Patents

Literature

75results about How to "Full reduction reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

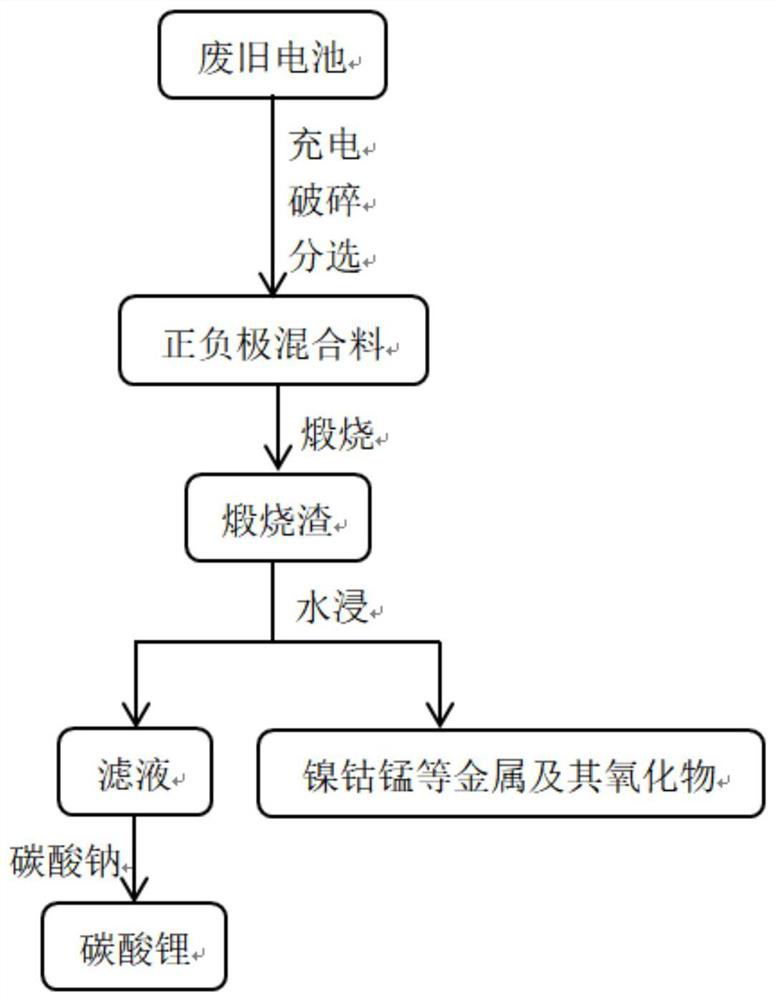

Upcast method for producing high-purity bright copper rod

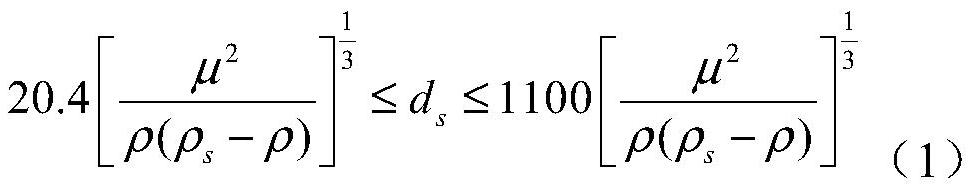

ActiveCN102168180ALight weightFull reduction reactionProcess efficiency improvementGraphite carbonWinding machine

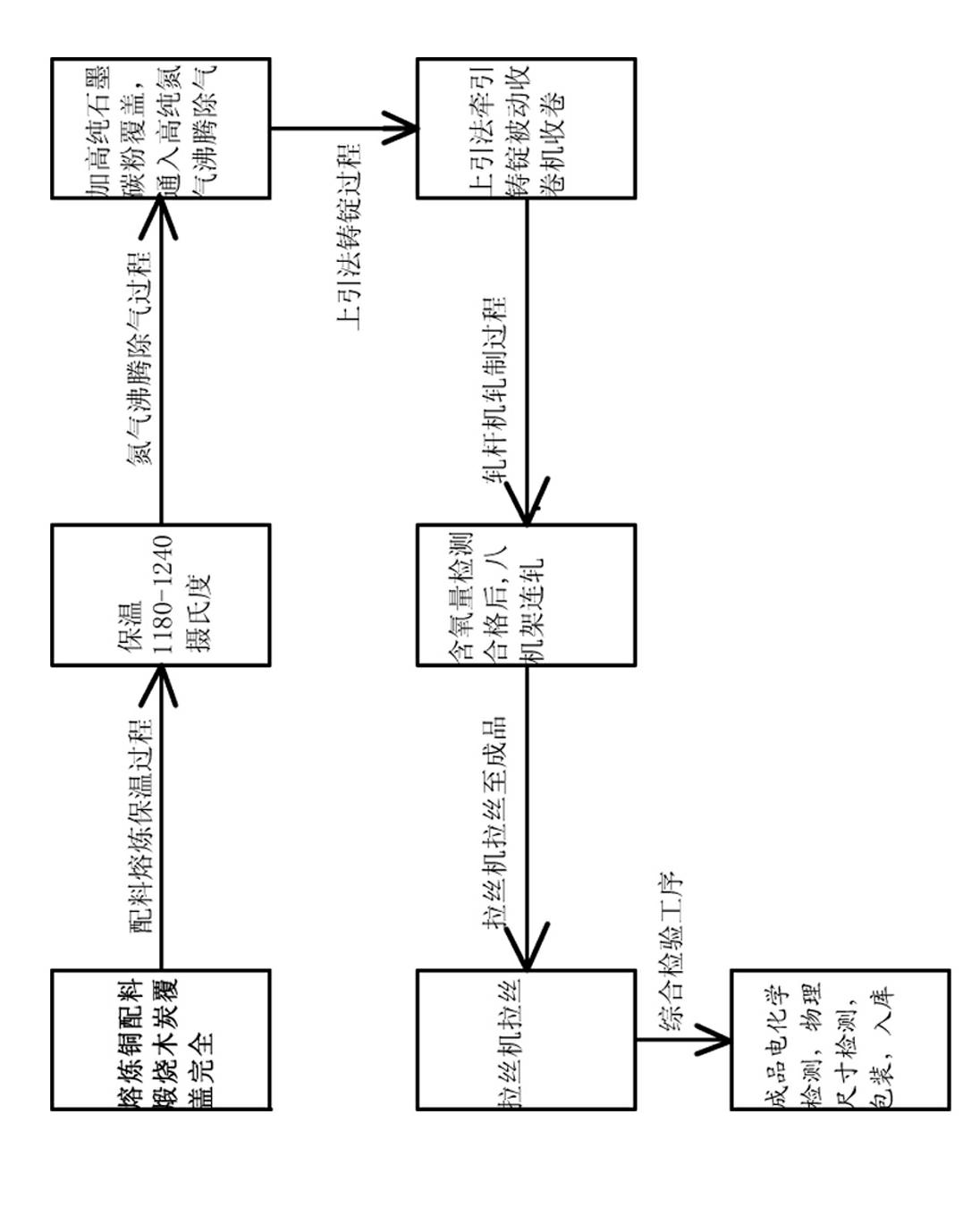

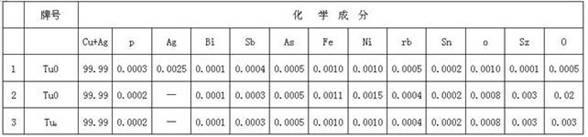

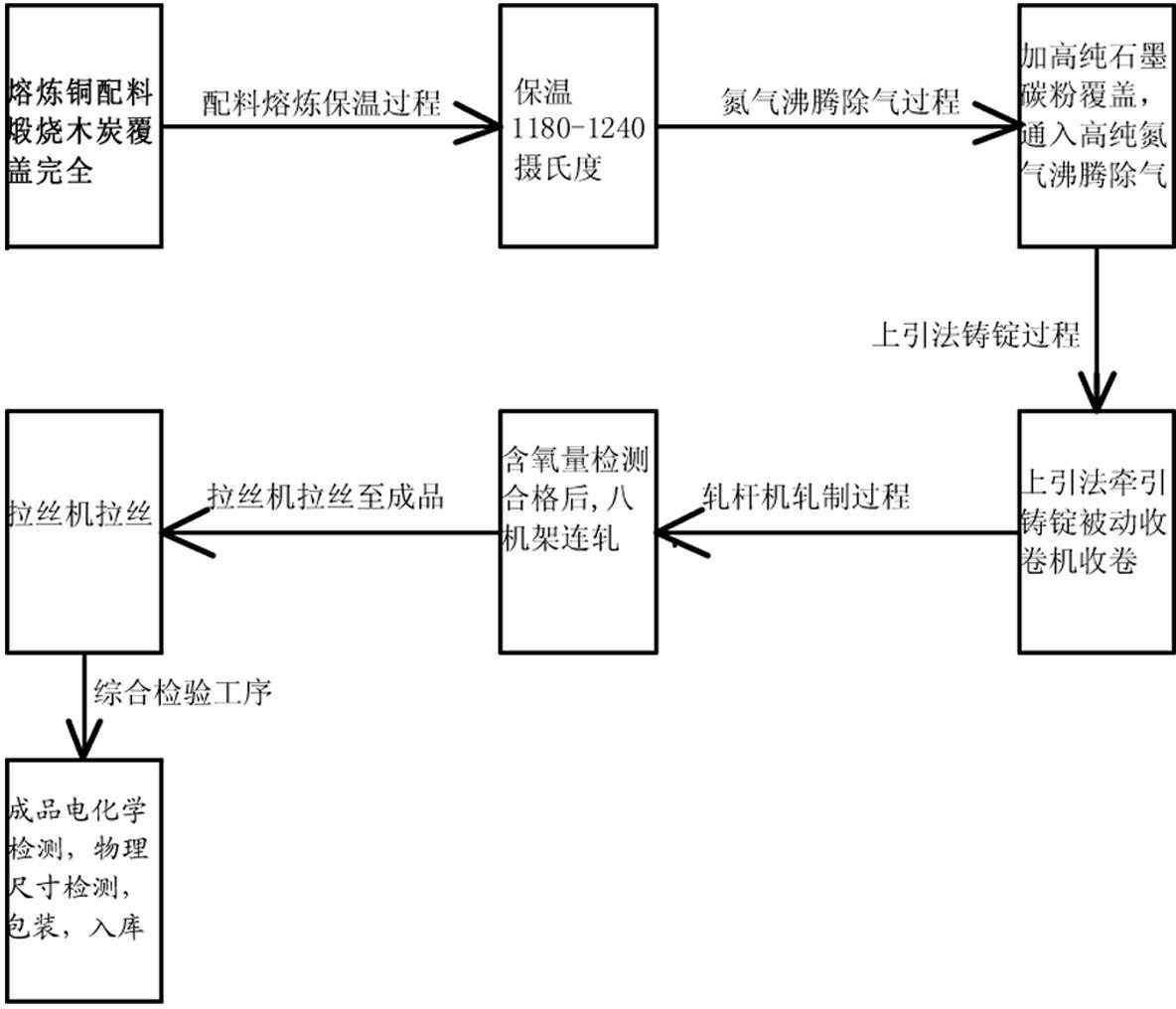

The invention relates to an upcast method for producing a high-purity bright copper rod. The method comprises the following steps of: drying smelting copper raw materials needed by smelting, mixing, adding the mixture into a smelting furnace, and covering firing charcoal with the thickness of between 100 and 150mm on starting molten copper until red copper is entirely molten, wherein molten copper constantly flows toward a heat preservation furnace under the action of fluid force; boiling the high-temperature molten copper and degassing before ingot guiding, adding prepared high-purity graphite carbon powder onto the liquid level of the molten red copper in the heat preservation furnace, and aerating high-purity nitrogen at the position which is 50 to 100mm lower than the liquid level of the heat preservation furnace; covering the firing charcoal after boiling and degassing, covering a furnace cover, performing draw casting operation, drawing a draw casting machine for draw casting bythe upcast method, cooling in a graphite crystallizer by the upcast method to obtain a qualified high-purity oxygen-free copper rod blank, and winding on a drawn cast ingot passive winding machine; and performing multi-pass rolling and fine-drawing on the high-purity oxygen-free high-brightness copper rod blank by an eight-rack rod cold rolling mill, and drawing the blank until the copper rod is obtained by a wire drawing machine, namely obtaining a finished product after the copper rod passes the inspection.

Owner:ZHONGTIAN ALLOY TECH

Nano-silver antibacterial agent and preparation method thereof

InactiveCN103999873AIncrease viscosityImprove antibacterial propertiesBiocideDisinfectantsEmulsionAntibacterial agent

The invention provides a nano-silver antibacterial agent which includes nano-silver antibacterial stock solutions. Nano-silver is included in the nano-silver antibacterial stock solutions, and the content of the nano-silver is 0.00025 mol / kg to 0.02 mol / kg. The invention further provides a preparation method of the nano-silver antibacterial agent. The nano-silver antibacterial agent can be foam emulsion and sprays in a flow state, can be used as washing-free sprays, and is convenient for people to use when cleaning with water is inconvenient in travel.

Owner:杜一挺

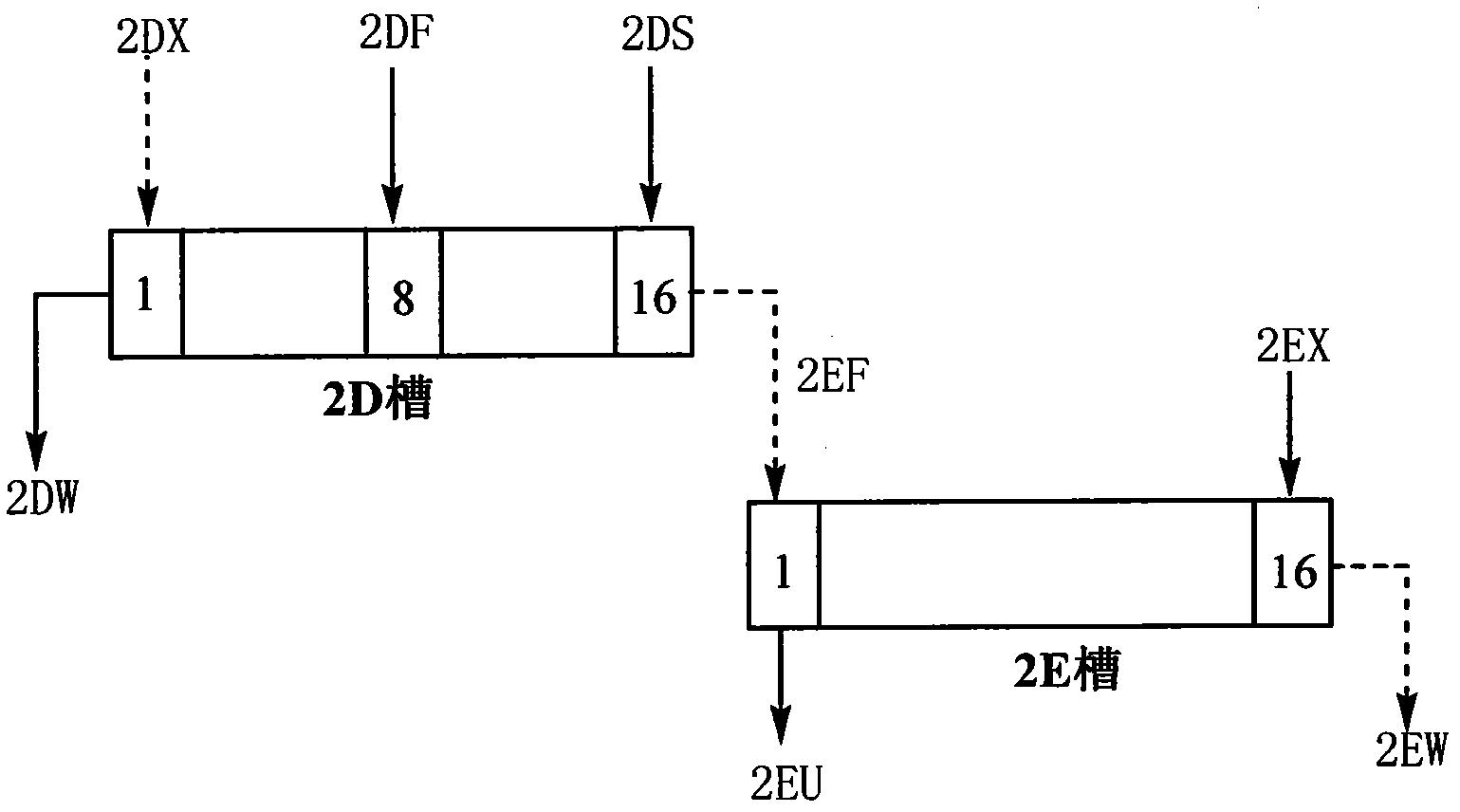

Method for cycle purification of uranium in Purex process

ActiveCN102290111AQuick restoreNo increase in solid waste volumeProcess efficiency improvementInorganic non-surface-active detergent compositionsMonomethyl hydrazineHydroxylamine

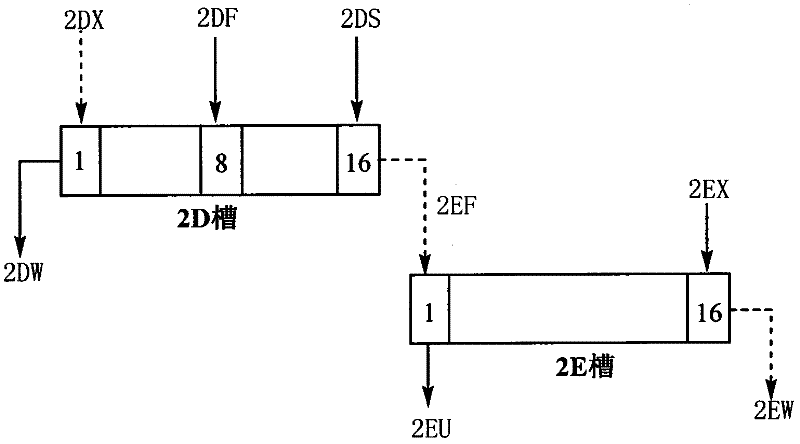

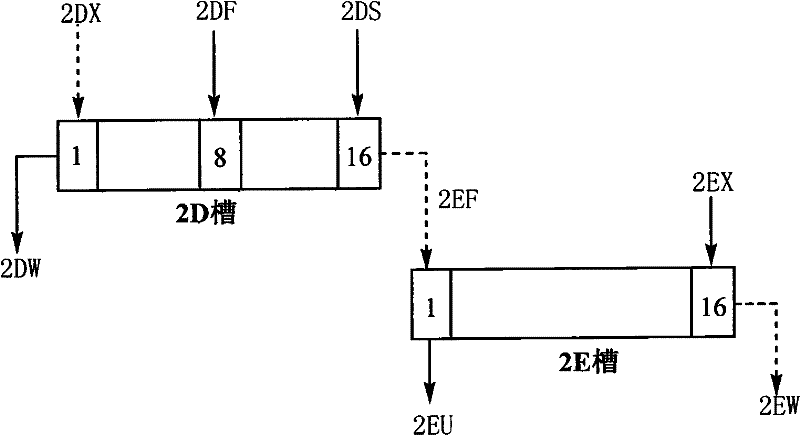

The invention discloses a method for cycle purification of uranium in a Purex process. The method comprises the following steps of: pretreating 1CU feed liquor, seasoning, and further purifying plutonium by using a washing agent in a two-dimensional (2D) tank, wherein the used washing agent in the 2D tank is a mixed solution of dimethyl hydroxylamine, monomethyl hydrazine and nitric acid, the concentration of the dimethyl hydroxylamine is 0.01 to 0.1mol / L, the concentration of the monomethyl hydrazine is less than or equal to 0.15mol / L, and the concentration of the nitric acid is 0.8 to 1.2mol / L. The dissipation factor (DF) (Pu / U) in the 2D tank is more than 1,000, and the content of the plutonium in 2EU feed liquor reaches a uranium product index.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Organic-inorganic combined pyrolusite reduction method

The invention discloses an organic-inorganic combined pyrolusite reduction method. In 10 parts (by weight) of pyrolusite powder, raw material ingredients are as follows in parts by weight: 0.1-0.3 part of organic reducing agent, 1-3 parts of inorganic reducing agent, 12-20 parts of concentrated sulfuric acid, 80-100 parts of water and 0.01-0.05 part of impurity remover. The method comprises the processes of infiltration reaction, one-step reduction, filtration and impurity removal, namely comprises the concrete steps: reacting the pyrolusite powder and the concentrated sulfuric acid for 10-30 minutes; then, sequentially adding the organic reducing agent and the inorganic reducing agent, reacting for 3-5 hours at the temperature of 60-95 DEG C, filtrating, then, adding the 0.01-0.05 part of impurity remover at the temperature of 35-50 DEG C, and reacting for 0.5-1.5 hours. According to the method, the leaching rate of manganese is higher than 90%, the problem of byproduct of a single organic reduction method is solved, and the problems of low manganese leaching rate or inorganic byproduct generation of a single inorganic reduction agent are solved; the manganese leaching rate is high, the cost of reducing agents is low, the requirements on reducing condition are low, the process is simple, the operation is easy, and the industrial production is facilitated, so that the method has relatively good economic and social benefits.

