Patents

Literature

176 results about "Total measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

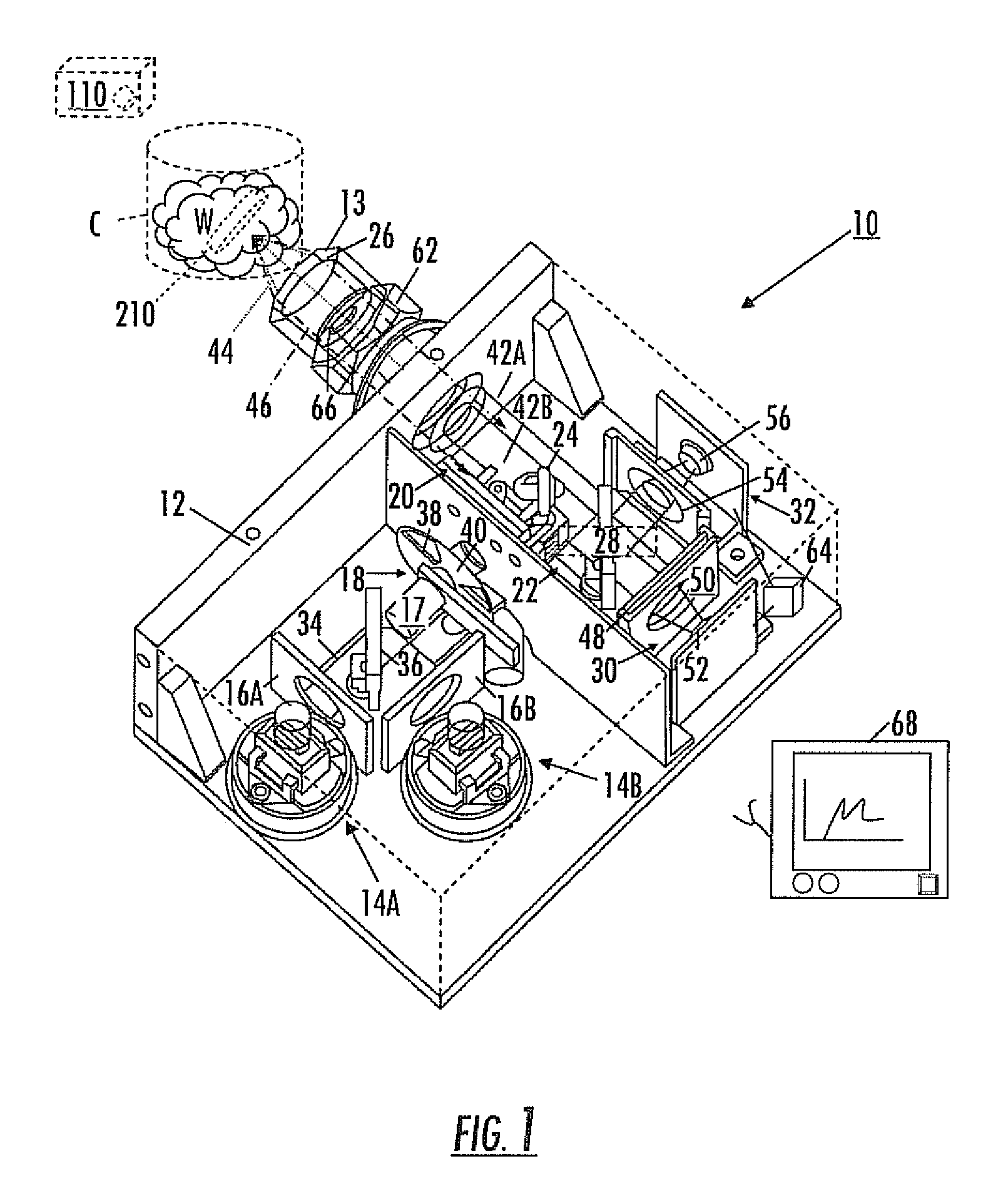

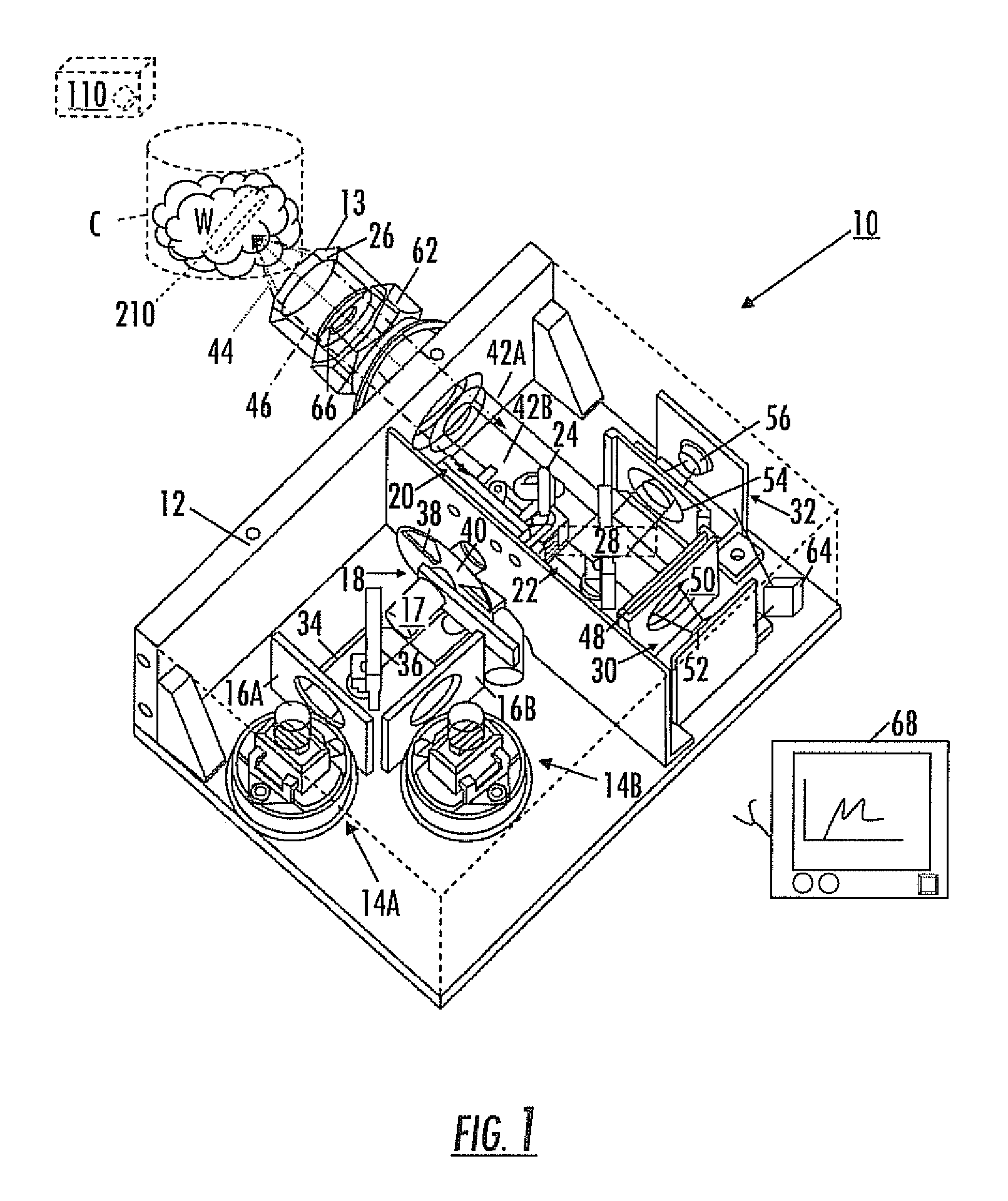

Non-intrusive multiphase flow meter

InactiveUS6945095B2SurveyMaterial analysis using sonic/ultrasonic/infrasonic wavesFiberDifferential pressure

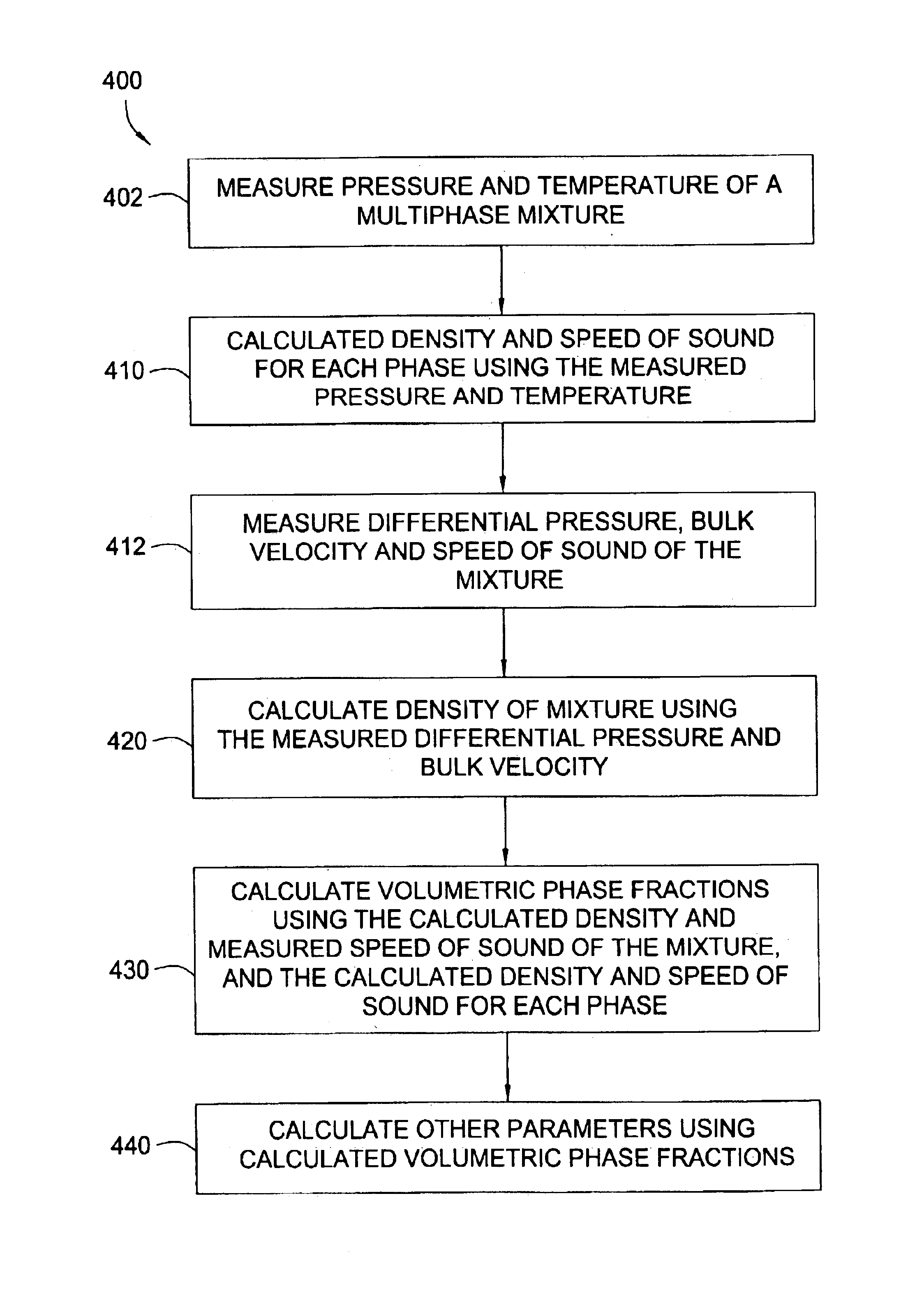

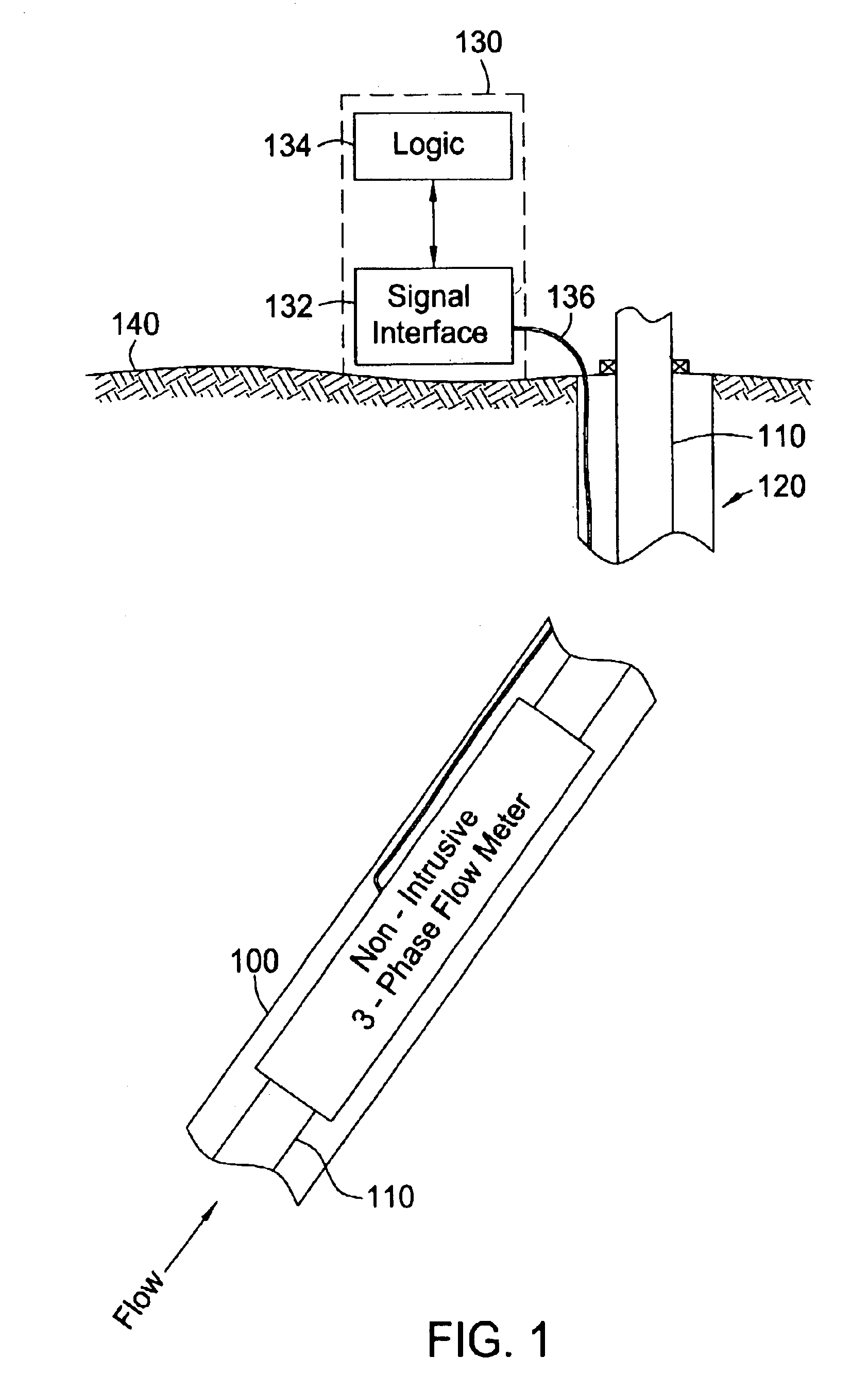

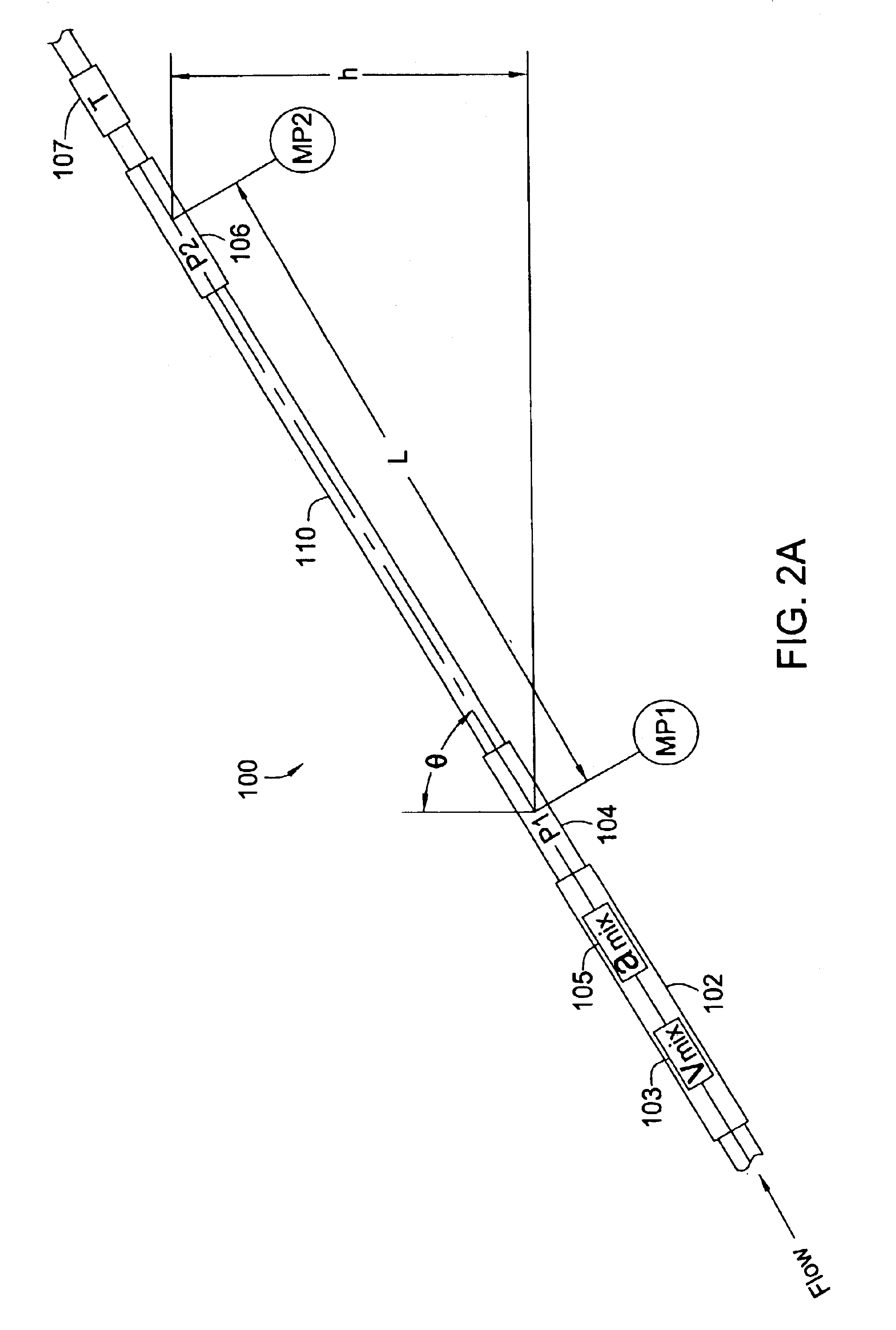

Embodiments of the present invention generally provide methods, apparatus, and systems for determining void fractions of individual phase components of a multiphase mixture. The void fractions may be determined based on measured parameters of the mixture as a whole, such as differential pressure, bulk velocity of the mixture and speed of sound in the mixture. According to some embodiments, the mixture parameters may be measured using non-intrusive fiber optic based sensors. Various other parameters may also be derived from the void fractions, such as individual phase flow rates, liquid holdup and watercut parameters (for oil and gas mixtures).

Owner:WEATHERFORD TECH HLDG LLC

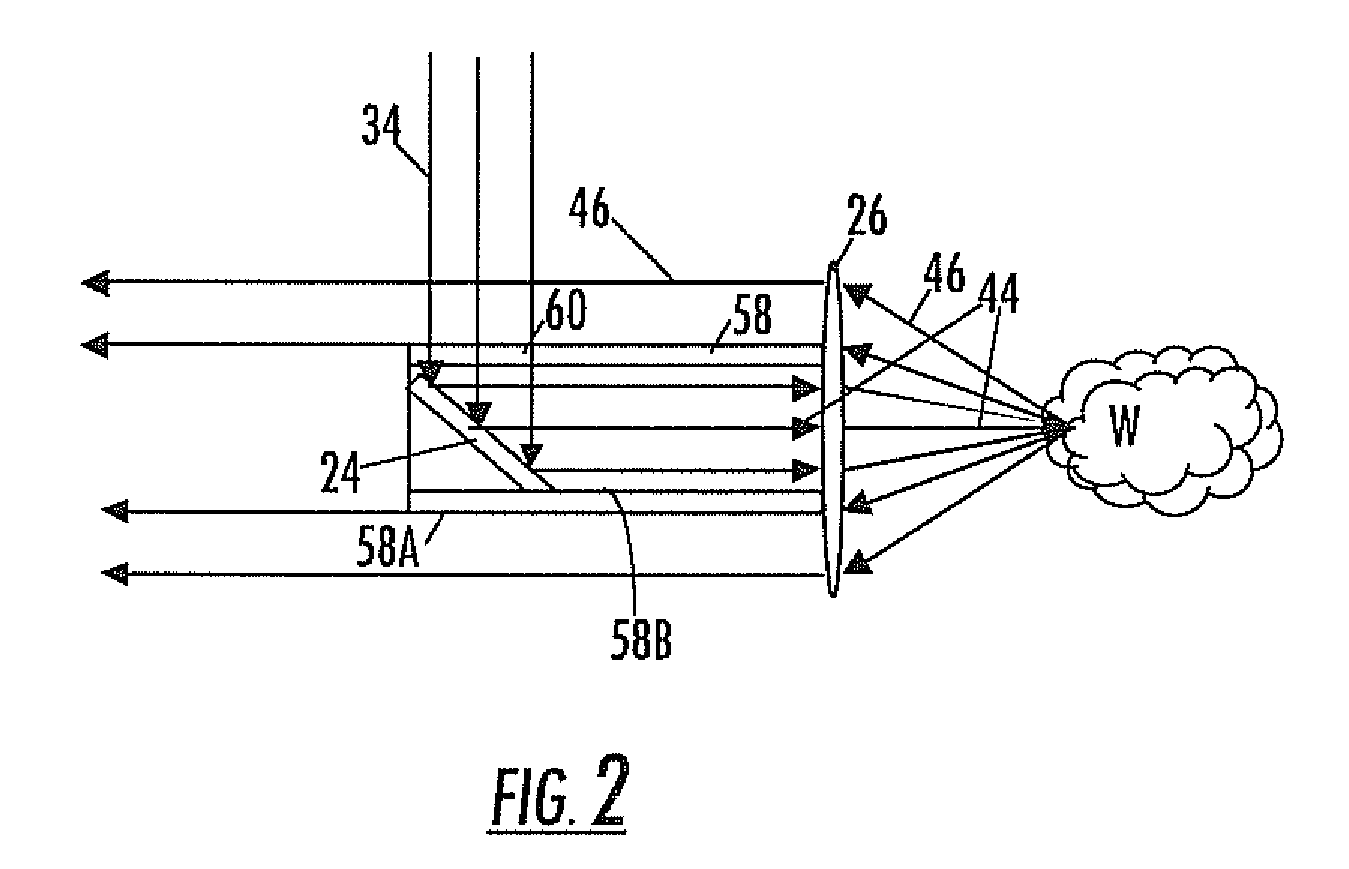

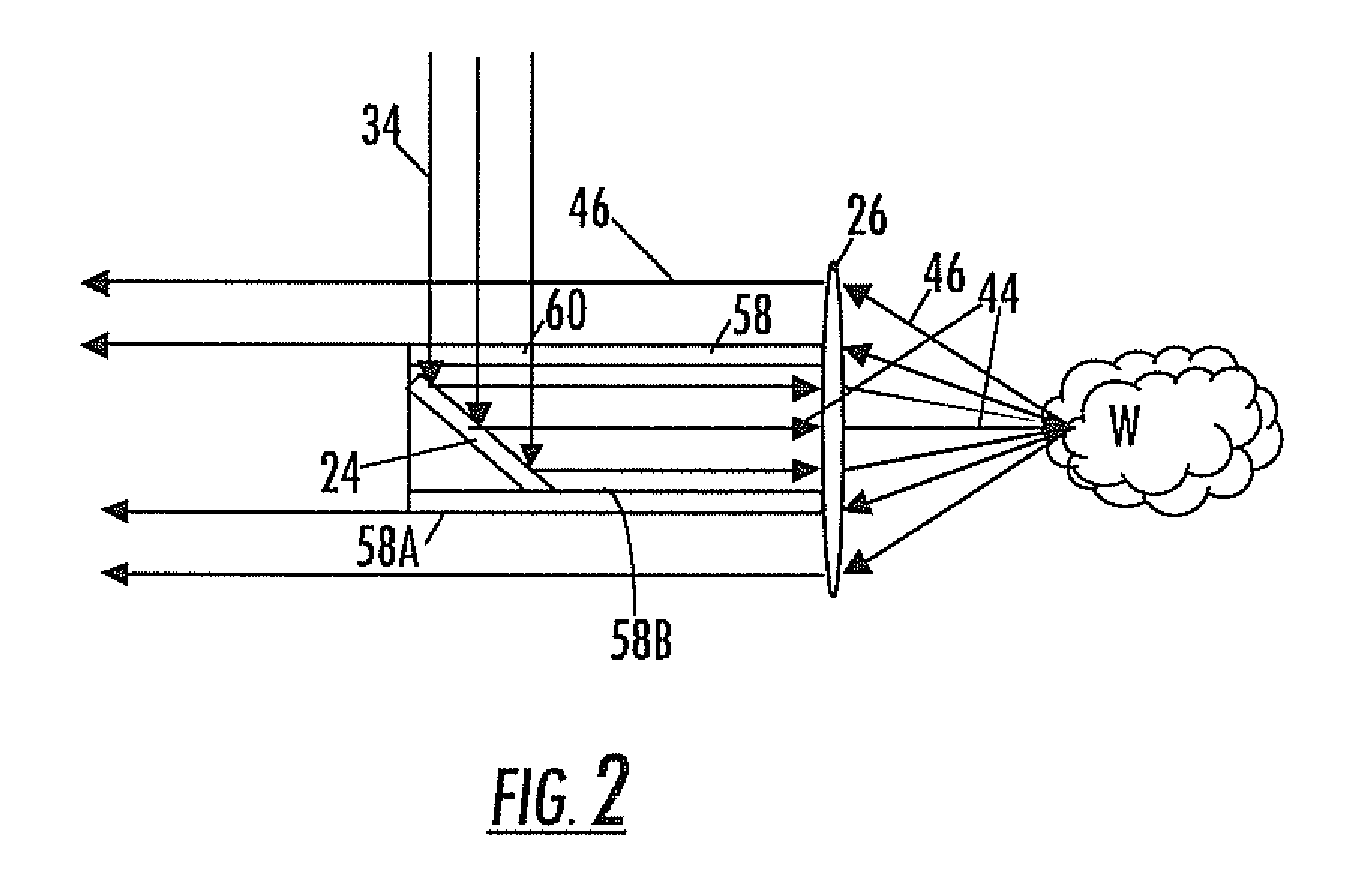

In-line process measurement systems and methods

ActiveUS20100073666A1Improve signal-to-noise ratioImprove accuracyRadiation pyrometryInterferometric spectrometryEngineeringProcess measurement

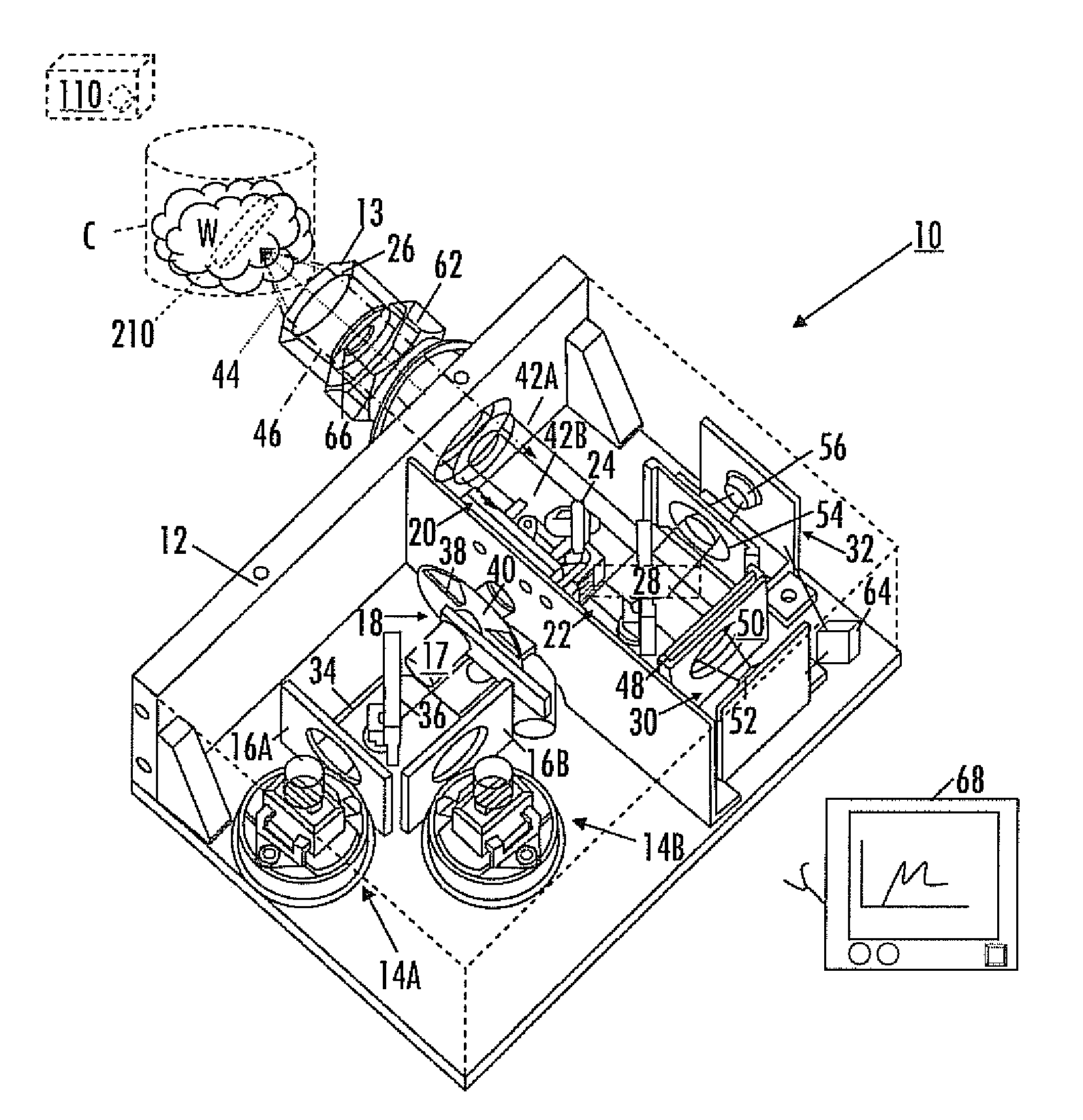

A method of using multivariate optical computing in real-time to collect instantaneous data about a process stream includes installing an optical analysis system proximate a process line, the process line being configured to move a material past a window of the optical analysis system; illuminating a portion of the material with a light from the optical analysis system; directing the light carrying information about the portion through at least one multivariate optical element in the optical analysis system to produce an instantaneous measurement result about the portion; and continuously averaging the instantaneous measurement result over a period of time to determine an overall measurement signal of the material.

