On-site calibration device of airborne tritium monitoring instrument

An on-site calibration and monitoring instrument technology, which is applied to measurement devices, instruments, scientific instruments, etc., can solve the problem that the on-site calibration device of the airborne tritium monitor has not been retrieved, the calibration work of the airborne tritium monitor has not been carried out, and the measurement results are accurate. In order to increase the cooling process, good thermal insulation performance, and increase the dispersion area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

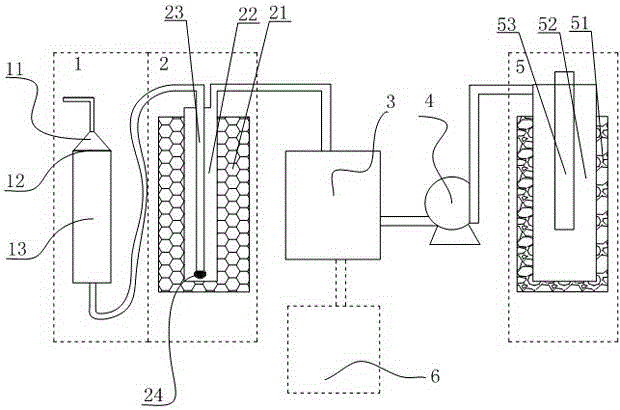

[0023] Such as figure 1 The schematic diagram shown, the on-site calibration device of the airborne tritium monitor, includes an air handler 1, a bubbling unit 2, a transfer instrument 3, an air pump 4, and a recovery unit 5 connected in sequence, wherein: the air handler 1 includes Filter 11, filter 11 is conical, and its bottom diameter is big and is provided with mesh plate, adopts stainless steel to make, the glass fiber paper that mesh hole is 0.5 μ m is installed on the mesh plate as filter membrane 12, filter membrane 12 It is located at the entrance of the dryer 13. The dryer 13 is a cylindrical structure with a diameter of about 5 cm and a length of about 37 cm. The internal thread at the interface is 12 mm. It is made of plexiglass tube and aluminum, and its two ends are tower-shaped structures. Used to connect with pipelines, the desiccant inside the drier 13 is color-changing silica gel and molecular sieve: the output of the drier 13 is connected to the bubbling un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com