Owner:GUANGXI UNIV FOR NATITIES

Method for analyzing magnetic roasting effects of iron ore having different granularity ranges

InactiveCN103468929AImprove experimental accuracyLittle external influenceMagnetic separationIronstoneCoal

The invention provides a method for analyzing the magnetic roasting effects of an iron ore having different granularity ranges. The method mainly comprises the following technological steps: 1, preparing an experiment ore sample and a reduction coal sample; 2, drying the ore sample; 3, uniformly spreading the ore sample and the coal sample on a clean roasting porcelain dish, sending to a box type electric resistance furnace, and carrying out magnetic roasting to obtain a roasted ore; 4, rapidly taking out the roasted ore, and carrying out water quenching cooling; 5, filtering the roasted ore obtained after the water quenching cooling; 6, drying the filtered roasted ore sample; 7, screening the dried roasted ore by grid sieves to form roasted ores respectively having granularity ranges of 0-1mm, 1-3mm, 3-5mm and 5-15mm, and respectively weighing; 8, grinding the roasted ores respectively having granularity ranges of 0-1mm, 1-3mm, 3-5mm and 5-15mm to 1-60 meshes; and 9, carrying out magnetic separation of the roasted ores respectively having granularity ranges of 0-1mm, 1-3mm, 3-5mm and 5-15mm. The experiment method has the advantages of high accuracy and few extraneous influence factors, and provides a basis for the selection of roasting conditions during the sieve fraction magnetic roasting of difficult-separation iron ores.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

Decoupling gas burner

The invention discloses a decoupling gas burner, and belongs to the technical field of combustion equipment. The decoupling gas burner comprises an outer cylinder body, a separation cylinder body, a gas outer cylinder body and a gas inner cylinder body which are sequentially arranged from outside to inside and coaxial, a first-stage air duct is formed in the gas inner cylinder body, a gas channelis formed between the gas inner cylinder body and the gas outer cylinder body, a second-stage air duct is formed between the gas outer cylinder body and the separation cylinder body, a third-stage airduct is formed between the separation cylinder body and the outer cylinder body, the decoupling burner further comprises a frustum-shaped cylinder body, the small-diameter end of the frustum-shaped cylinder body is connected to the end, which extends into a hearth, of the separation cylinder body, the outer diameter of the large-diameter end of the frustum-shaped cylinder body is smaller than theinner diameter of the outer cylinder body, and in the axial direction of the frustum-shaped cylinder body, the distance between the end, which extents into the hearth, of the outer cylinder body andthe large-diameter end of the frustum-shaped cylinder body is adjustable. According to the provided decoupling gas burner, the frustum-shaped cylinder body is arranged so that the decoupling gas burner can be suitable for different gas and hearth structures.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

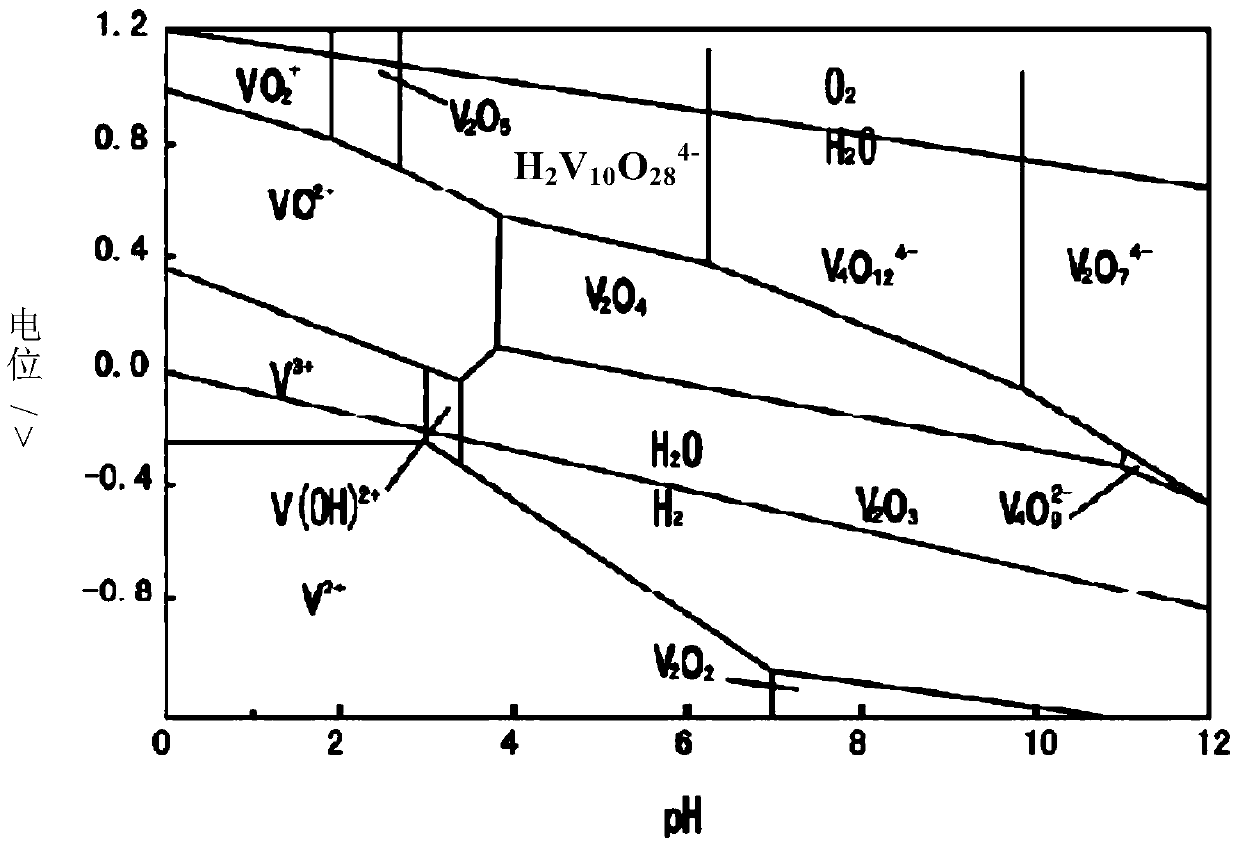

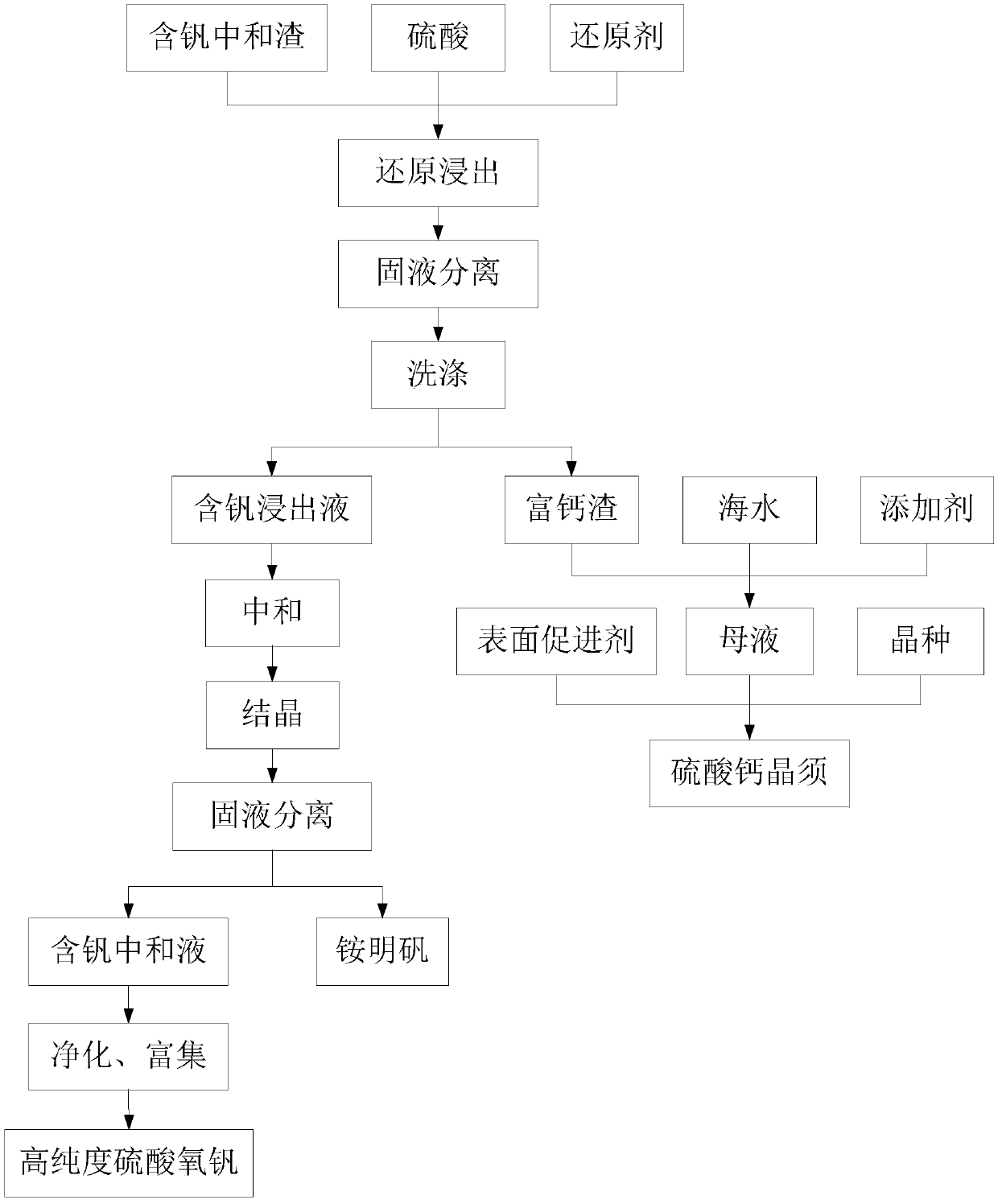

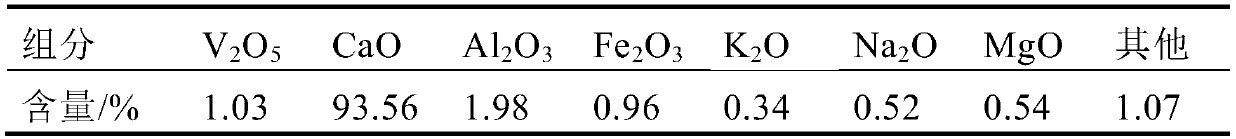

Recovery method of vanadium-containing neutralizing slag

ActiveCN109666796AHarmlessAchieve reductionPolycrystalline material growthFrom normal temperature solutionsRecovery methodSlag

The invention provides a recovery method of vanadium-containing neutralizing slag. The recovery method comprises the following steps of mixing the vanadium-containing neutralizing slag, concentrated sulfuric acid and water to obtain slurry; adding a reducing agent in the slurry, and performing reduction leaching; performing solid-liquid separation on the slurry obtained after reduction leaching, and cleaning filter residue with a sodium sulfate solution to obtain a vanadium-containing leaching solution and calcium-rich slag; adding ammonium sulfate in the vanadium-containing leaching solution,regulating the pH value of the leaching solution with ammonia water, performing cooling crystallization, and performing solid-liquid separation to obtain an ammonium alum crystal and a neutralizationsolution; and performing counter-current extraction, counter-current back extraction, upflow regeneration and counter-current washing on the neutralization solution, thereby obtaining a high-purity vanadyl sulfate solution. According to the recovery method, when the pollution of a vanadium element in the vanadium-containing neutralizing slag to environment is solved, the high value-added resourceutilization of the calcium-rich slag and the vanadium element in the vanadium-containing neutralizing slag is realized.

Owner:DALIAN RONGKE ENERGY STORAGE GRP CO LTD

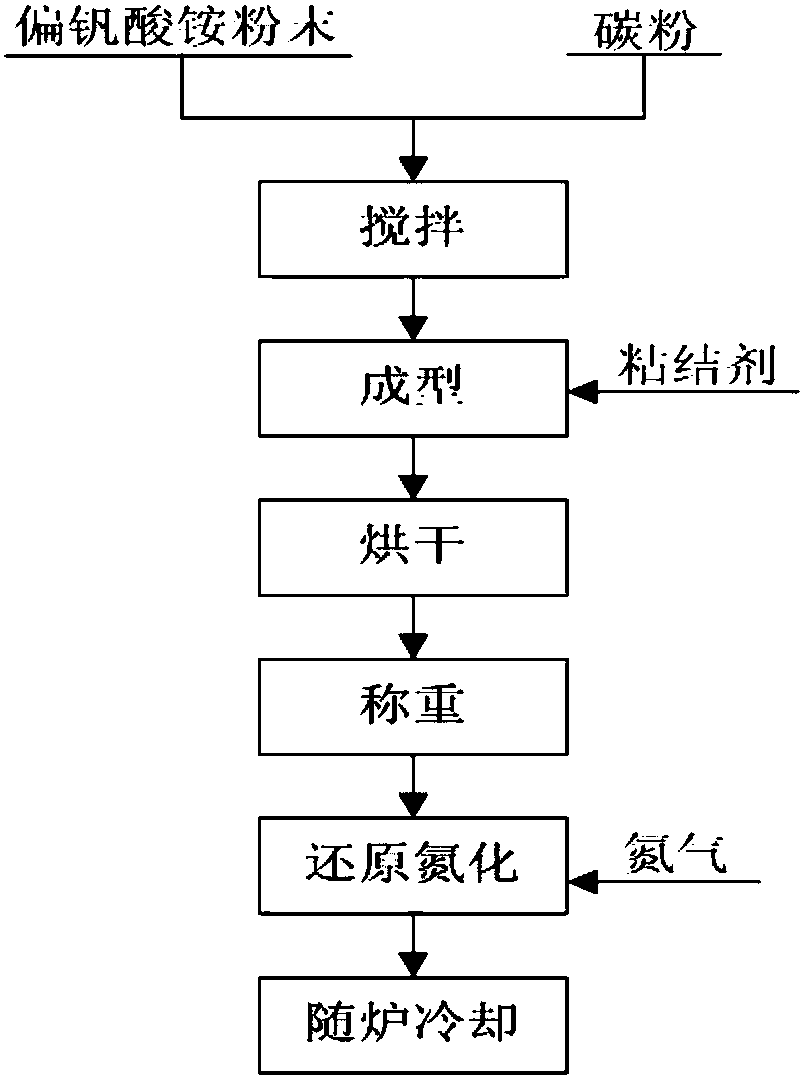

Method for preparing vanadium nitride

ActiveCN107673317AAvoid meltingAvoid wastingNitrogen-metal/silicon/boron binary compoundsVanadium nitrideNitrogen atmosphere

The invention discloses a method for preparing vanadium nitride, which comprises the following steps: step 1, carrying out pre-reduction on a test specimen prepared from ammonium metavanadate powder and carbon powder in a heating furnace by nitrogen, wherein in the pre-reduction process, a temperature in the heating furnace is 650 to 670 DEG C, nitrogen flow is 210 to 270mL / min, and heat preservation time of the heating furnace is 2 to 4 hours; step 2, after ending heat preservation in the step S1, warming the heating furnace to a temperature of 1,300 to 1,500 DEG C and carrying out final reduction on the test specimen, wherein the final reduction process, nitrogen flow in the heating furnace is 210 to 270mL / min, and heat preservation time of the heating furnace is 4 to 5 hours; step 3, after ending heat preservation in the step S2, carrying out furnace cooling on the test specimen in nitrogen atmosphere, so that the obtained test specimen is the vanadium nitride. According to the method disclosed by the invention, the vanadium nitride is prepared by the ammonium metavanadate, so that a calcination section can be omitted, and the aims of simplifying a production process, reducing production cost of an enterprise and reducing pollution are fulfilled.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

