Patents

Literature

203 results about "Pectolite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pectolite is a white to gray mineral, NaCa₂Si₃O₈(OH), sodium calcium hydroxide inosilicate. It crystallizes in the triclinic system typically occurring in radiated or fibrous crystalline masses. It has a Mohs hardness of 4.5 to 5 and a specific gravity of 2.7 to 2.9. The gemstone variety, larimar, is a pale to sky blue.

Catalytic dewaxing with trivalent rare earth metal ion exchanged ferrierite

InactiveUS6013171AMolecular sieve catalystsRefining to change hydrocarbon structural skeletonCation-exchange capacityIon exchange

A process for dewaxing waxy hydrocarbonaceous materials, such as hydrocarbon fuel and lubricating oil fractions to reduce their cloud and pour points comprises reacting the material with hydrogen in the presence of a dewaxing catalyst comprising at least one metal catalytic component and ferrierite in which at least a portion of its cation exchange positions are occupied by one or more trivalent rare earth metal cations. The rare earth ion exchanged ferrierite catalyst has good selectivity for lubricating oil production, particularly when dewaxing a Fischer-Tropsch wax hydroisomerate. Preferably at least 10% and more preferably at least 15% of the ferreirite cation exchange capacity is occupied by one or more trivalent rare earth metal cations.

Owner:EXXON RES & ENG CO

Catalyst composition, its preparation and use

A catalyst composition which comprises: a) a carrier which comprises at least 30 wt % of a binder selected from silica, zirconia and titania; at least 20 wt % of a pentasil zeolite, having a bulk silica to alumina ratio in the range of from 20 to 150 and being in its H+ form; and less than 10 wt % of other components, all percentages being on the basis of total carrier; b) platinum in an amount in the range of from 0.001 to 0.1 wt %, on the basis of total catalyst; and c) tin in an amount in the range of from 0.01 to 0.5 wt %, on the basis of total catalyst; its preparation and use; are provided.

Owner:SHELL OIL CO

Molecular sieve adsorbent for gas purification and preparation thereof

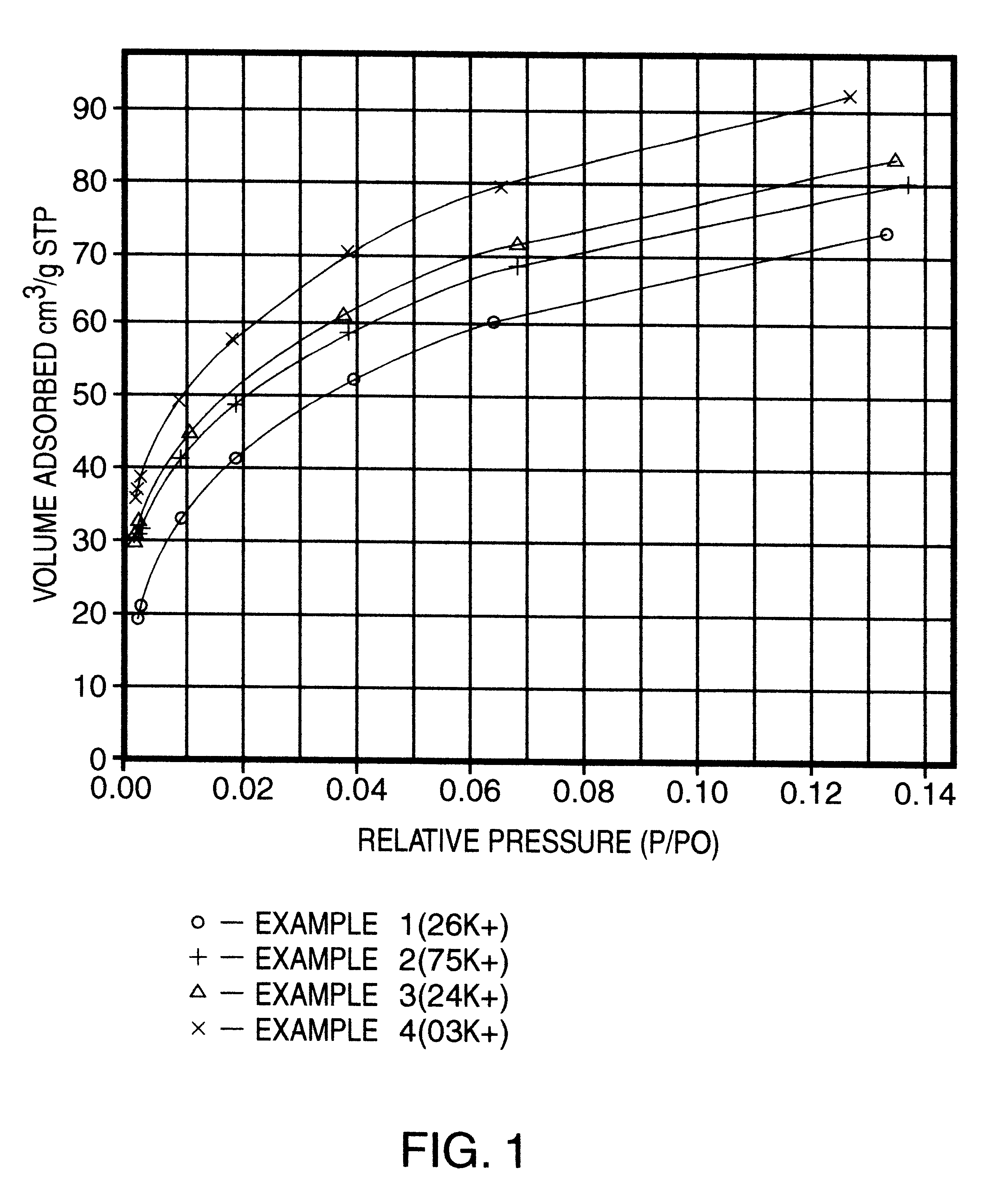

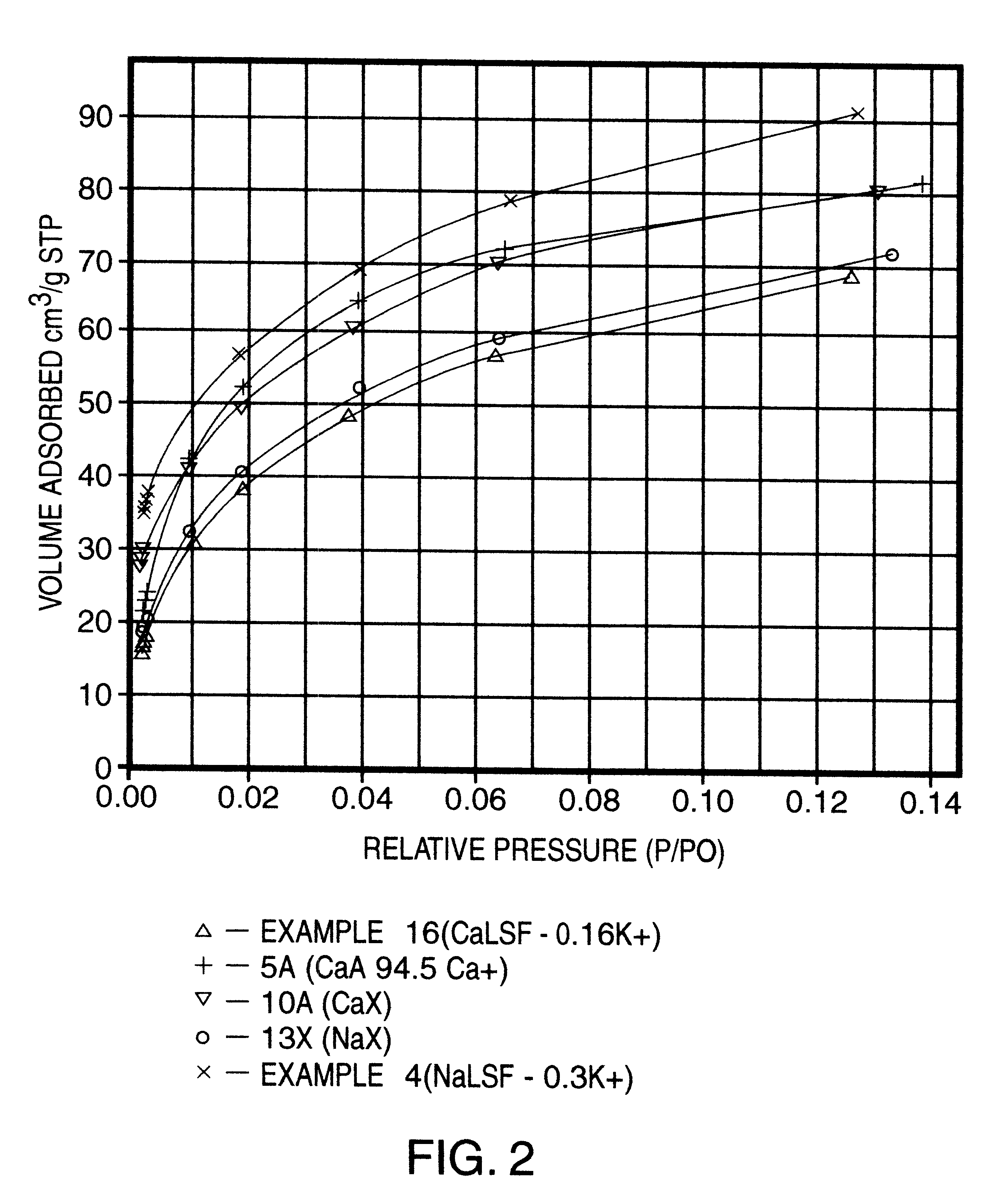

InactiveUS6183539B1Reduce resistanceImprove adsorption capacityMolecular sieve catalystsOther chemical processesMolecular sieveWater vapor

A molecular sieve adsorbent for the purification of gas streams containing water vapor and carbon dioxide and a process for its preparation. The adsorbent is a sodium form of a low-silica faujasite having a silica to alumina ratio of about 1.8:1 to about 2.2:1, a residual content of potassium ions less than about 8.0 percent (equiv.), a low content of crystalline and amorphous admixtures and crystal sizes generally within the range of 1-4 mum, blended with a binder.

