Patents

Literature

41results about How to "High chlorine capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dechlorinating agent used for removing HCl from gas by dry method and preparation method thereof

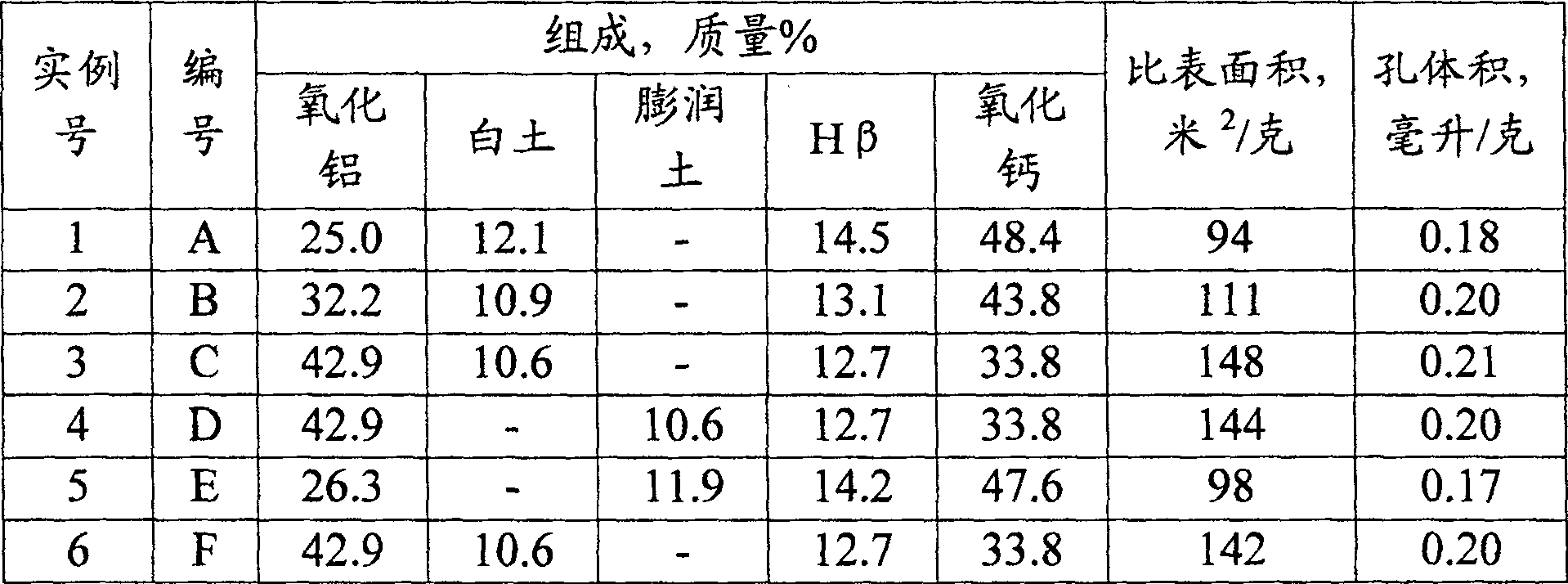

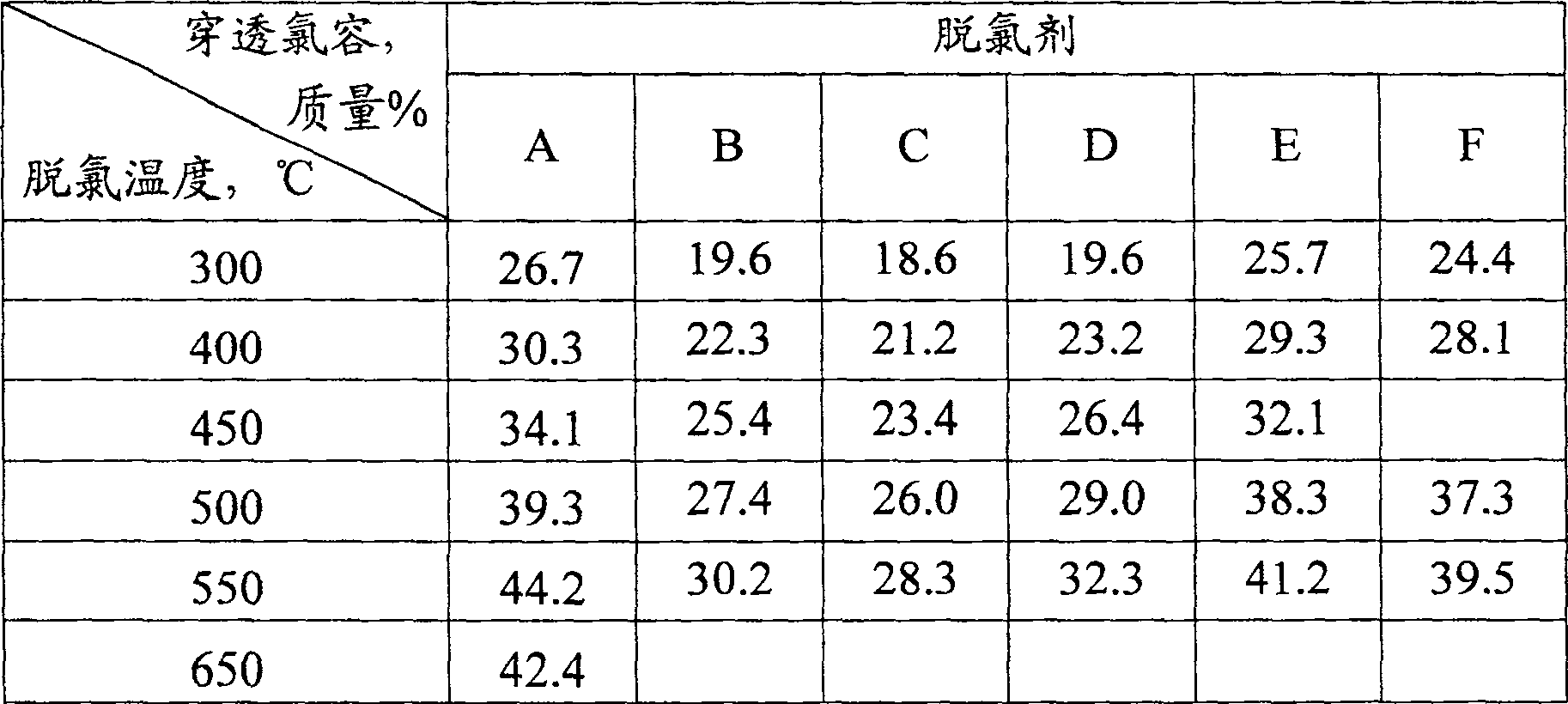

InactiveCN101773768AImprove dechlorination activityHigh activityOther chemical processesAluminium silicatesPorosityCross-link

The invention relates to a dechlorinating agent used for removing HCl from a gas by using a dry method and a preparation method thereof. The dechlorinating agent is prepared from Na2CO3, CaCO3, CaO and MaO as active constituents, crosslinked bentonite as a porous auxiliary agent, and methyl cellulose as a foaming agent and an auxiliary extrusion agent through extrusion forming, drying and roasting. The cross-linked bentonite is prepared by exchanging large-size poly aluminum cation with small-size simple cation, so that the crosslinked bentonite has great porosity factor and large specific surface. The specific surface and the pore volume of the crosslinked bentonite are larger than those of non-crosslinked bentonite. By using the crosslinked bentonite as the porous auxiliary agent, the specific surface of the dechlorinating agent is enlarged, and the dechlorinating activity and the chlorosity of the dechlorinating agent are increased. The dechlorinating agent prepared by using the crosslinked bentonite has a pore volume of 0.3-0.4 mL / g, a specific surface of 70-90 m<2> / g and a crushing strength of 60-80 N / cm, not only has lower price than pseudo-boehmite and a molecular sieve, but also has simple preparation process, high dechlorinating activity and great low-temperature penetration chlorosity.