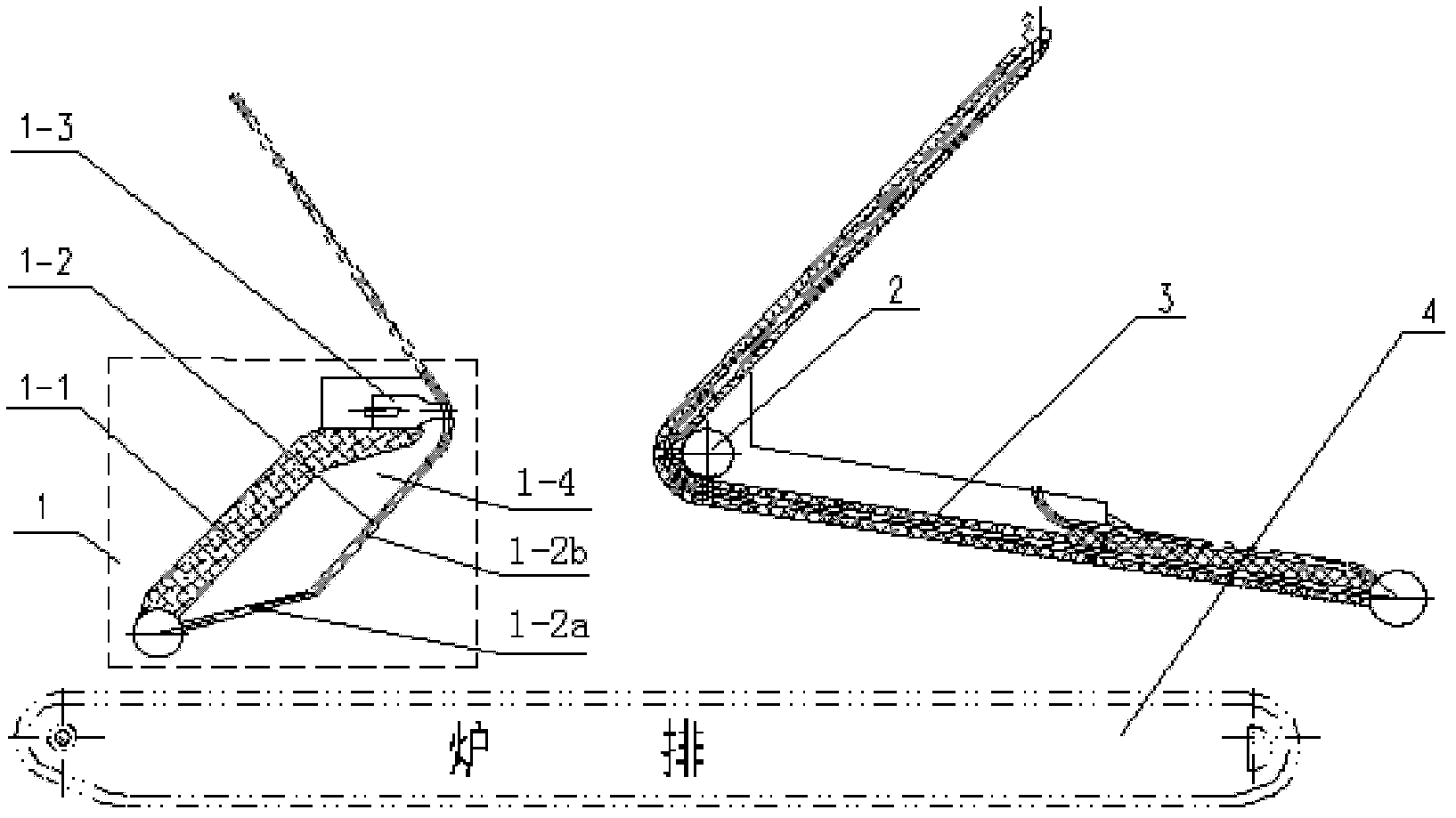

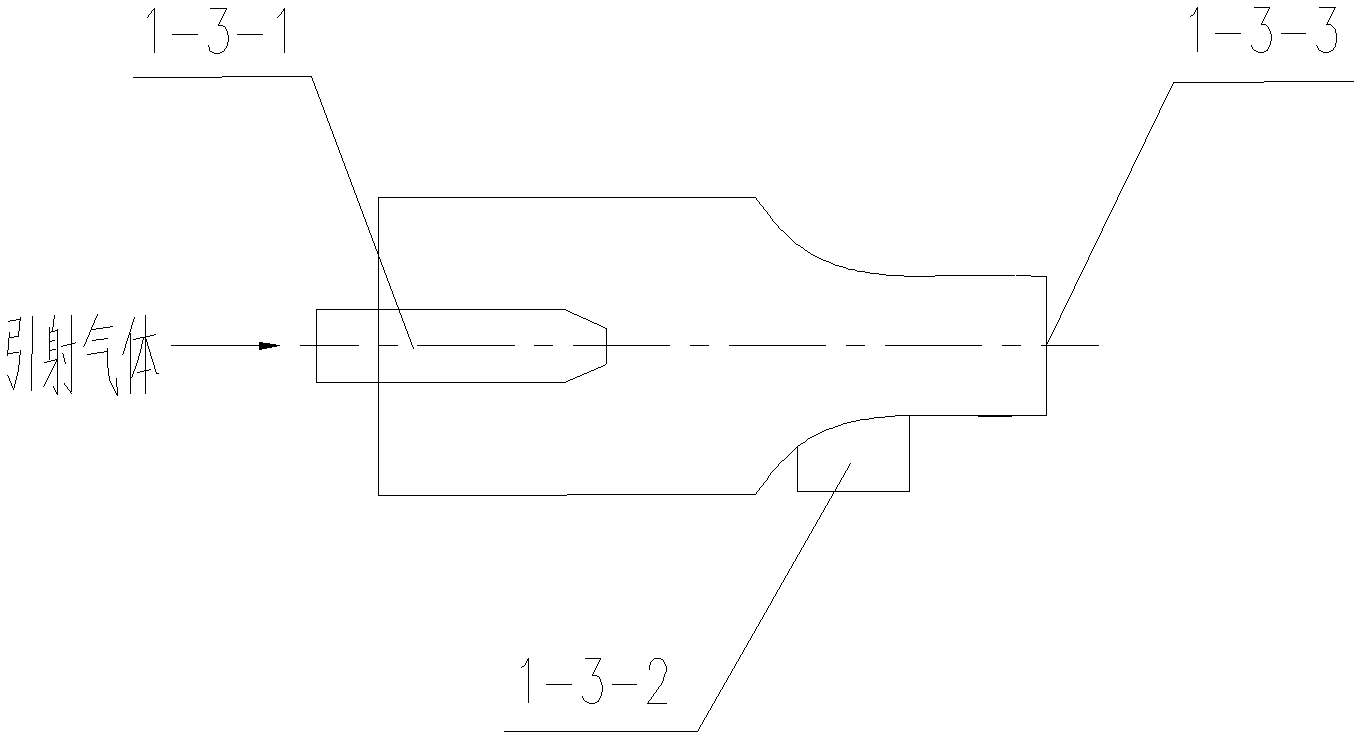

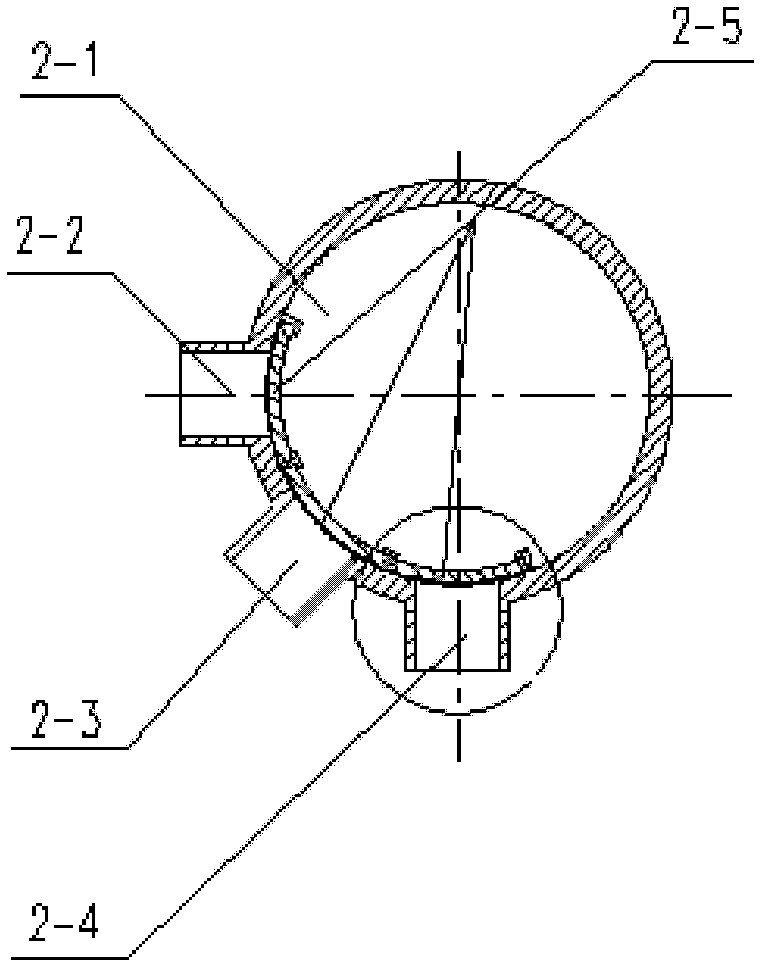

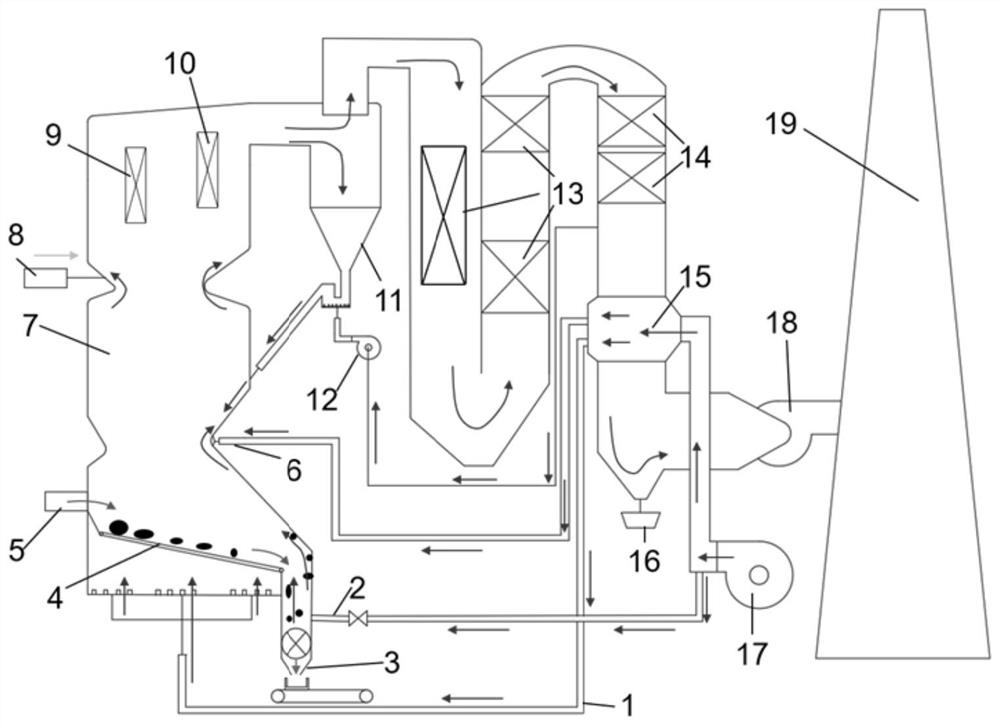

Compound furnace arch and compound secondary air structure for cooperatively controlling generation of nitrogen oxide (NOX)

ActiveCN102679390AAvoid premature mixed combustionWell mixedCasings/liningsNon-combustible gases/liquids supplyNitrogen oxidesVolatiles

The invention relates to a compound furnace arch and a compound secondary air structure for cooperatively controlling generation of an NOX. A front arch water cooled furnace wall protrudes into a furnace to form a cavity with a fire-resistant front arch, an ejector is arranged at the throat portion of the front arch to eject volatiles, a compound secondary air device is arranged at the throat portion of a rear arch, and a nozzle of the ejector and a rear arch secondary air horizontal nozzle are arranged at an interval horizontally and oppositely. Compared with the prior art, according to the compound furnace arch and the compound secondary air structure for cooperatively controlling generation of nitrogen oxides, the volatiles are drawn out from the cavity between the front arch furnace wall and the front arch water cooled furnace wall and reacted with the NOX in high temperature flue gas, simultaneously high temperature ammonia jetting can be achieved during deep removal of NOX, so that technology integration of actively and cooperatively removing the NOX of stage combustion of fuels of the compound front arch and the ejector, stage combustion of compound secondary air and volatile re-burning is achieved, NOX emission levels of chain grate furnaces or grate-fired furnaces using similar principles are obviously reduced, and standard emission of the NOX of industrial grate-fired furnaces is achieved.

Owner:XI AN JIAOTONG UNIV

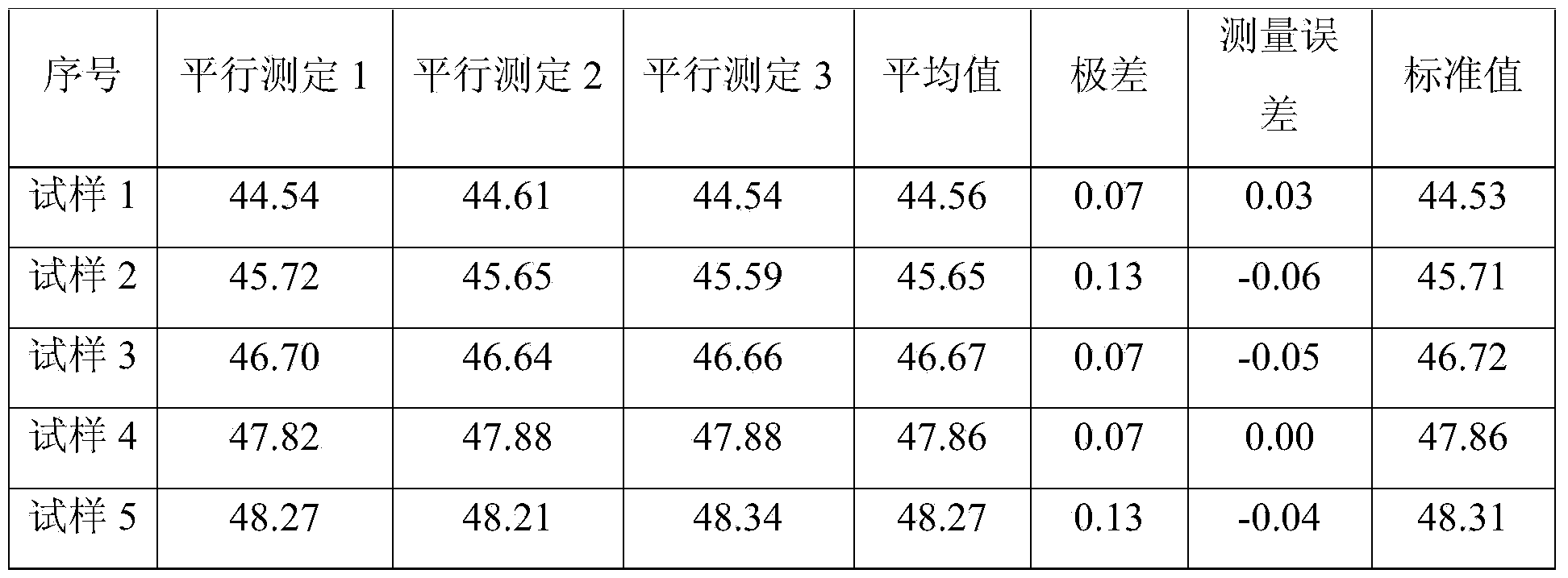

Method for measuring content of titanium dioxide in titanium concentrate

InactiveCN104267143AEasy to operateFull reduction reactionChemical analysis using titrationPhosphoric acidAcid dissolution

The invention relates to a method for measuring the content of titanium dioxide in titanium concentrate, and belongs to the field of analytical tests in titanium slag smelting. The method comprises the following steps: heating the titanium concentrate and strong phosphoric acid for reaction, isolating air in a medium of hydrochloric acid and sulfuric acid, reducing titanium (IV) to titanium (III) by aluminum, and in an oxalic acid environment, taking a neutral red solution as an indicator and titrating by a ferric ammonium sulfate standard solution until the solution is stably blue. According to the method, the acid dissolution process is carried out by strong phosphoric acid and an electrical furnace, and the operation is easy and quick; moreover, the operation time is short, five samples are simultaneously measured by the method, and the total measurement time is 1.5 hours; while the measurement time is 2.5 hours by a standard method of YB / T159.4-1999; the time is shortened by 40%.

Owner:四川安宁铁钛股份有限公司

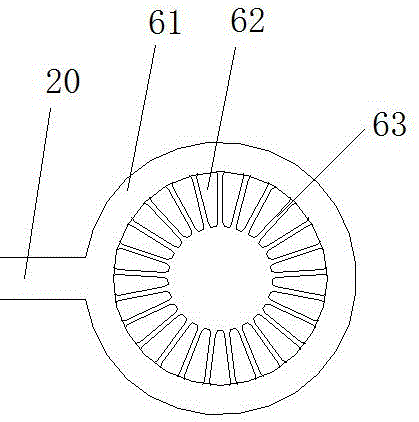

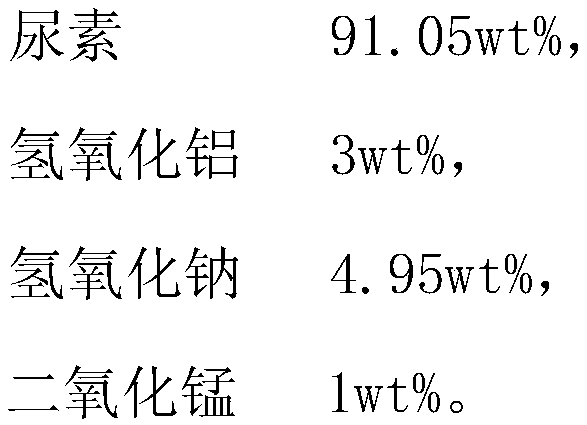

Ammonia process SCR-SNCR coupling flue gas denitrification reactor

PendingCN106731792AImprove processing efficiencyEasy to handleGas treatmentDispersed particle separationFlue gasNitrogen oxide

The invention discloses an ammonia process SCR-SNCR coupling flue gas denitrification reactor which comprises a denitrification body. The denitrification body comprises a hearth, a transition section, a catalyzing section and a gas outlet section, a first reducing section is arranged between the hearth and the transition section, a second reducing section is arranged between the transition section and the catalyzing section, the periphery of the first reducing section is sleeved with an annular ammonia spraying mechanism, and the periphery of the second reducing section is sleeved with an ammonia equivalent injection mechanism. The annular ammonia spraying mechanism and the ammonia equivalent injection mechanism are both connected with an ammonia adding system, and a multi-channel gas mixer is arranged between the second reducing section and the catalyzing section. The catalyzing section is provided with at least one layer of catalyst module. The SCR-SNCR reactor is simple in overall structure, reasonable in design and low in cost, nitric oxide treatment efficiency is greatly improved, ammonia spraying operation is more uniform and comprehensive, a reducer and nitric oxide can be mixed more fully for reacting, reaction efficiency is high, the effect is good, and the reactor is good in airtightness, more environmentally friendly and safer.

Owner:江苏诺伊拓环保工程有限公司

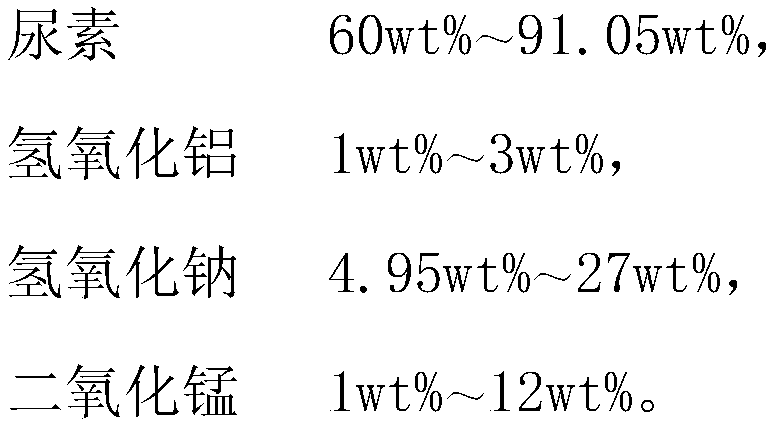

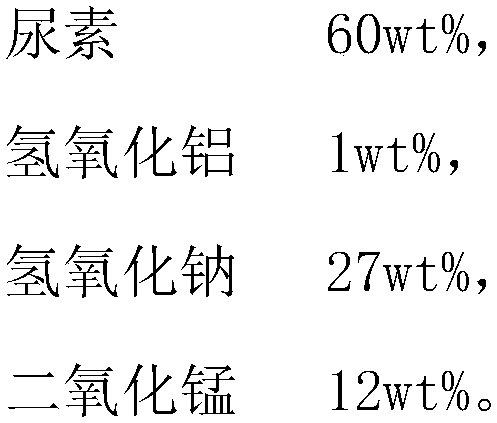

Macromolecular dry-process denitration agent, and preparation method and application thereof

InactiveCN110639341ASimple ingredientsImprove denitrification effectGas treatmentDispersed particle separationAluminium hydroxideEngineering

The invention discloses a macromolecular dry-process denitration agent, and a preparation method and application thereof. The macromolecular dry-process denitration agent consists of the following rawmaterials in percentage by weight: 60-91.05 wt% of urea, 1-3 wt% of aluminum hydroxide, 4.95-27 wt% of sodium hydroxide and 1-12 wt% of manganese dioxide. The macromolecular dry-process denitration agent is formed by scientifically compounding and processing the raw materials according to the designed proportion, and thus the effects that nitrogen oxide and nitrogen dioxide in boiler flue gas areconverted into nitrogen and water and the boiler flue gas is discharged up to standard can be achieved. The macromolecular dry-process denitration agent has simple components and a good denitration effect, and practice proves that denitration efficiency can reach 85% or above.

Owner:沈阳华盟环保节能工程有限公司

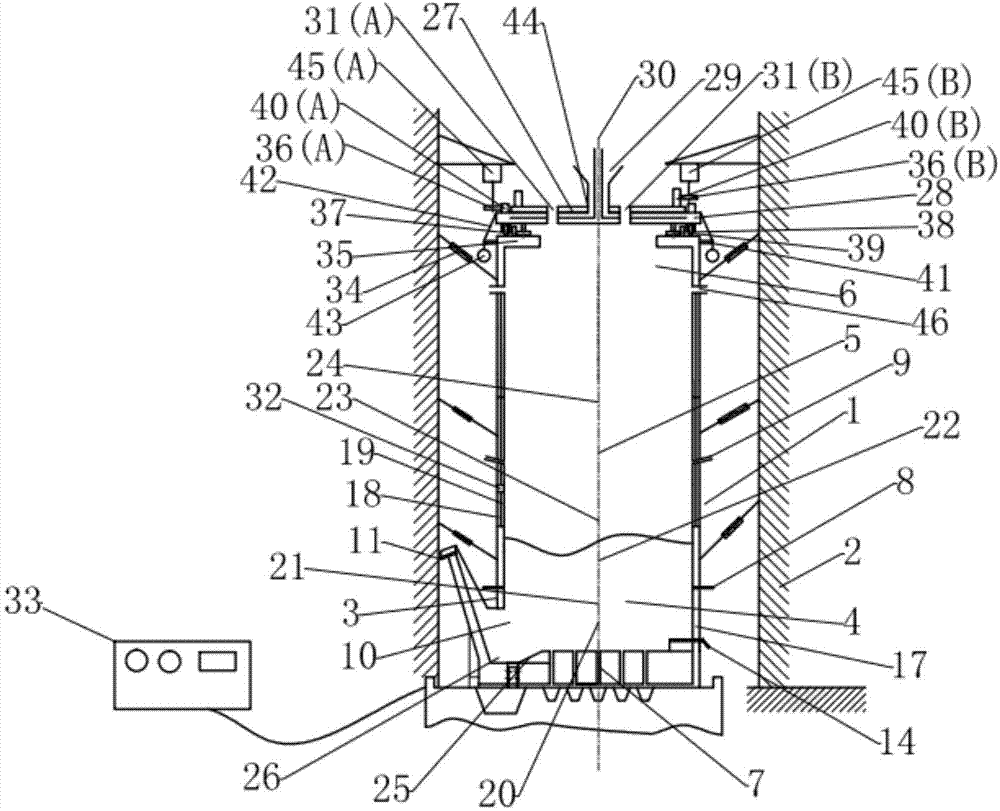

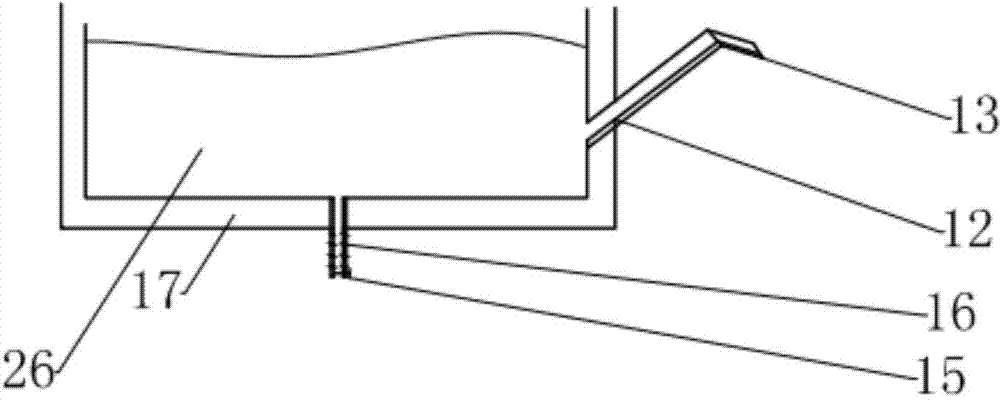

Magnesium smelting technique by microwave heating

The invention discloses a magnesium smelting technique by microwave heating and relates to the field of magnesium smelting techniques. The upper end of the round wall of a furnace body is connected with an expander by bricklaying through a refractory material, and the lower end of the round wall of the furnace body is fixed with a tray; the expander is movably connected with a support in a sliding manner; the lower end of a microporous ceramic tube is fixed with the tray while the upper end of the microporous ceramic tube is fixed with the support; the furnace body is fixed with a microwave generator and a shell; the shell is fixed with an upper flange and a lower flange; a gaseous magnesium collecting chamber is formed by the wall of the furnace body above the support, an upper convergent section of the shell and the inner side of the upper flange; a gaseous magnesium outlet tube is penetrated from the gaseous magnesium collecting chamber and then is fixed with the furnace body and the shell; a slag chamber is formed by the wall of the furnace body below the tray, a lower convergent section of the shell and the inner side of the lower flange; a magnesium ball is put in the microporous ceramic tube; slag is put in the slag chamber; the power of the microwave generator is 1-500KW, the frequency of the microwave generator is 300-3000MHz, the temperature of the microwave generator is 1200-1350 DEG C, and the smelting time is 15-60 minutes; the magnesium ball is acquired by roasting dolomite to acquire magnesium oxide and calcium oxide and then mixing silicon iron and fluorite with magnesium oxide and calcium oxide. The magnesium smelting technique by microwave heating is used for smelting magnesium, which is a microwave new energy heating technology.

