Patents

Literature

59 results about "Standard uncertainty" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

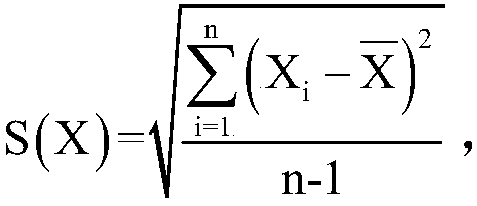

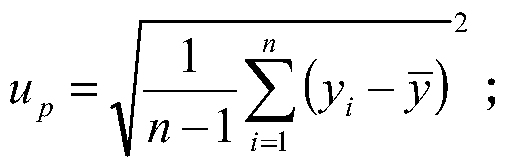

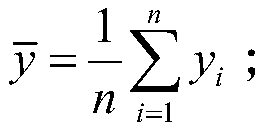

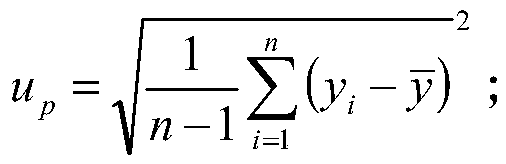

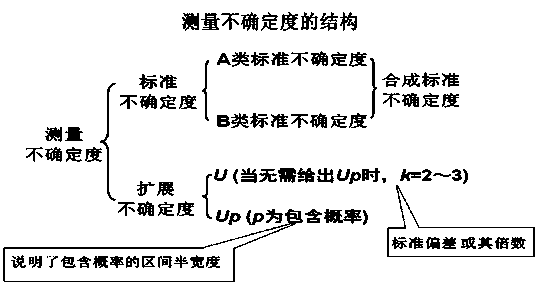

The standard uncertainty of the measurement is the standard deviation of the set of readings (the sample) divided by the square root of the number of readings (see equation below). Standard uncertainty of the mean indicates how much a value averaged from several readings is expected to vary from the true mean.

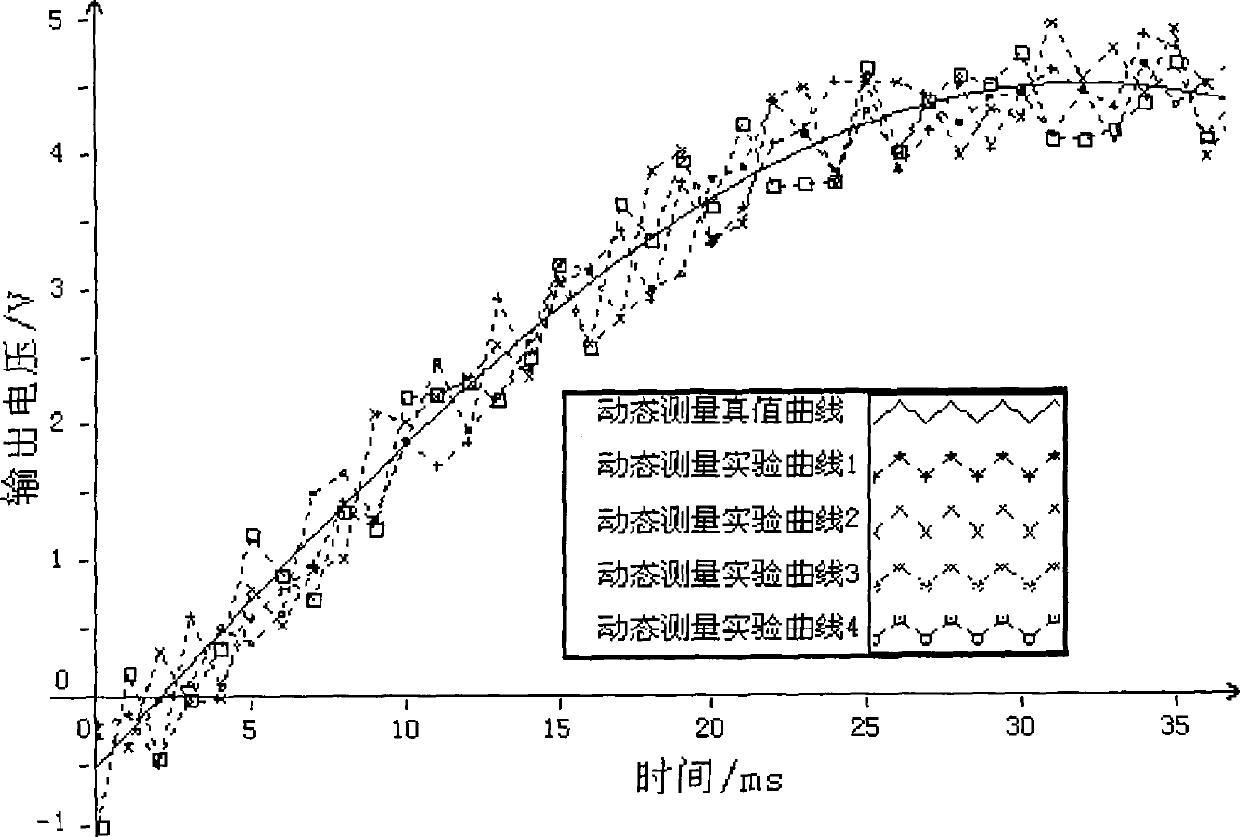

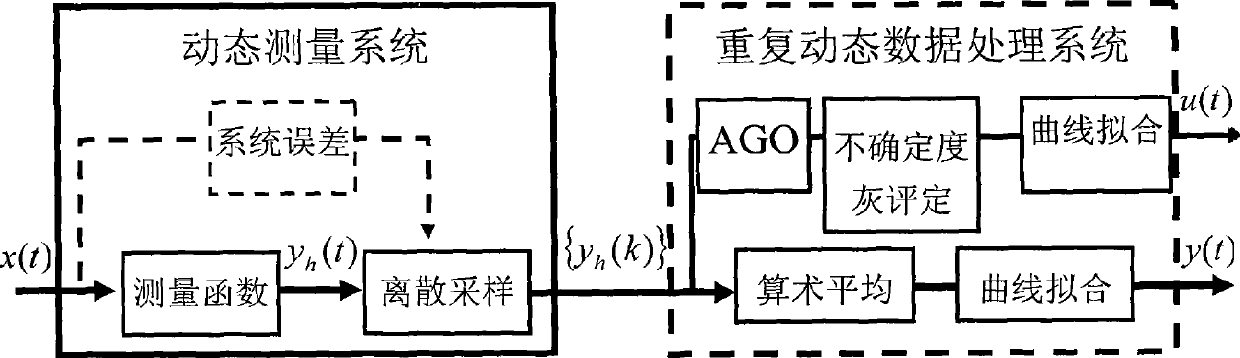

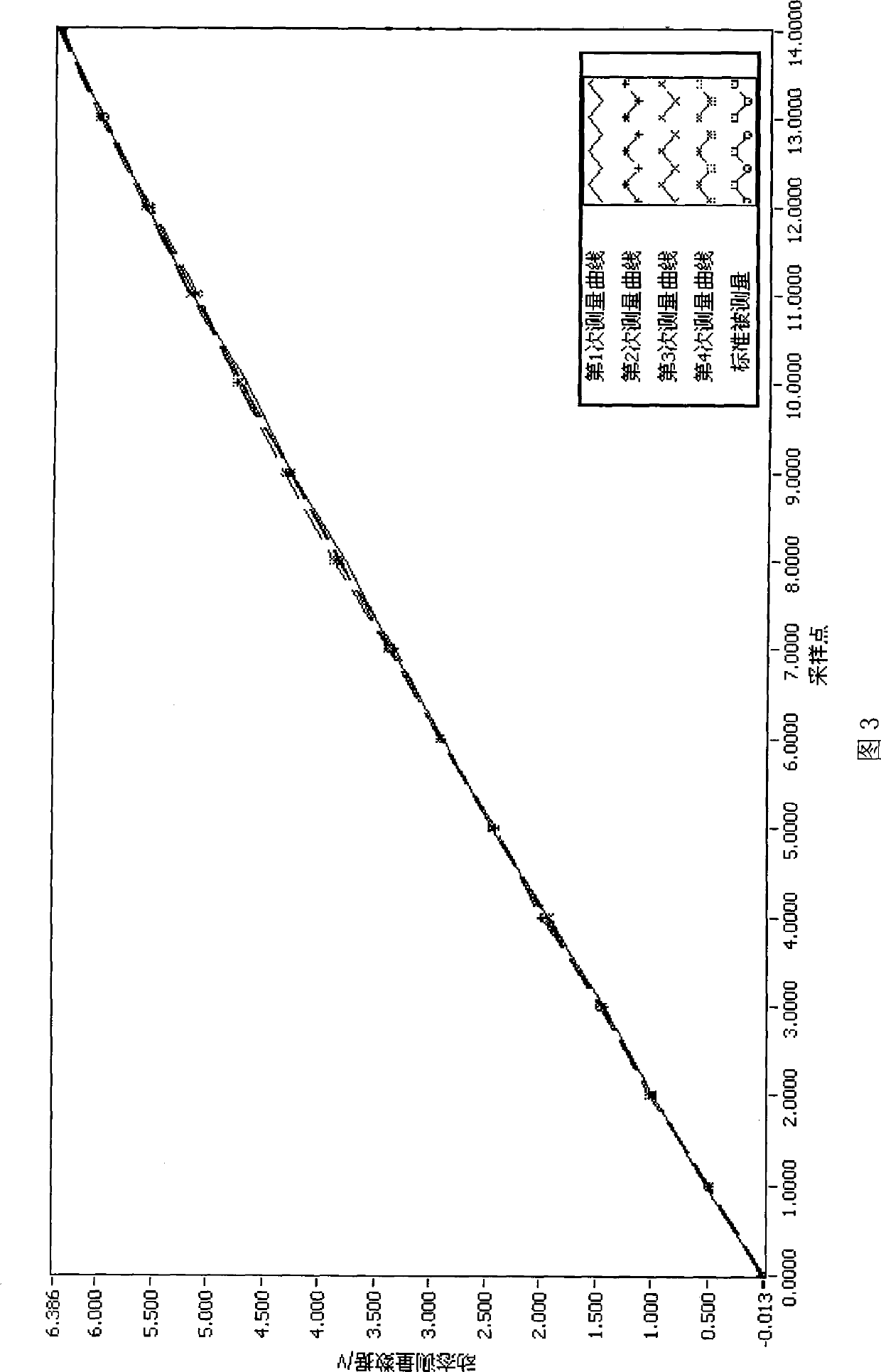

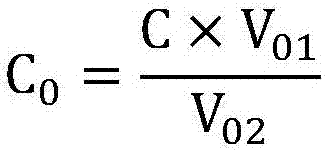

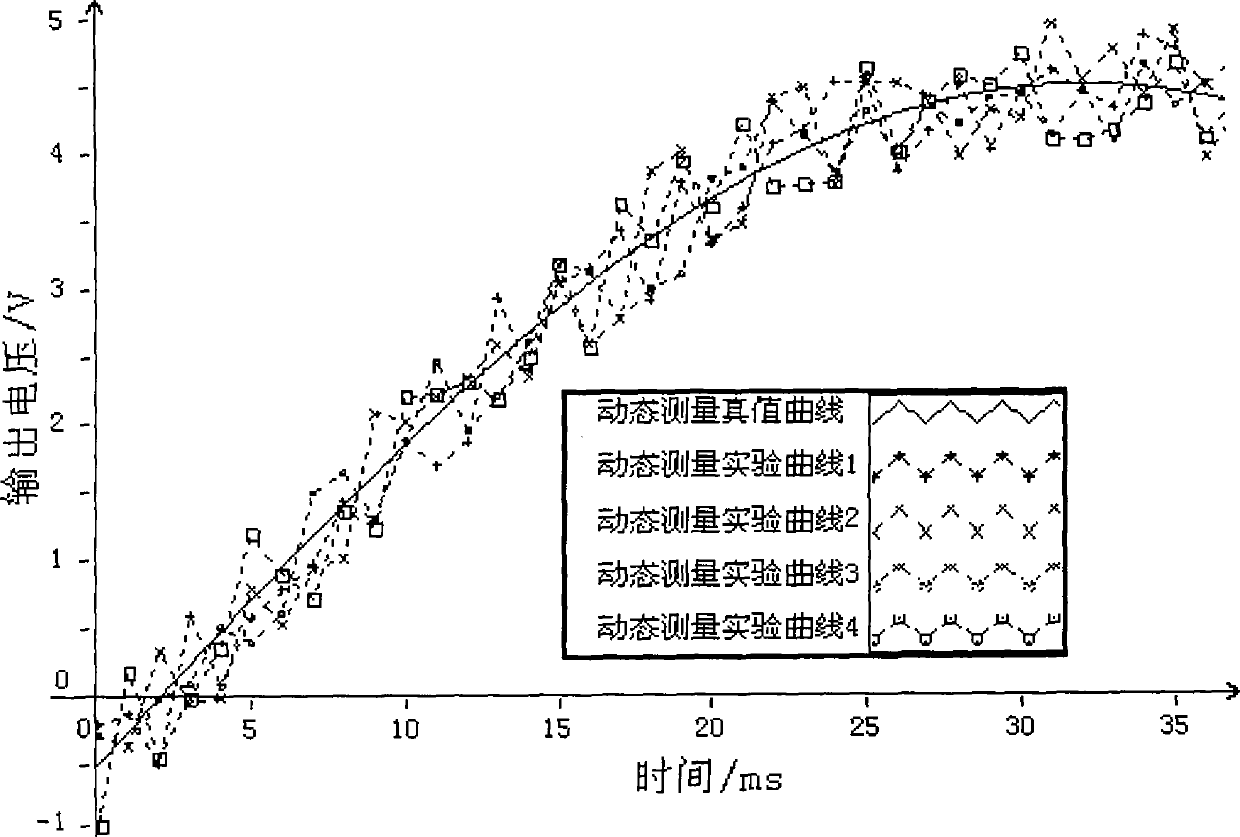

Repeat dynamic measurement data processing method based on grey system theory

InactiveCN101398311AAchieve the correct assessmentHigh precisionComplex mathematical operationsSpecial purpose recording/indication apparatusData processing systemStandard uncertainty

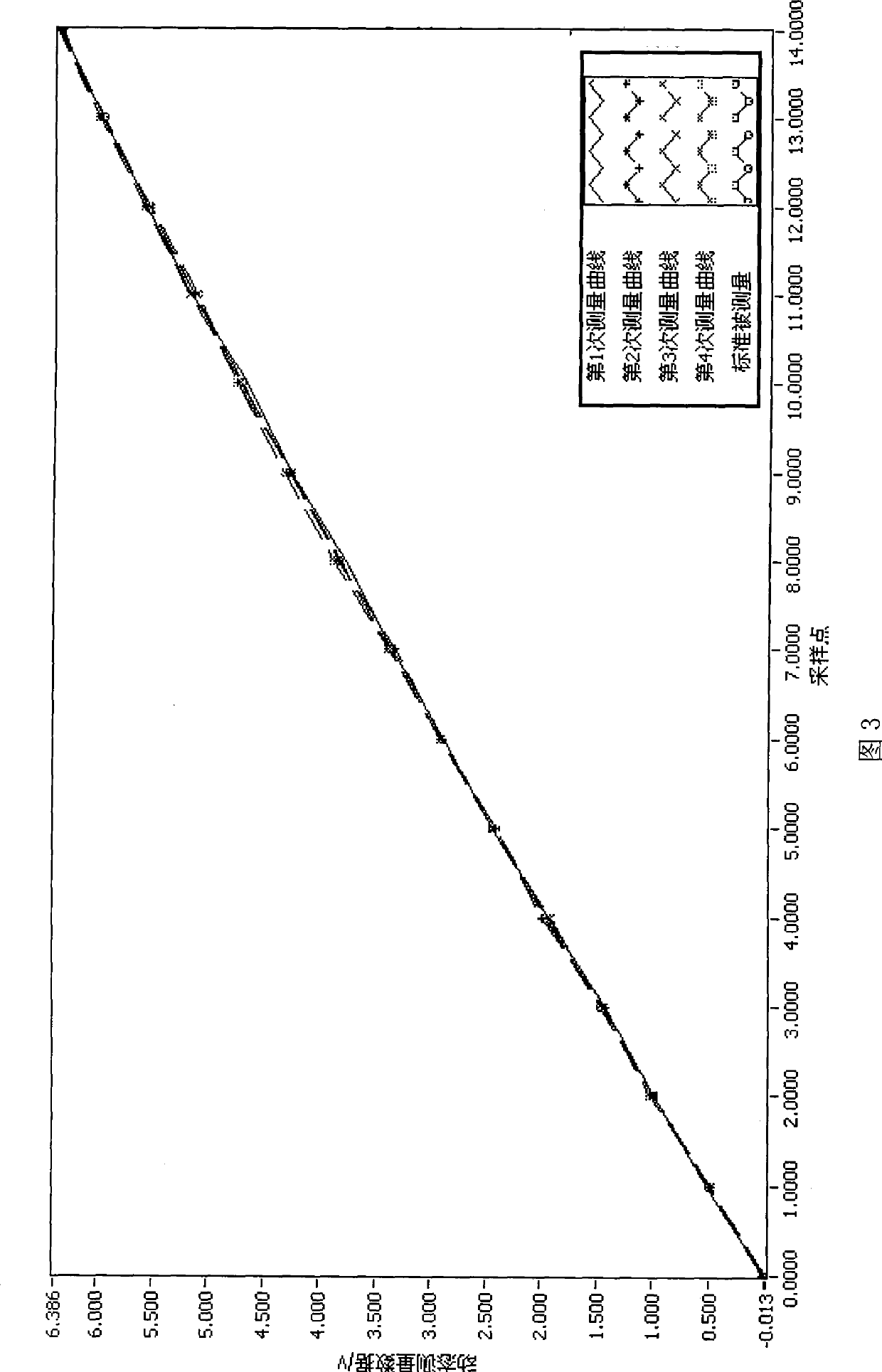

The invention provides a repeated dynamic measurement data processing method based on a grey system theory, comprising the steps as follows: 1. a signal x(t) to be measured is measured by a dynamic measurement system; according to detailed measurement function operation, discrete sampling is carried out to sampling points at all time; and the dynamic measurement data sequence is obtained after the error correcting data of the corresponding measurement system is accumulated; 2. in a repeated dynamic measurement data processing system, the entered dynamic measurement data sequence and values on sampling points at all time are averaged; 3. the dynamic measurement average value is calculated according to an orthogonal polynomial high-order data fitting principle, thus working out a dynamic measurement expected function y(t) fitting curve model; 4. the measured values on the sampling points at all time are accumulatively added according to the grey system theory, and an grey estimation technique used for uncertainty is used for working out the uncertainty of the dynamic measurement standard on the sampling points at all time; curve fitting is carried out, thus obtaining the dynamic measurement uncertainty function mathematic model u(t); and 5. dynamic measurement expected function fitting curve model in the step 3 and the dynamical measurement uncertainty function model are combined.

Owner:BEIHANG UNIV

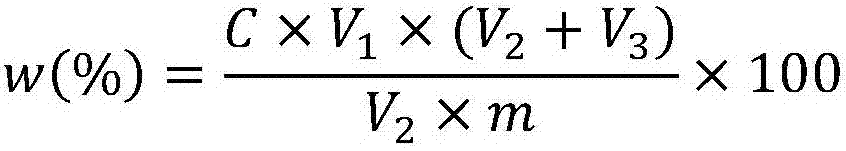

Isotope dilution mass spectrometry method for determining content of uranium in uranium niobium alloy

InactiveCN104597174AEasy to measureOvercoming Disadvantages of Susceptibility to InterferenceComponent separationElement analysisDecomposition

The invention discloses an isotope dilution mass spectrometry method for determining the content of uranium in a uranium niobium alloy. A formula for calculating the content of uranium in the uranium niobium alloy is derived according to an isotope dilution mass spectrometry principle. A decomposition process of the uranium niobium alloy is researched, the sampling quantity and the amount of a diluent are optimized, and the influences of mass spectrum line interference and alloy element interference on a measurement result are discussed. The method comprises the following steps: adding nitric acid and hydrofluoric acid to quantitatively dissolve the uranium niobium alloy, adding a quantitative amount of a uranium isotope diluent to directly prepare a mixed sample solution, determining the mixed solution and the uranium isotope proportion in the uranium niobium alloy sample through mass spectrometry, and calculating the content of uranium in the uranium niobium alloy. Quantitative separation of uranium is not needed by the determined method. An XRF technique, an ICP-AES technique and an element analysis technique are used to measure the content of niobium and the total content of impurity elements in the uranium niobium alloy, and back stepping is carried out to obtain the corresponding uranium content order in order to verify the accuracy of the analytical result, and the obtained result is consistent with a result obtained through the experiment method. When the method disclosed in the invention is used to analyze the uranium niobium alloy sample, the relative standard uncertainty of determination results is 0.2% (6 determinations), and the expanded uncertainty is 0.5% (95% confidence level).