Owner:HALLIBURTON ENERGY SERVICES INC

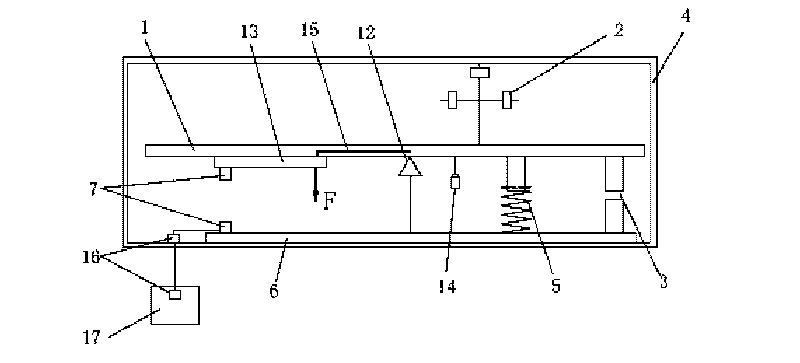

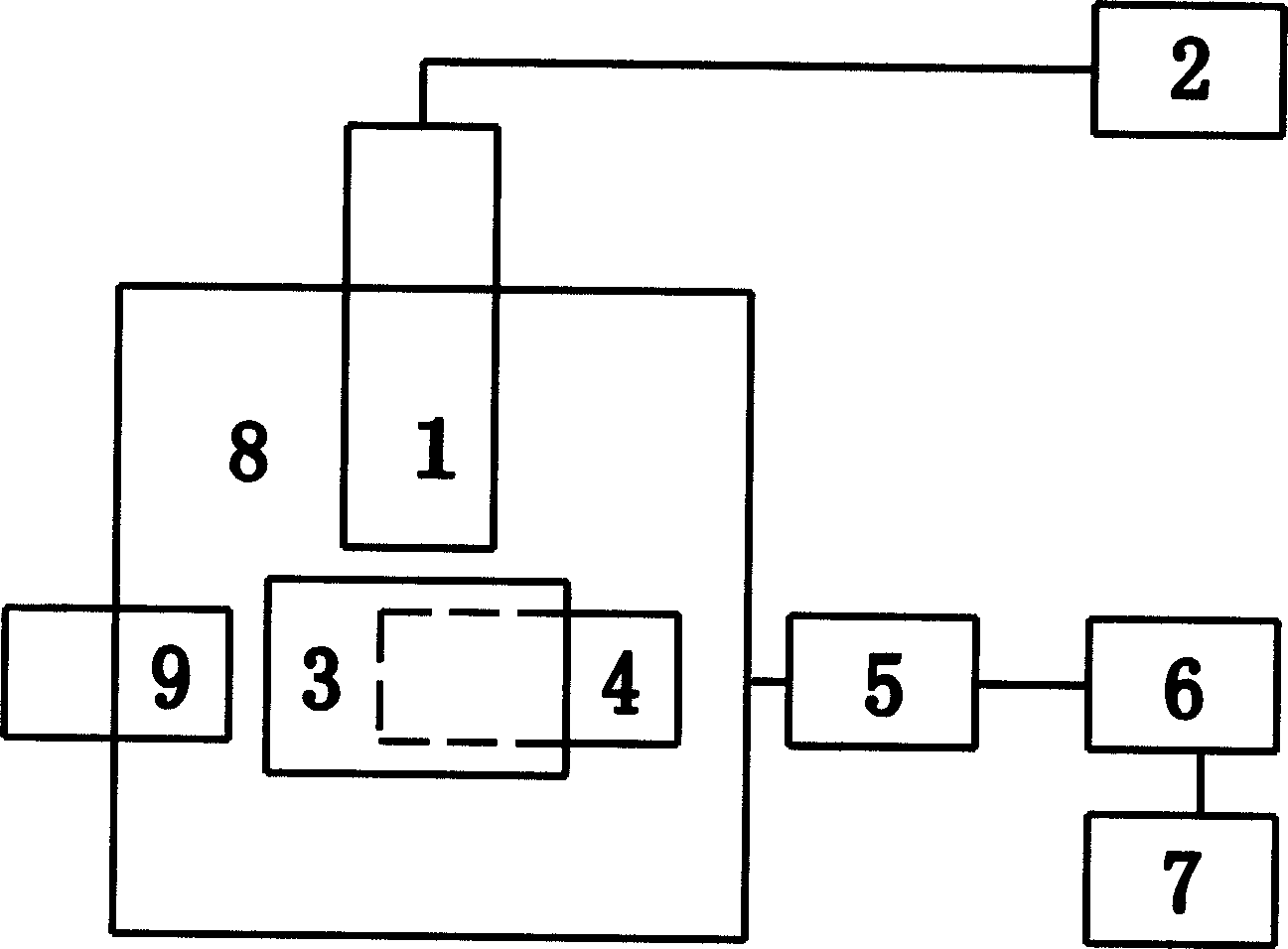

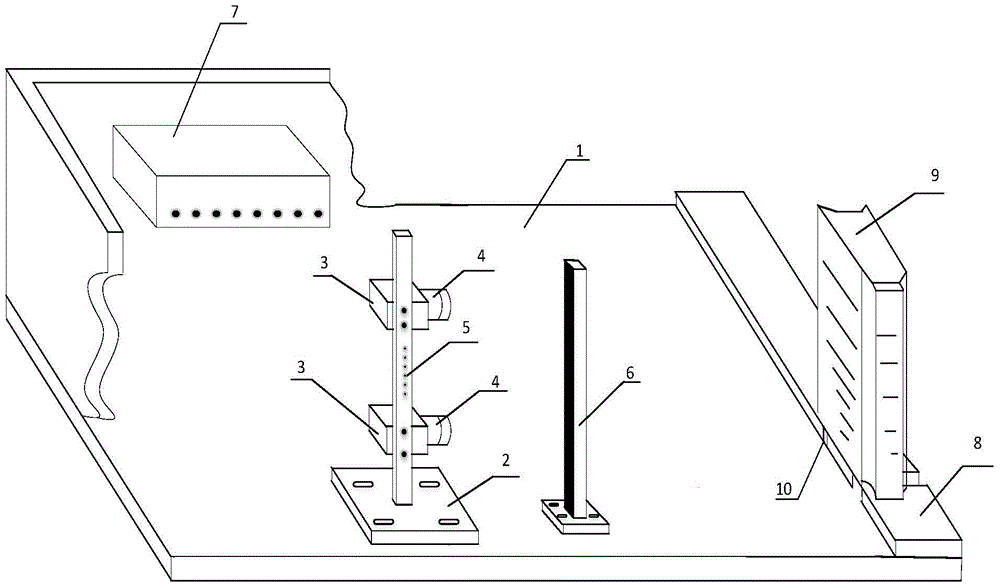

Device for measuring micro-thrust

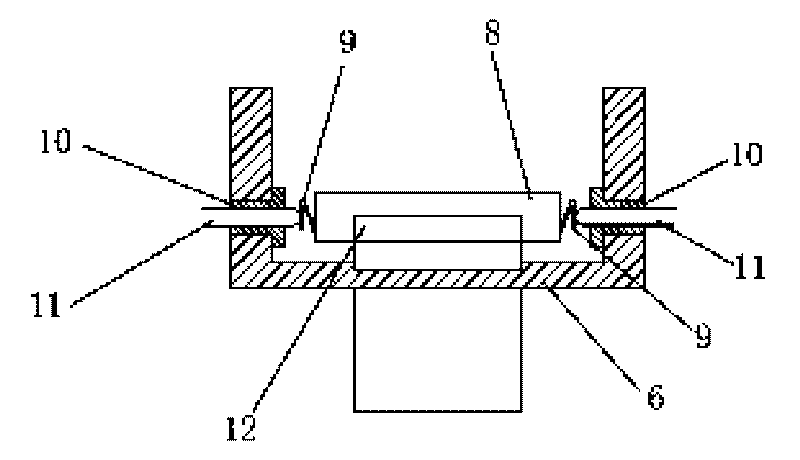

InactiveCN101726382ARemove the influence of thrust measurementEliminate the effects ofApparatus for force/torque/work measurementMeasurement deviceTransducer

The invention relates to a device for measuring a micro-thrust, which comprises a test computer, a scale, a displacement transducer, an electromagnetic damper, a communication line of a system to be tested, and a power supply line of the system to be tested. The scale comprises a scale support, a scale support cutter fixed on the scale support, a beam of the scale arranged on the scale support cutter, and a balance mass block arranged at the right end of the beam of the scale. A weight can be suspended at the right end of the scale beam; the displacement transducer is arranged at the right end part of the scale beam; and the electromagnetic damper is arranged between the right end of the scale beam and the scale support. The power supply line of the system to be tested is led in from the contact position of the scale support and the scale beam, and fixed on the scale beam. The device for measuring the micro-thrust solves the technical problem that the conventional device for measuring the micro-thrust cannot eliminate the influence on the deformation of various air and liquid supply pipelines and power supply lines in a micro-thrust system. The device for measuring the micro-thrust integrally measures the micro-thrust system, and radically eliminates the influence on micro-thrust measurement of a propellant supply line.

