Integral Pd-Pt catalyst for purifying industrial organic waste gas and preparation method thereof

A technology for organic waste gas and catalyst, which is applied in the field of monolithic Pd-Pt catalyst and its preparation, can solve the problems of uncertain content of cerium-zirconium oxide and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] (1) The first coating: weigh 21g of cerium-rich mixed rare earth oxide (containing cerium oxide: 90wt%, lanthanum oxide: 6.5wt%, praseodymium oxide + neodymium oxide: wt3.5%), pseudoboehmite viscose Mixture 350g (containing 105g of alumina), 70g of acidic silica sol (containing 14g of silica), that is, the mass ratio of cerium-rich mixed rare earth oxide: alumina: silica is 15:75:10. Add another 500ml of deionized water to dilute, ball mill for 4 hours, and adjust the acidity to pH=3.5 with concentrated nitric acid. The cordierite honeycomb ceramic carrier (200 mesh / in 2 , appearance 100mm*100mm*40mm) impregnate the above slurry, and blow out the excess slurry in the pores of the honeycomb ceramic carrier with high-pressure gas. It was then dried at 110°C and calcined at 500°C for 4 hours. The coating amount of the first coat was 35 g / L.

[0016] (2) The second coating: Weigh 1.6g KOH and add 2L of deionized water to prepare an aqueous solution, impregnate the cordie...