Owner:青岛齐力铸钢有限公司

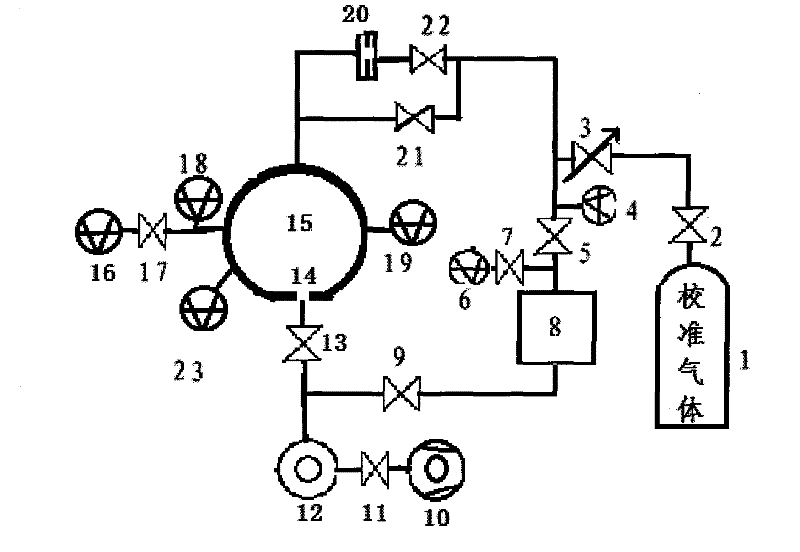

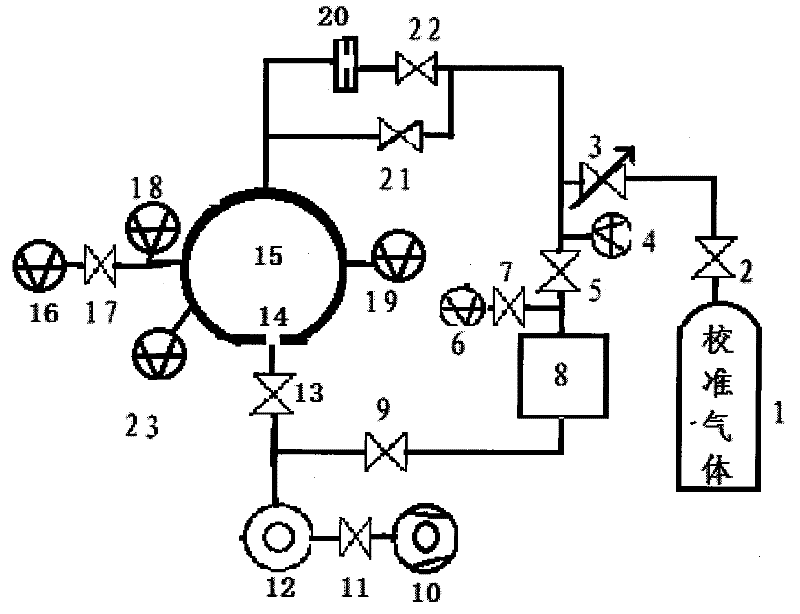

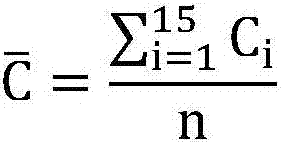

Calibration apparatus of on-site wide-range vacuum gauge and method thereof

InactiveCN102393275ALarge rangeHigh precisionFluid pressure measurementCapacitanceStandard uncertainty

The invention, which belongs to the measurement technology field, relates to a calibration apparatus of an on-site wide-range vacuum gauge and a method thereof. The calibration apparatus comprises: an air source, a pressure-reducing valve, a micro-adjustable valve, a monitoring vacuum meter, five vacuum stop valves, three capacitance film gauges, a pressure stabilizing chamber, a first stop valve, a mechanical pump, a second solenoid valve, a molecular pump, an all-metal angle valve, a vacuum chamber, a calibrated vacuum gauge, and a vacuum monitoring vacuum gauge. Besides, a current limitingair exhaust micropore is arranged in the vacuum chamber; and an air inlet micropore is arranged in the fifth vacuum stop valve. In addition, according to the method, a calibration range of the vacuumgauge is in a pressure intensity rang of from 10 <5> to 10 <-7> Pa; a standard uncertainty within the pressure intensity range of from 10 <5> to 10 < -1> Pa is 1.5%; a standard uncertainty within therange of from 10 <-2> to 10 <-6> Pa is 2.0%; and when the pressure intensity is 10 <-7> Pa, a standard uncertainty is 5 %; and the method has advantages of wide measuring range and high precision andis suitable for on-site operation. Moreover, the apparatus has advantages of small volume and light weight.

Owner:江苏东方航天校准检测有限公司

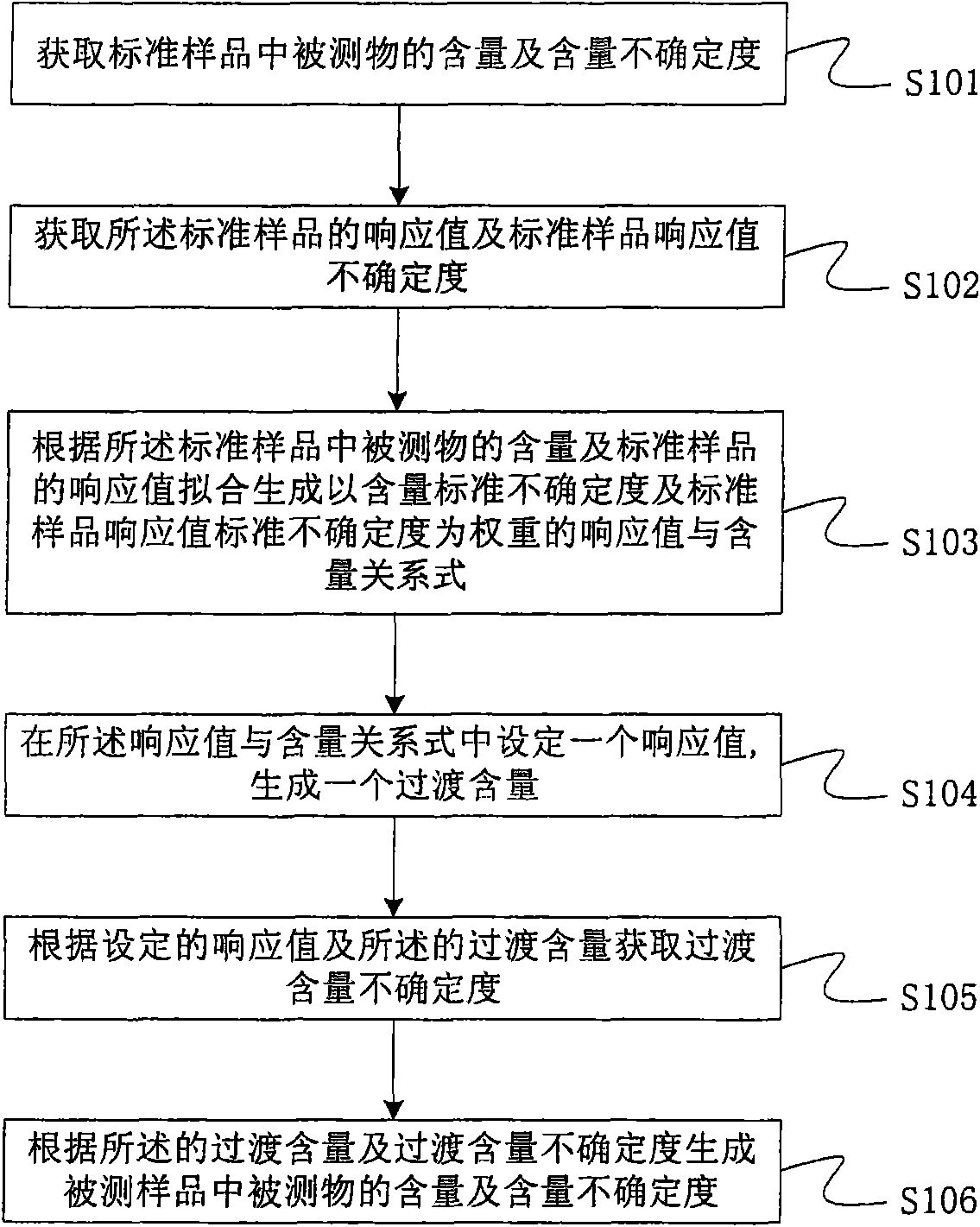

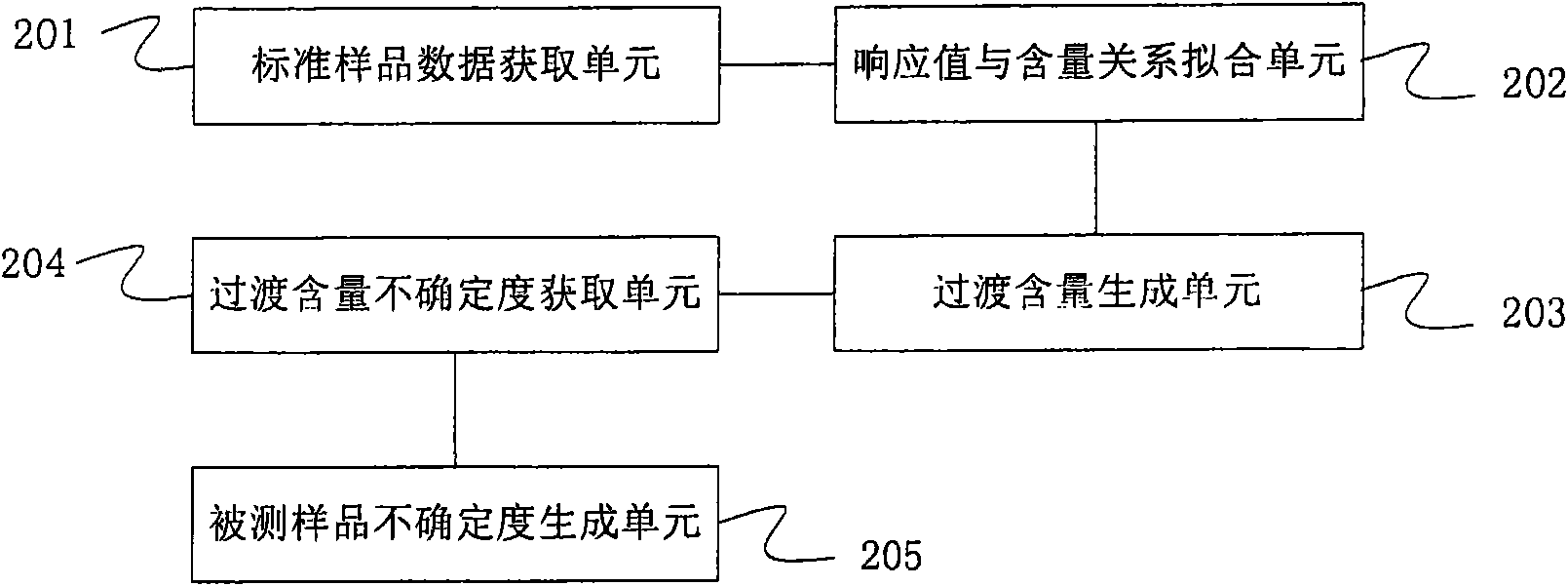

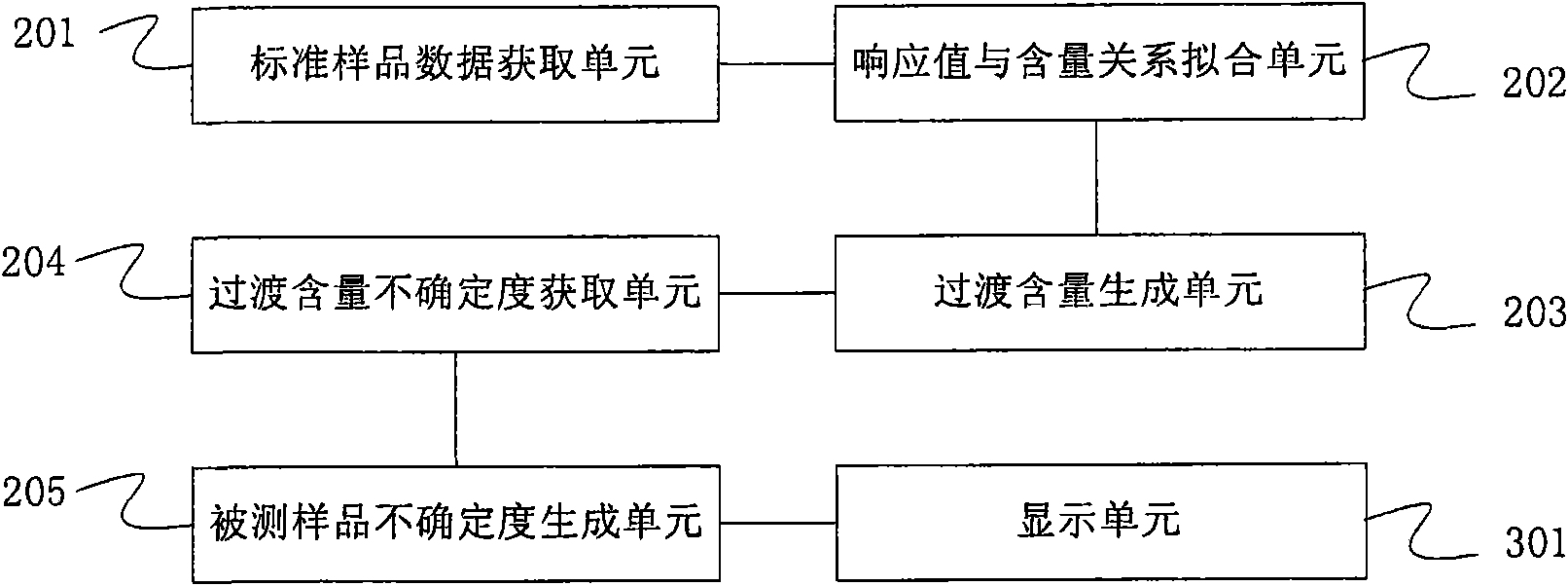

Method and device for analyzing uncertainty

InactiveCN101603958ARealize measurementColor/spectral properties measurementsAnalyteStandard uncertainty

The invention provides a method for analyzing uncertainty, which comprises: obtaining analyte content and content standard uncertainty in a standard sample; obtaining response of the standard sample and response standard uncertainty of the standard sample; fitting based on the analyte content in the standard sample and response of the standard sample to generate a relationship between response and content taking the content standard uncertainty and the response standard uncertainty of the standard sample as weight; setting a response in the relationship between response and content to generate a transition content; obtaining a transition content standard uncertainty based on the set response and the transition content; generating analyte content and content standard uncertainty in the standard sample based on the transition content and the transition content standard uncertainty. Through introducing uncertain factors of each point of a fitting curve, evaluation data processing of uncertainty in a measurement process is realized.

Owner:江苏力维检测科技有限公司

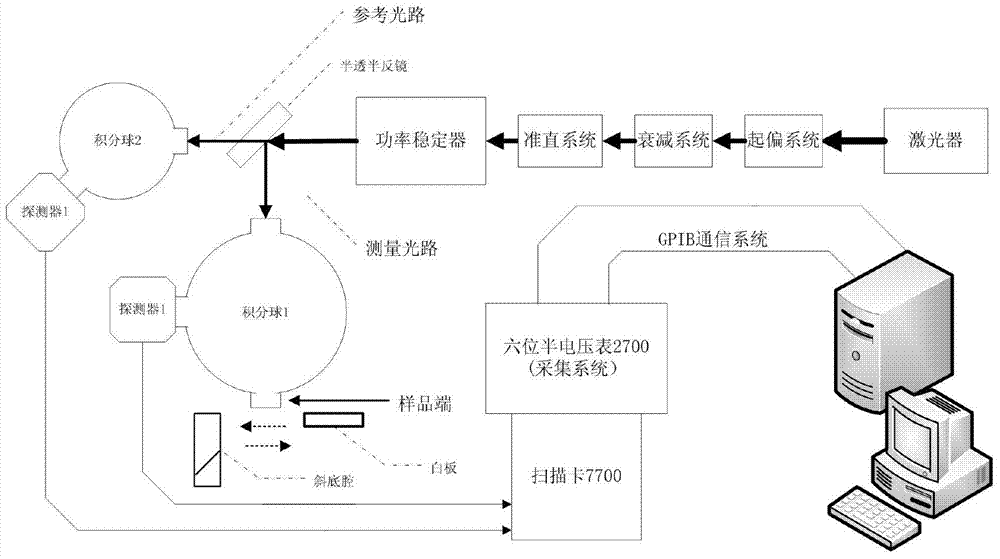

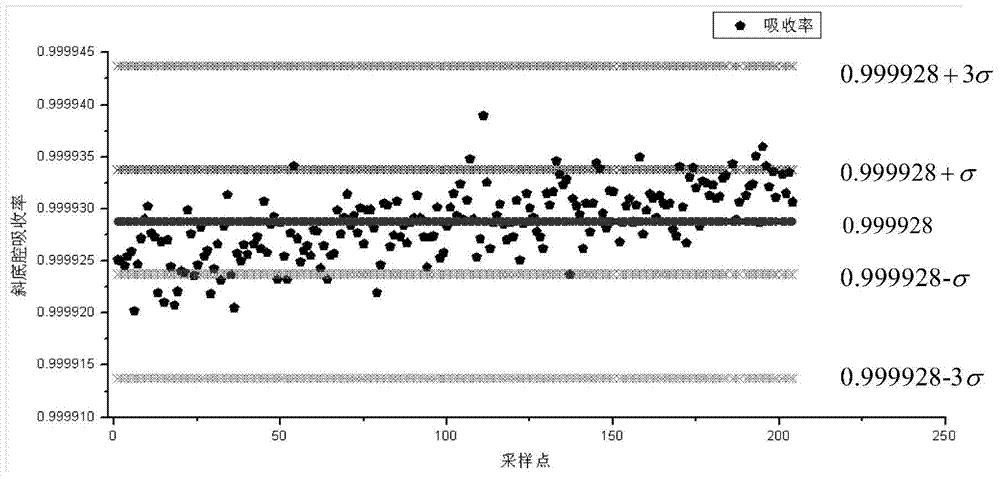

Method for measuring absorption rates of cavities on basis of substitution process and efficiency of detectors

The invention discloses a method for measuring absorption rates of cavities on the basis of a substitution process and the efficiency of detectors, and belongs to the field of optical radiation measurement. The method has the advantages that the standard uncertainty of the method is superior to 0.001%, and the method not only is applicable to measuring the absorption rates of the cavities with high absorption rates, but also is applicable to measuring the absorption rates of the common cavities; the measured absorption rates of the cavities with sloping bottoms are 0.999928+ / -0.000005; laser light is divided into measurement light beams and reference light beams by a partially-transparent and partially-reflecting mirror in measurement procedures, the stability of the laser light is monitored by a reference light path, signal voltages are measured, and ratios of the signal voltages of a signal light path to the signal voltages of the reference light path are defined as the efficiency of the detector; change trend of random errors due to drifting of the laser light has similar effects on the measurement light path and the reference light path, so that the random errors can be reduced by the aid of each ratio of two corresponding signals; the absorption rates of the cavities are measured by the aid of the efficiency of the detectors, accordingly, the standard uncertainty can be improved, and the absorption rates of the cavities with the high absorption rates can be measured.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

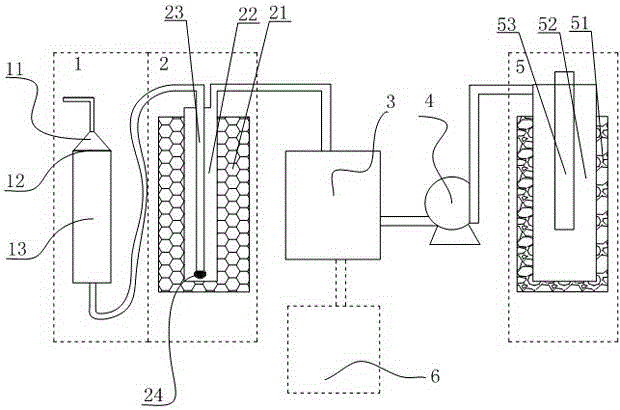

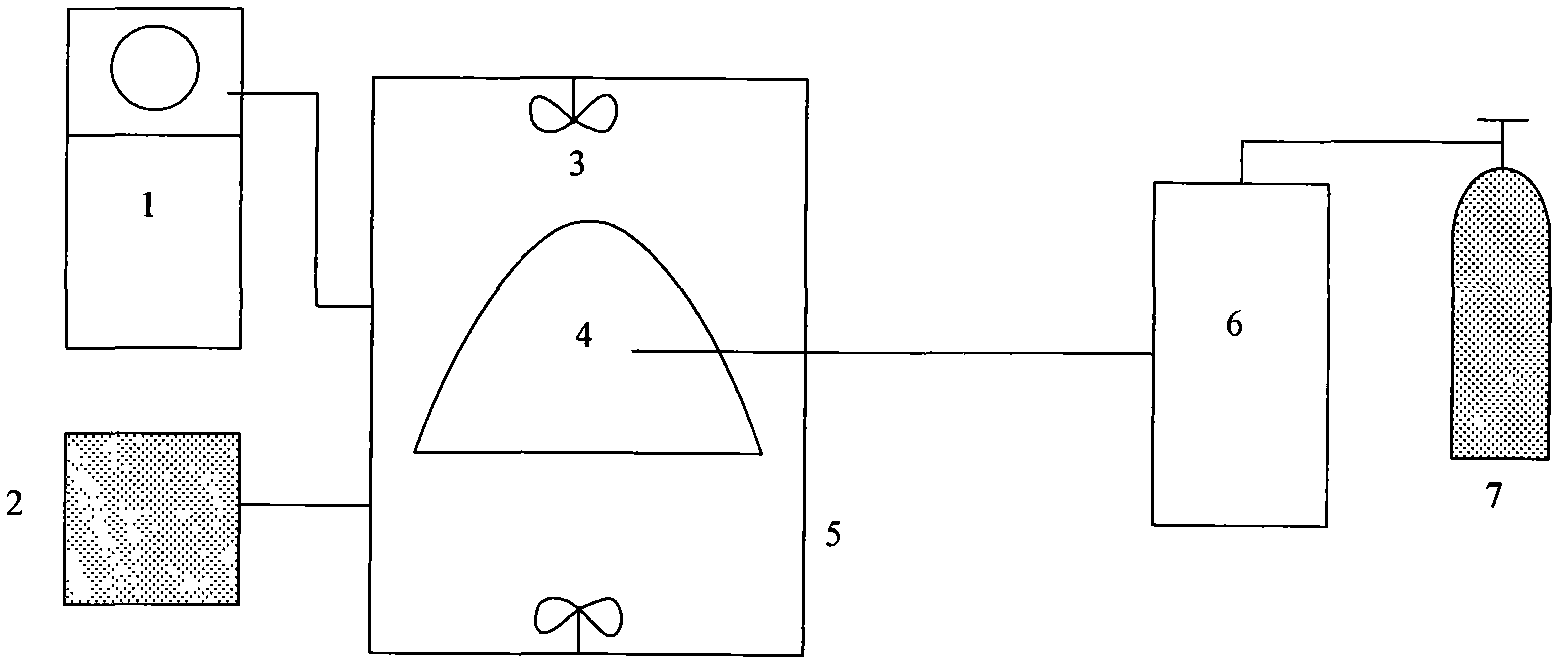

On-site calibration device of airborne tritium monitoring instrument

InactiveCN104536028AIncrease contact areaLarge dispersion areaX/gamma/cosmic radiation measurmentWater vaporStandard uncertainty

