Patents

Literature

44results about How to "Appropriate bulk density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

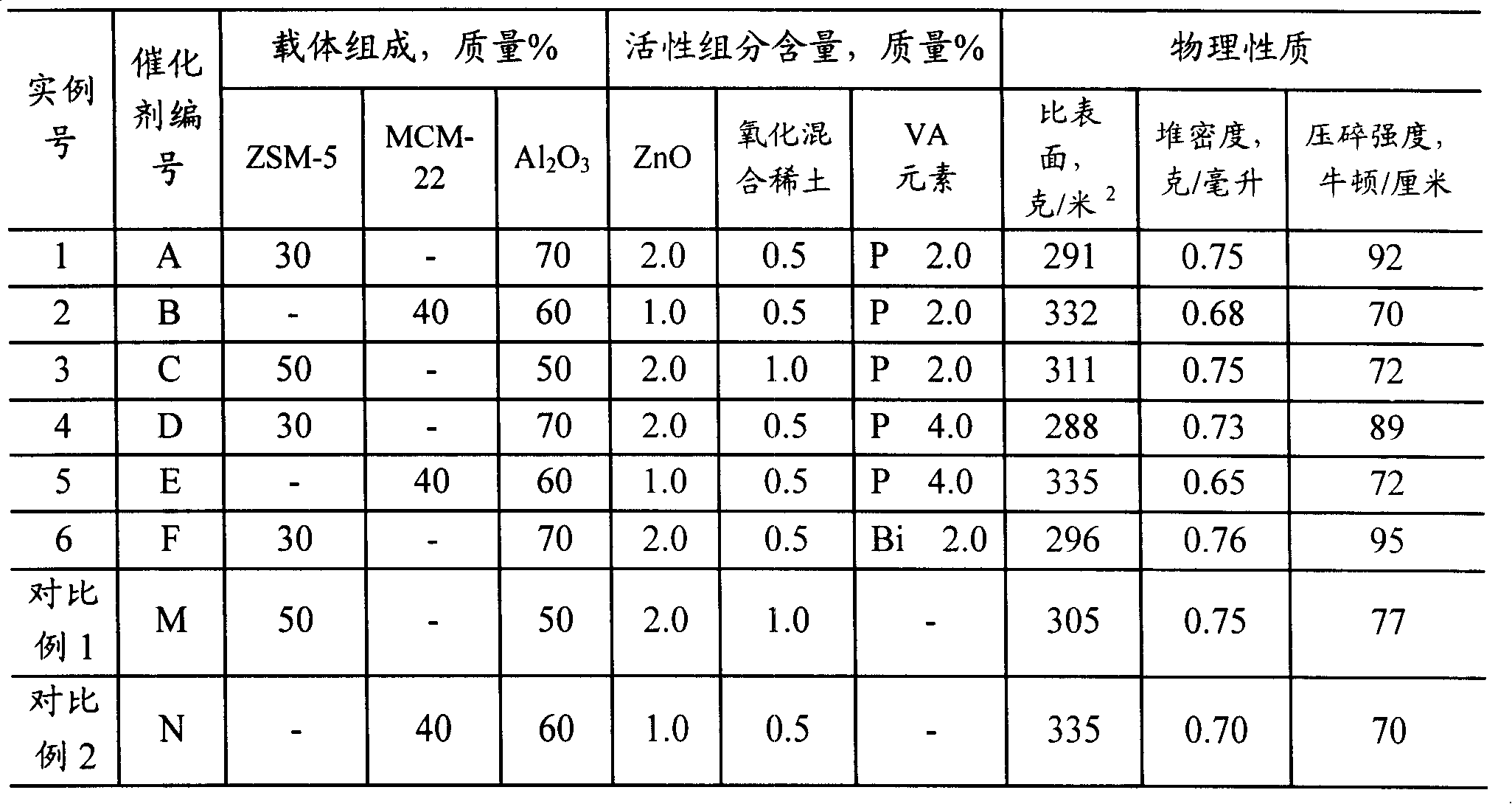

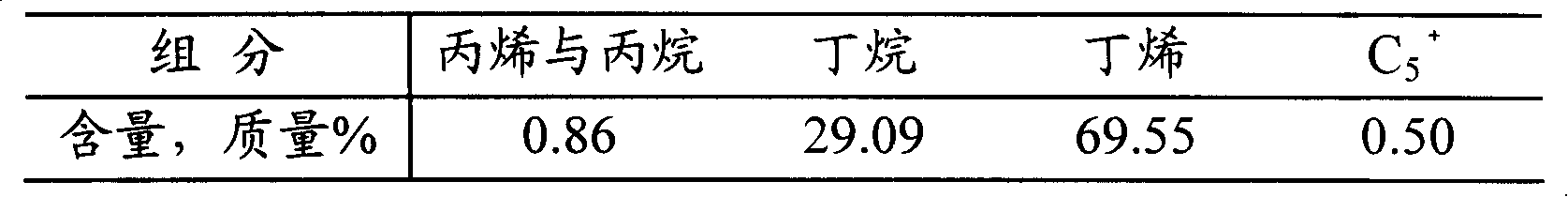

Light hydrocarbon aromatization catalyst and its preparing process

ActiveCN101172250AInhibit carbon depositionExtended service lifeMolecular sieve catalystsHydrocarbonsRare earthAromatization

The invention relates to light hydrocarbon aromatization catalyst, which includes a composite carrier and the components with the following content in the catalyst: 0.5 to 5.0 mass percent of ZnO, 0.1 to 5.0 mass percent of rare earth oxide, and 1.0 to 70 mass percent of VA element. The composite carrier comprises 20 to 70 mass percent of ZSM series zeolite or MCM series zeolite and 30 to 80 masspercent of binder. The light hydrocarbon aromatization catalyst has high yield of aromatic hydrocarbon and longer service life.