Owner:长春惠工净化工业有限公司

Dechlorination agent and preparation method thereof

ActiveCN103386244AImprove adsorption efficiencyHigh dechlorination precisionDispersed particle separationHigh concentrationChemical reaction

Owner:康健科技(山东)有限公司

High-accuracy liquid-phase dechlorinating agent and preparation method thereof

ActiveCN105542836AHigh precisionIncrease polarityRefining with metal oxidesHydrocarbon oils treatmentActivated carbonOpen framework

The invention provides a high-accuracy liquid-phase dechlorinating agent. The dechlorinating agent is prepared from the following components in percentage by weight: 5-20 percent of CuO, 5-10 percent of CaO, 4-8 percent of KOH and the balance of modified activated carbon, wherein the modified activated carbon is activated carbon which is subjected to acidification and oxidation. According to the dechlorinating agent, the modified activated carbon is adopted as a carrier, the open-framework structure of the activated carbon can be optimized, the pore volume and specific surface area can be increased, the content of the oxygen-containing functional group on the surface of the activated carbon can be increased, the carrier polarity can be improved, the combination degree between the carrier and the active ingredient can be enhanced, loss of the active ingredient can be reduced, hydrogen chloride which is a polar molecule can be easily and stably adsorbed on the surface of the modified activated carbon having relatively large polarity, and the dechlorinating accuracy can be improved. Furthermore, the reaction activity of the dechlorinating agent and hydrogen chloride can be increased due to the synergistic effect of three active substances in the dechlorinating agent, and maximization of chlorine capacity of the dechlorinating agent can be effectively realized, so that the chlorine capacity of the liquid dechlorinating agent can be more than or equal to 16 percent, and the dechlorinating accuracy is lower than 0.5ppm.

Owner:SHENYANG SANJUKAITE CATALYST

Dechlorinating agent for high-temp gas and its preparing process

InactiveCN1334139AImprove stabilityHigh adsorption activityOther chemical processesDispersed particle separationAlkaline earth metalAdhesive

A high-temp dechlorinating agent is prepared from natural sepiolite as both active component and carrier, alkali-metal and alkali-earth metal compound as active component, and the inorganic or organic adhesive and pore-enlarging agent for high reaction power and stability. It can be used to remove hydrogen chloride from high-temp (650 deg.C) gas to lower than 0.5 ppm and make chlorine content reach 36%. Its advantages are high purifying power and chlorine content, simple preparing process and low cost.

Owner:EAST CHINA UNIV OF SCI & TECH

Normal-temperature dechlorination agent and preparation method thereof

InactiveCN103877939ALarge specific surface areaHigh porosityOther chemical processesDispersed particle separationCalcium hydroxideNitrate

The invention provides a normal-temperature dechlorination agent and a preparation method thereof. The normal-temperature dechlorination agent comprises a carrier, an active component MOF material supported by the carrier, and an adhesive agent calcium hydroxide; the MOF material is prepared by dissolving an organic ligand and metal ions in a solvent through a hydrothermal reaction method; the organic ligand is selected from substituted or unsubstituted aromatic polycarboxylic acids containing one or more rings, and from substituted or unsubstituted aromatic polycarboxylic acids containing at least a hetero atom and containing one or more rings; and the metal ligand is most preferably selected from nitrates or chlorides. The normal-temperature dechlorination agent has relatively large specific surface area, simple in synthetic technology, superior in performances and wide in application scope.

Owner:SHANGHAI UNIV OF ENG SCI

Antichlor used for purifying reforming regeneration gas and preparation method of antichlor

ActiveCN105478000AHigh reactivityIncrease acidityGas treatmentDispersed particle separationMass ratioAntichlor

The invention provides an antichlor used for purifying reforming regeneration gas. The antichlor is prepared from, by mass, 85-90wt% of a composite oxide carrier and 10-15wt% of alkaline earth metal oxide. The composite oxide carrier is a mixture formed by Al2O3, SiO2 and ZrO2 at the mass ratio of 80:(80-100):(1-3), the specific surface area of the composite oxide carrier is 310-340 m<2> / g, and the total acid content is 0.31-0.45 mmol / g. According to the antichlor, composite oxide with a specific composition is adopted as the carrier, the total acid content of the carrier can be easily controlled within a proper range so that the bonding force between metal active components and the carrier can be regulated and controlled to be moderate, accordingly, it is guaranteed that the antichlor has both high chlorine capacity and high anti-hardening capability, and thus the antichlor has broad industrialized application prospects.

Owner:SHENYANG SANJUKAITE CATALYST

High-temperature dechlorinating agent and preparing method thereof

ActiveCN101274211AImprove thermal stabilityImprove stabilityDispersed particle separationCatalytic reformingCalcium hydroxide

The invention relates to a high-temperature dechlorination agent, which consists of 0 to 42 wt percent of CaOH, 18 to 70 wt percent of CaO, 20 to 40 wt percent of hydrotalcite, 7 to 17 wt percent of clay and 0 to 7 wt percent of adhesive. Based on the high-temperature dechlorination agent, the invention further discloses a preparation method of the high-temperature dechlorination agent. The high-temperature dechlorination agent prepared by the preparation method can be applied to a coal gasification fuel cell (MCFC) system, a coal gasification combination circulation power generation (IGCC) system and catalytic reforming regeneration gas so as to remove the HCl; furthermore, the dechlorination agent has high chlorine content and good dechlorination effect.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Antichlor and preparation method thereof

ActiveCN106861386ARaise the ratioEvenly dispersedGas treatmentDispersed particle separationAlkaline earth metalOrganic chloride compound

The invention discloses an antichlor and a preparation method thereof. The antichlor uses a composite oxide as a carrier to be loaded with oxides of alkali metal and / or alkaline earth; the composite oxide carrier contains theta aluminum oxide and calcium oxide. The composite oxide carrier is prepared by a coprecipitation method; calcium oxide is introduced into a carrier framework structure; the breakthrough chlorine content can reach 17.6 percent at the normal temperature. Through high-temperature roasting, the prepared aluminum oxide with the theta material phase structure reduces the surface hydroxyl quantity; the physical adsorption of HCl on the antichlor is reduced to the maximum degree; the phenomenon of antichlor surface acidity enhancement due to HCl physical adsorption concentration is reduced, so that the phenomenon of green oil generation through olefin polymerization due to acid catalysis is reduced; the phenomenon of organic chloride generation through reaction of olefin and HCl due to acid catalysis can be avoided. In addition, through the prepared composite oxide carrier, the intensity of the antichlor is obviously improved; the agglomeration or pulverization phenomenon under the water-containing steam work condition can be eliminated.

