Cigarette pack lamination layer number measurement method and device by multi-camera array

A quantity measurement, multi-camera technology, applied in image data processing, instruments, calculations, etc., can solve the problems of inability to achieve super-high-stacked smoke mark image acquisition, inability to complete high-stacked paper counting tasks, and inability to balance, etc. Achieve the effect of strong real-time performance, simple use method and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below with reference to the drawings and specific embodiments of the specification.

[0027] The flow of the multi-camera array cigarette label stacked paper counting method of the present invention:

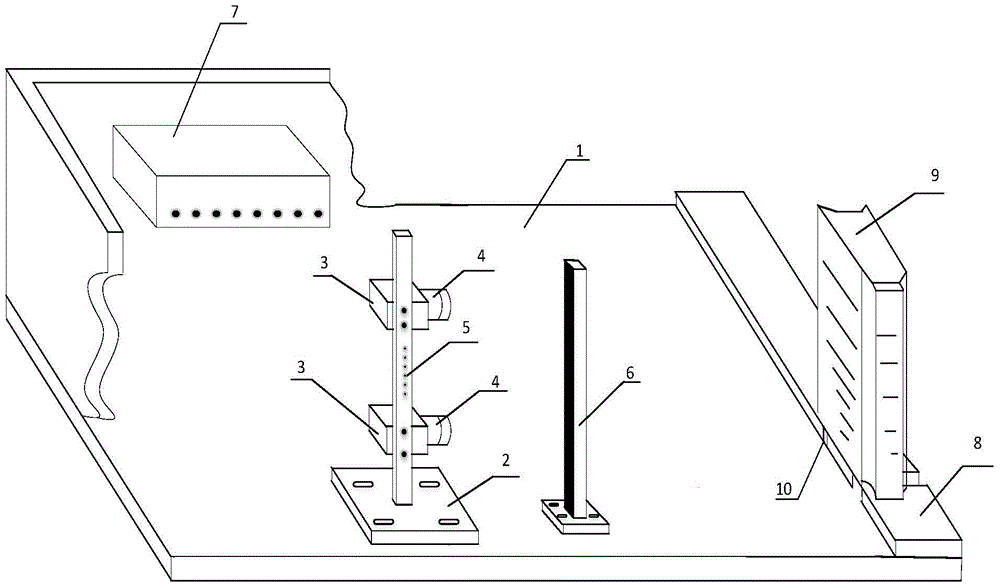

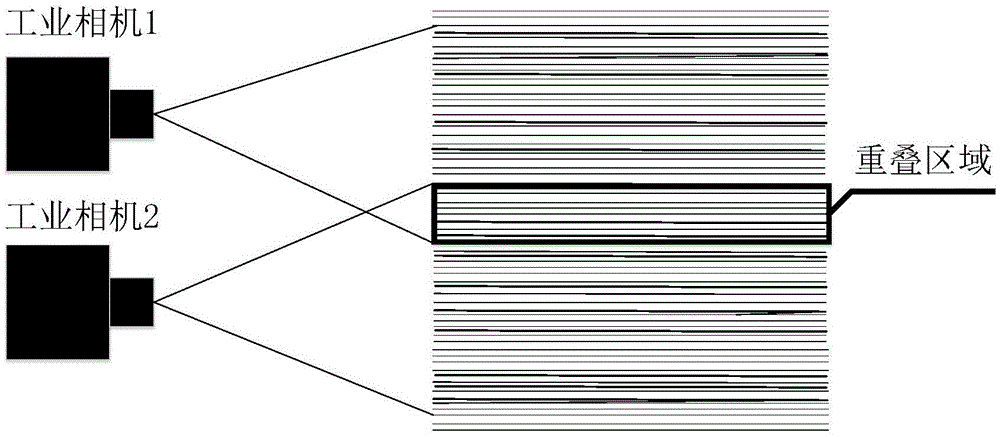

[0028] (1) Setting and adjusting the imaging device: adjust the installation position of the multi-camera array, and make the multi-camera field of view have enough overlap area, and adjust the imaging device according to the category of the current batch of products and the layer thickness, mainly including the camera position Movement, lens focus, aperture adjustment.

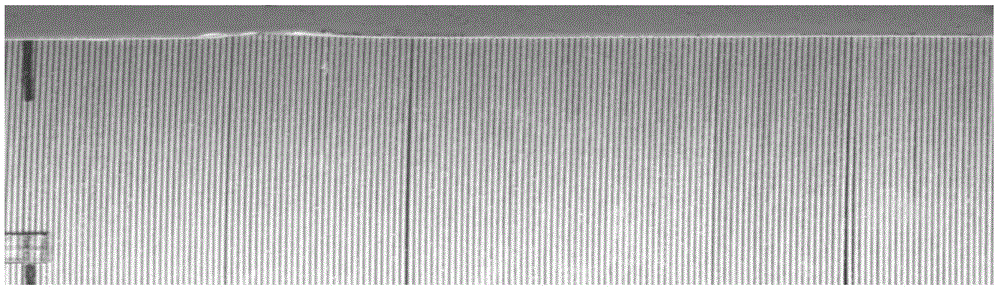

[0029] (2) Obtain the side image of the multi-camera array scanning cigarette label stack: Place the cigarette label stack on the support platform to obtain multiple scanned images with overlapping areas, and the collected images are directly sent to the straight line detection and image stitching module.

[0030] (3) The images collected by each camera a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com