Owner:CHINA PETROLEUM & CHEM CORP +1

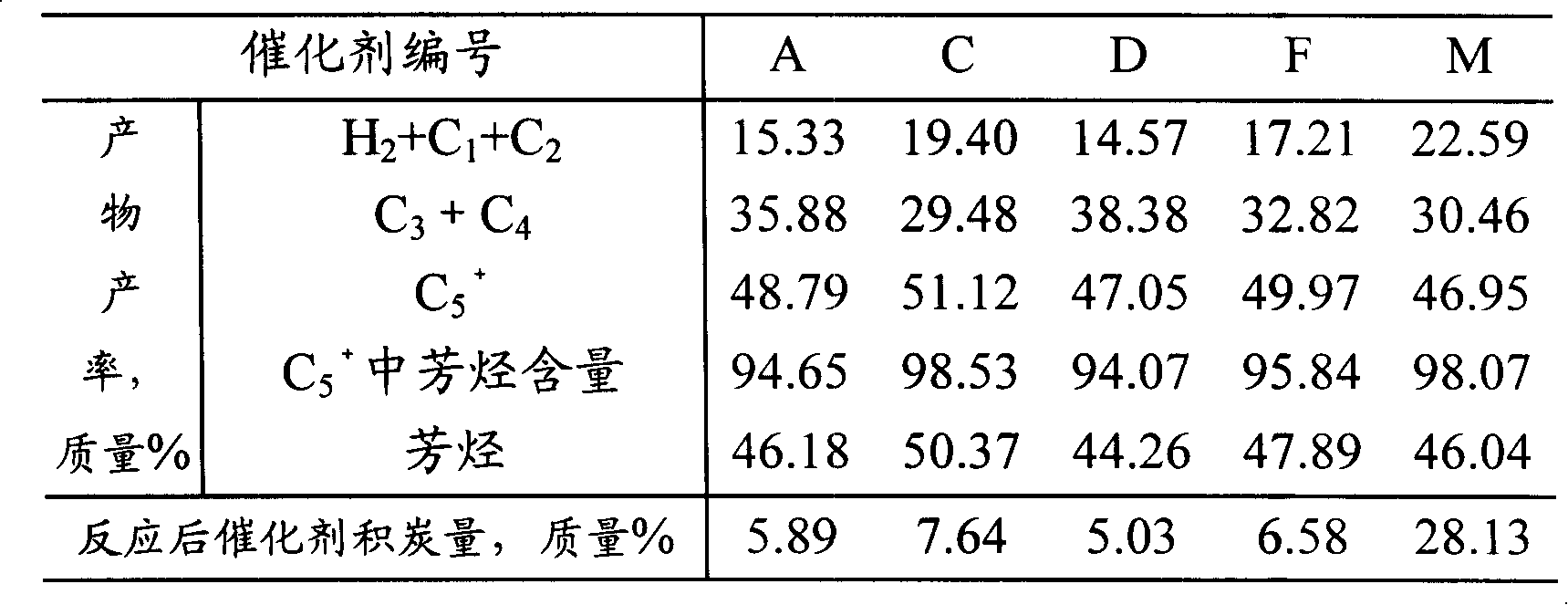

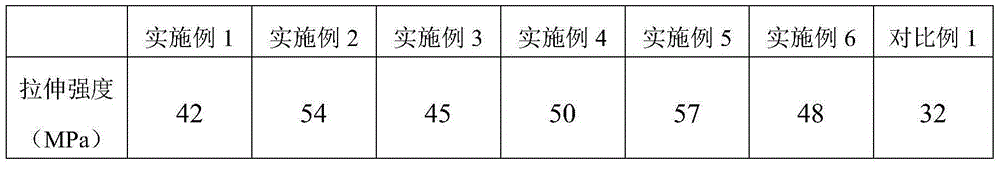

Fireproof thermal-insulating plate and preparation process thereof

InactiveCN102808459AImprove tensile propertiesAppropriate bulk densityHeat proofingFire proofingGlass fiberMicrometer

A fireproof thermal-insulating plate comprises, by weight, 16-20 parts of closed-cell expanded perlite, 3-5 parts of closed-cell vitrified micro bubbles, 11-14 parts of binder, 2-4 parts of water repellent, 0.4-0.6 part of fiberglass, and 8-12 parts of water. The closed-cell vitrified micro bubbles are 1-5mm in particle size. The closed-cell vitrified micro bubbles are 0.1-1.5mm in particle size. The fiberglass is 6-12mm in length and 5-20 micrometers in diameter. The invention further discloses a preparation process of the fireproof thermal-insulating plate. The fireproof thermal-insulating plate and the preparation process have the advantages that the closed-cell expanded perlite is used as a main setup frame, the closed-cell vitrified micro bubbles are used for assisting in gap filling, a small amount of fiberglass is added to improve tensile strength of the thermal-insulating plate, and accordingly the thermal-insulating plate is proper in volume weight, low in cost and fine in compressive property; the binder and other materials are all made of inorganic minerals and inorganic compounds with fine fireproof performance; and the preparation process is simple.

