Patents

Literature

334 results about "Measurement uncertainty" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In metrology, measurement uncertainty is the expression of the statistical dispersion of the values attributed to a measured quantity. All measurements are subject to uncertainty and a measurement result is complete only when it is accompanied by a statement of the associated uncertainty, such as the standard deviation. By international agreement, this uncertainty has a probabilistic basis and reflects incomplete knowledge of the quantity value. It is a non-negative parameter.

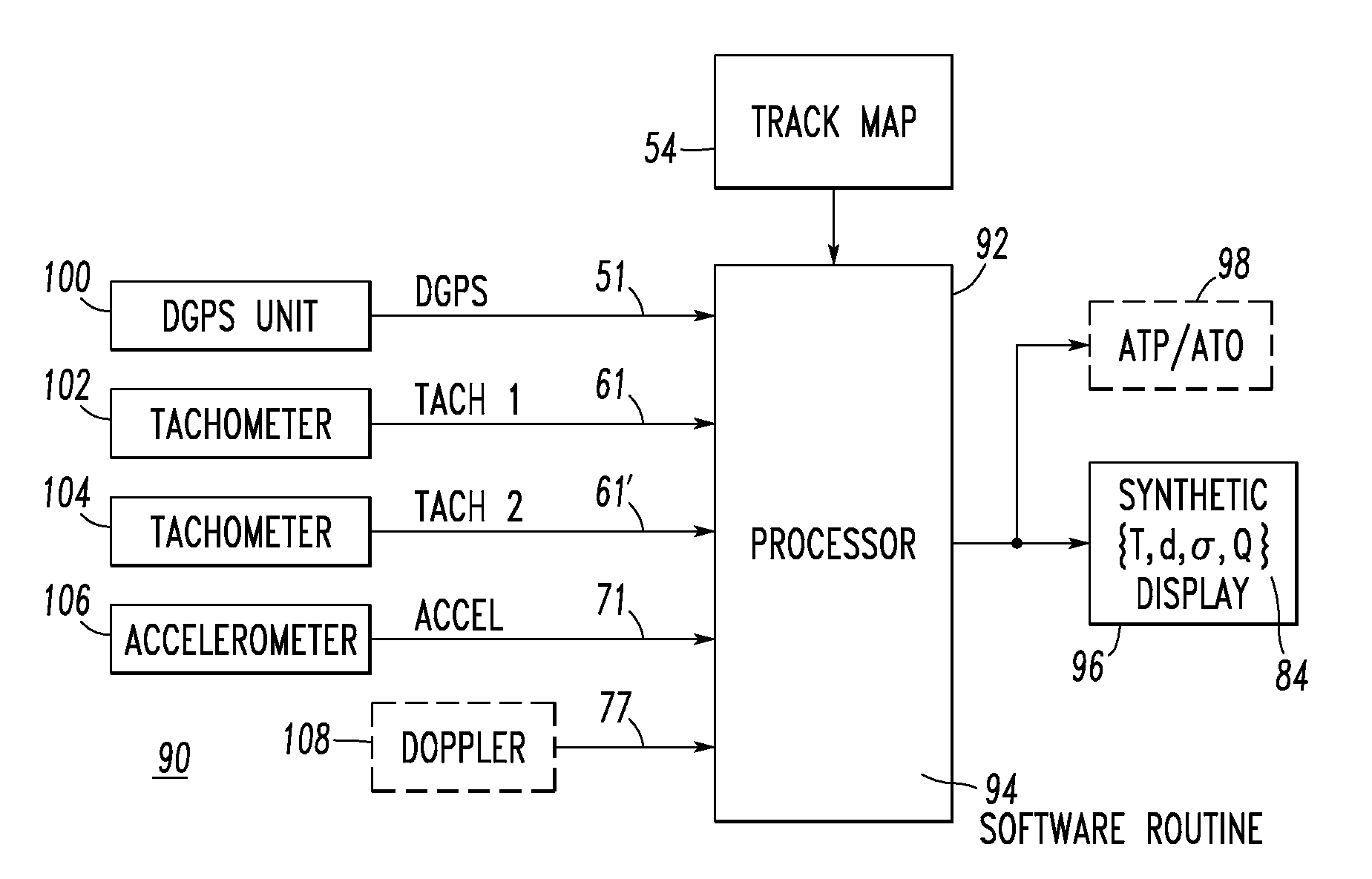

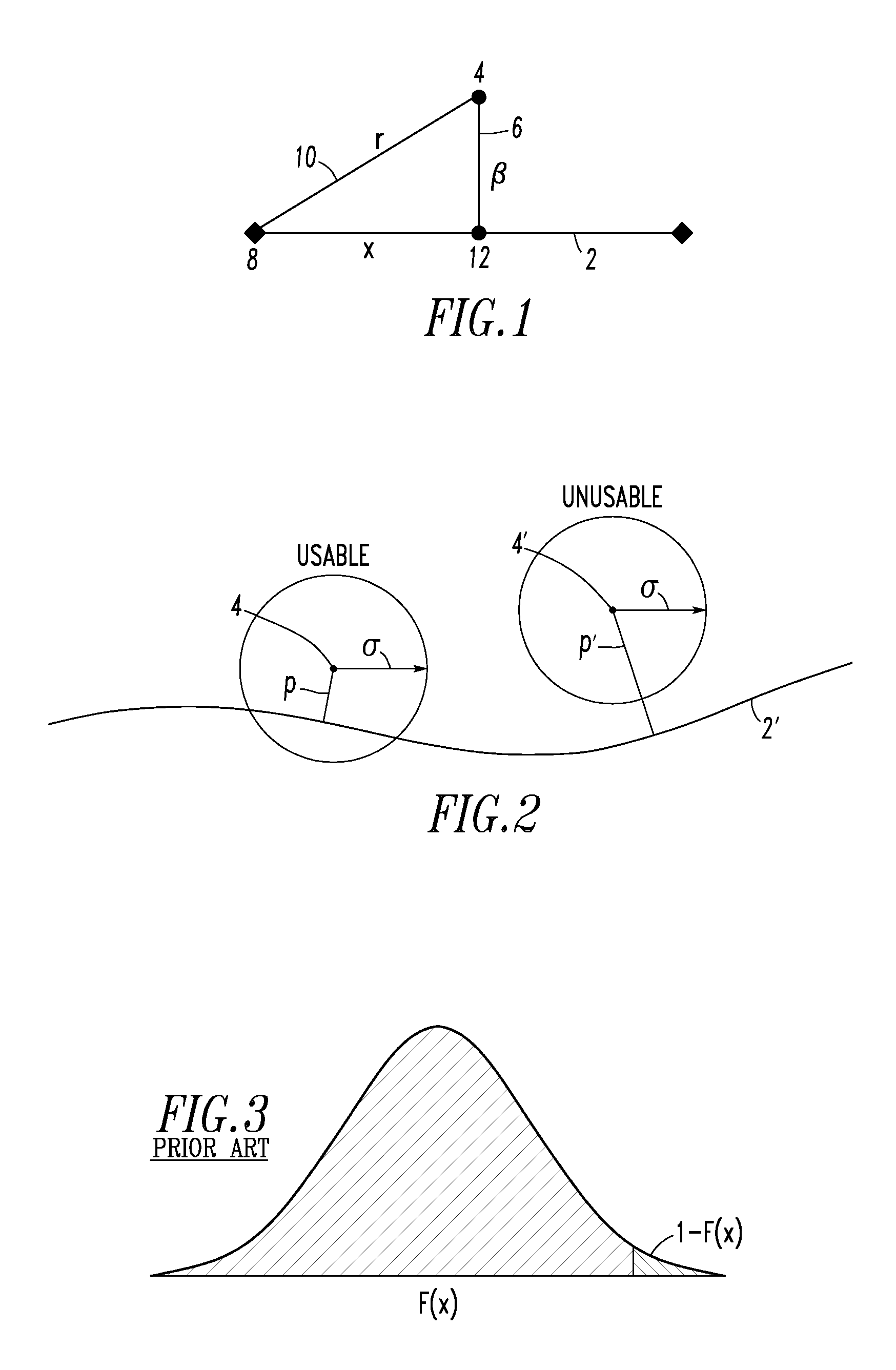

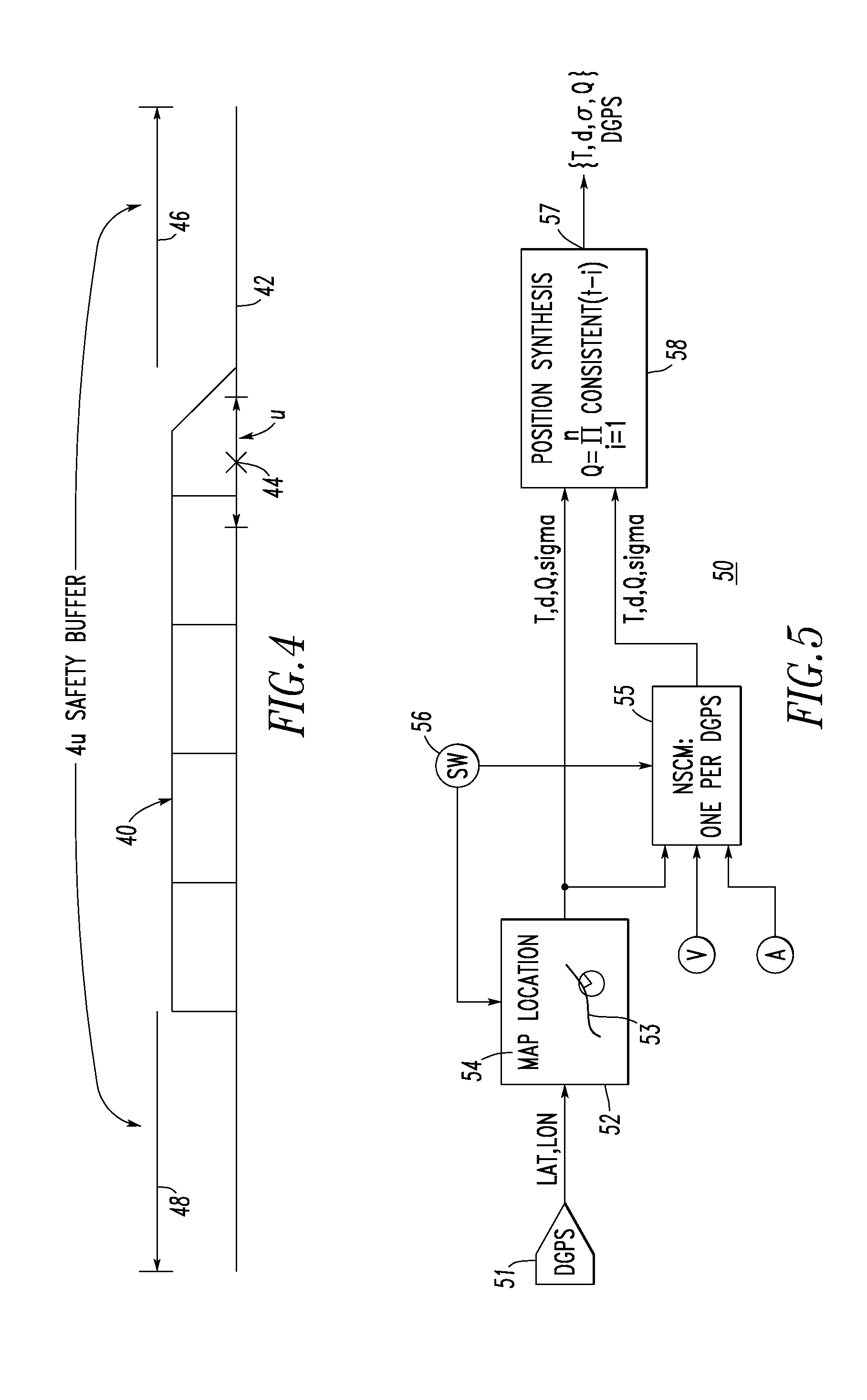

System and method for vitally determining position and position uncertainty of a railroad vehicle employing diverse sensors including a global positioning system sensor

ActiveUS20100312461A1Analogue computers for vehiclesAnalogue computers for trafficAccelerometerEngineering

A system vitally determines a position of a train. The system includes a plurality of diverse sensors, such as tachometers and accelerometers, structured to repetitively sense at least change in position and acceleration of the train, a global positioning system sensor, which is diverse from each of the diverse sensors, structured to repetitively sense position of the train, and a track map including a plurality of track segments which may be occupied by the train. A processor cooperates with the diverse sensors, the global positioning system sensor and the track map. The processor includes a routine structured to provide measurement uncertainty for each of the diverse sensors and the global positioning system sensor. The routine cross-checks measurements for the diverse sensors, and cross-checks the global positioning system sensor against the track map. The routine provides the vitally determined position of the train and the uncertainty of the vitally determined position.

Owner:ANSALDO STS USA INC

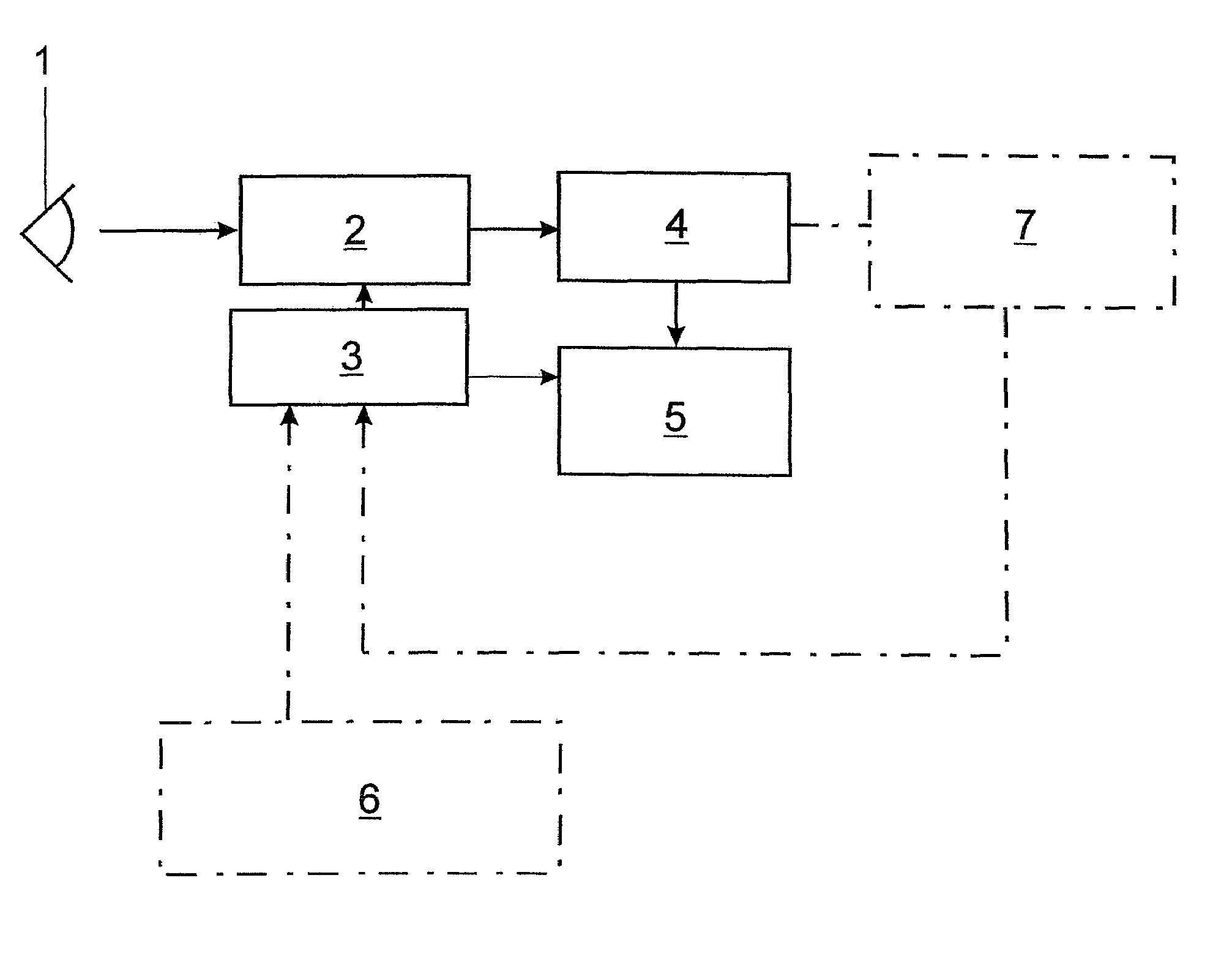

Apparatus and method for the analysis of retinal vessels

ActiveUS7677729B2Good reproducibilityReduce measurement uncertaintyProjector film strip handlingCamera film strip handlingVeinMedicine

The object of an apparatus and a method for the analysis of retinal vessels is to improve the reproducibility of individually determined artery-to-vein ratios and to reduce the measurement uncertainty in determining the artery-to-vein ratio in order to substantially increase the individual validity of the determined values for vessel diagnosis. At least two images are recorded successively as an image sequence in a predetermined timed sequence adapted to the vasomotricity of the vessels and are evaluated such that a mean artery-to-vein ratio is formed from artery-to-vein ratios that are determined on the basis of the at least two images.

Owner:IMEDOS INTELLIGENTE OPTISCHE SYST DER MEDIZIN & MESSTECHNIK GMBH

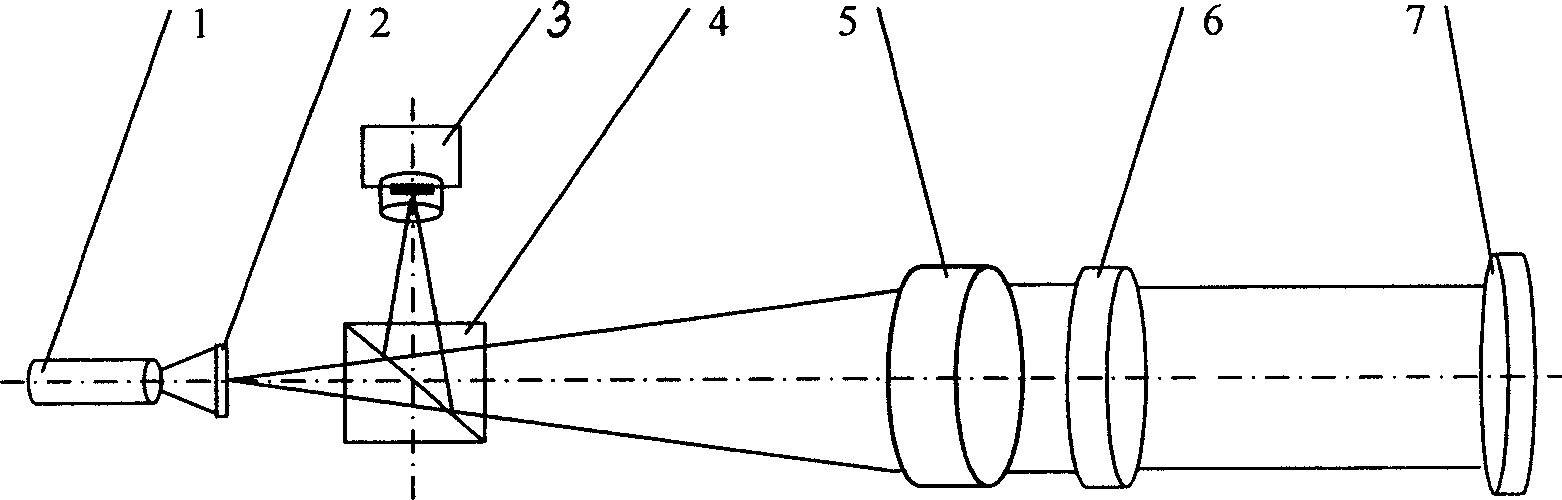

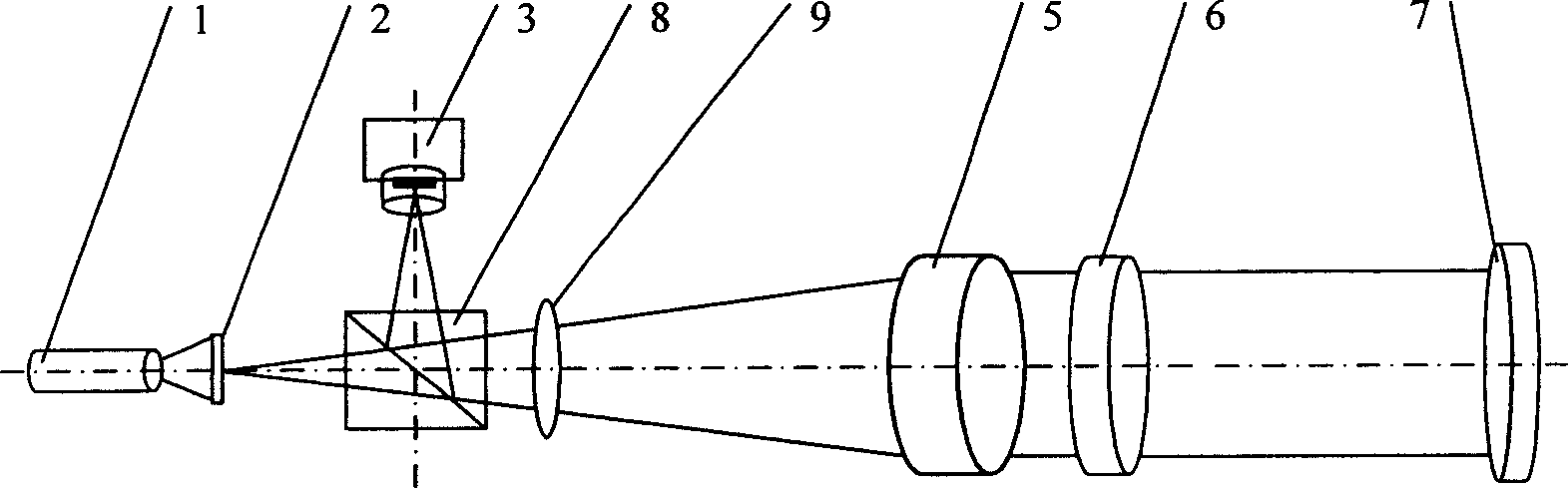

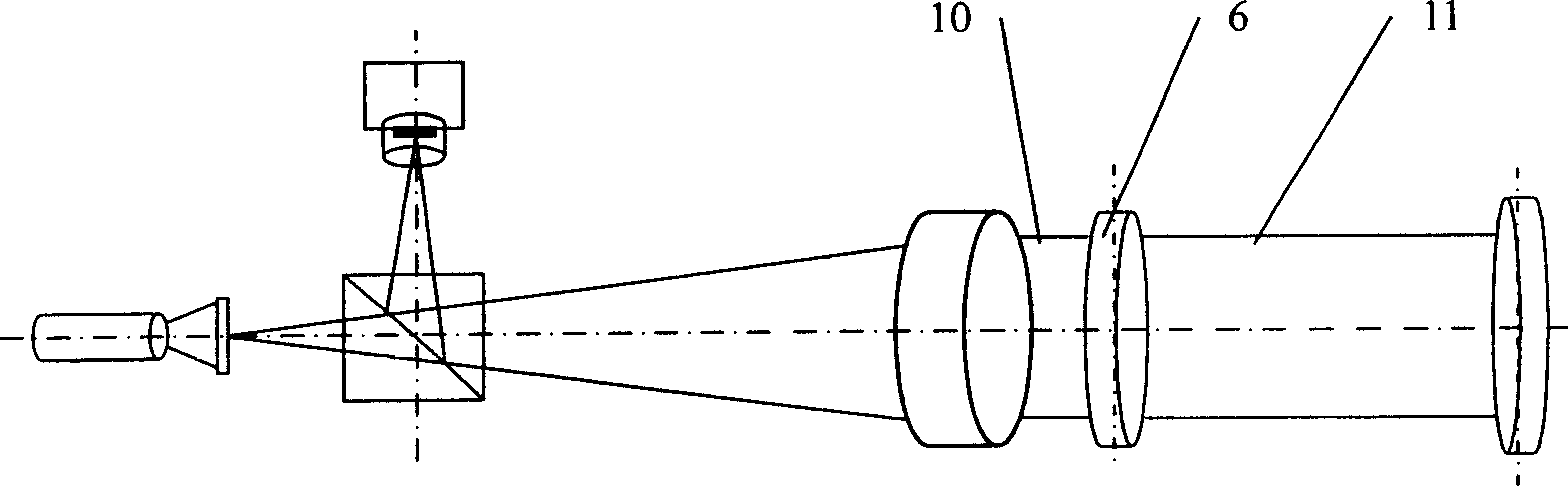

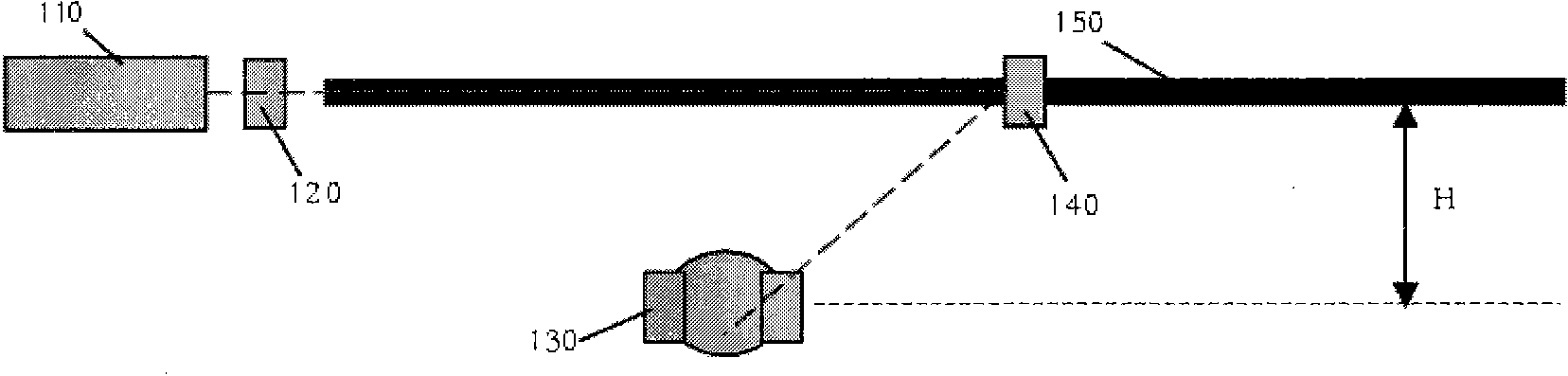

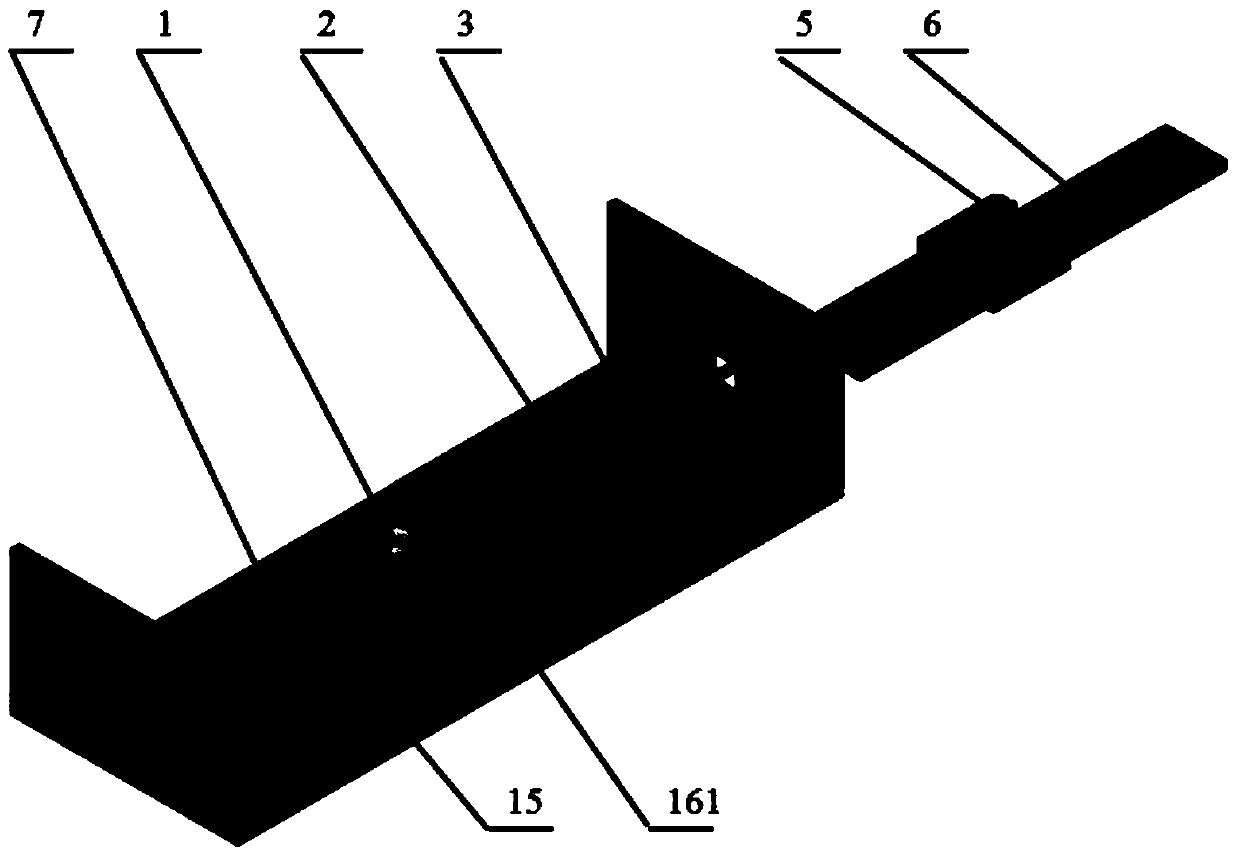

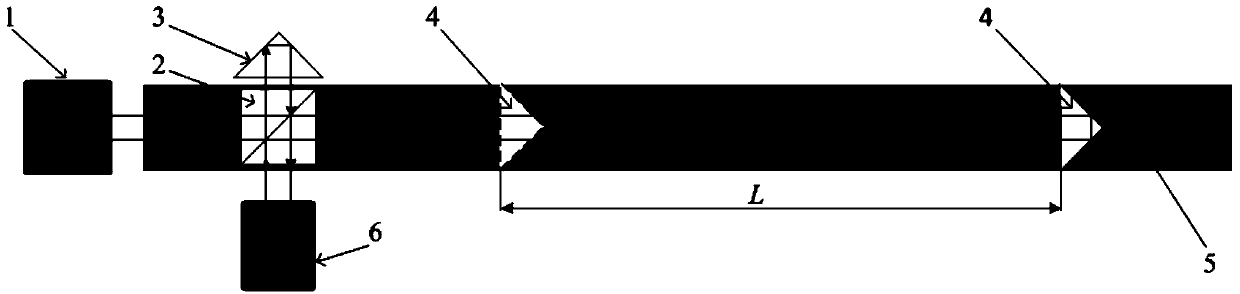

2D photoelectric auto collimation equipment and measuring method based on dynamic differential compensation process

ActiveCN1687702AAccurately measure the amount of changeGood effectUsing optical meansBeam splitterPrism

The invention belongs to the precise instrument manufacturing and detecting technology, especially relates to the bidimensional photoelectric self-alignment equipment and method based on dynamic differentiation compensation method. The equipment comprises the light source, the calibrated board, the CCD image sensor, the beam splitter prism, the aligning object lens, the measuring reflecting lens and the beam splitter between the aligning object lens and the reflecting lens. The two faces of the beam splitter are separately plated with the splitting film and the reflection reducing coating; the surface coarseness of the photic base plate is more than 0.08 um, and paralleling degree of the two faces is smaller than 10'; the light splitting ratio is 52 / 48 is less than or equal to T / R is less than or equal to 72 / 28 and the reflection reducing coefficient alpha is greater than or equal to 99%. The invention improves the stability and the repetition of the measuring.

