Method for preparing vanadium nitride

A technology of vanadium nitride and nitrogen, applied in the field of metallurgy, can solve the problems of low heat utilization rate, environmental pollution and high energy consumption, and achieve the effects of uniform reduction reaction, low raw material cost and simplified production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

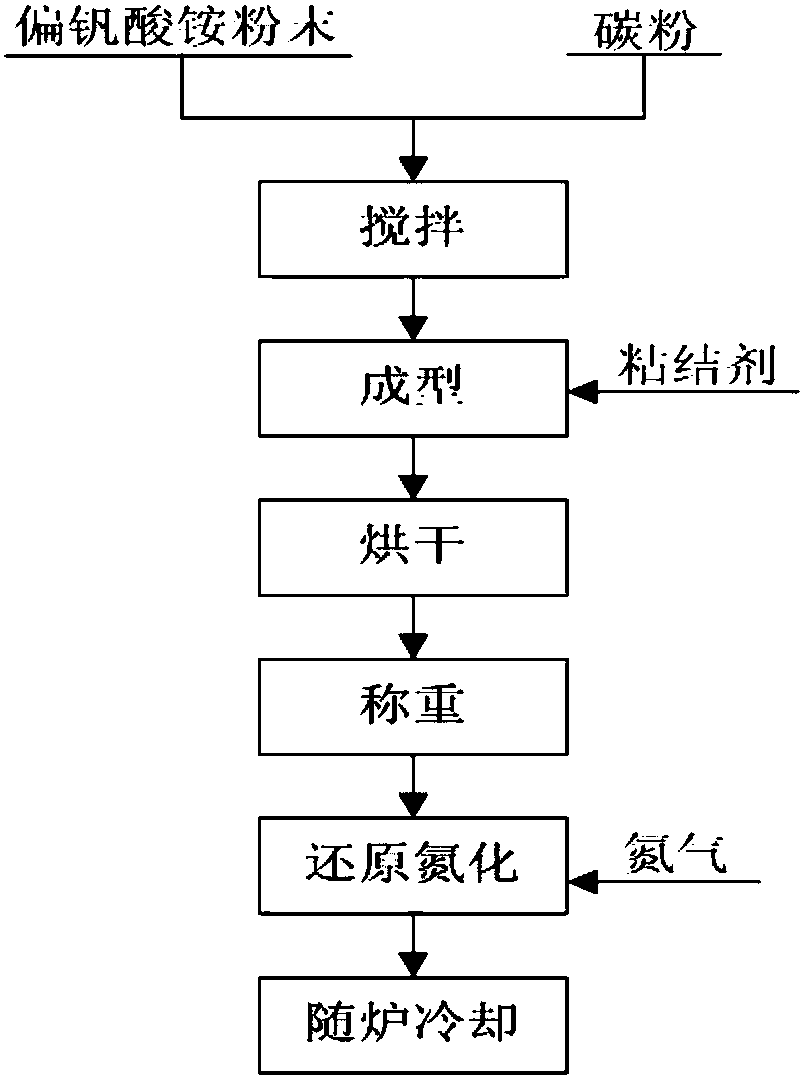

[0032] The method for preparing vanadium nitride of the present embodiment may further comprise the steps:

[0033] Step 1, drying the ammonium metavanadate powder and carbon powder at 100-105°C for 1-2 hours, and then sieve the ammonium metavanadate powder and carbon powder to 200 mesh with a standard inspection sieve;

[0034] Step 2, mix the dry ammonium metavanadate powder and carbon powder evenly, wherein the mass ratio of ammonium metavanadate to carbon powder is 1:0.256, then add 5% water by mass to the mixture and mix well , and then press the mixture into a cylindrical sample of Ф15mm×10mm by a desktop powder tablet press at 8MPa, and then dry the pressed sample in an electric blast drying oven at 100-105°C for 3 hours;

[0035] Step 3, put the sample into the tubular heating furnace, and conduct the heating furnace at 200°C: step a, vacuumize and feed nitrogen; step b, then stop feeding nitrogen to vacuum the heating furnace; step c, repeat Step a and step b 3 times...

Embodiment 2

[0040] The method for preparing vanadium nitride of the present embodiment comprises the steps:

[0041] Step 1, drying the ammonium metavanadate powder and carbon powder at 100-105°C for 1-2 hours, and then sieve the ammonium metavanadate powder and carbon powder to 200 mesh with a standard inspection sieve;

[0042] Step 2, mix the dry ammonium metavanadate powder and carbon powder evenly, wherein the mass ratio of ammonium metavanadate to carbon powder is 1:0.25, then add 6% water by mass to the mixture and mix well , and then press the mixture into a cylindrical sample of Ф15mm×10mm by a desktop powder tablet press at 8MPa, and then dry the pressed sample in an electric blast drying oven at 100-105°C for 3.5 hours;

[0043]Step 3, put the sample into the tubular heating furnace, and conduct the heating furnace at 200°C: step a, vacuumize and feed nitrogen; step b, then stop feeding nitrogen to vacuum the heating furnace; step c, repeat Step a and step b twice, and then he...

Embodiment 3

[0048] The method for preparing vanadium nitride of the present embodiment may further comprise the steps:

[0049] Step 1, drying the ammonium metavanadate powder and carbon powder at 100-105°C for 1-2 hours, and then sieve the ammonium metavanadate powder and carbon powder to 200 mesh with a standard inspection sieve;

[0050] Step 2, mix the dry ammonium metavanadate powder and carbon powder evenly, wherein the mass ratio of ammonium metavanadate to carbon powder is 1:0.27, then add 7% water by mass to the mixture and mix well , and then press the mixture into a cylindrical sample of Ф15mm×10mm by a desktop powder tablet press at 8MPa, and then dry the pressed sample in an electric blast drying oven at 100-105°C for 4 hours;

[0051] Step 3, put the sample into the tubular heating furnace, and conduct the heating furnace at 200°C: step a, vacuumize and feed nitrogen; step b, then stop feeding nitrogen to vacuum the heating furnace; step c, repeat Step a and step b 4 times,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com