The invention discloses an on-site calibration device of an airborne tritium monitoring instrument. The on-site calibration device of the airborne tritium monitoring instrument comprises an air processor, a bubbling unit, a transmission instrument, an aspirator pump and a recovery unit, all of which are sequentially connected, wherein the air processor is used for filtering and drying inlet air, the bubbling unit is used for bubbling tritiated water to form saturated tritium flow, the transmission instrument is used for being connected with a calibrated detection instrument and measuring the activity and concentration of the tritium flow generated on site, the aspirator pump is used for pumping the tritium flow into the recovery unit for recovery after the activity and concentration of the tritium flow generated on site are detected, and the recovery unit is used for cooling and recovering the recovered tritium flow. The ranges of the activity and concentration of the tritium flow generated by the on-site calibration device of the airborne tritium monitoring instrument in a bubbling mode depend on the total activity of the tritium flow for bubbling and can meet the calibration of most existing nuclear facilities using the measuring span of the tritium monitoring instrument. The uncertainty of the synthesis standard of the activity and concentration of the bubbled tritium flow is less than or equal to 10 percent, and the recovery rate of the tritiated water vapor by the recovery unit is more than 99 percent.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

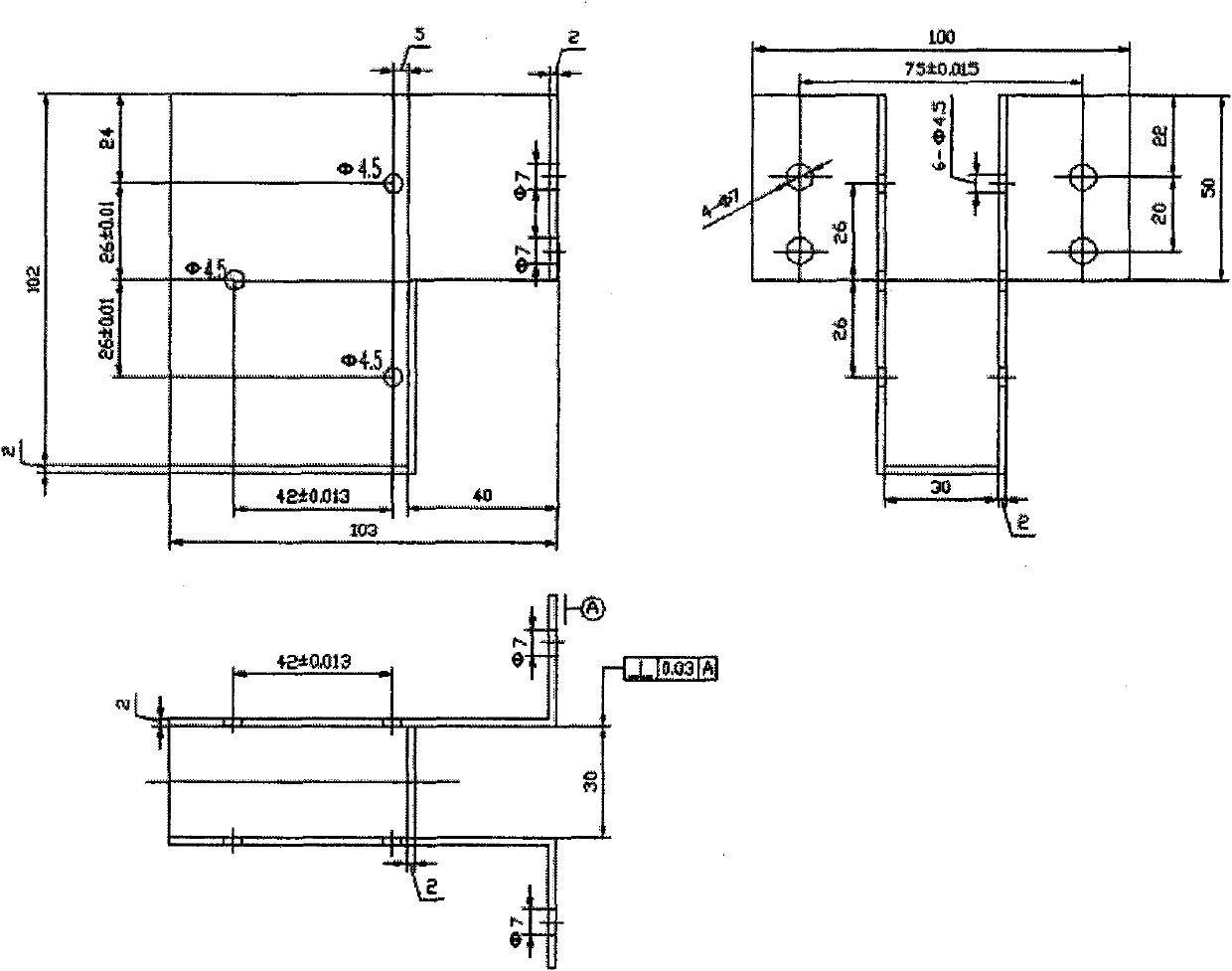

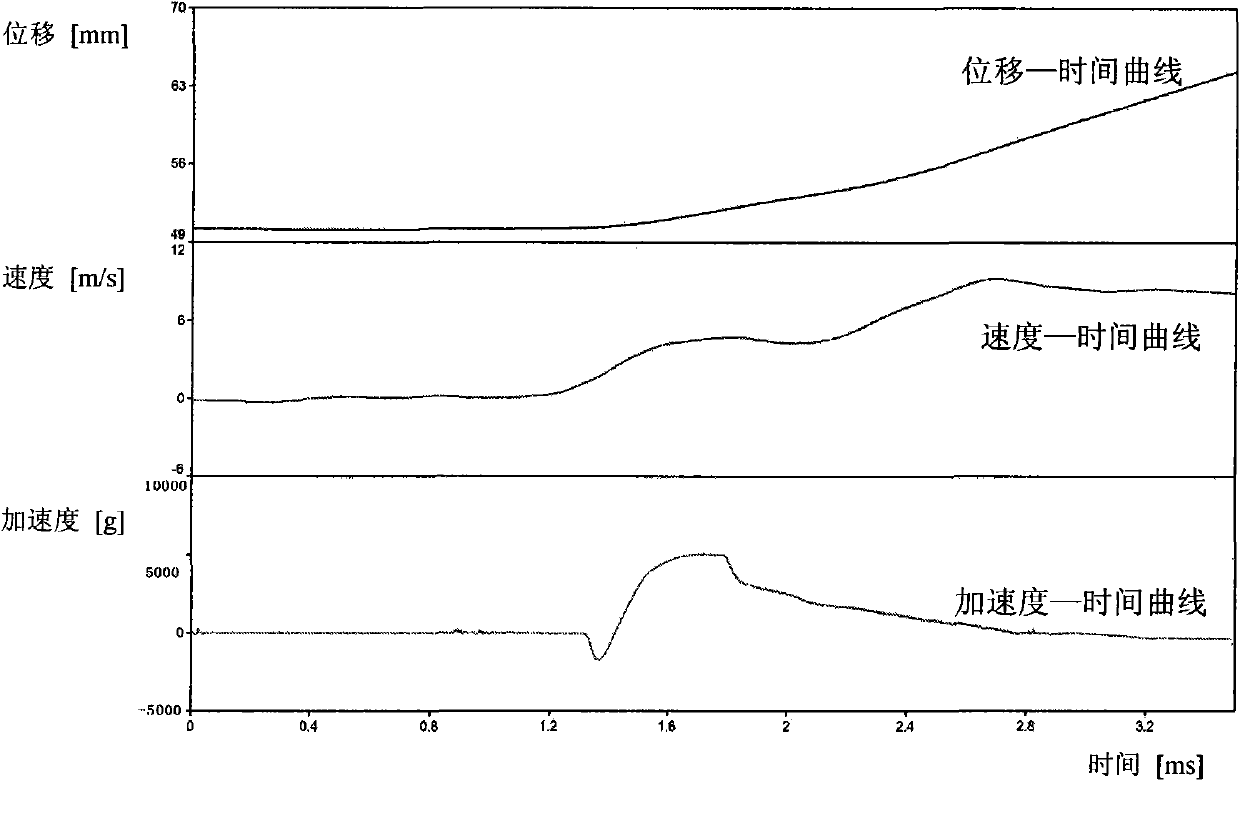

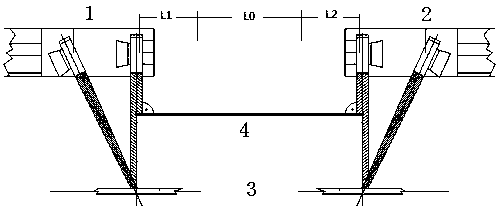

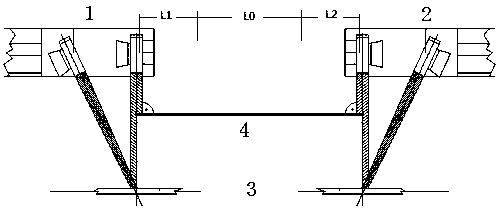

High-precision measuring method of separating characteristic of hot work separating device

InactiveCN101907444AEasy to installImprove measurement performanceAcceleration measurementUsing optical meansStandard uncertaintyHot work

The invention provides a high-precision measuring method of the separating characteristic of a hot work separating device, which gives consideration to the simple installation of a measuring structure, the safety and reliability of a measuring system and the high measuring precision. The uncertainty of the relative standard of the measuring system which is matched with the method is 0.184%. Compared with the conventional method, the measuring performance is more stable and the measuring precision is higher. The method not only can measure the displacement-time relationship, the separating time, the separating speed, the separating acceleration and the separating impulse of the hot work separating device with high precision, but also can be widely applied to measuring the motion characteristic of the motion parts of the other work done hot work product, and has good application foreground for accurately testing and researching the separating motion characteristic of the hot work separating device.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

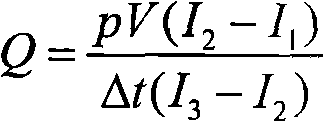

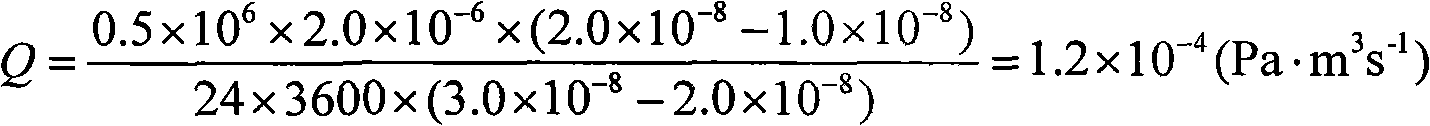

Uncertainty determination method of spacecraft total leak rate test result

The invention discloses an uncertainty determination method of a spacecraft total leak rate test result. The method comprises the following steps of: determining an uncertainty source; determining uncertainty component introduced by a system effect; determining uncertainty component introduced by measurement repeatability; determining synthesis standard uncertainty; and determining expansion uncertainty. By the system, the uncertainty caused by the system effect and the uncertainty caused by the measurement repeatability are firstly evaluated, and the synthesis standard uncertainty and the expansion uncertainty are obtained according to the test result by utilizing an uncertainty basic theory. Direct basis is provided for reliability evaluation of the spacecraft total leak rate test result.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

Method for evaluating uncertainty of torque wrench measuring result

InactiveCN102589802AReduce blindnessIntegrityForce/torque/work measurement apparatus calibration/testingStandard uncertaintyRepeatability

The invention discloses a method for evaluating the uncertainty of a torque wrench measuring result, comprising the following steps of: firstly, putting a torque wrench to be measured into a measurement system to measure the measured value of the torque wrench, and carrying out statistics on all uncertainty components which influence the measuring result; indicating the repeatability-introduced standard uncertainty component u1; and according to the instrument and sensor-introduced standard uncertainty component um, and the torque wrench-introduced standard uncertainty component uw, evaluating the standard uncertainty component u8 introduced by the error of a torque wrench setting value, the environment factor-introduced standard uncertainty component u9, and the torque loading device-introduced standard uncertainty component ul, synthesizing the standard uncertainty u6 equal to the square root of sum of the square of u1, um, uw, u8, u9 and ul, and computing the spreading uncertainty U=k u6 (k=2). According to the method, each uncertainty component introduced by the torque loading device is wholly analyzed in a quantization way, and the repeatability and the careless omission can be avoided, so that the problems of imperfection and inaccuracy when the uncertainty of a torque wrench standard evaluating device (a torque wrench standard evaluating apparatus) is evaluated and the uncertainty of the torque wrench measuring result is evaluated can be solved.

Owner:刘军

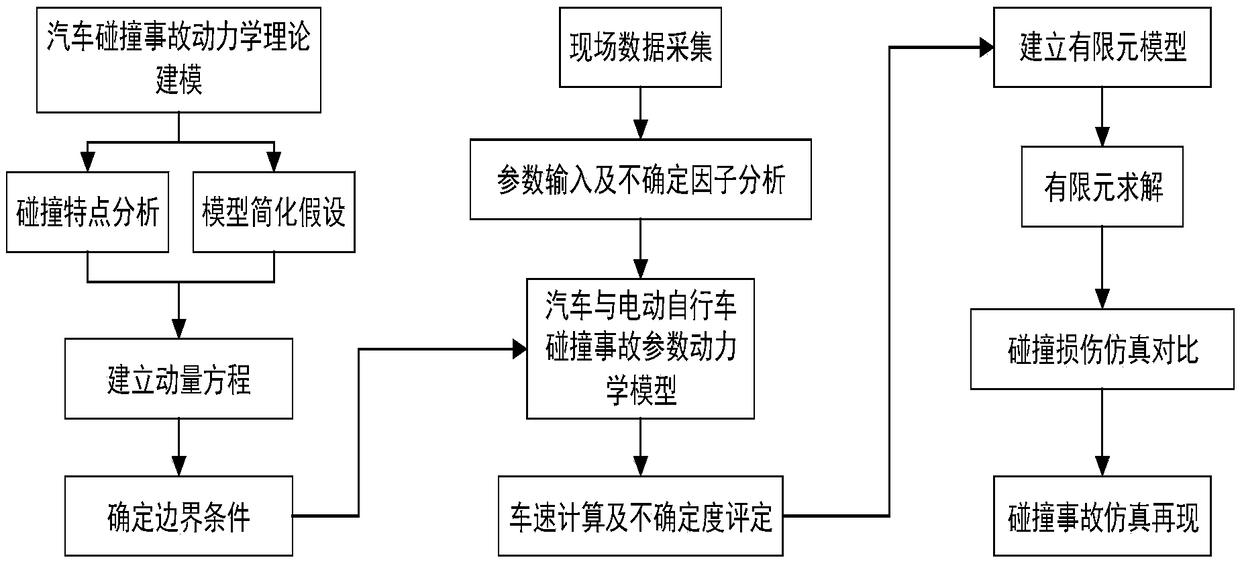

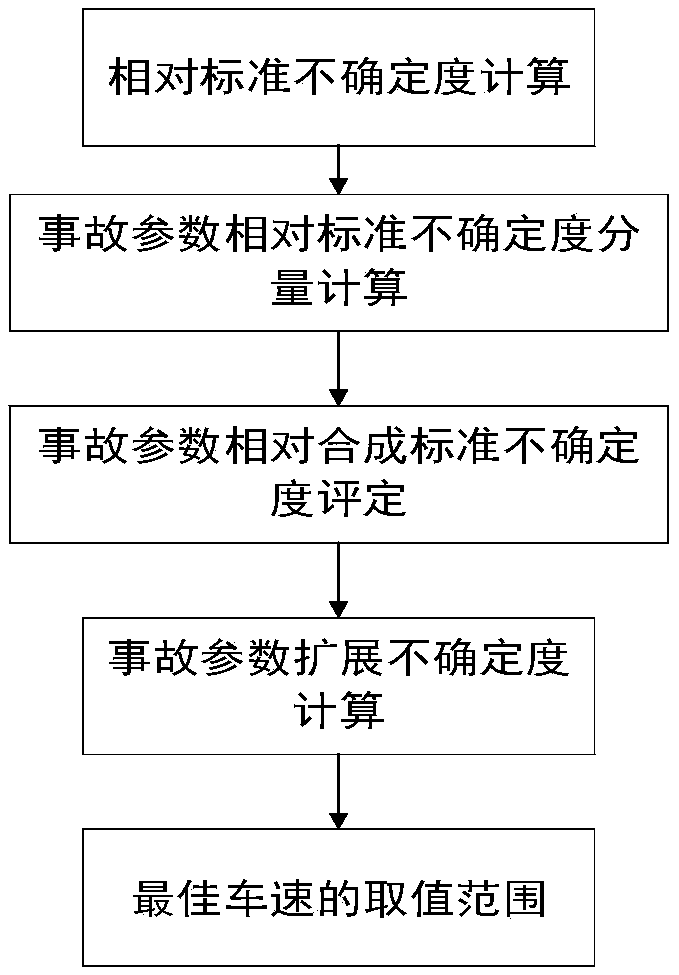

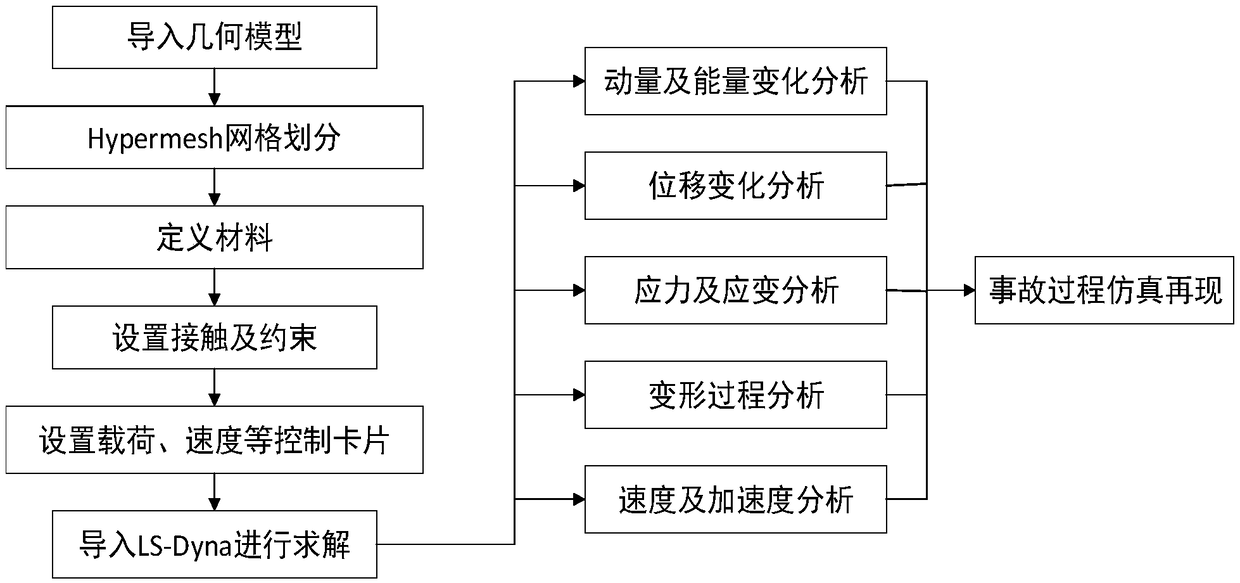

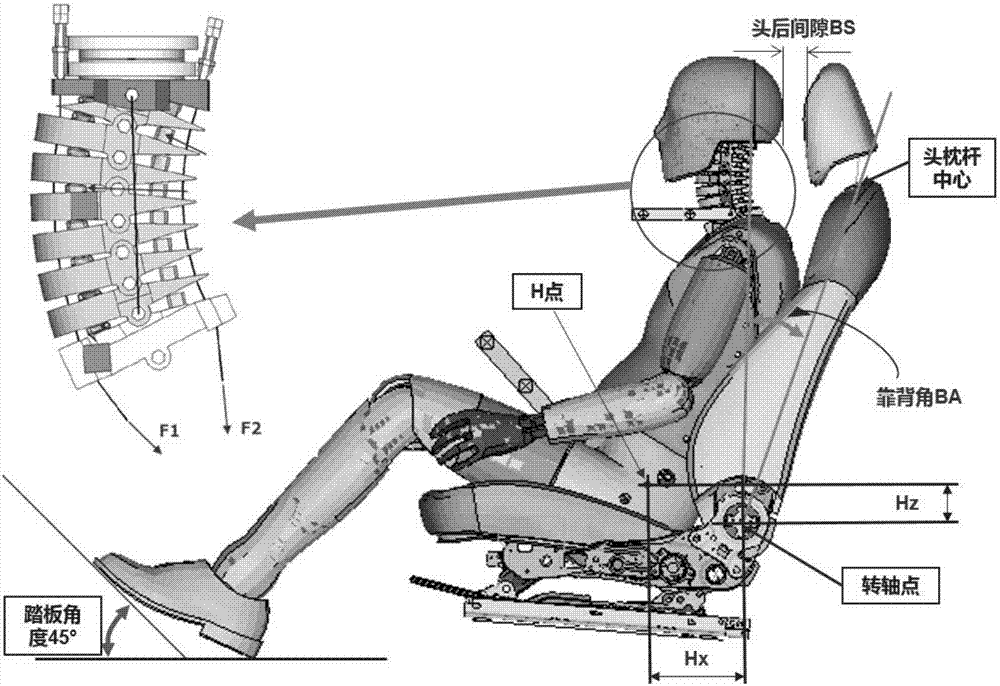

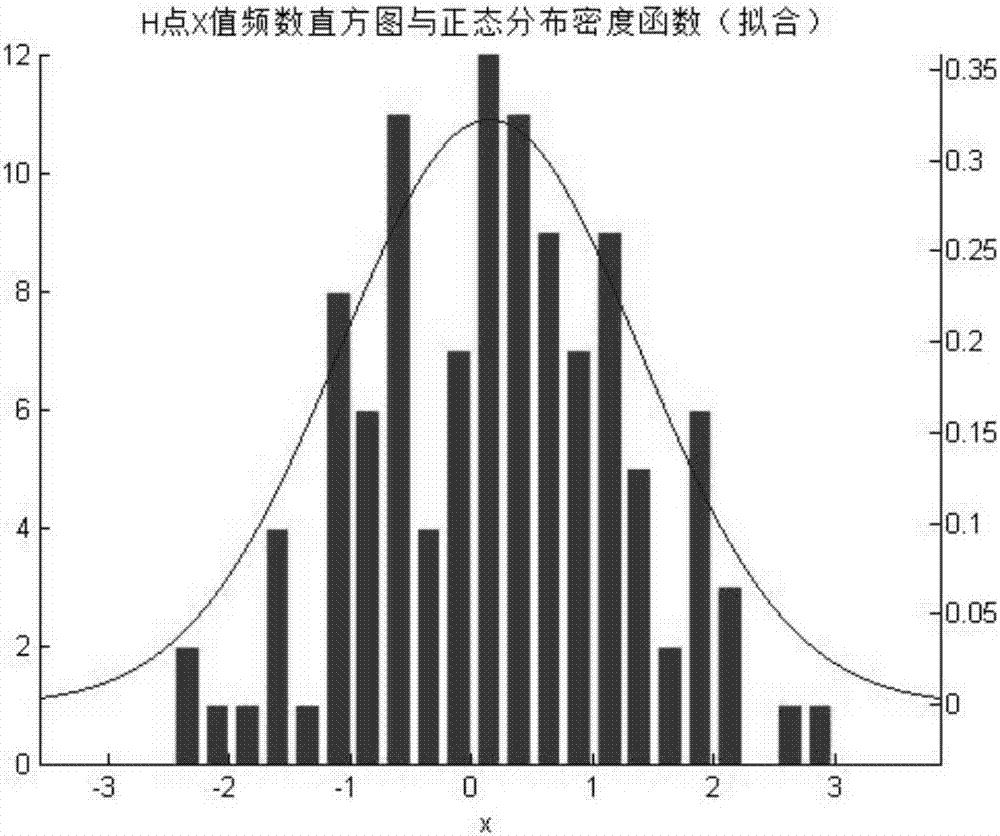

Computer simulation based automobile collision accident reconstruction method

PendingCN108920757AGeometric CADDesign optimisation/simulationStandard uncertaintyReconstruction method