Owner:日照大象房屋建设有限公司

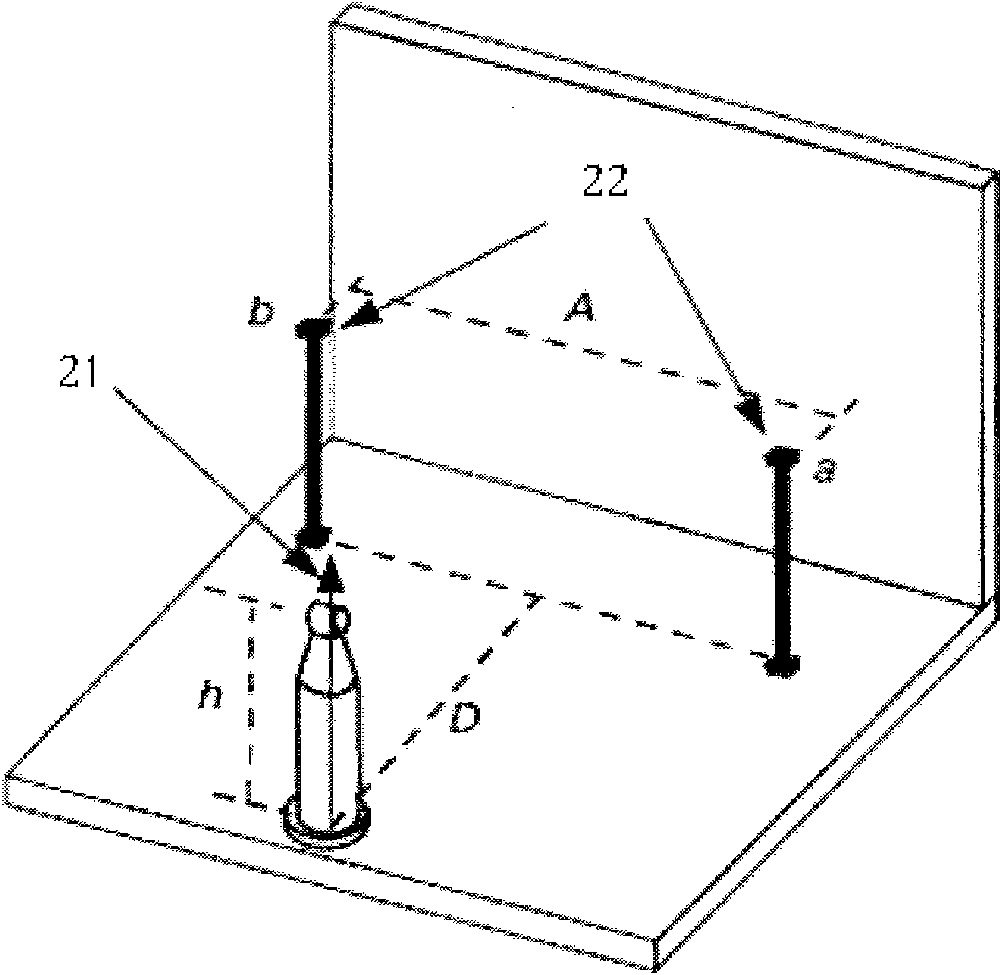

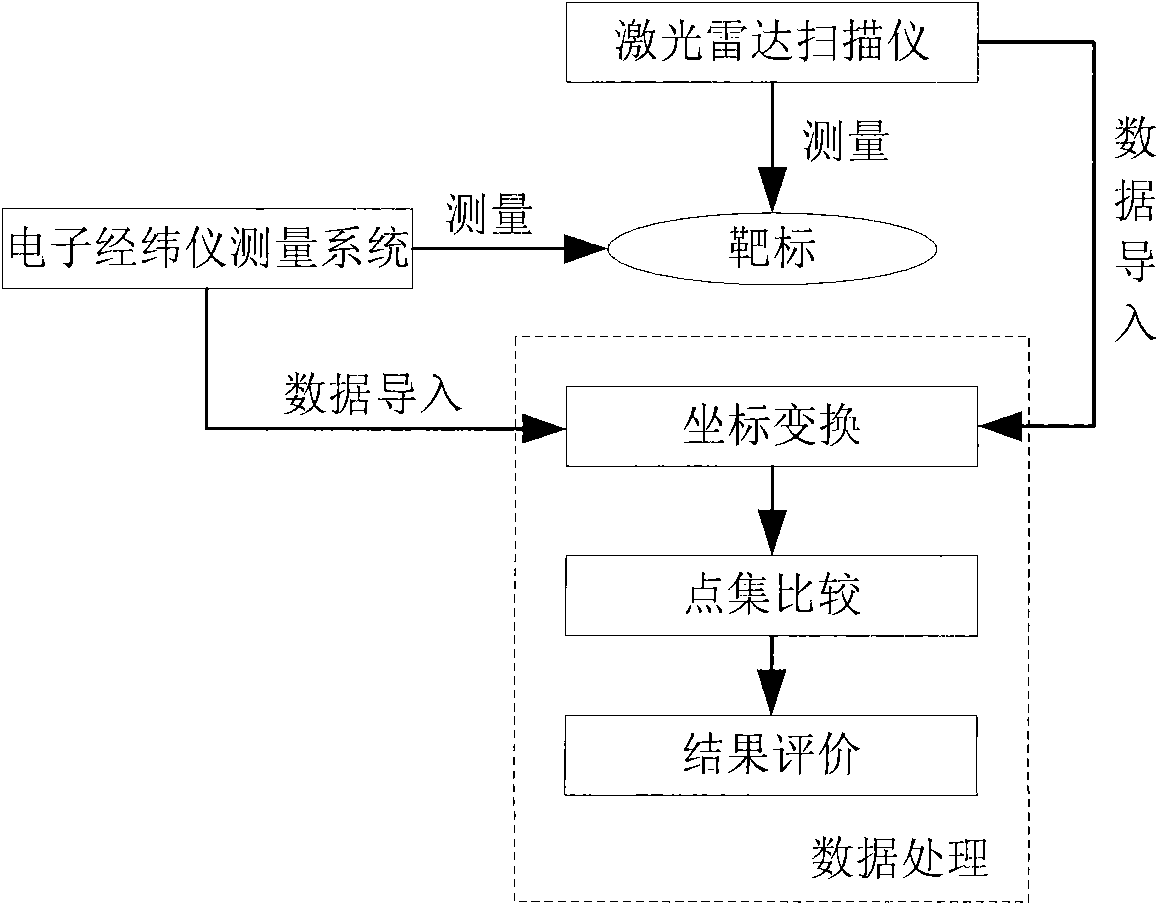

Method for calibrating spatial coordinate measuring system of electronic theodolite

ActiveCN101655344AReduce dependenceHigh precisionWave based measurement systemsUsing electrical meansTheodoliteRadar

The invention discloses a method for calibrating a spatial coordinate measuring system of an electronic theodolite, which aims to meet the need that the measuring system of the electronic theodolite calibrates in the range of tens of meters in any direction at an angle of horizontal 360 DEG and pitching + / -45 DEG. The method comprises the following steps of: placing instruments and targets; 2, using a laser radar scanner to assign a value to the targets to form a standard instrument group; step 3, the calibrated system of the electronic theodolite measures each target to obtain measured values; step 4, converting the measured values of the electronic theodolite to a measurement coordinate system of the laser radar scanner; and step 5, comparing the converted measured values of the electronic theodolite with a standard value thereof, and obtaining the measurement deviation and measurement uncertainty evaluation of the measuring system of the electronic theodolite through software analysis. The method meets the need that the measuring system of the electronic theodolite calibrates in the range of tens of meters in any direction at the angle of horizontal 360 DEG and pitching + / -45 DEG.

Owner:BEIJING AEROSPACE INST FOR METROLOGY & MEASUREMENT TECH

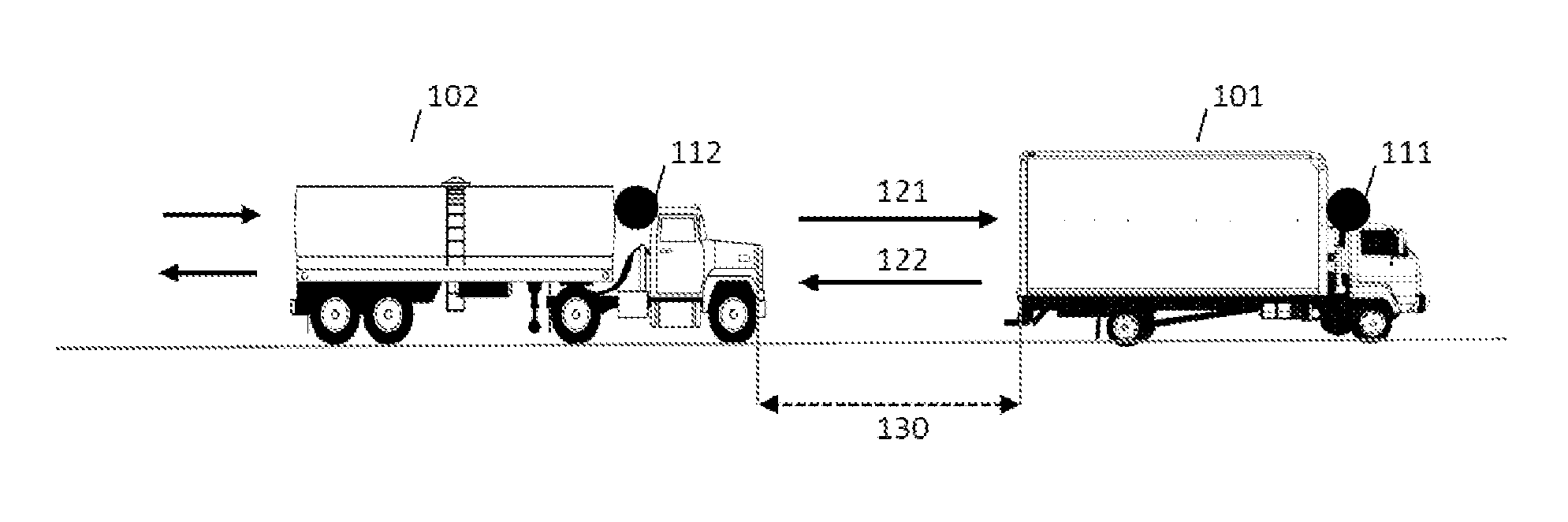

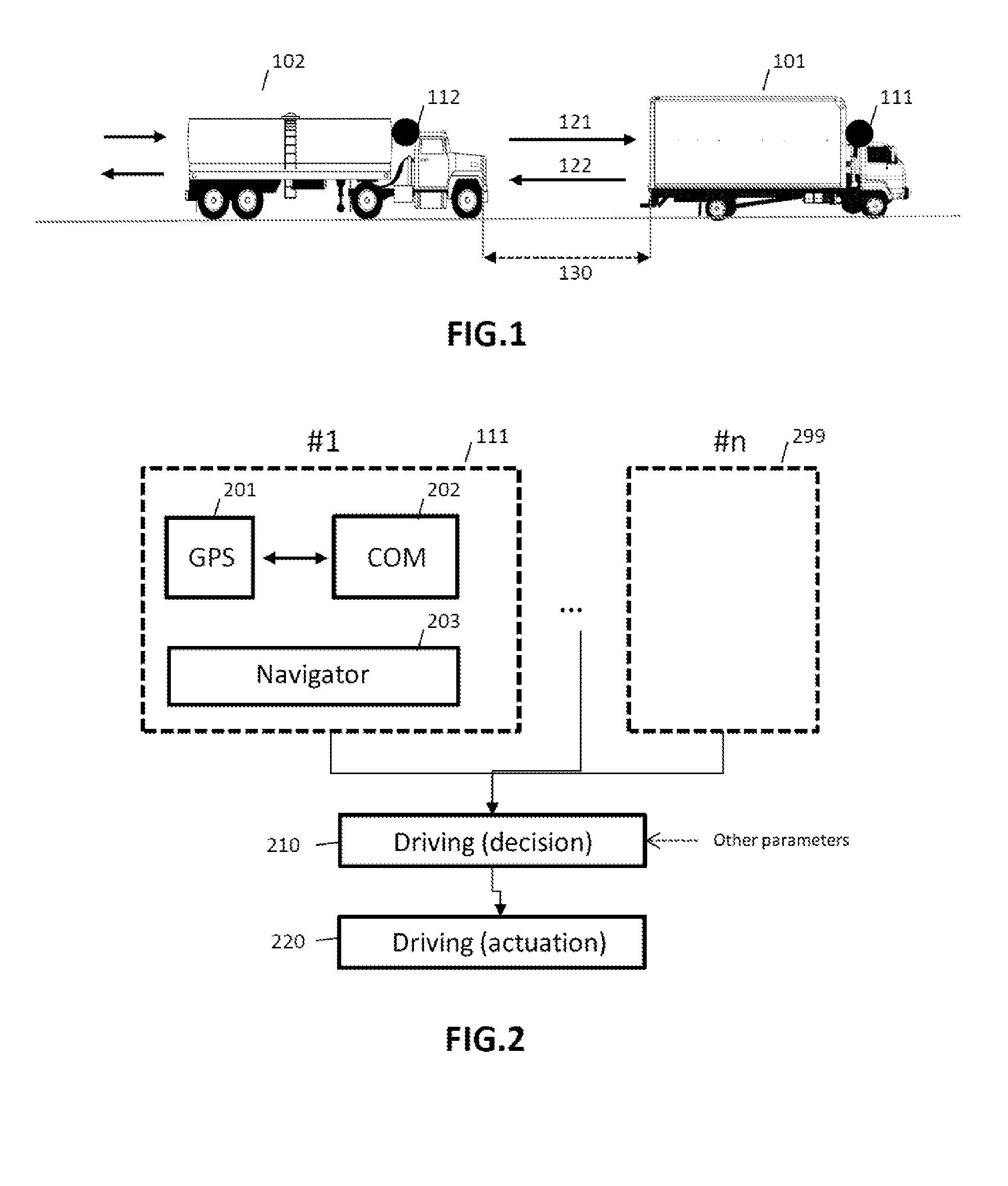

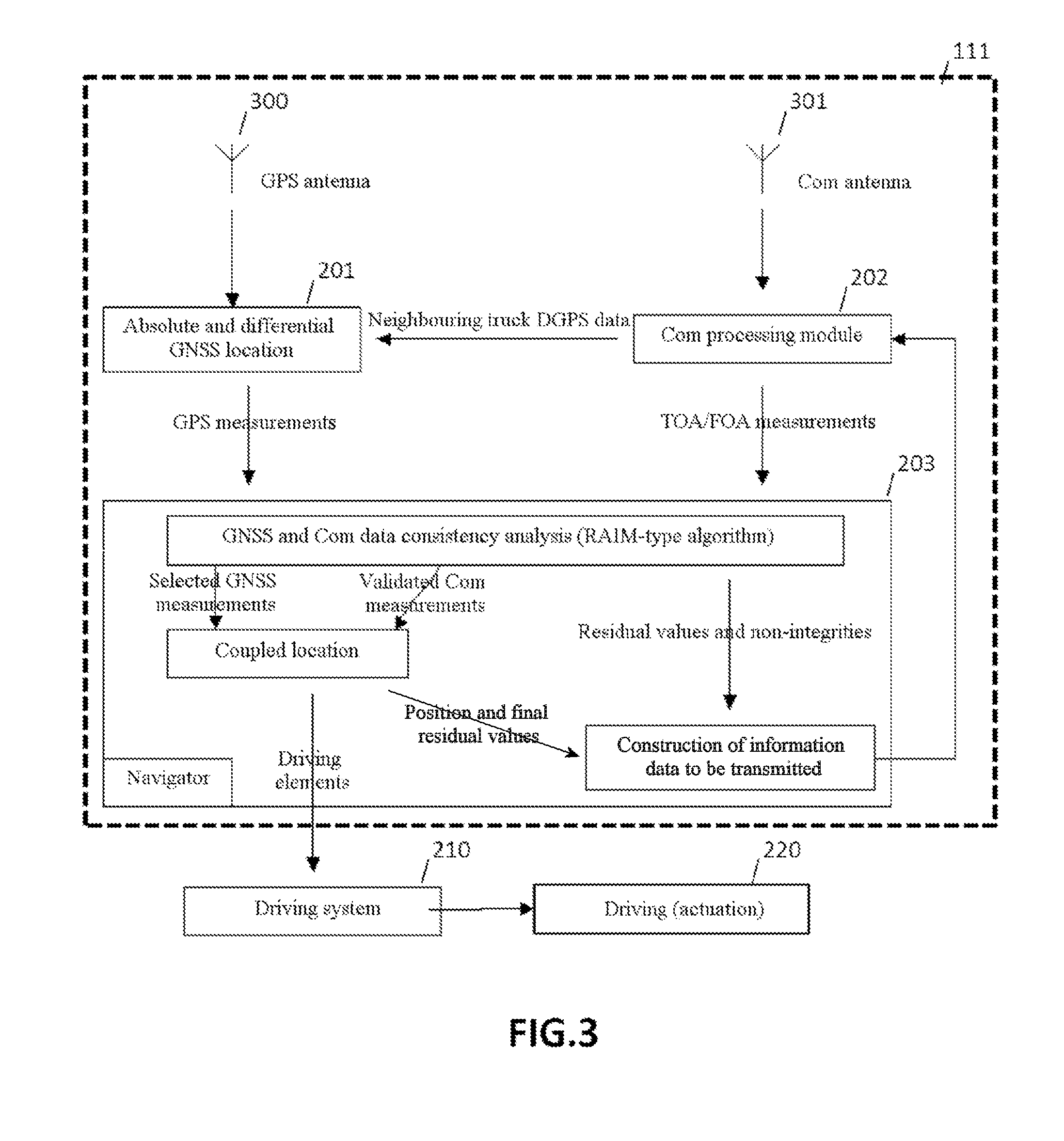

Driving vehicles in convoy

ActiveUS20150269845A1Good propagation time measurement qualityExternal condition input parametersSatellite radio beaconingEngineeringSignal-to-quantization-noise ratio

A method is implemented by computer for the management of a convoy comprising at least two vehicles, each of the at least two vehicles comprising satellite positioning means and vehicle-to-vehicle communication means, the method comprising the determination of the relative positioning of the vehicles, the determination comprising the measurement of the propagation time of a signal between vehicles by the communication means, the clocks associated with the communication means being synchronized via satellite positioning means at a reference clock time. Developments comprise the communication between the vehicles of various data (e.g. measurement uncertainties, signal-to-noise ratios, residual values), the determination of absolute locations, the use of an SBAS-type system, the use of differential GPS, the use of Doppler measurements for the turns or even the exclusion of a failing satellite. A computer program product and associated systems are described.

Owner:THALES SA

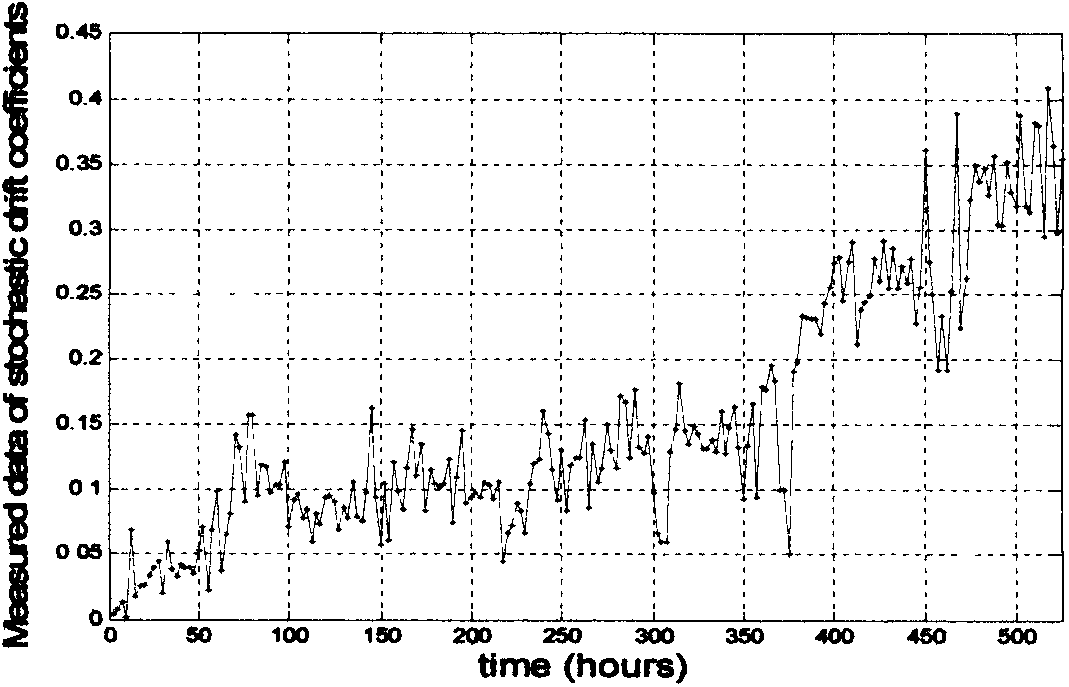

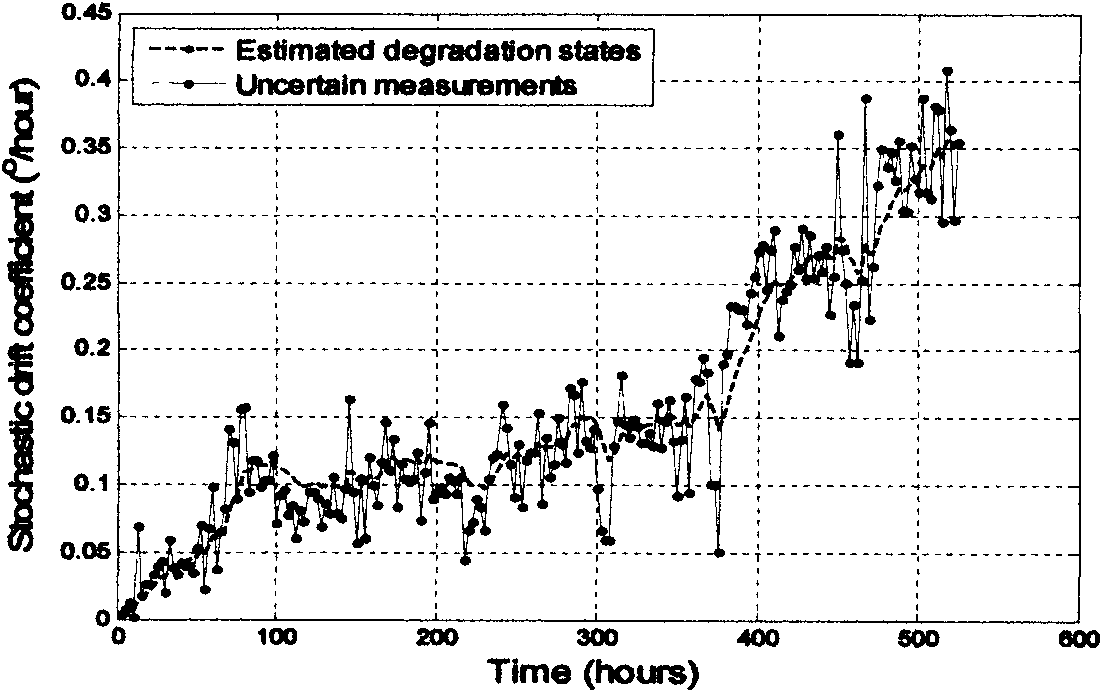

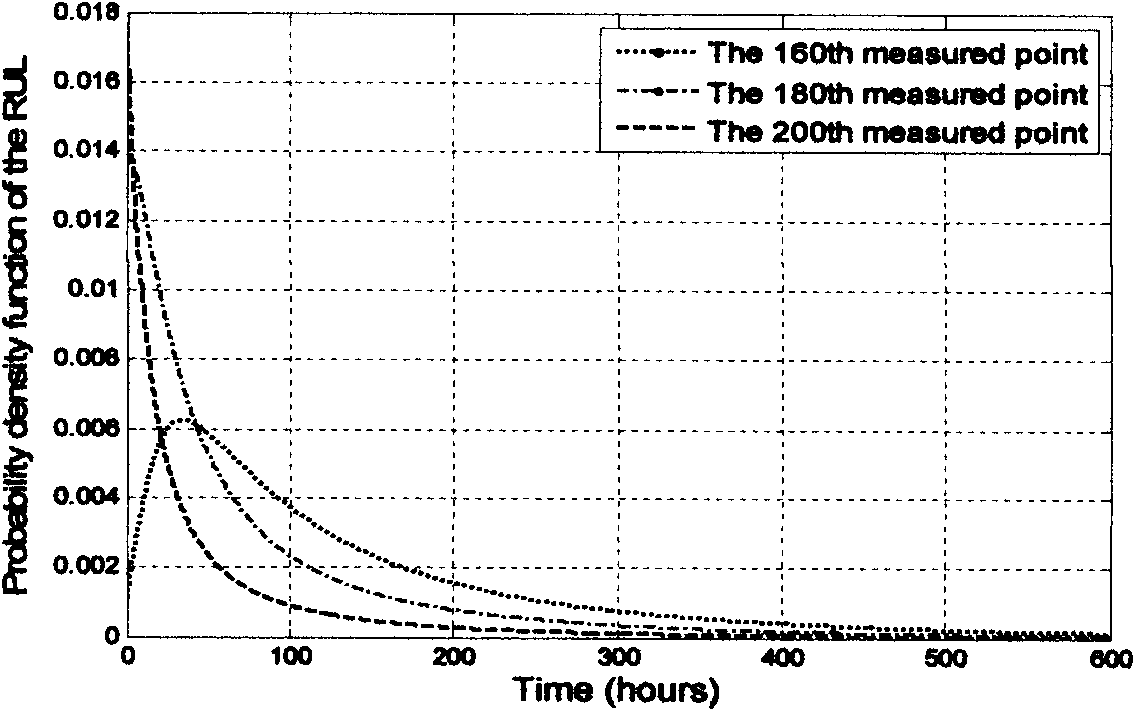

Equipment residual service life prediction method under the condition of uncertain degradation measured data

ActiveCN103488881ASave moneyAvoid economic lossSpecial data processing applicationsModel parametersAnalysis tools

The invention belongs to the technical field of reliability engineering, and relates to an equipment residual service life prediction method under the condition of uncertain degradation measured data. The method includes the following steps: creating an equipment performance degradation model under the condition of the uncertain degradation measured data, estimating model parameters, estimating an equipment potential performance degradation state and predicating residual service life. The equipment residual service life prediction method under the condition of the uncertain degradation measured data is provided, degradation state uncertainty and measurement uncertainty are considered, characteristic quantity of individual service life and overall reliability service life of equipment are predicated and analyzed, and the method can serve as an effective analysis tool for predicating the residual service life of the equipment so as to provide powerful theoretical basis and technical support to state-based maintenance of the equipment, so that expenditure is reduced, unnecessary economic loss is avoided, and good engineering application value is realized.