Owner:ZEOCHEM LLC

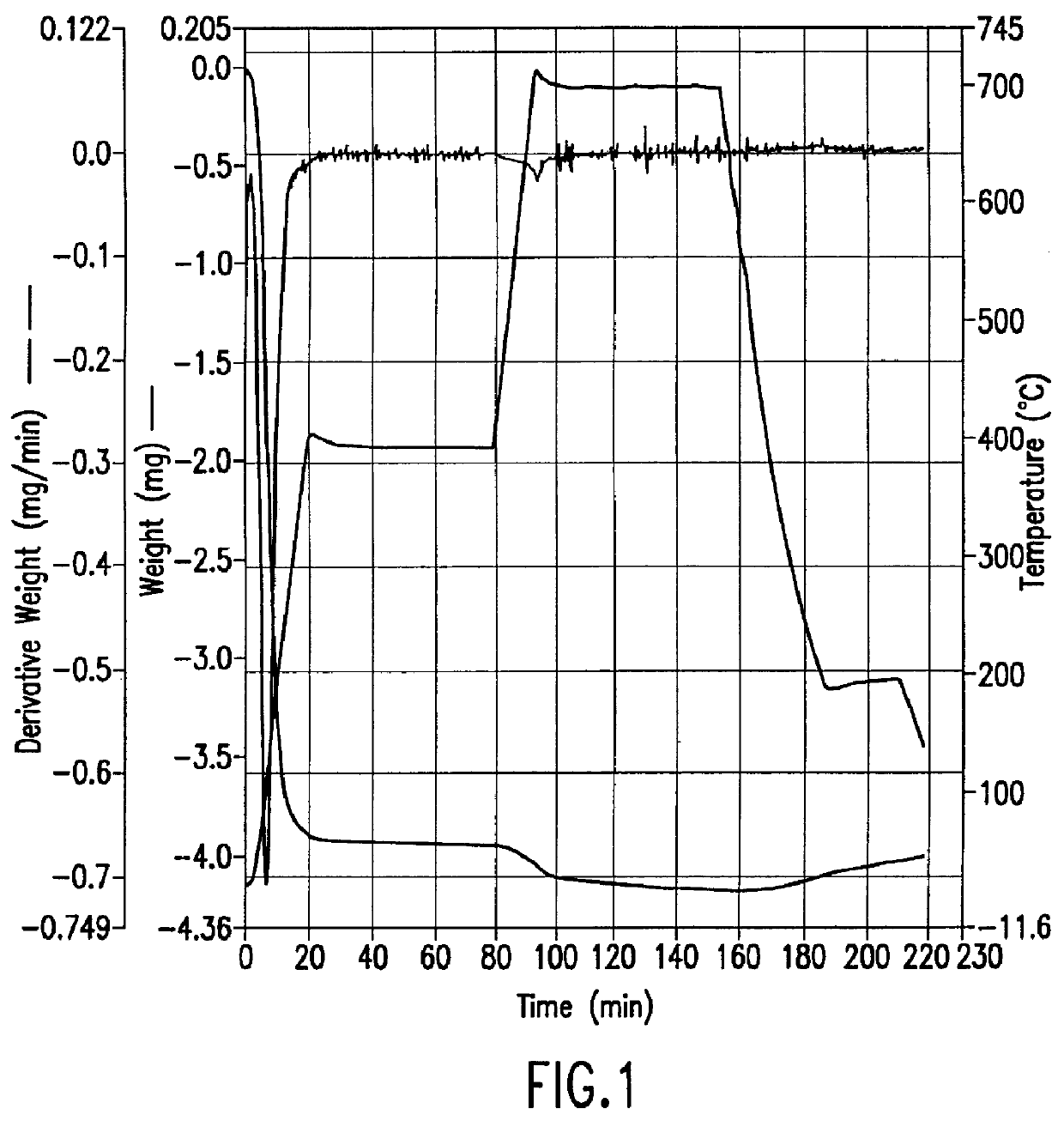

Methods for removal of water from gases using superheated zeolites

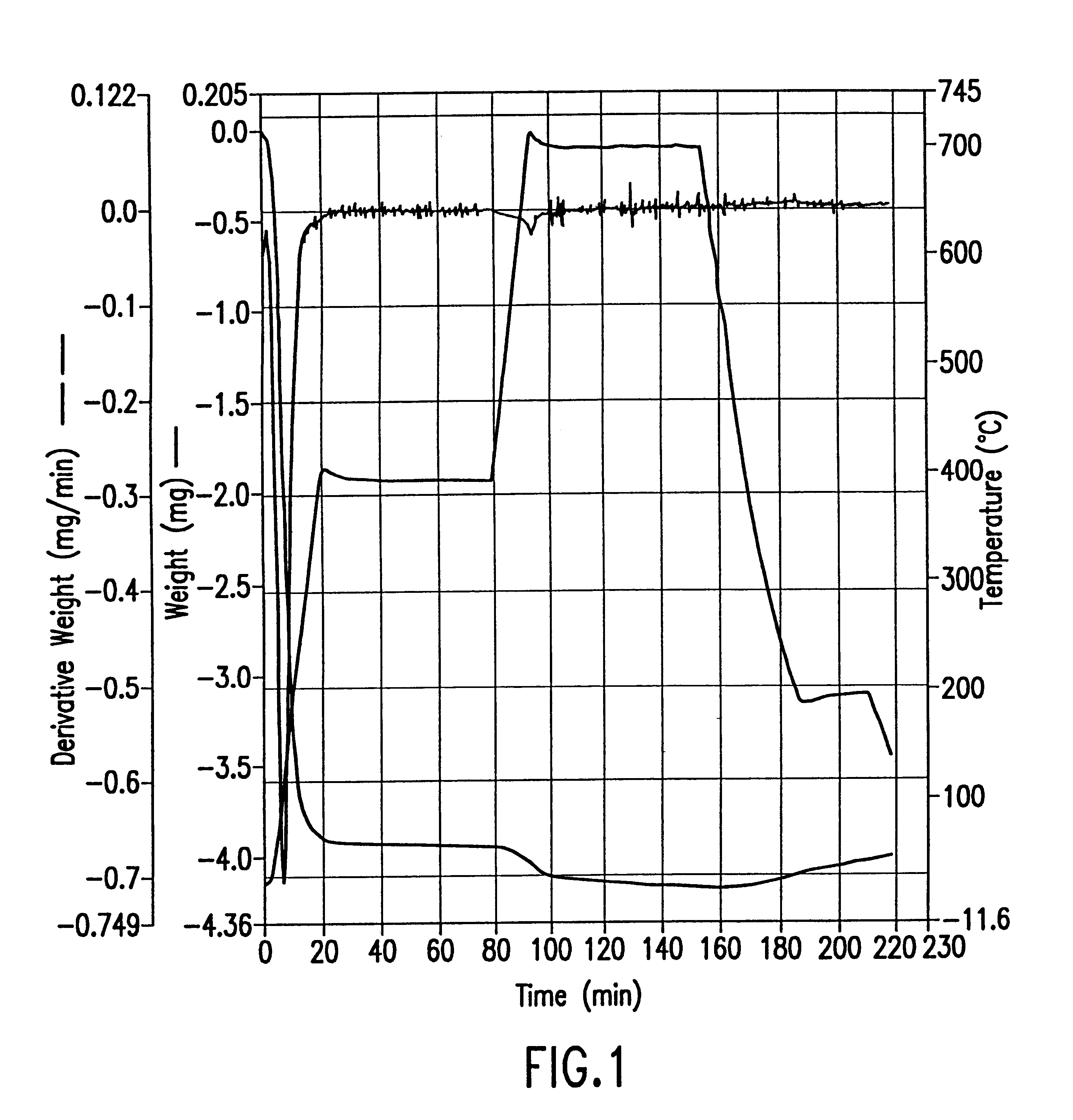

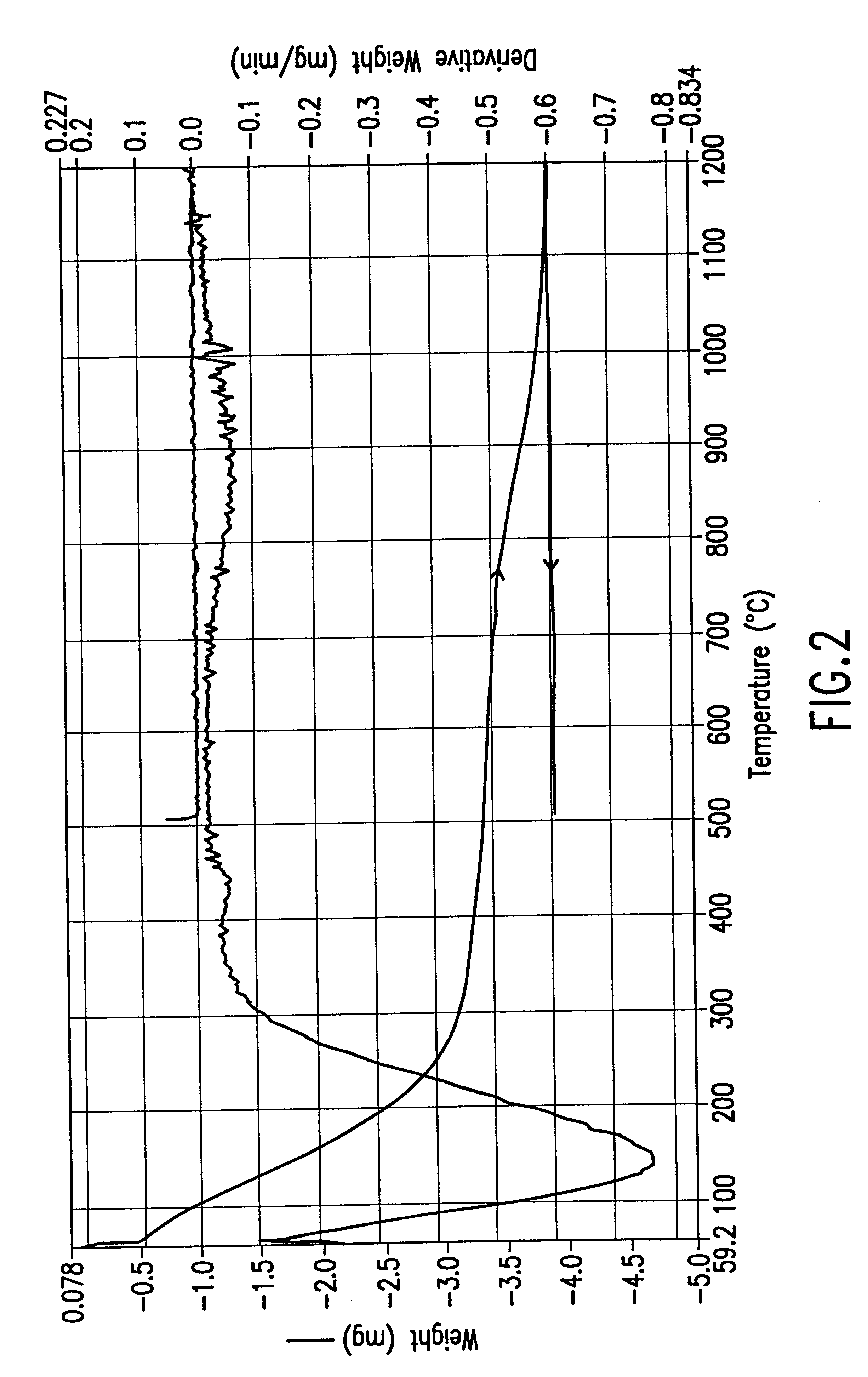

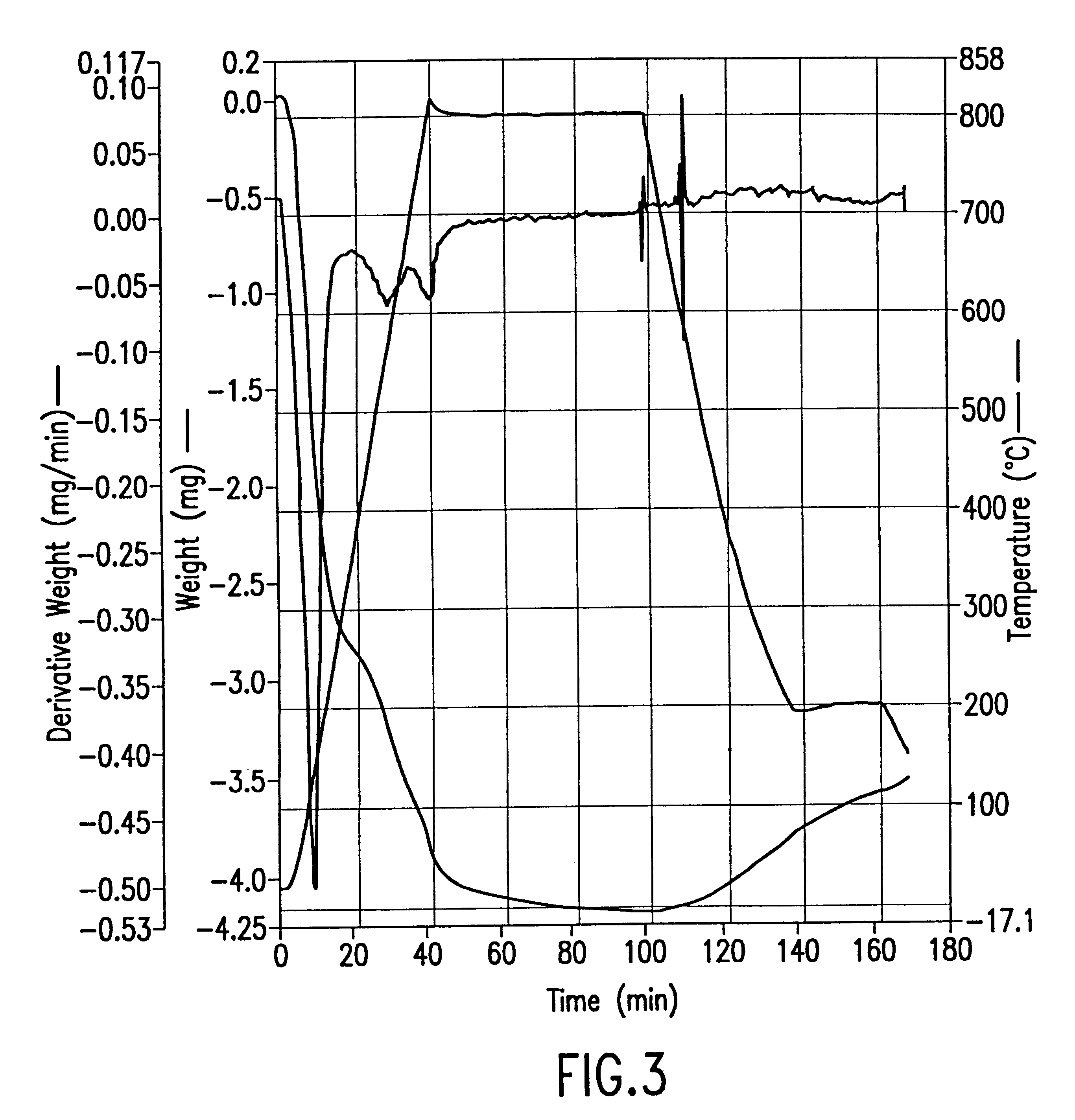

InactiveUS6110258AHigh silica-to-alumina ratioReduce metal contentGas treatmentMolecular sieve catalystsBoiling pointSilicon dioxide

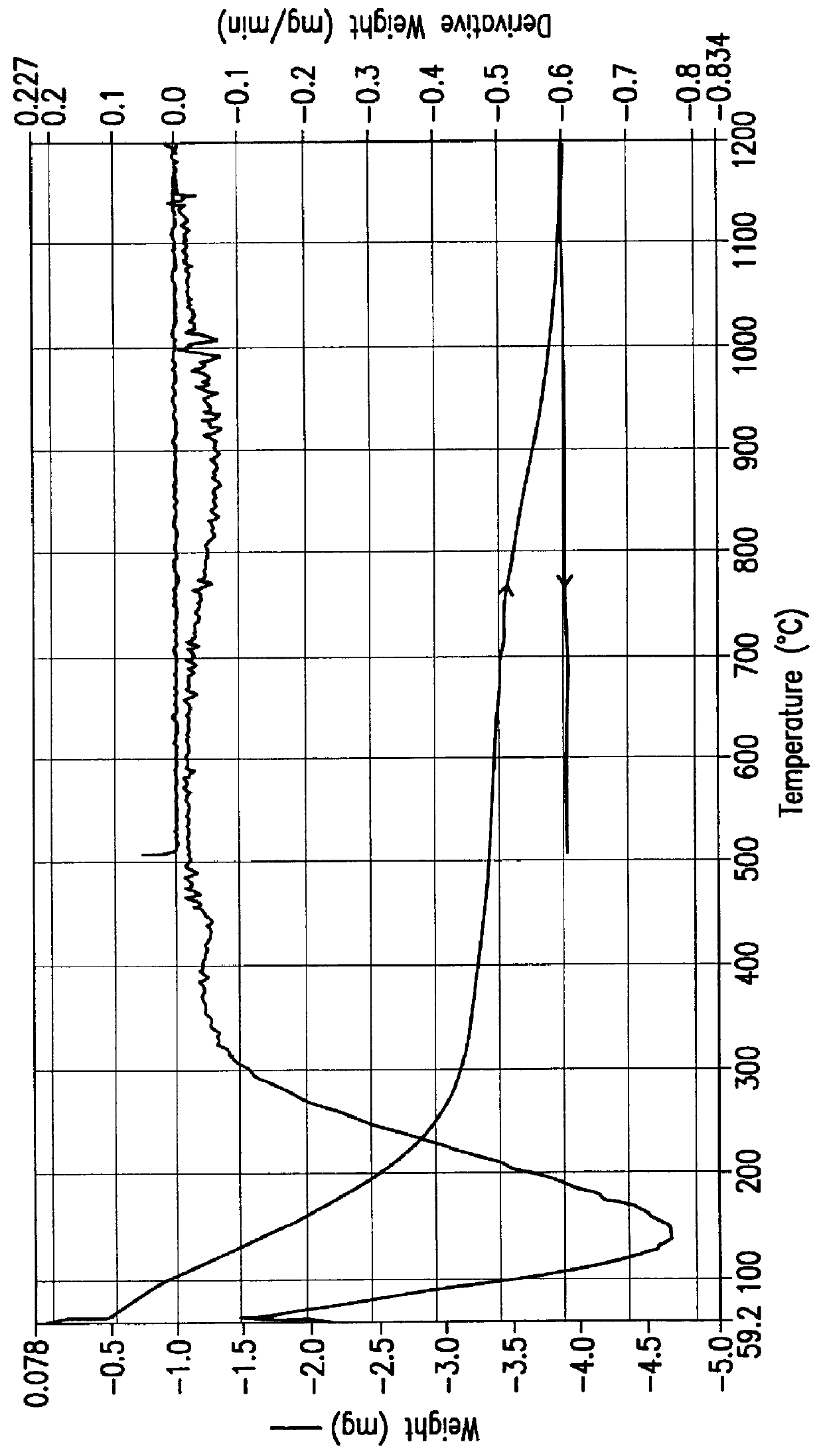

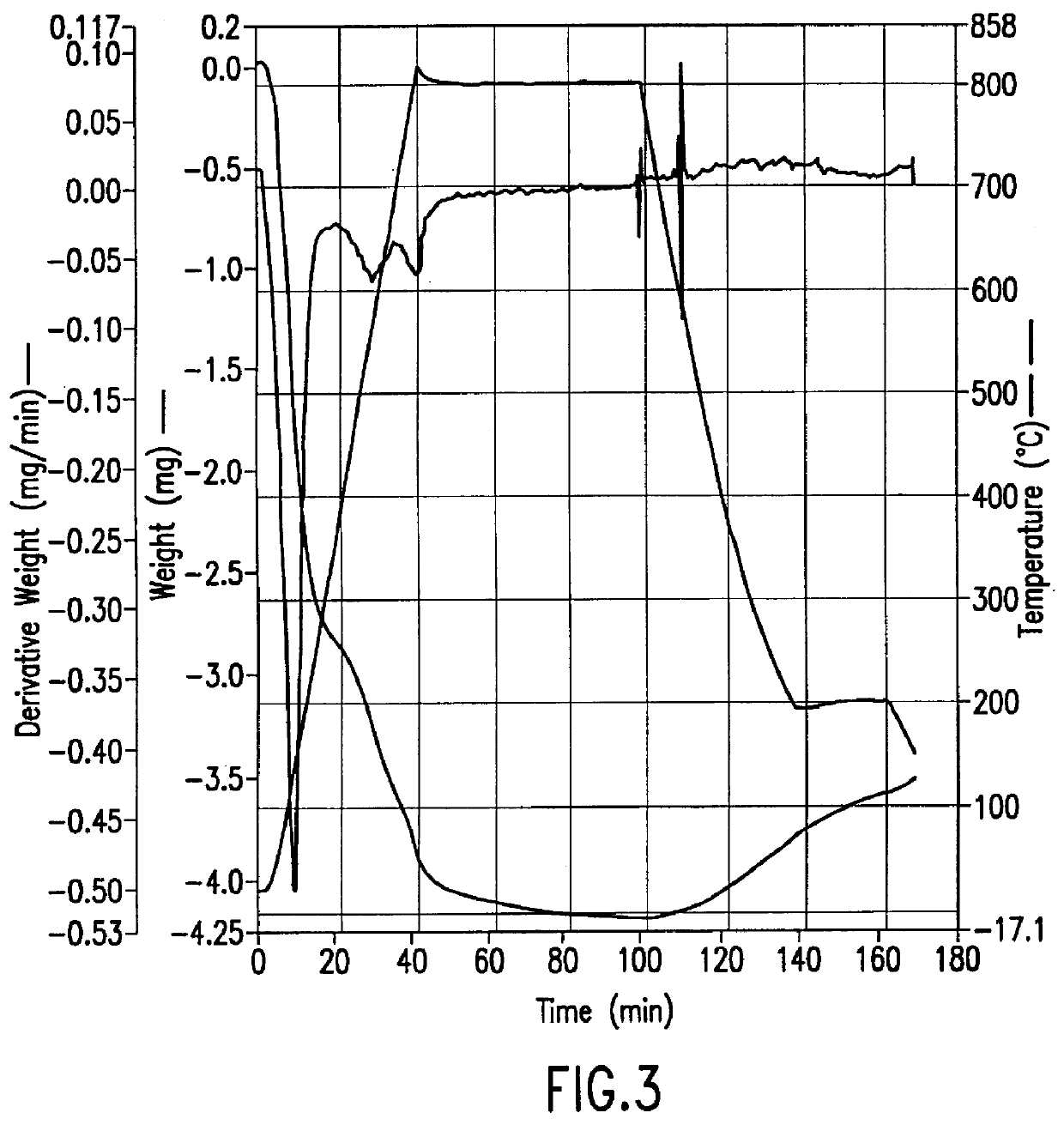

A method for removing trace moisture from a gas is disclosed. The method involves heating a zeolite having a high silica-to-alumina ratio to about 400 DEG C. to remove physically absorbed water from the zeolite, followed by heating the zeolite to a temperature in excess of 650 DEG C., to form a superheated zeolite. Heating to temperatures of 650 DEG C. or above is believed to cause dehydroxylation of the zeolite. A method for the preparation of a dehydroxylated zeolite is also disclosed. The superheated zeolite is contacted with the gas, thereby adsorbing water from the gas. A dehydroxylated zeolite for removing trace moisture from a gas wherein the zeolite has a high silica-to-alumina ratio and a low level of metallic impurities is also disclosed. The zeolite and methods of the invention are particularly useful for removing trace water from acid gases such as hydrogen chloride and hydrogen bromide.

