Process for producing ocean mussel adhesion protein water-proof biological adhesive agent

A mussel adhesive protein and bioadhesive technology, which is applied in the field of preparation of marine mussel adhesive protein waterproof bioadhesive, can solve the problem that it is difficult to meet the needs, less adhesive protein, and expensive adhesive protein products and other issues, to achieve the effect of low cost, simple operation and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1: Preparation of marine mussel adhesive protein waterproof bioadhesive Mcfp-1-12

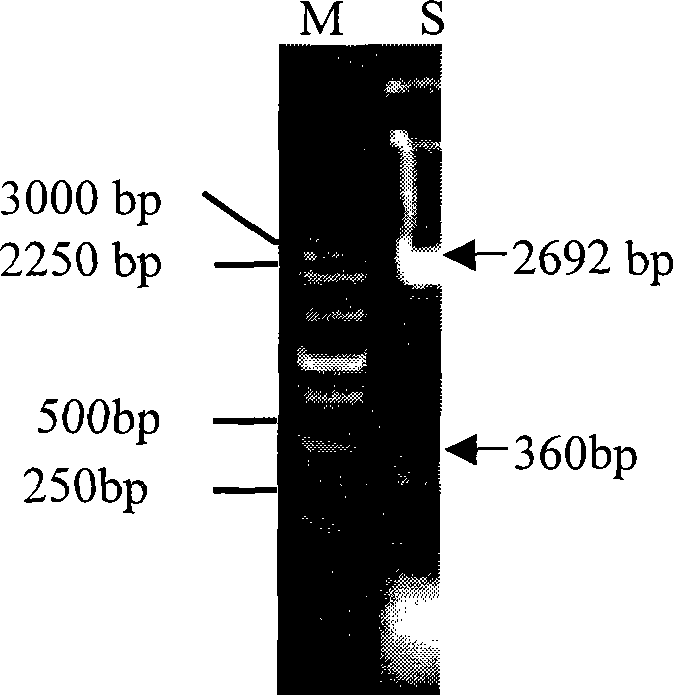

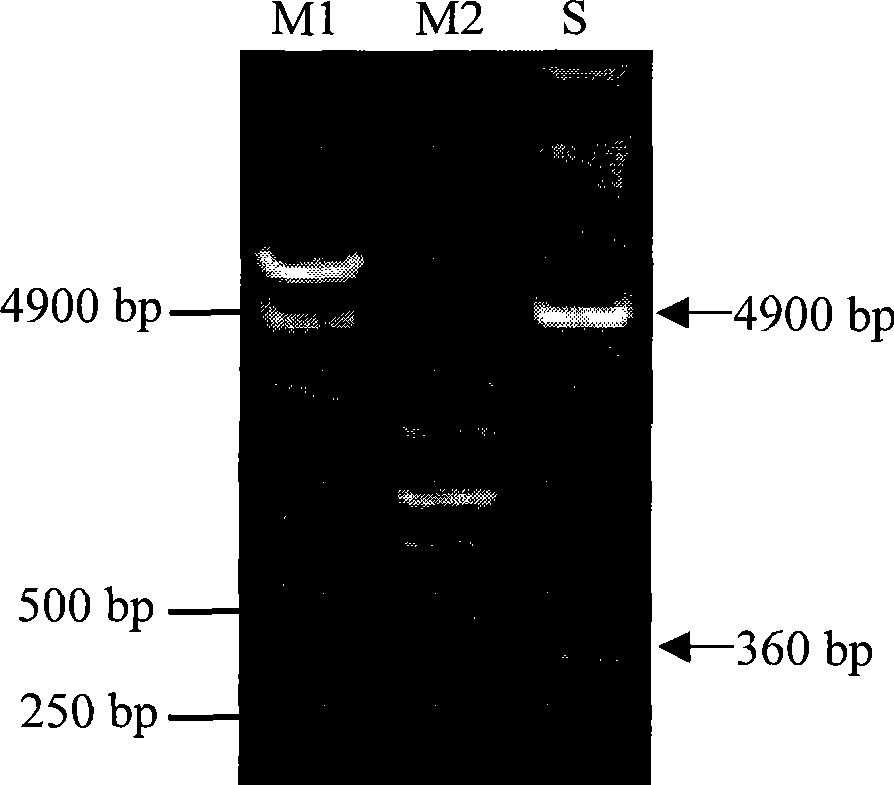

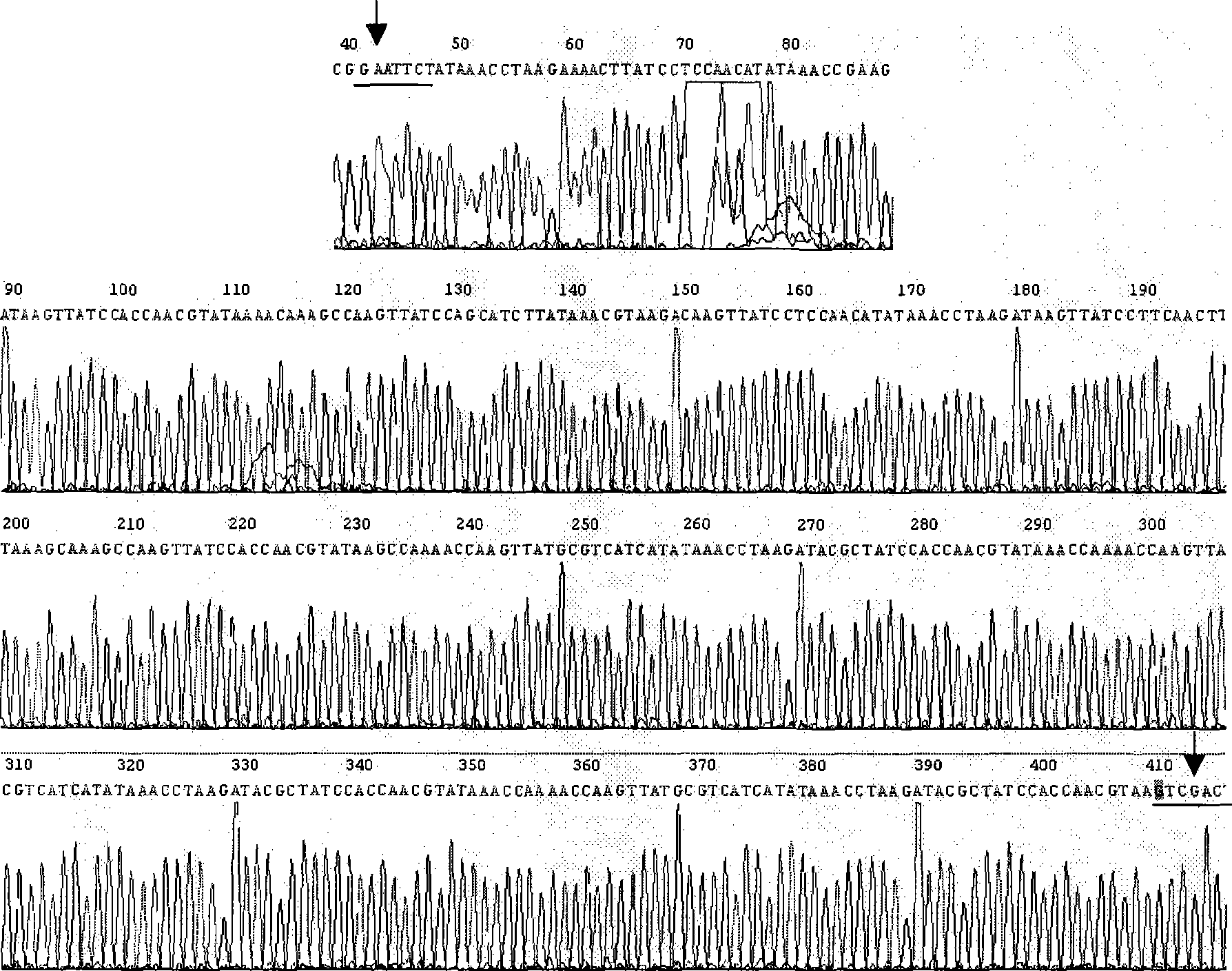

[0037] 1. Obtain the target gene fragment by PCR and connect it to the cloning vector: excise the foot from the live mussel M.coruscus, extract the total RNA, and reverse transcribe it into cDNA. According to the sequence of the Mcfp-1 gene (sequence from Genbank No.D63777) of the thick-shelled mussel M.coruscus, the 12 amino acid residues from the 692nd to the 811th amino acid residues (sequence from Genbank No.Q25434) of the coding Mcfp-1 Design PCR primers (synthesized by Shanghai Sangon Bioengineering Technology Service Co., Ltd.) from the DNA fragment of the continuous decapeptide repeat sequence. When designing the primers, add EcoR I and Sal I restriction sites to the ends of the forward primer and reverse primer, respectively. , the primer sequences are as follows:

[0038] Primer F: 5'-ccgaattctataaacctaagaaaacttatcc-3',

[0039] Primer R: 5'-atgtcgacttacgttggtggatagcg...

Embodiment 2

[0090] Example 2: Adhesion of the adhesive Mcfp-1-12 on different material surfaces in a humid environment

