Patents

Literature

116results about How to "Large dispersion area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-temperature dechlorinating agent and preparing method thereof

ActiveCN101274211AImprove thermal stabilityImprove stabilityDispersed particle separationCatalytic reformingCalcium hydroxide

The invention relates to a high-temperature dechlorination agent, which consists of 0 to 42 wt percent of CaOH, 18 to 70 wt percent of CaO, 20 to 40 wt percent of hydrotalcite, 7 to 17 wt percent of clay and 0 to 7 wt percent of adhesive. Based on the high-temperature dechlorination agent, the invention further discloses a preparation method of the high-temperature dechlorination agent. The high-temperature dechlorination agent prepared by the preparation method can be applied to a coal gasification fuel cell (MCFC) system, a coal gasification combination circulation power generation (IGCC) system and catalytic reforming regeneration gas so as to remove the HCl; furthermore, the dechlorination agent has high chlorine content and good dechlorination effect.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

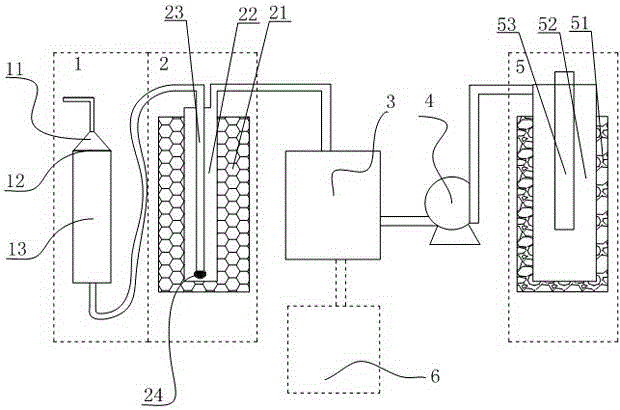

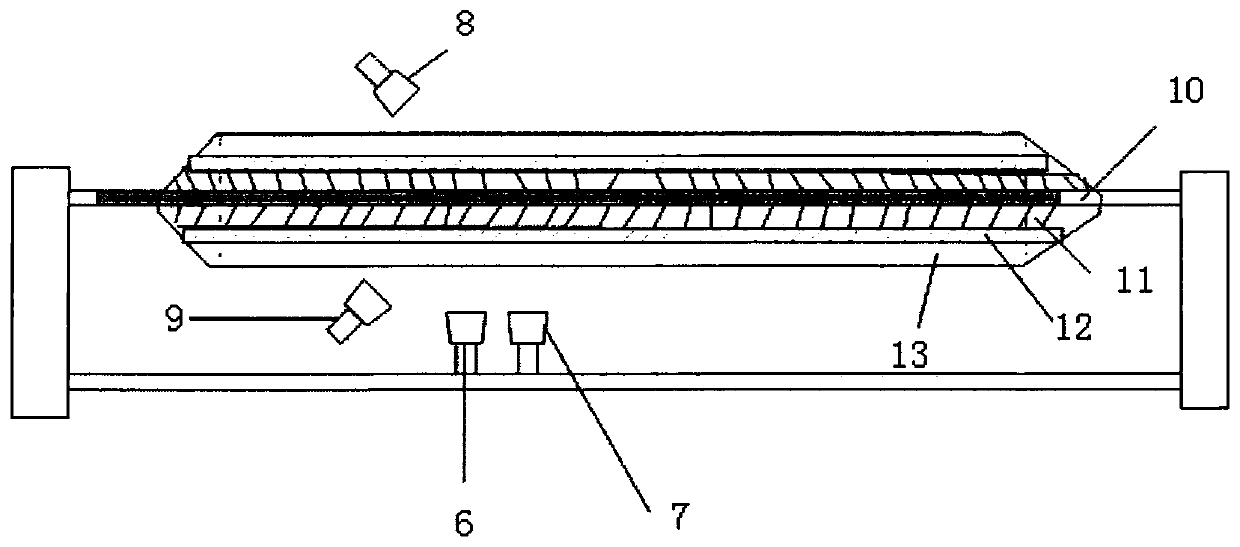

On-site calibration device of airborne tritium monitoring instrument

InactiveCN104536028AIncrease contact areaLarge dispersion areaX/gamma/cosmic radiation measurmentWater vaporStandard uncertainty

The invention discloses an on-site calibration device of an airborne tritium monitoring instrument. The on-site calibration device of the airborne tritium monitoring instrument comprises an air processor, a bubbling unit, a transmission instrument, an aspirator pump and a recovery unit, all of which are sequentially connected, wherein the air processor is used for filtering and drying inlet air, the bubbling unit is used for bubbling tritiated water to form saturated tritium flow, the transmission instrument is used for being connected with a calibrated detection instrument and measuring the activity and concentration of the tritium flow generated on site, the aspirator pump is used for pumping the tritium flow into the recovery unit for recovery after the activity and concentration of the tritium flow generated on site are detected, and the recovery unit is used for cooling and recovering the recovered tritium flow. The ranges of the activity and concentration of the tritium flow generated by the on-site calibration device of the airborne tritium monitoring instrument in a bubbling mode depend on the total activity of the tritium flow for bubbling and can meet the calibration of most existing nuclear facilities using the measuring span of the tritium monitoring instrument. The uncertainty of the synthesis standard of the activity and concentration of the bubbled tritium flow is less than or equal to 10 percent, and the recovery rate of the tritiated water vapor by the recovery unit is more than 99 percent.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