Owner:于洪喜

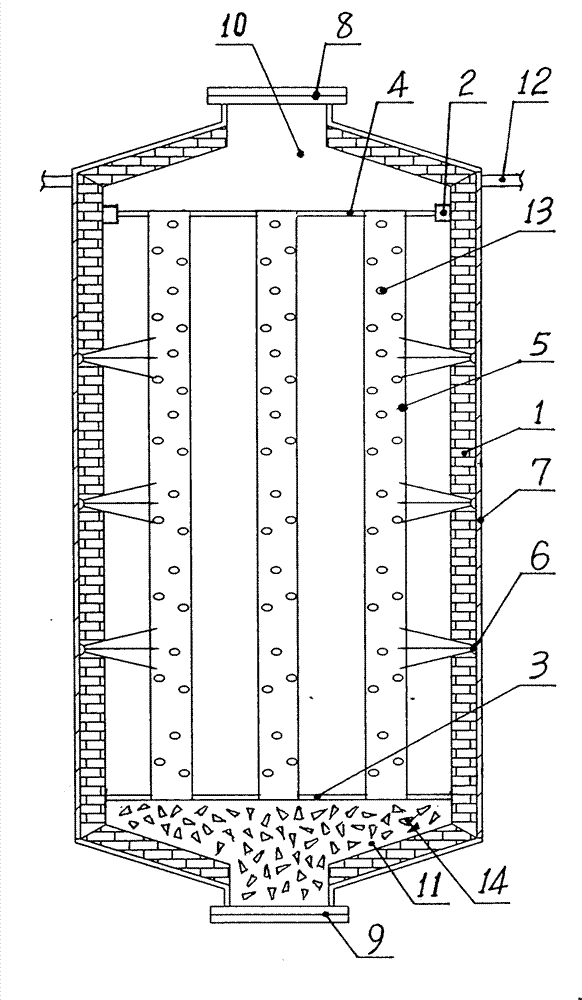

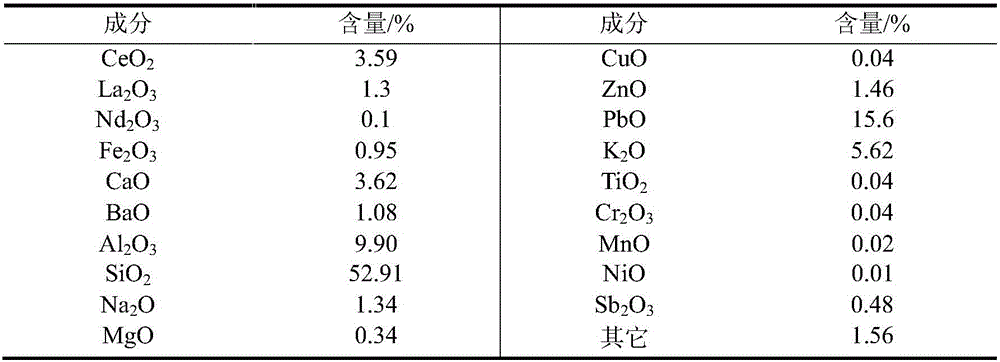

Recovery method of waste rare earth polishing powder

ActiveCN106498189AEfficient recyclingAvoid pollutionAlkali metal silicatesProcess efficiency improvementRecovery methodResource utilization

A recovery method of waste rare earth polishing powder comprises the following steps: weighing waste rare earth polishing powder, a reducing agent and strong base according to a ratio, uniformly mixing, and carrying out a reduction reaction at 600-800 DEG C for 60-240 min to obtain a reduction product; carrying out water quenching on the reduction product to room temperature to obtain a cooled product; carrying out hydrocyclone separation on the cooled product to obtain a mixture of a rare earth-rich material and a silicate aqueous solution and metallic lead; and filtering the mixture of the rare earth-rich material and the silicate aqueous solution to obtain the silicate aqueous solution and the rare earth-rich material. The pollution of lead in the waste rare earth polishing powder to the environment is solved, and resource utilization of valent rare earth, lead and silicon in the waste rare earth polishing powder is realized. The content of lead in the rare earth-rich material after the technical treatment is negligible. Leaching toxicity of heavy metal in the rare earth-rich material meets the national standard, and harmless, reduction and resource treatment of the waste rare earth polishing powder are realized. The method is in line with the goals of our national circular economy development and energy conservation and emission reduction.

Owner:NORTHEASTERN UNIV

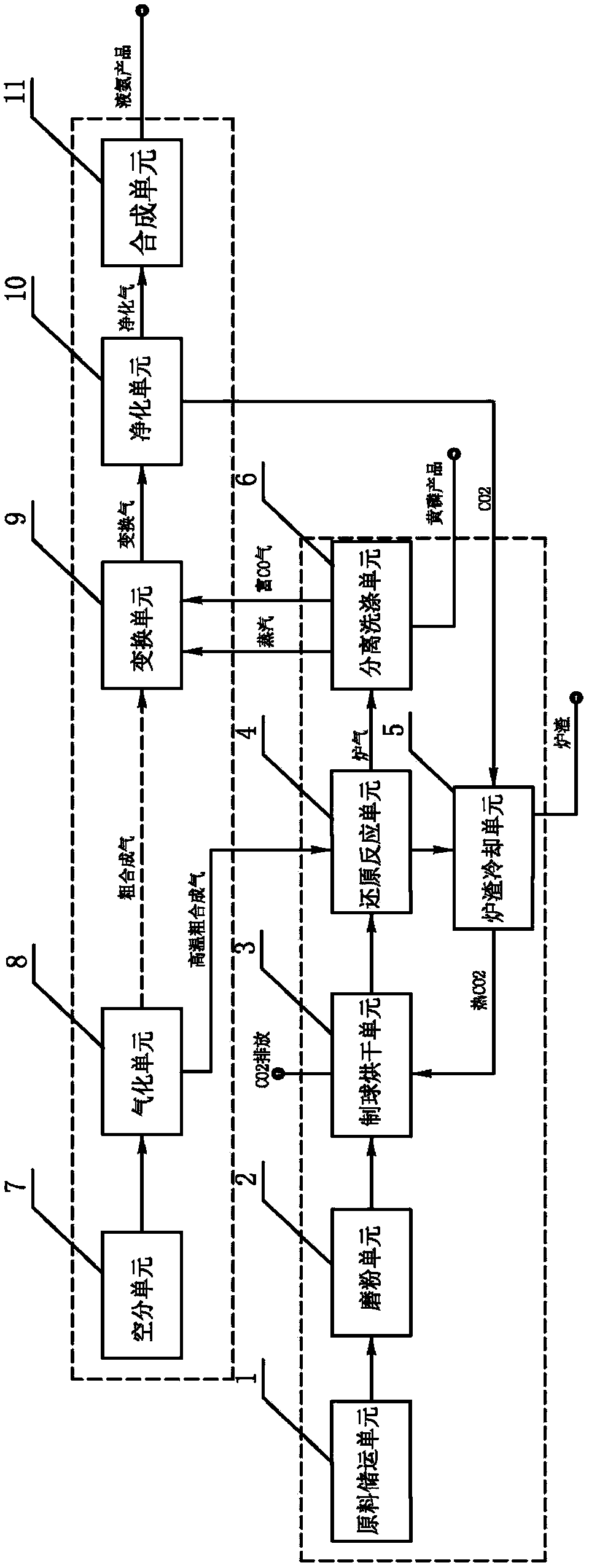

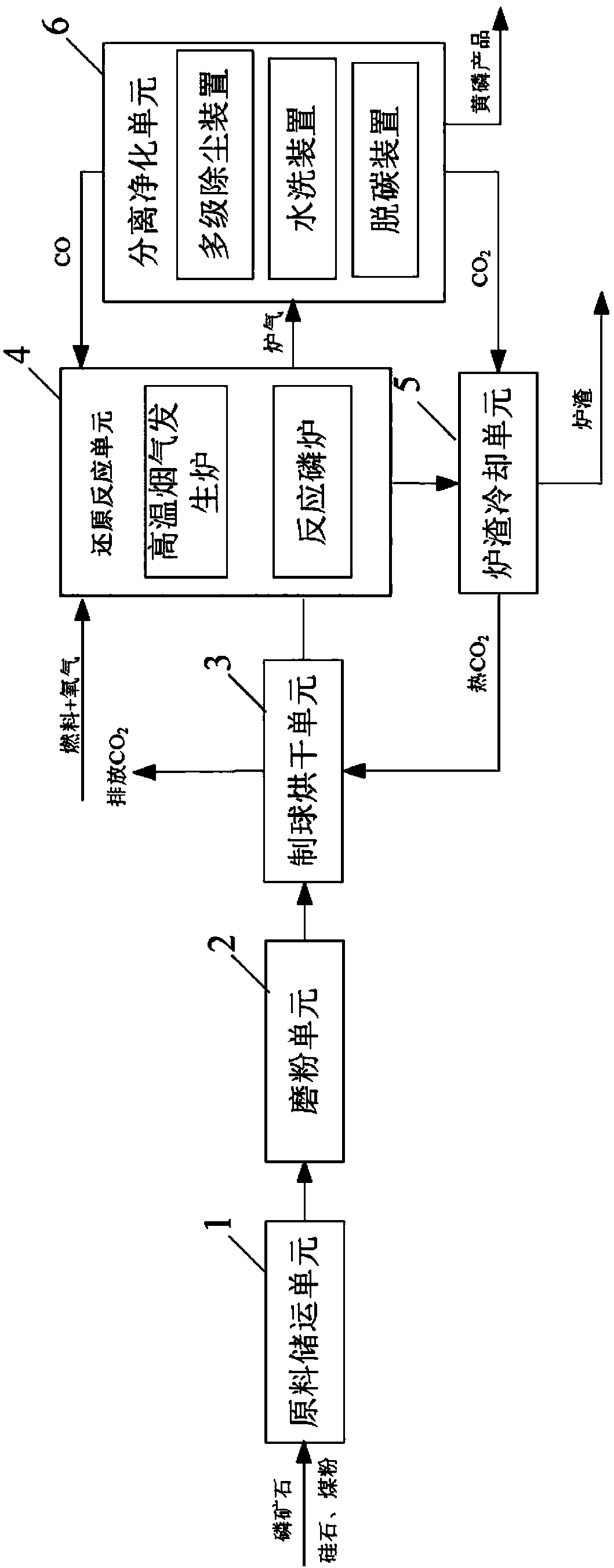

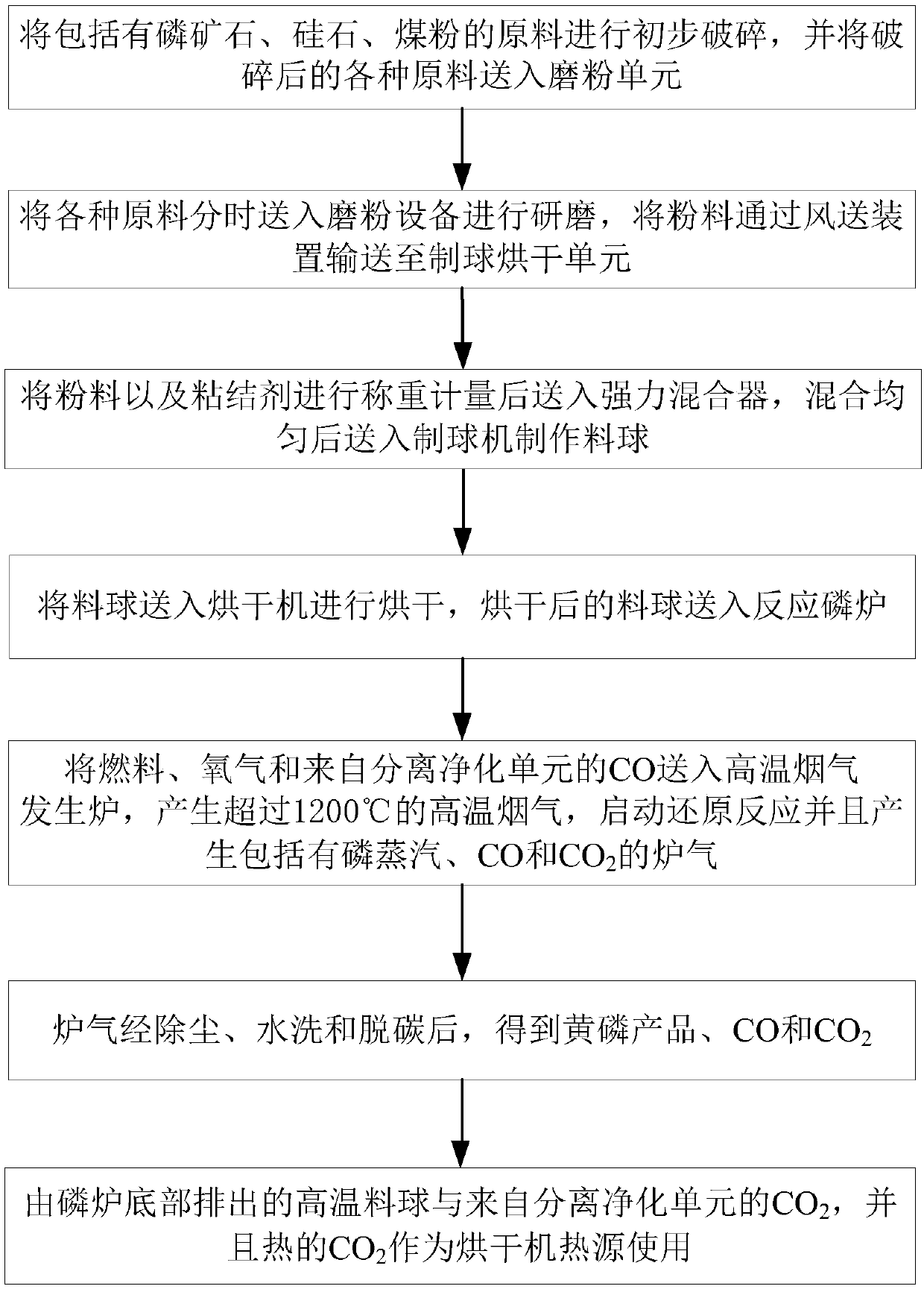

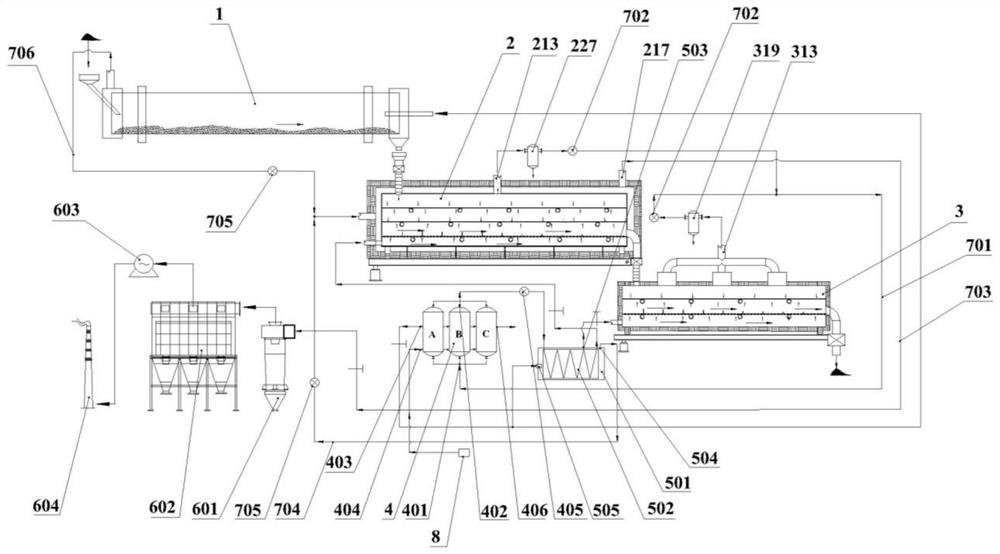

Chemical co-production equipment and method for phosphorus and coal

PendingCN107739025AUnavailable solutionImprove utilization efficiencyGasification processes detailsPhosphorus compoundsSyngasSlag

The invention discloses chemical co-production equipment and a method for phosphorus and coal. The equipment is characterized in that high-temperature crude synthesis gas produced in a coal gasifyingreaction is taken as a heat source for producing yellow phosphorus, so that the problem that heat at a high-temperature segment of the crude synthesis gas produced in the coal gasifying reaction cannot be used is solved; moreover, heat can be supplied to yellow phosphorus production, and the energy utilization rate is high; meanwhile, a reaction product CO produced during yellow phosphorus production and the crude synthesis gas are taken as raw materials of synthesis ammonia, so that the yield of liquid ammonia is increased, and a production process is efficient and contributes to energy saving and environment protection. The chemical co-production equipment for the phosphorus and coal comprises a raw material storing-transporting unit, a grinding unit, a pelletizing-drying unit, a reducing reaction unit, a slag cooling unit, a separating-washing unit, an air separating unit, a gasifying unit, a converting unit, a purifying unit and a synthesizing unit. The chemical co-production equipment and method have the advantages of simplified process flow, technically mature in units, energy saving, environmental friendliness and low application risk, and a beneficial technical option is provided for phosphorus and coal chemical complementation in various fields.

