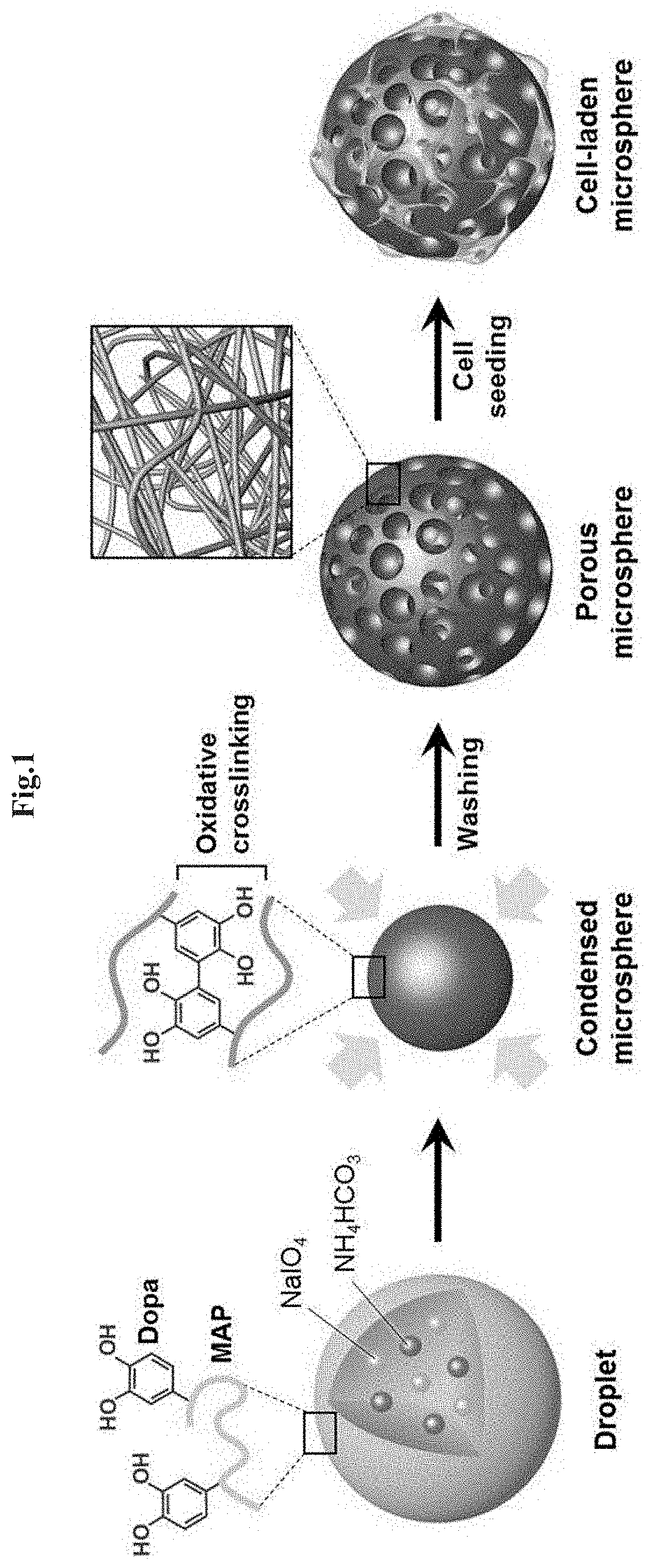

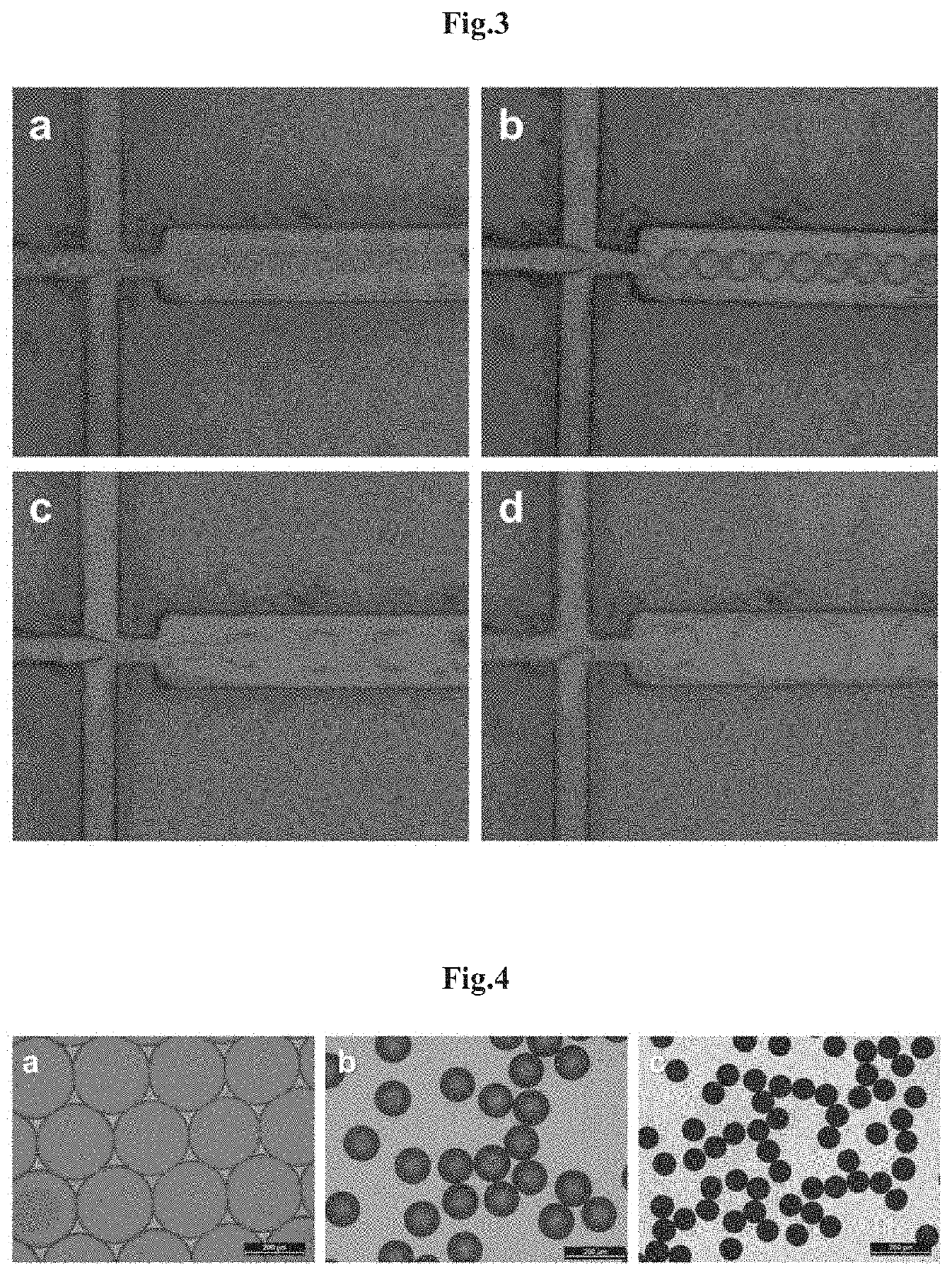

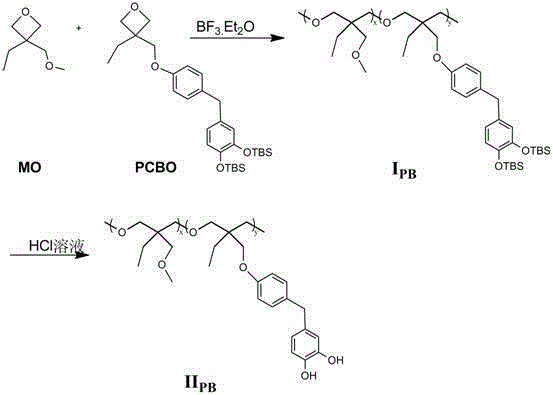

Porous microspheres including mussel adhesive protein, and method for manufacturing same

PendingUS20200291077A1Efficient deliveryWide applicationPowder deliveryAntibody mimetics/scaffoldsTissue defectDrug carrier

The present invention relates to a porous microsphere comprising a mussel adhesive protein and a method of preparing the same. The porous microsphere comprising the mussel adhesive protein according to the present invention is capable of minimally invasive bio-injection through syringes to efficiently deliver therapeutic stem cells to the sites of tissue defects as cell carriers. Further, the present invention may be widely applied to scaffolds for tissue engineering, drug carriers, or the like, which may be suitably applied to the size of the defected site of tissue.

