Preparation method of PEGDA-mussel adhesive protein-collagen composite hydrogel with strong adhesion and high mechanical strength

A mussel adhesion protein and composite hydrogel technology, which is applied in the field of preparation of PEGDA-mussel adhesion protein-collagen composite hydrogel, can solve the problems of poor adhesion, low mechanical strength and limitations of composite colloidal tissues Application and other issues, to achieve good biological safety, low cost, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

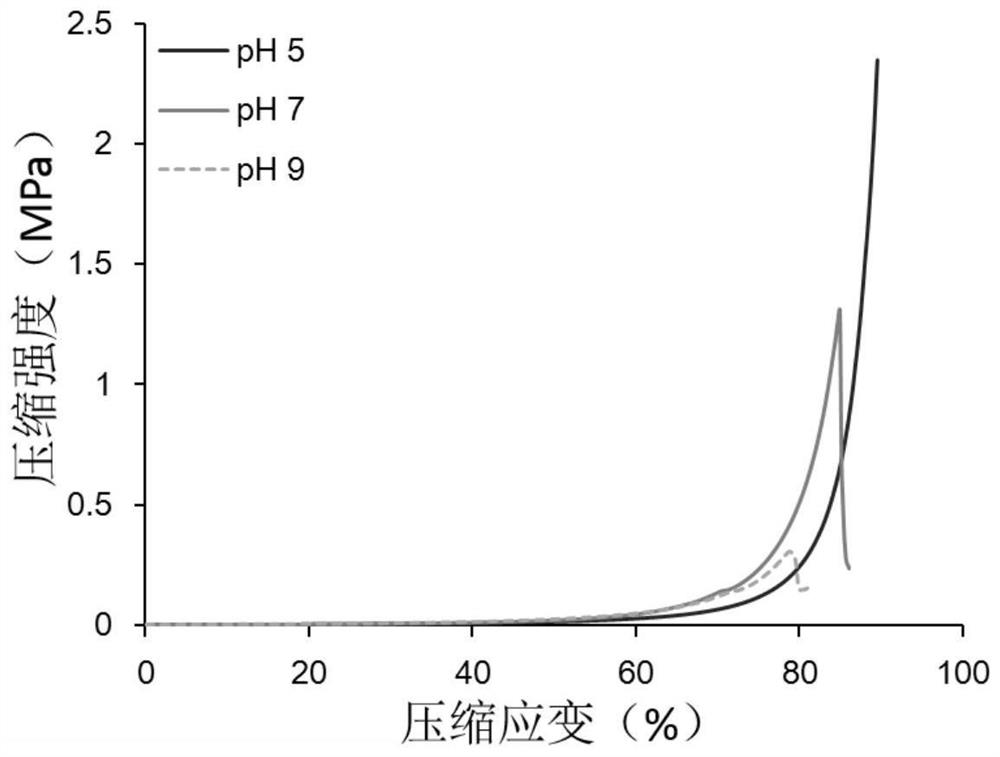

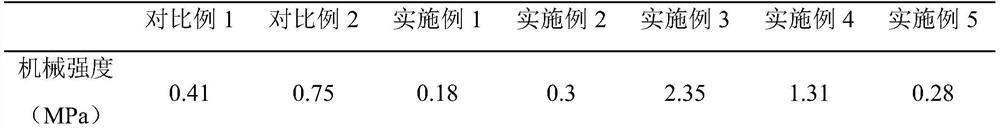

[0031] Example 1: Preparation method of PEGDA-mussel adhesion protein-collagen composite hydrogel.

[0032] 1) Dissolve the mussel adhesive protein in 5% acetic acid solution, stir at 4°C for 5 minutes to obtain the mussel adhesive protein acetic acid solution, where the mass volume concentration of mussel adhesive protein is 0.01g / mL;

[0033] 2) Directly dissolve fish skin collagen solids in the mussel adhesion protein acetic acid solution in step 1), stir for 4 hours at 4°C to obtain a mussel adhesion protein-fish skin collagen solution, in which the quality of the fish skin collagen The volume concentration is 1mg / mL;

[0034] 3) Add 4M sodium hydroxide solution dropwise to the mussel adhesion protein-fish skin collagen solution obtained in step 2), and stir to adjust the pH to 9 at 4°C;

[0035] 4) Then, add the PEGDA solid to the mussel adhesion protein-fish skin collagen solution with pH 9 to make the PEGDA mass and volume concentration 0.05g / mL. After it is completely dissolve...

Embodiment 2

[0036] Example 2: Preparation method of PEGDA-mussel adhesion protein-collagen composite hydrogel.

[0037] 1) Dissolve mussel adhesion protein in 5% acetic acid solution, stir at 4°C for 5 minutes to obtain mussel adhesion protein acetic acid solution, wherein the mass volume concentration of mussel adhesion protein is 0.05 g / mL;

[0038] 2) Dissolve the fish skin collagen solid directly in the mussel adhesion protein acetic acid solution and stir at 4°C for 4 hours to obtain the mussel adhesion protein-fish skin collagen solution, in which the mass volume concentration of fish skin collagen is 2 mg / mL;

[0039] 3) Add 4M sodium hydroxide solution dropwise to the mussel adhesion protein-fish skin collagen solution obtained in step 2), and stir to adjust the pH to 7 at 4°C;

[0040] 4) Then, add the PEGDA solid to the mussel adhesion protein-fish skin collagen solution with pH 7 to make the PEGDA mass and volume concentration 0.1g / mL. After it is completely dissolved, add 5mg / mL phot...

Embodiment 3

[0041] Example 3: Preparation method of PEGDA-mussel adhesion protein-collagen composite hydrogel.

[0042] 1) Dissolve the mussel adhesive protein in an acetic acid solution with a volume concentration of 5%, stir at 4°C for 5 minutes to obtain the mussel adhesive protein acetic acid solution, in which the mass volume concentration of the mussel adhesive protein is 0.1g / mL;

[0043] 2) Directly dissolve the methacrylamide collagen solid in the mussel adhesive protein acetic acid solution in step 1), stir at 4°C for 4 hours to obtain the mussel adhesive protein-methacrylamide collagen solution, wherein The mass volume concentration of acrylamide collagen is 4mg / mL;

[0044] 3) Add 4M sodium hydroxide solution dropwise to the mussel adhesion protein-methacrylamide collagen solution obtained in step 2), stir and adjust the pH to 5 at 4°C;

[0045] 4) Then, add the PEGDA solid to the mussel adhesion protein-methacrylamide collagen solution with pH 5 to make the PEGDA mass volume concentr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com