Patents

Literature

356results about "Refractive power measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

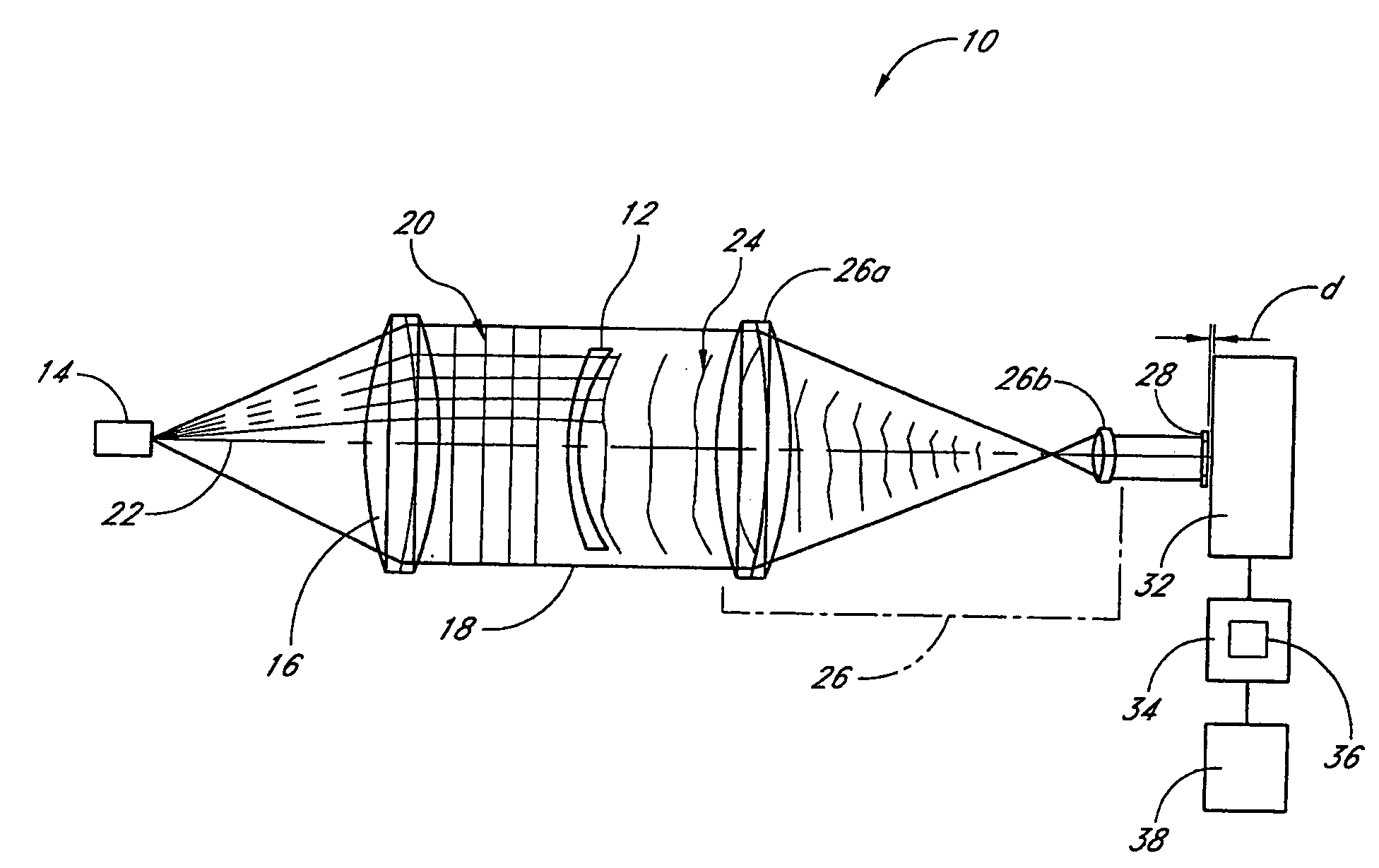

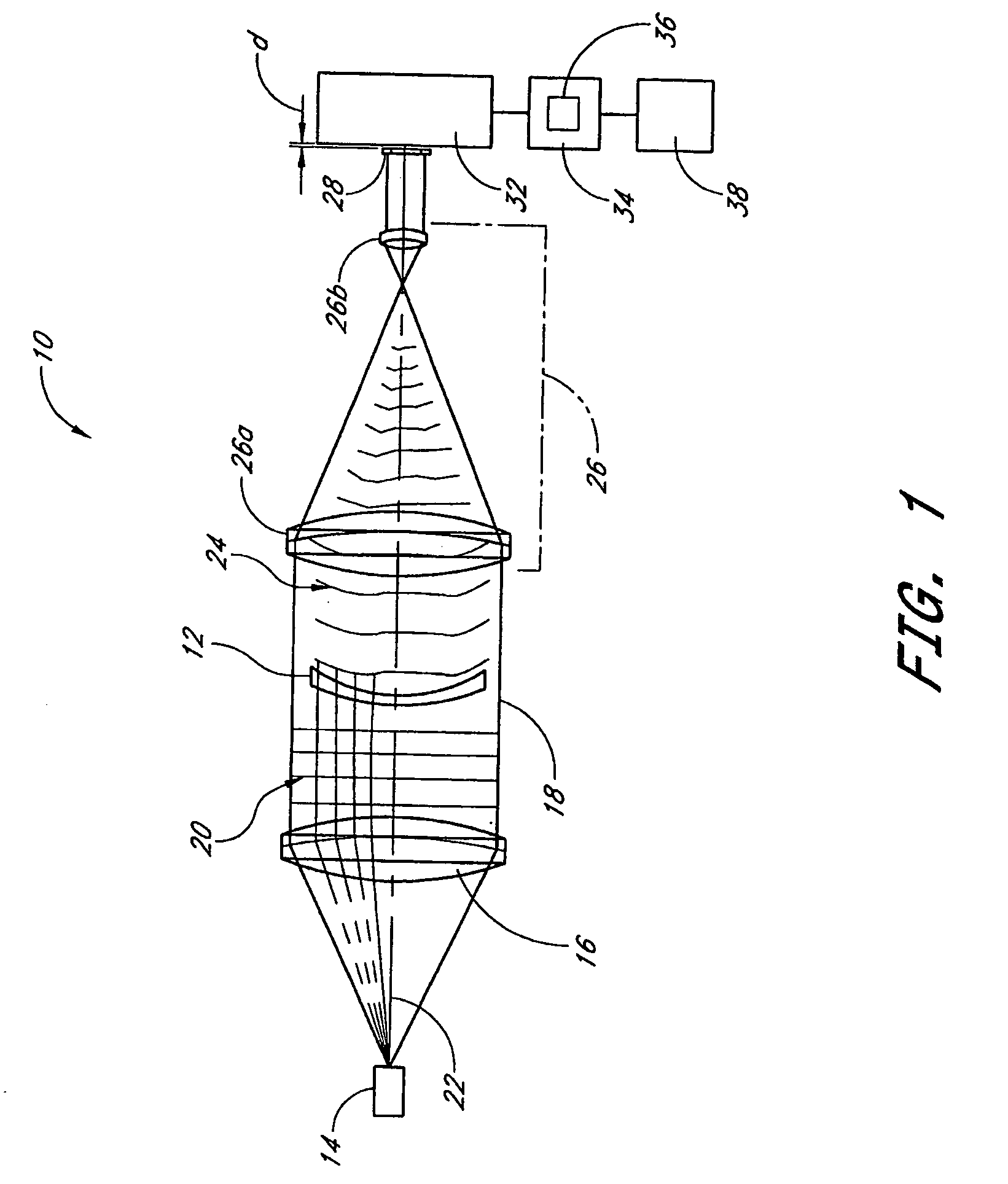

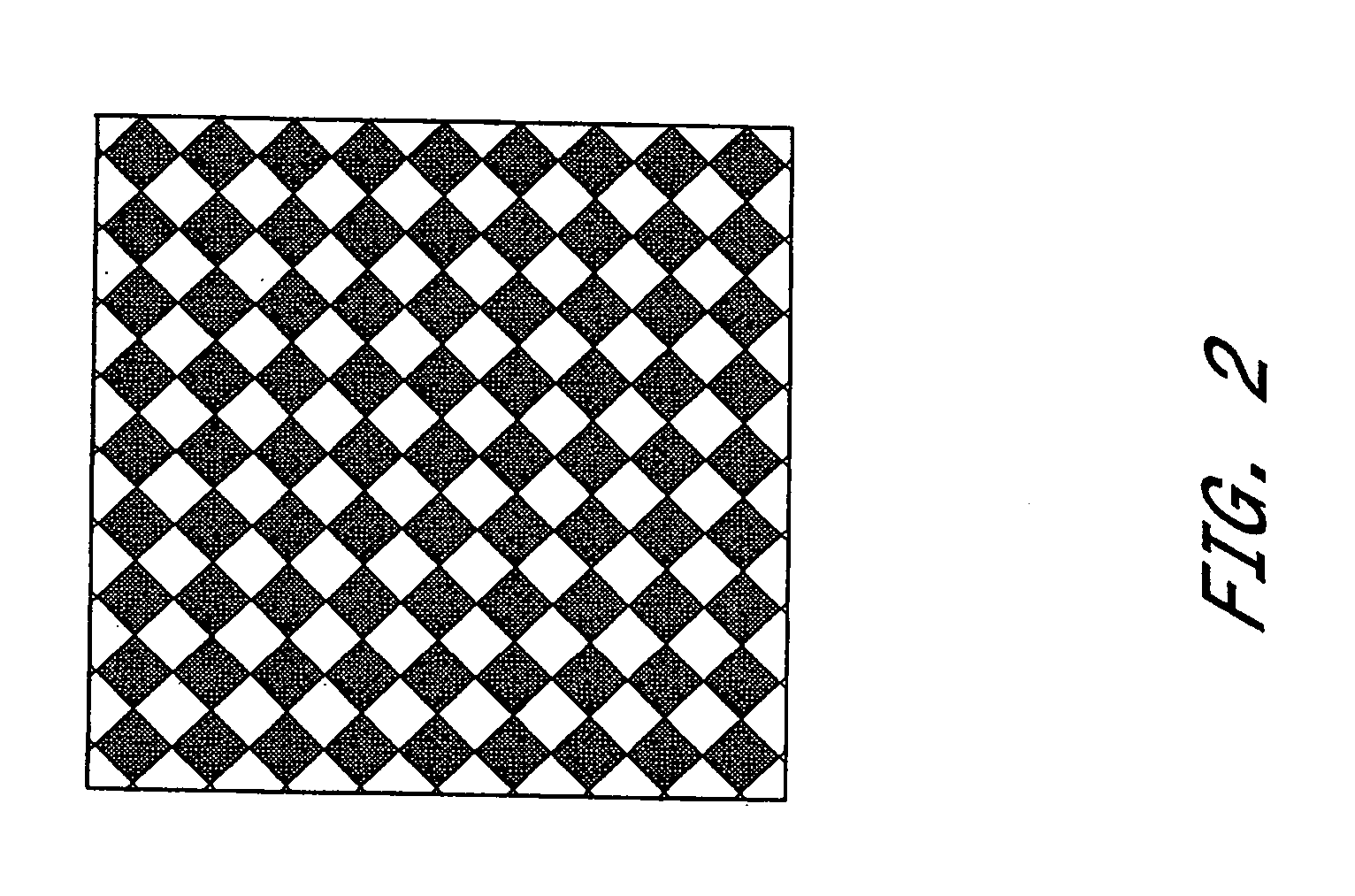

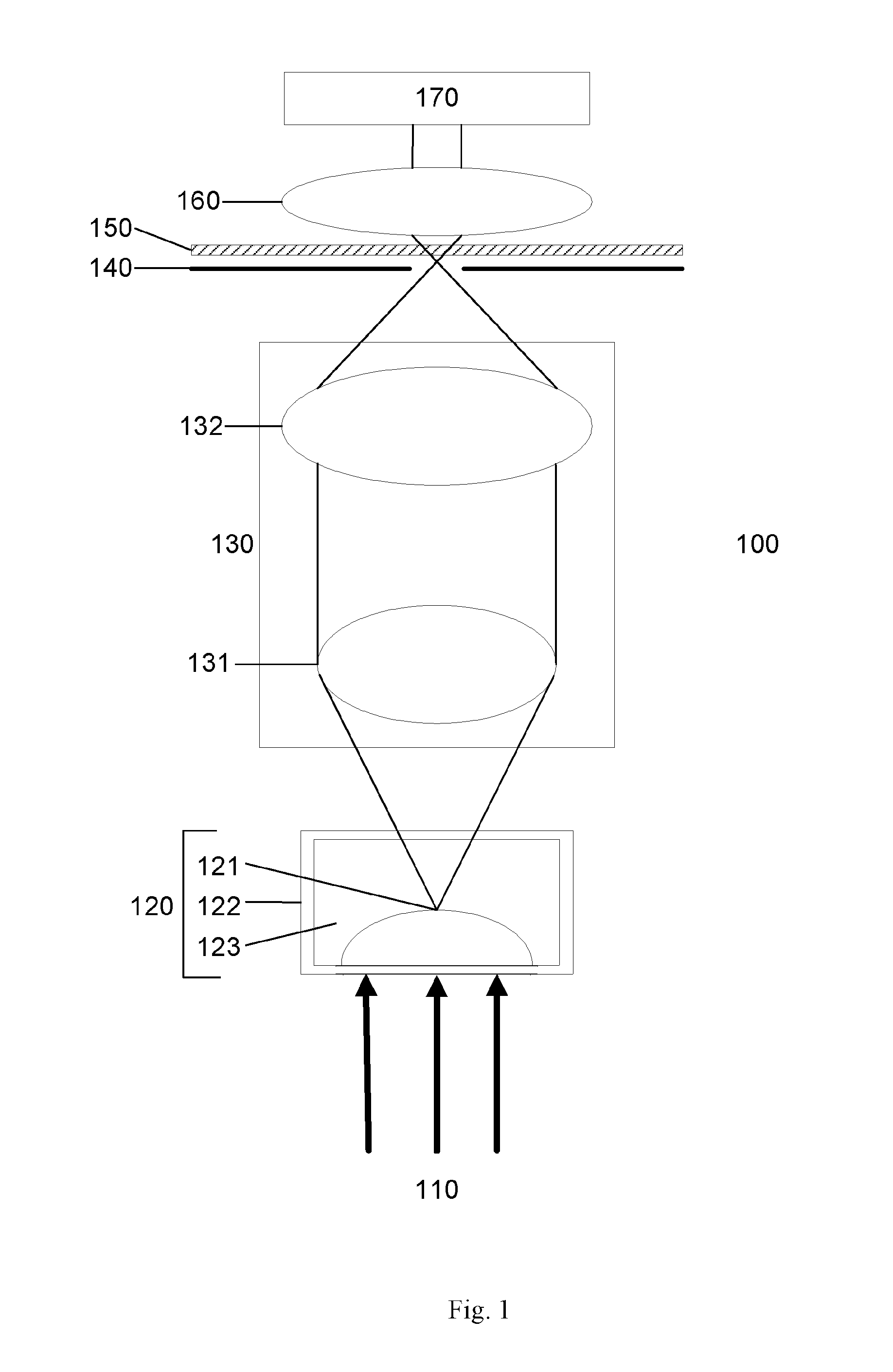

Lensometers and wavefront sensors and methods of measuring aberration

Wavefront measuring systems and methods are disclosed which may be employed, for example, in detecting phase aberrations in a spectacle lens and in an eye. Various embodiments include disposing a modulation pattern in the path of a return beam from the spectacle lens or the eye, and imaging a diffraction pattern at a self-imaging plane relative to the modulation pattern with a detector. The diffraction pattern is analyzed and the results are used to produce a representation of the wavefront phase characteristics that describe aberrations in the lens or eye being measured. Illumination and processing techniques for improving the measurement results are dislcosed. Various embodiments comprise systems adaptable to both measure aberrations in lenses in spectacles as well as in a patient's eyes.

Owner:ENTERPRISE PARTNERS VI

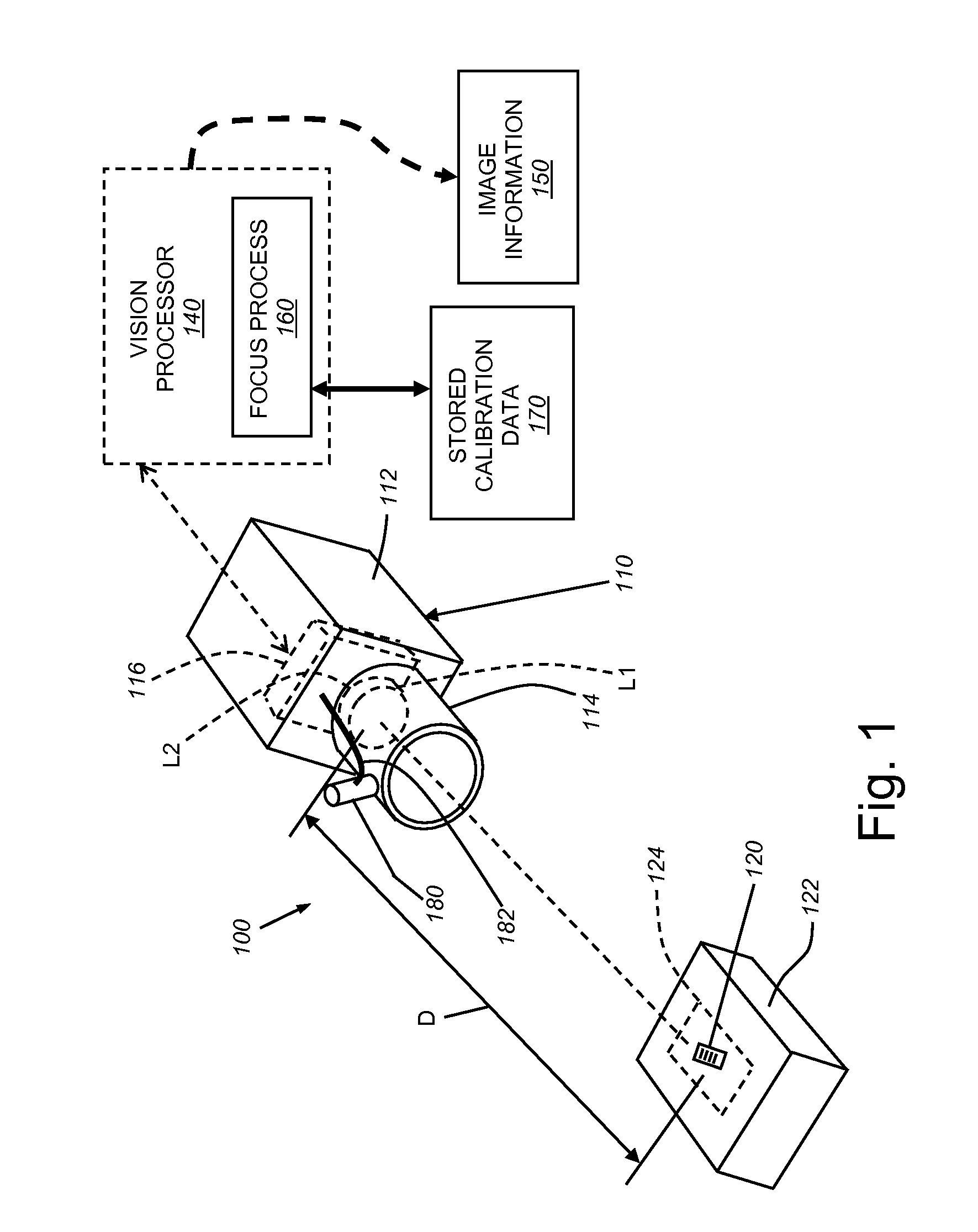

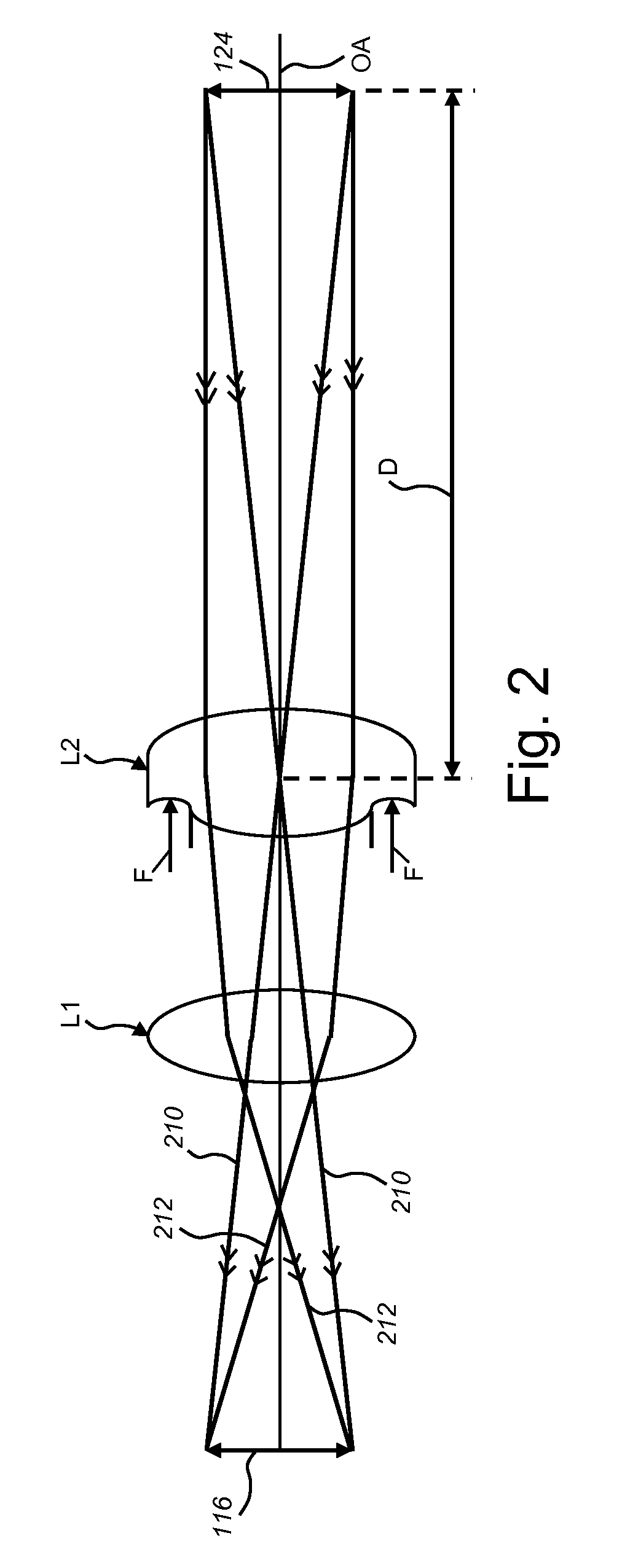

System and method for determining and controlling focal distance in a vision system camera

This invention provides a system and method for determining and controlling focal distance in a lens assembly of a vision system camera using an integral calibration assembly that provides the camera's image sensor with optical information that is relative to focal distance while enabling runtime images of a scene to be acquired along the image axis. The lens assembly includes a variable lens located along an optical axis that provides a variable focus setting. The calibration assembly generates a projected pattern of light that variably projects upon the camera sensor based upon the focus setting of the variable lens. That is, the appearance and / or position of the pattern varies based upon the focus setting of the variable lens. This enables a focus process to determine the current focal length of the lens assembly based upon predetermined calibration information stored in association with a vision system processor running the focus process.

Owner:COGNEX CORP

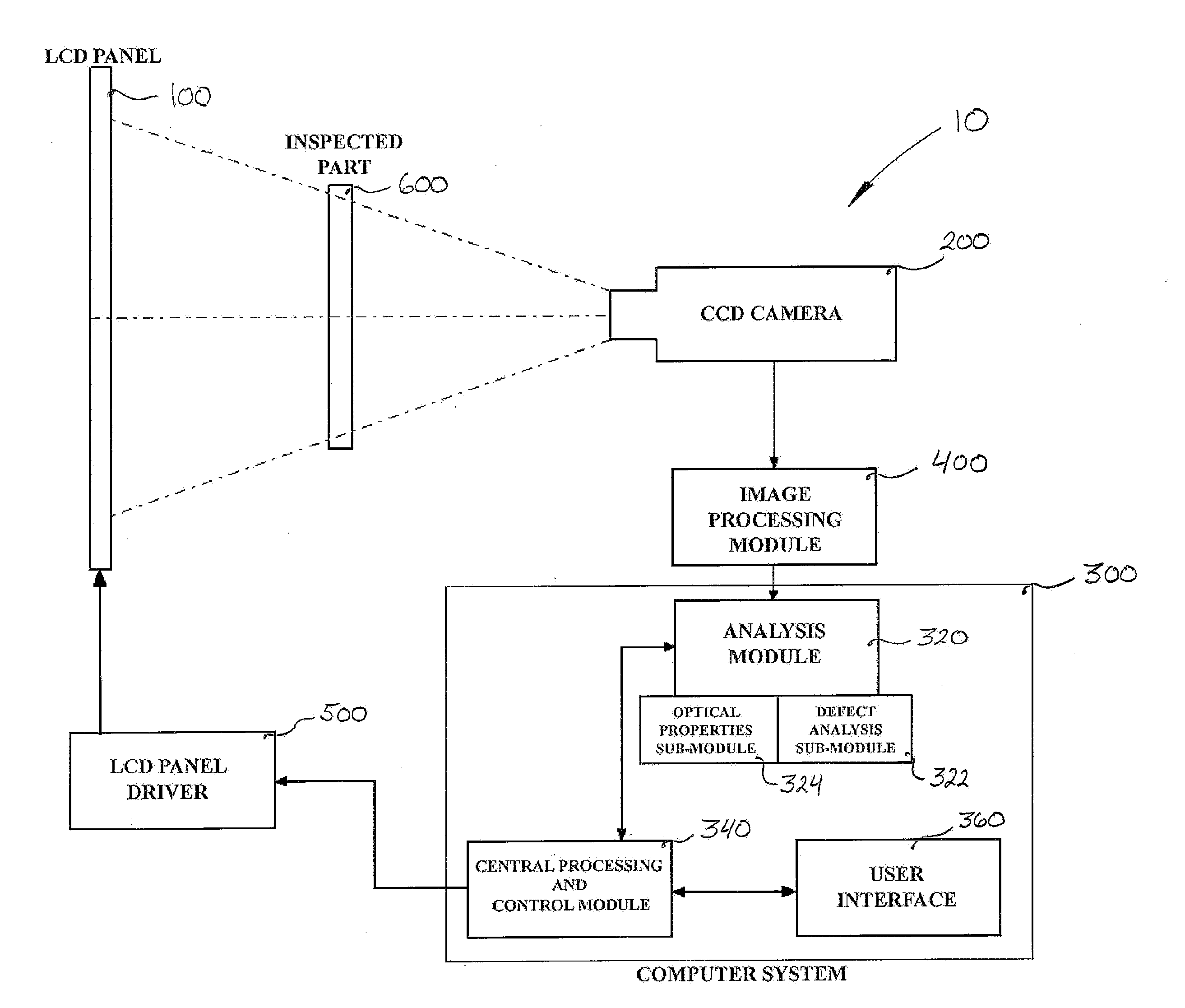

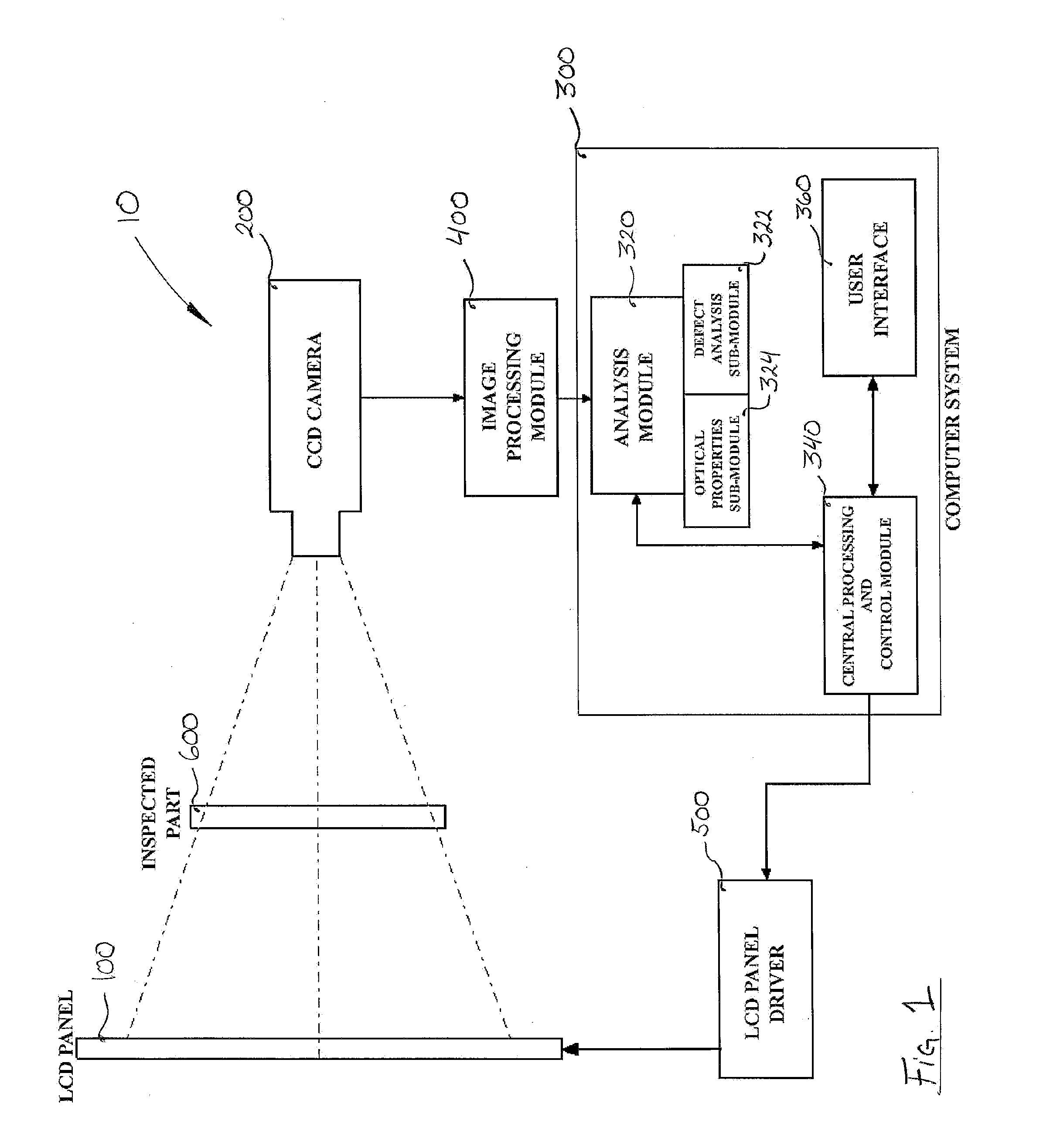

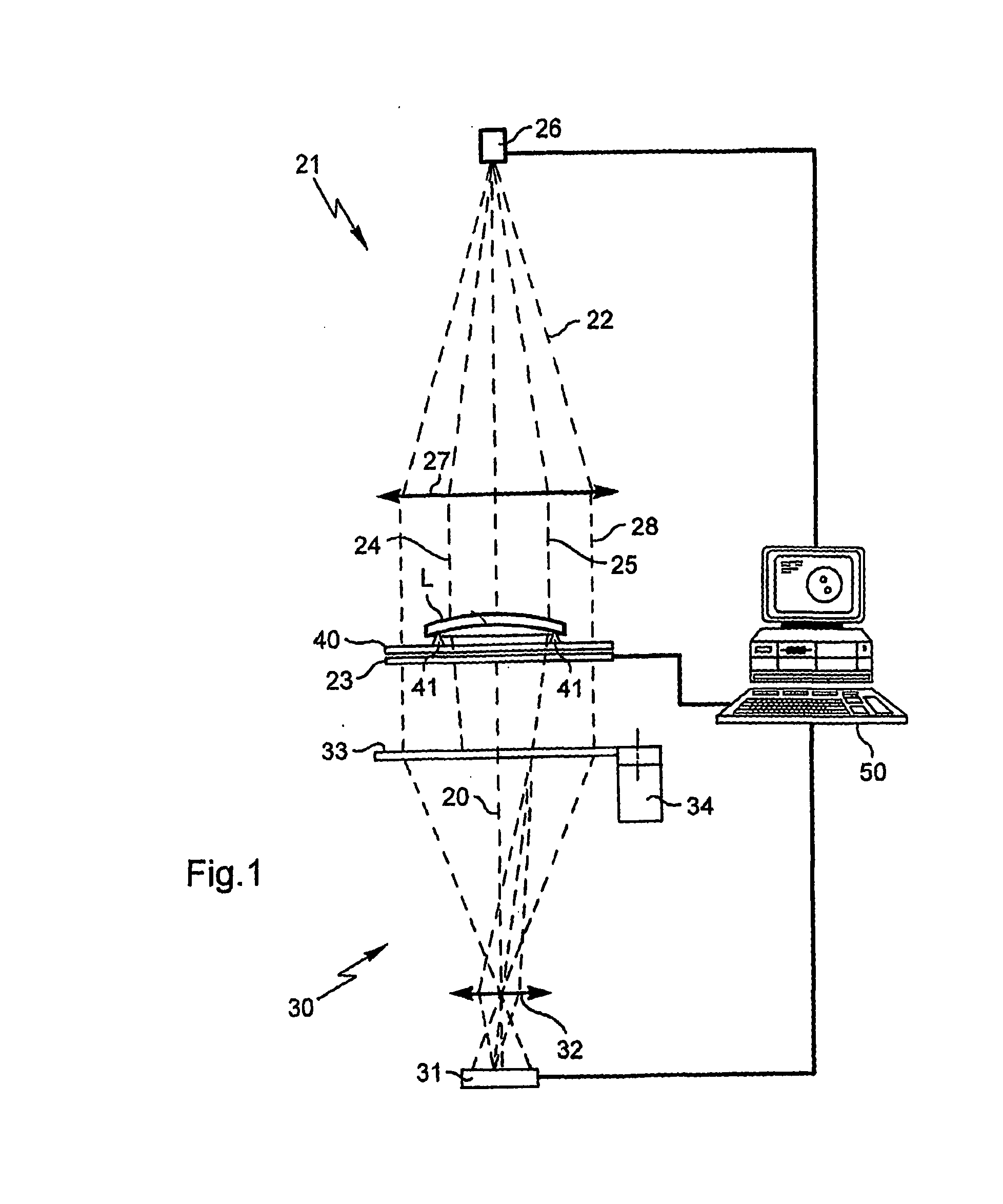

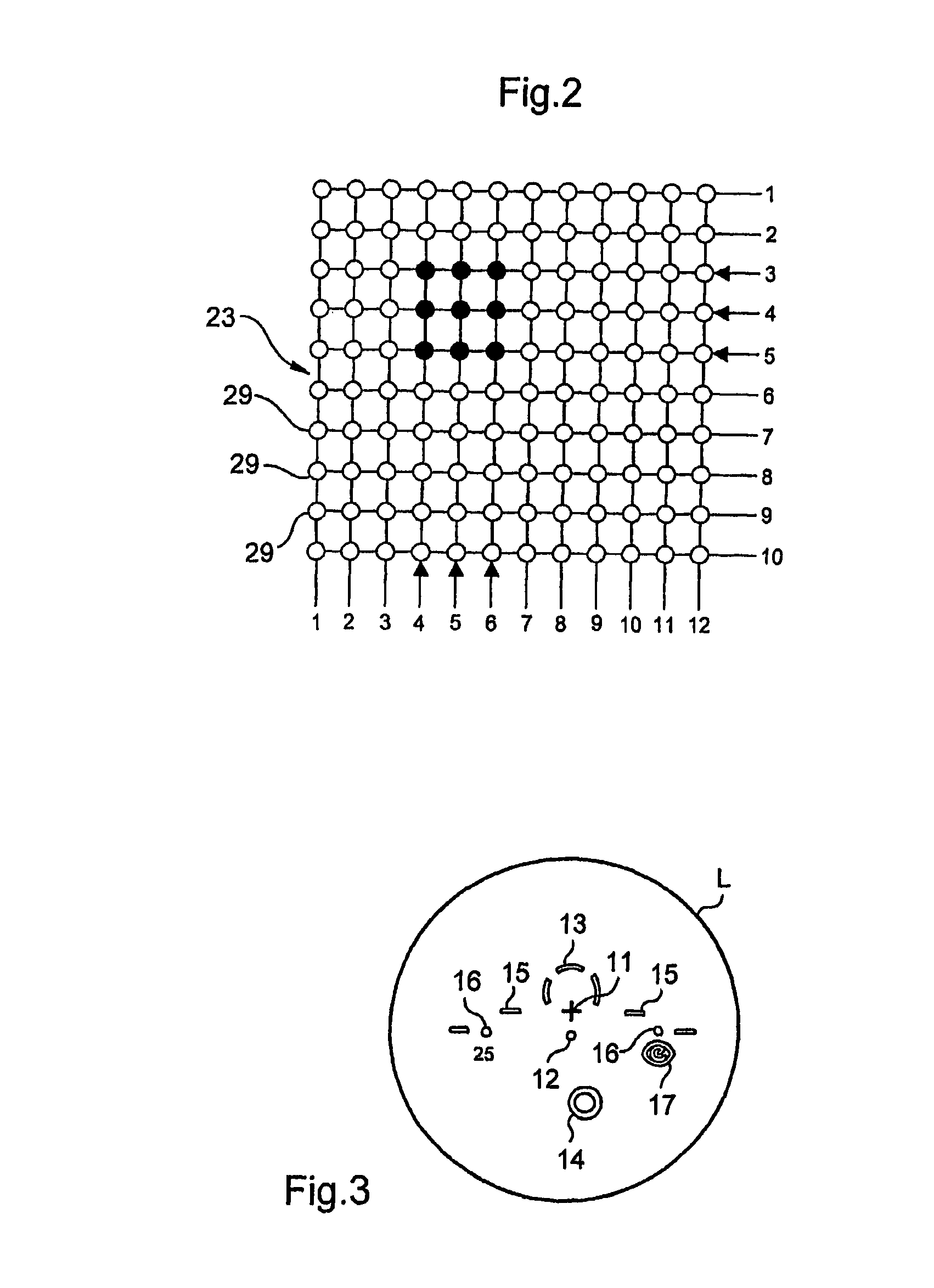

Transparent material inspection system

InactiveUS20080111989A1Detection moreRaise checkMaterial analysis by optical meansUsing optical meansVisorImaging data

A system for the inspection of the optical quality of a part, object or product having a portion comprising transparent material such as ophthalmologic lenses, protective eyewear, visors, eyewear shield and the like is provided. A liquid crystal display (LCD) screen emits variable patterns of light through the transparent part under inspection to a charged coupled device (CCD) camera that captures the image and transmits the image data to an image processing module. The processed image data are then transmitted to an analysis module which then generally measures the dimensions of the part, the transparency, the colour and the optical strength. The analysis module also advantageously detects and measures the presence of dots, stains, scratches, optical distortions, fingerprints, cloudiness and other optical artefacts and / or defects in the transparent material. Accordingly, the patterns emitted by the LCD screen are designed to measure the optical specifications and highlight potential optical defects.