Embodiment 2

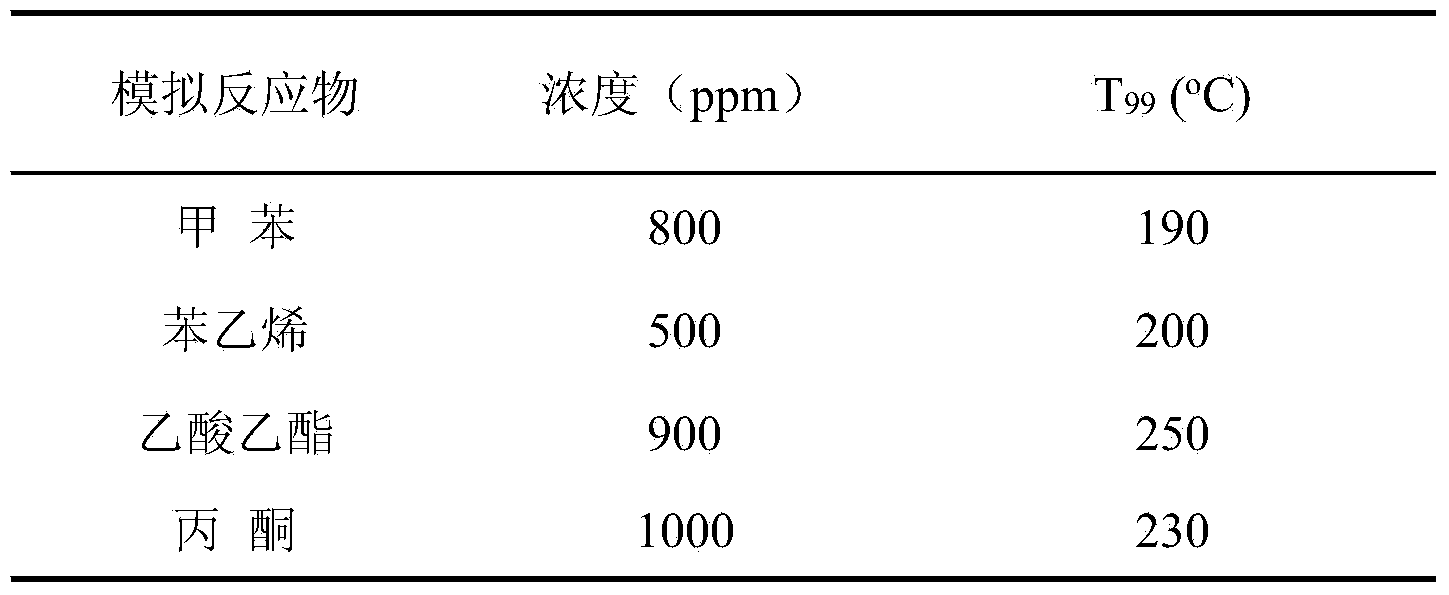

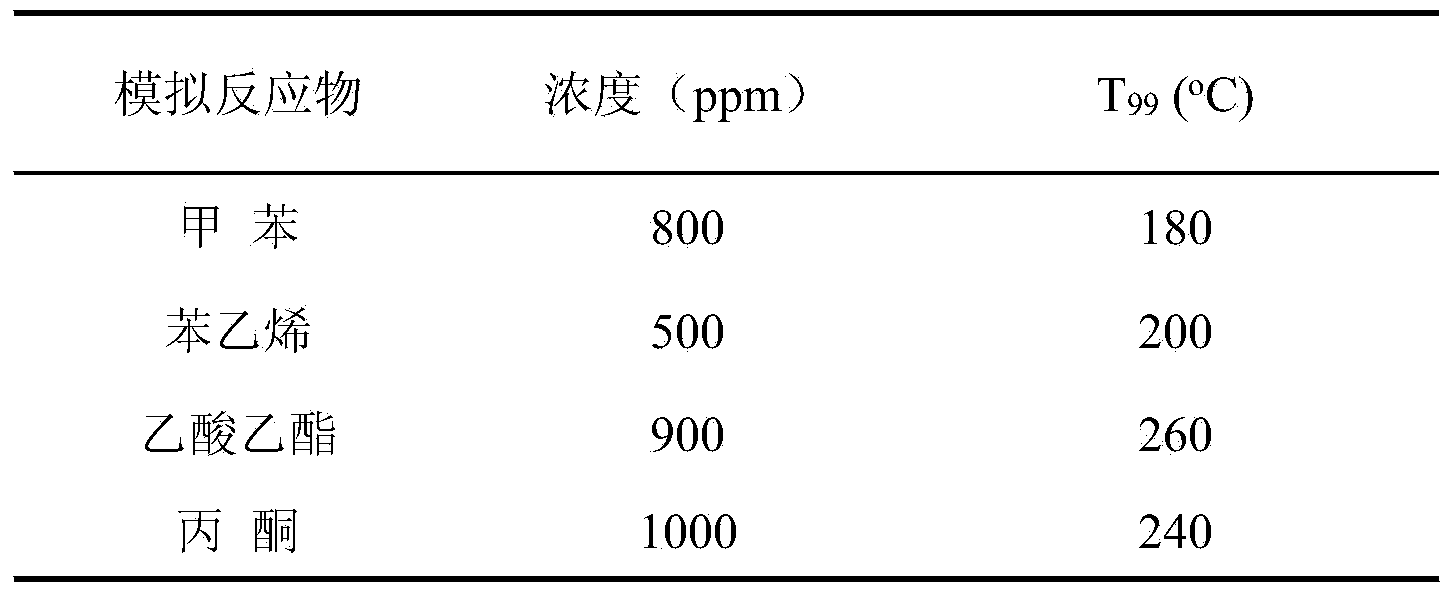

[0022] The first coating and the second coating of the catalyst are the same as in Example 1, except that the mass ratio of the third coating Pd and Pt is 1:1, that is, the H containing Pd4.8g is weighed. 2 PdCl 4 solution and Pt4.8g of H 2 PtCl 6 solution, add deionized water to make a 60L solution, and adjust the acidity to pH=4.5 with concentrated nitric acid. The 32L cordierite honeycomb ceramic carrier coated with the above two coatings was impregnated in it to make H 2 PdCl 4 and H 2 PtCl 6 Adsorbed on the surface of the carrier, the cordierite honeycomb ceramics containing noble metals Pd and Pt are separated from the aqueous solution, dried at 110°C, and calcined at 500°C for 4 hours to obtain the Pd-Pt catalyst of the present invention. The total amount of noble metals Pd and Pt of the third coating is 0.3 g / L. The catalyst activity evaluation results are shown in Table 2. Catalyst evaluation conditions were the same as in Example 1.