Owner:PLA SECOND ARTILLERY ENGINEERING UNIVERSITY

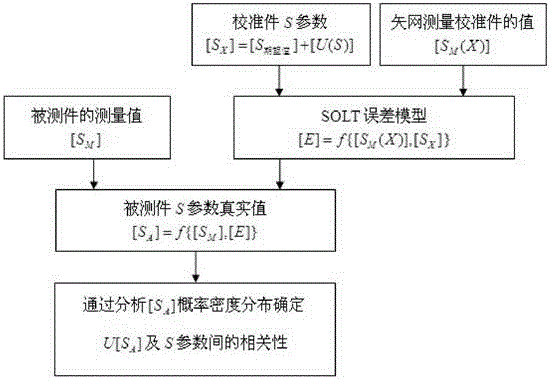

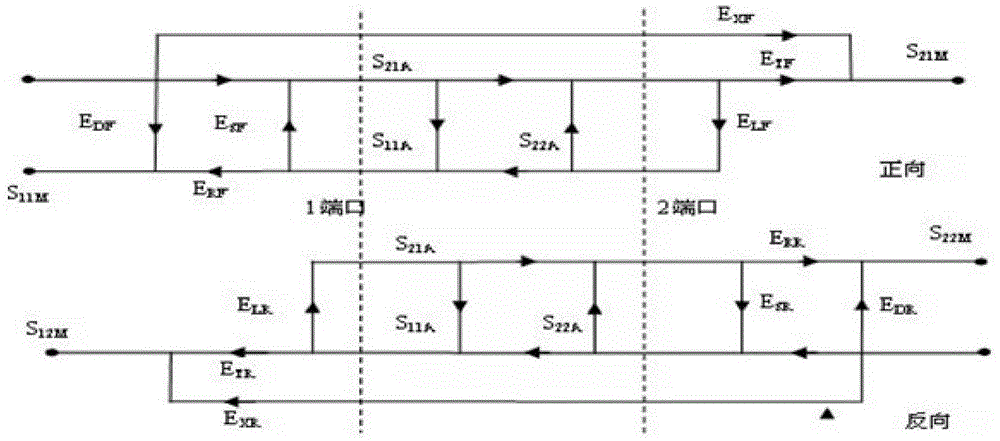

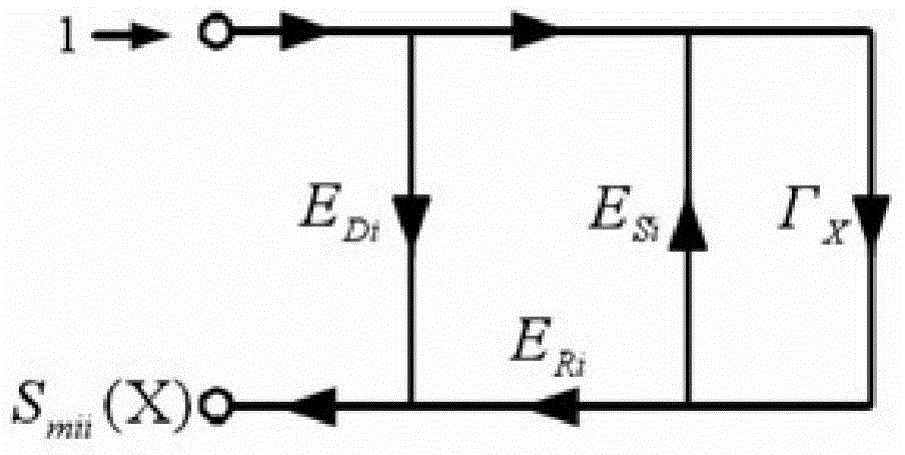

Method for determining uncertainty of S parameter measurement conducted through vector network analyzer

ActiveCN103983931AAvoid the problem of imperfect uncertaintyImprove accuracyElectrical measurementsSimulation methodsMeasurement uncertainty

The invention discloses a method for determining the uncertainty of the S parameter measurement conducted through a vector network analyzer, and relates to the technical field of calibration methods for the vector network analyzer. The method is achieved through MCM simulation, and therefore the problem that the relevance between S parameters needs to be considered when the uncertainty is evaluated through a GUM method and the problem that the uncertainty obtained through an experience algorithm is incomplete are solved. The method starts from the definition of a calibration piece, self-calibration is conducted on the vector network analyzer based on an SOLT calibration method, the uncertainty introduced through the calibration piece is transmitted to a measured piece through the vector network analyzer, and finally the measurement uncertainty of the S parameters of the measured piece measured by the vector network analyzer and the relevance between the S parameters are obtained through the MCM simulation method so that it can be ensured that performance of obtaining the accurate S parameters of the measured piece can be achieved for the vector network analyzer and measurement accuracy can be improved.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP

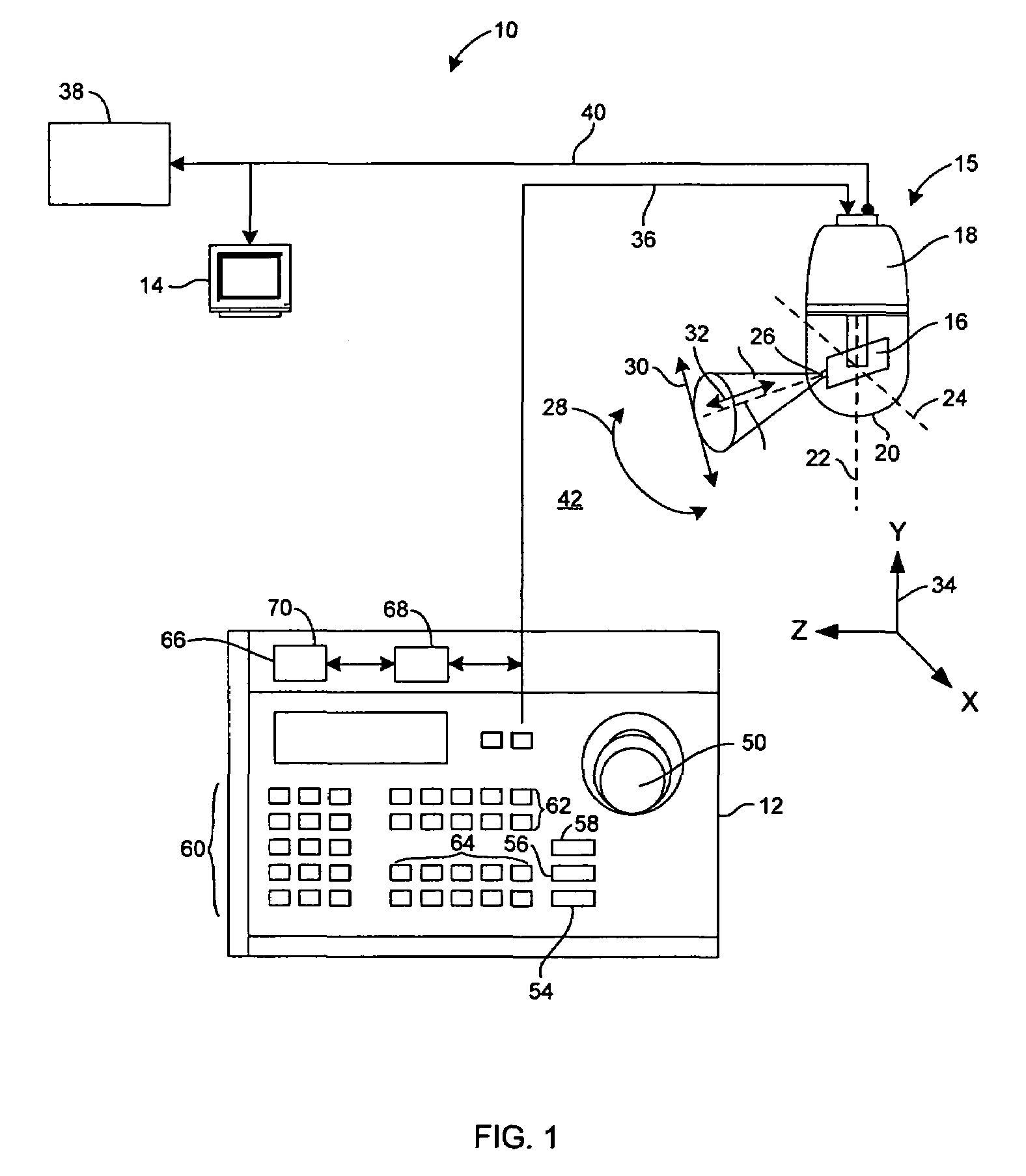

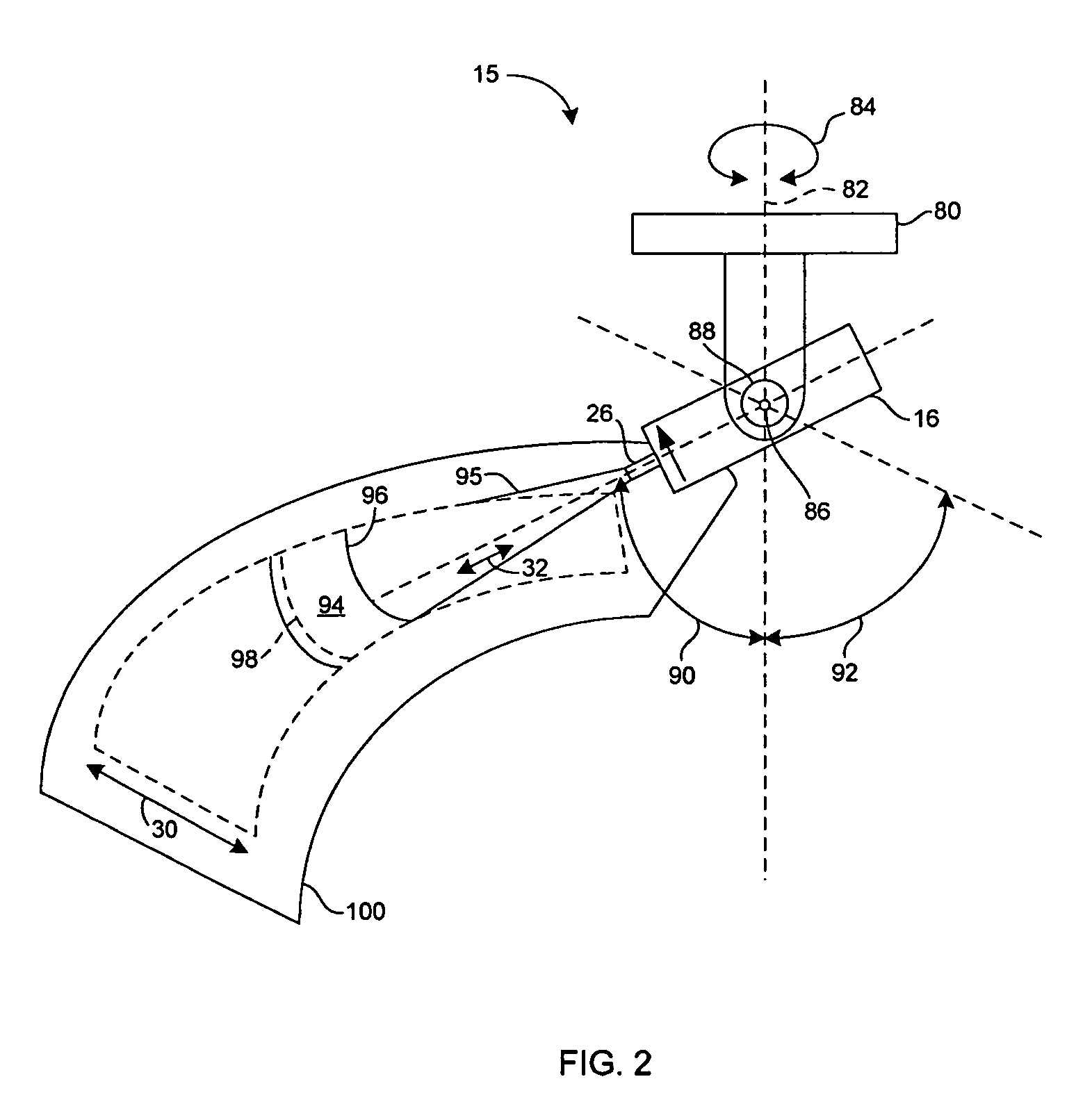

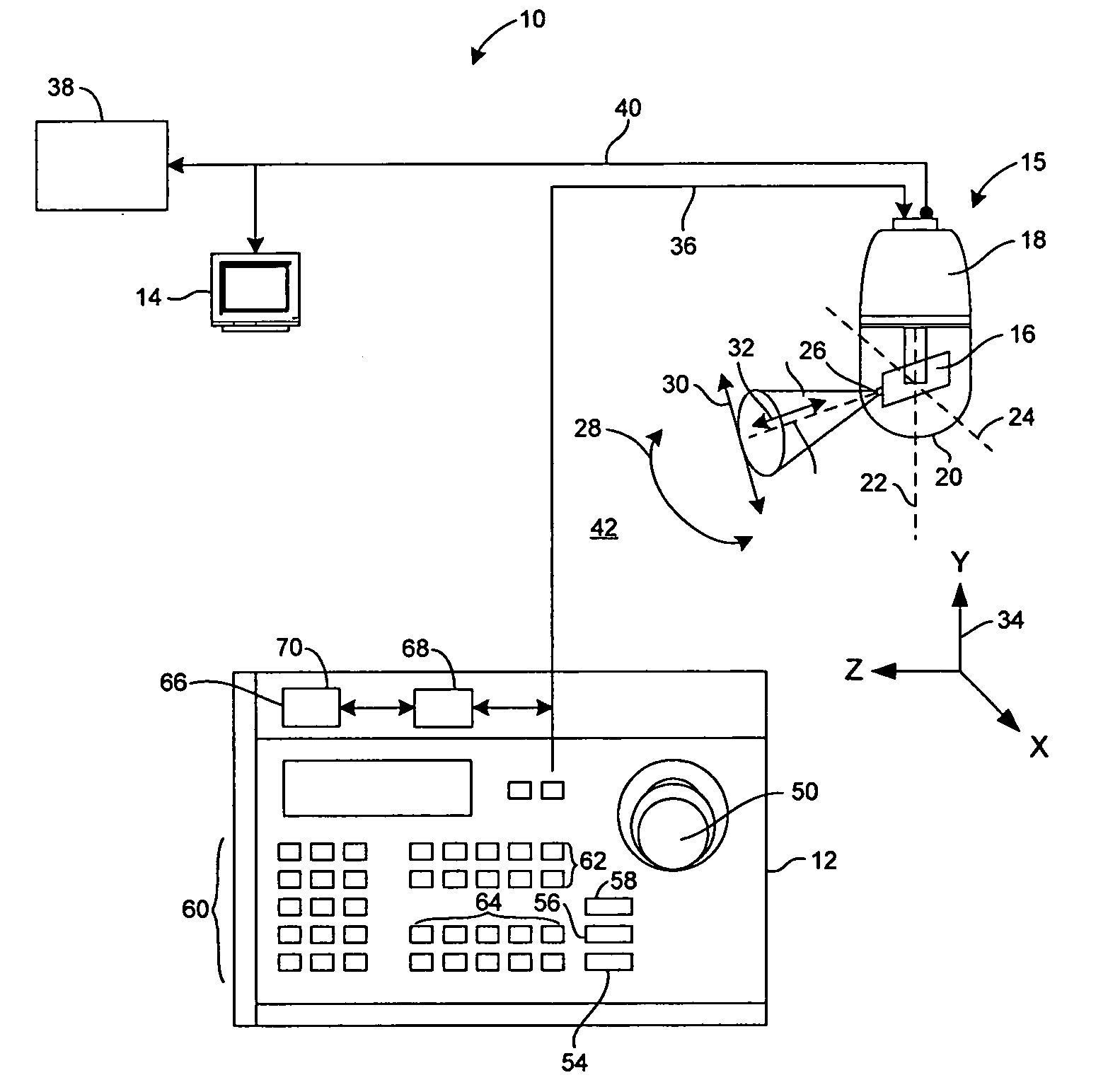

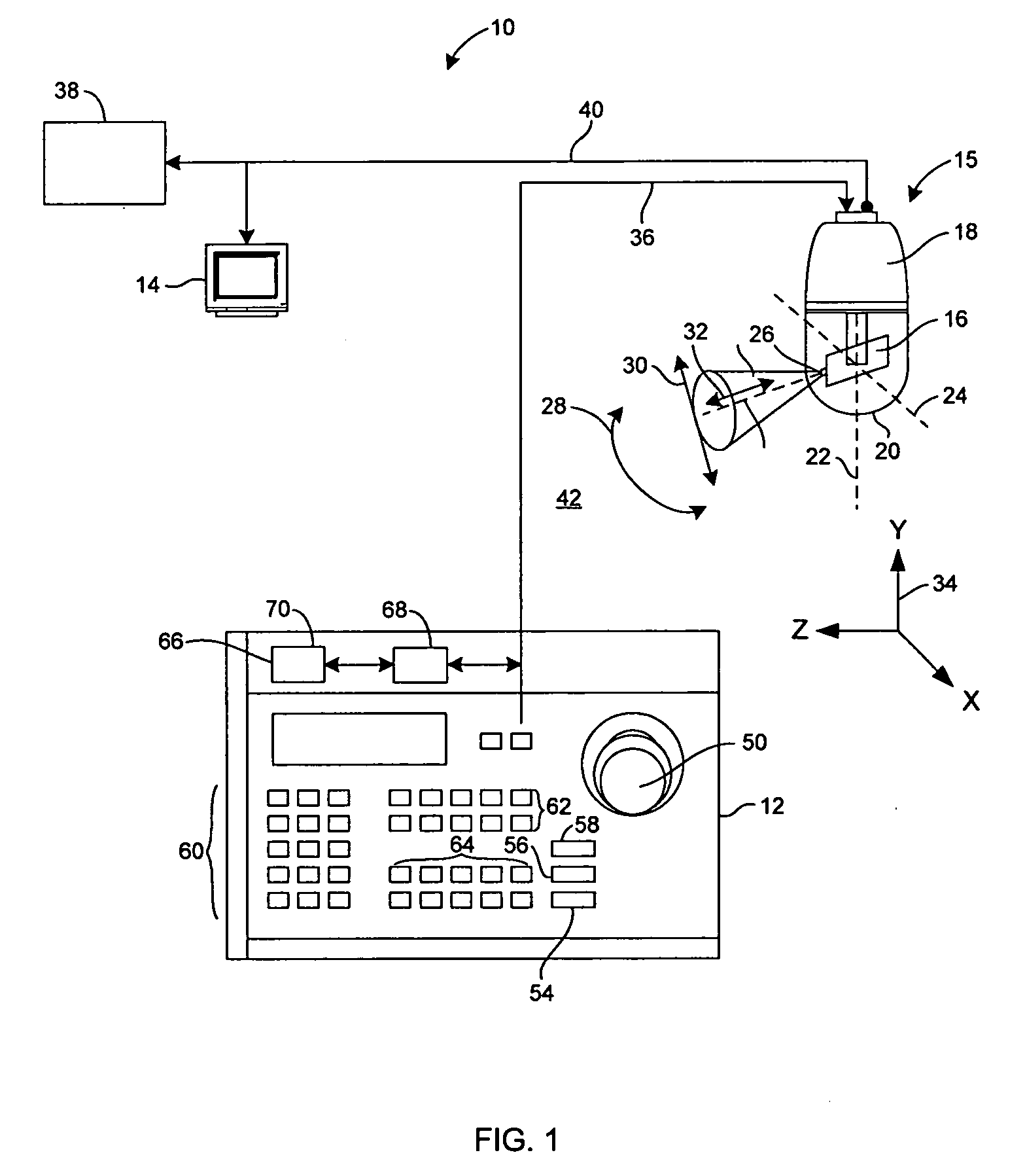

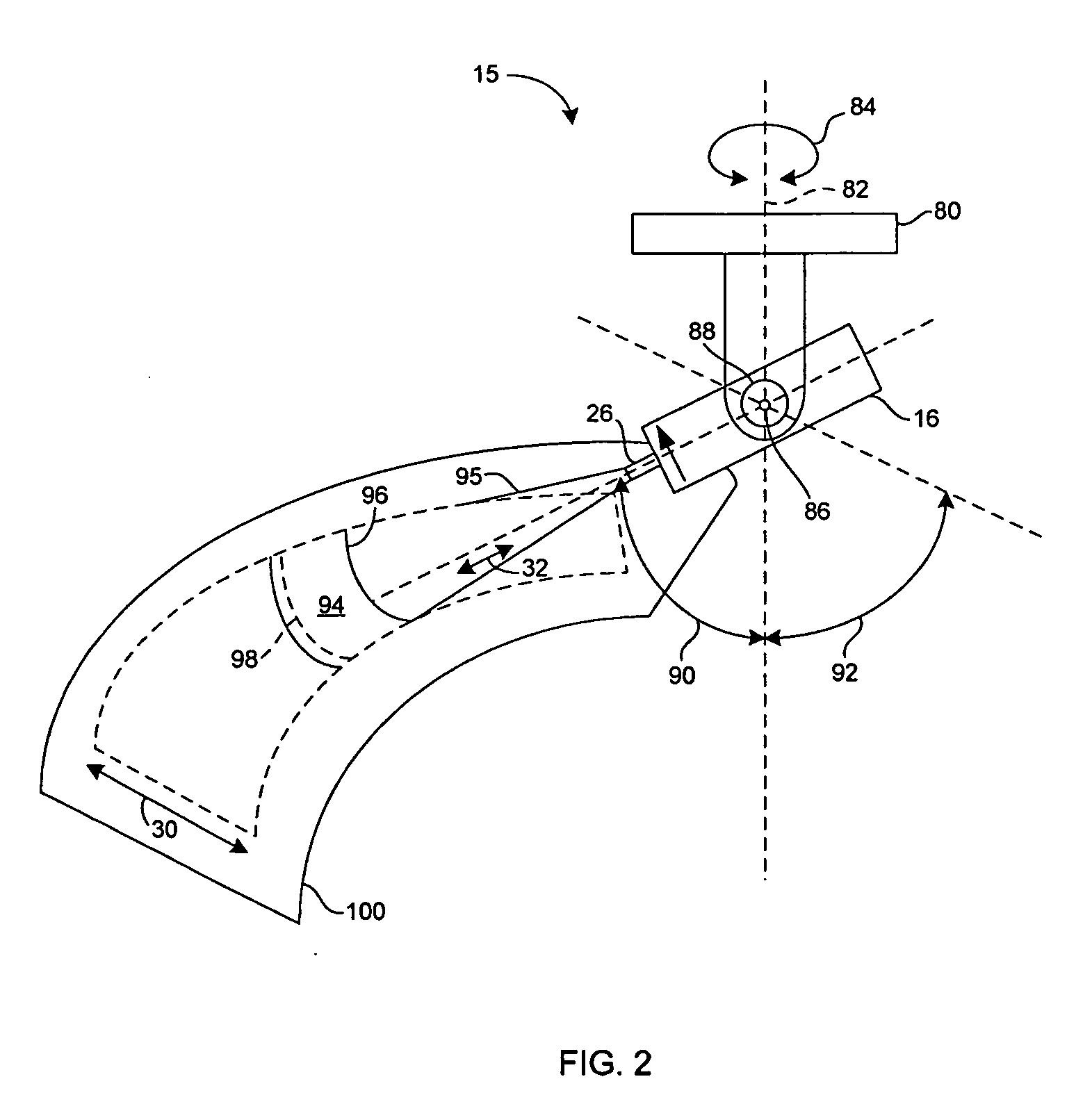

Method and system for camera autocalibration

A method for calibrating a projective camera is provided. The method includes acquiring information by detecting at least one object on a substantially flat ground plane within a field of view. A projective camera calibration is performed. A measurement uncertainty is considered to yield a plurality of camera parameters from the projective camera calibration.

Owner:UTC FIRE & SECURITY AMERICAS CORPORATION INC

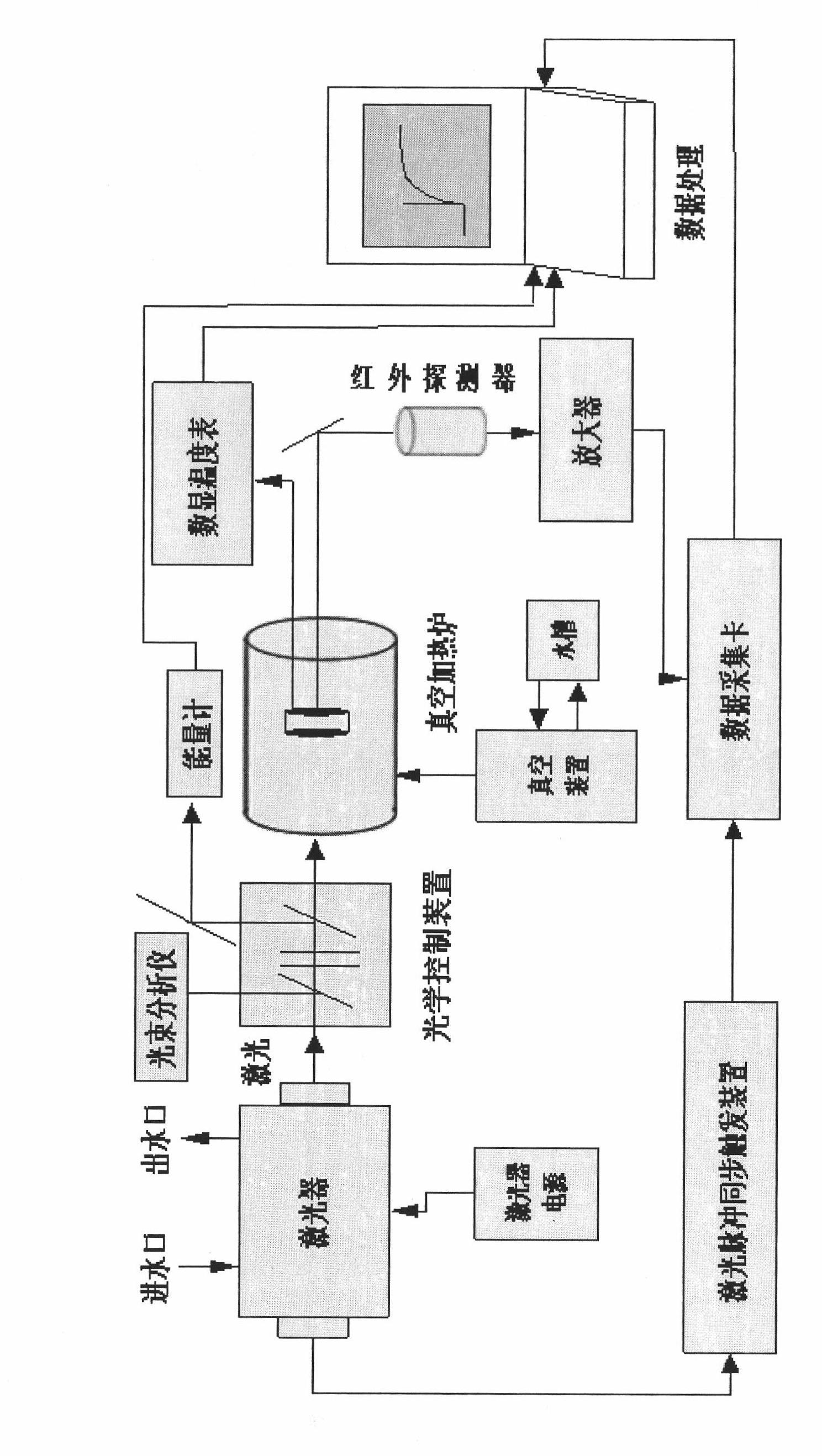

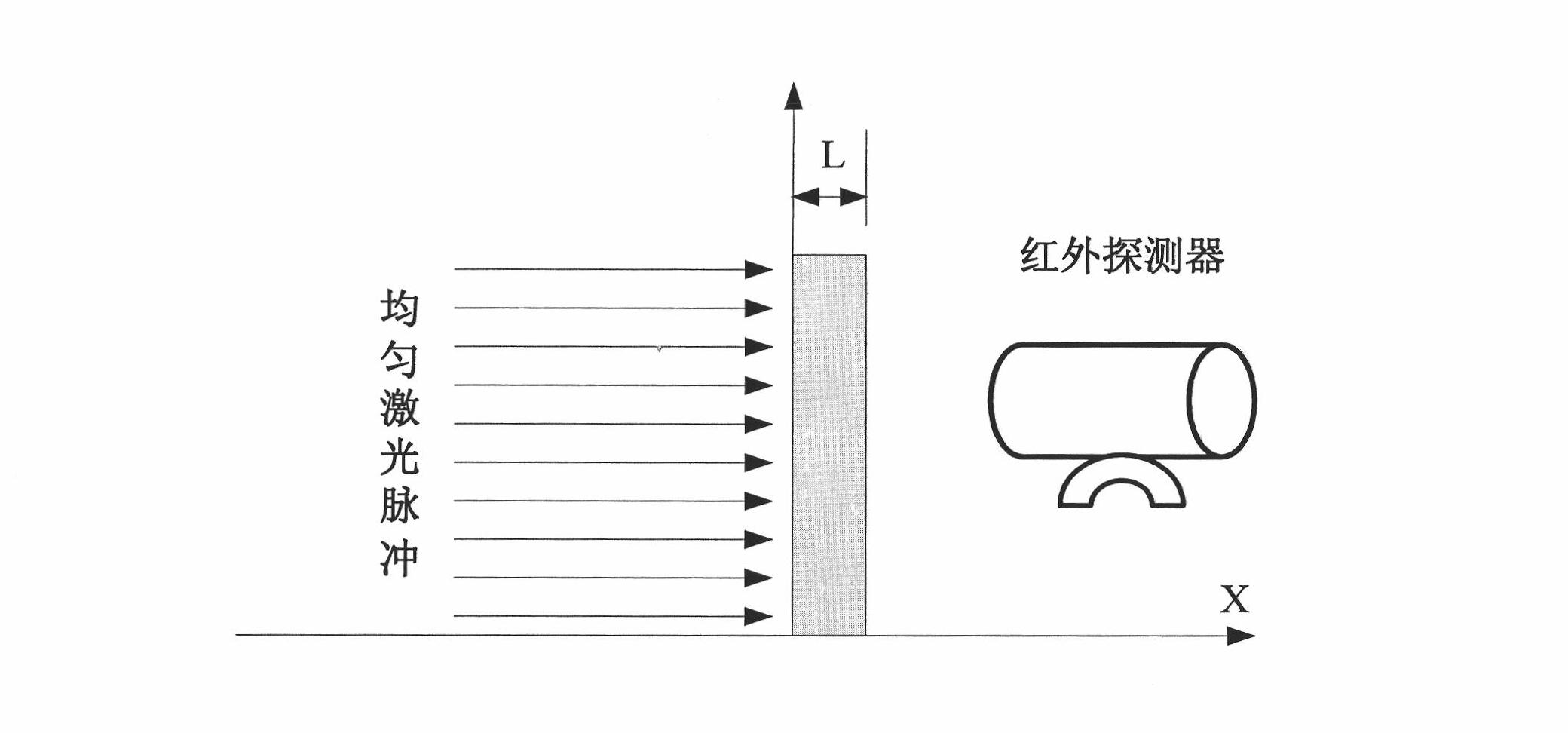

Device for measuring thermal diffusivity

InactiveCN101929968AMonitor strength in real timeCorrect response timeMaterial thermal conductivityMaterial heat developmentSample MeasureMeasurement device

The invention provides a device for measuring a thermal diffusivity. The device comprises an excitation light source, an optical control device, a vacuum heating furnace, a temperature controlling device, a temperature measuring device and a data acquiring and processing device, wherein the excitation light source generates excitation light beams; the optical control device is provided with an optical component group, a light beam mass spectrometer and an energy meter and regulates the energy of the excitation light beams through a replaceable optical element in the optical component group; a heating element for heating a sample is arranged in the vacuum heating furnace; the temperature controlling device is used for controlling the heating temperature of the vacuum heating furnace; the temperature measuring device amplifies a temperature rise signal of the sample measured by a detector through a pre-amplifier and transmits the amplified signal to the data acquiring and processing device; the data acquiring and processing device comprises a data acquiring system and a data processing system; the data acquiring system transmits all acquired data signals to the data processing system; and the data processing system analyzes and repeatedly and theoretically corrects the data signals. The device for measuring the thermal diffusivity designed by the invention has the advantages of reducing the measuring repeatability of the thermal diffusivity of a material to be less than 1 percent, lowering uncertainty of measurement, improving the level of thermal diffusivity measurement and laying foundations for the establishment of a standard thermal diffusivity device in China, the preparation of a standard thermal diffusivity substance and the establishment of a standard thermal diffusivity database.