Owner:DUFOUR CHRISTIAN +1

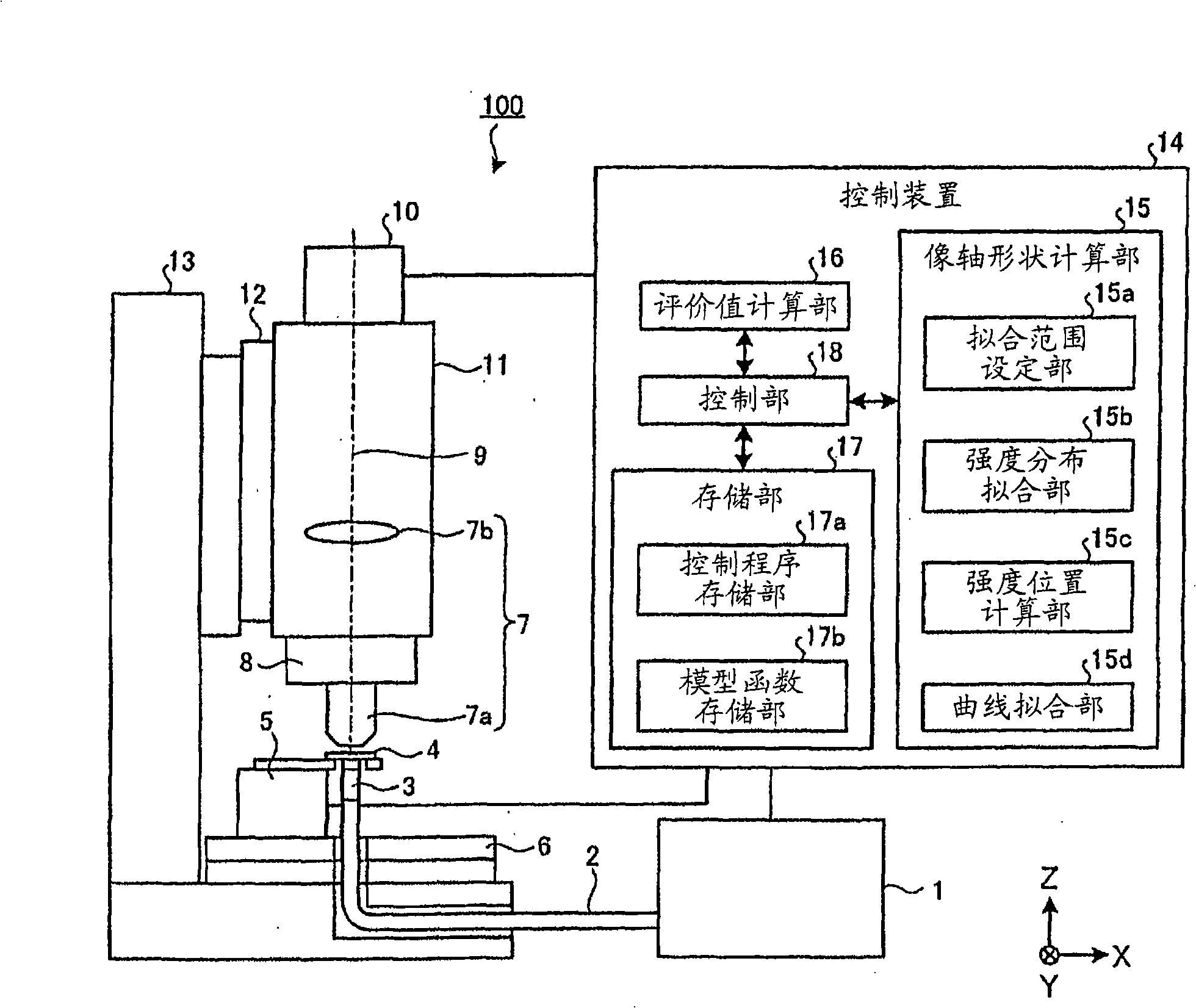

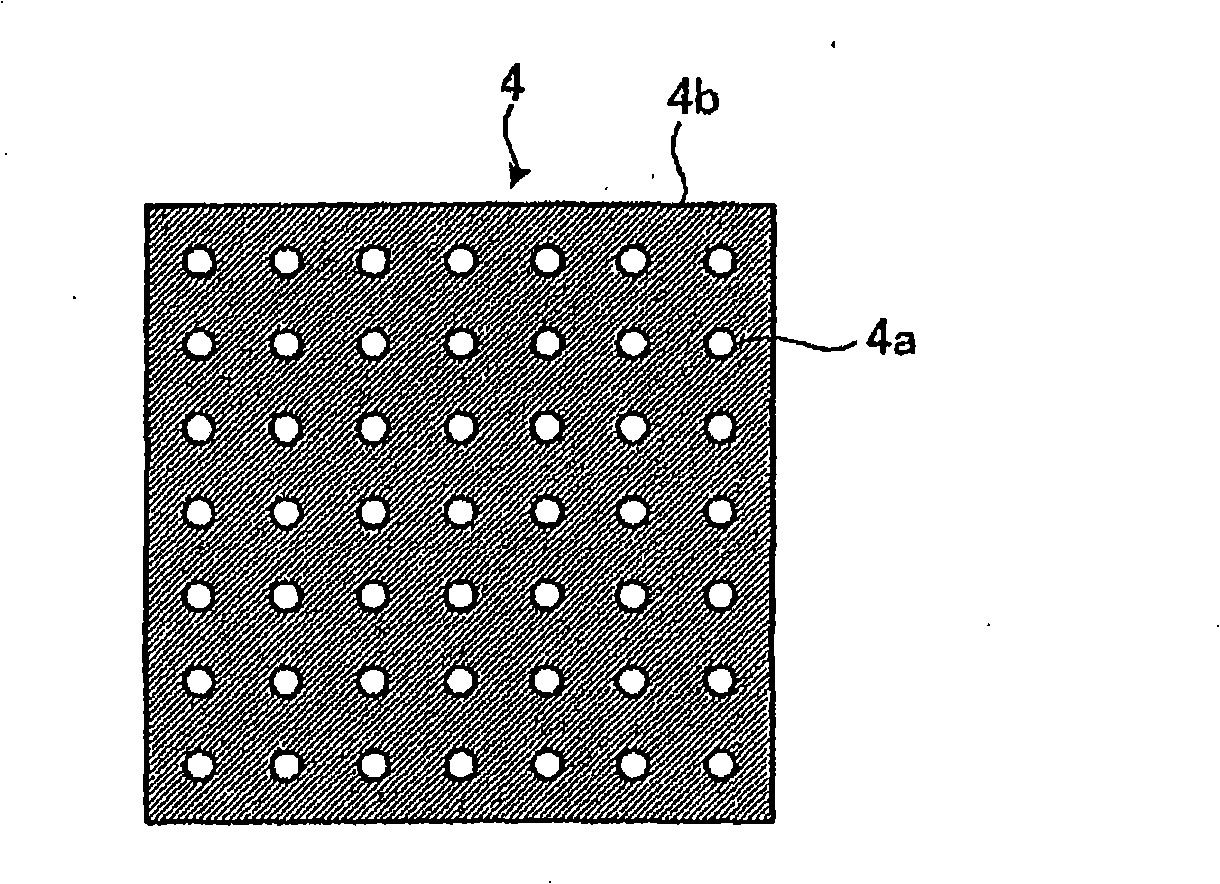

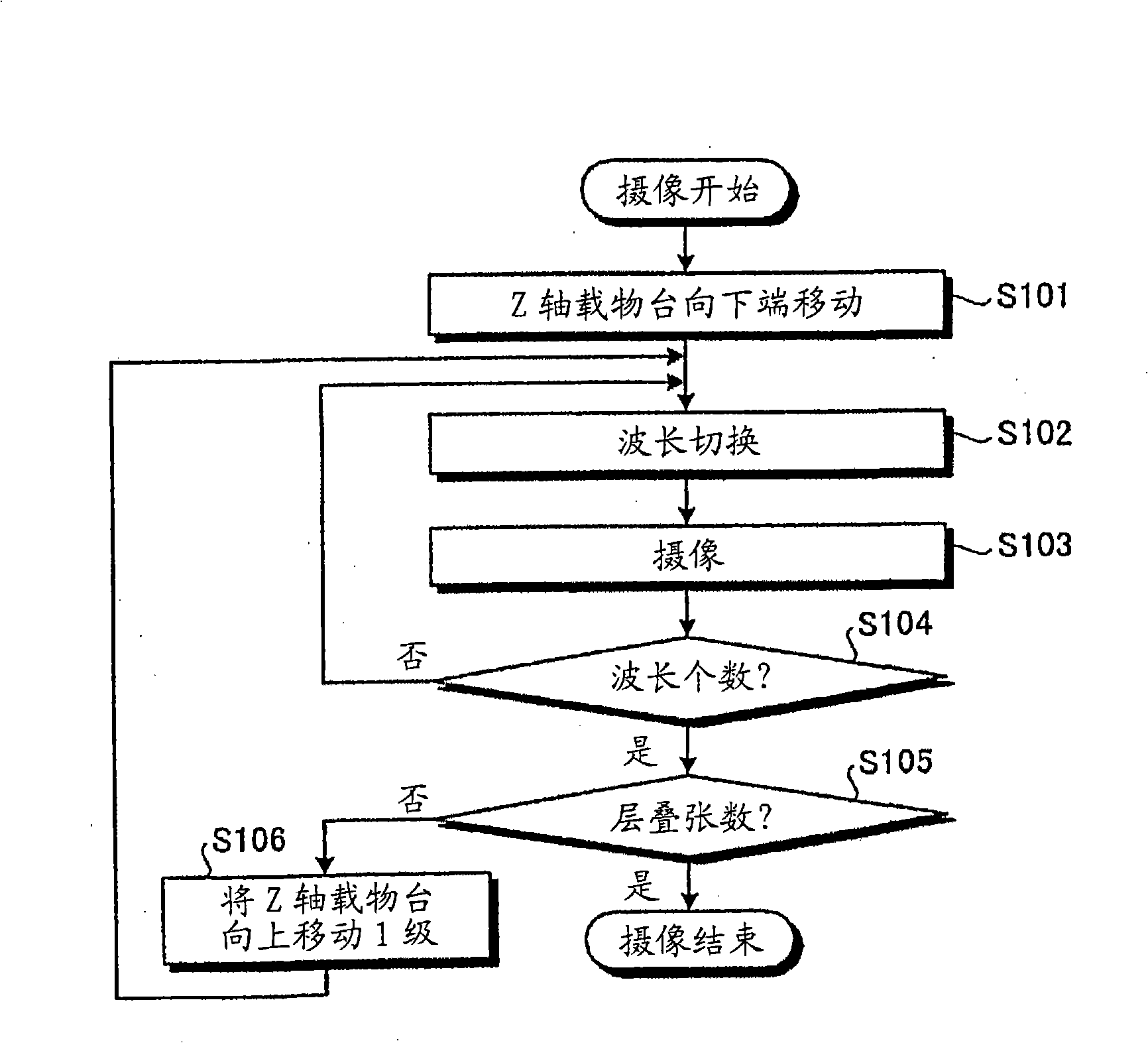

Optical system evaluation apparatus, optical system evaluation method and program thereof

Owner:EVIDENT CORP

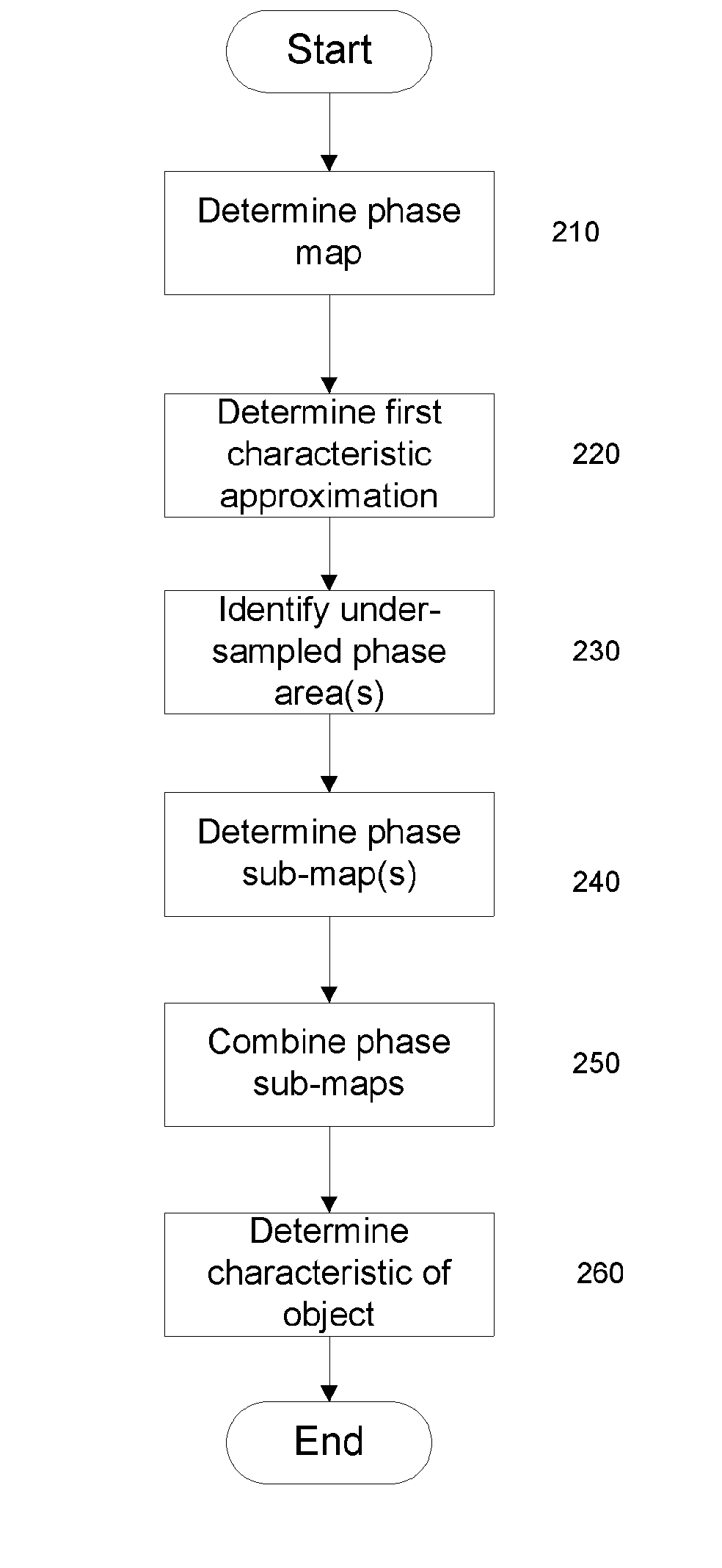

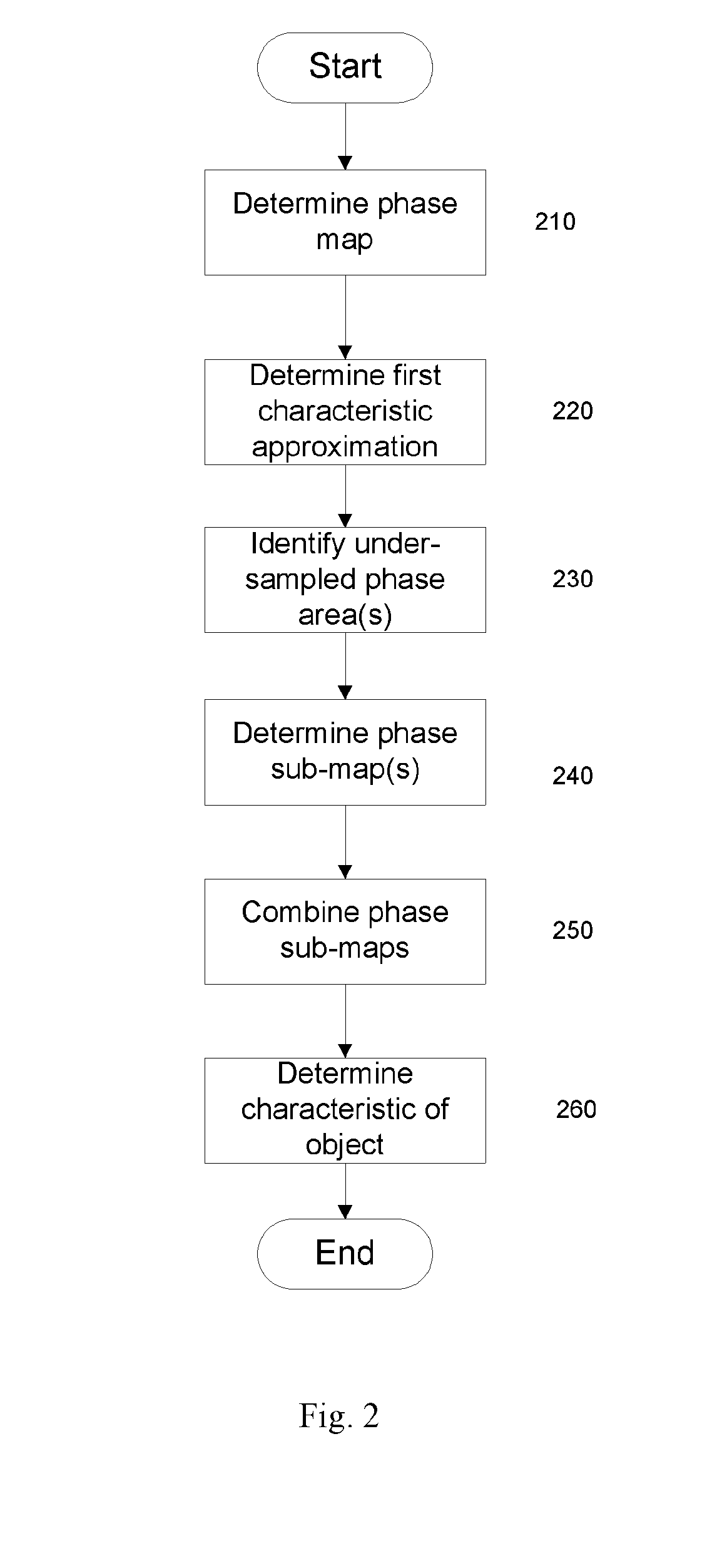

Method and apparatus for determining object characteristics

Embodiments of the invention provide a method of determining one or more characteristics of a target object, comprising determining a first phase map for at least a region of a target object based on radiation directed toward the target object, determining one or more further phase maps for a sub-region of the region of the target object, determining a number of phase wraps for the sub-region based on a plurality of phase maps for the sub-region, and determining a characteristic of the region of the target object based on the number of phase wraps for sub-region and the first phase map. Embodiments of the invention also relate to a method of determining one or more characteristics of a target object, comprising determining a phase map for at least a region of a target object based on one or more diffraction patterns, determining a wavefront at a plane of the object based upon the phase map, and determining a refractive property of the object based on the wavefront.

Owner:PHASE FOCUS

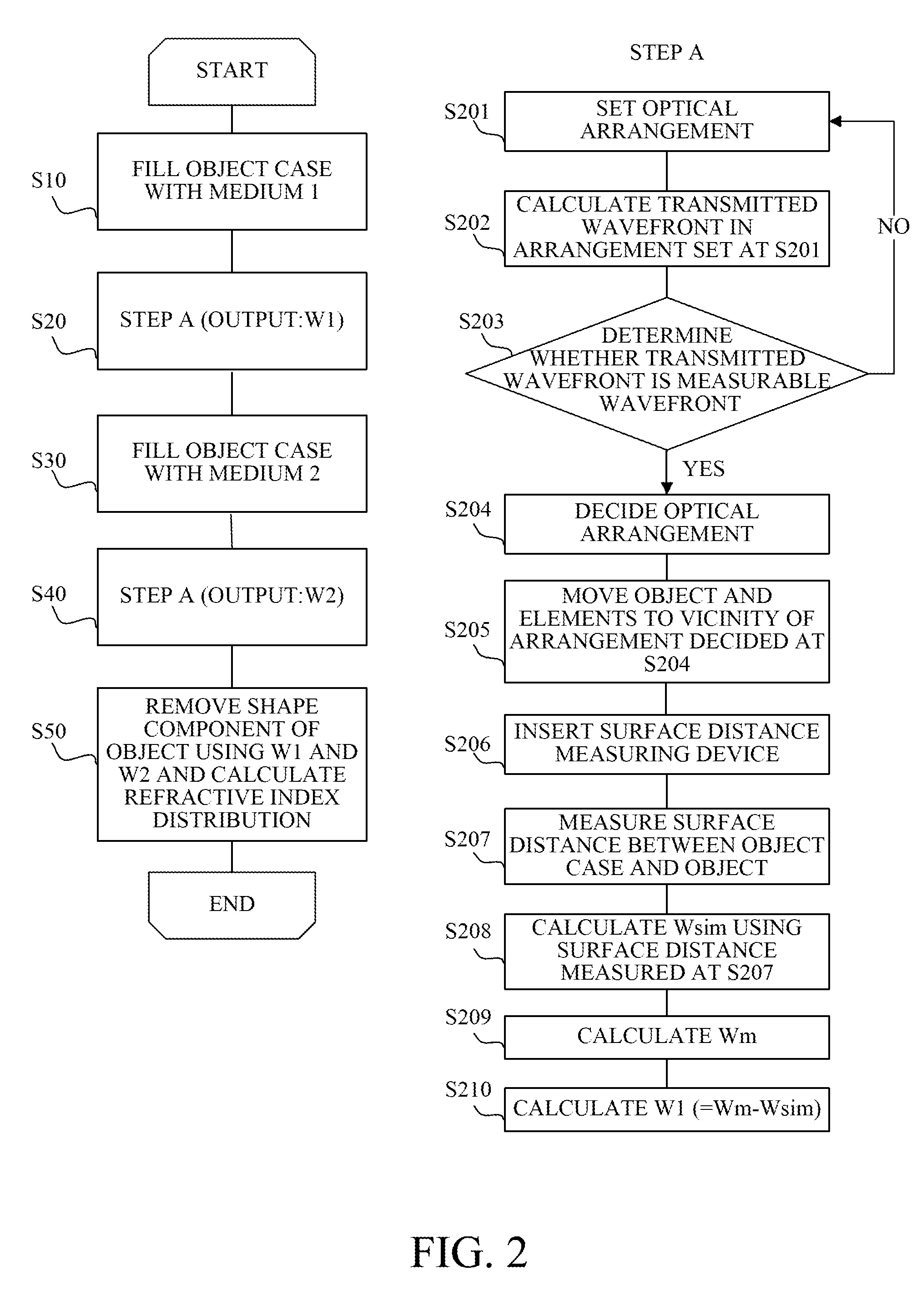

Refractive index distribution measuring method and refractive index distribution measuring apparatus

InactiveUS20110134438A1High precision measurementPhase-affecting property measurementsUsing optical meansWavefrontPhysics

The measuring method includes a step of causing reference light to enter an object placed in a first medium to measure a first transmitted wavefront, a step of causing the reference light to enter the object placed in a second medium to measure a second transmitted wavefront, a step of measuring first and second placement positions where the object is placed in the first and second media, and a calculating step of calculating an internal refractive index distribution of the object by using measurement results of the first and second transmitted wavefronts. The calculating step calculates the internal refractive index distribution from which a shape component of the object is removed by using the measurement results of the first and second transmitted wavefronts, and first and second reference transmitted wavefronts of a reference object to be placed at positions identical to the first and second placement positions.

Owner:CANON KK

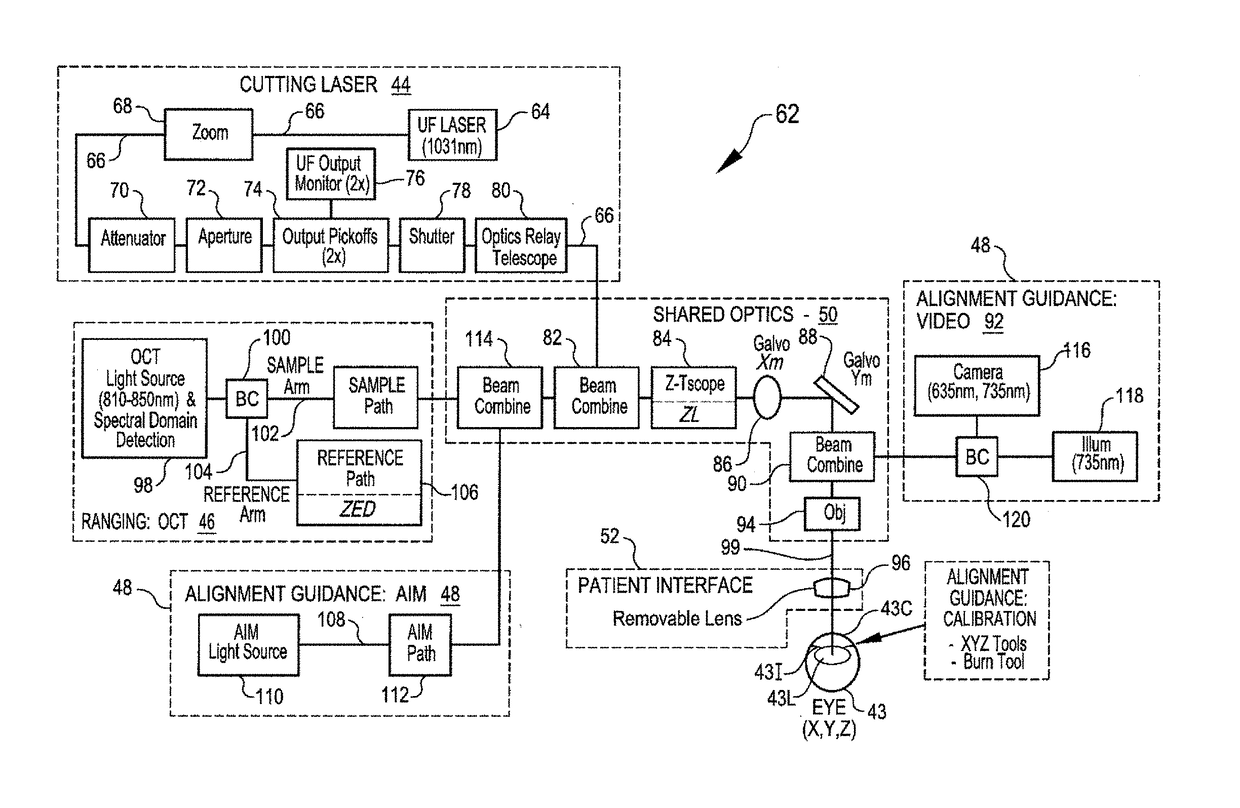

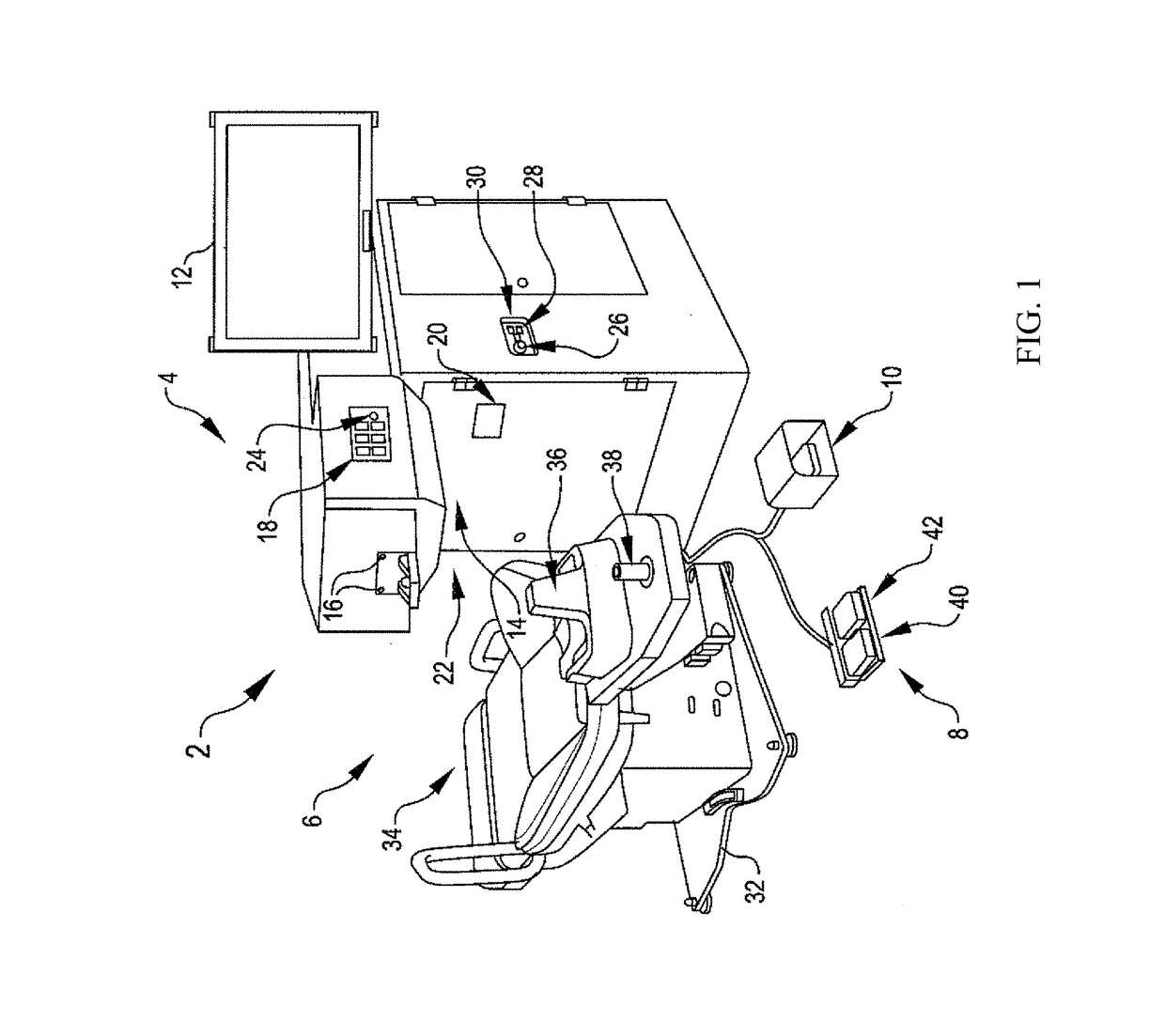

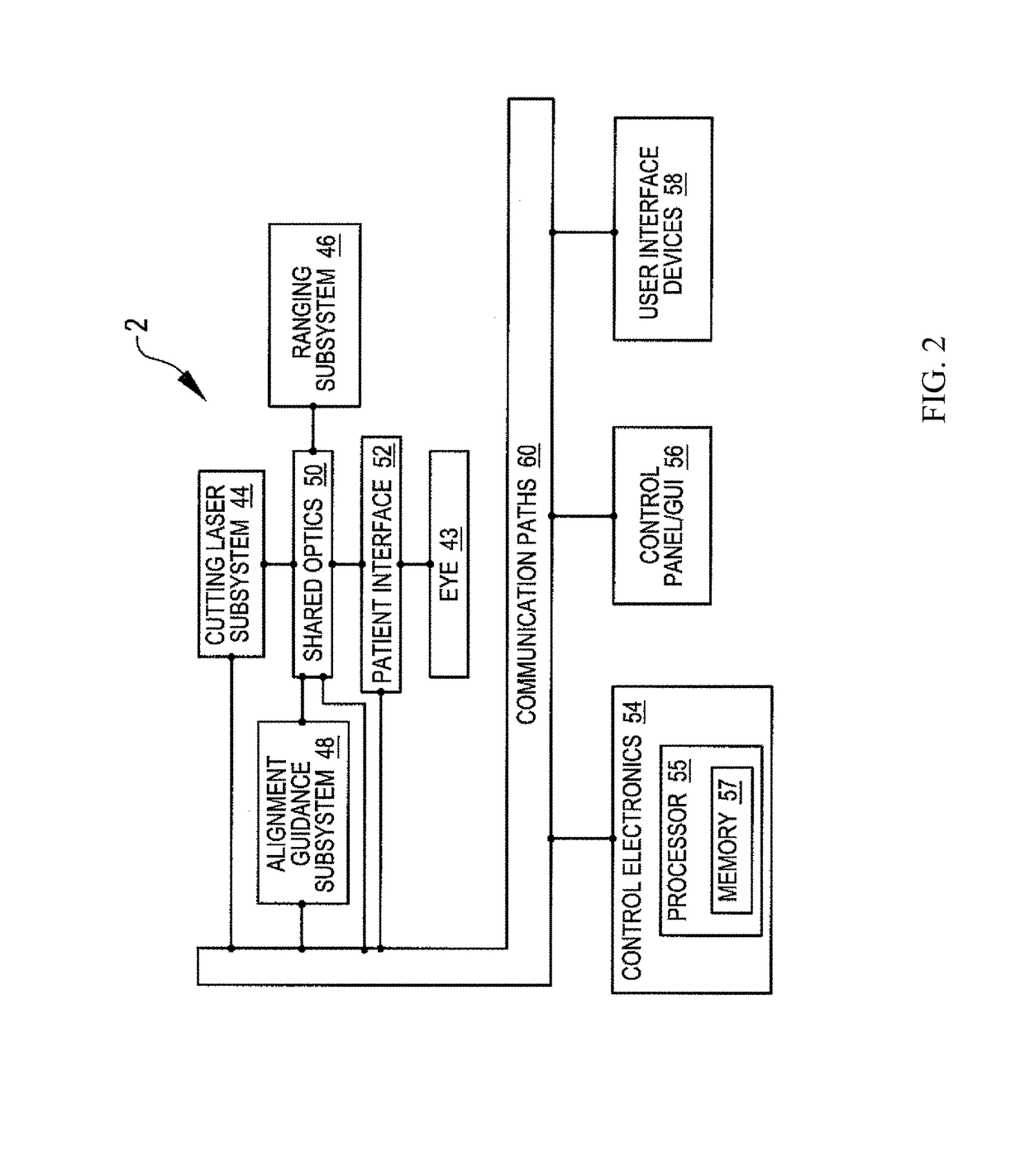

Methods and systems for opthalmic measurements and laser surgery and methods and systems for surgical planning based thereon

ActiveUS20170189233A1Improve accuracyLaser surgeryPhase-affecting property measurementsCorneal surfaceOptical scanners

An ophthalmic measurement and laser surgery system includes: a laser source; a corneal topography subsystem; an axis determining subsystem; a ranging subsystem comprising an Optical Coherence Tomographer (OCT); and a refractive index determining subsystem. All of the subsystems are under the operative control of a controller. The controller is configure to: operate the corneal topography subsystem to obtain corneal surface information; operate the axis determining subsystem to identify one or more ophthalmic axes of the eye; operate the OCT to sequentially scan the eye in a plurality of OCT scan patterns, the plurality of scan patterns configured to determine an axial length of the eye; operate the refractive index determining subsystem so to determine an index of refraction of one or more ophthalmic tissues, wherein at least one of the corneal surface information, ophthalmic axis information, and axial length is modified based on the determined index of refraction.

Owner:AMO DEVMENT

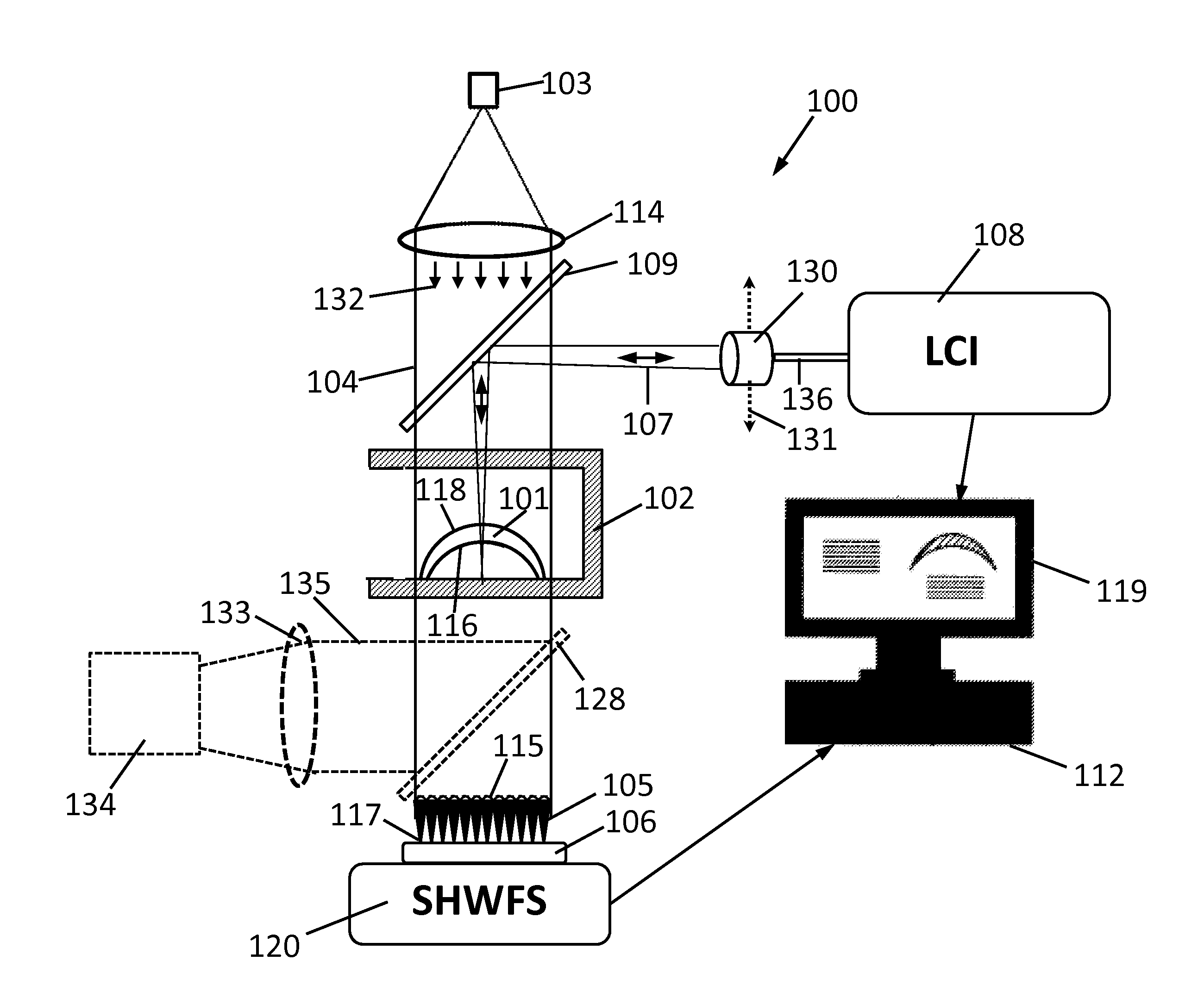

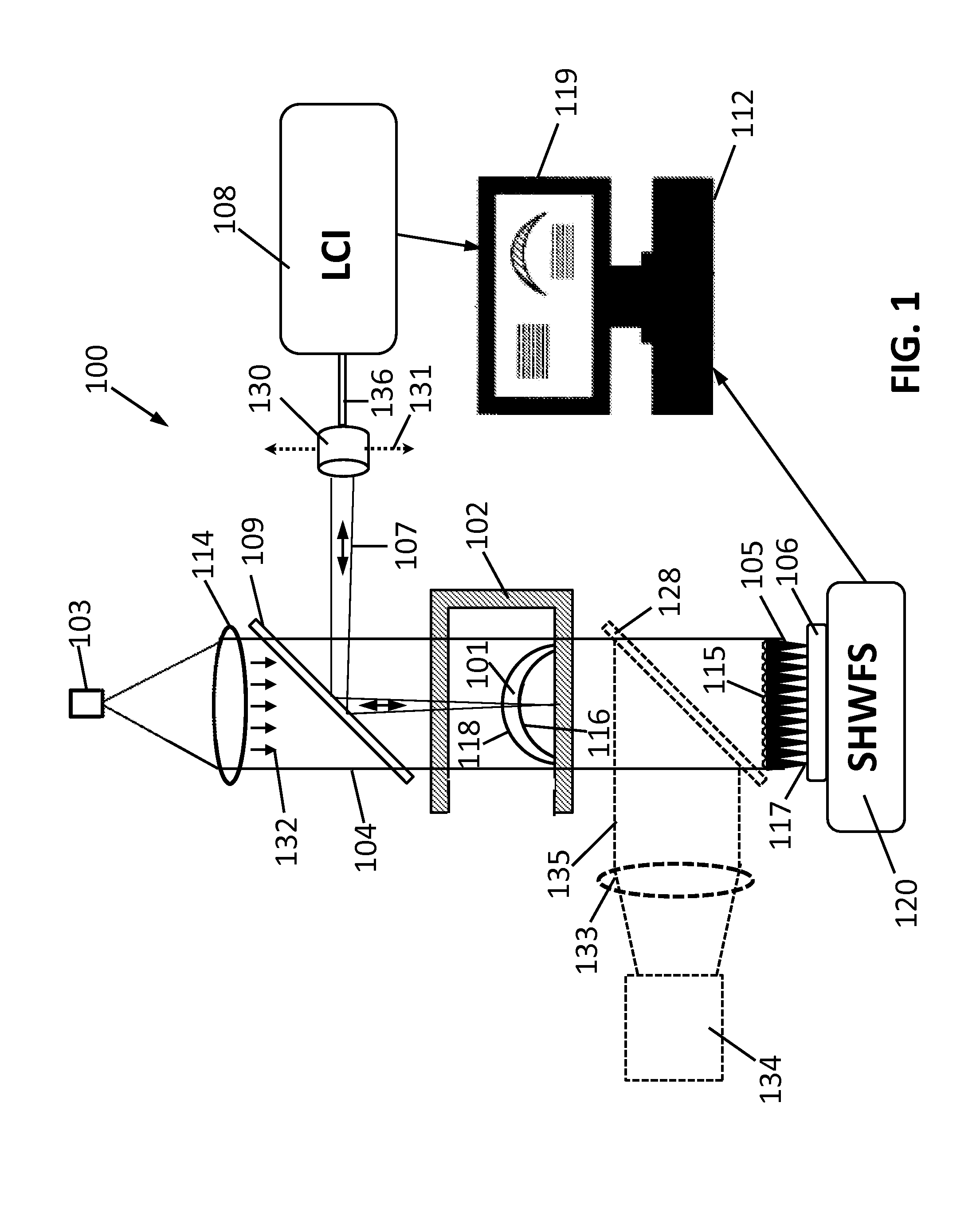

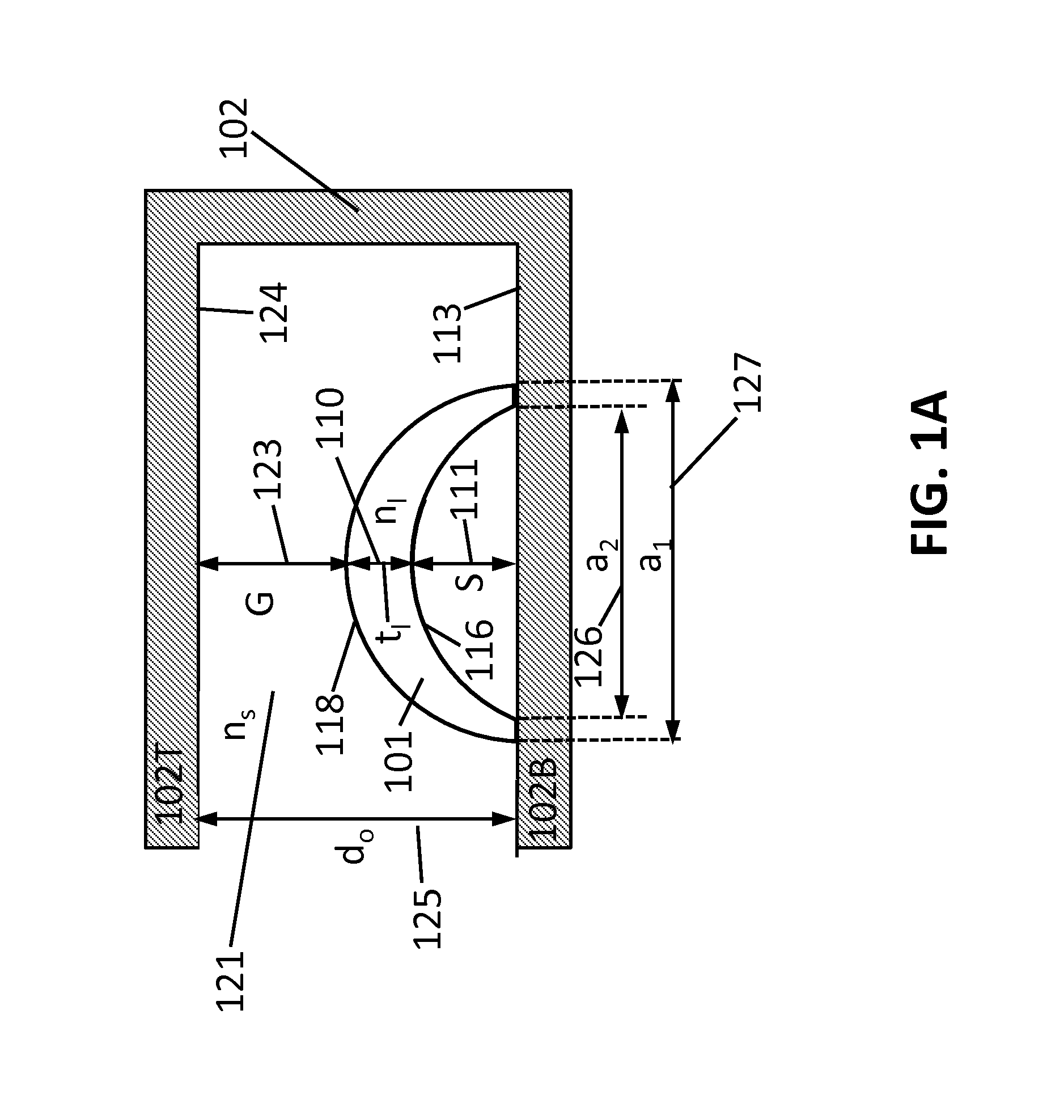

Apparatus and method for evaluation of optical elements

ActiveUS20140253907A1Reduce coherenceMaterial analysis by optical meansRefractive power measurementSensor arrayLight beam

An apparatus for measuring the optical performance characteristics and dimensions of an optical element comprising a low coherence interferometer and a Shack-Hartmann wavefront sensor comprising a light source, a plurality of lenslets, and a sensor array is disclosed. The low coherence interferometer is configured to direct a measurement beam along a central axis of the optical element, and to measure the thickness of the center of the optical element. The light source of the Shack-Hartmann wavefront sensor is configured to emit a waveform directed parallel to and surrounding the measurement beam of the interferometer, through the plurality of lenslets, and to the sensor array. A method for measuring the optical performance characteristics and dimensions of a lens using the apparatus is also disclosed.