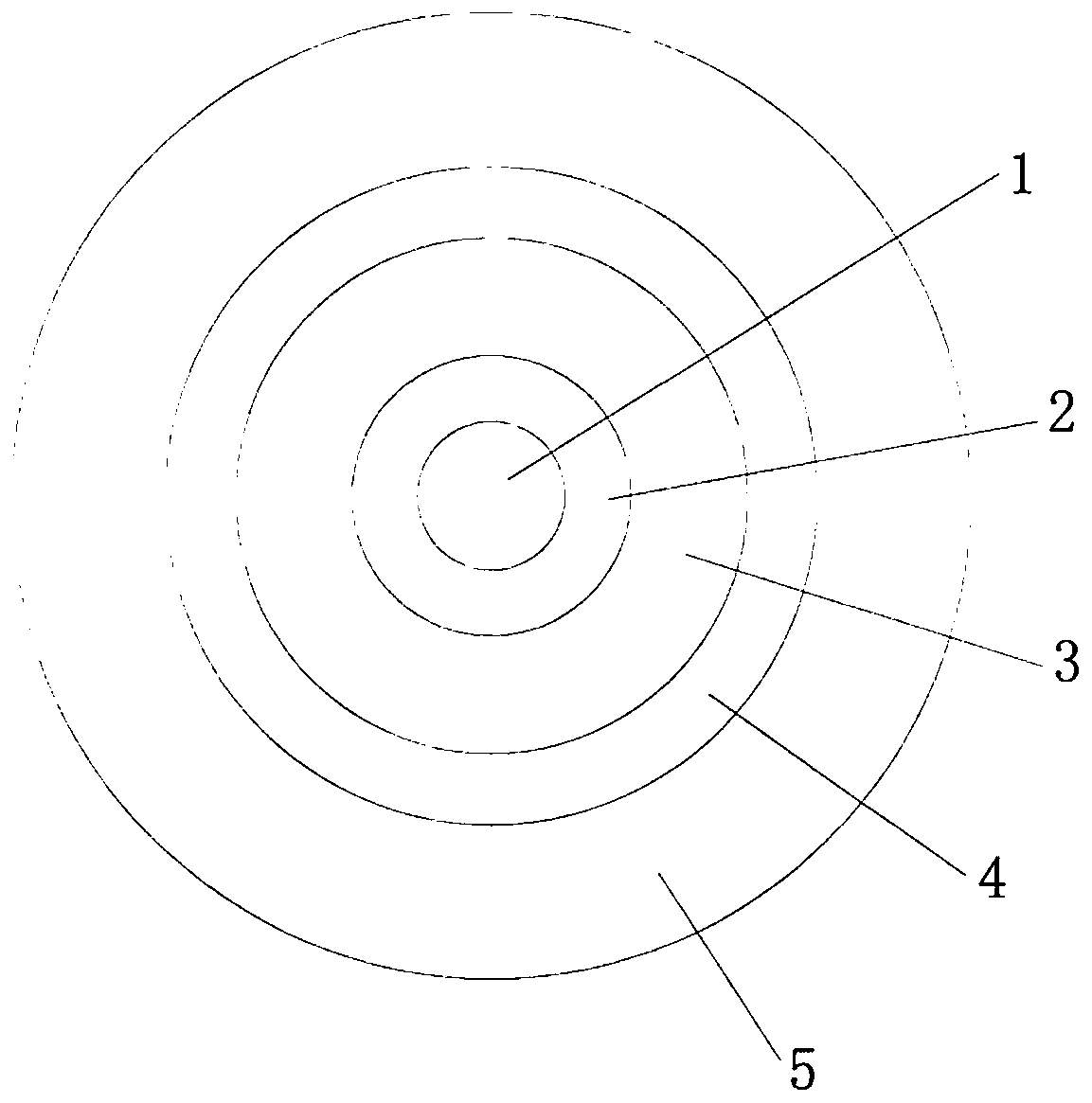

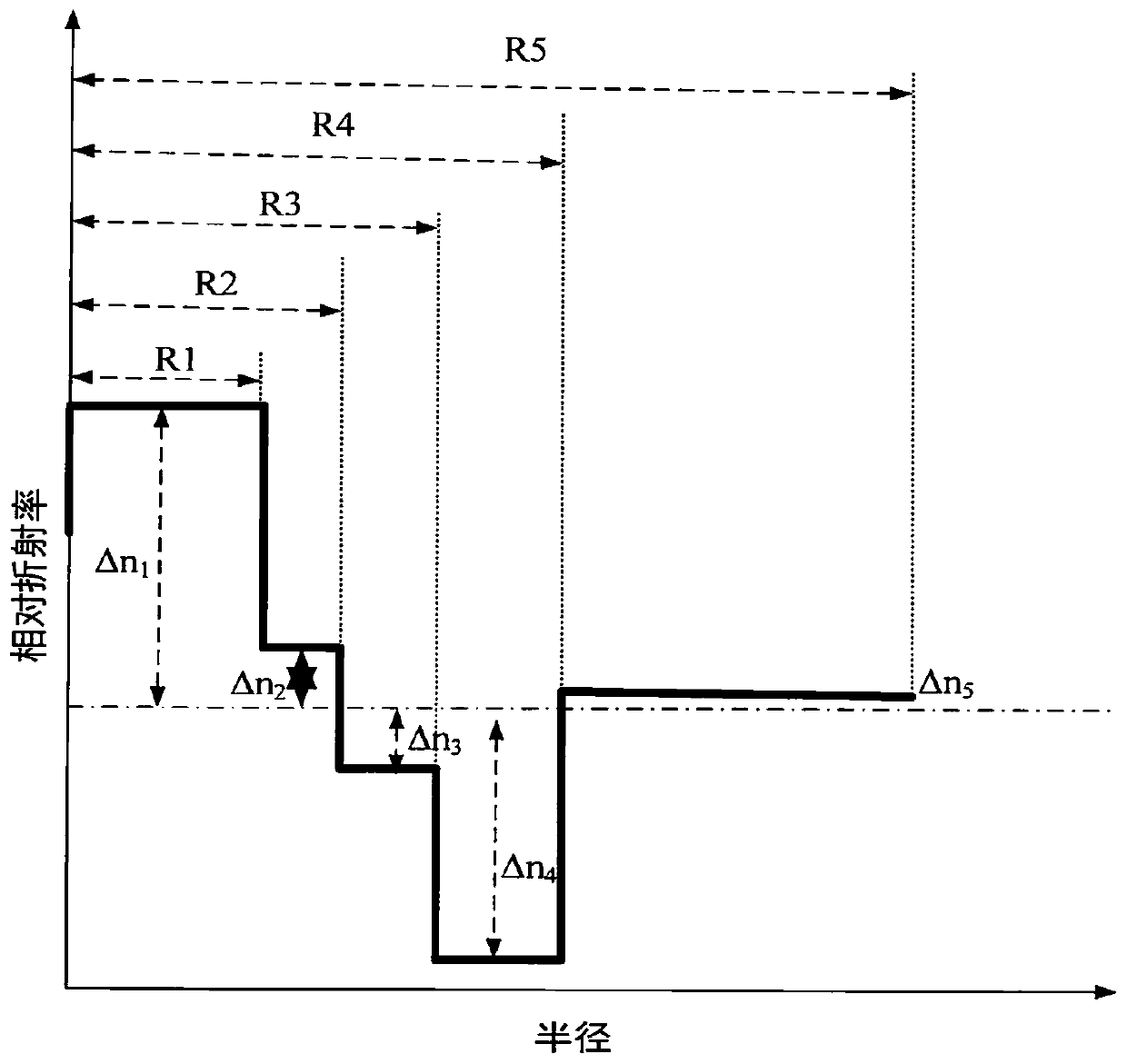

Single-mode fiber and fabrication method thereof

ActiveCN110794509ALow loss and large effective areaBending Loss ImprovementsGlass optical fibreGlass making apparatusPhysicsChemistry

The invention relates to a single-mode fiber and a fabrication method thereof. A bare fiber comprises a core layer and a wrapping layer, wherein the core layer comprises a first core layer, a second core layer and an inner wrapping layer, the relative refractivity difference Delta 1 of the first core layer is more than 0.2% but less than 0.35%, the relative refractivity difference Delta 2 of the second core layer is more than or equal to 0.15% but less than or equal to 0.25%, the refractivity radius of the inner wrapping layer is 24-36 micrometers, the relative refractivity difference Delta 3of the inner wrapping layer is more than or equal to -0.12% but less than or equal to 0%, the wrapping layer comprises a sunken wrapping layer and an external wrapping layer, the relative refractivitydifference Delta 4 of the sunken wrapping layer is more than or equal to -0.40% but less than or equal to -0.28%, and the external wrapping layer is a high-hardness pure quartz sleeve. With the adoption of a method for on-line assembly and drawbenching by two sleeves and a core rod, fiber annealing for many times is performed during the drawbenching process, a coating layer with low modulus is coated in a surface of the fiber, a coating layer with high modulus is coated outside the surface of the fiber, and the fiber with low loss, large effective area and high strength is fabricated. The method is simple, the viscosity of the cord rod can be adjusted according to a demand, the fiber attenuation is reduced without employing a pure silicon core scheme, and production on a large scale is facilitated.

Owner:FASTEN HONGSHENG GRP CO LTD +1

Chinese medicinal gel formulation and its preparing process

Disclosed is a Chinese medicinal gelling agent which comprises, 7.5-12.5 wt% of mentha-camphor, 5.5-8.5 wt% of curcuma longa pieces, 5.5-8.5 wt% of dahurian angelica root pieces, 2.5-4.4 wt% of pollen pieces, 2.5-4.4 wt% of red peony root pieces, 2-4 wt% of nitrogen ketone, 1.5-3 wt% of Carbomer, 0.3-0.5 wt% of polysorbate, 0.1-0.3 wt% of triethanolamine and balancing water. The invention also discloses the preparing process.

