Light hydrocarbon aromatization catalyst and its preparing process

A catalyst and aromatization technology, which is applied in the field of light hydrocarbon aromatization catalyst and preparation thereof, can solve the problems of less than 20% of total utilization rate, low utilization rate of light hydrocarbons, and large amount of carbon deposits on the catalyst, and achieves suitable bulk density, The effect of reducing the amount of carbon deposits and inhibiting carbon deposits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The preferred preparation method of the catalyst of the present invention comprises the steps of:

[0024] (1) Peptize the binder precursor with acid, add ZSM series zeolite or MCM series zeolite and stir to form a slurry, then drop the slurry into an oil ammonia column to form a ball, dry and roast the ball to obtain a composite carrier ,

[0025] (2) The composite carrier is impregnated with an impregnating solution prepared from a compound containing zinc, a compound containing rare earth elements and a compound containing group VA elements, then dried and calcined.

[0026] In the above method, step (1) is to prepare a composite carrier. First, the precursor of the binder is peptized with an acid. The acid can be nitric acid, hydrochloric acid, formic acid or acetic acid, preferably nitric acid, and the precursor of the binder is preferably pseudo-thin water. aluminum stone. When peptizing, the suitable ratio of the mass of the acid to the alumina contained in the...

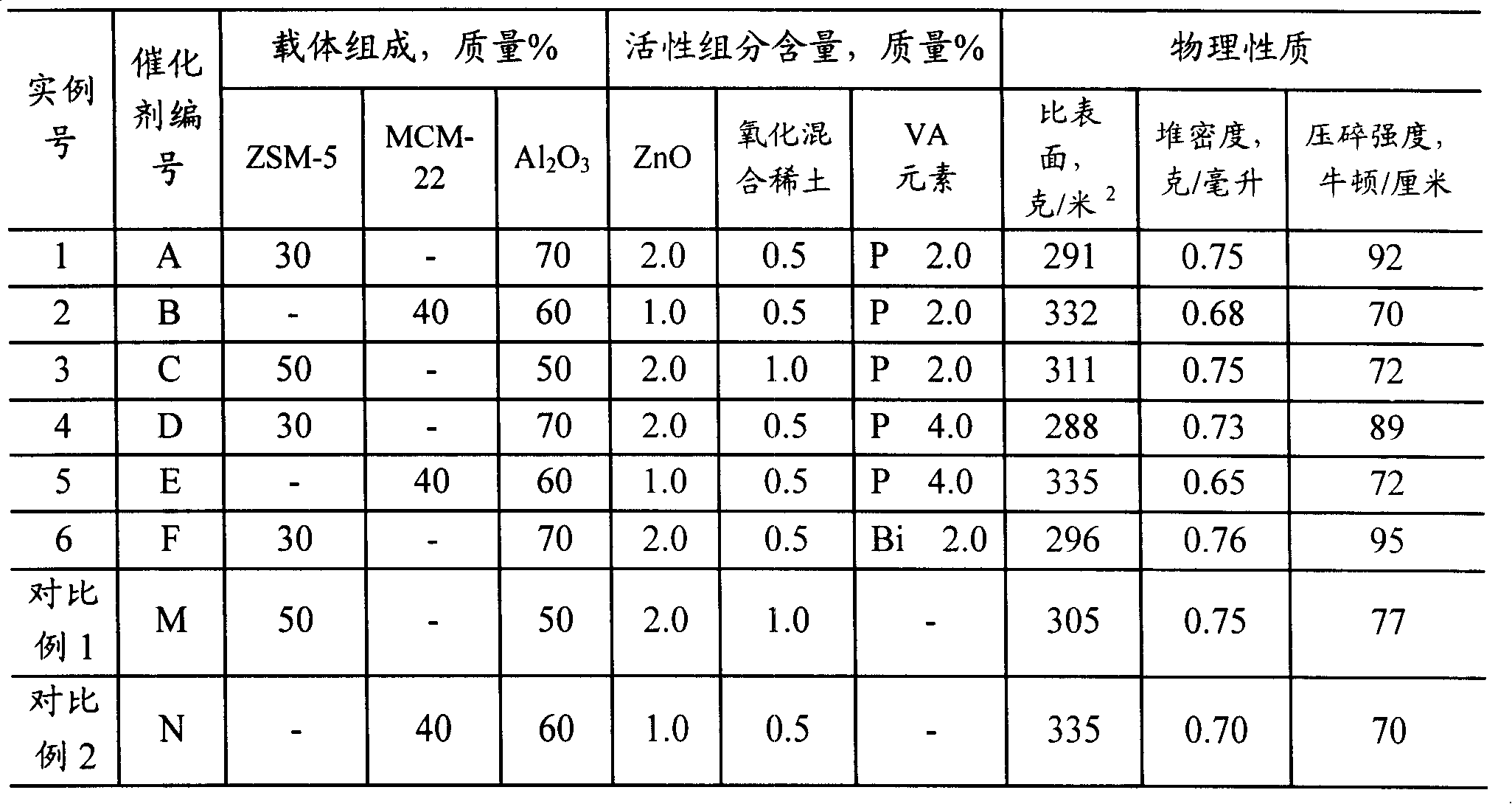

example 1

[0036] Catalyst of the present invention is prepared

[0037] (1) Preparation of composite carrier

[0038] Get 94.6 grams of pseudo-boehmite powder (production of Sasol company, Aluminum oxide content 74 mass %), under stirring condition, join in the nitric acid aqueous solution that 300 grams concentration is 1.1 mass %, after stirring for 2 hours peptization, add 33.0 grams of silica / alumina molar ratio is the HZSM-5 zeolite of 60 powder (91% zeolite content), stirred at high speed for 3 hours. Drop the prepared slurry into an oily ammonia column containing 8% by mass of ammonia water, take out the wet bulb formed in the oily ammonia column, dry at 60°C for 10 hours, and roast at 550°C for 3 hours to obtain a composite carrier, which is a composite carrier containing HZSM- 5 zeolite 30% by mass alumina pellets.

[0039] (2) Preparation of catalyst

[0040] Get 50 grams of composite carrier, use 50 grams of zinc nitrate containing 4.7 mass %, mixed rare earth chloride 1...

example 2

[0042] Prepare composite carrier by the method of example 1 (1) step, difference is that 81.1 gram of SB powders are added in the nitric acid aqueous solution of 270 gram 1.3 mass % and carry out peptization, then add 44.5 gram of silica / alumina mol ratios and be the HMCM of 25 -22 zeolite (90% zeolite content) is used to prepare a slurry, and the obtained slurry is formed by dropping balls, dried and roasted to obtain a composite carrier that is alumina pellets containing 40% by mass of HMCM-22 zeolite.

[0043] Take above-mentioned composite carrier, prepare catalyst B by the method for example 1 (2) step, difference is that the content of zinc nitrate in the impregnating liquid is 2.3 mass %, the composition and physical properties of prepared catalyst B are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com