Owner:MATHESON TRI GAS INC

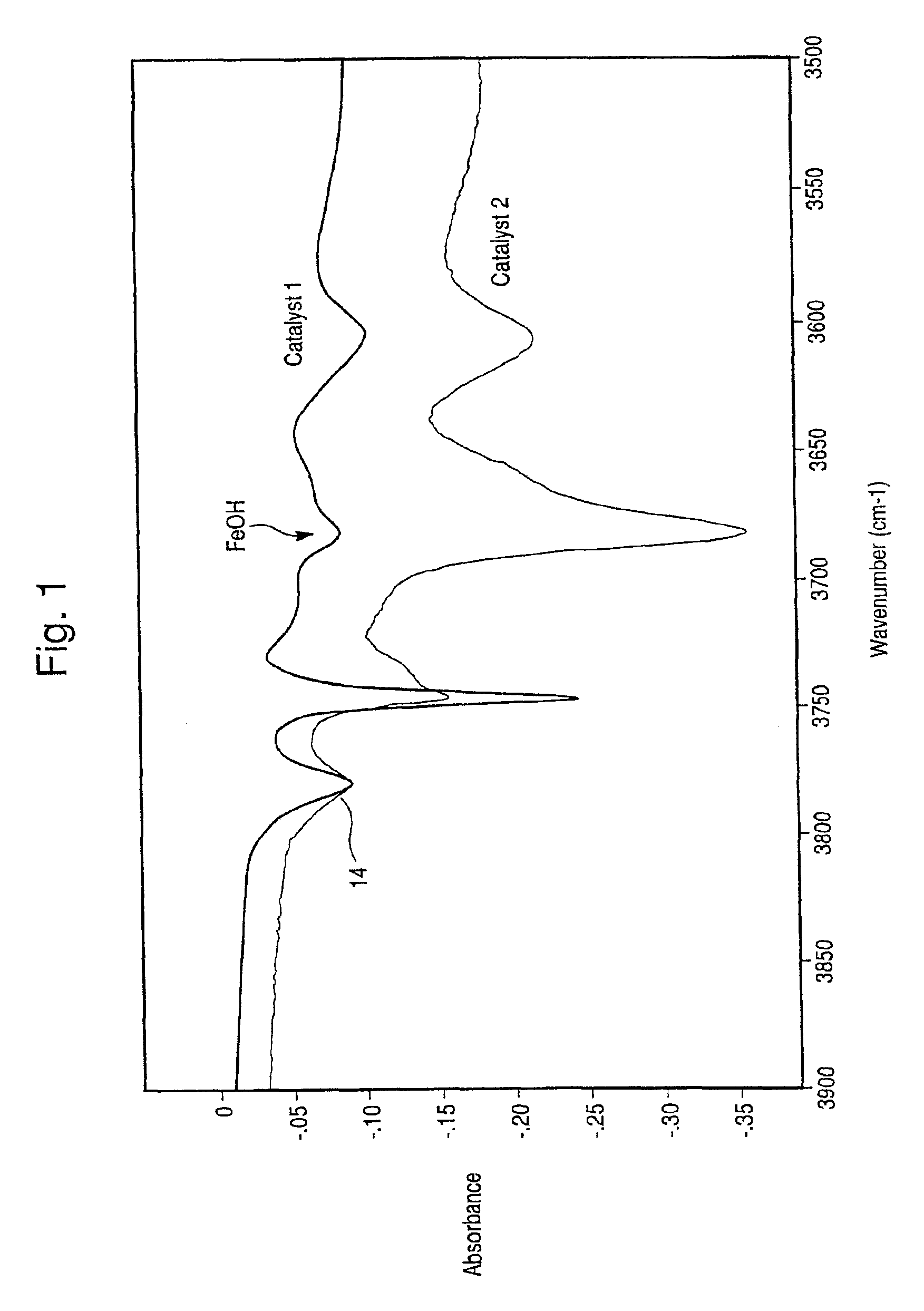

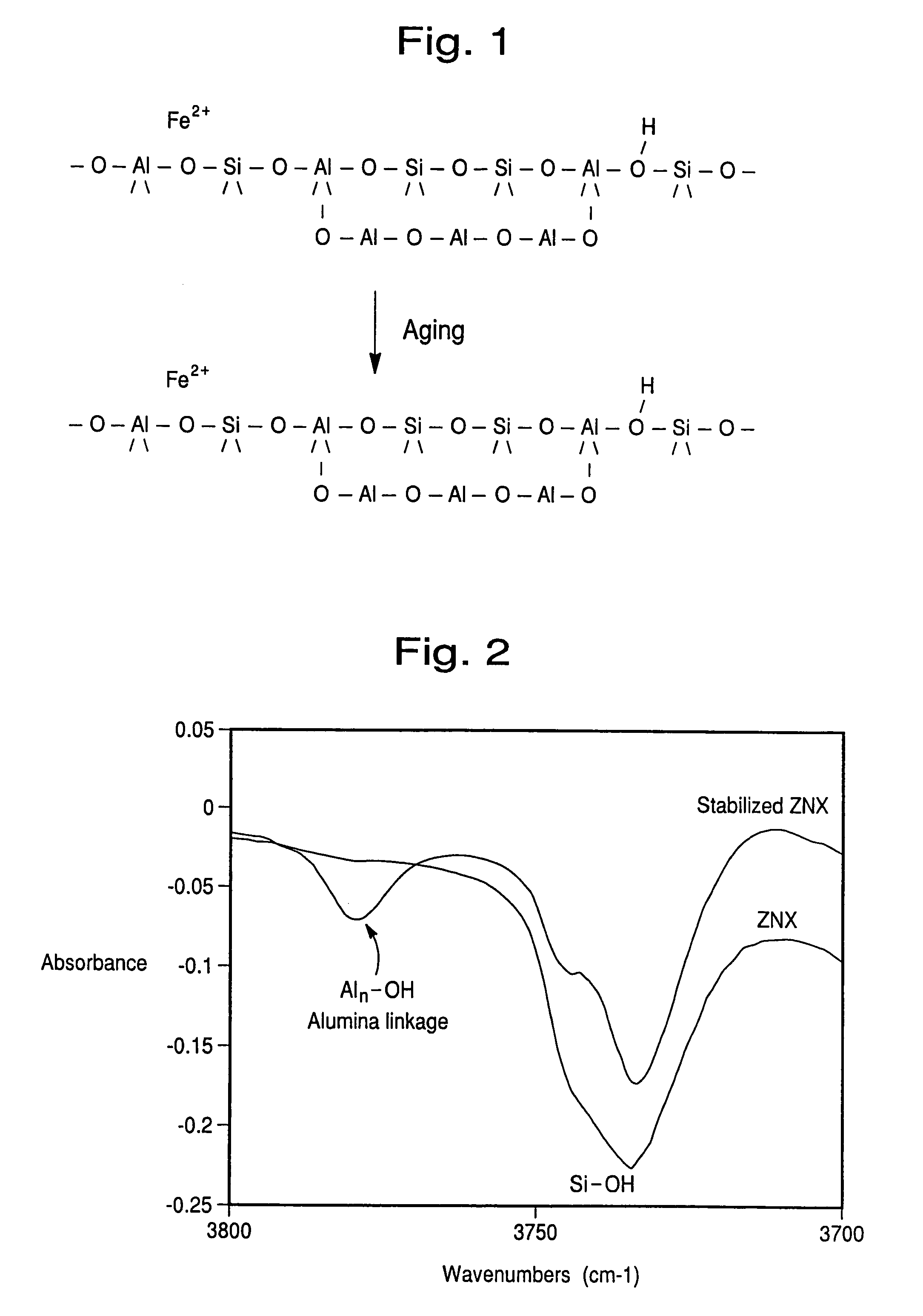

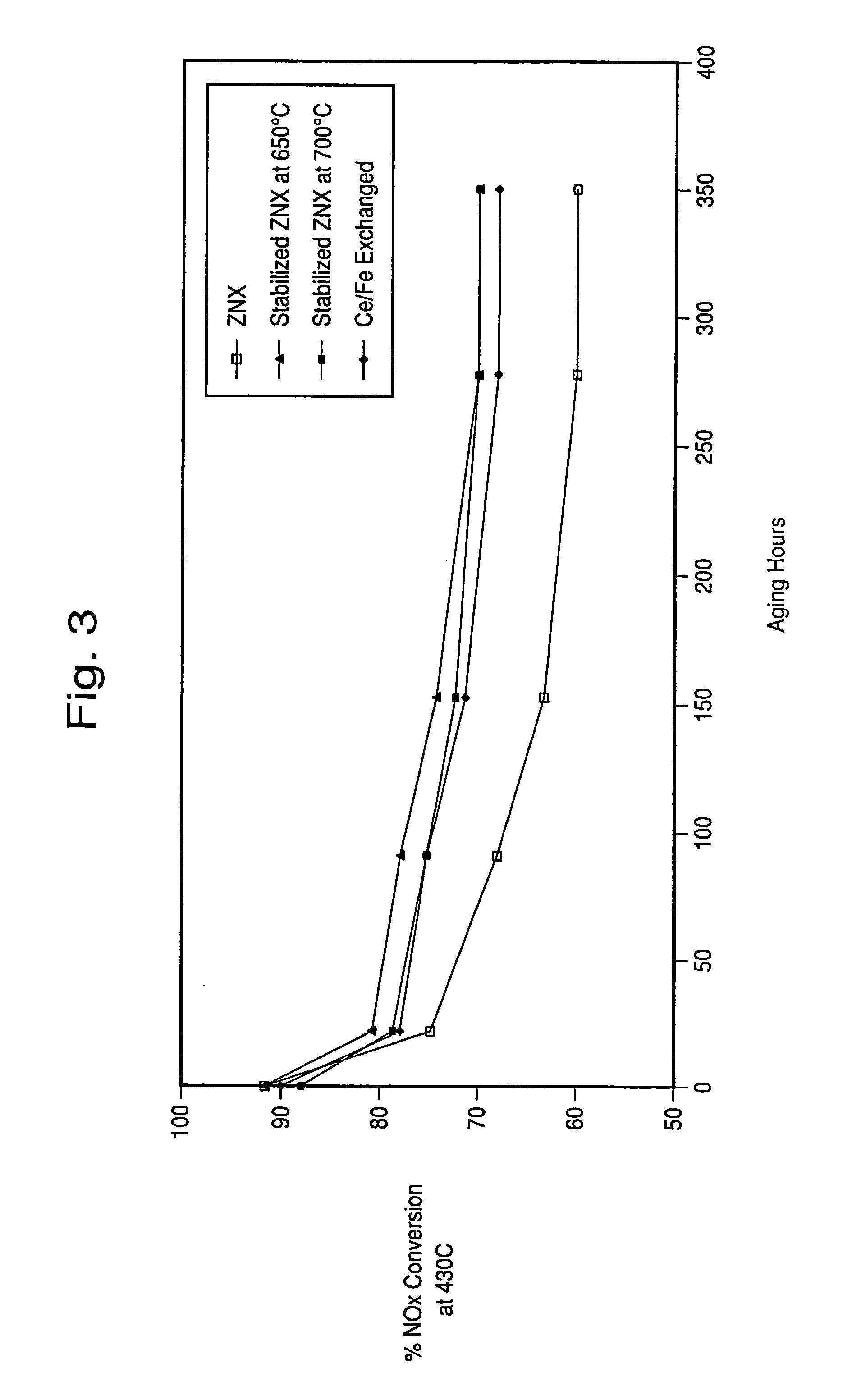

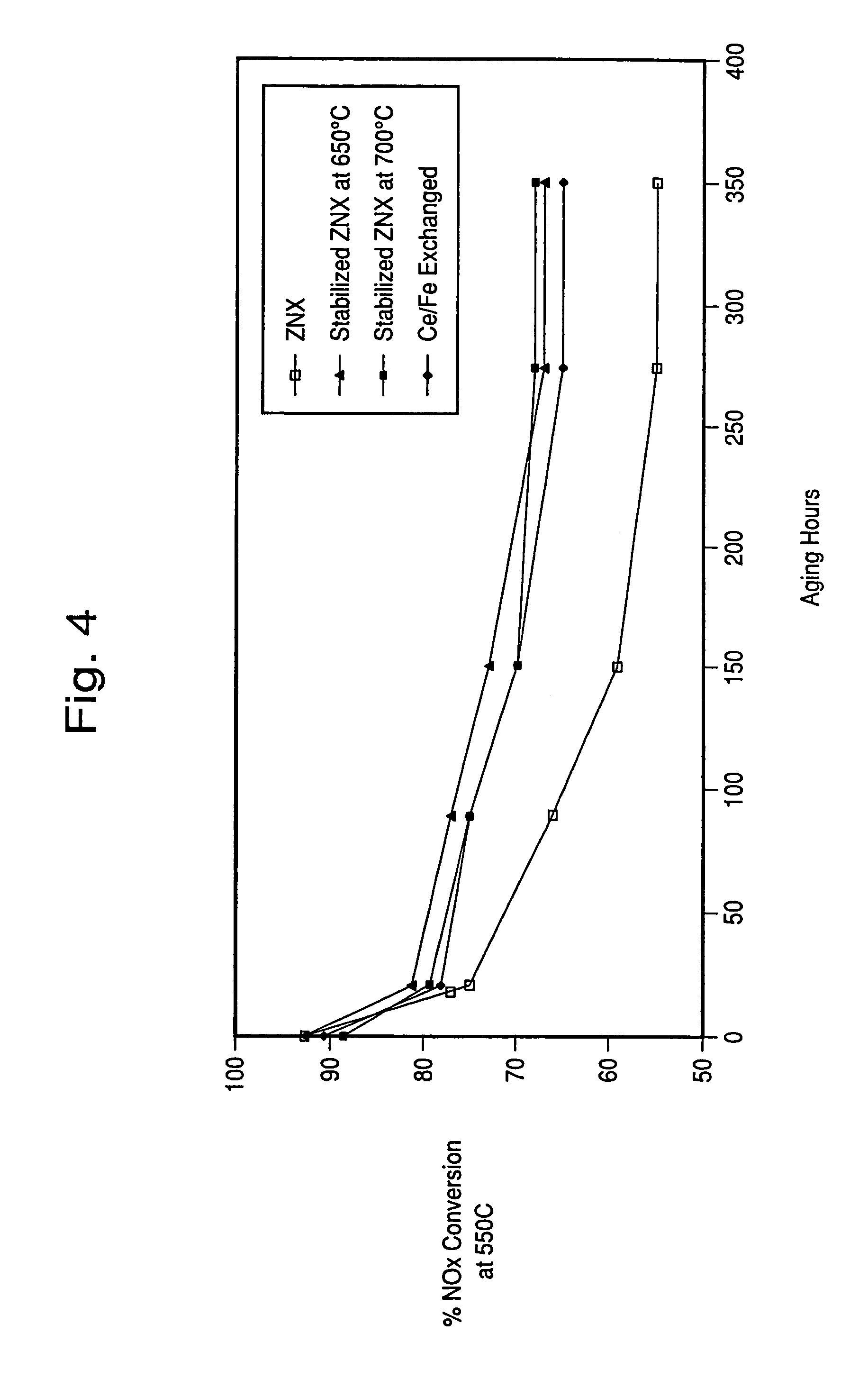

Hydrothermally stable metal promoted zeolite beta for NOx reduction

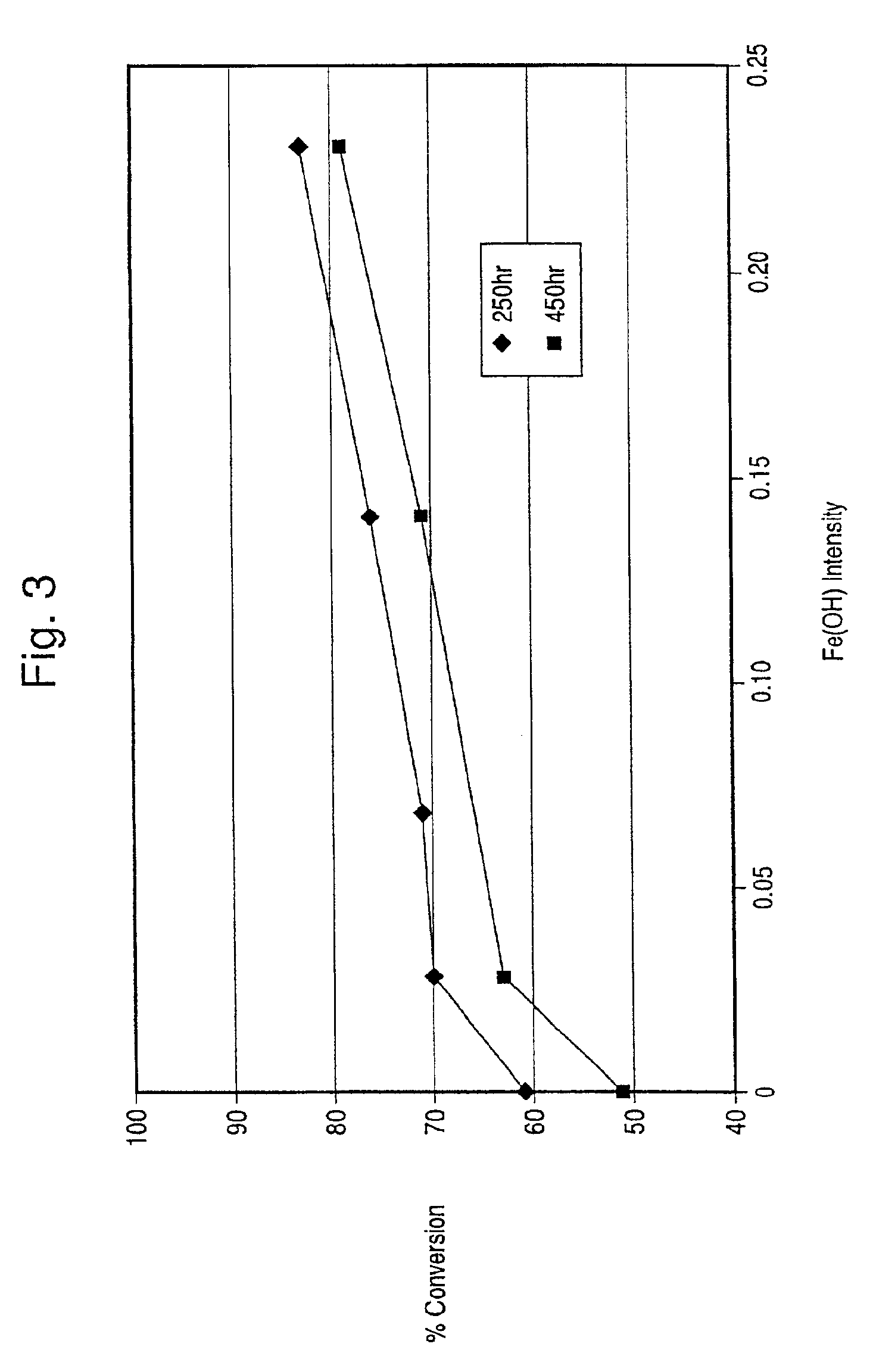

InactiveUS6914026B2Increasing Fe(OH) content of catalystGood hydrothermal stabilityMolecular sieve catalystsDispersed particle separationIron saltsIon exchange

The present invention is directed to an iron-promoted zeolite beta catalyst useful in the selective catalytic reduction of nitrogen oxides with ammonia in which the iron-promoted zeolite beta is treated so as to provide increased amounts of the iron promoter in the form of Fe(OH).The stabilized zeolite is formed by cation exchange of an iron salt into a zeolite beta which has a reduced sodium content such as by exchanging a sodium beta with ammonium or hydrogen cations. A zeolite beta having a reduced carbon content and a Si / Al ratio of no more than 10 also increases the Fe(OH) content of the iron-promoted catalyst. The iron-promoted catalyst which has the iron in the form of Fe(OH) is characterized by a peak at 3680±5 cm−1 in the IR spectra.

Owner:ENGELHARD CORP

Methods for removal of impurity metals from gases using low metal zeolites

InactiveUS6395070B1High silica-to-alumina ratioReduce metal contentGas treatmentMolecular sieve catalystsBoiling pointTrace metal

A method for removing trace moisture from a gas is disclosed. The method involves heating a zeolite having a high silica-to-alumina ratio to about 400° C. to remove physically adsorbed water from the zeolite, followed by heating the zeolite to a temperature in excess of 650° C., to form a superheated zeolite. The superheated zeolite is contacted with the gas, thereby adsorbing water from the gas. A dehydroxylated zeolite for removing trace moisture from a gas wherein the zeolite has a high silica-to-alumina ratio and a low level of metallic impurities is also disclosed. A method for removing metallic impurities from a gas using the low metals zeolite is also disclosed. The zeolites and methods of the invention are particularly useful for removing trace water and trace metal impurities from acid gases such as hydrogen chloride and hydrogen bromide.

Owner:MATHESON TRI GAS INC

Catalyst for hydrogenation treatment of diesel oil and its preparation method

InactiveCN1400284AImprove catalytic performanceHigh activityMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsCobaltTungsten

The present invention relates to a catalyst for hydrotreating diesel oil, it contains one carrier and molybdenum and / or tungsten and nickiel and / or cobalt loaded on said carrier. The described carrier is composed of alumina and zeolite, and the weight ratio of the alumina and zeolite is 90:10-50:50, and the described alumina is formed from microporous alumina anjd macroporous alumina according tothe weight ratio of 75:25-50:50, in which the micrporous alumina is the alumina whose proe volume whose diameter is less than 80 angstrom pore is above 95% of total pore volume, and the macroporous alumia is the alumina whose pore volume whose diameter is 60-600 angstrom pore is above 70% of total pore volume.

Owner:CHINA PETROLEUM & CHEM CORP +1

ZSM-5/SAPO-11 composite zeolite and catalytically cracked gasoline hydrogenation quality-improved catalyzer and the methoer for preparing the same

ActiveCN101081370AImprove product qualityEquilibrium HydrodesulfurizationMolecular sieve catalystsHydrocarbon oils refiningIsomerizationHydrodesulfurization

The present invention is one kind of catalyst with ZSM-5 / SAPO-11 composite zeolite for hydrogenating and modifying catalytically cracked gasoline and its preparation process. The composite zeolite is prepared through compounding solution A with aluminum sulfate, sulfuric acid and water; compounding solution B with water glass, tetraethyl ammonium hydroxide and water; mixing solution A and solution B to form homogeneous colloid; crystallizing the colloid mixture at 150-180 deg.c for 24-72 hr; adding phosphoric acid, pseudoboehite, silica sol and SAPO-11 synthesizing template agent; and final crystallizing at 170-200 deg.c for 24-48 hr to obtain sodium type composite zeolite. The catalyst with the composite zeolite as carrier has excellent hydrogenating and desulfurizing performance, high stability, high gasoline yield, high isomerization activity and certain aromatization activity, and may be applied in producing high quality clean gasoline product.

Owner:BEIJING CUP GREEN CATALYTIC TECH

Catalyst and process for producing light aromatic hydrocarbons and light alkanes from hydrocarbonaceous feedstock

InactiveUS20090023968A1Large acid densityModerate activityMolecular sieve catalystsCatalyst activation/preparationPolycyclic aromatic hydrocarbonAlkane

The present invention provides a catalyst comprising metallic Pt and / or Pd supported on a binder-free zeolite for producing light aromatic hydrocarbons and light alkanes from hydrocarbonaceous feedstock, wherein the amount of metallic Pt and / or Pd is of 0.01-0.8 wt %, preferably 0.01-0.5 wt % on the basis of the total weight of the catalyst, and the binder-free zeolite is selected from the group consisting of mordenite, beta zeolite, Y zeolite, ZSM-5, ZSM-11 and composite or cocrystal zeolite thereof. The present invention also provides a process for producing light aromatic hydrocarbons and light alkanes from hydrocarbonaceous feedstock using said catalyst.

Owner:CHINA PETROCHEMICAL CORP +1

Technique for hydro-thermal synthesis of high purity zeolite and fly ash zeolite adsorbing agent from fly ash

InactiveCN101503202AImprove adsorption capacitySimple processOther chemical processesCrystalline aluminosilicate zeolitesSorbentMaterials science

The invention provides a process for hydrothermally synthesizing fly ash into a highly-pure zeolite and a fly ash zeolite adsorbent, which comprises the following steps: adding alkali solution into fly ash, obtaining solution containing silicon elements and aluminum elements under the hydrothermal condition, adding a certain amount of base soluble Al2O3 or SiO2 in the solution containing the silicon elements and the aluminum elements, and then preparing the highly-pure zeolite after hydrothermal reaction is carried out for a certain time; and adding the fly ash or the fly ash which is not dissolved under the hydrothermal condition into sodium hydroxide or sodium carbonate to be mixed uniformly (be calcined at a certain temperature), carrying out the hydrothermal condition, and then obtaining the fly ash zeolite adsorbent. The invention has simple process; the purity of the prepared highly-pure zeolite can achieve above 90 percent; and the prepared fly ash zeolite adsorbent has stronger adsorption capacity for heavy metal ions or organic wastewater.