Owner:WANHUA CHEM GRP CO LTD

C9 petroleum resin prehydrogenation catalyst and preparation method and application

ActiveCN109621973AHigh activityGood dispersionHeterogenous catalyst chemical elementsCatalyst activation/preparationSulfurActive component

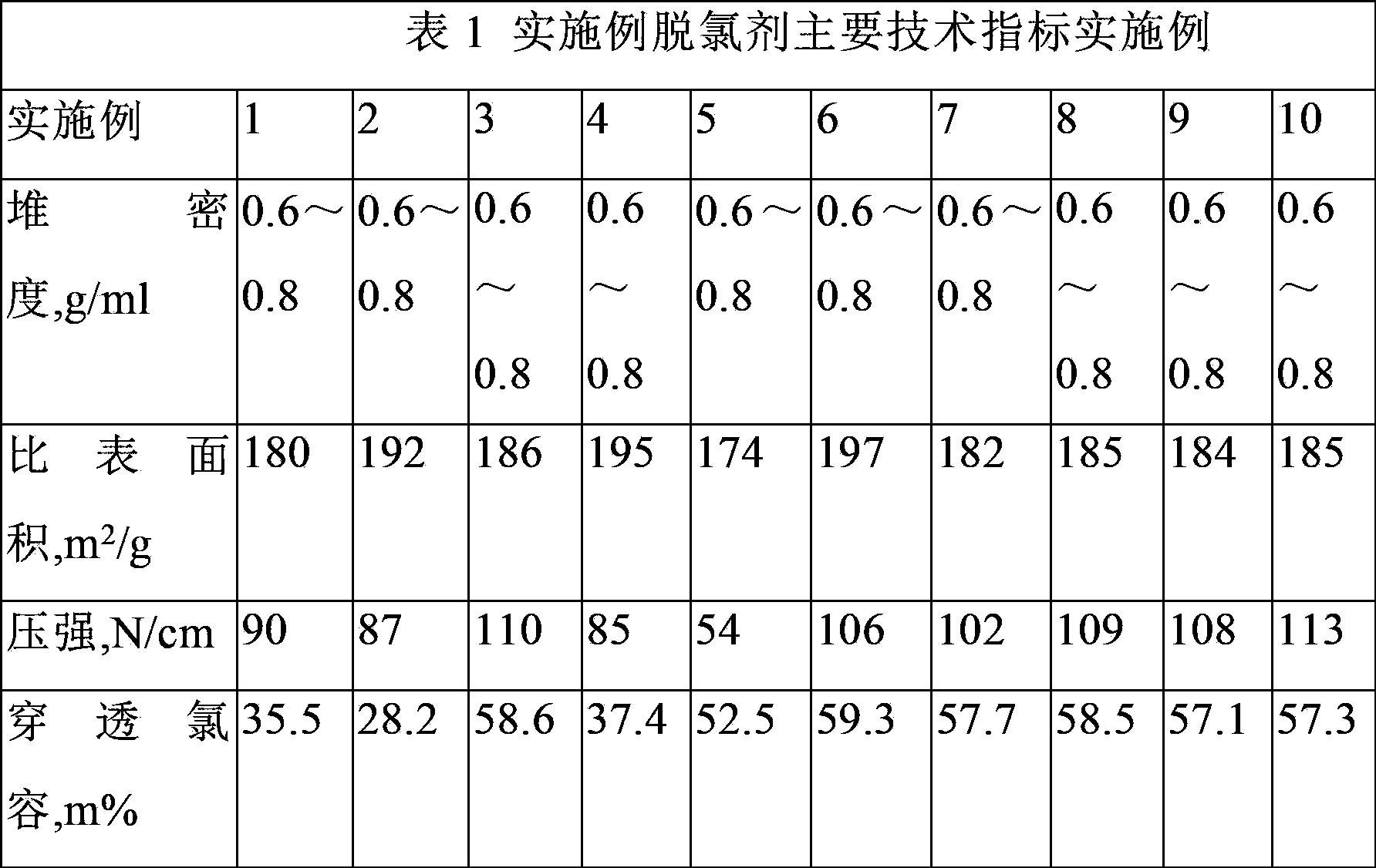

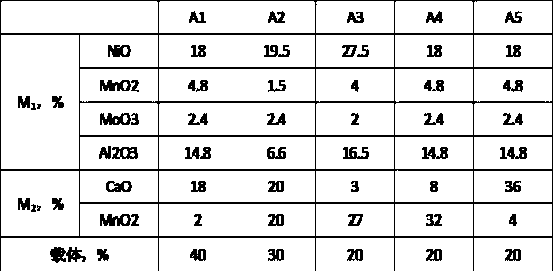

The invention discloses a C9 petroleum resin prehydrogenation catalyst. The C9 petroleum resin prehydrogenation catalyst, by weight, comprises 30-50% of an active component M1 of a laminar structure,20-40% of an additive component M2 and the balance a carrier according to 100 weight percentages, the component M1 comprises Ni, Mn, Al and Mo, the component M2 comprises Ca and Mn, and the carrier isamorphous form aluminum silicon. The invention further discloses a preparation and application of the catalyst. The catalyst is used for C9 petroleum resin prehydrogenation, has the functions of hydrogenation adsorption desulfurization and dechlorination, and can effectively avoid sulfur and chlorine poisoning of a main hydrogenation catalyst at a late stage.

Owner:WUHAN KELIN FINE CHEM

High temperature antichlor and preparation method thereof

ActiveCN103041769AHigh adsorption activityImprove thermal stabilityOther chemical processesDispersed particle separationActive componentAntichlor

The invention discloses a high temperature antichlor and a preparation method thereof. The antichlor comprises one or more of Ca(NO3)2, Ca(OH)2, Mg(NO3)2, Cu(NO3)2 and Zn(NO3)2, aluminum salt of Al(NO3)3 or Al(OH)3, and 20-47% of clay taking Al2Si2O5(OH)4 as a primary component, wherein the one or more of Ca(NO3)2, Ca(OH)2, Mg(NO3)2, Cu(NO3)2 and Zn(NO3)2 is or are taken as active component or active components and the aluminum salt of Al(NO3)3 or Al(OH)3 is taken as a carrier and an additive. The invention further discloses the preparation method for the high temperature antichlor, and the preparation method comprises the steps of uniformly mixing the materials, adding into a reaction kettle for dissolving, rotating, heating, filtering, washing and drying, roasting, forming and pelletizing the obtained solid to obtain the high temperature antichlor. The prepared antichlor can be used for efficiently and deeply removing chlorine gas in smoke at the temperature of 723-1023 K DEG C, and the chlorine penetration capacity reaches more than 60%.

Owner:SOUTHEAST UNIV

Low temperature liquid phase de-chlorinating agent and preparation method and applications thereof

ActiveCN107876016AOvercoming the drawbacks of requiring the use of phase transfer catalystsAvoid uniformityOther chemical processesHydrocarbon oils refiningSodium acetateCatalytic reforming

The invention provides a low temperature liquid phase de-chlorinating agent, which is composed of a component A and a component B. The component B is adsorbed on the component A. The component A is active carbon, which has been modified by a modifier. The component B is sodium acetate or sodium citrate. The mass ratio of the component A to the component B is (4-9):1, and the modifier accounts for20 to 35 wt% of the component A, and the balance being active carbon. The invention also provides a method for preparing the low temperature liquid phase de-chlorinating agent and an application of the de-chlorinating agent in catalytic reforming to generate de-chlorinated oil. The provided de-chlorinating agent perfectly solves the problem that in the prior art, the organic chlorine removing effect of a de-chlorinating agent is not good, and is capable of converting organic chlorine into inorganic chlorine and absorbing inorganic chlorine.