Owner:BEIJING AEROSPACE MWAY TECH CO LTD

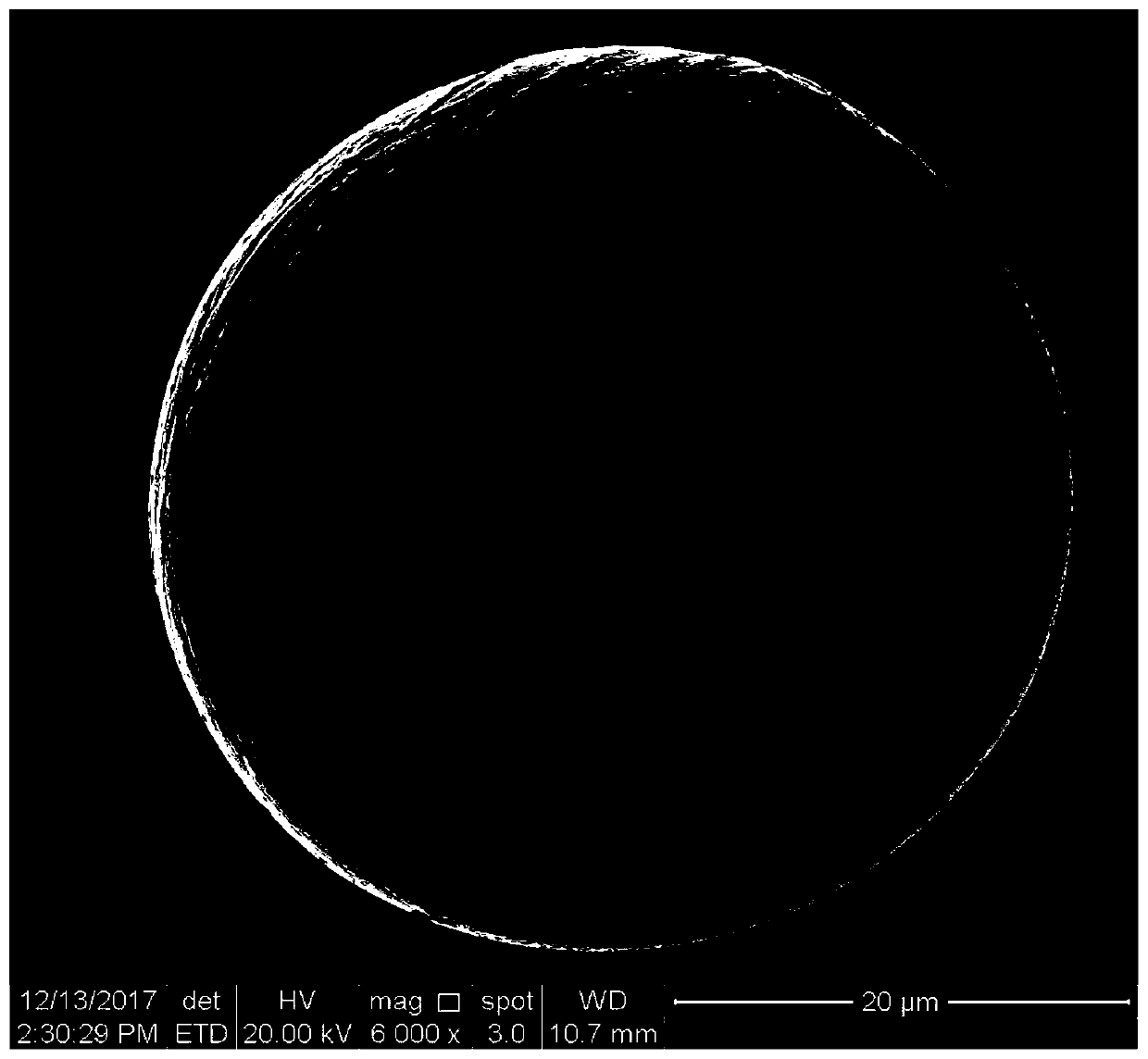

Method for reducing oxygen content of titanium powder prepared by using hydrogenation dehydrogenation method

The embodiment of the invention provides a method for reducing the oxygen content of titanium powder prepared by using a hydrogenation dehydrogenation method, and belongs to the technical field of powder metallurgy. The method comprises the following steps that active metal is fed into an inductive coupled plasma torch to excite ionization to obtain a strong reducing induction coupling plasma torch, wherein working gas and side gas of the inductive coupled plasma torch are mixed gas A of helium and argon; the mixed gas A is taken as powder feeding gas to feed the titanium powder prepared by the hydrogenation dehydrogenation method into the strong reducing induction coupling plasma torch established through the step (1), and the titanium powder is separated from the strong reducing induction coupling plasma torch after being molten and is deposited and cooled to obtain reduced titanium powder; and the obtained reduced titanium powder is washed to remove residual active metal and oxidesattached to the surface of the reduced titanium powder, and the titanium powder is filtered out and then is washed, filtered and dried to obtain the low-oxygen titanium powder. According to the method, the oxygen content of the hydrogenation dehydrogenation titanium powder can be reduced to hundreds of ppm from thousands of ppm.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

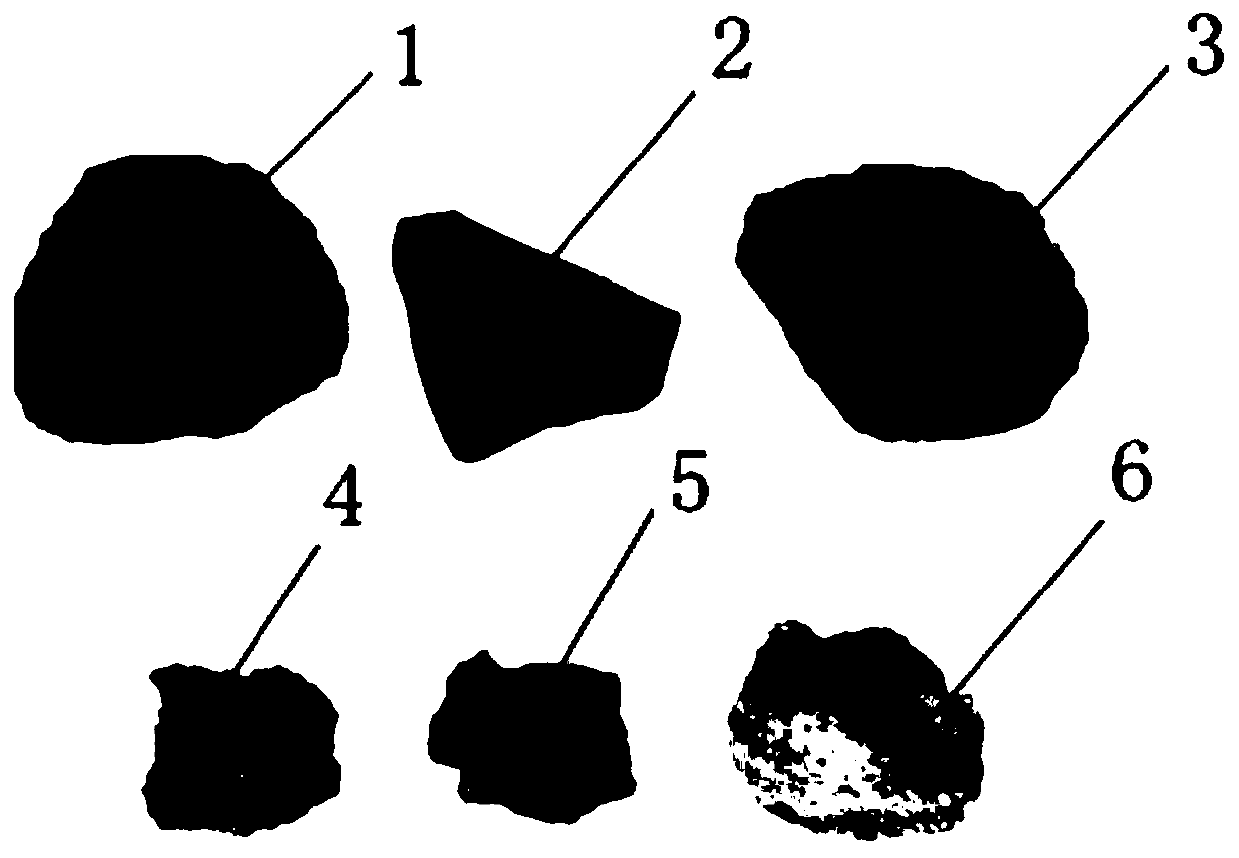

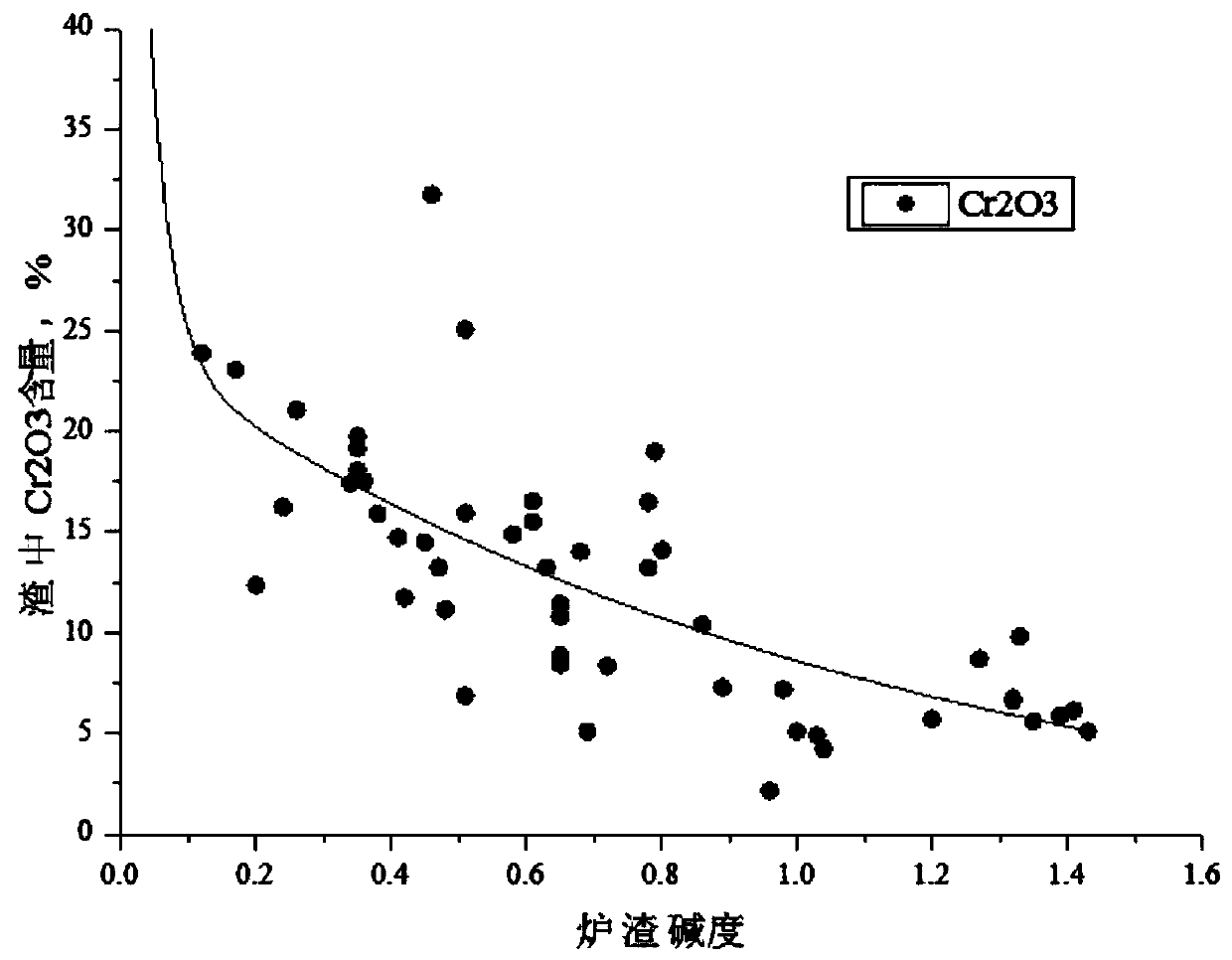

Electric furnace for producing Cr13 series stainless steel and smelting control method for refining furnace

ActiveCN109897938AReduce control difficultyReduce the probability of splash accidentsElectric furnaceProcess efficiency improvementChromiumCr element

The invention provides an electric furnace for producing Cr13 series stainless steel and a smelting control method for a refining furnace, wherein the process flow of the control method is as follows:raw material preparation - electric furnace trough type tapping - VOD blowing process - refining furnace process - molding process. The invention has the following beneficial effect: the lectric furnace for producing the Cr13 series stainless steel and the smelting control method for the refining furnace provided by the invention have the following advantages: the Cr element metal yield of the prepared Cr13 series stainless steel is greater than or equal to 95%, and compared with the prior art, the smelting time is shortened by more than 30min ; the smelting cost of Cr13 series stainless steel is greatly reduced, avoids genearating aluminum-chromium spinel inclusions in molten steel, has a significant improvement on the purity of molten steel, and can meet the increasingly quality requirement of stainless steel products in the downstream industries of steel enterprises.