The invention discloses a computer simulation based automobile collision accident reconstruction method. The method includes: acquiring accident scene data, and drawing an accident scene drawing; constructing an automobile collision kinematic model for computational analysis; finding out uncertainty impact factors, and determining an uncertainty assessment method; inputting related accident parameters including automobile brake traces, adhesion coefficients and collision angles; assessing accident automobile speed standard uncertainty u(xi); calculating a relative combined standard uncertaintycomponent u(yi) on the basis of the parameter u(xi), and further calculating relative combined standard uncertainty; solving extension uncertainty according to the relative combined standard uncertainty; introducing computer simulation verification, establishing an automobile finite element simulation model, and performing analytical calculation. By introduction of an uncertainty principle into an automobile accident judicial expertise process, influences of each uncertain factor on accident automobile speed can be considered fully; by introduction of computer simulation, an accident occurrence process is restored, and data support is provided for judicial expertise.

Owner:HUAIYIN INSTITUTE OF TECHNOLOGY

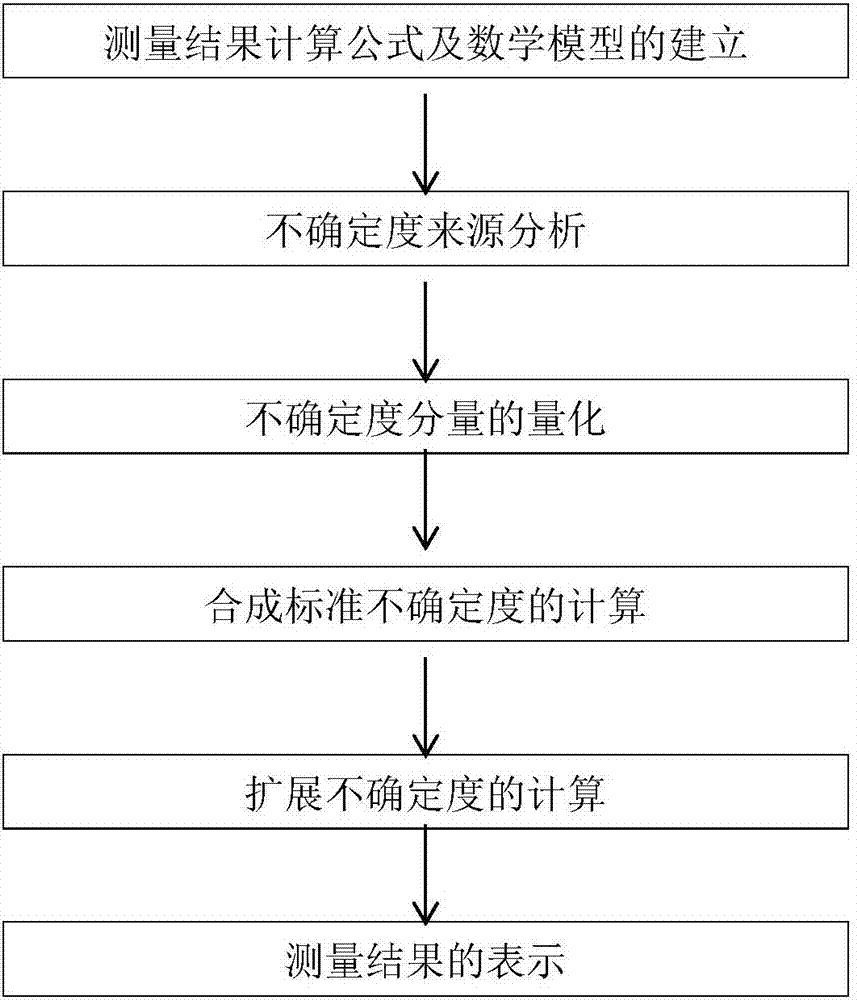

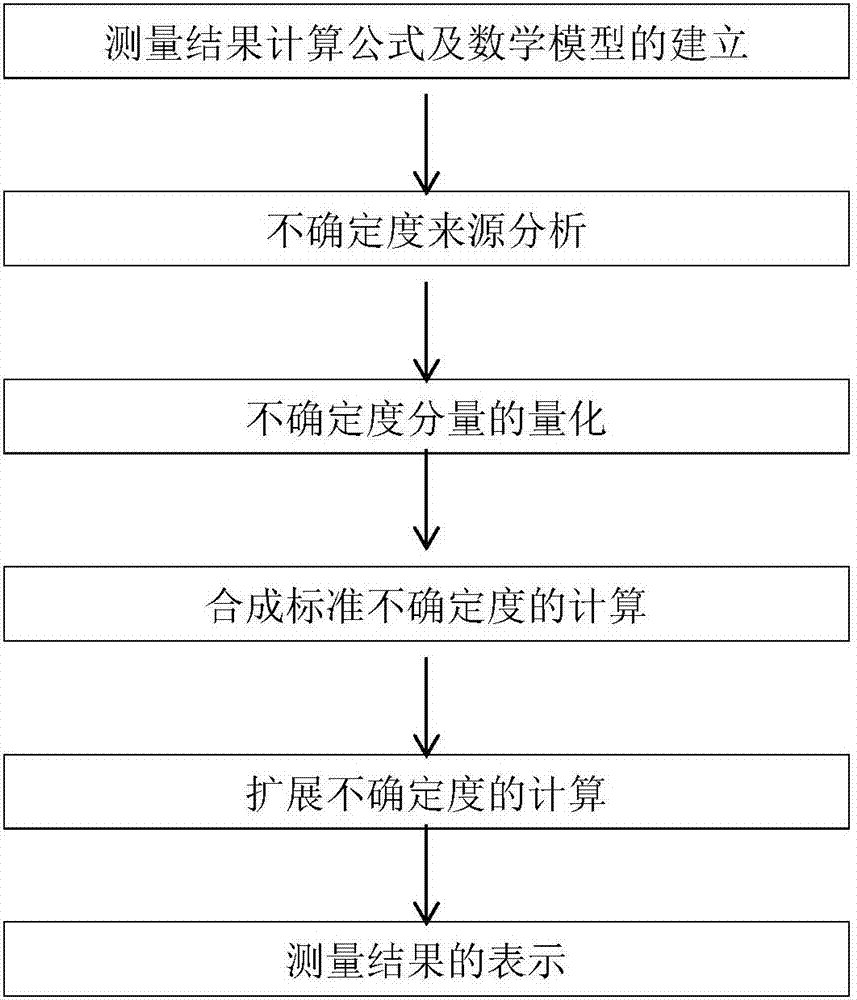

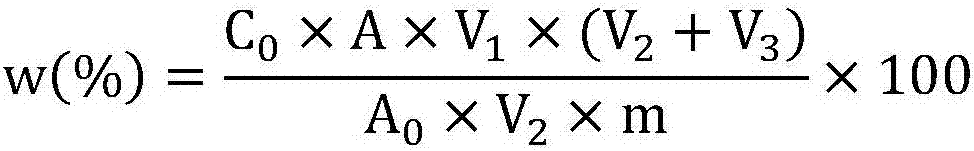

Method of evaluating uncertainty of test results of drug components by working curve method

InactiveCN107169292AReasonable calculationReliable calculationChemical property predictionSpecial data processing applicationsStandard uncertaintyMathematical model

The invention discloses a method of evaluating uncertainty of test results of drug components by a working curve method. The method comprises following steps: establishment of measurement result calculating formulas and mathematics models, analysis of uncertainty source, quantification of uncertainty components, calculation of synthesis standard uncertainty, calculation of expanded uncertainty and expression of measurement results. By means of the method in the invention, the main source affecting uncertainty can be accurately reflected so as to provide more reliable examination determination results.

Owner:INST OF FORENSIC SCI OF MIN OF PUBLIC SECURITY

Non-contact electrometer calibrating device and method

ActiveCN106443544AReduce uncertaintyAvoid jitterElectrical measurementsElectrical resistance and conductancePlanar electrode

The invention provides a non-contact electrometer calibrating device and method and aims at reserving a standard distance between the front end face of a non-contact electrometer and a standard flat plate electrode during calibration, improving the position accuracy of the electrometer and reducing test amount uncertainty difference of the calibrating device. The non-contact electrometer calibrating device comprises a standard planar electrode, a flat plate, a displacement platform, a fixing part and a depth ruler. The electrical portion includes a high-voltage source, a voltmeter, a voltage divider and a protective resistor. The non-contact electrometer calibrating method comprises the steps of electrometer installation, standard distance calibration, electrometer positioning and voltage testing. The stability during non-contact electrometer measurement and measurement value stability are improved. According to the best embodiment of the invention, the standard distance accuracy is up to 0.01 mm, and the standard uncertainty is 0.5% or below.

Owner:BEIJING INST OF RADIO METROLOGY & MEASUREMENT

Method for evaluating uncertainty of content detection result of polychlorinated biphenyl in single-point quantitative aquatic products

InactiveCN108680671ARealize uncertainty quantitative calculationAccurate and reliable quality and safety inspection dataComponent separationStandard uncertaintyInternal standard

The invention relates to a method for evaluating uncertainty of content detection result of polychlorinated biphenyl in single-point quantitative aquatic products and belongs to the technical field ofchemical detection. The method comprises the following steps: measuring the polychlorinated biphenyl content of the aquatic products by a gas chromatography-ECD method, quantifying by an internal standard method, analysing main sources of the uncertainty, quantifying uncertainty component, calculating synthetic standard uncertainty, calculating expanded uncertainty and representing the measuringresult. Accurate analysis and reasonable expression of uncertainty of sample treatment process, instrument measuring process and quantitative analysis process are realized by establishing uncertaintycalculation mathematic models, analyzing related uncertainty sources and performing reasonable quantitative calculation on each component.

Owner:FISHERIES SCI RES INST OF JILIN PROVINCE

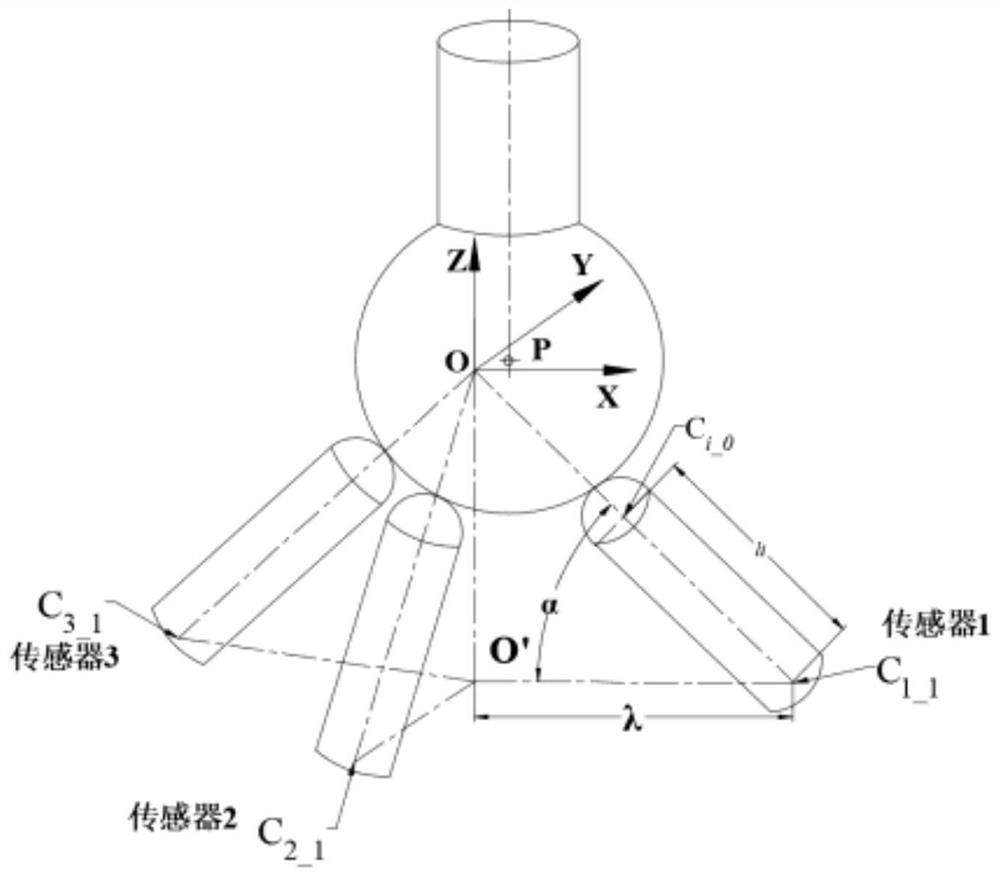

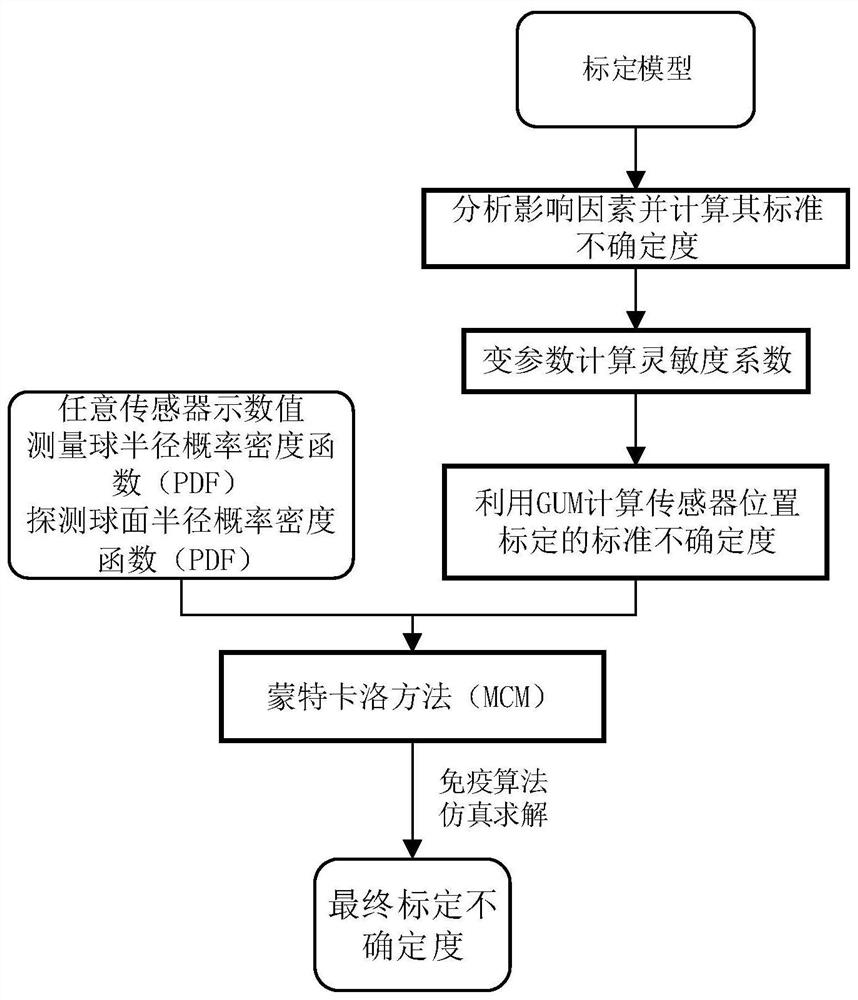

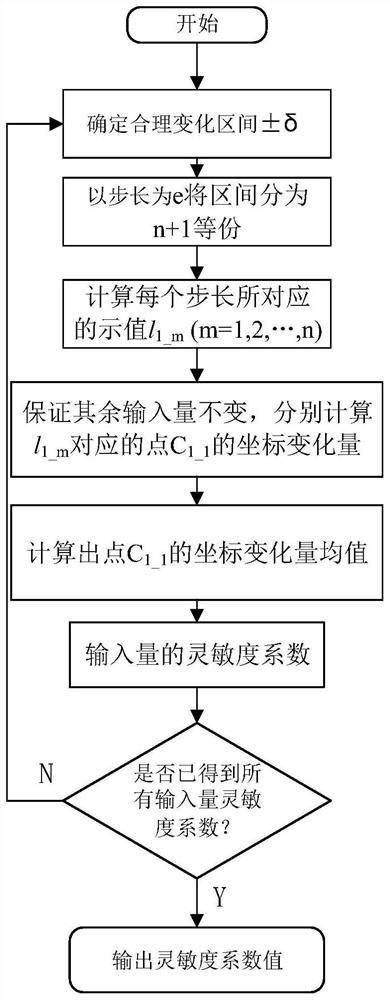

Metrology-based R-test calibration uncertainty evaluation method

ActiveCN113031514AAvoid complex calculationsAccurate assessmentGeometric CADProgramme controlAlgorithmStandard uncertainty

The invention discloses a metrology-based R-test calibration uncertainty evaluation method, which comprises the following steps: firstly, aiming at a contact type R-test calibration process, on the basis of a measurement model and a measurement principle of the contact type R-test calibration process, analyzing various influence factors and corresponding standard uncertainty, and calculating by adopting a variable parameter method to obtain a sensitivity coefficient; then, using the GUM for calculating the position coordinate uncertainty component of the sensor, and finally, achieving final calibration uncertainty evaluation based on the MCM. According to the method, an original evaluation method is improved based on the contact R-test calibration principle, so that the purpose of improving the calibration evaluation precision is achieved, and the method is widely applied to various contact R-tests.