Owner:NO 11 INST OF NO 6 ACADEMY OF CHINA AEROSPACE SCI & TECH

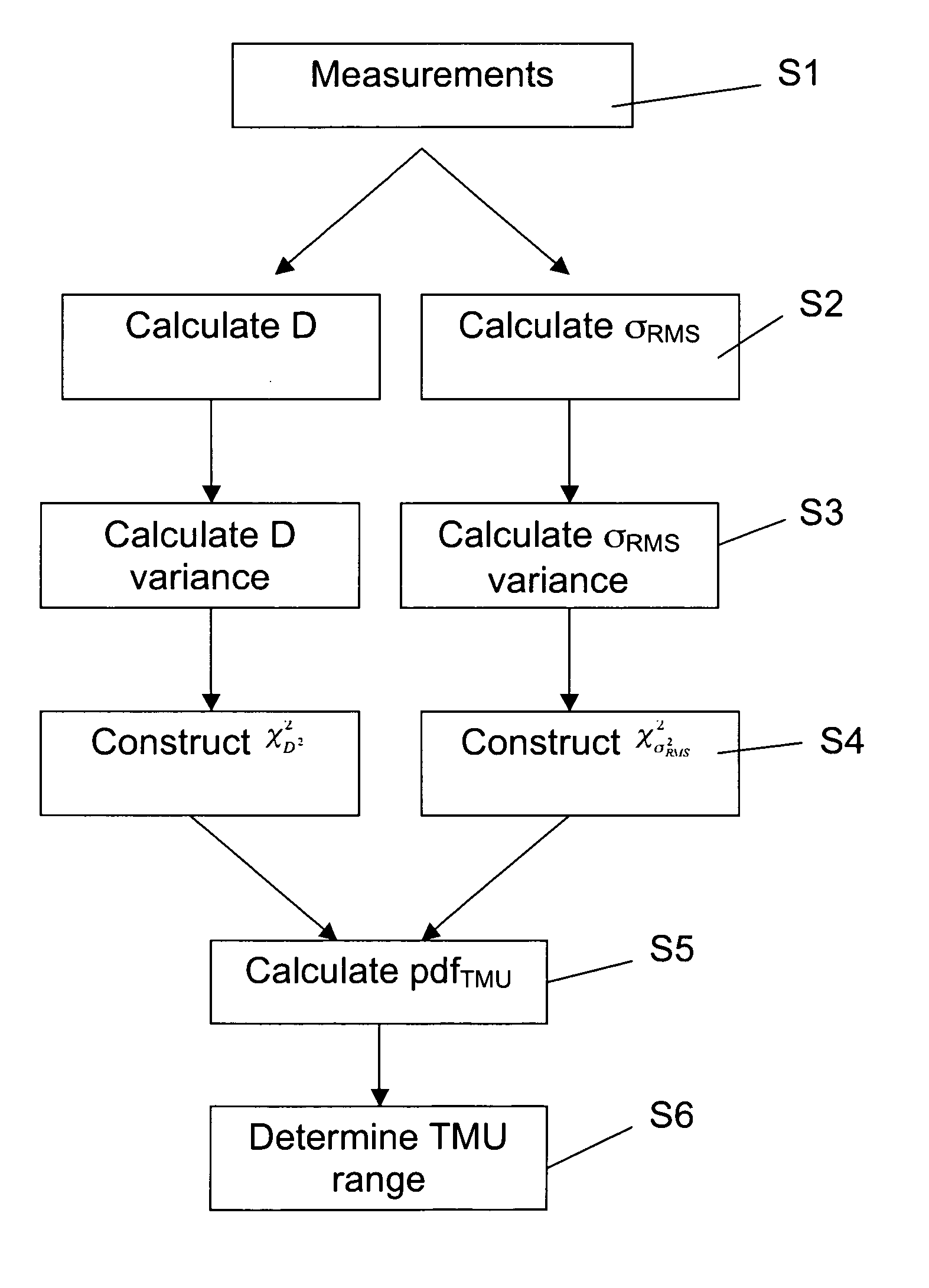

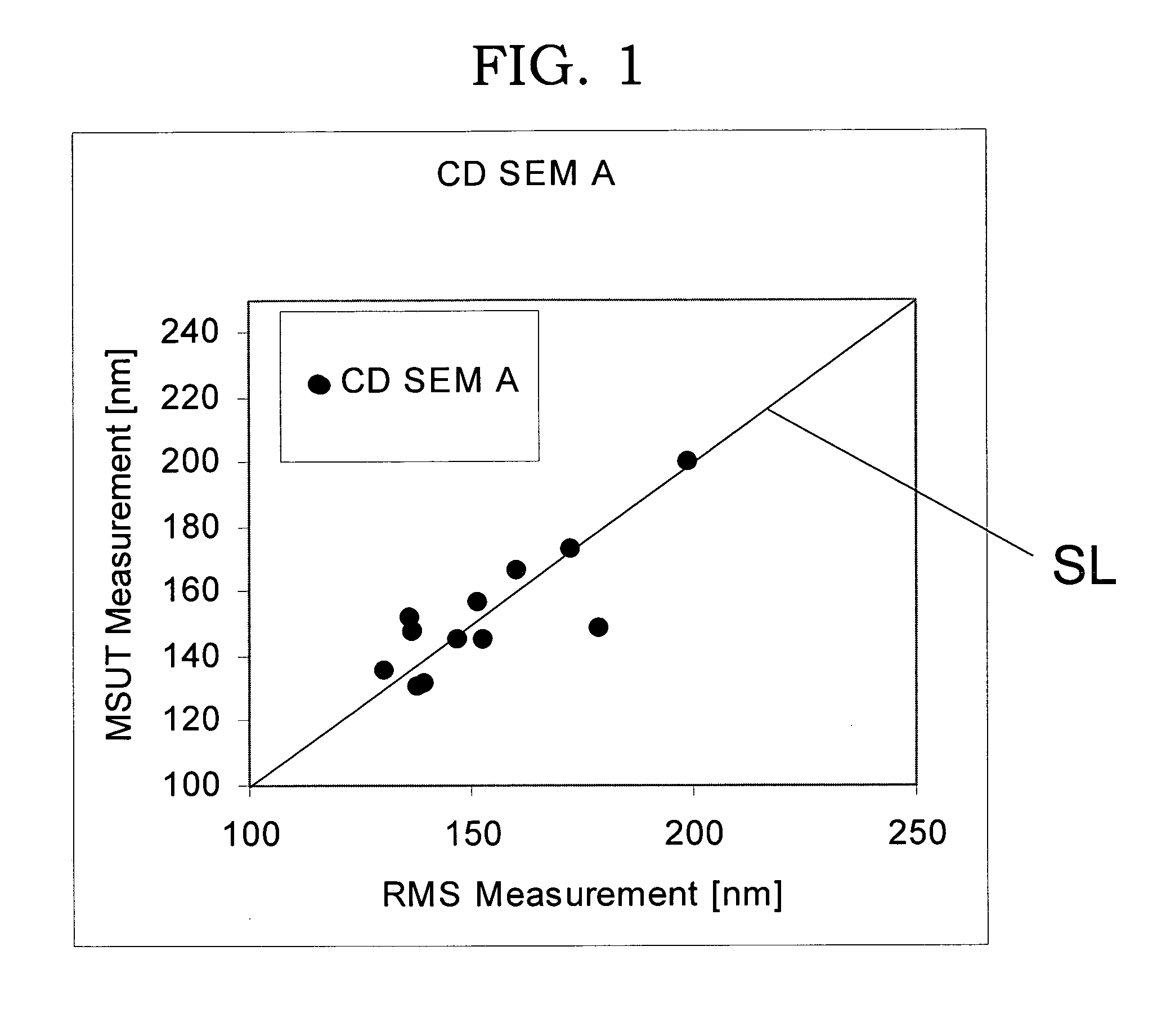

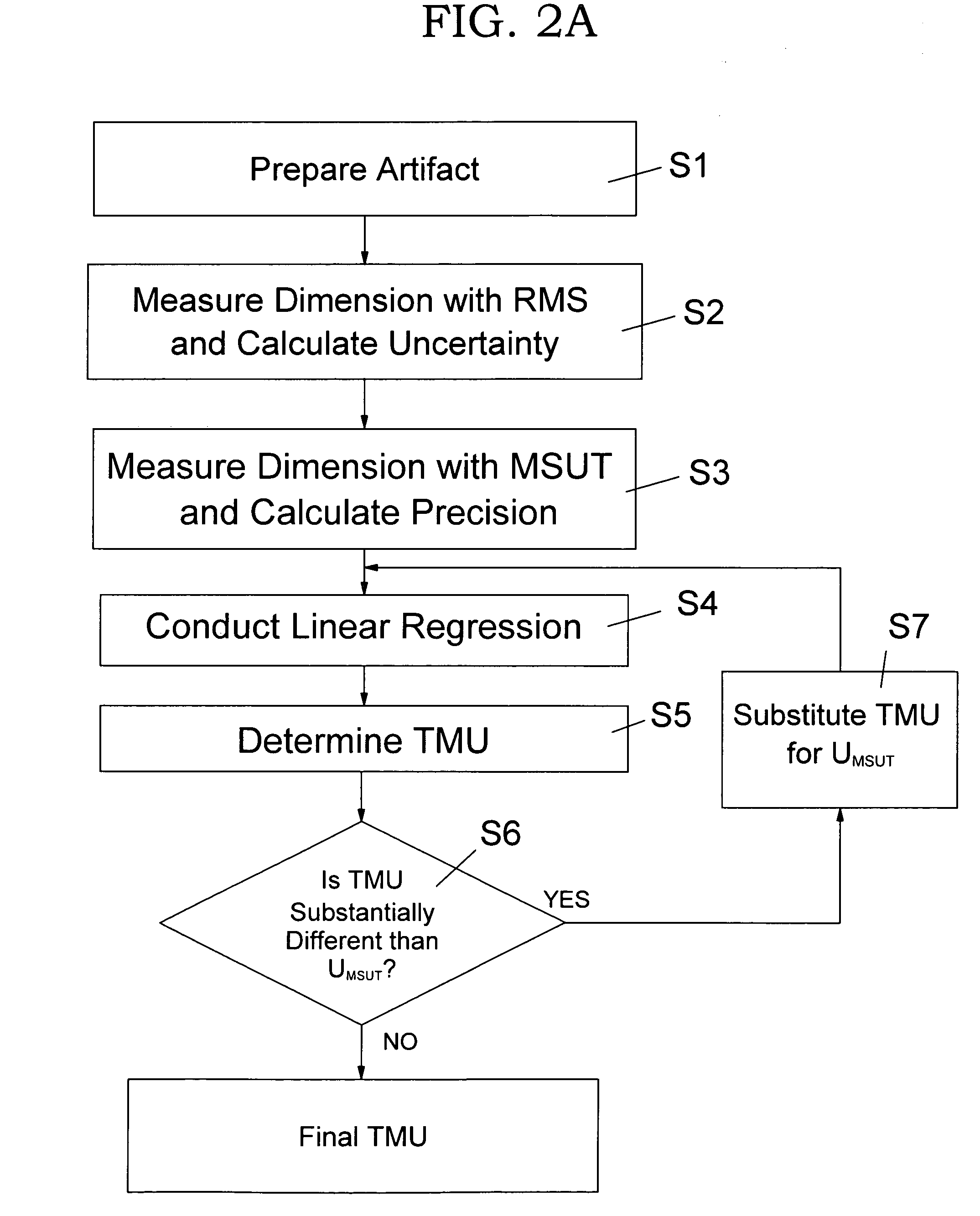

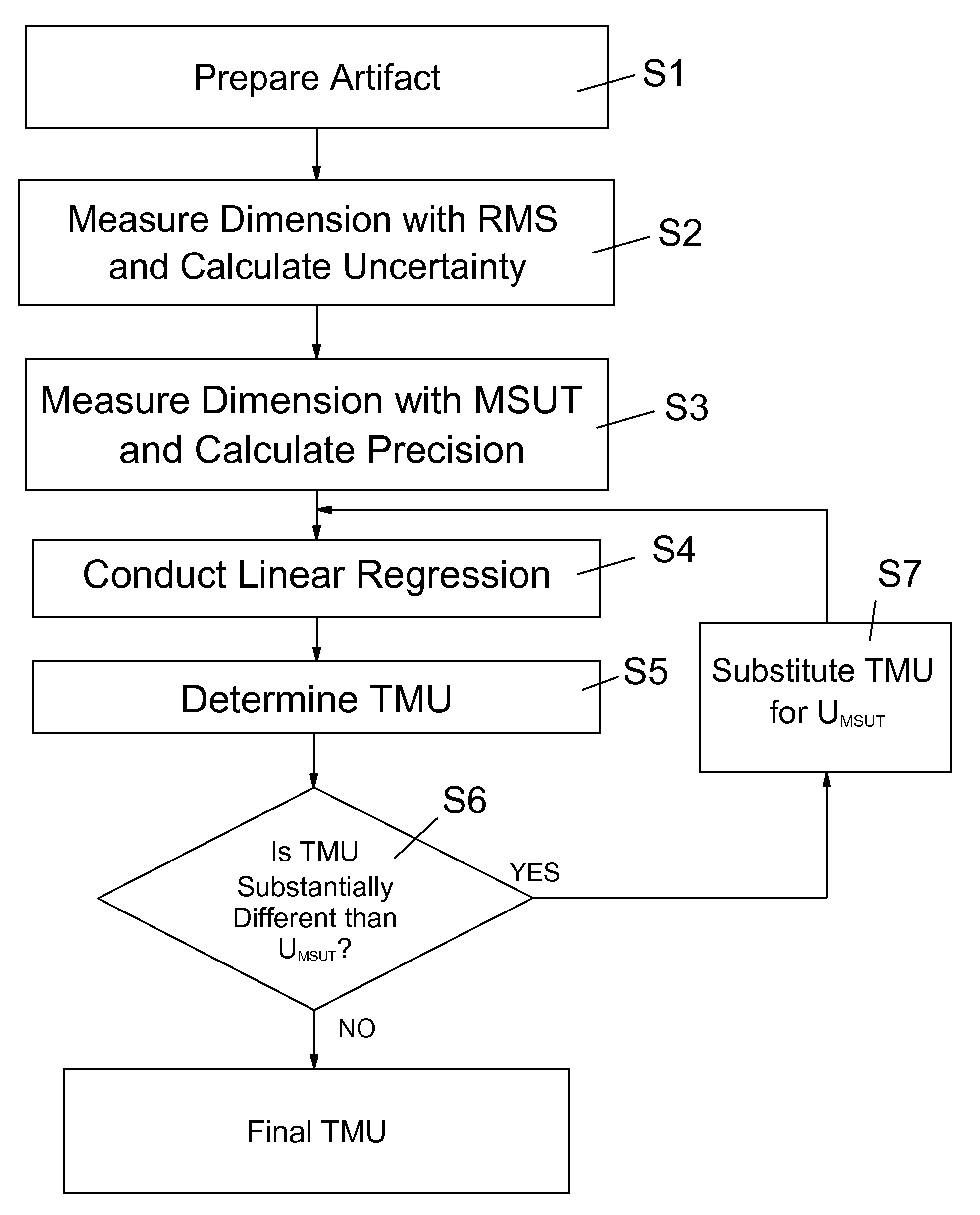

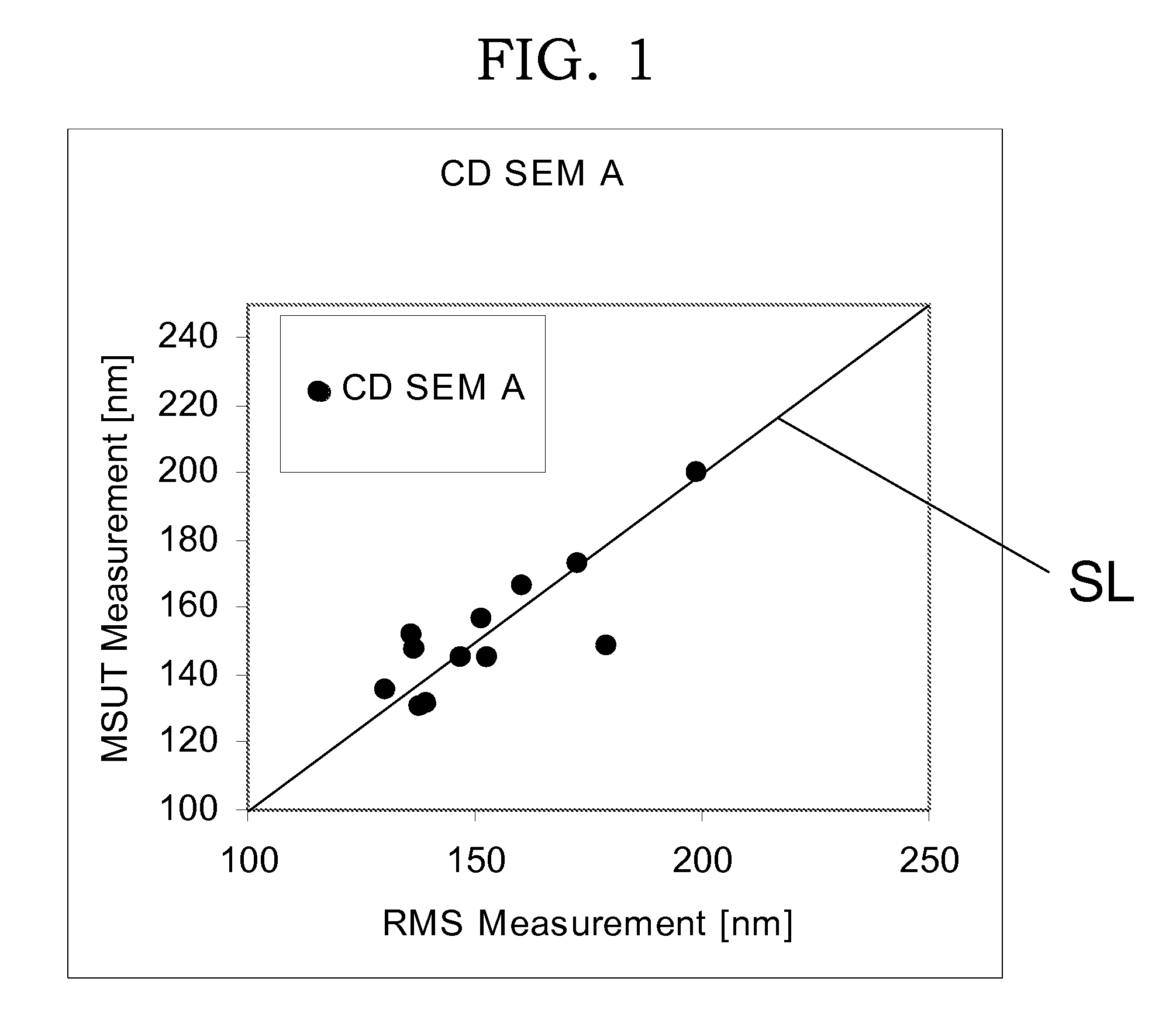

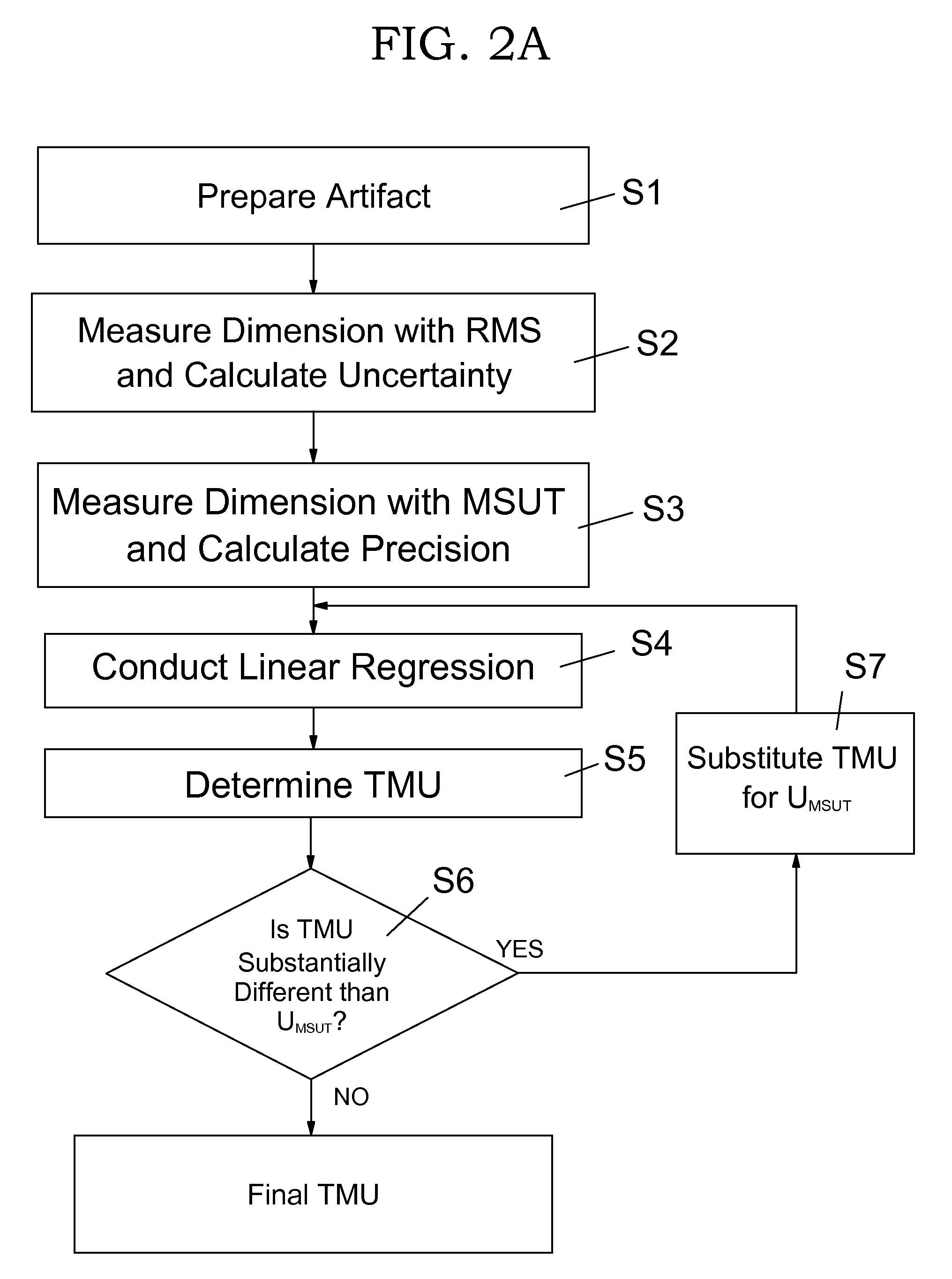

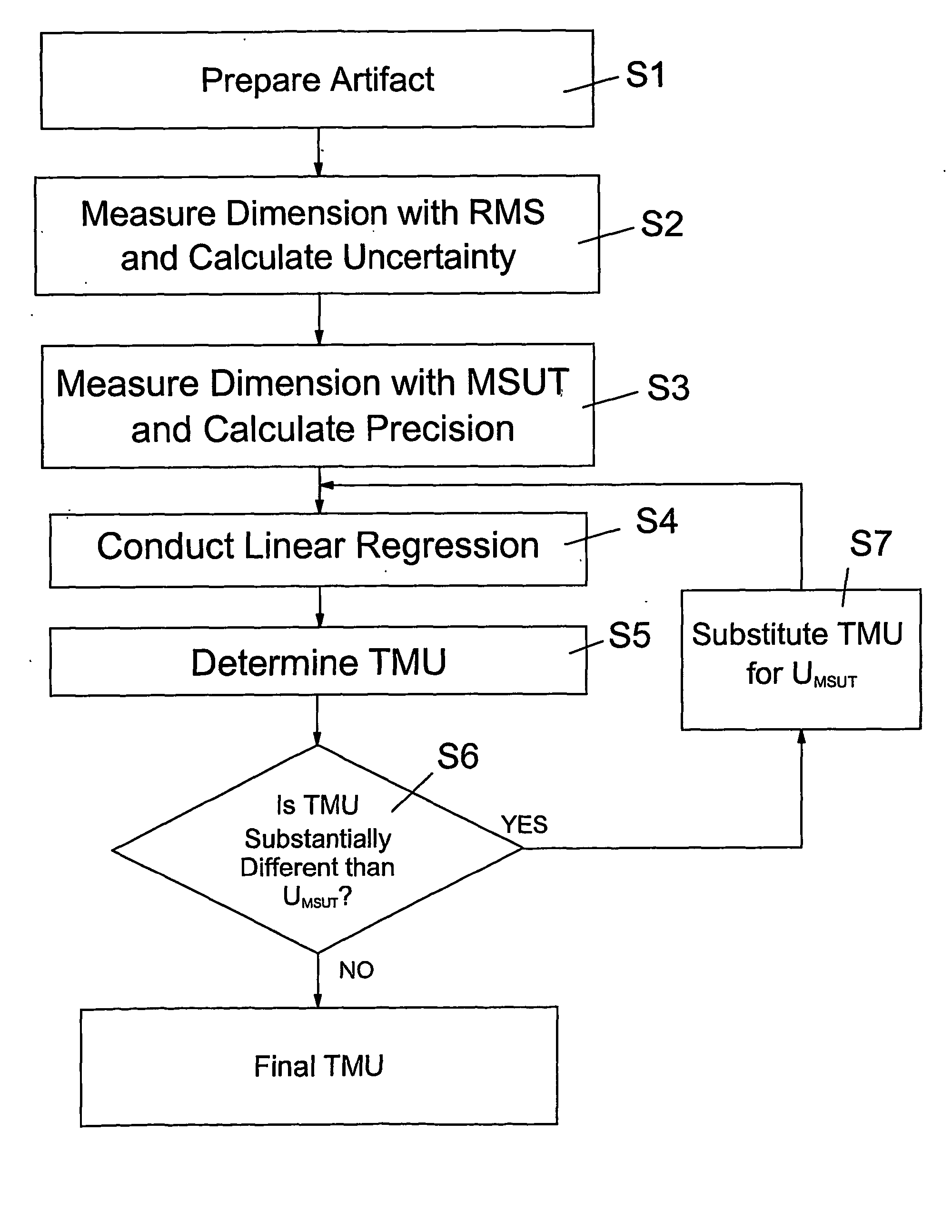

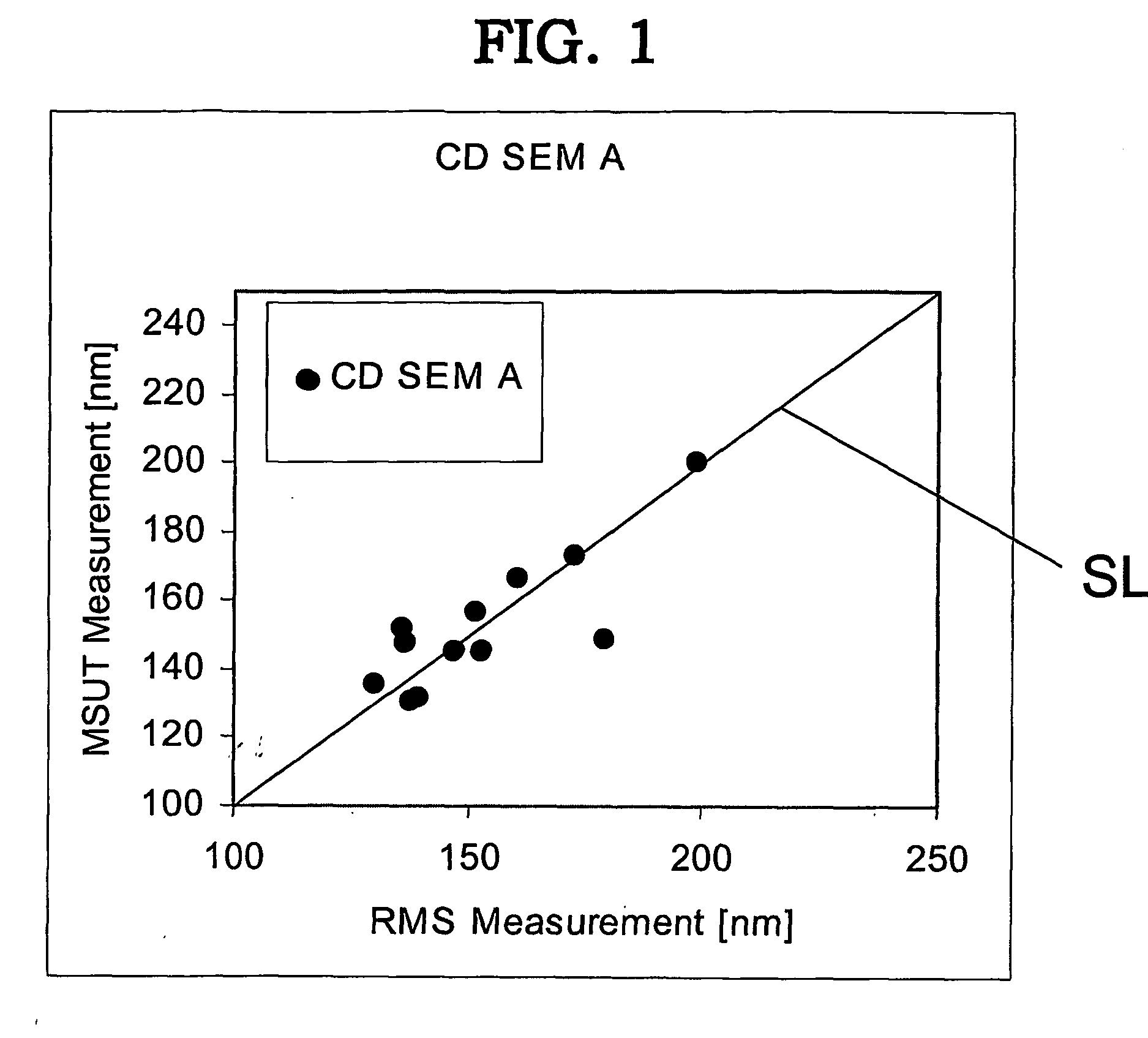

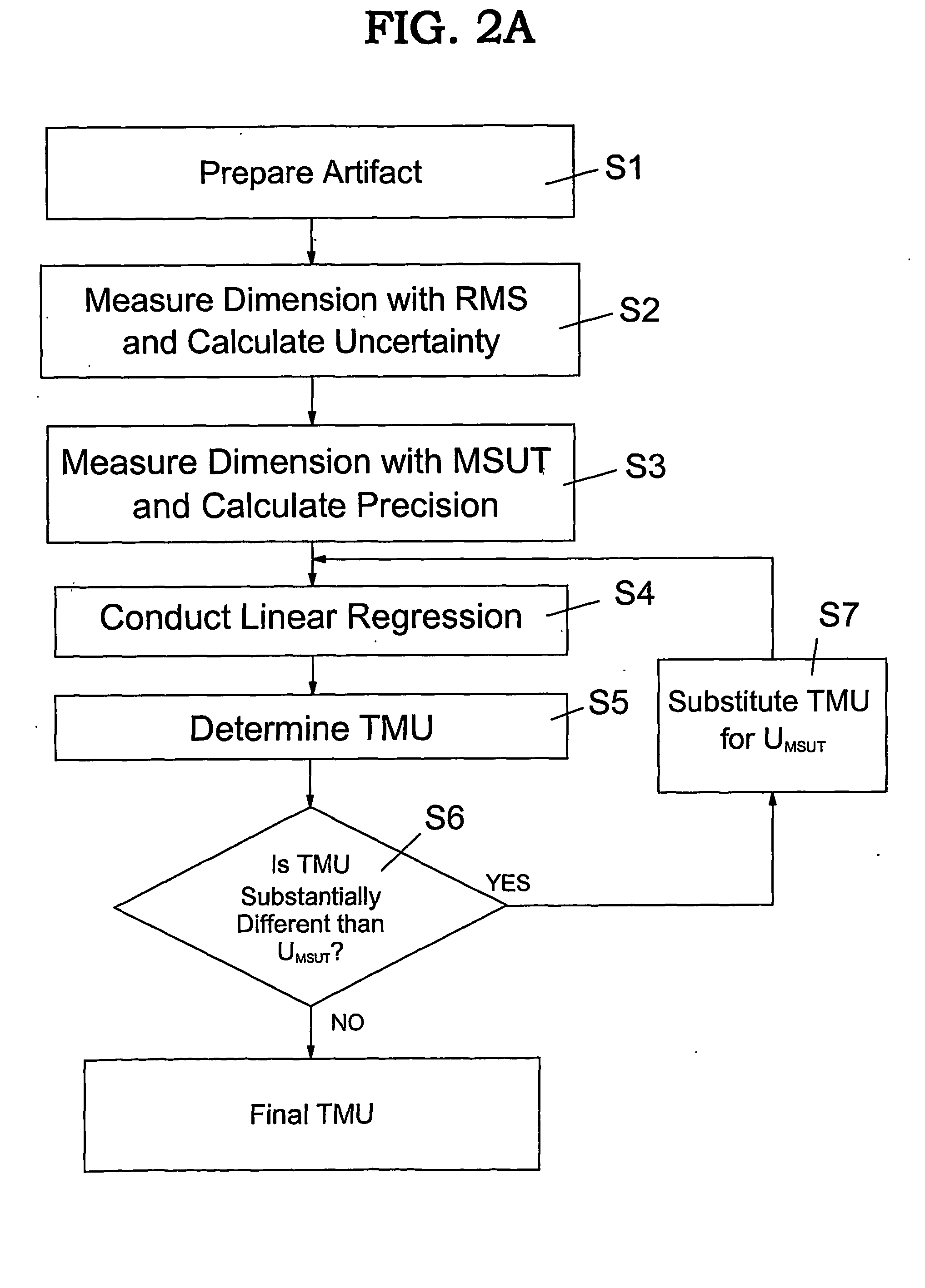

Assessment and optimization for metrology instrument including uncertainty of total measurement uncertainty

InactiveUS20050197772A1Improves TMU analysisEasy to analyzeSemiconductor/solid-state device testing/measurementDigital computer detailsMetrologySystem under test

Methods and related program product for assessing and optimizing metrology instruments by determining a total measurement uncertainty (TMU) based on precision and accuracy. The TMU is calculated based on a linear regression analysis and removing a reference measuring system uncertainty (URMS) from a net residual error. The TMU provides an objective and more accurate representation of whether a measurement system under test has an ability to sense true product variation. The invention also includes a method for determining an uncertainty of the TMU.

Owner:IBM CORP

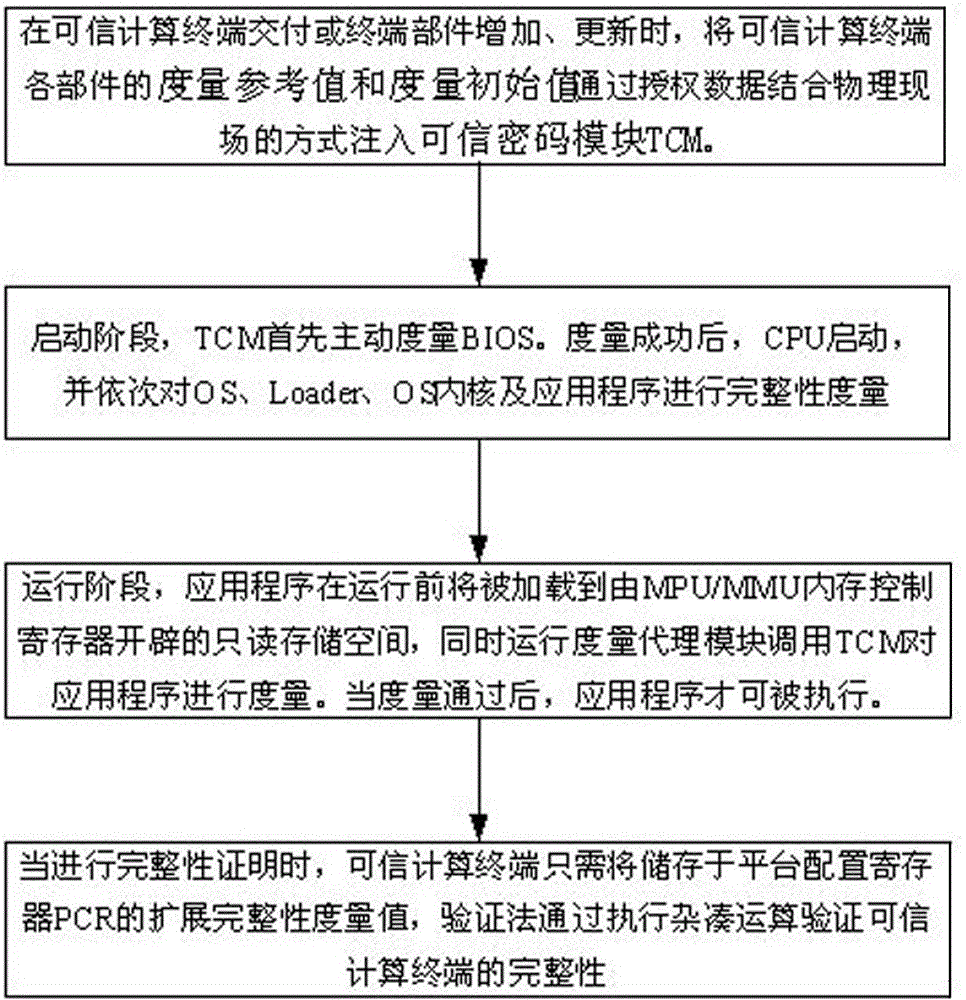

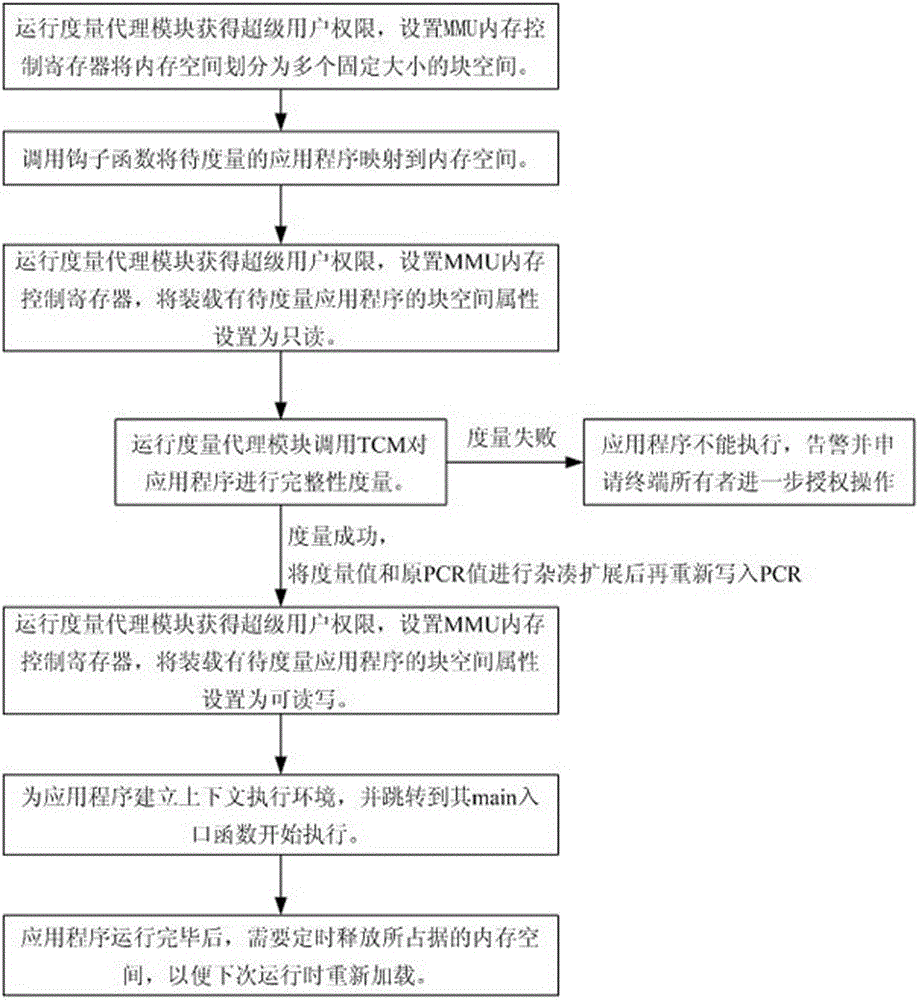

Trusted computing terminal integrity measuring and proving method and device

ActiveCN105608386AResist attackPrevent decipheringInternal/peripheral component protectionPlatform integrity maintainanceApplication softwareTotal measurement

The invention relates to the field of trusted computing, and particularly provides a terminal integrity detecting and proving method and device based on trusted computing for solving problems in the prior art. On the condition of not increasing additional hardware requirements and special instructions, an isolated and safe integrity dynamic measurement environment is built for an application program, and parallel barrier-free operation of other application programs in the measurement process is ensured. In the integrity proving process, the actual measurement value of each component in a computing terminal is concealed, and the problem that a hacker decode the version, configuration, firmware and other information of the terminal through the actual measurement values is effectively prevented; when the trusted computing terminal is subjected to integrity detection, extension integrity measurement values and the total measurement frequency stored in a platform configuration register PCR are sent to a verifier after being signed, and the verifier can detect the integrity of the trusted computing terminal by executing hash operation.

Owner:成都三零嘉微电子有限公司

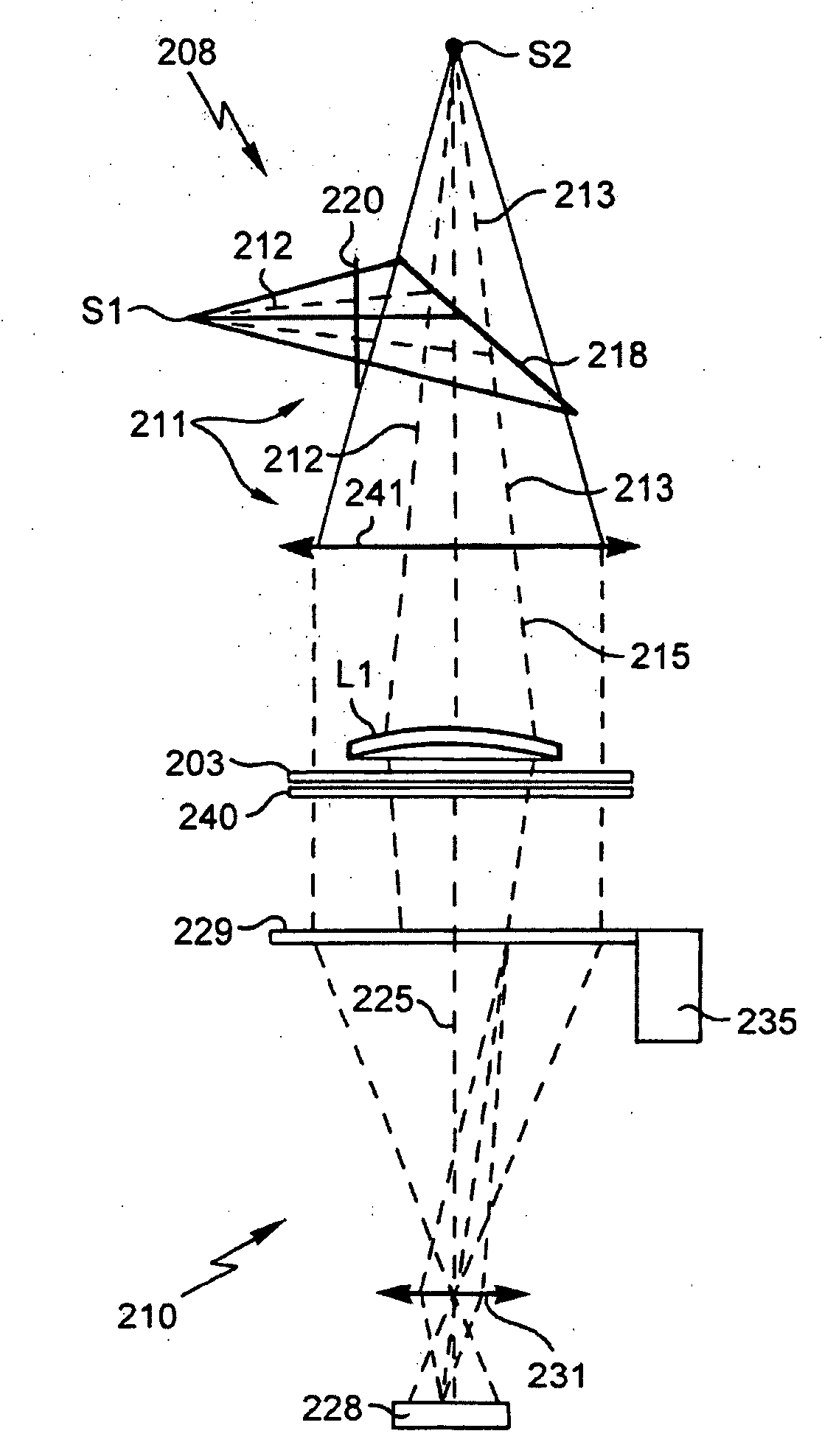

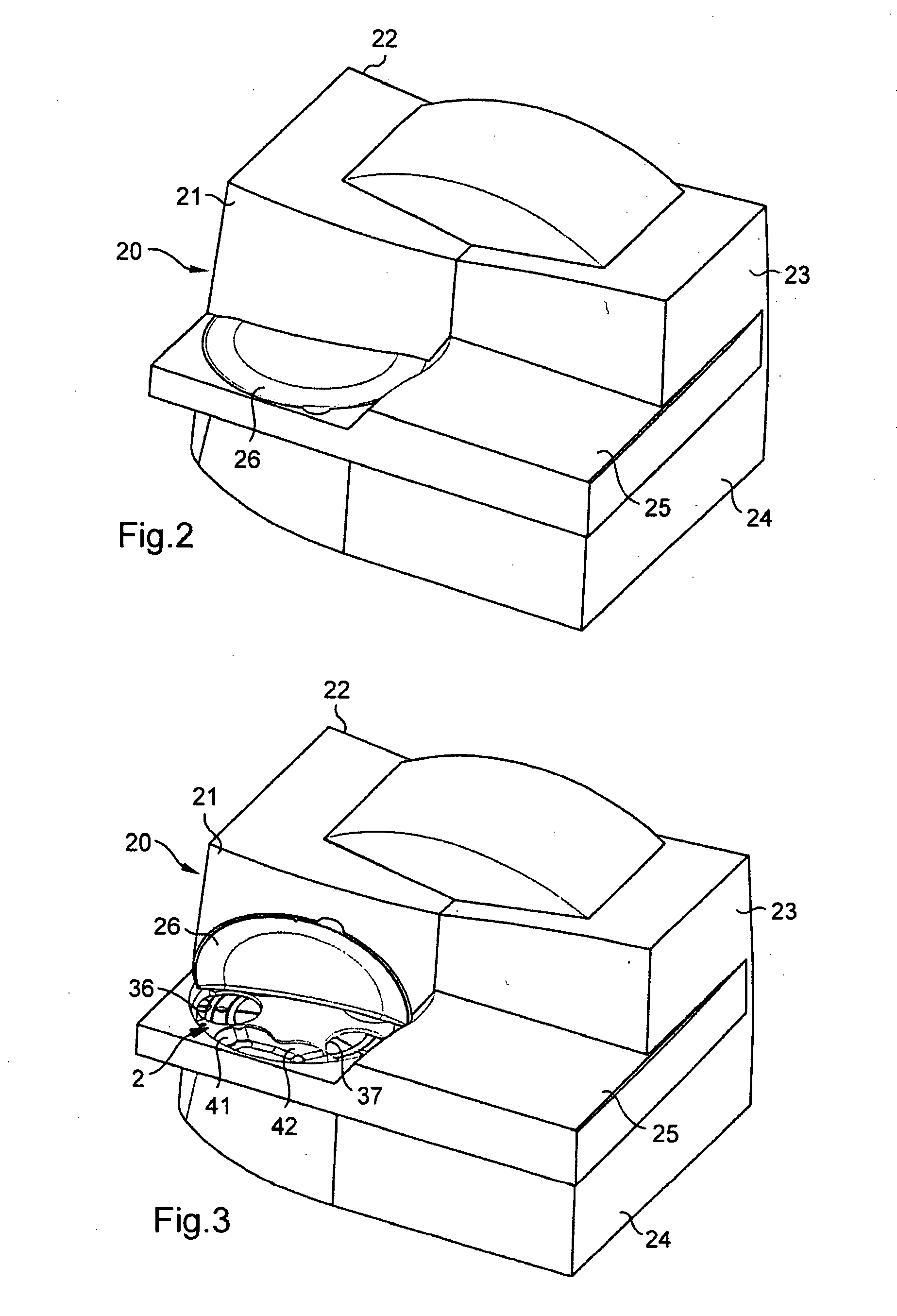

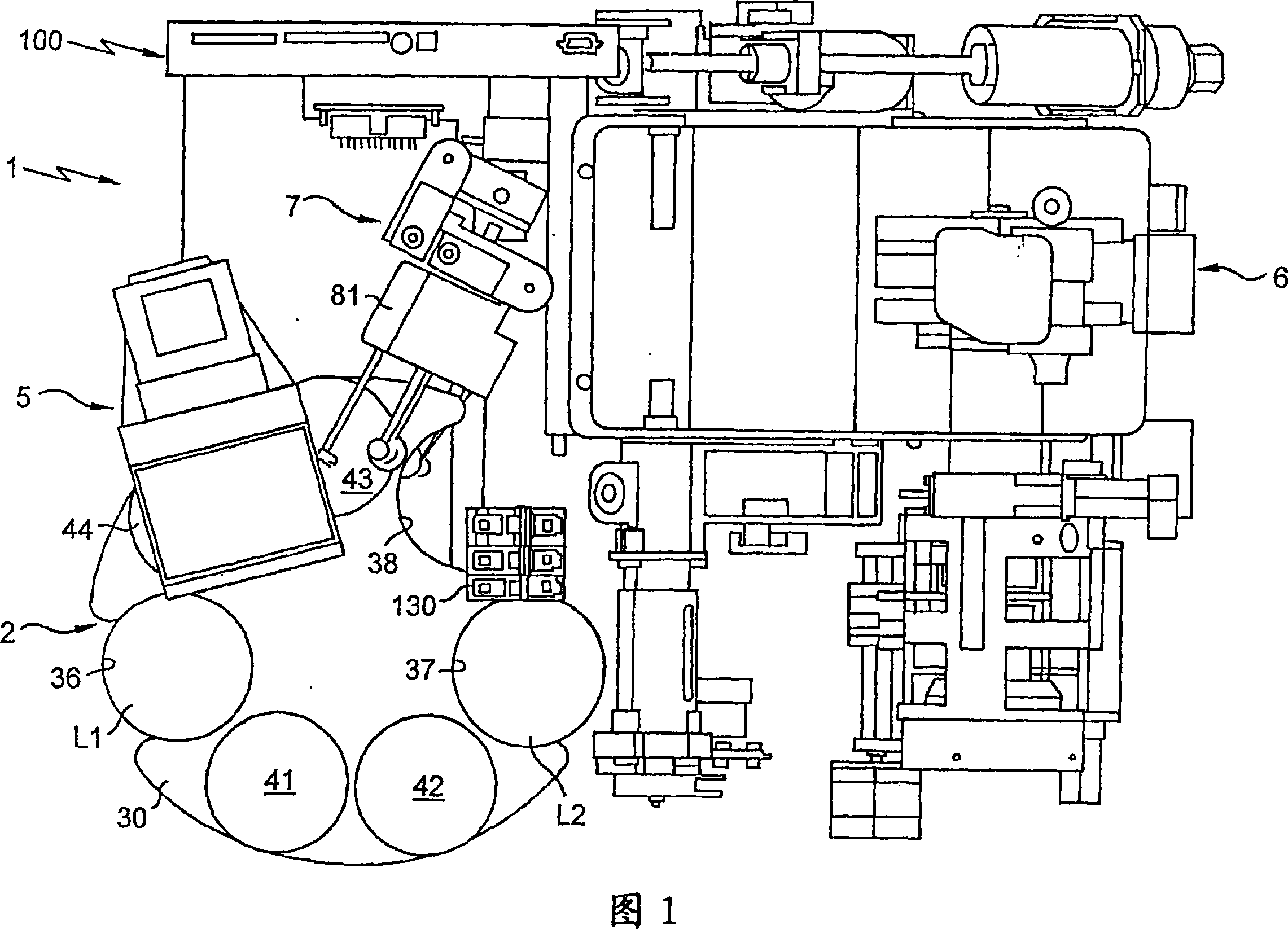

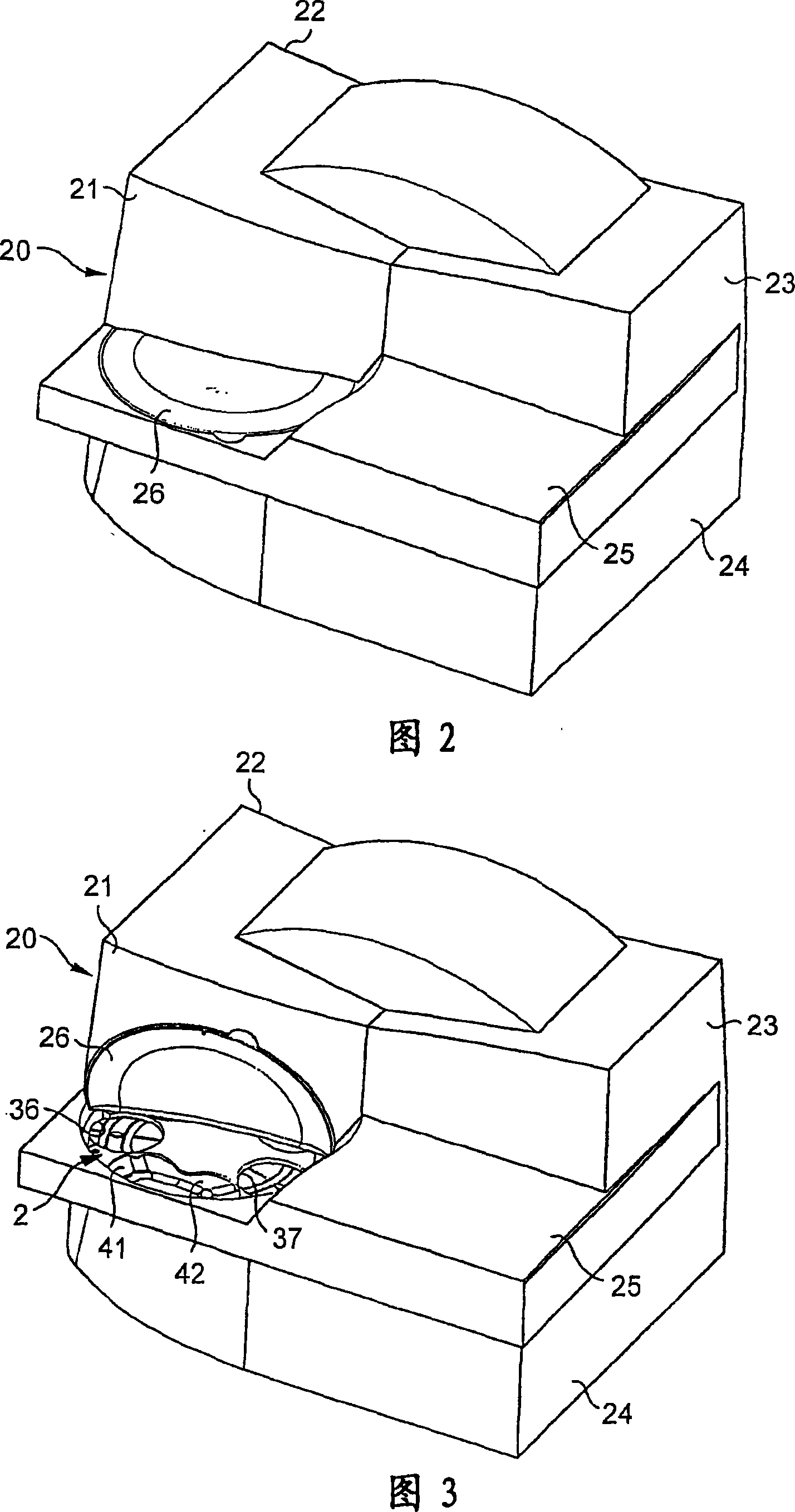

Method and a device for measuring the power of an ophthalmic lens by combined feeling and contactless overall measurement

ActiveUS20070273870A1Increase flexibilityImprove versatilityUsing optical meansRefractive power measurementOptical propertyMeasurement point

A method includes a step of contactless optical measurement of the local value of at least one refringence optical characteristic of the lens over defined local zone around the measurement point of the lens, and at least one step of determining the axial position of the measurement point on one of the faces of the lens; the axial position of the measurement point obtained is compared with the local value of the optical characteristic of the lens at the measurement point as determined from the contactless optical measurement, in order to deduce therefrom at least one vertex optical power of the lens at the measurement point.

Owner:ESSILOR INT CIE GEN DOPTIQUE

Neutron cement multi-element analyzer

InactiveCN1632544AQuality improvementLow costMaterial analysis using wave/particle radiationShieldingNeutron irradiationNuclear reaction

This invention relates to a cement multi-element analysis device. The neutron multi-element analysis device uses the neutron generator in the D-D reaction as neutron source and emits rapid neutrons of 2.5 Mev. The neutron reacts with the cement element to generate multi-nuclear reaction with different energy radiation gamma rays. The gamma ray detector is to detect the r rays generated by the elements in the cements. The r signals are through main amplifier and are transmitted to the micro machine for monitoring. It uses multi-path gamma spectrum device to test the area of the characteristics gamma ray peak and gives the relative nucleus content through test formula.