Owner:WUHAN UNIV

Screw air elutriation fine-coal remover for dry classification before fine coal preparation

InactiveCN102921635AEffective dispersionSolve the blockageSievingGas current separationClassification methodsEngineering

The invention belongs to the technical field of fines removal classification before coal preparation and particularly relates to a screw air elutriation fine-coal remover for dry classification before fine coal preparation. The fine-coal remover comprises a primary classification region which uses a spiral airflow conveying method and a secondary classification region which uses a tangential airflow jetting rotating classification method. During the declining process, materials are subjected to the comprehensive action of spiral centrifugal force and airflow conveying force, intensifying classification is obtained under the comprehensive action, primary fine materials which are subjected to primary classification enter the secondary classification region, are subjected to secondary classification and are discharged, downward negative pressure is introduced into the secondary classification region, and materials can be discharged smoothly when large classification grain sizes are required. By the aid of the fine-coal remover, the problem of blocking of screening holes is solved, the classification grain sizes can be adjusted and controlled at will in a range from 0 to 13 mm in accordance with requirements, and a new technology is provided for power coal fines removing and washing.

Owner:ANHUI UNIV OF SCI & TECH

Tea polyphenol pellet and method for preparing the same

InactiveCN101219123AControl releaseReduce the frequency of takingOrganic active ingredientsPill deliveryPharmaceutical AdjuvantsPolyphenol

The invention provides a tea polyphenols micro-pill that is prepared from tea polyphenols and pharmaceutical adjuvant, which is characterized in that the pharmaceutical adjuvant is an excipient and a bonding agent. The tea polyphenol micro-pill comprises (by weight percentage) that: tea polyphenols 20-80 percent, the excipient 15-79 percent and the bonding agent 1-5 percent. The tea polyphenols micro-pill can be made into sustained-release preparation or enteric-coated preparation. The pharmacological experiment indicates that the tea polyphenols micro-pill of the invention has good effect on radioresistance, anti-aging, etc.

Owner:JF PHARMALAND TECH DEV

Modified perovskite-structure photoelectric conversion material and preparation method thereof

ActiveCN105514284AReduce reunionLarge dispersion areaSolid-state devicesSemiconductor/solid-state device manufacturingHydrotalciteCrystal structure

The invention discloses a modified perovskite-structure photoelectric conversion material and a preparation method thereof, and belongs to the field of photoelectric conversion materials, especially perovskite-structure photoelectric conversion materials. A modified photoelectric conversion material of a special structure and high photoelectric conversion efficiency is prepared by a technical scheme as follows: hydrotalcite is modified and oxidized, and the crystal structure of hydrotalcite is recovered in a solution; hydrotalcite exchanges ions in a solution with lead halide forming one precursor of a perovskite-structure crystal; and hydrotalcite reacts with methylamine halide forming the other precursor of the perovskite-structure crystal to form a perovskite-structure crystal of a hydrotalcite interlayer.

Owner:南京点援微材料科技有限公司

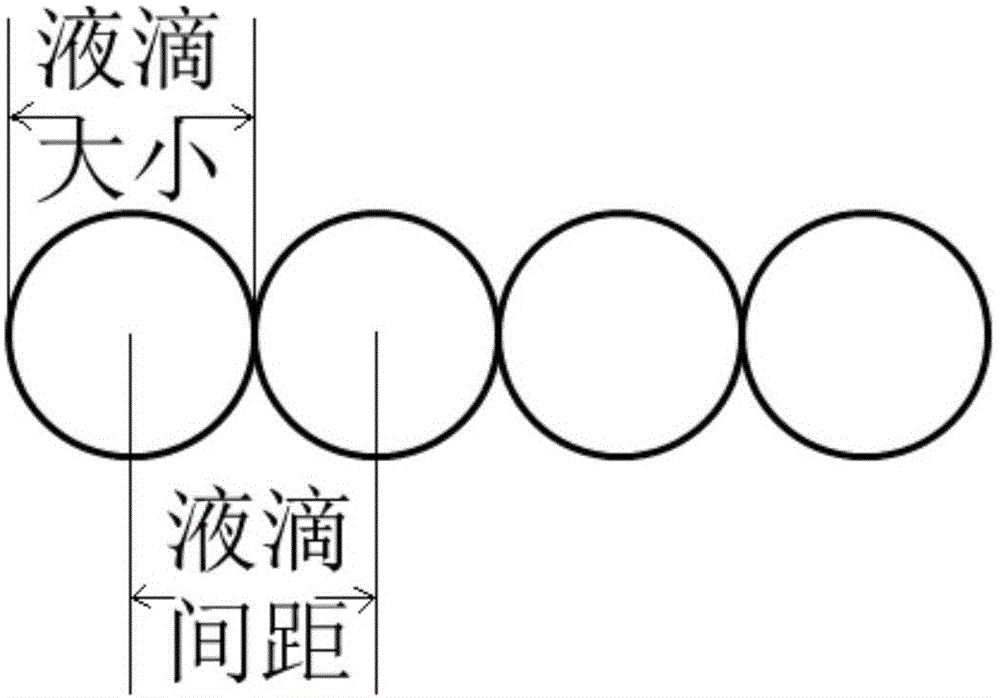

Method for processing microelectrode on PDMS substrate based on inkjet printing technology

InactiveCN104977338AGood adhesionOvercoming the problem of poor electrode continuityPrintingMaterial electrochemical variablesSilver electrodeMicroelectrode

The invention relates to a method for processing a microelectrode on a PDMS substrate based on an inkjet printing technology. The method comprises: preparing a PDMS substrate, wherein a PDMS monomer and a curing agent are uniformly mixed according to a mass ratio of 10:1, gas bubbles are removed, the PDMS mixed with the curing agent is poured onto the surface of a polished silicon wafer, and the obtained material is placed into a constant temperature oven for 2 h to cure; increasing adhesion of the PDMS on the metal electrode; and carrying out splitting and re-combination on the effective pixel part in the original electrode pattern by using a digital image treatment method, and then carrying out spray printing in a one-by-one manner according to the effective pixel in the new pattern. According to the present invention, the problem of poor electrode continuity caused by the surface tension of the liquid droplet is overcome, the hydrophobic property of the PDMS surface is improved, the processing efficiency is improved, and the poor adhesion of the silver electrode on the PDMS surface is solved; and the method has characteristics of high efficiency, convenience and high automation degree, and the processed electrode has characteristics of good PDMS surface adhesion and high quality.

Owner:TIANJIN UNIV

Honeysuckle extract pellet and preparation method thereof

InactiveCN102462722AIncrease the areaReduce dosageAntibacterial agentsGranular deliveryMedicinePharmaceutic Adjuvant

The invention provides a honeysuckle extract pellet preparation which is prepared from a honeysuckle extract and pharmaceutic adjuvants and is characterized in that the pharmaceutic adjuvants comprise an excipient and a binding agent; and the pellet preparation comprises 1-40wt% of the honeysuckle extract, 55-98wt% of the excipient and 1-5wt% of the binding agent. The pellet preparation can be prepared into a sustained-release preparation or an enteric preparation according to requirements. Pharmacology experiments show that the pellet provided by the invention has the effects of resisting bacteria, diminishing inflammation, improving the immunity and the like.

