Optical system evaluation apparatus, optical system evaluation method and program thereof

一种光学系统、评价装置的技术,应用在测量装置、光学仪器测试、测试光学性能等方向,能够解决评价精度降低、光学特性评价精度降低、很难确保光学系统光学系统评价装置稳定性等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

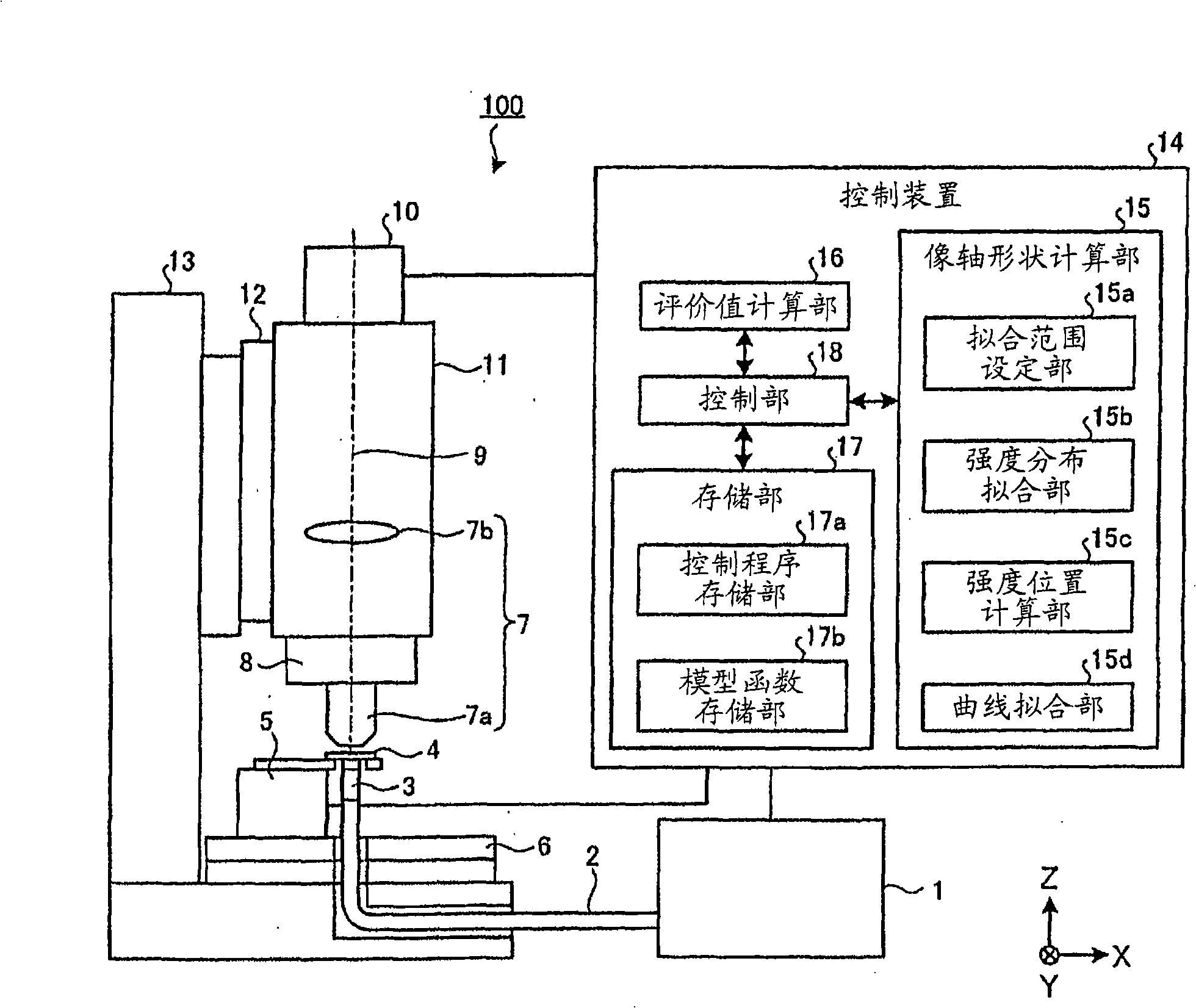

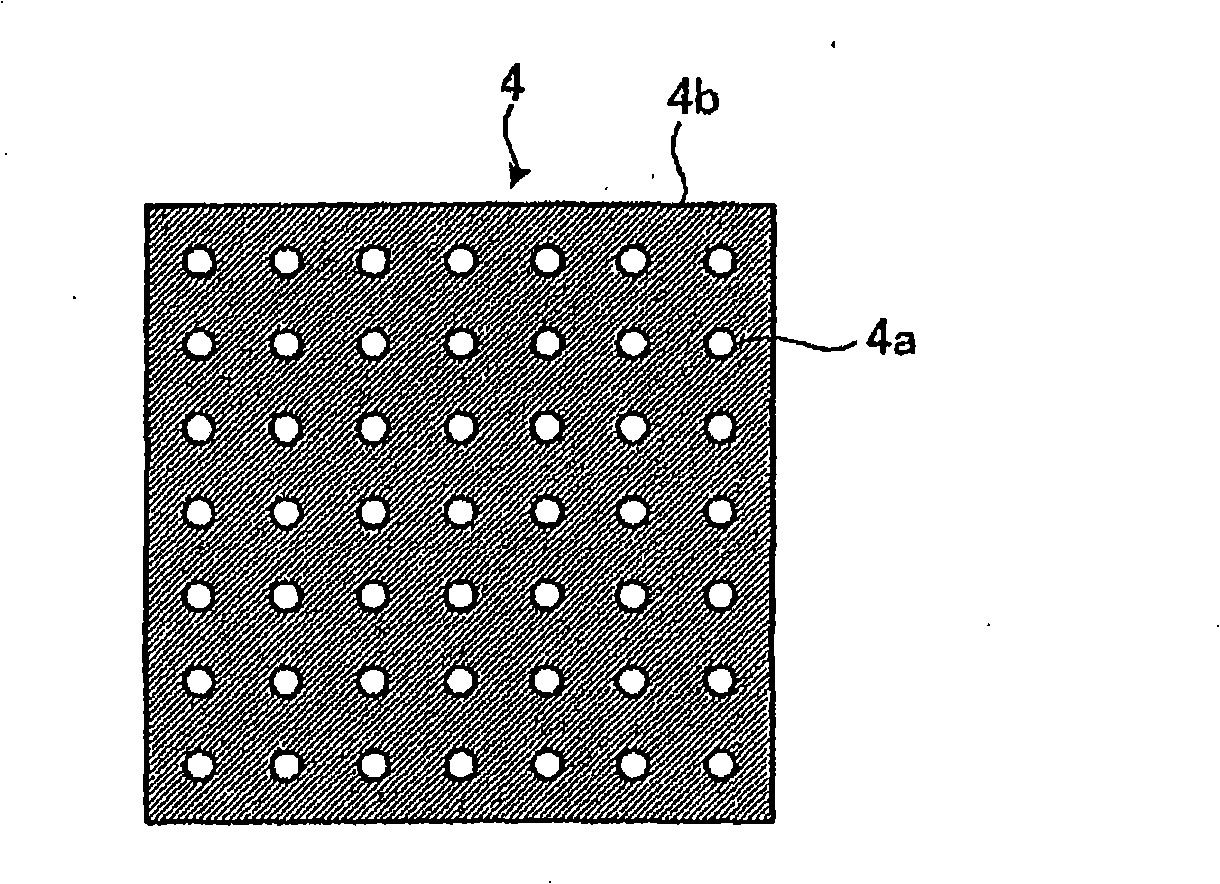

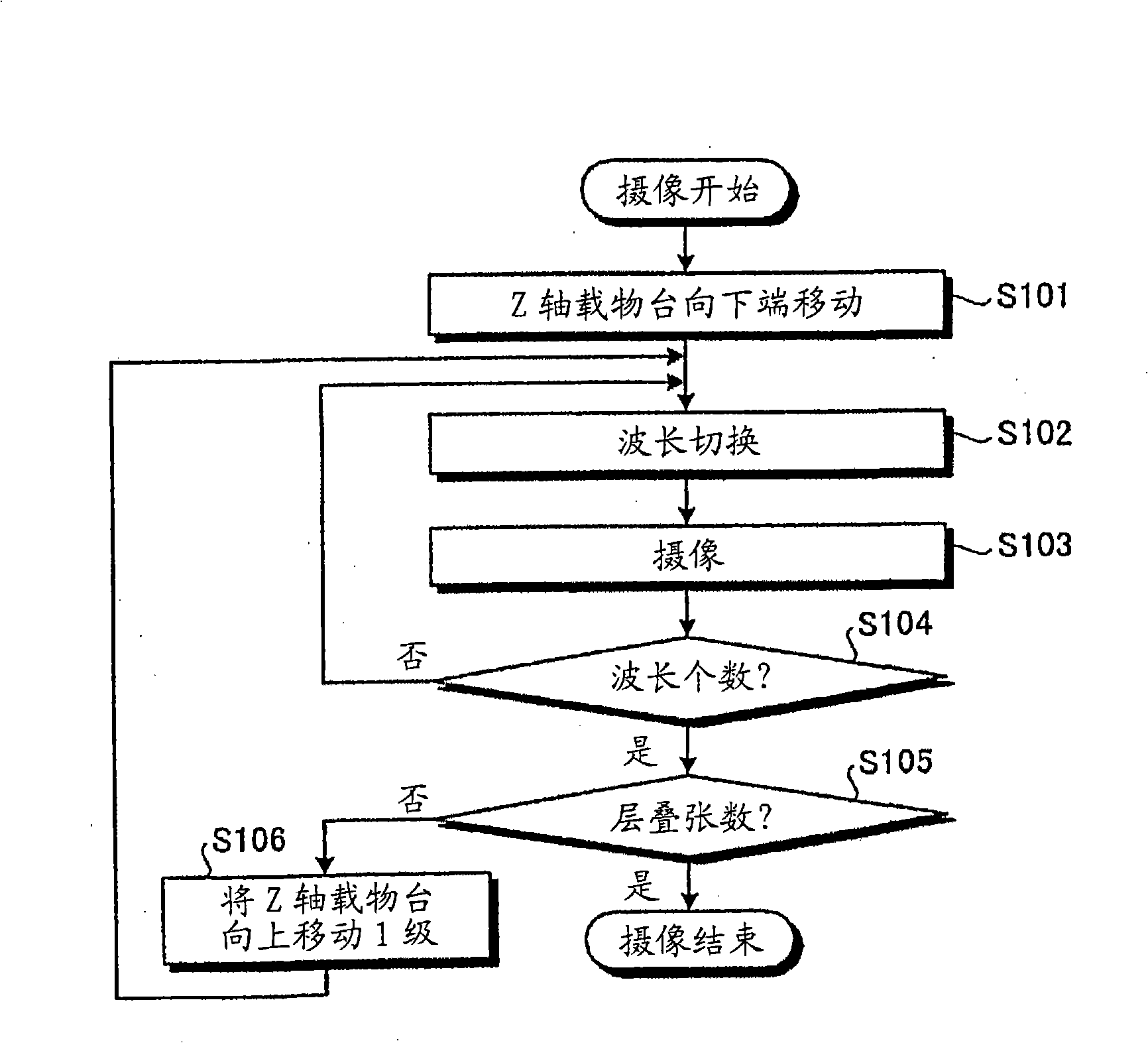

[0052] First, an optical system evaluation device according to Embodiment 1 of the present invention will be described. figure 1 It is a figure showing the structure of the main part of the lens evaluation apparatus 100 which is the optical system evaluation apparatus of this Embodiment 1. FIG. As shown in this figure, the lens evaluation device 100 includes: a sample 4 with a plurality of holes arranged in a planar shape; a light source 1, which