Owner:吉林省科仑辐射技术开发有限公司

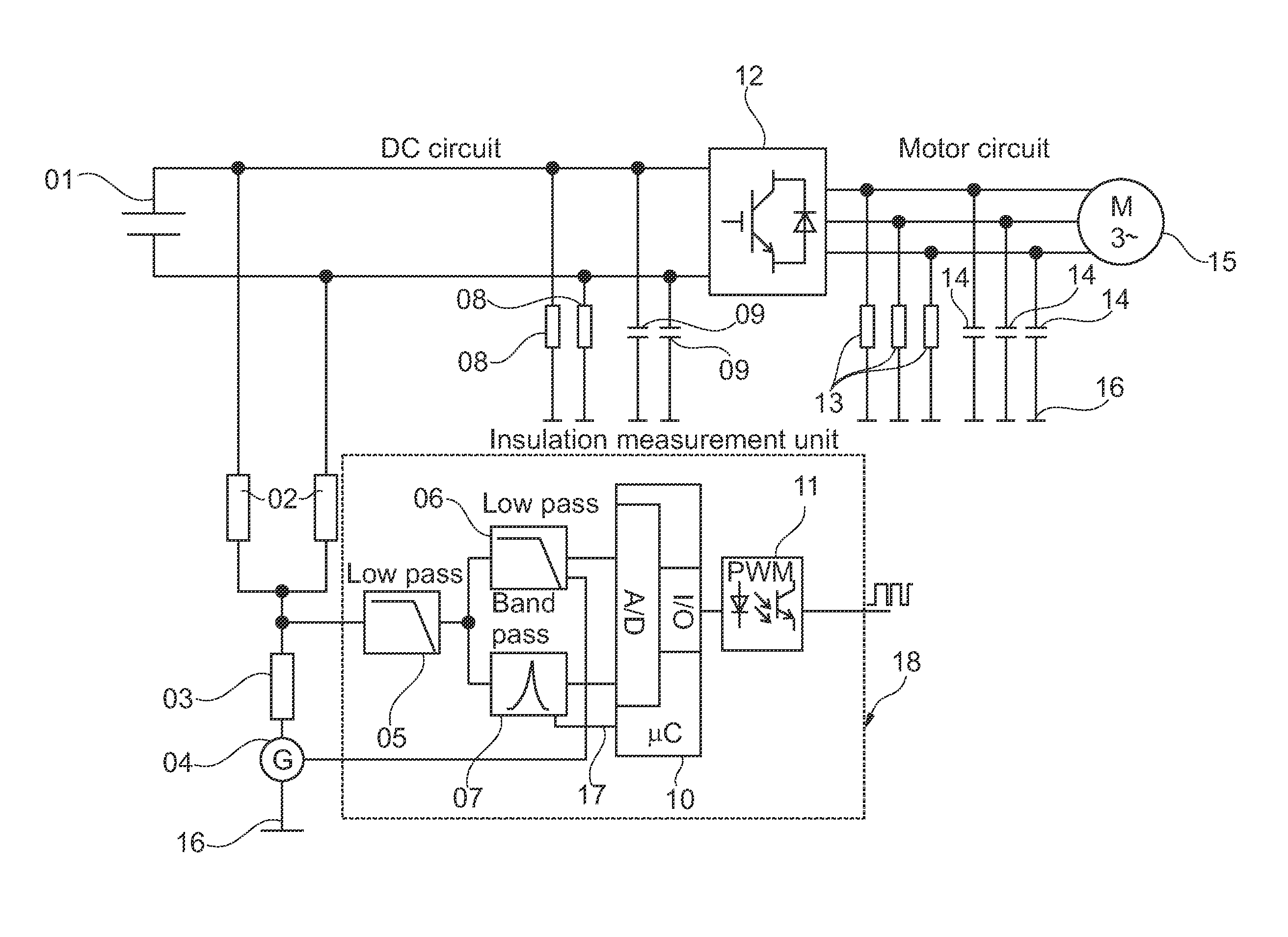

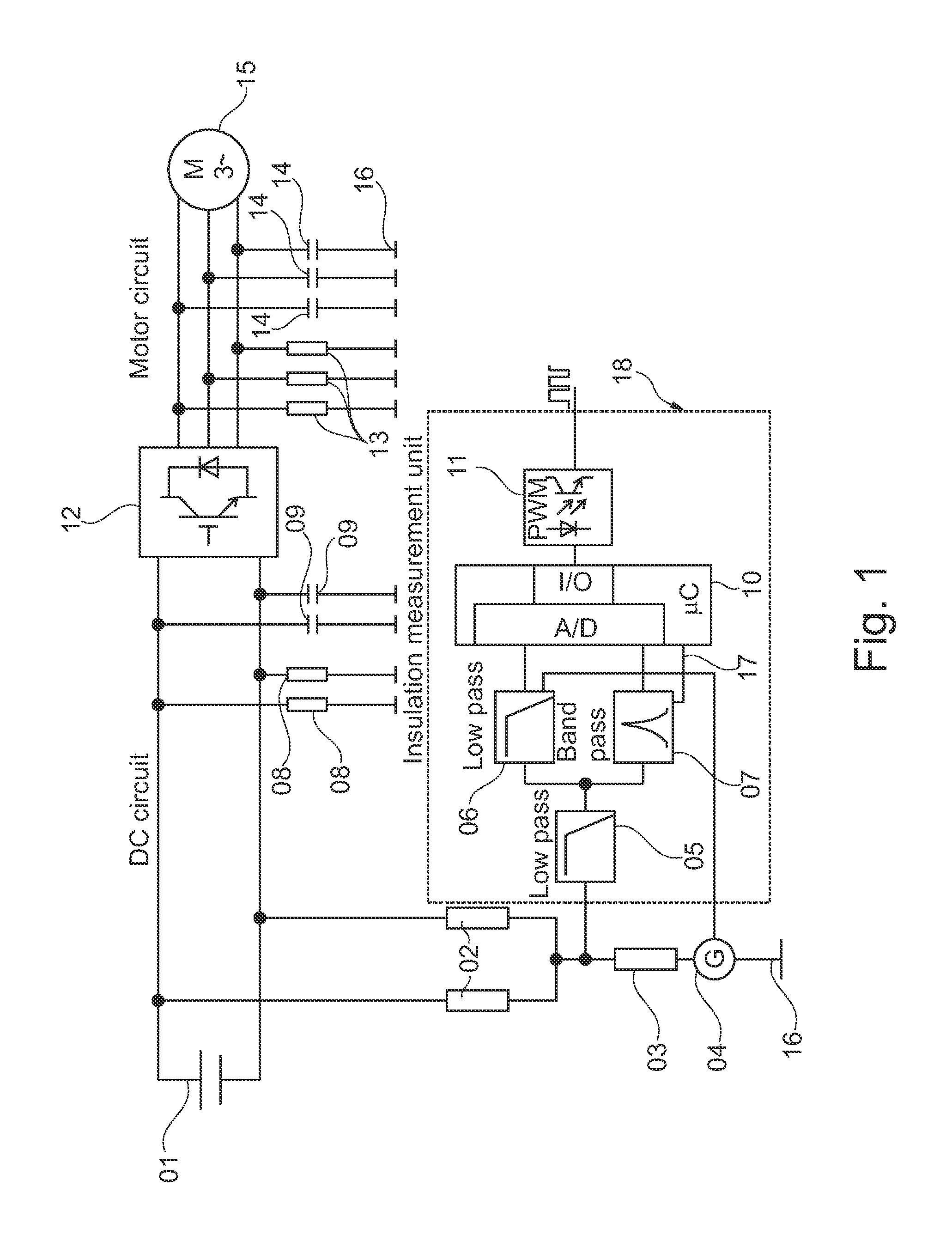

Method and device for monitoring the insulation of ungrounded DC and AC voltage networks

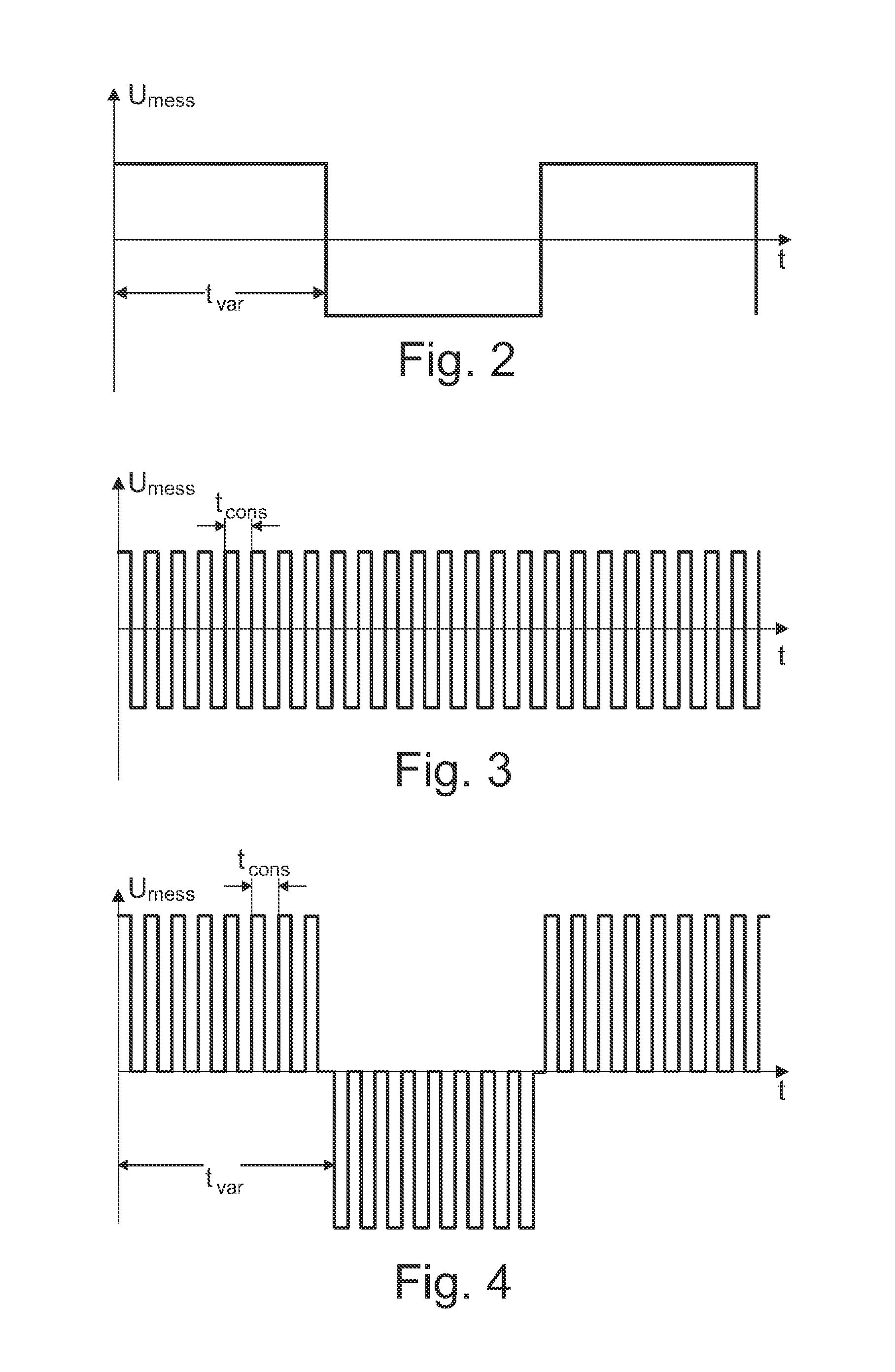

ActiveUS9069025B2Reliable recordAccurate monitoringVery high resistance measurementsImpedence measurementsHybrid vehicleCons

The invention relates to a method and a device for monitoring the insulation of an ungrounded DC and / or AC voltage network. The method includes the following steps: (a) generating a measurement DC voltage Umess= that is connected to a ground on one side for a tvar; predeterminable measuring time frame tvar; (b) generating and superposing at least one measurement AC voltage Umess˜ connected to a ground and having a measurement duration tcons with the measurement DC voltage Umess− for forming a total measurement voltage Umess; (c) feeding the total measurement voltage Umess into the voltage network to be monitored; and (d) determining an insulating resistance R= from the measurement DC voltage Umess− and an insulating impedance Z from the measurement AC voltage Umess˜. The devise is configured to carry out the above method. The method and the device are suited in particular for monitoring the insulation in electric and hybrid vehicles.

Owner:BENDER SA

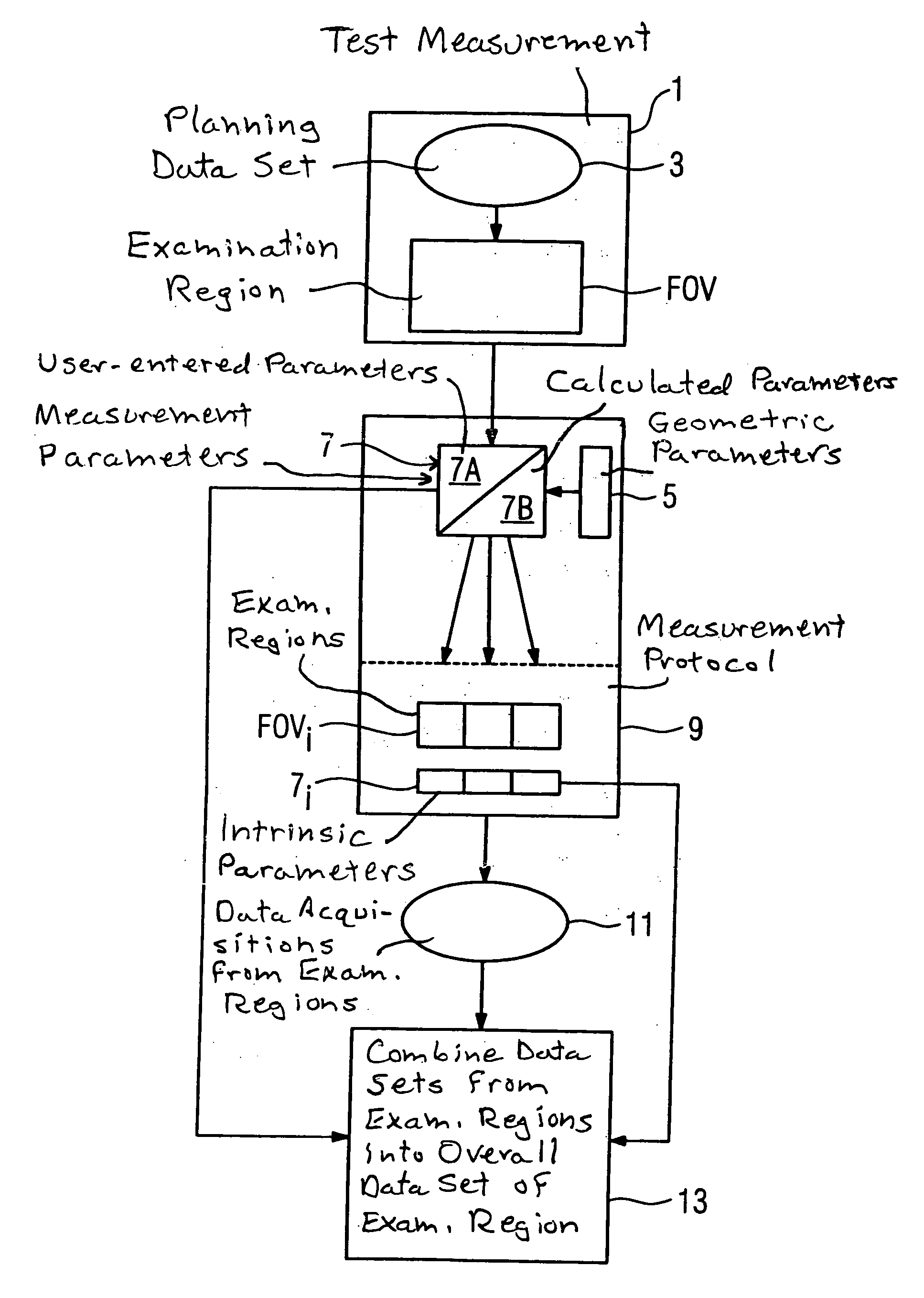

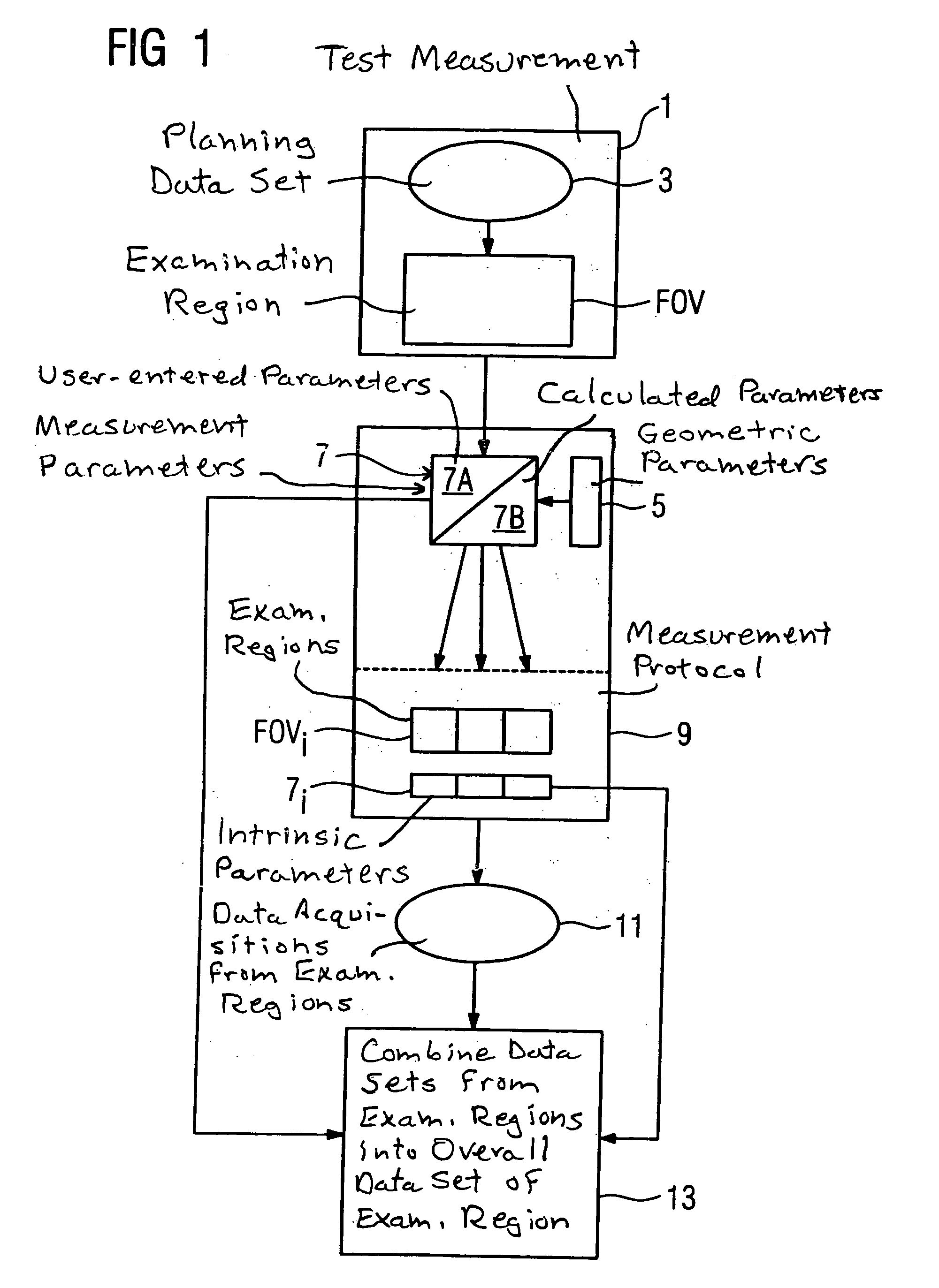

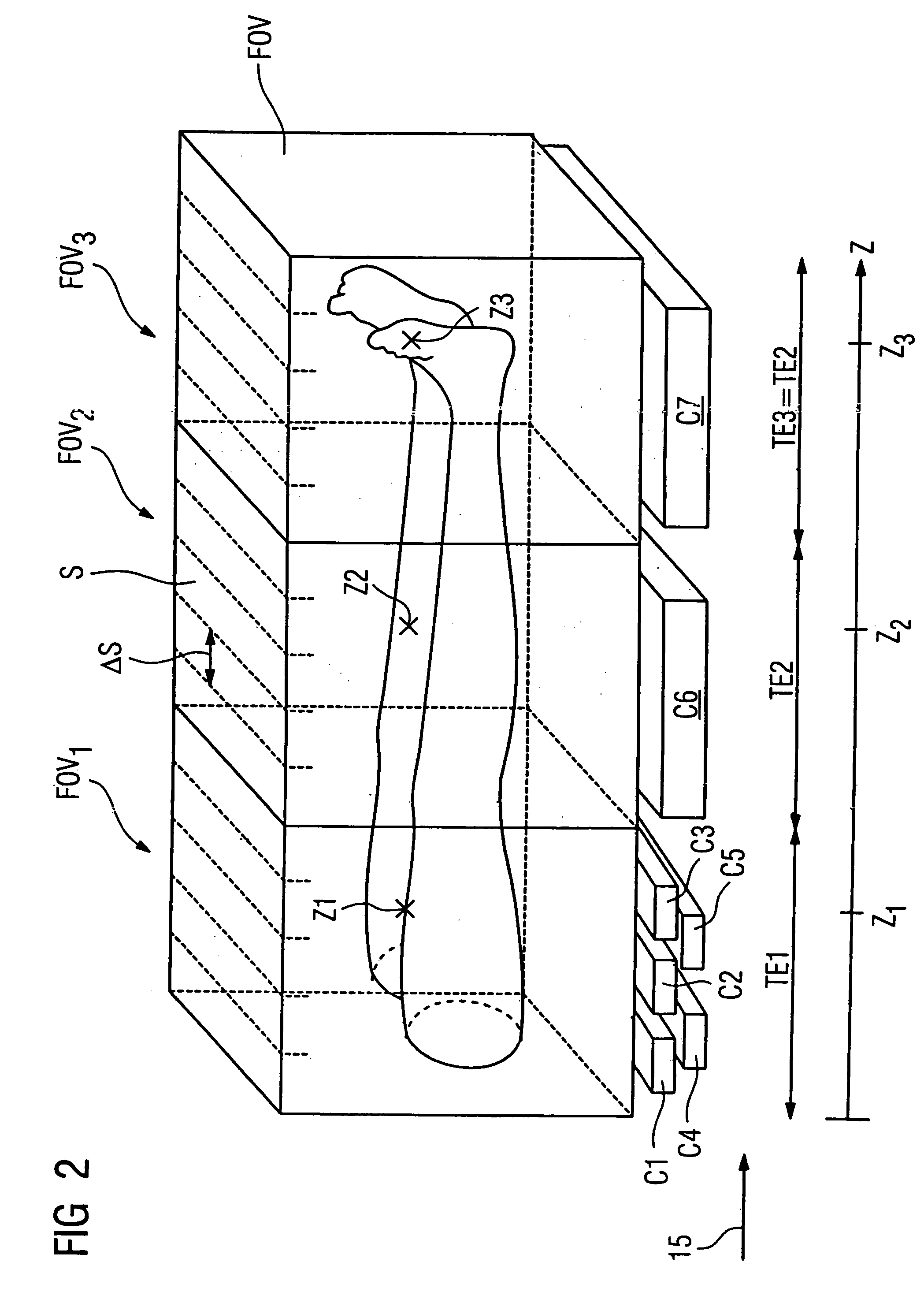

Method for acquiring magnetic resonance data from a large examination region

In a method for data acquisition from an examination region with a magnetic resonance apparatus, the examination region being larger than a maximum acquisition region of the magnetic resonance apparatus, a planning data set is generated and the examination region is established using the planning data set. The examination region is automatically separated into a number of acquisition regions by a computer of the magnetic resonance apparatus. Each of the acquisition regions is limited in terms of its dimensions by the maximum acquisition region. A measurement protocol is created that includes a first group of measurement protocol parameters that are applicable for all acquisition regions and a further group of measurement parameters applicable specifically for only one acquisition region. The acquisition regions are automatically positioned in series within the maximum acquisition volume with the measurement protocol in order to generate a measurement data set for each acquisition region. The measurement data sets are subsequently combined into an overall measurement data set of the examination region by the computer and using the measurement parameters of the measurement protocol.

Owner:SIEMENS HEALTHCARE GMBH

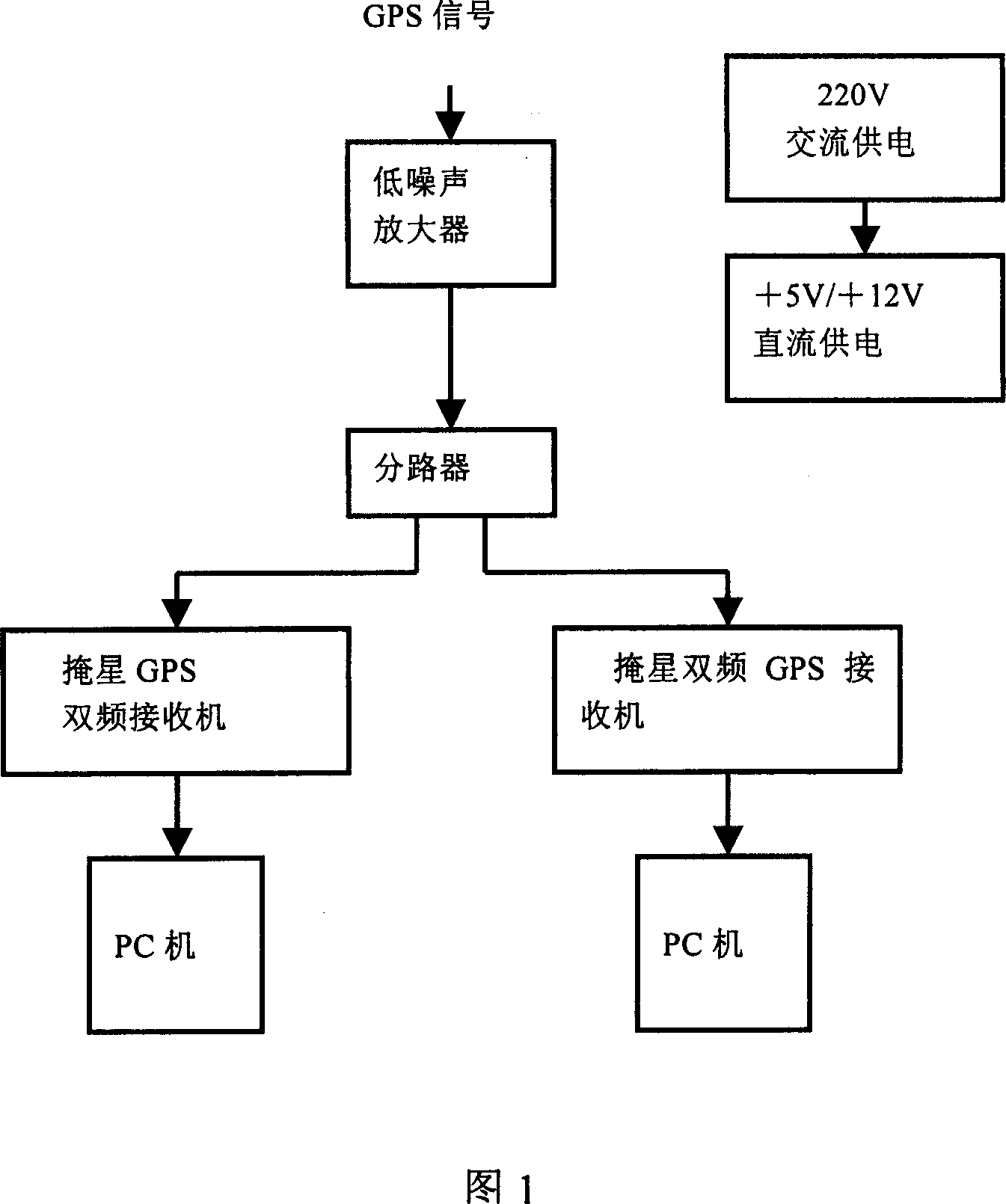

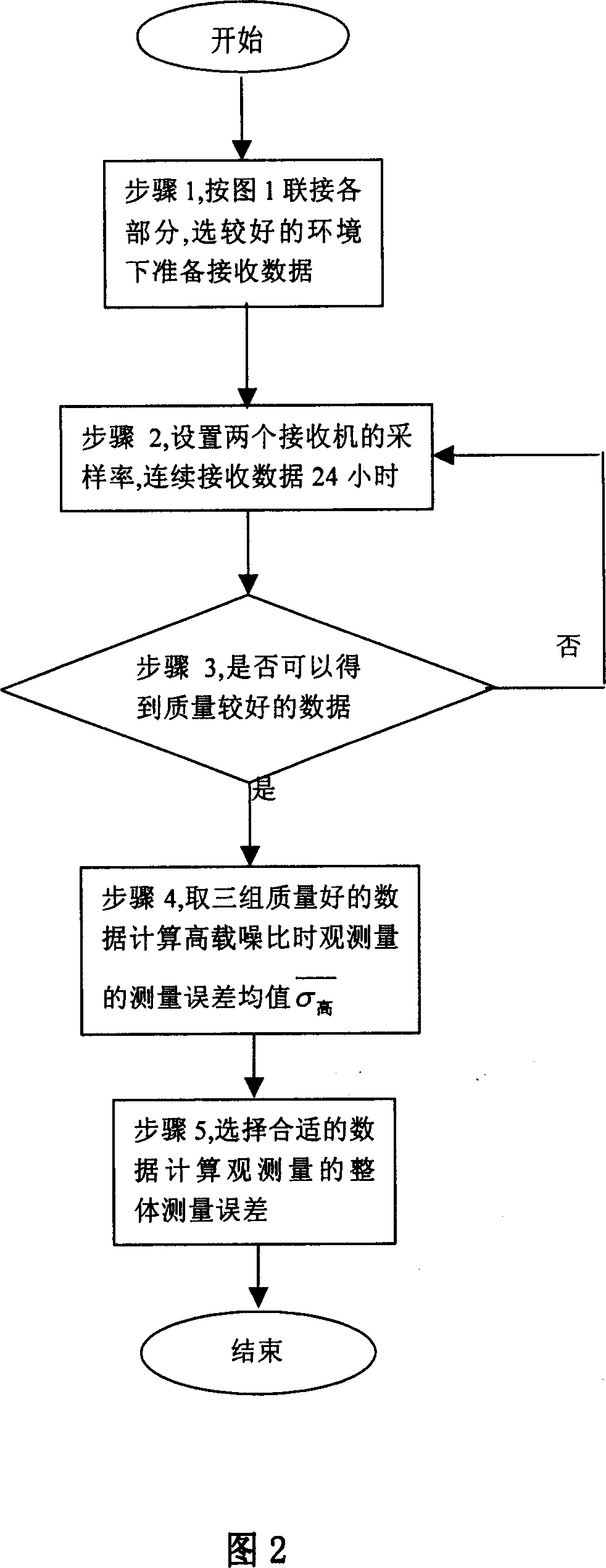

Method for detecting shift error of occultation double-frequency GPS receiver

InactiveCN101059560ABeacon systems using radio wavesPosition fixationObservational errorDual frequency

The invention relates to globe positioning system GPS receiver technical field, in particular to a method for measuring the obscuration error of dual-frequency obscuration GPS receiver. The method uses two obscuration receivers in one antenna which are same object receivers, or one is provided with known measurement error, and another one is the object receiver, to use the two measurement errors of the two receivers to obtain the measurement error of the obscuration receiver. The method comprises that 1, the GPS signal via the antenna of the obscuration receivers receive real GPS signal, 2, setting the sample rate of the receivers, 3, analyzing the data of the two receivers, 4, calculating the high-load noise ratio measurement error and averaging, via the high-quality data, 5, calculating out the integral measurement error.