Owner:JF PHARMALAND TECH DEV

Catalysts used in production of promoter 2,2'-dithiobisbenzothiazole, and preparation method thereof

InactiveCN102350350AEasy to prepareEasy to industrializeOrganic chemistryMolecular sieve catalystsCerium nitrateCopper nitrate

The invention relates to catalysts used in the production of a promoter 2,2'-dithiobisbenzothiazole, and a preparation method of the catalysts. The catalysts can be one or more selected from metal salts of copper acetate, copper sulfate, copper nitrate, cobalt acetate, cobalt sulfate, cobalt nitrate, cerium acetate, cerium sulfate, cerium nitrate, chrome acetate, chrome sulfate, chrome nitrate, and the like. Carriers of the catalysts can be one or more selected from SiO2, Al2O3, TiO2, mesoporous material molecular sieve, microporous material molecular sieve, and the like. Prepared catalysts are used in a reaction for synthesizing DM by using an oxygen oxidizing method, and the reaction is used for representing performances of the catalysts, wherein a catalyst dosage is 0.01 to 0.1% of the reactant by weight. The catalysts provided by the invention are advantaged in reasonable formulation, low dosage, and good catalytic effect. The catalysts contain active components and carriers. Dispersion areas of the active components are enlarged, such that contact areas between the active components and the reactants are enlarged. Therefore, reaction speed is improved, and the catalyst dosage is reduced. Also, reaction conditions are optimized, such that the yield of DM is higher than 98%.