Owner:SHAANXI UNIV OF TECH

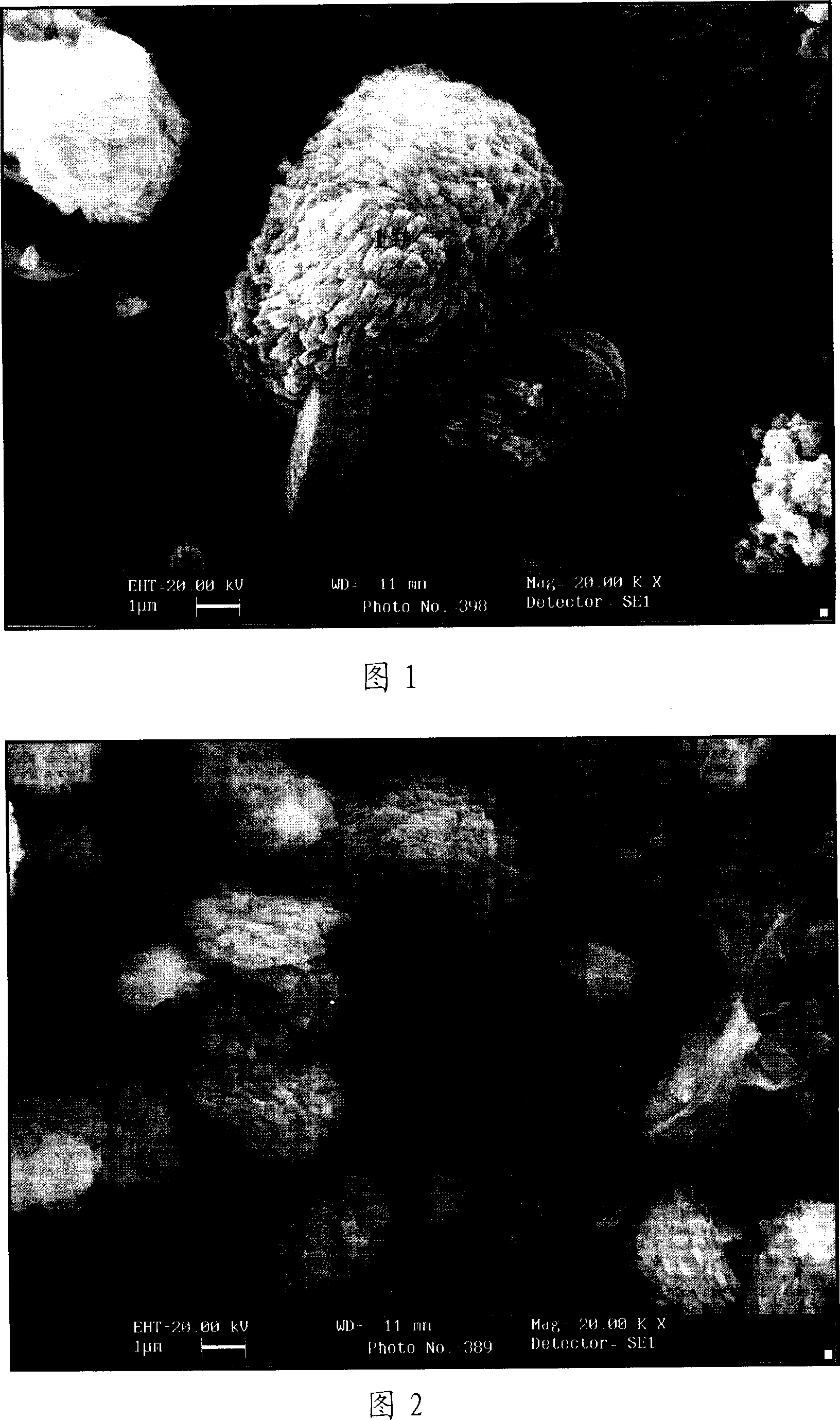

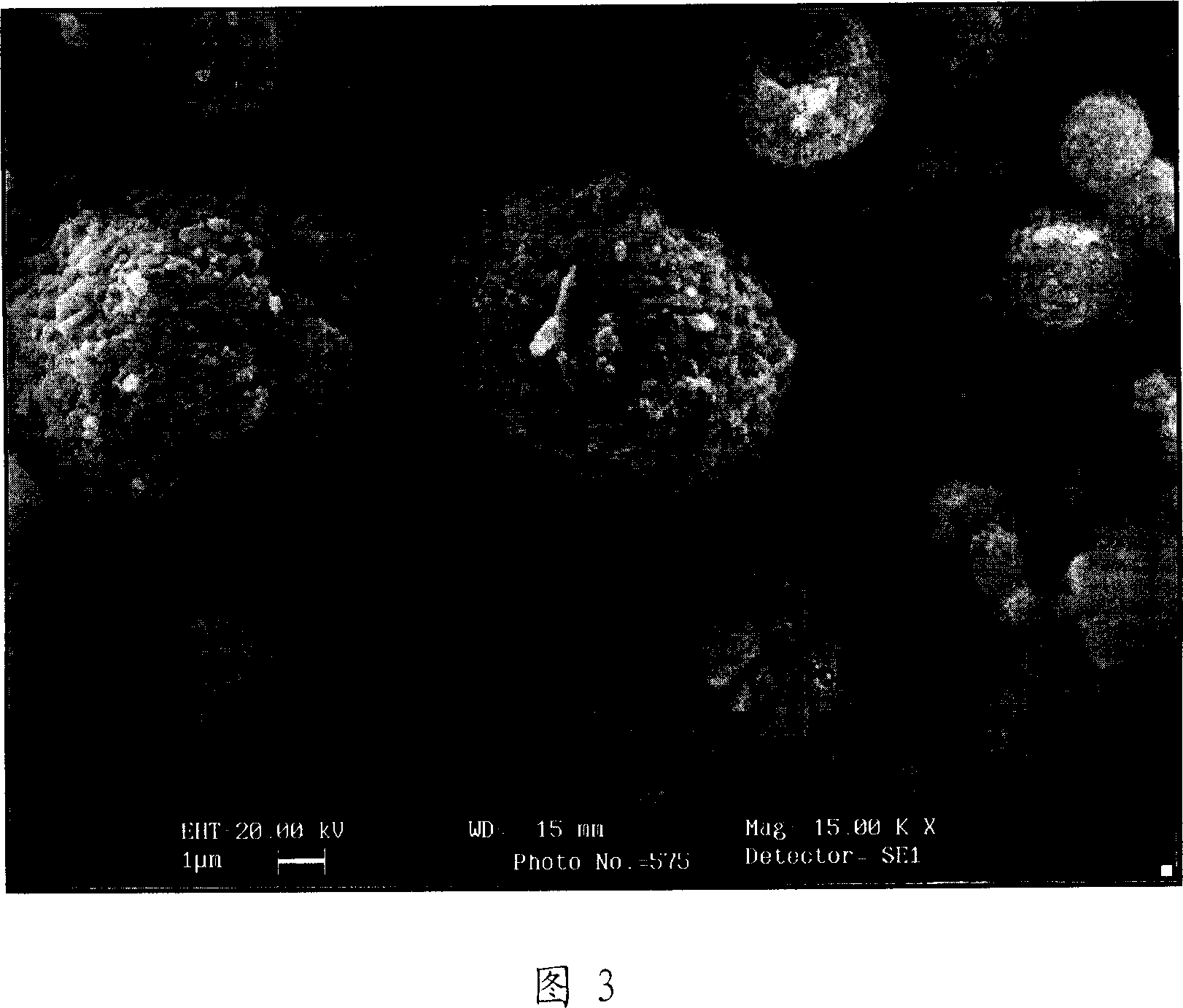

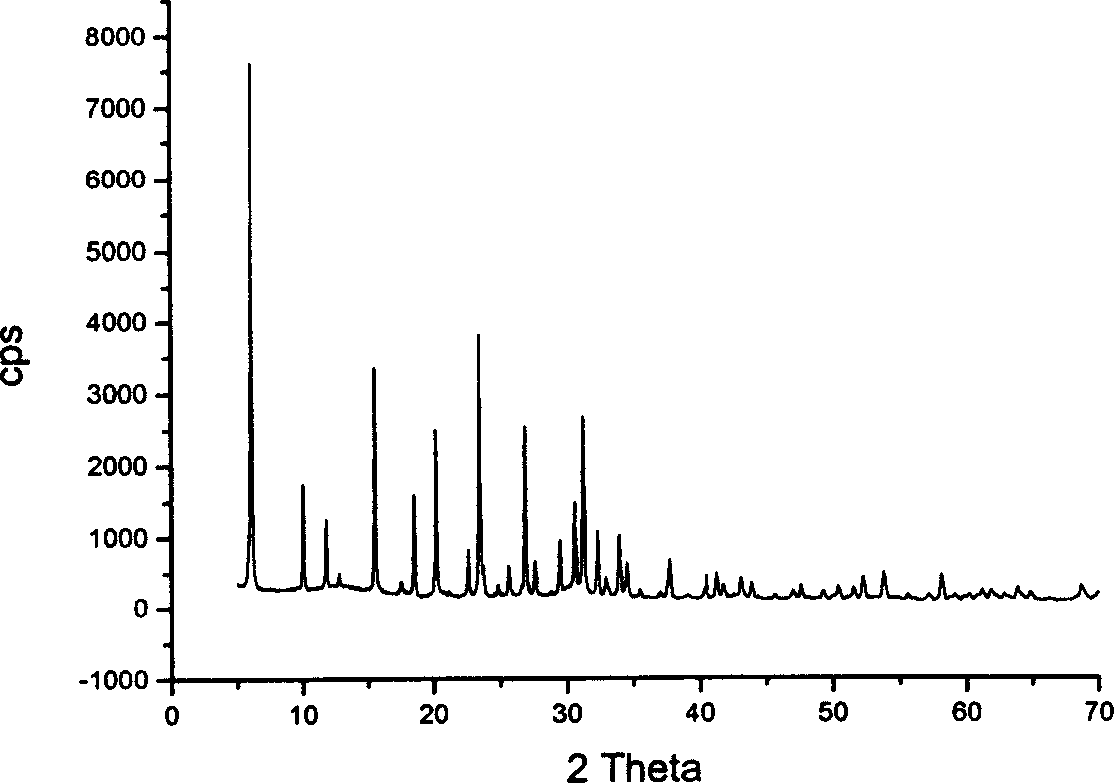

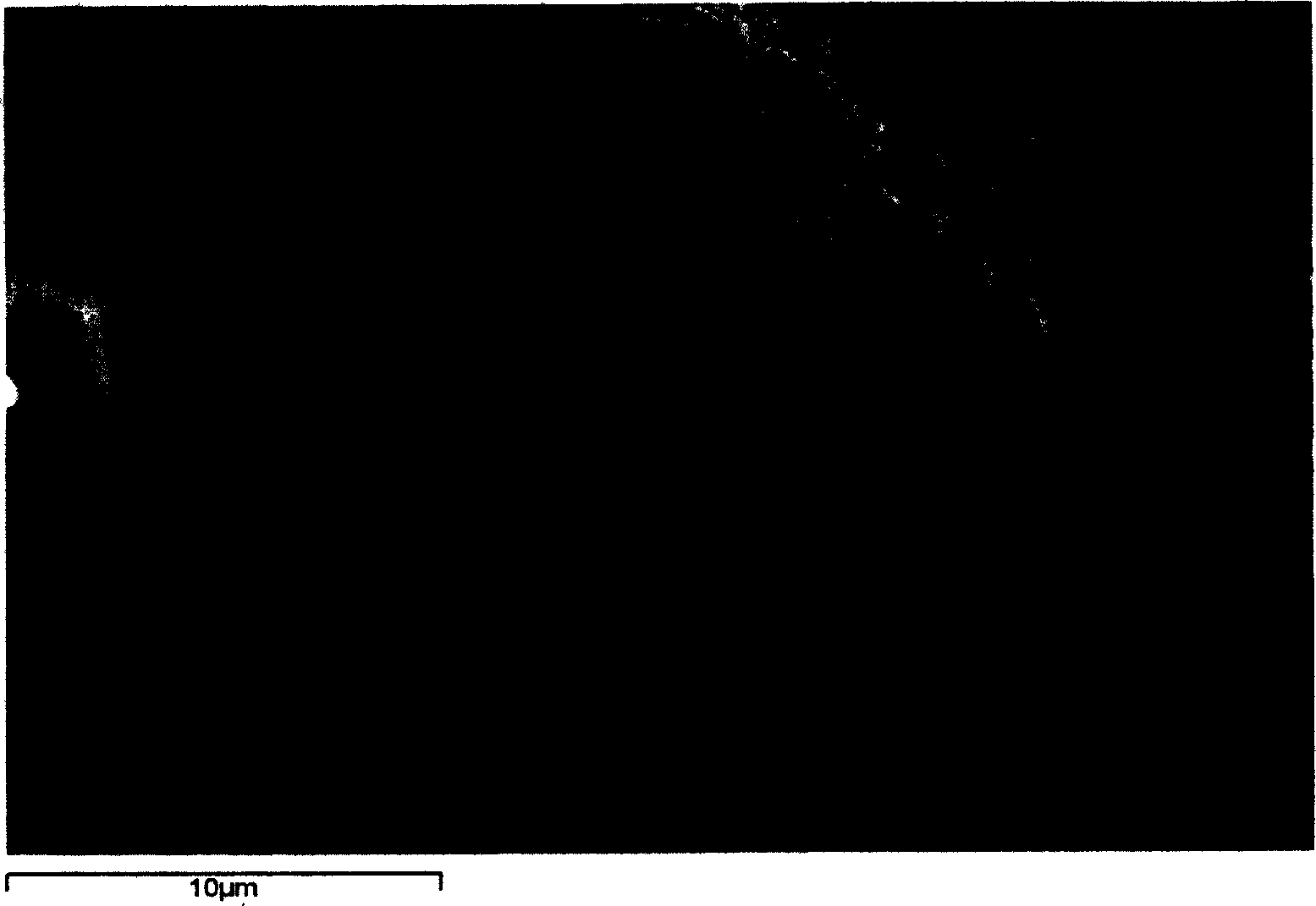

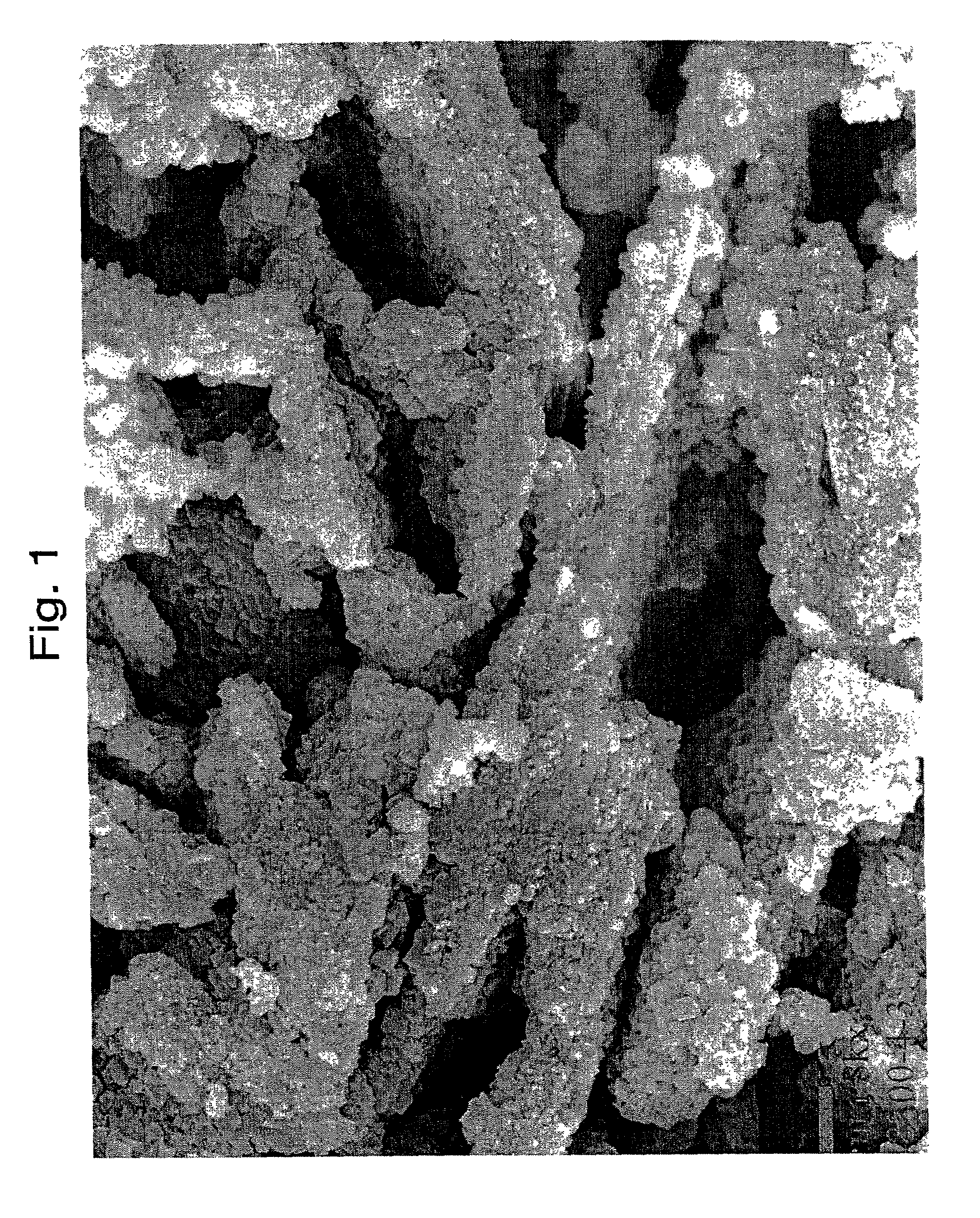

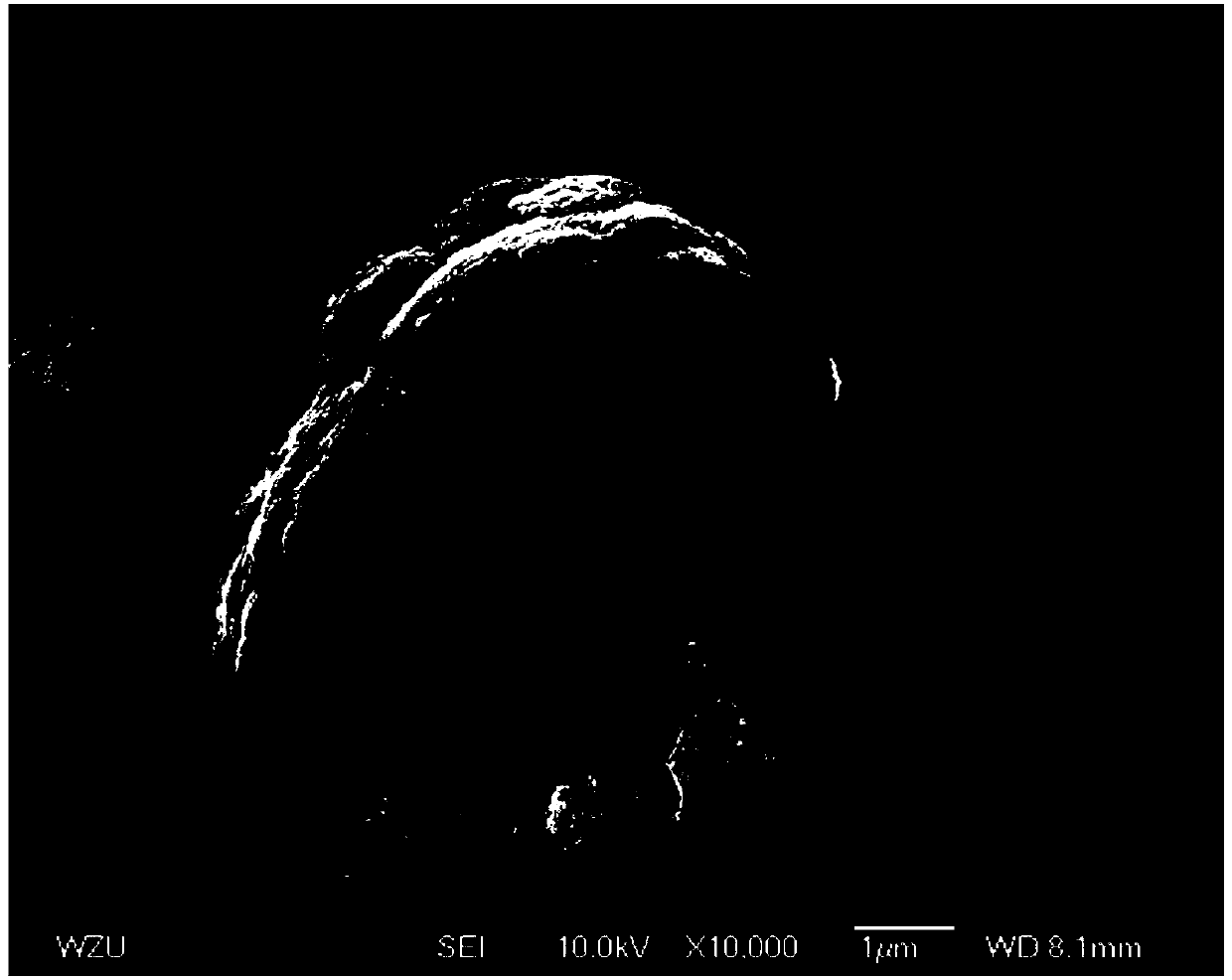

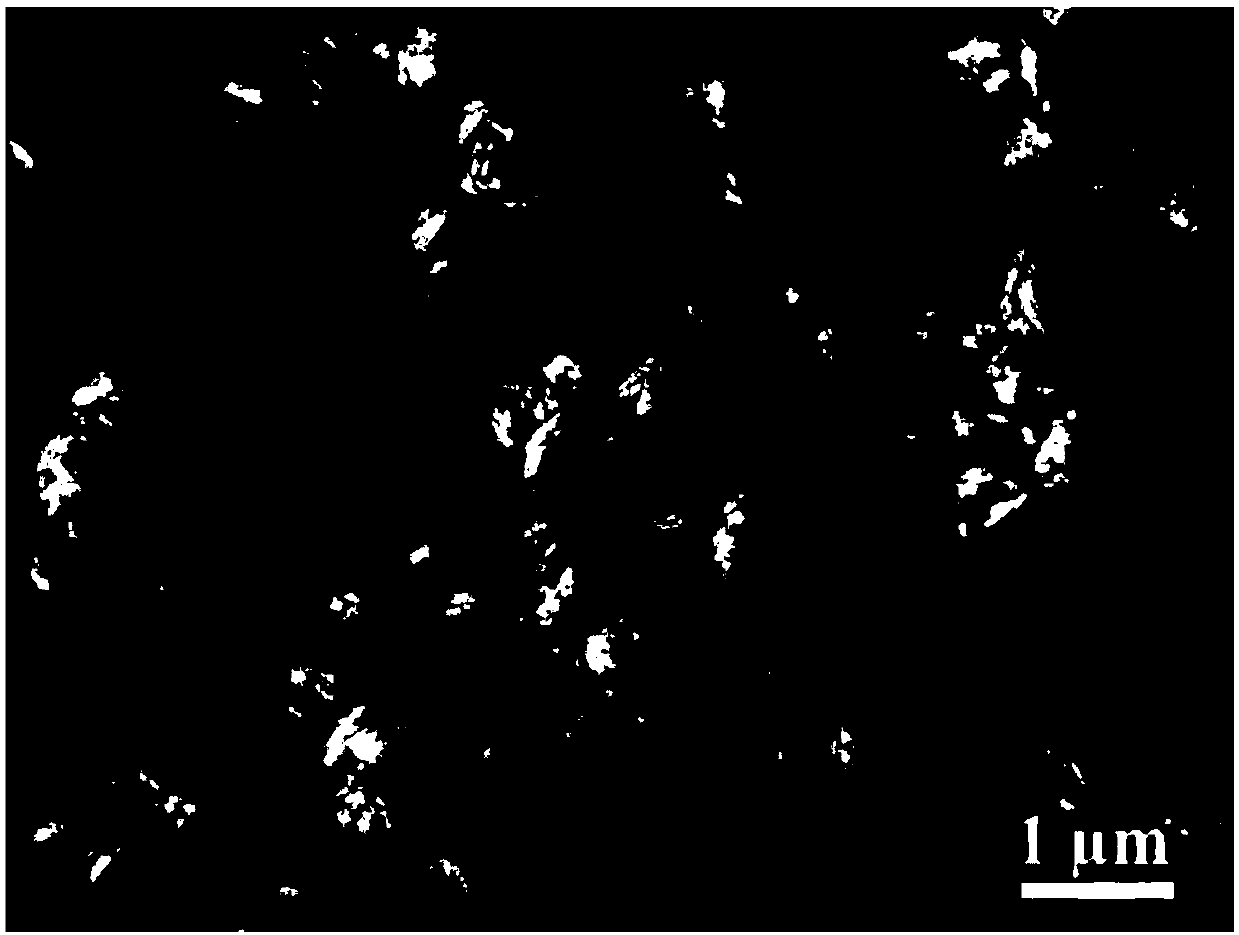

Nano-grade Y type zeolite synthesized from kaolin and its preparation metod

InactiveCN1533982ASpecial nest structureSmall grainCatalytic crackingMolecular sieve catalystsKaoliniteFuel oil

A nano-class Y zeolite prepared from raw kaolinite powder through crystallizing has 30-85 wt.% for NaY content. Its primary particles can be rod-shaped, flaky or block crystal. Its secondary particle is the nest-type sphere. It can be made into HY, REY, or REHY and used as the catalyst for catalytic cracking.