Owner:SOUTHWEST JIAOTONG UNIV

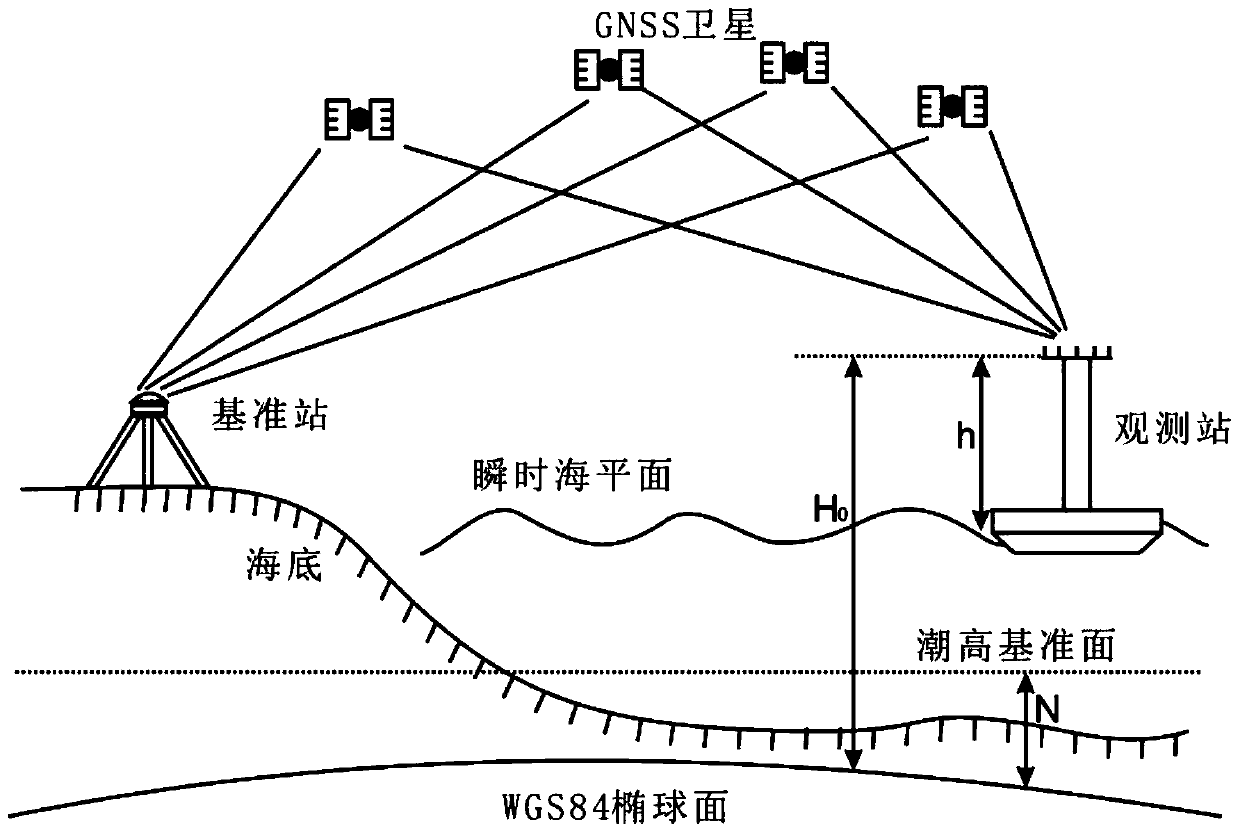

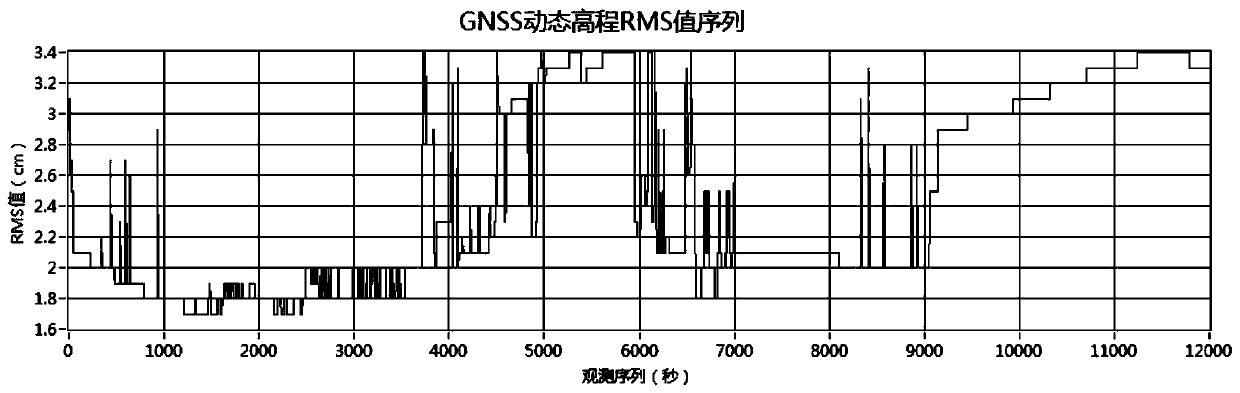

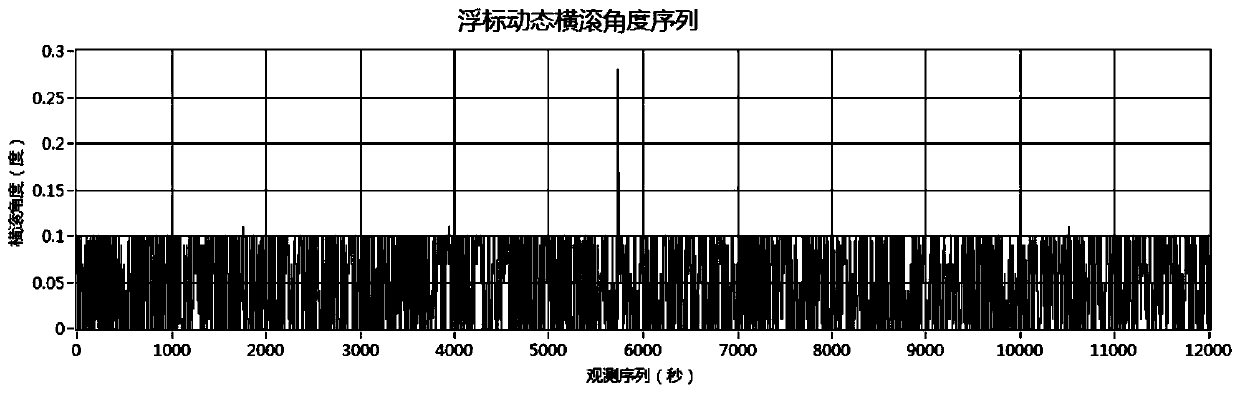

A tide level measurement uncertainty evaluation method based on a GNSS ocean buoy

ActiveCN109783846AQualified and reliable measurement resultsGood serviceSpecial data processing applicationsOcean observationsStandard uncertainty

The invention discloses a tide level measurement uncertainty evaluation method based on a GNSS ocean buoy. The method comprises the following steps: 1establishing tide level measurement model, determining an uncertainty component in the model; respectively calculating the dynamic standard uncertainty of the uncertainty component; synthesizing the standard uncertainty of the tide level measurementresult per minute; arranging the standard uncertainty per minute according to a time sequence to obtain a tide level synthesis standard uncertainty sequence in an observation time period; and finallycalculating the expanded uncertainty. According to the uncertainty evaluation method disclosed by the invention, the accuracy of uncertainty evaluation of the data result of the GNSS tide level measurement buoy can be improved, the GNSS tide level measurement buoy is ensured to provide a qualified and reliable measurement result, and the GNSS tide level measurement buoy can better serve in the field of marine observation.

Owner:THE FIRST INST OF OCEANOGRAPHY SOA +1

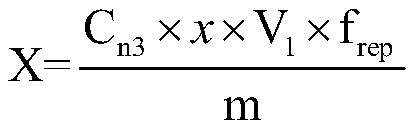

Uncertainty evaluation method for calculating polychlorinated biphenyl content detection results in aquatic products through internal standard curve method

InactiveCN108459126ARealize uncertainty quantitative calculationAccurate and reliable aquatic product quality and safety inspection dataComponent separationAquatic speciesMathematical model

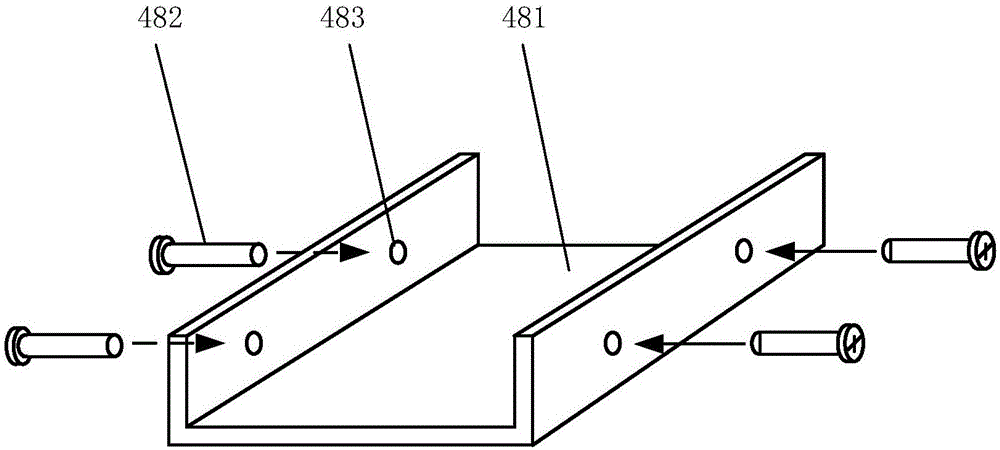

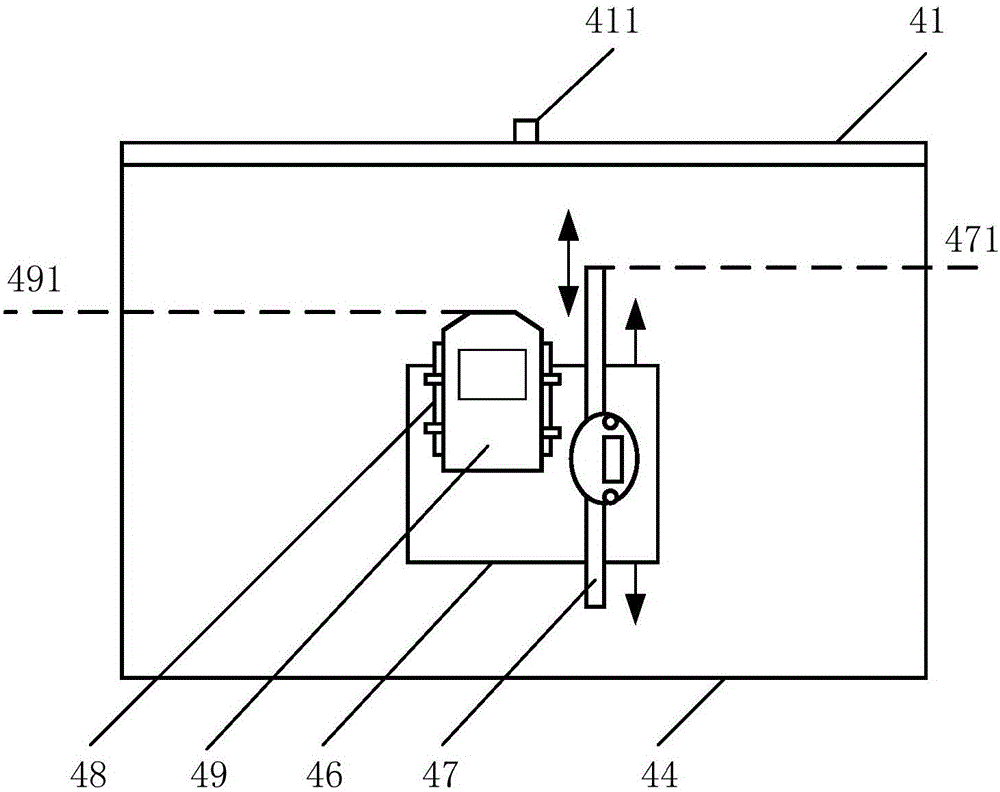

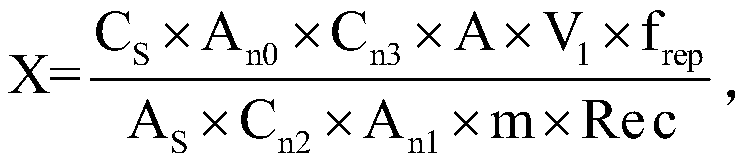

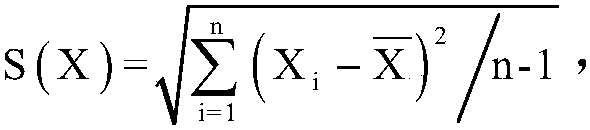

The invention discloses an uncertainty evaluation method for calculating polychlorinated biphenyl content detection results in aquatic products through an internal standard curve method and belongs tothe technical field of aquatic product quality safety detection and analysis. The method comprises the following steps: 1, calculating polychlorinated biphenyl content of aquatic species by adoptinga method for determining by a gas chromatograph and drawing an internal standard curve; 2, establishing a quantitative mathematical model X=(Cn3*x*V1*frep) / m of uncertainty of the polychlorinated biphenyl content detection results in aquatic products; 3, analyzing an uncertainty source; 4, determining assessment of each component of the uncertainty; 5, calculating the synthetic standard uncertainty. According to the method disclosed by the invention, by establishing the uncertainty calculation mathematical model, analyzing the related uncertainty source and performing reasonable quantified calculation on each component, accurate analysis and reasonable expression of the uncertainty in a sample treatment process, an instrument determination process and an internal standard curve quantitative analysis process can be realized.

Owner:FISHERIES SCI RES INST OF JILIN PROVINCE

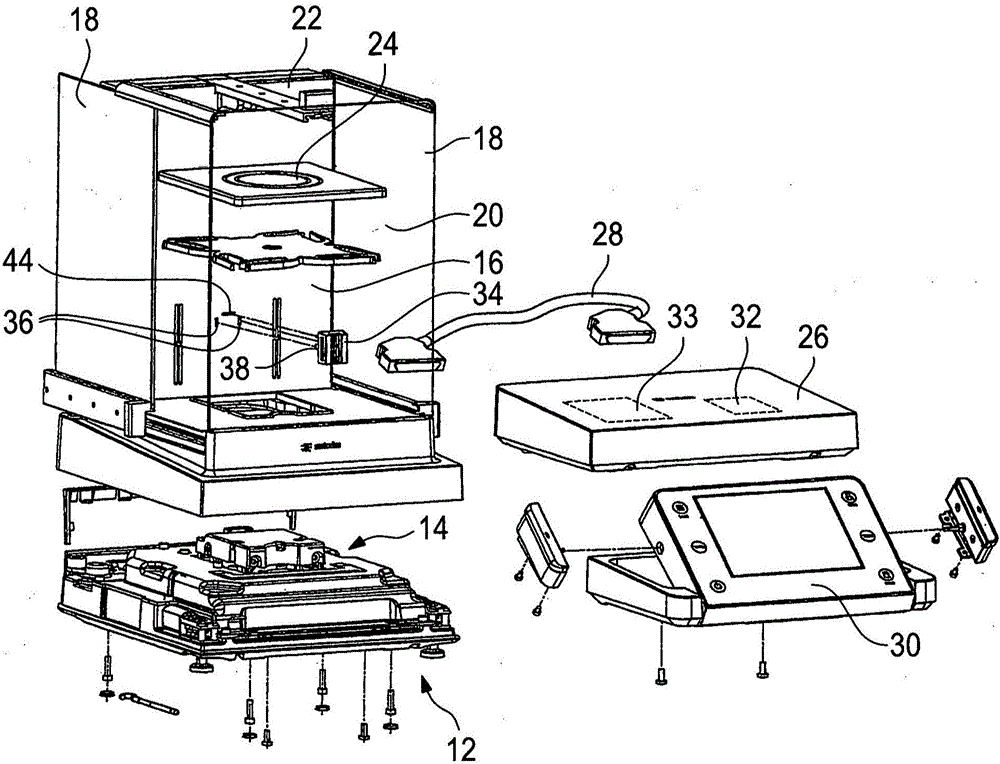

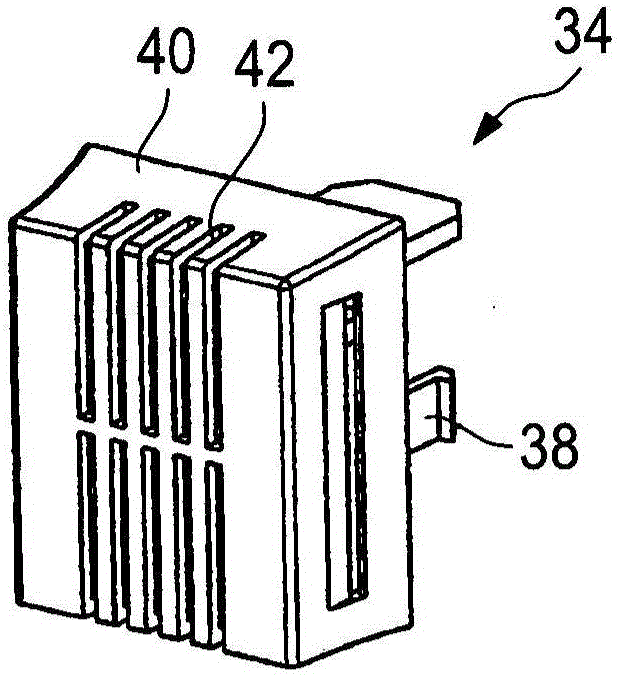

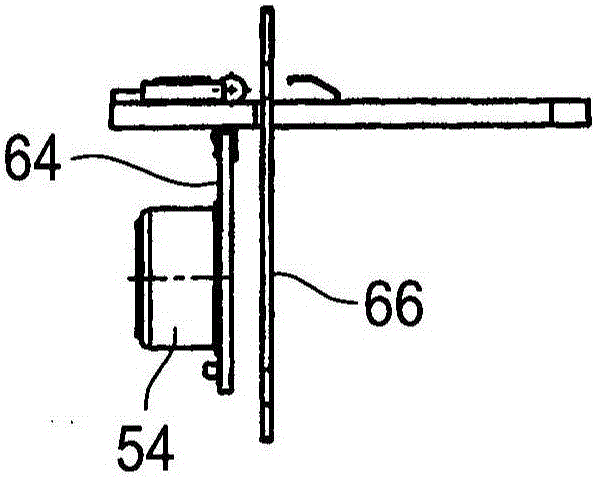

Precision scale or mass comparator with module for detecting a measurement uncertainty

InactiveCN105705917AAvoid transmission errorsSpecific gravity by measuring pressure differencesWeighing apparatus testing/calibrationStandard uncertaintyEngineering

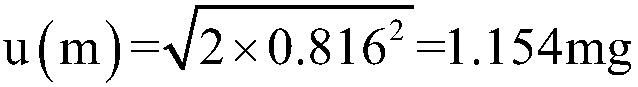

The invention relates to a precision scale with a scale chamber (16), a windshield (18, 20, 22) which surrounds the scale chamber (16), an air conditioning module (34) which is removably arranged in the scale chamber (16), a processor (32) which is arranged in the precision scale, a data input unit which is arranged on the precision scale, and a data transmission path with which data can be exchanged between the air conditioning module (34) and the processor (32), said processor (32) containing a measurement uncertainty detection module (33) with which the measurement uncertainty of the scale can be ascertained. The invention also relates to an air conditioning module for electrically coupling to a precision scale in a removable manner, said air conditioning module (34) forming a sealed unit and having an air pressure sensor (62), a humidity sensor (54), an air temperature sensor (52), and a part of a data transmission path via which data can be transmitted to a processor outside of the air conditioning module. The invention finally relates to a method for determining the measurement uncertainty of a precision scale comprising a scale chamber (16) which is separated from the surroundings by a windshield and in which an air pressure sensor (62), a humidity sensor (54), and an air temperature sensor (52) are arranged, said sensors (52, 54, 62) being coupled to a processor (32). Goods to be weighed, in the form of a test object, are weighed, and the following steps are carried out: - ascertaining the air pressure, the humidity, and the air temperature in the scale chamber (16) using the sensors (52, 54, 62); - weighing the test object; - determining the standard uncertainty of the weighing method; - determining the standard uncertainty of the mass of the test object; and - ascertaining a total uncertainty of the scale result.

Owner:SARTORIUS LAB INSTR GMBH & CO KG

Method for measuring uncertainty of industrial CT geometric dimension based on spherical die body

PendingCN111060042AReduce the effect of uncertainty componentsImprove measurement accuracyUsing wave/particle radiation meansSystems analysisStandard uncertainty

The invention relates to a method for measuring uncertainty of an industrial CT geometric dimension based on a spherical die body, and belongs to the technical field of industrial CT dimension measurement. The method comprises the following steps: selecting a ball model as a detected workpiece and carrying out calibration detection to obtain a calibration certificate; performing industrial CT scanning reconstruction on the detected workpiece; completing geometric dimension measurement of the ball model; and calculating standard uncertainty of geometric dimension measurement; and calculating expansion uncertainty. The method is based on the calibrated ball model, and evaluation steps and a mathematical model for industrial CT measurement uncertainty of a specific task are preliminarily established by adopting an experimental evaluation method; the system analyzes the influence of a calibration process, a measurement process, a detected workpiece, a system error and the like on the uncertainty of the measurement result and the maximum measurement uncertainty contribution mainly comes from the system error of the industrial CT equipment, and the influence of the uncertainty componentcan be greatly reduced by performing system calibration on the industrial CT equipment before measurement and thus the measurement accuracy is improved.

