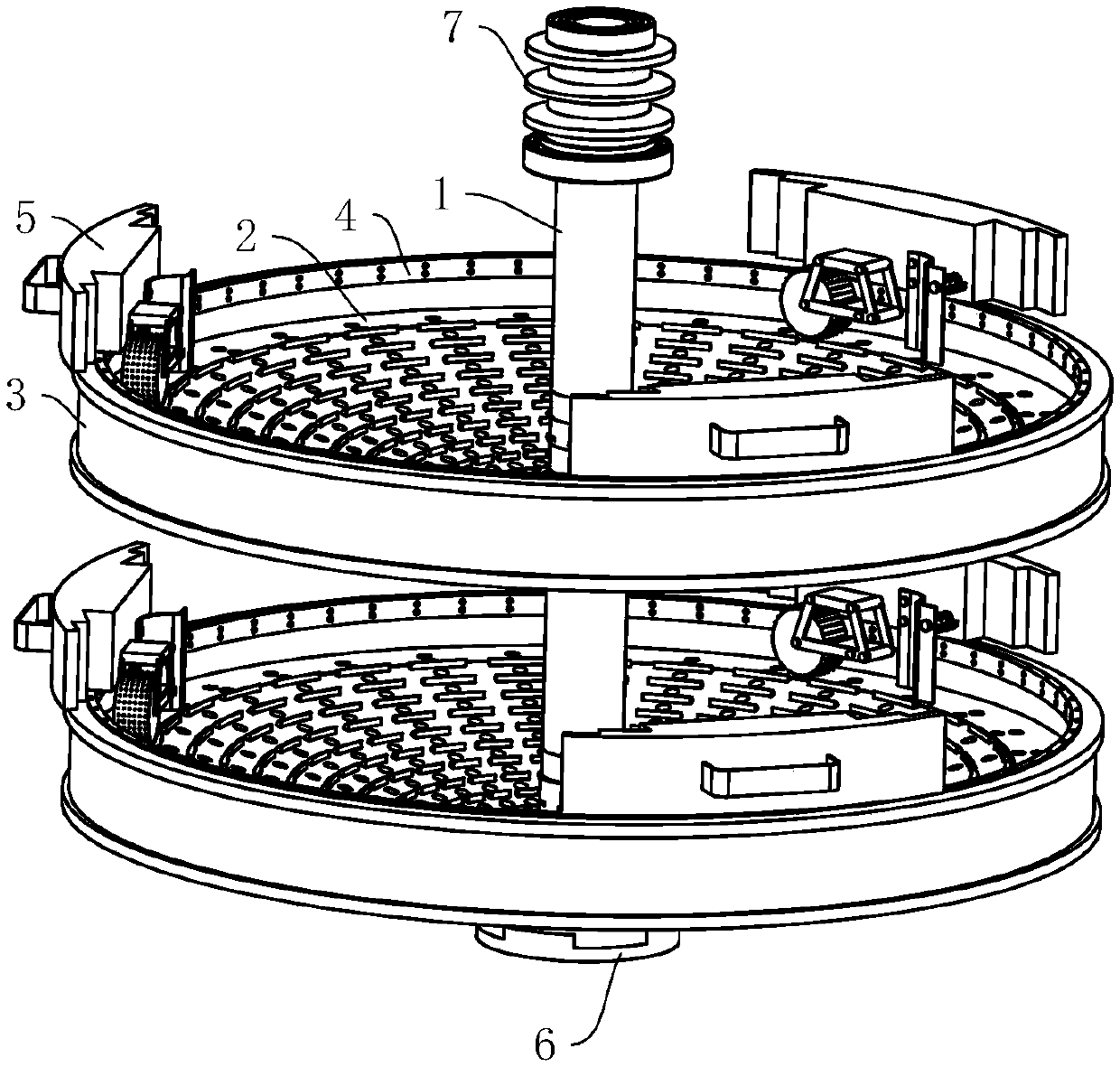

Multistage superfine grinding device

A technology of ultrafine pulverization and driving device, which is applied in the direction of solid separation, filter screen, grid, etc. It can solve the problems of incomplete pulverization, adverse effects of raw material quality, and low work efficiency, so as to improve the efficiency of crushing and screening and speed up pulverization Screening efficiency, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