Owner:NAT INST OF METROLOGY CHINA +1

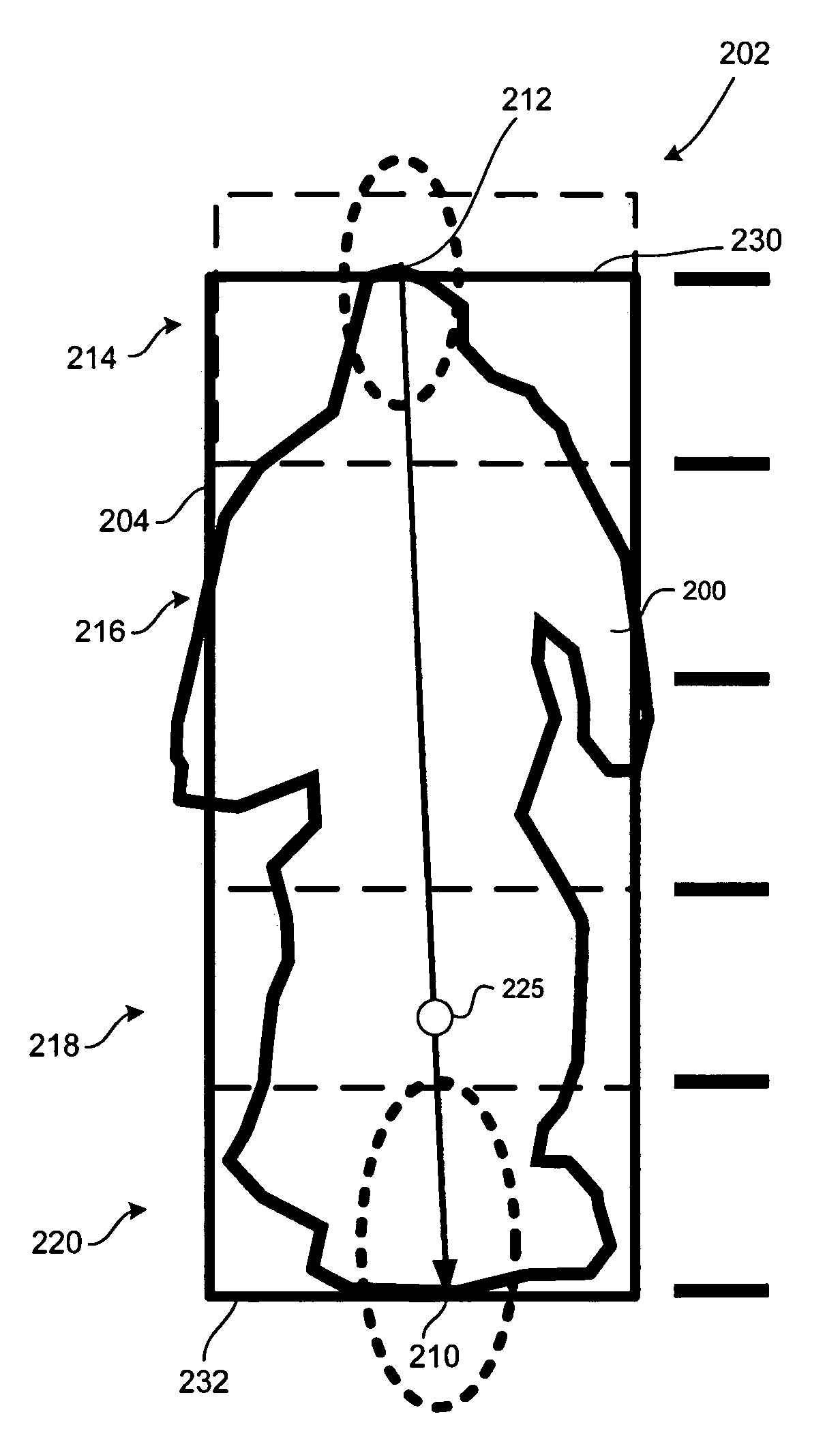

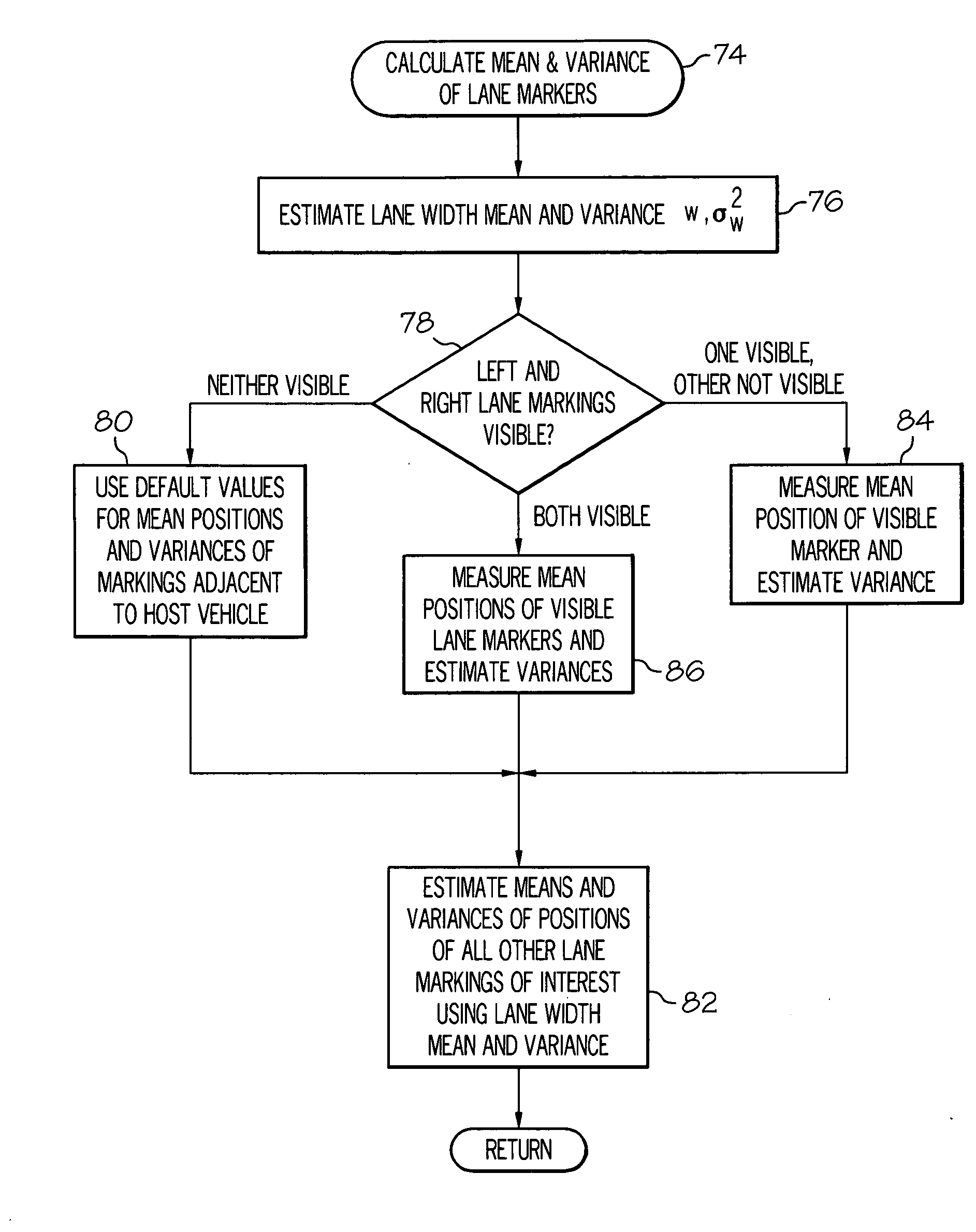

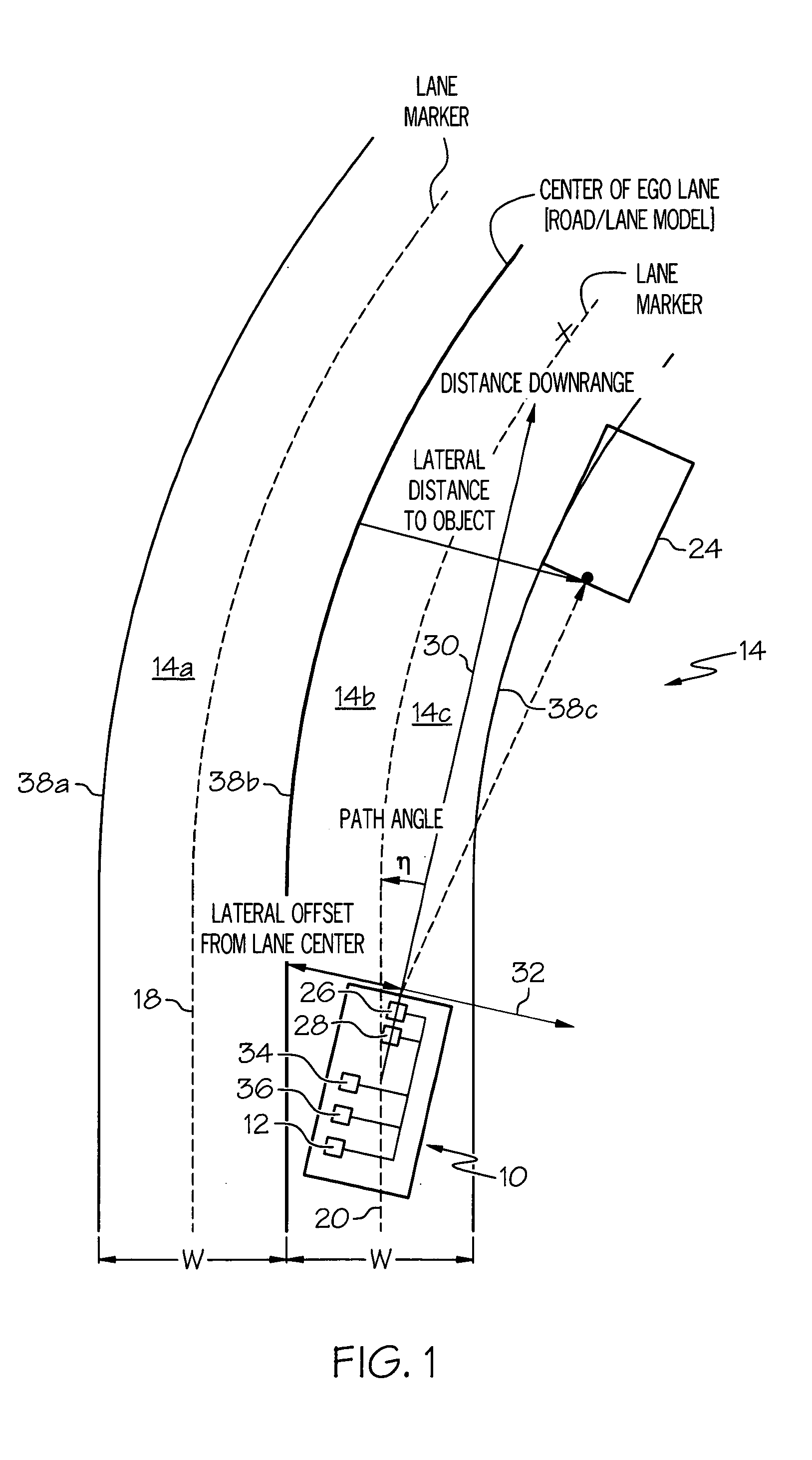

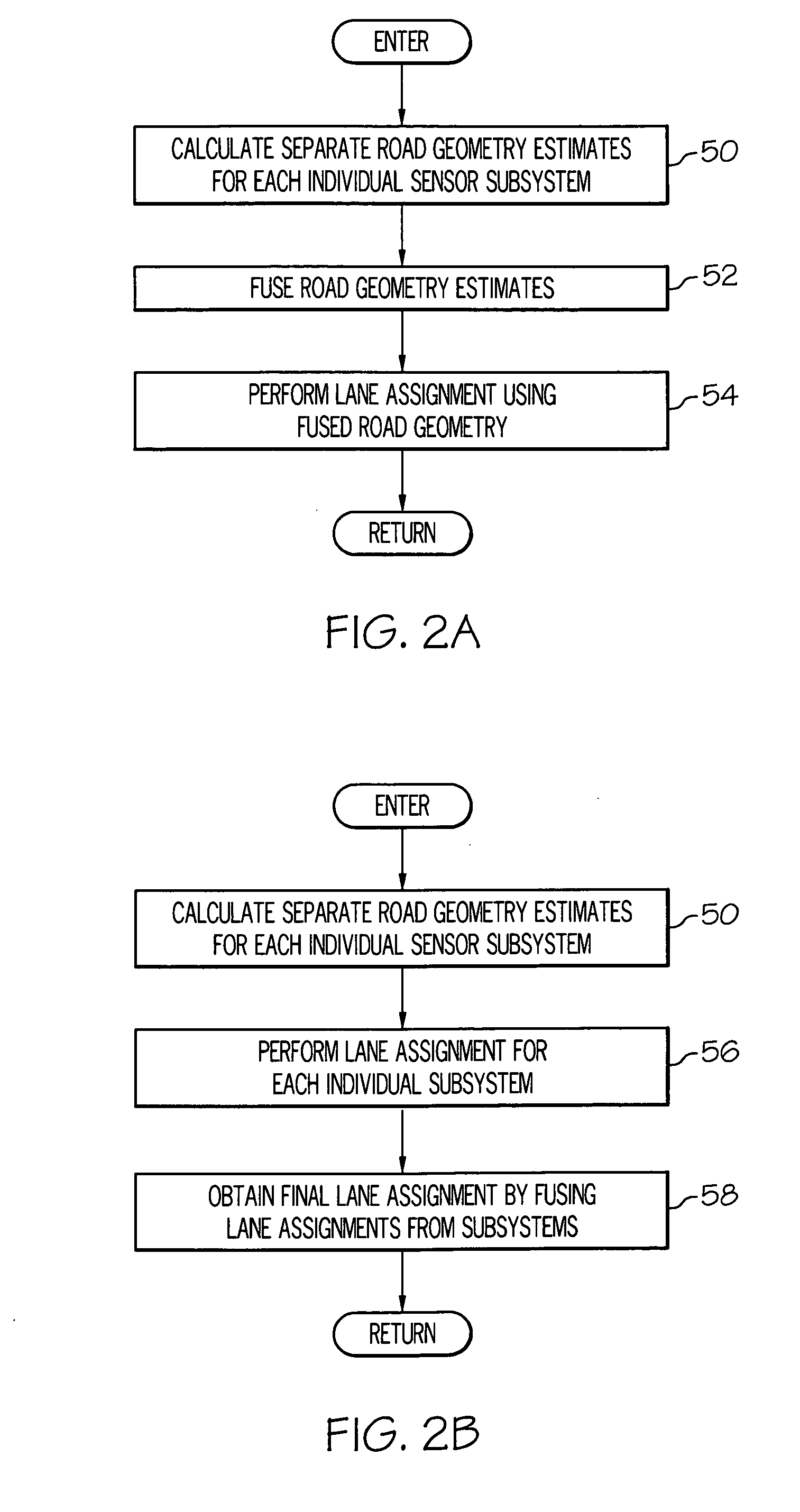

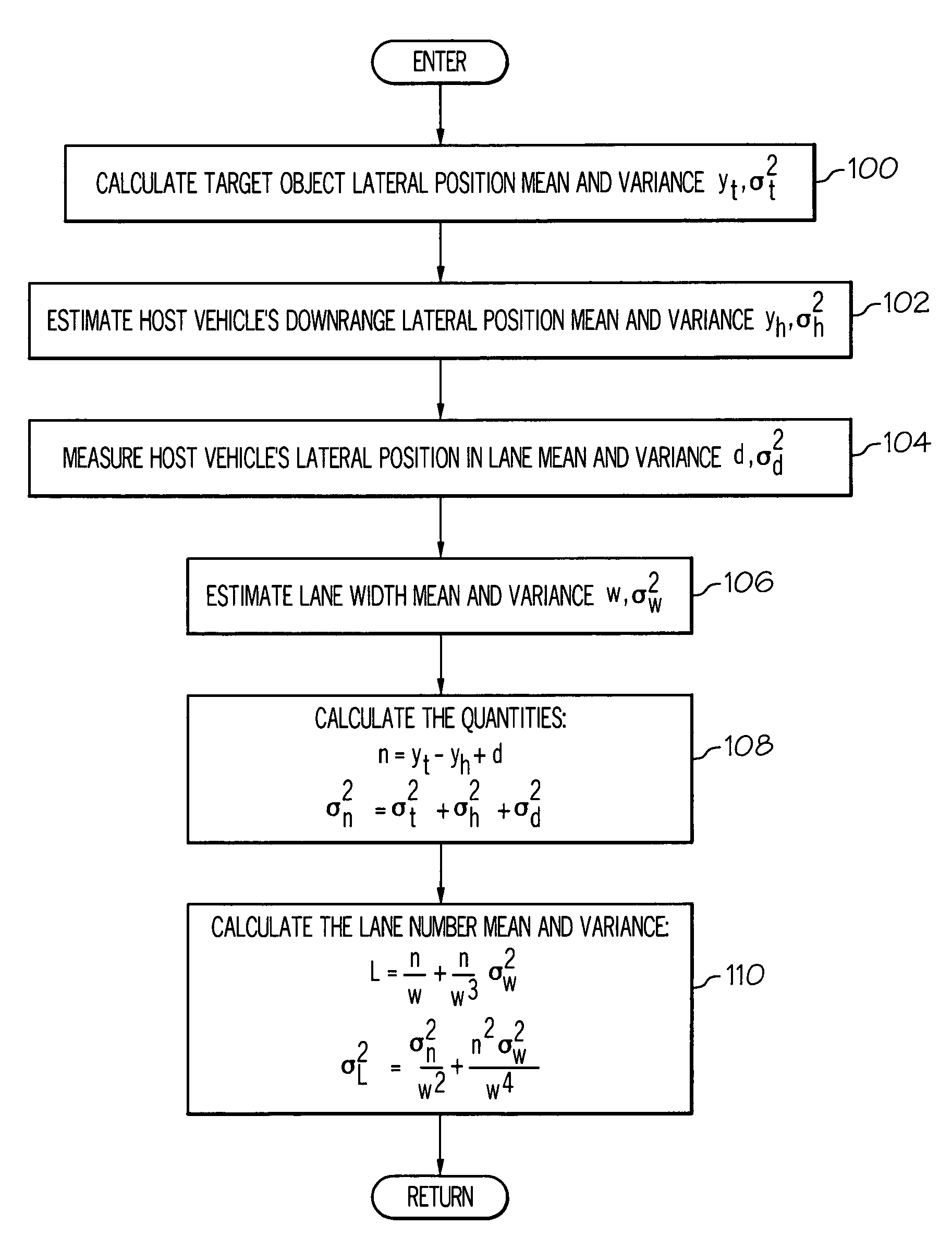

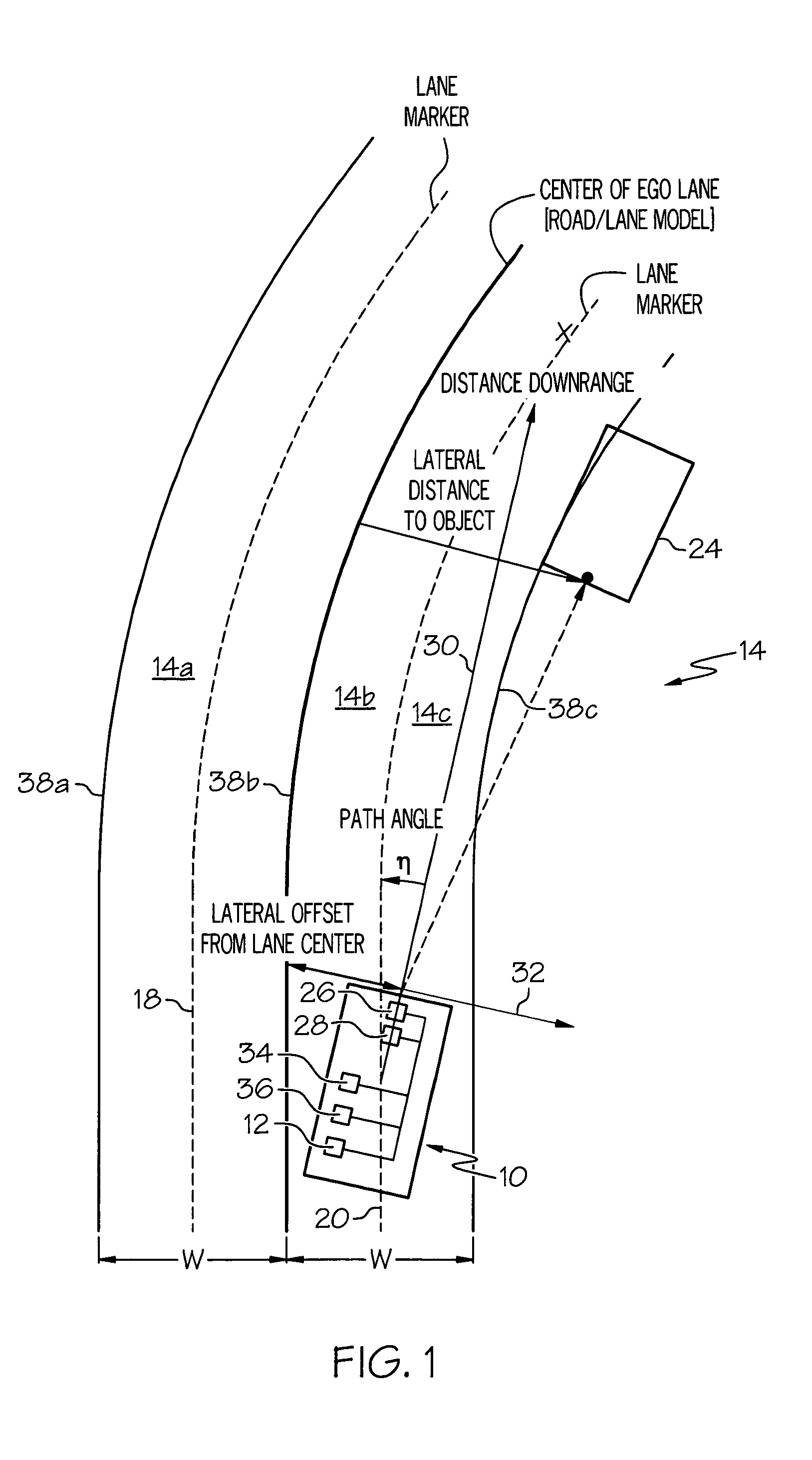

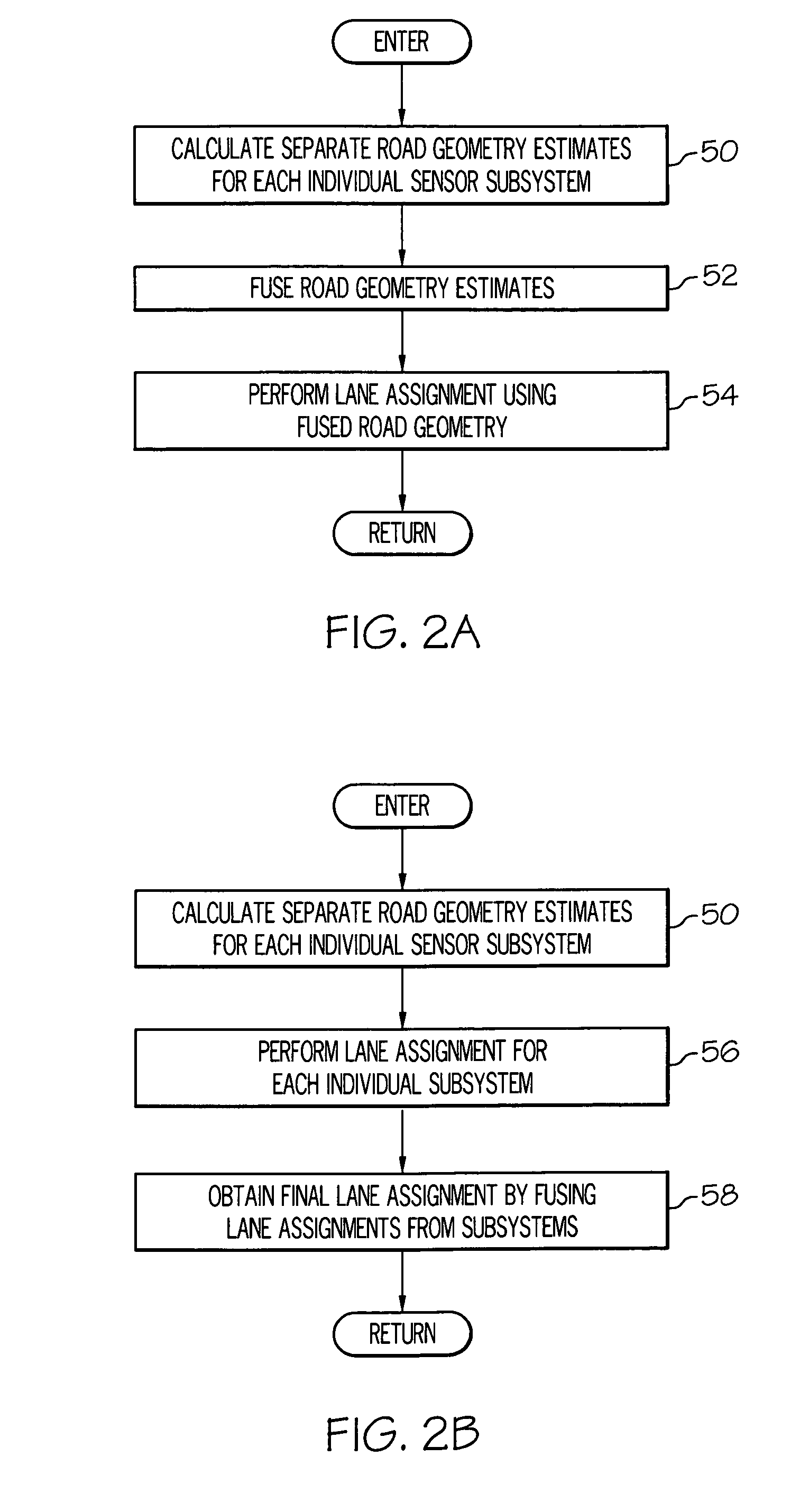

Probabilistic lane assignment method

ActiveUS20100076684A1Anti-collision systemsComplex mathematical operationsPattern recognitionAlgorithm

An improved probabilistic lane assignment method for detected objects in the scene forward of a host vehicle. Road / lane model parameters, preferably including an angular orientation of the host vehicle in its lane, are estimated from host vehicle sensor systems, taking into account measurement uncertainty in each of the constituent parameters. A probabilistic assignment of the object's lane is then assessed based on the road / lane model parameters and object measurements, again taking into account measurement uncertainty in both the road / lane model and object measurements. According to a first embodiment, the probabilistic assignment is discrete in nature, indicating a confidence or degree-of-belief that the detected object resides in each of a number of lanes. According to a second embodiment, the probabilistic assignment is continuous in nature, providing a lateral separation distance between the host vehicle and the object, and a confidence or degree-of-belief in the lateral separation distance.

Owner:APTIV TECH LTD

Method and system for camera autocalibration

A method for calibrating a projective camera is provided. The method includes acquiring information by detecting at least one object on a substantially flat ground plane within a field of view. A projective camera calibration is performed. A measurement uncertainty is considered to yield a plurality of camera parameters from the projective camera calibration.

Owner:UTC FIRE & SECURITY AMERICAS CORPORATION INC

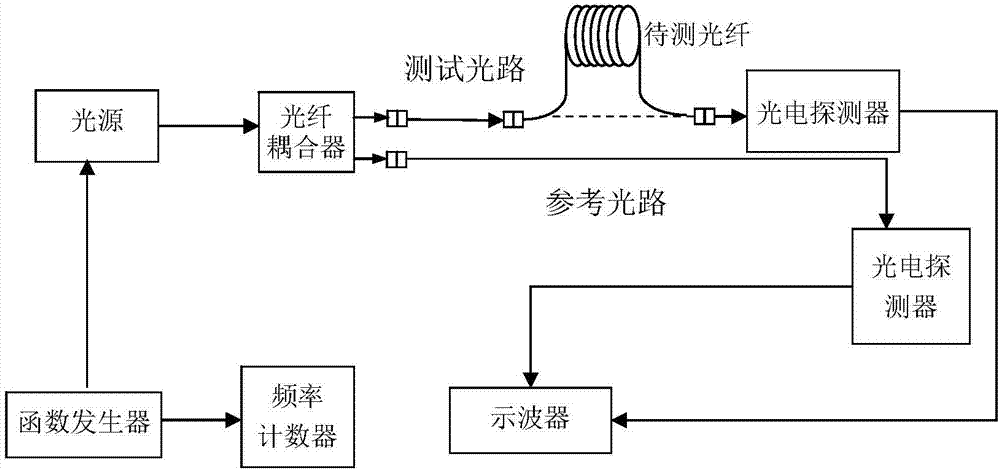

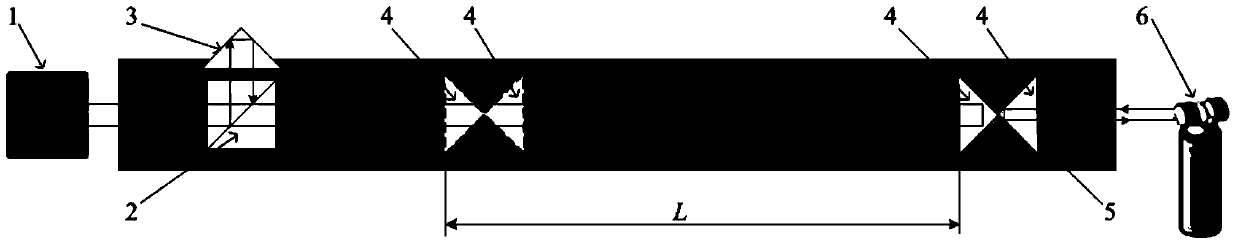

Optical fiber length measuring system and measuring method

ActiveCN103591895AImprove measurement accuracyReduce measurement uncertaintyUsing optical meansFiberObservational error

The invention discloses an optical fiber length measuring system and a measuring method for measuring optical fiber length by using the optical fiber length measuring system. The measuring system judges the overlay state of two ways of optical signal pulses by adopting a method of combining frequency counting and graphical analyzing, the measuring error brought by the fact that delay inequality is read by an oscilloscope directly can be avoided, and the measuring accuracy of the optical fiber length can be improved. According to the optical fiber length measuring system and the measuring method, an internal modulation mode is adopted by a light source, the elimination of the dependency on the polarization state of optical signals by the optical fiber length measuring system can be facilitated, and the influences on uncertainty of measurement when polarization and reflection components and the like are used for measuring the optical fiber length can be eliminated. Due to the fact that the optical fiber length measuring system and the measuring method are free of the influences of the polarization state of the light source, the length of single mode fibers can be measured, the length of the multimode fibers can also be measured, and the problems of the accurate calibration of the length of the multimode fibers and the length value traceability of a multimode optical time-domain reflectometer are solved.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

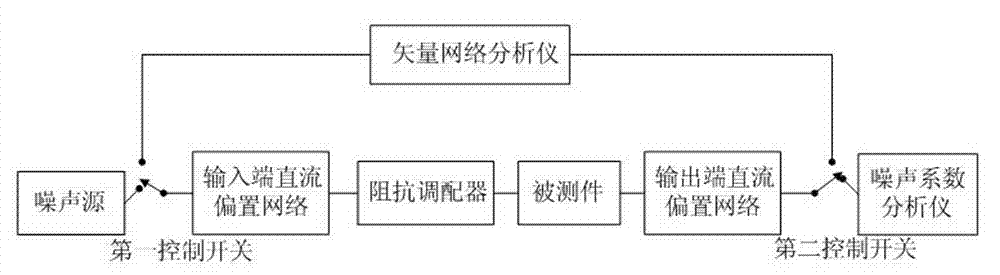

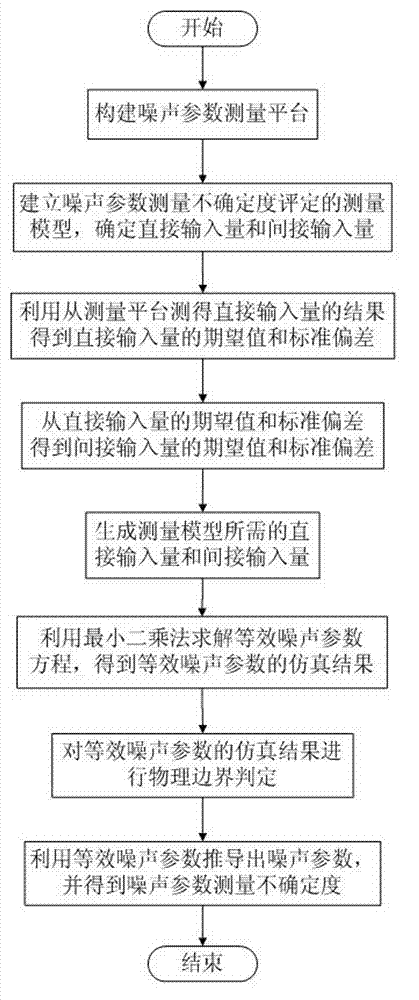

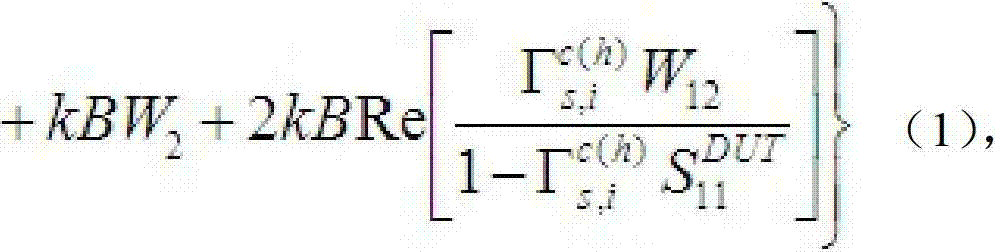

Noise parameter measurement uncertainty evaluation method based on multi-chip module (MCM)

ActiveCN103049639AAutomatically judge the number of simulationsAchieve contrastSpecial data processing applicationsNational standardParameter distribution

The invention discloses a noise parameter measurement uncertainty evaluation method based on a multi-chip module (MCM) and belongs to the field of measurement metering. The method includes utilizing an equivalent noise parameter equation as a measurement model for noise parameter measurement uncertainty evaluation, utilizing physical quantity measured from a measurement platform to calculate the function equation and obtain data reflecting equivalent noise parameter distribution condition, leading out noise parameter and noise parameter distribution from the equivalent noise parameter and finally obtaining uncertainty for noise parameter measurement. The method effectively combines digital random simulation, physical measurement boundary criterion and least square method optimization criterion, and enables noise parameter uncertainty evaluation to be effective, real and reliable. The method satisfies the national standard, and is flexible in simulation mode, multiple in applicable measurement system variety and strong in universality.

