Recovery method of vanadium-containing neutralizing slag

A recovery method and calcium-enriched technology, applied in the field of waste treatment, can solve problems such as vanadium pollution, and achieve the effects of enhancing the leaching rate, simplifying the preparation process, and saving fresh water resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

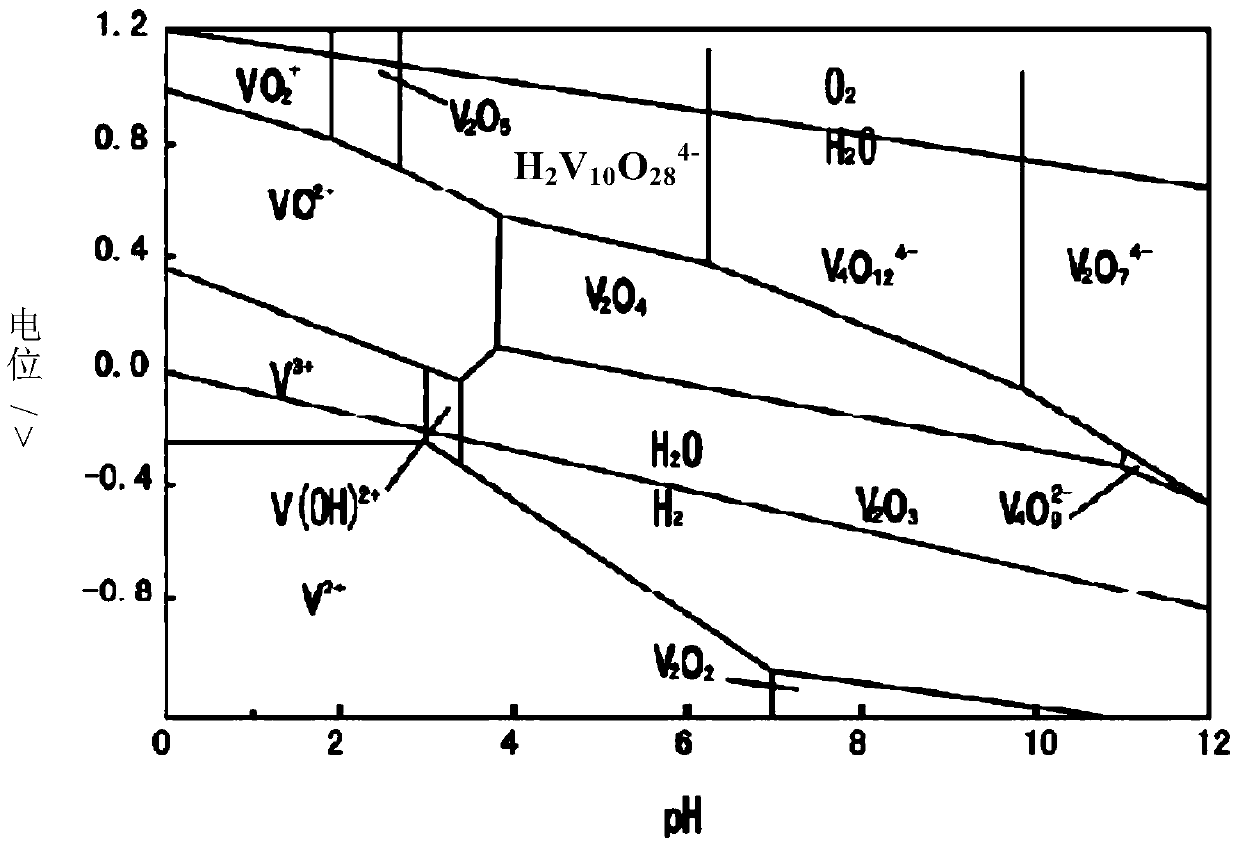

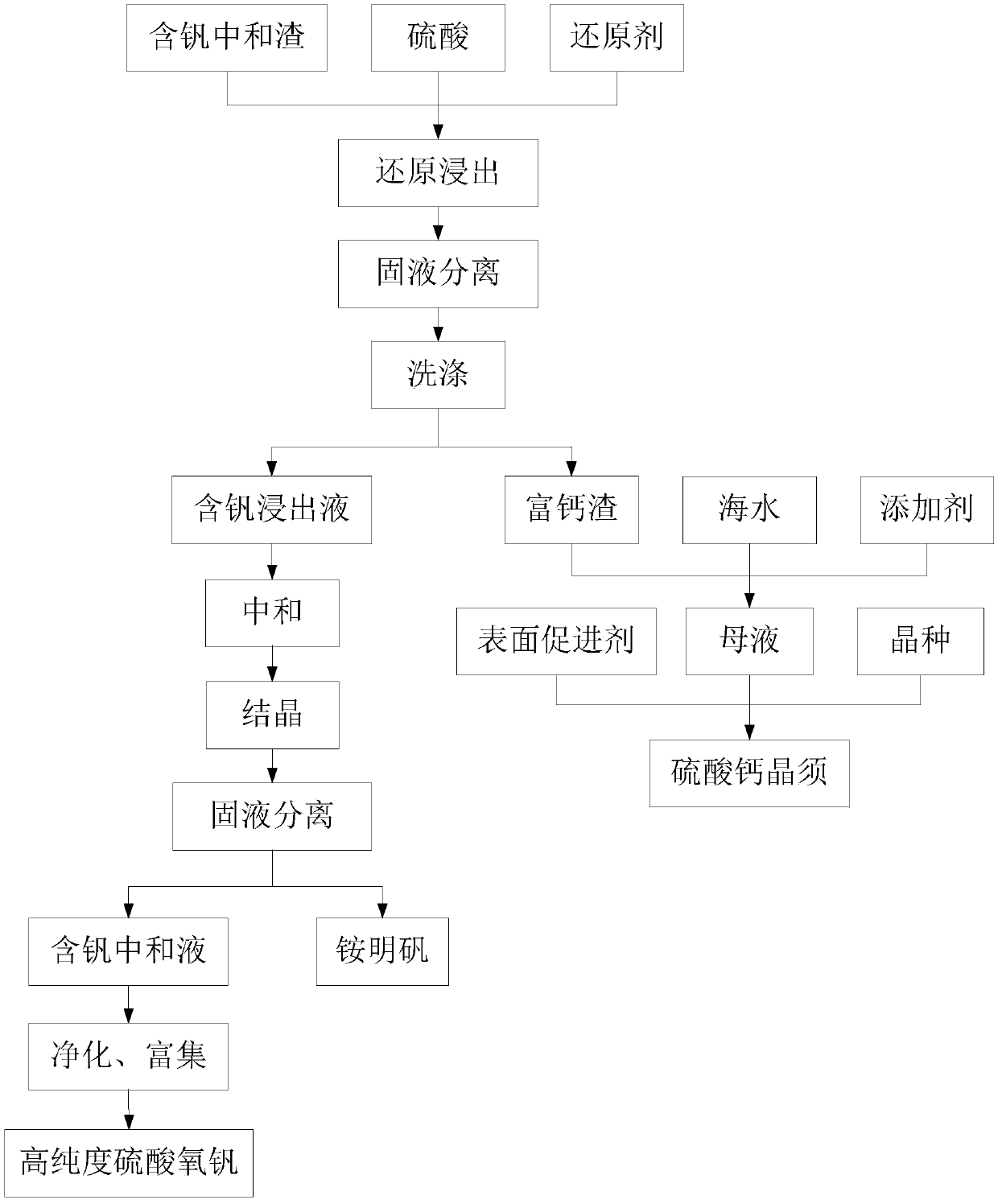

Method used

Image

Examples

Embodiment 1~4

[0041] Crushing, grinding and drying vanadium-containing neutralized slag and calcium-rich slag, the particle size is below 37 μm;

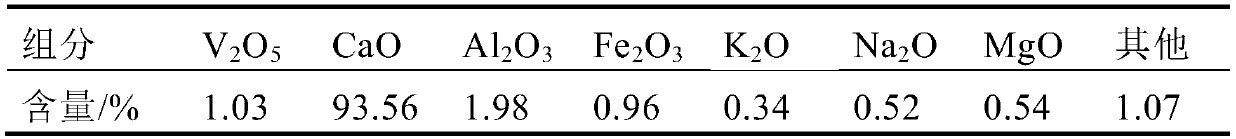

[0042] The main chemical composition of vanadium-containing neutralization slag is shown in Table 1.

[0043] Table 1

[0044]

Embodiment 1

[0046] This embodiment discloses a method for recovering vanadium-containing neutralized slag, comprising the following steps:

[0047] Step (1) Weigh 1000g of vanadium-containing neutralization slag, 60g of 94%wt concentrated sulfuric acid and 800g of water, and mix them uniformly to obtain a suspension;

[0048] Step (2) Place the suspension in an Erlenmeyer flask, heat and stir, and add 15 g of anhydrous sodium sulfite to the reaction vessel, and perform reduction leaching for 120 min at a reduction leaching temperature of 80° C. and a stirring speed of 200 r / min;