Owner:CHINA PETROLEUM & CHEM CORP +1

Zeolite adsorbent and its preparation method

ActiveCN101007261AGood removal effectMeet emission standardsOther chemical processesWater/sewage treatment by sorptionSorbentEmission standard

The invention discloses a zeolite adsorbent and its preparation method, the zeolite adsorbent is powder particles using zeolite as main raw material; it mixes 60-95% zeolite, 30% filler, 1-30% binding agent, 0-20% hole agent and 0-20% acid to prepare colloid which solid content is 10-60%; After spray-dries it, then it roasts power particles which droplet method volume>0.5 ml / g. The exchange capacity is large, it can remove the ammonia nitrogen, calcium magnesium ion, fluorinion or heavy metallic ion in sewage water effectively and reach sewage water emission standard.

Owner:岳阳明科催化技术有限公司

Alkaline phosphate-activated clay/zeolite catalysts

Zeolite / clay / phosphate catalysts can be prepared by a process wherein a composition of zeolite-clay-phosphate is brought to a pH level of about 7.0 to about 14.0. The resulting slurry is then age reacted for about 0.5 to about 24 hours. Thereafter the slurry is dried to produce a zeolite / clay / phosphate catalyst particles that are particularly characterized by their high levels of zeolite stability.

Owner:INTERCAT SAVANNAH

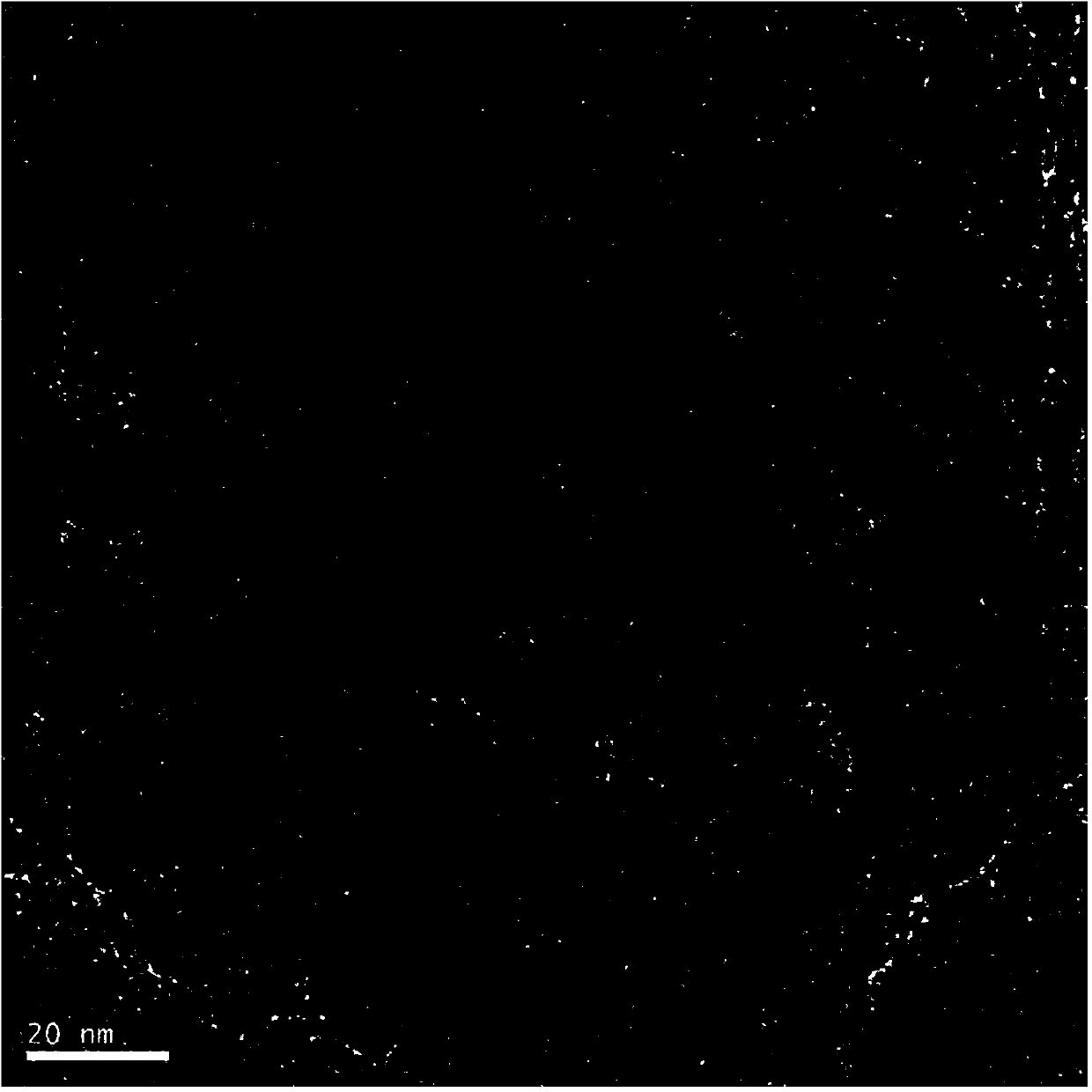

Preparation method for mordenite with high Si/Al ratio and small crystal particle

ActiveCN102602957ANovel Crystal MorphologyIncrease surface areaNanotechnologyMordenite aluminosilicate zeoliteSynthesis methodsFiltration

The invention discloses a preparation method for mordenite with a high Si / Al ratio and a small crystal particle, which comprises the following steps of: firstly, dissolving an Al source in sodium oxide solution; after an Si source is added, stirring and dispersing for certain time at room temperature and under strong magnetic force; mixing the Al source solution and the Si source solution which are evenly dispersed into glue at the room temperature; adding inorganic lamellar precursors, such as lamellar zeolite molecular sieves, lamellar silicate and the like to serve as seed crystal; after mixture is stirred and mixed evenly at the room temperature and under the strong magnetic force, transferring into a reaction crystallization kettle; at the temperature of 150-170DEG C, carrying out crystallization reaction for 0.5-3 days; and obtaining a solid product after common suction filtration, washing and drying. The synthesis method disclosed by the invention has the characteristics that expensive organic amine template is not used as structure-directing agent, and instead, the easily-obtained inorganic lamellar precursors with abundant source and low price are used as the seed crystal to directly synthesize a mordenite molecular sieve with the high Si / Al ratio. The prepared nanometer mordenite molecular sieve has the advantages of high degree of crystallinity and purity, controllable particle size and morphology, low cost and small environment pollution, and is convenient for industrially producing on a large scale.

Owner:EAST CHINA NORMAL UNIV

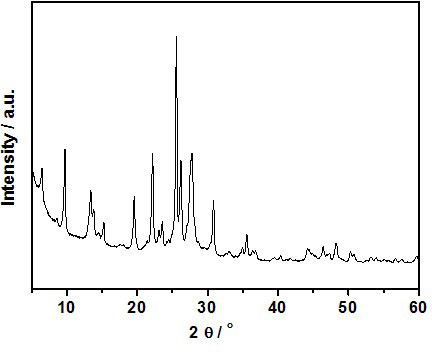

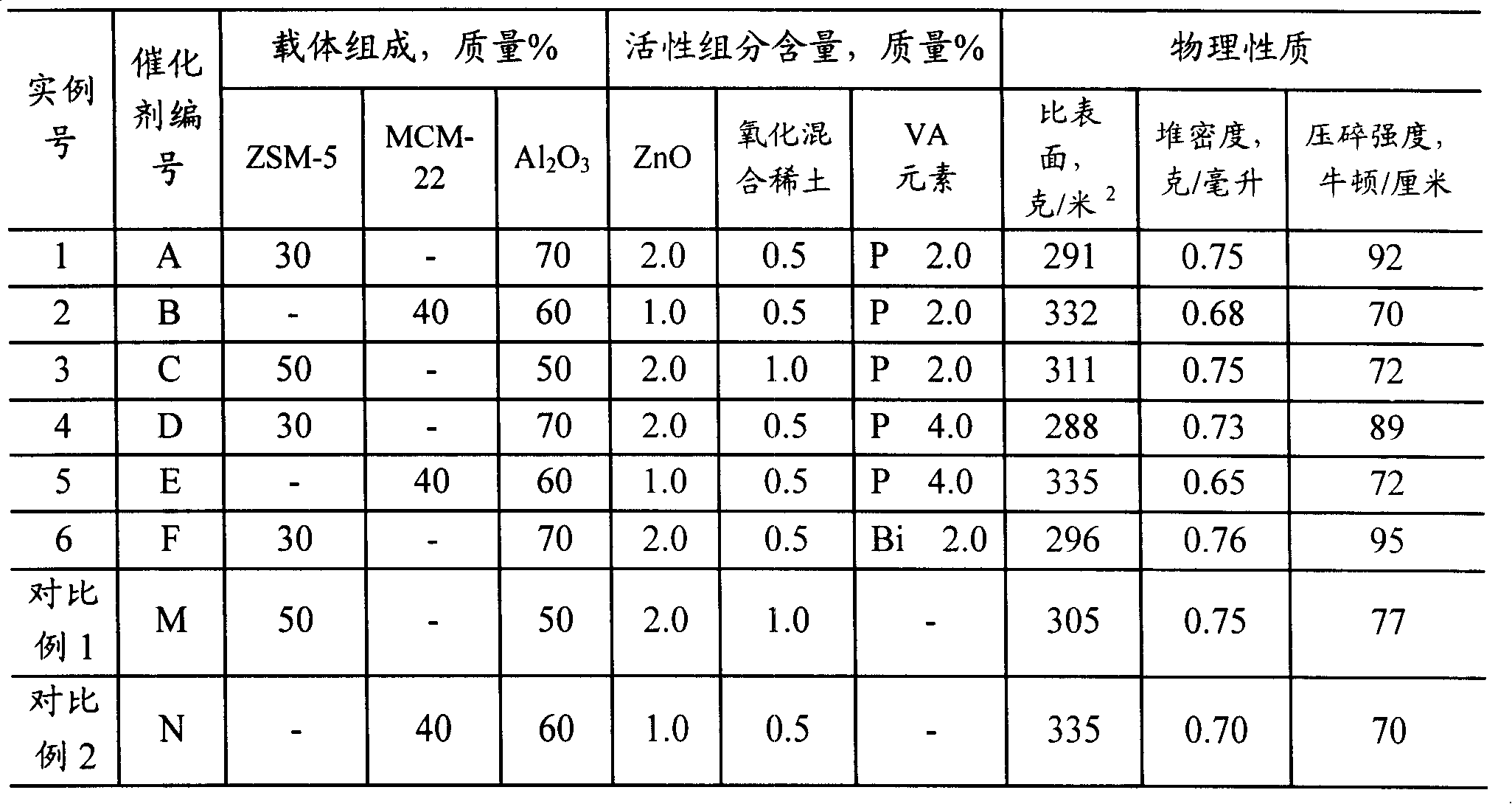

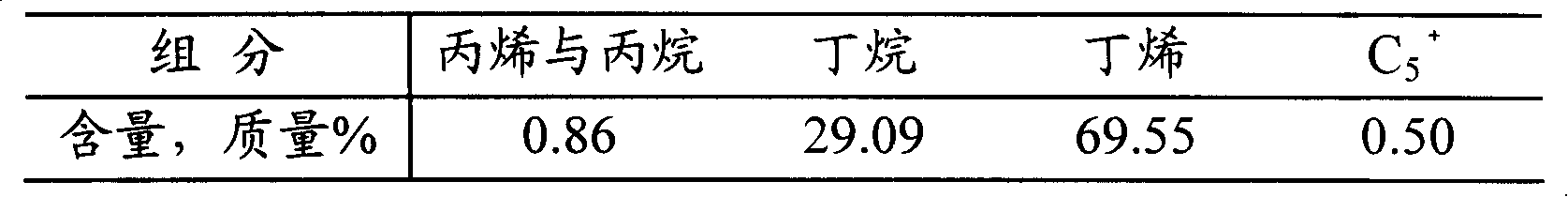

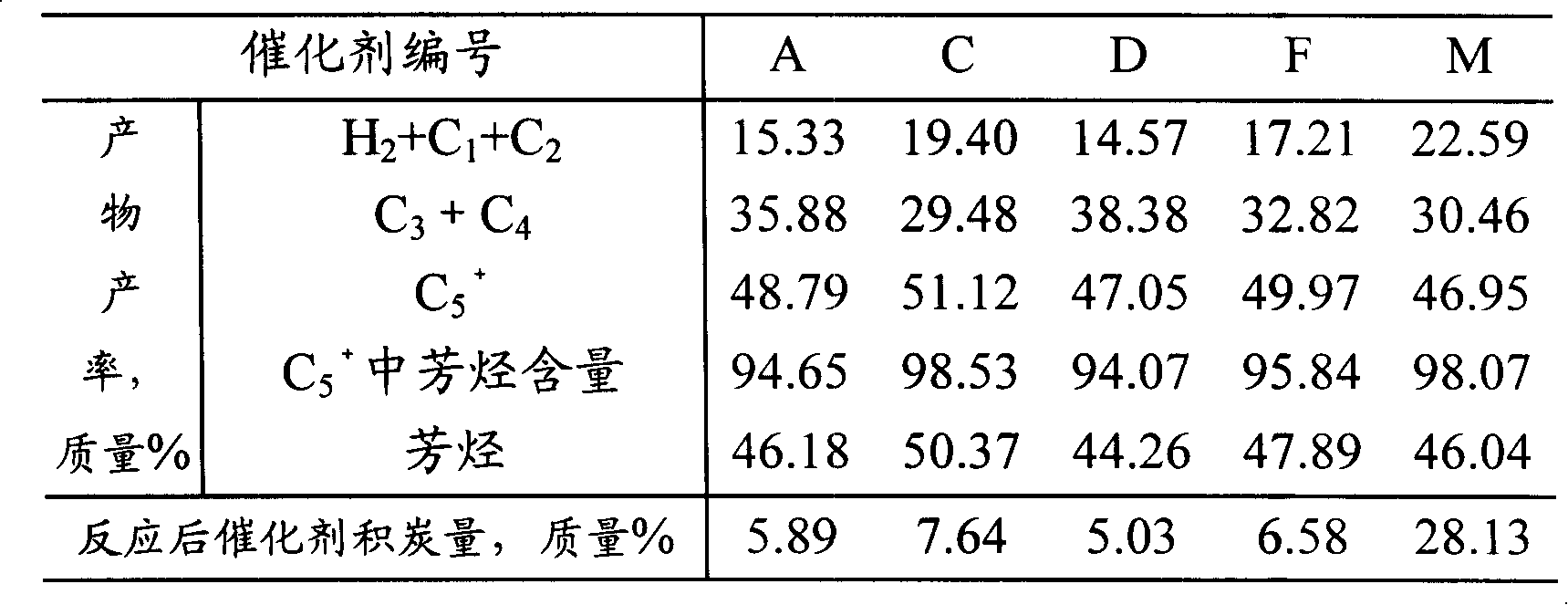

Light hydrocarbon aromatization catalyst and its preparing process

ActiveCN101172250AInhibit carbon depositionExtended service lifeMolecular sieve catalystsHydrocarbonsRare earthAromatization

The invention relates to light hydrocarbon aromatization catalyst, which includes a composite carrier and the components with the following content in the catalyst: 0.5 to 5.0 mass percent of ZnO, 0.1 to 5.0 mass percent of rare earth oxide, and 1.0 to 70 mass percent of VA element. The composite carrier comprises 20 to 70 mass percent of ZSM series zeolite or MCM series zeolite and 30 to 80 masspercent of binder. The light hydrocarbon aromatization catalyst has high yield of aromatic hydrocarbon and longer service life.

Owner:CHINA PETROLEUM & CHEM CORP +1

Anion easy-cleaning functional ceramic additive and preparation method thereof, ceramic prepared by using additive and preparation method thereof

The invention belongs to the technical field of ceramics, and particularly relates to an anion easy-cleaning functional ceramic additive and a preparation method thereof, a ceramic prepared by using the additive and a preparation method thereof. The additive is prepared from the following raw materials in percentage by mass: 10-16% of Chongguang stones with a particle size of 5-20 microns, 16-25% of tourmaline with a particle size of 5-15 microns, 5-15% of copper pectolite with a particle size of 5-20 microns, 8-12% of nano titanium dioxide, 6-8% of nano zinc oxide, 5-10% of lead-free frits, 7-20% of rare earth materials, 8-10% of superfine alumina, 8-15% of superfine quartz powder and 5-10% of sodium carbonate. The preparation method of the additive comprises the following steps of carrying out mixed ball-milling on the lead-free frits, the rare earth materials, the superfine alumina, the superfine quartz powder and the sodium carbonate firstly; and then, adding the Chongguang stones, the tourmaline, the copper pectolite, the nano titanium dioxide and the nano zinc oxide into the obtained product, and ball-milling the obtained mixture, so that the additive with a particle size of 1-10 microns is obtained. The additive disclosed by the invention has a self-polarizing performance, and has strong adsorption and decomposition functions, so that negative ions are produced; and after the additive is added into a ceramic, the ceramic is extremely easy to clean and not stained, and has no hidden dirt, therefore, the ceramic has a strong affinity to water.

Owner:ZIBO BAIKANG ECONOMIC & TRADE

Nano crystallite composite filter material and supplement of manufacture method thereof

The invention extends the connotation range required to be protected on the basis of a previously issued patent ZL200710025045.4, i.e., a nanometer microcrystalline composite filter material and a preparation method thereof, belonging to the field of a water disposal technique material. According to weight percentage, the nanometer microcrystalline composite filter material comprises 3-95 percent of attapulgite clay, 5-80 percent of sepiolite clay, 2-25 percent of kaolinite clay, 2-97 percent of tubular halloysite, 5-75 percent of diatomite, 5-75 percent of natural zeolite (clinoptilolite, mordenite and the like), 0-25 percent of pillared montmorillonite, 0-50 percent of expanded vermiculite, 0-5 percent of expanded perlite and 0-50 percent of active carbon or bamboo carbon powders. All raw materials which are powder shapes are mixed according to proportion and stirred to granulate by adding an inorganic adhesive, then sintered and activated at the temperature of 900-500 DEG C (inert gas is required for sintering and activating the filter material added with active carbon). The nanometer microcrystalline composite filter material has smooth shape, rough surface and uniform particle size, with the diameter of 1-10mm, and is used for biological filter tanks and high-class adsorption filter materials in deep purification systems of drinking water and reclaimed water sewage disposal systems.

Owner:傅成义

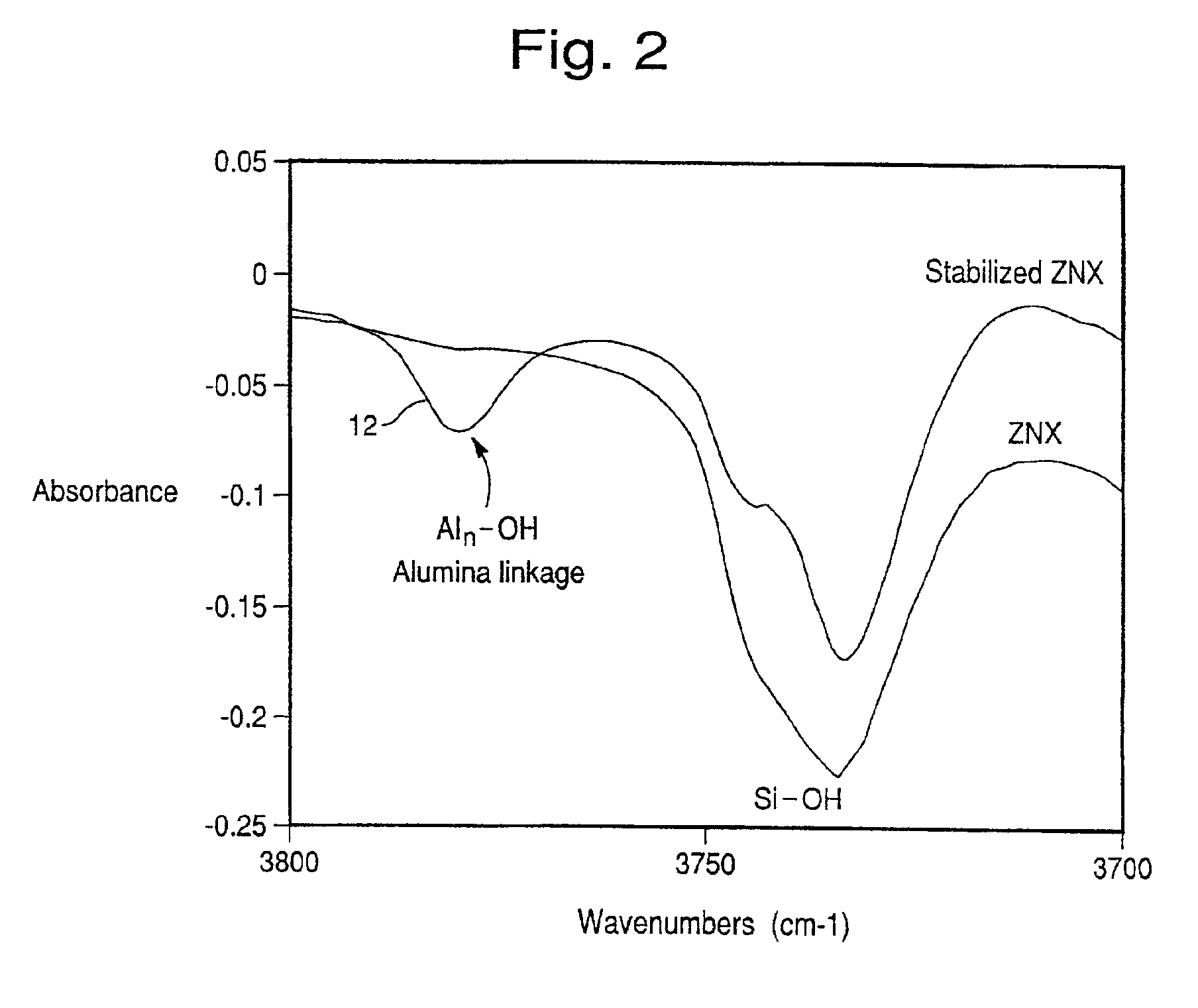

Hydrothermally stable metal promoted zeolite beta for NOx reduction

InactiveUS7332148B2Good hydrothermal stabilityImprove stabilityAluminosilicate zeolite type ZSM-12Aluminium compoundsNitrogen oxidesIr absorption

A stabilized metal promoted aluminosilicate zeolite, useful in the selective catalytic reduction of nitrogen oxides with ammonia, having a silica to alumina mole ratio of at least 8 and less than 30 and an FT-IR absorption peak at 3781 plus or minus 2 cm−1 which stabilizes the zeolite against further dealumination such as under oxidizing and harsh hydrothermal conditions.