Owner:LUMETRICS

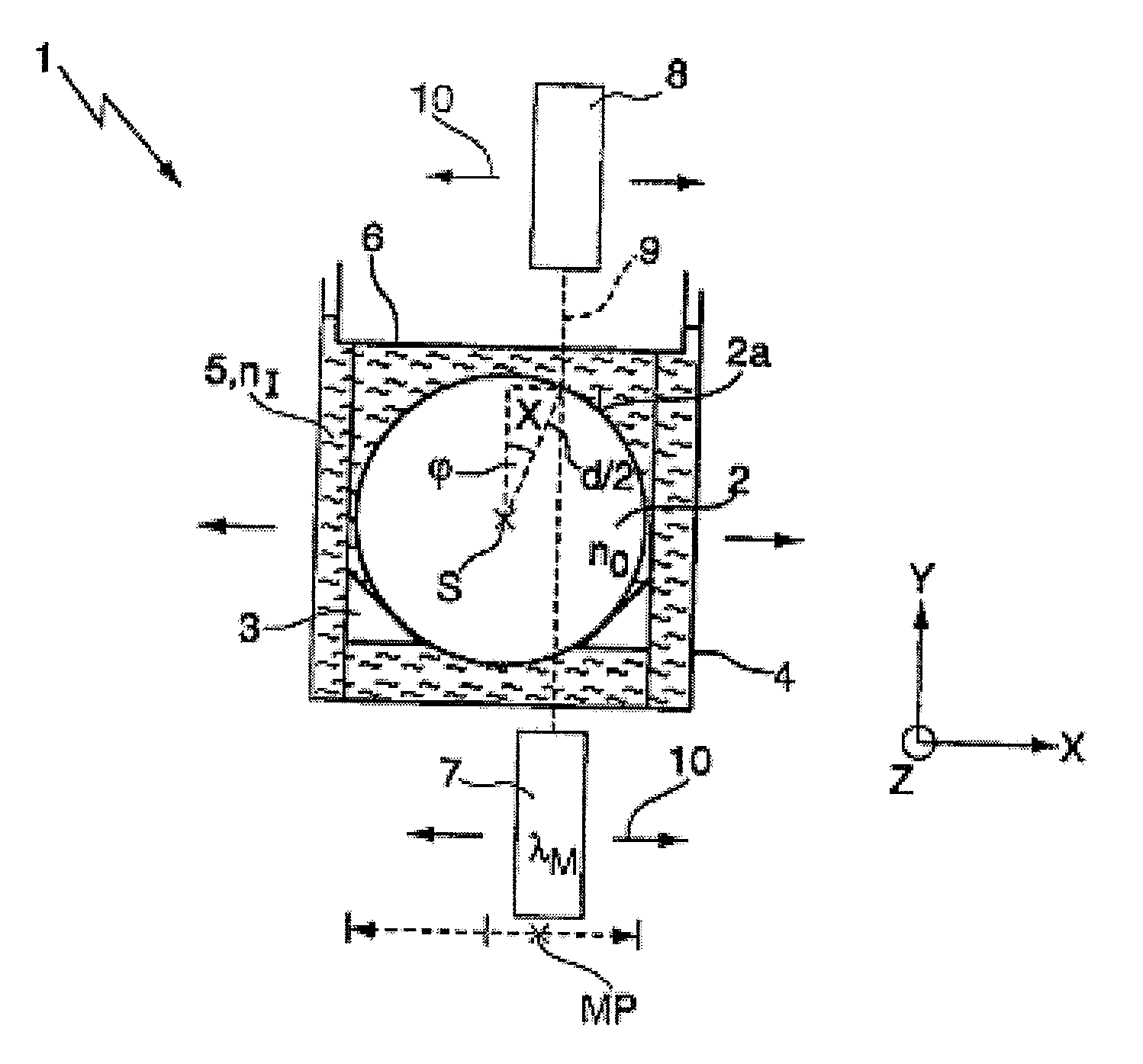

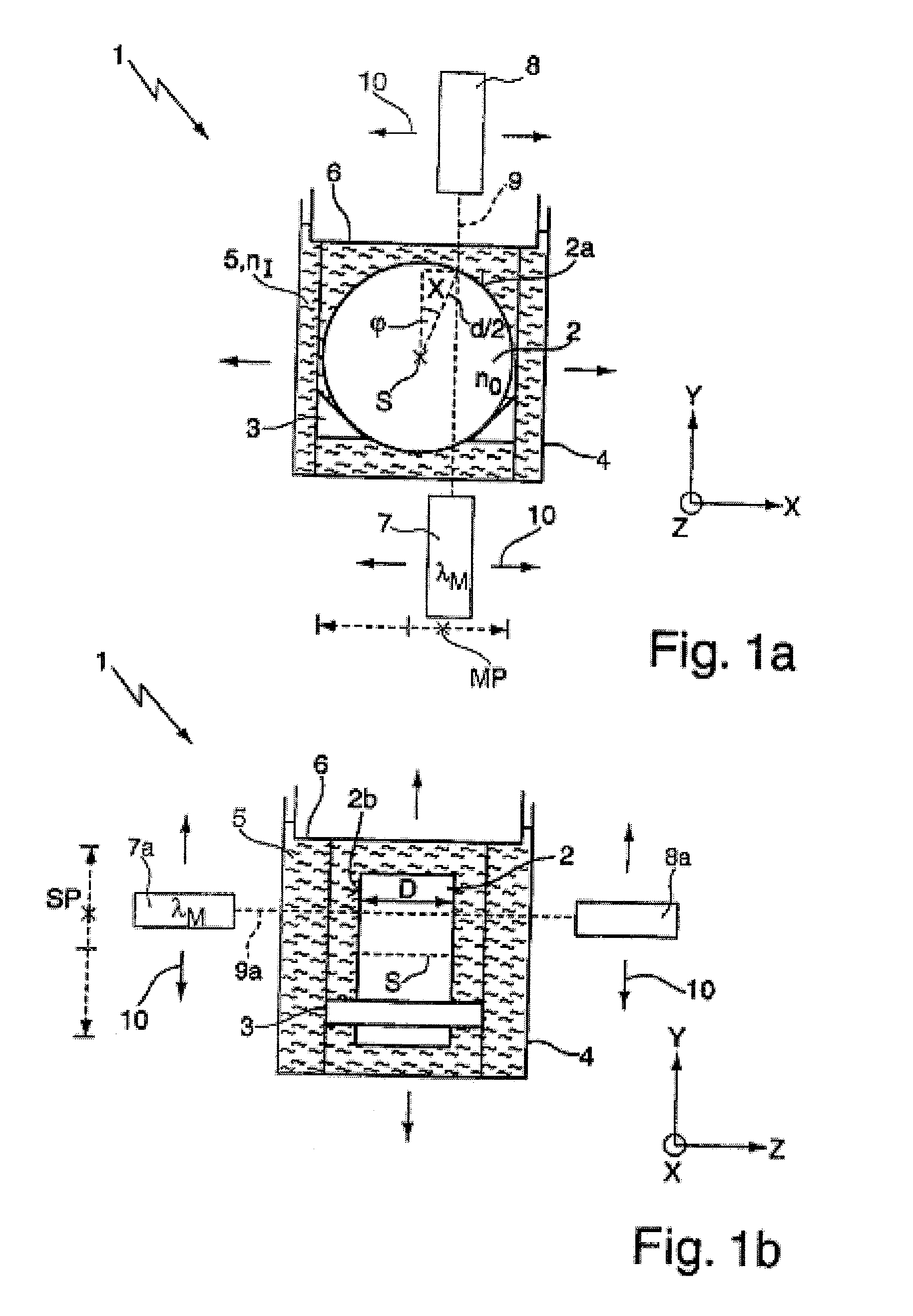

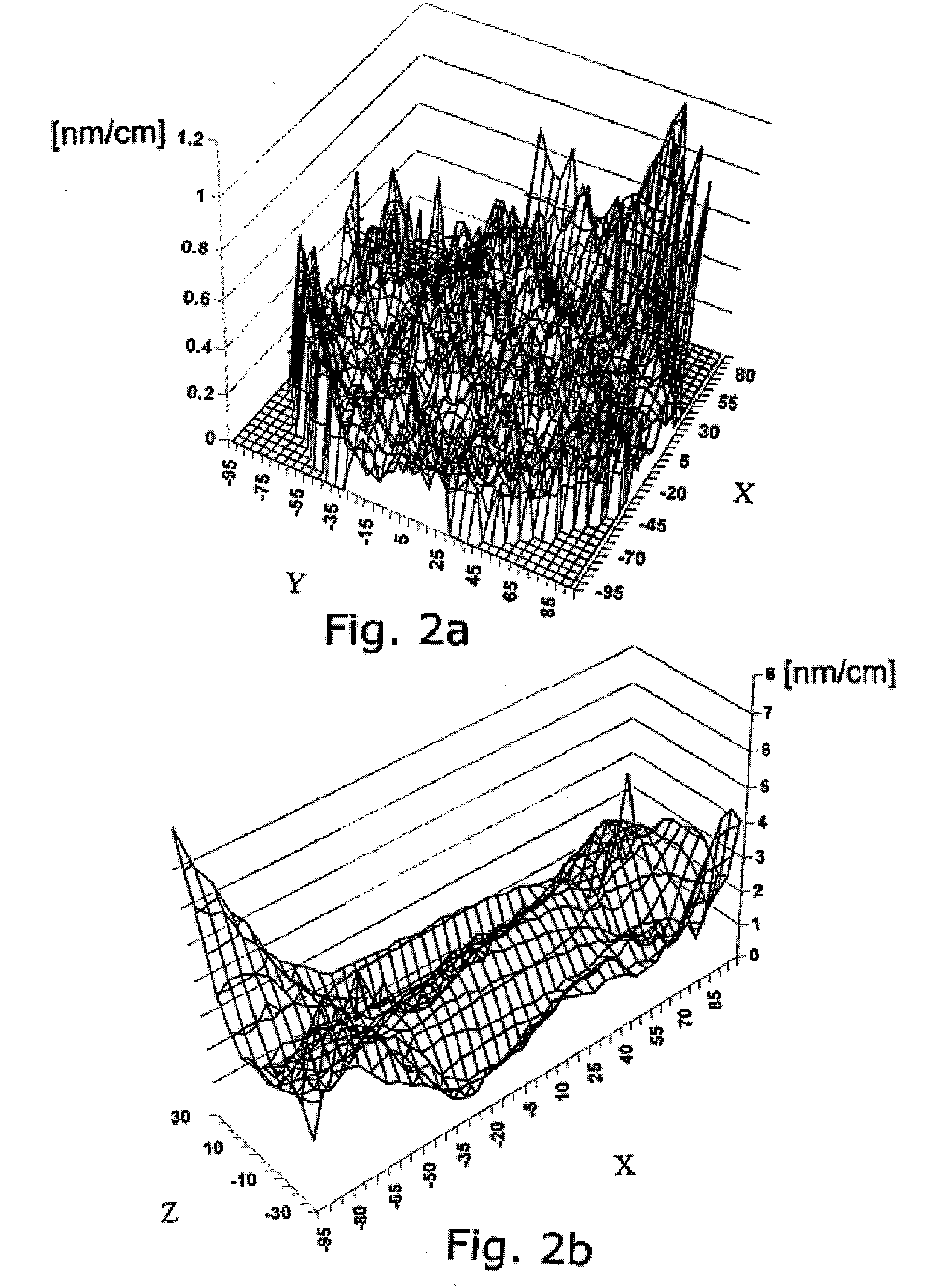

Method for the spatially resolved measurement of birefringence, and a measuring apparatus

InactiveUS20100103420A1Prevent overflowSpilling over can be preventedMethods for obtaining spatial resolutionLight polarisation measurementSpatially resolvedAxis of symmetry

A method for the spatially resolved measurement of the birefringence distribution of a cylindrically symmetrical blank (2) made from an optical material transparent to at least one wavelength λB between 180 nm and 650 nm, in particular at 193 nm, including: irradiating the blank (2), arranged in a container (4) with an immersion fluid (5), at a jacket-side measurement position (MP) using a measuring light beam (9) which runs in a measuring direction (Y) preferably perpendicular to the axis of symmetry (S) of the blank (2), as well as varying the jacket-side measurement position (MP) by moving the measuring light beam (9) and the blank (2) relative to one another in two directions (X, Z) perpendicular to the measuring direction (Y) for the purpose of spatially resolved measurement of the non-axial birefringence distribution of the blank (2).

Owner:CARL ZEISS SMT GMBH

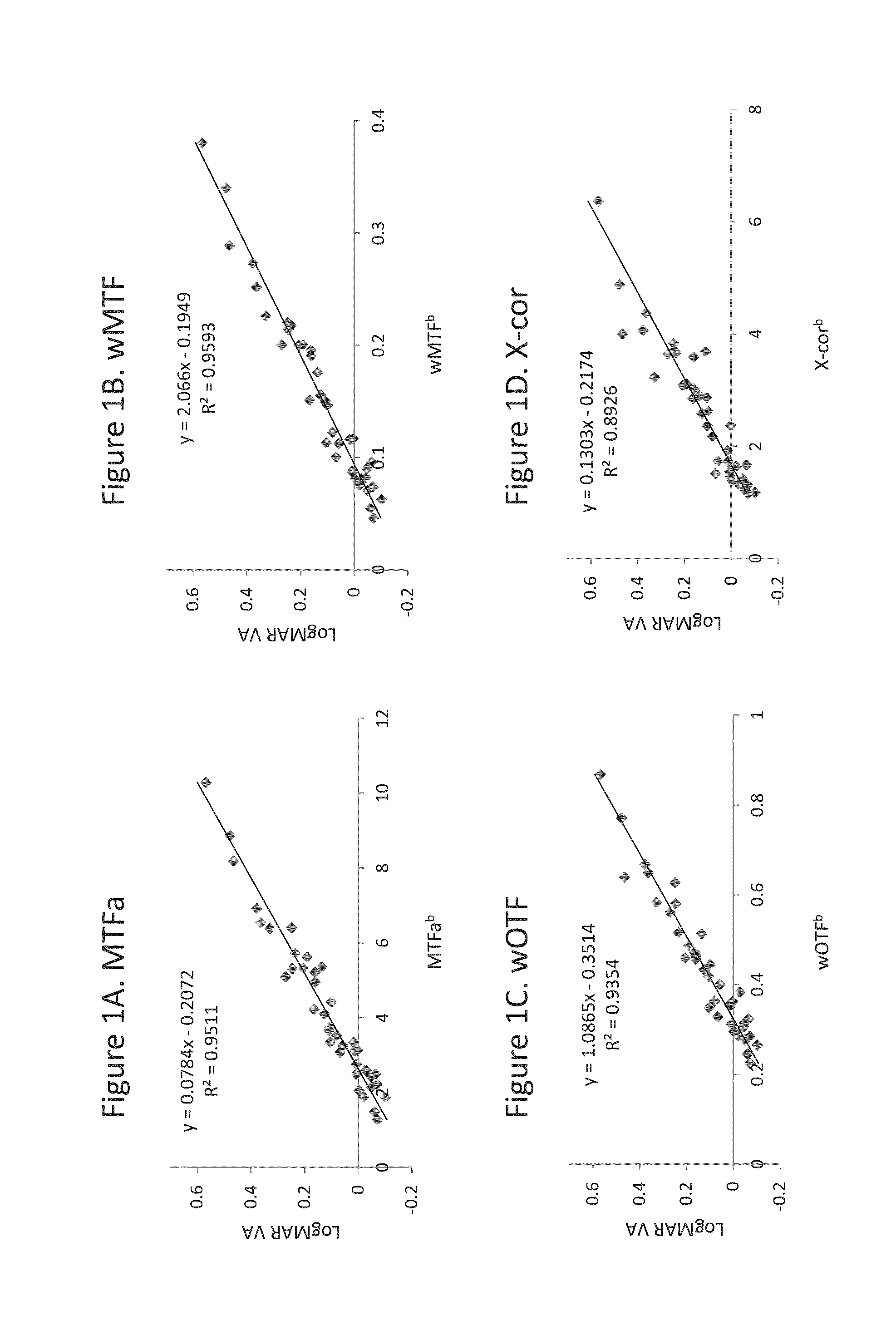

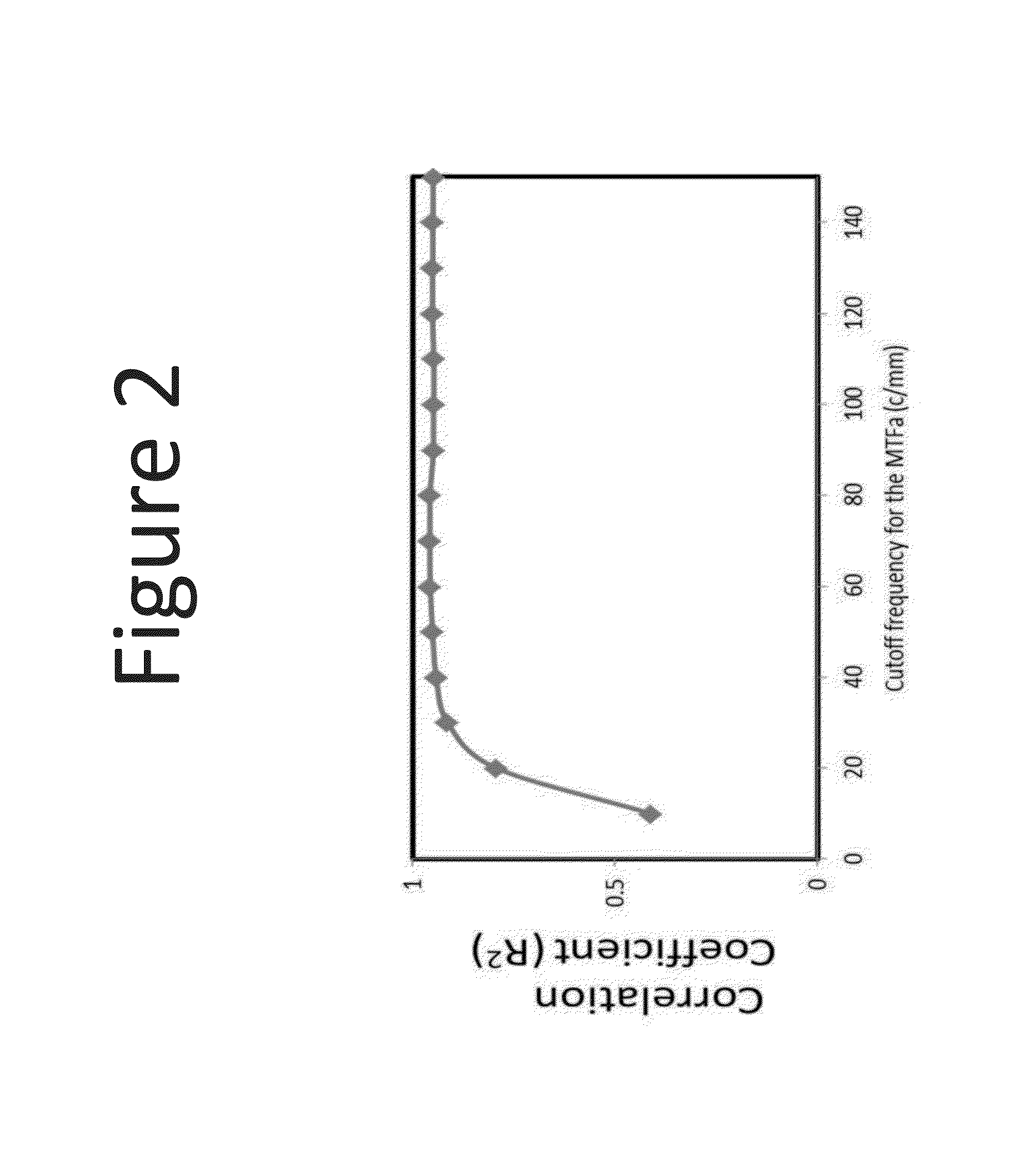

Apparatus, systems and methods for improving visual outcomes for pseudophakic patients

ActiveUS20160161364A1Easy to predictImprove performanceMedical simulationRefractive power measurementPseudophakiaComputer science

A system and method of characterizing through-focus visual performance of an IOL using metrics based on an area under the modulation transfer function for different spatial frequencies at different defocus positions of the IOL. Also disclosed is a system and method of characterizing through-focus visual performance of an IOL using a metric based on an area under a cross-correlation coefficient for an image of a target acquired by the IOL at different defocus positions of the IOL.

Owner:AMO GRONINGEN

Methods and devices for refractive correction of eyes

Methods and devices are provided to obtain refractive correction with superior visual acuity (e.g., 20 / 10) by achieving an astigmatism-free customized refractive correction. The astigmatism-free customized refractive correction involves obtaining an objective and precise measurement of cylindrical power in a resolution between 0.01 D and 0.10 D in an eye using an objective aberrometer, reliably relating the cylindrical axis obtained from the objective aberrometer to that in a phoroptor, determining an optimized focus error of an eye through subjective refraction with a phoroptor, generating a customized refraction by combining the objective measured cylindrical power, the objective measured cylindrical axis, and the subjectively measured focus power, fabricating a custom lens with a tolerance finer than 0.09 D based on the generated customized refraction, and delivering an ophthalmic lens that can provide an astigmatism-free refractive correction for an eye.

Owner:PERFECT VISION TECH HK

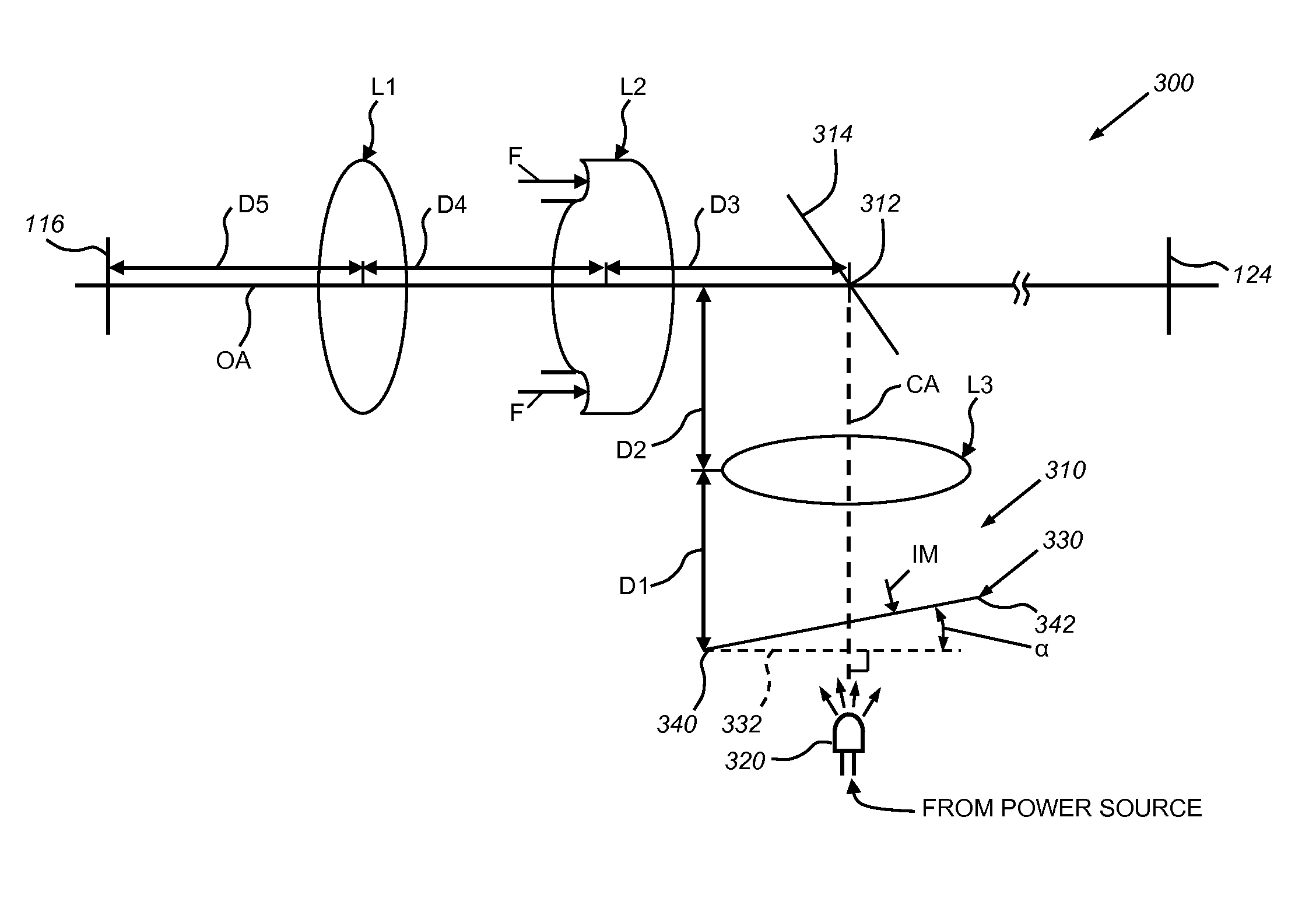

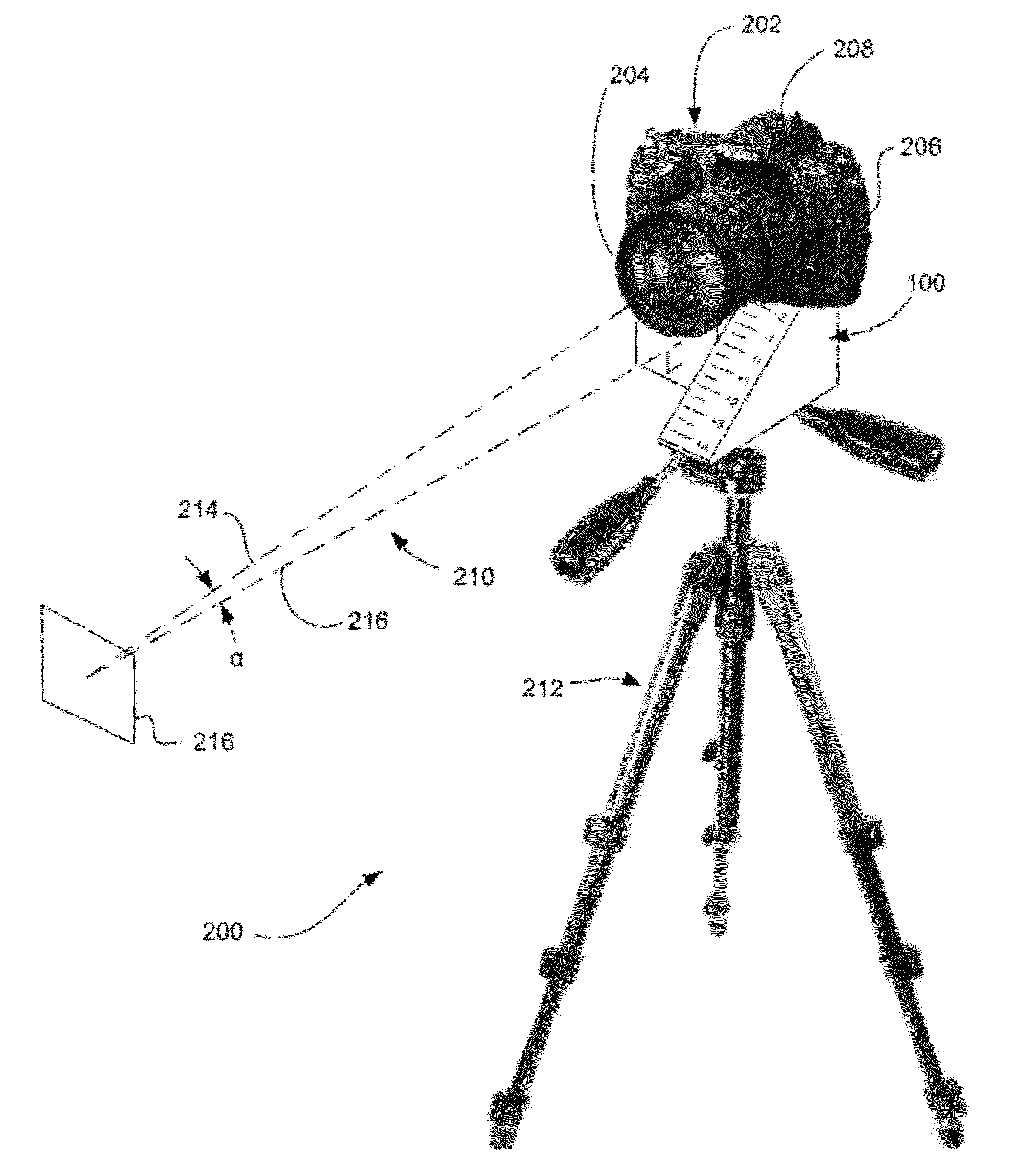

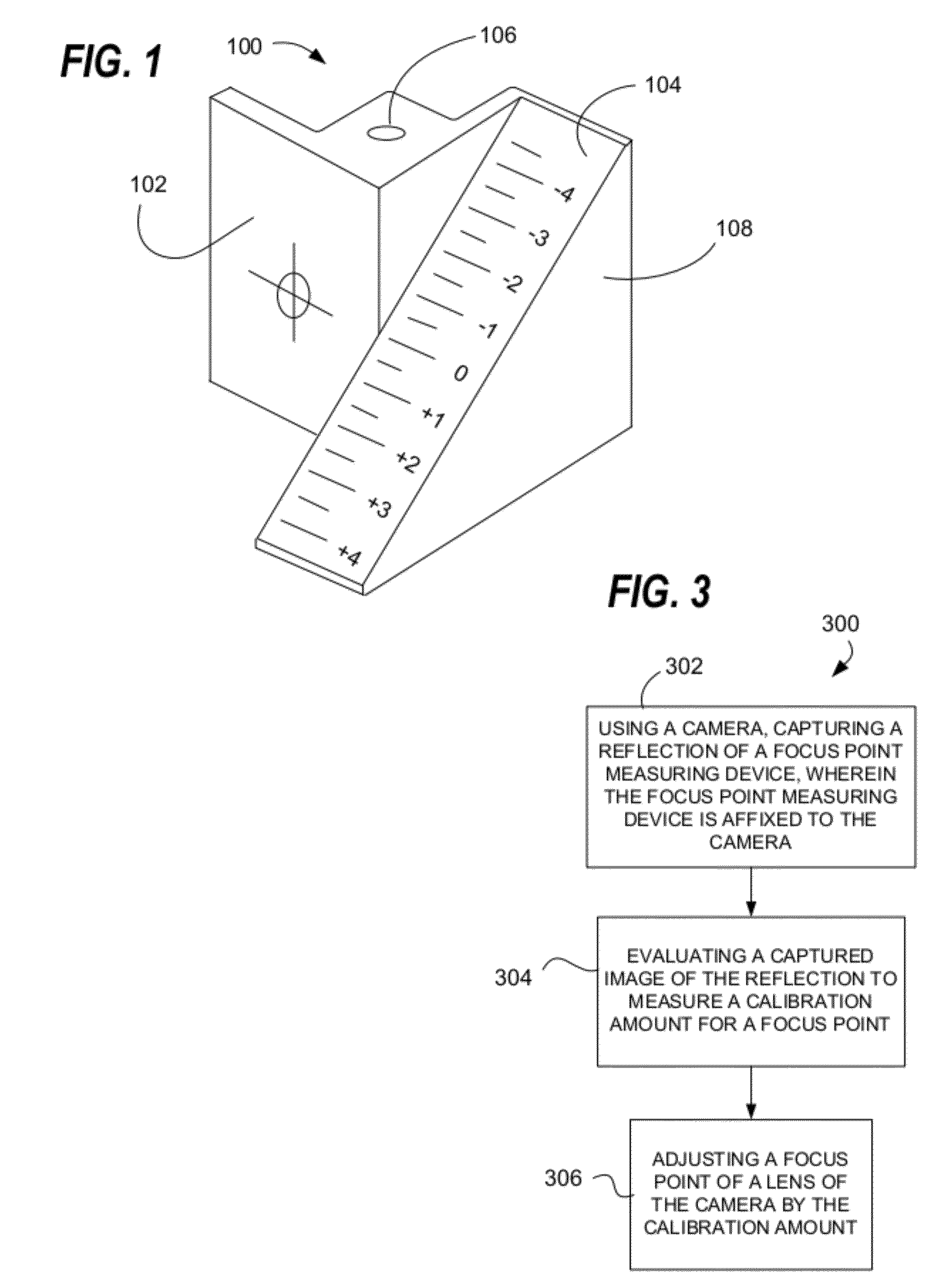

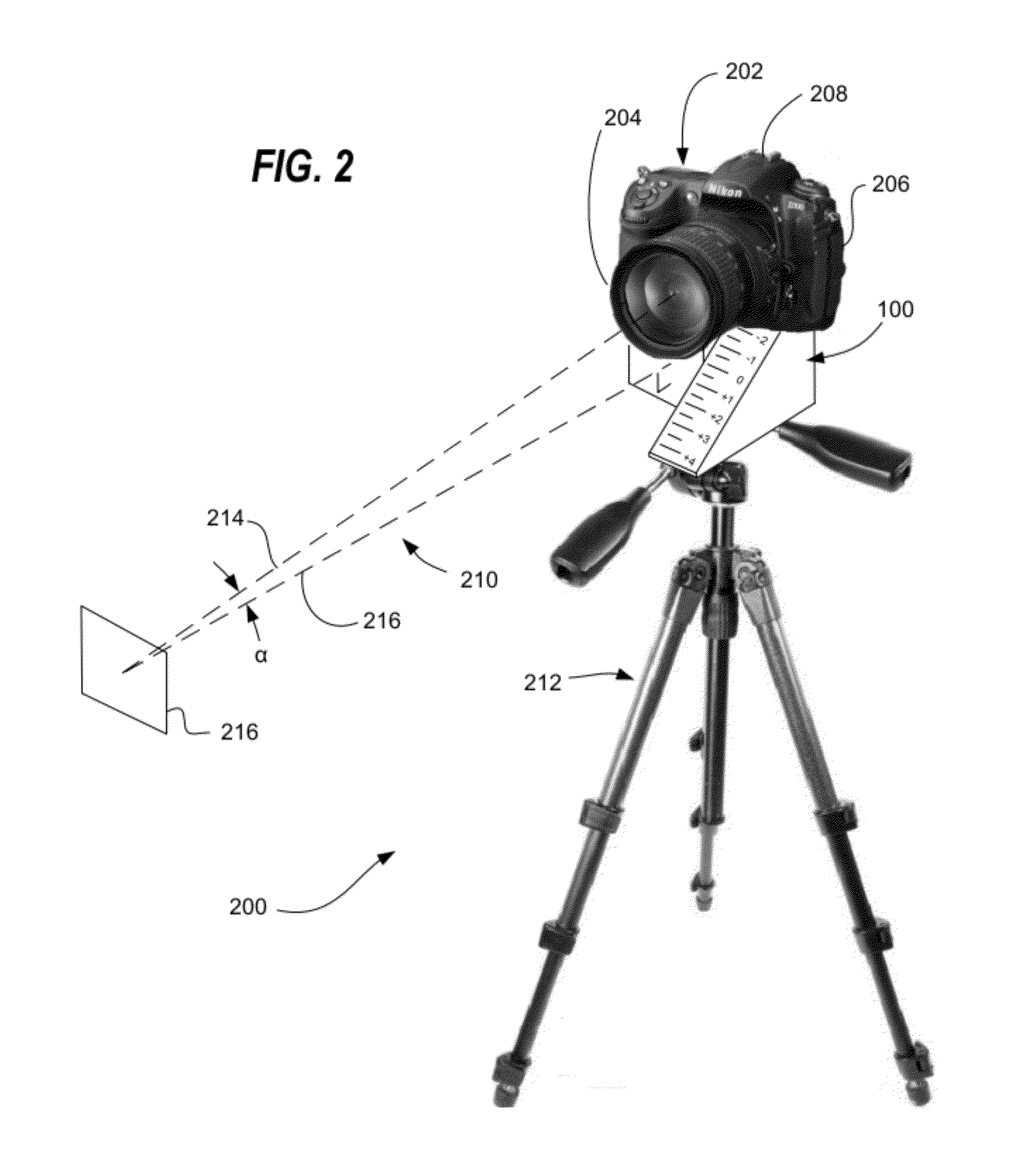

Autofocus calibration for long lenses

InactiveUS20120170922A1Projector focusing arrangementCamera focusing arrangementCamera lensTarget surface

A method for calibrating a focus point for a camera lens may include capturing a reflection of a focus point measuring device that is affixed to the camera. The method may include evaluating a captured image of the reflection to measure a calibration amount for a focus point, and adjusting a focus point of a lens of the camera by the calibration amount. The focus point measuring device may include a substantially planar target surface defining a plane, and a ruled target surface inclined at substantially 45° to the substantially planar target and extending through the plane thereof, marked to indicate respective distances in front of and behind the plane. The device may further include a fixture for holding the substantially planar target surface and the ruled target surface in a defined orientation to the camera, enabling performance of the method.