Owner:POSTECH ACAD IND FOUND

A preparation method for bionic mussel glue based on oxetane derivatives

InactiveCN103289074BEfficient synthesisAchieve the perfect combinationPolyether adhesivesPolymer dissolutionSide chain

The present invention involves a preparation method based on the oxygen cycle -borne derivatives synthetic bionic mussel glue. The main steps are: using two types of oxygen cytane derivatives to open the co -phenolic hydroxyl group to be protected with child teaThe polymer of the phenol -side chain structure, which is protected by the polymer to obtain a polymer containing a phenyl phenol structure. After dissolving, add a certain amount of cross -linked agent and stir evenly.It is characterized by: 1) This synthesis method is simple and efficient, and the raw materials and reagents used in the reaction process are cheap and easy to obtain, and the easy operation process and realize industrial production;The simulation of high molecules of natural mussel adhesion protein properties to achieve a certain purpose of a certain biocompatibility and unified high adhesion intensity is a new type of bionic mussels synthesis technology.New bionic polymer materials for effective protein ingredients provide new ways.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

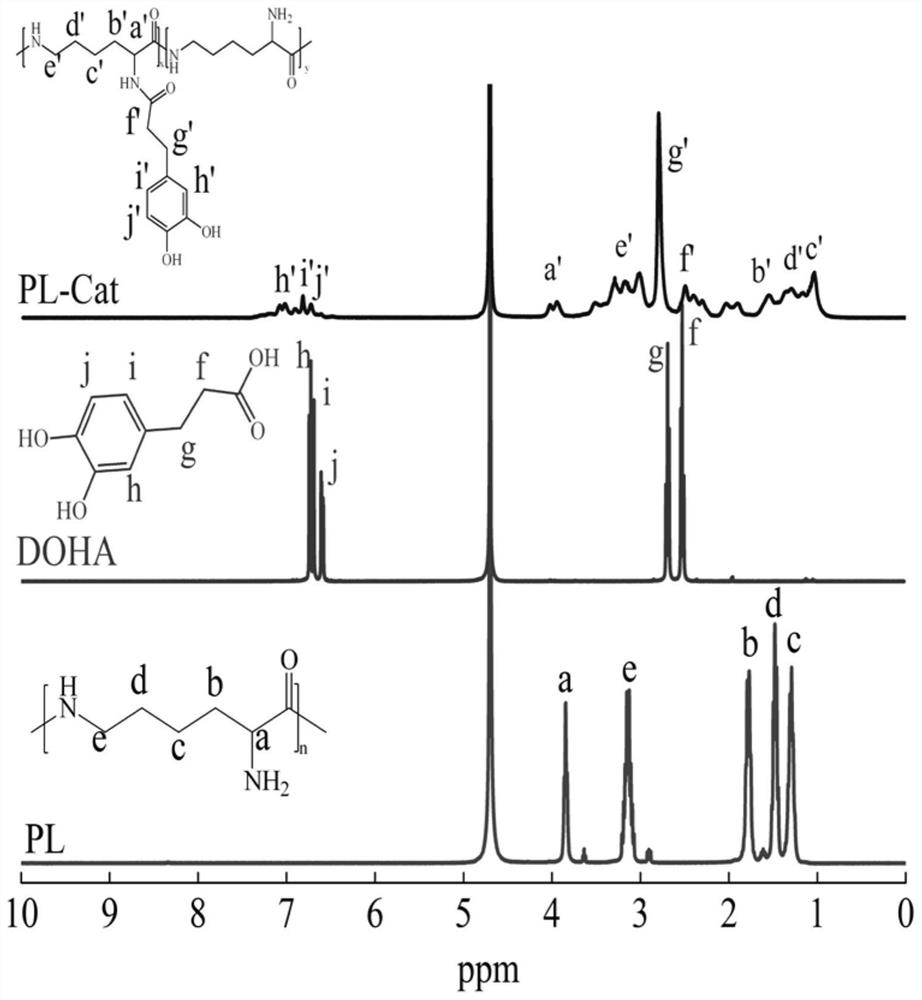

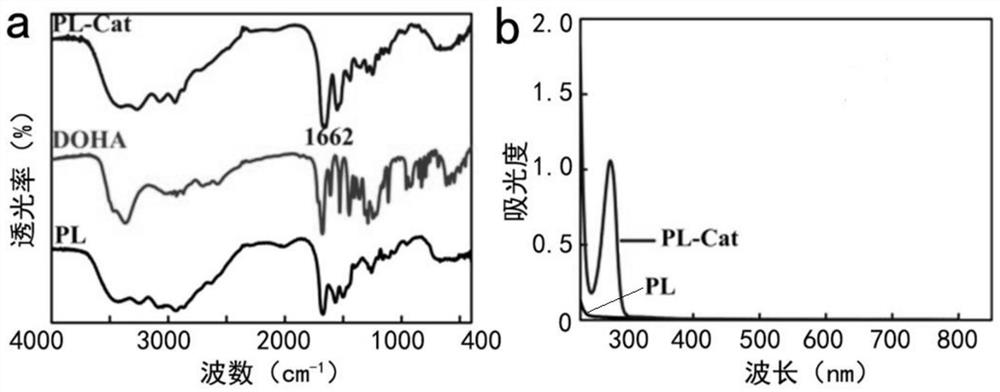

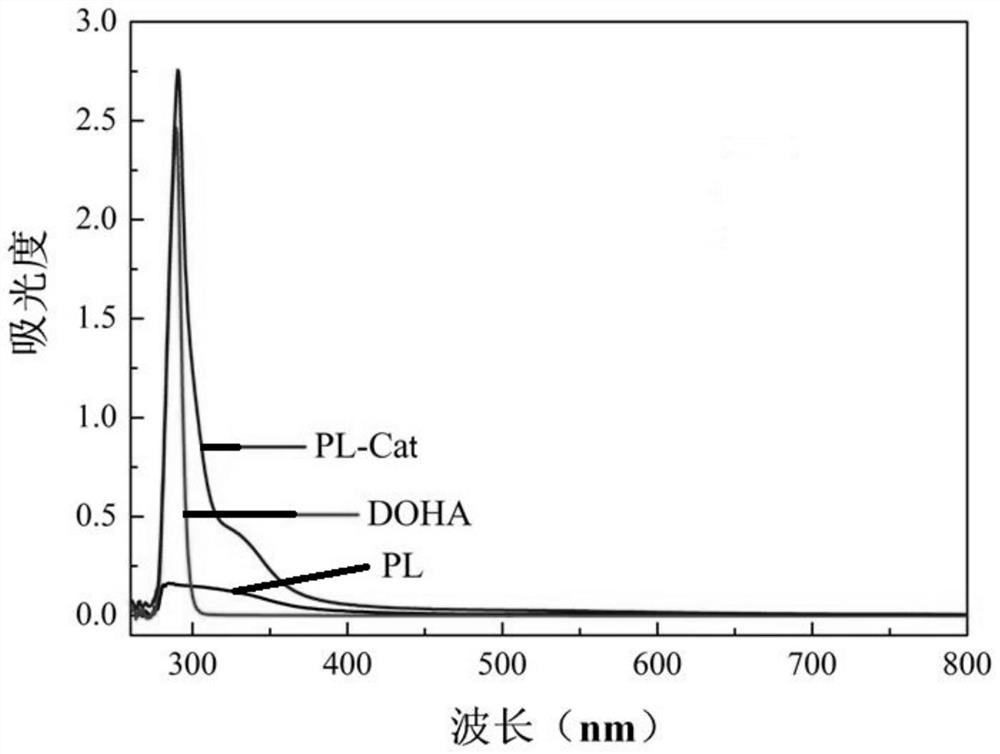

Mussel-like coordination adhesive based on epsilon-polylysine and preparation method of mussel-like coordination adhesive

The invention discloses a mussel-like coordination adhesive based on epsilon-polylysine and a preparation method of the mussel-like coordination adhesive. Key factors of a mussel adhesion environmentare introduced into the design of a biological adhesive; and the prepared adhesive has tissue adhesion performance and low cytotoxicity. The preparation method comprises the following steps of: firstly, uniformly mixing epsilon-polylysine with 3,4-dihydroxyphenylpropionic acid under an oxygen-free condition, then adding 1-(3-dimethylaminopropyl)-3-ethyl carbodiimide hydrochloride and N-hydroxysuccinimide into the mixture, and performing mixing and reacting to obtain the main component catechol modified epsilon-polylysine of the adhesive; dissolving PL-Cat in distilled water, adding Fe<3+> intothe distilled water, and adding NaOH to adjust the pH to be weakly alkaline, so that the PL-Cat / Fe adhesive can be obtained. The adhesive has good adhesive strength and low cytotoxicity, and has a wide application prospect in tissue engineering.