Owner:XINING SPECIAL STEEL

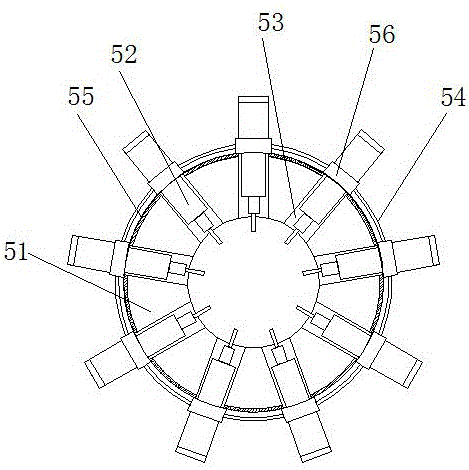

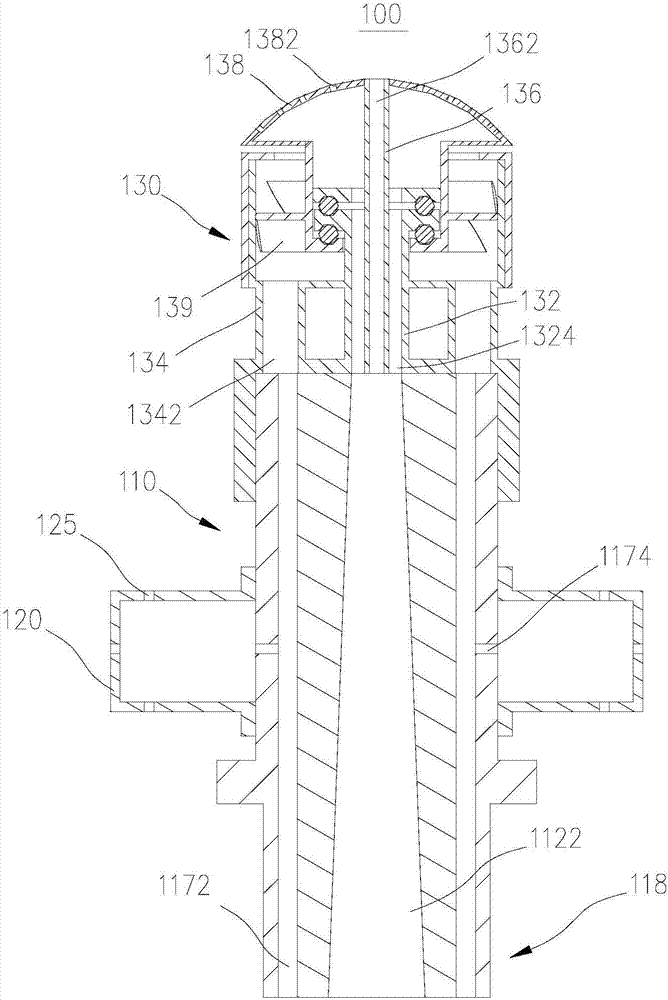

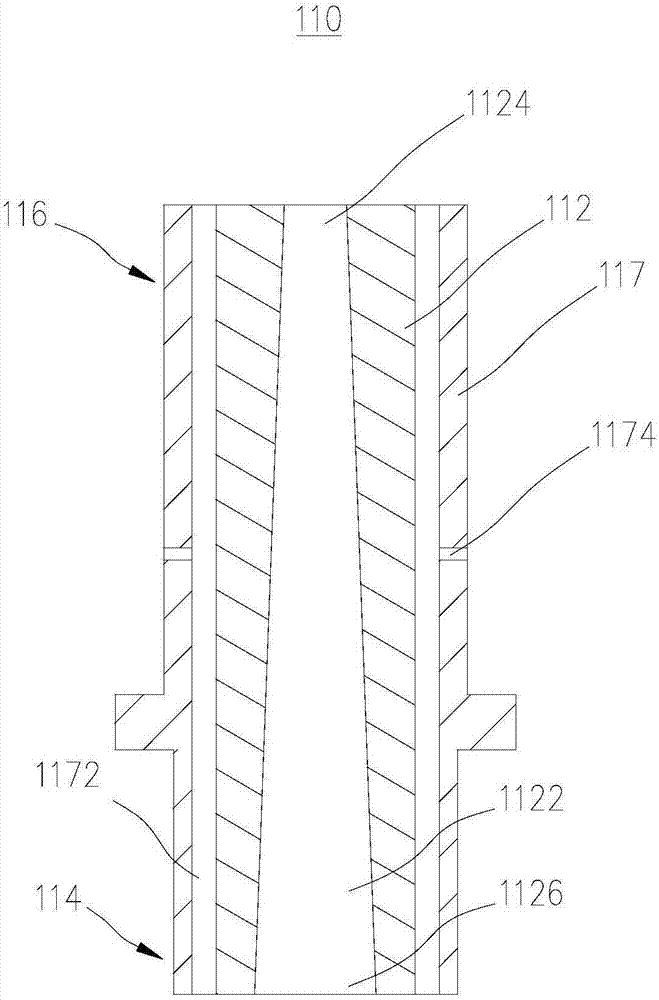

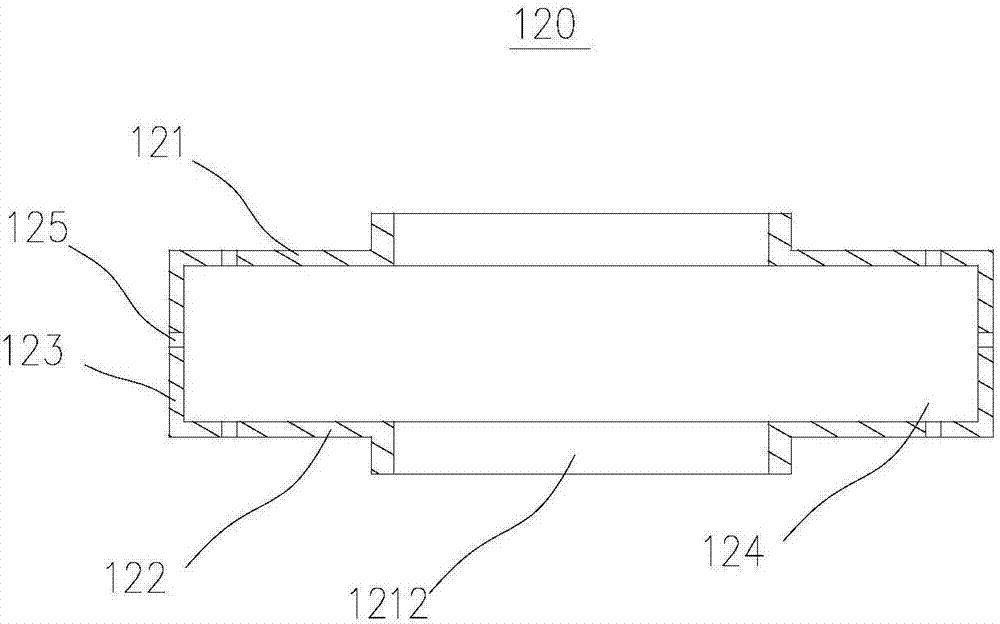

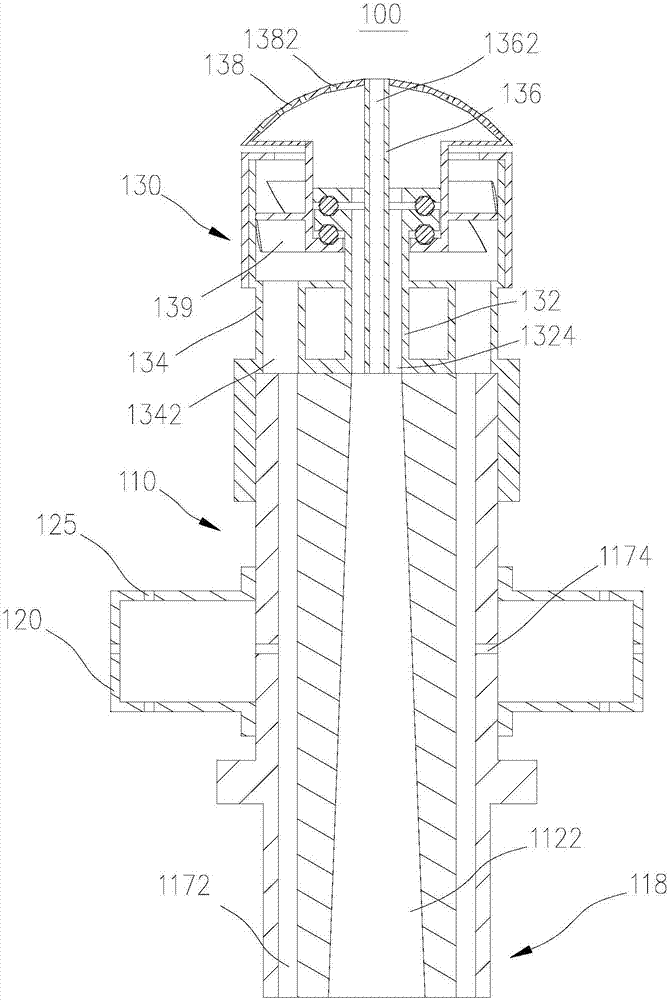

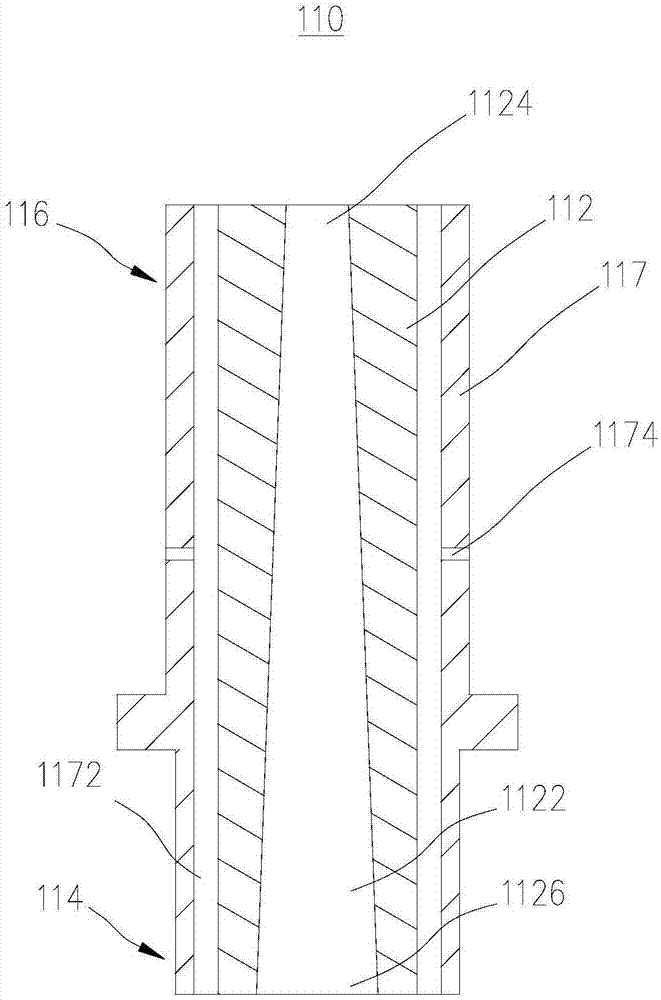

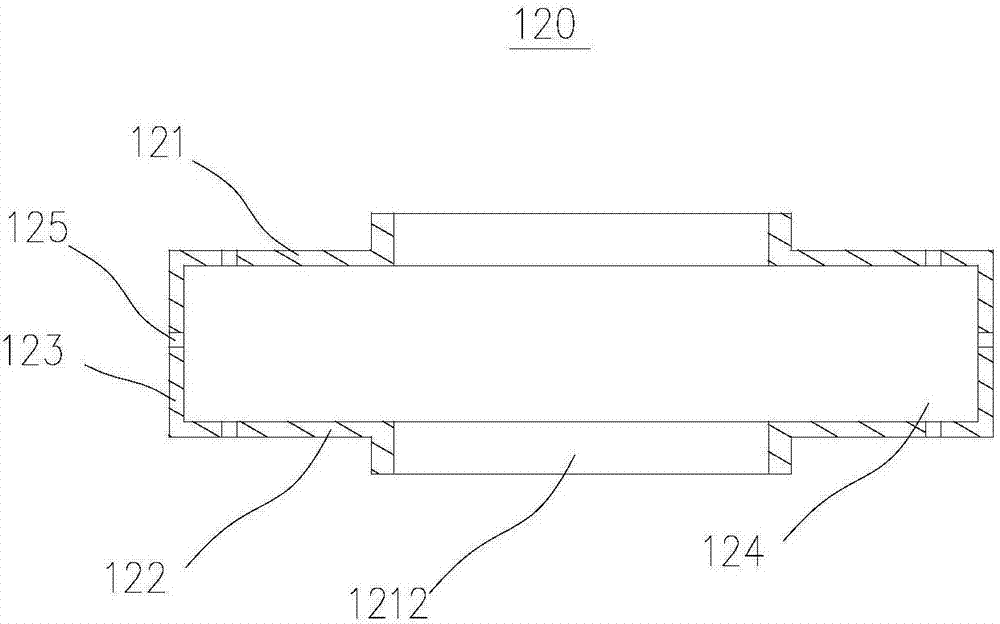

Nozzle for polycrystalline silicon reduction furnaces with 48 pairs of sticks

The invention provides a nozzle for polycrystalline silicon reduction furnaces with 48 pairs of sticks. The nozzle belongs to the production field of polycrystalline silicon. The nozzle mainly comprises a cylinder core. The core consists of a first inner tube and a first outer tube. The first outer tube is set and covered on the first inner tube. The first inner tube comprises a main channel. The flow area of the air outlet of the main channel is smaller than the air inlet. The gap between the first outer tube and the first inner tube forms an auxiliary channel. The core is installed on a chassis through an interconnecting piece. Due to the flow area of the air inlet is larger than the flow area of the air outlet, air is passing through the main channel with an increasingly faster speed and eventually reaches the top of the reduction furnace. After passing through the auxiliary channel, a part of the air in the auxiliary channel gets to the middle of the reduction furnace, and the other part of the air gets to the bottom of the reduction furnace through a plurality of side vent holes on the first outer tube. The material gas can be evenly distributed in the entire reduction furnace, which leads to the fully performing of the reduction reaction.

Owner:ASIA SILICON QINGHAI

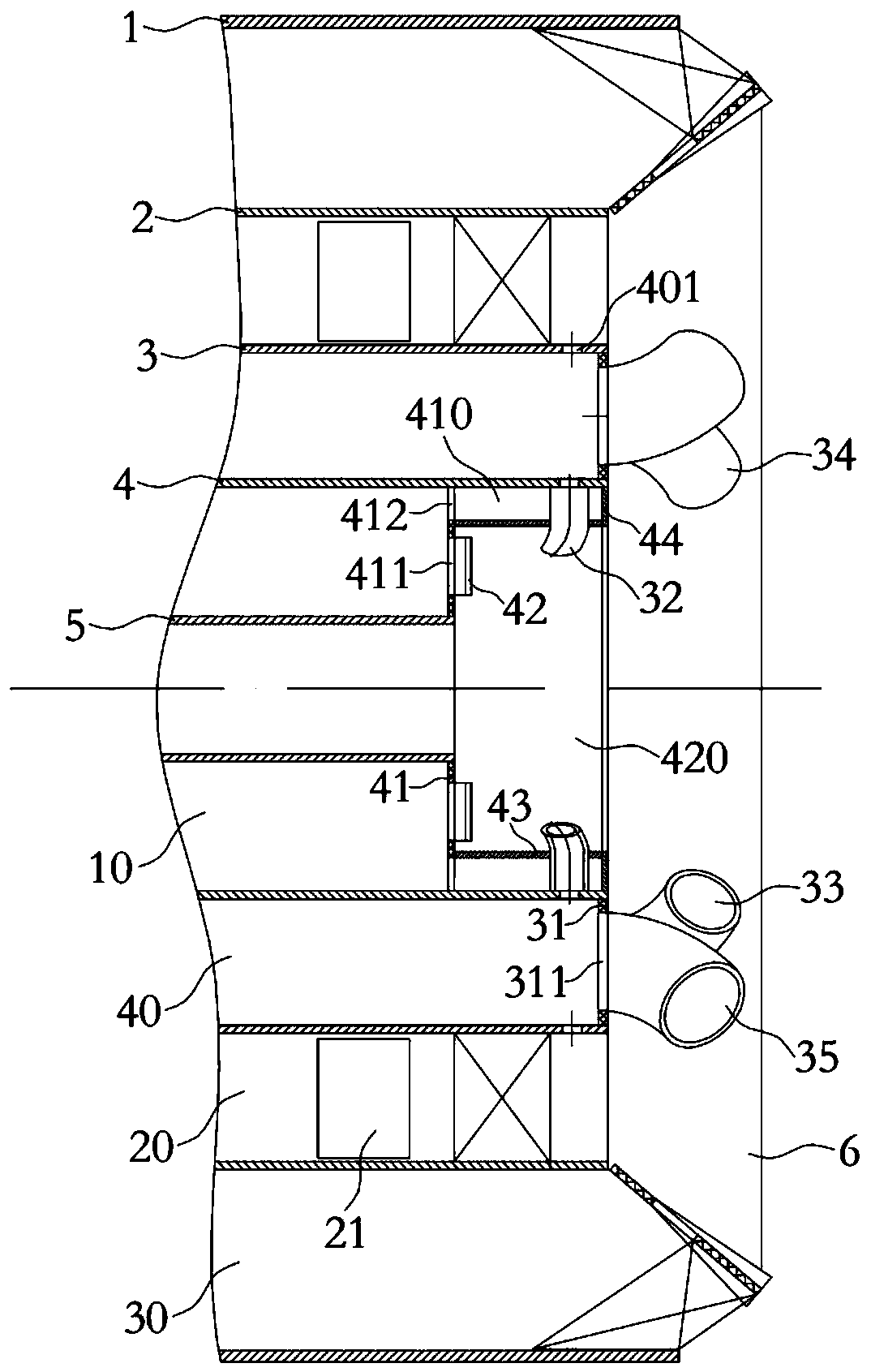

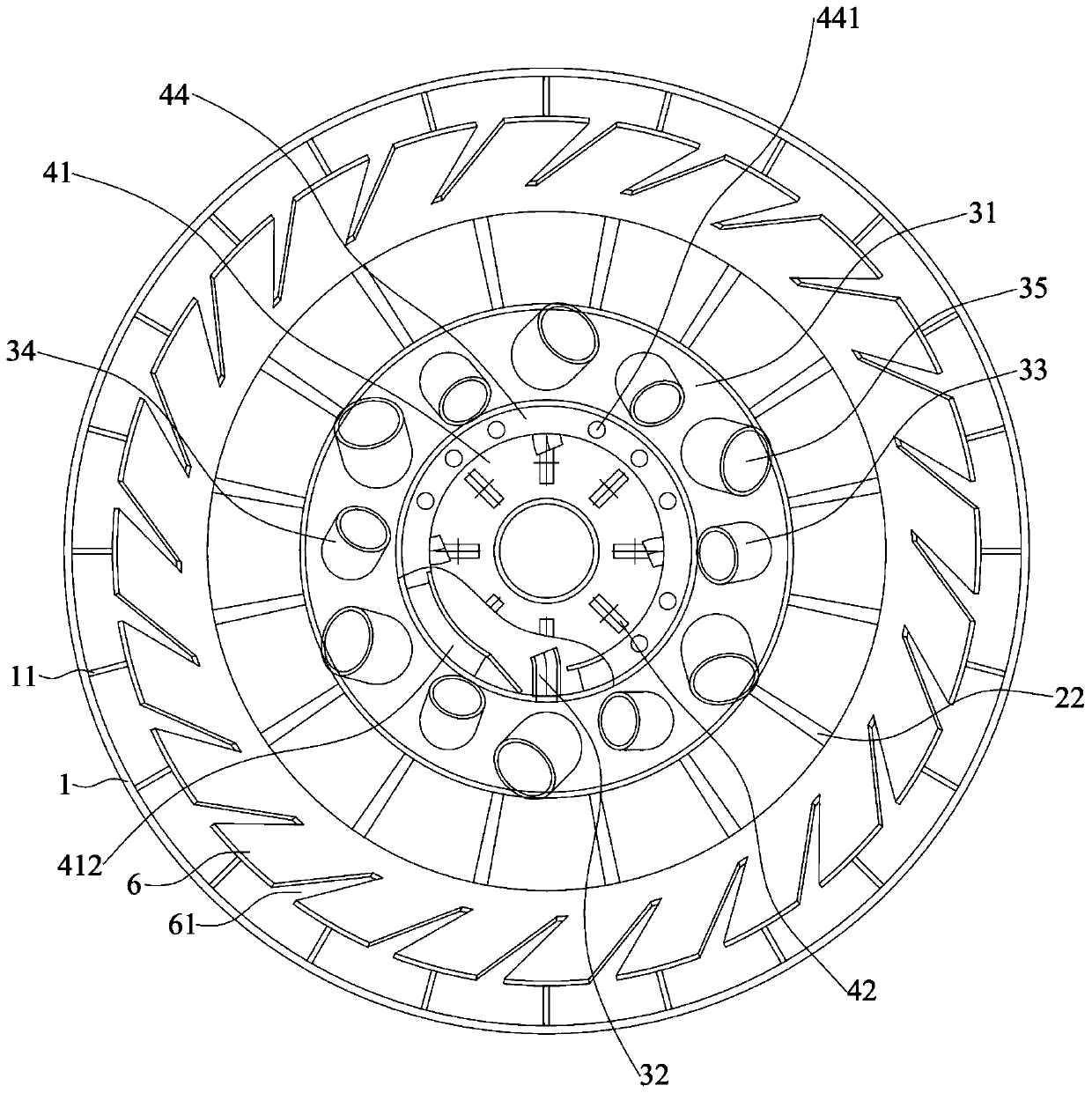

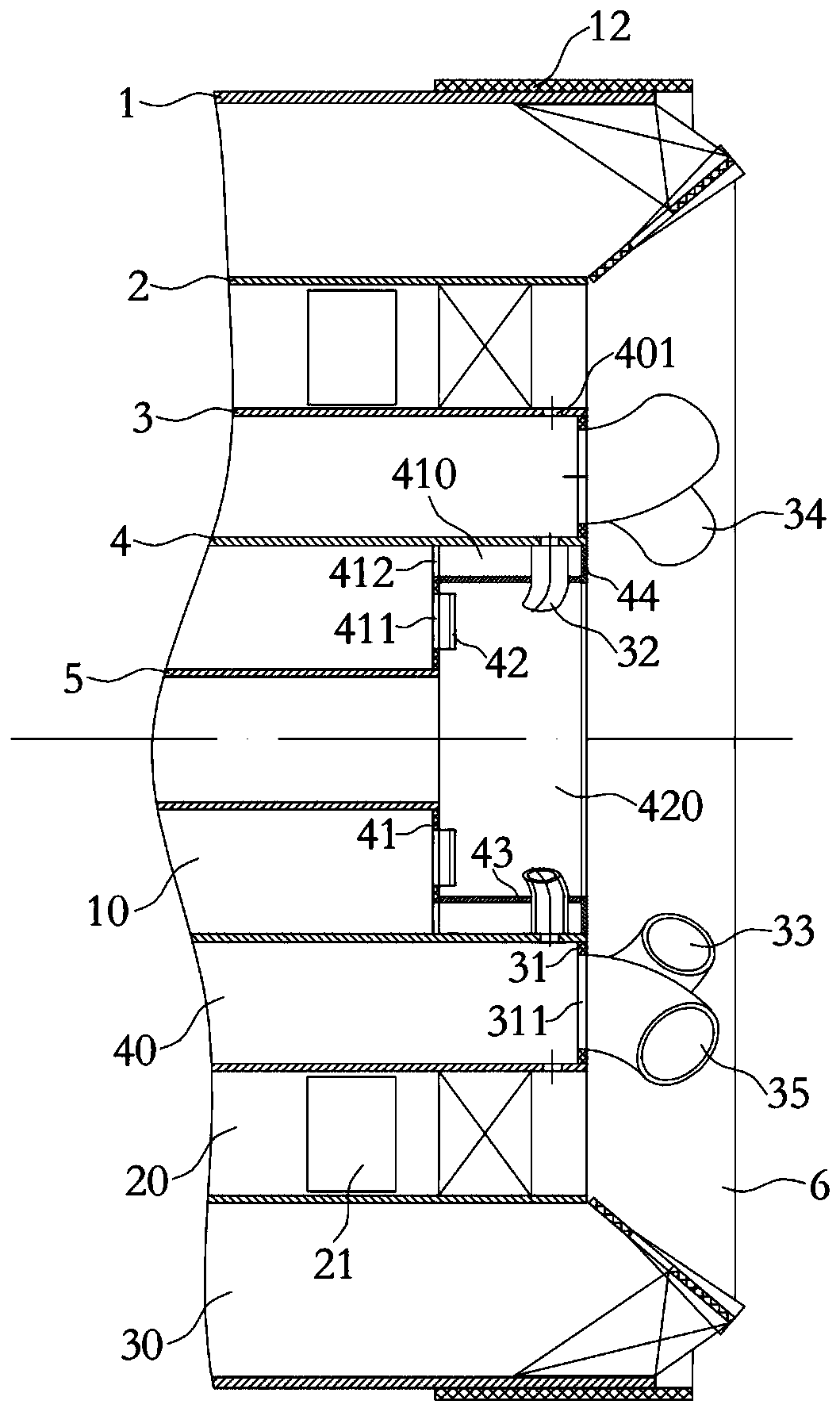

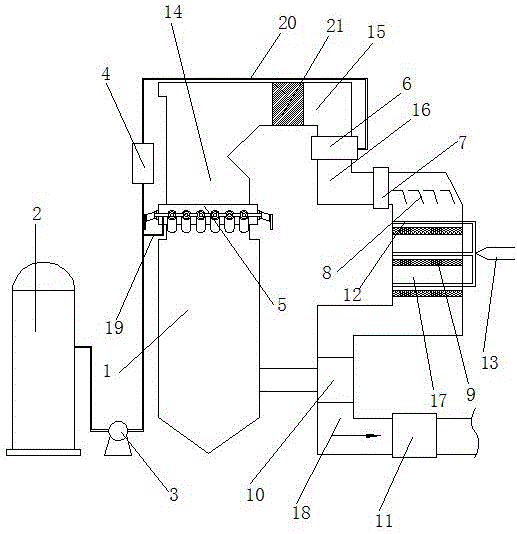

Combined regenerated lead oxygen-enriched three-blowing energy-saving smelting furnace

InactiveCN103834817AIncrease heightGuaranteed contactIncreasing energy efficiencyGas emission reductionSlagWater jacket

The invention discloses a combined regenerated lead oxygen-enriched three-blowing energy-saving smelting furnace. A furnace body 1 is arranged vertically, the whole furnace body 1 is divided into a lower section, a middle section and an upper section, the lower section is a smelting area 4 and comprises a stationary area 20, a bubbling area 21, and a reduction area 22 from bottom to top, the middle section is a waste heat utilization area 5, the lower half part of the waste heat utilization area is a secondary combustion area 23, the upper half part of the waste heat utilization area is a raw material preheating area 24, the upper section is a smoke discharging and feeding area 6. The vertical furnace body is more convenient to fully use the waste heat of the offgas for preheating the raw material, so that the energy-saving effect is remarkably improved, the dosage of the reducing agent is reduced, and the content of lead in the slag is lowered. The novel furnace body adopts a metal water jacket component and is combined by segmental hoisting, thus being convenient to maintain, and greatly lowering the maintenance cost.