Owner:青岛昱全智能科技有限公司

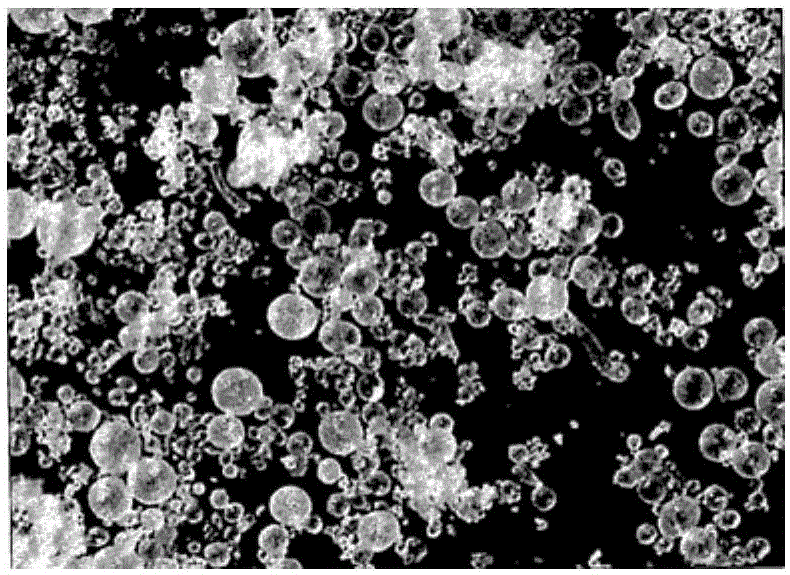

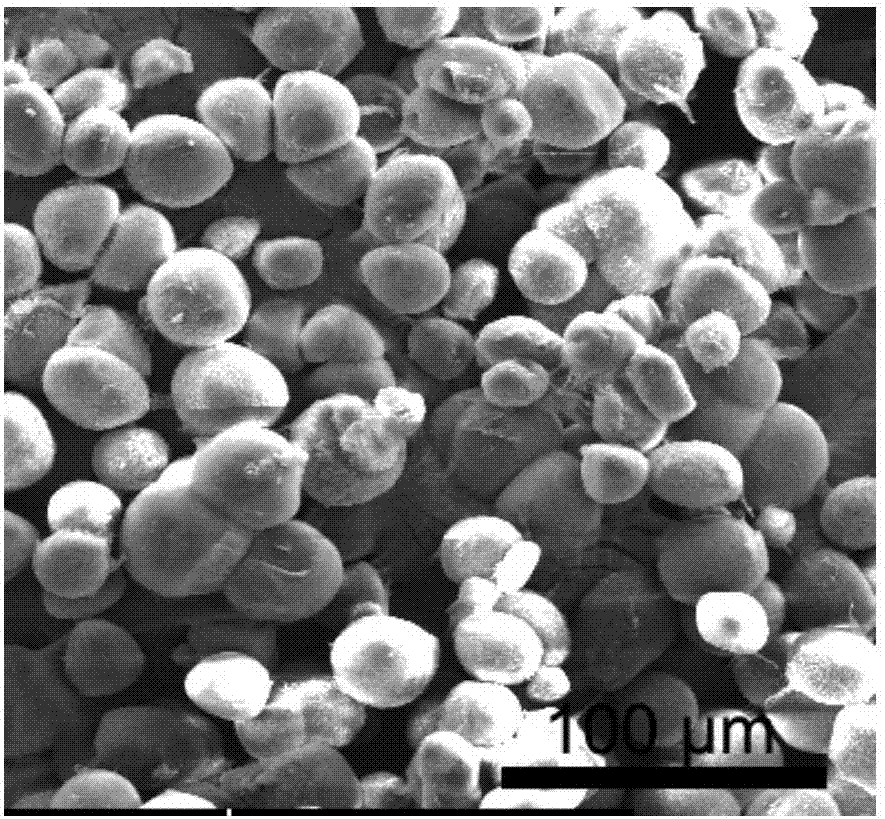

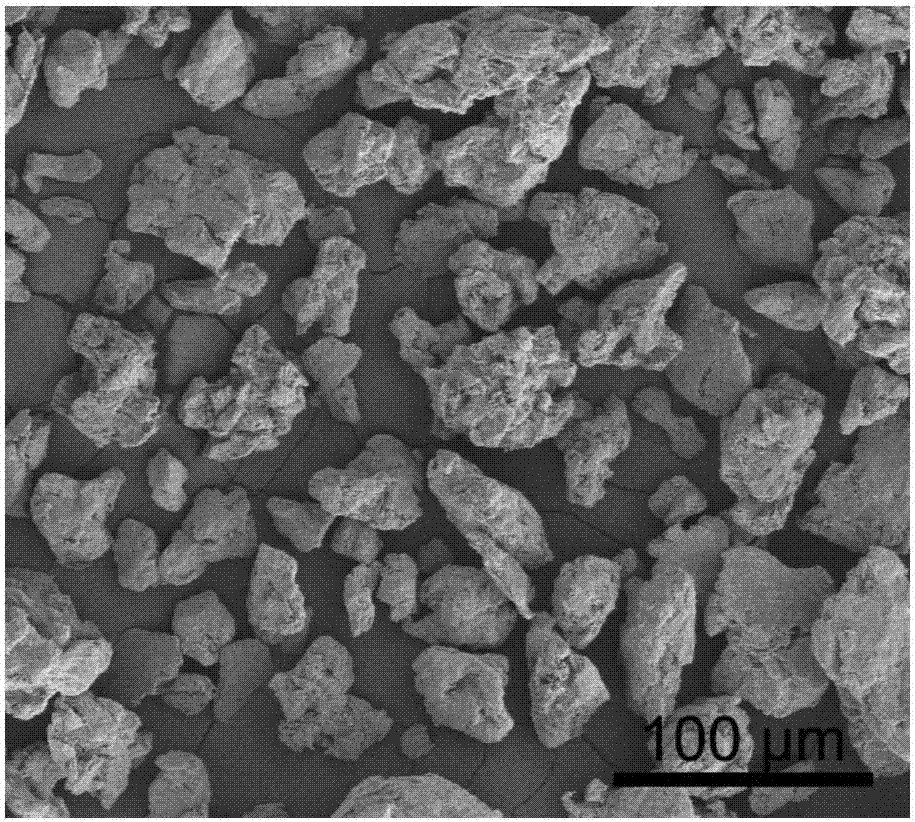

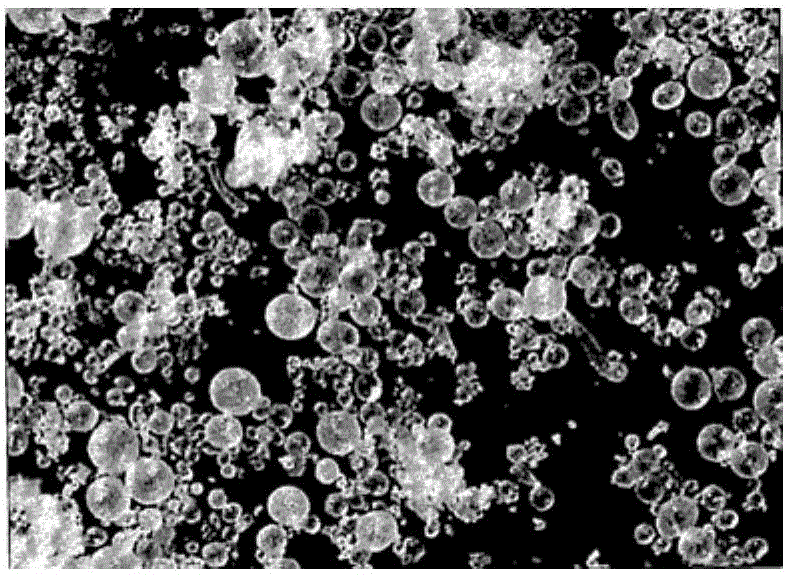

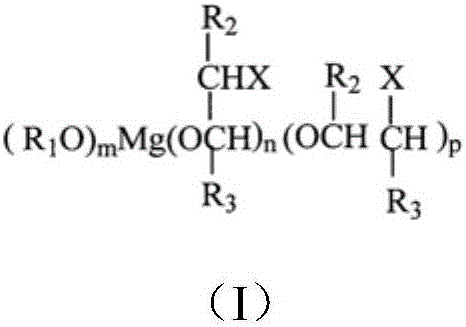

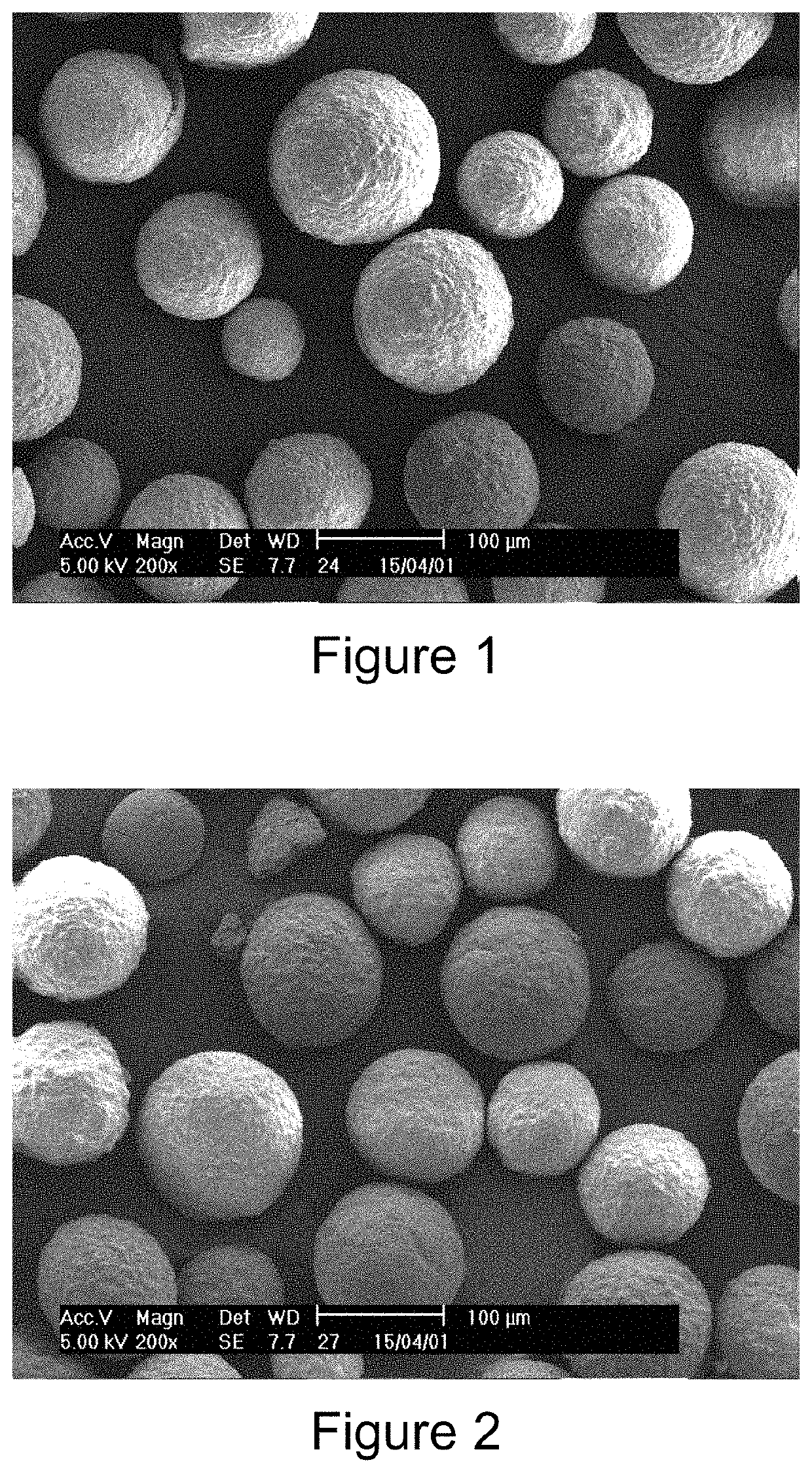

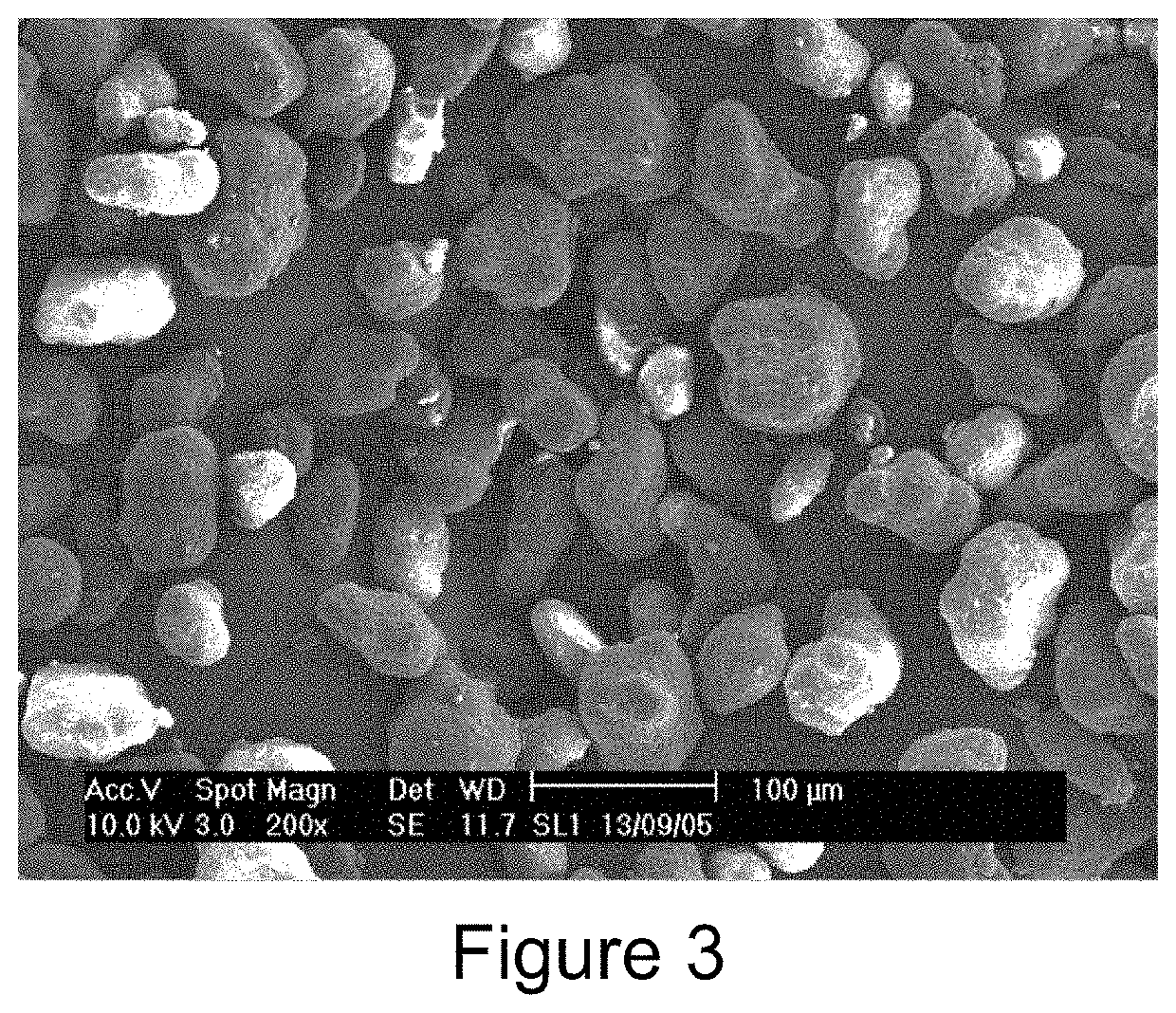

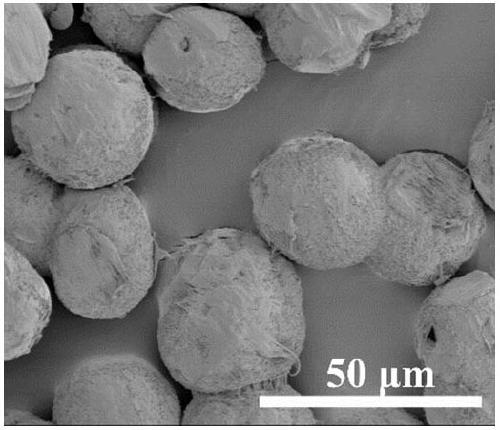

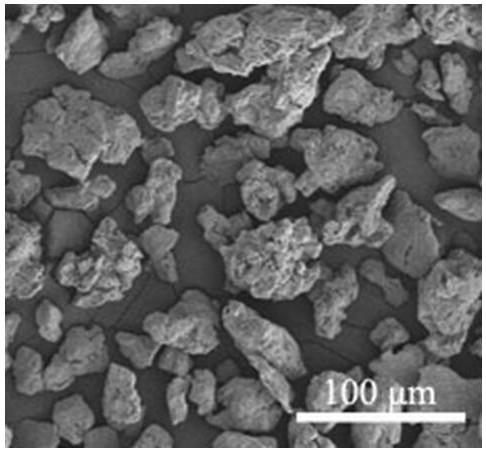

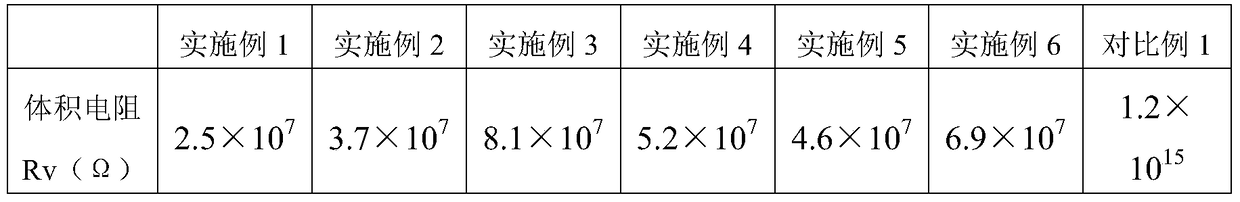

Catalyst used for olefin polymerization and preparation method thereof

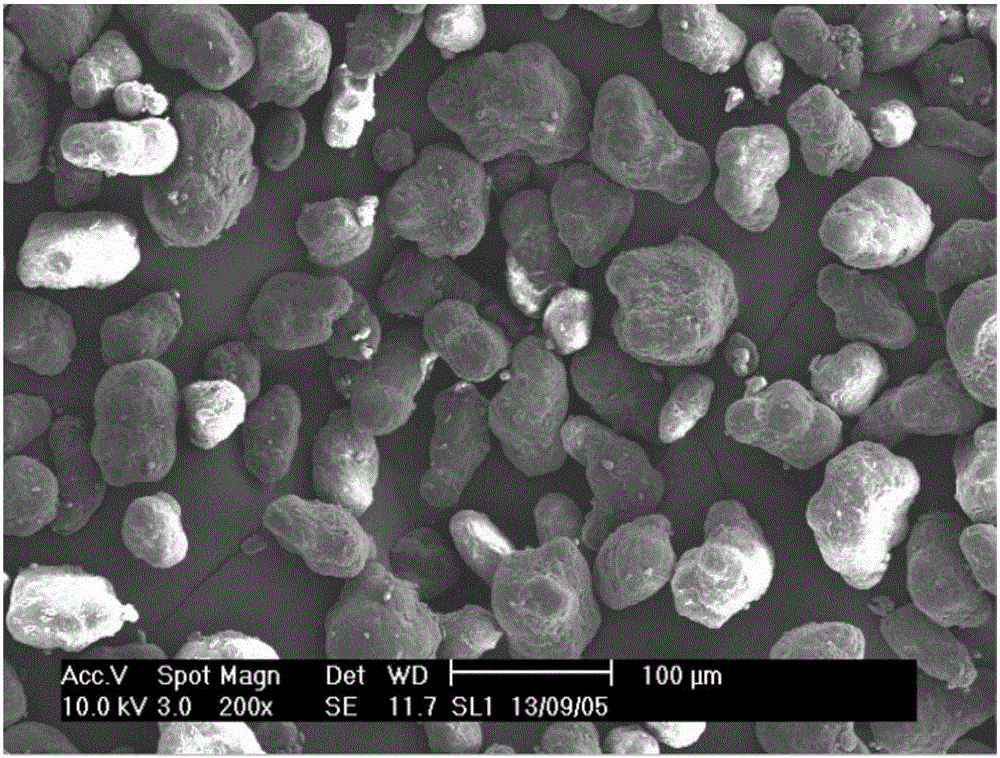

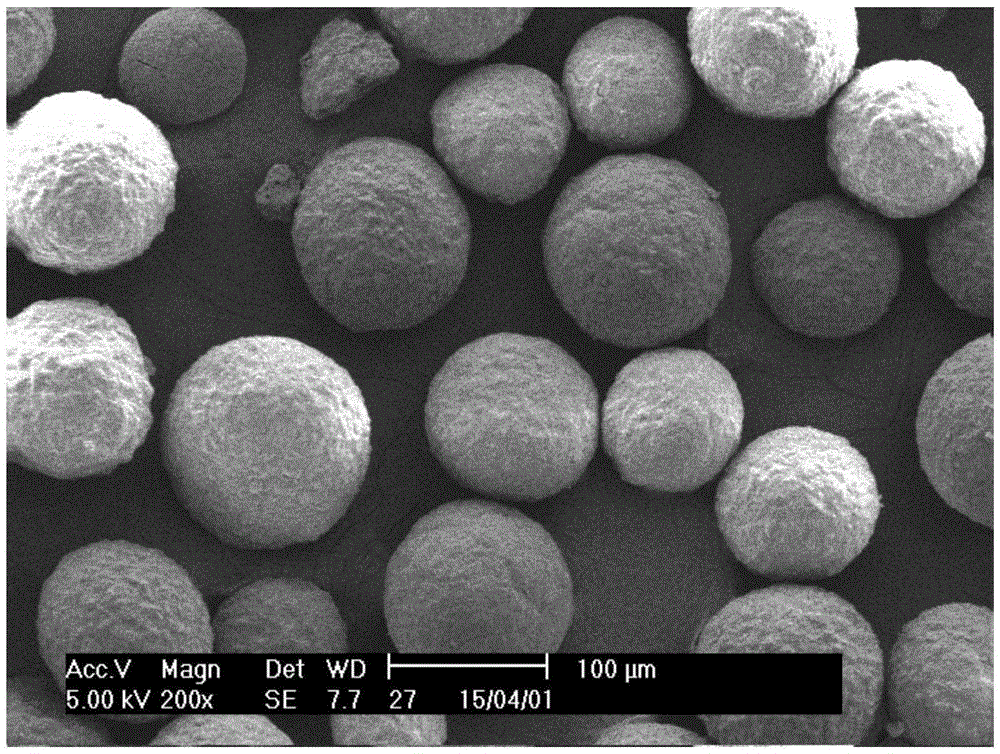

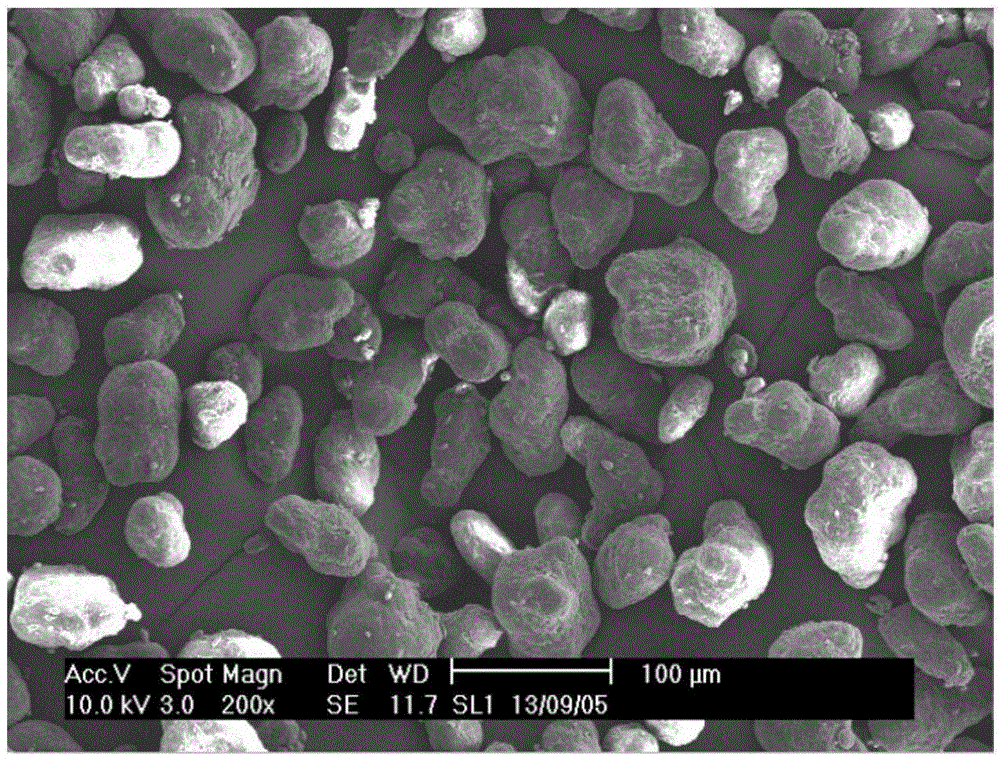

The invention relates to a catalyst used for olefin polymerization and a preparation method thereof. The preparation method is as follows: in a reactor, under the protection of nitrogen, adding an organic solvent and a titanium compound, cooling to-30 to-10 DEG C, adding a carrier, maintaining at-30 to-10 DEG C, and stirring for 30-40min; slowly heating to 100 to 120 DEG C, in the heating process, adding an electron donor compound, reacting at 100-120 DEG C for 30-40min, filtering a liquid, again adding the titanium compound, heating to 110 to 130 DEG C, maintaining at 110 to 130 DEG C for 30-40min, filtering the liquid, washing an obtained solid, and drying under vacuum to obtain a target product. In a magnesium halide alcohol adduct formation process, a forming agent and a particle form control agent are added, the particle size distribution of the obtained carrier is more concentrated, the carrier is used for preparing the catalyst, activity and hydrogen sensitivity of the catalyst can be improved when the carrier is used for olefin polymerization especially for propylene polymerization, the bulk density of an obtained polymerization product is moderate, and the polymerization product is basically free of abnormity materials.