Owner:NAT SPACE SCI CENT CAS

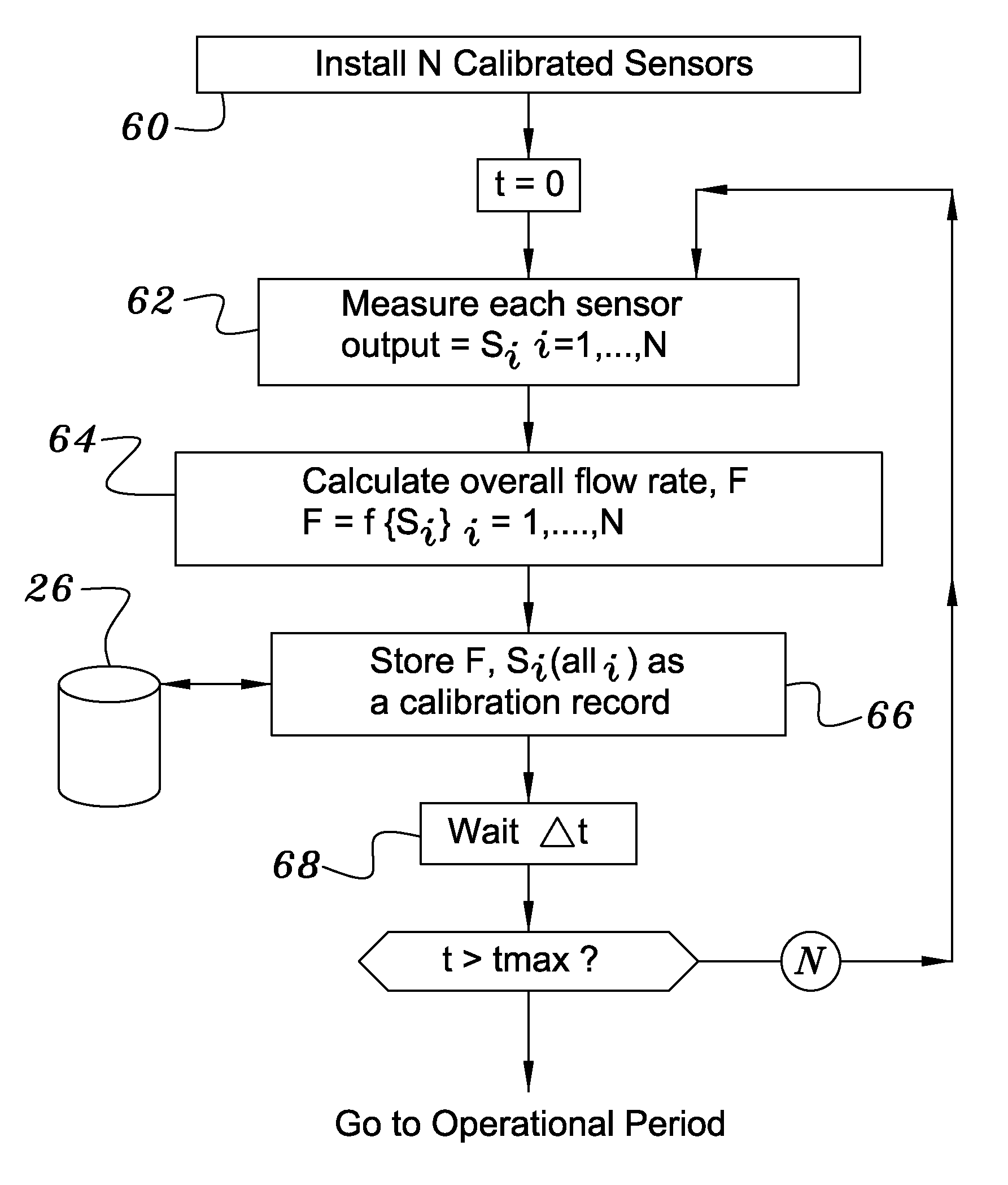

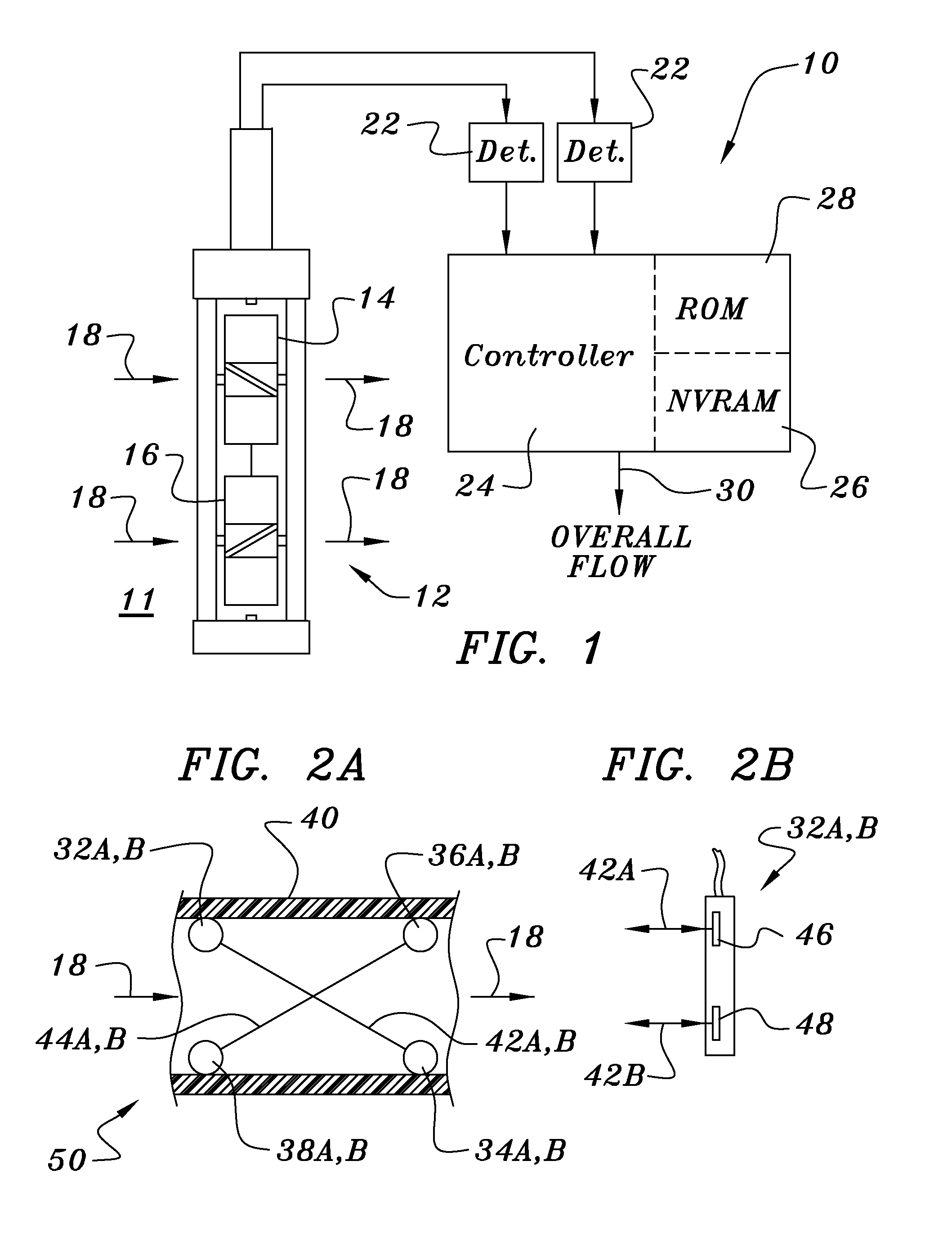

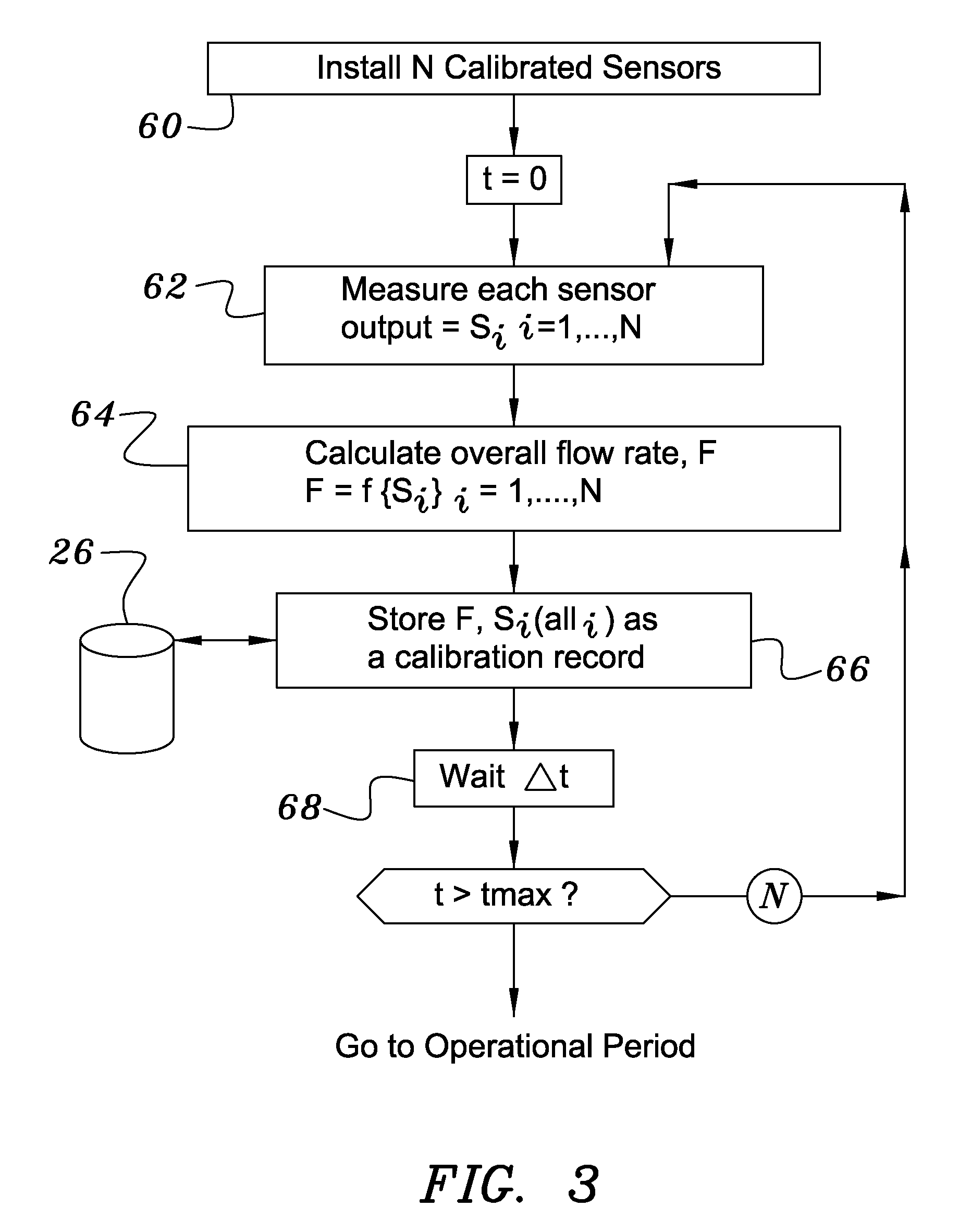

Multiple sensor flow meter

InactiveUS7480577B1Need for correctionGood serviceFluid pressure measurementVolume flow measuring devicesMultiple sensorEngineering

Combining a plurality of local flow measurements made at more than one location to generate a composite flow value can improve the accuracy of the overall measurement. The reliability and long term accuracy of a multi-sensor flow measurement are improved by a two-step process. During an initial learning period, when all of the local sensors are providing accurate local measurements, a calibration table is built up that associates each calculated composite flow value with the set of local flow signal values from which it was calculated. In a subsequent operational period each time the composite flow rate is to be determined the flow meter apparatus first checks to see if all the local sensors are working properly and, if one of them is not working properly, its output is replaced with the corresponding value from the calibration table.

Owner:ONICON INC

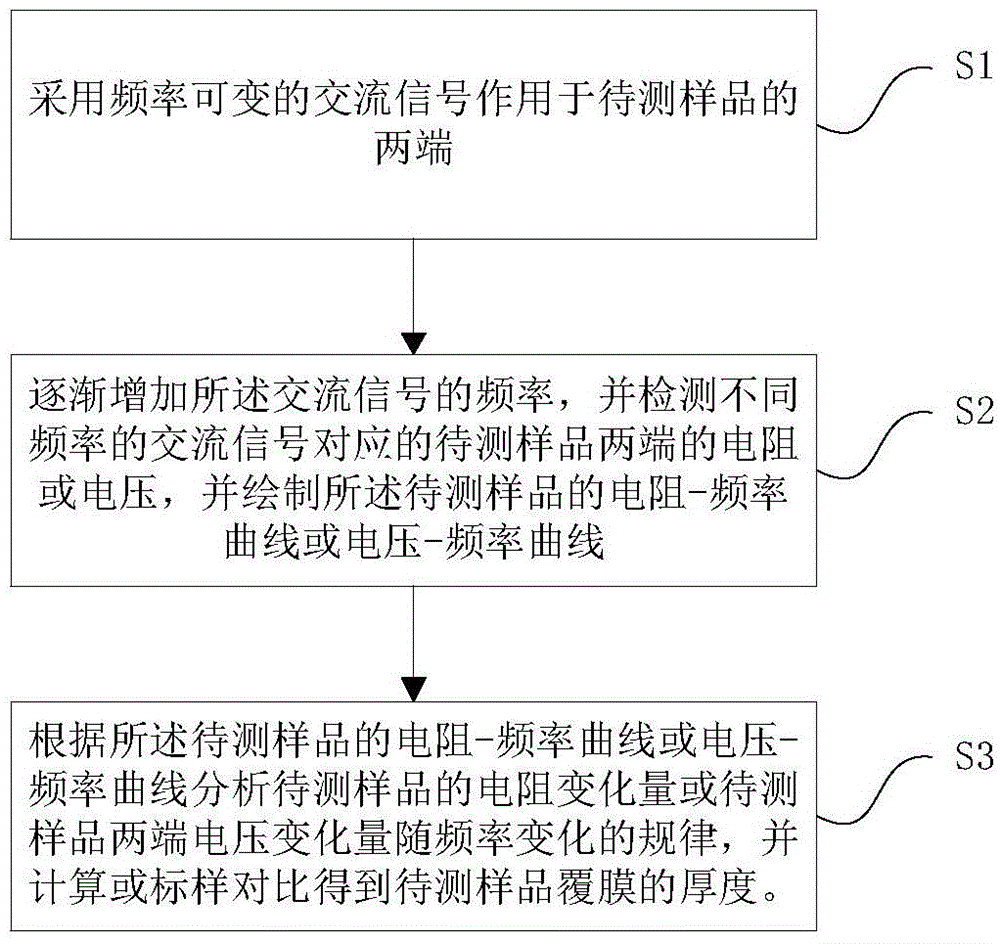

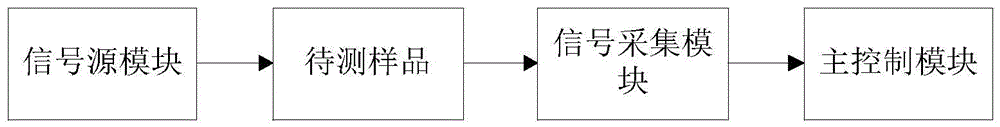

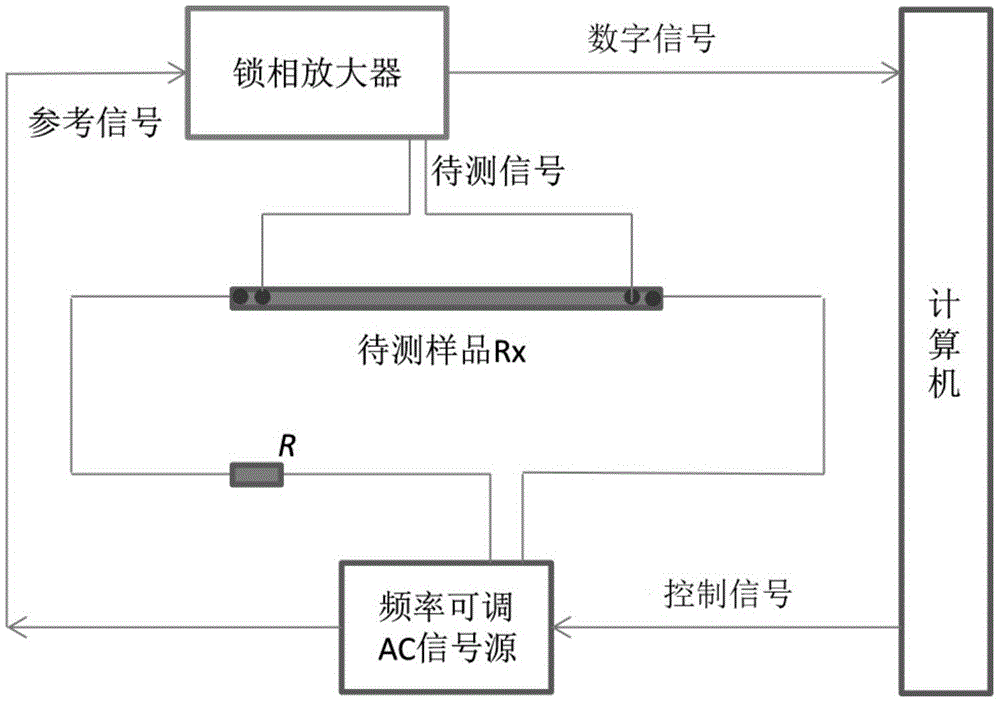

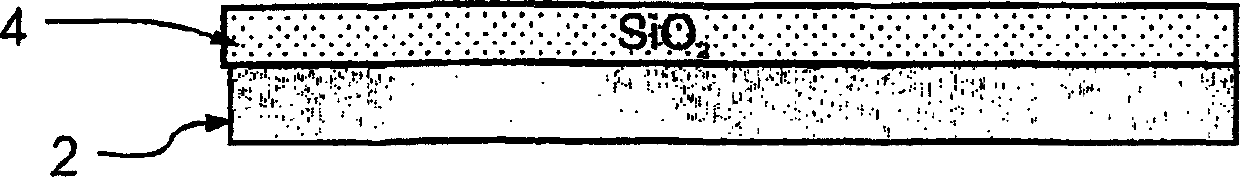

Skin effect-based sample surface coating nondestructive test method and system

ActiveCN105675657AHigh detection sensitivityImprove detection efficiencyElectrical/magnetic thickness measurementsMaterial resistanceElectrical resistance and conductanceSkin effect

The invention relates to a skin effect-based sample surface coating nondestructive test method and system. The method comprises acting two ends of a sample to be detected through a frequency-variable AC signal, gradually increasing AC signal frequency, detecting resistance or voltage at the two ends of the sample to be detected, wherein the resistance or voltage is corresponding to AC signals with different frequencies, drawing a resistance-frequency curve or a voltage-frequency curve of the sample to be detected, analyzing a rule of change of the resistance change amounts of the sample to be detected or the voltage change amounts of two ends of the sample to be detected along with frequency change, and carrying out calculation or comparison with a standard sample to obtain thickness of the coating on the sample to be detected. The method and system realize integral measurement of the sample to be detected, has high detection sensitivity, realizes automatic measurement and has high detection efficiency. Through the skin effect, the surface defects of the material at high frequency are sensitive to a high frequency signal. Through change of AC signal frequency, coating surface defect and crack depth distribution information is acquired.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

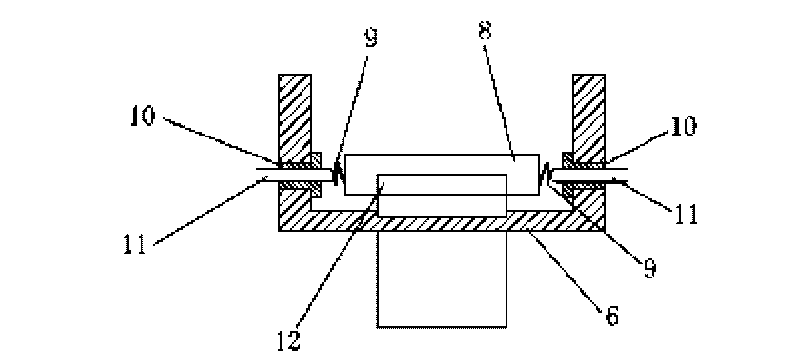

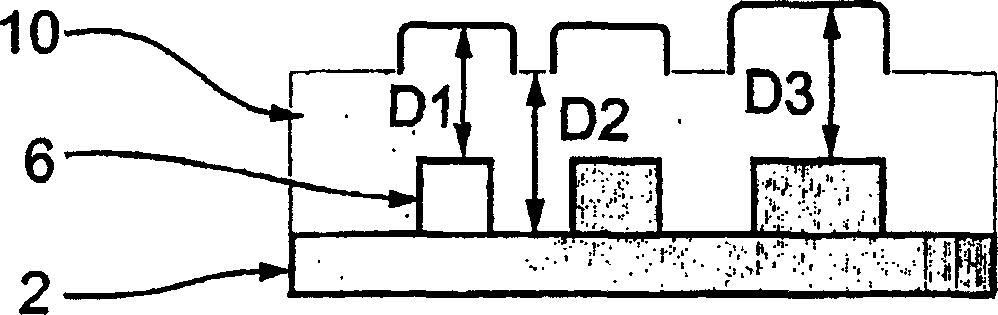

Method and apparatus for measuring stress in semiconductor wafers

InactiveCN1618004ASemiconductor/solid-state device testing/measurementElectronic circuit testingLayer thicknessTotal measurement

Integral measurement apparatus (50) and method for measuring layer thickness and bow in a wafer. The device comprises: a monochromatic light source (52), a white light source (100), a first switch (102) for switching between the white light source and the monochromatic light source, a switch for directing light from the switched light source to the semiconductor wafer A plurality of optical heads (56) at different locations on the surface (54), a first optical processor (104) for spectrally processing reflected light from the wafer, a second optical processor (104) for processing the reflected light to determine the degree of curvature in the wafer Two optical processors (58), and a second optical switch (106) for switching the reflected light from the wafer between the first optical processor and the second optical processor for spectral processing of white light to determine layer thickness , processes monochromatic light to determine the bend.

Owner:TEVET PROCESS CONTROL TECH

Assessment and optimization for metrology instrument including uncertainty of total measurement uncertainty

InactiveUS20080151268A1Improves TMU analysisEasy to analyzeSemiconductor/solid-state device testing/measurementDigital computer detailsMetrologySystem under test

Methods and related program product for assessing and optimizing metrology instruments by determining a total measurement uncertainty (TMU) based on precision and accuracy. The TMU is calculated based on a linear regression analysis and removing a reference measuring system uncertainty (URMS) from a net residual error. The TMU provides an objective and more accurate representation of whether a measurement system under test has an ability to sense true product variation. The invention also includes a method for determining an uncertainty of the TMU.

Owner:IBM CORP

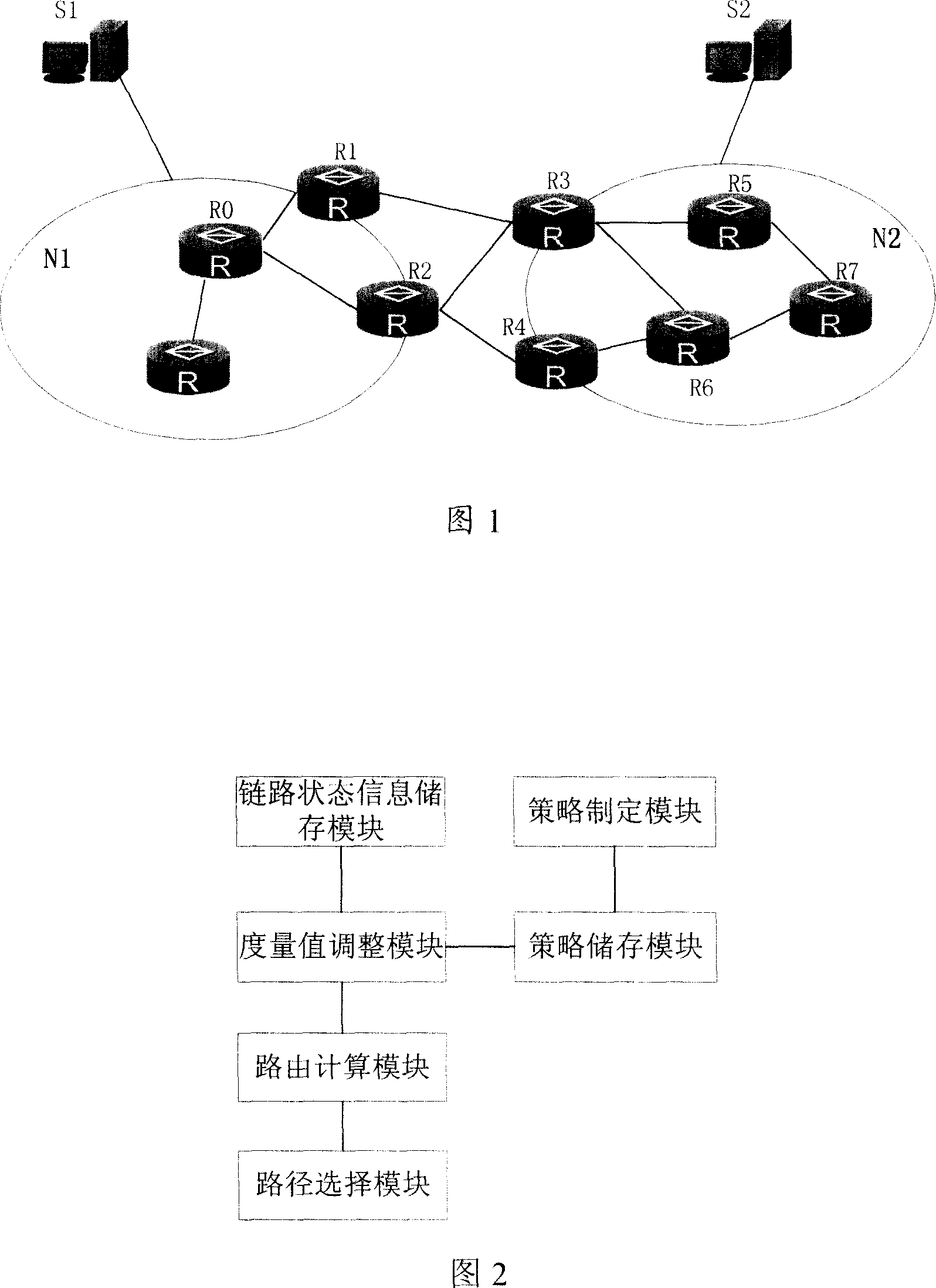

Route selection method and device

InactiveCN101001203AMetric modificationFlexible choiceData switching by path configurationTotal measurementReal-time computing

This invention discloses a route selection method and a device, in which, said method includes: a server receives and stores the link state information sent by NE to adjust the measurement values of the links in the state information and carries out route computation based on the measurement value and selects the route with the minimum total measurement value as the transmission data of said NE when it receives the route computation request from the NE.

Owner:HUAWEI TECH CO LTD

Stereo image measuring device

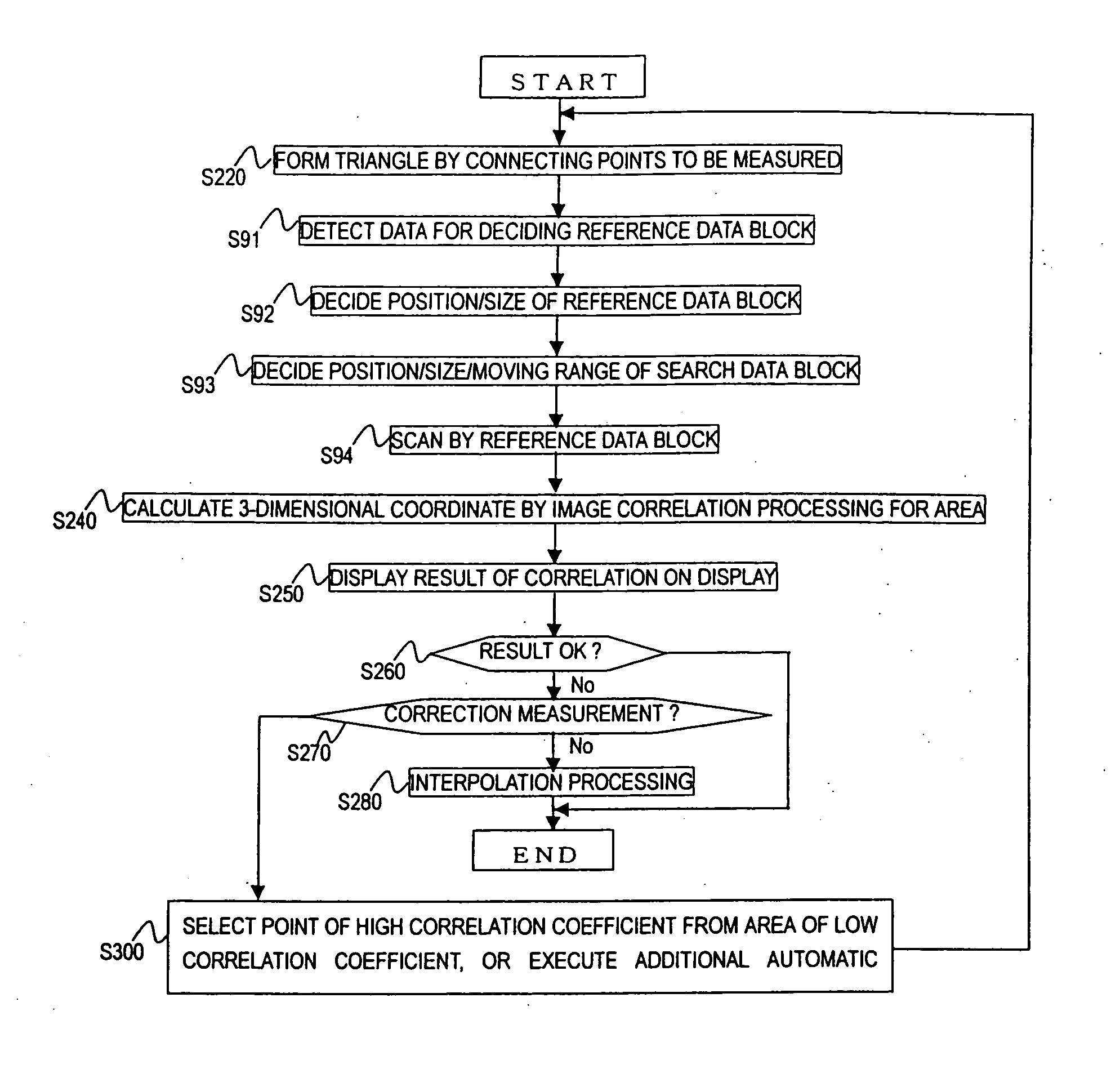

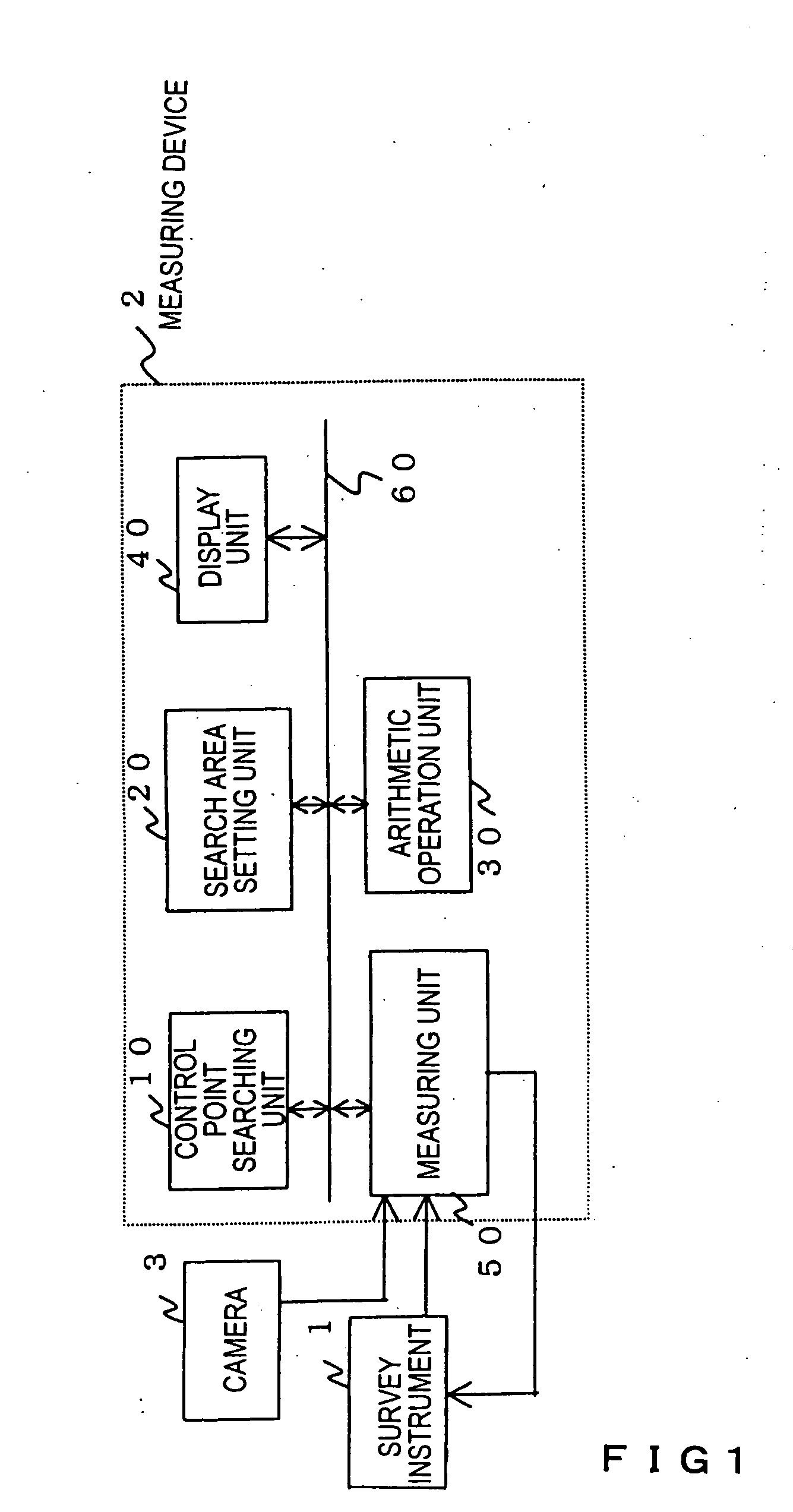

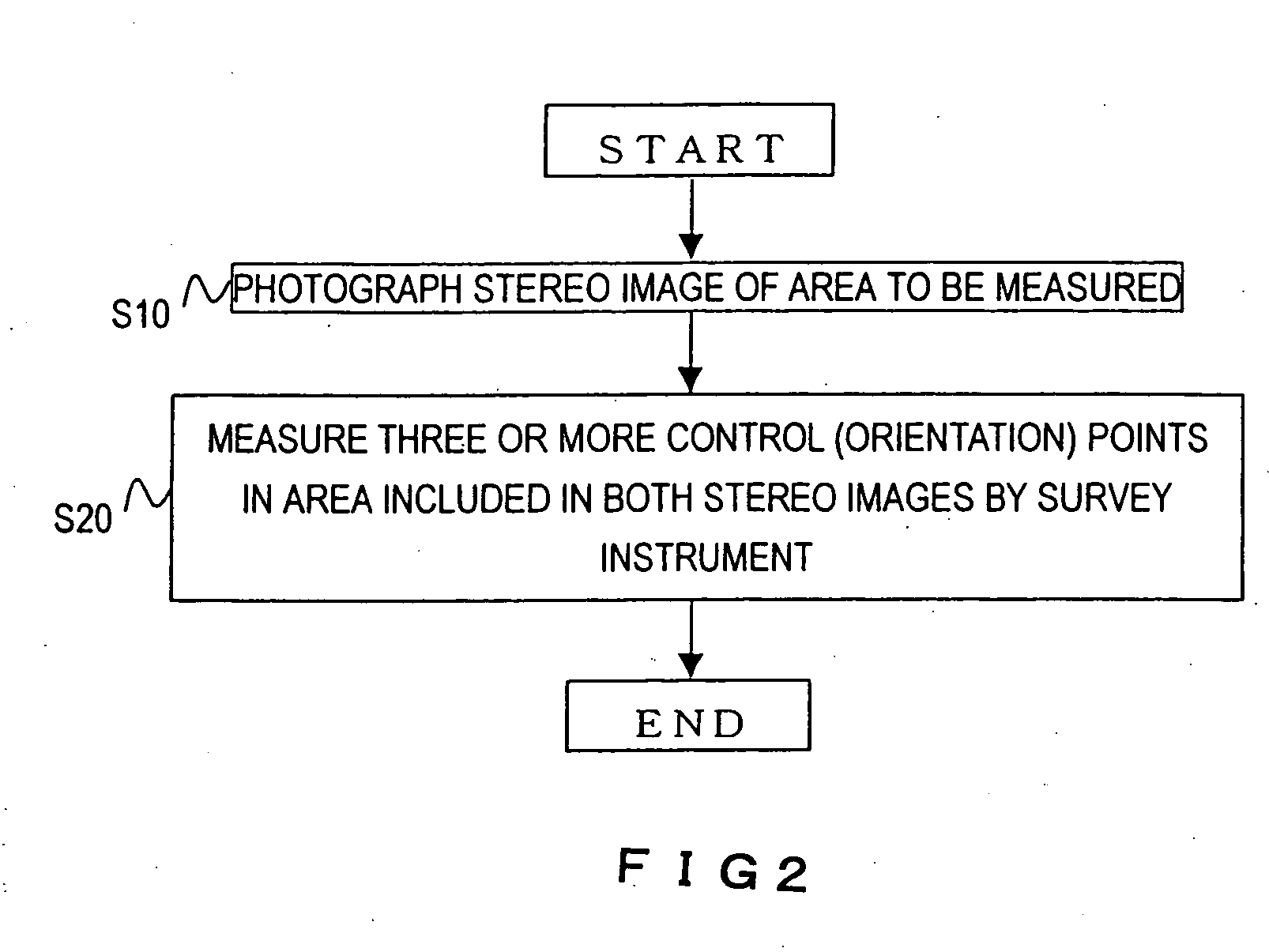

InactiveUS20060013474A1Improve reliabilityEliminate failure problemsImage enhancementImage analysisStereo matchingSurvey instrument