Owner:ANHUI HUAXIN LEAD IND GROUP +1

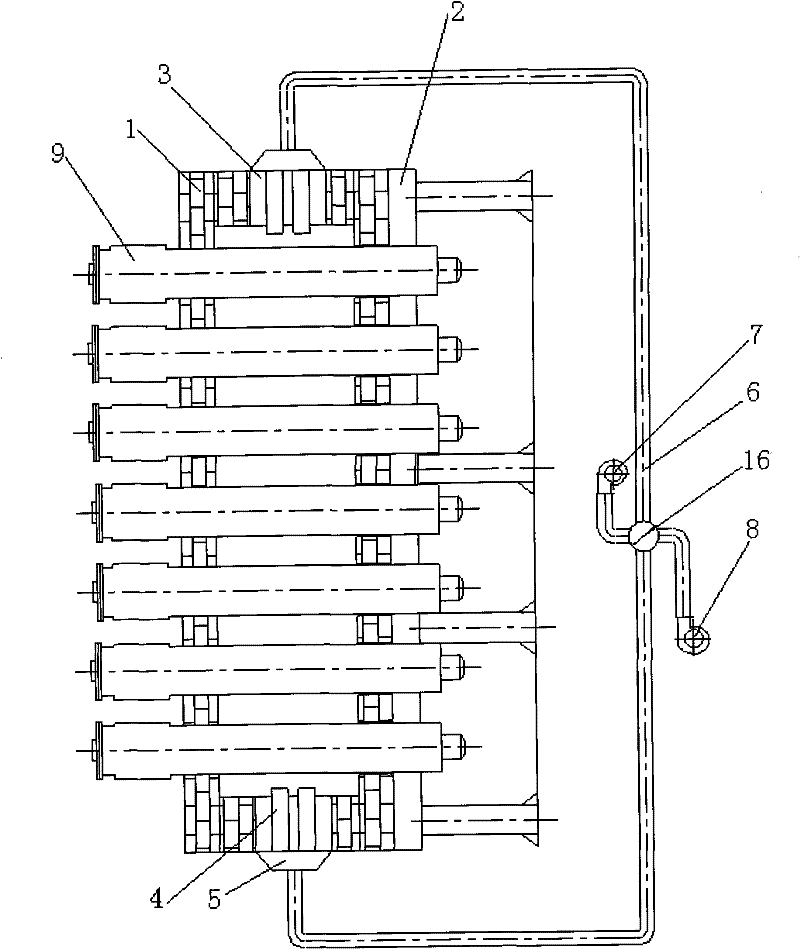

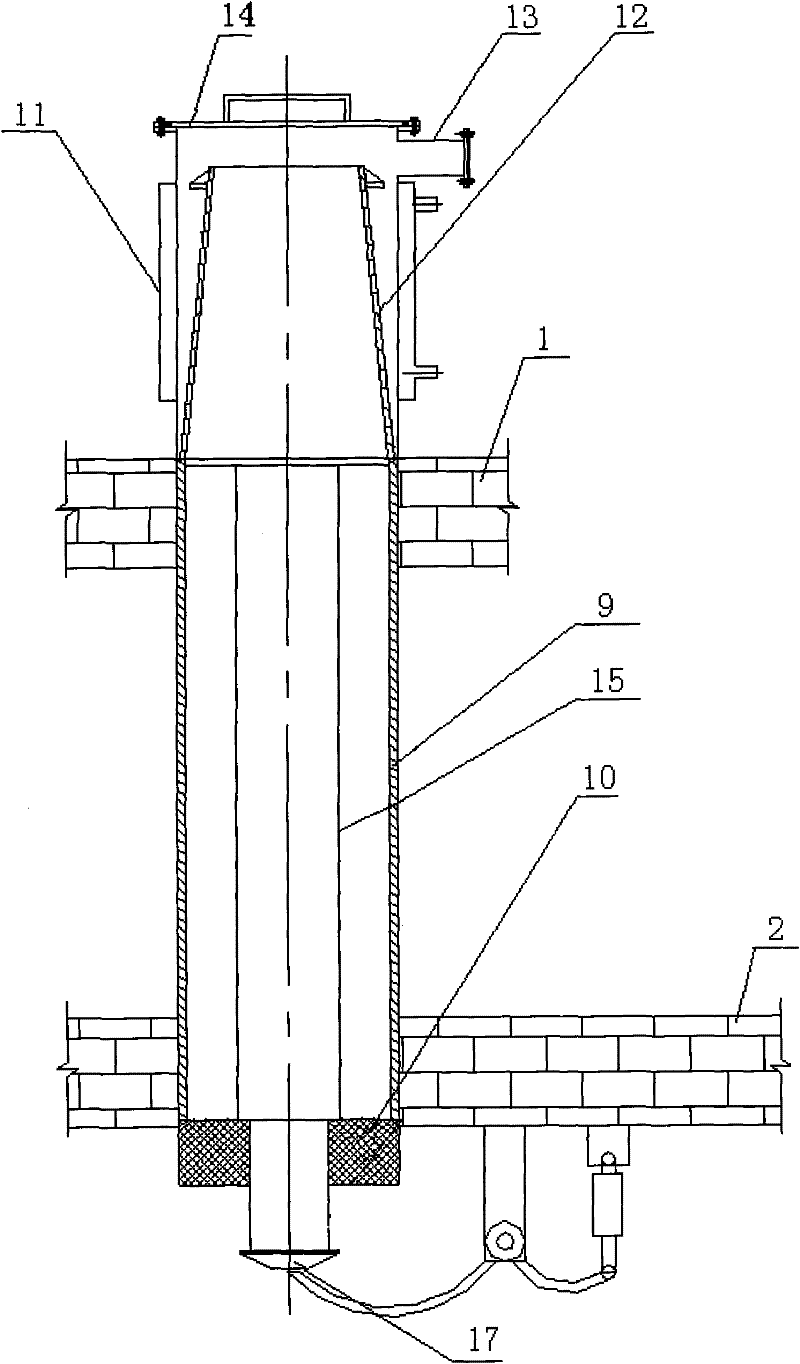

Equipment and method for producing yellow phosphorus from middle-low-grade phosphate ore

PendingCN107686099ASolving underutilizedImprove utilization efficiencyChemical industryCement productionPhosphateFlue gas

The invention discloses equipment and a method for producing yellow phosphorus from middle-low-grade phosphate ore. The yellow phosphorus production equipment can be used for preparing the yellow phosphorus from the middle-low-grade phosphate ore, further improves an energy utilization efficiency and effectively controls pollutant generation at the same time. The yellow phosphorus production equipment comprise a grinding unit, a ball making and drying unit, a reduction reaction unit, a furnace slag cooling unit and a separating and purifying unit, wherein the grinding unit comprises a grindingdevice and an air conveying device; the ball making and drying unit comprises a mixer, a ball making machine and a drying machine; the reduction reaction unit comprises a high temperature flue gas generation furnace and a reaction phosphorus furnace; the separating and purifying unit is communicated with the reaction phosphorus furnace, the high temperature flue gas generation furnace and the furnace slag cooling unit; the furnace slag cooling unit is communicated with the ball making and drying unit. The invention further discloses the method for producing the yellow phosphorus from the middle-low-grade phosphorus ore. According to the equipment, heat contained in CO and high temperature furnace slag is comprehensively utilized, and a part of fuel is supplemented at the same time, so that the energy utilization efficiency is improved.

Owner:BEIJING AEROSPACE MWAY TECH CO LTD

Vertical heat accumulating type reduction furnace

The invention discloses a vertical heat accumulating type reduction furnace, relating to metal magnesium and metal calcium melting, in particular to a vertical metal magnesium and metal calcium reduction furnace. The vertical heat accumulating type reduction furnace is characterized by comprising a reduction furnace body, a heating device, a fuel and combustion supporting gas introducing-in device and a reducing reaction tank in a vertical pipe shape, wherein the center of the reducing tank body between a reducing-tank sealing member and a taper-shaped crystallizer is coaxially provided with a vertical through pipe of which the side wall is provided with a through hole. The vertical heat accumulating type reduction furnace disclosed by the invention has the advantages of short construction period and high speed of becoming effective. The vertical heat accumulating type reduction furnace body is supported by a concrete or steel structure bracket; the furnace structure is not complex and is convenient to build and install. The steps of loading, taking the crystallizer and deslagging can be mechanically and quickly operated to save labor force cost. Hot airflow rises in the hearth, which is favorable for carrying out a reduction reaction and ensures that a reduction period is shortened. Compared with a lateral tank reduction furnace, the vertical heat accumulating type reduction furnace has the advantage of saving more energy.

Owner:于思静 +1

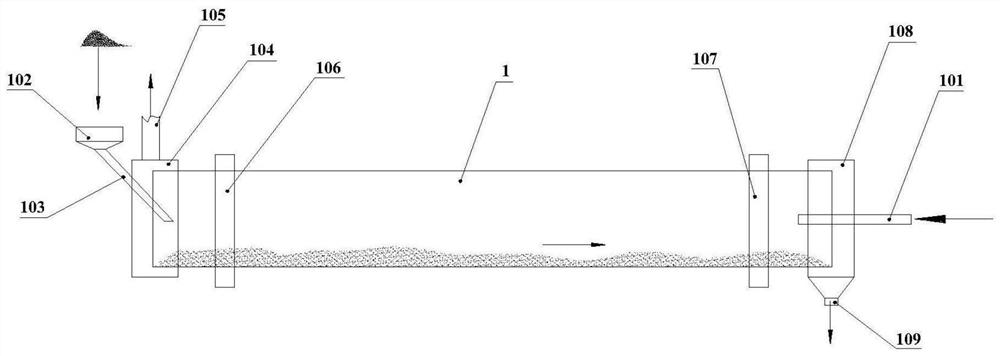

Device and method for metal oxide fine ore gas-based reduction

ActiveCN112301178ALower recovery costsReduce usageProcess efficiency improvementMolecular sieveGas solid

The invention discloses a device for metal oxide fine ore gas-based reduction. The device sequentially comprises an oxidizing roasting system, a gas-based pre-reduction system and a gas-based deep reduction system according to a process sequence. The device further comprises a molecular sieve pressure swing adsorption system, a pure hydrogen muffle heat exchange heating furnace system and a dust removal and smoke exhaust system. According to the device, CO and H2 are separated out through the molecular sieve pressure swing adsorption device, after CO coal gas is firstly adopted for oxidizing,roasting and heating fine ore, fine ore with sensible heat of 900-1000 DEG C passes through a boiling pre-reduction furnace and is subjected to gas-solid boiling type sufficient contact and reductionreacting with H2 heated through muffle heat exchange, then boiling type sufficient deep reduction reacting is carried out on a gas-solid boiling deep reduction furnace and warm H2, and a high-qualityreduced iron (DRI) product is deeply reduced by utilizing high-temperature sensible heat of the fine ore in the gradual cooling process. The invention further comprises a method for carrying out metaloxide fine ore gas-based reduction by using the device.

Owner:烟台市红森林节能环保科技有限公司

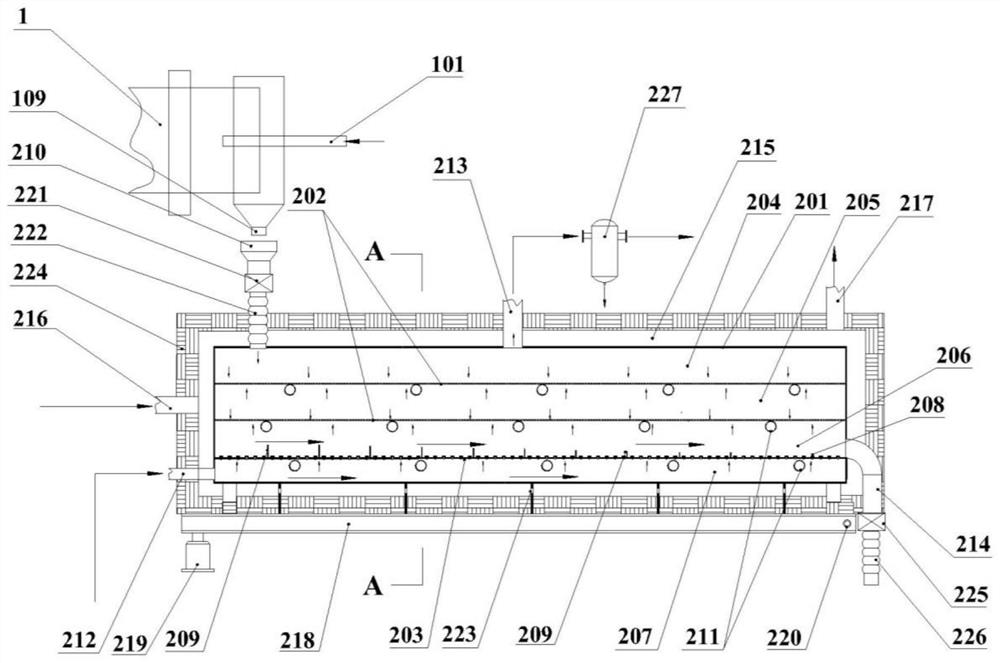

Slag burnout system and method of biomass boiler

PendingCN111981473AHigh thermal efficiencyGood for burnoutFluidized bed combustionApparatus for fluidised bed combustionAir preheaterSlag

The invention discloses a slag burnout system and method of a biomass boiler. The slag burnout system comprises a boiler body, a cyclone separator, an ash cooling air pipeline and denitration equipment, wherein a water cooling wall and a first superheater are arranged in the boiler body; an inlet of the cyclone separator communicates with an exhaust port of the boiler body; a slag outlet of the cyclone separator communicates with a first necking structure of the boiler body through a return pipeline; an air outlet of the cyclone separator communicates with a flue gas pipeline; a second superheater, a coal economizer and an air preheater are sequentially arranged in the flue gas pipeline in the flue gas flowing direction; an inlet of the air preheater communicates with an air feeder throughan air feeding pipeline; and an outlet of the air preheater communicates with a primary air pipeline and a secondary air pipeline. According to the slag burnout system and method, through circulatingfluidization and keeping of upward ash cooling air in a slag well, boiler ash can be fully burnt out, sensible heat of the ash is fully utilized, the boiler efficiency can be improved, and ash deposition corrosion is reduced.

Owner:南方电网综合能源(广州)有限公司赤水分公司 +3

Purifying process for synthesizing graphite core column for industrial diamonds

The invention discloses a purifying process for synthesizing graphite core column for industrial diamonds; by making use of the ability of carbon in graphite to reduce at high temperature, pre-evacuating, degassing and dewatering at held temperature are carried out, air and adsorbed water in pores of a graphite core column are discharged, the temperature is raised to 1045+ / -15 DEG C, vacuum degree is maintained stably between 120-240 Pa, reaction reaches deep in metal oxides by the aid of permeability of carbon monoxide gas, and reducing is more thorough. The process saves electricity since a pump is stopped at high temperature and reducing time is shortened; by providing conditions and using self-produced gas to replace reducing gas to be charged, resources are saved, and impurities are not introduced; the process provides thorough and effective purification, is high in efficiency and has huge economic benefit.

Owner:ZHONGNAN DIAMOND CO LTD

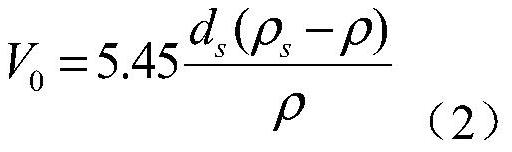

Method for recycling valuable metals from waste lithium ion batteries

InactiveCN112259821AHigh recovery rateHigh purityWaste accumulators reclaimingProcess efficiency improvementElectrical batteryLithium carbonate

The invention discloses a method for recycling valuable metals from waste lithium ion batteries, and belongs to the technical field of waste battery recycling. The method comprises the following steps: (1) charging a waste lithium ion battery; (2) crushing the charged battery, and sorting the materials to obtain a mixture of a positive electrode material and a negative electrode material; (3) calcining the mixture of the positive electrode material and the negative electrode material at high temperature; (4) putting the calcined material into water, performing stirring, performing filtering, adding sodium carbonate into the filtrate to obtain lithium carbonate, and taking the filter residue as a metal simple substance and an oxide thereof. Part of lithium ions are transferred to the negative electrode material through charging, and then the lithium and other metals can be recycled through simple processes such as calcination and water leaching of the positive electrode and negative electrode mixture. The method is simple, effective and suitable for large-scale production.

Owner:SINOSTEEL NANJING NEW MATERIALS RES INST CO LTD +1

Upcast method for producing high-purity bright copper rod

ActiveCN102168180BLight weightFull reduction reactionProcess efficiency improvementOxygenNitrogen gas

The invention relates to an upcast method for producing a high-purity bright copper rod. The method comprises the following steps of: drying smelting copper raw materials needed by smelting, mixing, adding the mixture into a smelting furnace, and covering firing charcoal with the thickness of between 100 and 150mm on starting molten copper until red copper is entirely molten, wherein molten copper constantly flows toward a heat preservation furnace under the action of fluid force; boiling the high-temperature molten copper and degassing before ingot guiding, adding prepared high-purity graphite carbon powder onto the liquid level of the molten red copper in the heat preservation furnace, and aerating high-purity nitrogen at the position which is 50 to 100mm lower than the liquid level of the heat preservation furnace; covering the firing charcoal after boiling and degassing, covering a furnace cover, performing draw casting operation, drawing a draw casting machine for draw casting bythe upcast method, cooling in a graphite crystallizer by the upcast method to obtain a qualified high-purity oxygen-free copper rod blank, and winding on a drawn cast ingot passive winding machine; and performing multi-pass rolling and fine-drawing on the high-purity oxygen-free high-brightness copper rod blank by an eight-rack rod cold rolling mill, and drawing the blank until the copper rod is obtained by a wire drawing machine, namely obtaining a finished product after the copper rod passes the inspection.