Owner:XIAN ORIGIN CHEM TECH

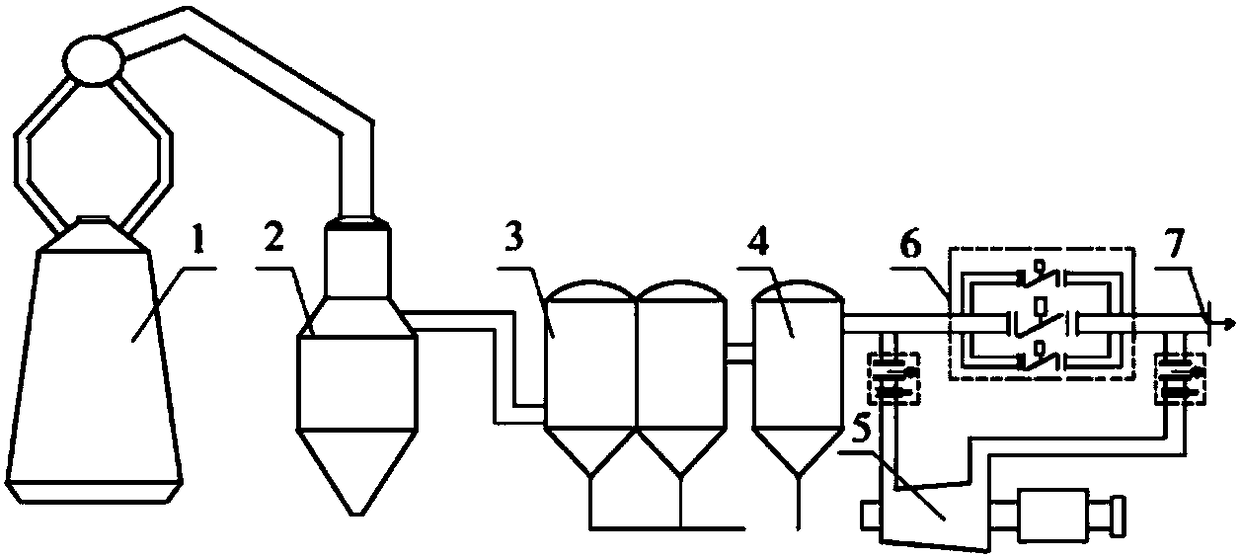

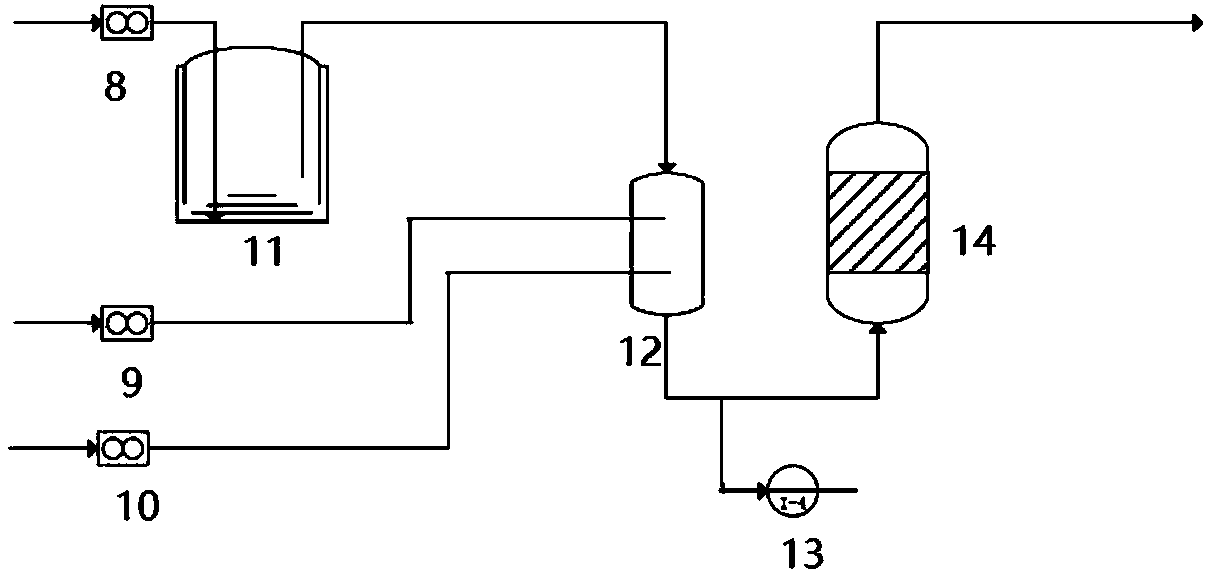

Blast furnace coal gas dechlorinating agent, preparation method of dechlorinating agent and dechlorinating method thereof

InactiveCN108531224AImprove efficiencyHigh hydrogen chloride contentGas purification with selectively adsorptive solidsSolid state reaction methodBULK ACTIVE INGREDIENT

The invention discloses a blast furnace coal gas dechlorinating agent, a preparation method of the dechlorinating agent and a dechlorinating method thereof. The blast furnace coal gas dechlorinating agent has the active ingredients of calcium carbonate. The calcium carbonate, bonding agents and water are kneaded together; then strip extrusion is performed; the keeping in good health over the nightis performed in natural environment; then, the drying is performed at a higher temperature. The intensity is 80N / cm or more; after the single-time use, the water washing can be performed; then, multi-time dichlorination can be performed; after the water washing, the intensity is 50N / cm or more; the mass percentage of the active ingredient calcium carbonate in the dechlorinating agent is 28.2 to 90 percent; the active ingredient calcium carbonate can be heavy calcium carbonate with the granularity being 1250 to 1500 meshes, light calcium carbonate with the granularity being 1250 to 1500 meshes, calcium carbonate prepared by a nanometer stage coprecipitation method, and calcium carbonate prepared by a nanometer stage solid phase reaction method. During the dichlorination, 20 to 25 particlesof raw particle dechlorinating agents with the length being about 5mm are filled in the lower end of the contact air source; 3 to 5ml of granulation dechlorinating agents being 20 to 40 meshes are filled at the upper side. The preparation process is simple; the cost is low; the performance is excellent.

Owner:BEIJING PEKING UNIV PIONEER TECH

Dechlorinating agent and preparation method and application thereof

InactiveCN111013532AHigh chlorine capacityImprove efficiencyOther chemical processesHydrocarbon oils refiningPotassiumCopper oxide

The invention provides a dechlorinating agent as well as a preparation method and application thereof. The dechlorinating agent comprises a binder and a carrier, and also comprises 3.3-6.6 wt% of copper oxide and 5-25wt% of potassium permanganate, based on the total mass amount of the dechlorinating agent. Manganese atoms in potassium permanganate contain a large number of empty orbits, and chlorine atoms in organochlorine contain three pairs of lone electrons, so that adsorption and removal on organochlorine are improved; moreover, the oxidability of potassium permanganate can change the contents of acidic groups and basic groups on the surface of the carrier, so that the chemical properties of the surface of the carrier are changed, and the adsorption performance of the carrier to organochlorine and hydrogen chloride is improved; on the other hand, potassium permanganate can generate a synergistic effect with copper oxide and an adhesive, so that the affinity between each component and the carrier is improved, the loss of each component in the use process is reduced, and the chlorine capacity and the dechlorination efficiency of the dechlorinating agent are further improved; agglomeration among metal ions can be prevented, so that the metal ions are kept in a dispersed state on the surface of the carrier; and the chlorine capacity and the dechlorination efficiency of the dechlorinating agent are further improved.