Owner:INST OF APPLIED ELECTRONICS CHINA ACAD OF ENG PHYSICS

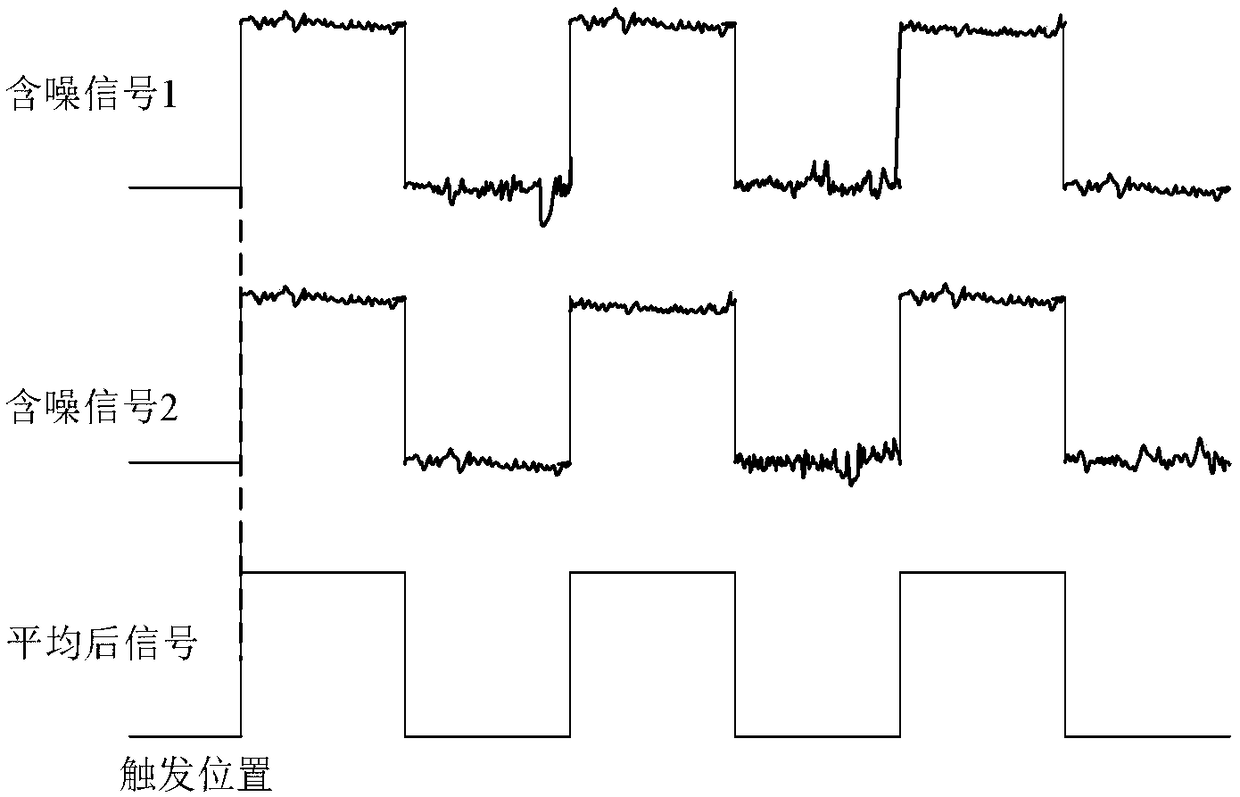

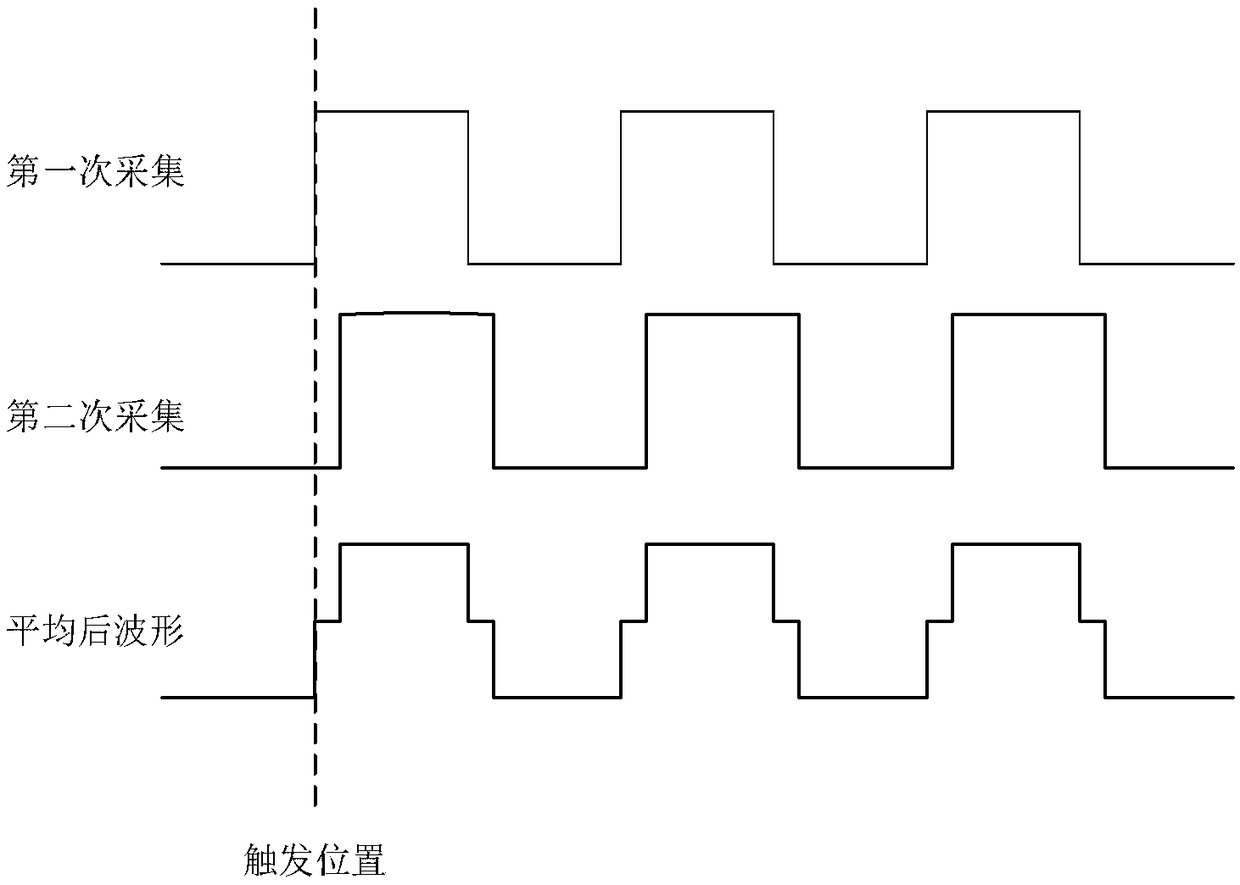

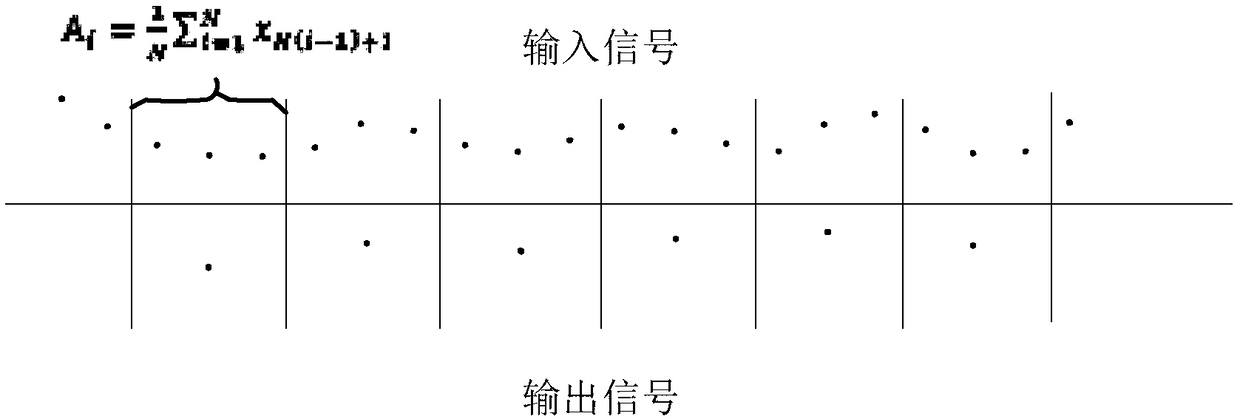

Digitalizer mean filtering method based on density estimation

ActiveCN109194305AImprove signal-to-noise ratioAvoid influenceDigital technique networkPattern recognitionSpectral density estimation

The present invention discloses a digitalizer mean filtering method based on density estimation. The method comprises the steps of: performing oversampling of a digitalizer, performing grouping for anobtained data sample sequence to obtain a plurality of sub samples, adding the sub samples to the density estimation samples, employing a fusion method of density estimation and Bayes information toobtain a probability density function of the data sample sequence, and calculating and obtaining the standard uncertainty of the data sample sequence; and performing re-grouping of the data sample sequence according to the oversampling multiples, obtaining the confidence interval of each sub sample after the repeat groups are obtained according to the standard uncertainty to obtain gross error elimination, and performing average extraction of the obtained samples to obtain final samples. The digitalizer mean filtering method based on density estimation can perform density estimation for the data sample sequence grouping obtained by sampling, and can set the confidence interval based on the density estimation result to perform gross error elimination so as to allow the mean filtering resultto be more accurate.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Method for online calibration of width gauge

ActiveCN109990712ANo maintenance timeSave time and costUsing electrical meansUsing optical meansMetrologyStandard uncertainty

A method for online calibration of a width gauge belongs to the technical field of metrology and calibration methods, and is used for on-line accurate calibration of width gauges. The technical solution is that the method comprises the following steps of determining the relationship between the quantity provided by the measurement standard and a corresponding indication, determining the relationship of a measurement result obtained by the indication by using the information, and sequentially performing calibration measurement, calculation of an indication value error of the width gauge, calculation of repeatability of the indication, calculation of indication drift, data processing of calibration methods, and evaluation of standard uncertainty. The method provided by the invention, which is a major breakthrough in the online calibration problems of large equipment in the metallurgical industry, uses the error theory to design the standard equipment, determines the measurement requirements of the product, uses statistical methods to check the consistency of the measurement results, evaluates the measurement uncertainty of the measurement results and proves that the requirement meeting of quantity transfer and calibration development. Compared with the traditional inspection calibration method, the method provided by the invention saves a lot of time and labor costs, and is morescientific, active, reliable, accurate and easier to implement.

Owner:TANGSHAN IRON & STEEL GROUP +1

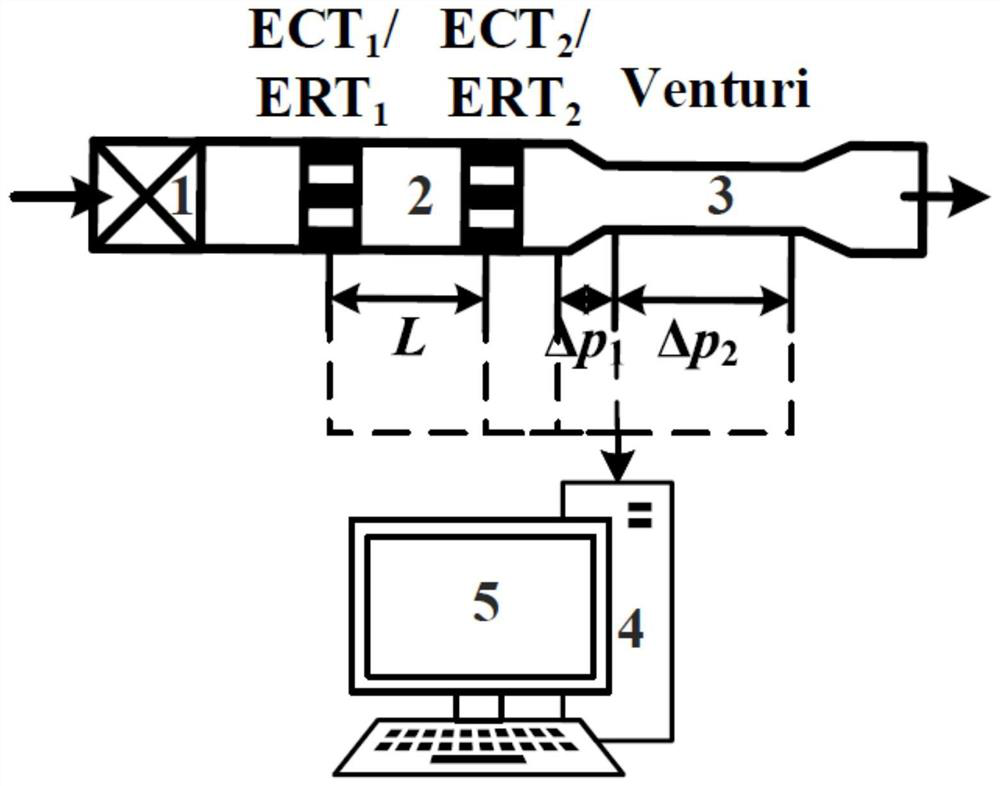

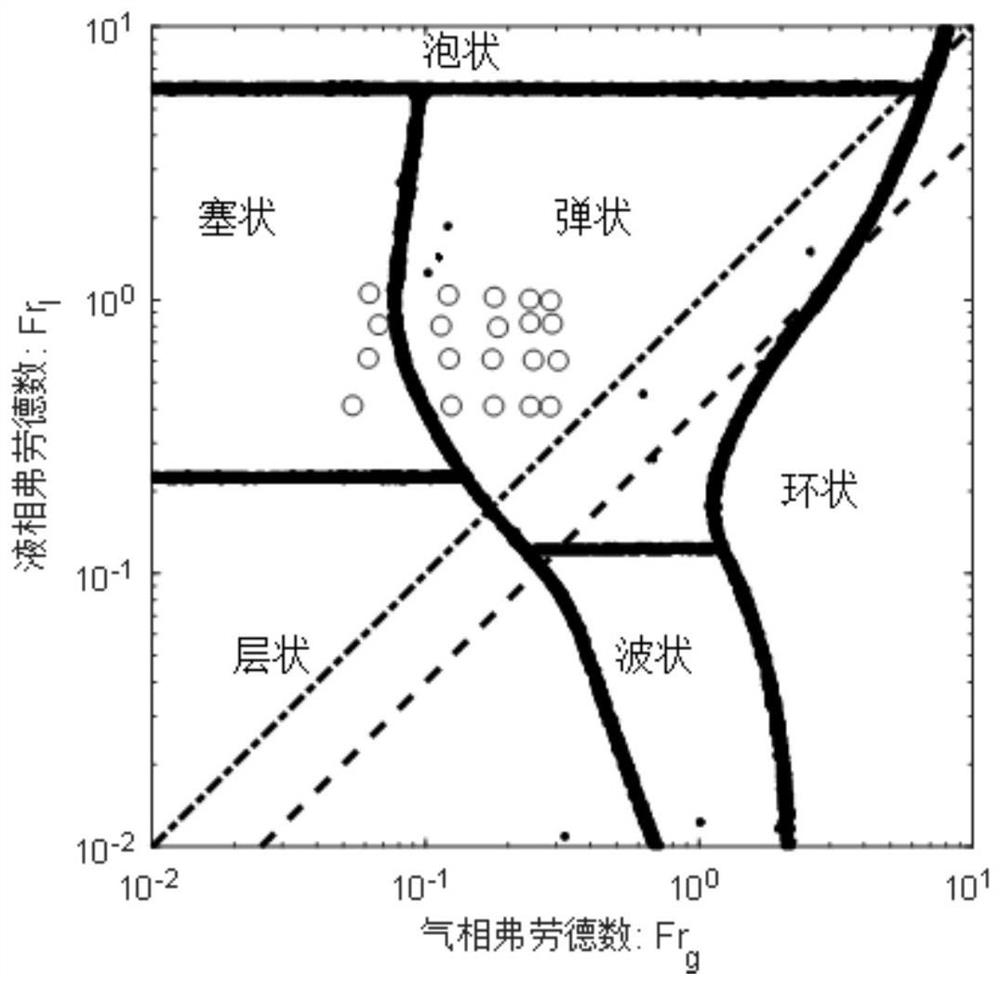

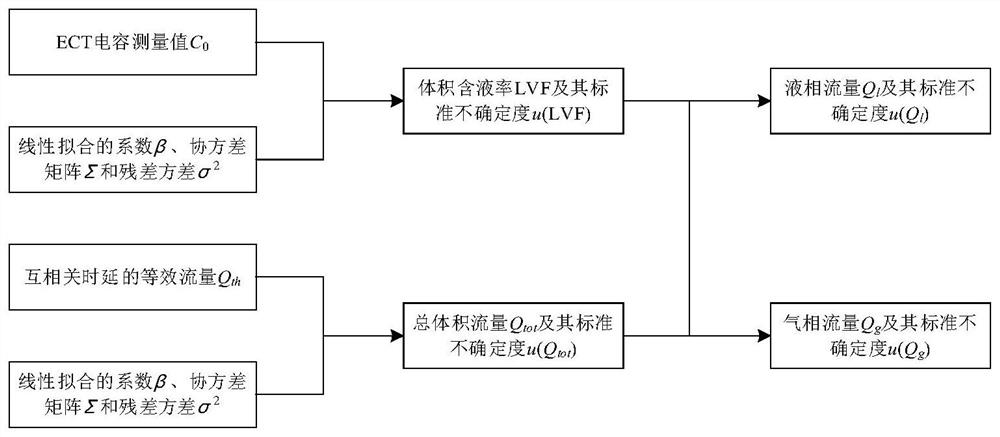

Multi-phase flow measurement method and system based on uncertainty analysis

The invention discloses a multi-phase flow measurement method and system based on uncertainty analysis. The method comprises the following steps of: based on an equivalent flow of cross-correlation time delay and a capacitance measurement value, obtaining liquid phase flow and relative standard uncertainty thereof, and gas phase flow and standard uncertainty thereof through multiple linear regression fitting; based on the capacitance measurement value and a differential pressure measurement value, obtaining liquid phase flow and relative standard uncertainty thereof as well as gas phase flow and standard uncertainty thereof through multiple linear regression fitting; on the basis of the differential pressure measurement value and the equivalent flow of cross-correlation time delay, obtaining liquid phase flow and relative standard uncertainty thereof as well as gas phase flow and standard uncertainty thereof through multiple linear regression fitting; and comparing the uncertainties obtained in different modes, and taking the gas and liquid flow corresponding to the minimum uncertainty and the uncertainty as quality indexes for flow measurement. Errors of measurement results can be reduced, and operation and maintenance personnel can be helped to know the accuracy of the measurement results.

Owner:深圳市联恒星科技有限公司

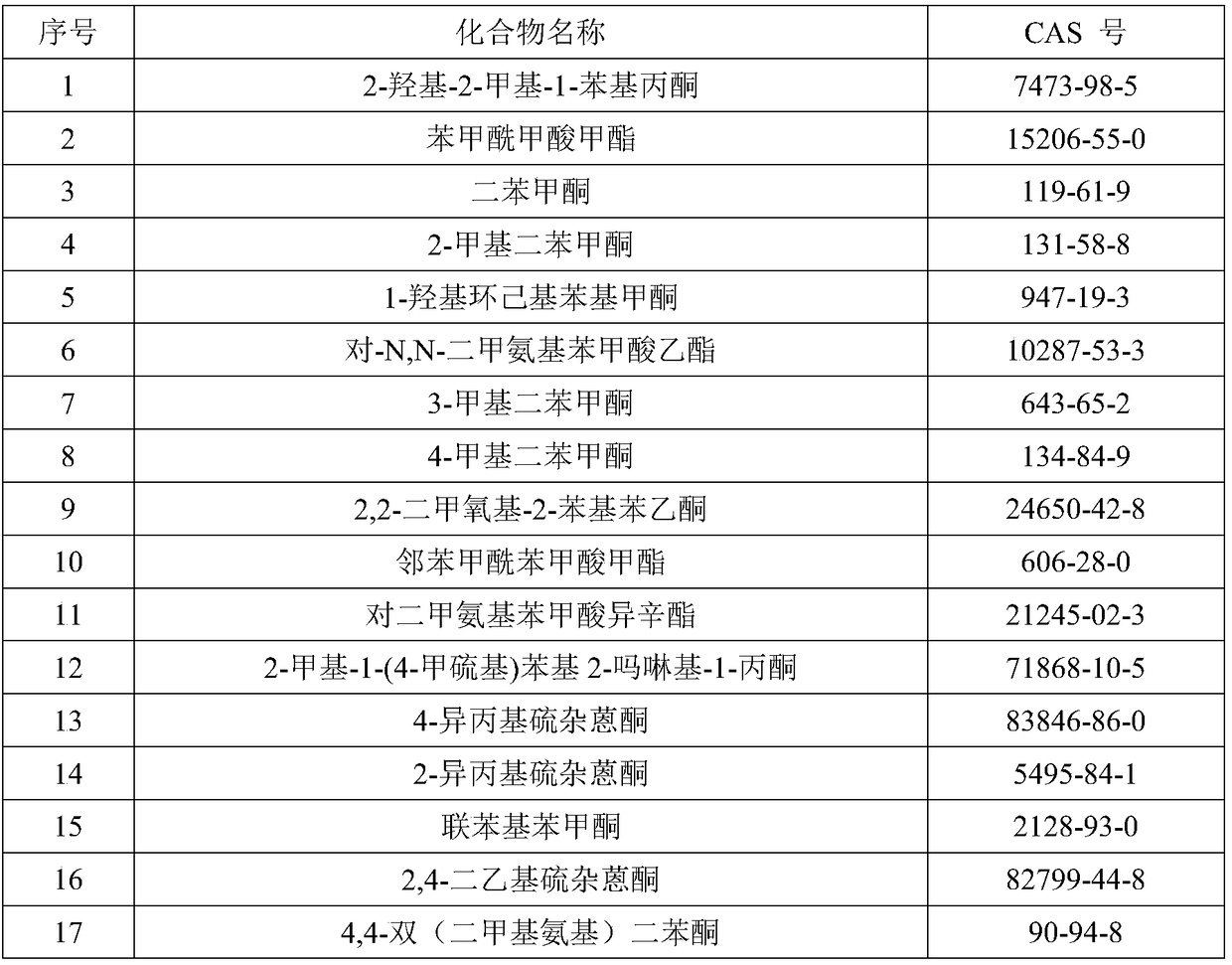

A photoinitiator mixed solution standard material and a preparing method thereof

ActiveCN108931591AReduce uncertaintyDoes not affect deliveryComponent separationMetrological traceabilityStandard uncertainty

A photoinitiator mixed solution standard material and a preparing method thereof are disclosed. The standard material is a standard solution containing 18 photoinitiators, with the definite concentration value and corresponding combined standard uncertainty of each photoinitiator meeting related standard requirements. The method includes (1) purifying 18 photoinitiator crude products; (2) evaluating definite values and uncertainty of the purified products; (3) preparing a mixed solution standard of the 18 photoinitiators; and (4) evaluating definite values and uncertainty of the mixed solutionstandard material of the 18 photoinitiators. The photoinitiator mixed solution standard has good stability during storage at 0 DEG C, a definite value evaluating method is accurate, source tracing isreliable, and relative combined uncertainty is low (0.5-2.0%). The photoinitiator mixed solution standard material can overcome a problem that testing methods at present cannot achieve metrological traceability, increases comparison consistency of each unit testing result, and fills the gap of development of photoinitiator mixed solution standard materials at home and abroad.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

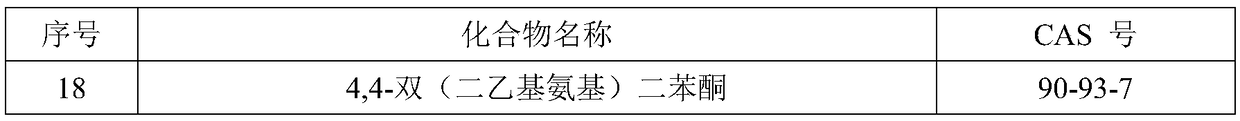

Bayes principle-based complex experiment uncertainty evaluation method

InactiveCN107122547AImprove inspection levelQuality improvementDesign optimisation/simulationSpecial data processing applicationsTruth valueAlgorithm

The invention relates to a Bayes principle-based complex experiment uncertainty evaluation method. The method comprises the following steps of: determining that a complex experiment is measured and determining main influence factors of the complex experiment; obtaining probability density distribution functions of the influence factors of the complex experiment; carrying out experiment sampling according to the probability density distribution functions of the influence factors by adoption of a Latin hypercube sampling method, so as to obtain an experiment design table of the influence factors, and carrying out experiment according to parameters of the design table to obtain a result of the complex experiment under each input parameter, wherein a part of data of the experiment result is used as prior samples and the other part is used as currently measured samples; calculating a mean value of the prior samples and a standard difference of the mean value, and a mean value of the currently measured samples and a standard difference of the mean value; and calculating a measured truth value, a standard uncertainty and a comprising interval corresponding to a comprising probability via posterior distribution, and taking the calculation result to evaluate the uncertainty. According to the method, when experiments results of complex experiments are given, the experiment uncertainties can be given and the experiment results can be evaluated, so that experiment improvement schemes can be made.