[0049] Step (3) After the slurry after reduction leaching is separated from solid and liquid, wash the filter residue with 1000 g of sodium sulfate solution with a concentration of 5% wt to obtain vanadium-containing leaching solution and calcium-rich slag. After testing, the concentration of vanadium in the vanadium-containing leaching solution is 6.08 g / L, the leaching rate of vanadium is as high as 99.5%, and...

Embodiment 2

[0056] This embodiment discloses a method for recovering vanadium-containing neutralized slag, the steps (1)-(5) of which are the same as in Example 1, and also include the following steps:

[0057] Step (6) Weigh 50g of calcium-rich slag obtained in step (3), 500g of seawater, 8g of anhydrous sodium carbonate, 8g of anhydrous magnesium carbonate and 40g of industrial hydrochloric acid, and mix them uniformly to obtain a suspension. Stir for 120min;

[0058] Step (7) solid-liquid separation can obtain 520ml mother liquor, add 2.5g sodium dodecyl sulfonate in mother liquor, 5g concentration is the concentrated sulfuric acid of 92%, 0.4g calcium sulfate dihydrate crystal, at temperature is 101 ℃, stirs Respond for 2 hours at a speed of 100r / min;

[0059] Step (8) Filter the obtained slurry while it is hot, rinse the filter cake with clean water, and dry the filter cake in a constant temperature drying oven at 180°C for 4 hours to obtain anhydrous calcium sulfate whiskers, which...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com