Gas dechlorinating agent and preparing method thereof

A dechlorination agent and gas technology, which is applied in the field of high temperature gas dechlorination agent and preparation, can solve problems such as application limitations, and achieve the effects of large specific surface area, high chlorine capacity, gas purification degree, and chlorine capacity improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

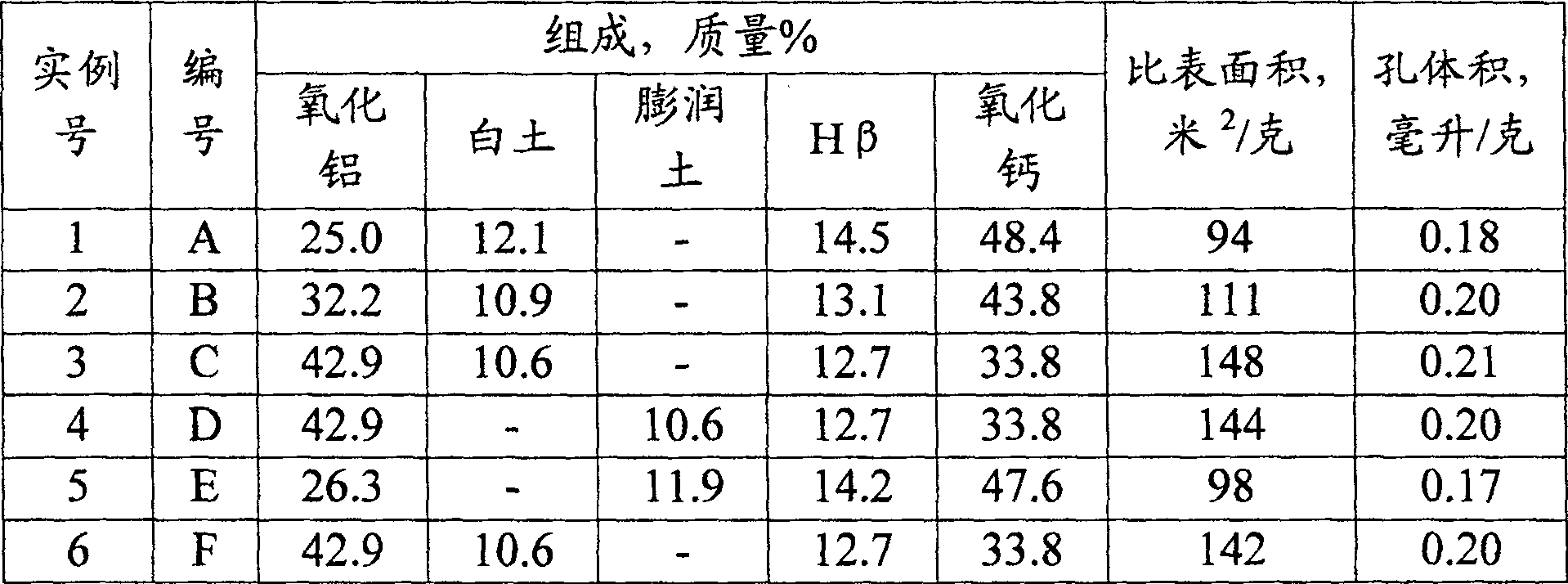

[0018] The preparation method of the dechlorination agent provided by the present invention comprises mixing alumina precursors, alkaline earth metal oxides or their precursors, zeolite and modifiers into raw materials, then adding a pore-enlarging agent and mixing evenly, and then adding an appropriate amount of water to extrude the strips Molding, sintering at 450-700°C, the modifier is clay or bentonite.

[0019] The zeolite is preferably a large-pore hydrogen zeolite, more preferably Hβ, the precursor of alumina is preferably pseudoboehmite, the alkaline earth metal oxide is preferably calcium oxide, and the precursor of the alkaline earth metal oxide is preferably calcium hydroxide, calcium carbonate or carbonic acid hydrogen calcium.

[0020] The pore-enlarging agent is preferably methylcellulose or urea. The amount of the pore-enlarging agent added is 0.5-10% by mass of the raw material, preferably 1-5% by mass.

[0021] In the above-mentioned extrusion forming proces...

example 1

[0026] (1) Preparation of Hβ zeolite

[0027] Na-type beta zeolite was treated with 1 mol / L NH 4 The Cl solution was ion-exchanged at 95°C for 3 hours, and the NH 4 The ratio of Cl solution to zeolite beta is 5:1, dried at 120° C. for 2 hours, and calcined at 550° C. for 4 hours to obtain zeolite H beta with Na content less than 0.1% by mass.