The present invention discloses a stereo image measuring device capable of carrying out high-speed and highly reliable three-dimensional measurement for a stereo image, easily correcting any omitted measurement, measurement errors or the like, and achieving a much higher speed, efficiency and reliability for measurement as a whole. A survey instrument measures a number of control points on site. A camera is, for example a digital camera, a film camera or the like. A control point search unit executes correlation between a control point measured beforehand by the instrument survey and an image. A search area setting unit sets a search area to be used for image correlation processing based on the control points correlated by the control point search unit, and sets respective data blocks, i.e., a reference data block and a search data block. An arithmetic operation unit executes orientation calculation, and image correlation processing (stereo matching) for the search area set by the search area setting unit. A display unit is a stereo monitor, a personal computer monitor or the like providing stereoscopic vision. A measuring unit executes additional measurement when the result of correlation processing is not satisfactory.

Owner:KK TOPCON

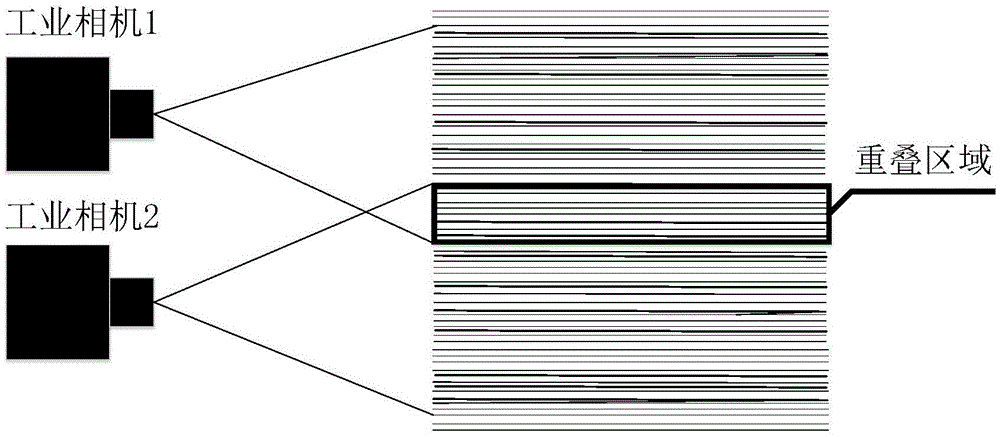

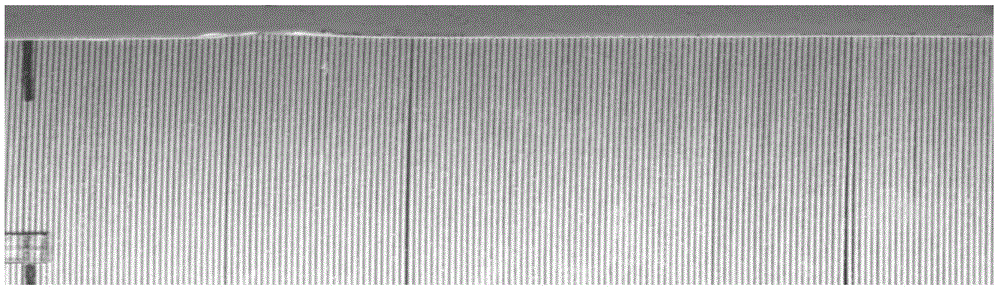

Cigarette pack lamination layer number measurement method and device by multi-camera array

InactiveCN105574845ASatisfy counting tasksMeet testing needsImage enhancementImage analysisMulti cameraImage correction

The invention discloses a cigarette pack lamination layer number measurement method and device by a multi-camera array. The method comprises the following steps of (1) arranging and adjusting an imaging device; (2) acquiring a cigarette pack lamination layer scanning image, acquiring multiple images of adjacent lamination layer end surfaces with enough overlap regions by the camera array, and transferring the acquired images to a counting module; and (3) carrying out processing such as image correction, maximum narrow-strip direction field linear detection and dotted line dual image splicing on partially-overlapped adjacent images, achieving complete lamination layer end surface image reconstruction, and finally, completing the total measurement of cigarette pack number by vertically transect sampling and counting. The method has the advantages of high measurement accuracy, high instantaneity, wide application range and convenience in operation.

Owner:HUNAN UNIV

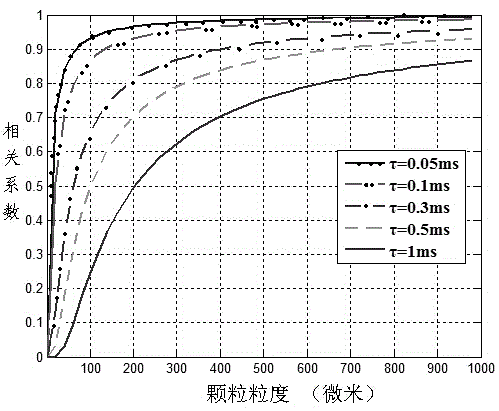

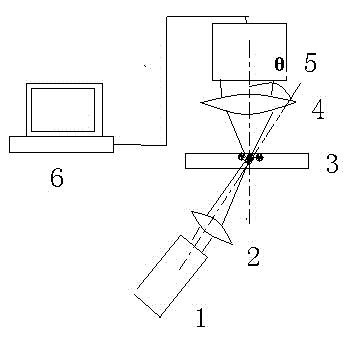

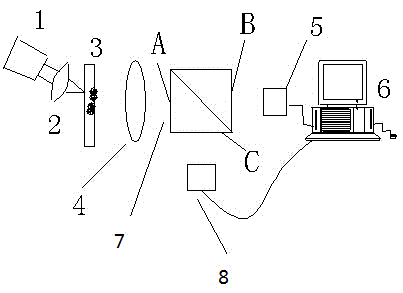

Nano-particle size measurement device and method

ActiveCN104568683AEasy to handleReduced measurement timeParticle size analysisCorrelation coefficientParticle size measurement

The invention discloses a nano-particle size measurement device and method. The device consists of a laser source, a sample cell, lenses, an area array photosensitive device and a computer, wherein laser beams emitted by the laser source irradiate nanoparticles in the sample cell after being converged, dynamic light scattering signals are generated by the particles performing Brownian movement in the sample cell under the irradiation of incident laser, and are converged after passing through the second lens, the area array photosensitive device arranged on the focal plane of the lens performs recording at a time interval of Deltatau to obtain two dynamic light scattering signal images of movement of the nanoparticles, and transmits the images to the computer, and the computer calculates a correlation coefficient of the two images by adopting a correlation algorithm, and determines the particle size of the nanoparticles according to the correlation coefficient. The device and the method have the benefits that measurement time is greatly shortened, and can reach the microsecond level, a data processing process is simple and low in time consumption, and the total measurement time can be millisecond or microsecond time.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

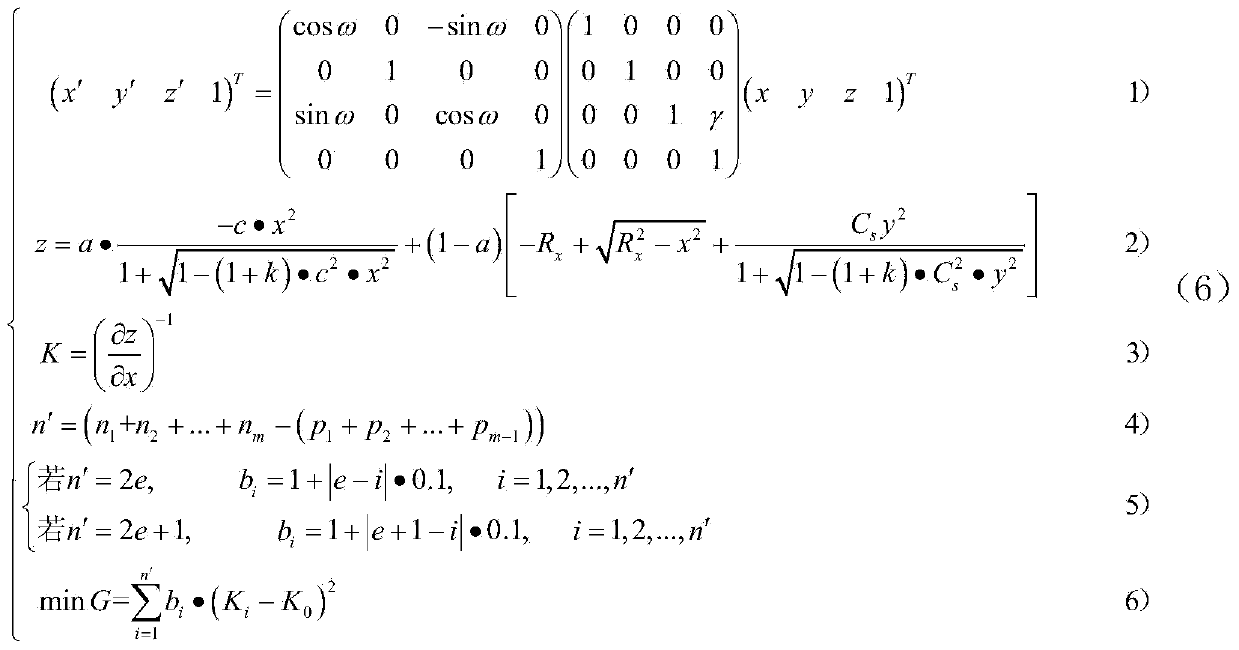

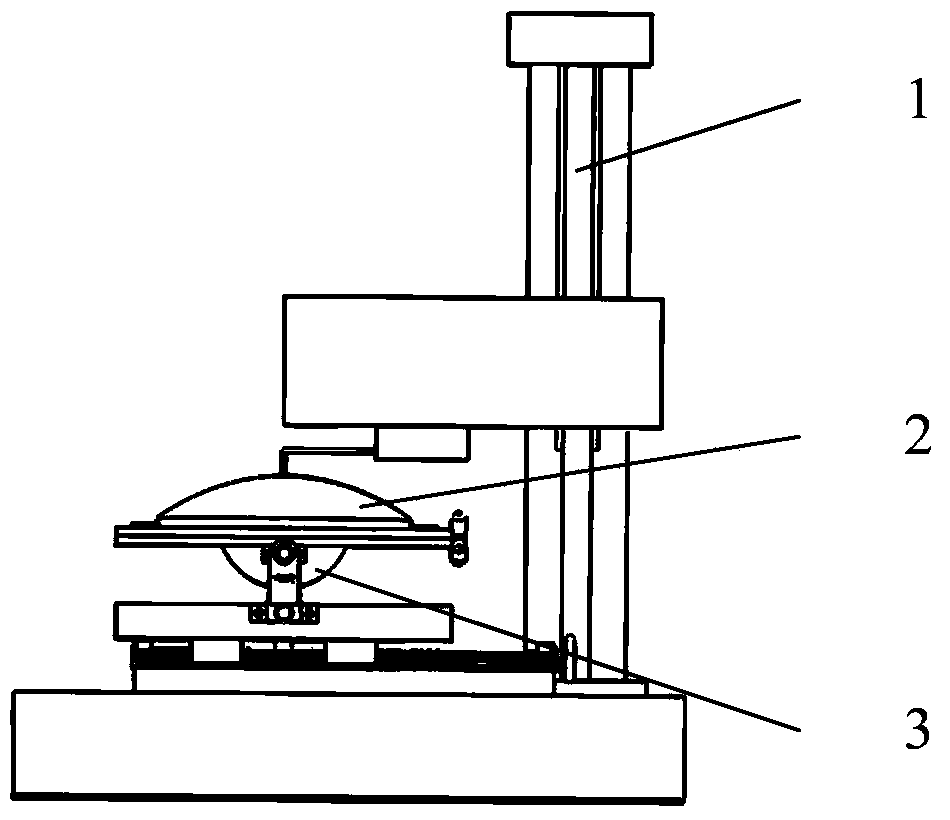

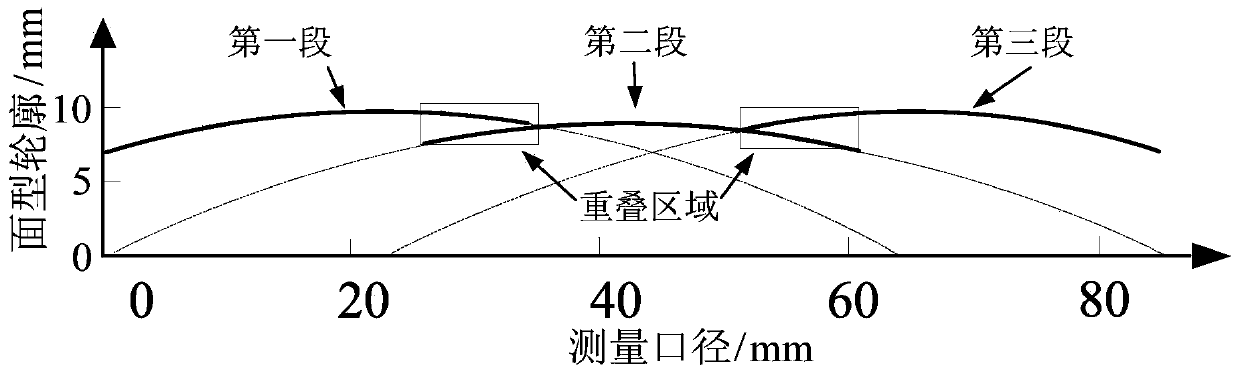

Method for measuring contour of large-caliber aspheric surface optical element at grinding stage

The invention discloses a method for measuring the contour of a large-caliber aspheric surface optical element at the grinding stage, and relates to the field of aspheric surface optical element measurement. A contour line of the large-caliber aspheric surface optical element at the grinding stage is divided into sections, the number of the sections is set to be M, and overlapping areas need to be reserved between every two adjacent sections and are set to be p1, p2, ..., pm-1. The divided M sections are respectively measured through a measuring device, and the measuring data of each section are obtained. The measuring data of the divided M sections of the large-caliber aspheric surface optical element are spliced based on the multi-body system theory, the Taylor series, the principle of least squares and the data of the overlapping areas. Redundant data, produced when the sections are spliced, of the overlapping areas are removed based on the curvature principle and the aspheric surface equation least square fit method. The contour of all the sections with the redundant data removed is comprehensively optimized, and the overall measuring result of the contour of all the sections is obtained.

Owner:XIAMEN UNIV

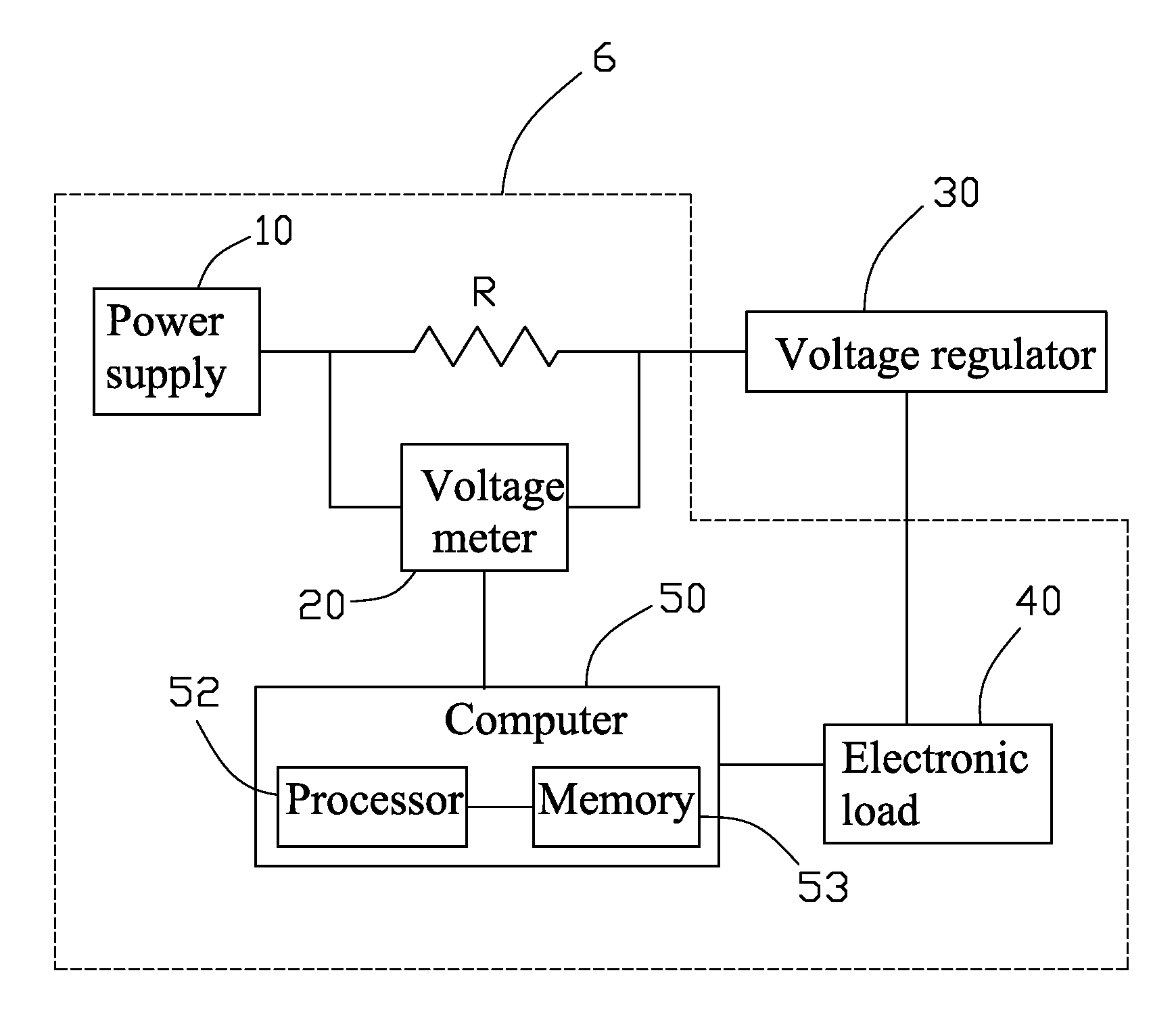

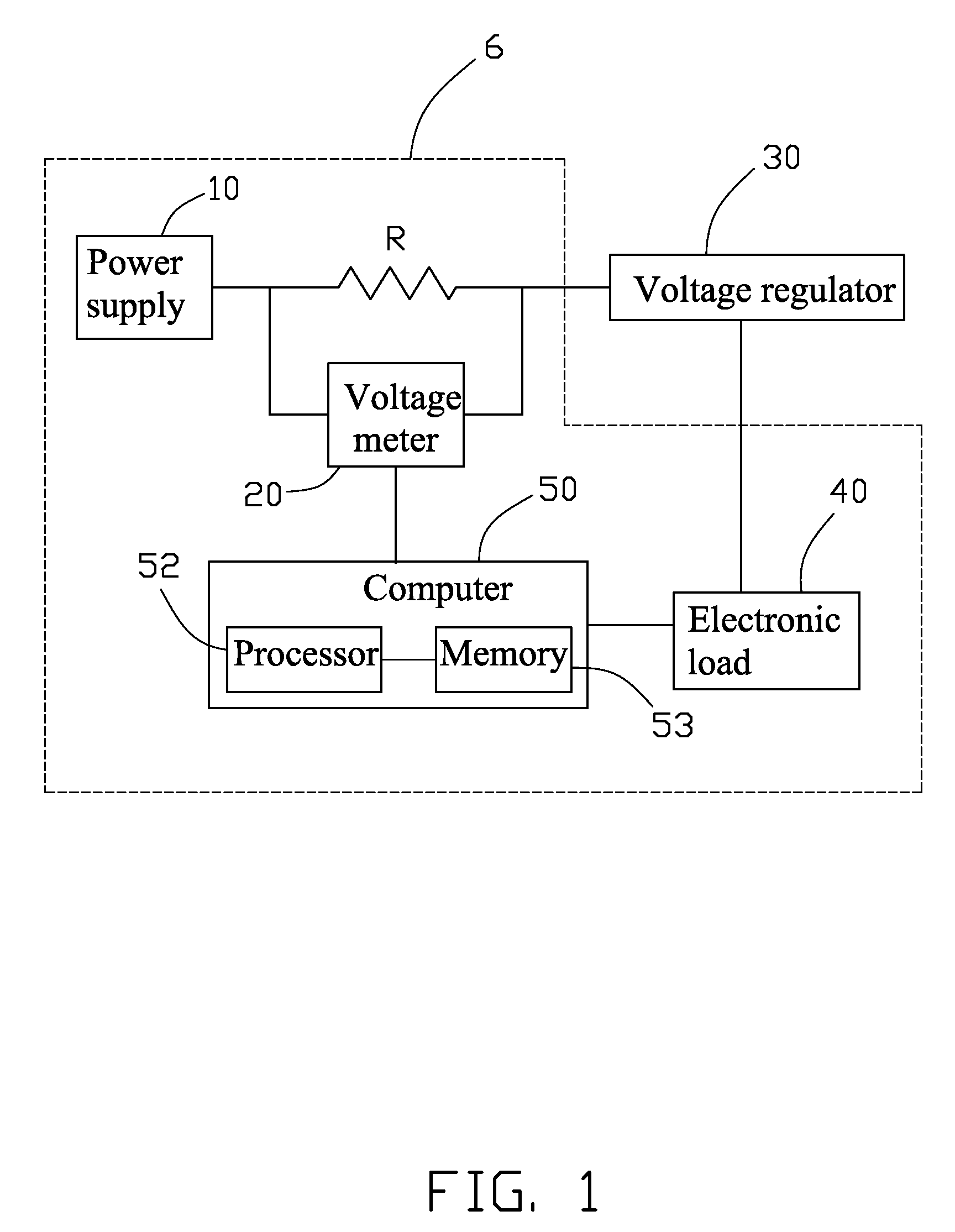

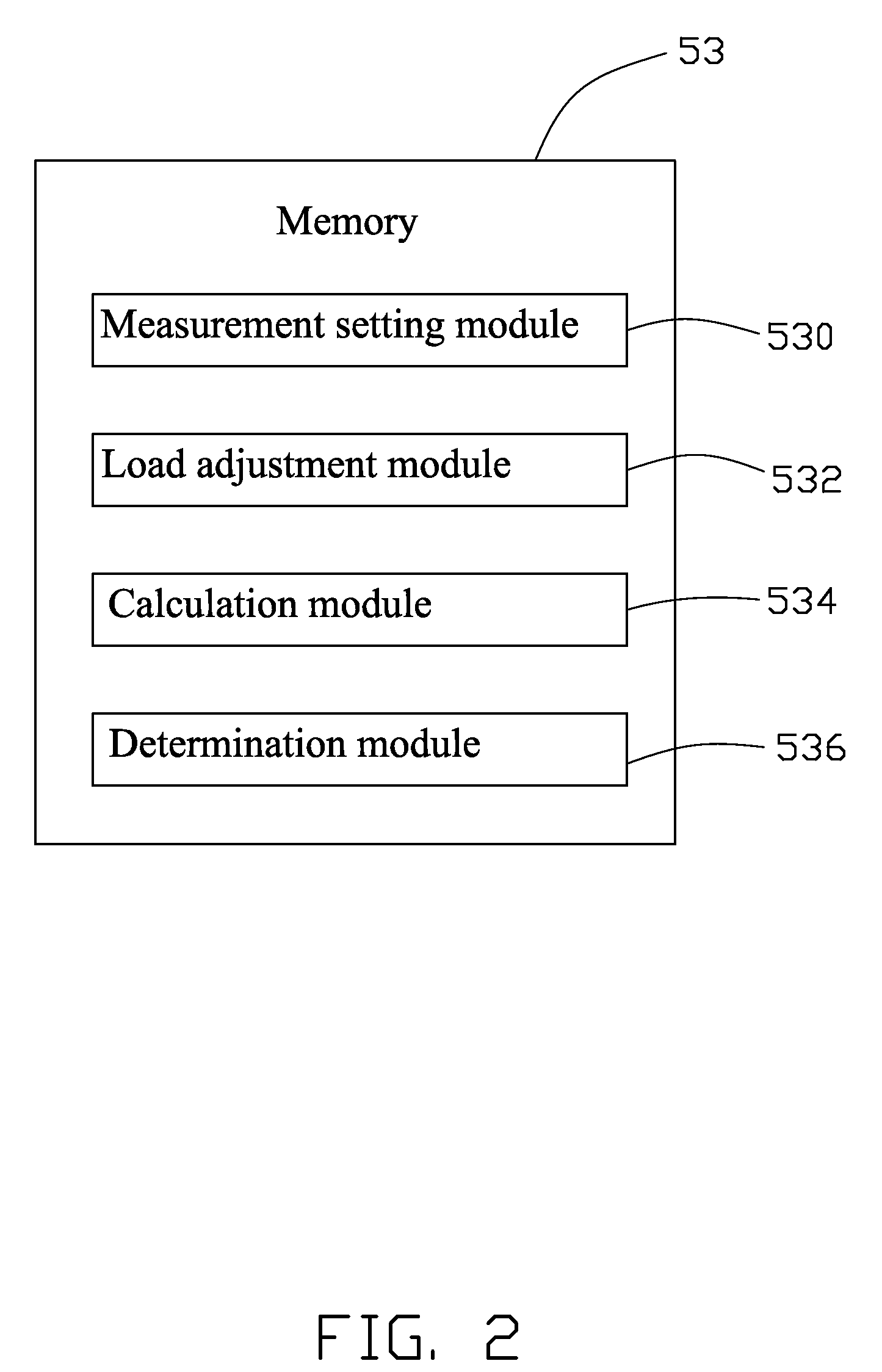

Power conversion efficiency measurement system and method

InactiveUS7928720B2Measurement using dc-ac conversionMeasurement using ac-dc conversionElectronic loadComputer module

A system measures power conversion efficiency of a voltage regulator. A measurement setting module presets a maximum output current and a total measurement number, and calculates each target output current of the voltage regulator. A load adjustment module adjusts an impedance of the electronic load to equal current passing through the electronic load to the target output current of the voltage regulator. A calculation module calculates each output power and input power, and power conversion efficiencies for each sequence number of measurement.

Owner:HON HAI PRECISION IND CO LTD

In-line process measurement systems and methods

ActiveUS8212216B2Improve signal-to-noise ratioGood accuracy and precisionRadiation pyrometryAbsorption/flicker/reflection spectroscopyProcess measurementTotal measurement

A method of using multivariate optical computing in real-time to collect instantaneous data about a process stream includes installing an optical analysis system proximate a process line, the process line being configured to move a material past a window of the optical analysis system; illuminating a portion of the material with a light from the optical analysis system; directing the light carrying information about the portion through at least one multivariate optical element in the optical analysis system to produce an instantaneous measurement result about the portion; and continuously averaging the instantaneous measurement result over a period of time to determine an overall measurement signal of the material.

Owner:HALLIBURTON ENERGY SERVICES INC

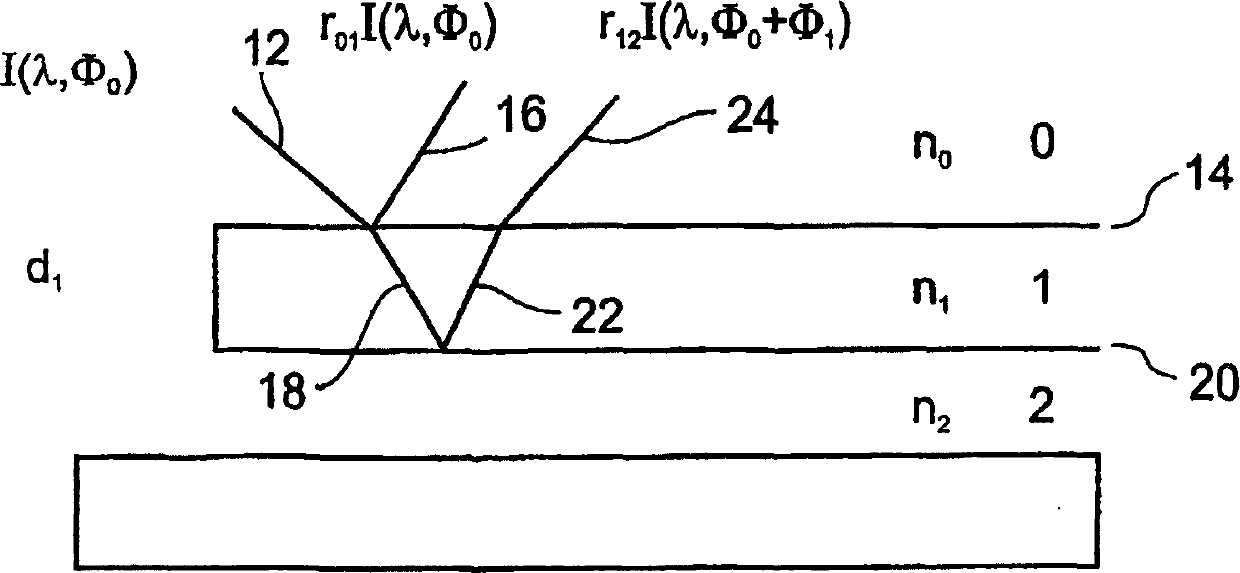

Method and a device for measuring the power of an ophthalmic lens by combined feeling and contactless overall measurement

The invention concerns a method comprising a step of contact-free optical measuring of the local value of at least one optical refraction characteristic of said lens on a local zone delimited about said measuring point of the lens, at least one step of tracing said lens during which the axial position of said measuring point on one of the sides of the lens is determined; combining the axial position of the measuring point obtained by tracing with the local value of the lens optical characteristic at the measuring point determined on the basis of the contact-free optical measurement, to deduce therefrom at least one front optical power of the lens in that measuring point.