Owner:UNIV OF SHANGHAI FOR SCI & TECH +1

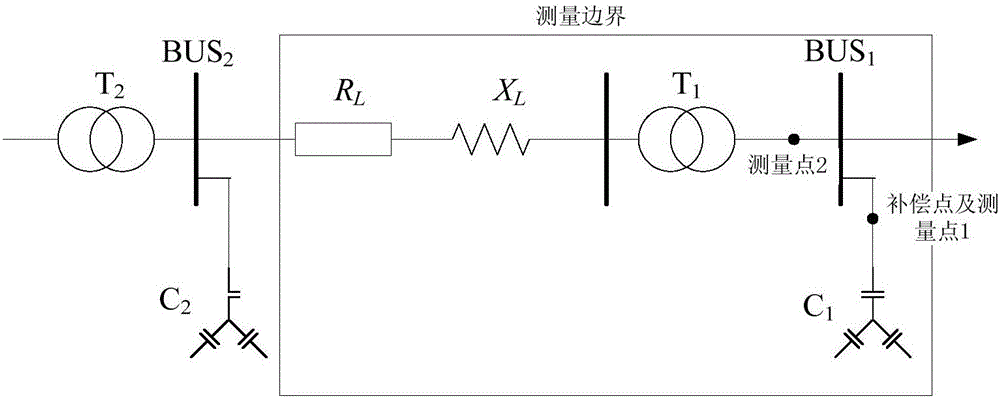

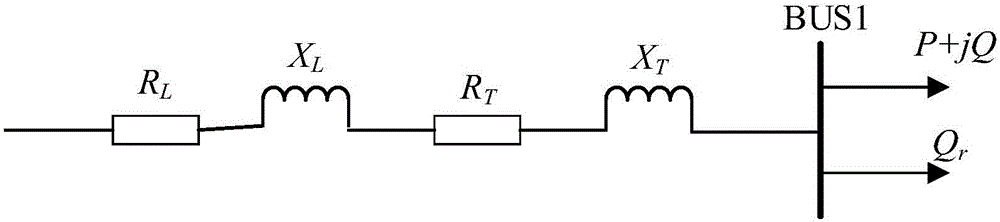

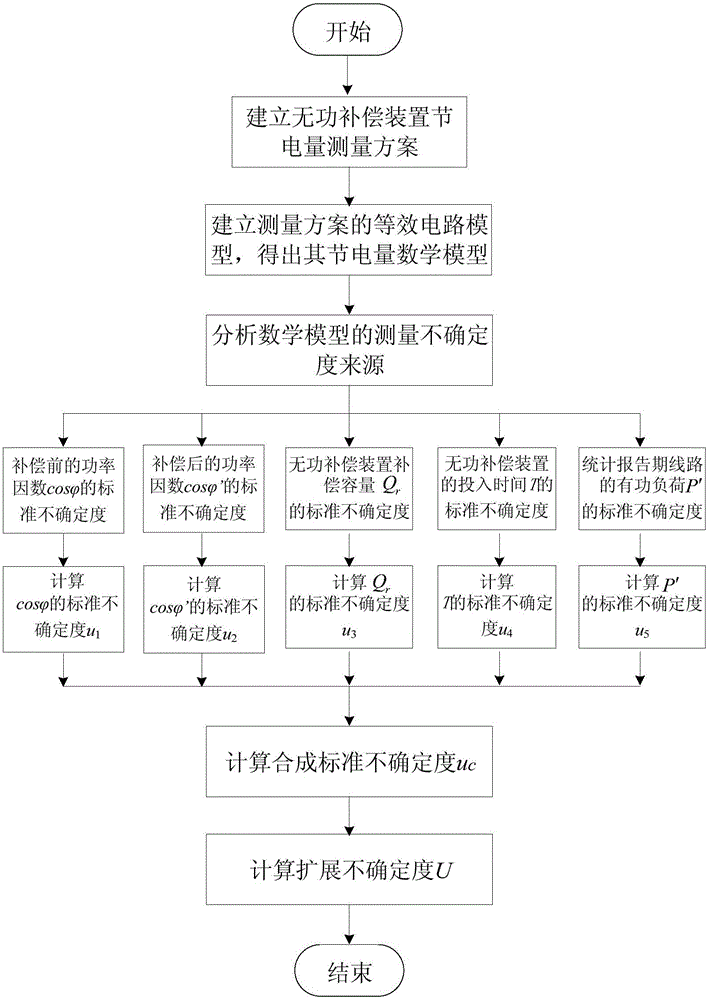

Parallel reactive power compensation device electricity saving quantity measurement uncertainty evaluation method

ActiveCN106597083AReasonable precisionAccurate and reliableElectric devicesPower measurement by current/voltagePower compensationElectricity

The invention discloses a parallel reactive power compensation device electricity saving quantity measurement uncertainty evaluation method. The method includes the following steps that: (1)a parallel reactive power compensation device electricity saving quantity measurement scheme is established; (2) the equivalent circuit model of the measurement scheme is established, the digital model of parallel reactive power compensation device electricity saving quantity is obtained according to the circuit model, and the digital model is adopted as the measurement model of parallel reactive power compensation device electricity saving quantity measurement uncertainty evaluation; (3) the components of uncertainty are calculated; (4) the components of the uncertainty are merged into a standard uncertainty uc; and (5) the extended uncertainty U of the measurement result of the parallel reactive power compensation device electricity saving quantity is calculated. The parallel reactive power compensation device electricity saving quantity measurement uncertainty evaluation method provided by the invention is of great significance for the further improvement of the accuracy of electricity saving quantity results, has high operability and can provide references for the electricity saving quantity measurement uncertainty evaluation of electricity saving projects such as transformer economic operation and line boosting transformation.

Owner:STATE GRID HUNAN ELECTRIC POWER CO LTD ELECTRIC POWER SCI RES INST +2

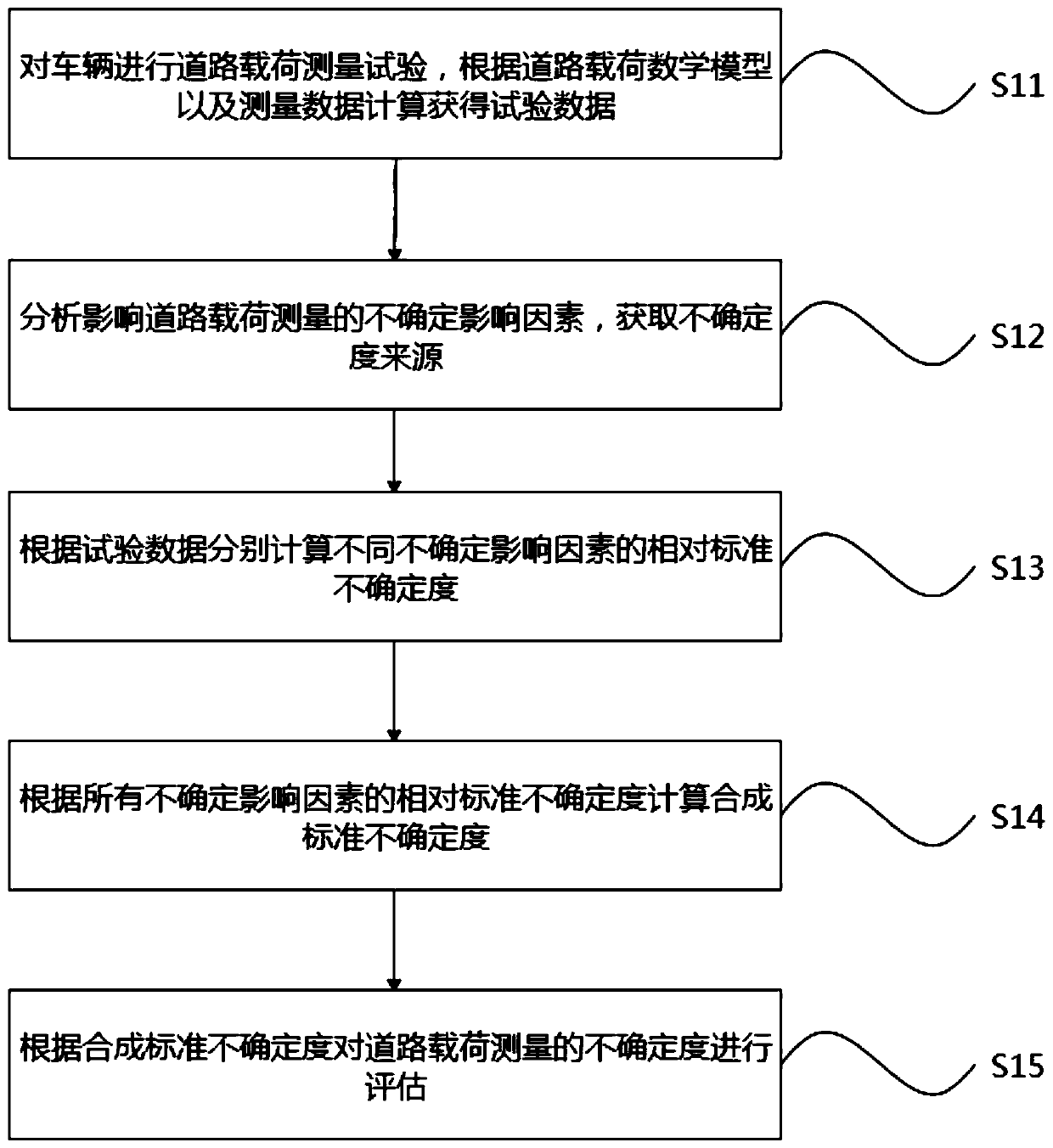

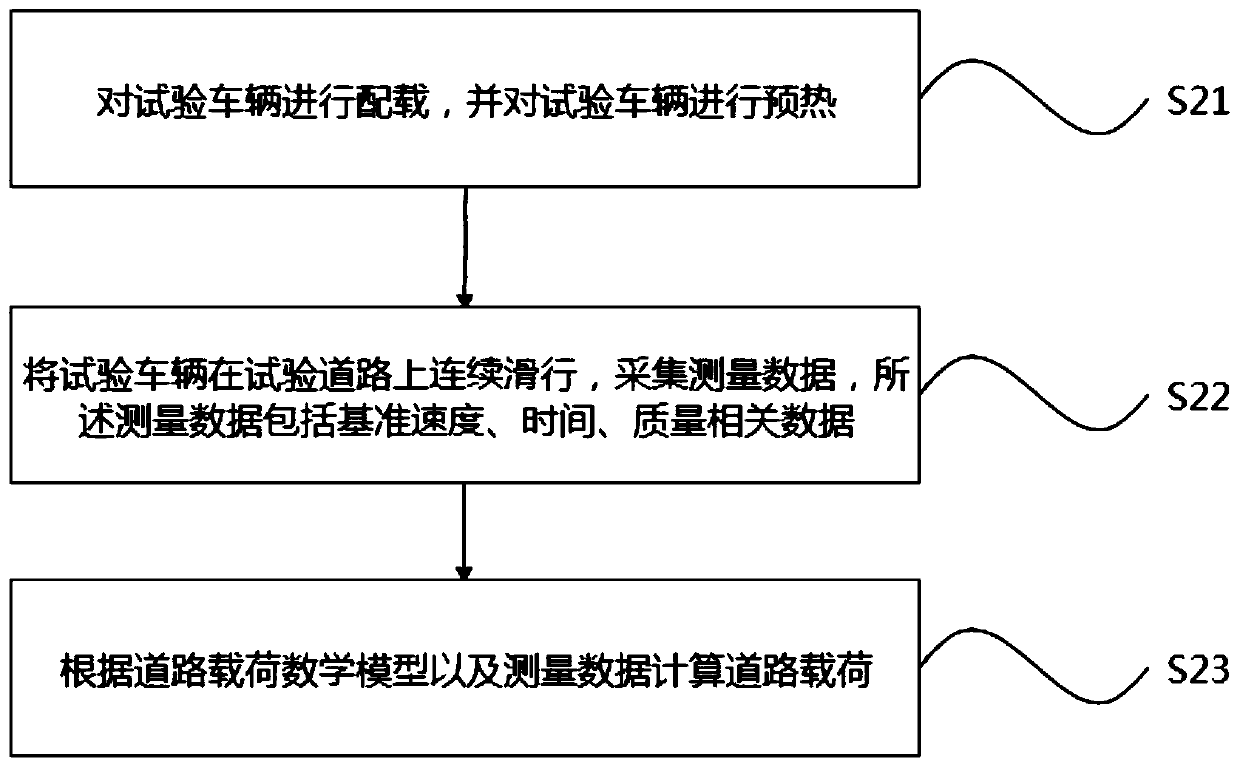

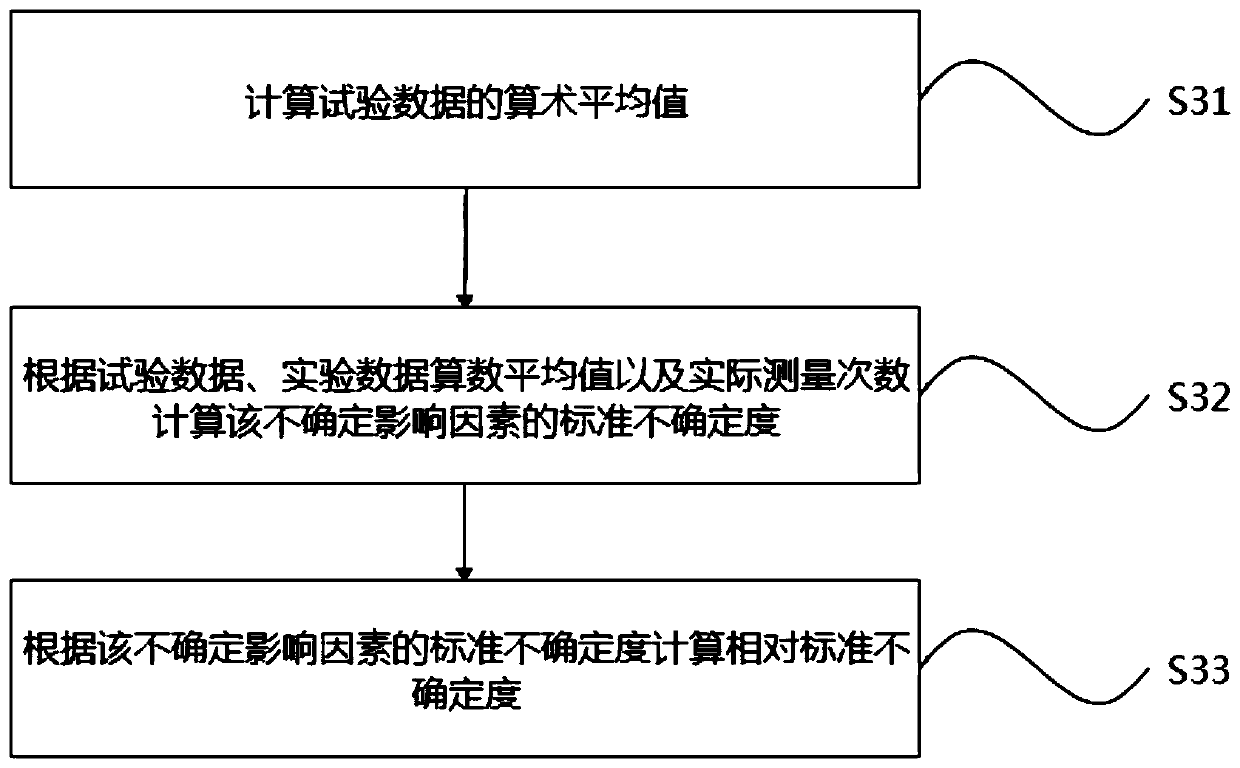

Uncertainty evaluation method for road load measurement

PendingCN111597620AIncrease credibilityGeometric CADDesign optimisation/simulationStandard uncertaintyComputer science

The invention provides an uncertainty evaluation method for road load measurement. The method comprises the steps: carrying out the road load measurement test of a vehicle, and obtaining test data through calculation according to a road load mathematic model and measurement data; analyzing an uncertainty source, and determining uncertainty influence factors influencing road load measurement; respectively calculating relative standard uncertainty of different uncertain influence factors according to the test data; calculating a synthetic standard uncertainty according to the relative standard uncertainty of all the uncertain influence factors; and evaluating the uncertainty of road load measurement according to the synthetic standard uncertainty. The method can help testers to determine thereliability of the road load measurement result, and therefore the credibility of the road load measurement test result can be improved.

Owner:海南热带汽车试验有限公司

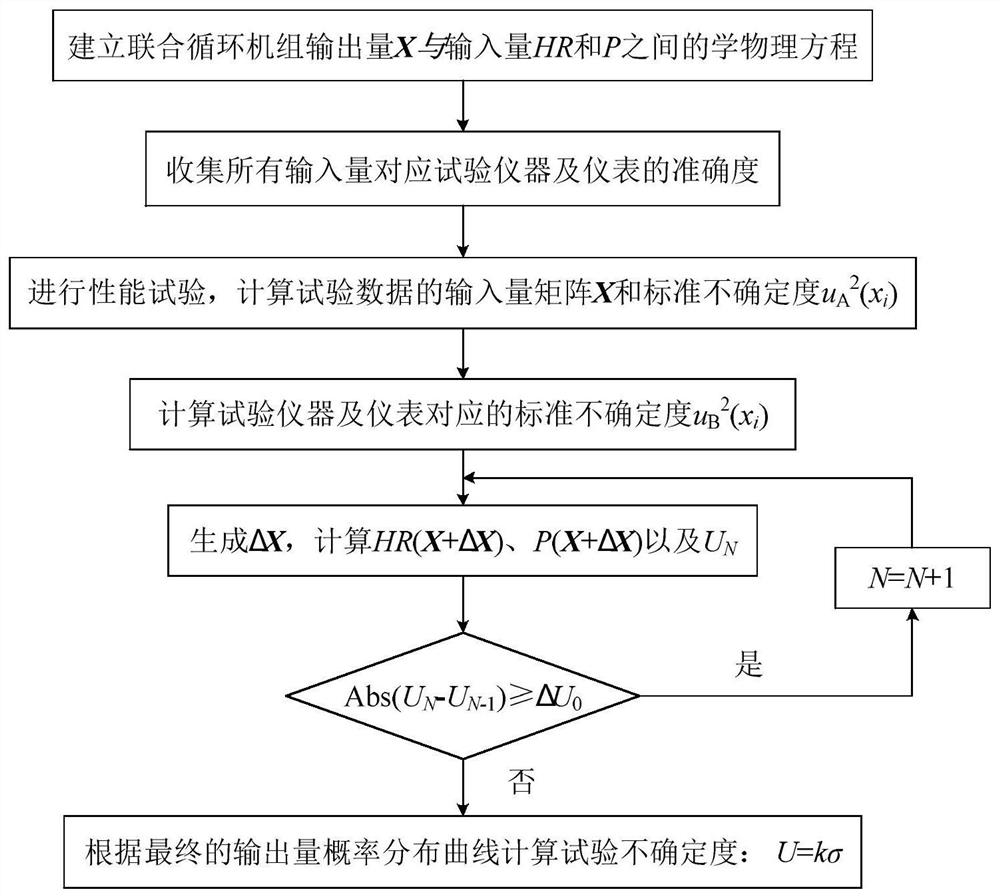

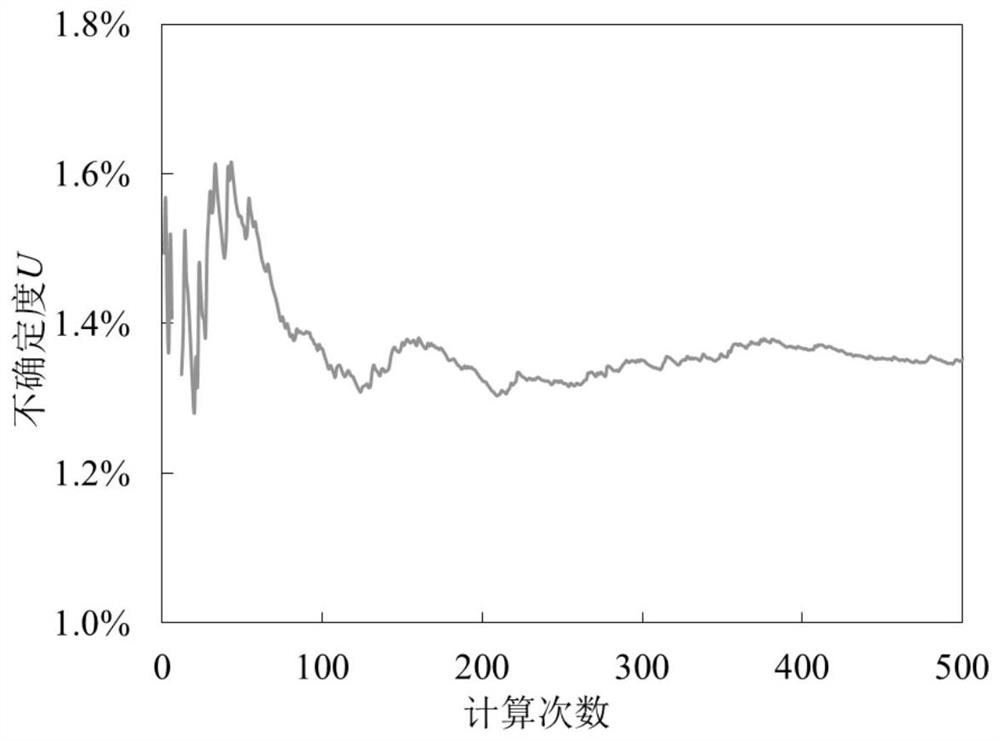

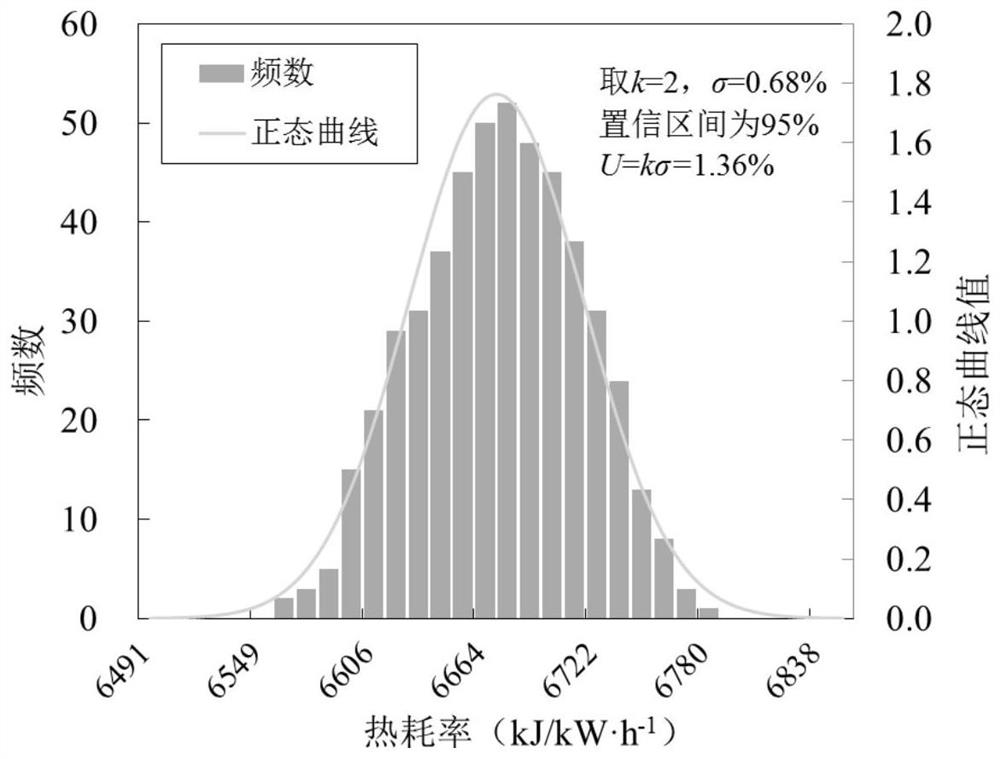

Uncertainty evaluation method for overall thermal performance test of combined cycle unit