[0091] Add 10 μl of the adhesive Mcfp-1-12 with a concentration of 1.44 mg / ml to the surfaces of cleaned plastic, glass, metal titanium and aluminum, and at the same time add bovine serum albumin (BSA, bovine serum) of the same concentration albumin), the fusion polypeptide GST-Mcfp-1-12 and CELL-TAK without thrombin digestion were used as negative and positive controls, respectively, and the proteins added in this group of experiments were tyrosine-modified and unmodified, respectively. Histones were used as controls. Place it in a humid environment at 25°C for 12 hours, take it out and dry it, rinse it with distilled water for 2 hours; then stain it with Coomassie brilliant blue, such as Figure 4 As shown, the results show that on glass slide A and metal titanium C, the adhesive Mcfp-1-12 has similar adhesion ability to CELL-TAK, while on plastic Petri dish D and me...

Embodiment 3

[0092] Embodiment 3: the mensuration of adhesive agent Mcfp-1-12 adsorption amount on silicon gold sheet

[0093] Add the adhesive Mcfp-1-125μl with a concentration of 1.44mg / ml dropwise to the surface of the Pico EQCM quartz wafer (Outlet (Tianjin) Scientific Instrument Technology Co., Ltd.), and at the same time add the same concentration of BSA, without thrombin The digested fusion polypeptide GST-Mcfp-1-12 and CELL-TAK were used as negative and positive controls, respectively. In addition, the proteins added in this group of experiments were tyrosine-modified and unmodified as controls. Place it in a humid environment at 25°C for 12 hours, take it out and dry it, and rinse it with distilled water for 2 hours; after vacuum drying, measure its frequency change with a QCM instrument to obtain the value of its adhesion. Such as Figure 5 , the results showed that the adhesive Mcfp-1-12 had stronger adhesive ability than other control groups.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com