Owner:ESSILOR INT CIE GEN DOPTIQUE

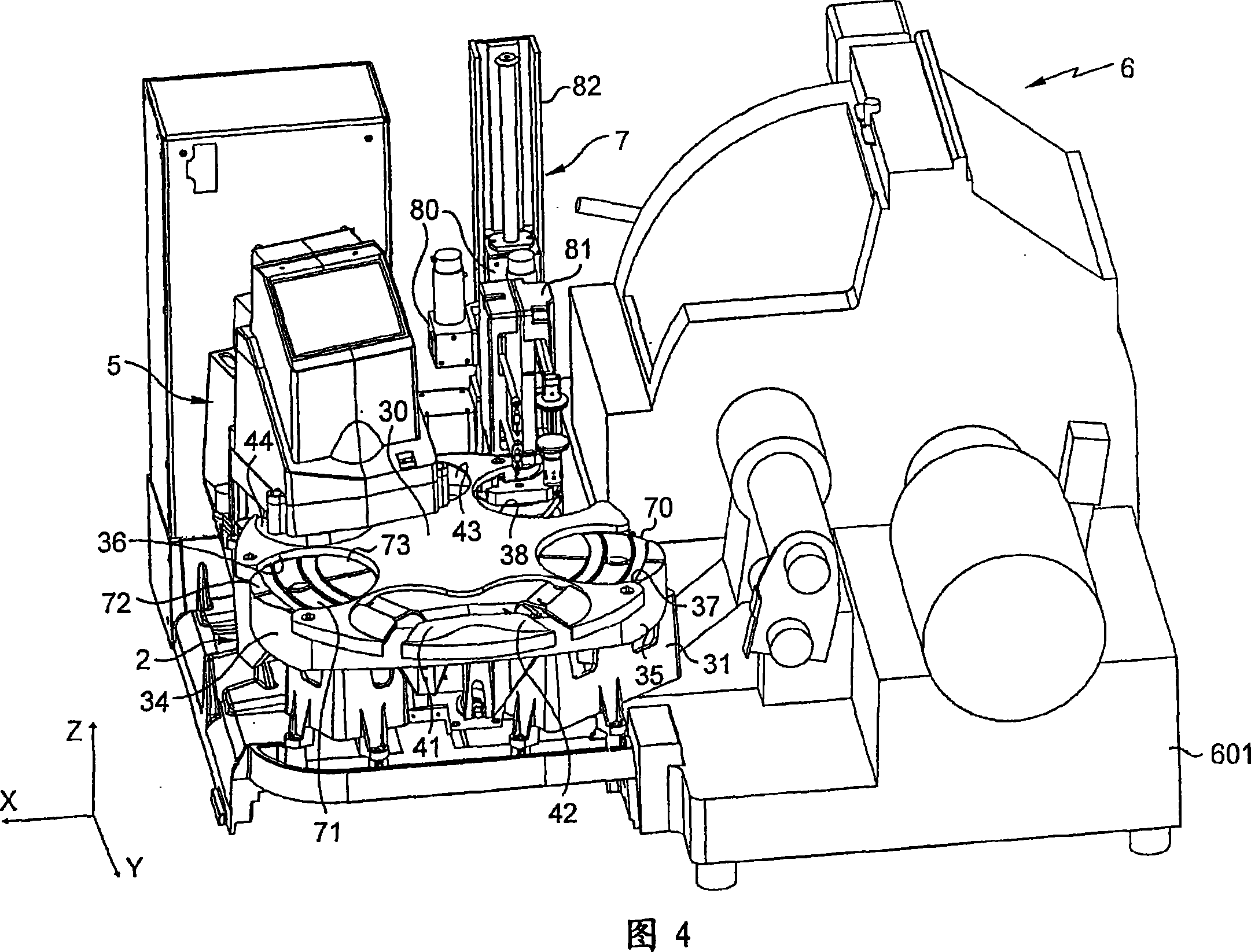

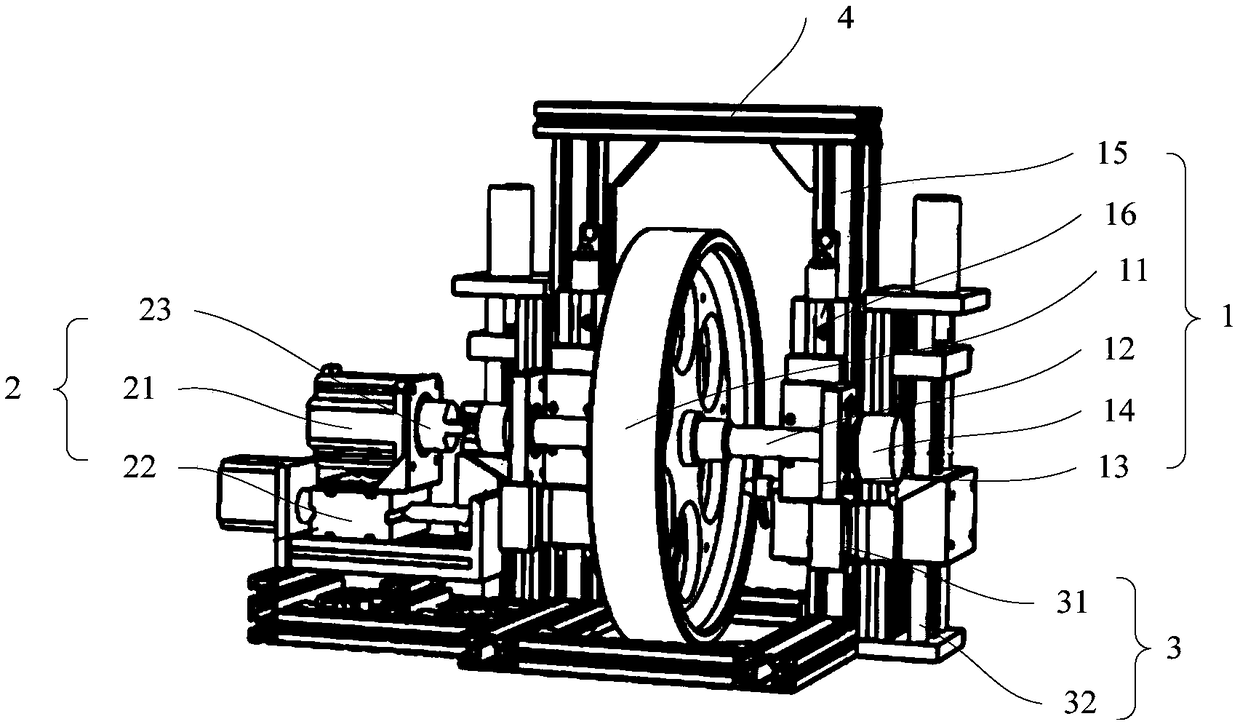

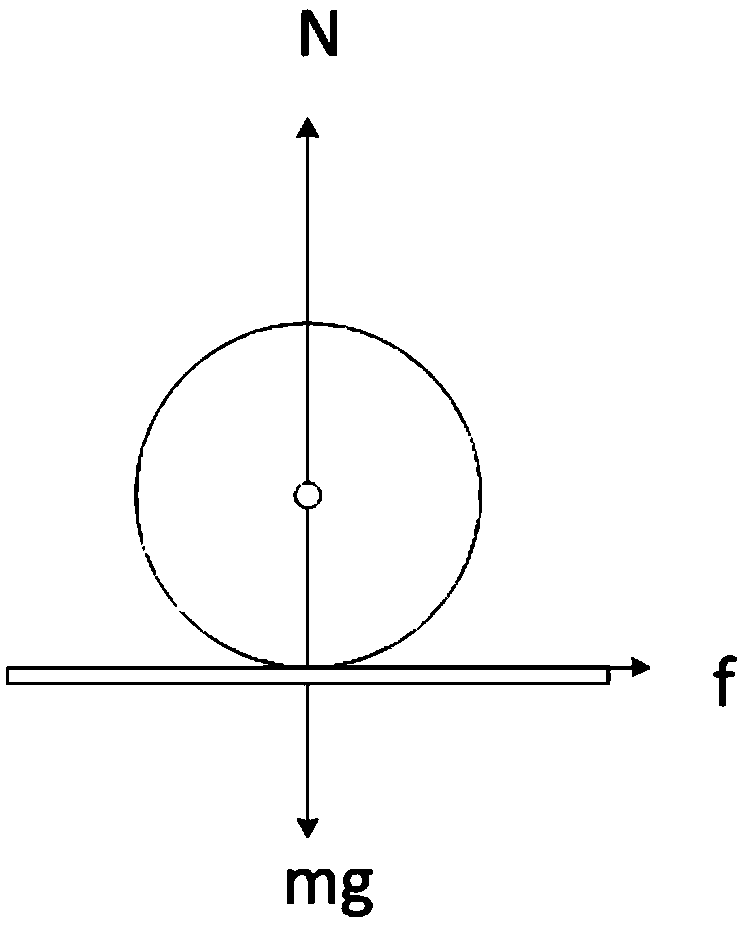

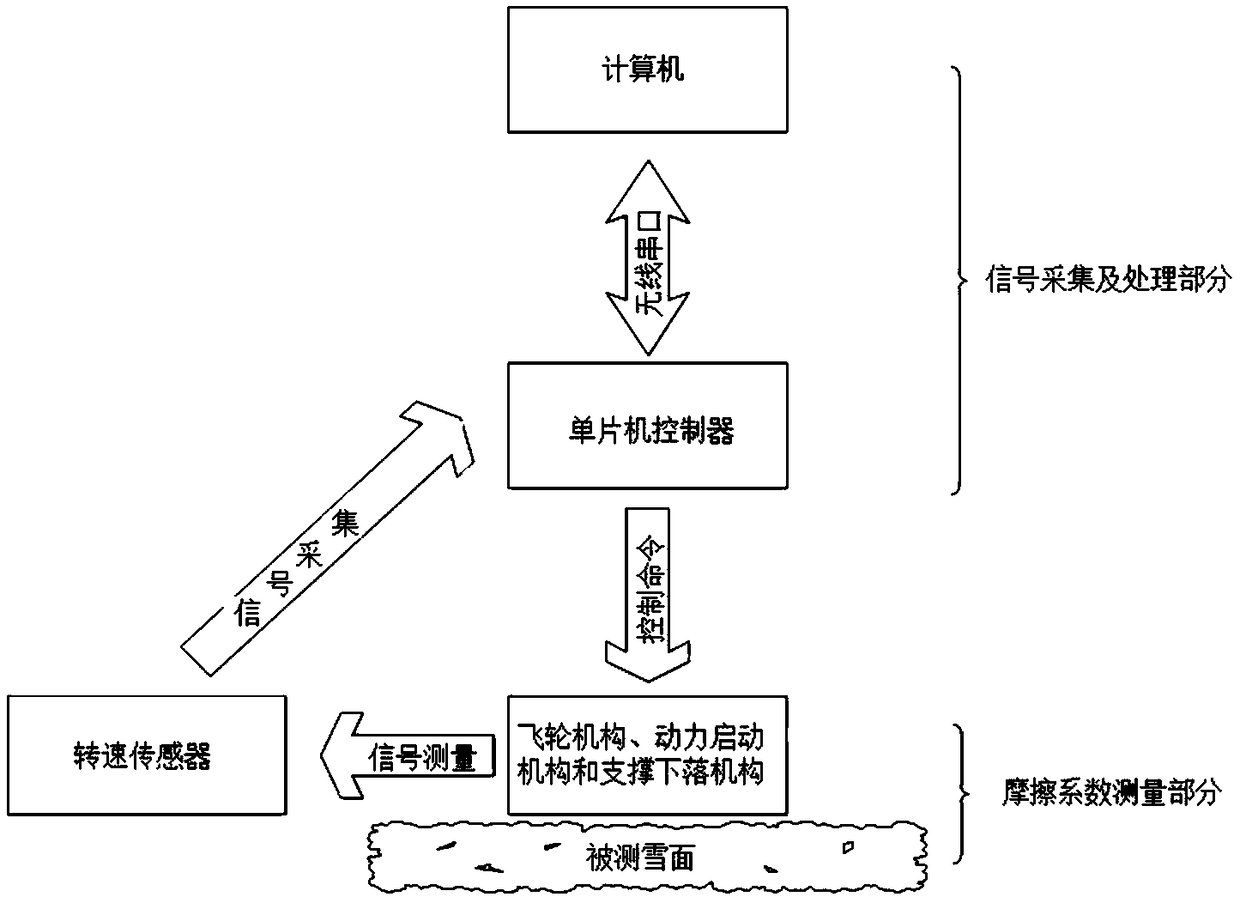

Snowfield friction coefficient measuring device and measuring method

InactiveCN109507106ASimple structureEasy to controlUsing mechanical meansMaterial analysisEngineeringFlywheel

The application relates to the technical field of snowfield friction coefficient measuring, in particular to a snowfield friction coefficient measuring device and a measuring method. The snowfield friction coefficient measuring device comprises a flywheel mechanism, a power starting mechanism and a supporting falling mechanism, wherein the flywheel mechanism comprises a flywheel, a supporting shaft, a bearing pedestal and a rotating speed sensor; the flywheel rotates with the supporting shaft as a rotating shaft; two ends of the supporting shaft are separately carried on the supporting fallingmechanism through the bearing pedestal; the rotating speed sensor is arranged at one end of the supporting shaft, and is used for detecting the rotating speed of the flywheel; the power starting mechanism is detachably connected with the supporting shaft, and is used for driving the flywheel to rotate; and the supporting falling mechanism can ascend or descend, and is used for driving the flywheel mechanism to be in contact with or separated from a snowfield. In a solving process of friction coefficients, linear acceleration is converted into rotational acceleration, and the snowfield friction coefficient measuring device is simple in structure, meets the portable requirement, and has the characteristic of accurate control, and can adapt to low temperature environment of a ski field, theoverall measuring process is stable, and the measuring is convenient and accurate.

Owner:SHENYANG SPORT UNIV +1

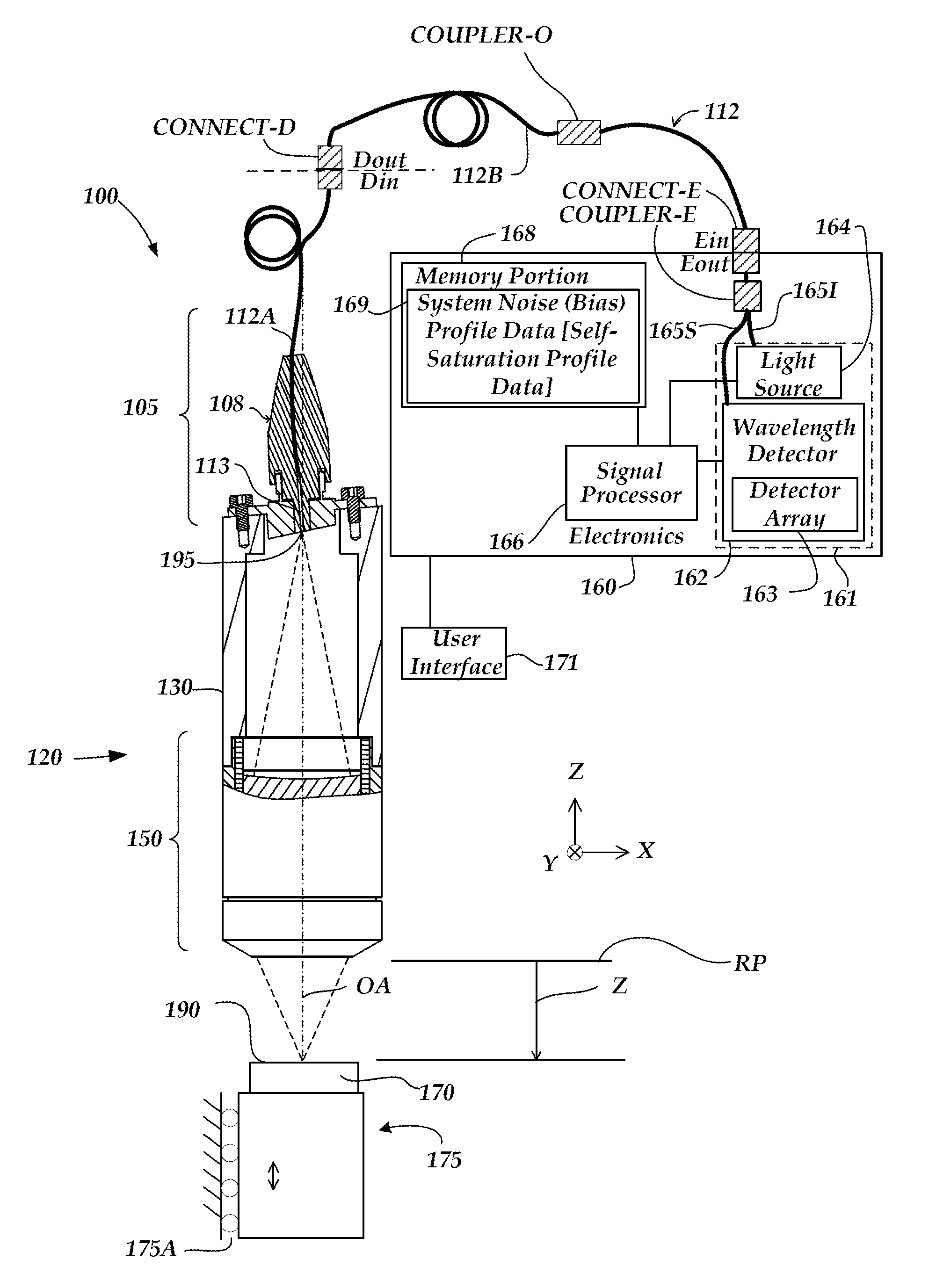

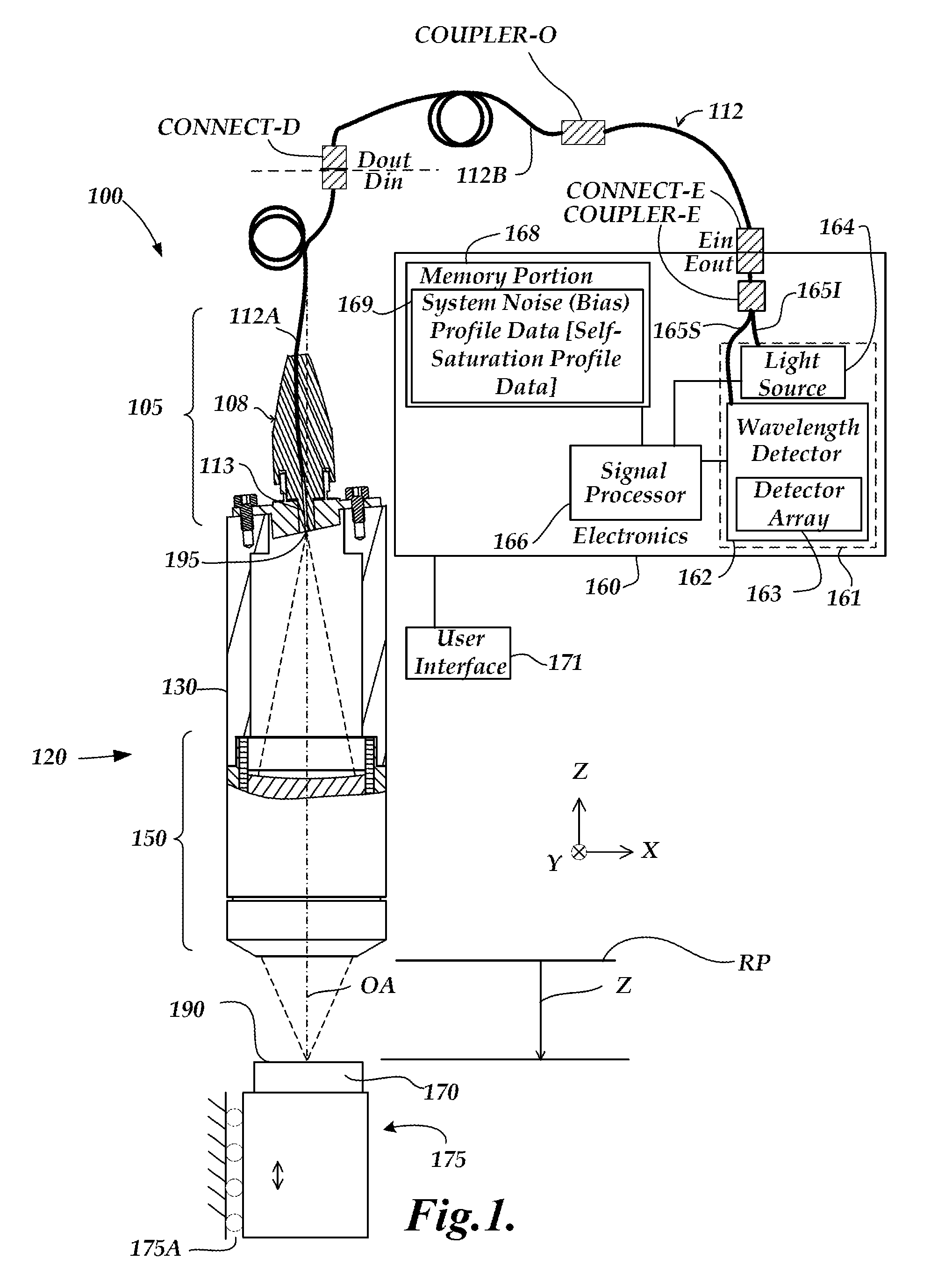

Chromatic range sensor including high sensitivity measurement mode

A method is provided for operating a chromatic range sensor (CRS) system, which may comprise a chromatic point sensor (CPS) system including an optical pen, to measure a low reflectivity surface. The CRS system may include a high sensitivity measurement mode in which it uses an unconventional low sampling rate or “long” self-saturating exposure time, to measure the low reflectivity surface. The “long” self-saturating exposure time may cause one or more detector pixels to self-saturate to at least a saturation threshold level, which prevents them from indicating a valid wavelength peak. Such pixels may define an invalid peak portion of a nominal total measurement range. The CRS may still detect a valid wavelength peak or height measurement, when the surface is located in a valid subset of the nominal total measurement range of the CRS system determined such that it excludes the invalid peak portion.

Owner:MITUTOYO CORP

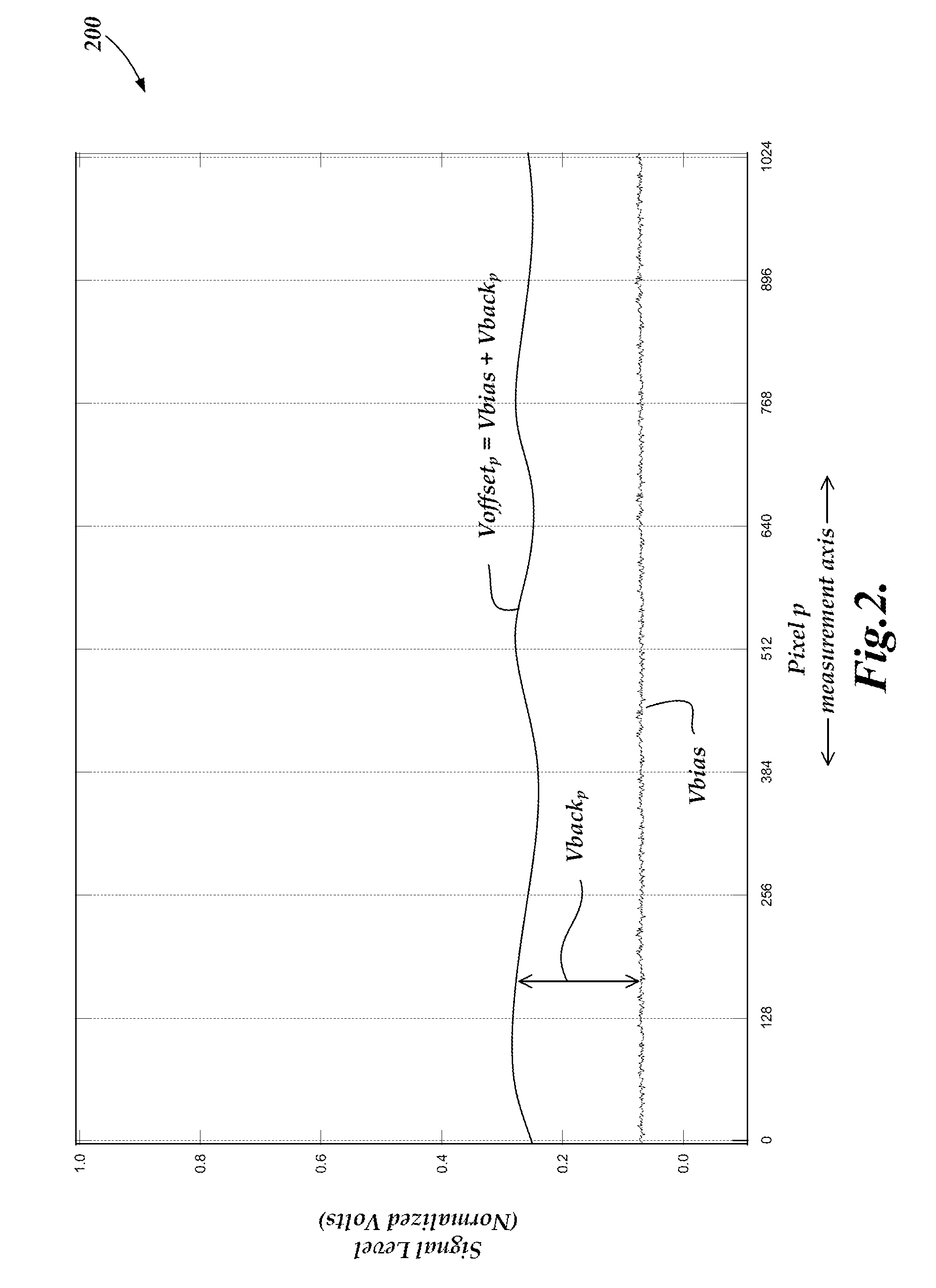

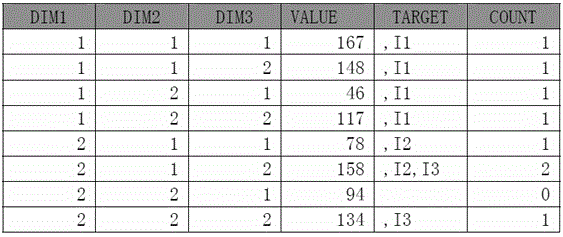

Indicator calculating method and system based on dimension combinations

ActiveCN105354272AImprove computing powerImprove efficiencyMulti-dimensional databasesSpecial data processing applicationsAlgorithmTotal measurement

Embodiments of the present invention provide an indicator calculating method and system based on dimension combinations. The method comprises: acquiring common attributes, dimensions, and measurement values of all data, wherein each piece of data has at least two dimensions; statistically acquiring all dimension combinations in the data, wherein a total measurement value of the dimension combinations is a sum of measurement values of all data comprised by the dimension combinations; generating a dimension statistics table, wherein each row of the dimension statistics table represents a dimension combination, and the dimension statistics table comprises at least: columns that represent dimensions, columns that represent total measurement values corresponding to the dimension combinations, and columns that represent dimension combinations subjected to indicator statistics; acquiring all indicators, wherein each indicator is a statistical condition defined by a dimension value range of several dimensions in a dimension combination; determining a dimension combination represented by each indicator, and adding a label to the corresponding dimension combination in the dimension statistics table; and traversing each row of the dimension statistics table, and determining whether there is a row that is labelled more than once or not labelled.

Owner:CHINACCS INFORMATION IND

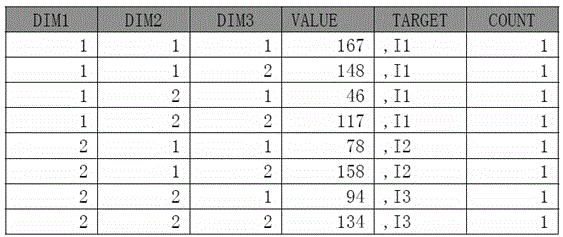

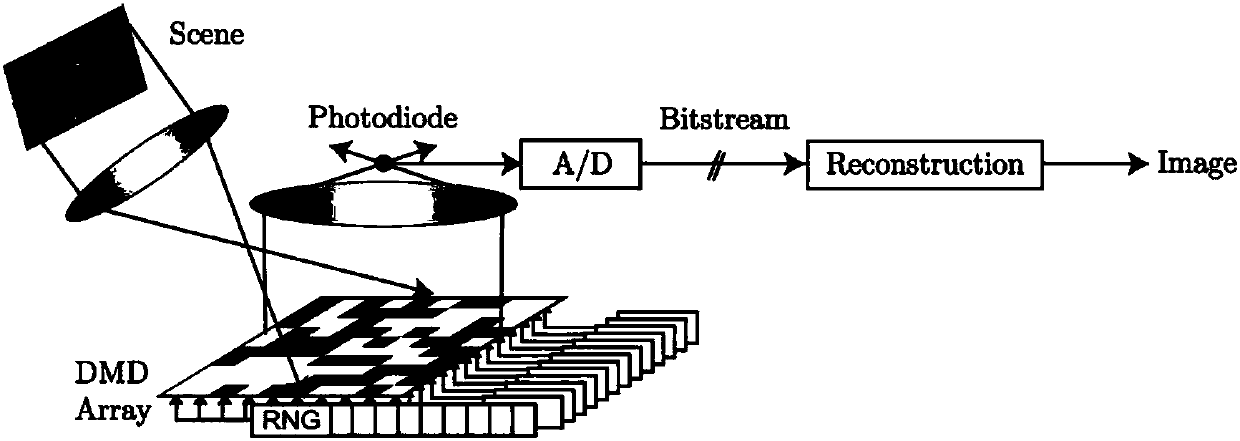

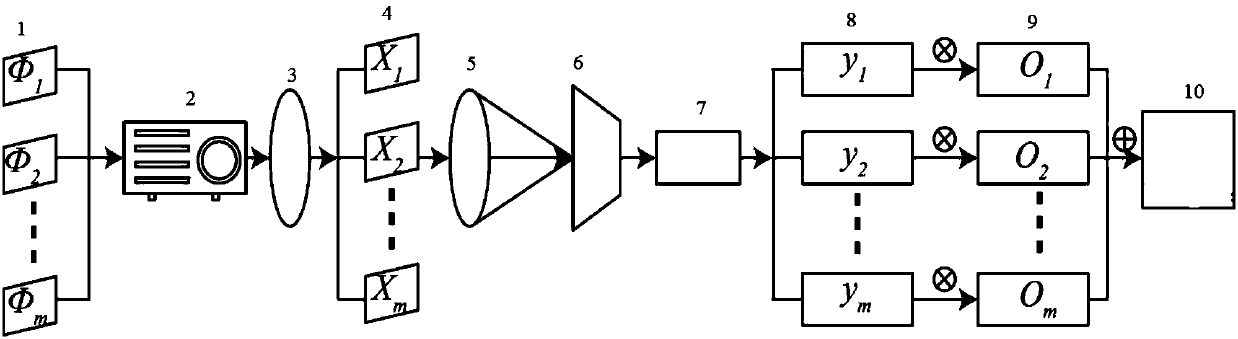

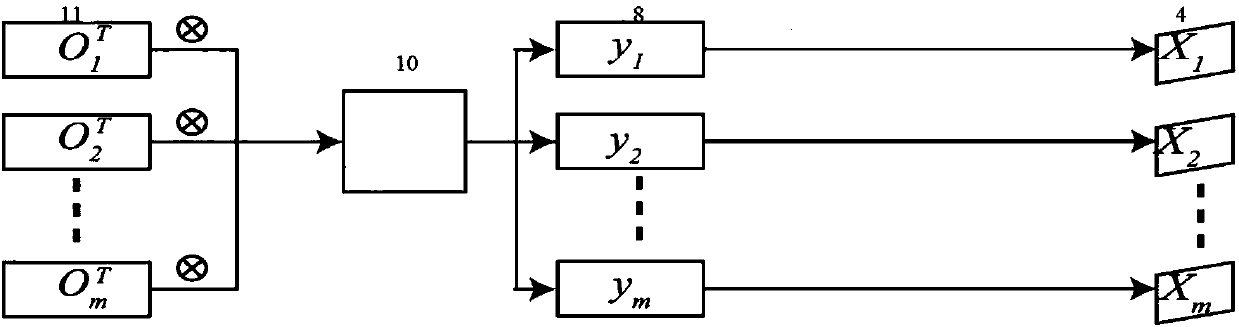

Method for hiding multiple images in QR code based on compressed sensing and orthogonal modulation

InactiveCN107948461AAchieve hiddenIncrease flexibilityPictoral communicationQuadrature modulationOrthogonal collocation

The invention discloses a method for hiding multiple images in a QR code based on compressed sensing and orthogonal modulation, and belongs to the field of optical image hiding and encryption. According to the method disclosed by the invention, a total measurement value expressed by decimal numerals of multiple images is obtained by using the compressed sensing and orthogonal modulation technologyand is stored in the form of the QR code; during decoding, the QR code is scanned by using a mobile phone or other photoelectric devices to obtain the total measurement value again, and then block reconstruction of the whole image or the partial reconstruction in the multiple images is achieved according to the needs. From an optical encryption point of view, the compressed sensing and orthogonalmodulation process of the invention can also be considered as two security levels, which must be completely correct at two levels to obtain the reconstructed images, and thus having good encryption performance.