Owner:THE 13TH RES INST OF CHINA ELECTRONICS TECH GRP CORP +1

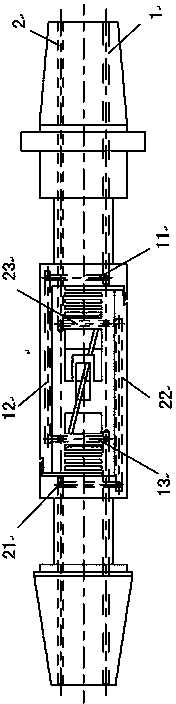

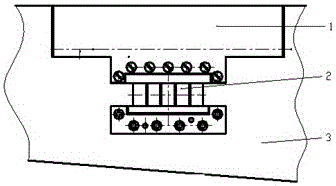

Water cooling balance

ActiveCN104180966AEliminate the effects of aerodynamic measurementsExtended service lifeAerodynamic testingLeaking waterCooling effect

The invention discloses a water cooling balance which comprises a rod-type balance and a water-cooled jacket. Two water flow pipelines are arranged in the rod-type balance. The two ends of each water flow pipeline are arranged on the two end faces of the rod-type balance respectively. A switching joint is arranged between the water-cooled jacket and the rod-type balance and fixed to one end face of the rod-type balance through a screw. A water inlet switching pipeline and a water outlet switching pipeline are arranged on the switching joint. One end of the water inlet switching pipeline and one end of the water outlet switching pipeline correspond to openings of the two water flow pipelines on the end faces of the rod-type balance in position and the other end of the water inlet switching pipeline and the other end of the water outlet switching pipeline correspond to a water inlet and a water outlet of the water-cooled jacket in position. The defects that a corrugated pipe type water cooling balance is large in drag measurement error and inconvenient to install and use and a corrugated pipe is prone to being damaged and leaking water are overcome. In addition, due to the fact that corrugated pipe related devices are omitted, the length of the balance is reduced, the diameter of the balance is increased, the rigidity and the cooling effect of the balance are greatly improved, the temperature effect is reduced, and measurement uncertainty is obviously reduced.

Owner:INST OF HIGH SPEED AERODYNAMICS OF CHINA AERODYNAMICS RES & DEV CENT

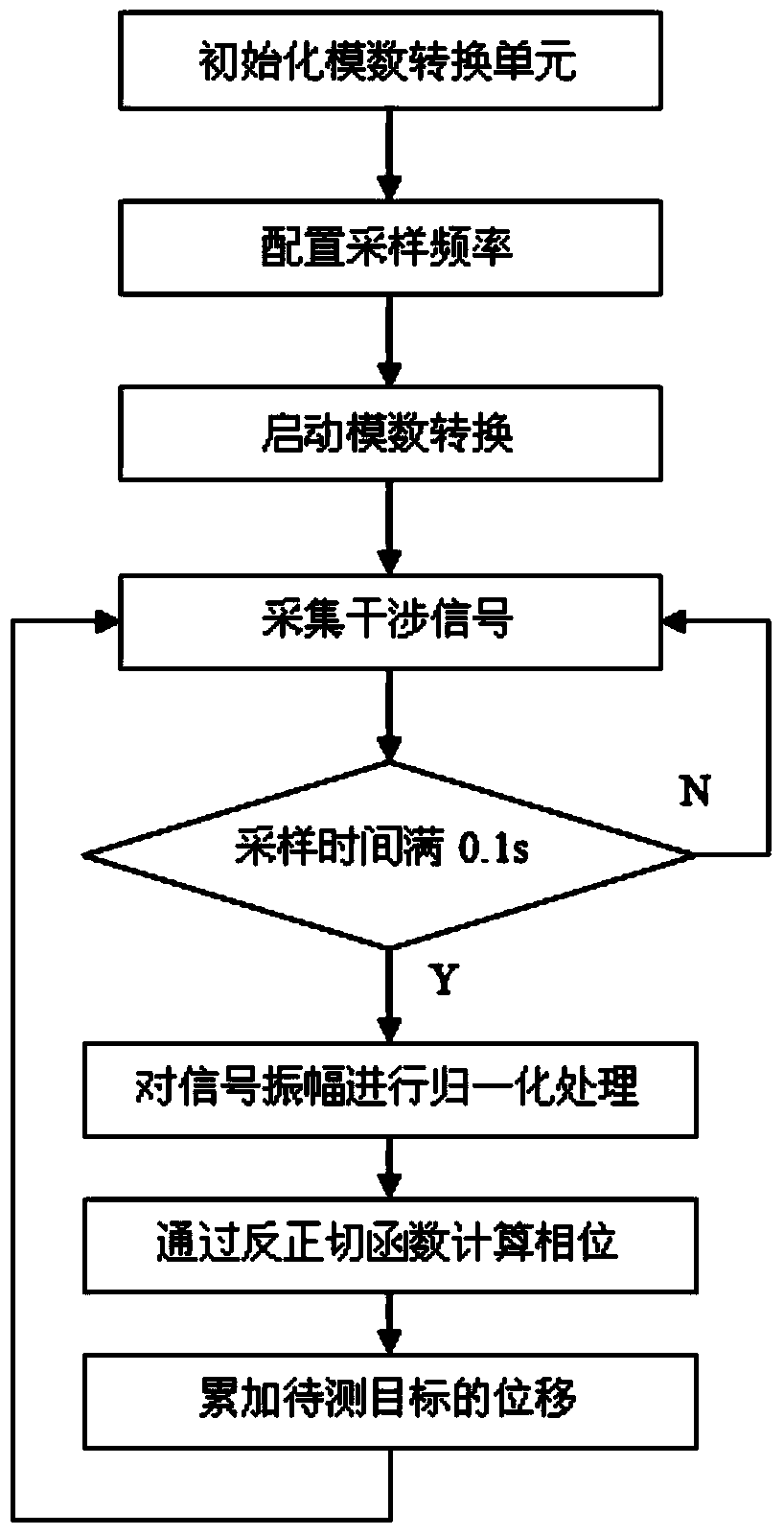

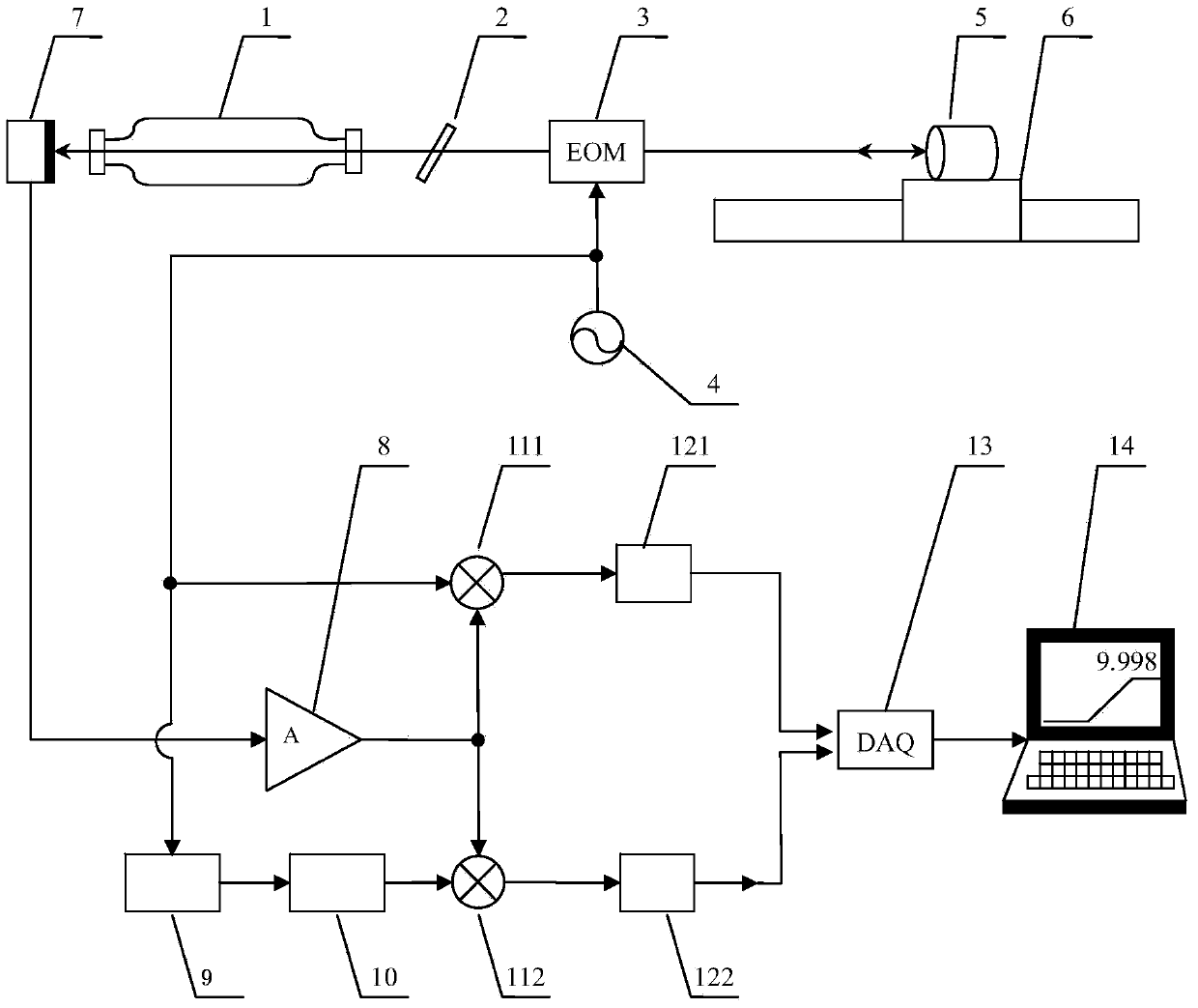

Sinusoidal phase modulation type laser self-mixing interferometer and measuring method thereof

InactiveCN103528511ASimple structureCompact structureUsing optical meansElectromagnetic wave reradiationFrequency multiplierOmega

The invention discloses a sinusoidal phase modulation type laser self-mixing interferometer and a measuring method thereof. The interferometer comprises a helium-neon laser, a variable neutral density filter, an electro-optical crystal modulator, a target to be measured, a photoelectric detector and a signal generator. The signal generator is used for generating sinusoidal signals with frequency of omega<m>, wherein one loop of signals is used for driving the electro-optical crystal modulator, one loop of signals is used as base-frequency signal output and the other loop of signals passes through a frequency doubler and a phase shifter and then outputs doubled-frequency signals with frequency of 2 omega<m>. The output of the photoelectric detector is amplified by an operational amplifier and then is respectively mixed with the base-frequency signals and the doubled-frequency signals to obtain two loops of signals. The signals are subject to low-pass filtering and then a computer unit controls an analog-to-digital conversion unit to acquire and demodulate a phase, so as to obtain and display the real-time displacement of the target to be measured. After the interferometer is calibrated, relative measurement accuracy of 10<-6>*L can be obtained, the measurement uncertainties within the measurement ranges of 100mum and 300mum are respectively 10nm and 0.15mum, and the measurable speed range is 0-60mm / s.

Owner:NANJING NORMAL UNIVERSITY

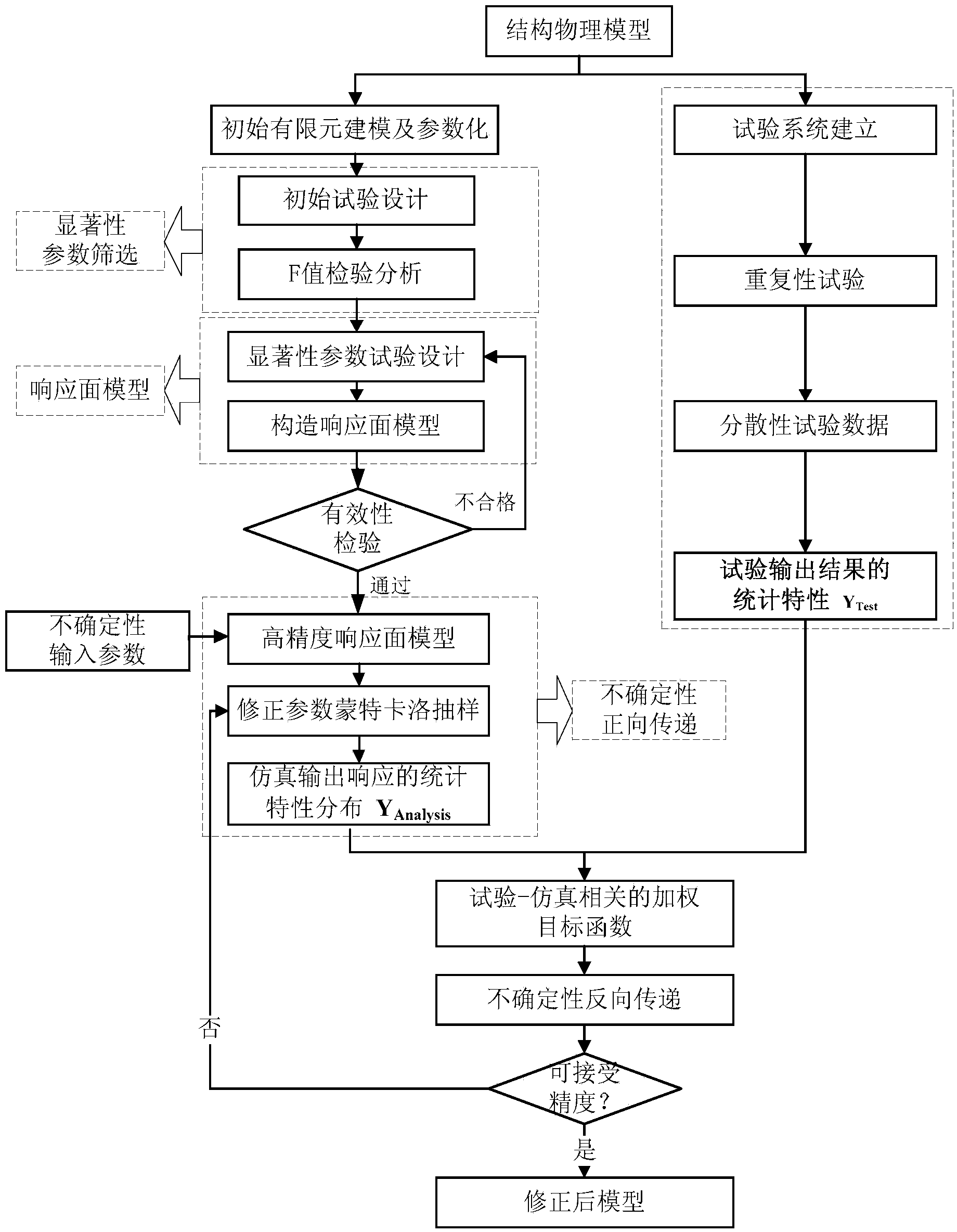

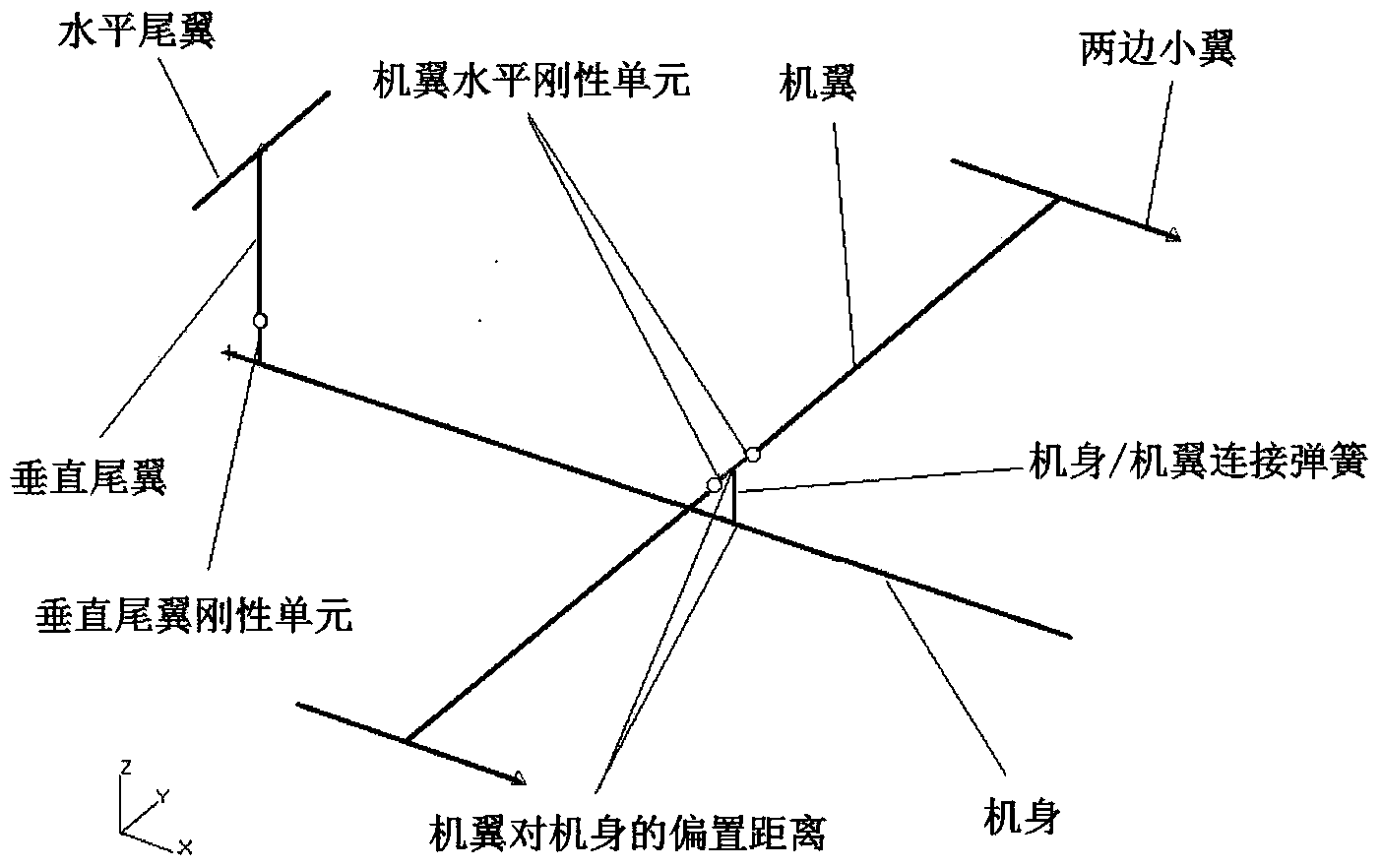

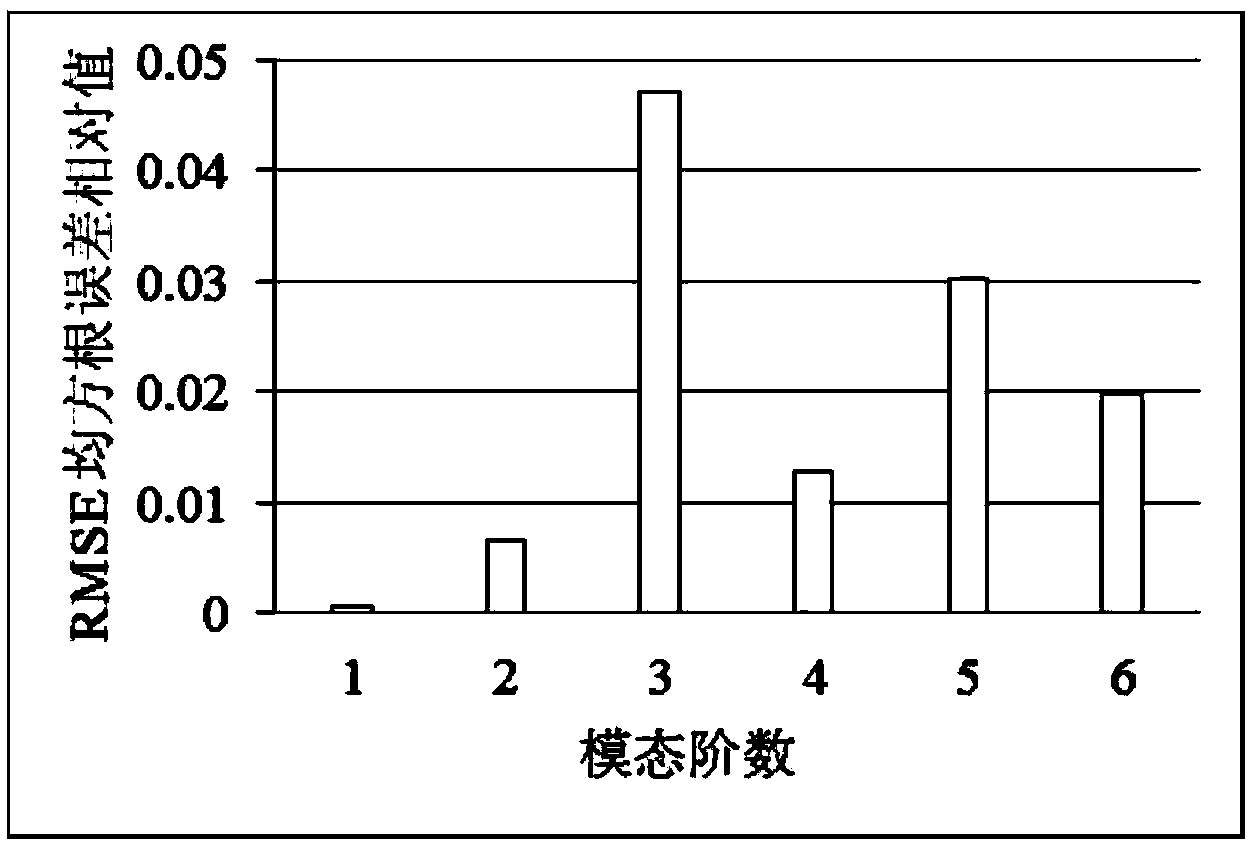

Structure finite element model correcting method based on multi-element uncertainty

InactiveCN103902785AReduce the numberAvoid correctionSpecial data processing applicationsApplicability domainElement model

A structure finite element model correcting method based on multi-element uncertainty comprises the following steps: (1) building an initialized parameterization equivalent finite element model in finite element software; (2) screening out significance parameters; (3) obtaining sample points, and constructing an incomplete variable high-order response surface model; (4) judging validity of the response surface model, if the validity of the response surface model meets the requirement, executing the next step, and if the validity of the response surface model does not meet the requirement, executing the step (3) again; (5) building a rapid random sampling analysis model with the combination of a high-order response surface and the Monte Carlo method, and conducting statistics on a mean value and a covariance matrix of simulation output responses; (6) conducting statistics on a mean value and a covariance matrix of test output results; (7) constructing a weighting objective function of the mean values and covariances of tests and simulation; (8) reversely estimating a mean value and a covariance matrix of input parameters; (9) judging whether the mean value and the covariance matrix of the input parameters meet correction accuracy or not, if yes, stopping iteration, and if not, executing the step (8) again. According to the structure finite element model correcting method, the calculated amount of the iteration is reduced, the application range is wide, and optimization of a large-scale parameter range is achieved.

Owner:BEIHANG UNIV

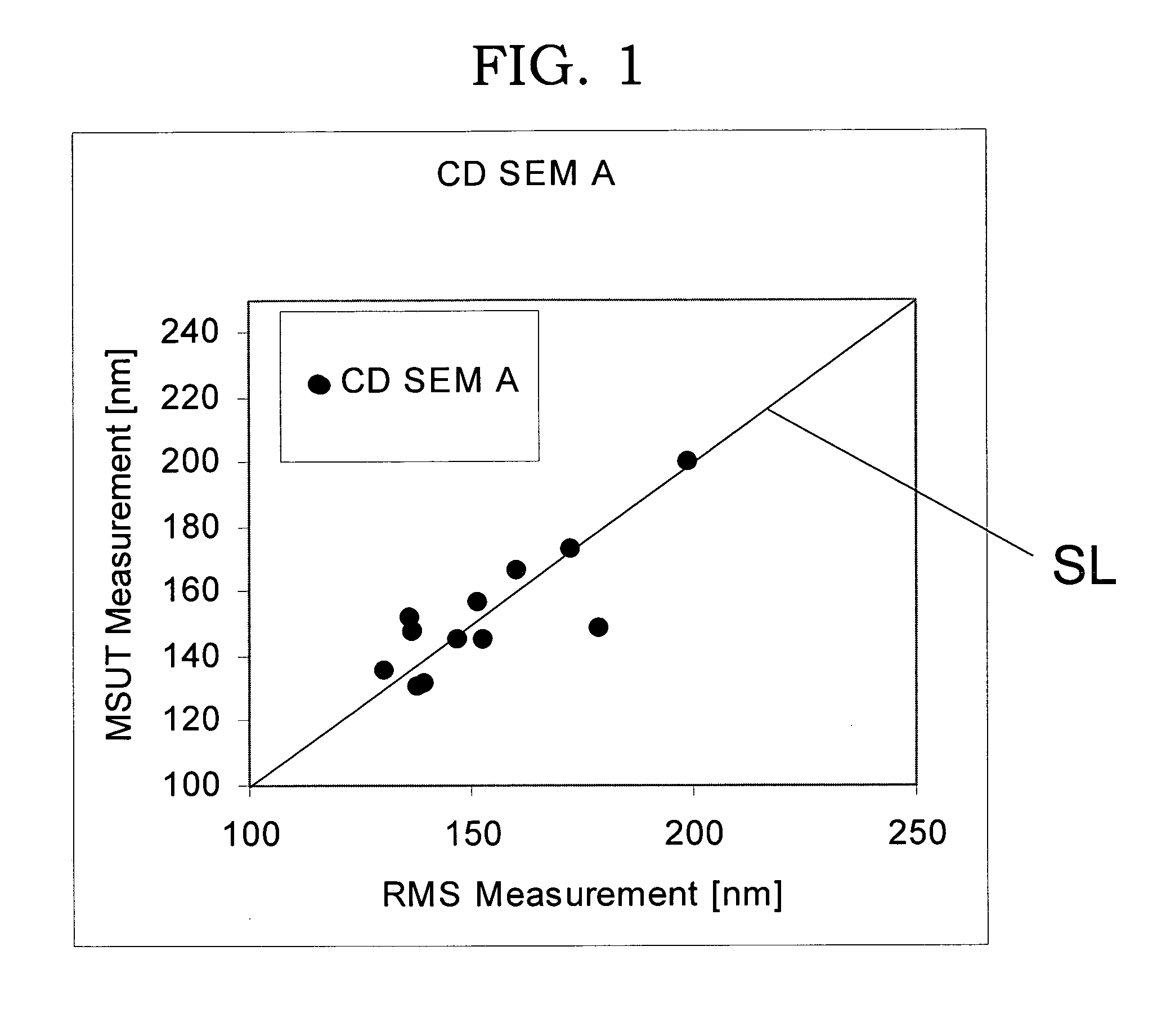

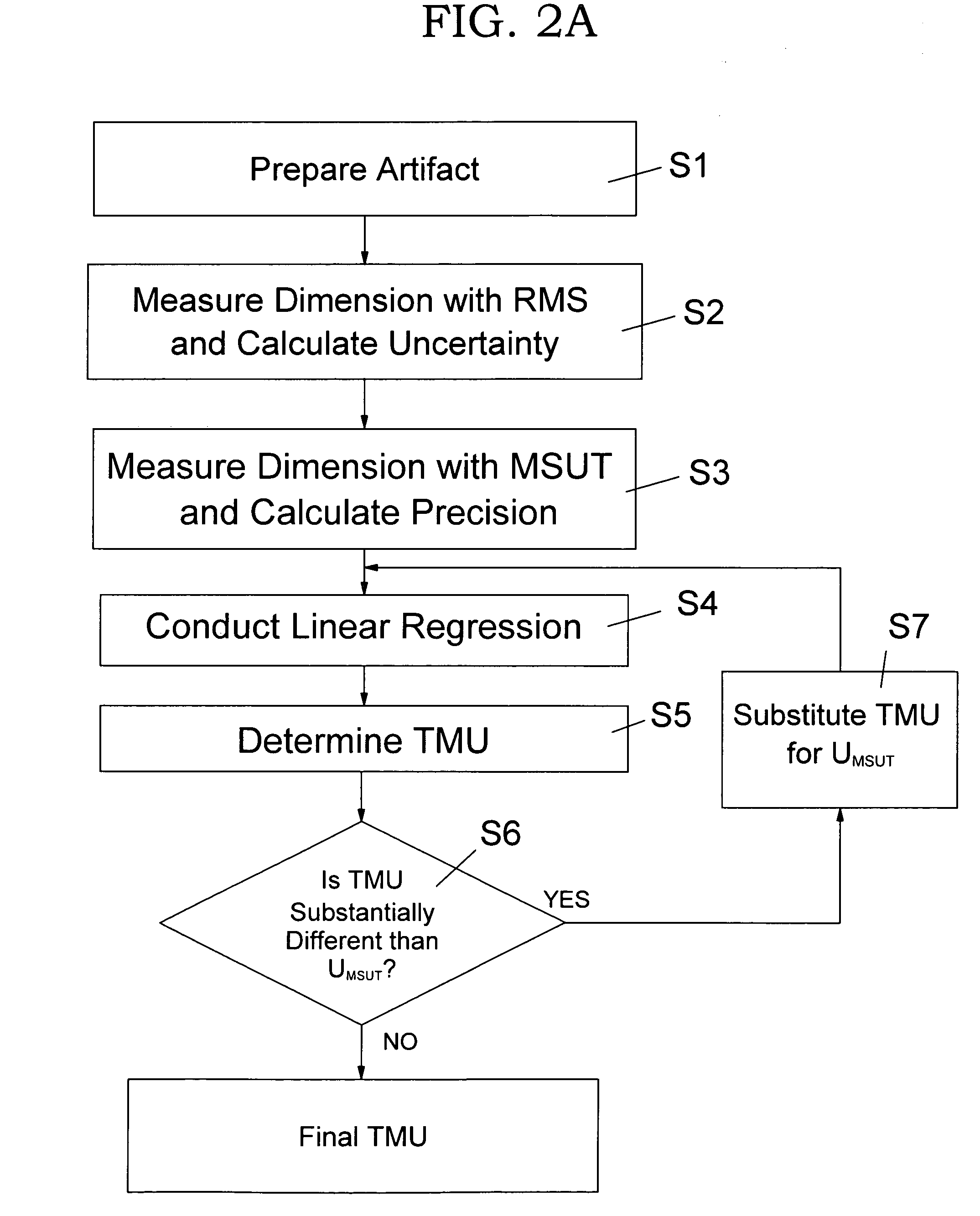

Assessment and optimization for metrology instrument including uncertainty of total measurement uncertainty

InactiveUS20050197772A1Improves TMU analysisEasy to analyzeSemiconductor/solid-state device testing/measurementDigital computer detailsMetrologySystem under test

Methods and related program product for assessing and optimizing metrology instruments by determining a total measurement uncertainty (TMU) based on precision and accuracy. The TMU is calculated based on a linear regression analysis and removing a reference measuring system uncertainty (URMS) from a net residual error. The TMU provides an objective and more accurate representation of whether a measurement system under test has an ability to sense true product variation. The invention also includes a method for determining an uncertainty of the TMU.