Owner:ENGELHARD CORP

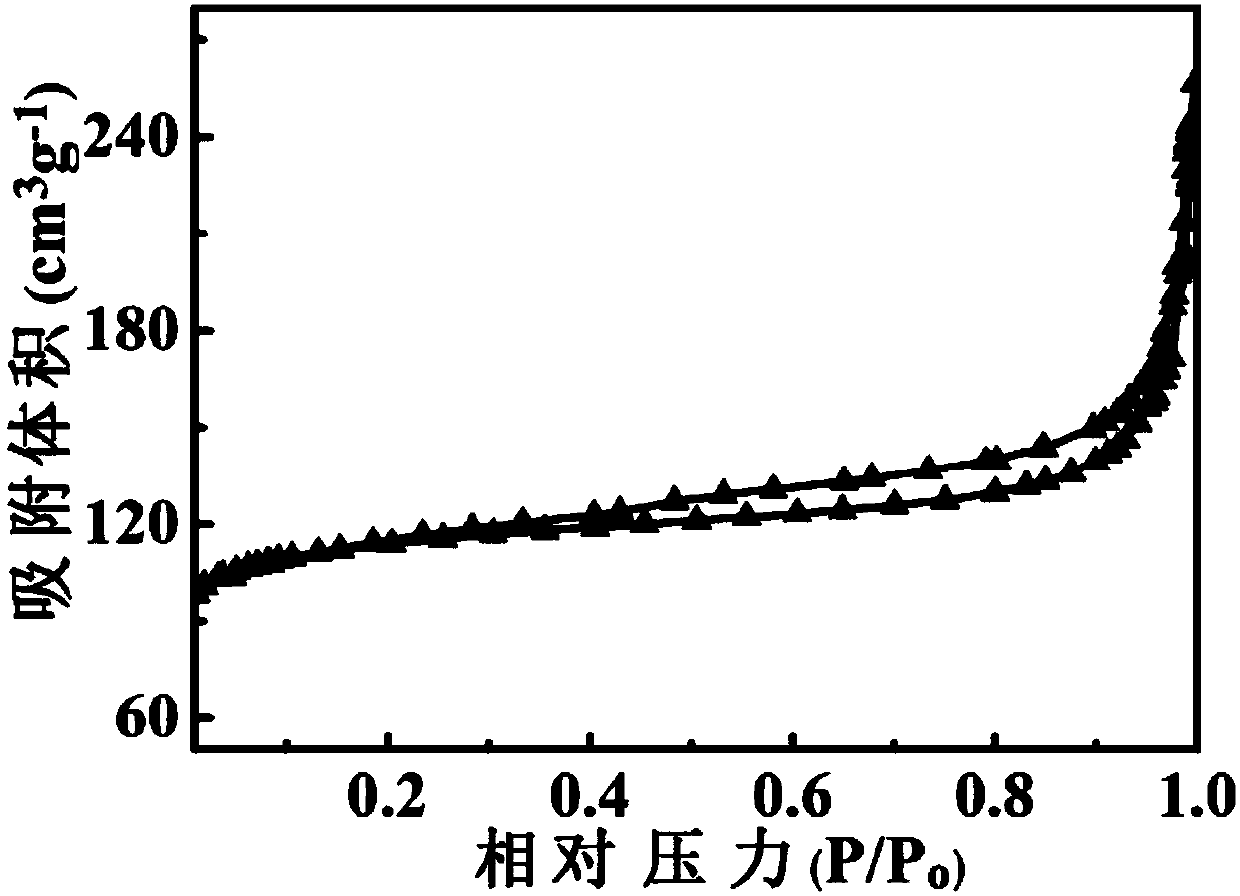

Hydrocracking catalyst

ActiveUS7192900B2Large specific surface areaLow unitAluminium compoundsMolecular sieve catalystsNitrogenSilicon dioxide

Hydrocracking catalyst composition comprising an optional metal hydrogenation component supported on a carrier comprising a zeolite of the faujasite structure having a unit cell size in the range of from 24.10 to 24.40 Å, a bulk silica to alumina ratio (SAR) above about 12, and a surface area of at least about 850 m2 / g as measured by the BET method and ATSM D4365-95 with nitrogen adsorption at a p / po value of 0.03.

Owner:SHELL USA INC

Amination catalyst and preparation method thereof

ActiveCN101406845AHigh catalytic activityImprove catalytic selectivityMolecular sieve catalystsOrganic compound preparationDodecaneMordenite

The invention discloses an amination catalyst and a preparation method thereof, which aims to solve the problem that the amination catalyst is not high in activity and selectivity. The compositions in weight percentage of the amination catalyst are: 15 to 25 percent of A, 5 to 10 percent of B, 1 to 3 percent of C, 0.1 to 1.5 percent of D, and the balance being h-type mordenite, wherein the A is alumina; the B is titanium oxide; the C is metallic ion W<6+>, Re<7+> or Bi<3+>; the D is metallic ion Cs<+>; and the metals exist in the form of elements or oxides. The preparation method comprises the following steps of loading the components C and D on the h-type mordenite, well mixing the components C and D with the alumina and ethanolamine titanate dodecane alcohol ester, molding, roasting and activating the mixture. The catalyst is used for synthesizing ethylene dimine under the conditions of ethanolamine and ammonia phase.

Owner:XIAN MODERN CHEM RES INST

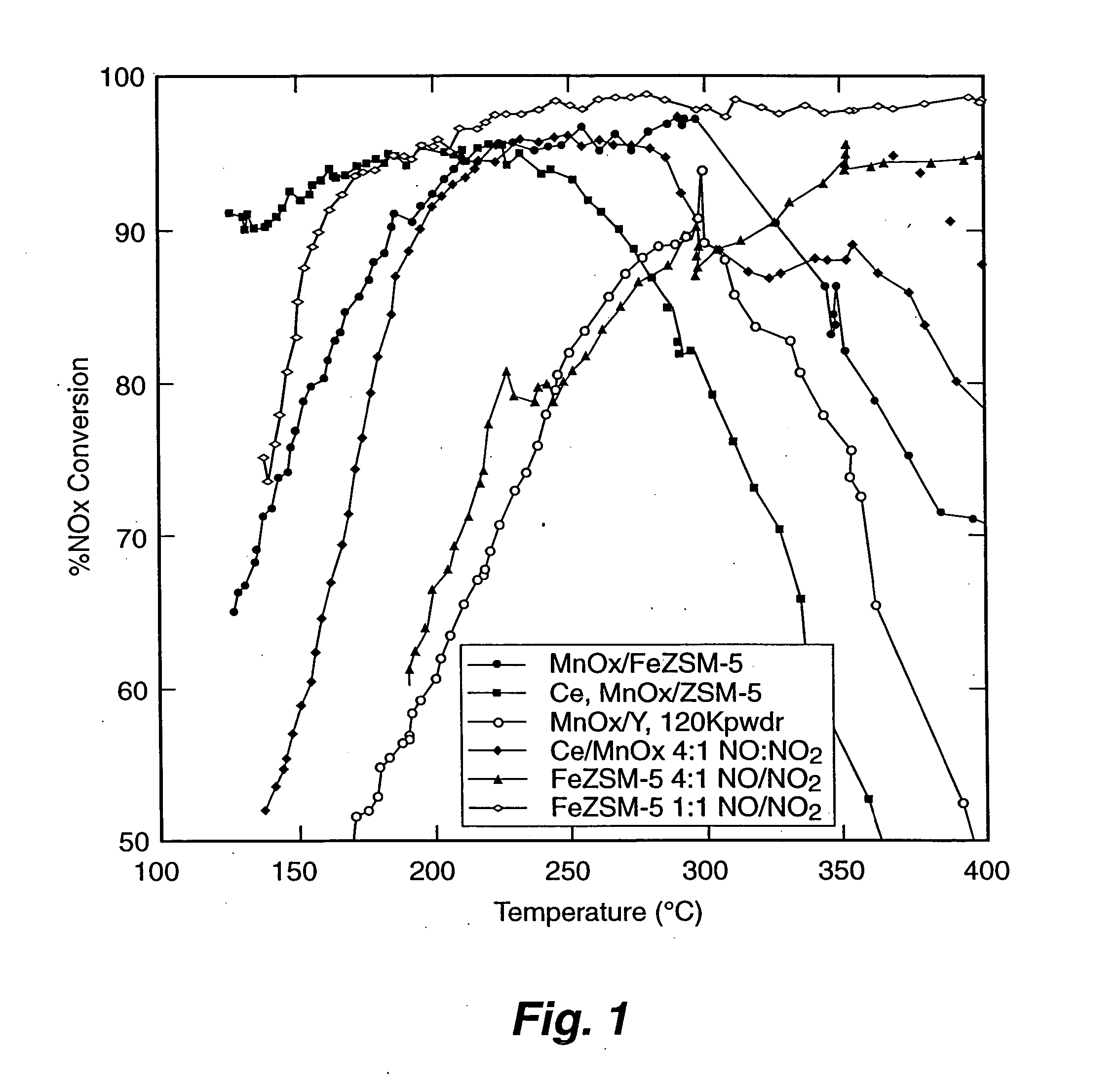

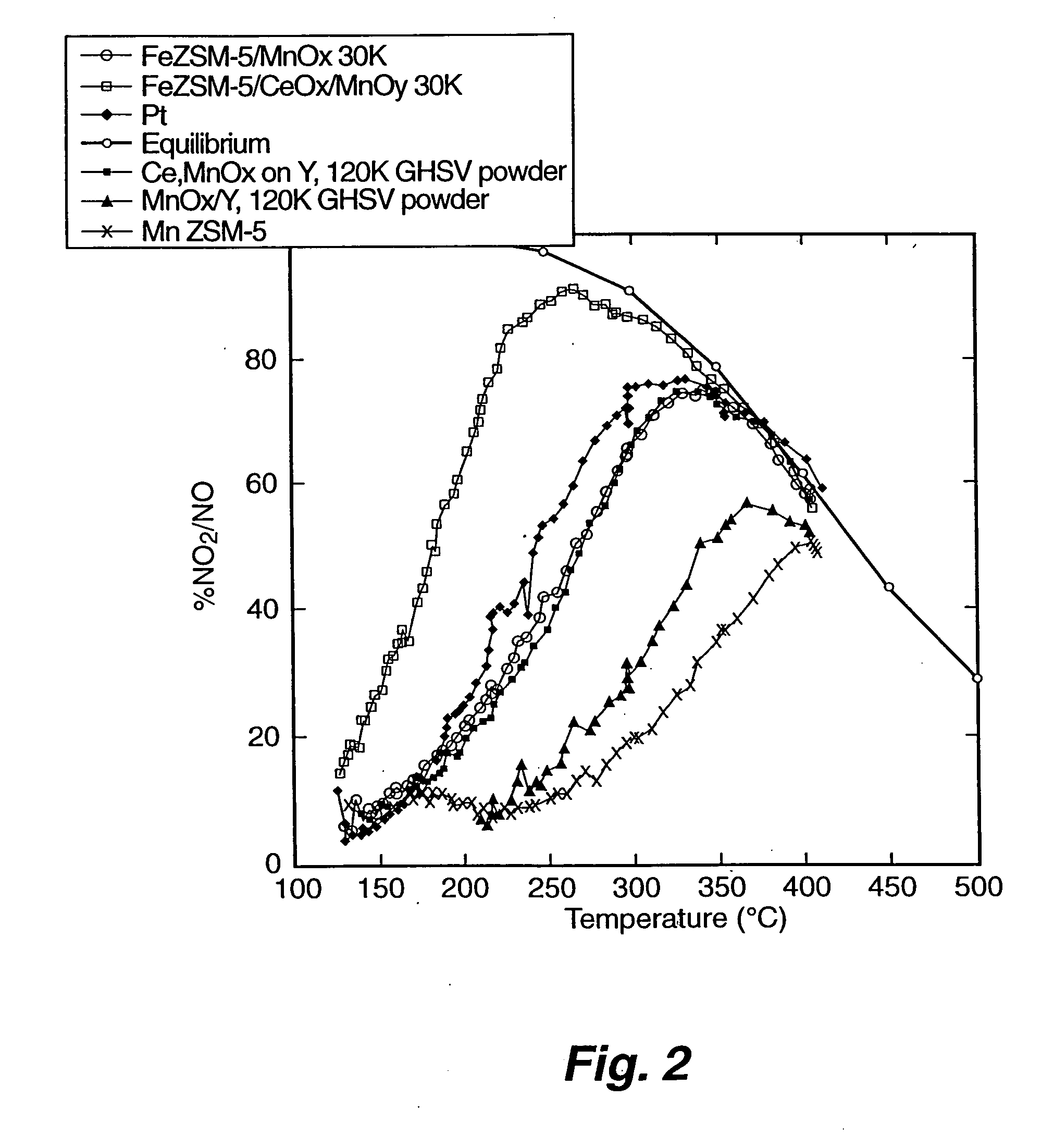

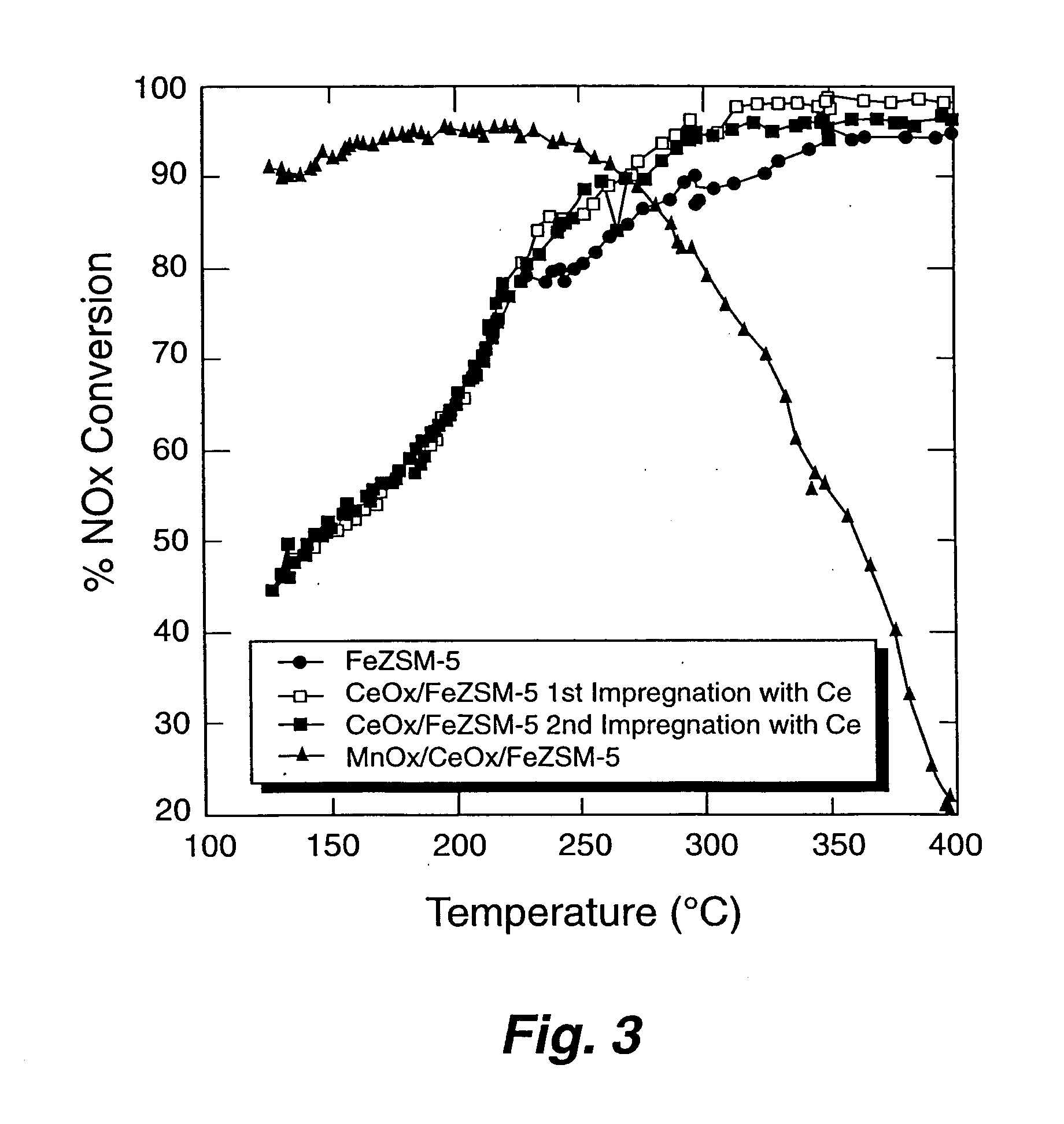

Catalyst and method for reduction of nitrogen oxides

InactiveUS20060159607A1Reduce the temperatureNitrous oxide captureNitrogen compoundsCerium nitrateIron salts

A Selective Catalytic Reduction (SCR) catalyst was prepared by slurry coating ZSM-5 zeolite onto a cordierite monolith, then subliming an iron salt onto the zeolite, calcining the monolith, and then dipping the monolith either into an aqueous solution of manganese nitrate and cerium nitrate and then calcining, or by similar treatment with separate solutions of manganese nitrate and cerium nitrate. The supported catalyst containing iron, manganese, and cerium showed 80 percent conversion at 113 degrees Celsius of a feed gas containing nitrogen oxides having 4 parts NO to one part NO2, about one equivalent ammonia, and excess oxygen; conversion improved to 94 percent at 147 degrees Celsius. N2O was not detected (detection limit: 0.6 percent N2O).

Owner:LOS ALAMOS NATIONAL SECURITY

Process for making titanium-MWW zeolite

ActiveUS8124555B2Molecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsTitaniumBoron

Titanium-MWW zeolite is prepared by heating a gel formed from a titanium compound, a silicon source, a boron source, an MWW-templating agent, and water at a temperature in the range of 35° C. to 75° C. for a period of 8 to 30 hours to form a pre-crystallized gel, and heating the pre-crystallized gel to a temperature in the range of 160° C. to 190° C. for a period of 5 or more days to form the titanium-MWW zeolite. The zeolite, after it is contacted with an acid, is useful in olefin epoxidation with hydrogen peroxide.

Owner:LYONDELL CHEM TECH LP

Heavy aromatic hydrocarbon light catalyst, preparation method and application thereof

ActiveCN101607207AHigh aromatics conversion activityHigh yieldMolecular sieve catalystsHydrocarbon oils refiningRheniumCatalytic effect

The invention relates to a heavy aromatic hydrocarbon light catalyst, a preparation method and application thereof. In a composite carrier, H type MCM-56 zeolite is between 50 and 80 wt percent, Al2O3 is between 20 and 50 wt percent, metals or oxides thereof of tin, bismuth, lanthanum, molybdenum, nickel, chrome and cobalt are 3 to 20 wt percent, or platinum, palladium, rhenium or oxide thereof are 0.1 to 2wt percent. The catalyst is applicable to the light preparation of benzene, methylbenzene and dimethylbenzene by heavy aromatic hydrocarbon; and the catalyst has good catalytic effect on a hydrodealkylation light reaction of C9 heavy aromatic hydrocarbon, the transformation ratio of C9 aromatic hydrocarbon is 76.89 wt percent, the yield of BTX is 48.37 wt percent, the selectivity of the BTX is 80.50 mol percent, no phenylethane is generated in a product, and the dimethylbenzene has high content.