[0023] Table 2: Perform...

Embodiment 3

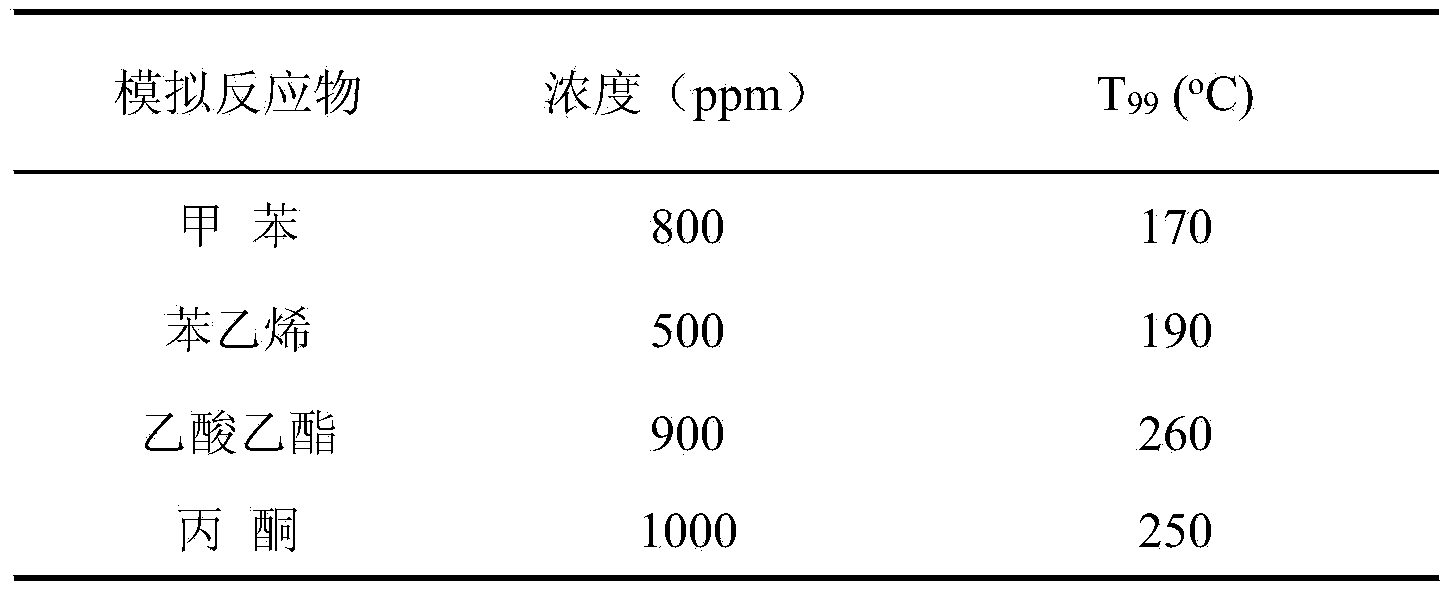

[0026] The first coating and the second coating of the catalyst are the same as in Example 1, except that the mass ratio of the third coating Pd and Pt is 1:4, that is, the H containing Pd1.92g is weighed. 2 PdCl 4 solution and Pt7.68g of H 2 PtCl 6 solution, add deionized water to make a 60L solution, and adjust the acidity to pH=4.5 with concentrated nitric acid. The 32L cordierite honeycomb ceramic carrier coated with the above two coatings was impregnated in it to make H 2 PdCl 4 and H 2 PtCl 6 Adsorbed on the surface of the carrier, the cordierite honeycomb ceramics containing noble metals Pd and Pt are separated from the aqueous solution, dried at 110°C, and calcined at 500°C for 4 hours to obtain the Pd-Pt catalyst of the present invention. The total amount of noble metals Pd and Pt of the third coating is 0.3 g / L. The catalyst activity evaluation results are shown in Table 3. Catalyst evaluation conditions were the same as in Example 1.

[0027] Table 3: Perfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com