Owner:TIANJIN UNIV

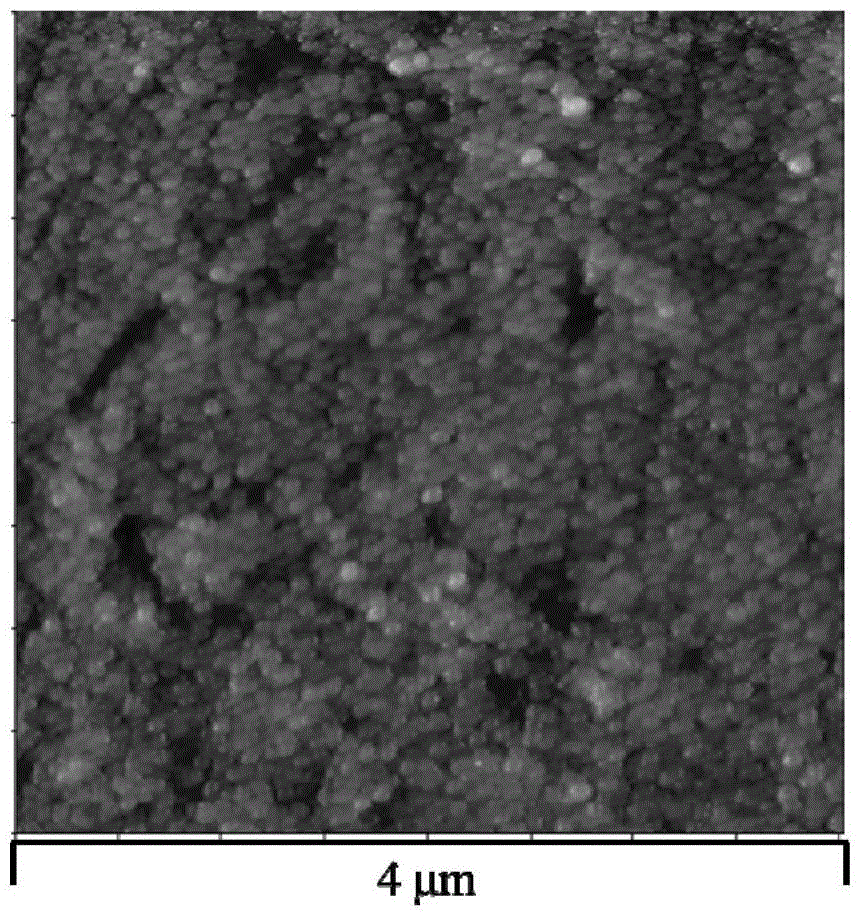

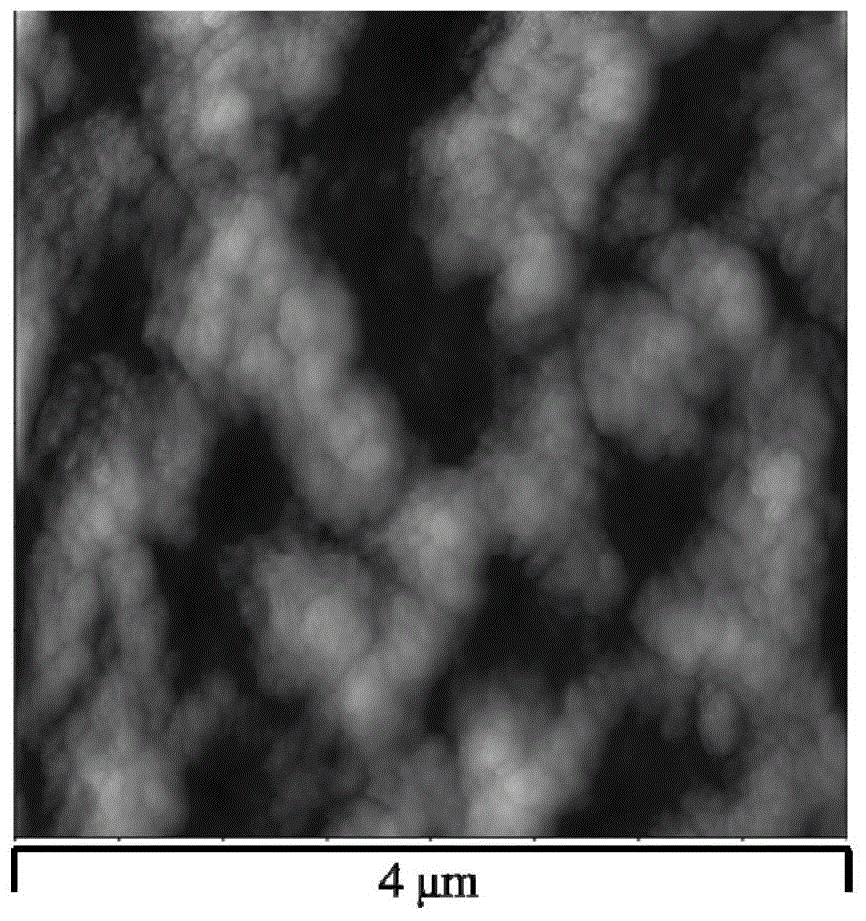

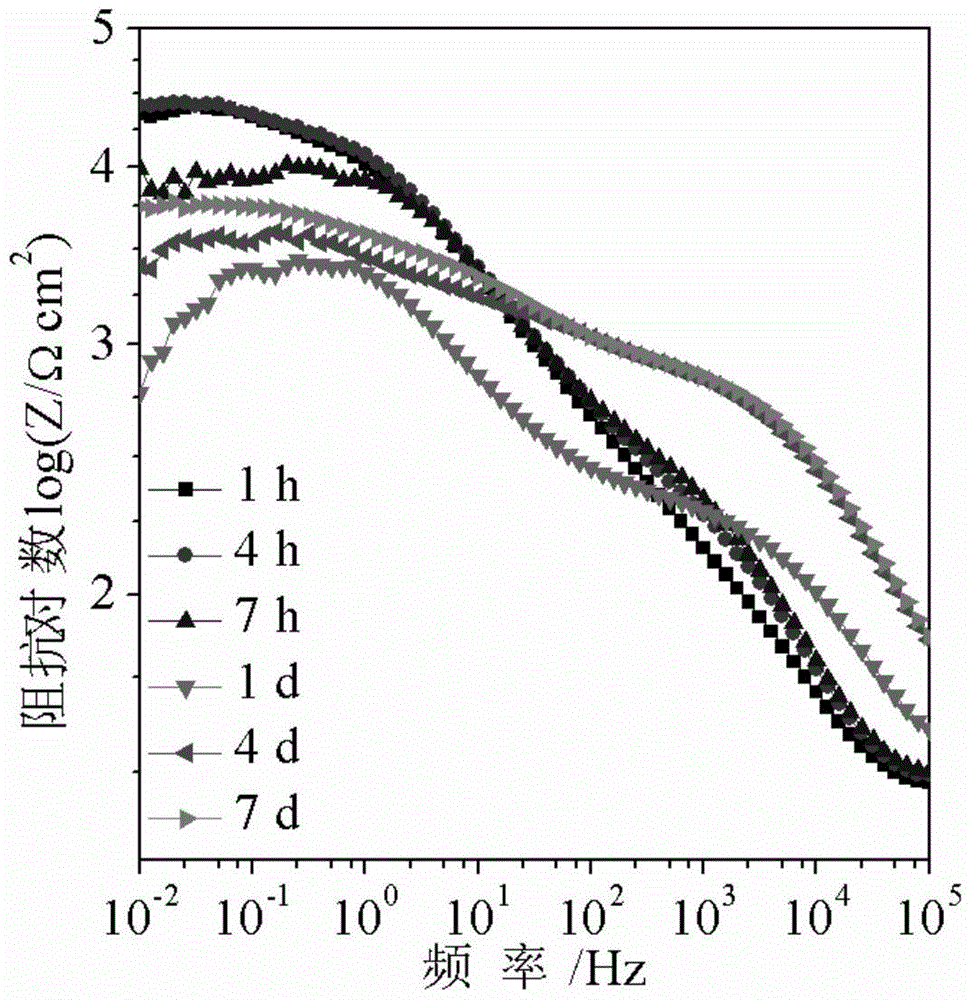

Metal Surface Treatment Method Based on Composite Film of Chitosan and Mussel Adhesin

ActiveCN104862757BImprove corrosion resistanceControllable biodegradation rateElectrolytic organic material coatingProtein solutionMetallic materials