Owner:SHUSTER GARY S

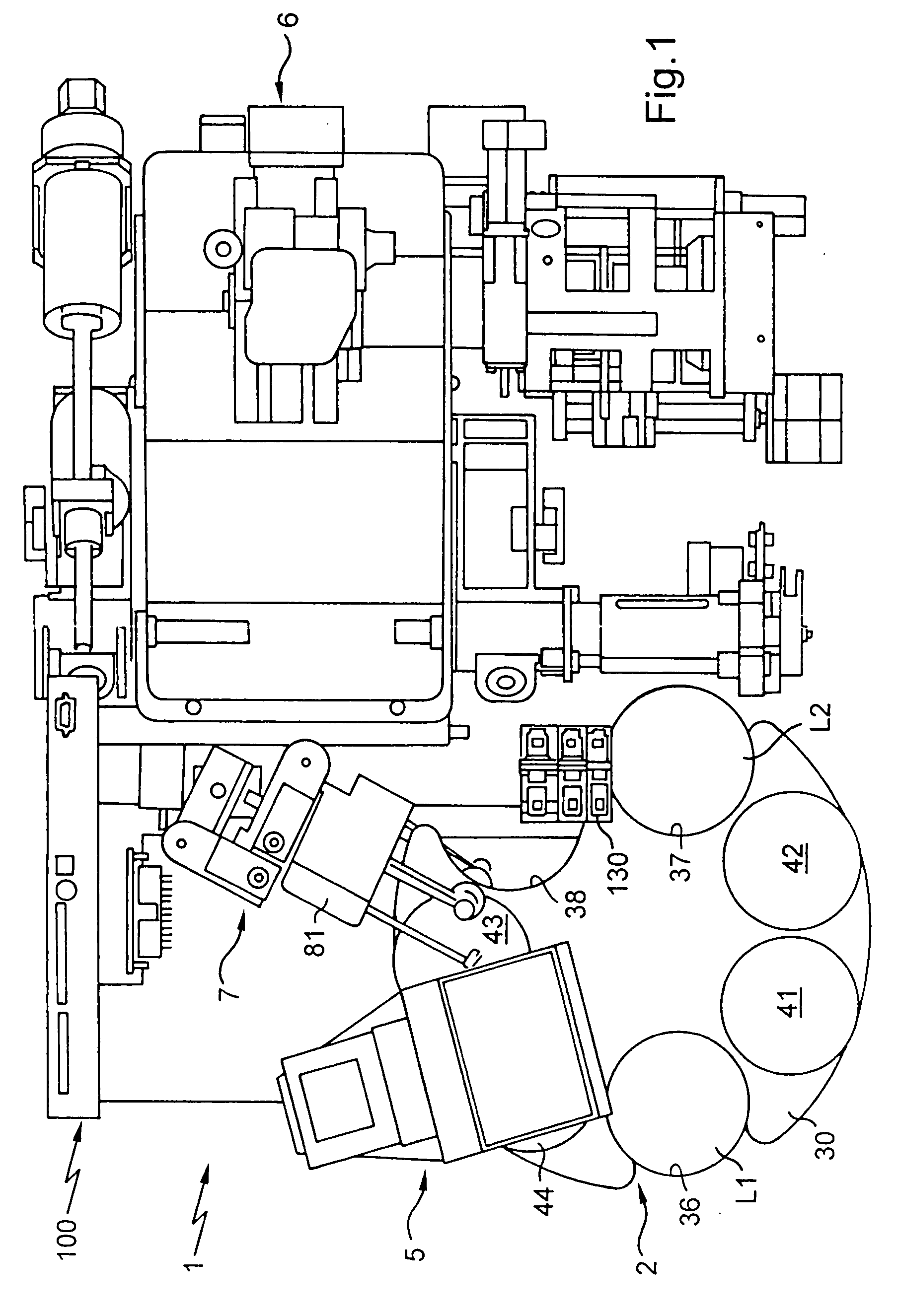

Method and a device for measuring the power of an ophthalmic lens by combined feeling and contactless overall measurement

ActiveUS20070273870A1Increase flexibilityImprove versatilityUsing optical meansRefractive power measurementOptical propertyMeasurement point

A method includes a step of contactless optical measurement of the local value of at least one refringence optical characteristic of the lens over defined local zone around the measurement point of the lens, and at least one step of determining the axial position of the measurement point on one of the faces of the lens; the axial position of the measurement point obtained is compared with the local value of the optical characteristic of the lens at the measurement point as determined from the contactless optical measurement, in order to deduce therefrom at least one vertex optical power of the lens at the measurement point.