Owner:营口风光新材料股份有限公司

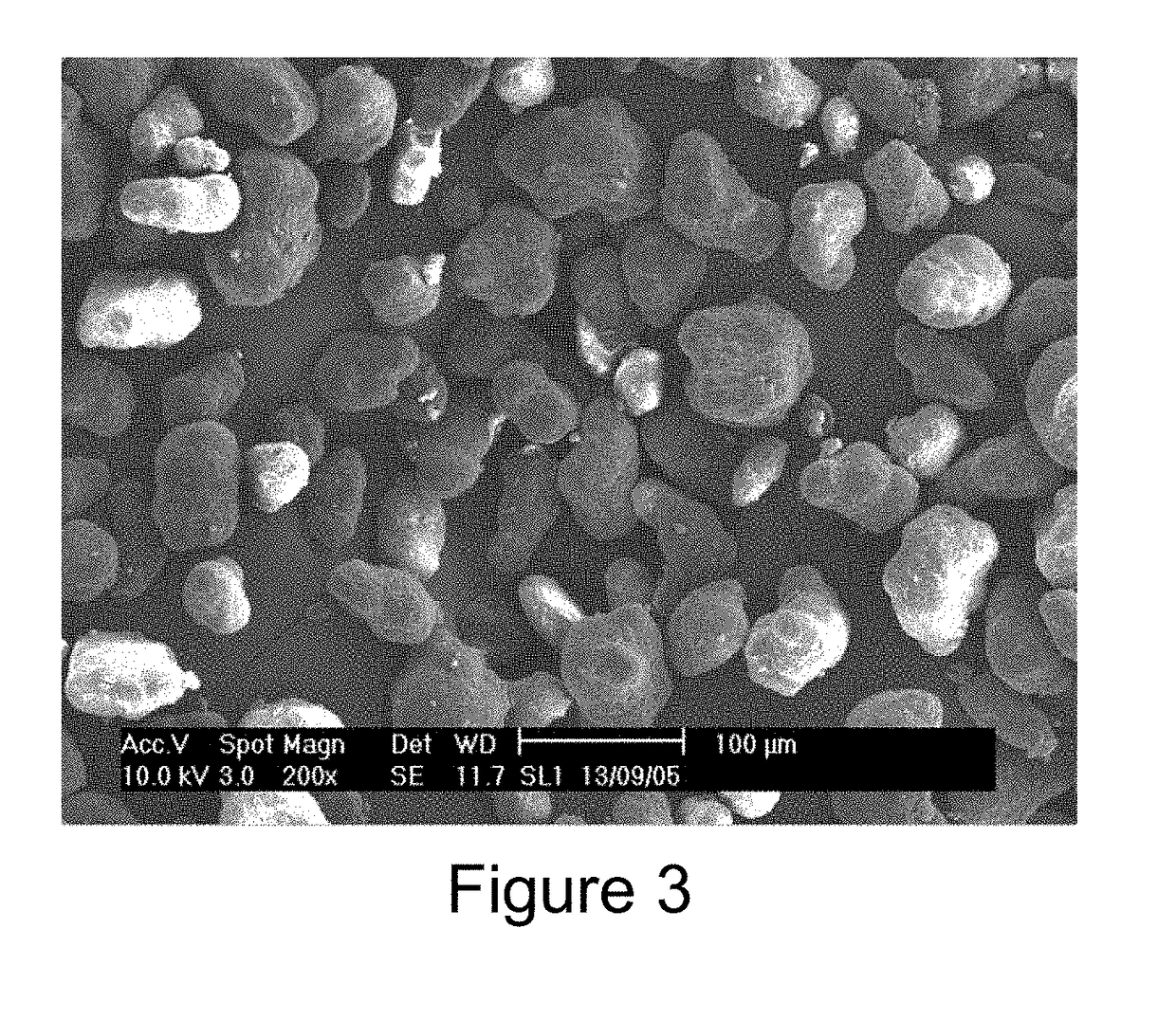

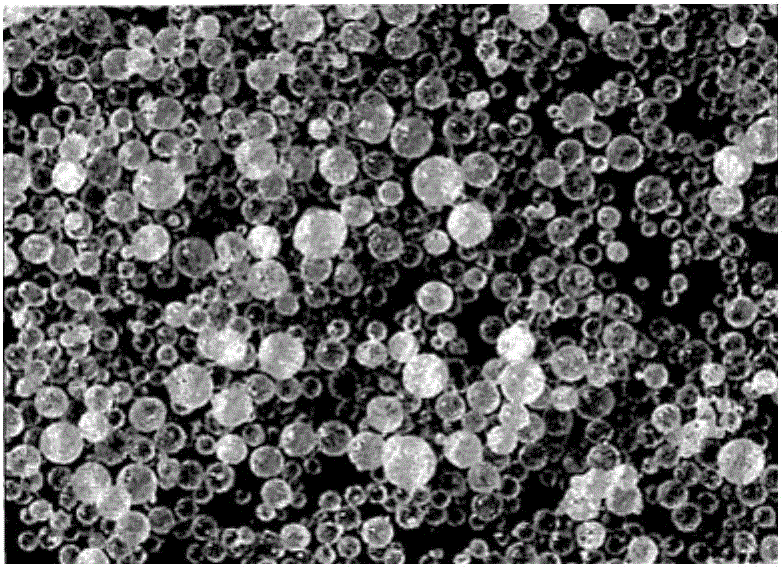

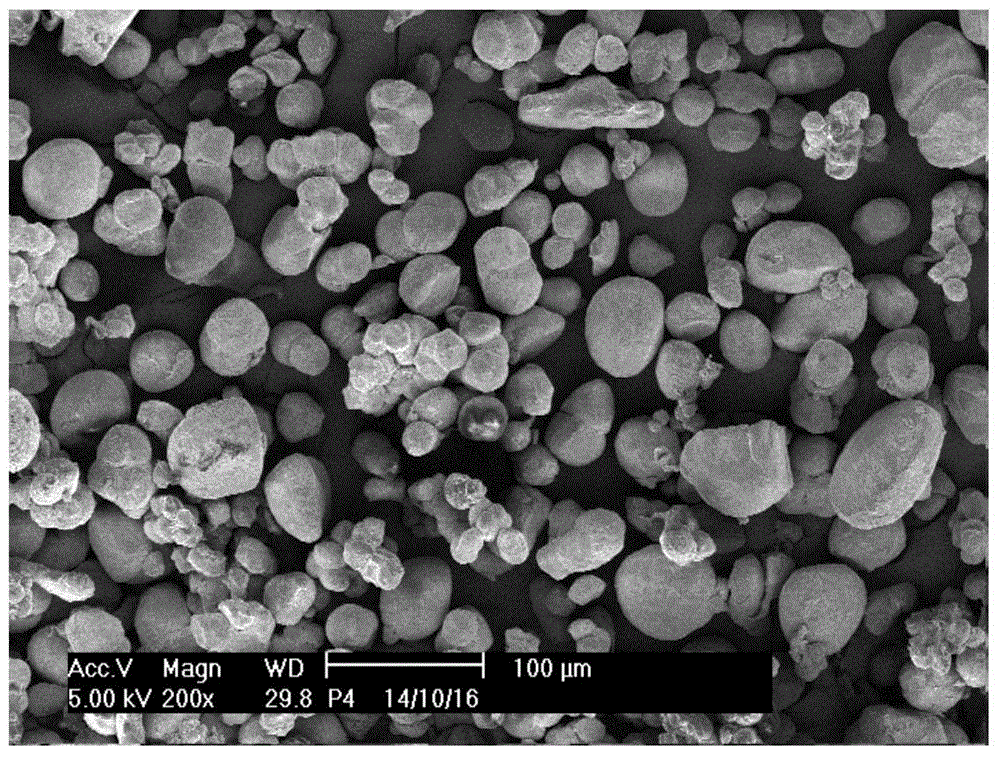

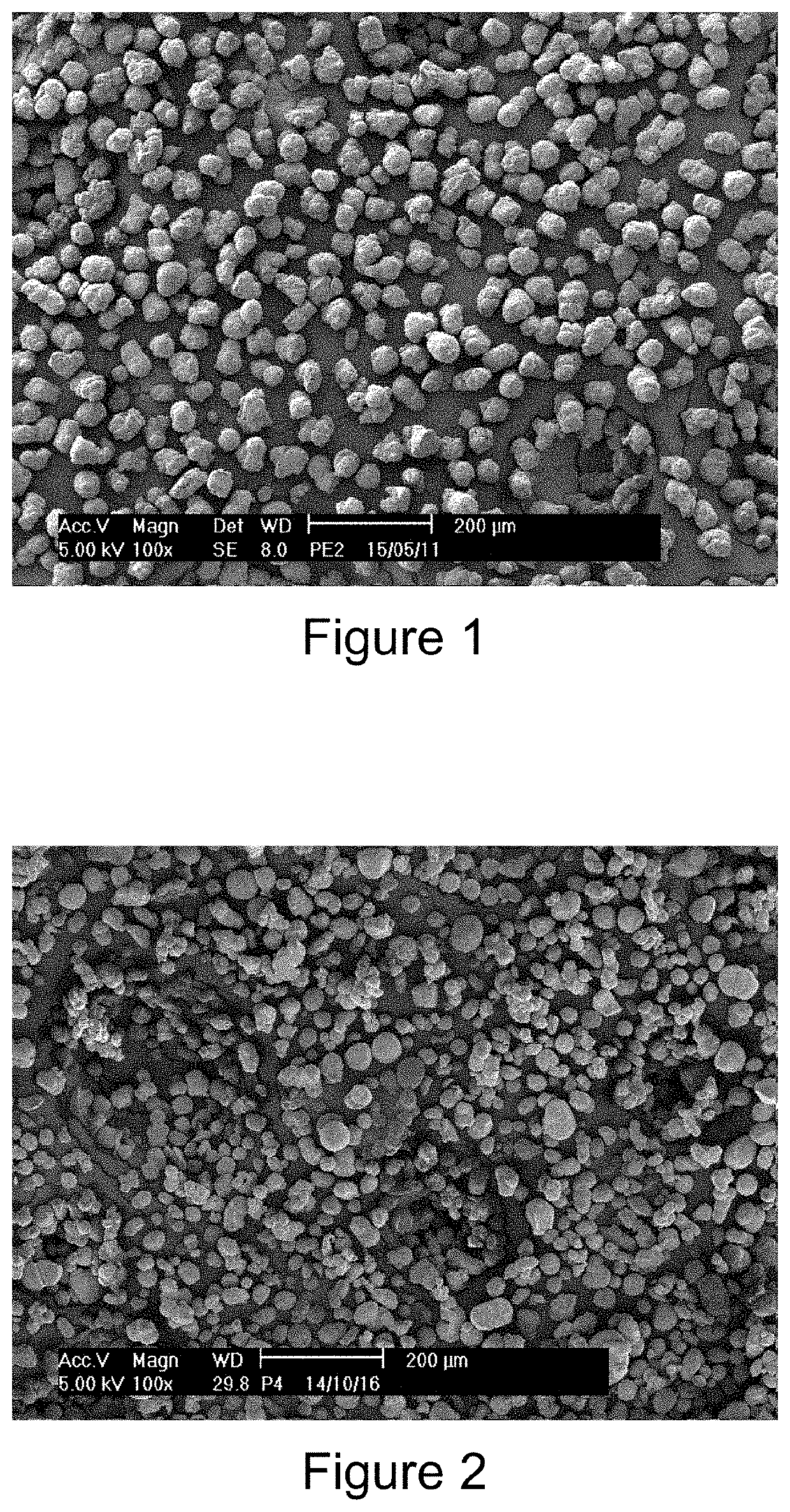

Polyolefin resin powder suitable for selective laser sintering and its preparation method

