Skin effect-based sample surface coating nondestructive test method and system

A non-destructive testing and skin effect technology, applied in measuring devices, electromagnetic measuring devices, electromagnetic/magnetic thickness measurement, etc., can solve problems such as large errors, achieve high detection efficiency, high detection sensitivity, and achieve the effect of automatic measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

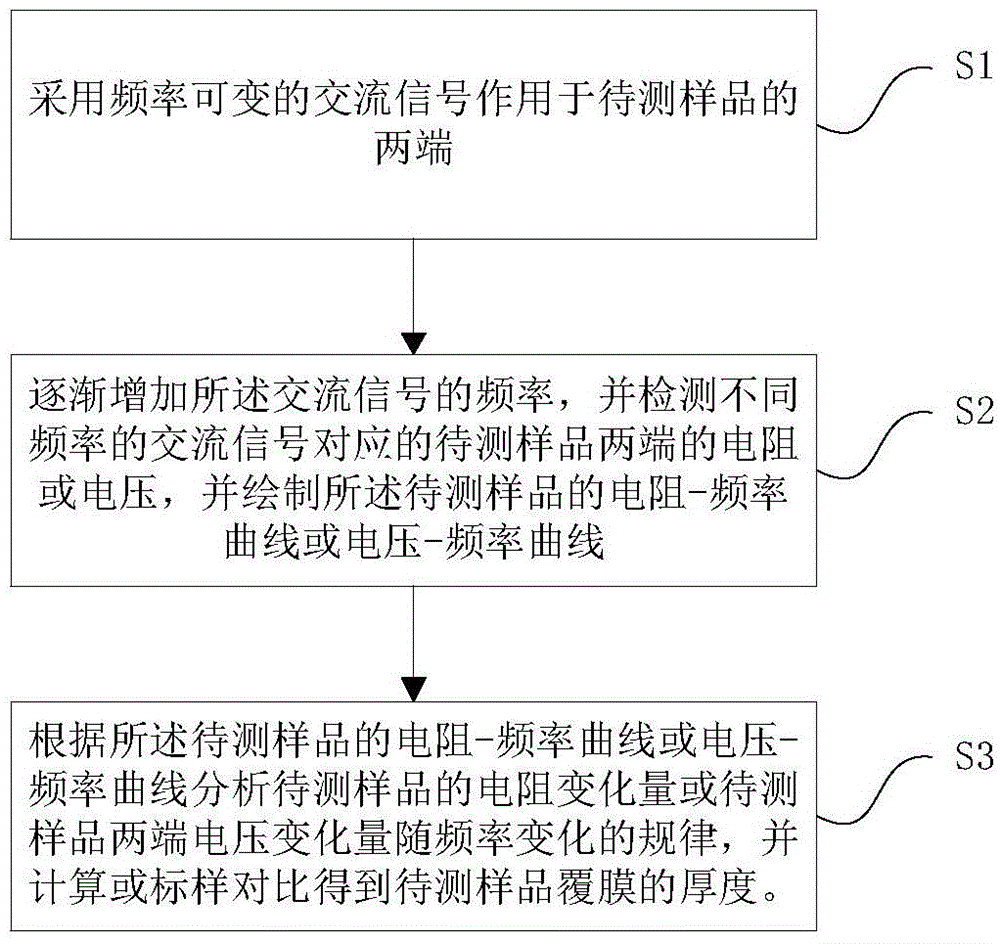

[0049] Embodiment 1, a non-destructive testing method for sample surface coating based on the skin effect, the following will be combined with the attached figure 1 A non-destructive testing method for sample surface coating based on the skin effect of the present invention is introduced in detail.