Owner:PETROCHINA CO LTD

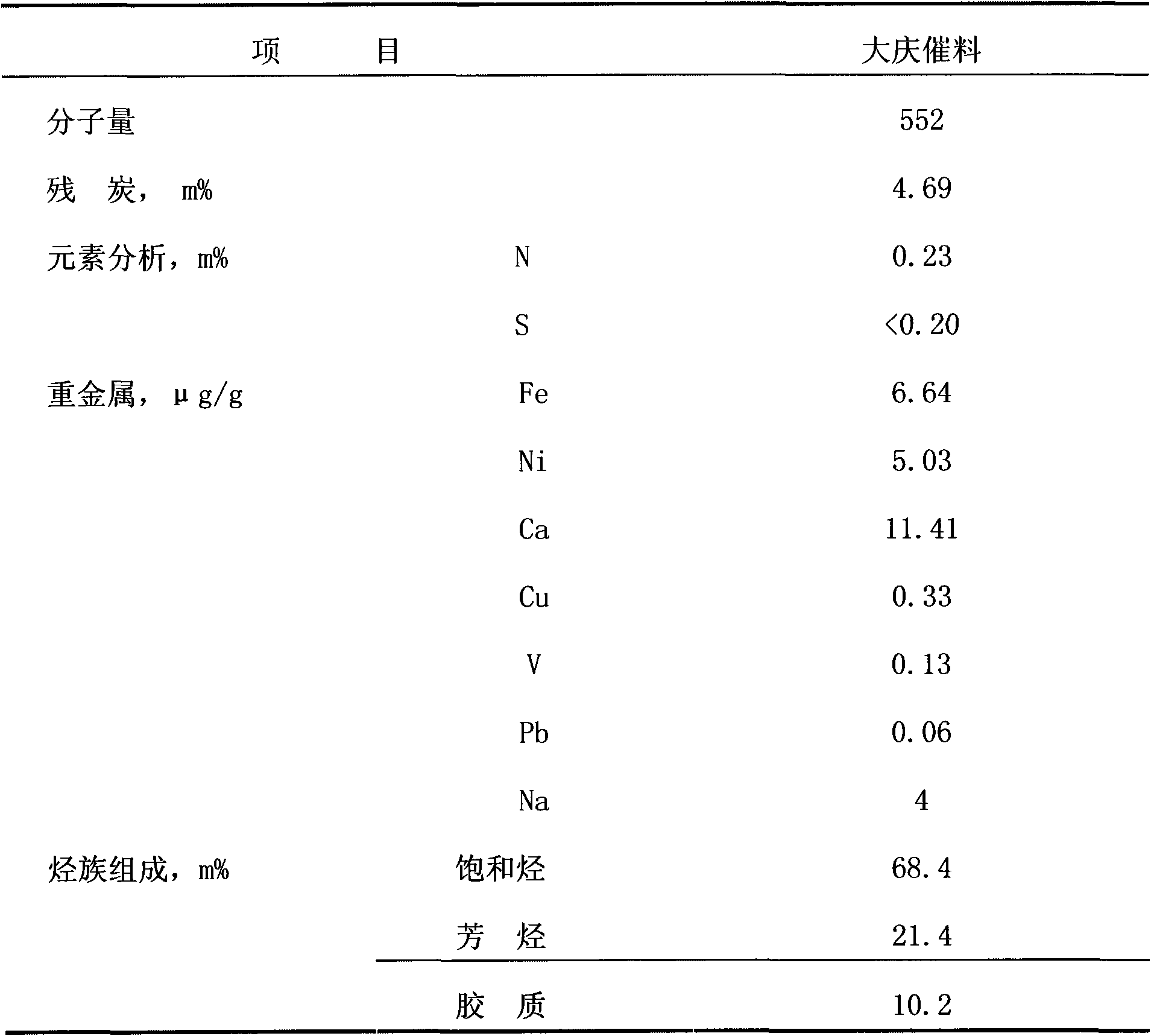

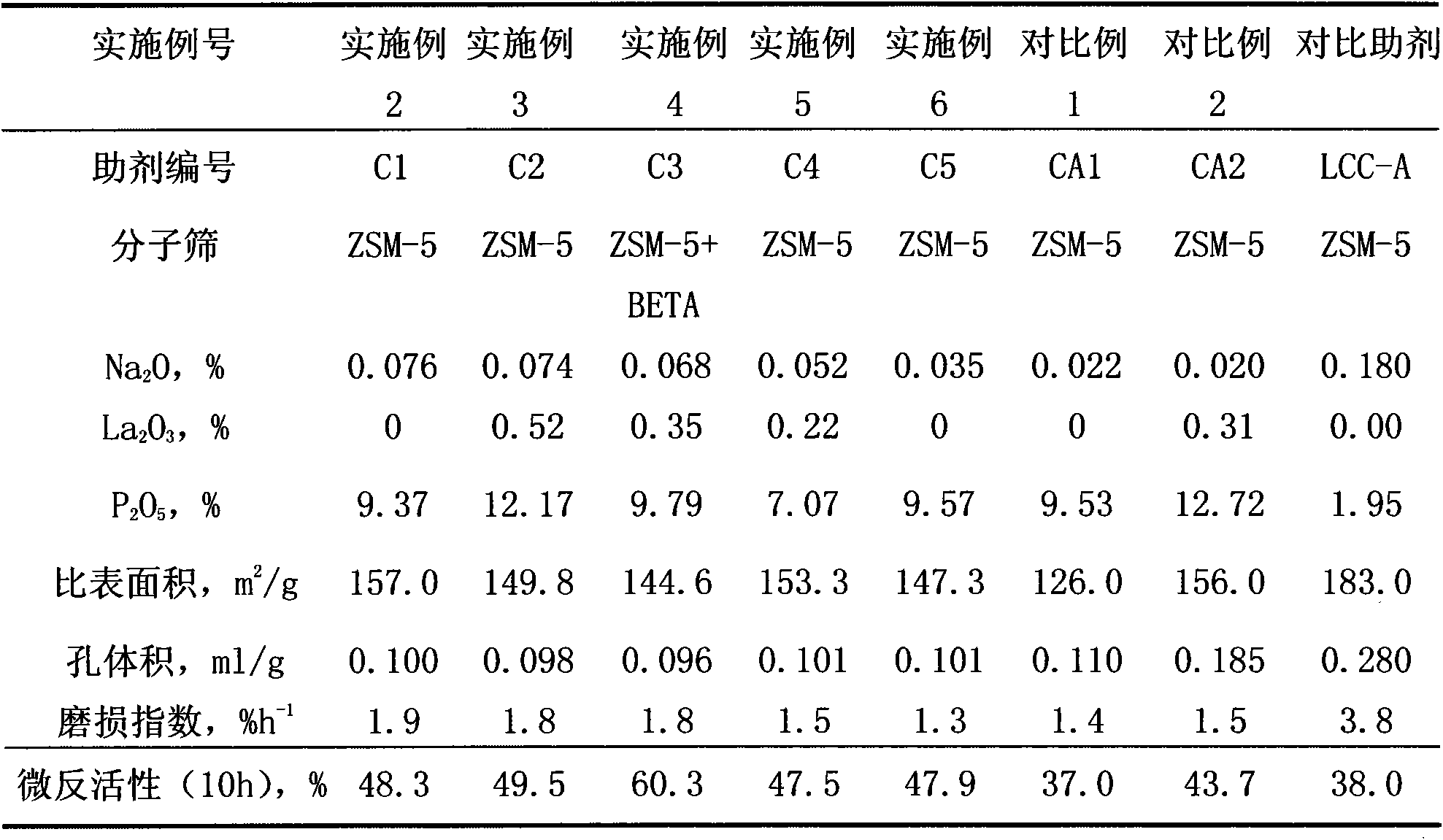

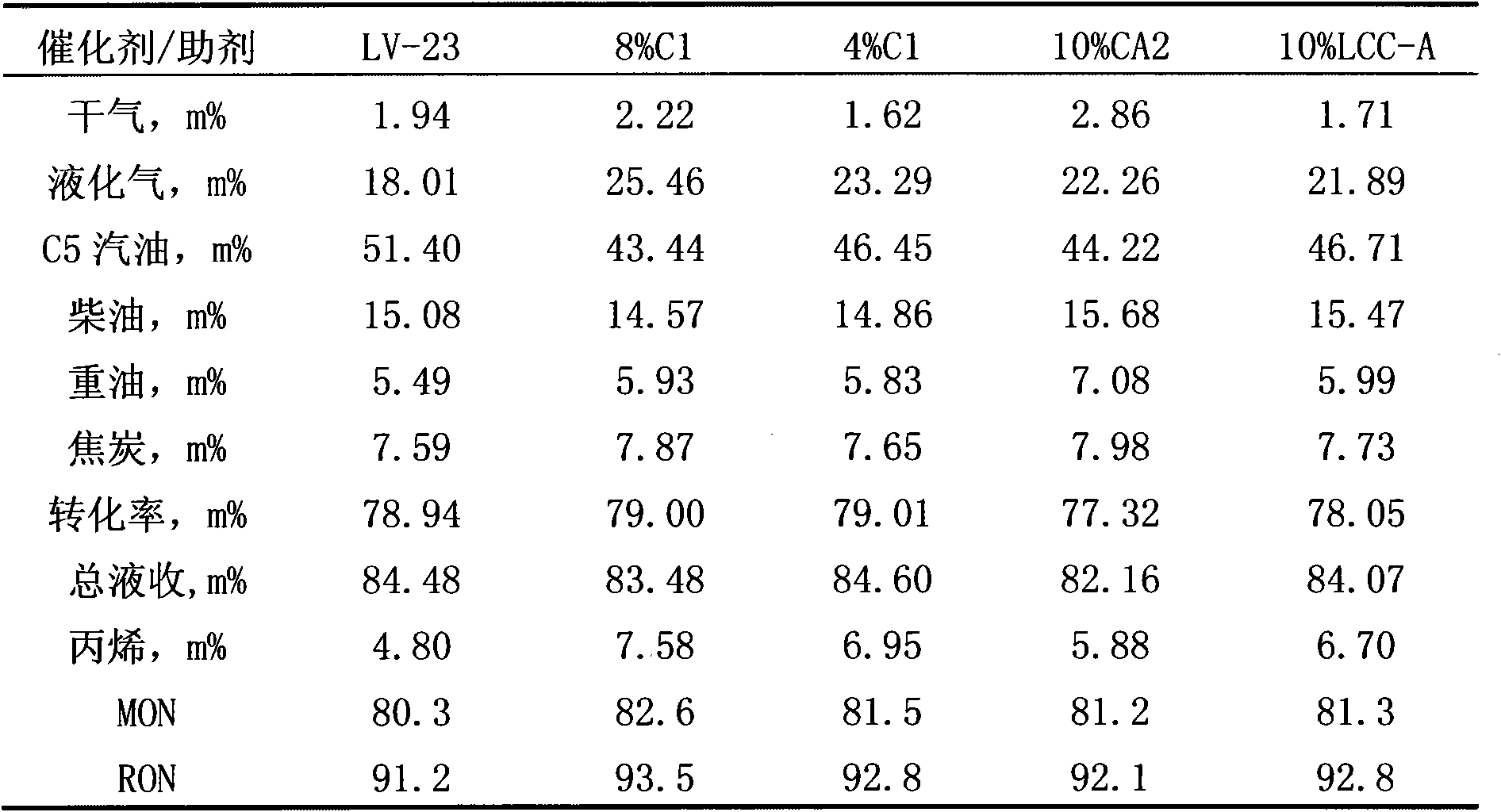

Catalytic cracking propylene additive and preparation method thereof

ActiveCN102049284AImprove stabilityReduce viscosityCatalytic crackingMolecular sieve catalystsAdhesiveALUMINUM PHOSPHATE

The invention relates to a catalytic cracking propylene additive. The additive measured in the total weight of 100 percent is characterized by being prepared from the following components in percentage by weight: 30-80 percent of molecular sieve including 28-78 percent of ZSM-5 zeolite, 10-65 percent of clay and 5.0-20.0 percent of P2O5, preferable 7.0-15.0 percent as well as 0-1.0 percent of La2O3. Aluminum phosphate sol is adopted as an adhesive to improve the abrasive strength of the additive, improve the solid content of spraying slurry and avoid the chlorine contents of the spraying slurry and the additive. The prepared catalytic cracking propylene additive remarkably improves the activity, slightly lessens the activity of a main catalyst when mixing with the main catalyst for use, can improve the product distribution, have favorable dry gas and coke selectivity and simultaneously improve the propylene yield and the gasoline octane number.

Owner:PETROCHINA CO LTD

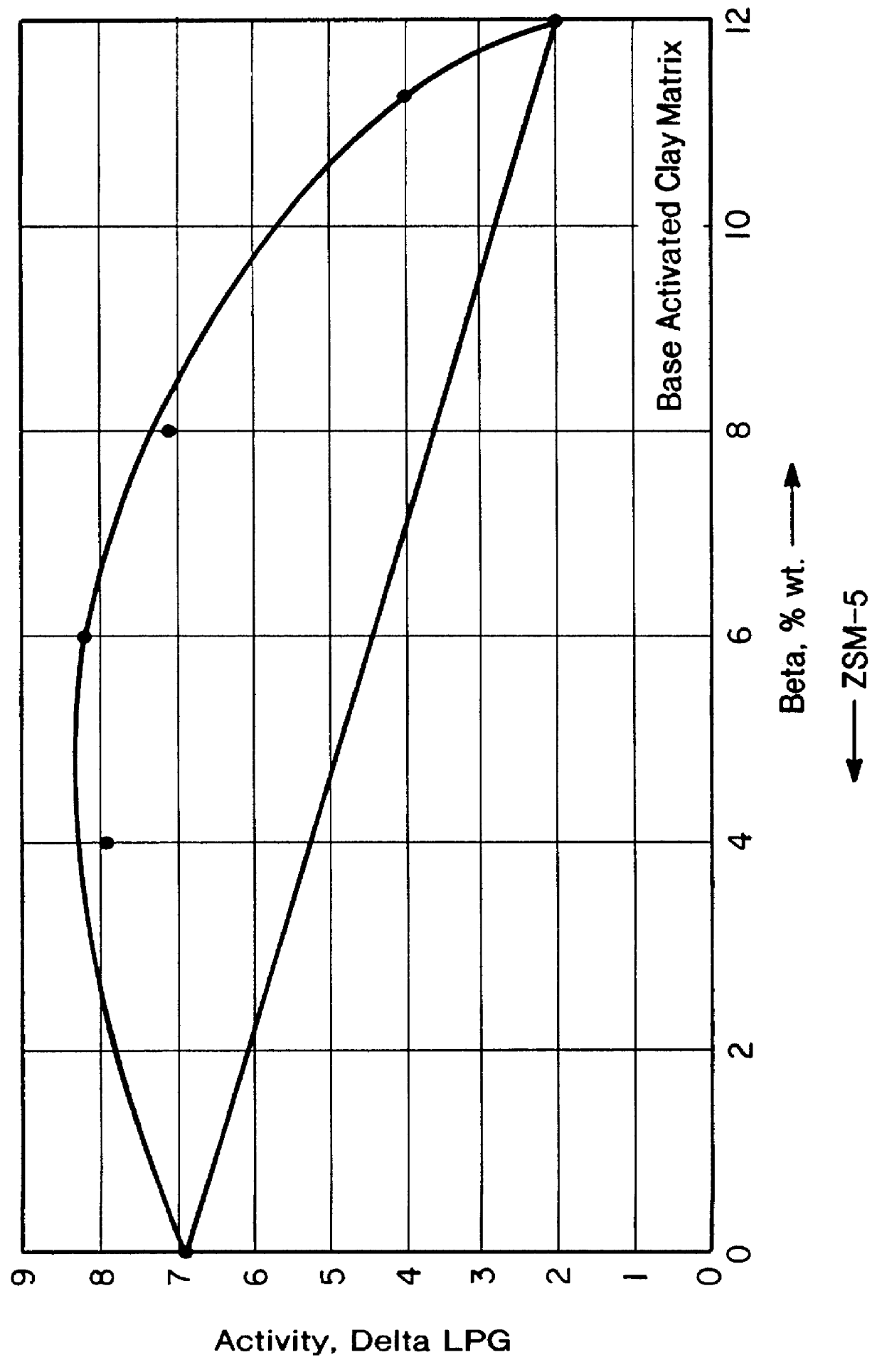

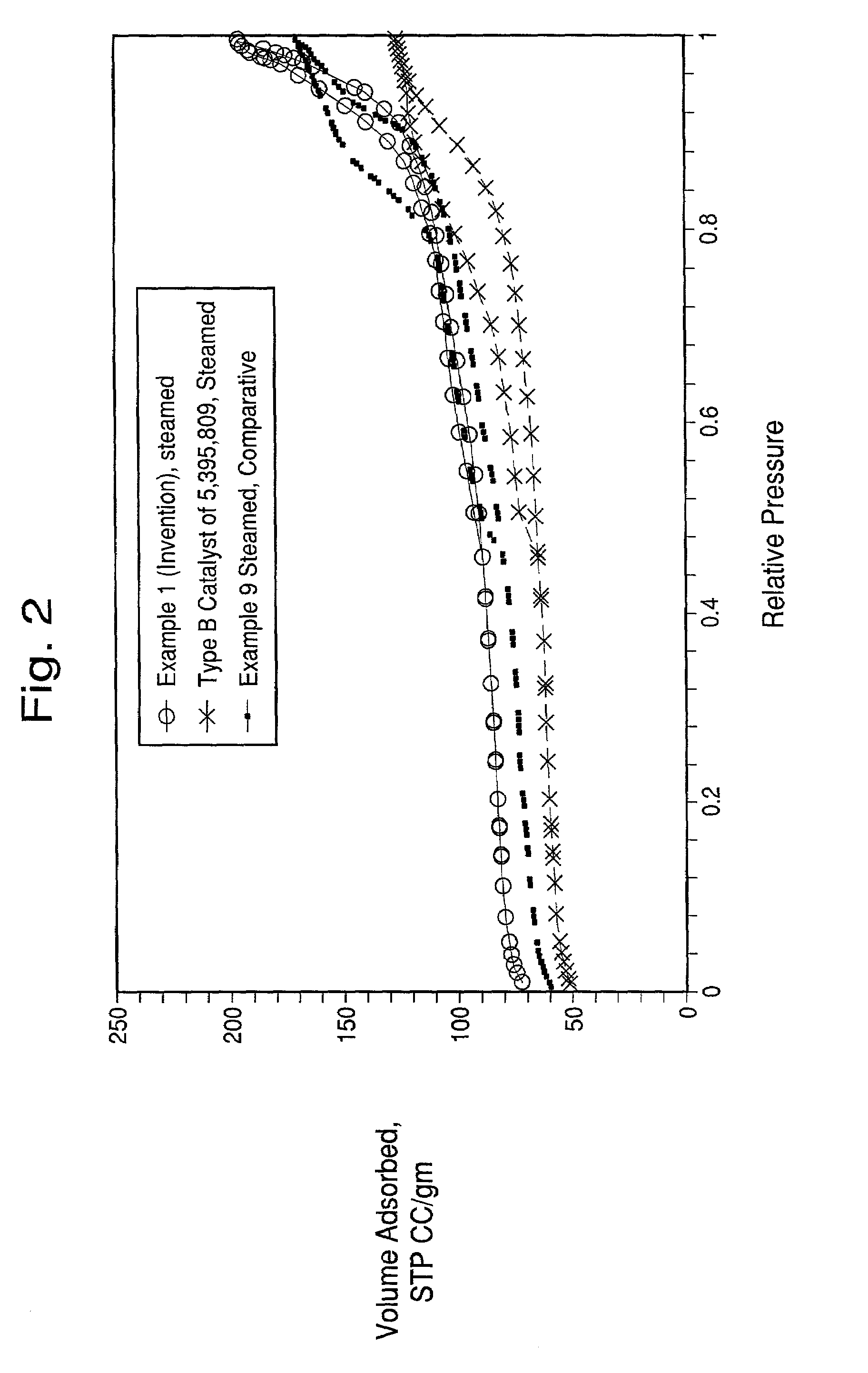

Method of enhancing the activity of FCC catalysts

InactiveUS7101473B2Enhance and control activityEfficient conversionCatalytic crackingMolecular sieve catalystsMicrosphereSlurry

An additive to enhance the activity of an FCC catalyst containing zeolite and matrix components comprises zeolite microspheres having a novel morphology comprising a macroporous matrix and crystallized zeolite freely coating the walls of the pores of the matrix. The additives formed from microspheres containing a metakaolin and kaolin calcined through its exotherm, the latter calcined kaolin being derived from a kaolin having a high pore volume. Kaolin having a high pore volume can be a pulverized ultrafine kaolin or a kaolin which has been pulverized to have an incipient slurry point less than 57% solids.

Owner:ENGELHARD CORP

Lithium exchanged zeolite X adsorbent blends

A lithium exchanged zeolite X adsorbent blend with improved performance characteristics produced by preparing a zeolite X, preparing a binder which includes highly dispersed attapulgite fibers wherein the tapped bulk density of the highly dispersed attapulgite fibers measured according to DIN / ISO 787 is more than about 550 g / ml, mixing the zeolite X with the binder to form a mixture, forming the mixture into a shaped material, ion exchanging the zeolite X at least 75% with lithium ions, and calcining the shaped material.