Owner:KEMAI CHEM

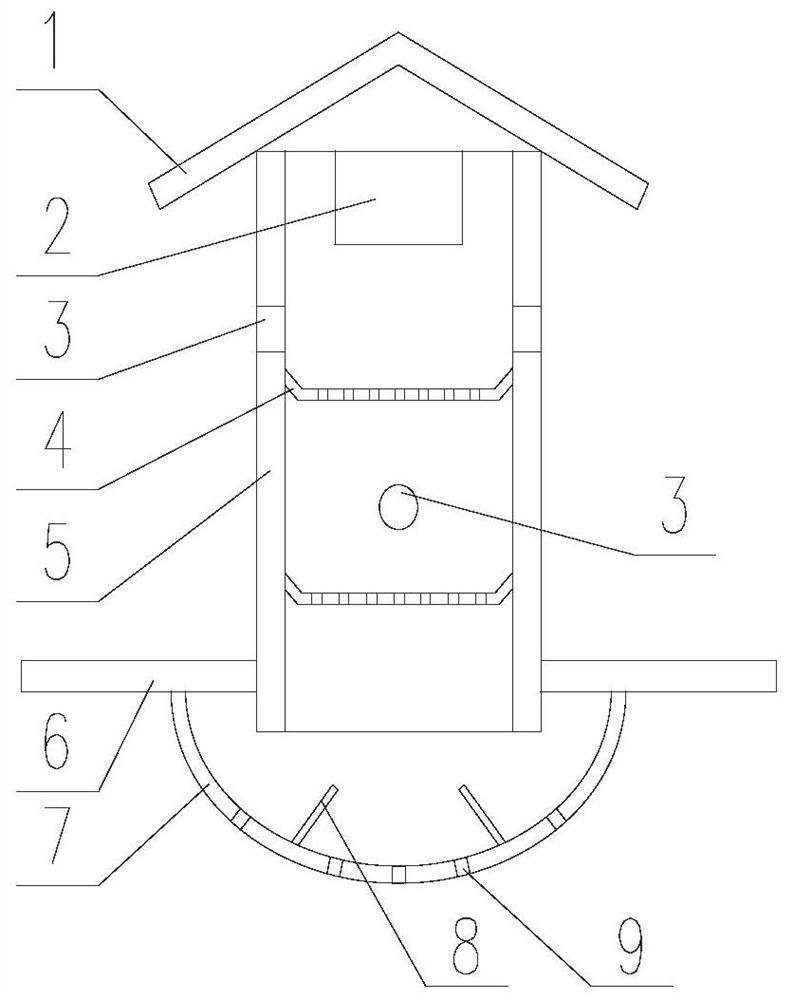

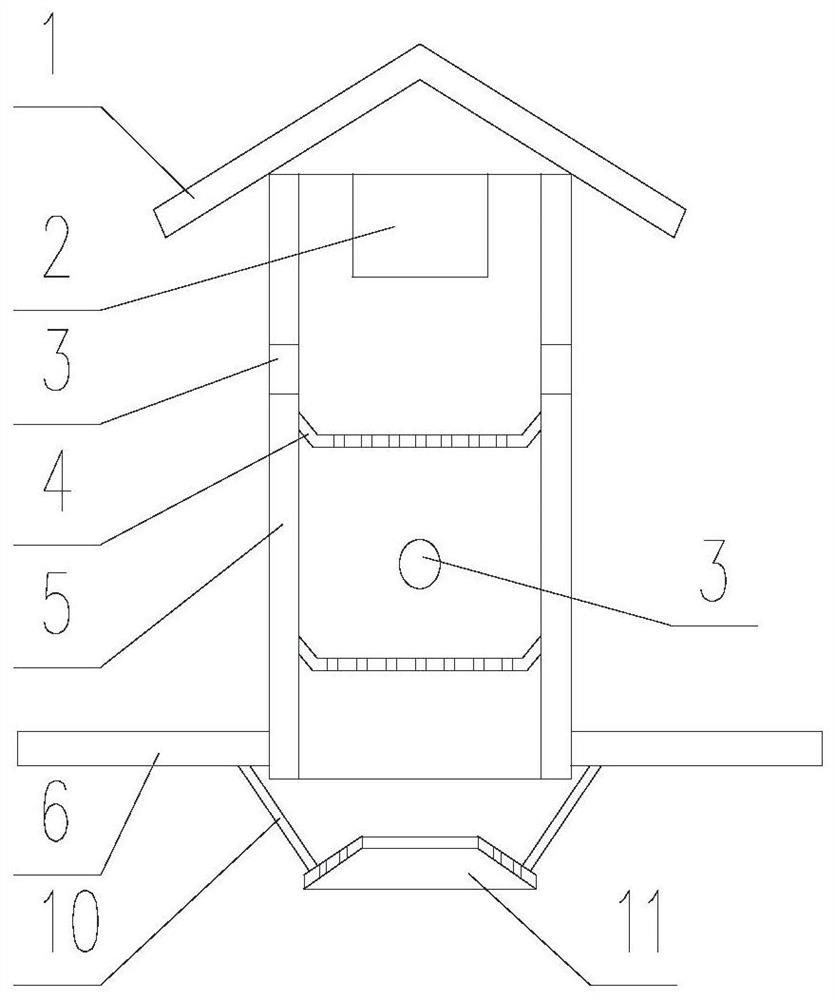

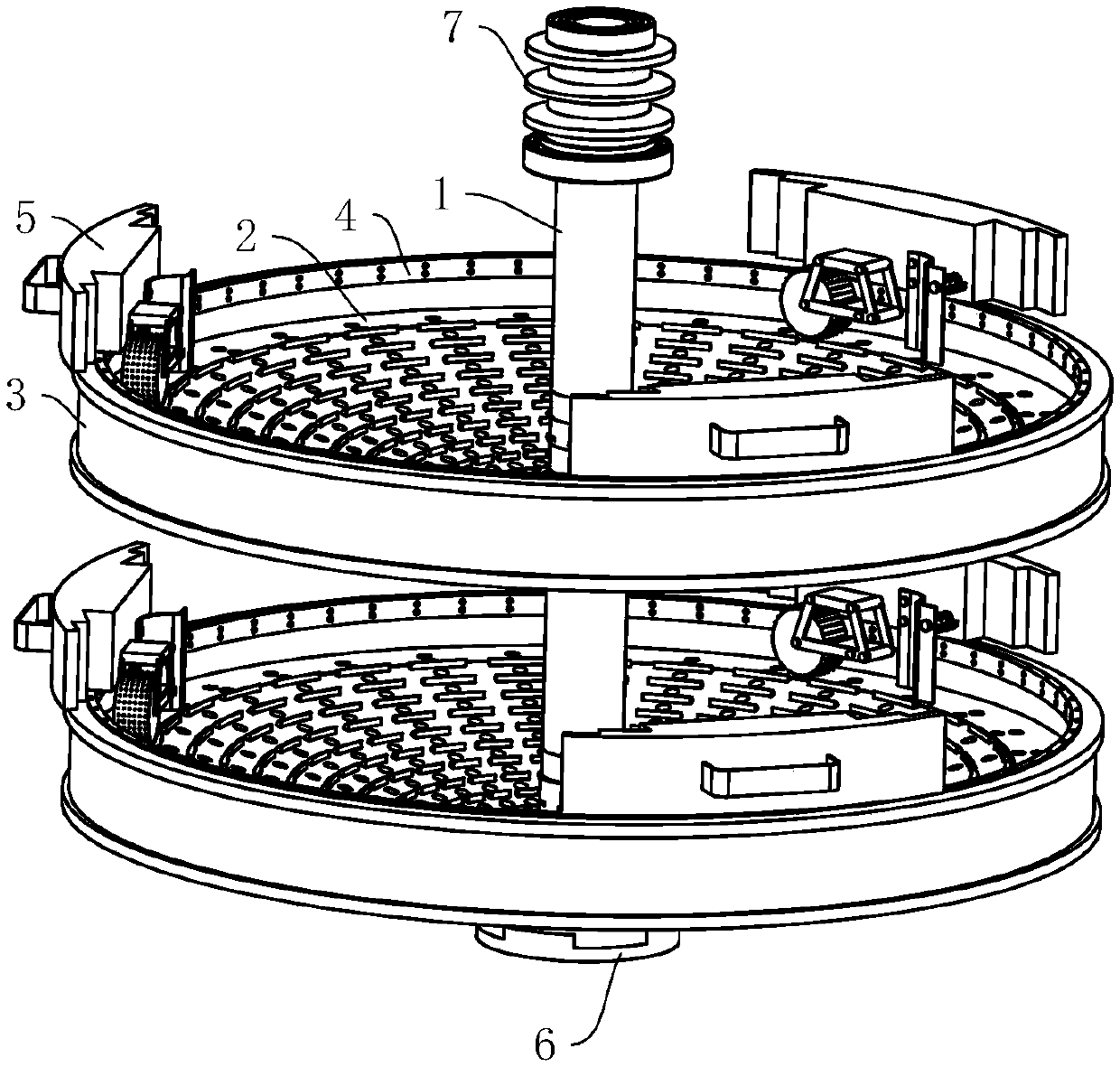

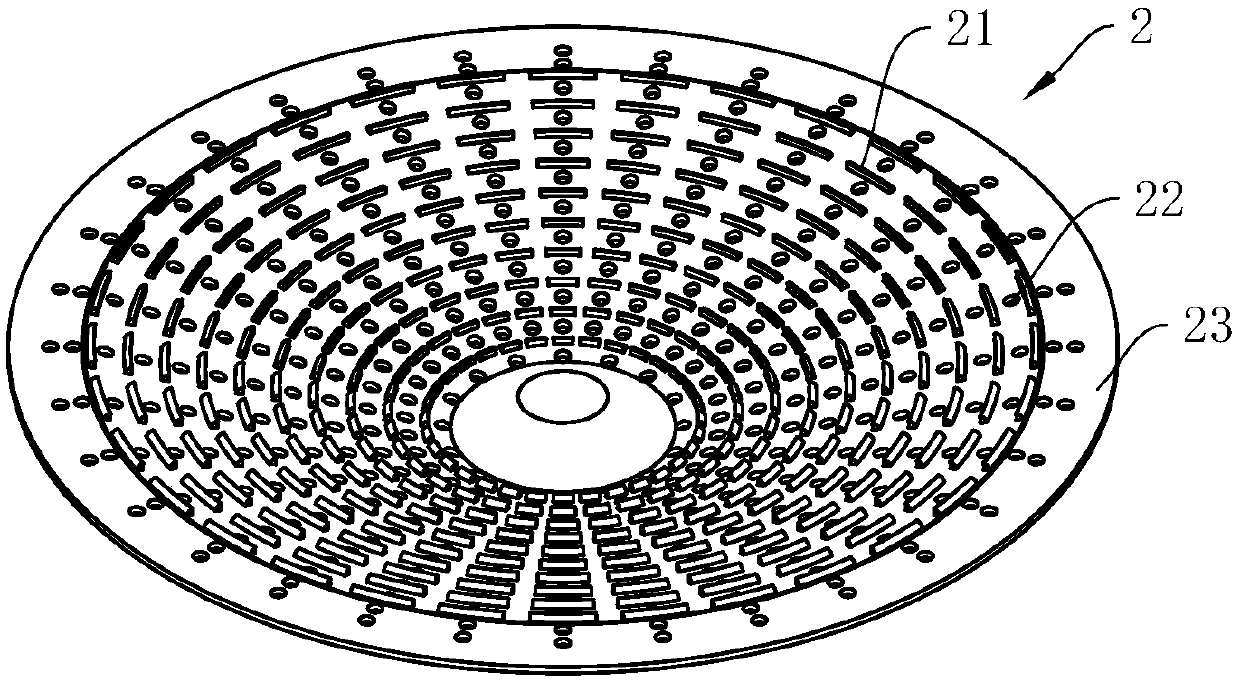

Gas-liquid distribution device

ActiveCN111992145AAvoid uneven distributionImprove solubilityChemical/physical processesCircular discFluid phase

The invention discloses a gas-liquid distribution device, which comprises an umbrella cap, an overflow pipe and a distribution disc which are arranged from top to bottom; the umbrella cap is conical and umbrella-shaped and is arranged at the upper end of the overflow pipe; the overflow pipe is a circular pipe with two open ends; the lower end is fixed on a mounting hole of the distribution plate;a gas-phase channel is arranged at the joint of the overflow pipe and the umbrella cap, one or two or more layers of overflow holes are evenly formed in the pipe wall in the circumferential directionto serve as liquid-phase channels, a liquid collecting disc is arranged below each layer of overflow holes in the overflow pipe, the liquid collecting discs are concave flat-bottom discs and fixedly connected with the pipe wall of the overflow pipe through convex concave edges, and distribution holes are evenly distributed in the bottoms of the liquid collecting discs for gas-liquid two-phase passing. According to the invention, gas-liquid two-phase contact can be enhanced, the gas-liquid two-phase atomization effect is promoted, and the wall flow phenomenon in the overflow pipe is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +2

Zinc gluconate pellets and preparation method thereof

InactiveCN101703478AGood dispersionQuick effectOrganic active ingredientsMetabolism disorderGluconic acidDissolution

The invention provides a zinc gluconate pellet preparation, which is prepared from zinc gluconate and pharmaceutic adjuvant, and is characterized in that: the pharmaceutic adjuvant is an excipient and an adhesive, wherein in the pellet preparation, the weight percent of the zinc gluconate is 10 to 80 percent, the weight percent of the excipient is 12 to 89 percent and the weight percent of the adhesive is 1 to 8 percent. The pellet preparation can be prepared into a slow release preparation or an enteric-coated preparation. The zinc gluconate pellet preparation has high dissolution rate, and high bioavailability; and the method is simple, convenient, and easy to operate.

