Method for measuring content of titanium dioxide in titanium concentrate

A technology of titanium dioxide and determination method is applied in the field of analysis and testing in titanium slag smelting, which can solve the problems of many operation steps, long operation time, experiment failure, etc., and achieve the effects of accurate measurement results, sufficient reduction reaction, and guaranteed accuracy.

Inactive Publication Date: 2015-01-07

四川安宁铁钛股份有限公司

View PDF2 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] This method has the following disadvantages: 1. The high-temperature sample melting operation is complicated, and due to the strong alkalinity and strong oxidative properties of sodium peroxide, the corundum crucible is easily corroded, and it is very easy to break when it is used for the 2nd or 3rd time, and the sample leaks out, causing the experiment to fail

2. It needs to go through two times of aluminum sheet reduction, so there are many operation steps and long operation time

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0069] Reagent: phosphoric acid concentration 85%; ammonium sulfate solution (concentration 55g / L): use H 2 SO 4 :HCl:H 2 O=20:300:680 solution preparation; aluminum sheet: purity 99.80~99.99%; sodium bicarbonate: saturated solution; oxalic acid solution: concentration 60g / L; neutral red solution: concentration 5g / L; Concentration 0.03mol / L;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

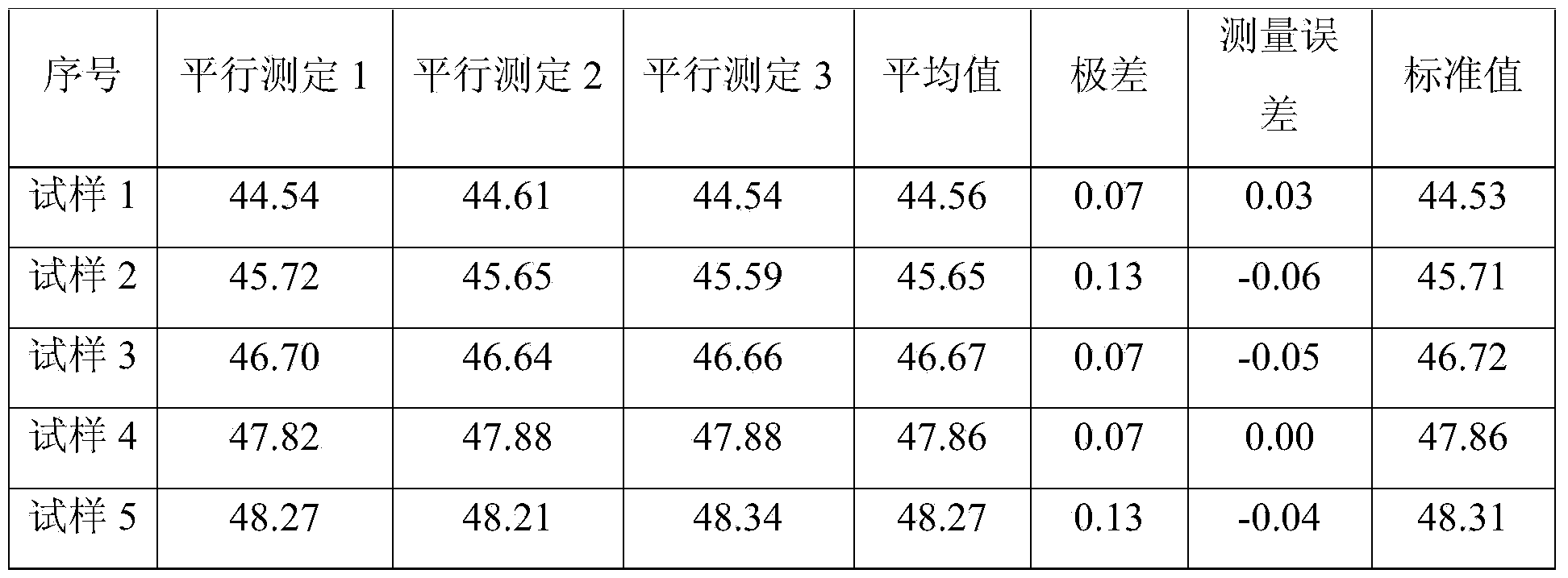

The invention relates to a method for measuring the content of titanium dioxide in titanium concentrate, and belongs to the field of analytical tests in titanium slag smelting. The method comprises the following steps: heating the titanium concentrate and strong phosphoric acid for reaction, isolating air in a medium of hydrochloric acid and sulfuric acid, reducing titanium (IV) to titanium (III) by aluminum, and in an oxalic acid environment, taking a neutral red solution as an indicator and titrating by a ferric ammonium sulfate standard solution until the solution is stably blue. According to the method, the acid dissolution process is carried out by strong phosphoric acid and an electrical furnace, and the operation is easy and quick; moreover, the operation time is short, five samples are simultaneously measured by the method, and the total measurement time is 1.5 hours; while the measurement time is 2.5 hours by a standard method of YB / T159.4-1999; the time is shortened by 40%.

Description

technical field [0001] The invention relates to a method for measuring titanium dioxide content in titanium concentrate, belonging to the field of analysis and testing in titanium slag smelting. Background technique [0002] The current standard for the chemical analysis method of titanium dioxide content in titanium concentrate (rock ore) is YB / T 159.1-1999. The summary of the method is as follows: the sample is melted with sodium peroxide, acidified with hydrochloric acid after leaching in water, in hydrochloric acid and sulfuric acid medium, the air is isolated, titanium (IV) is reduced to titanium (III) with metal aluminum, and titanium (III) is reduced to titanium (III) with thiocyanate As indicator, titrate with ferric ammonium sulfate standard solution. [0003] This method has the following disadvantages: 1. The high-temperature sample melting operation is complicated, and due to the strong alkalinity and strong oxidative properties of sodium peroxide, the corundum ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G01N31/16

Inventor 吴宝林罗阳勇杨正伟龚素英姚晓海曾茂祥

Owner 四川安宁铁钛股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com