Dechlorinating agent suitable for blast furnace gas, preparation method of dechlorinating agent and application of composition of dechlorinating agent

A blast furnace gas and dechlorination agent technology, which is applied in the removal of gas pollutants, combustible gas purification, combustible gas purification/transformation, etc., can solve the problems of high cost, dechlorination effect needs to be strengthened, and large amount of addition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037]

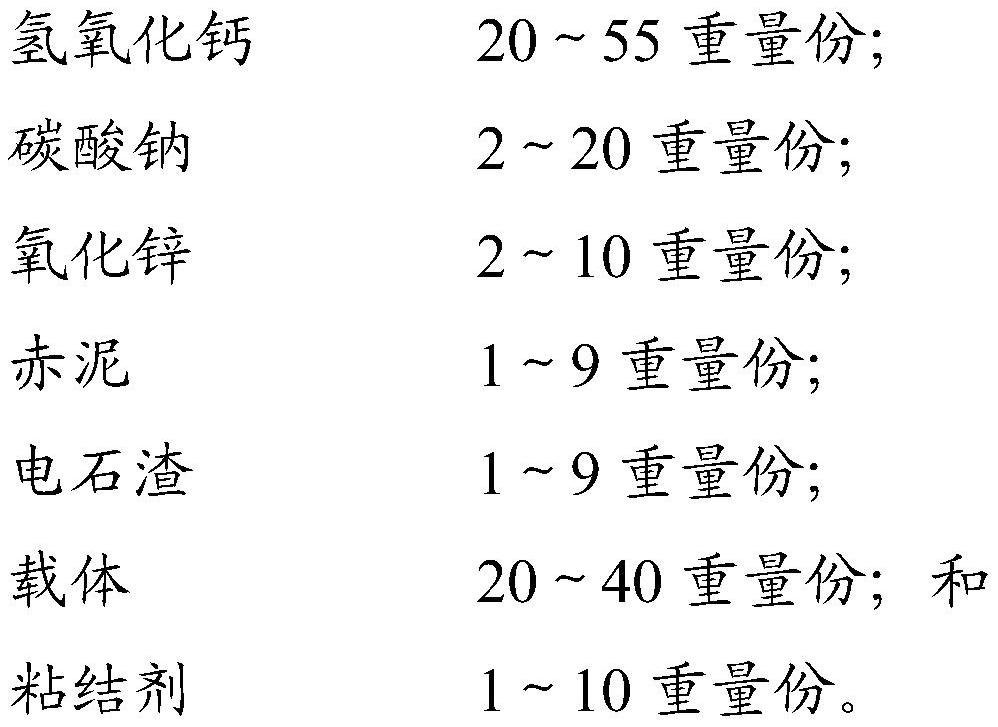

[0038] The preparation method of the dechlorination agent applicable to blast furnace gas of the present invention comprises the steps:

[0039] (1) kneading calcium hydroxide, sodium carbonate, zinc oxide, red mud, carbide slag and carrier to obtain the first mixture; (2) uniformly mixing the first mixture, binder and water to form the second mixture; The second mixture is molded to obtain a green body; (3) drying and then roasting the green body to obtain a dechlorination agent. The selection and dosage of raw materials are as described above, and will not be repeated here.

[0040] In the present invention, the kneading time may be 5-30 min; preferably 10-25 min; more preferably 12-20 min. This will aid in the thorough mixing of the ingredients.

[0041] In the present invention, extrusion molding can be used for molding. The resulting body can be a cylinder.

[0042] In the present invention, the drying temperature may be 80-120°C; preferably 90-110°C; more pr...

Embodiment approach

[0048] According to one embodiment of the present invention, it specifically includes the following steps:

[0049] (1) kneading calcium hydroxide, sodium carbonate, zinc oxide, red mud, carbide slag and carrier to obtain the first mixture;

[0050] (2) uniformly mixing the first mixture, binder and water to form a second mixture; molding the second mixture to obtain a green body;

[0051] (3) Drying the green body and then roasting to obtain the dechlorination agent.

[0052] The composition and parameters of the raw materials are as described above and will not be repeated here.

Embodiment 1 and comparative example 1~3

[0054] Kaolin, aluminate cement, calcium hydroxide, sodium carbonate, zinc oxide, red mud (D 50 40μm) and / or carbide slag (D 50 40 μm) were mixed and kneaded for 15 minutes to obtain the first mixture.

[0055] Moisten the first mixture, carboxymethyl cellulose, safflower powder and polyvinyl alcohol with water, mix well, roll and knead into a paste (the second mixture); extrude the paste to obtain a cylindrical green body (diameter is 3mm).

[0056] The green body was dried at 105°C for 2 hours, and then fired at 350°C for 1.5 hours to obtain a dechlorination agent.

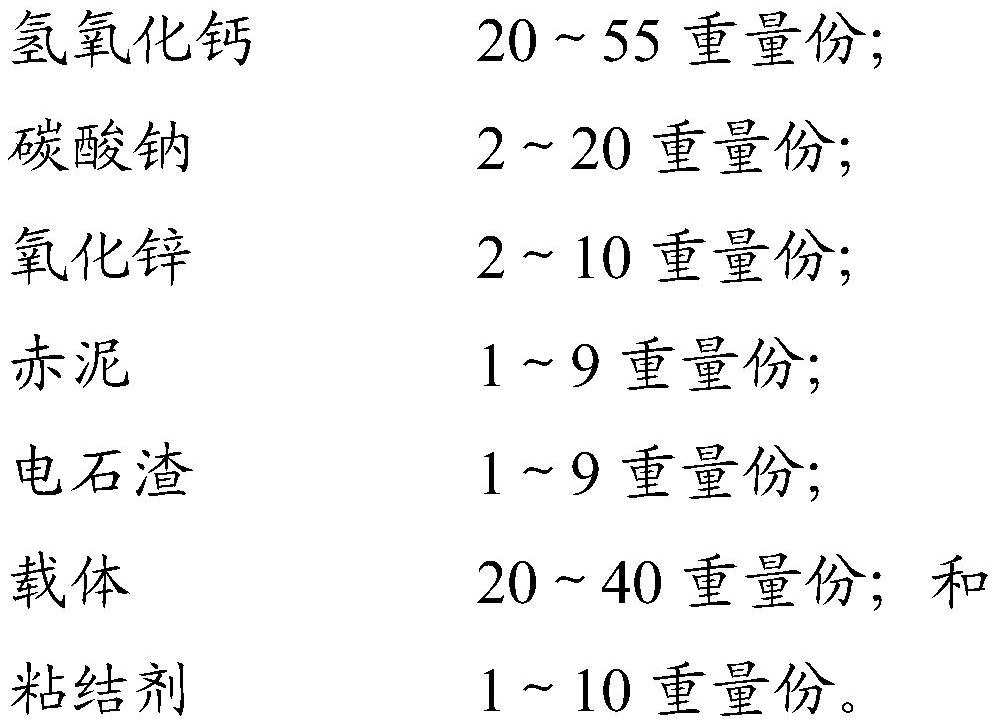

[0057] The amount of each raw material is shown in Table 1.

[0058] Table 1

[0059] Example 1 Comparative example 1 Comparative example 2 Comparative example 3 Kaolin (parts by weight) 17 17 17 20 Aluminate cement (parts by weight) 10 10 10 12 Calcium hydroxide (parts by weight) 45 45 45 50 Sodium carbonate (parts by weight) 10 10 10 10 Zinc oxide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com