Owner:IBM CORP

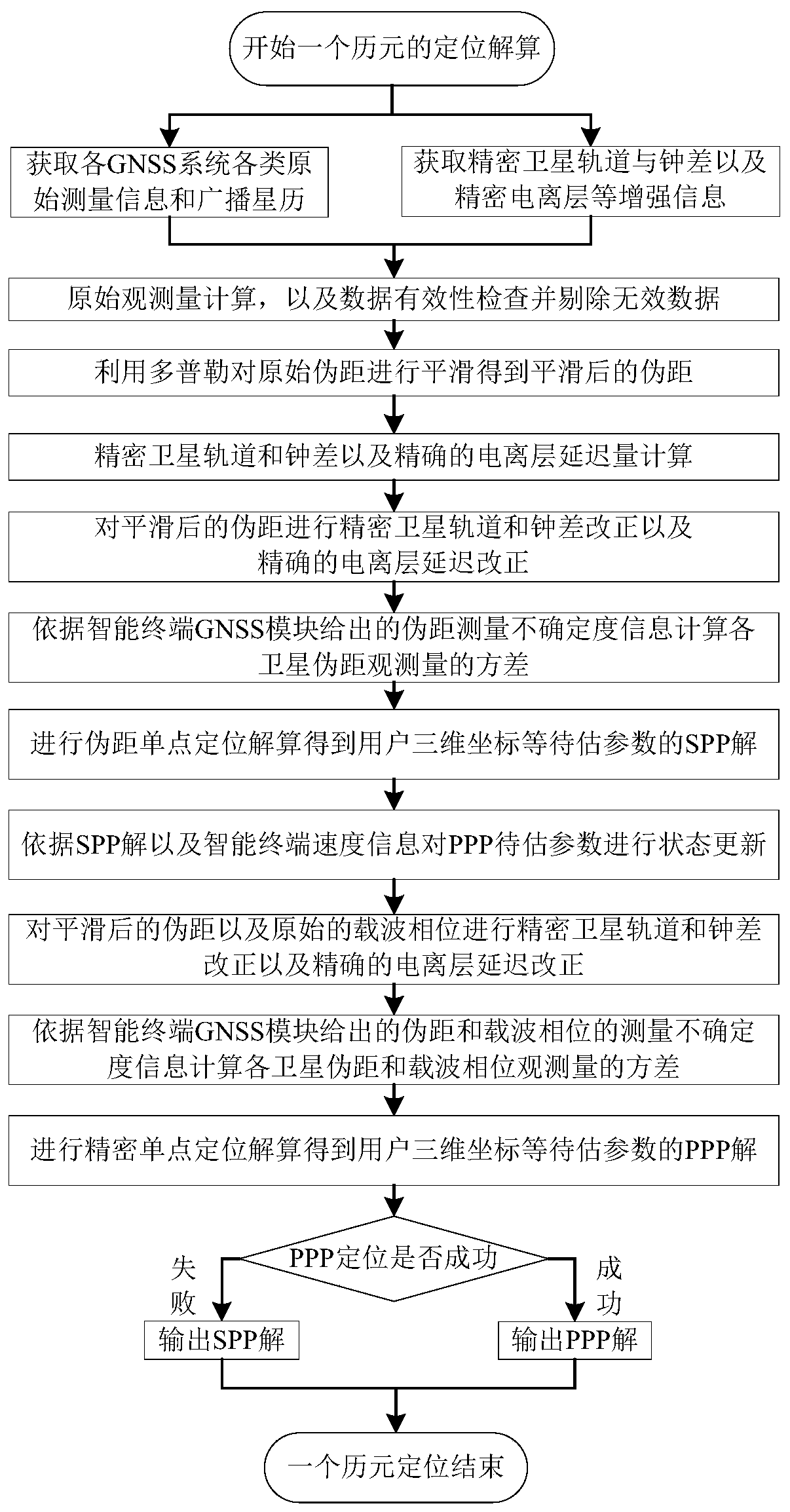

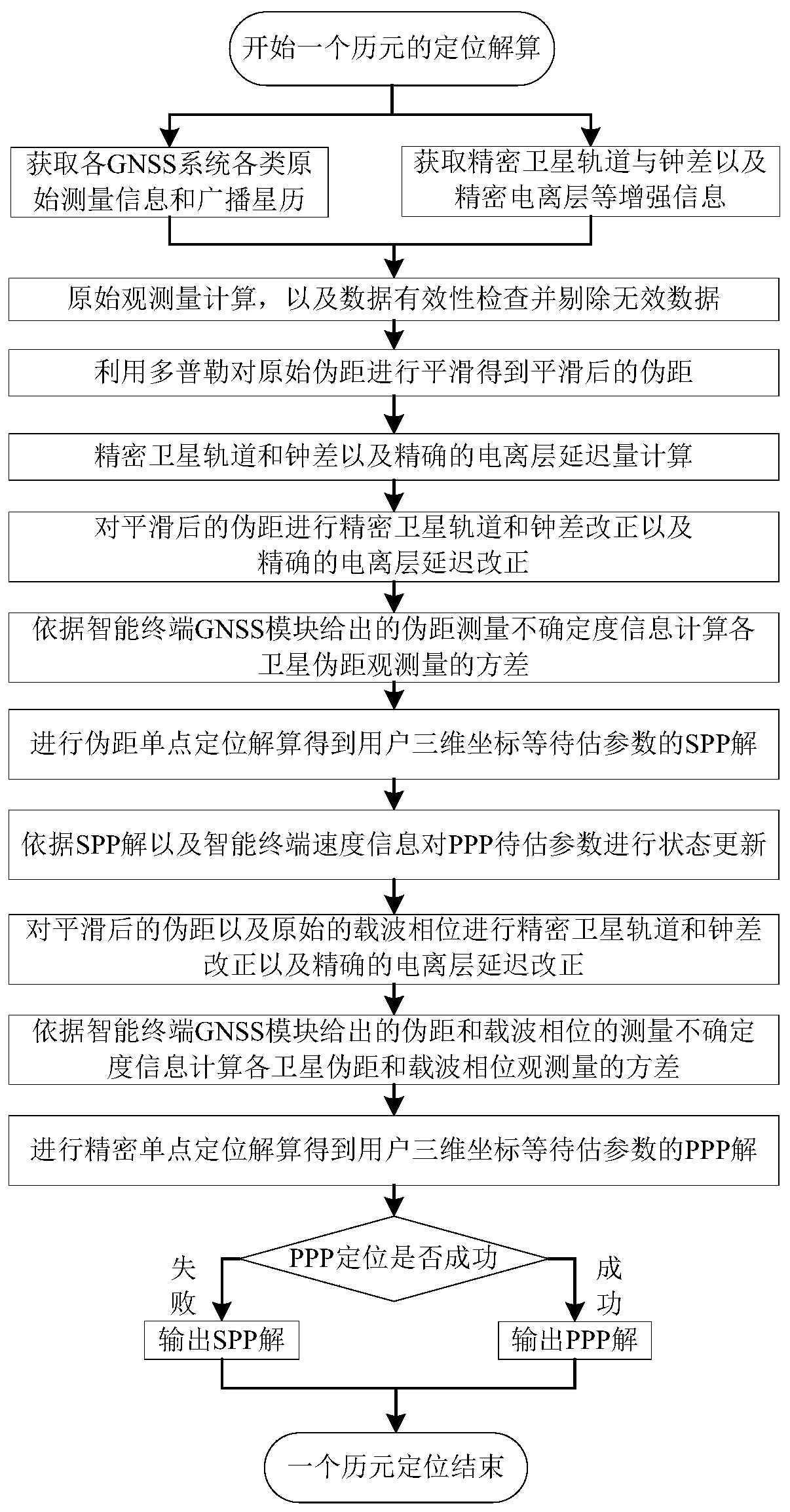

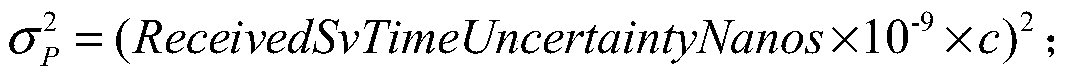

GNSS high precision positioning method for intelligent terminal

ActiveCN109709591APrecise positioningImprove calculation accuracySatellite radio beaconingLow noiseIonosphere

The invention discloses a GNSS high precision positioning method for an intelligent terminal. Original pseudorange observation values are smoothed by measuring a Doppler observation value with low noise and no cycle slip, and the measurement noise of the original pseudorange observed quantity of an intelligent terminal GNSS can be significantly reduced; a real-time precise satellite orbit and theclock difference correction information are utilized to precisely modify a satellite orbit and the clock difference calculated through the broadcast ephemeris and clock difference parameters, and calculation accuracy of the satellite orbit and the satellite clock difference can be significantly improved; the ionospheric delay information is accurately calculated through utilizing the real-time precise ionospheric information, and high precision correction of the ionospheric delay error can be realized; the pseudorange and carrier phase measurement uncertainty information is utilized to performpseudorange and carrier phase observed quantity variance, contribution of measurement accuracy of different satellite observed quantities to positioning solution can be more effectively distinguished, and the intelligent terminal can be finally substantially improved, especially for positioning performance of an intelligent handset.

Owner:ACAD OF OPTO ELECTRONICS CHINESE ACAD OF SCI

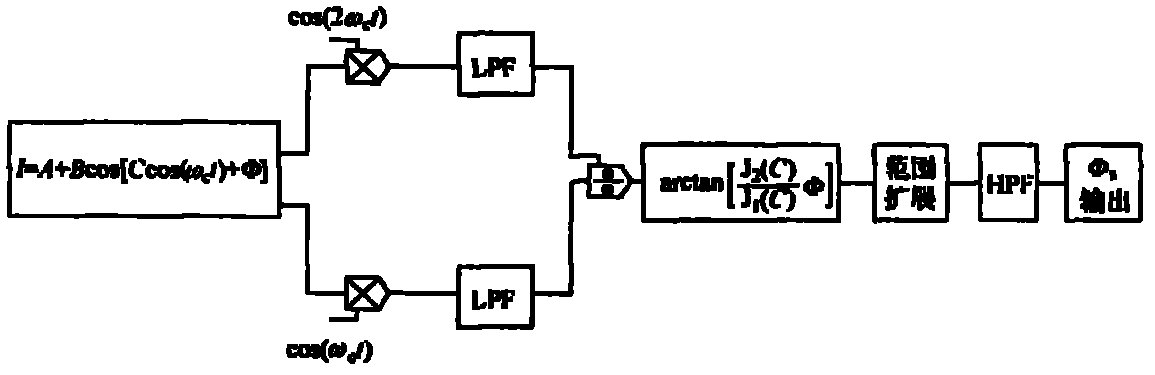

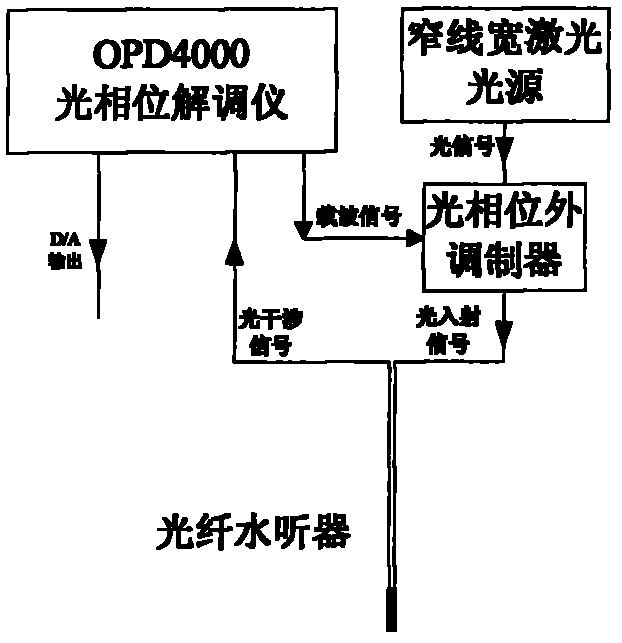

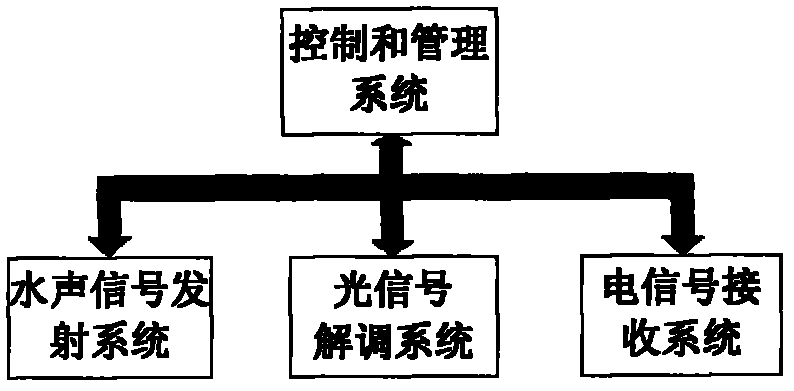

General calibration system and method of phase shift sensitivity based on optical phase demodulator

ActiveCN102072761ACalibration BandwidthLarge dynamic rangeSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansCarrier signalEngineering

The invention relates to a general calibration system and method of phase shift sensitivity based on an optical phase demodulator. The calibration system is established based on an OPD4000 optical phase demodulator for the calibration of phase shift sensitivity of an interference type optical fiber hydrophone. The calibration system is consisted of four sub-systems, namely a control and management system, an underwater sound signal emitting system, an optical phase demodulating system and an electrical signal receiving system. The optical phase demodulating sub-system is formed based on the principle of outer modulation demodulating technology of phase generation carrier, and can demodulate the interference optical phase in real time and output the result using a simulation signal. The system has the following beneficial effects that the frequency response for phase shift sensitivity of phase interference type optical fiber hydrophone is acquired accurately in real time, and the output in two data forms of simulation and digit is provided. The system is suitable for the calibration of phase shift sensitivity of phase interference type optical fiber hydrophone of each type with different arm length differences, and has the characteristics of wide calibration frequency band, wide dynamic range, low measurement uncertainty and the like, and is simple in operation.

Owner:THE 715TH RES INST OF CHINA SHIPBUILDING IND CORP

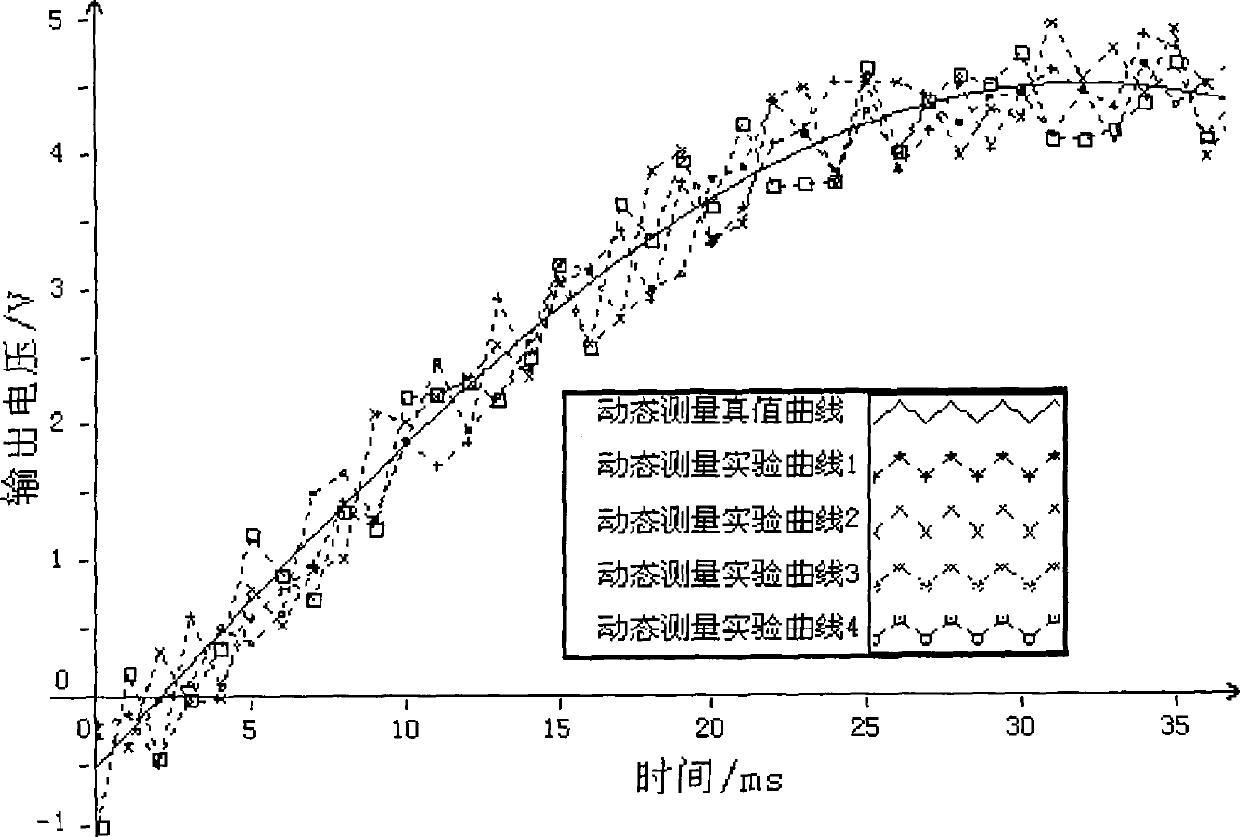

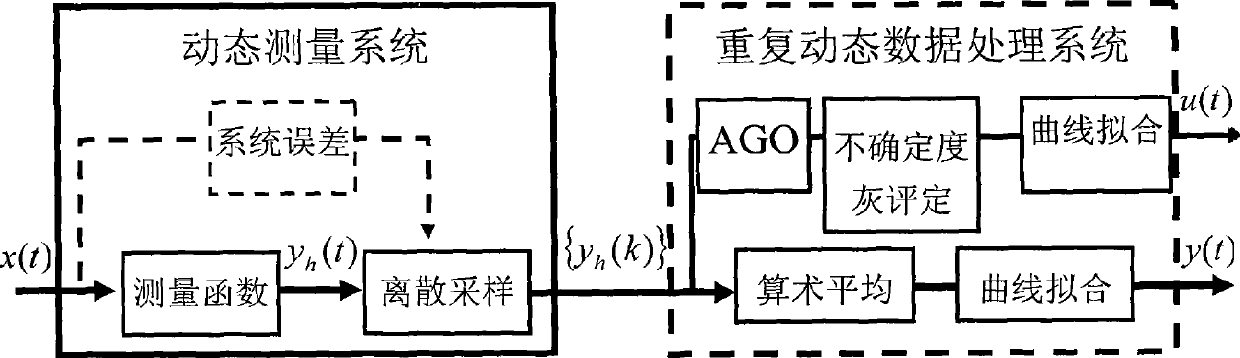

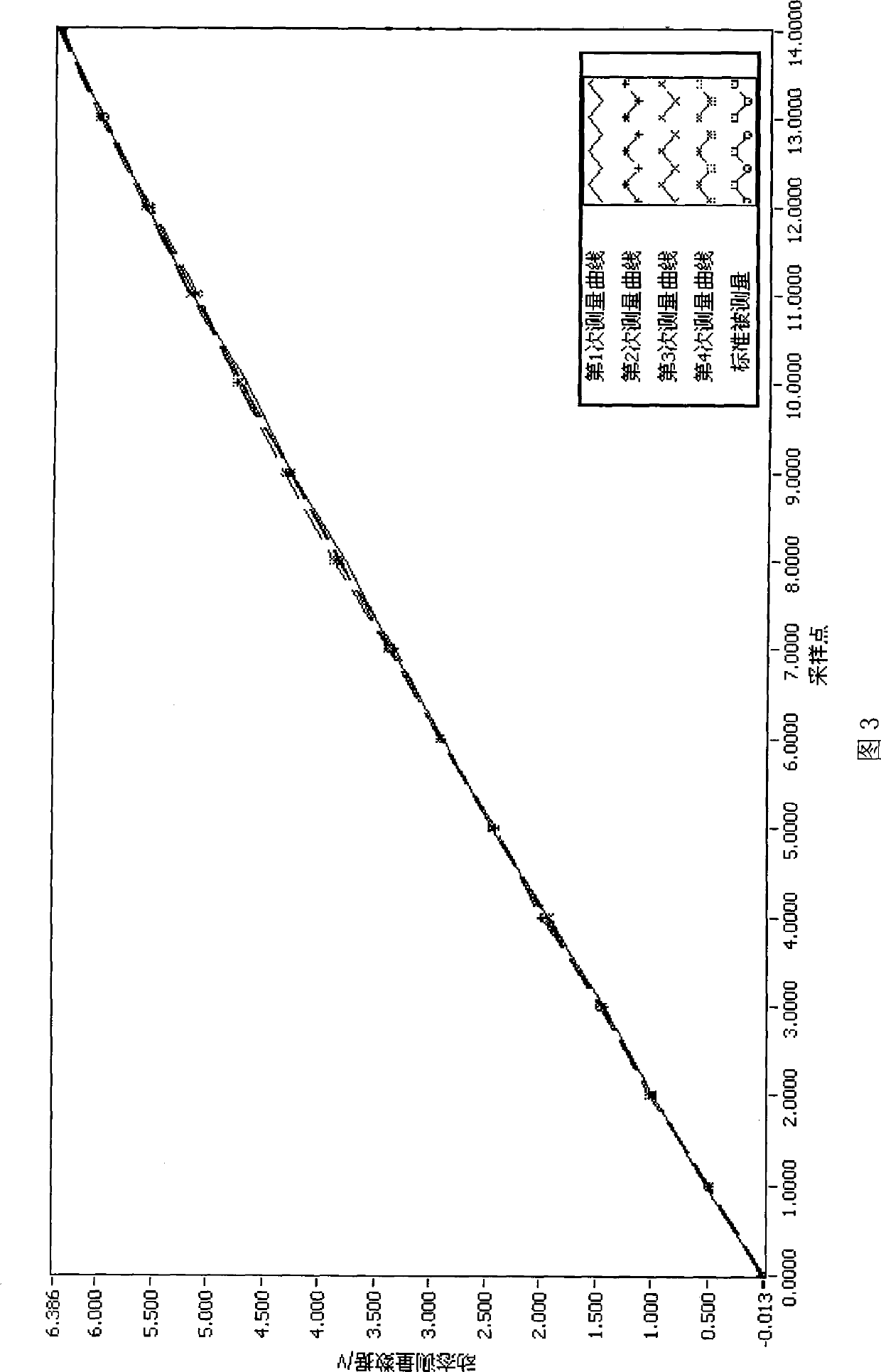

Repeat dynamic measurement data processing method based on grey system theory

InactiveCN101398311AAchieve the correct assessmentHigh precisionComplex mathematical operationsSpecial purpose recording/indication apparatusData processing systemStandard uncertainty

The invention provides a repeated dynamic measurement data processing method based on a grey system theory, comprising the steps as follows: 1. a signal x(t) to be measured is measured by a dynamic measurement system; according to detailed measurement function operation, discrete sampling is carried out to sampling points at all time; and the dynamic measurement data sequence is obtained after the error correcting data of the corresponding measurement system is accumulated; 2. in a repeated dynamic measurement data processing system, the entered dynamic measurement data sequence and values on sampling points at all time are averaged; 3. the dynamic measurement average value is calculated according to an orthogonal polynomial high-order data fitting principle, thus working out a dynamic measurement expected function y(t) fitting curve model; 4. the measured values on the sampling points at all time are accumulatively added according to the grey system theory, and an grey estimation technique used for uncertainty is used for working out the uncertainty of the dynamic measurement standard on the sampling points at all time; curve fitting is carried out, thus obtaining the dynamic measurement uncertainty function mathematic model u(t); and 5. dynamic measurement expected function fitting curve model in the step 3 and the dynamical measurement uncertainty function model are combined.

Owner:BEIHANG UNIV

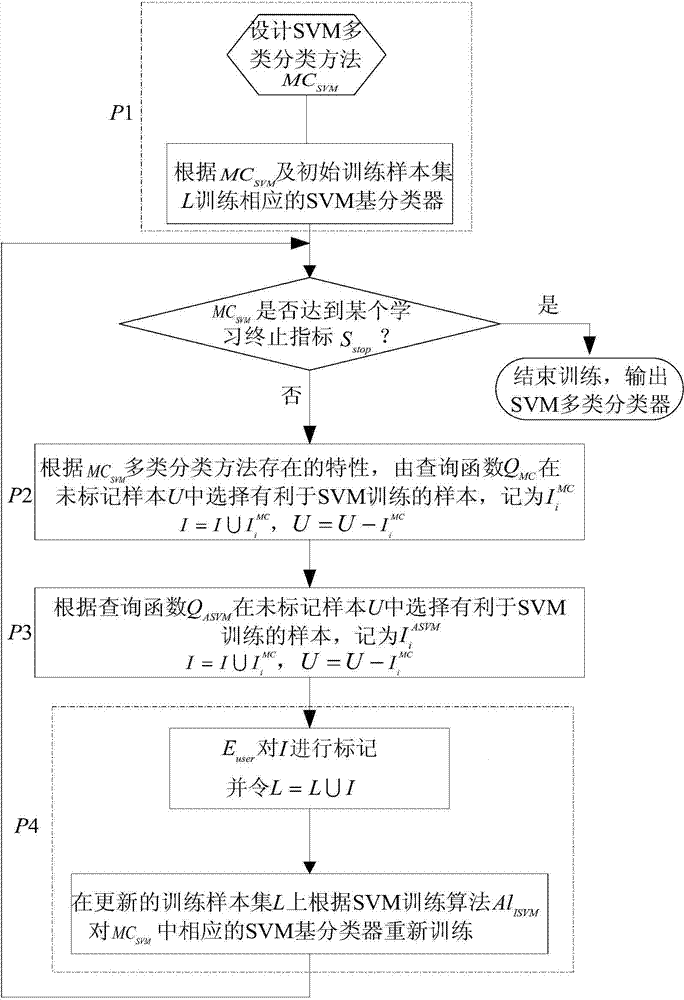

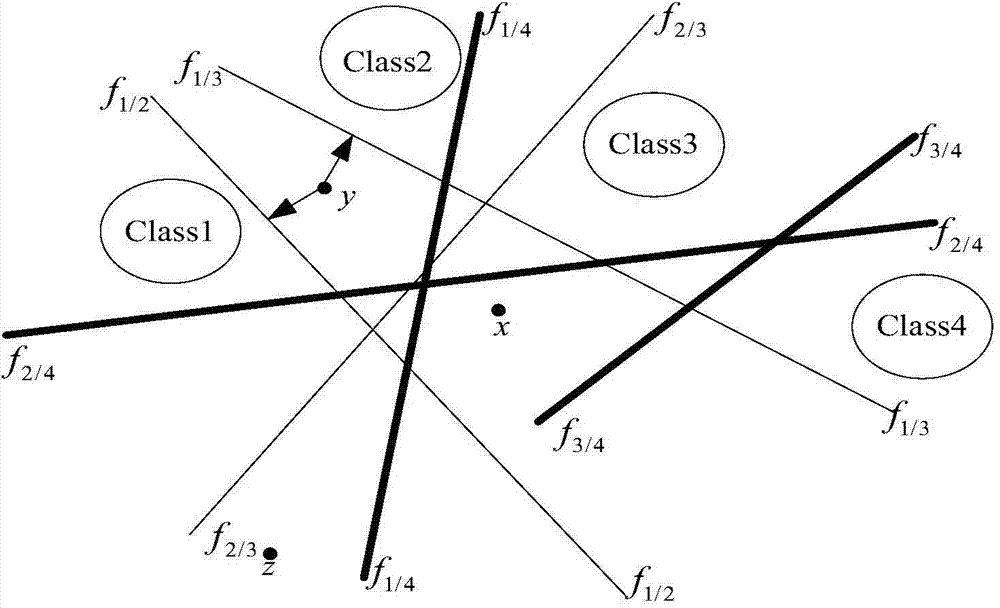

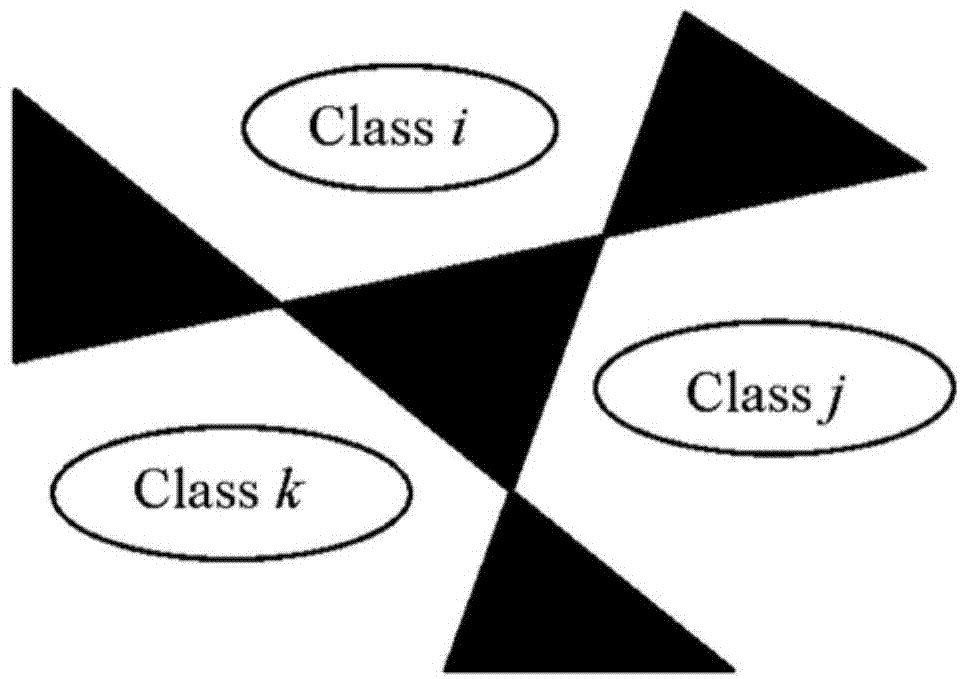

DDAG-based SVM multi-class classification active learning algorithm

InactiveCN104751182AAvoid choiceReduce marking costCharacter and pattern recognitionInference methodsSvm classifierClassification methods

The invention discloses a DDAG-based SVM multi-class classification active learning algorithm. The active learning through is adopted in the multi-class SVM learning process, the defects that according to the traditional 'one-to-many' or 'one to one' multi-class classification method, large amount of indivisible points or decision blind areas are provided during sample testing are utilized, the active learning algorithm based on the 'o-v-o' classification decision blind areas is provided, samples with the 'highest uncertainty' of the indivisible points or decision blind areas corresponding to a current learning device are selected actively, according to the limitation caused by the single active learning strategy during active learning, a multi-strategy integration active learning method on the basis of posterior probability and similarity measurement uncertainty is provided in the multi-class SVM learning process, the two active learning methods are combined effectively, the sample labeling load is reduced in the multi-class SVM learning process, the learning sample labeling cost is reduced, and an SVM classification device with the best performance can be obtained through the least labeled sample training.

