Selective dechlorination absorbent, preparation method and use method

An absorbent and selective technology, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve the problems of no hydrogen chloride selectivity, and the chlorine capacity of dechlorination agents needs to be improved, so as to achieve good dechlorination effect and easy The operation realizes the effect of well-developed pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

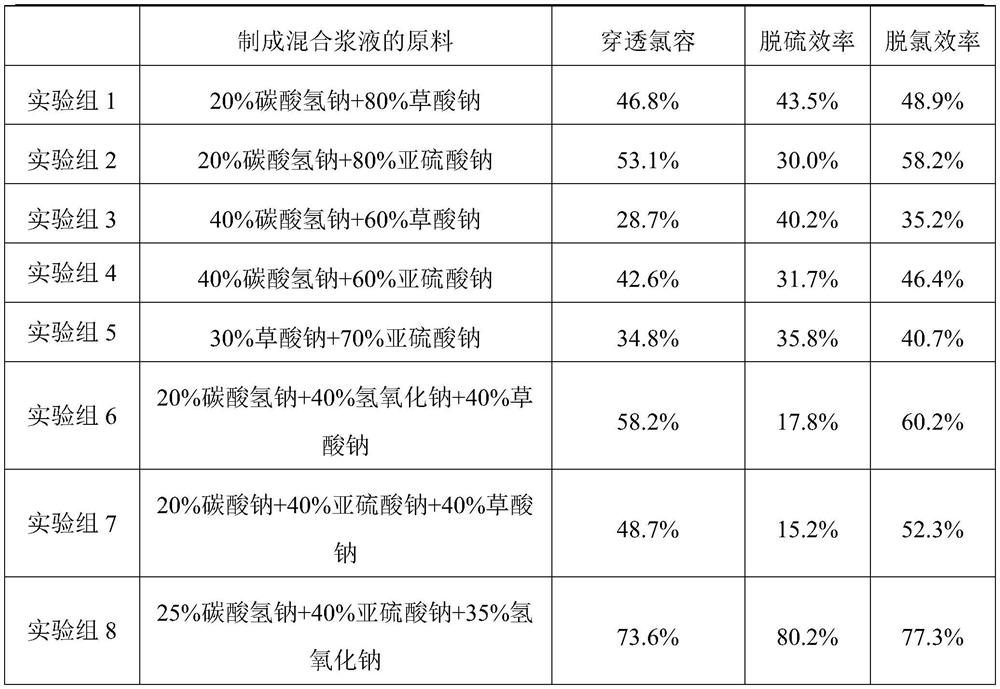

[0050] Dissolving sodium bicarbonate, sodium sulfite and sodium oxalate in water to obtain a mixed slurry, the mass content of sodium bicarbonate in the resulting mixed slurry is 20%; the mass content of sodium sulfite is 40%, and the mass content of sodium oxalate is 40%; the addition of water The mass is 10% of the mass of the mixture. Dry the mixed slurry at a temperature of 100°C for 3 hours, pass through a 120-mesh sieve into fine particles, and obtain a selective dechlorination absorbent, that is, a dechlorination agent.

[0051] Take 2 g of the dechlorination agent sample prepared in this example, fill it in a quartz reaction tube with a certain aspect ratio by vibration, place it in a tube furnace, and adjust the temperature to 100°C. Feed SO into the reaction tube 2 Mixed gas with HCl, the total gas volume is 200ml / min, in N 2 Make balance gas, use Fourier transform infrared spectrometer to monitor the concentration of HCl gas in real time, if the amount of HCl cont...

Embodiment 2

[0053] Dissolving sodium bicarbonate, sodium sulfite and sodium oxalate in water to obtain a mixed slurry, the mass content of sodium bicarbonate in the resulting mixed slurry is 10%; the mass content of sodium sulfite is 40%, and the mass content of sodium oxalate is 50%. The mass is 10% of the mass of the mixture. Dry the mixed slurry at a temperature of 120°C for 2 hours; pass through a 120-mesh sieve into fine particles to obtain a selective dechlorination absorbent, that is, a dechlorination agent.

[0054] Take 2 g of the dechlorination agent sample prepared in this example, fill it in a quartz reaction tube with a certain aspect ratio by vibration, place it in a tube furnace, and adjust the temperature to 100°C. Feed SO into the reaction tube 2 Mixed gas with HCl, the total gas volume is 200ml / min, in N 2 Make balance gas, use Fourier transform infrared spectrometer to monitor the concentration of HCl gas in real time, if the amount of HCl contained in the outlet gas ...

Embodiment 3

[0056] Dissolving sodium bicarbonate, sodium sulfite and sodium oxalate in water to obtain a mixed slurry, the mass content of sodium bicarbonate in the resulting mixed slurry is 10%; the mass content of sodium sulfite is 50%, and the mass content of sodium oxalate is 40%. The mass is 10% of the mass of the mixture. Dry the mixed slurry at 110°C for 2 hours, pass through a 120-mesh sieve to form fine particles, and obtain a selective dechlorination absorbent, that is, a dechlorination agent.

[0057] Take 2 g of the dechlorination agent sample prepared in this example, fill it in a quartz reaction tube with a certain aspect ratio by vibration, place it in a tube furnace, and adjust the temperature to 100°C. Feed SO into the reaction tube 2 Mixed gas with HCl, the total gas volume is 200ml / min, in N 2 Make balance gas, use Fourier transform infrared spectrometer to monitor the concentration of HCl gas in real time, if the amount of HCl contained in the outlet gas falls below ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com