Method for measuring contour of large-caliber aspheric surface optical element at grinding stage

A technology for measuring optical components and contours, which is applied in the field of measurement of aspheric optical components, and can solve problems such as large deviations in theoretical values, inability to apply measurement, poor surface roughness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In the following, in conjunction with the accompanying drawings, the present invention will be further described for measuring the contour of a large-diameter aspherical optical element in the grinding stage.

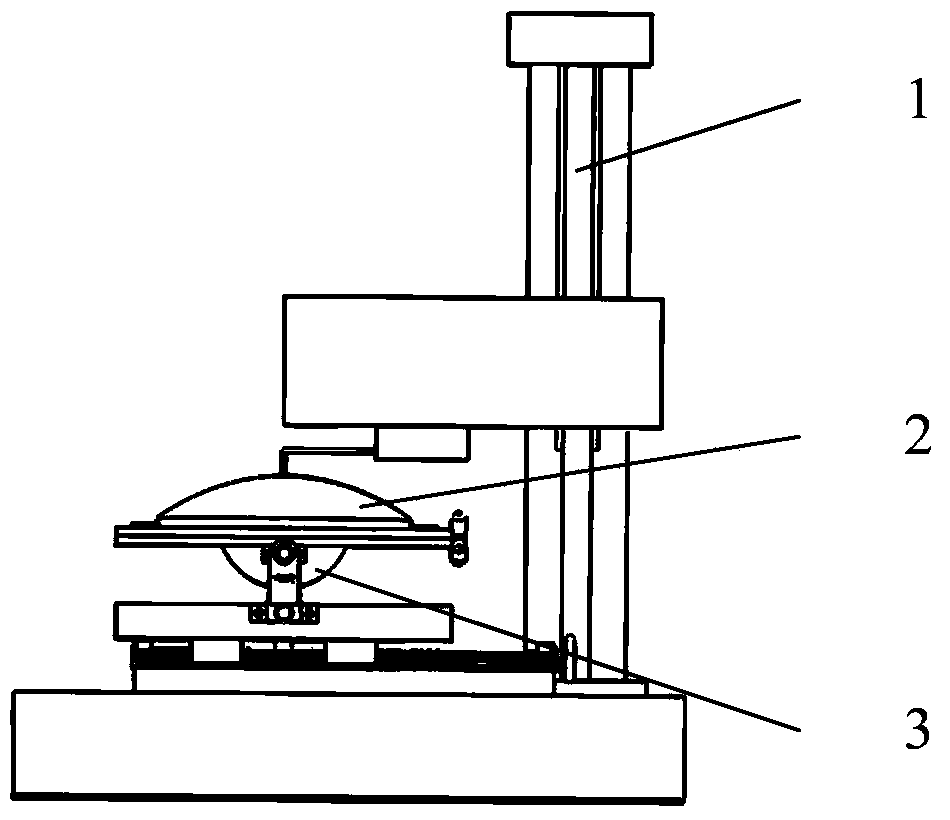

[0046] like figure 1 As shown, mark 1 is the profile measuring instrument, 2 is the optical element to be measured, the optical element is an aspherical surface with a diameter of 176mm, and 3 is a fixture for splicing and measuring large-diameter aspherical surfaces in the non-polishing stage. The X-axis travel of the fixture is 220mm, and the Y-axis With a stroke of 100mm, the tilt angle can be adjusted from -30° to 30°. Applying the present invention, the specific measurement steps are as follows:

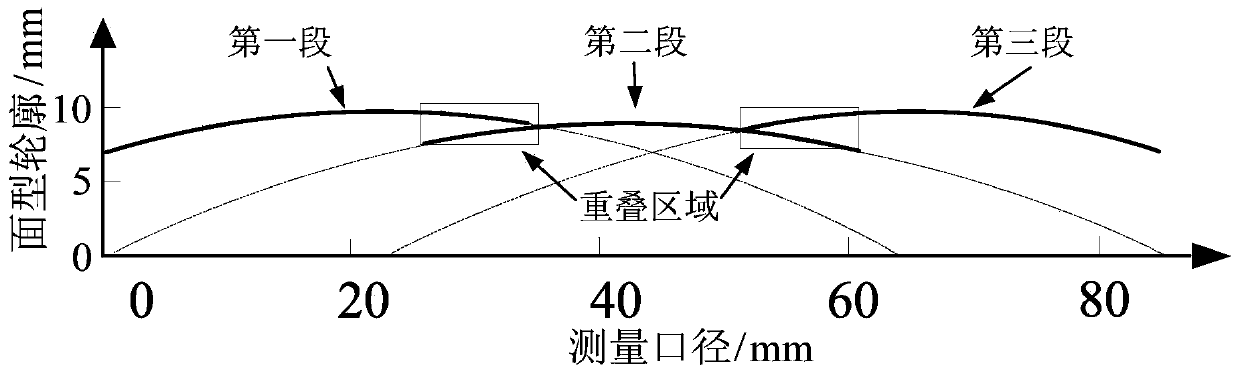

[0047] 1) Carry out segmentation planning and establishment of a local coordinate system for the measured aspheric optical element, segment a contour line of the aspheric optical element according to the actual situation, the number of segments is 3, and the lengt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com