Method for processing microelectrode on PDMS substrate based on inkjet printing technology

An inkjet printing, micro-electrode technology, applied in the direction of printing, material electrochemical variables, etc., can solve the problems of unfavorable droplet solvent evaporation, good electrode formation, small droplet diameter, etc., to improve inherent defects and poor adhesion , the effect of large dispersion area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The method for processing microelectrodes on a PDMS substrate based on the inkjet printing technology of the present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings.

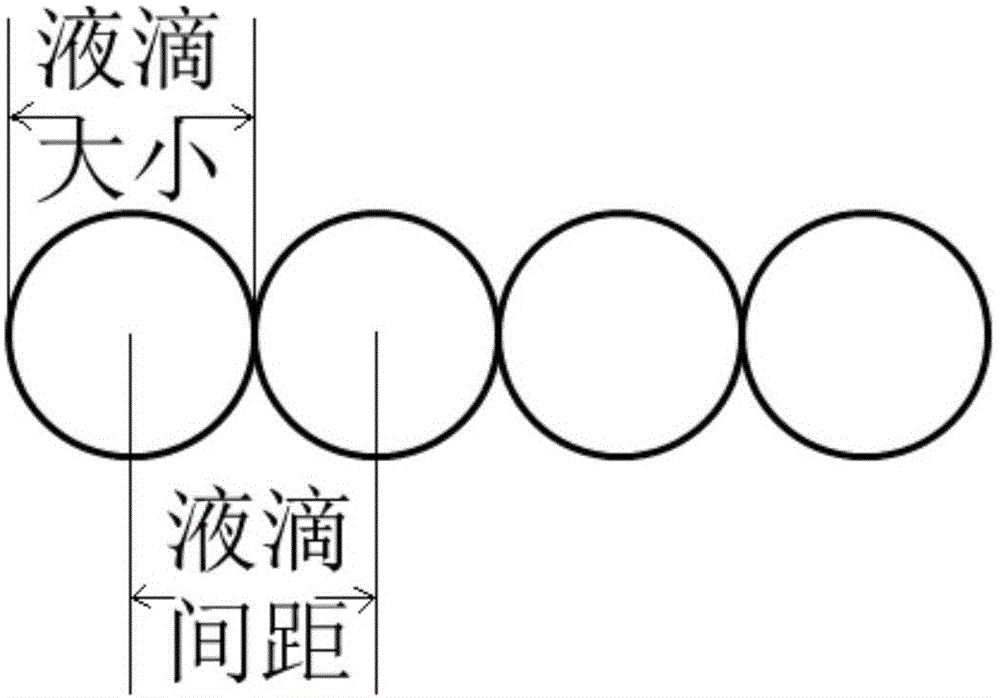

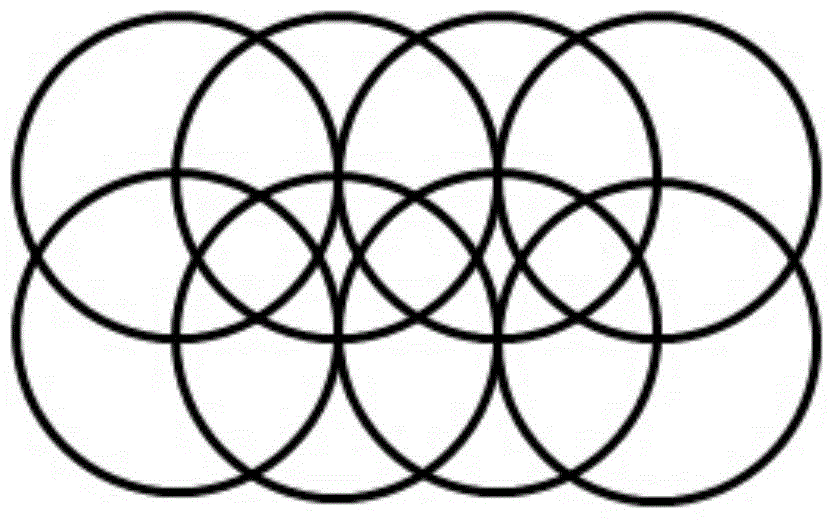

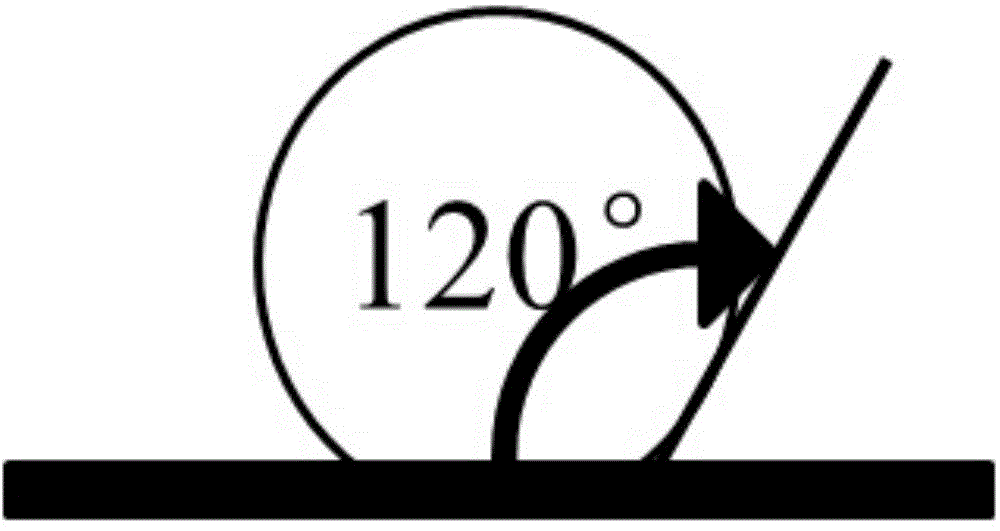

[0043]The method for processing microelectrodes on the PDMS substrate based on inkjet printing technology of the present invention adopts a model that is Dimatix 2831, Fujifilm, an inkjet printer capable of spraying silver nanoparticle solution of Japan, because the nozzle is printing the support rod The left and right movement of the upper body and the front and rear movement of the chassis, the silver nanoparticle droplets ejected from the nozzle can process the silver layer model of the two-dimensional structure. silver layer. Since the system prints according to the pre-designed image file, it only deposits silver nanoparticles where needed, no mask is required, and the processing process is efficient and simple.

[0044] The method for pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com