ActiveUS20180355122A1Improve the immunityReduce sizeAdditive manufacturing apparatusTransportation and packagingSolubilitySelective laser sintering

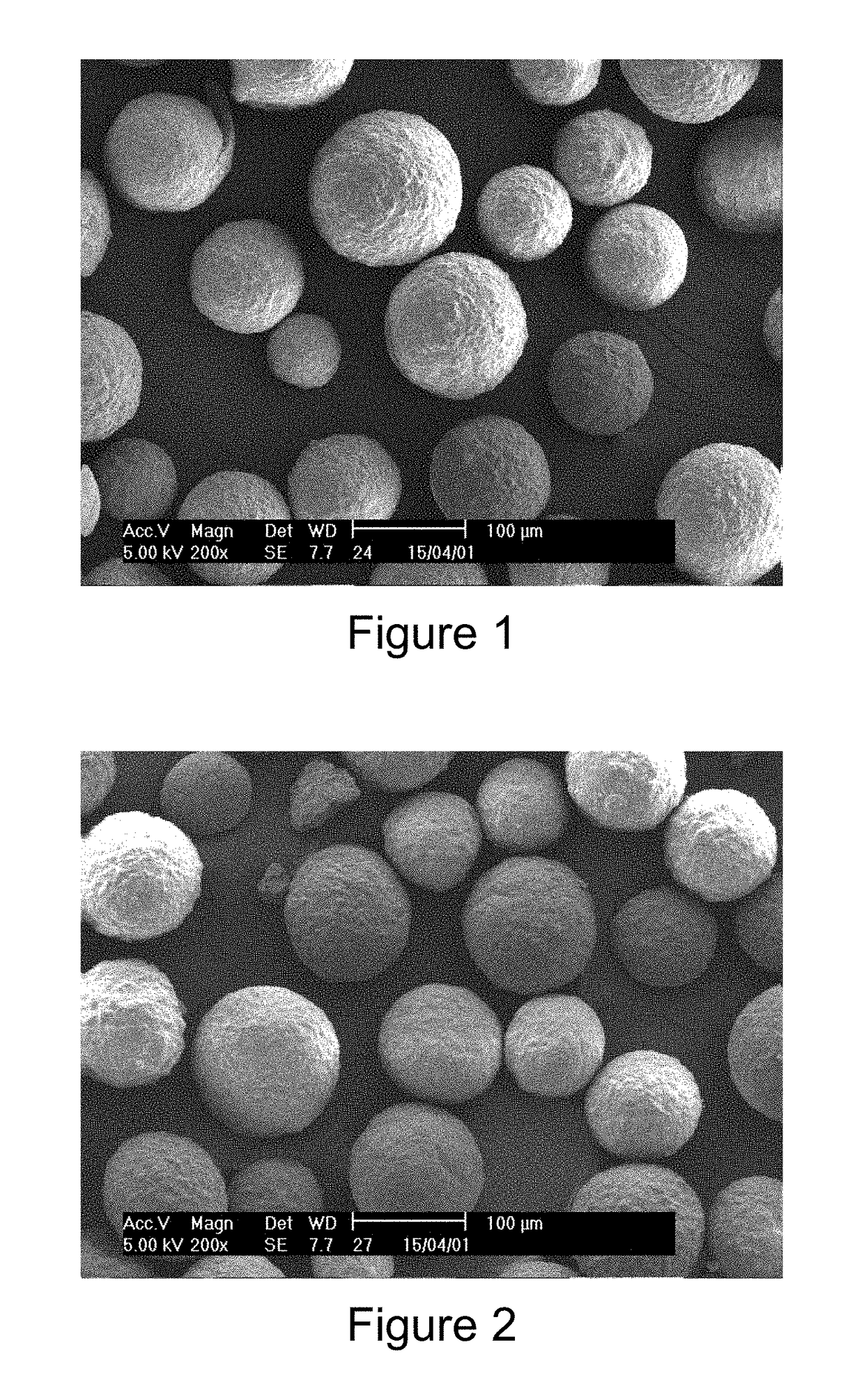

A method for preparing a polyolefin resin powder has the steps ofa) heat dissolving a polyolefin resin in an organic solvent having a solubility parameter less than or equal to the solubility parameter of the polyolefin resin to obtain a polyolefin resin solution;b) cooling the polyolefin resin solution to precipitate a solid, thereby obtaining a solid-liquid mixture;c) optionally adding an adjuvant to the solid-liquid mixture and mixing; andd) conducting solid-liquid separation and drying to obtain a polyolefin resin powder suitable for selective laser sintering.The difference between the solubility parameters of the organic solvent and of the polyolefin resin is within 0-20% of the solubility parameter of the polyolefin resin. The polyolefin resin powder obtained according to this method has good antioxidant property, good powder flowability, moderate size, smooth surface, suitable bulk density, and suitable dispersibility and particle size distribution.

Owner:CHINA PETROCHEMICAL CORP +1

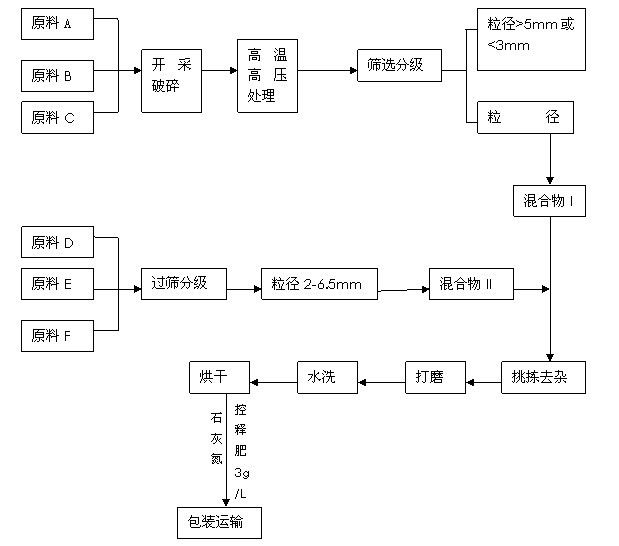

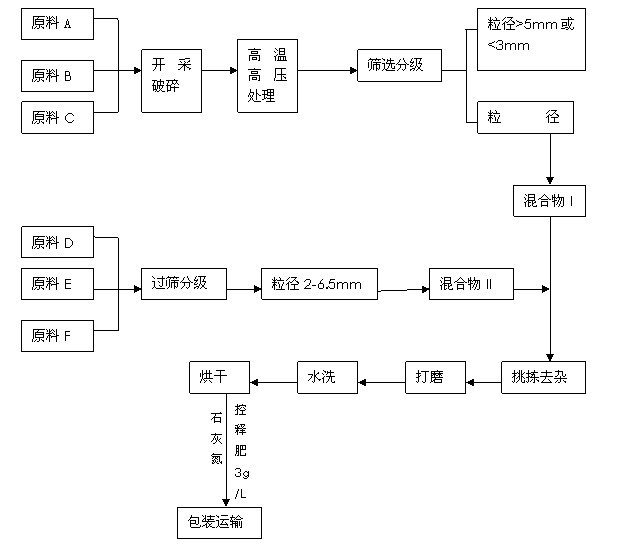

Cultivation medium

ActiveCN101889534AStable physical and chemical propertiesAppropriate bulk densityCultivating equipmentsSoilless cultivationWater dischargeDecomposition

The invention provides a cultivation medium, which comprises the following components in percentage by volume: 38 to 42 percent of Mako Hyuga stone, 16 to 21 percent of clinoptilolite, 5 to 7 percent of infusorial earth, 11 to 16 percent of red jade earth, 6 to 9 percent of allophone, 5 to 10 percent of Kiryu sand. In the invention, the Mako Hyuga stone, after high-temperature treatment, has the basic excellent properties of media, such as permeability, water discharge, insusceptibility to decomposition and breakage and high stability; and due to a chemical inertness, the Mako Hyuga stone can prevent the increase of surface adsorbates of the clinoptilolite exposed in the air for an overlong time and can prolong the service life of the clinoptilolite by 3 to 5 years effectively.