[0028] (2) Preparation of dechlorination agent

[0029] Get 28 grams of pseudo-boehmite, 10 grams of white clay, 12 grams of Hβ zeolite, and 50 grams of calcium hydroxide and mix them, add 2.5 grams of methylcellulose (sold by Guangzhou Chemical Reagent Company) and 2.5 grams of Sesame powder and mix evenly, then add 15ml of nitric acid with a concentration of 36% by mass and 45ml of deionized water were kneaded evenly, extruded and formed, and roasted at 650° C. for 4 hours to obtain dechlorination agent A. The composition and physical properties are shown in Table 1.

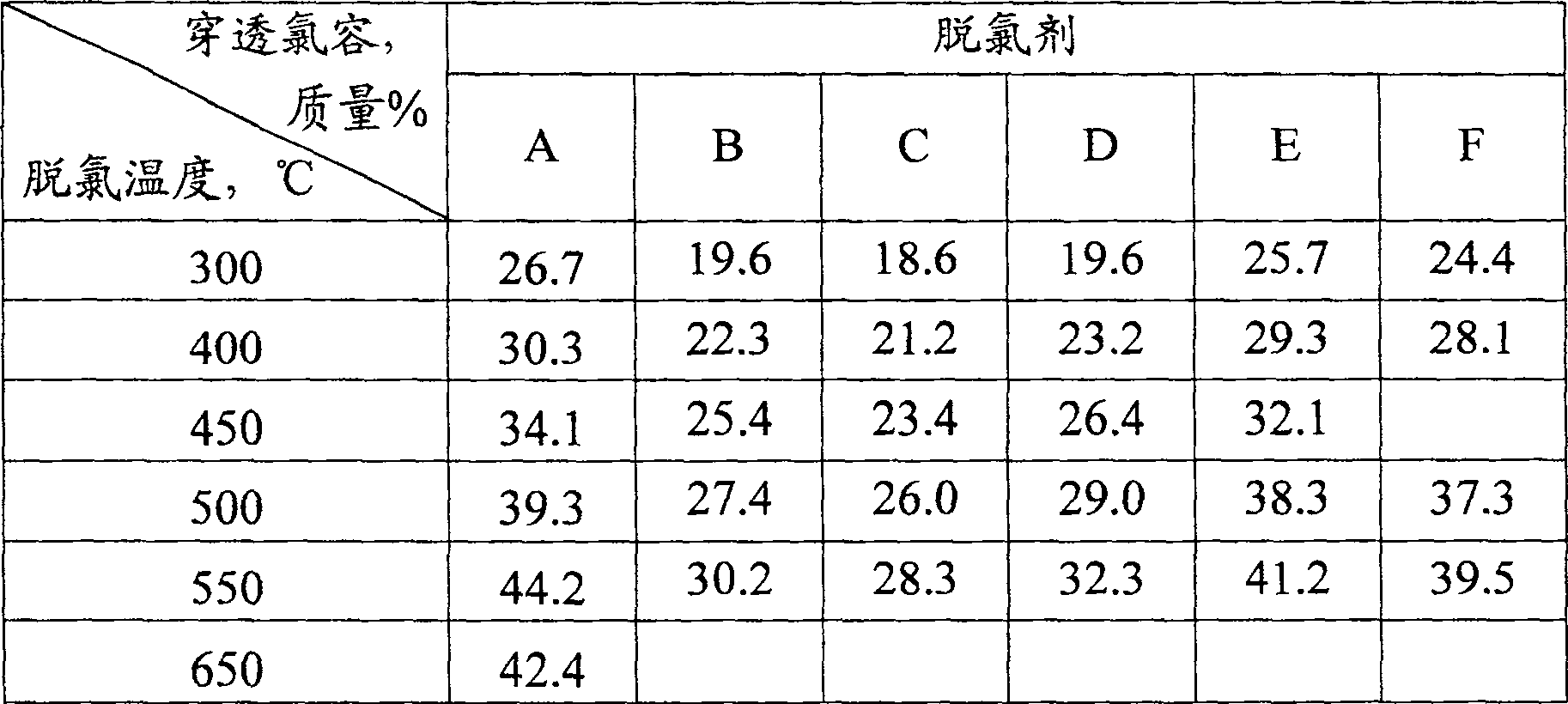

[0030] (3) Evaluation of dechlorination agent performance

[0...

example 2

[0033] Prepare Hβ by the method of example 1 (1) step, then prepare dechlorination agent by the method of (2) step, the difference is that the pseudo-boehmite that adds is 40 grams, the composition and physics of the dechlorination agent B that makes The properties are shown in Table 1.

[0034] The dechlorination performance of dechlorination agent B is evaluated by the method of example 1 (3) step, and the penetration chlorine capacity of dechlorination agent B at each adsorption temperature is shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com