The invention discloses a metal surface treatment method based on a chitosan and mussel adhesion protein composite membrane, and relates to high-molecular compounds. The method comprises specific steps that step-by-step polishing, ultrasonic cleaning and drying are carried out on a metal material surface to be treated, and then an electro-deposition is adopted to enable chitosan and mussel adhesion protein to form a composite membrane layer on the metal material surface; and electro-deposition specifically comprises the steps that chitosan is added into a chitosan buffer solution to form a chitosan solution; the mussel adhesion protein is added into a mussel adhesion protein buffer solution to form a mussel adhesion protein solution; and the metal material to be treated is sequentially immersed into the chitosan solution and the mussel adhesion protein solution to be electrically deposited, and after drying, the composite membrane layer is formed on the metal material surface. The composite membrane layer is formed on the metal material surface, and the electro-deposition step can be repeatedly carried out to form multiple composite coatings. The method is simple, easy to implement and particularly suitable for corrosion prevention of metallic biomaterials.

Owner:XIAMEN UNIV

A diblock fusion protein with dual functions of adhesion and antifreeze, its synthesis method and application

ActiveCN110776569BGrowth impactGentle and efficient processAntibody mimetics/scaffoldsHybrid peptidesEscherichia coliInclusion bodies

The present invention relates to a diblock fusion protein with dual functions of adhesion-antifreeze and its synthesis method and application; a gene expression carrier containing antifreeze protein gene and adhesion protein gene is prepared by using genetic engineering as a technical means, And transform it into host cells, make it overexpress the protein by inducer, separate and purify to obtain the fusion protein. The amino acid sequence of the fusion protein is SEQ ID NO.3, and the nucleotide sequence is SEQ ID NO.4. Mussel adhesion protein and antifreeze protein were fused at the gene level to construct a two-block fusion protein with dual functions of adhesion and antifreeze; the fusion protein was expressed by Escherichia coli fermentation, and purified by affinity chromatography Albumin, using acetic acid to purify inclusion bodies, constructs a high-purity separation and purification method, and realizes the one-step synthesis of fusion proteins by microorganisms. This process is mild and efficient, low in cost, low in equipment requirements, and easy to expand production in the later stage.

Owner:TIANJIN UNIV

Mussel adhesion and cell membrane antifouling double biomimetic multi-armed PEG and preparation method thereof

ActiveCN104804195BEnhanced inhibitory effectAntifouling/underwater paintsPaints with biocidesPolyethylene glycolCell membrane

The invention discloses a bi-biomimetic modified multi-arm PEG represented by the general structural formula (I), in which catechol imitates mussel adhesion and zwitterionic imitates cell outer membrane structure and its preparation method. Through simple direct coating methods such as drop coating, spray coating, dip coating or spin coating, multi-arm polyethylene glycol flexible chains and zwitterionic imitation cell outer membrane structures are constructed on the surface of various substrates mediated by polydopamine. Double anti-biofouling surface. The biomimetic modified multi-arm PEG provided by the invention provides the possibility to prepare functional polymers containing a variety of functional groups with adjustable proportions due to its branched structure and multiple modifiable terminals; As a mediating layer, polydopamine can form a dense and stable dual anti-biofouling coating on the surface of almost any substrate even when the catechol content in multifunctional multi-arm PEG is limited.

Owner:NORTHWEST UNIV

Preparation method of a strong adhesive and high mechanical strength pegda-mussel adhesion protein-collagen composite hydrogel

The invention discloses a method for preparing a PEGDA-mussel adhesion protein-collagen composite hydrogel with strong adhesion and high mechanical strength, belonging to the field of hydrogel technology. In order to improve the mechanical strength and tissue adhesion of collagen hydrogel, the invention provides a kind of preparation method of strong adhesion, high mechanical strength PEGDA mussel adhesion protein collagen composite hydrogel, the The method is to dissolve mussel adhesion protein in acetic acid solution to obtain mussel adhesion protein acetic acid solution, dissolve the collagen solid in mussel adhesion protein acetic acid solution to obtain mussel adhesion protein-collagen solution, and neutralize with alkali pH to 5‑9, add PEGDA solid until completely dissolved, add photoinitiation factor, ultraviolet light crosslinking to form PEGDA‑mussel adhesion protein‑collagen composite hydrogel. The preparation process of the invention is simple and easy to operate, and has broad application prospects in the fields of tissue engineering and medicine.

