Method of preparing macroporous/mesoporous zeolite molecular sieve through seed crystal induction

A technology of mesoporous zeolite and molecular sieve, applied in the field of zeolite molecular sieve and its preparation, can solve problems such as large diffusion resistance, and achieve the effects of simple method, simple process and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

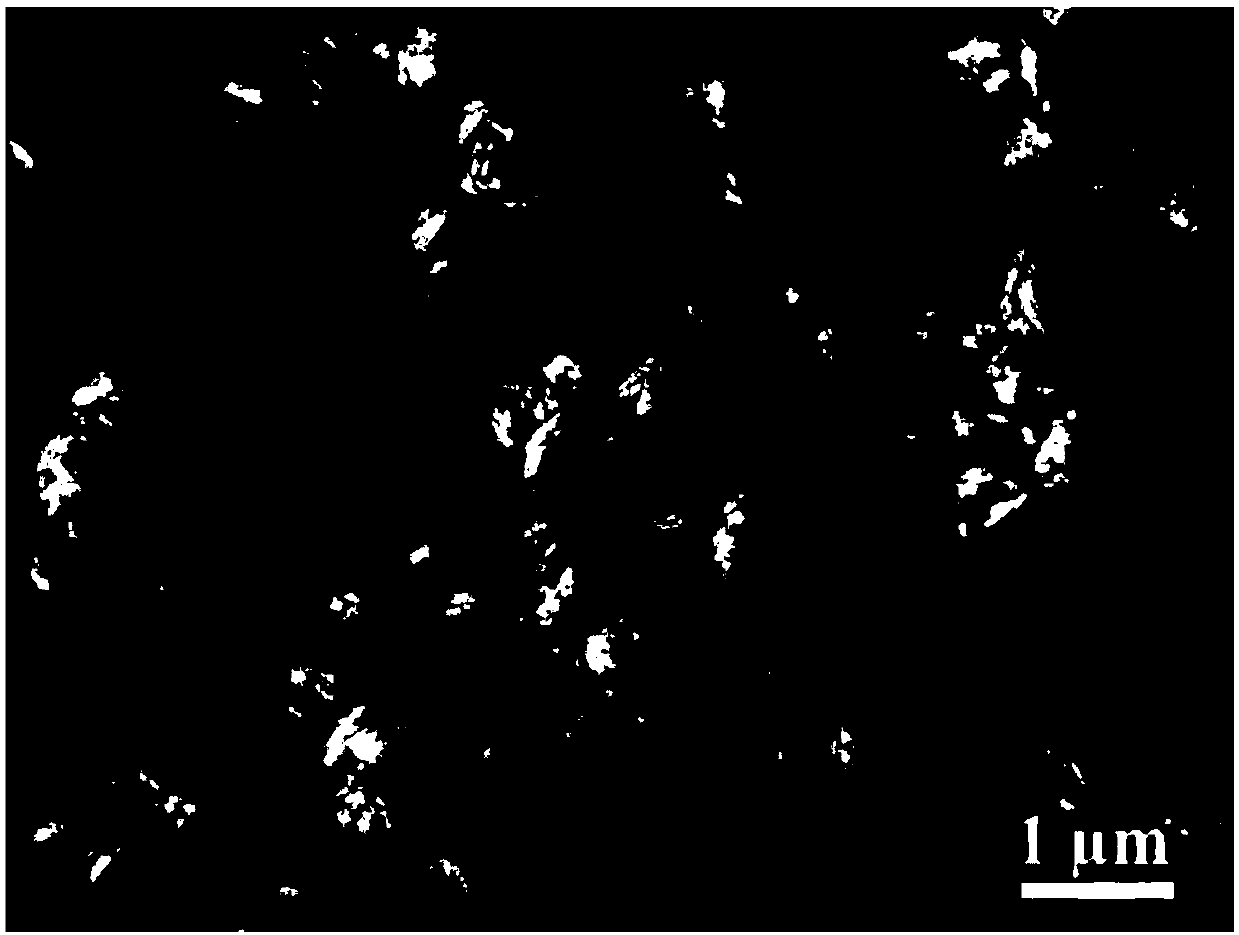

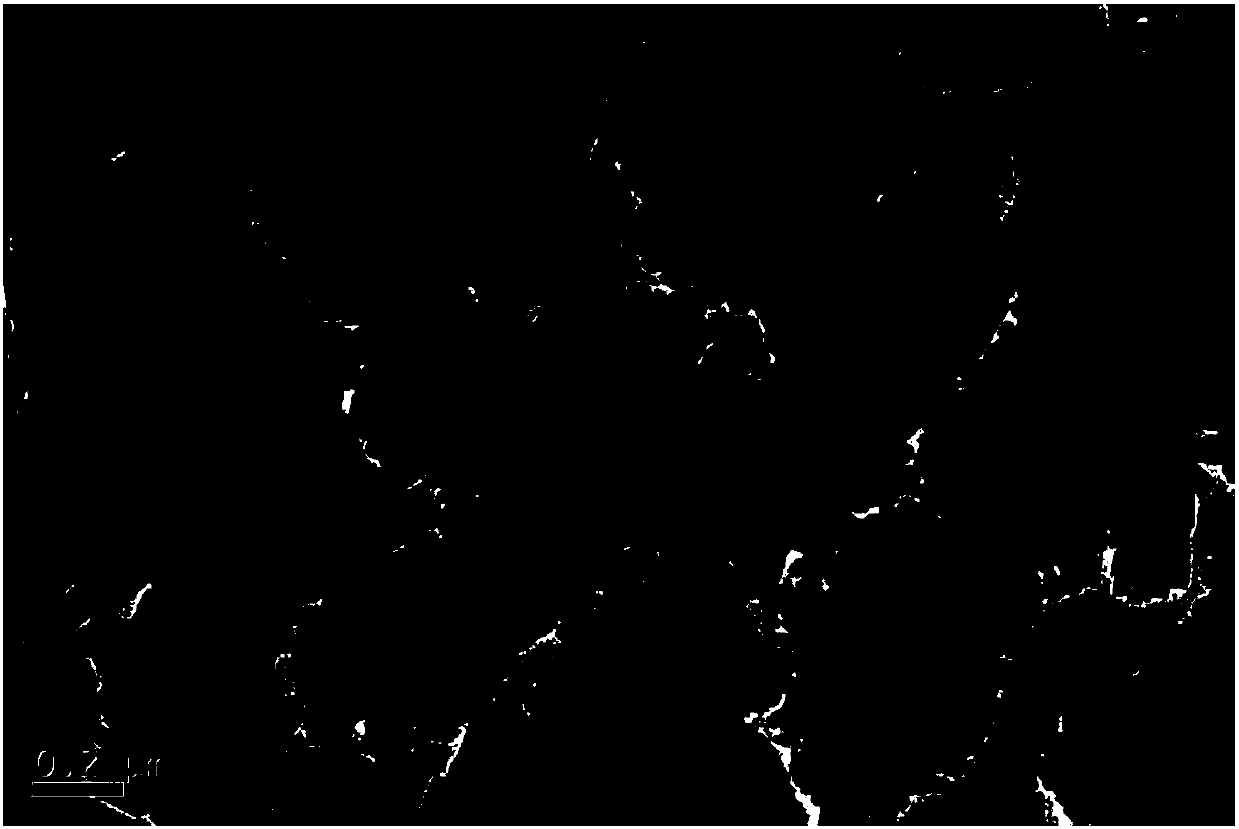

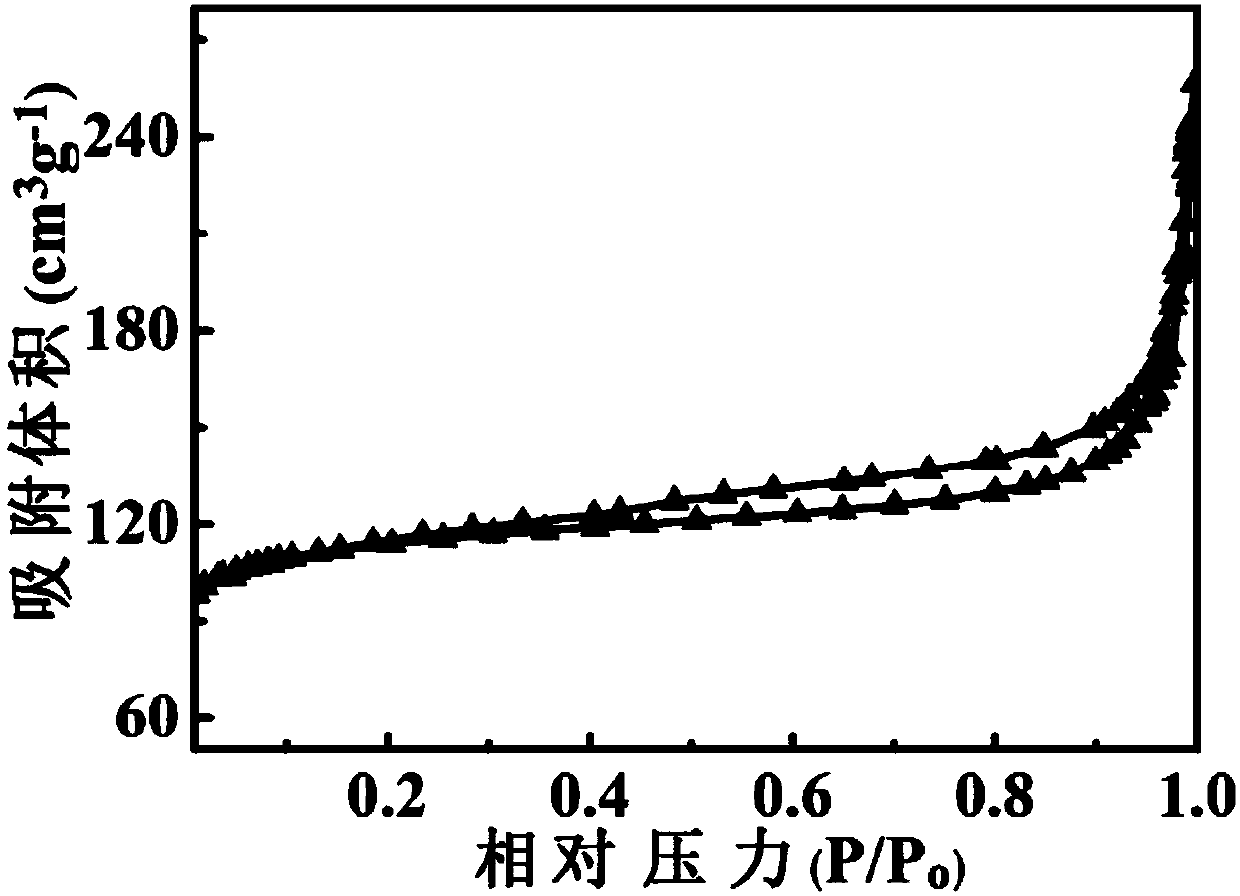

Embodiment 1

[0069] Add 51.6 g of 25% tetrapropylammonium hydroxide solution and ethyl orthosilicate into a round-bottomed flask containing deionized water and stir for 2 h, so that the molar ratio of the mixed solution is SiO 2 :TPAOH:H 2 O: EtOH=92:25:900:368 (EtOH comes from the hydrolysis reaction of tetraethyl orthosilicate and water), and then the mixture was heated to 100°C for 48 h to obtain ZSM-5 molecular sieve seeds . Then the above-mentioned ZSM-5 molecular sieve seed crystals (calculated based on silica) were mixed with NaOH, 29g 40wt% silica sol (based on SiO 2 to calculate), NaAlO 2 Mix and stir with deionized water at a molar ratio of 2.5:3.5:60:4:2500 