Owner:SHENYANG SANJUKAITE CATALYST

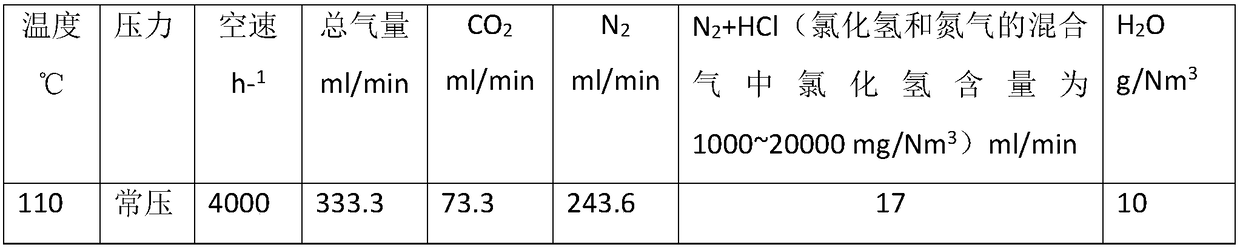

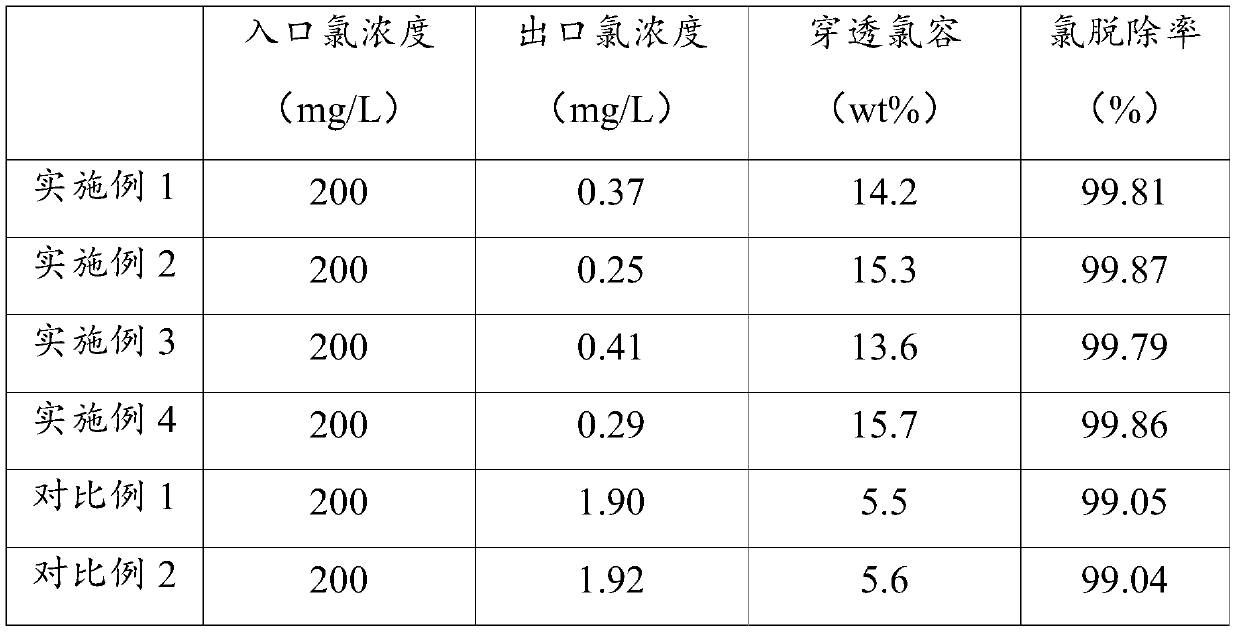

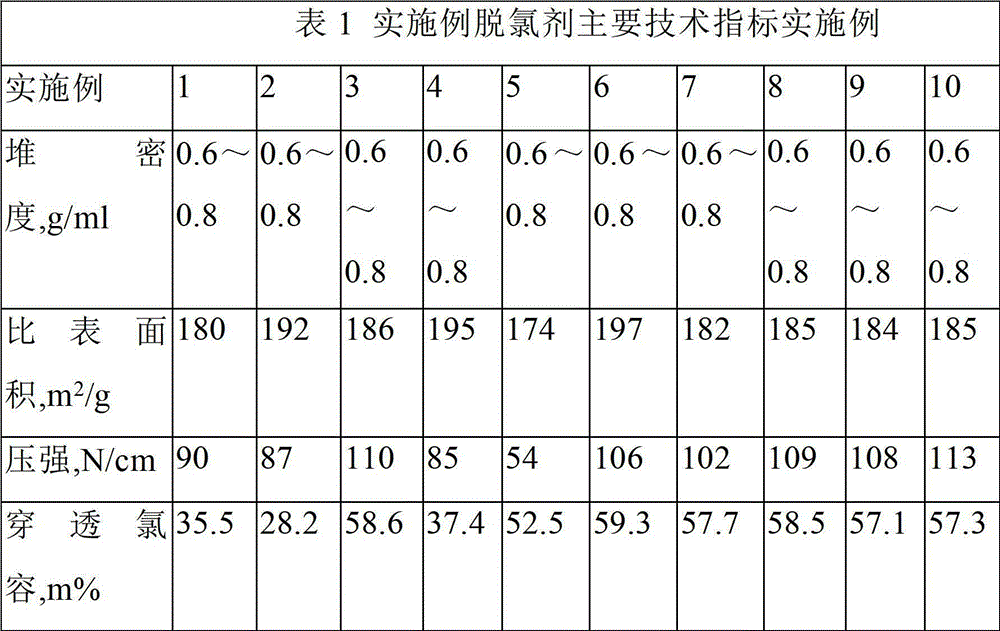

Normal-temperature gas-phase dechlorinating agent, preparation method therefor and application of normal-temperature gas-phase dechlorinating agent

ActiveCN107583417ALarge penetrating chlorine capacityIncrease the areaDispersed particle separationCalcium hydroxideSodium Bentonite

The invention belongs to the technical field of dechlorination and particularly relates to a normal-temperature gas-phase dechlorinating agent, a preparation method therefor and an application of thenormal-temperature gas-phase dechlorinating agent. The dechlorinating agent comprises a support and active ingredients, wherein the active ingredients comprise CaO and CuO, the support comprises bentonite and alkali modified fly ash, and the alkali modified fly ash is alkali solution modified fly ash. The preparation method disclosed by the invention comprises the steps of mixing calcium hydroxide, copper oxide, bentonite and the alkali modified fly ash, adding a binder into the mixture, carrying out strip extruding, carrying out drying, and carrying out roasting, thereby preparing the dechlorinating agent. The dechlorinating agent obtained by using the preparation method can achieve a dechlorination function at normal temperatures and has relatively high dechlorination accuracy and penetrating chlorosity.

Owner:SHENYANG SANJUKAITE CATALYST

High-activity dechlorinating agent for fixed bed and preparation method thereof

InactiveCN102068889ASolving for Ca(OH)

<sub>2</sub>

Disadvantages as an active ingredientLarge specific surface areaDispersed particle separationHydrocarbon oils refiningFixed bedBULK ACTIVE INGREDIENT

The invention relates to a high-activity dechlorinating agent for a fixed bed and a preparation method thereof. The preparation method comprises the following steps of: swelling methyl cellulose with deionized hot water; adding calcium chloride after the methyl cellulose is completely dissolved; uniformly stirring to completely dissolve the calcium chloride; dissolving NaOH in deionized water; dropwise adding NaOH aqueous solution into homogeneous phase aqueous solution of the methyl cellulose and Ca<+2> ions with violent stirring; performing centrifugal separation to obtain filter cakes; adding clay into the filter cakes; kneading and then extruding into strips; drying; calcining; and cooling to obtain the high-activity dechlorinating agent for the fixed bed. In the method, Ca(OH)2 precipitates are produced by precipitation reaction of the Ca<2+> and OH<-1>; the produced Ca(OH)2 is nanosized through dispersion, complexing and template action of the methyl cellulose; the clay is directly added without washing or drying after the precipitates are subjected to centrifugal separation; and the mixture is kneaded and extruded into strips so as to prepare a product. The defect that the commercial Ca(OH)2 is individually used as an active ingredient is overcome, and the high-activity dechlorinating agent has a large specific surface area and high chlorine content and dechlorinating activity, and the preparation process is simple and is low in cost.