Owner:ESSILOR INT CIE GEN DOPTIQUE

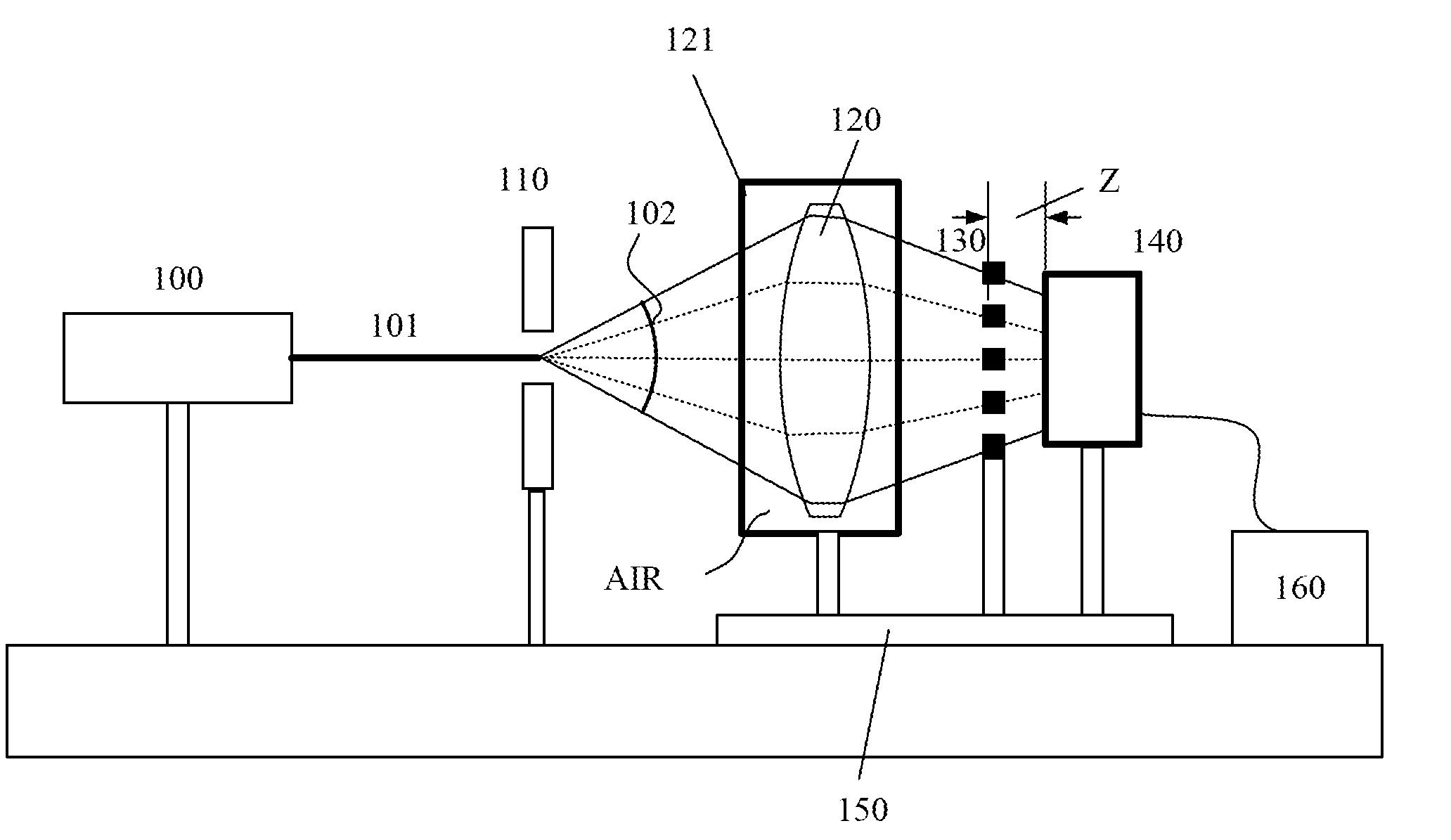

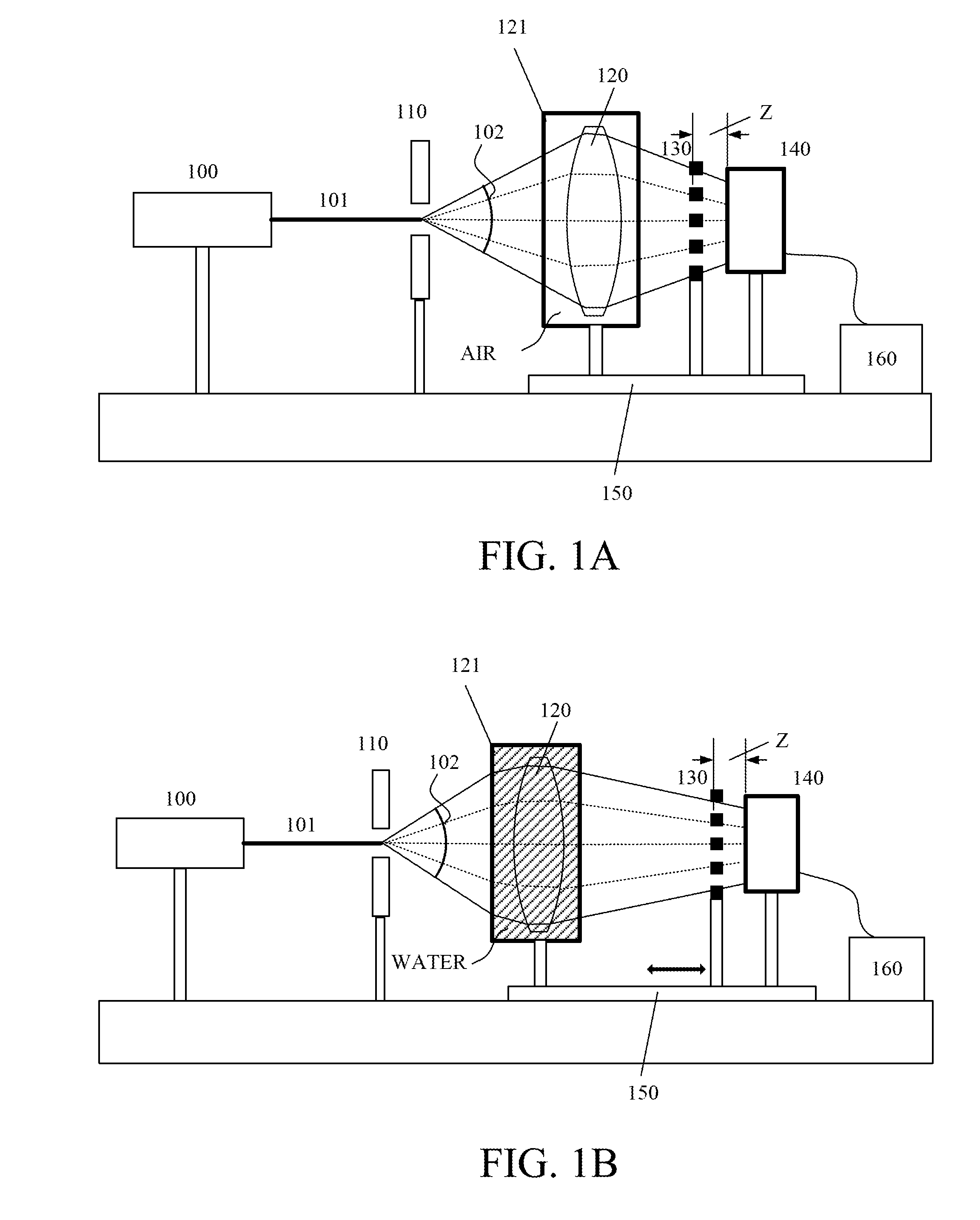

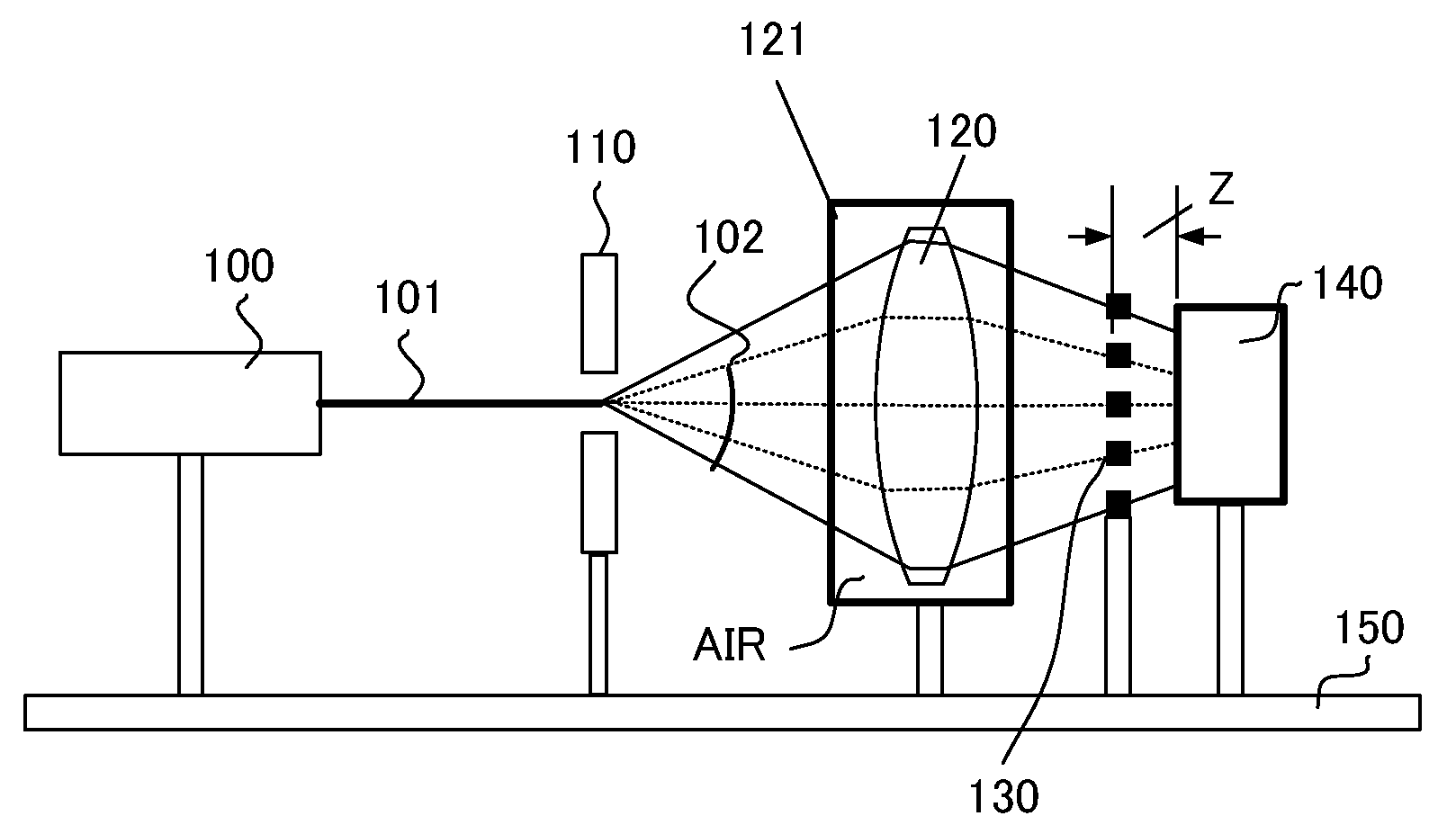

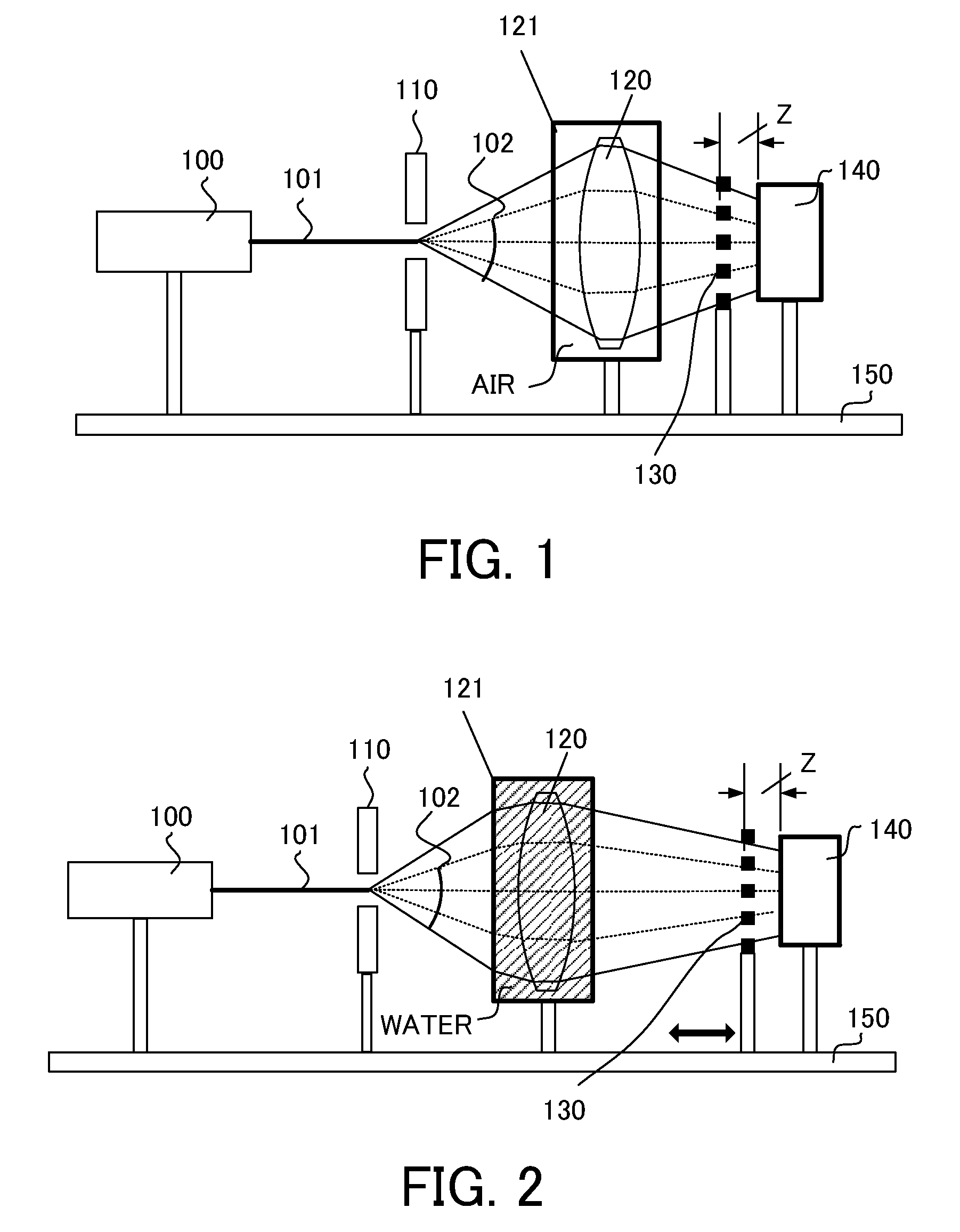

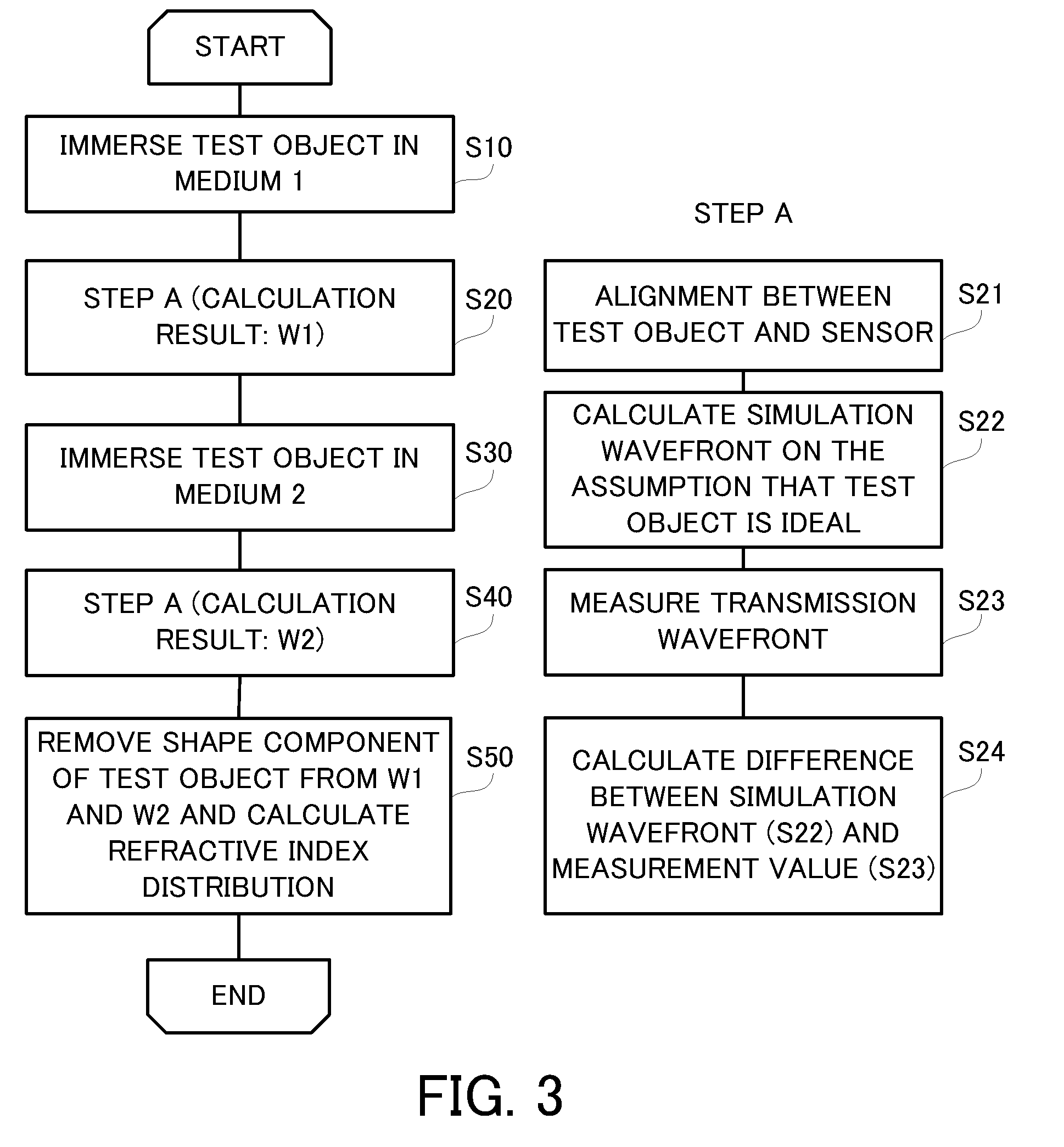

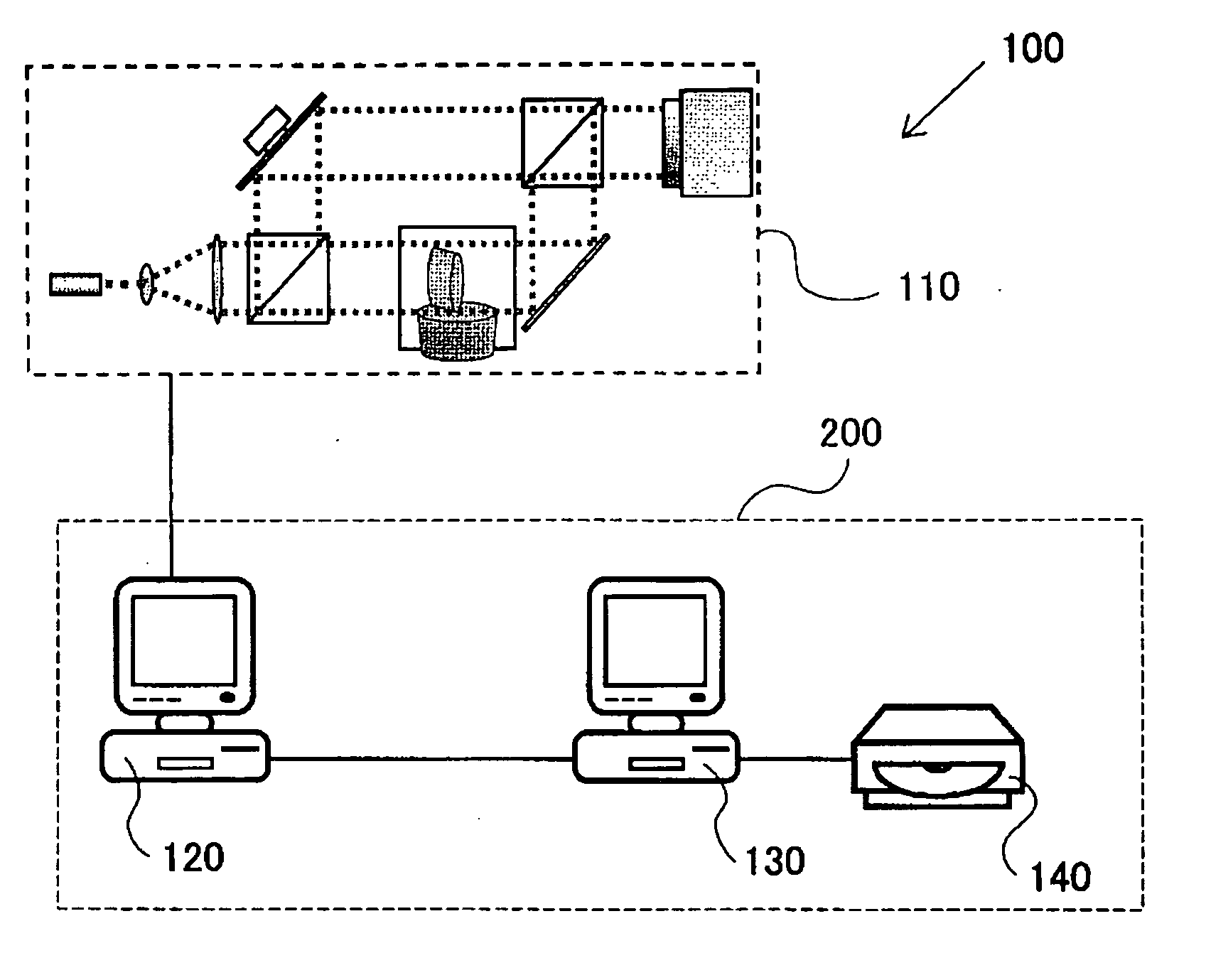

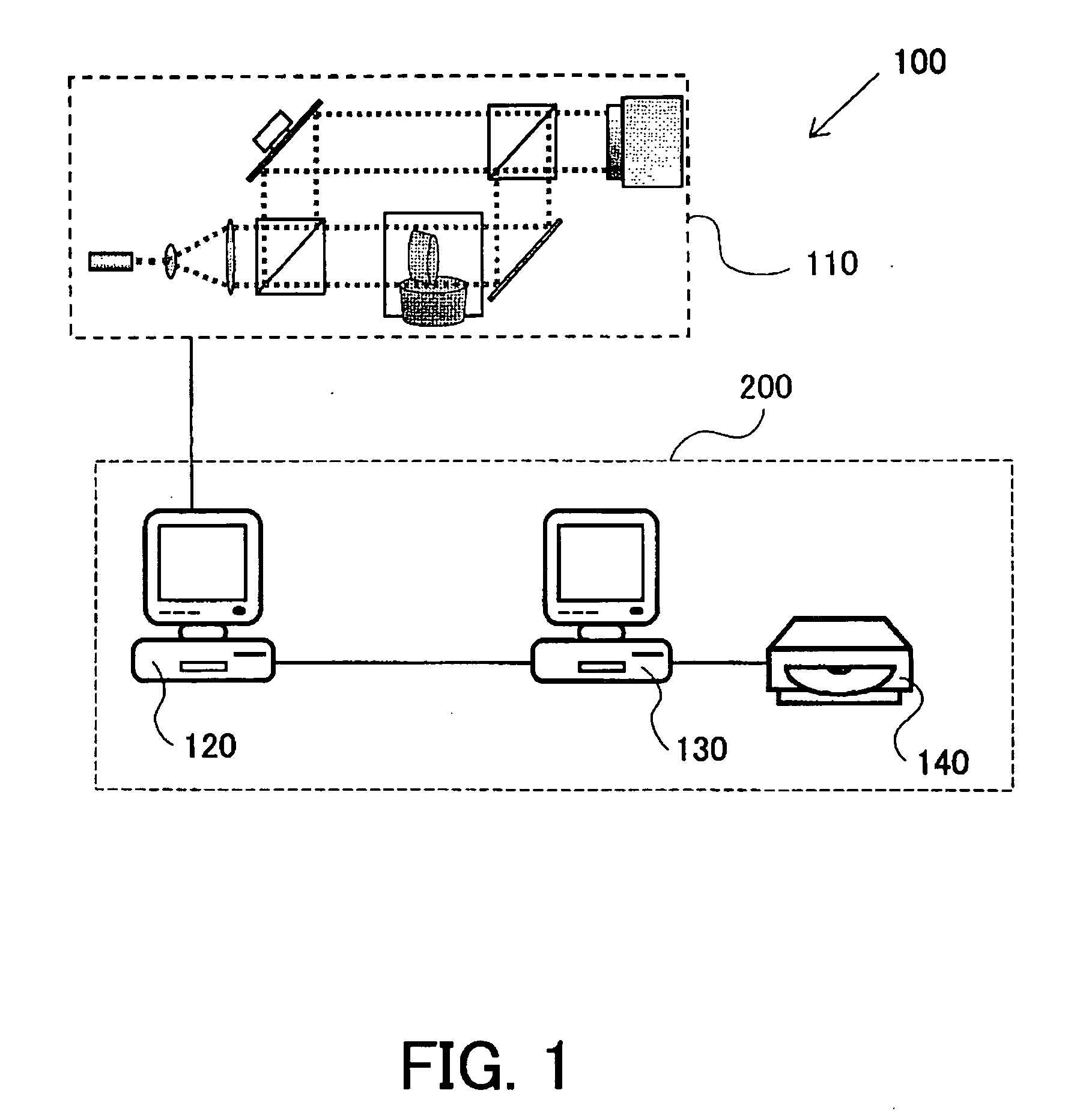

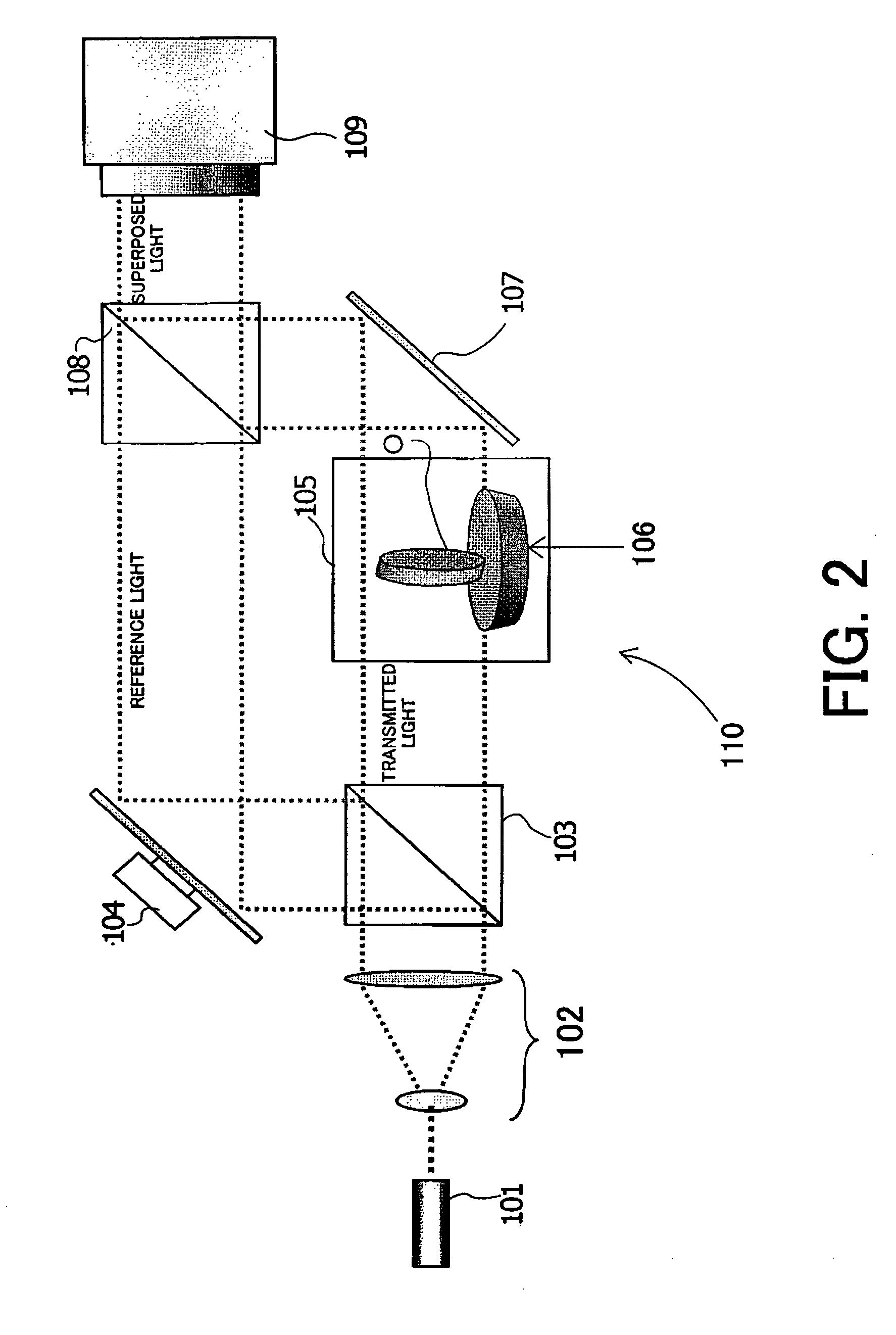

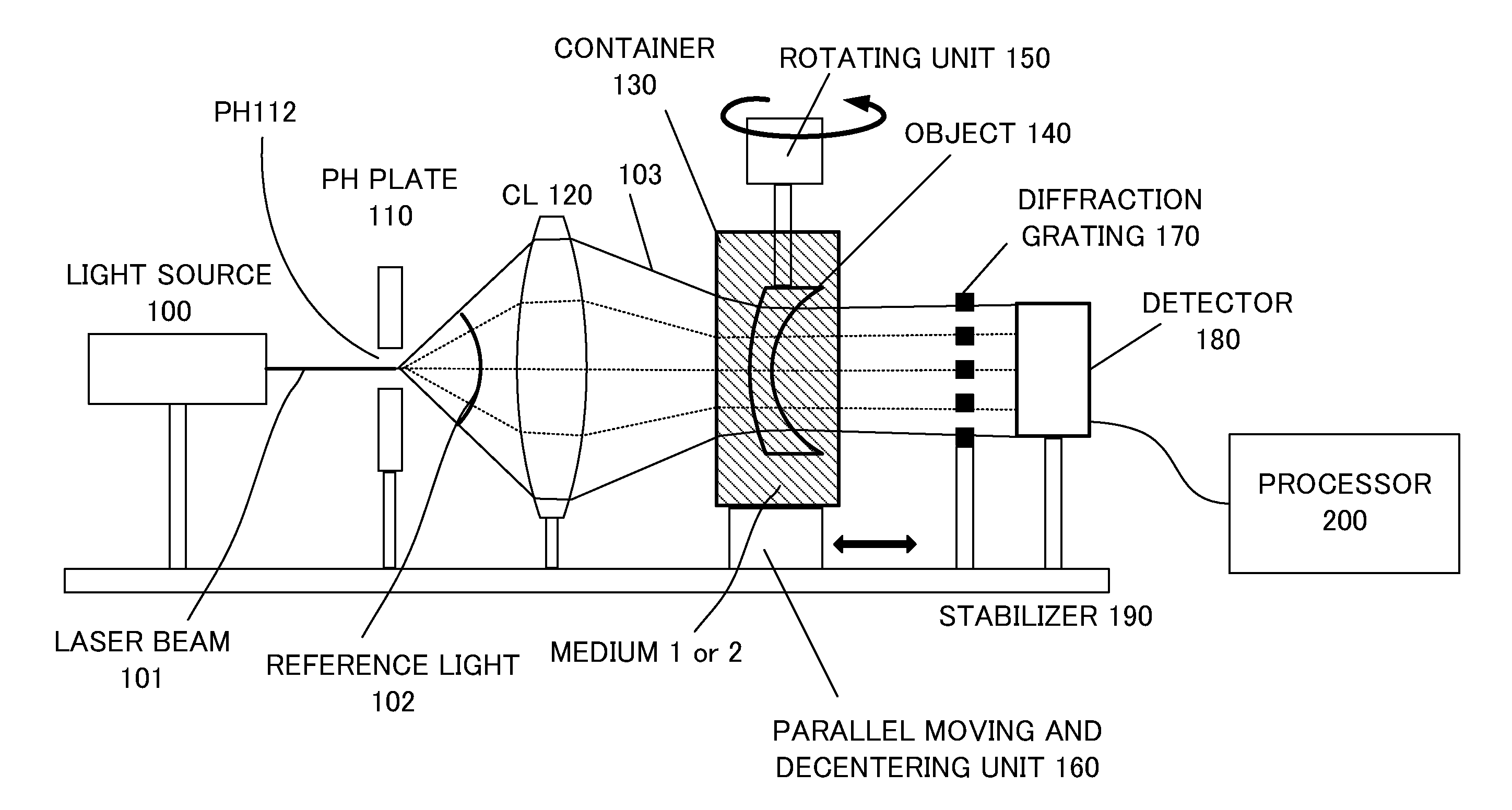

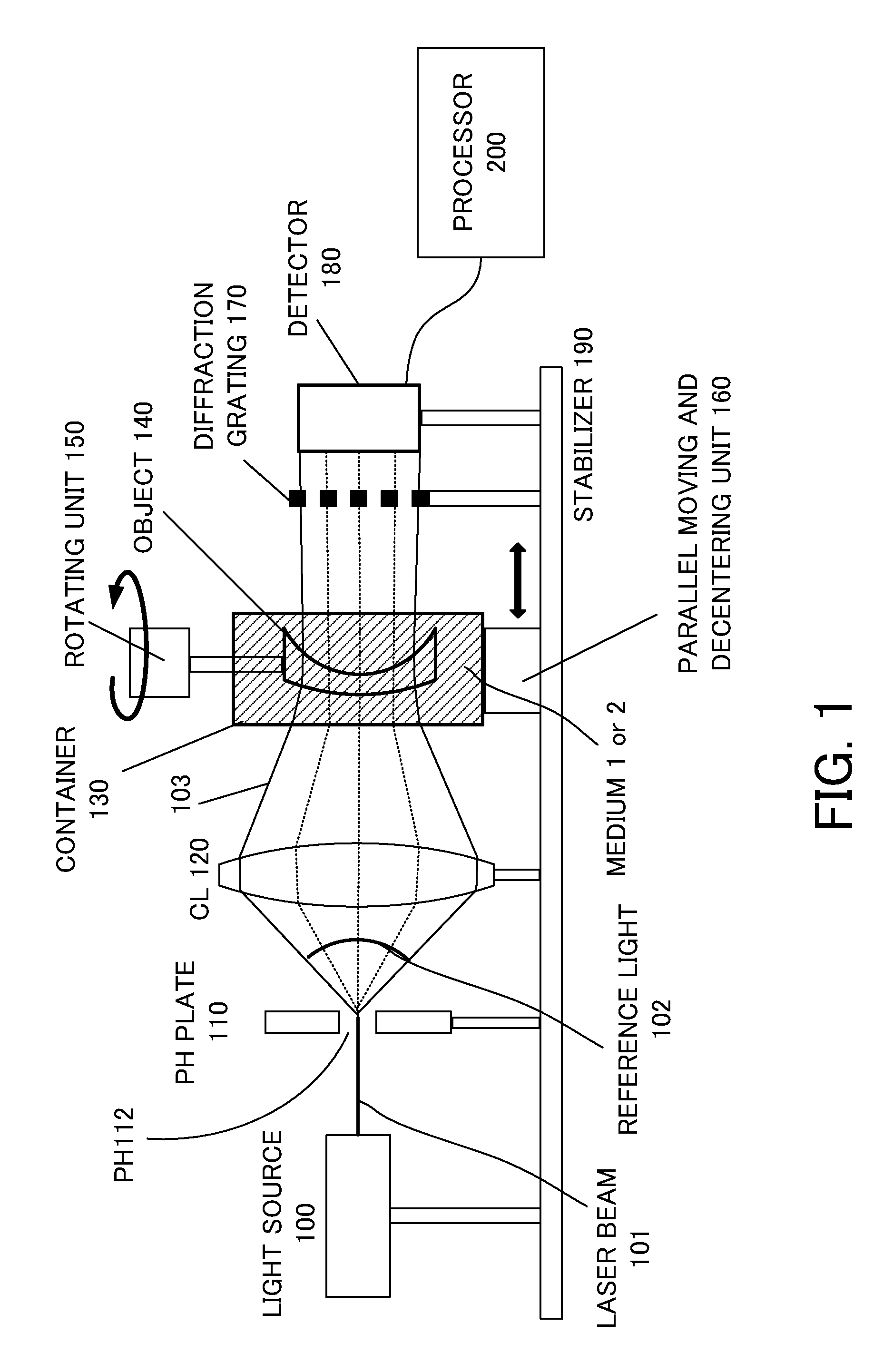

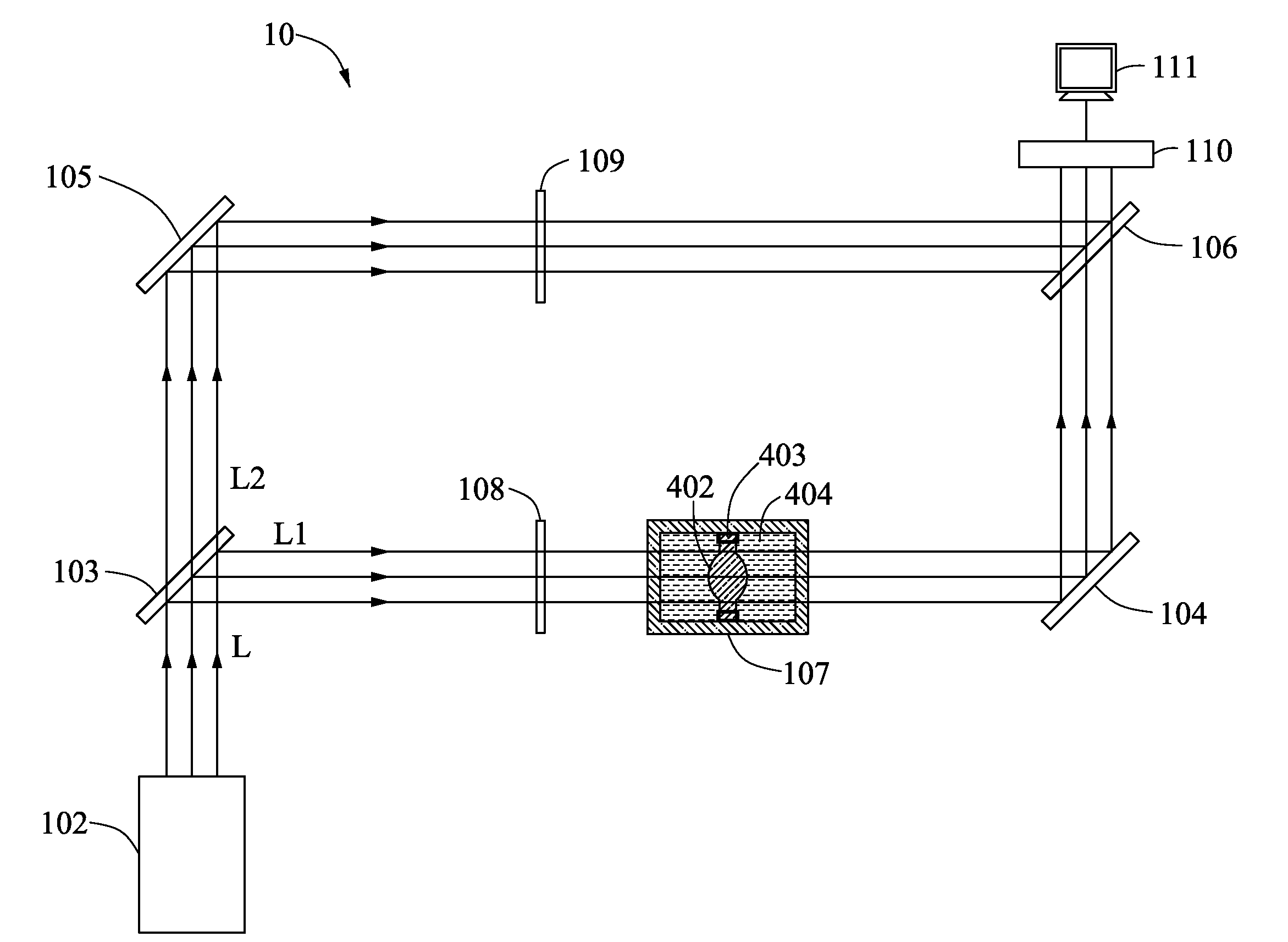

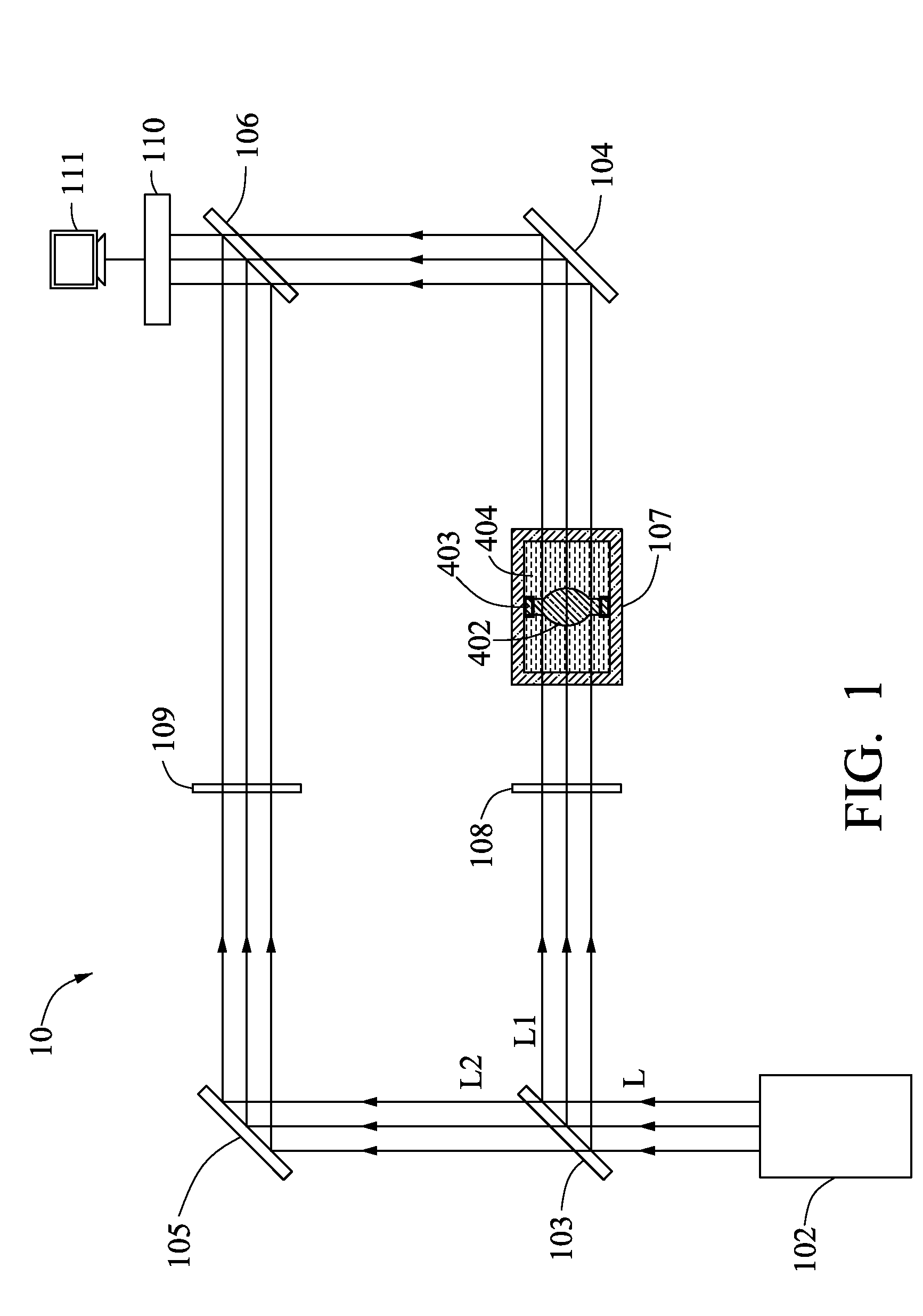

Refractive index distribution measurement method and refractive index distribution measurement apparatus

ActiveUS20100165355A1High precision measurementPhase-affecting property measurementsUsing optical meansWavefrontTest object

A refractive index distribution measurement method includes the steps of measuring a first transmission wavefront of a test object by introducing reference light to the test object immersed in a first medium having a first refractive index lower than that of the test object by 0.01 or more, measuring a second transmission wavefront of the test object by introducing the reference light to the test object immersed in a second medium having a second refractive index lower than that of the test object by 0.01 or more and different from the first refractive index, and obtaining a refractive index distribution of the test object based on a measurement result of the first transmission wavefront and a measurement result of the second transmission wavefront.

Owner:CANON KK

Image processing apparatus and refractive index distribution measuring apparatus

InactiveUS20060159332A1Improve accuracyHigh precision productionPhase-affecting property measurementsCharacter and pattern recognitionWavefrontImaging processing

An image processing apparatus is disclosed which can produce refractive index distribution data with high accuracy without limiting directions in which transmitted wavefronts are measured. The image processing apparatus has a simulating section which simulates a transmitted wavefront in each of the directions to produce a second transmitted wavefront image based on first refractive index distribution data, a comparing section which produces first information indicating the result of comparison between the second transmitted wavefront image and the first transmitted wavefront image, and a changing section which changes the first refractive index distribution data based on the first information to produce second refractive index distribution data. In the apparatus, the processing in the sections is repeated using the second refractive index distribution data as the first refractive index distribution data to produce the resulting second refractive index distribution data which is used as the output refractive index distribution data.

Owner:CANON KK

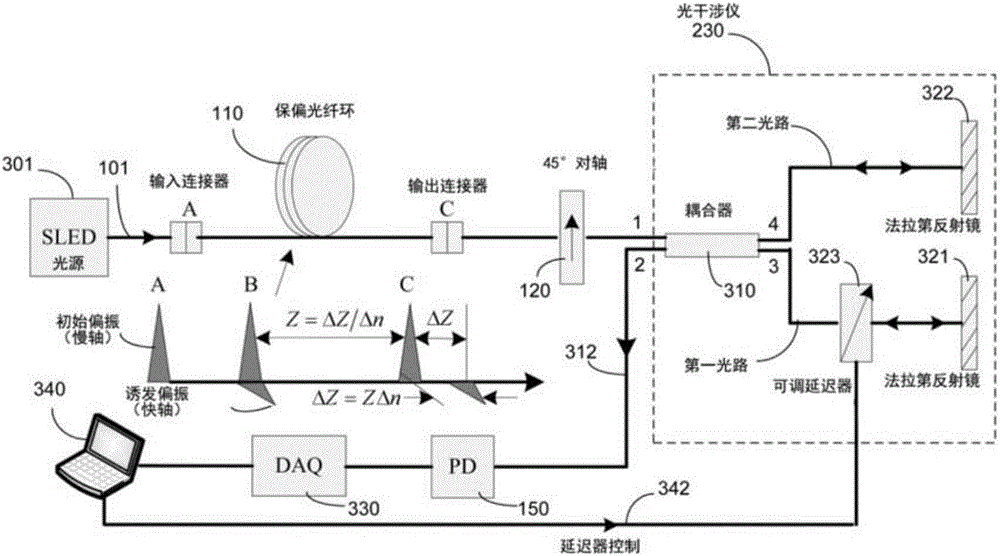

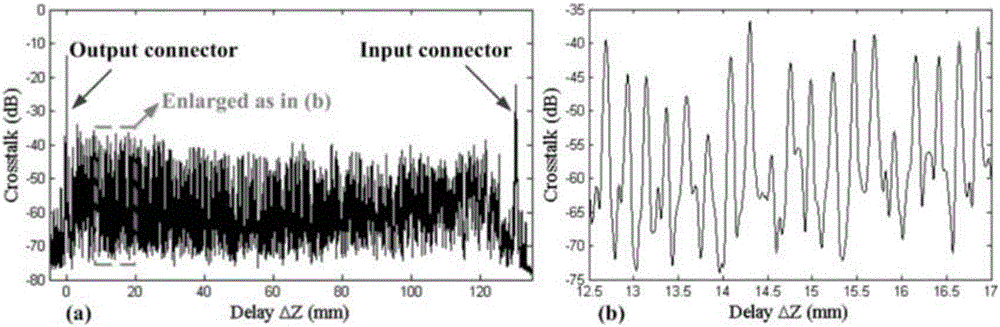

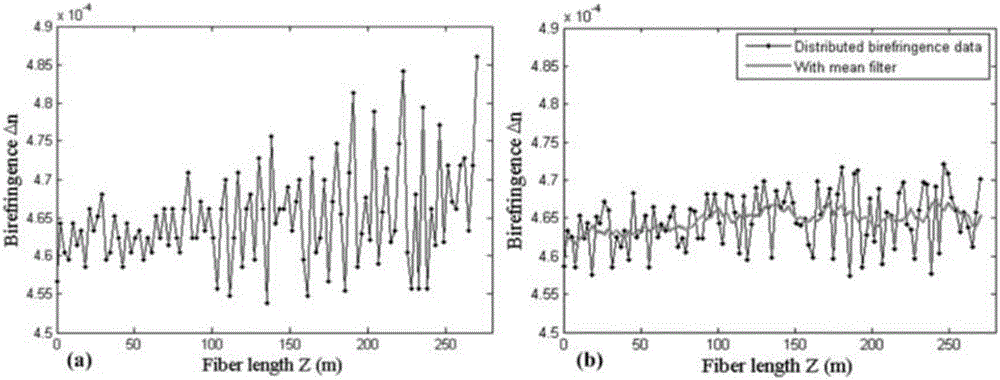

Method of comprehensively evaluating polarization maintaining optical fiber characteristic by using distributed polarization crosstalk analyzer and apparatus thereof

ActiveCN105865752ARefractive power measurementPolarization-maintaining optical fiberOptical polarization

A method of measuring a polarization correlation parameter of a doubly-refractive material and an apparatus are disclosed. The method comprises the following steps of presetting a series of polarization crosstalk peaks with known distance periods along a length of the doubly-refractive material; introducing probe light and entering into the doubly-refractive material, and detecting the probe light from the doubly-refractive material; processing the detected probe light so as to determine a sensed polarization crosstalk peak position with the known distance period and a width; and using the acquired polarization crosstalk peak position with the known distance period and the width to extract one or more polarization correlation parameters of the doubly-refractive material.