serves as an illumination unit for illuminating the sample 4; an optical fiber 2 and a light intensity uniformizing unit 3; The object table 5 as a moving unit holds and moves the sample 4 in the Z-axis direction; and the XY stage 6 moves the sample 4 in the X-axis direction and the Y direction.

[0053] In addition, the lens evaluation device 100 includes: an imaging lens 7b constituting the microscope optical system 7 and imaging the observation image of the sample 4 together with the objective lens 7a as the evaluation object opti...

Embodiment approach 2

[0133] Next, an optical system evaluation device according to Embodiment 2 of the present invention will be described. Figure 10 It is a diagram showing the configuration of main parts of a fluorescence confocal microscope 200 as an optical system evaluation device according to the second embodiment. As shown in the figure, the fluorescent confocal microscope 200 includes a laser light source 51, a dichroic mirror 53, an XY scanner 54, a total reflection mirror 55, an objective lens system 56, a sample 57, a Z-axis stage 58, and a confocal optical system 59 . A light detection system 60 , a control unit 61 , a computer 62 and a display unit 63 .

[0134] Illumination light (excitation light) from a laser light source 51 selectively emitting laser light of multiple wavelengths passes through an XY scanner 54 and a total reflection mirror 55 , and then is condensed by an objective lens system 56 at a focal position within a sample 57 . The reflected light (fluorescence) from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com