Owner:AIR FORCE UNIV PLA

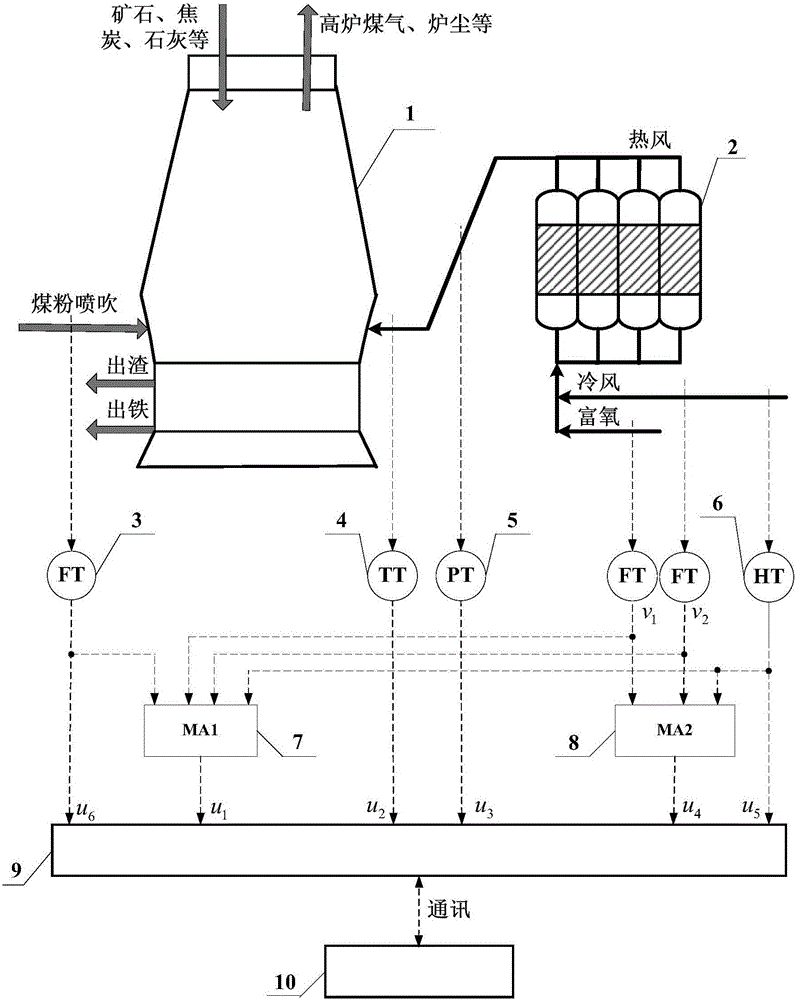

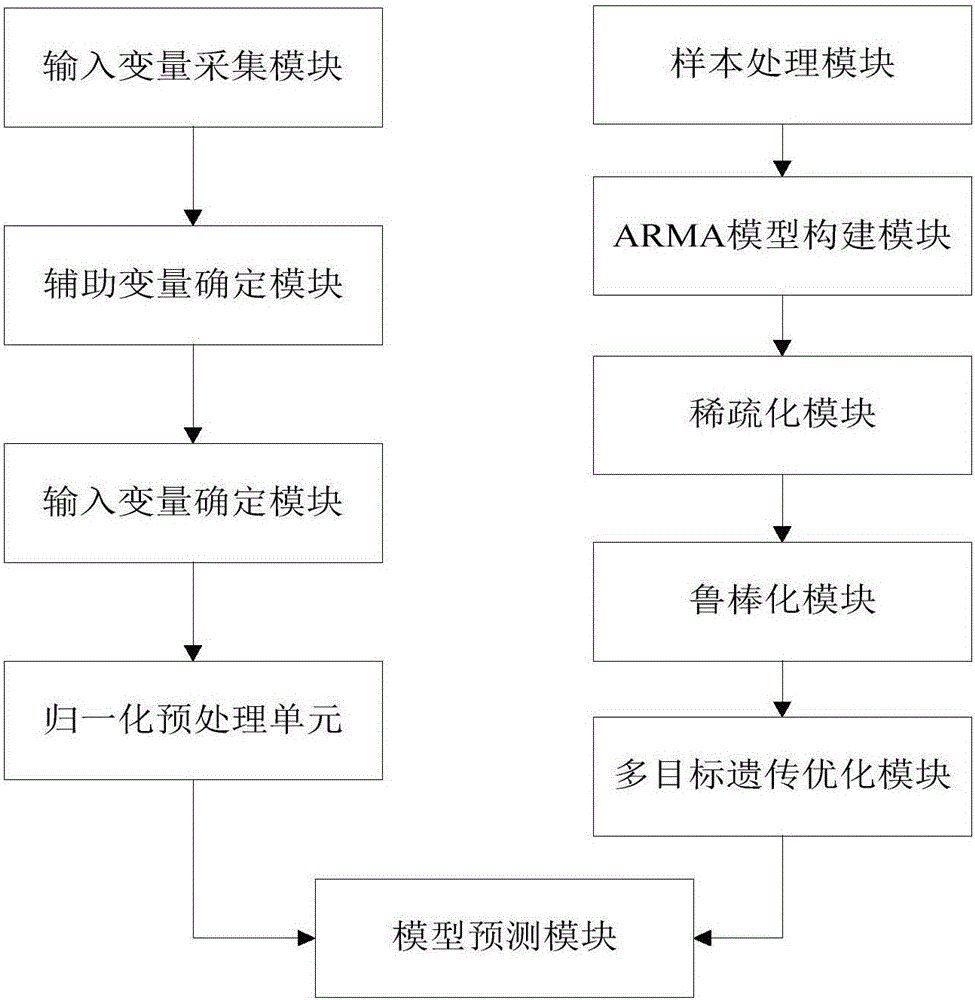

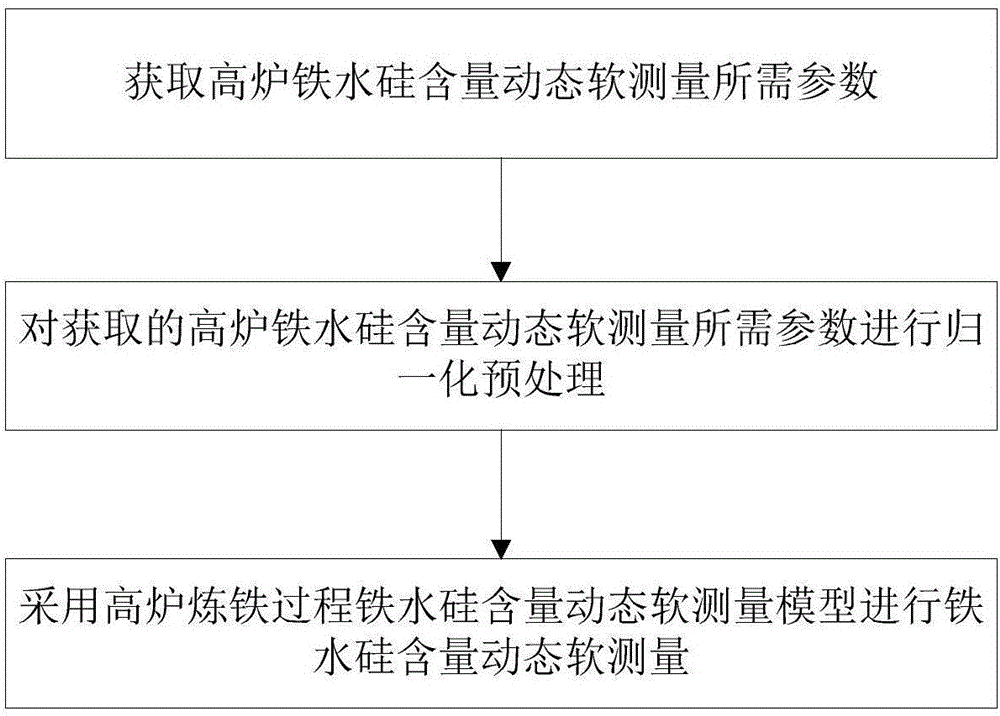

System and method for dynamical soft measurement of molten iron silicon content in blast furnace ironmaking process

ActiveCN105886680AAchieve sparsificationReduce workloadSteel manufacturing process aspectsBlast furnace detailsClosed loopSilicon

The invention provides a system and method for dynamic soft measurement of the molten iron silicon content in the blast furnace ironmaking process. The system comprises an actual data collection unit, a normalization pretreatment unit and a dynamic soft measurement unit. The method includes the steps that the parameters required by dynamic soft measurement of the blast furnace molten iron silicon content are obtained and comprise the operating parameters of the current furnace charge, the operating parameters of the previous furnace charge and the molten iron silicon content of the previous furnace charge; normalization pretreatment is conducted on the obtained parameters required by dynamic soft measurement of the blast furnace molten iron silicon content; and dynamic soft measurement of the molten iron silicon content is conducted through a model of dynamic soft measurement of the molten iron silicon content in the blast furnace ironmaking process. Compared with existing manual measurement or analysis of the molten iron silicon content, the workload of operators is reduced, measurement uncertainty introduced by manual operation is lowered, measurement timeliness and accuracy are improved, and the confidence level is high. The method has universality in prediction of the molten iron silicon content in the blast furnace ironmaking process, and closed-loop integrated control over the blast furnace molten iron quality and optimized operation can be achieved easily.

Owner:NORTHEASTERN UNIV

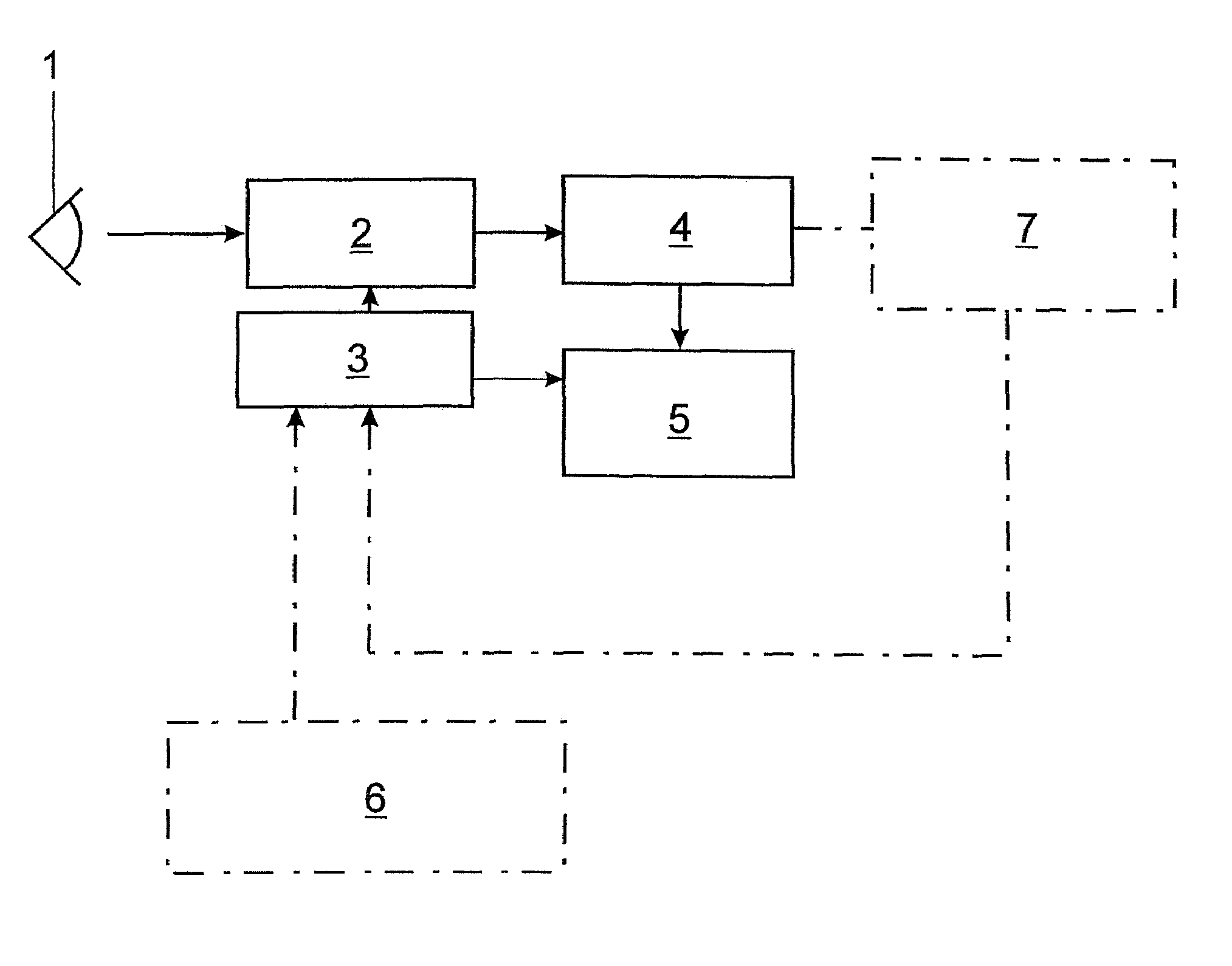

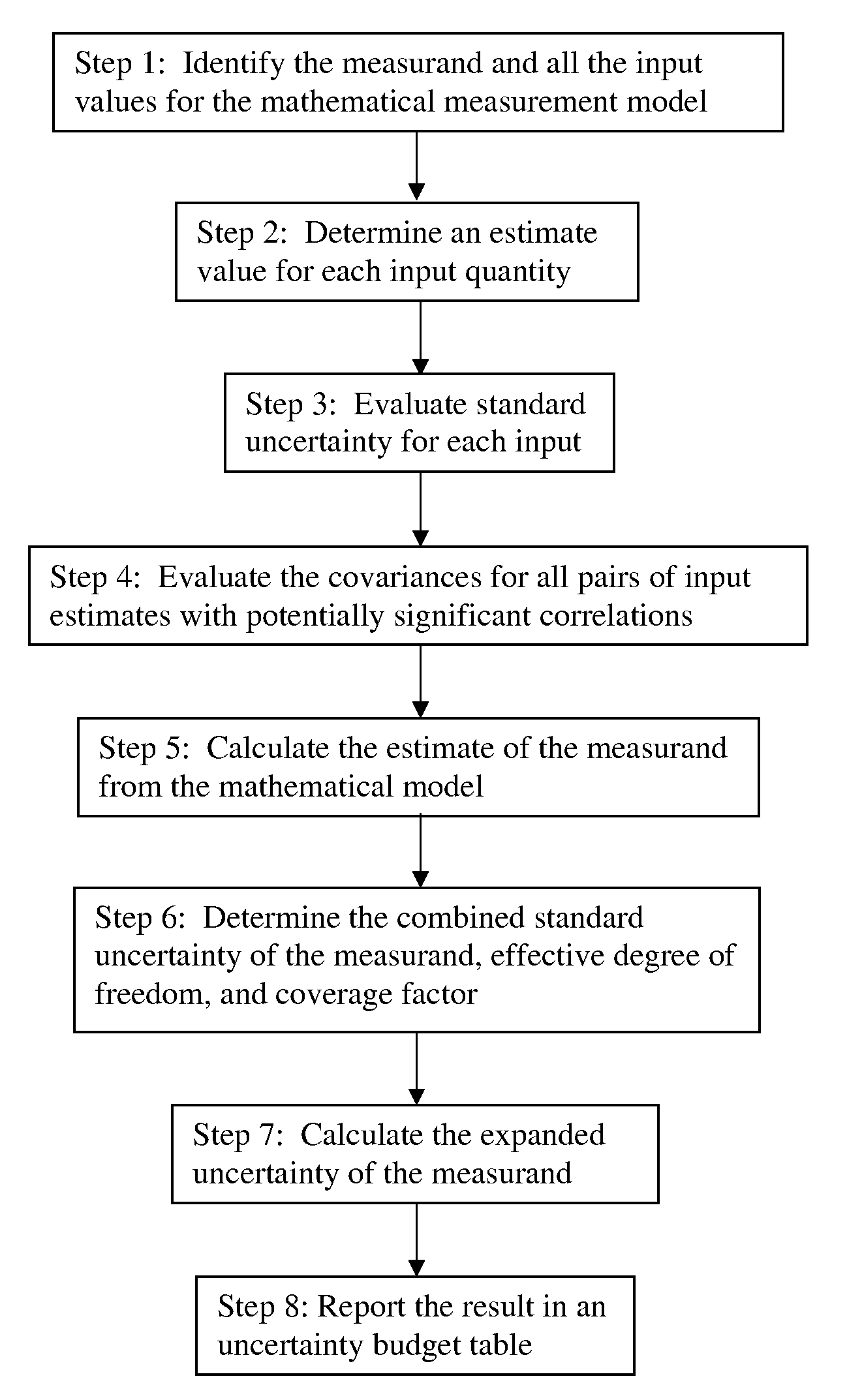

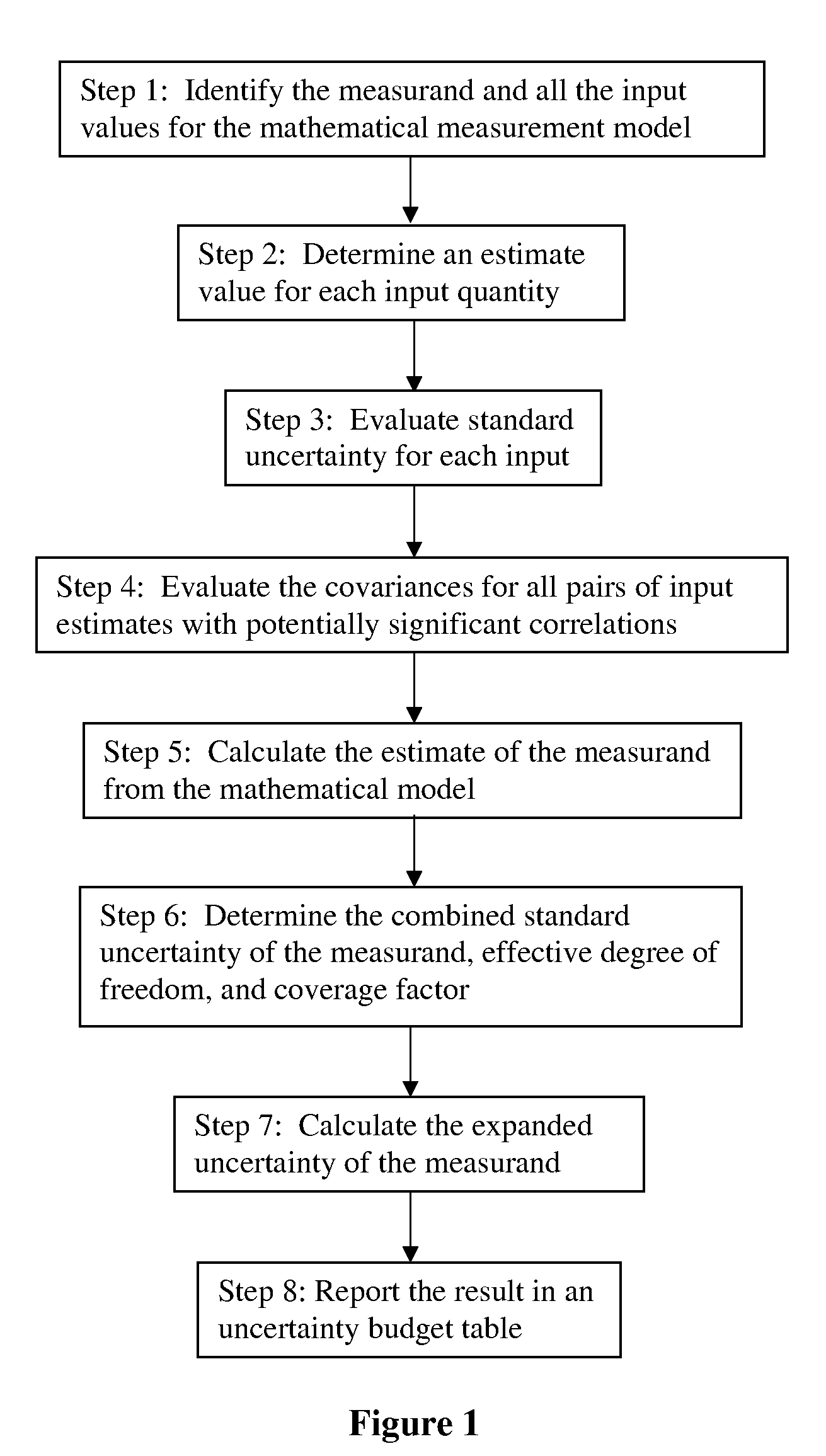

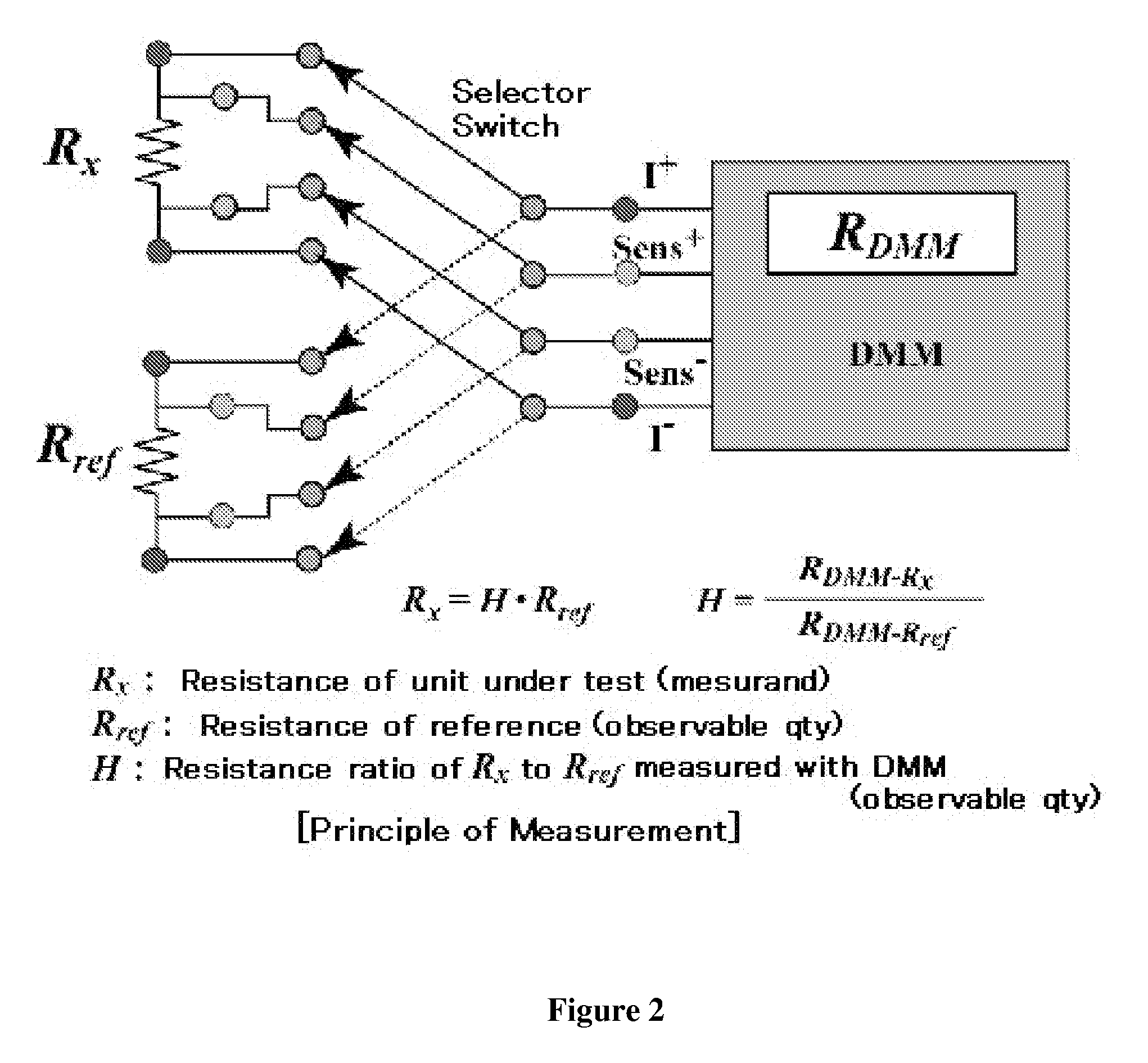

Method for the evaluation of measurement uncertainty, and a device and system thereof

InactiveUS20080125982A1Automated measurementSpecial tariff metersFlow propertiesMathematical modelReference device

A method of evaluating uncertainty associated with the value of a measurand derived from measurements of a device under test comprising providing a mathematical model wherein the measurand is expressed as a function of (i) at least one physically observable quantity, and (ii) the reference value of said physically observable quantity in a reference device; measuring the reference value of the reference device and the value of the measurand of the device under test; measuring the value of said at least one physically observable quantity; and determining at least one uncertainty value as a function of said physically observable quantity from said mathematical model, wherein the mathematical model takes into account the at least one source of uncertainty and the reference value of the reference device.

Owner:MTA JAPAN

Probabilistic lane assignment method

ActiveUS8055445B2Analogue computers for vehiclesAnalogue computers for trafficPattern recognitionAlgorithm

An improved probabilistic lane assignment method for detected objects in the scene forward of a host vehicle. Road / lane model parameters, preferably including an angular orientation of the host vehicle in its lane, are estimated from host vehicle sensor systems, taking into account measurement uncertainty in each of the constituent parameters. A probabilistic assignment of the object's lane is then assessed based on the road / lane model parameters and object measurements, again taking into account measurement uncertainty in both the road / lane model and object measurements. According to a first embodiment, the probabilistic assignment is discrete in nature, indicating a confidence or degree-of-belief that the detected object resides in each of a number of lanes. According to a second embodiment, the probabilistic assignment is continuous in nature, providing a lateral separation distance between the host vehicle and the object, and a confidence or degree-of-belief in the lateral separation distance.

Owner:APTIV TECH LTD

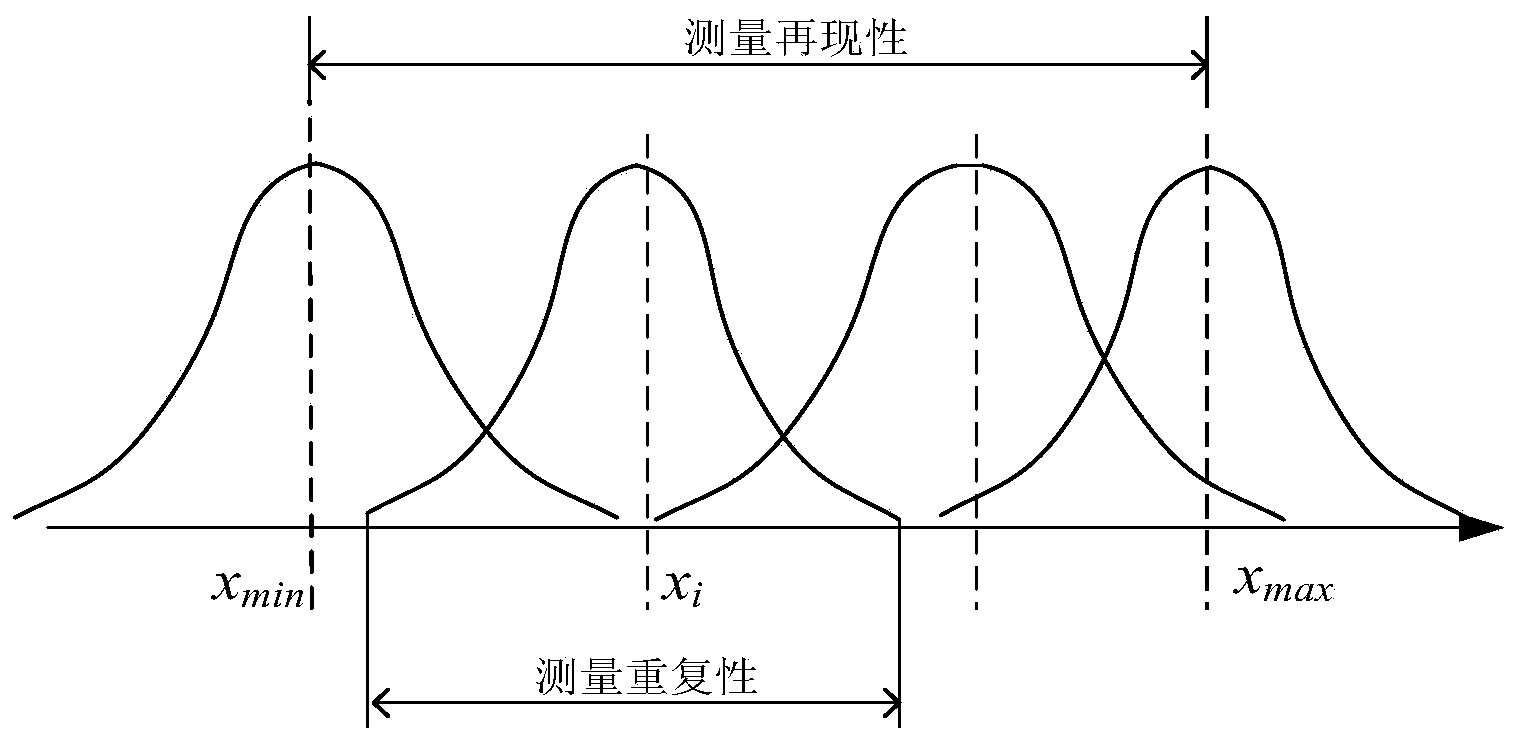

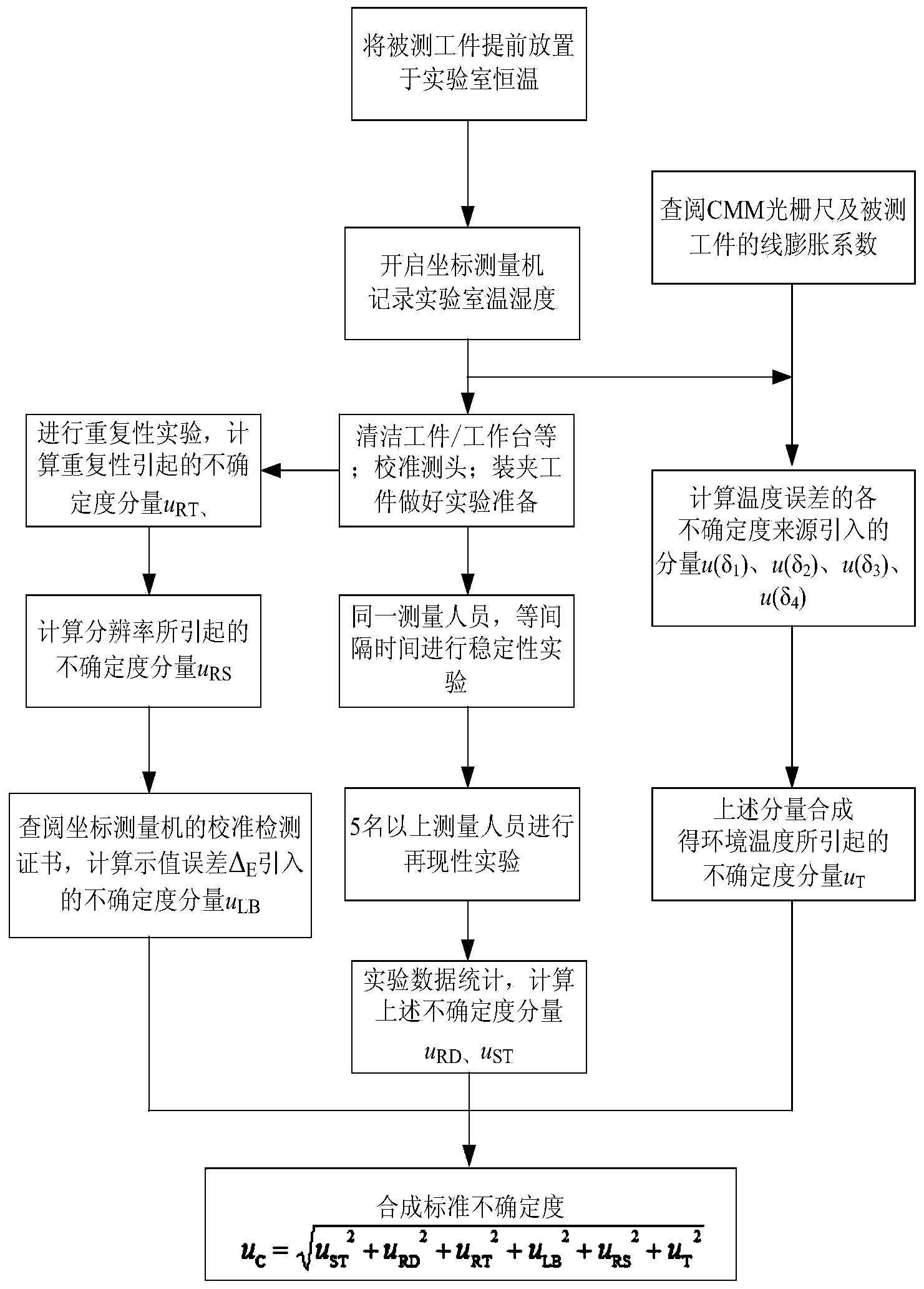

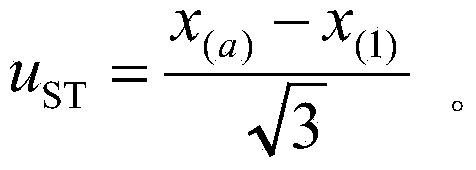

Method for assessing measurement uncertainty of coordinate measuring machine

InactiveCN104376211AUncertainty is accurate and reliableFull uncertaintySpecial data processing applicationsGratingStability index

The invention discloses a method for assessing measurement uncertainty of a coordinate measuring machine. The method of avoiding the complex relation among error sources of the coronate measuring machine and unknown transmission rules between the error sources is adopted, the method of analyzing characteristic indexes of a measurement system of the coordinate measuring machine is adopted, the method and approach of verifying or obtaining corresponding system characteristic index values of the measurement system, an integral calibration method and a detail experiment scheme for obtaining a stability index and a reproducibility index of the coordinate measuring machine are designed, the influence degree of actual temperature in temperature compensation, a standard grating rule and a linear expansion coefficient of a tested workpiece on a measurement result is considered, and the relatively integral measurement uncertainty of the coordinate measuring machine is obtained through synthesis in the root of square sum.