for 1 hour, so that all raw materials are mixed uniformly, then add it to a sealed high-pressure hydrothermal crystallization kettle, and crystallize at 180°C for 48 h . After the hydrothermal kettle was cooled to normal temperature, the product was taken out and filtered, washed repeatedly, dried at 110°C for 12 hours, a...

Embodiment 2

[0072] Add 32.3 g of tetrapropylammonium hydroxide solution and ethyl orthosilicate with a mass fraction of 40% into a round-bottomed flask containing deionized water and stir for 2 h, so that the molar ratio of the mixed solution is SiO 2 :TPAOH:H 2 O: EtOH=92:50:900:368 (EtOH comes from the hydrolysis reaction of tetraethyl orthosilicate and water), and then the mixture was heated to 100°C for 48 h to obtain ZSM-5 molecular sieve seeds . Then the above-mentioned ZSM-5 molecular sieve seed crystals (calculated based on silica) were mixed with NaOH, 29g 40wt% silica sol (based on SiO 2 to calculate), NaAlO 2 Mix and stir with deionized water at a molar ratio of 0.5:3.5:60:4:2500 for 1 hour, so that all raw materials are mixed uniformly, and then add it into a sealed high-pressure hydrothermal crystallization kettle, and crystallize at 180 °C for 48 h . After the hydrothermal kettle was cooled to normal temperature, the product was taken out and filtered, washed repeatedly,...

Embodiment 3

[0075] Add 51.6 g of 25% tetrapropylammonium hydroxide solution and ethyl orthosilicate into a round-bottomed flask containing deionized water and stir for 2 h, so that the molar ratio of the mixed solution is SiO 2 :TPAOH:H 2 O: EtOH=92:50:900:368 (EtOH comes from the hydrolysis reaction of tetraethyl orthosilicate and water), and then the mixture was heated to 120°C for 24 h to obtain ZSM-5 molecular sieve seeds . Then the above-mentioned ZSM-5 molecular sieve seed crystals (calculated based on silica) were mixed with NaOH, 29g 40wt% silica sol (based on SiO 2 to calculate), NaAlO 2 Mix and stir with deionized water at a molar ratio of 2.5:5.5:60:2:2500 for 1 hour, so that all raw materials are mixed uniformly, then add it into a sealed high-pressure hydrothermal crystallization kettle, and crystallize at 180 °C for 48 h . After the hydrothermal kettle was cooled to normal temperature, the product was taken out and filtered, washed repeatedly, dried at 110°C for 12 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com