Owner:JF PHARMALAND TECH DEV

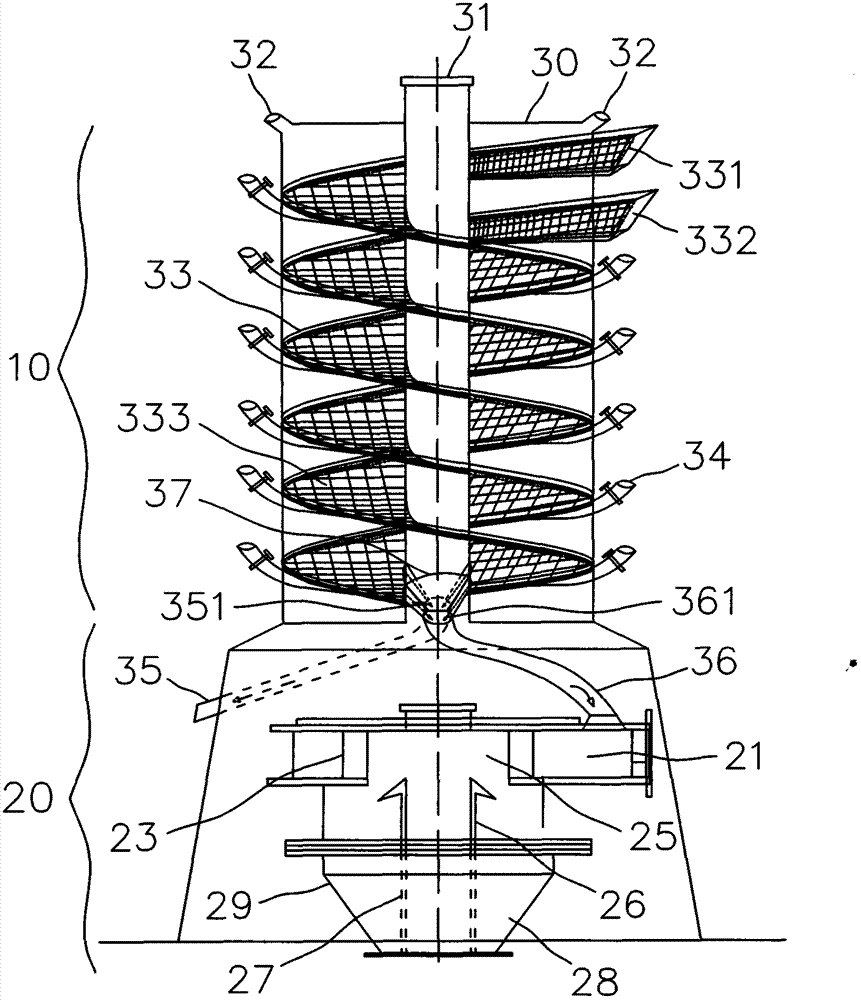

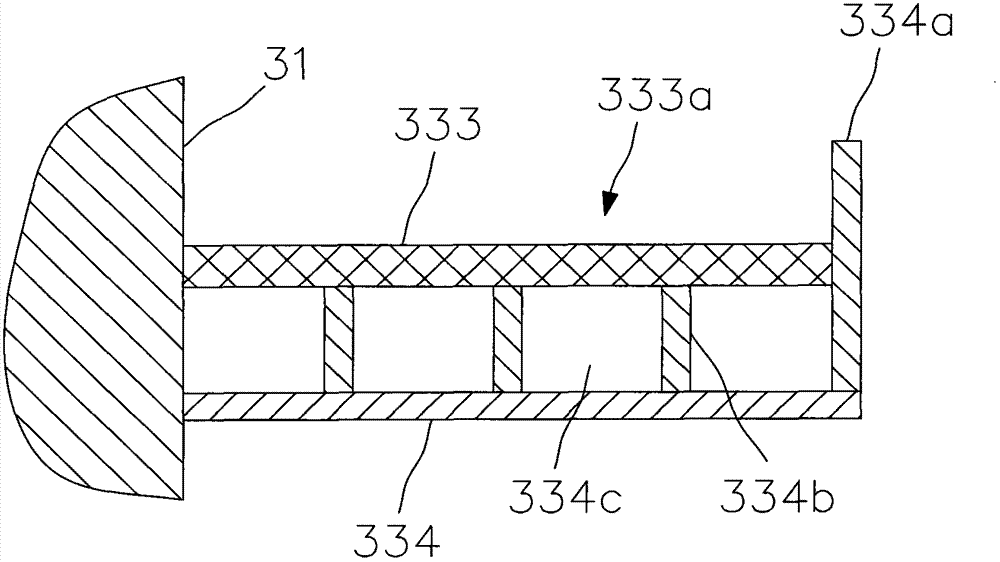

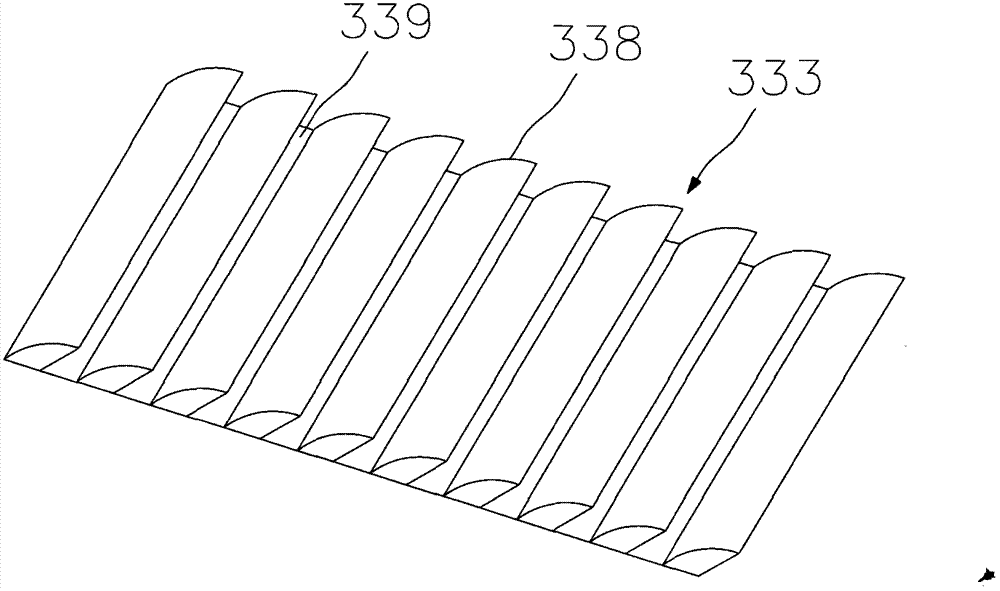

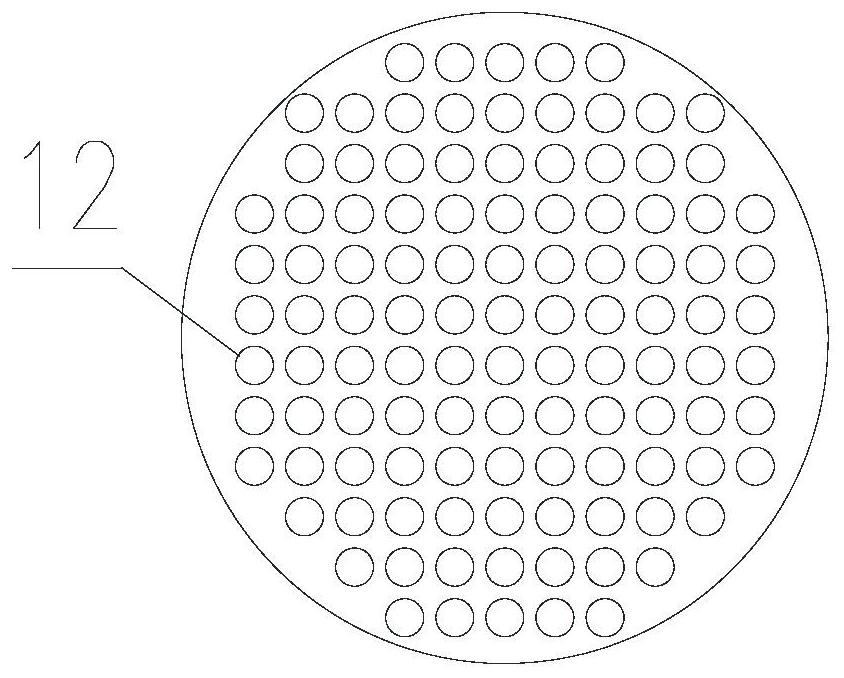

Multistage superfine grinding device

InactiveCN109550574ALarge dispersion areaAvoid gatheringSievingScreeningSuperfine grindingEngineering