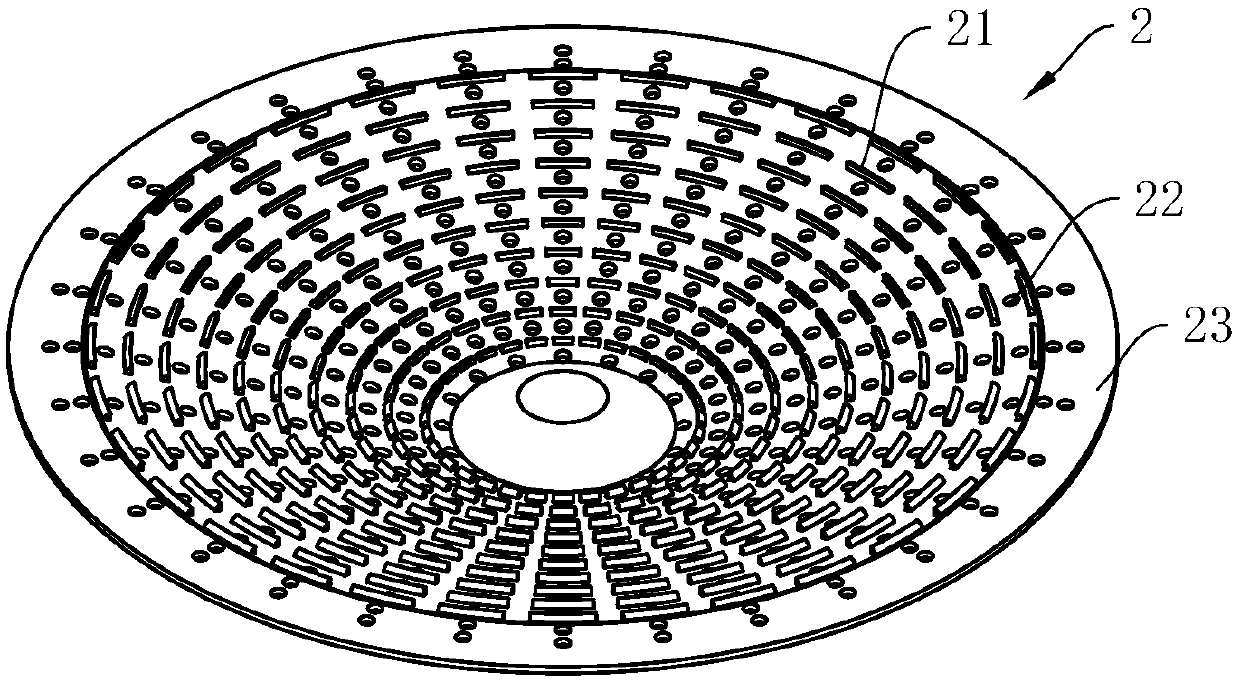

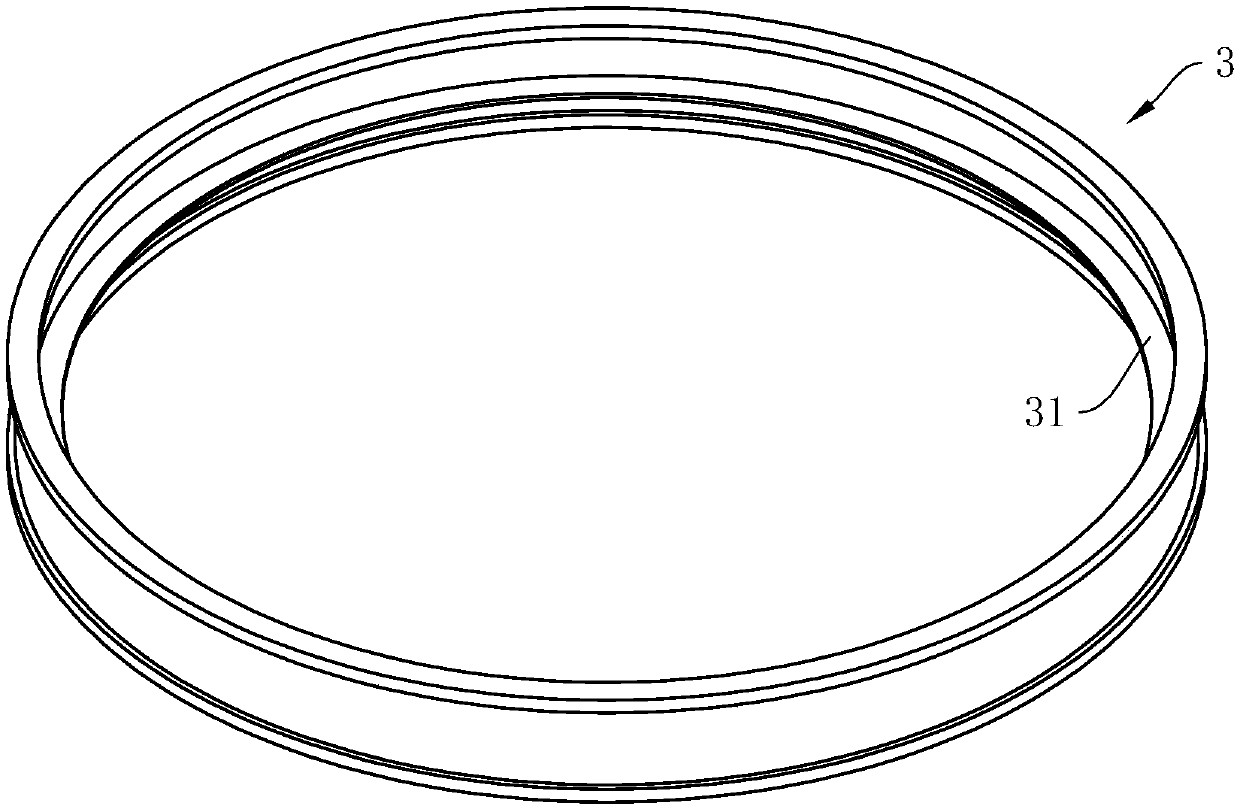

[0044] The multi-stage ultrafine pulverization device provided by the present invention comprises a hollow feeding and distributing shaft, at least two stages of distributing cones are arranged on the inner side of the feeding and distributing shaft, and the lower edge of the upper cone surface of the corresponding feeding and distributing cone on the feeding and distributing shaft There are multiple distributing ports along its circumference. Except for the last distributing cone, each distributing cone is provided with upper and lower transparent distributing holes, and the diameter of each dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com