The invention discloses an uncertainty evaluation method for an overall thermal performance test of a combined cycle unit. The uncertainty evaluation method comprises the following steps: a, establishing a mathematical physical equation between heat consumption rates and output powers of an input quantity and an output quantity; b, collecting the accuracy and parameter distribution types of test instruments and meters corresponding to all input quantities in the thermal performance test of the combined cycle unit; c, performing a thermal performance test, and calculating an input quantity matrix and standard uncertainty of test data; d, calculating the standard uncertainty of the test instrument and the instrument; e, generating a random variable delta X according to the test data and thestandard uncertainty of the test instrument and the instrument, and calculating corresponding output quantities HR (X + delta X) and P (X + delta X); and f, performing repetitive calculation, ending the calculation when the repetitive calculation result meets the condition that UN-UN-1 is less than or equal to delta U0, and calculating the final test uncertainty U according to the standard deviation sigma of the probability distribution curve. The uncertainty of the performance test of the combined cycle unit can be quickly and accurately calculated, and the method can be used for guiding theperformance test of the combined cycle unit.

Owner:XIAN THERMAL POWER RES INST CO LTD

Method for evaluating uncertainty of inspection results of drug component contents calculated by using external standard method

InactiveCN107132302AReasonable calculationReliable calculationComponent separationAlgorithmStandard uncertainty

The invention discloses a method for evaluating the uncertainty of inspection results of drug component contents. The method comprises the following steps: construction of both a calculation formula and a mathematical model for measurement results; analysis of the sources of uncertainty; quantification of uncertainty components; calculation of synthesized standard uncertainty; calculation of expanded uncertainty; and expression of measurements. The method provided by the invention can accurately reflect main sources influencing uncertainty and can provide more reliable examination determination results.

Owner:INST OF FORENSIC SCI OF MIN OF PUBLIC SECURITY

Repeat dynamic measurement data processing method based on grey system theory

InactiveCN101398311BAchieve the correct assessmentHigh precisionComplex mathematical operationsData processing systemStandard uncertainty

The invention provides a repeated dynamic measurement data processing method based on a grey system theory, comprising the steps as follows: 1. a signal x(t) to be measured is measured by a dynamic measurement system; according to detailed measurement function operation, discrete sampling is carried out to sampling points at all time; and the dynamic measurement data sequence is obtained after the error correcting data of the corresponding measurement system is accumulated; 2. in a repeated dynamic measurement data processing system, the entered dynamic measurement data sequence and values on sampling points at all time are averaged; 3. the dynamic measurement average value is calculated according to an orthogonal polynomial high-order data fitting principle, thus working out a dynamic measurement expected function (t) fitting curve model; 4. the measured values on the sampling points at all time are accumulatively added according to the grey system theory, and an grey estimation technique used for uncertainty is used for working out the uncertainty of the dynamic measurement standard on the sampling points at all time; curve fitting is carried out, thus obtaining the dynamic measurement uncertainty function mathematic model u(t); and 5. dynamic measurement expected function fitting curve model in the step 3 and the dynamical measurement uncertainty function model are combined.

Owner:BEIHANG UNIV

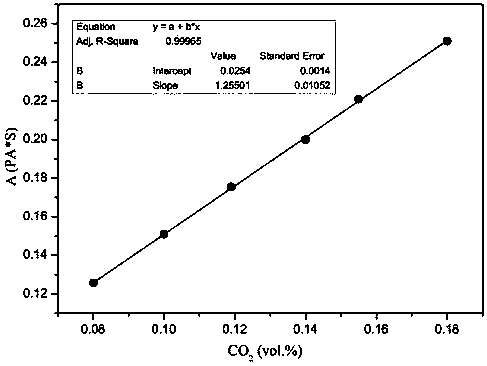

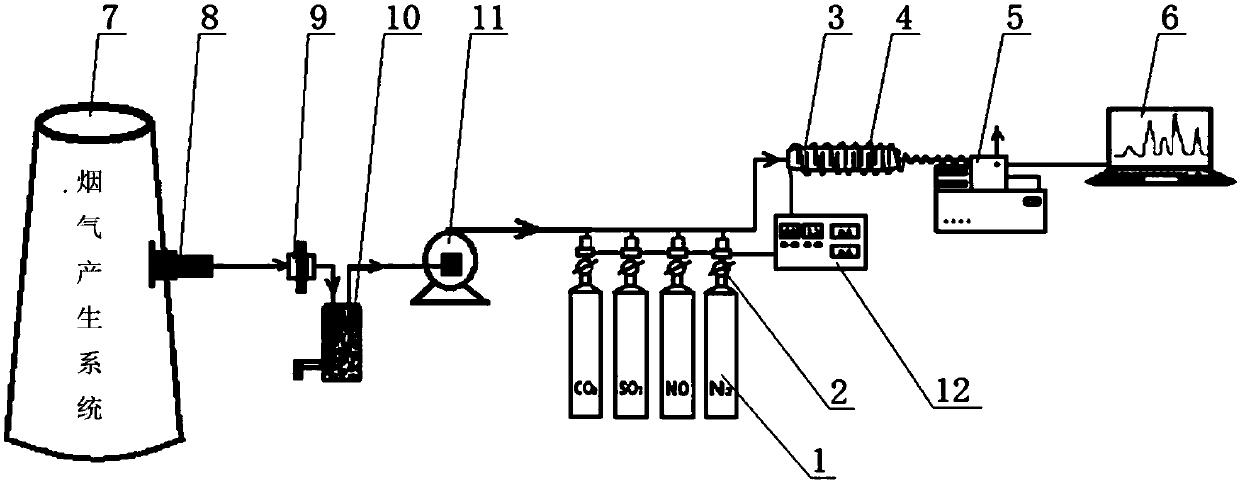

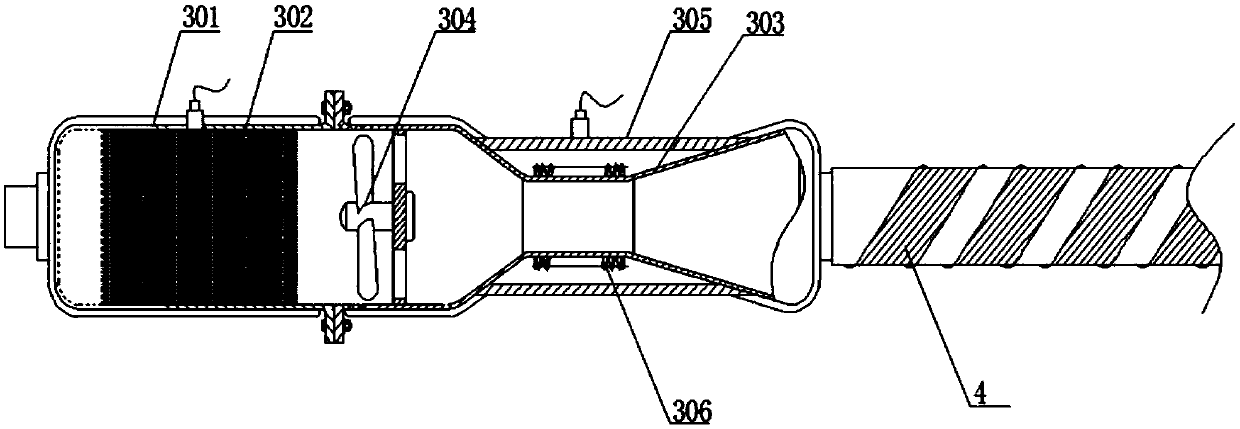

Uncertainty Analysis Method for Determination of Carbon Dioxide Concentration in Industrial Flue Gas Based on Infrared Spectroscopy

InactiveCN107179289BEliminate distractionsGood repeatabilityMaterial analysis by optical meansStandard uncertaintyFlue gas

The invention discloses an uncertainty analysis method for measuring a carbon dioxide (CO2) concentration in an industrial flue gas based on infrared spectrometry. The method comprises the following steps of (1), constructing a carbon dioxide measurement system to measure the CO2 concentration in the industrial flue gas; (2), determination the sources of uncertainties: a standard uncertainty introduced by repeated measurement, a standard uncertainty introduced by linear regression, a standard uncertainty introduced by a standard gas, a standard uncertainty introduced by instrument measurement, a standard uncertainty introduced by an intercept and a standard uncertainty introduced by a slope; (3), synthesizing a relative standard uncertainty; (4), synthesizing a relative expanded uncertainty. By using the method, uncertainty components introduced by a system error and a random error are completely analyzed in uncertainty analysis and evaluation processes; the measurement uncertainty of the CO2 concentration in the industrial flue gas is finally obtained. Related data is accurate and reliable; reliable method and basis are provided for metering the carbon emission of the industrial flue gas.

Owner:HENAN PROVINCE INST OF METROLOGY

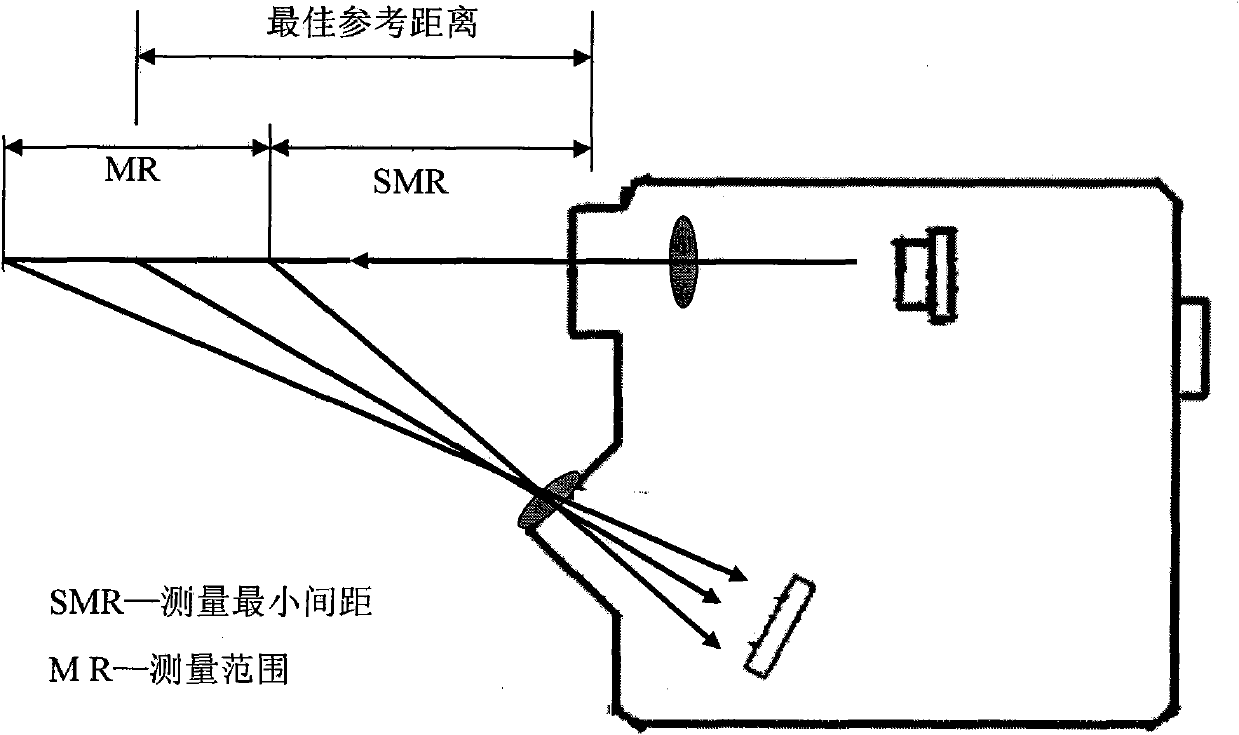

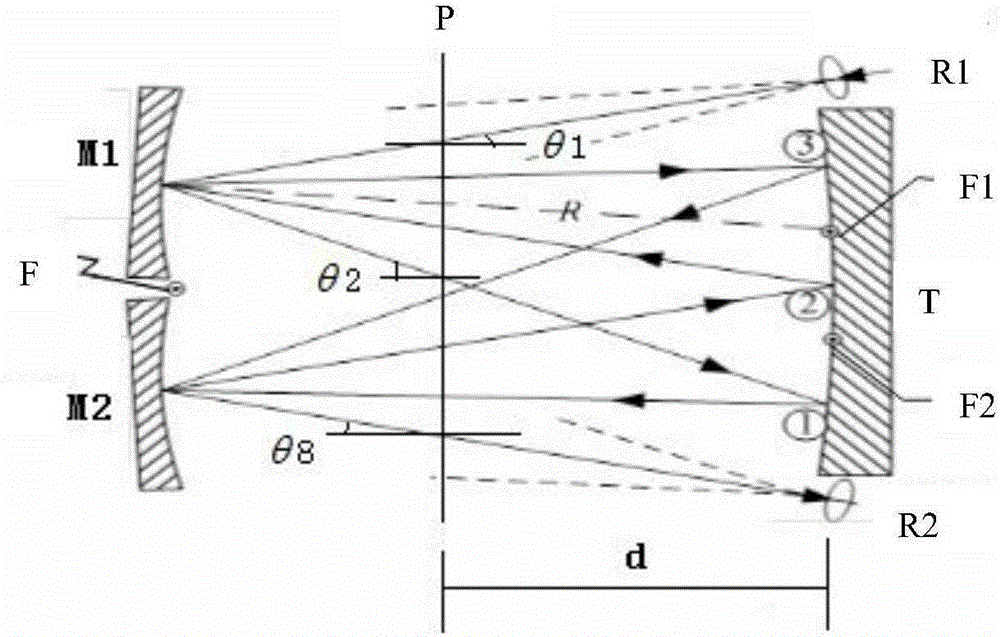

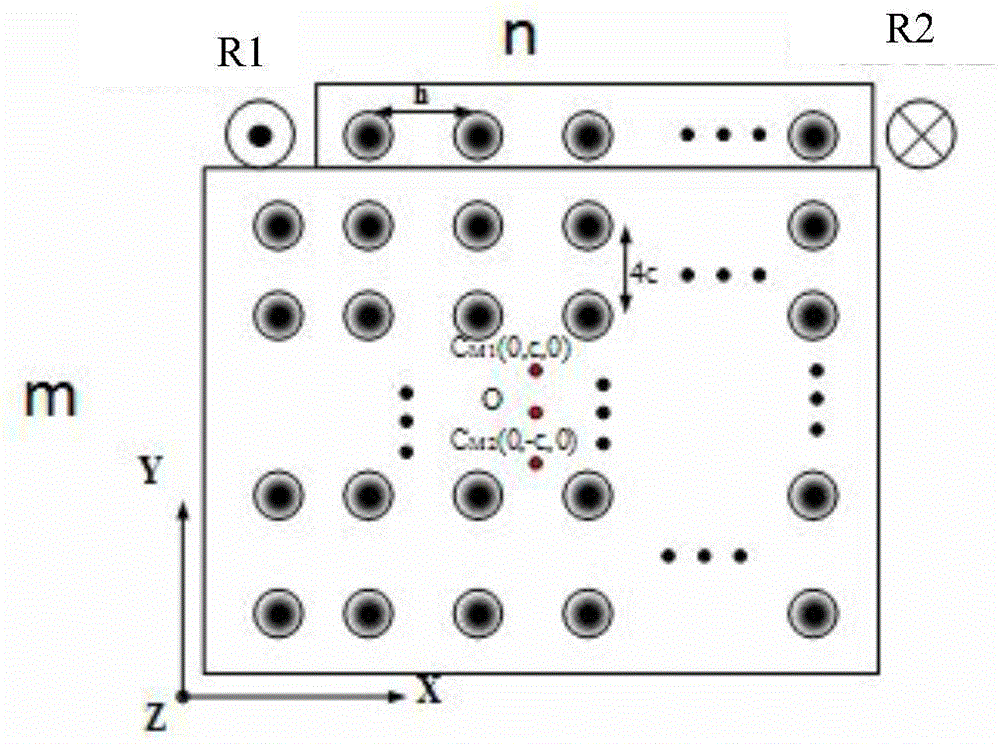

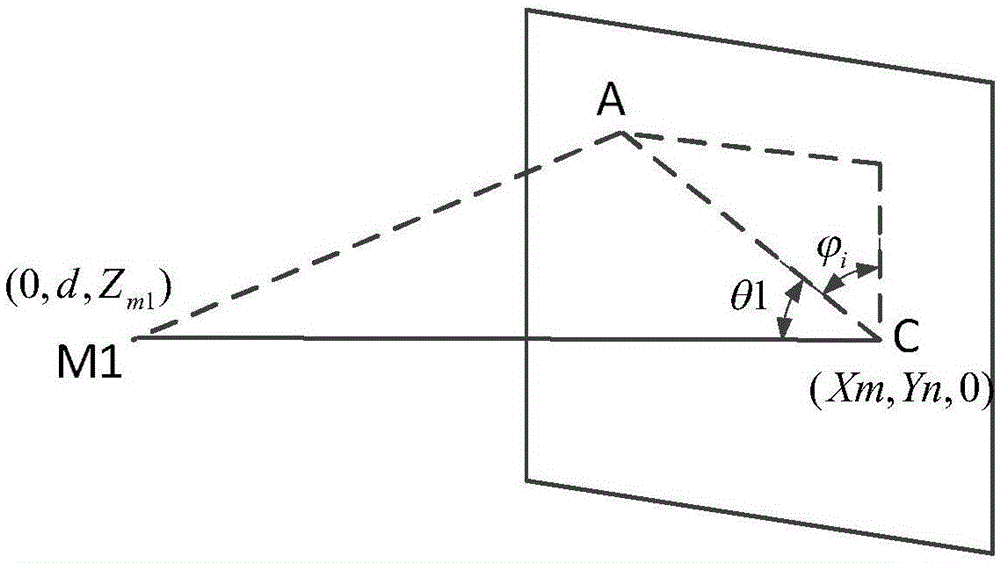

Multiple optical path refractive cavity calibration method based on variable angle optical density

InactiveCN105136701AHigh precisionColor/spectral properties measurementsStandard uncertaintyLight beam

The invention discloses a multiple optical path refractive cavity calibration method based on the variable angle optical density. Basic parameters of a refractive cavity are analyzed and calculated to get all optical density values arising from the interaction of a refracting beam of the refractive cavity and a standard optical density sheet; and a total optical density value Ds(lambda) is obtained. The standard optical density sheet is placed in the refractive cavity whose optical density value Dc(lambda) is measured; measuring deviation of the refractive cavity is calculated according to the formula sigma(D lambda) = Dc(lambda) - Ds(lambda), a standard uncertainty of the refractive cavity and a calibrated expanded uncertainty are calculated according to the measuring deviation, and the obtained calibrated expanded uncertainty is the detection limit of the multiple optical path refractive cavity. The calibration method is entirely based on optical measurement without any need of standard air assessment, eliminates the complex influence of uncertainties of introduced gas, achieves calibration of the refractive cavity at a low-uncertainty level, and improves the calibration accuracy of the detection limit.

Owner:TSINGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com