Owner:长春惠工净化工业有限公司

Dechlorination agent and preparation method thereof

ActiveCN103386244BImprove adsorption efficiencyHigh dechlorination precisionDispersed particle separationHigh concentrationChemical reaction

The invention discloses a dechlorination agent and a preparation method thereof. The dechlorination agent is prepared from the following materials: 15-70wt% of carrier, 15-60wt% of active components, 1-10wt% of a pore-forming agent, 1-5wt% of an extrusion aid and 2-10wt% of a binder, wherein the carrier is at least one of weak acid salt, kaolin, pseudo-boehmite or Al2O3. The preparation method comprises the steps of mixing the materials, adding water, mixing, kneading, extruding, drying and calcining. The dechlorination agent has the advantages of high adsorption efficiency against high-concentration or low-concentration HCl at normal temperature, high dechlorination precision, high chlorine content of above 30% and a certain adsorption effect against organic chlorides; chemical reaction adsorption is adopted for adsorption against HCl, the adsorption is performed at normal temperature and normal pressure, energy consumption is not required, and the absorbed HCl and the active component in the dechlorination agent perform reaction to form a stable chemical substance to exist in an adsorber bed layer; and the dechlorination agent further has the advantages of low toxicity, high stability, easiness in filling and unloading, and no secondary pollution.

Owner:康健科技(山东)有限公司

Dechlorinating agent suitable for blast furnace gas, preparation method of dechlorinating agent and application of composition of dechlorinating agent

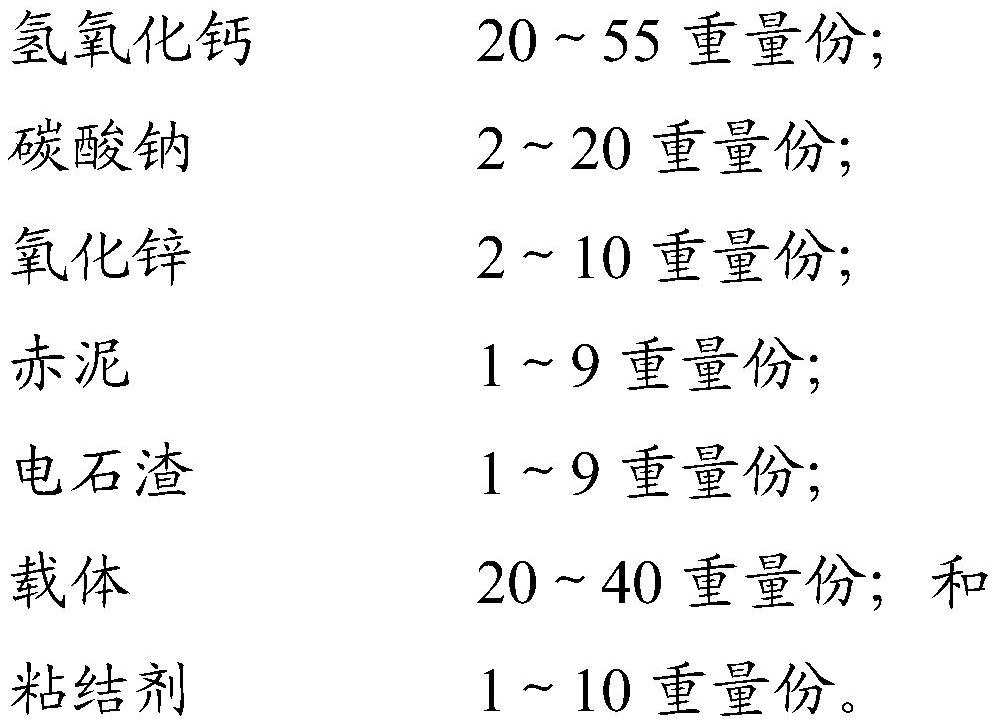

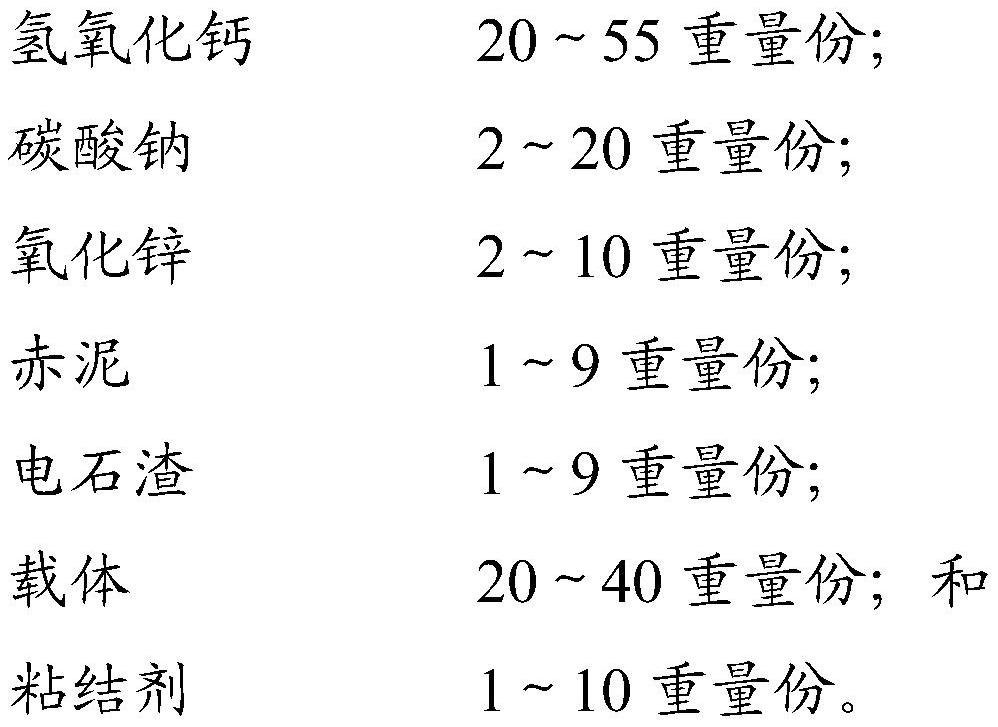

The invention discloses a dechlorinating agent suitable for blast furnace gas and a preparation method of the dechlorinating agent. The dechlorinating agent is prepared from the following raw materials in parts by weight: 20-55 parts of calcium hydroxide; 2-20 parts by weight of sodium carbonate; 2-10 parts by weight of zinc oxide; 1-9 parts by weight of red mud; 1-9 parts by weight of carbide slag; 20-40 parts by weight of a carrier; and 1-10 parts by weight of a binder. The dechlorinating agent has relatively high chlorine capacity. The invention also discloses application of a composition in improving the chlorine capacity of the dechlorinating agent suitable for blast furnace gas.

Owner:ZHONGJING ENVIRONMENTAL TECH CO LTD

Normal temperature dechlorination agent and preparation method thereof

InactiveCN103877939BLarge specific surface areaHigh porosityOther chemical processesDispersed particle separationCalcium hydroxideNitrate

The invention provides a normal-temperature dechlorination agent and a preparation method thereof. The normal-temperature dechlorination agent comprises a carrier, an active component MOF material supported by the carrier, and an adhesive agent calcium hydroxide; the MOF material is prepared by dissolving an organic ligand and metal ions in a solvent through a hydrothermal reaction method; the organic ligand is selected from substituted or unsubstituted aromatic polycarboxylic acids containing one or more rings, and from substituted or unsubstituted aromatic polycarboxylic acids containing at least a hetero atom and containing one or more rings; and the metal ligand is most preferably selected from nitrates or chlorides. The normal-temperature dechlorination agent has relatively large specific surface area, simple in synthetic technology, superior in performances and wide in application scope.