Owner:SICHUAN UNIV

Assessment and optimization for metrology instrument

InactiveUS20050222804A1Semiconductor/solid-state device testing/measurementDigital computer detailsMetrologySystem under test

Methods and related program product for assessing and optimizing metrology instruments by determining a total measurement uncertainty (TMU) based on precision and accuracy. The TMU is calculated based on a linear regression analysis and removing a reference measuring system uncertainty (URMS) from a net residual error. The TMU provides an objective and more accurate representation of whether a measurement system under test has an ability to sense true product variation.

Owner:INT BUSINESS MASCH CORP

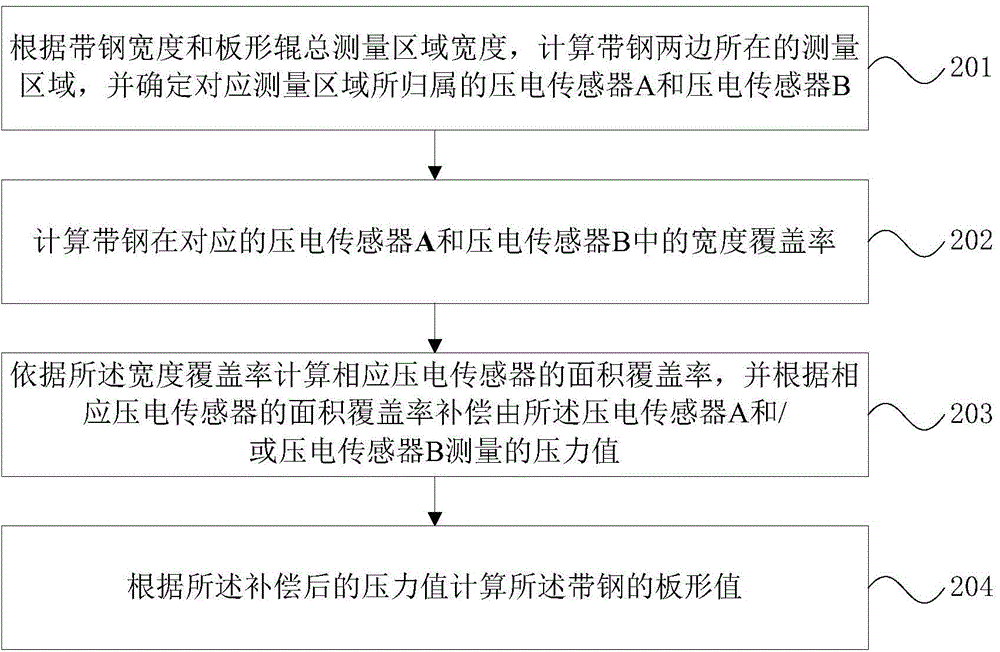

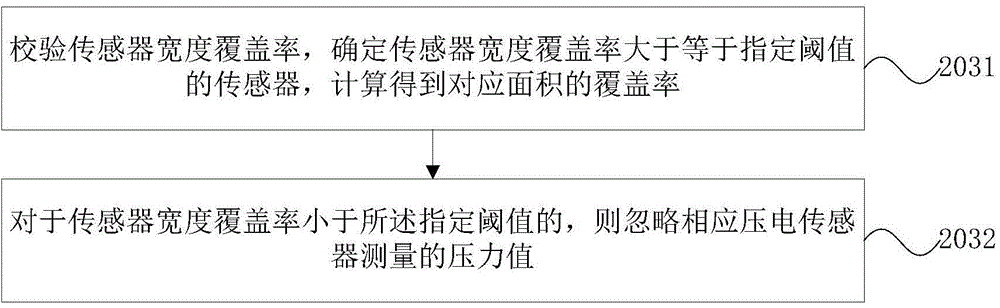

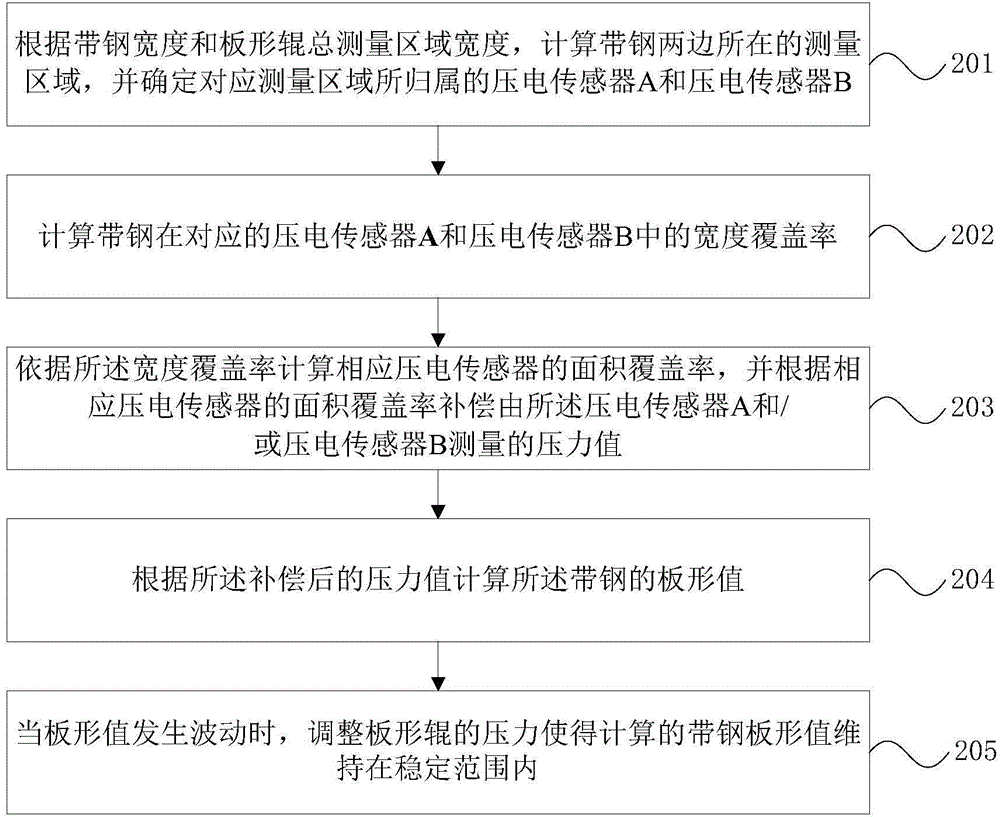

Edge portion measurement signal compensation method and device for contact type plate-shaped roller

The invention is suitable for the field of strip steel cold rolling, and provides an edge portion measurement signal compensation method for a contact type plate-shaped roller. The plate-shaped roller is provided with n piezoelectric sensors. The method includes the steps of calculating measurement areas where the two edges of strip steel are located according to the width of the strip steel and the width of a total measurement area of the plate-shaped roller, determining the piezoelectric sensor A and the piezoelectric sensor B which belong to the corresponding measurement areas, calculating the width coverage rates of the strip steel in the corresponding piezoelectric sensor A and the piezoelectric sensor B, calculating the area coverage rates of the corresponding piezoelectric sensors according to the width coverage rates, compensating for the pressure value measured through the piezoelectric sensor A and / or the piezoelectric sensor B according to the area coverage rates of the corresponding piezoelectric sensors, and calculating the plate shape value of the strip steel according to the pressure value which is compensated for. By means of the method, the width coverage rates of the piezoelectric sensors where the edges of the two sides of the strip steel are located are converted into the area coverage rates, the pressure value of the corresponding sensors is compensated for on the basis of the area coverage rates, and the true plate shape value of the strip steel is obtained through the pressure value which is compensated for.

Owner:WISDRI ENG & RES INC LTD

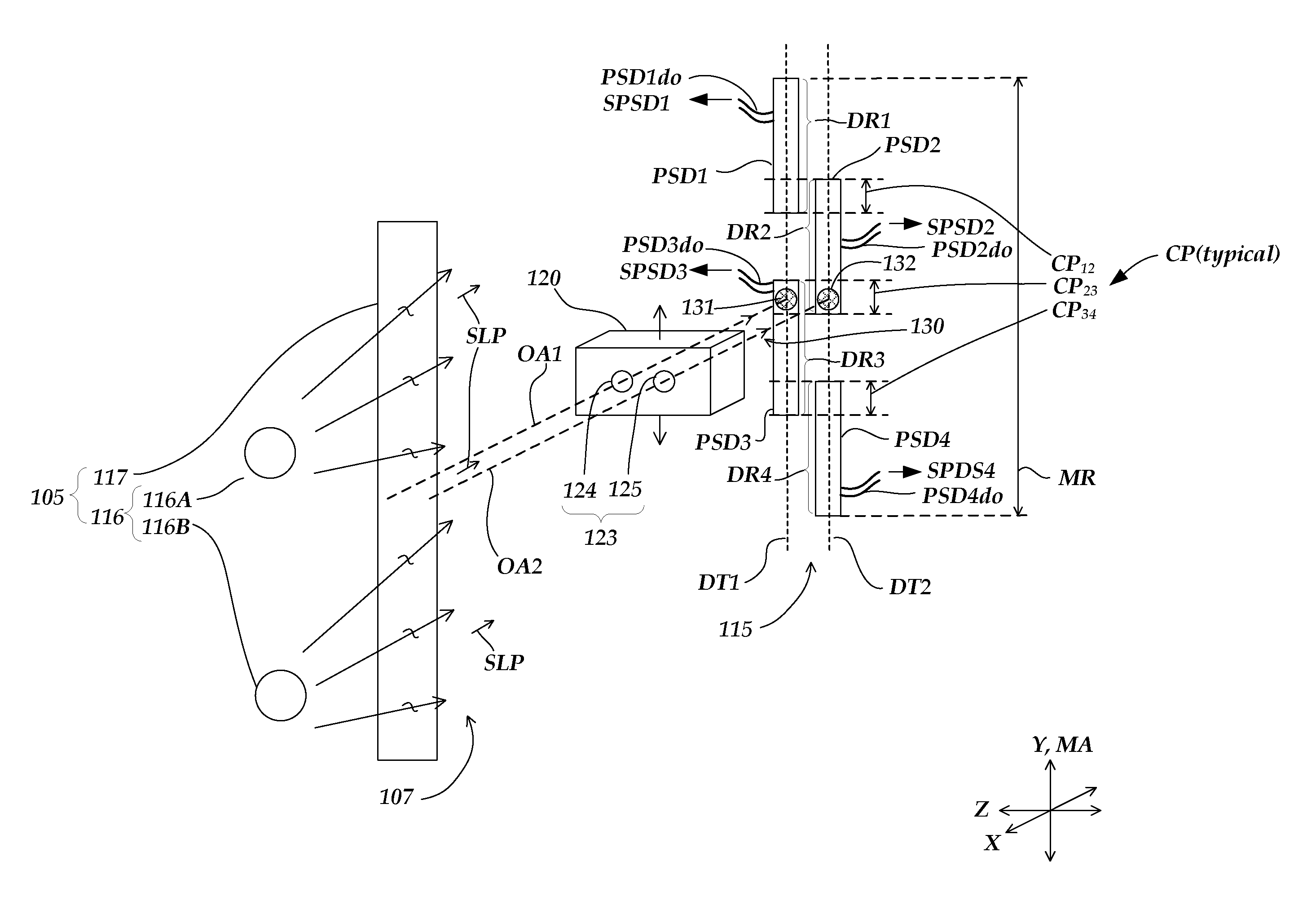

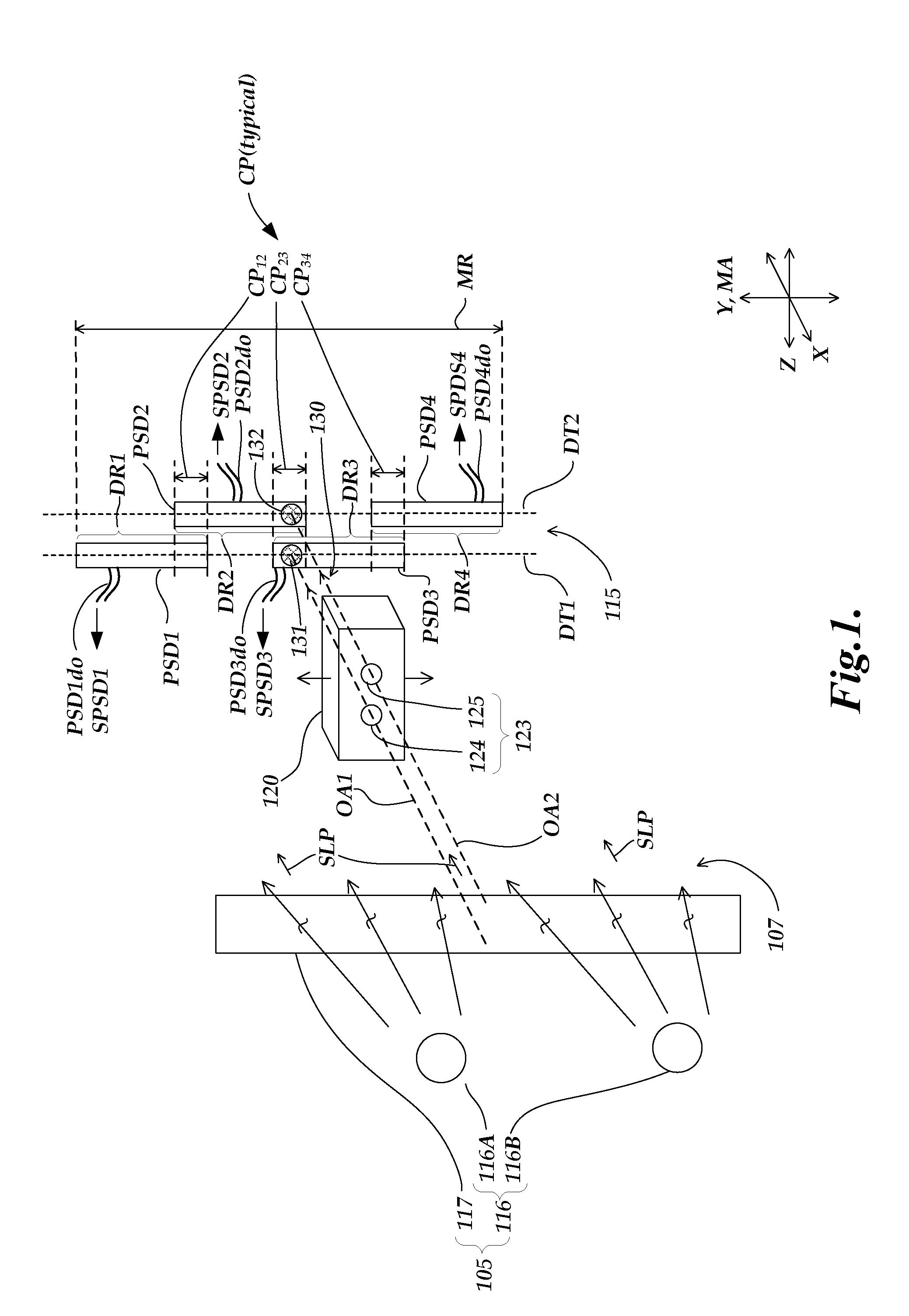

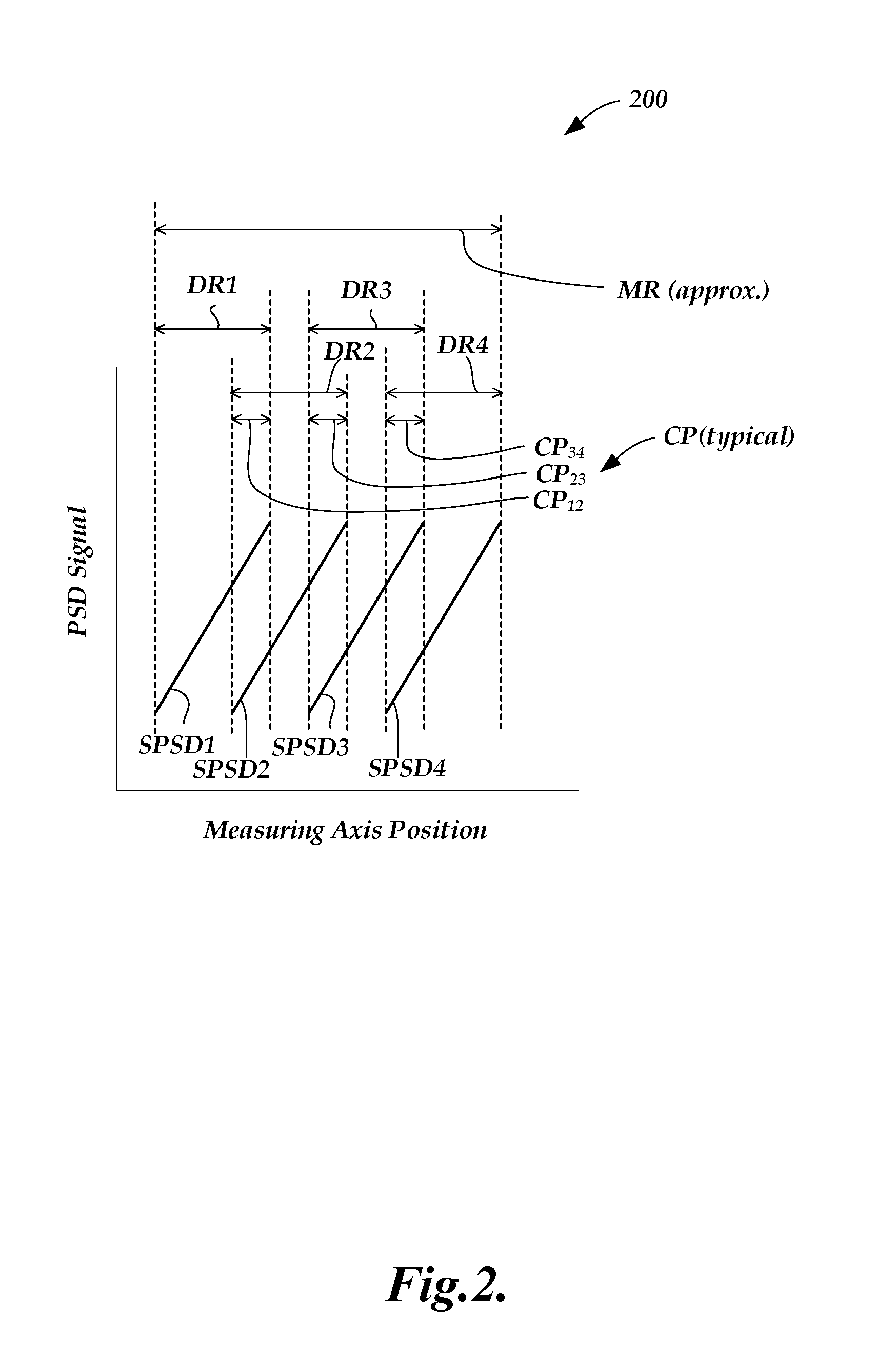

Displacement sensor using multiple position sensitive photodetectors

ActiveUS20120262733A1Using optical meansConverting sensor outputPhotovoltaic detectorsImage resolution

A position sensing device having a high range to resolution ratio comprises a light source arrangement, a moving aperture arrangement and a multiple position sensitive detector (PSD) arrangement. The multiple PSD arrangement comprises a plurality of position sensitive detectors arranged along at least two detection tracks along a measuring axis. Each of the plurality of position sensitive detectors shares a common portion of a total measuring range along the measuring axis with an adjacent position sensitive detector which is on a different detector track. The total measurement range is larger than the detector range of each of the position sensitive detectors.

Owner:MITUTOYO CORP

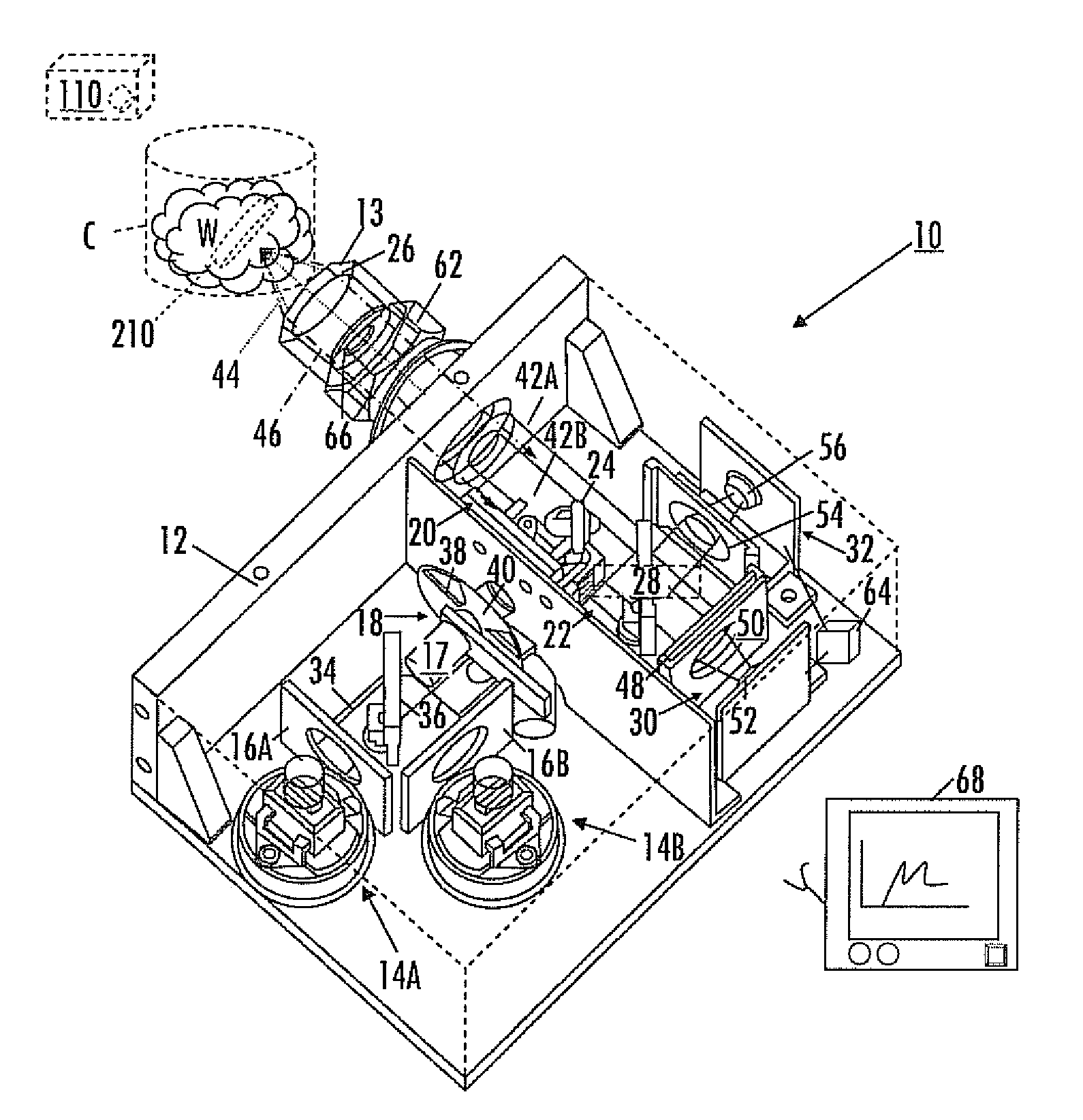

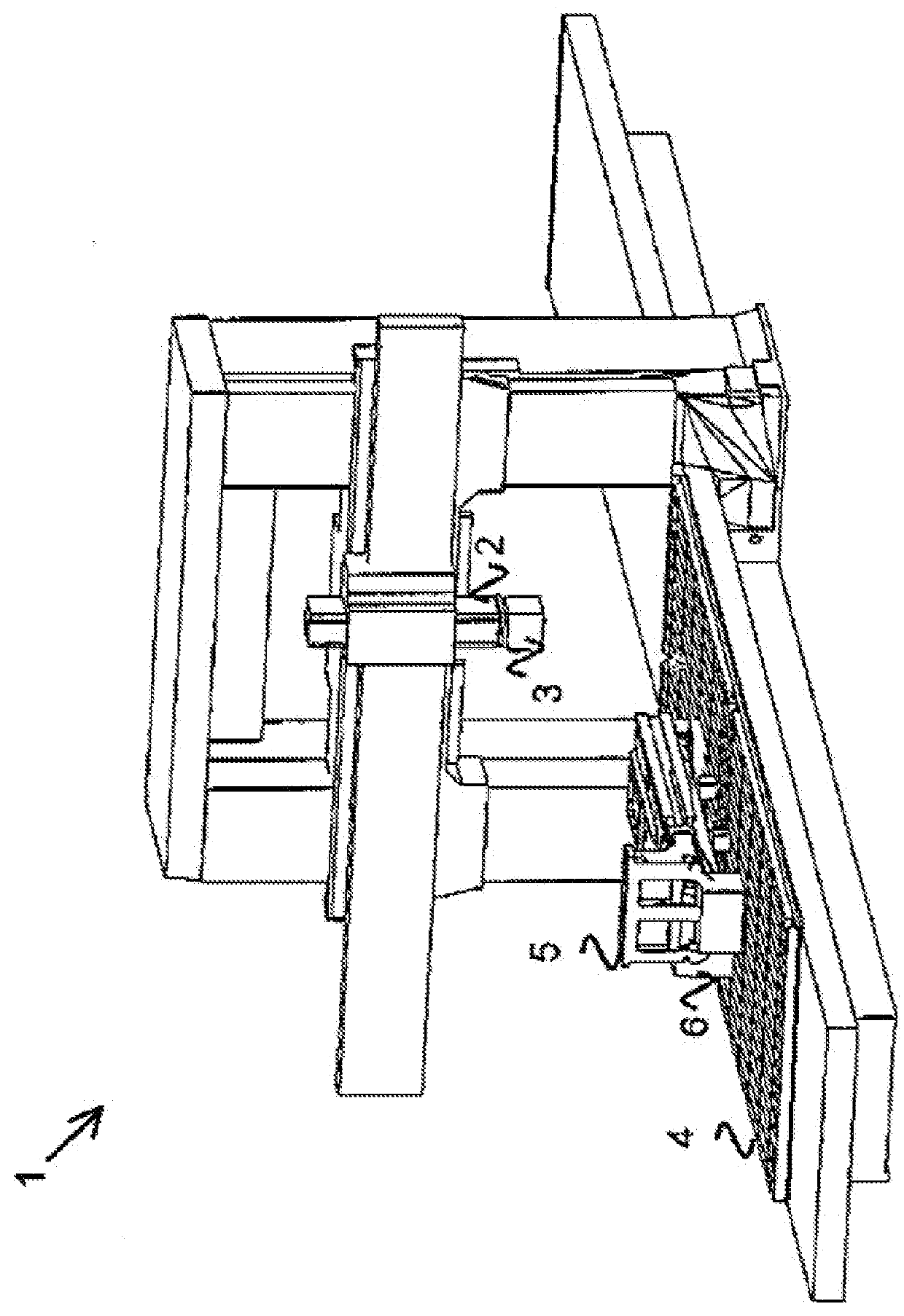

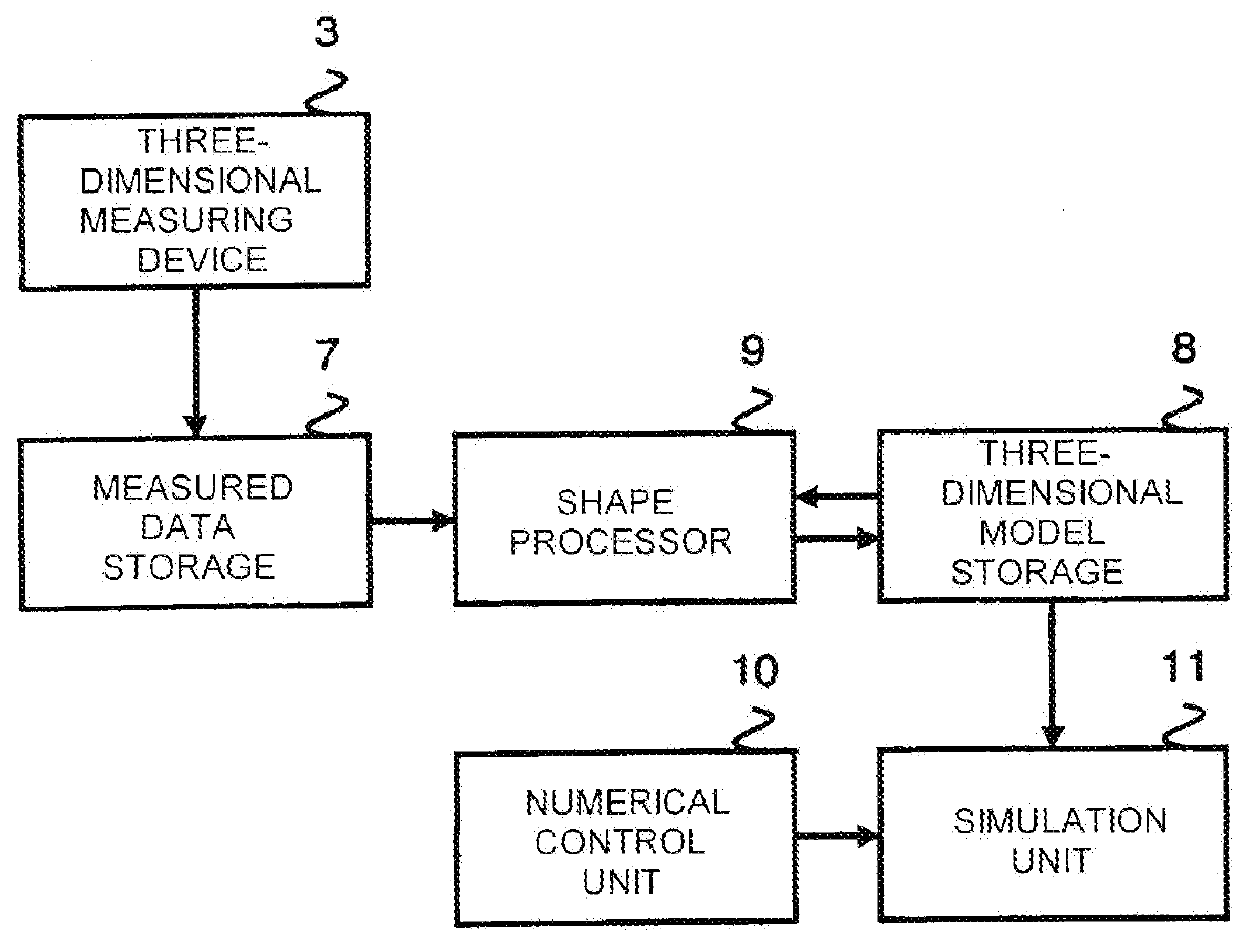

Numerical Controller

A numeric controller is provided with a three-dimensional model storage which stores a three-dimensional model of at least one of a workpiece and a jig; a three-dimensional measuring unit which integrally measures shapes of the workpiece and the jig fixed to the machine tool; and a shape processor generating an integrally measured model based on the measured data, in which the workpiece and the jig being integrally recognized, measured by the three-dimensional measuring unit, and further generating, regarding at least one of the workpiece and the jig, an individually measured model in which the workpiece or the jig is individually measured based on the generated integrally measured model and the three-dimensional model of the workpiece or the jig.

Owner:OKUMA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com