Owner:ZEOCHEM LLC

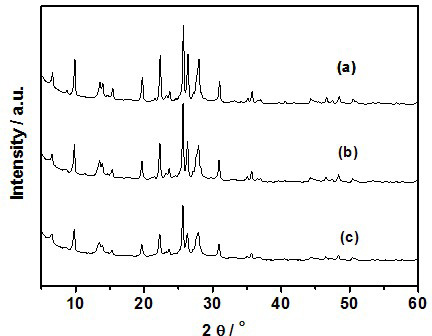

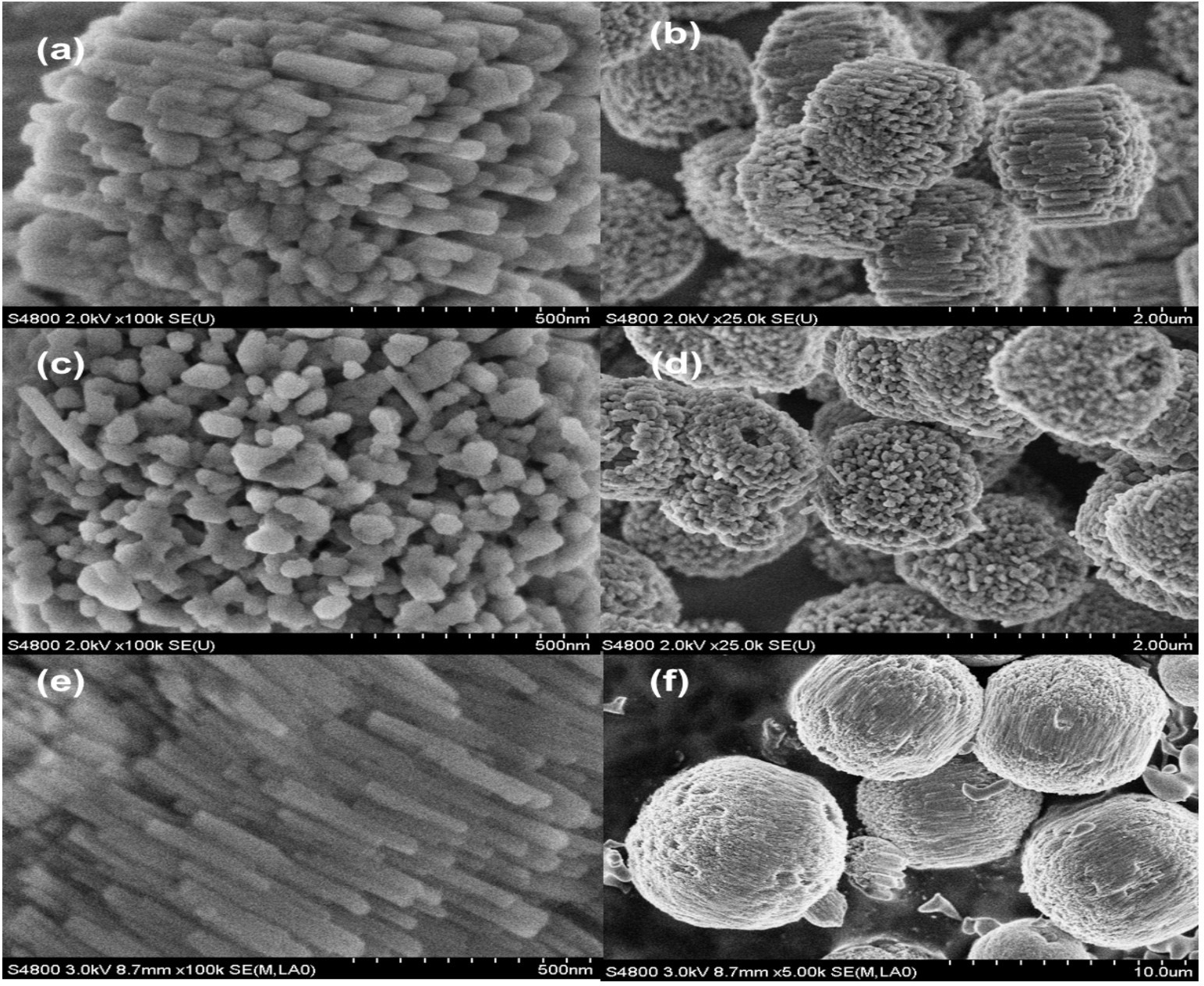

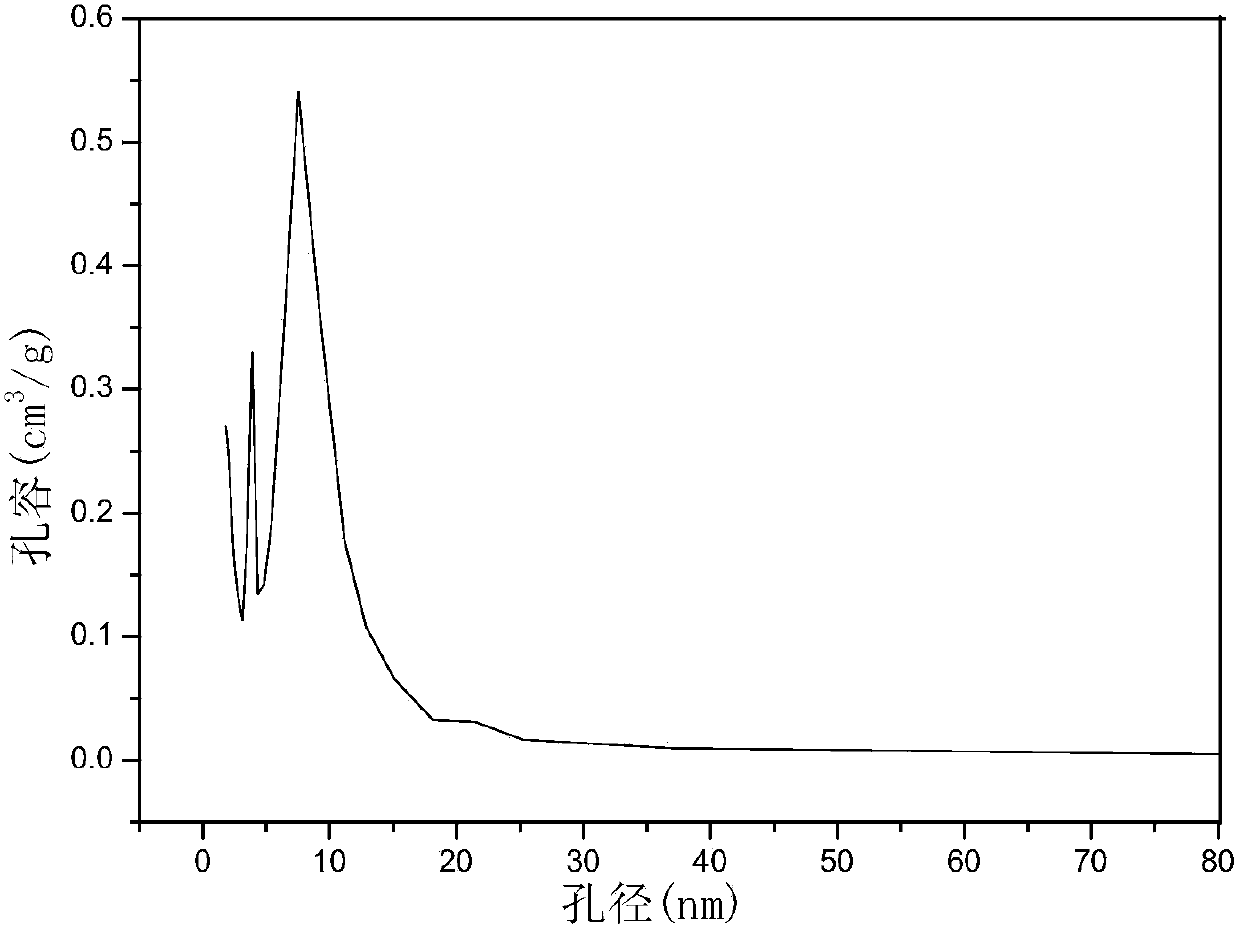

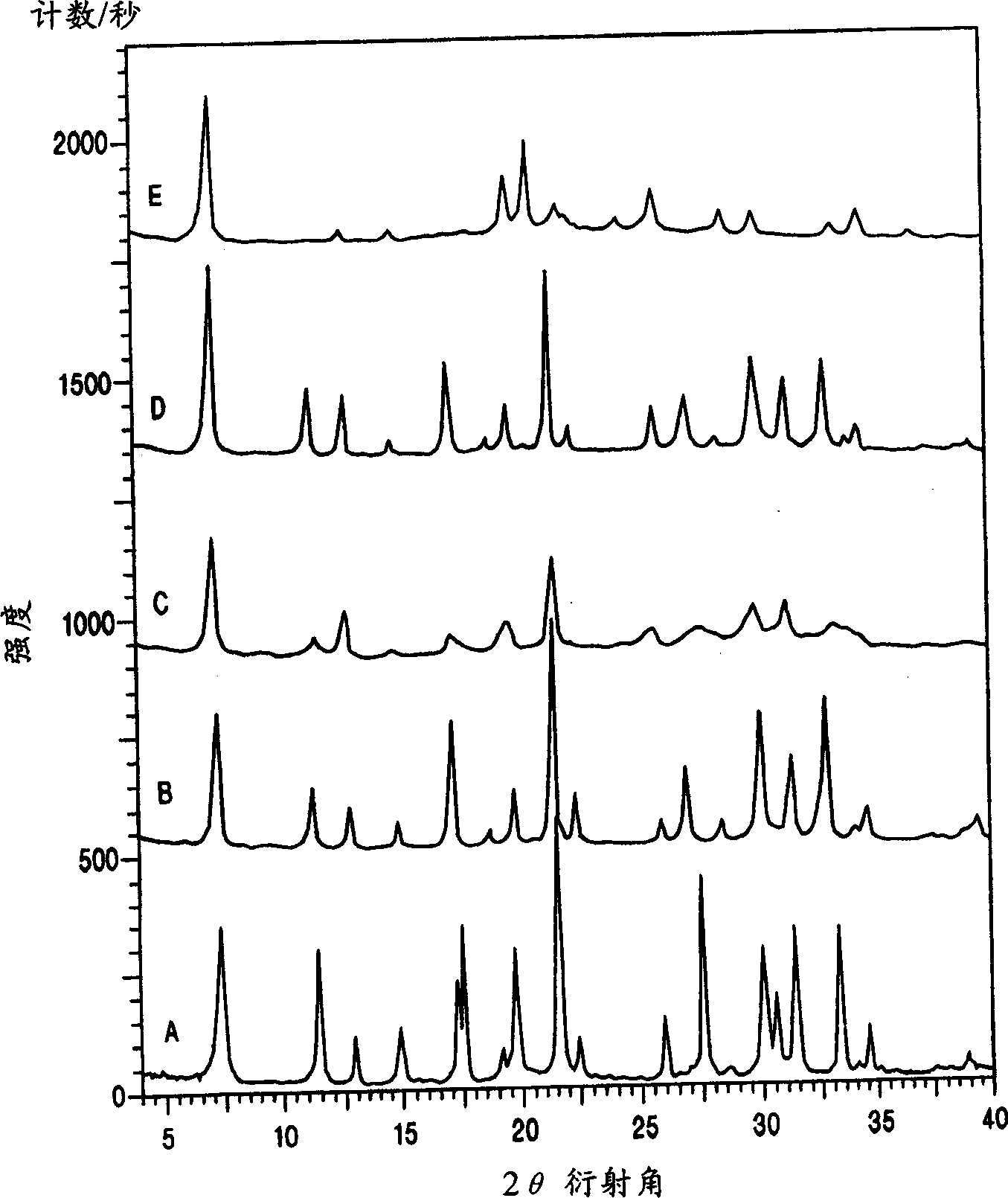

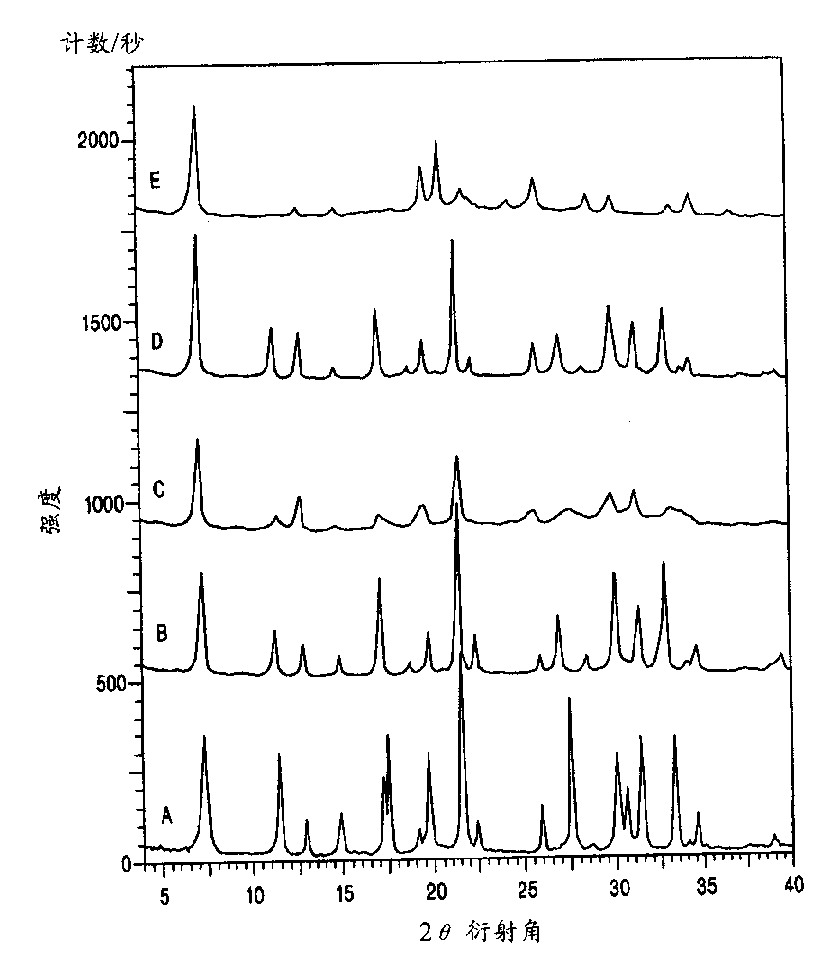

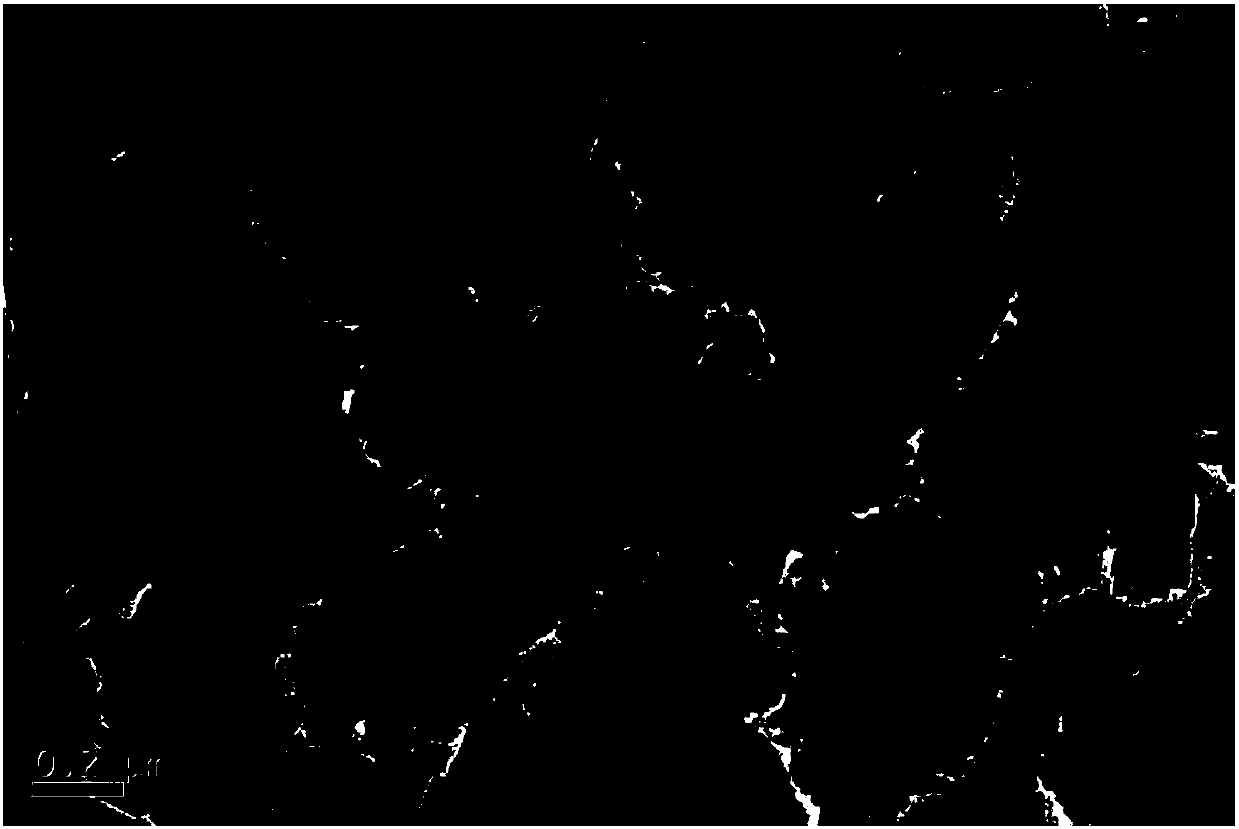

Mesoporous ZSM-5 zeolite, mesoporous ZSM-5 zeolite-loaded metal sulfide catalyst and application

ActiveCN103787368ALower synthesis costThe synthesis method is simpleMolecular sieve catalystsHydrocarbon oil crackingMethyl carbamateHydrodesulfurization

The invention discloses mesoporous ZSM-5 zeolite, a mesoporous ZSM-5 zeolite-loaded metal sulfide catalyst and an application. The synthesizing method of the mesoporous ZSM-5 zeolite comprises the following steps: (1) after uniformly mixing diallylamine and concentrated hydrochloric acid, adding dimethyl diallyl ammonium chloride, uniformly stirring and reacting for 1-6 hours at 60-120 DEG C, and cooling to obtain a template agent DMMC (Dimethylol Methyl Carbamate); (2) preparing acidified aluminum sulfate liquor by aluminum sulfate, concentrated sulfuric acid and water; (3) adding water into water glass, uniformly stirring, adding NaOH, adding the template agent DMMC after cooling to room temperature, continuously stirring for 2-5 hours, then adding the acidified aluminum sulfate liquor under stirring, and stirring for 2-8 hours to obtain a gel in a final state; (4) crystallizing the gel in the final state obtained in the step (3), filtering, drying and calcining to obtain the mesoporous ZSM-5 zeolite. The mesoporous ZSM-5 zeolite-loaded metal sulfide catalyst prepared by taking the mesoporous ZSM-5 zeolite as a carrier is applied to hydrodesulfurization of 4, 6-dimethyl dibenzothiophene and hydrocracking reaction of n-decane, thereby greatly improving the raw material conversion ratio.

Owner:WENZHOU UNIVERSITY

Synthesis of aluminium riched AFI zeolite

InactiveCN1363517AHigh purityOther chemical processesDispersed particle separationGmeliniteSilicon dioxide

A low silica and a high purity gmelinite zeolite that have a SiO2 / Al2O3 ratio of about 10 or less are provided.

Owner:PRAXAIR TECH INC

Flocculating agent for treating sewage in Chinese patent medicine production enterprises and preparation method thereof

ActiveCN102887581ANot easy to recycleBiodegradableOther chemical processesWater/sewage treatment by flocculation/precipitationMedicinePhytic acid

The invention discloses a flocculating agent for treating sewage in Chinese patent medicine production enterprises, wherein the flocculating agent comprises the following compositions: 30-45% of carapace crushed materials, 3-12% of modified chitosan, 0.05-0.5% of nanometer titanium dioxide, 0.1-0.5% of phytic acid, and 45-55% of zeolite; in order to optimize the effect, the flocculating agent is also added with 1-5% of white mica and 1-5% of active carbon. The flocculating agent provided by the invention is utilized to treat the sewage; the flocculating agent provided by the invention has very high efficiencies of removing COD (chemical oxygen demand) and BOD (biochemical oxygen demand); and the flocculating agent provided by the invention is efficient and economical.

Owner:JIANGSU SHANGDA WATER AFFAIR

Method of preparing macroporous/mesoporous zeolite molecular sieve through seed crystal induction

InactiveCN107640777ASimple methodWide variety of sourcesMolecular sieve catalystsOther chemical processesNanoparticleCrystallinity

The invention discloses a method of preparing macroporous / mesoporous zeolite molecular sieve through seed crystal induction. The method includes: using an organic template plate to prepare zeolite molecular sieve seed crystal; adding a small amount of the seed crystal into synthesis liquid of a zeolite molecular sieve, and performing simple high-temperature hydrothermal crystallization to obtain the mesoporous / macroporous zeolite molecular sieve uniform in size. The macroporous / mesoporous zeolite molecular sieve prepared by the method is formed by self-assembling zeolite molecular sieve nanorods or nanoparticles of 5-500nm, and rich mesoporous / macroporous pores exist among the zeolite molecular sieve nanorods or nanoparticles. The method is simple, safe and suitable for ZSM-5, ZSM-11, beta-type or TS-1 molecular sieves. The method is simple and safe, and the macroporous / mesoporous zeolite molecular sieve is high in purity and crystallinity, controllable in mesoporous / macroporous structure and suitable for serving as a membrane separation material or a catalyst for catalytic reaction.

Owner:SOUTH CHINA UNIV OF TECH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com