Owner:ZHONGTIAN ALLOY TECH

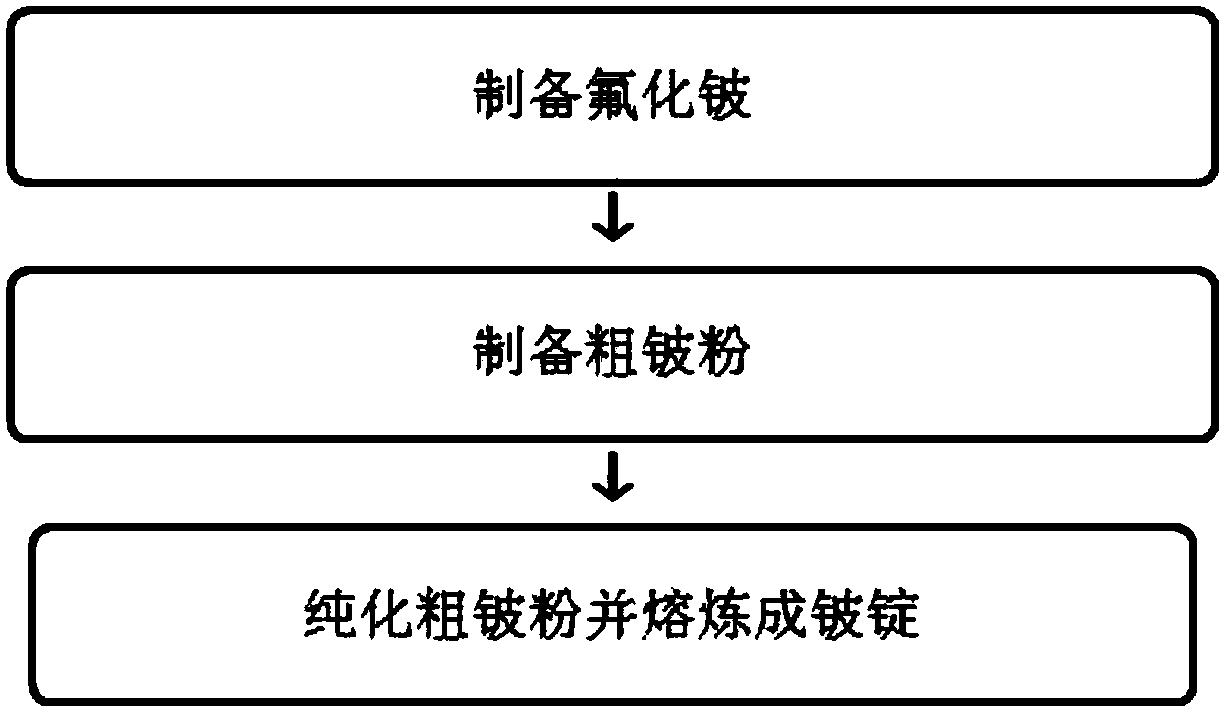

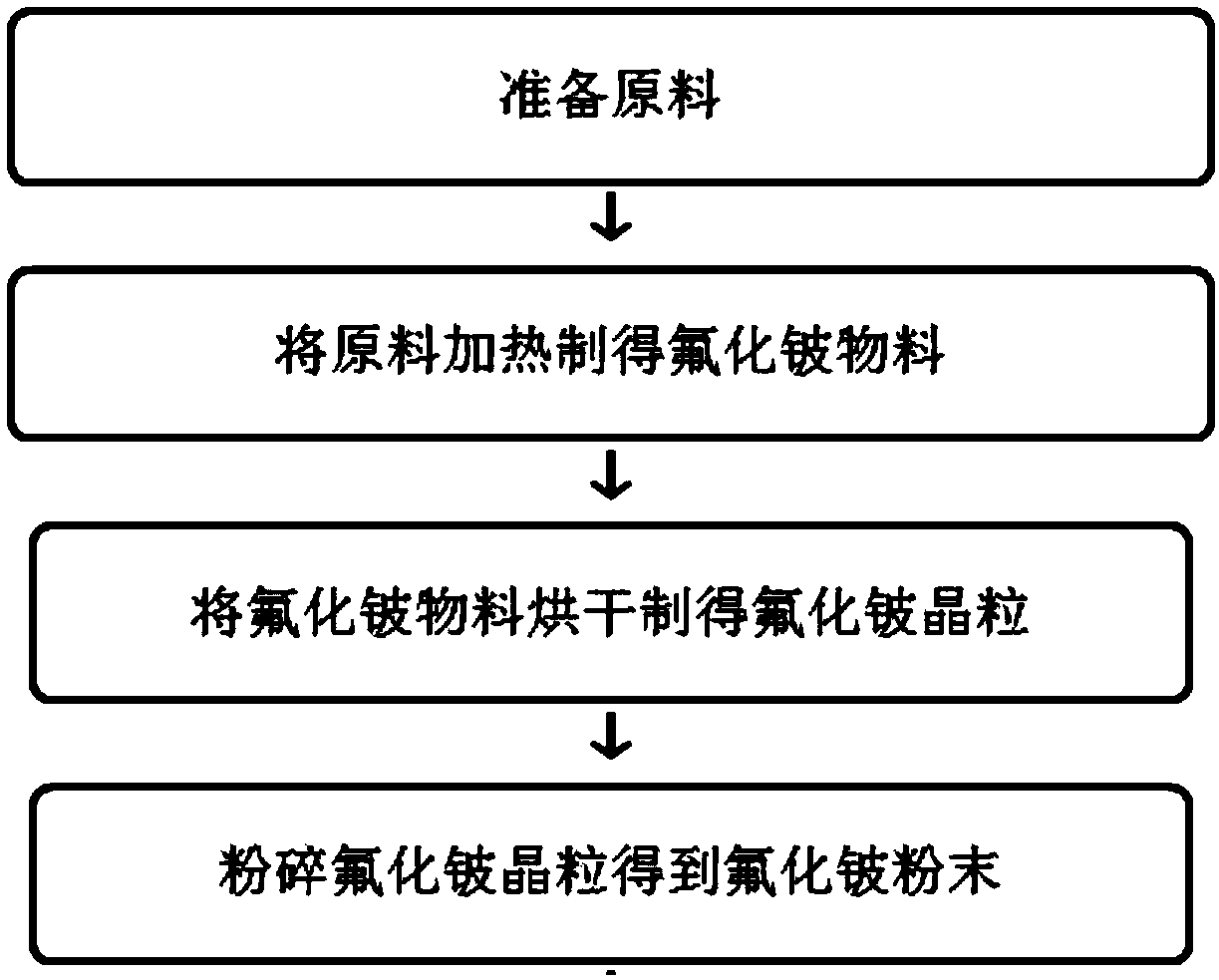

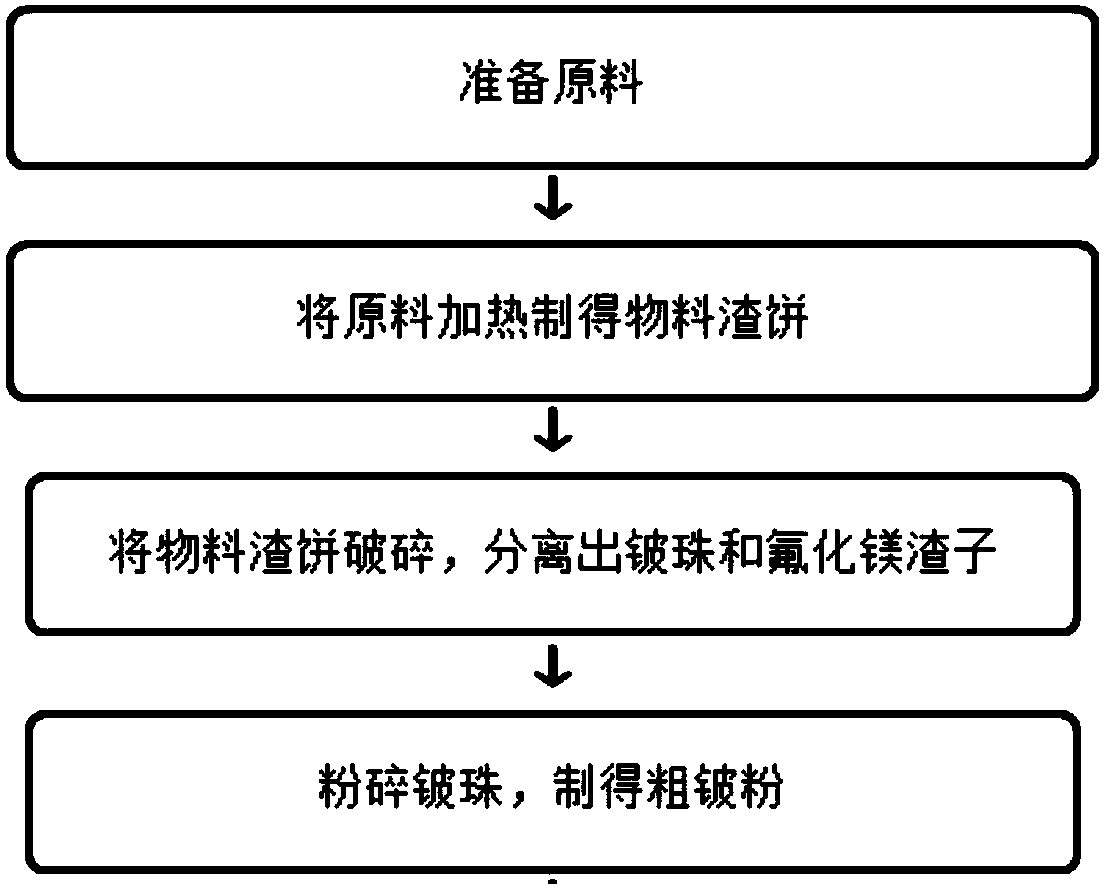

Thermal dissociation reactor, method for purifying coarse beryllium powder into ingots and method for preparing ultra-high pure metallic beryllium

The invention relates to a thermal dissociation reactor, a method for purifying coarse beryllium powder into ingots and a method for preparing ultra-high pure metallic beryllium. The thermal dissociation reactor comprises an iodine containing furnace, a low-temperature reactor and a high-temperature reactor, wherein the iodine containing furnace communicates with the low-temperature reactor, and the low-temperature reactor communicates with the high-temperature reactor. The method for purifying the coarse beryllium powder into the ingots through the thermal dissociation reactor comprises the following steps that the coarse beryllium powder and iodine are reacted in the thermal dissociation reactor, and the mass ratio of the coarse beryllium powder to the iodine is 5:1; beryllium iodide vapor is generated; the beryllium iodide vapor is thermally dissociated and decomposed into metallic beryllium and iodine vapor; collection is carried out to obtain pure beryllium powder; and the pure beryllium powder is smelted into the beryllium ingots in an electron beam smelting furnace. The thermal dissociation reactor is reasonable in structure, simple to assemble and convenient to use; and according to the method for purifying the coarse beryllium powder into the ingots through the thermal dissociation reactor, the operation is simple, the medicament is saved, the energy is saved, the environment is protected, the cost is low, and the purity of the beryllium is extremely high.

Owner:陆世强

Nozzles for 48-pair rod polysilicon reduction furnace

Owner:ASIA SILICON QINGHAI

Method for cycle purification of uranium in Purex process

ActiveCN102290111BQuick restoreNo increase in solid waste volumeProcess efficiency improvementInorganic non-surface-active detergent compositionsMonomethyl hydrazineHydroxylamine

The invention discloses a method for cycle purification of uranium in a Purex process. The method comprises the following steps of: pretreating 1CU feed liquor, seasoning, and further purifying plutonium by using a washing agent in a two-dimensional (2D) tank, wherein the used washing agent in the 2D tank is a mixed solution of dimethyl hydroxylamine, monomethyl hydrazine and nitric acid, the concentration of the dimethyl hydroxylamine is 0.01 to 0.1mol / L, the concentration of the monomethyl hydrazine is less than or equal to 0.15mol / L, and the concentration of the nitric acid is 0.8 to 1.2mol / L. The dissipation factor (DF) (Pu / U) in the 2D tank is more than 1,000, and the content of the plutonium in 2EU feed liquor reaches a uranium product index.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

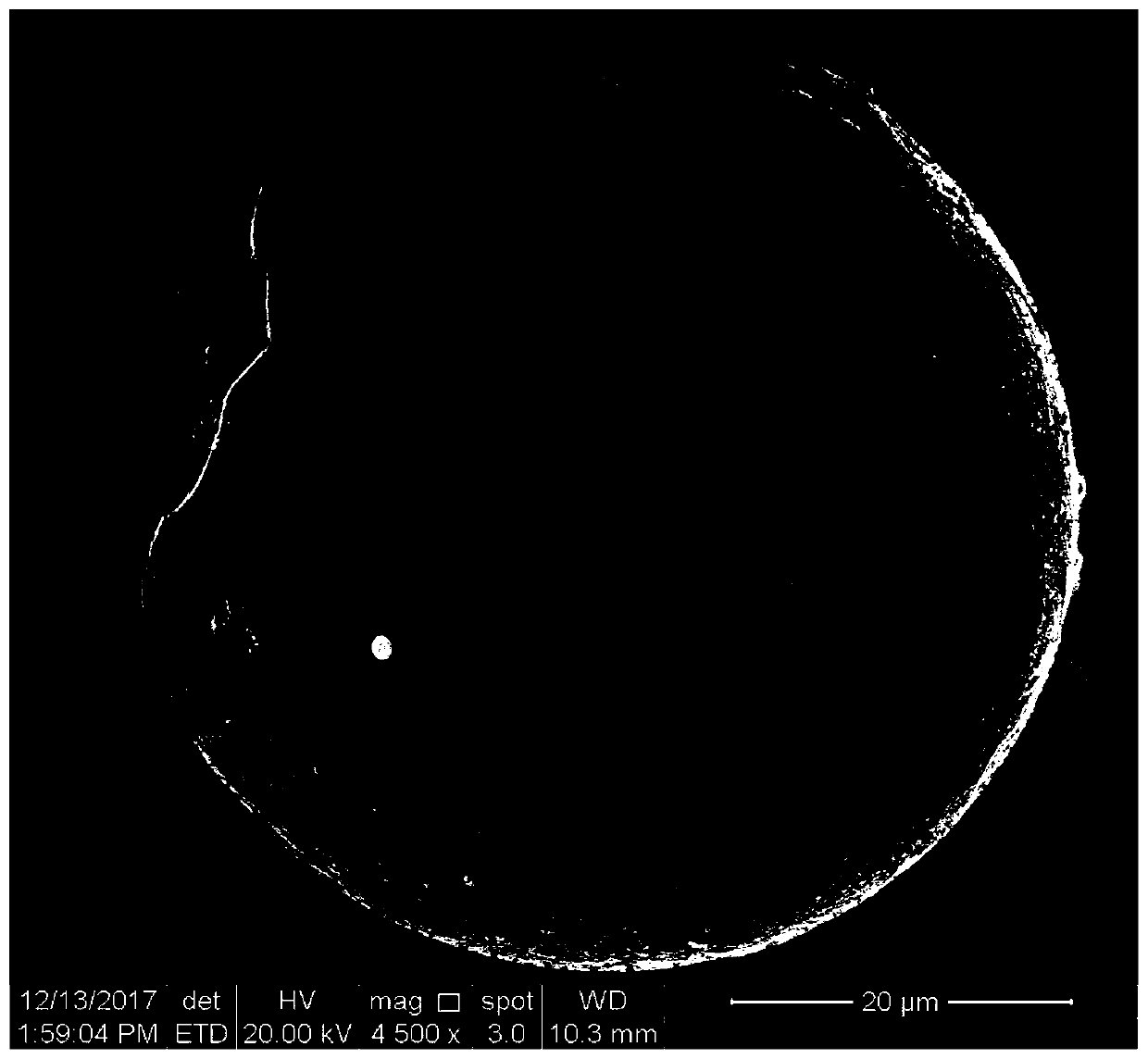

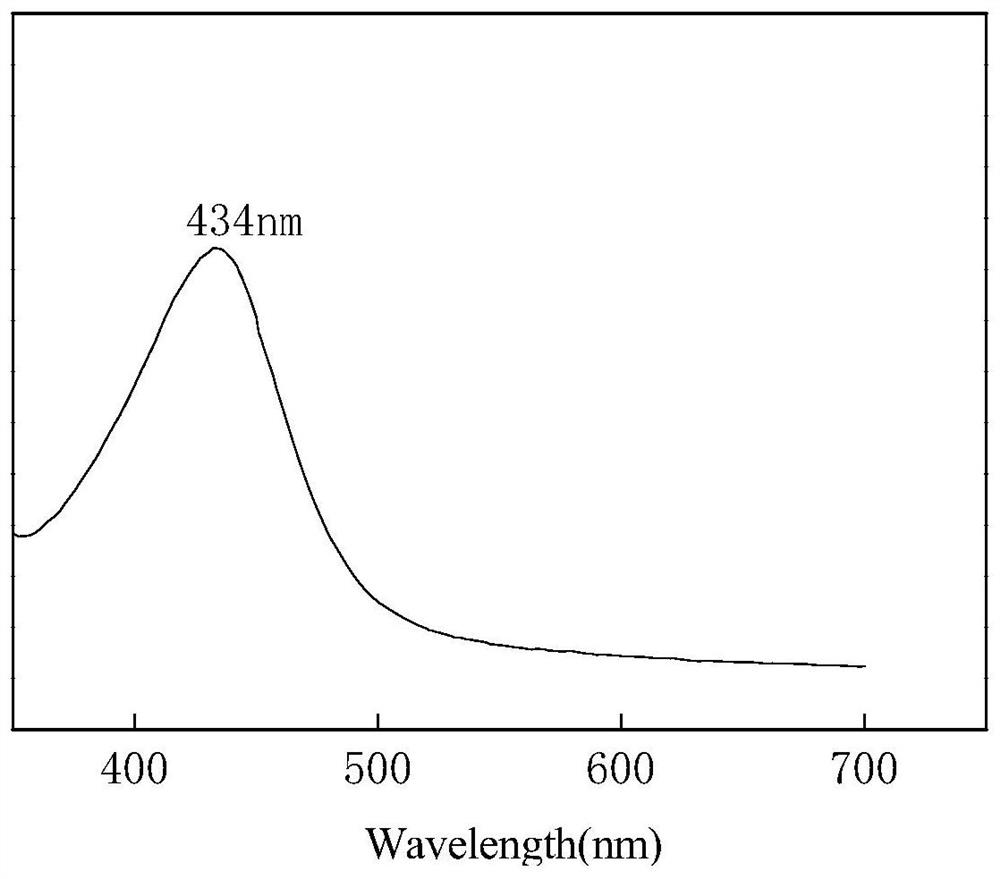

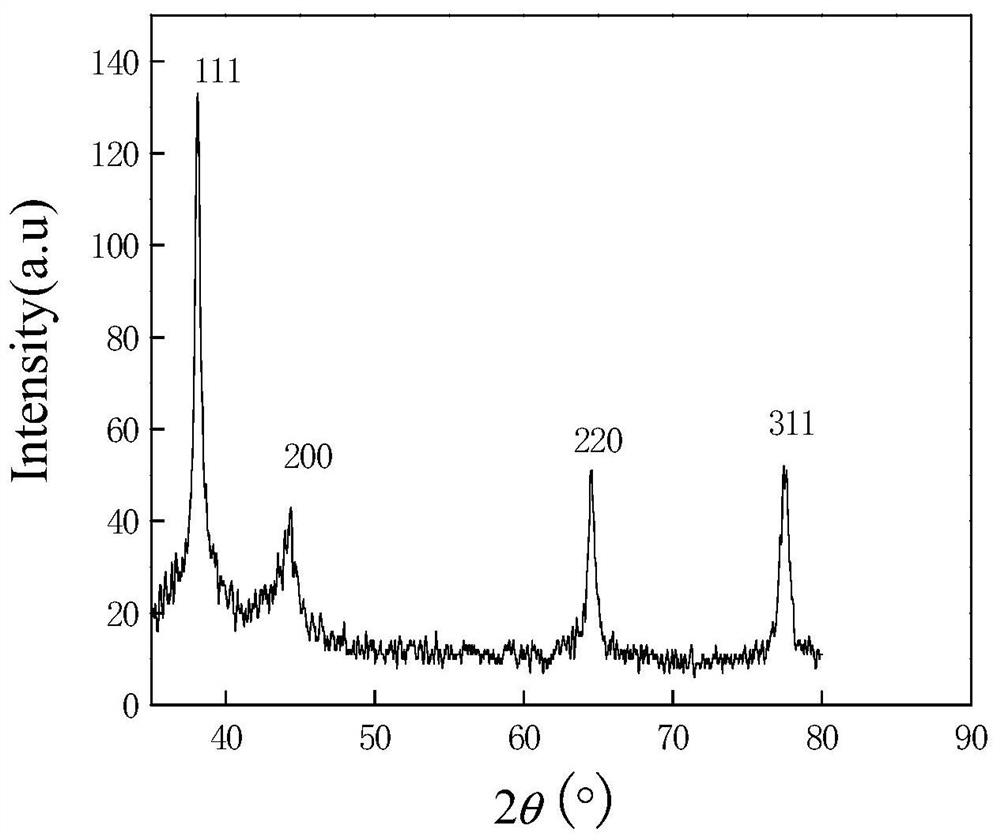

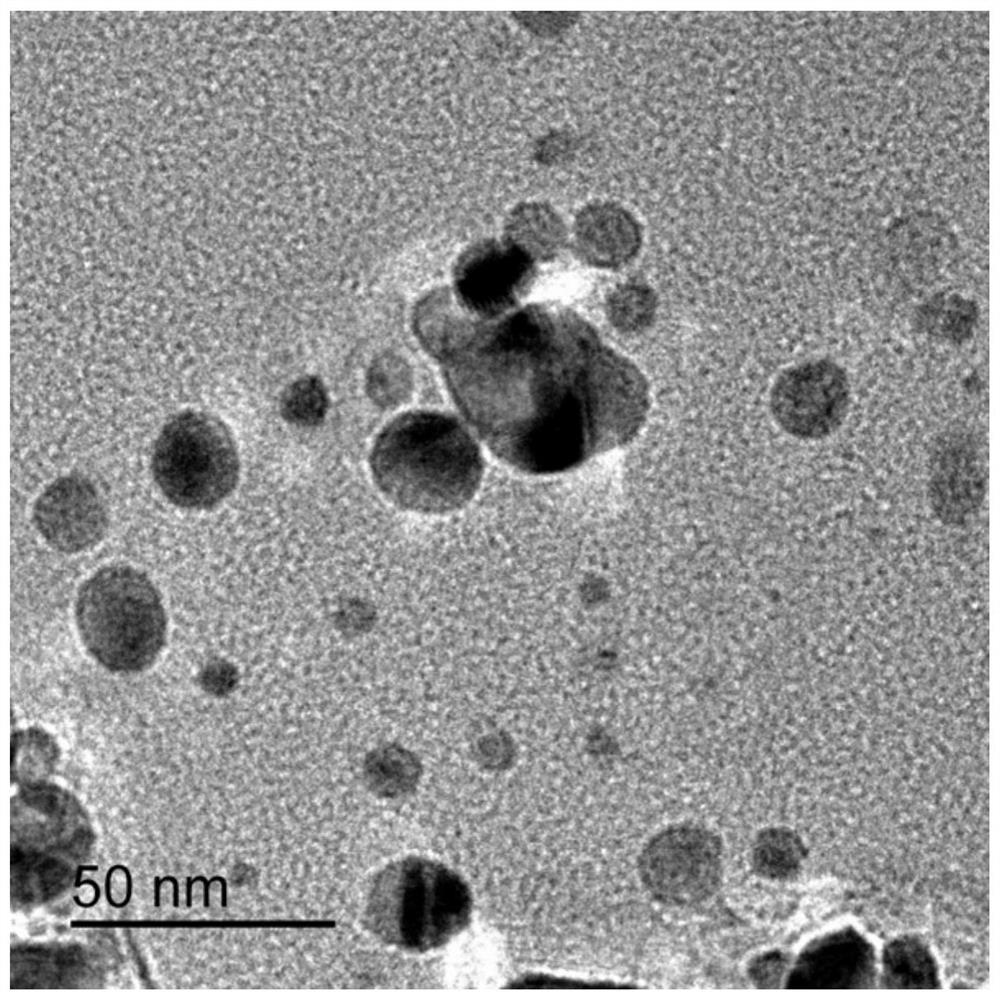

A kind of method that carvacrol microemulsion system prepares nano-silver

ActiveCN108746663BSolve the problem of insoluble in waterIncrease contactMaterial nanotechnologyTransportation and packagingEngineeringMacromolecular Substances

The invention discloses a method for preparing nano-silver from a carvacrol microemulsion system. The carvacrol microemulsion is prepared by using a high-pressure homogeneous technology, and the silver ammonia solution is added to the microemulsion system. React for a period of time until the color of the solution turns dark brown and no longer deepens, and a suspension containing nano-silver is obtained. After the suspension is centrifuged in a centrifuge, after being washed with deionized water and ethanol, it is heated at 80°C to 100°C. °C to obtain nano-silver powder. The preparation method provided by the invention is green and environmentally friendly. During the reaction process, silver ions are adsorbed at the oil-water interface by the active groups of carvacrol in the microemulsion, and then reduced to nano-silver. Under the combined effect of group complexation, the nano-silver is stabilized on the surface of the microemulsion, and the surface of the nano-silver is complexed by macromolecular substances, thereby obtaining spherical nano-silver particles with a particle size of 10-50nm with good dispersion and stable existence.

Owner:渭南职业技术学院

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com