Owner:苏州光环科技有限公司

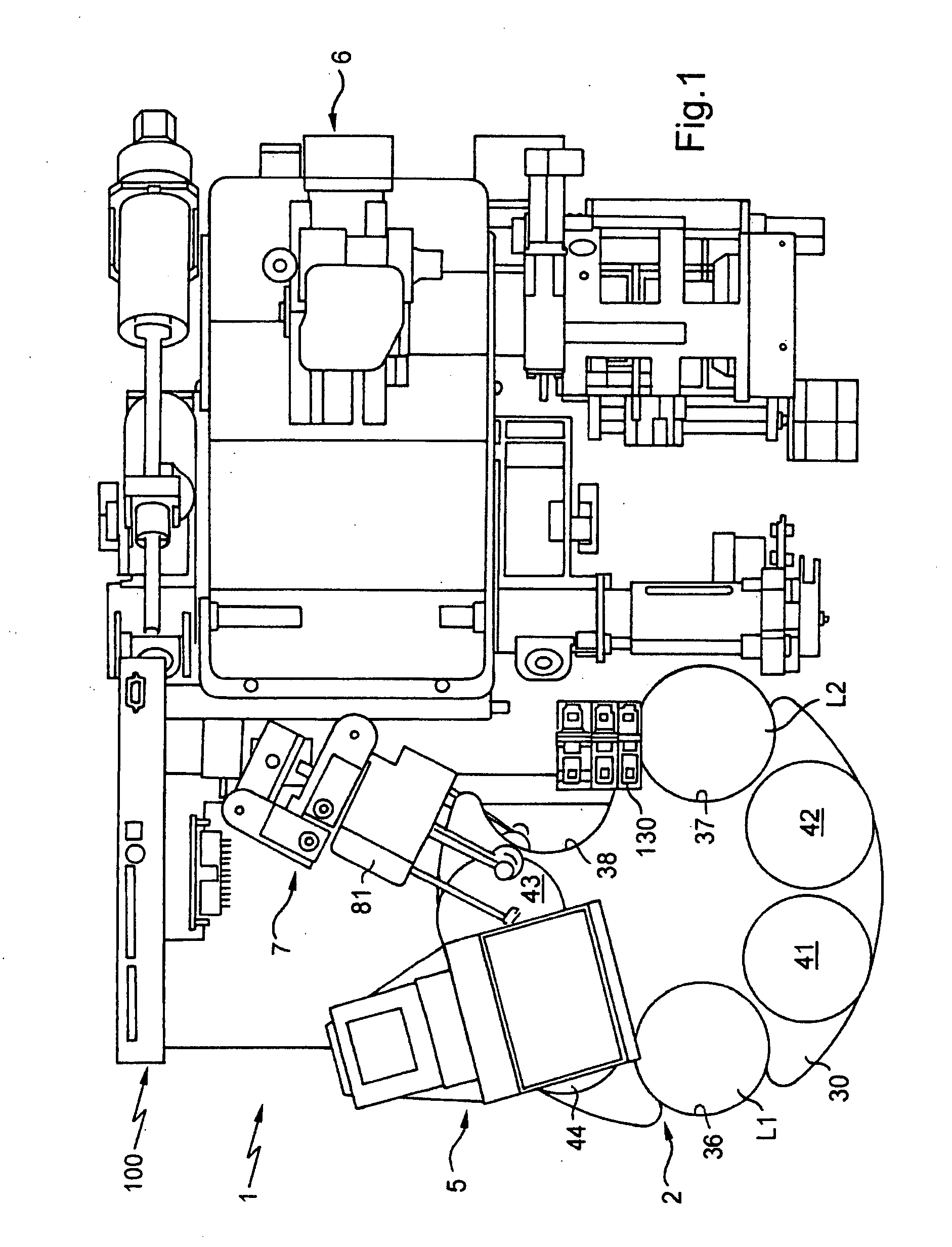

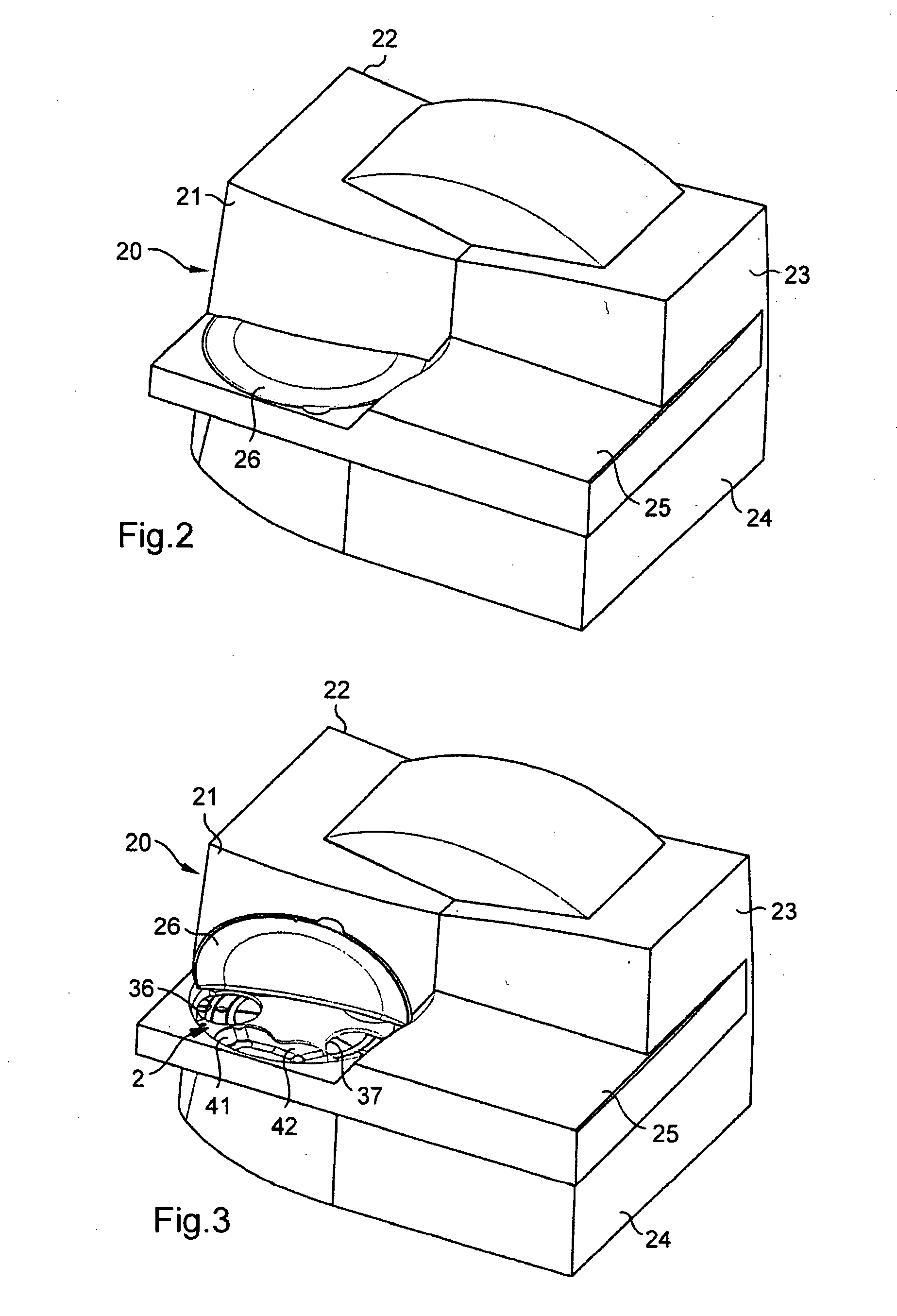

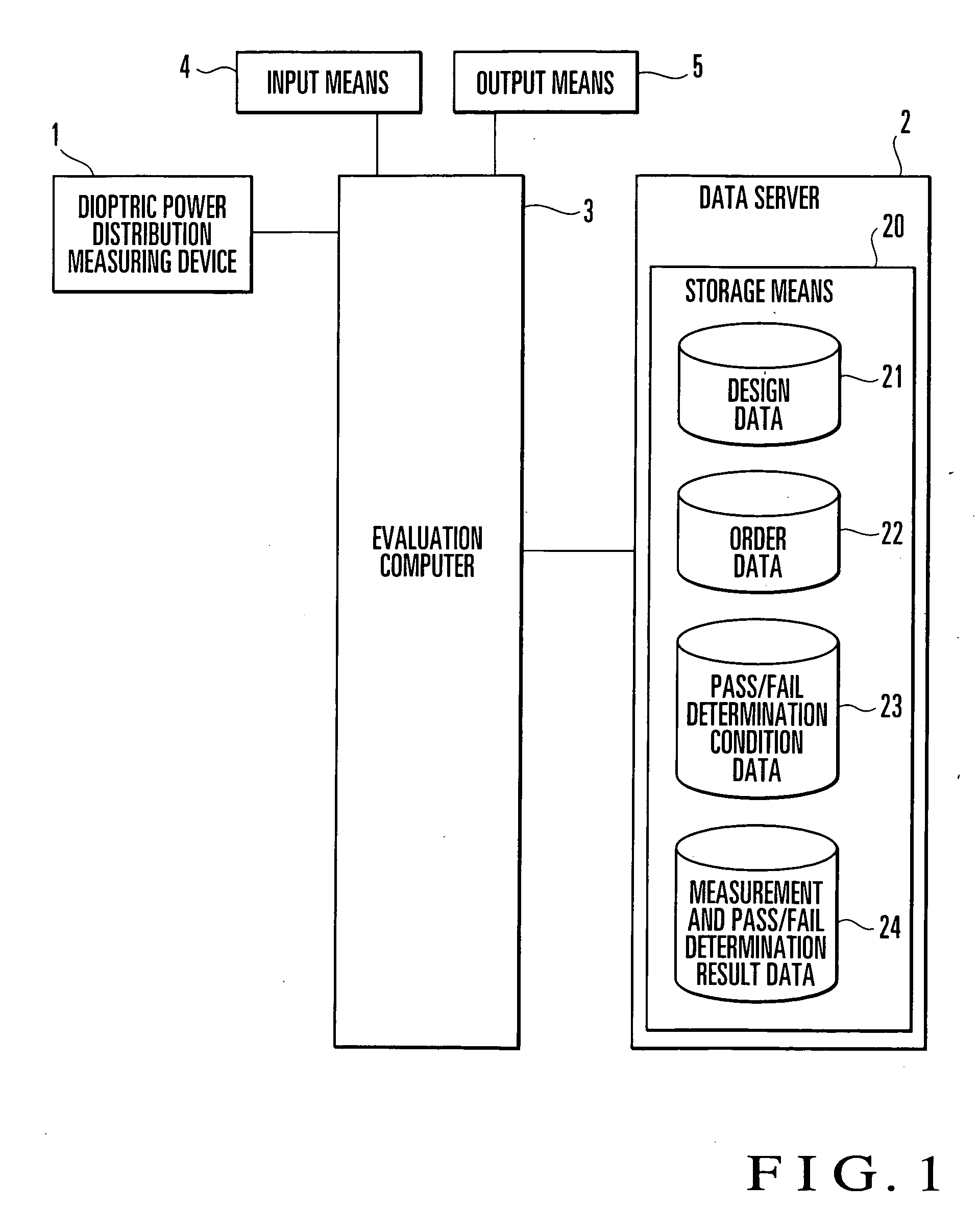

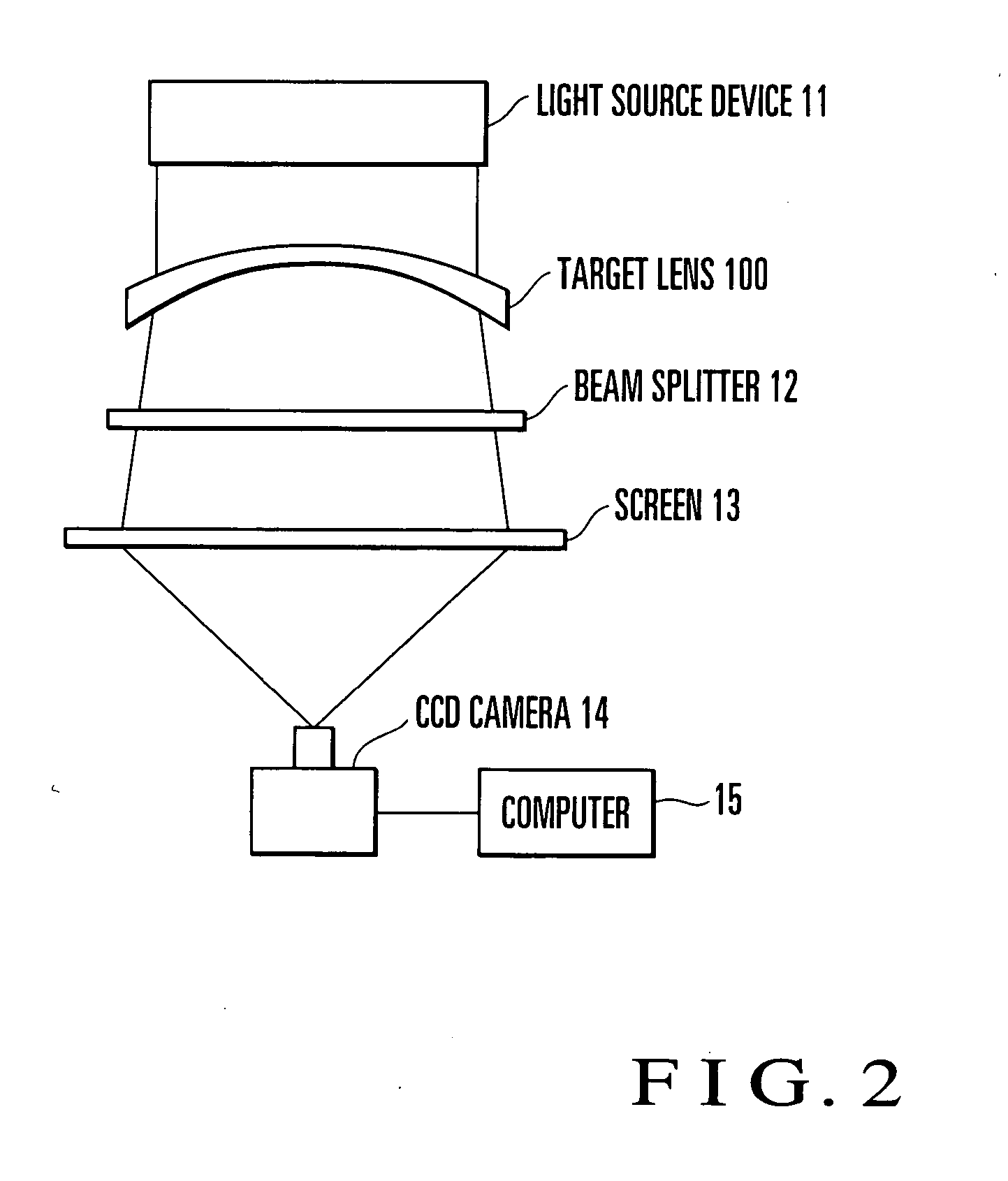

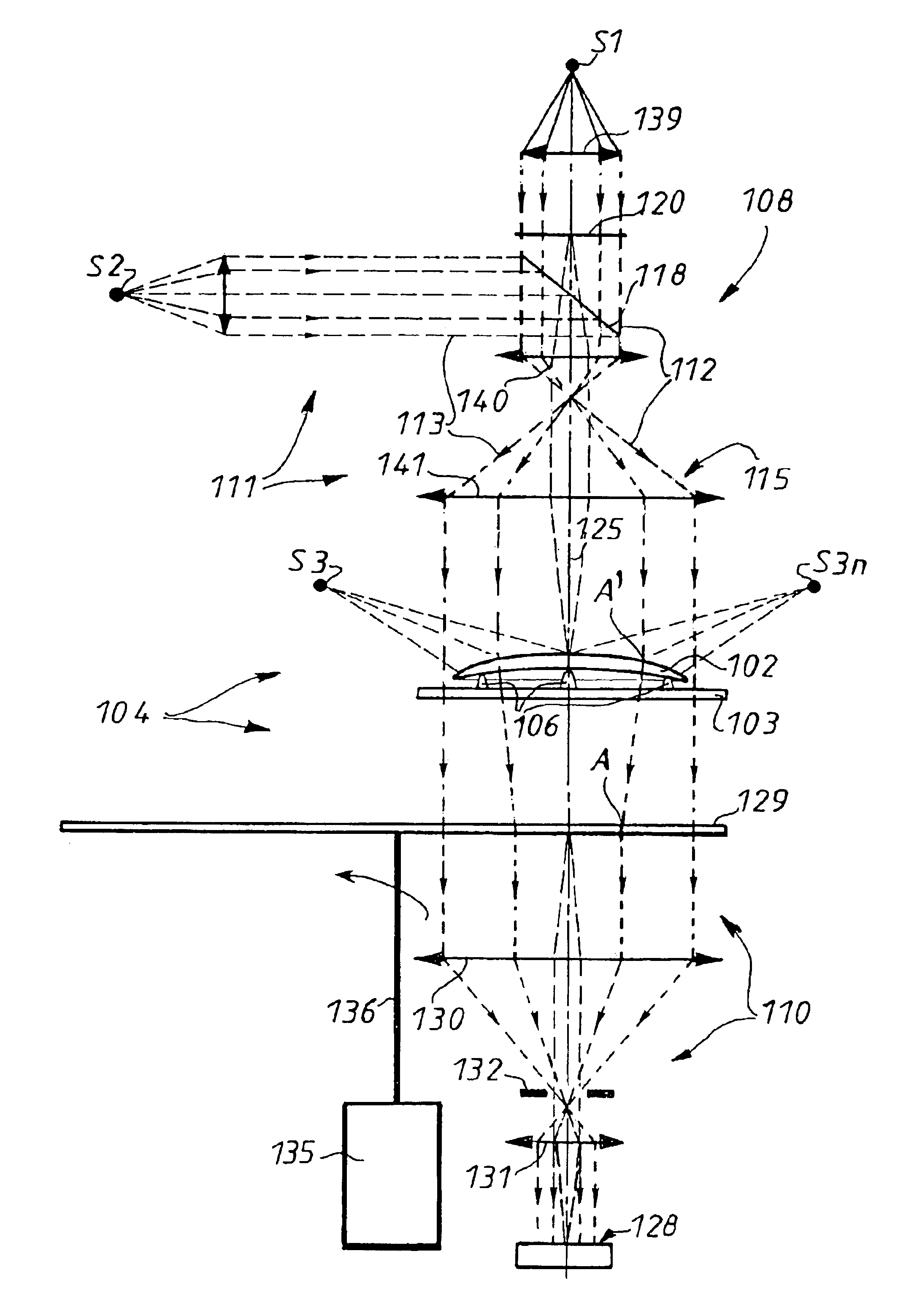

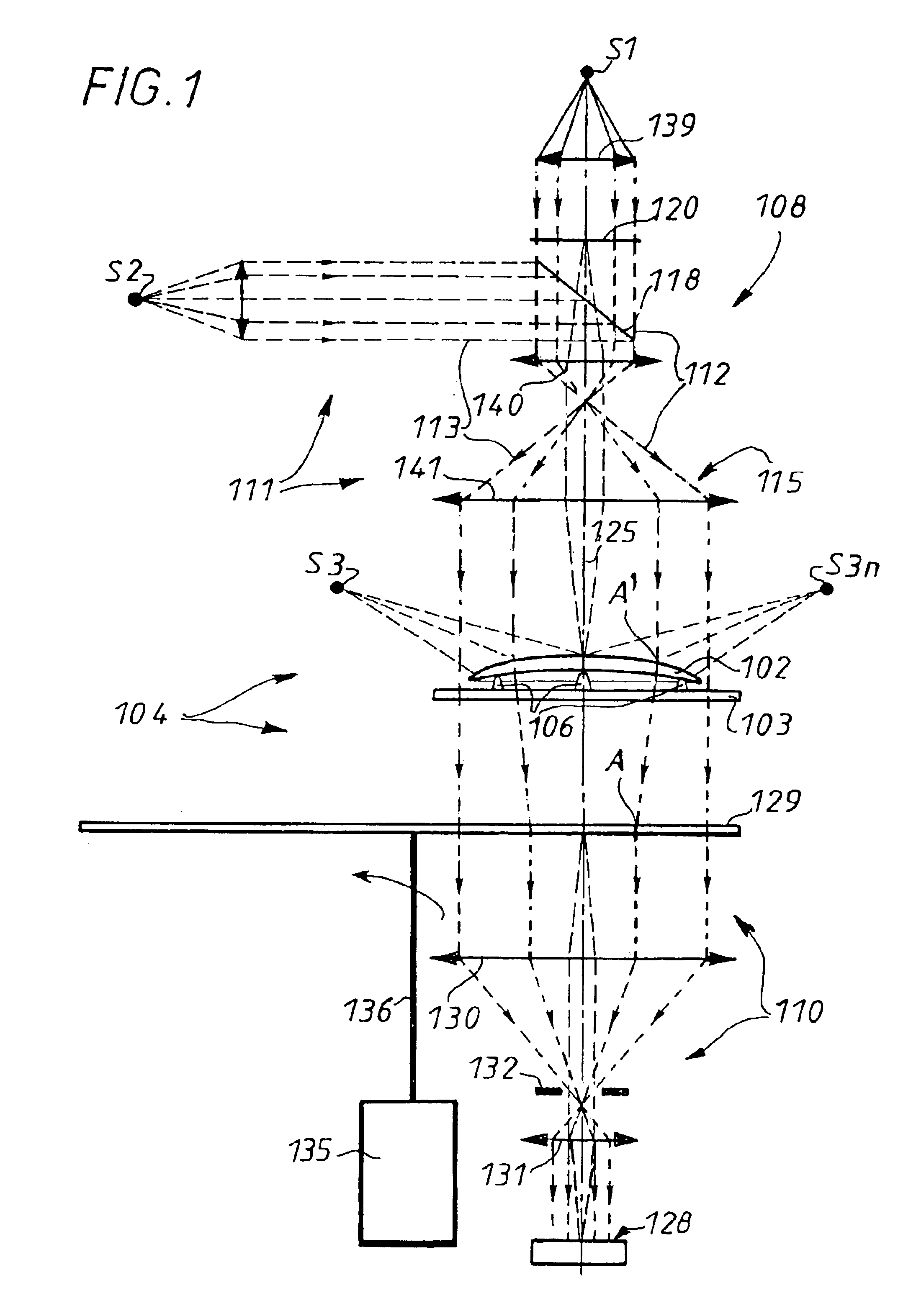

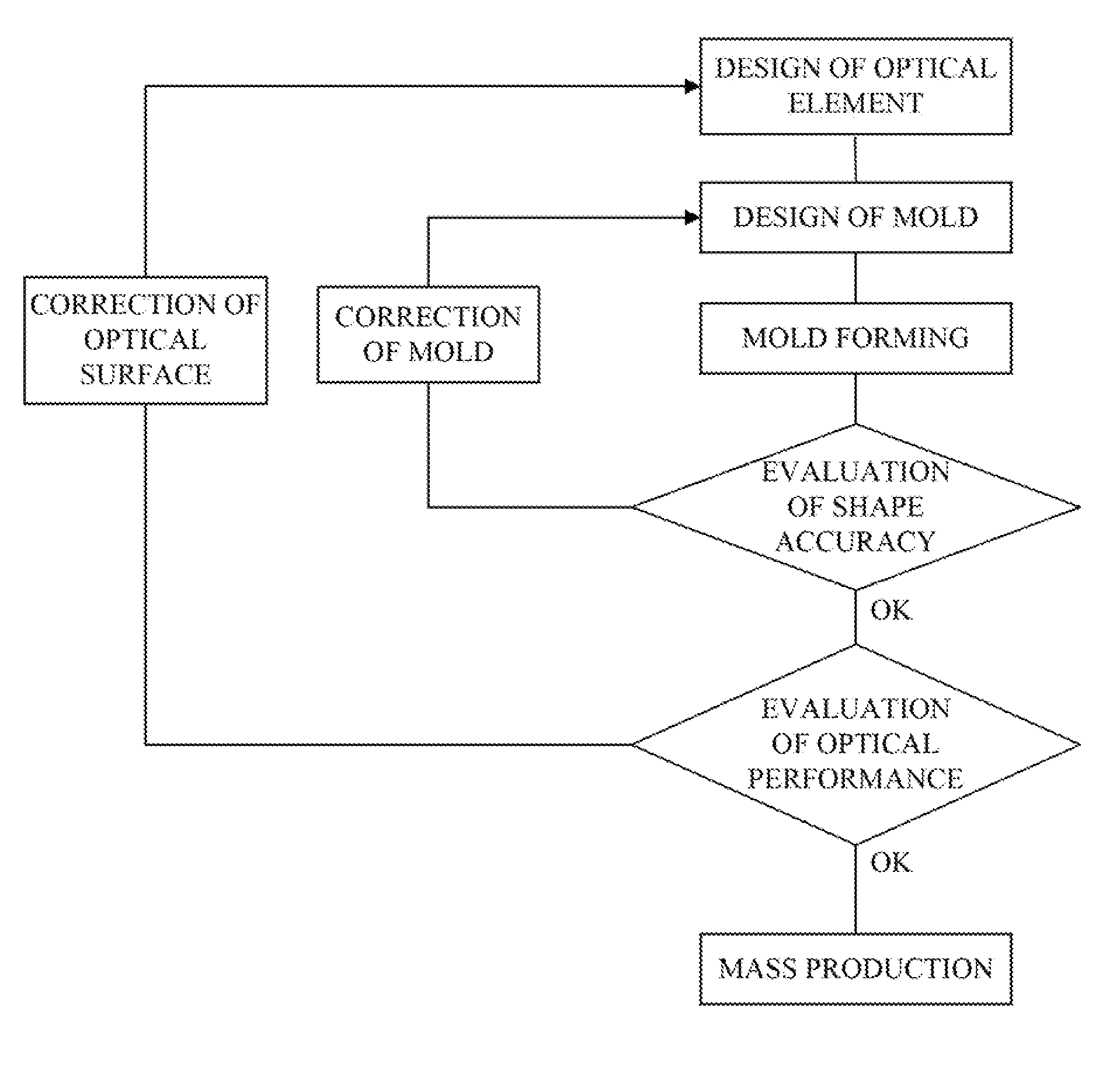

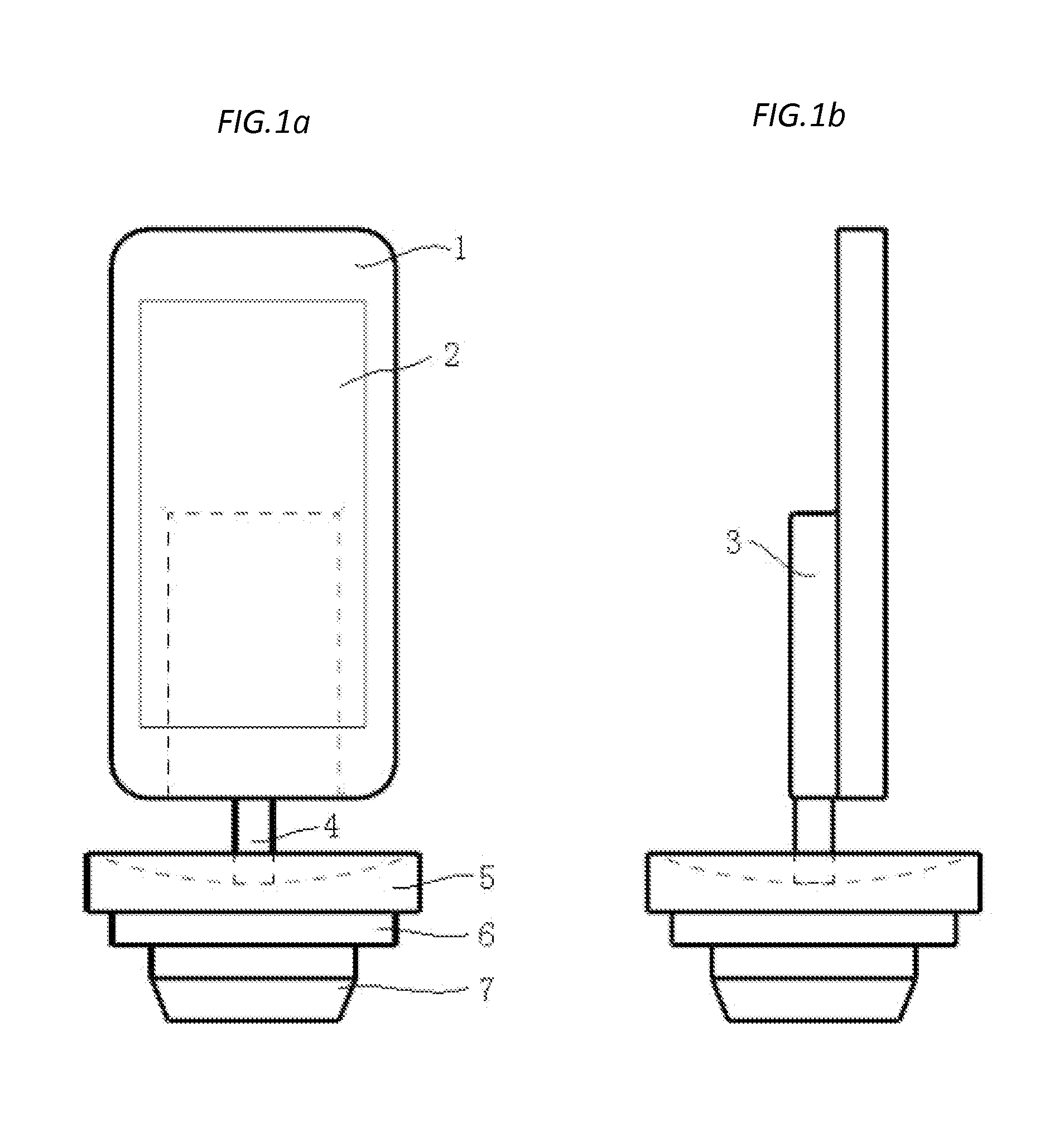

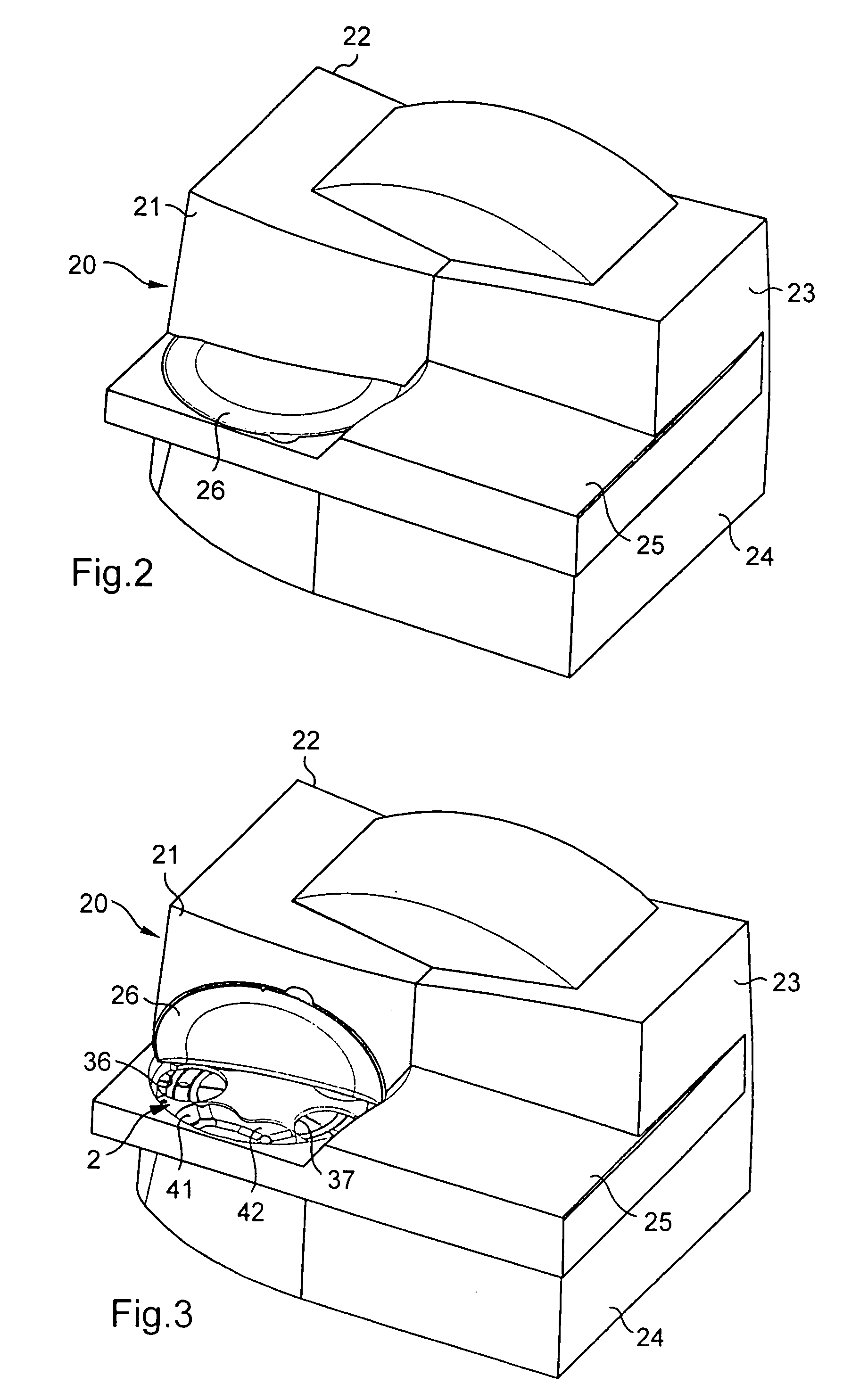

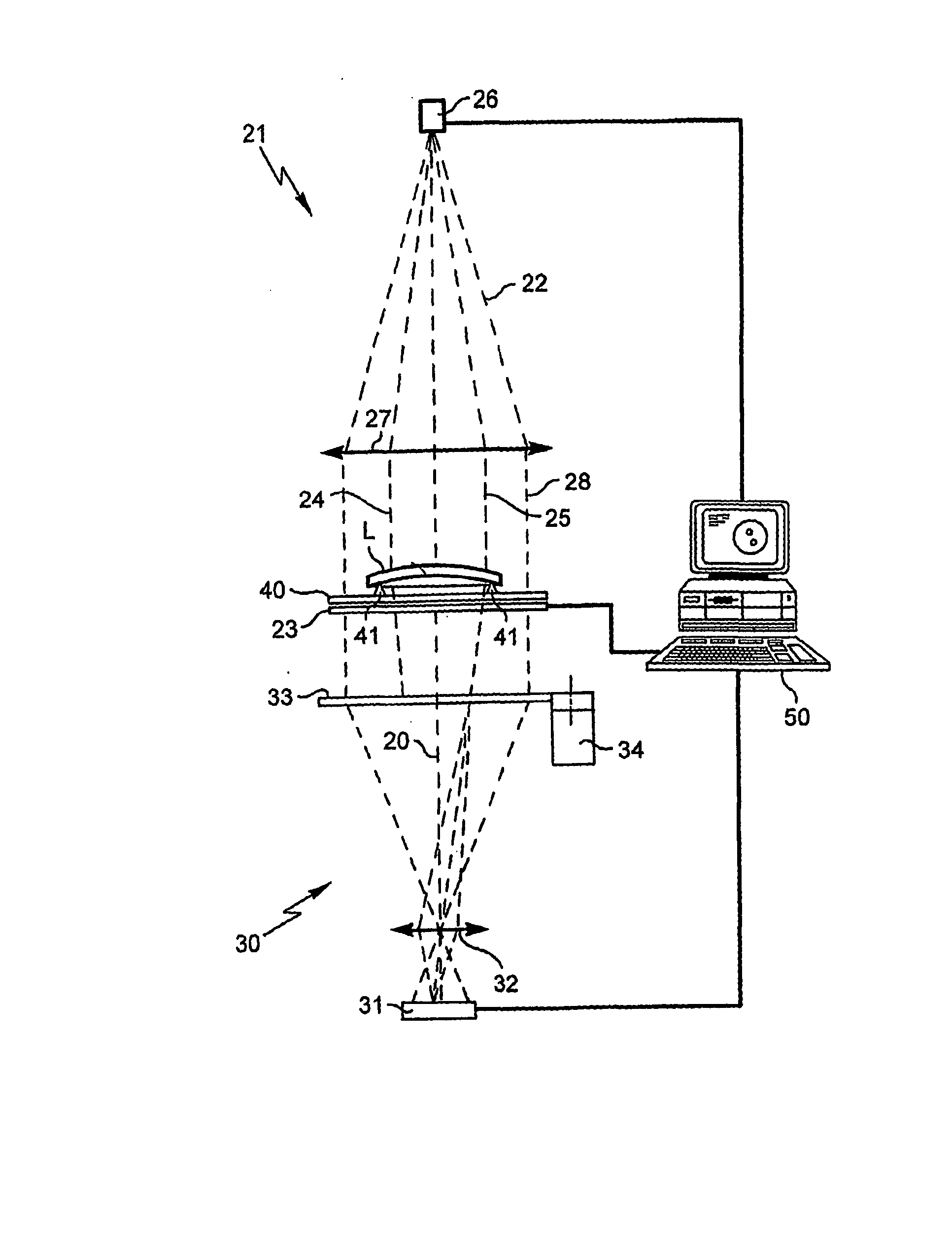

Method and device for evaluating spectacle lens or mold for molding spectacle lens, and method and system for manufacturing spectacle lens

InactiveUS20050179863A1Using optical meansRefractive power measurementVirtual spaceMeasurement point

A dioptric power distribution measuring device (1) measures the dioptric power distribution of a target lens. A computer (3) constructs a design lens spatial model in a virtual space, and calculates the dioptric power distribution of the design lens spatial model by performing simulation processing for incident / exit light for only the same point in the design lens spatial model as a measurement point on the target lens. The computer then compares the calculated dioptric power distribution with the dioptric power distribution of the target lens which is measured by the dioptric power distribution measuring device (1).

Owner:HORMANN BROCKHAGEN +1

Device for automatically detecting characteristics of an ophthalmic lens and an automatic device for fitting a centering and drive peg incorporating it

Owner:ESSILOR INT CIE GEN DOPTIQUE

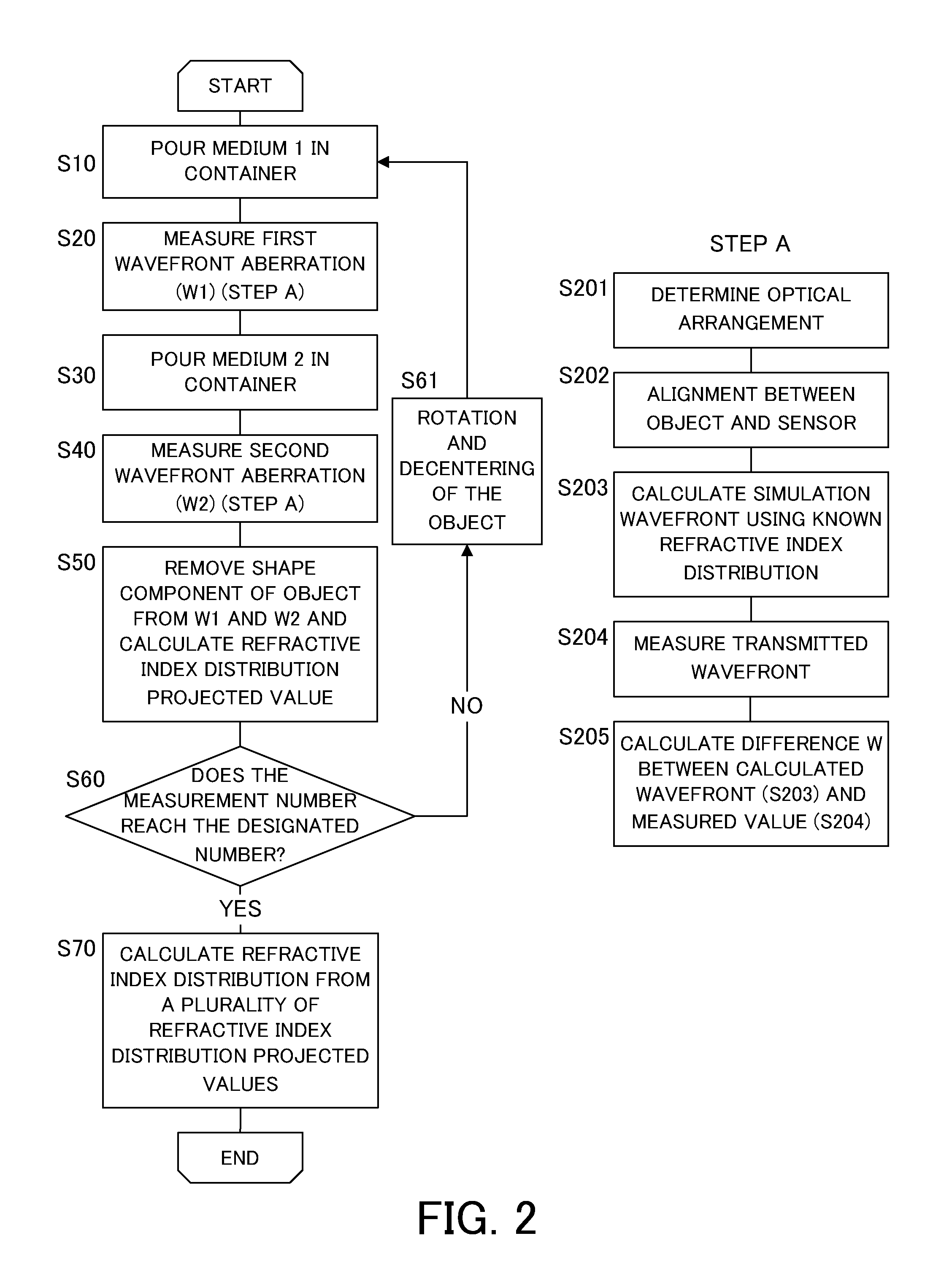

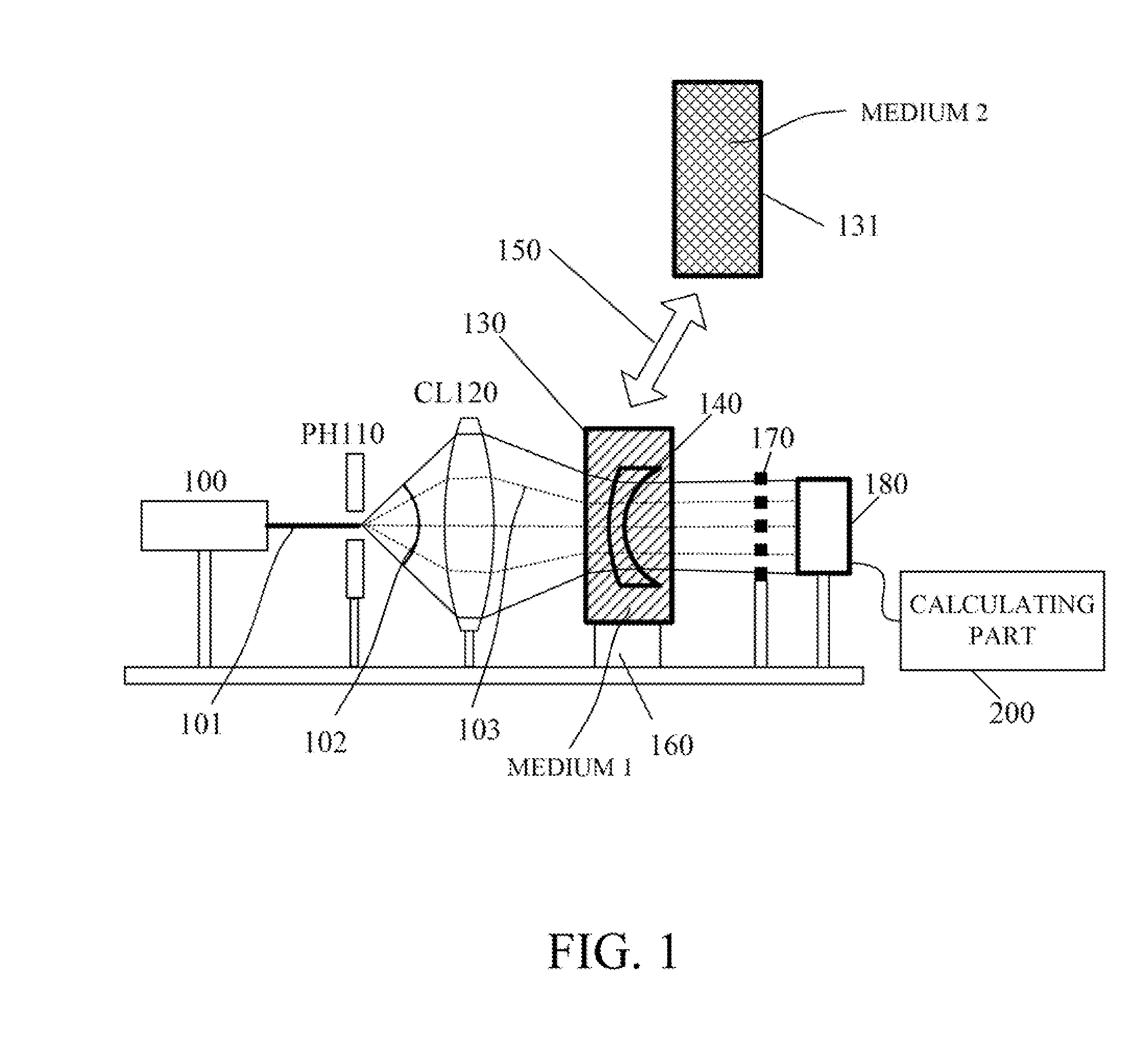

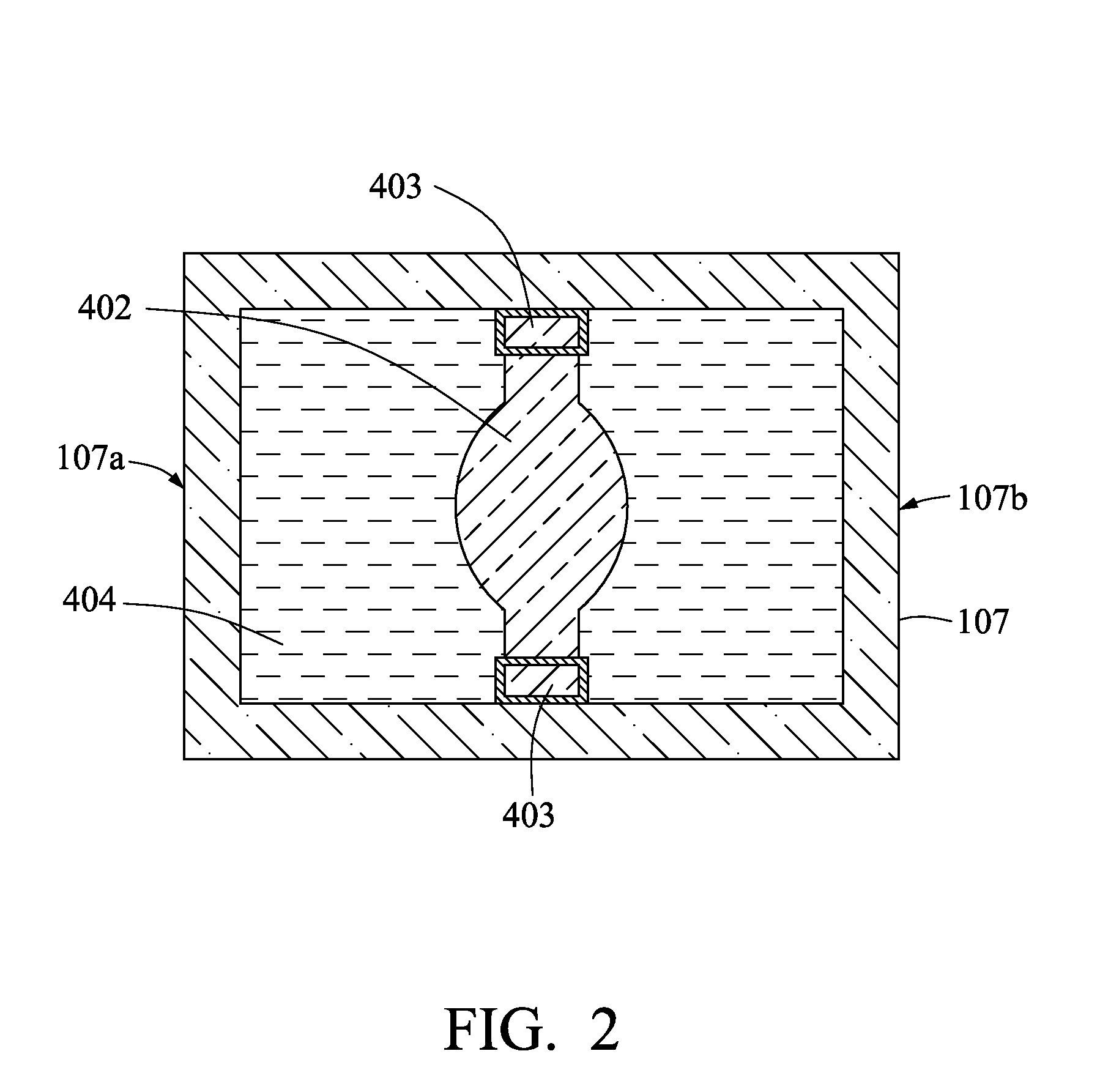

Refractive index distribution measuring method and refractive index distribution measuring apparatus

InactiveUS20110292379A1High precision measurementPhase-affecting property measurementsOptical articlesWavefrontObject based

A method includes the steps of measuring a first transmitted wavefront in a first medium having a first refractive index and a second transmitted wavefront in a second medium having a second refractive index different from the first refractive index, and obtaining a refractive index distribution projected value of the object in each orientation by removing a shape component of the object utilizing measurement results of the first transmitted wavefront and the second transmitted wavefront and each transmitted wavefront of a reference object that has the same shape as that of the object and a specific refractive index distribution and is located in one of the first medium and the second medium with the same orientation as that of the object, and calculating a three-dimensional refractive index distribution of the object based on a plurality of refractive index distribution projected values corresponding to the plurality of orientations.

Owner:CANON KK

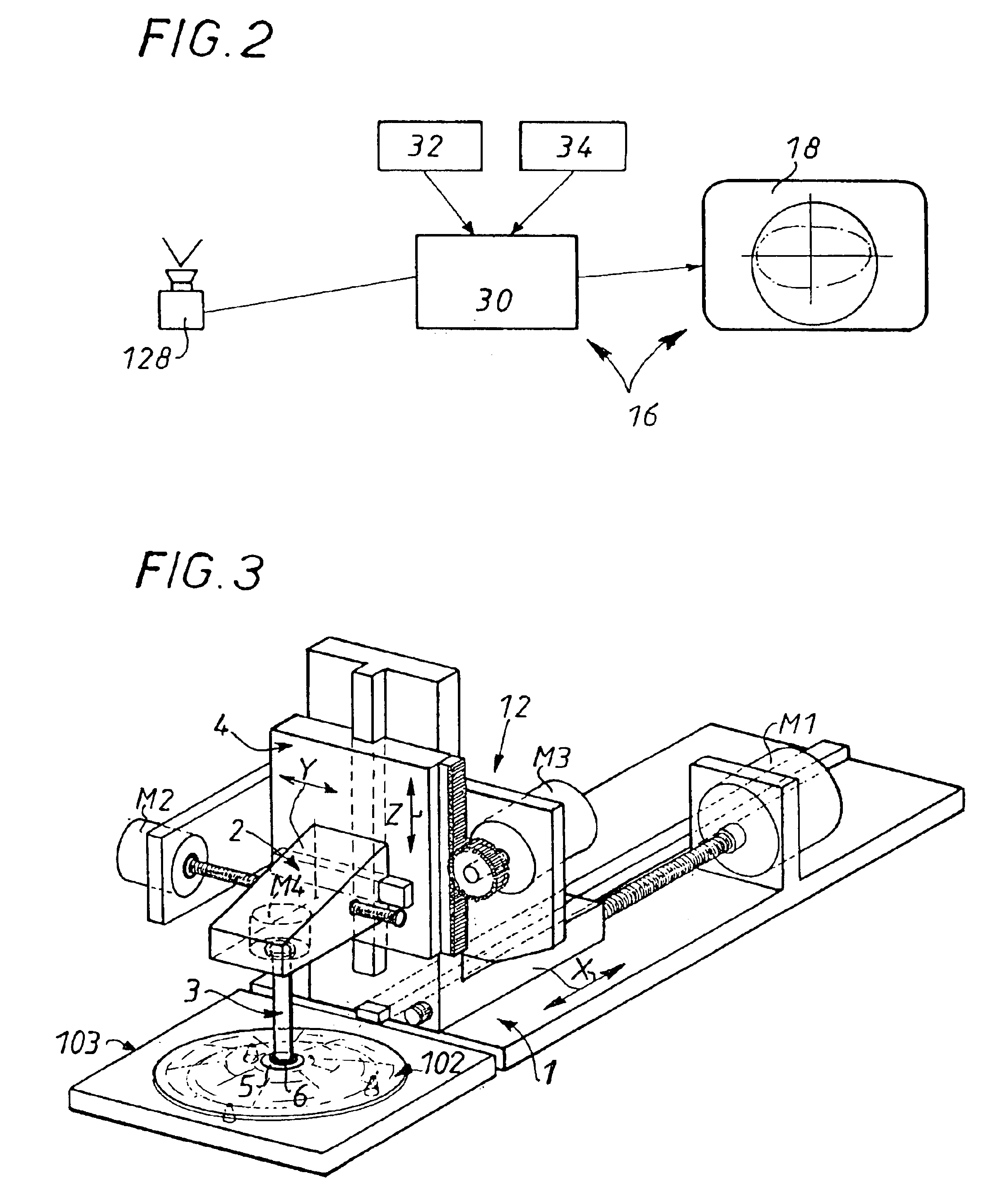

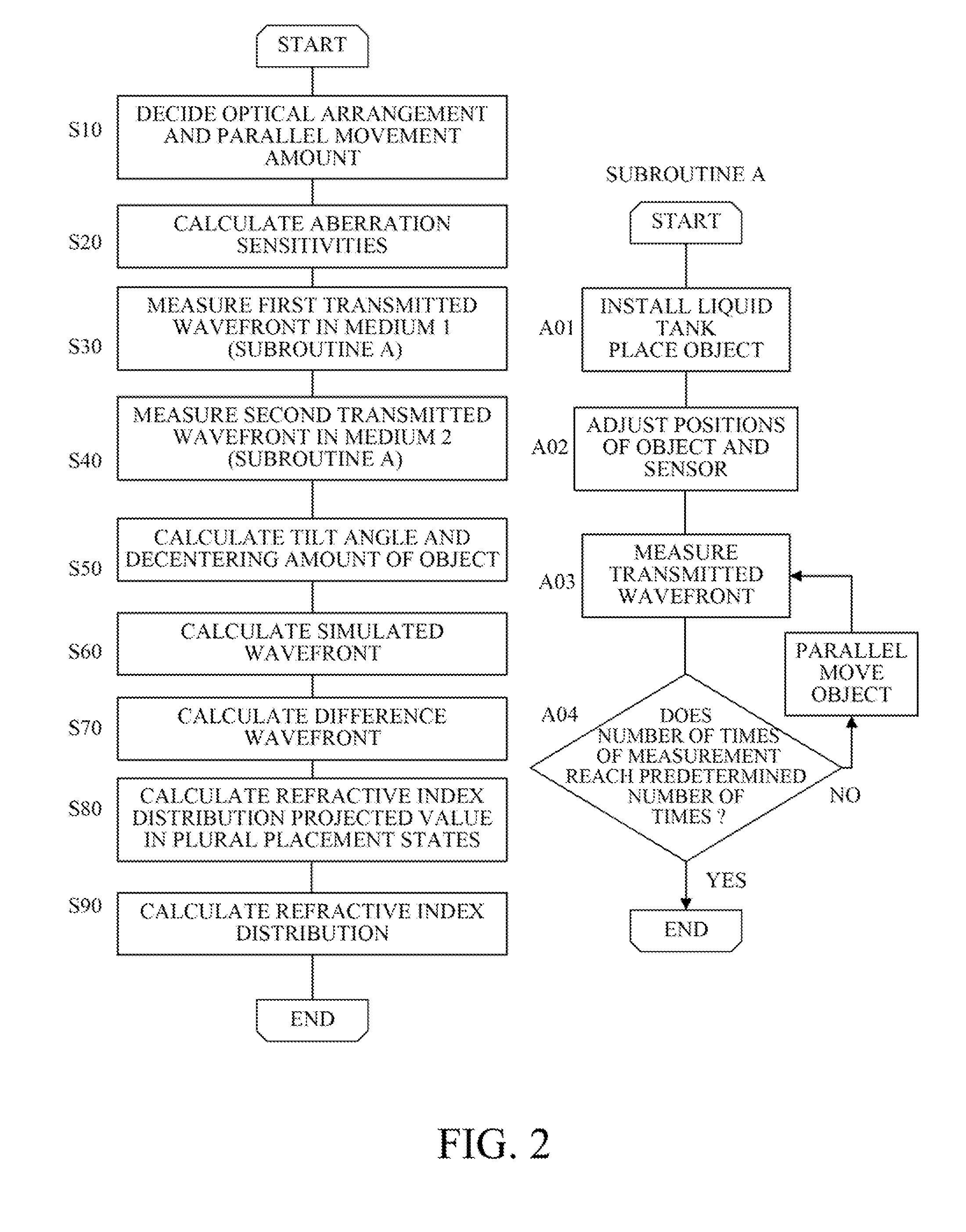

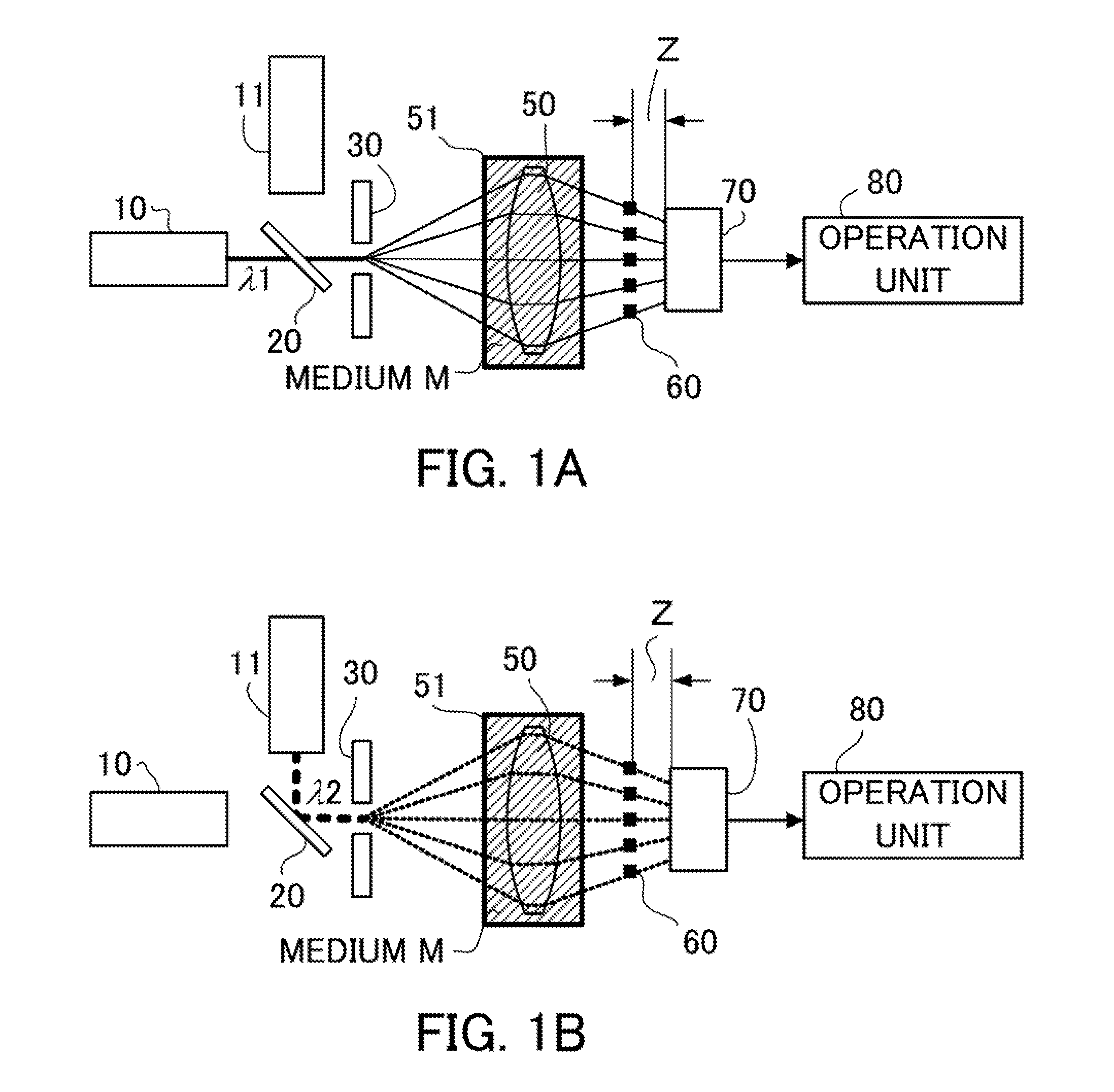

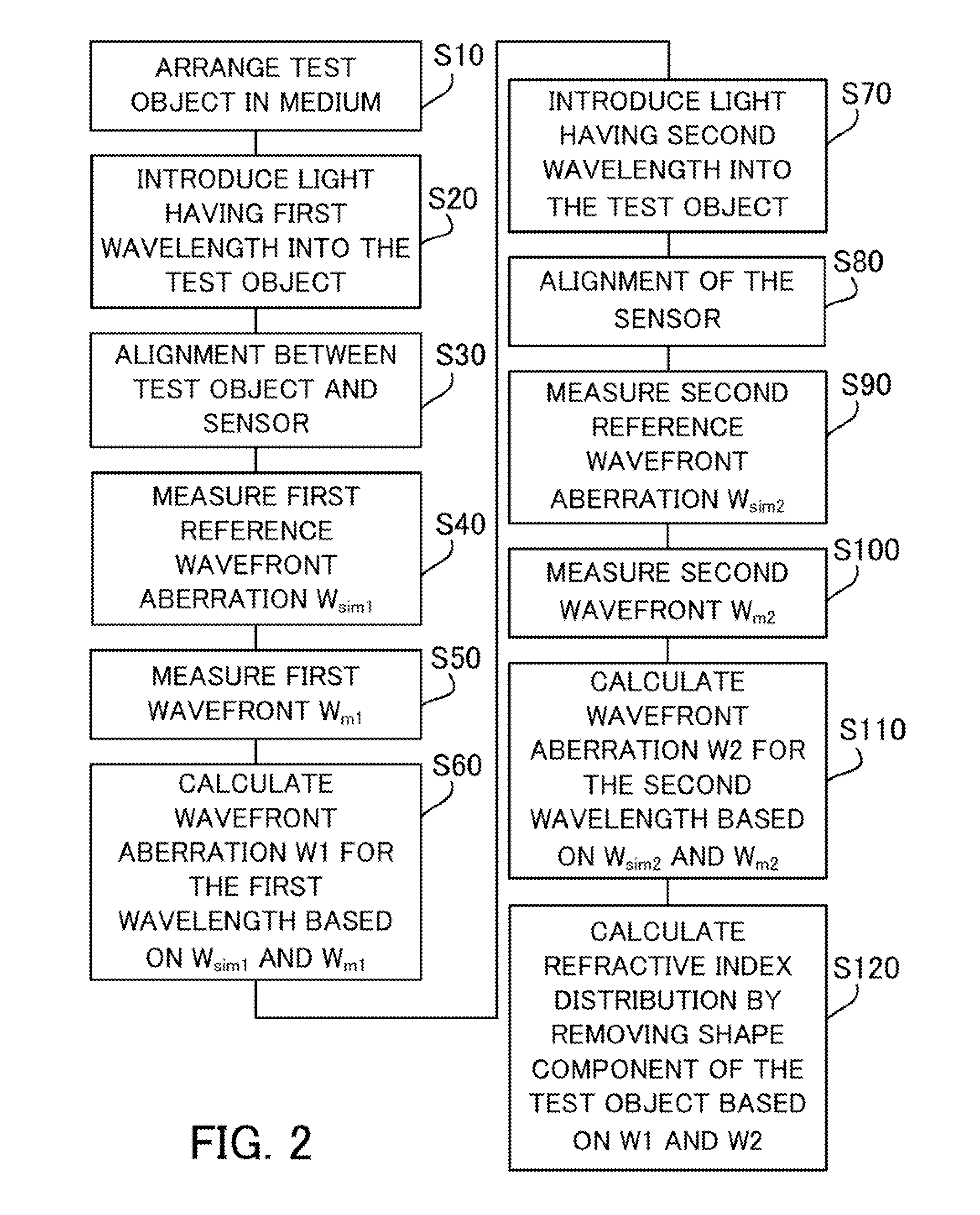

Refractive index distribution measuring method, refractive index distribution measuring apparatus and method of producing optical element

InactiveUS20120139136A1Accurate calculationHighly accurate placementPhase-affecting property measurementsOptical articlesWavefrontPhysics

The method measures first transmitted wavefronts and second transmitted wavefronts by respectively causing reference light to enter an object placed in plural placement states in a first medium and a second medium, calculates an aberration sensitivity with respect to changes of the placement state of the object, and calculates an alignment error of the object in each placement state by using the aberration sensitivity and the first and second transmitted wavefronts measured in each placement state. The method further calculates first and second reference transmitted wavefronts respectively acquirable when causing the reference light to enter the reference object placed in placement states including the alignment errors in the first medium and the second medium, and calculates a refractive index distribution of the object which a shape component thereof is removed, by using the first and second transmitted wavefronts and the first and second reference transmitted wavefronts.