Owner:HEFEI UNIV OF TECH

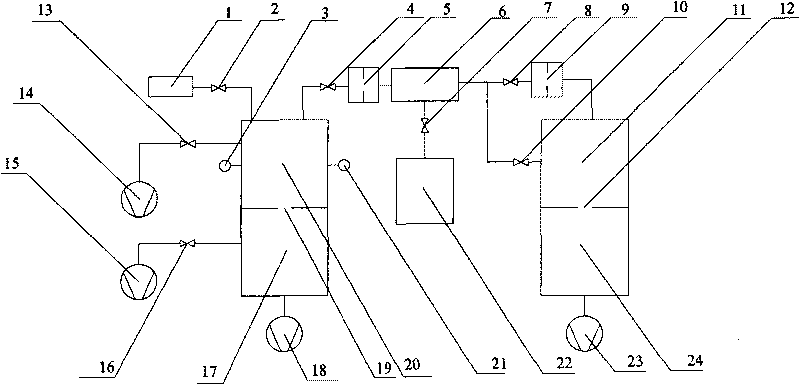

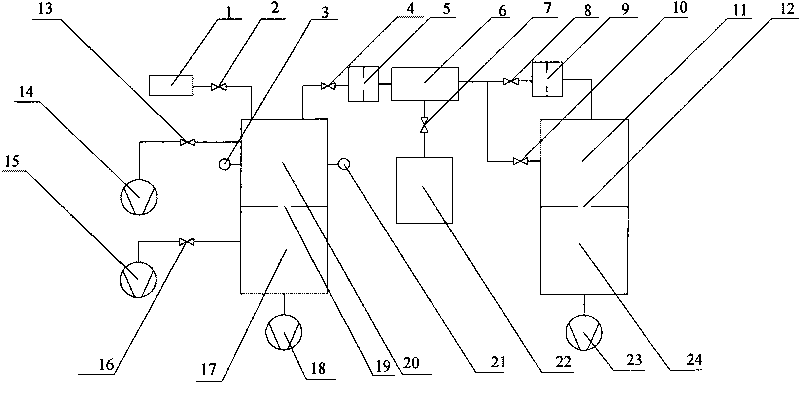

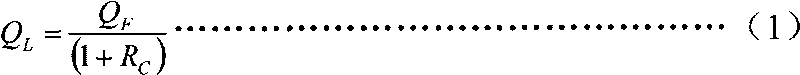

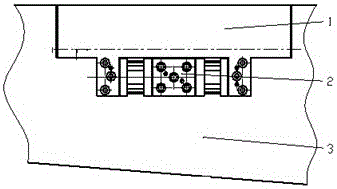

Device and method for calibrating flow-dividing vacuum leaking hole

ActiveCN101713696AWide measurement rangeReduce measurement uncertaintyDetection of fluid at leakage pointMeasurement of fluid loss/gain rateUltra-high vacuumEngineering

The invention relates to a device and a method for calibrating a flow-dividing vacuum leaking hole, in particular to the device and the method for calibrating the vacuum leaking hole, the leakage value of which is less than 1*10-8 Pa.m3 / s by adopting flow-dividing technology, and belongs to the field of measuring technology. The device consists of the calibrated leaking hole, a valve, an ionization gauge, a small hole, a flow-dividing chamber, a non-evaporable getter pump, an ultrahigh vacuum calibrating chamber, a metering hole, a very high vacuum pumping chamber, an oil-free bi-turbo molecular pump air exhauster set, a quadrupole mass spectrometer, a flow meter, a super-high vacuum calibrating chamber, the metering hole, a super-high vacuum pumping chamber and a common molecular pump air exhauster set. The method adopts a fixed flow method gas micro-flow meter to provide a known gas flow rate, so the measuring range of the flow rate is wide and uncertainty of the measurement is low; and by adopting a flow-dividing method to calibrate the vacuum leaking hole, the method of the invention completely avoids a nonlinear error of the quadrupole mass spectrometer and can precisely calibrate the vacuum leaking hole the leakage value of which is less than 1*10-8 Pa.m3 / s.

Owner:NO 510 INST THE FIFTH RES INST OFCHINA AEROSPAE SCI & TECH

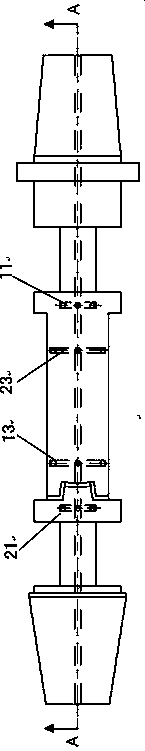

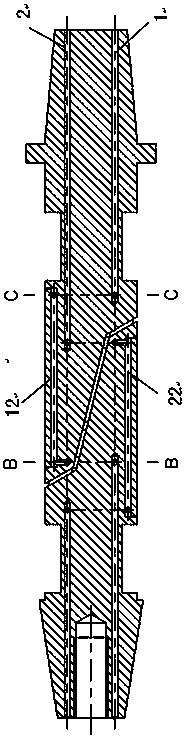

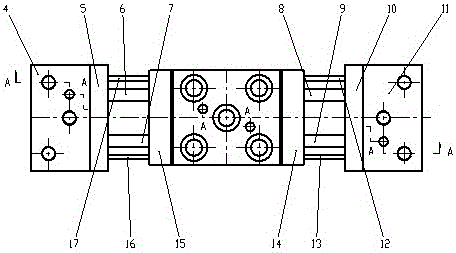

Piece type hinge moment balance

The invention discloses a piece type hinge moment balance. The balance is of an all-steel overall piece type integrated structure, and comprises a fixed connection end, four groups of balance components and two floating connection ends, wherein two ends at the same horizontal plane of the fixed connection end are provided with rigid transition sections respectively; the four groups of balance components are distributed at two sides of the rigid transition sections of the fixed connection end; and the inner side of each floating connection end is provided with a rigid transition section, and the two floating connection ends are connected with the balance components. According to the structure of the piece type hinge moment balance, the additional moment of the balance can be reduced, the matching performance of loads is improved, and aerodynamic force measurement with an axial force can be realized. Meanwhile, interference imposed on measurement by wing deformation can be reduced, thereby enabling the uncertainty of measurement to be significantly reduced, and acquiring an aerodynamic force measurement result with high precision and accuracy.

Owner:INST OF HIGH SPEED AERODYNAMICS OF CHINA AERODYNAMICS RES & DEV CENT

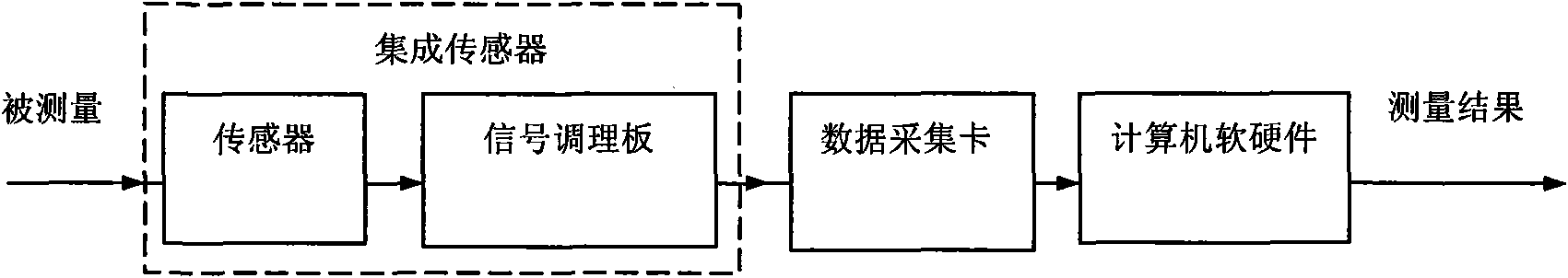

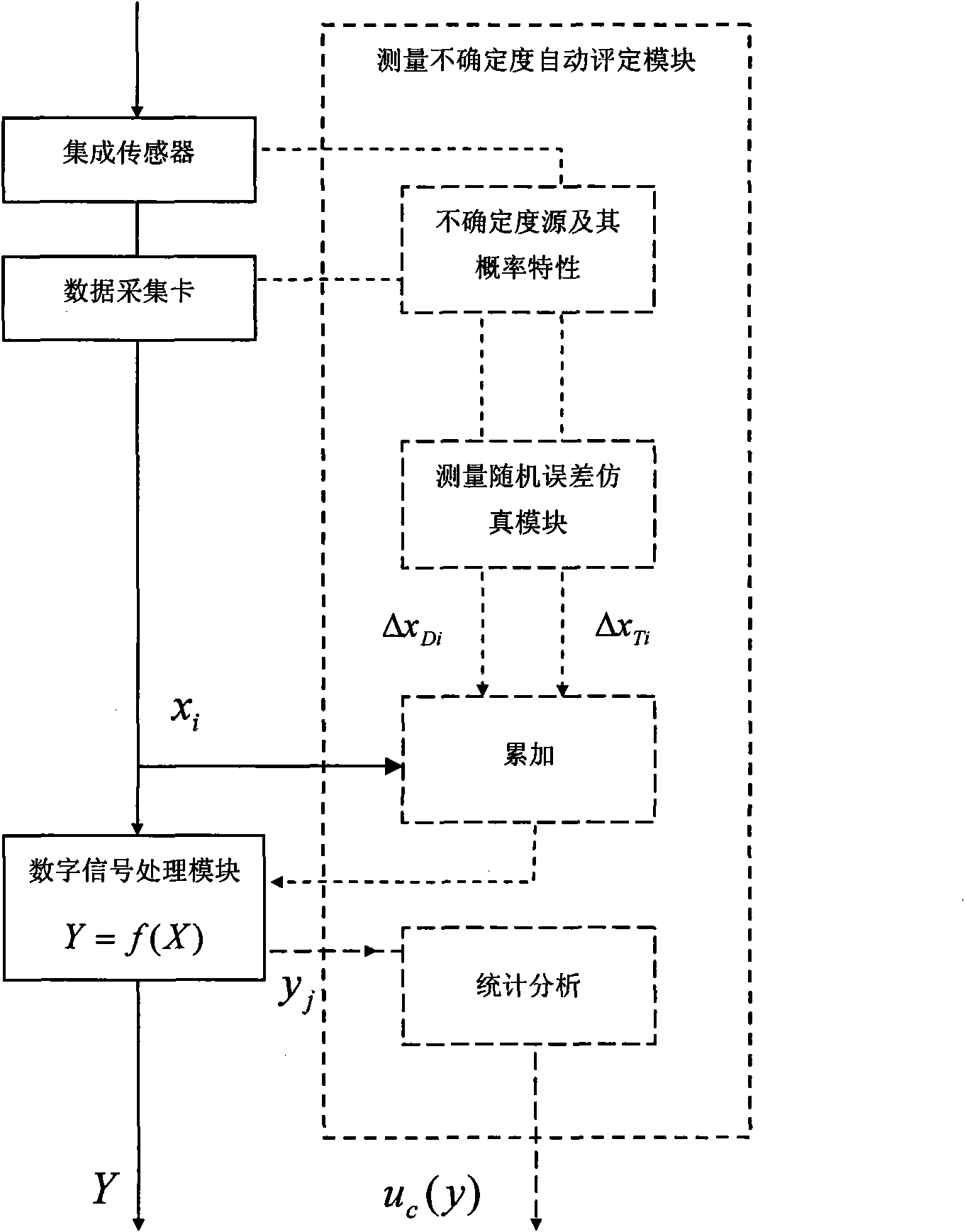

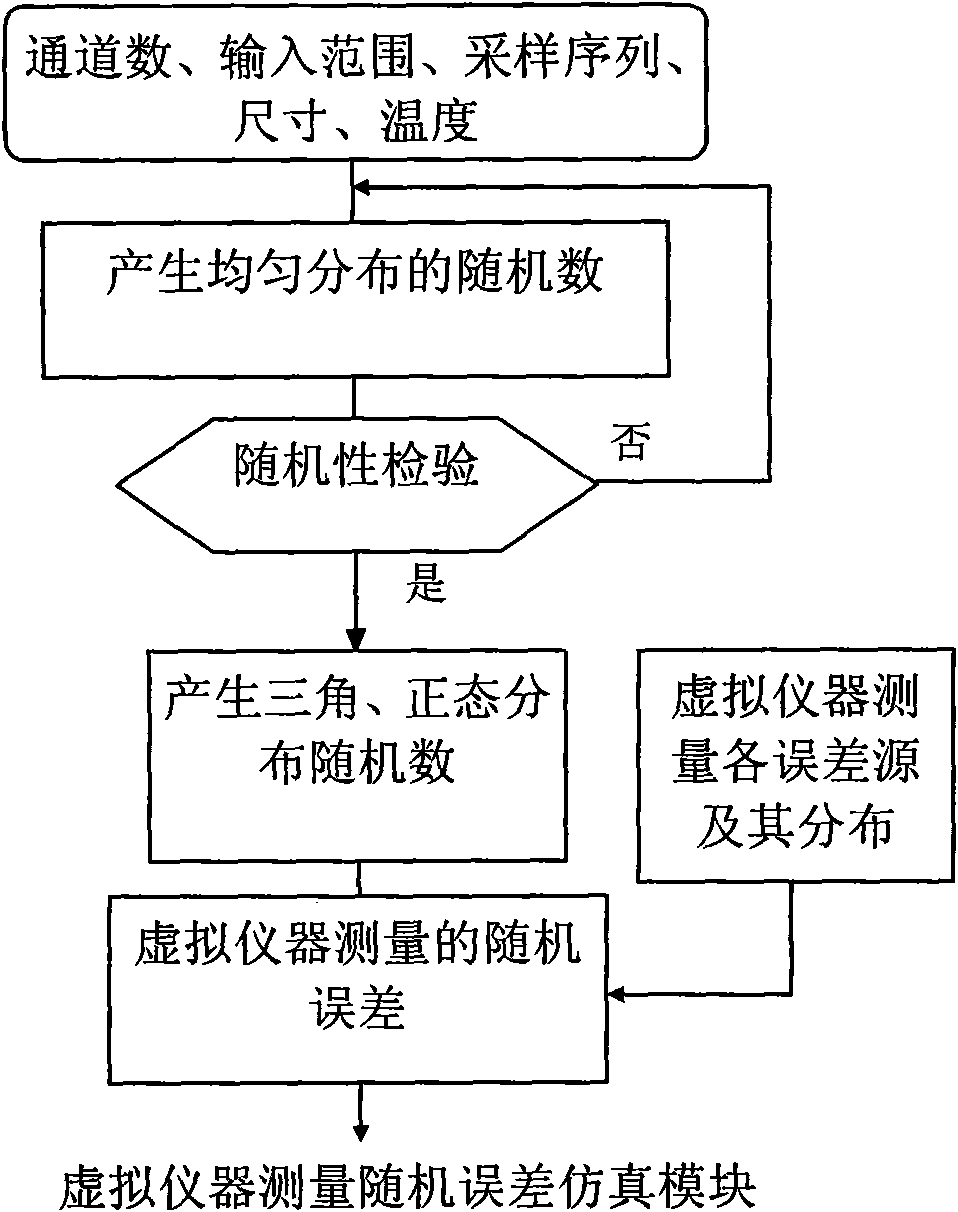

Method for automatically evaluating uncertainty of measurement of virtual instrument

InactiveCN101581587ASolve the problem of automatic evaluation of measurement uncertaintyAvoid the limitations of large samples and low precisionComplex mathematical operationsObservational errorErrors and residuals

The invention relates to a method for automatically evaluating uncertainty of measurement of a virtual instrument, aiming at realizing analysis and processing of measuring signals in a form of software as well as applying a Monte Carto method to evaluate the uncertainty of measurement of the virtual instrument by avoiding the limitation to explicit expression, resolution and linearity of measurement mechanism in the traditional method for evaluating the uncertainty of measurement; the method has the core that measurement error simulation data generated according to random variable sampling principle is blended into measurement programs to obtain a plurality of pseudo measuring results, and the uncertainty of measurement of the virtual instrument is evaluated by the statistic of the pseudo measuring results.

Owner:BEIHANG UNIV

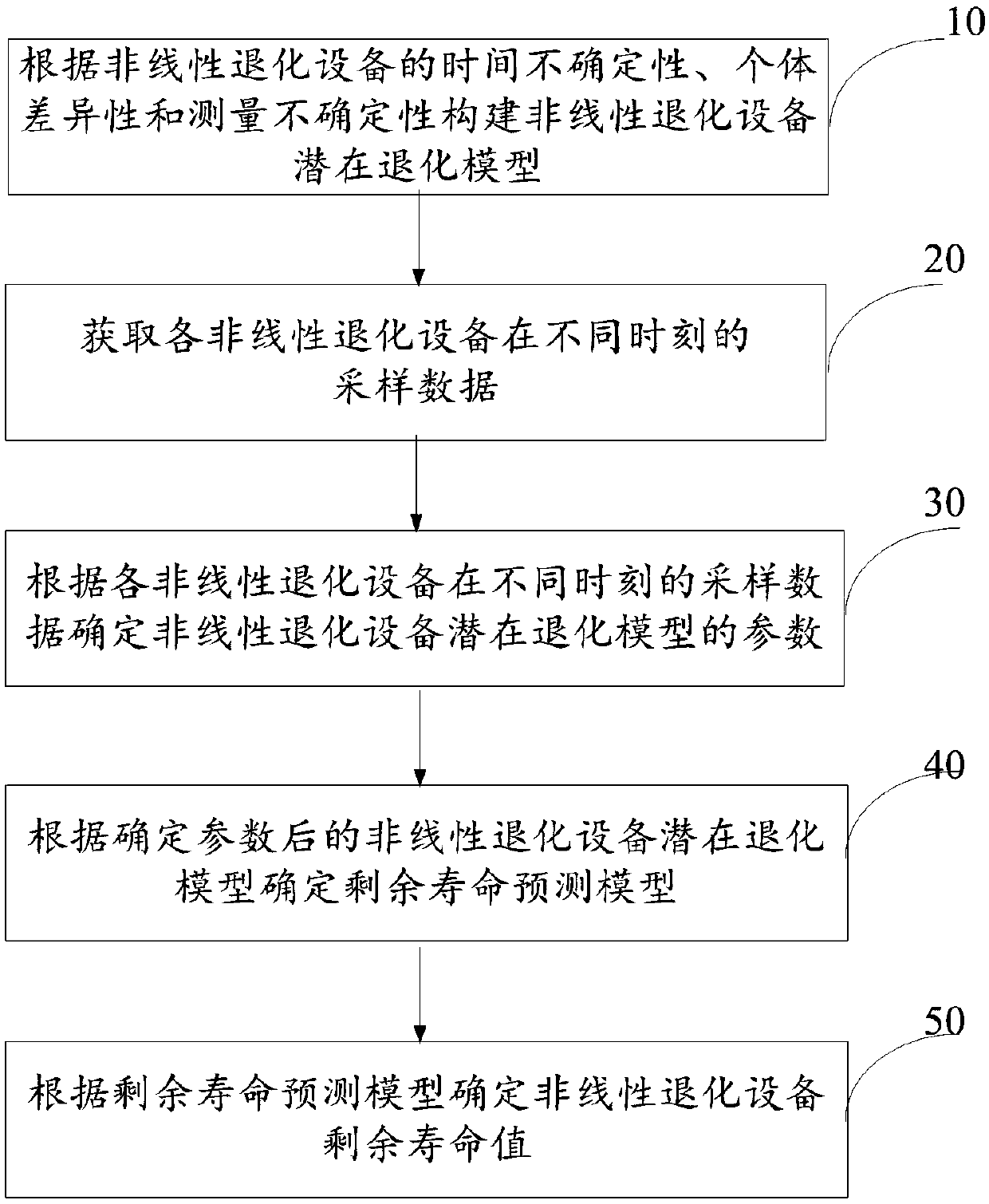

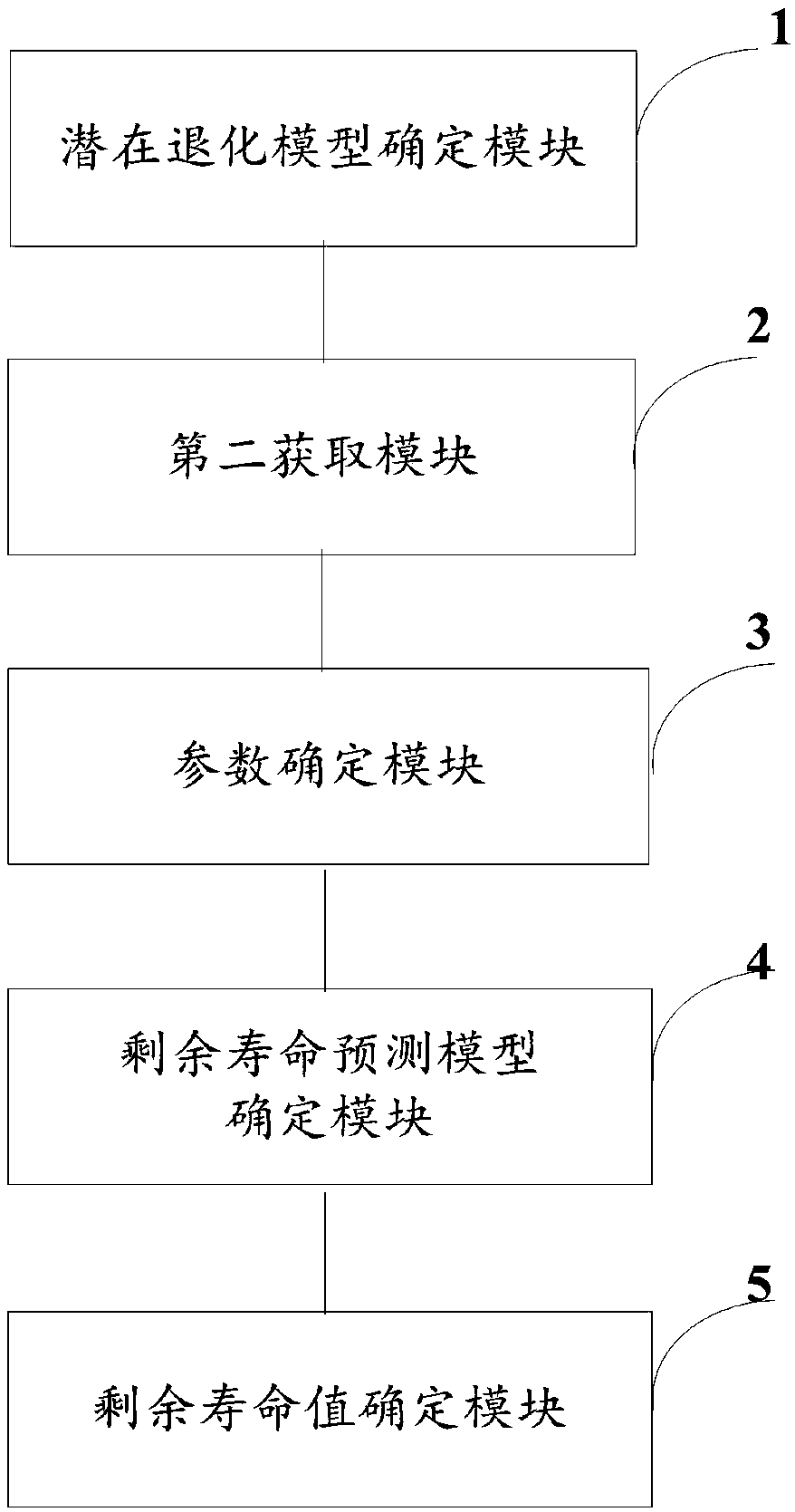

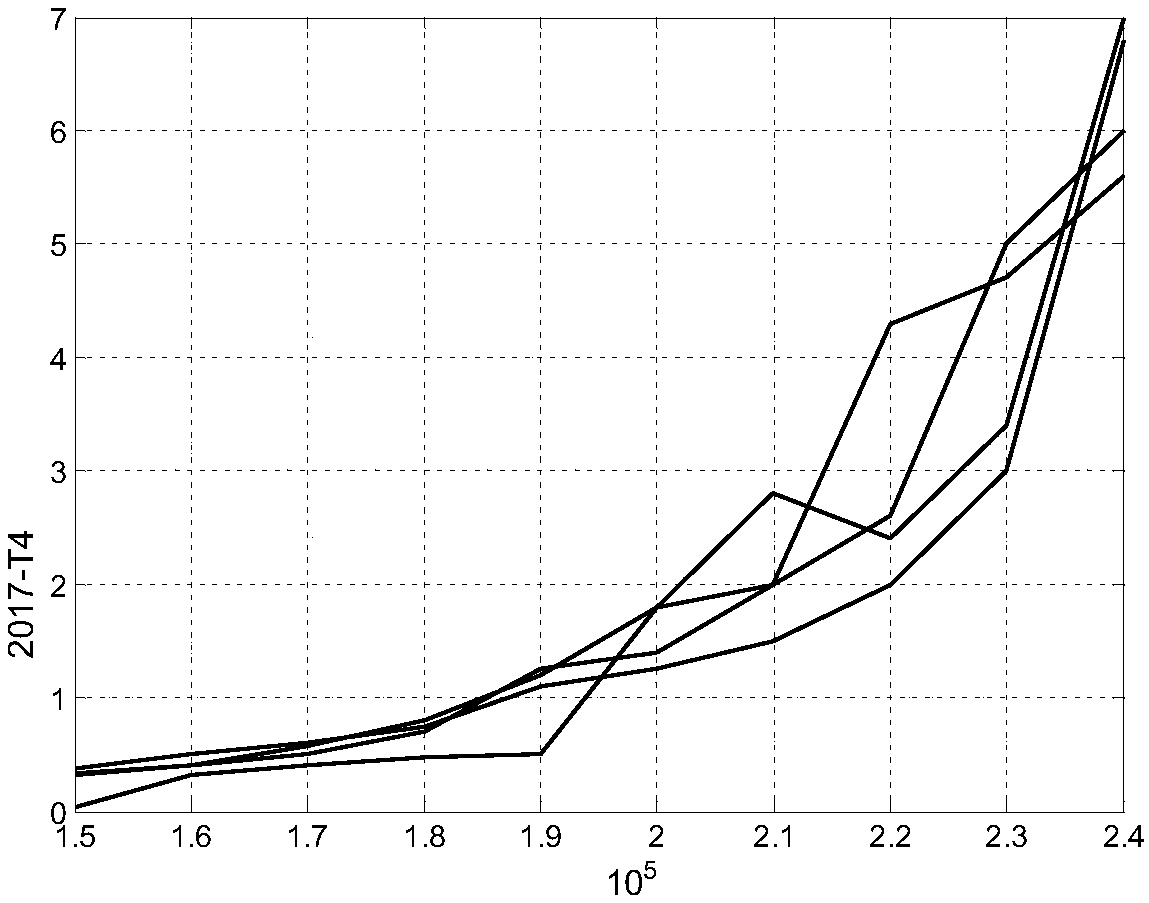

Prediction method and system for remaining service life of nonlinear degradation equipment

InactiveCN108304685AImprove accuracySpecial data processing applicationsInformaticsReliability engineeringLife span

The invention discloses a prediction method and system for the remaining service life of nonlinear degradation equipment. The method comprises the steps that according to time uncertainty parameters,individual difference parameters and measurement uncertainty parameters of the nonlinear degradation equipment, a nonlinear degradation equipment potential degradation model is established; sampling data of all the nonlinear degradation equipment at different moments is acquired; according to the sampling data of all the nonlinear degradation equipment at different moments, parameters of the nonlinear degradation equipment potential degradation model are determined; according to the nonlinear degradation equipment potential degradation model with the determined parameters, a remaining servicelife prediction model is determined; according to the remaining service life prediction model, a remaining service life value of the nonlinear degradation equipment is determined. According to the prediction method and system, the time uncertainty, individual difference and measurement uncertainty of the nonlinear degradation equipment are comprehensively considered, then the nonlinear degradationequipment potential degradation model is established, the remaining service life of the nonlinear degradation equipment is predicted, and then the accuracy of service life prediction is improved.

Owner:中国人民解放军火箭军工程大学

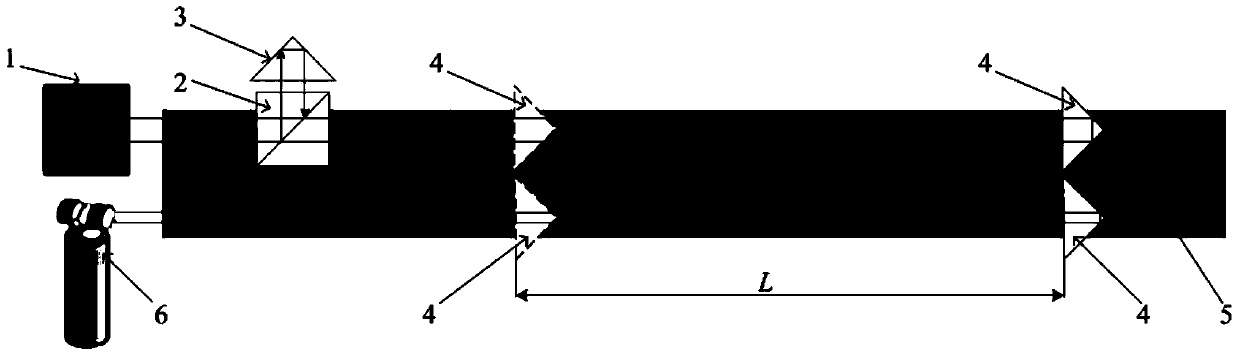

Large-length laser interferometer measurement system for eliminating Abbe error

ActiveCN104215181AHigh precisionThe principle is simpleUsing optical meansOperabilityLaser interference

The invention discloses a laser interferometer measurement system for eliminating Abbe error. The system comprises three independent laser interference length measuring systems and a high-precision long guide rail. With the use of the three independent laser interference length measuring systems which are placed in an arbitrary triangle, equivalent measuring optical paths with a starting point at any position of an the initial plane are constructed. Meanwhile, with the three independent laser interference length measuring systems having the same optical path with a device under test, measurement uncertainty caused by the fact that an Abbe principle is not met. The laser interferometer measurement system for eliminating Abbe error has the advantages of being simple in technical principles, low in costs, strong in operability and capable of improving accuracy of the large-length laser interferometer measurement system.

Owner:NAT INST OF METROLOGY CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com