Owner:SHANGHAI UNIV OF ENG SCI

Dechlorination agent and preparation method thereof

InactiveCN104492368AHigh mechanical strengthHigh chlorine capacityOther chemical processesAluminium silicatesCalcium hydroxideSulfate

The invention provides a dechlorination agent. Ferrous sulfate, calcium powder and high-sulfur capacity powder are taken as effective raw materials, ferrous sulfate and calcium hydroxide in the calcium powder are firstly used for reacting to generate iron hydroxide oxide and calcium sulfate, iron hydroxide oxide which is produced by reacting and the high-sulfur capacity powder which is directly added and takes iron hydroxide oxide as a main component are jointly used as active components, the synergy between the two active components is fully exerted, and the chlorine capacity of the dechlorination agent is effectively improved; and simultaneously, calcium sulfate which can be autogenously produced in the reaction process and has a bonding effect is further used to optimize a pore canal, a specific surface area and distribution of an active center in the structure of the dechlorination agent, and the mechanical strength of the dechlorination agent can be further effectively improved. The dechlorination agent provided by the invention has relatively high chlorine capacity and mechanical strength, and data shows that the chlorine capacity of the dechlorination agent is above 65% and the mechanical strength is above 100N / cm.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Medium-high temperature dechlorination agent for removing hcl gas and preparation method thereof

ActiveCN103830996BEfficient deep removalLarge specific surface areaDispersed particle separationSodium bicarbonateAdhesive

Owner:SOUTHEAST UNIV

A kind of normal temperature gas phase dechlorination agent and its preparation method and application

ActiveCN107583417BLarge penetrating chlorine capacityIncrease the areaDispersed particle separationCalcium hydroxideGas phase

The invention belongs to the technical field of dechlorination, and in particular relates to a normal-temperature gas-phase dechlorination agent and a preparation method and application thereof. The dechlorination agent includes a carrier and an active component, the active component includes CaO and CuO, the carrier is bentonite and alkali-modified fly ash, and the alkali-modified fly ash is fly ash modified by alkali solution. The preparation method of the present invention is prepared by mixing calcium hydroxide, copper oxide, bentonite and alkali-modified fly ash, adding a binder, extruding, drying, and roasting. The dechlorination agent obtained by using the preparation method can The dechlorination function can be realized under the condition of high dechlorination precision and breakthrough chlorine capacity.

Owner:SHENYANG SANJUKAITE CATALYST

Normal-temperature dechlorinating agent for organochlorine and preparation method and application thereof

InactiveCN110841591AEnhance low temperature adsorption capacityFully dispersedOther chemical processesDispersed particle separationPtru catalystAdhesive

The invention provides a normal-temperature dechlorinating agent for organochlorine and a preparation method and application thereof. The normal-temperature dechlorinating agent for organochlorine isprepared from the following raw materials in parts by weight: 70-120 parts of an active component precursor, 3-10 parts of an adsorbent, 10-25 parts of a pore forming agent, 20-35 parts of an adhesiveand 0.05-5 parts of a bonding hydration agent, wherein the adhesive comprises sodium bentonite, and the bonding hydration agent is soluble alkali. The normal-temperature dechlorinating agent and thepreparation method thereof have the following beneficial effects: activated aluminum oxide powder is added as an auxiliary agent, so the low-temperature adsorption capacity of the dechlorinating agentcan be effectively enhanced; the bonding hydration agent is prehydrated in the forming process, so the adhesive agent can be fully dispersed, the structural strength of the dechlorinating catalyst isimproved, the effect of a pore-forming agent can be fully played, the micropore structure and specific area of a catalyst are increased, and the chlorine capacity and chlorine removal precision of the catalyst are improved; and moreover, in the existing preparation process, standing for one to two days is required so as to prevent deformation in the calcining process, but however, the curing timein the preparation method is short, and preparation time is further saved.

Owner:湖北浚然新材料有限公司

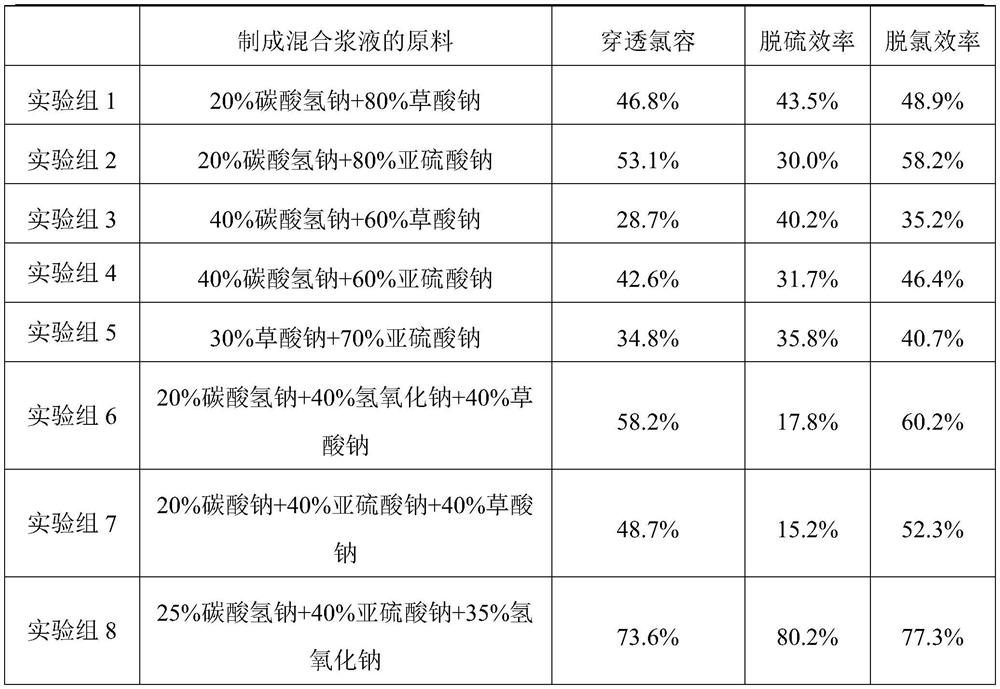

Selective dechlorination absorbent, preparation method and use method

ActiveCN114159965AGuaranteed efficient selectivityImprove dechlorination effectGas treatmentDispersed particle separationSodium bicarbonateSulfite salt

The invention belongs to the field of flue gas deacidification and material preparation, and discloses a selective dechlorination absorbent, a preparation method and a use method. The absorbent for selective dechlorination comprises sodium bicarbonate, sodium sulfite and sodium oxalate, and the mass ratio of sodium bicarbonate to sodium sulfite to sodium oxalate is (1-2): (3-5): (3-5). The preparation method comprises the following steps: (1) weighing sodium bicarbonate, sodium sulfite and sodium oxalate, uniformly mixing to obtain a mixture, then adding water, and stirring until the mixture is pasty to obtain mixed slurry; (2) standing the mixed slurry in an open air for cooling, and naturally airing; and (3) drying the air-dried mixed slurry, and crushing and sieving the dried mixed slurry to obtain the selective dechlorination absorbent. The absorbent provided by the invention can react with more hydrogen chloride, but does not react with other acidic components, has efficient selectivity on hydrogen chloride, is simple in preparation method and high in chlorine capacity, and has a wide application prospect.