The invention relates to the technical field of probiotic production equipment, and provides a multistage superfine grinding device. The device comprises a hollow feeding and distributing shaft, and at least two stages of distributing cones are arranged on the inner side of the feeding and distributing shaft, a plurality of material distributing holes are arranged in the position, corresponding tothe lower edges of the upper conical surfaces of the material distributing cones, on the feeding and distributing shaft; except for the last stage of material distributing cone, each stage of material distributing cone is provided with material distributing holes which are communicated up and down, and the aperture of each stage of material distribution holes are smaller than the aperture of thematerial distributing holes of the previous stage; and a sieve tray is arranged on the feeding and distributing shaft and located below each stage of material distributing cone in a rotating mode, andthe sieve trays is provided with sieve holes which are communicated up and down, the sieve trays are driven by the sieve tray driving device to rotate, and the raw materials are crushed and screened.According to the multistage superfine grinding device, raw material particles can be rapidly feeding and distributing, and step-by-step rapid crushing and screening can be realized, so that the crushing efficiency is improved, and the quality of the powder can be ensured.

Owner:山东君康生物科技有限公司

Dangshen extract pellet and preparation method thereof

InactiveCN102462721AReduce dosageQuality improvementDigestive systemGranular deliveryCodonopsis pilosulaBody fluid

The invention provides a dangshen extract pellet preparation, which is prepared from a dangshen extract and pharmaceutical adjuvants, and is characterized in that: an excipient and a bonding agent are taken as the pharmaceutical adjuvants; and the pellet preparation comprises the following components in percentage by weight: 30-70 percent of a dangshen extract, 20-65 percent of an excipient and 1-10 percent of a bonding agent. The pellet preparation can be prepared into a slow-release or enteric preparation as required. As proved by a pharmacological experiment, the pellet disclosed by the invention has the effects of tonifying middle-jiao and qi, invigorating the spleen, promoting the production of body fluid, and the like.

Owner:JF PHARMALAND TECH DEV

Suction and overflow combined type gas and liquid separator

InactiveCN105498642AWell mixedEvenly distributedChemical/physical processesHydrocarbon oils treatmentFixed bedTemperature difference

The invention relates to the technical field of hydrogenation reactor equipment of fixed beds, and discloses a suction and overflow combined type gas and liquid separator. The suction and overflow combined type gas and liquid separator comprises a bubble cap, an overflow pipe, a center pipe and a crushing plate, wherein the bubble cap, the overflow pipe, the center pipe and the crushing plate are coaxially connected; the bottom surfaces of the overflow pipe and the center pipe are flush with the lower surface of a tower tray plate; the crushing plate is connected with a bolt at the bottom part of the center pipe through a fastener; the top part of the overflow pipe is provided with an overflow port; a second positioning part is arranged at the lower part of the overflow pipe; the bottom surface of the second positioning part is in contact with the upper surface of the tower tray plate; a cover plate is arranged at the top part of the center pipe; the pipe wall, exposing out of the bubble cap, of the upper part of the center pipe is provided with a plurality of gas inlets, the middle part of the pipe wall of the center pipe is provided with a plurality of gas outlets, and the highest location of the corresponding gas outlet is lower than the bottom part of the overflow port. The suction and overflow combined type gas and liquid separator has the advantage that the gas and liquid separator and the tower tray plate form the gas and liquid distribution panel, and the gas and liquid phase raw materials are uniformly distributed to the catalyst bed layer, and are in full contact with the catalyst, so that the radial temperature difference of the catalyst bed layer is decreased, the oil quality is improved, and the production cost is saved.

Owner:LANZHOU LS GRP

Chondroitin sulfate pellet and preparation method thereof

InactiveCN101703475AGood dispersionQuick effectOrganic active ingredientsAntipyreticDissolutionBioavailability

The invention provides a chondroitin sulfate pellet preparation, which is prepared from chondroitin sulfate and pharmaceutic adjuvant. The pellet preparation is characterized in that the pharmaceutic adjuvant is excipient and bonding agent, wherein the pellet preparation comprises the following components in percentage by weight: 10 to 90 percent of the chondroitin sulfate, 3 to 89 percent of the excipient, and 1 to 7 percent of the bonding agent. The pellet preparation can be prepared into a slow-release preparation or an enteric-coated preparation as requested. The chondroitin sulfate pellet preparation has high dissolution rate and high bioavailability, and the method is simple and convenient and is easy to operate.

Owner:JF PHARMALAND TECH DEV

Astragalus polyose pellet and preparation method thereof

InactiveCN101444489AGood dispersionQuick effectOrganic active ingredientsMetabolism disorderAstragalus polysaccharideBioavailability

The invention provides an astragalus polyose pellet preparation composed of astragalus polyose and medical supplementary materials. The astragalus polyose pellet preparation is characterized in that the medical supplementary materials are excipients and binders; and in the pellet preparation, the content of astragalus polyose 0.5-70 percent by weight, the content of excipients is 30-99.5 percent by weight, and the content of binders is 1-5 percent by weight. The pellet preparation has high dissolution rate and high bioavailability, and the preparation method is simple, convenient and easy for operation.

Owner:JF PHARMALAND TECH DEV

Catalyst for diphenylguanidine (DPG) serving as accelerating agent in oxygen oxidation synthesis production process, and preparation method thereof

InactiveCN102350349AEasy to prepareEasy to industrializeOrganic chemistryMolecular sieve catalystsCerium nitrateManganese

The invention relates to a catalyst for diphenylguanidine (DPG) serving as an accelerating agent in an oxygen oxidation synthesis production process and a preparation method thereof. The catalyst is one or more of metal salts, such as copper acetate, copper sulfate, copper nitrate, cobalt acetate, cobalt sulfate, cobalt linoleate, cobalt nitrate, cerium acetate, cerium sulfate, cerium nitrate, manganese acetate, manganese sulfate, manganese nitrate and the like; and a carrier of the catalyst is one or more of active carbon, SiO2, Al2O3, TiO2, a mesoporous material molecular sieve, a micropore material molecular sieve and the like. The prepared catalyst is used in reaction of synthesizing the DPG by oxygen oxidation; and the reaction is used for reflecting the performance of the catalyst. The use amount of the catalyst is 0.02 to 0.1 percent of the weight of reactants. The catalyst provided by the invention has the advantages of rational formula, small use amount and good catalysis effect, and contains active ingredients and the carrier; furthermore, the dispersion area of the active ingredients is enlarged, so the contact area between the active ingredients and the reactants is enlarged and the reaction speed is increased; meanwhile, the use amount of the catalyst is reduced; and yield of CBS is up to over 97 percent under the optimized reaction conditions.

Owner:KEMAI CHEM

Magnolia bark extract pellet and preparation method thereof

InactiveCN102462716AControl releaseReduce the frequency of takingAntibacterial agentsNervous disorderMedicinePharmaceutic Adjuvant

The invention provides a magnolia bark extract pellet preparation which is prepared from a magnolia bark extract and pharmaceutic adjuvants and is characterized in that the pharmaceutic adjuvants comprise an excipient and a binding agent; and the pellet preparation comprises 10-60wt% of the magnolia bark extract, 35-89wt% of the excipient and 1-5wt% of the binding agent. The pellet preparation can be prepared into a sustained-release preparation or an enteric preparation according to requirements. Pharmacology experiments show that the pellet provided by the invention has the effects of sterilizing, tranquilizing and allaying excitement and the like.