[0050] Such as figure 1 As shown, a non-destructive testing method based on the skin effect of the sample surface coating, including the following steps:

[0051] Step 1: Use an AC signal with a variable frequency to act on both ends of the sample to be tested;

[0052] Step 2: Gradually increase the frequency of the AC signal, and detect the resistance or voltage at both ends of the sample to be tested corresponding to the AC signal of different frequencies, and perform curve drawing to obtain the resistance-frequency curve or voltage- frequency curve;

[0053] Step 3: According to the resistance-frequency curve or voltage-frequency curve of the sample to be tested, analyze th...

Embodiment 2

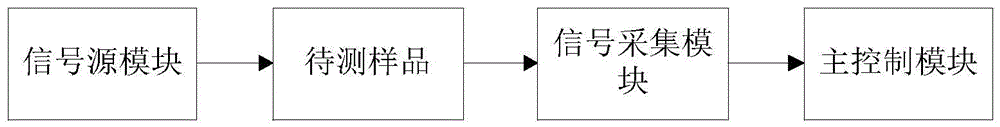

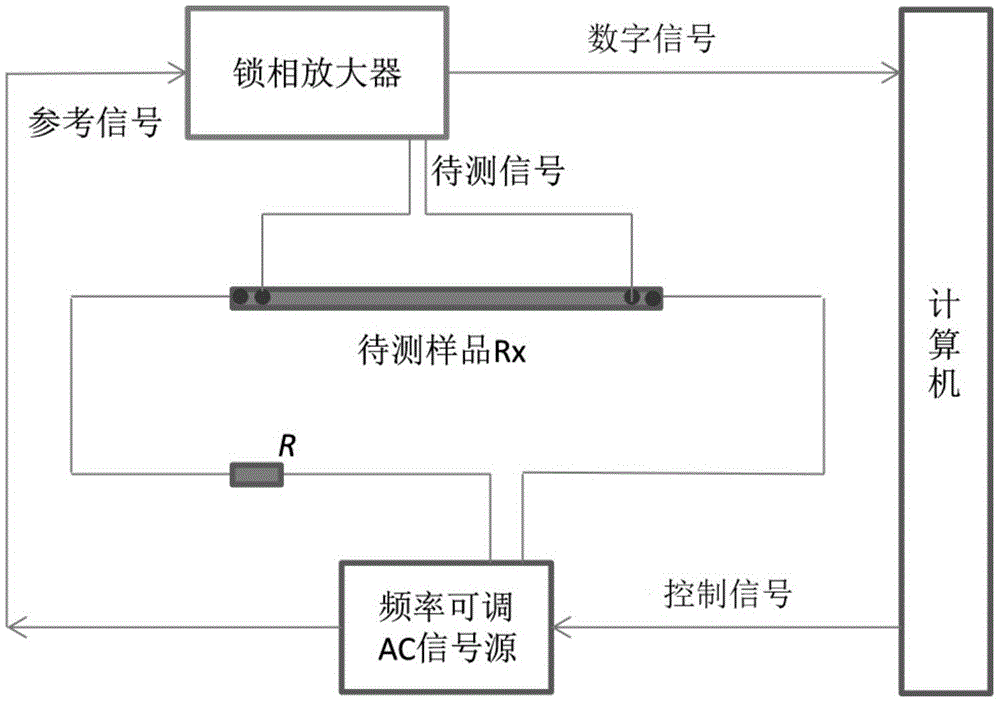

[0092] Embodiment 2, a non-destructive testing system based on the skin effect of the sample surface coating, the following will be combined with the attached figure 2 A non-destructive testing system for sample surface coating based on the skin effect of the present invention will be described in detail.

[0093] Such as figure 2 As shown, a non-destructive testing system based on the skin effect of the sample surface coating, including a signal source module, a signal acquisition module and a main control module.

[0094] Wherein, the signal source module is used to provide frequency-adjustable AC signals for both ends of the sample to be tested; the signal acquisition module is used to detect the resistance or voltage at both ends of the sample to be tested when AC signals of different frequencies act on the sample to be tested and sent to the main control module; the main control module is used to draw a curve according to the resistance or voltage at both ends of the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com