Owner:CANON KK

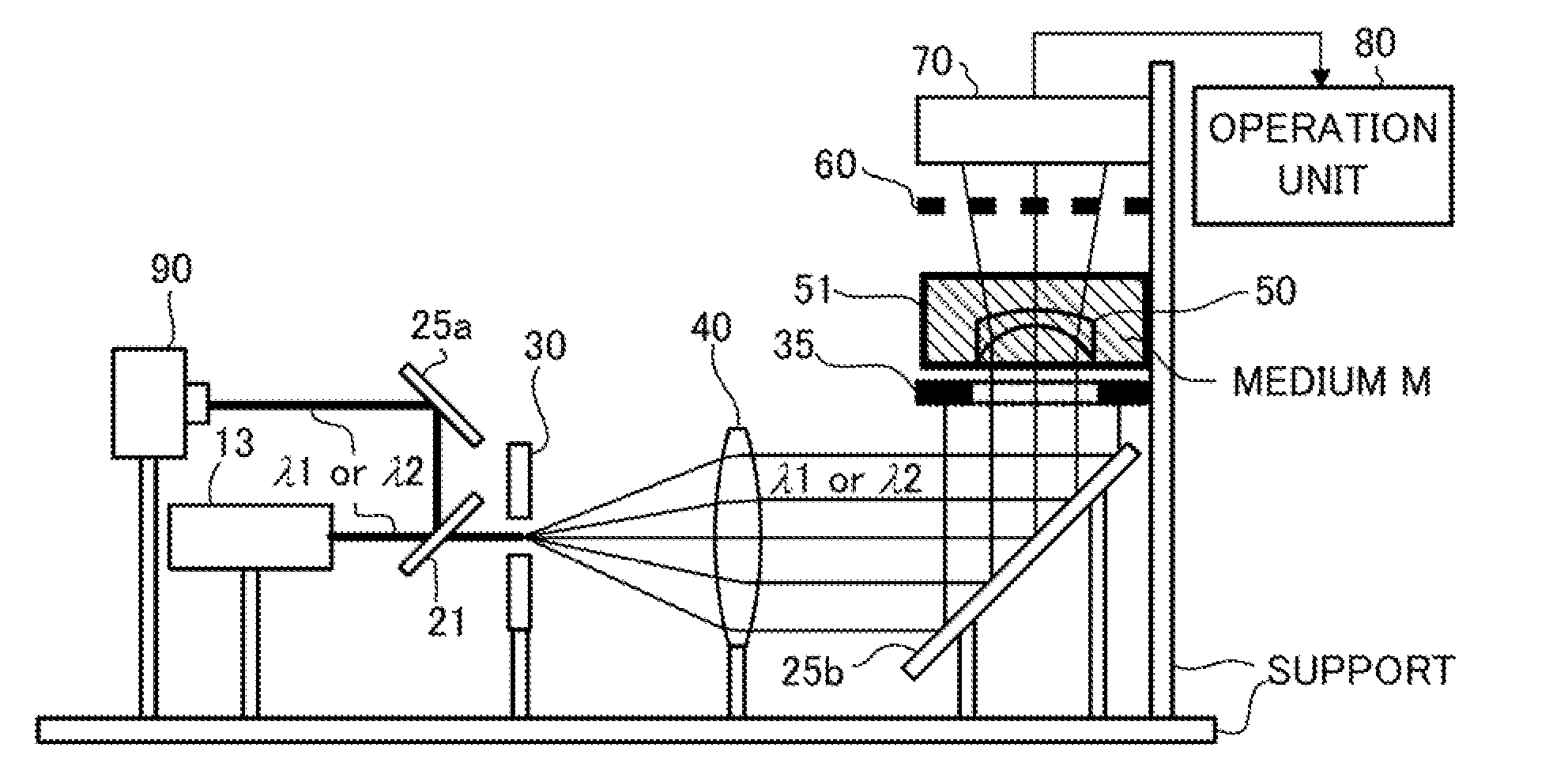

Refractive index distribution measuring method and refractive index distribution measuring apparatus

ActiveUS20120241989A1Quickly and highly precisely measurePhase-affecting property measurementsOptical articlesWavefrontMeasurement test

A method includes measuring a transmitted wavefront of a test object by introducing reference light into the test object arranged in a medium having a refractive index different from a refractive index of the test object, and calculating a refractive index distribution of the test object by using a measurement result of the transmitted wavefront. The measuring step measures a first transmitted wavefront for a first wavelength and a second transmitted wavefront for a second wavelength different from the first wavelength. The calculating step calculates the refractive index distribution of the test object by removing a shape component of the test object utilizing measurement results of the first and the second transmitted wavefront, and a transmitted wavefront of a reference object arranged in the medium for each of the first and second wavelengths. The reference object has the same shape as the test object and a specific refractive index distribution.

Owner:CANON KK

Refractive-index measurement system and method for measuring refractive-index

InactiveUS20090161114A1Phase-affecting property measurementsUsing optical meansBeam splitterRefractive index

A refractive-index measurement system includes a light source, a first beam splitter, a first reflective mirror, a second reflective mirror, a second beam splitter, a container, a first polarizer, and a second polarizer. The first beam splitter splits light emitted from the light source into first and second light beams. The first light beam and the second light beam are reflected by the first reflective mirror and the second reflective mirror, respectively, incident into the second light beam splitter. The container is positioned along an optical pathway of first light beam. The container accommodates a lens and is filled with a medium having a refractive index substantially the same as a theoretical refractive index of the lens. The first polarizer is positioned along the optical pathway of the first light beam. The second polarizer is positioned along an optical pathway of the second light beam.

Owner:HON HAI PRECISION IND CO LTD

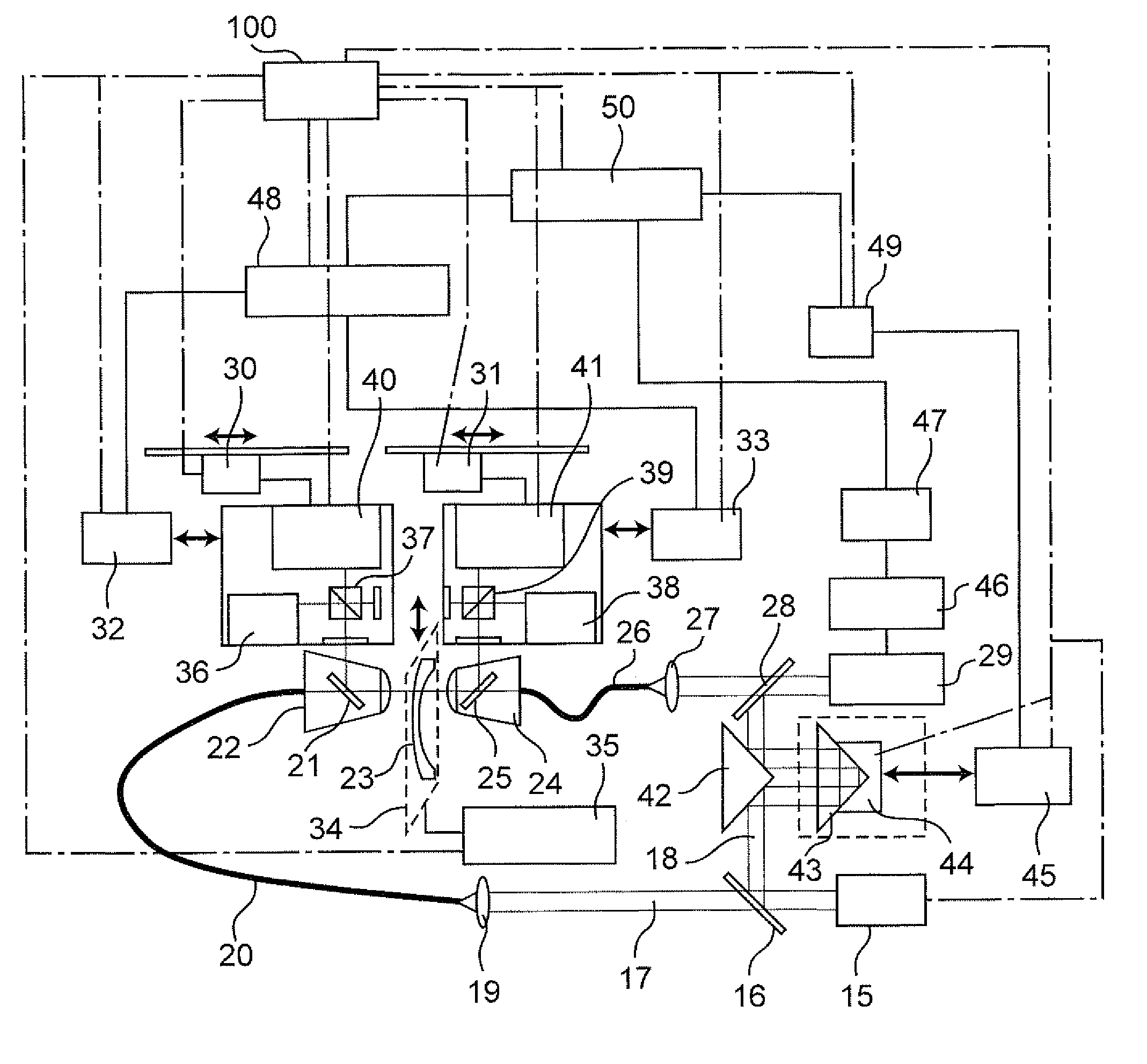

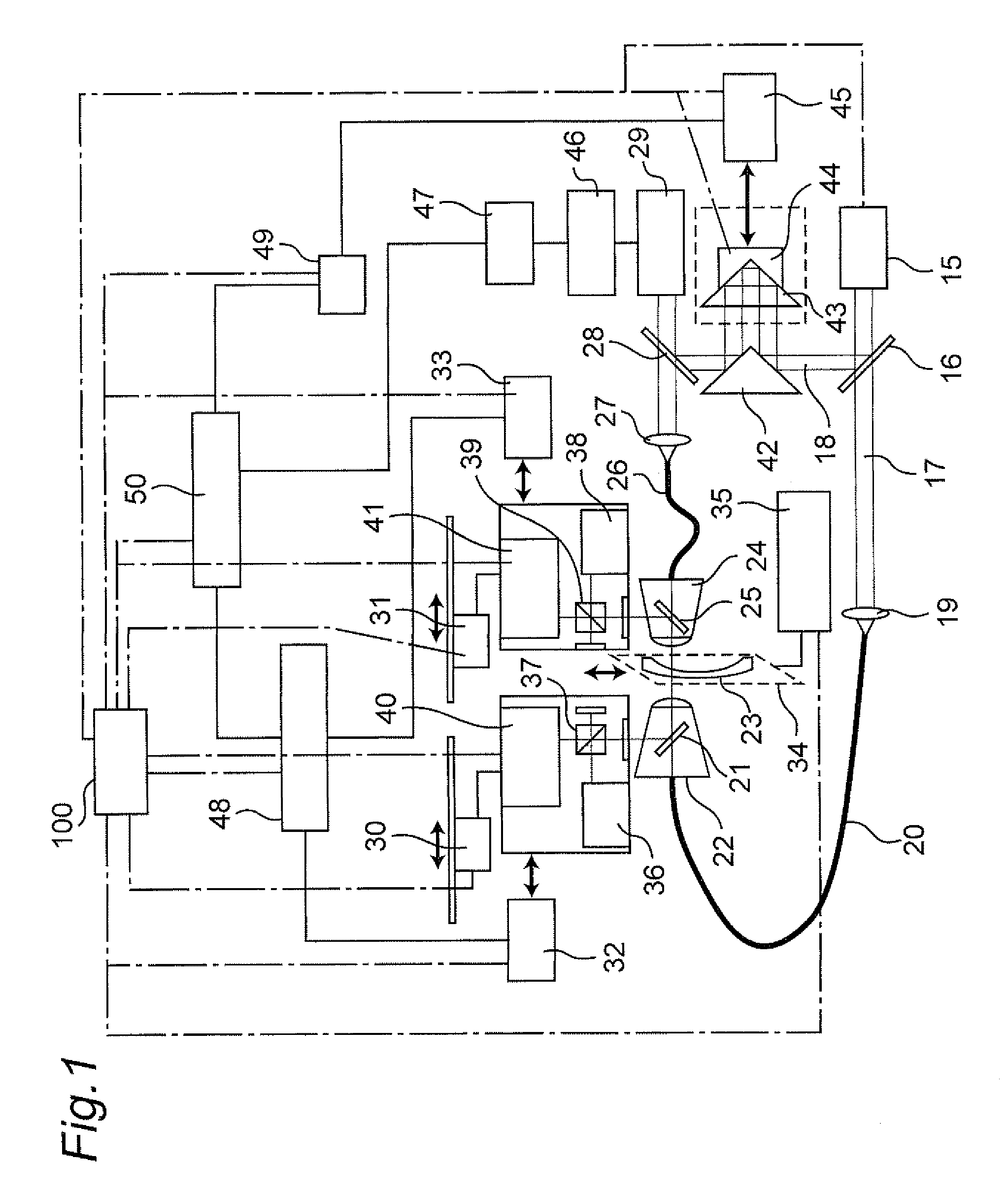

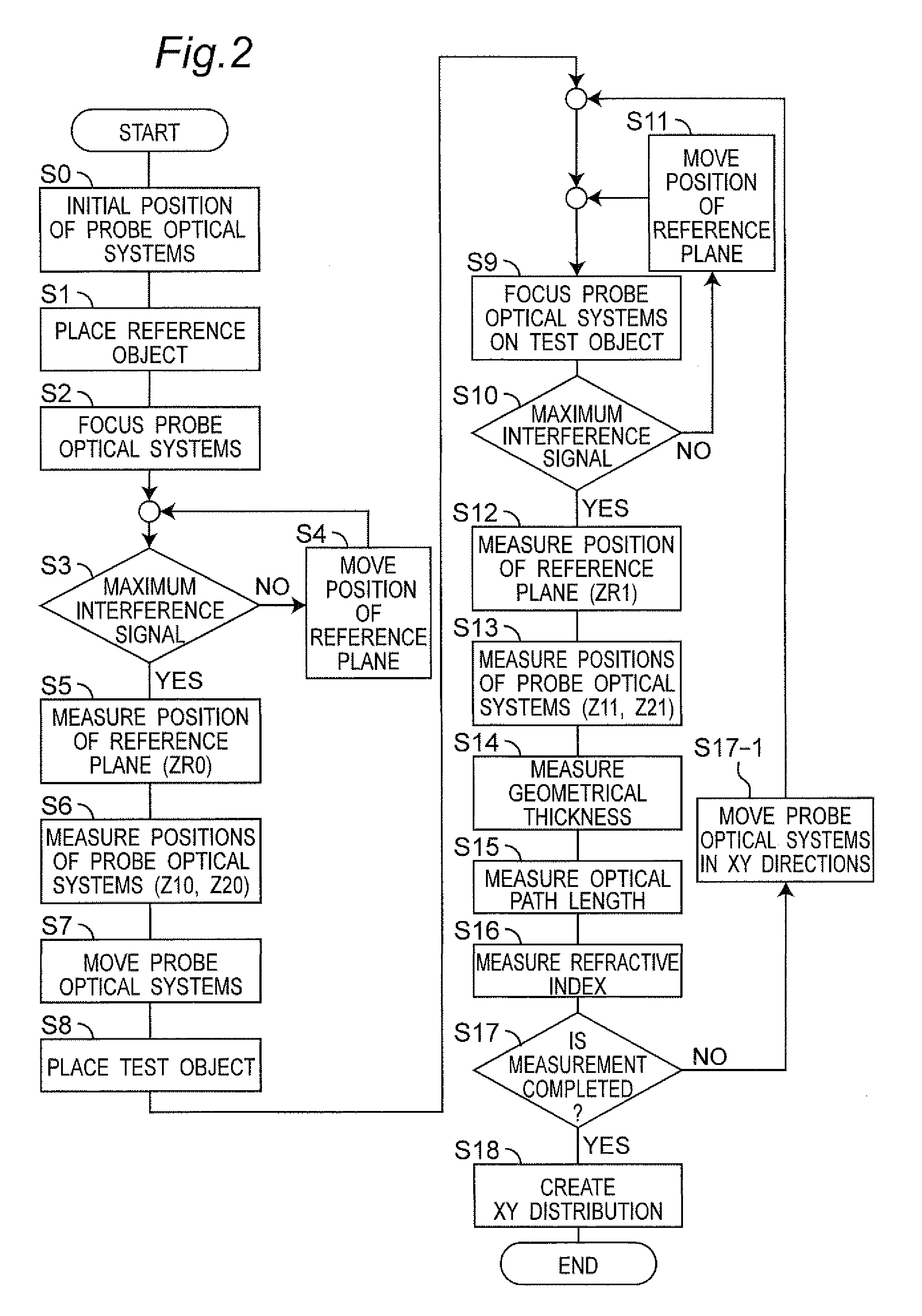

Refractive index measuring apparatus

InactiveUS20110051127A1Easy to measurePhase-affecting property measurementsRefractive power measurementOptical path lengthTest object

By using two probe optical systems for measurement by disposing the probe optical systems with a test object sandwiched therebetween, an optical path length of light transmitted through the test object which is identified locally is calculated using an interference signal thereof. In addition, a geometrical thickness of the same part is calculated by measuring positions of the probe optical systems, whereby two calculated values are obtained. Based on the values and a calculated value for a reference object, a refractive index distribution of the test object is obtained.

Owner:PANASONIC CORP

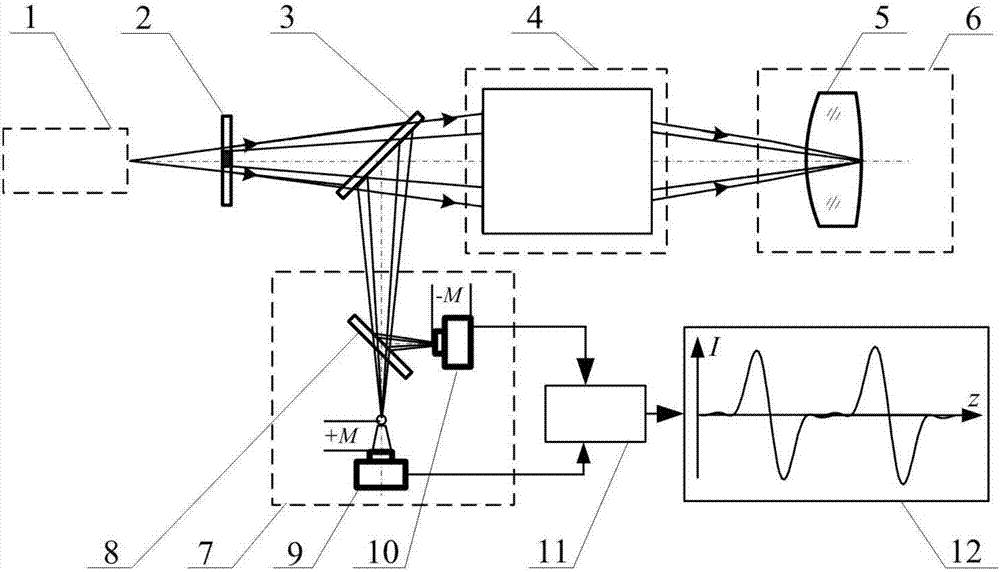

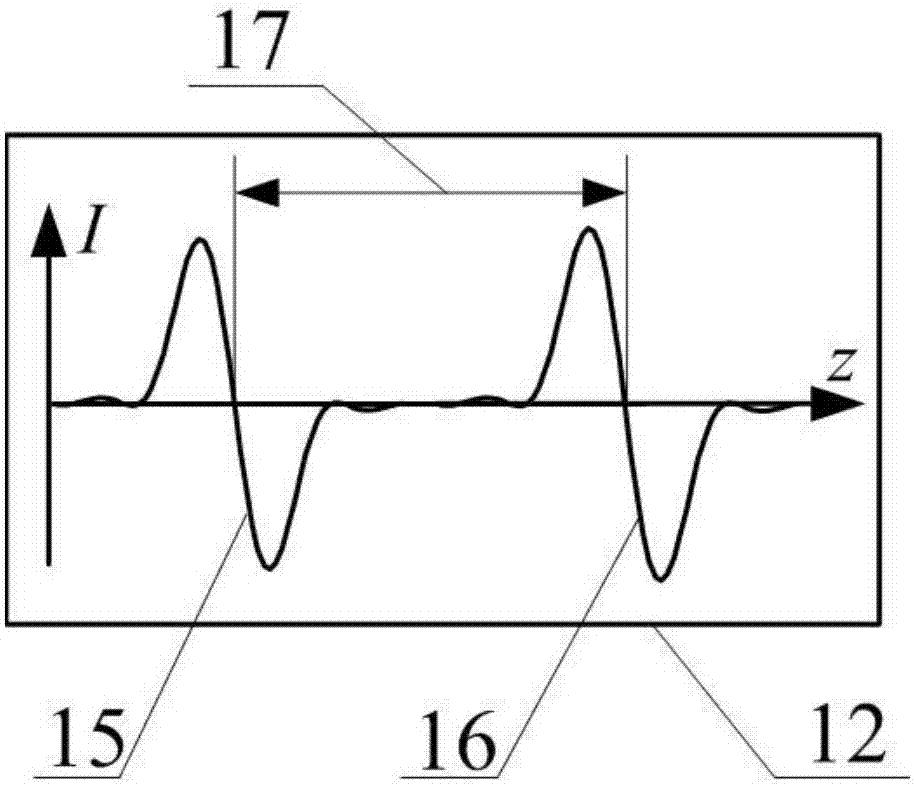

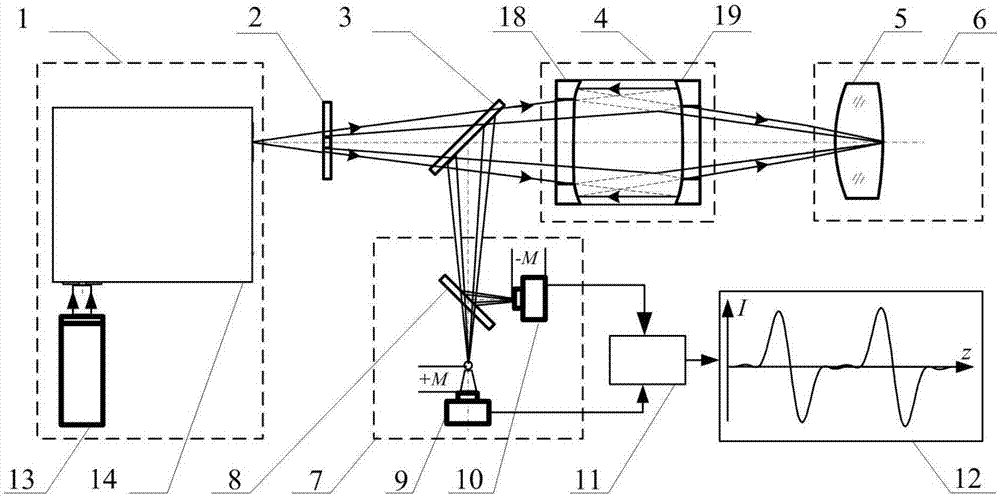

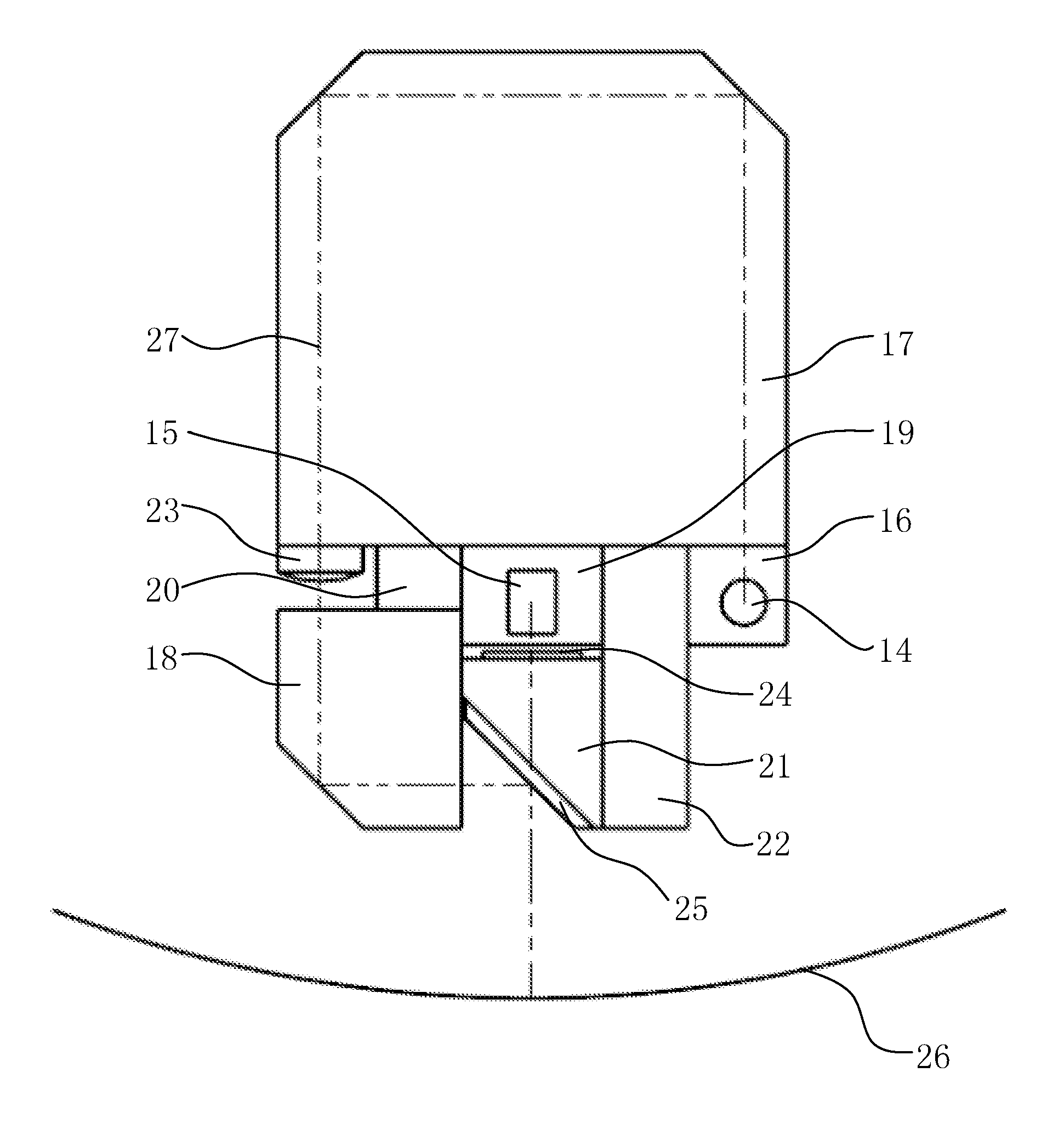

Method and device for measuring refractive index of broadband differential confocal infrared lens element

ActiveCN107462405ANo sampling requiredNo sample preparation requiredRefractive power measurementEffect lightRefractive index

The invention relates to a method and a device for measuring a refractive index of a broadband differential confocal infrared lens element and belongs to the technical field of precise optical measurement. The method disclosed by the invention comprises the following steps: generating a specified wavelength lighting point light source through a wavelength gating system by adopting a blackbody source; performing tomographic focus fixing on vertexes of the front and rear surfaces of a measured lens by utilizing a differential confocal light path, and measuring to obtain the optical thickness of the measured lens; and calculating to obtain the refractive index of the lens element by a ray tracing algorithm, thereby realizing high-precision non-contact measurement of the refractive index of the infrared lens element in a visible-to-infrared broadband range under any wavelength condition. According to the method disclosed by the invention, the measured lens does not need to be subjected to destructive sampling, nondestructive direct measurement of the refractive index of the infrared lens element in the visible-to-infrared range under any wavelength condition is realized for the first time, and the method has the advantages of being convenient in measurement process, high in measurement accuracy and high in environmental disturbance resistance and can provide a brand new effective technical approach for detecting the refractive index of the lens element.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Handheld apparatus for measuring lens surface power

ActiveUS20150330865A1Reduce complexityImprove stabilitySpectales/gogglesUsing optical meansOptical measurementsHand held devices

This invention discloses a handheld apparatus for measuring surface power or radius of prescription ophthalmic spectacle lenses, optical lenses or molds blocked with or without chuck during Rx production, and after comparing measurement results with designed data, providing correction data to the processing machines via wireless connection for correction processing if needed. The handheld apparatus integrates an optical measurement head into a monolithic optical system.

Owner:TOPLENS HANGZHOU

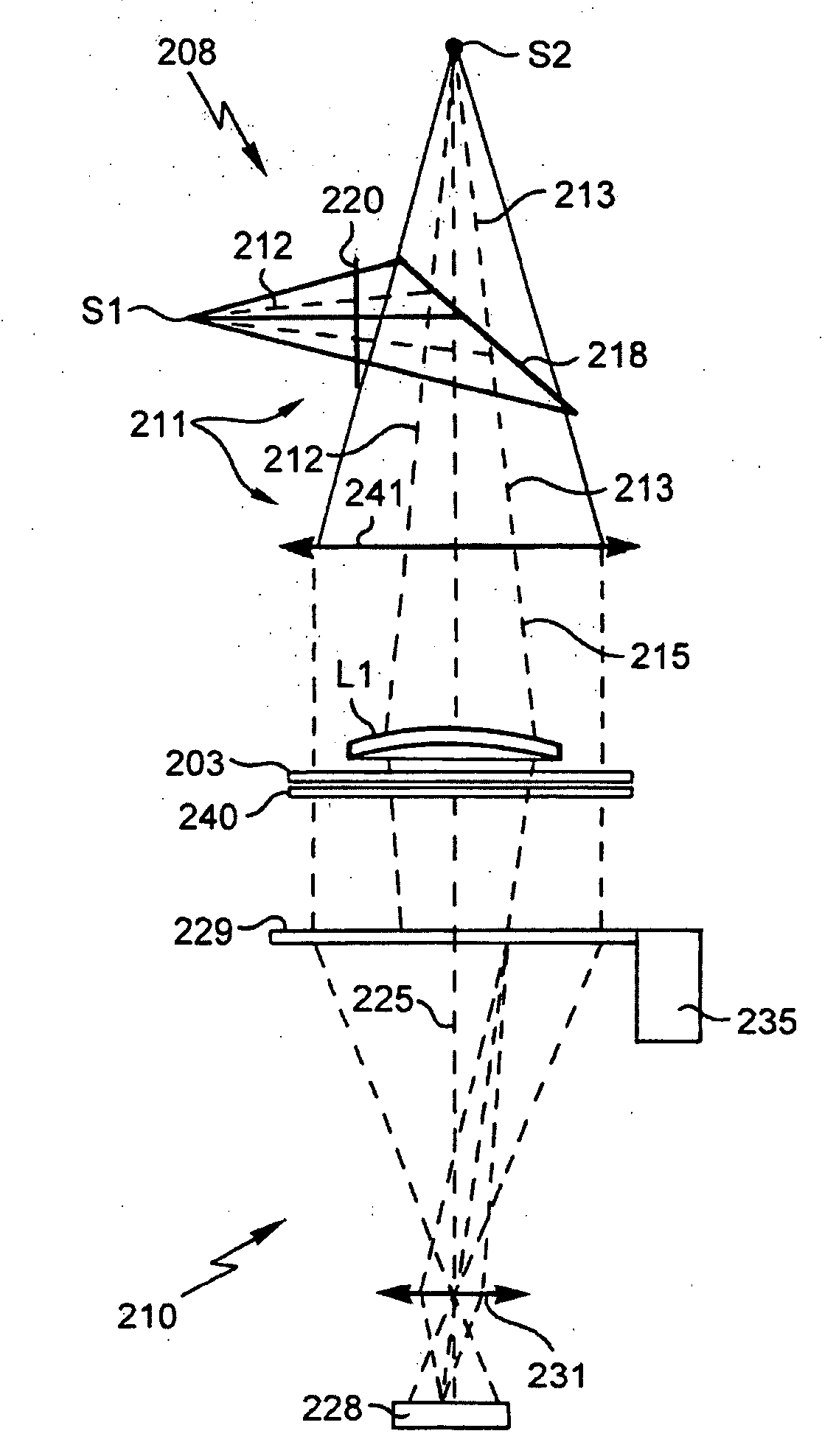

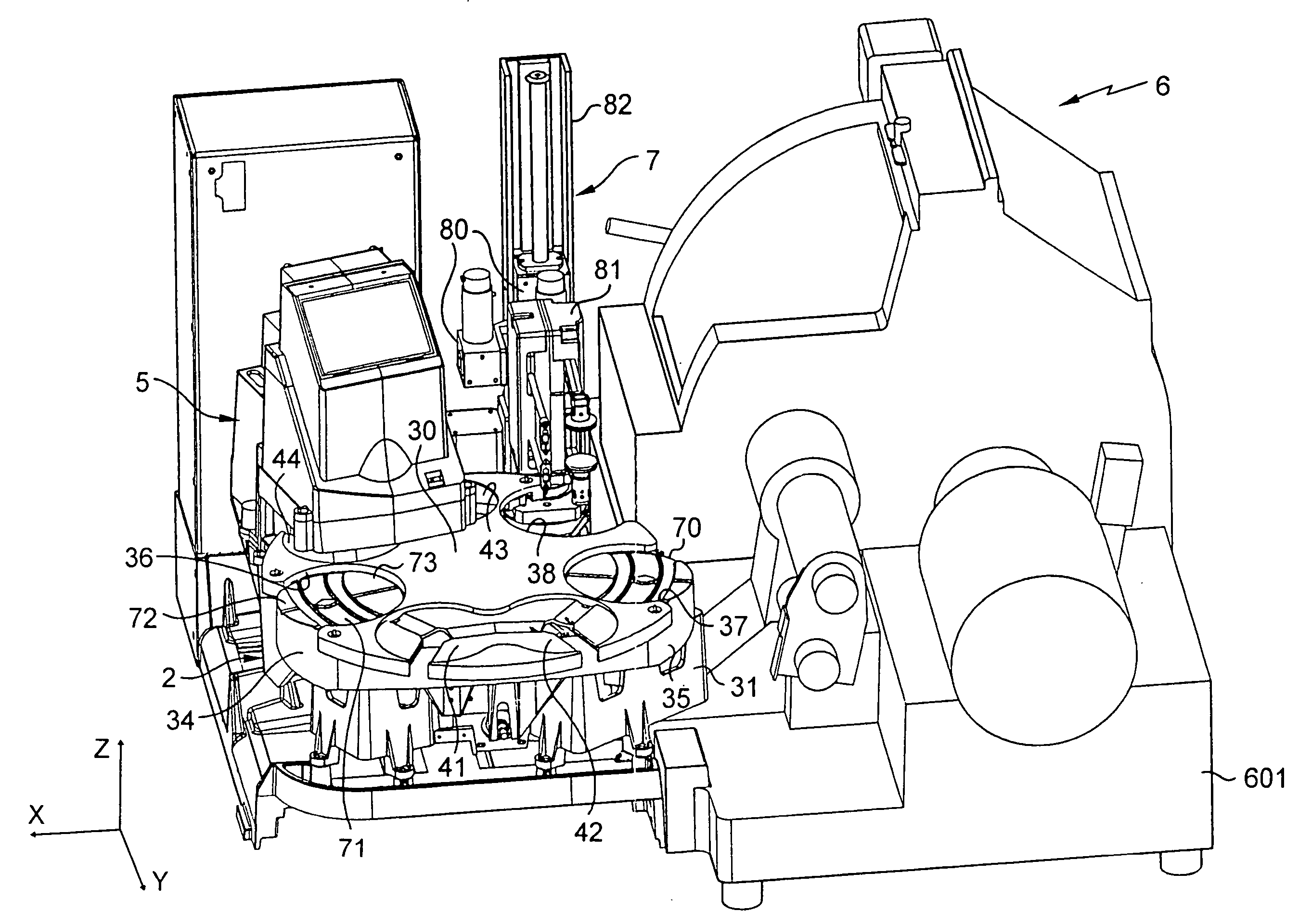

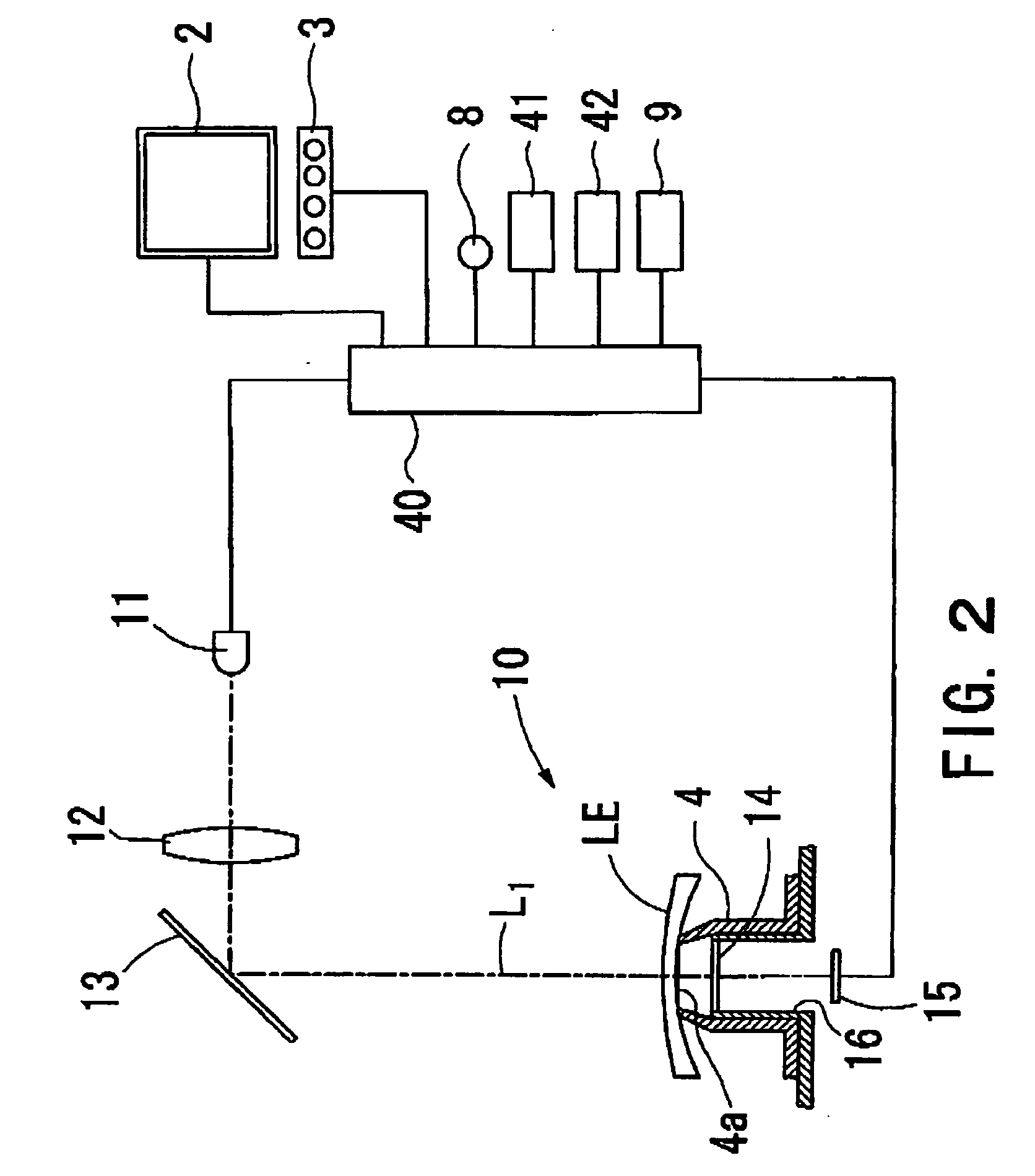

Device For Automatically Measuring Characteristics Of An Ophthalmic Lens

ActiveUS20070291258A1Improve accuracyImprove performanceUsing optical meansRefractive power measurementMeasurement deviceLight beam

A device for automatically measuring characteristics of an ophthalmic lens (L1), includes: a support (2) designed to receive such a lens; on one first side of the lens support, illuminating elements (208) including an optical system for producing a light beam directed towards the ophthalmic lens mounted on the support; and on a second side of the support, elements for analyzing (210) the image transmitted by the ophthalmic lens mounted on the support and illuminated by the illuminating elements (208); elements for splitting the light beam including a first mask (220) forming a Hartmann array and arranged on the first side of the lens support to be illuminated, upstream of the lens by the light beam.