Owner:JF PHARMALAND TECH DEV

Beta-carotene pellet and method for preparing the same

InactiveCN101219126AGood dispersionQuick effectOrganic active ingredientsAntinoxious agentsBeta-CaroteneAdjuvant

The invention provides a beta-carotene micro-pill prepared from beta-carotene and medicinal adjuvant, characterized in that the medicinal adjuvant comprises an excipient and a bonding agent; the content of the beta-carotene in the beta-carotene micro-pill is 1-10 weight percent, the excipient 70-95 weight percent and the bonding agent 1-5 weight percent. The beta-carotene micro-pill of the invention has the advantages of high dissolution rate, high bioavailability, easy preparation method and convenient and easy operation.

Owner:JF PHARMALAND TECH DEV

Red ginseng extract pellet and preparation method thereof

InactiveCN102462715AEffectiveSmall fluctuations in blood concentrationNervous disorderImmunological disordersPharmaceutical preservativesGINSENG EXTRACT

The invention provides a red ginseng extract pellet preparation, which is prepared from a red ginseng extract and pharmaceutical adjuvants, and is characterized in that: an excipient and a bonding agent are taken as the pharmaceutical adjuvants; and the pellet preparation comprises the following components in percentage by weight: 2-80 percent of a red ginseng extract, 15-97 percent of an excipient and 1-5 percent of a bonding agent. The pellet preparation can be prepared into a slow-release or enteric preparation as required. As proved by a pharmacological experiment, the pellet has the effects of reinforcing vital energy, restoring pulses, preventing exhaustion, tonifying qi and controlling blood.

Owner:JF PHARMALAND TECH DEV

Sea buckthorn extract pellet and preparation method thereof

InactiveCN101444547AQuick effectImprove bioavailabilityMetabolism disorderDigestive systemHippophae rhamnoidesPharmaceutical preservatives

The invention provides a sea buckthorn extract pellet preparation composed of sea buckthorn and medical supplementary materials. The sea buckthorn extract pellet preparation is characterized in that the medical supplementary materials are excipients and binders; and in the pellet preparation, the content of sea buckthorn extract 2-75 percent by weight, the content of excipients is 20-97 percent by weight, and the content of binders is 1-5 percent by weight. The pellet preparation has high dissolution rate and high bioavailability, and the preparation method is simple, convenient and easy for operation.

Owner:JF PHARMALAND TECH DEV

Donkey-hide gelatin micro-pills and preparation method thereof

The invention discloses a pellet formulation of donkey-hide gelatin which is prepared by donkey-hide gelatin and pharmaceutical excipients, wherein the pharmaceutical excipients are excipient and adhesive. In the pellet formulation, the weight percentage of the donkey-hide gelatin is 20-80 %, the weight percentage of the excipient is 20-80%, and the weight percentage of the adhesive is 1-5%. The pellet formulation can be made into sustained release formulation or enteric-coated formulation according to the requirements. The inventive pellet formulation has high dissolution rate and bioavailability, easy and convenient preparation method, and easy operation.

Owner:JF PHARMALAND TECH DEV

Pearl powder micro-pills and preparation method thereof

The invention discloses a pellet formulation of pearl powder which is prepared by pearl powder and pharmaceutical excipients, wherein the pharmaceutical excipients are excipient and adhesive. In the pellet formulation, the weight percentage of the pearl powder is 5-80%, the weight percentage of the excipient is 20-95%, and the weight percentage of the adhesive is 1-5%. The inventive pellet formulation has high dissolution rate and bioavailability, easy and convenient preparation method, and easy operation.

Owner:JF PHARMALAND TECH DEV

Levorotation carnitine pellet and method for preparing the same

InactiveCN101219133AGood dispersionQuick effectOrganic active ingredientsNervous disorderMedicineDissolution

The invention provides a levocarnitine micro-pill which is prepared from levocarnitine and pharmaceutic adjuvant, characterized in that the pharmaceutic adjuvant is an excipient and a bonding agent; the content of the levocarnitine in the levocarnitine micro-pill is 10 to 90 weight percent; the excipient 20-80 weight percent and the bonding agent 1-5 weight percent. The levocarnitine micro-pill of the invention has the advantages of high dissolution rate, high bioavailability, easy preparation method and convenient and easy operation.

Owner:JF PHARMALAND TECH DEV

Sea cucumber peptide micro-pills and preparation method thereof

InactiveCN101455680AQuick effectImprove bioavailabilityPeptide/protein ingredientsDigestive systemPeptidePharmaceutical Excipient

The invention discloses a pellet formulation of sea cucumber peptide which is prepared by sea cucumber peptide and pharmaceutical excipients, wherein the pharmaceutical excipients are excipient and adhesive. In the pellet formulation, the weight percentage of the sea cucumber peptide is 2-85%, the weight percentage of the excipient is 20-80%, and the weight percentage of the adhesive is 1-5%. The inventive pellet preparation has high dissolution rate and bioavailability, easy and convenient preparation method, and easy operation.

Owner:JF PHARMALAND TECH DEV

American ginseng extract pellet and preparation method thereof

InactiveCN102462717ALess excipientsStable qualityNervous disorderDigestive systemCardiovascular functionsAdhesive

The invention provides an American ginseng extract pellet preparation, which is prepared from an American ginseng extract and pharmaceutical adjuvants and is characterized in that the pharmaceutical adjuvants comprise an excipient and an adhesive; and in the pellet preparation, the weight percentage of the American ginseng extract is 1-75%, the weight percentage of the excipient is 17-98% and the percentage of the adhesive is 1-8%. The pellet preparation can be prepared into a sustained-release or intestine-soluble preparation as required. Pharmacological experiments show that the pellet provided by the invention has the actions of resisting fatigue, resisting aging, enhancing human immunity, improving cardiovascular functions and the like.

Owner:JF PHARMALAND TECH DEV

Compound hyaluronic acid pellet and preparation method thereof

The invention provides a compound hyaluronic acid pellet preparation. The compound hyaluronic acid pellet preparation is prepared from hyaluronic acid, VC and pharmaceutical accessories and is characterized in that the pharmaceutical accessories include an excipient and an adhesive; and the compound hyaluronic acid pellet preparation contains 5-20% by weight of hyaluronic acid, 1-5% by weight of VC, 70-85% by weight of the excipient and 1-5% by weight of the adhesive. The compound hyaluronic acid pellet preparation disclosed by the invention has high dissolution rate and bioavailability; and a preparation method is simple, convenient and easy to operate.

Owner:JF PHARMALAND TECH DEV

Tremella extract pellet and preparation method thereof

InactiveCN102462705AControl releaseReduce the frequency of takingDigestive systemAntinoxious agentsMedicinePharmaceutic Adjuvant

The invention provides a tremella extract pellet preparation which is prepared from a tremella extract and pharmaceutic adjuvants and is characterized in that the pharmaceutic adjuvants comprise an excipient and a binding agent; and the pellet preparation comprises 10-65wt% of the tremella extract, 30-89wt% of the excipient and 1-5wt% of the binding agent. The pellet preparation can be prepared into a sustained-release preparation or an enteric preparation according to requirements. Pharmacology experiments show that the pellet provided by the invention has the effects of strengthening sperms, tonifying the kidney, strengthening the lung, promoting the production of the body fluid, relieving a cough, reducing pathogenic fire, moisturizing the intestine, reinforcing the stomach, tonifying Qi and blood, toughening a body and the like.

Owner:JF PHARMALAND TECH DEV

Micro-pills containing apple polyphenol, and preparation method of micro-pills

InactiveCN104664397AGood dispersionQuick effectFood shapingFood preparationPharmaceutical AdjuvantsBioavailability

Owner:JF PHARMALAND TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com