Edge portion measurement signal compensation method and device for contact type plate-shaped roller

A technology for measuring signals and compensation methods, which is applied in the field of strip steel cold rolling, and can solve problems such as radial force deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

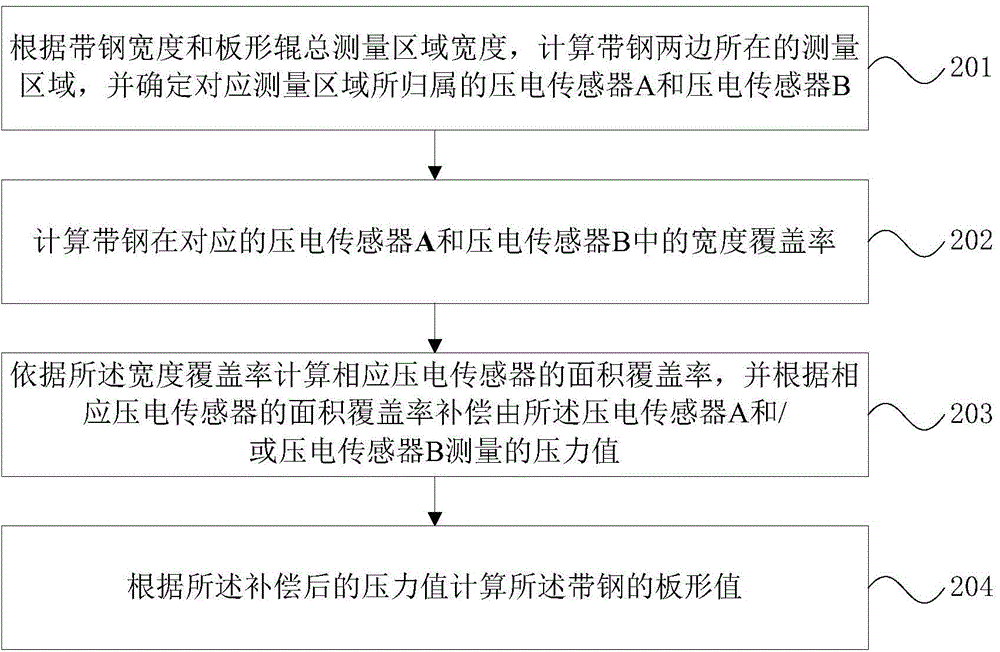

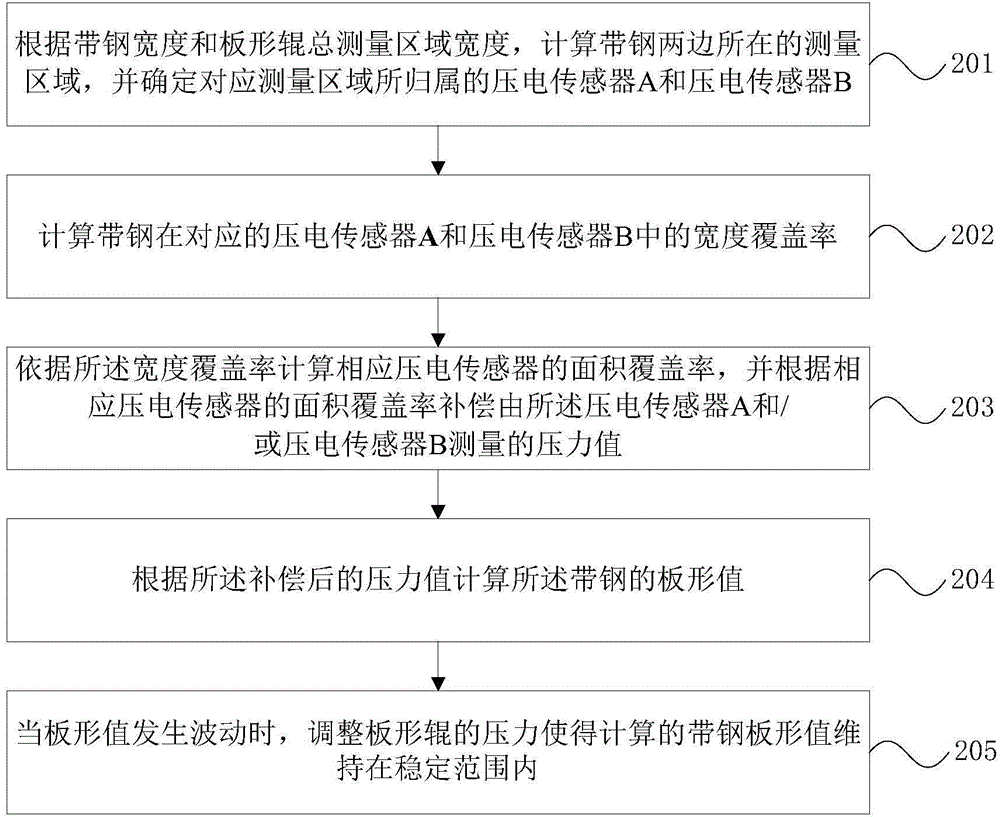

[0028] Such as figure 1 Shown is a flow chart of a method for compensating signals for contact-type plate-shaped roll edge measurement provided by the present invention, wherein n piezoelectric sensors are installed on the plate-shaped roll, and each piezoelectric sensor corresponds to its own measurement area. The sum of the measurement areas of the n piezoelectric sensors constitutes the total measurement area of the plate-shaped roller, the n is greater than or equal to 1, and the method includes the following steps:

[0029] In step 201, according to the width of the steel strip and the width of the total measurement zone of the shape roll, the measurement zones on both sides of the strip are calculated, and the piezoelectric sensor A and the piezoelectric sensor B to which the corresponding measurement zone belongs are determined.

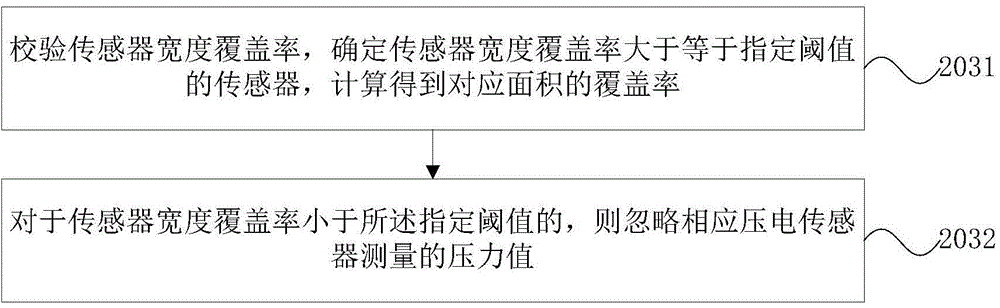

[0030] In step 202, the width coverage ratio of the steel strip in the corresponding piezoelectric sensor A and piezoelectric sensor B is c...

Embodiment 2

[0053] The embodiment of the present invention also provides a contact type measuring signal compensating device for the shape roll edge, such as Figure 5 As shown, it includes a plate-shaped roller 11, n piezoelectric sensors 12 and a processor (the processor is installed in the server 10), wherein n piezoelectric sensors are installed on the plate-shaped roller, and each piezoelectric sensor Corresponding to respective measurement areas, the sum of the measurement areas of the n piezoelectric sensors constitutes the total measurement area of the plate-shaped roller, and the device also includes a processor:

[0054] The processor is used to calculate the measurement area where the two sides of the strip are located according to the width of the strip steel and the total measurement area width of the shape roll, and determine the piezoelectric sensor A and the piezoelectric sensor B to which the corresponding measurement area belongs; The width coverage in the correspondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com