Owner:QINGDAO INST OF BIOENERGY & BIOPROCESS TECH CHINESE ACADEMY OF SCI

Surfactant adhesive composition

ActiveUS20210070816A1Strong adhesionGood dispersionPeptide/protein ingredientsAntibody mimetics/scaffoldsPolymer scienceActive agent

Provided are a surfactant adhesive protein comprising an amphiphilic peptide, as a surfactant adhesive protein, at the carbon or amine terminal, a silicone oil and an anticancer composition comprising the surfactant adhesive, where the surfactant adhesive enables homogeneous dispersion of hydrophilic or hydrophobic particles in a hydrophobic or hydrophilic solvent on the basis of strong adhesive strength of the mussel adhesive protein, and the surface adhesive can be favorably used as a surface coating agent requiring antibacterial or antiviral functions as well as a cosmetic product or an ink.

Owner:TME THERAPEUTICS CO LTD

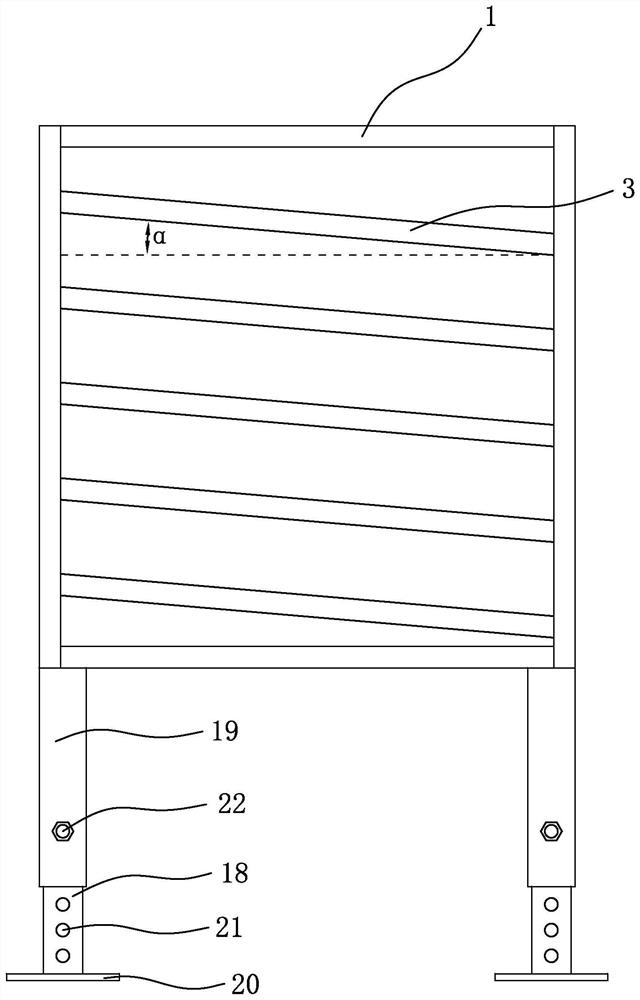

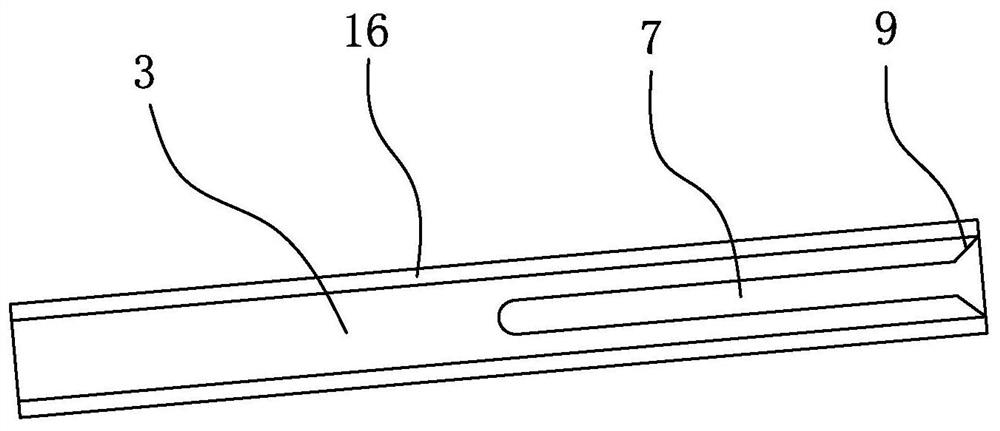

A kind of attachment base for thick-shelled mussel spat

ActiveCN113598102BEasy to pourWill not pollute each otherClimate change adaptationPisciculture and aquariaClassical mechanicsWater flow

Owner:MARINE FISHERIES RES INST OF ZHEJIANG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com