Owner:ESSILOR INT CIE GEN DOPTIQUE

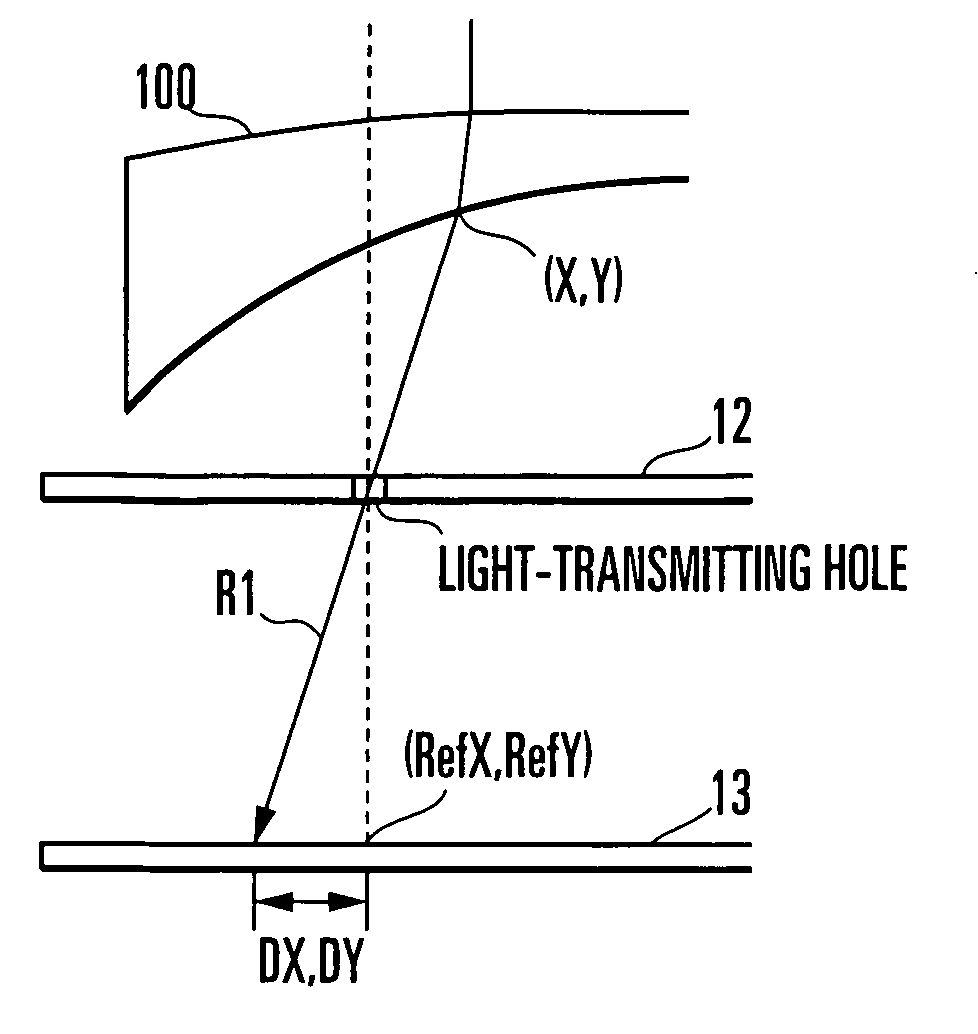

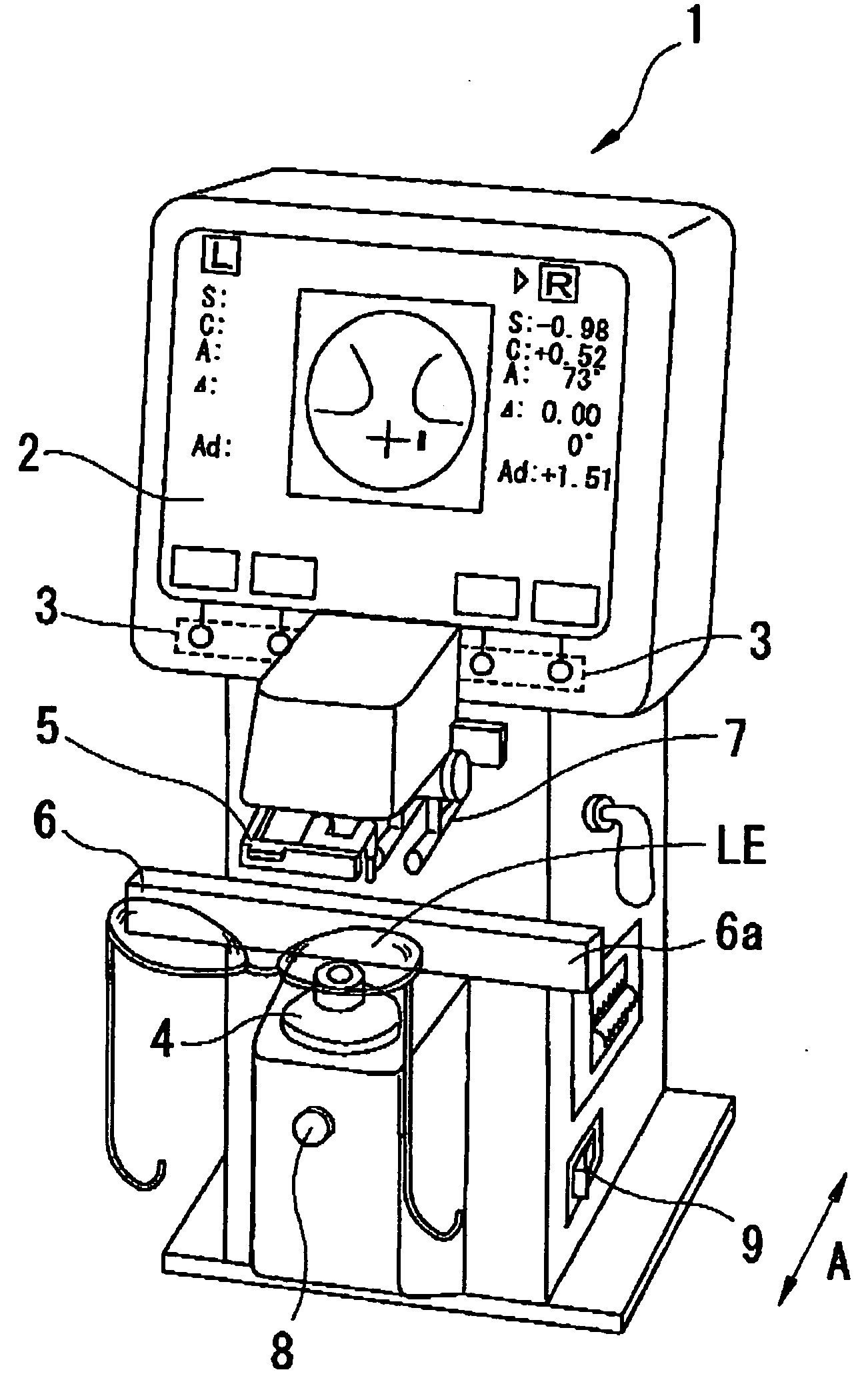

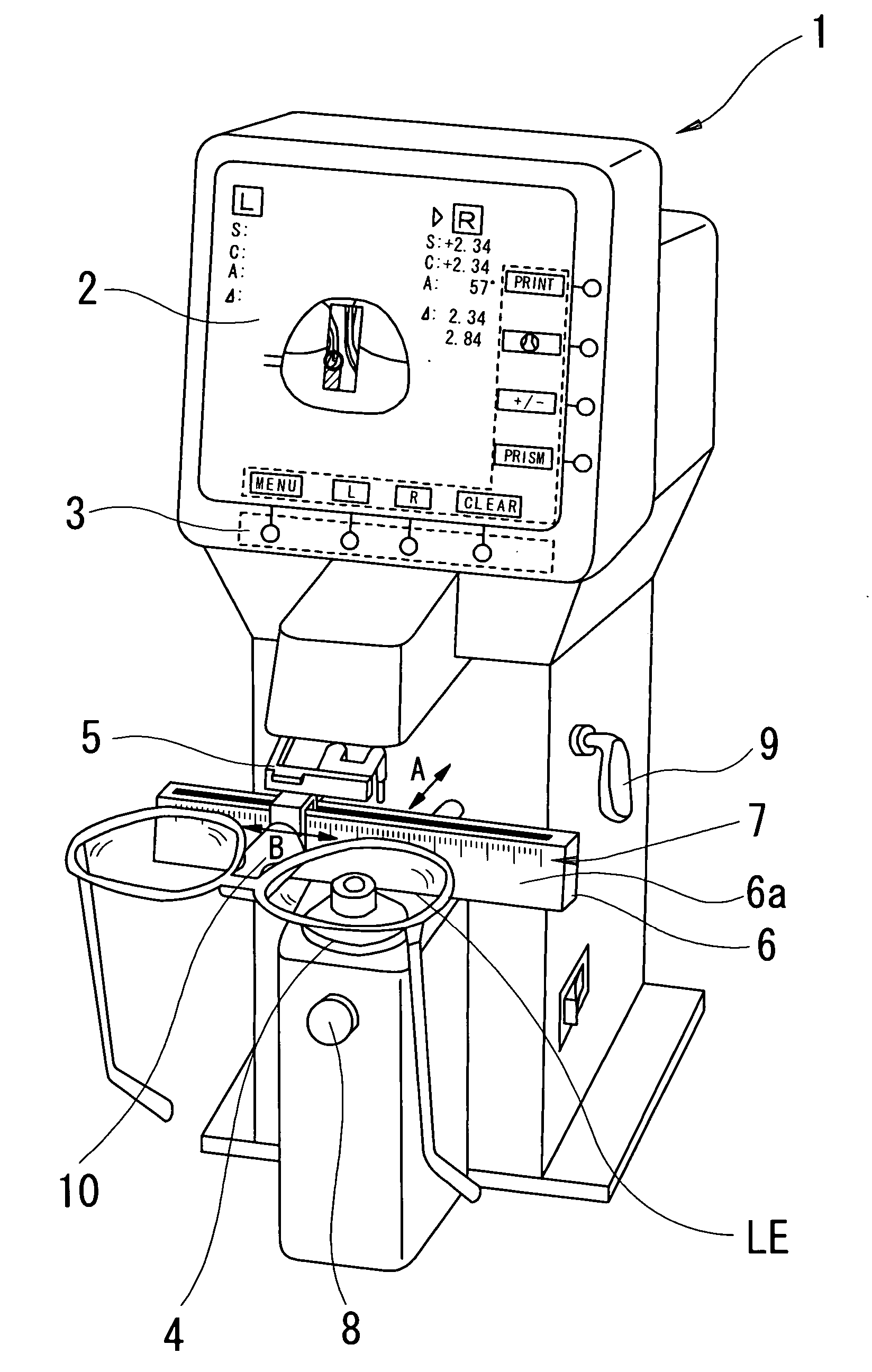

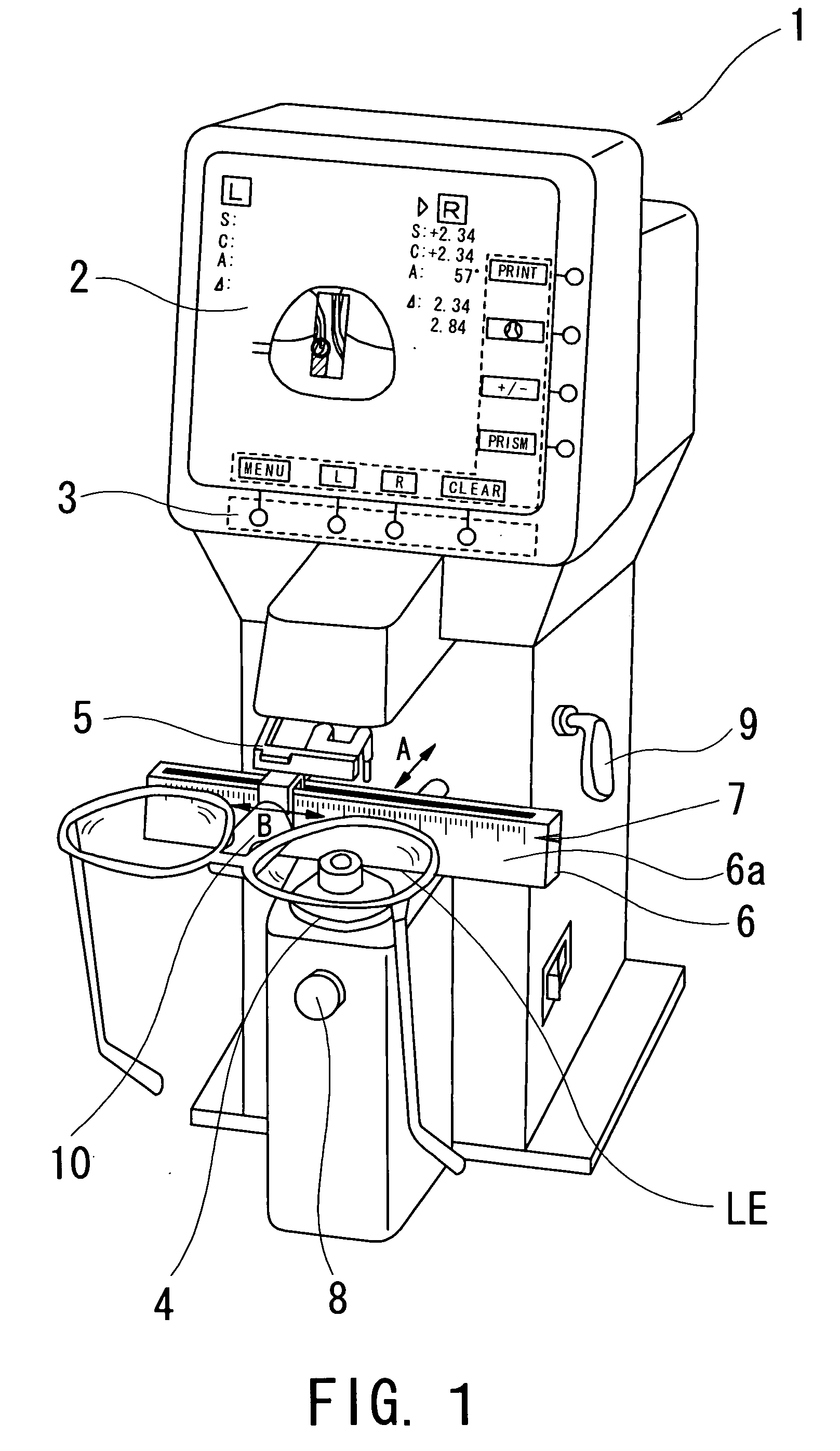

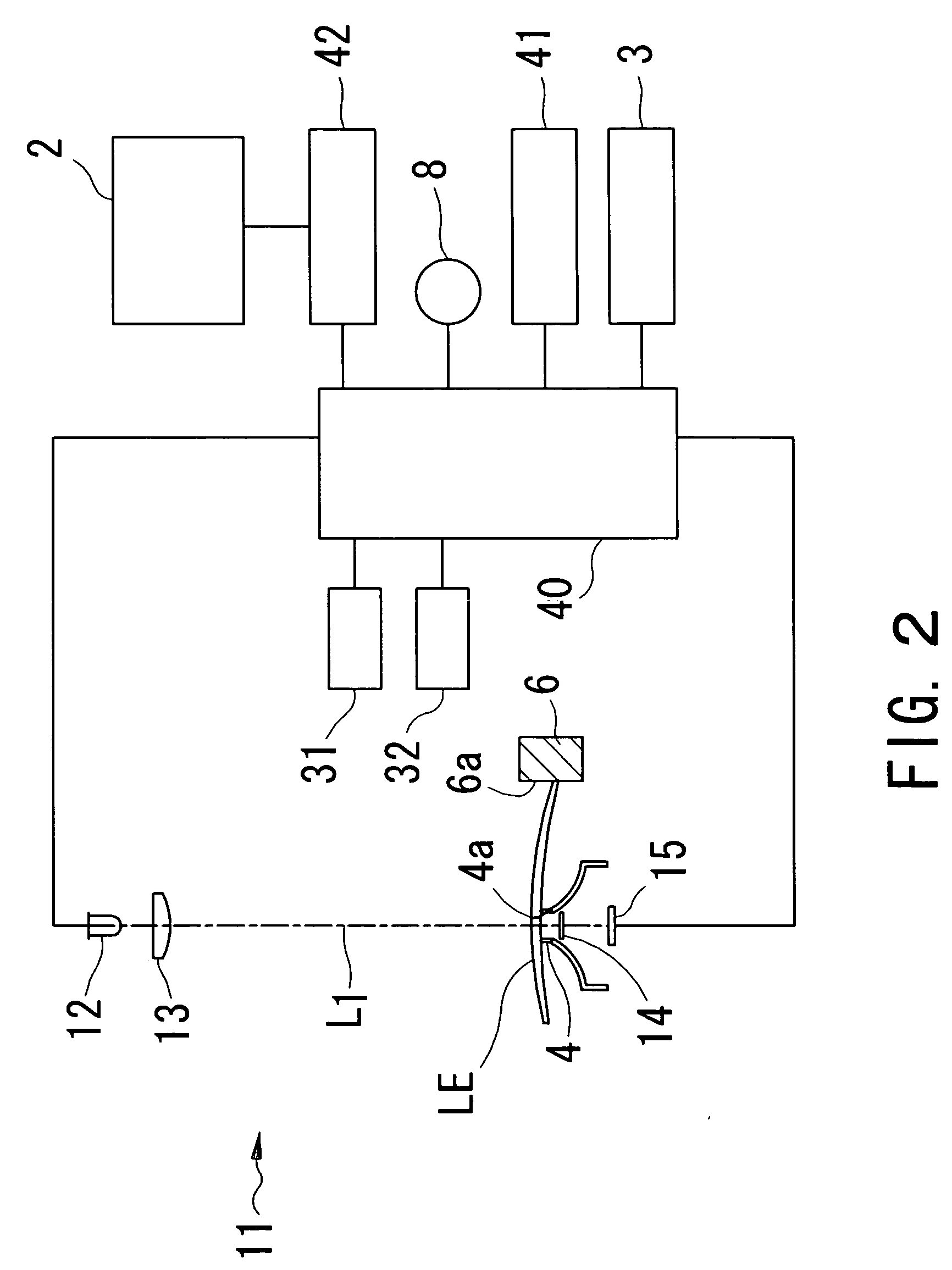

Lens meter

InactiveUS20050190360A1Easy and efficient measurementMeasuring even a progressive lens and the like easily and efficientlyUsing optical meansRefractive power measurementCoordinate changePower application

A lens meter obtaining 0D-reference-coordinates of target-images not detected in a reference state and measuring even progressive lenses, has a lens rest, an optical system having an optical axis, a light source, measurement targets and a photo-sensor, a part calculating optical characteristics based on coordinates-change of target-images in a measurement state with the lens on the rest and axis from those in a reference state without the lens thereon, and an information memory. The part makes the memory store image-coordinates not detected in the reference state obtained during assembly / adjustment, and based on image-coordinates detected in the reference state after power application and before measurement and stored coordinates, obtains image-coordinates not detected in the reference state after power application and before measurement, and calculates characteristics based on coordinates-change of target-images detected in the measurement state from those detected in the reference state before measurement and obtained image-coordinates.

Owner:NIDEK CO LTD

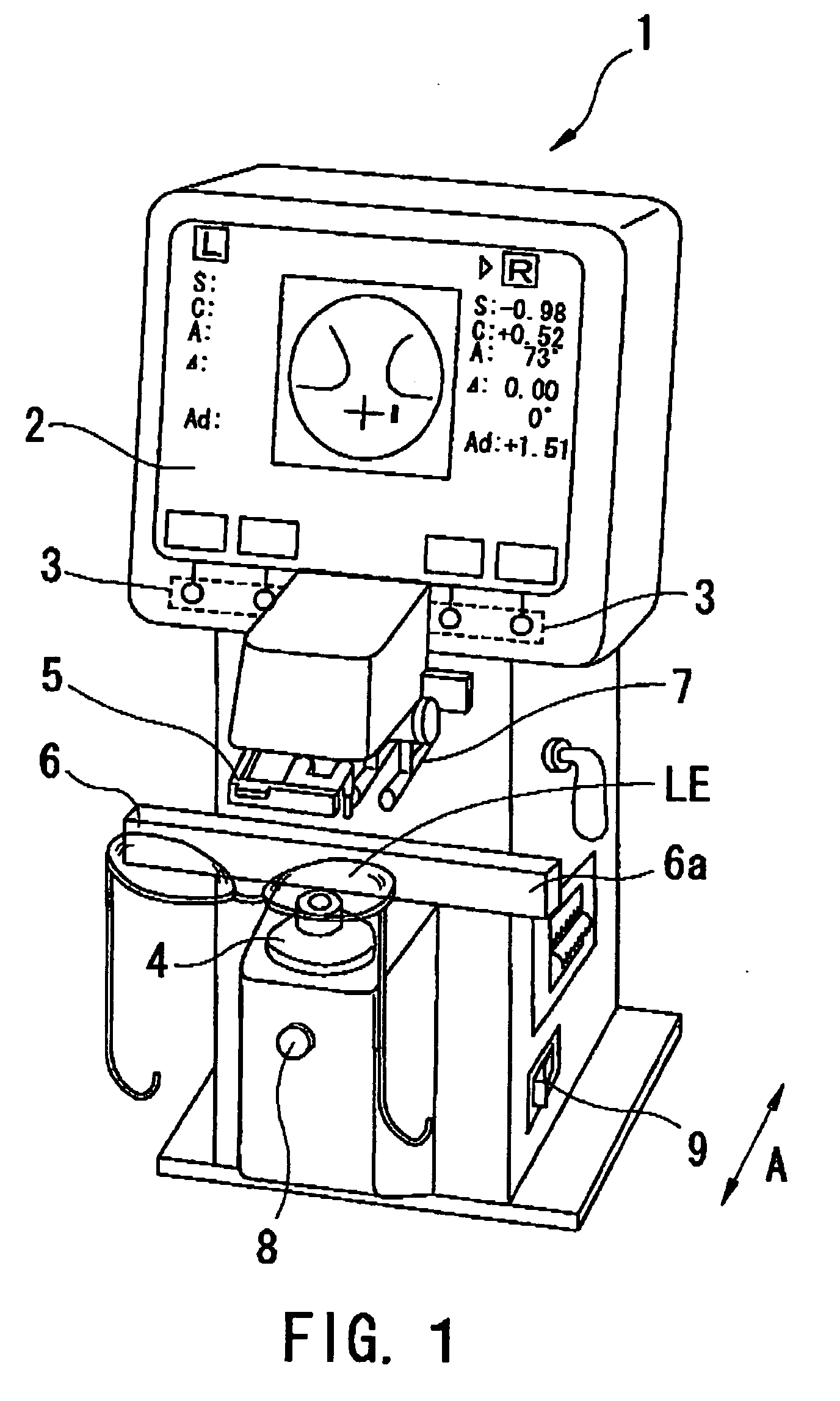

Lens meter

ActiveUS20050237513A1Low cost structurePhase-affecting property measurementsUsing optical meansLight beamPosition dependent

A lens meter for measuring refractive power distribution of a progressive power lens and displaying its distribution map, has a lens rest having an aperture, an optical system including an axis, a source projecting a light bundle along the axis, a plate having targets and a two-dimensional image sensor detecting images by the bundle passing through the lens, aperture and plate, a part calculating the distribution within a measurement region from detection results, a part detecting a lens-position in a two-dimensional direction orthogonal to the axis, a device guiding movement on the rest to shift the measurement region and obtaining the distribution within an analysis region including distance, progressive and near portions, a part storing the distribution in the measurement region in association with the detected position, a display part, and a part controlling to display the distribution map within the analysis region based on the stored distribution and position.

Owner:NIDEK CO LTD

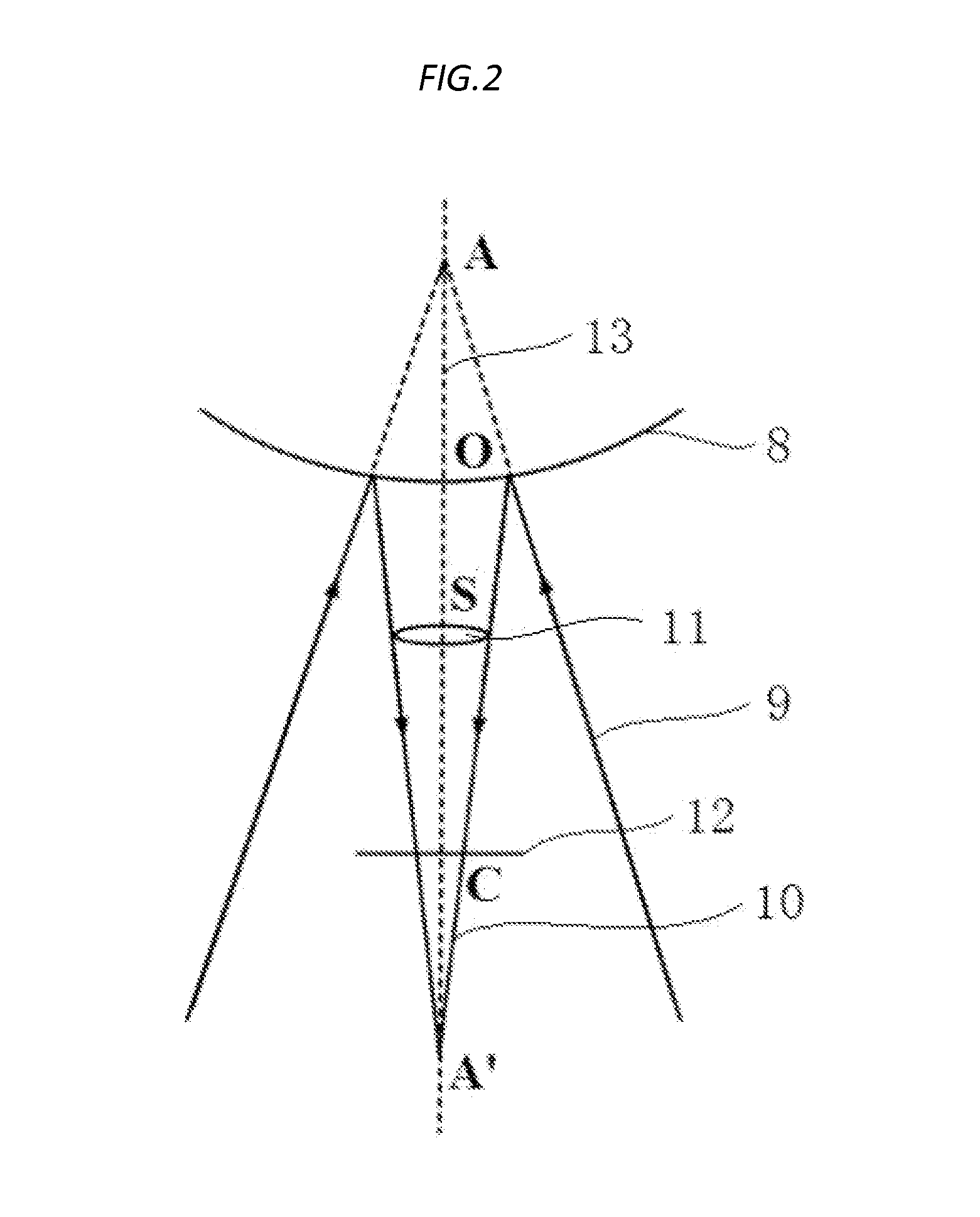

Method And Apparatus For Locally Measuring Refractive Characteristics Of A Lens In One Or Several Specific Points Of Said Lens

InactiveUS20080062410A1The process is fast and accurateSave hardware resourcesUsing optical meansRefractive power measurementMeasurement deviceMeasurement point

The measurement apparatus includes: a support arranged to receive a lens; lighting element including an optical system for generating a collimated light beam directed towards the lens under measurement installed on the support; detachment elements for detaching light rays from the light beam, for detaching a localized group of at least three non-coplanar light rays grouped together about a measurement axis in a measurement cylinder of section substantially smaller than the section of the lens under measurement; acquisition elements for identifying the deflections imparted by the lens on the detached light rays and for delivering a signal representative of the deflections; and an electronic and computer system programmed to deduce from said deflections the value of the refractive characteristic of the lens at the measurement point.

Owner:ESSILOR INT CIE GEN DOPTIQUE

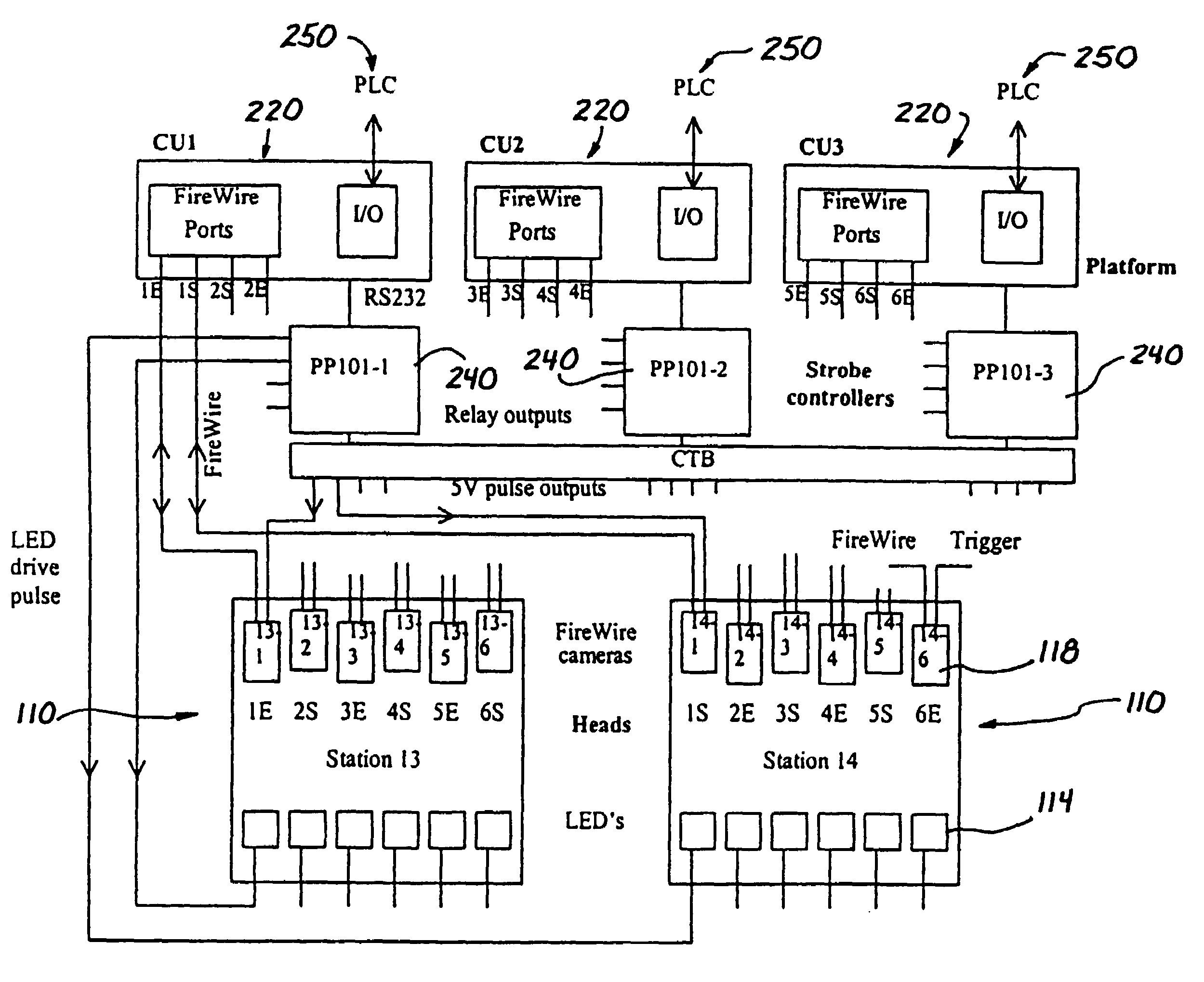

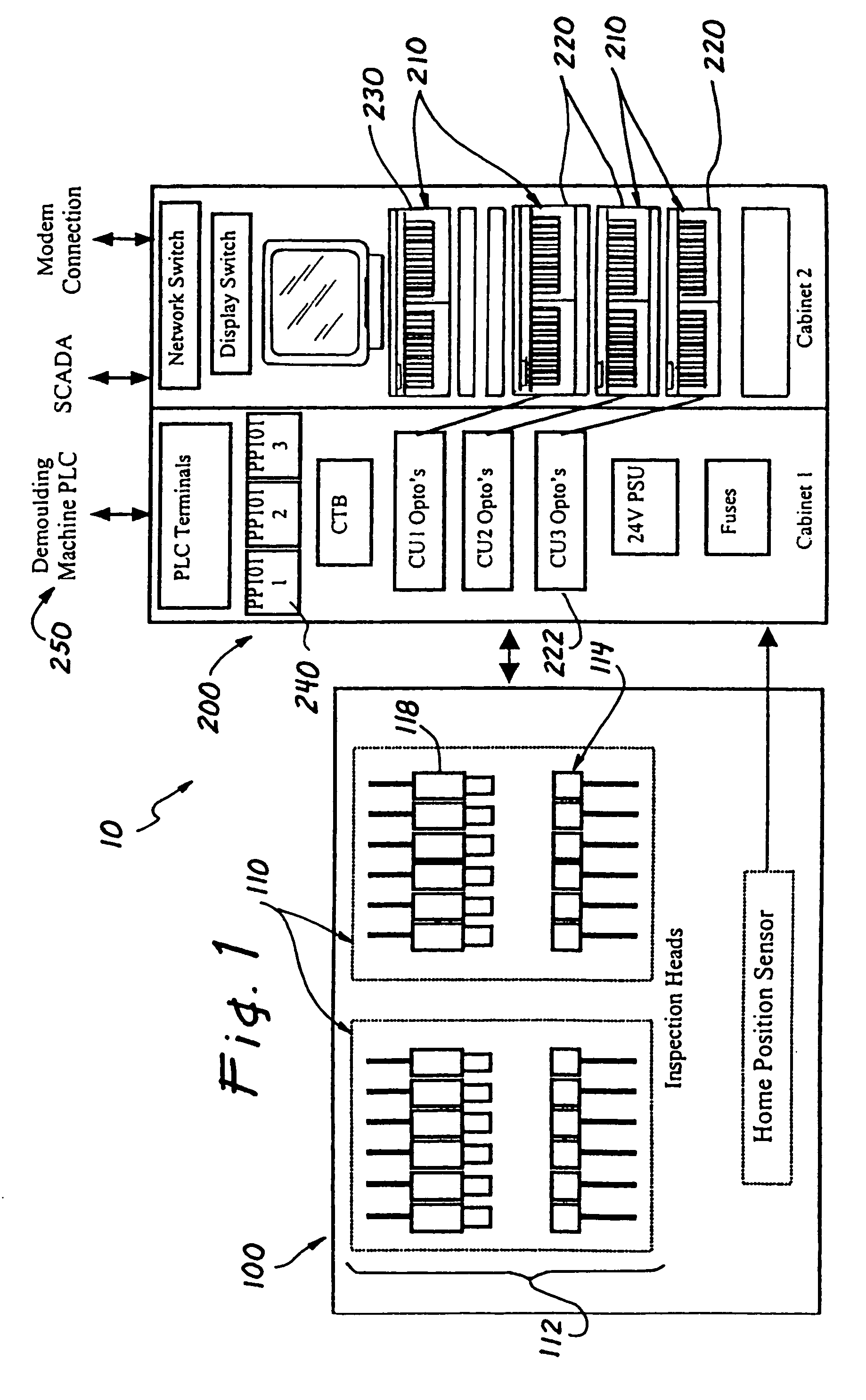

Systems and methods for inspection of ophthalmic lenses

ActiveUS7256881B2Accurate detectionReduce false rejectionsSpectales/gogglesInvestigating moving fluids/granular solidsDigital imageEye lens

An automated lens inspection system that images the edge and surface of an ophthalmic lens transmits light through the ophthalmic lens to a camera to create a complete digital image of the lens edge or lens surface. The digitized image(s) is(are) analyzed to detect defects or abnormalities of the ophthalmic lens. Methods of inspecting ophthalmic lenses are also disclosed.

Owner:COOPERVISION INT LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com