Owner:UNIV OF SCI & TECH BEIJING

Antichlor for catalytic reforming regenerated gas and preparation method

InactiveCN100453147CImprove purification effectHigh chlorine capacityOther chemical processesDispersed particle separationCatalytic reformingAntichlor

The invention discloses a catalytic reforming resurgent gas antichlor and it's preparing method. The antichlor comprises (by weight percent): Ca(OH)2 or CaO 30%-60%, MgCO3 or MgO 20%-30%, K2CO3 or KOH 10%-15%, foraminous zeolite or siallitic soil 5%-15%, alhydrogel powder or silicasol 5%-15%; The total of the raw materials are 100%. The suing range comprises: IFP-I type reforming regeneration craft, IFP- II type reforming regeneration craft, UOP type reforming regeneration craft and other types of reforming regeneration craft.

Owner:XIAN ORIGIN CHEM TECH

Inorganic dechlorinating agent, preparation method and application thereof

PendingCN113736508APreserve the pore structureAvoid churnRefining with metal oxidesHydrocarbon oils treatmentAlkali metal oxideSodium aluminate

The invention discloses an inorganic dechlorinating agent, a preparation method and an application thereof, the inorganic dechlorinating agent comprises a basic carrier, the basic carrier is coated with a rare earth oxide layer to form a composite carrier, the composite carrier is coated with an active component layer, the basic carrier is Al2O3, and the active component is alkali metal oxide; based on the total amount of the inorganic dechlorinating agent, the molar fraction of each component is as follows: 1-50% of alkali metal oxide, 0.5-5% of rare earth oxide and the balance of Al2O3; the rare earth oxide interacts with the surface of Al2O3, an alkali stable structure is formed on the surface of Al2O3, alkali metal is inhibited from acting with Al2O3 to generate sodium aluminate, the pore structure of alumina is better reserved, meanwhile, the rare earth oxide interacts with sodium oxide, sodium oxide is stabilized, loss of active components is prevented, more sodium oxide exists in the form of sodium hydroxide and better reacts with HCl, and therefore, the chlorine capacity is improved.

Owner:润和科华催化剂上海有限公司

A kind of high-precision liquid phase dechlorination agent and preparation method thereof

ActiveCN105542836BHigh precisionIncrease polarityRefining with metal oxidesMetal/metal-oxides/metal-hydroxide catalystsActivated carbonFluid phase

The invention provides a high-precision liquid-phase dechlorination agent, which is composed of the following components: 5-20wt% of CuO, 5-10wt% of CaO, 4-8wt% of KOH, and the balance is modified activated carbon; Modified activated carbon is activated carbon that has been acidified and oxidized. The dechlorination agent of the present invention uses modified activated carbon as a carrier, which can not only optimize the pore structure of activated carbon, increase the pore volume and specific surface area, but also increase the content of oxygen-containing functional groups on the surface of activated carbon, improve the polarity of the carrier, and enhance the carrier and activity. The combination degree between components reduces the loss of active components, and because hydrogen chloride is a polar molecule, it is easier to be stably adsorbed on the surface of modified activated carbon that also has a higher polarity, which is conducive to improving the dechlorination accuracy. Simultaneously, the synergistic effect of above-mentioned three active substances in the dechlorination agent of the present invention has increased the reactivity of dechlorination agent and hydrogen chloride, has realized the maximization of chlorine capacity of dechlorination agent effectively, makes the liquid phase dechlorination agent of the present invention The chlorine capacity is as high as 16%, and the dechlorination accuracy is as low as 0.5ppm.

Owner:SHENYANG SANJUKAITE CATALYST

High-temperature gas antichlor

InactiveCN109513302ASimple preparation processLow costGas treatmentDispersed particle separationCalcium hydroxideAntichlor

The invention relates to high-temperature gas antichlor. The antichlor is prepared from the following raw materials in parts by weight: 20-26 parts of clay, 12-17 parts of calcium carbonate, 8-12 parts of calcium oxide, 22-28 parts of calcium hydroxide and 10-15 parts of hydrotalcite. The antichlor is prepared by the following steps: weighing raw materials in the weight ratio, mixing, grinding, screening through a 100-mesh screen, and uniformly mixing; and extruding and molding the mixed material with water, drying and roasting at the temperature 600-750 DEG C for 2-4 hours. The process for preparing the gas antichlor is simple and has low cost; and the gas antichlor has stable performance, high chlorine tolerance and good purity, and can be widely applied to removal of hydrogen chloride in high-temperature fuel gas and high-temperature gas.

Owner:庄壮

A kind of low temperature liquid phase dechlorination agent and its preparation method and application

ActiveCN107876016BOvercoming the drawbacks of requiring the use of phase transfer catalystsAvoid uniformityOther chemical processesHydrocarbon oils refiningSodium acetateActivated carbon

The invention provides a low temperature liquid phase de-chlorinating agent, which is composed of a component A and a component B. The component B is adsorbed on the component A. The component A is active carbon, which has been modified by a modifier. The component B is sodium acetate or sodium citrate. The mass ratio of the component A to the component B is (4-9):1, and the modifier accounts for20 to 35 wt% of the component A, and the balance being active carbon. The invention also provides a method for preparing the low temperature liquid phase de-chlorinating agent and an application of the de-chlorinating agent in catalytic reforming to generate de-chlorinated oil. The provided de-chlorinating agent perfectly solves the problem that in the prior art, the organic chlorine removing effect of a de-chlorinating agent is not good, and is capable of converting organic chlorine into inorganic chlorine and absorbing inorganic chlorine.

Owner:XIAN ORIGIN CHEM TECH

Novel high-temperature dechlorinating agent and preparation method thereof

PendingCN113893662AExtend your lifeImprove high temperature resistanceGas treatmentDispersed particle separationPtru catalystPhysical chemistry

The invention discloses a novel high-temperature dechlorinating agent and a preparation method thereof. The dechlorinating agent is filled in a fixed bed reactor, hydrogen chloride in regenerated flue gas is purified and removed through a solid dechlorinating method, and the dechlorinating agent is composed of an active component, a carrier, a pore-forming agent, a binder and a reinforcing agent, and specifically comprises the following components in parts by weight: 30-55 parts of the active component, 20-30 parts of the binder, 10-15 parts of the carrier, 5-10 parts of the pore-forming agent and 2-5 parts of the reinforcing agent. Through the use of the carrier and the binder, the prepared high-temperature dechlorinating agent has relatively high strength, relatively high water resistance, relatively high argillization resistance, relatively high temperature resistance, relatively high oxygen resistance and relatively high CO2 carbonation resistance; the penetrating chlorine capacity of the high-temperature dechlorinating agent reaches 40%, rapid loss of active components during use of the dechlorinating agent is reduced, harm and influence of loss of the active components of the dechlorinating agent on production of a reforming catalyst are reduced, and the dechlorinating agent which is stable to develop, high in chlorine capacity and long in service life is achieved.

Owner:昆山市精细化工研究所有限公司

Gas dechlorinating agent and preparing method thereof

ActiveCN100509139CLarge specific surface areaHigh chlorine capacityOther chemical processesDispersed particle separationSodium BentoniteAlkaline earth oxides

A gas dechlorination agent, comprising 10-60% by mass of alumina, 5-60% by mass of modifier, 1-15% by mass of zeolite and 5-80% by mass of alkaline earth metal oxide, the modified The agent is clay or bentonite. The dechlorination agent can effectively remove hydrogen chloride in gas at high temperature, and has a high breakthrough chlorine capacity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com