Owner:虹越花卉股份有限公司

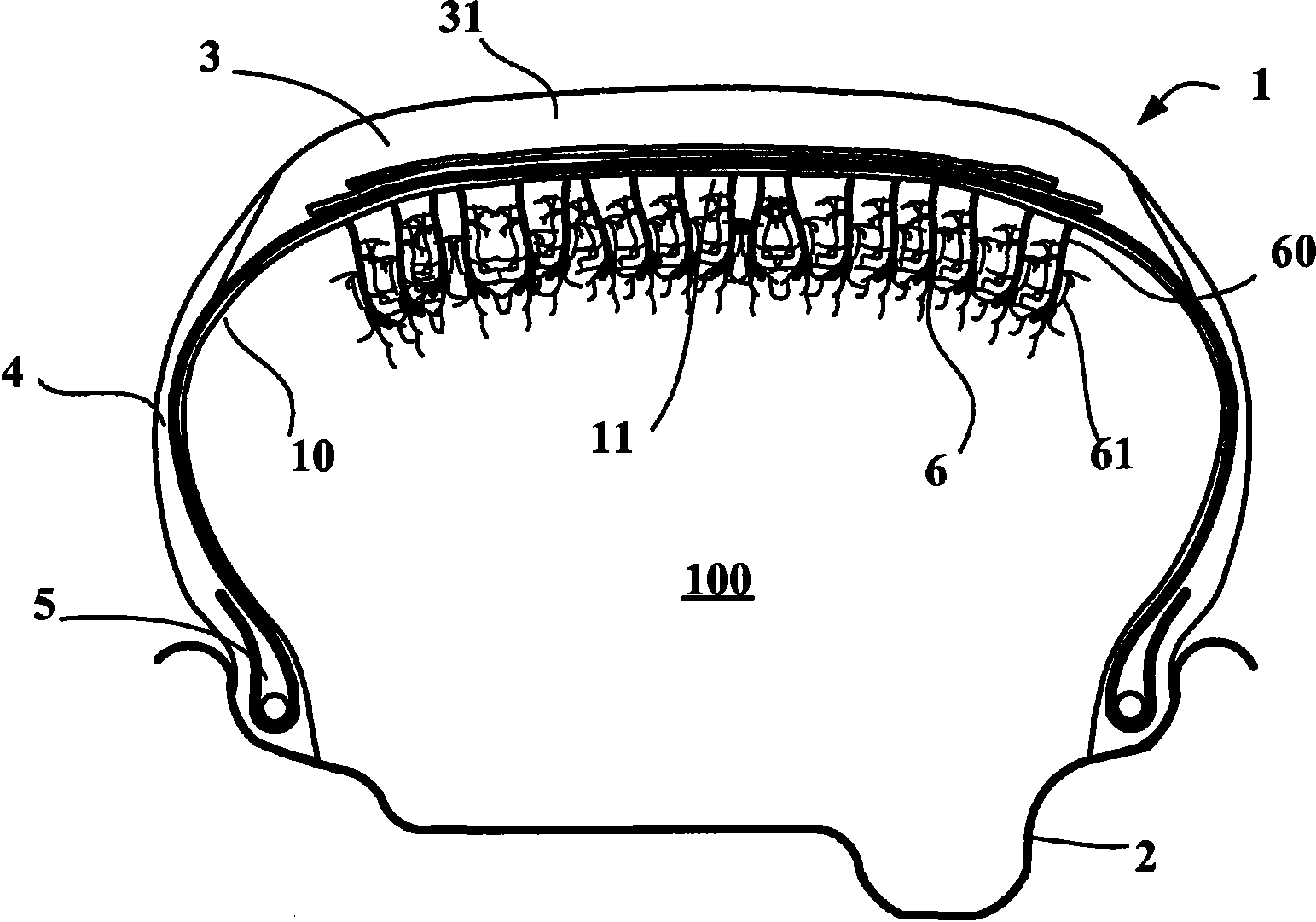

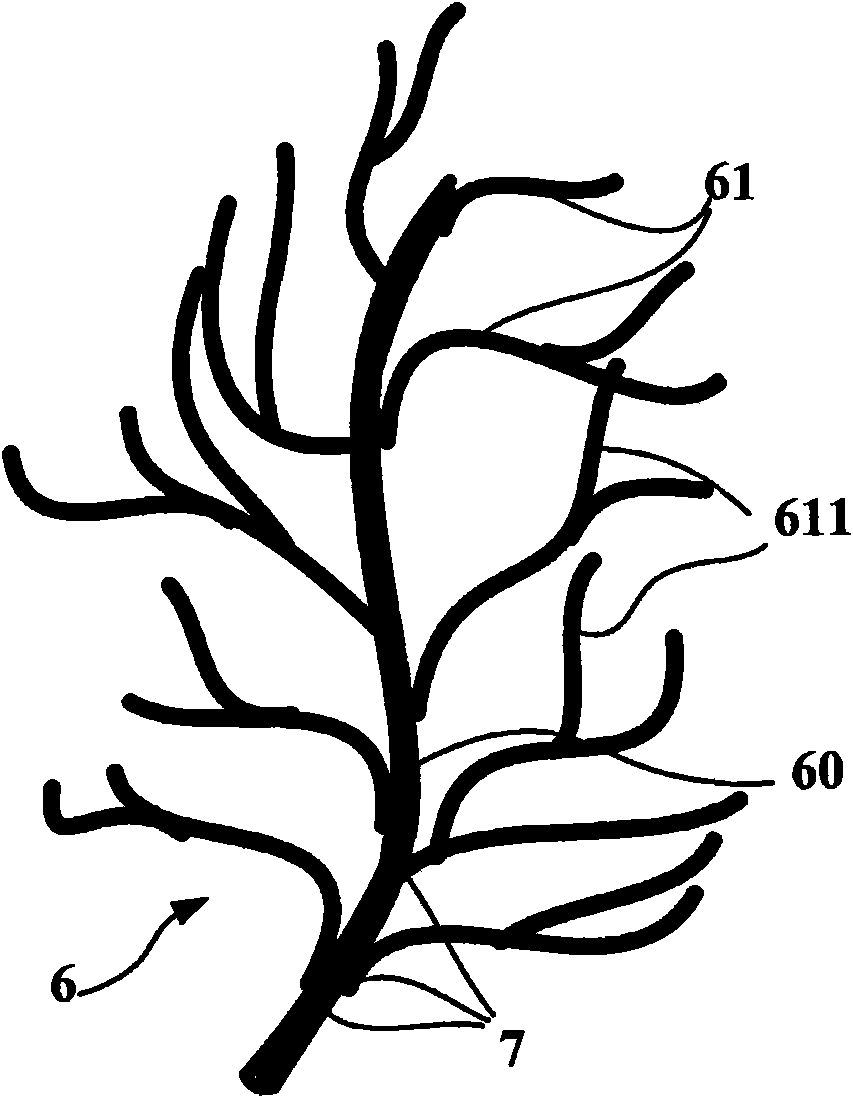

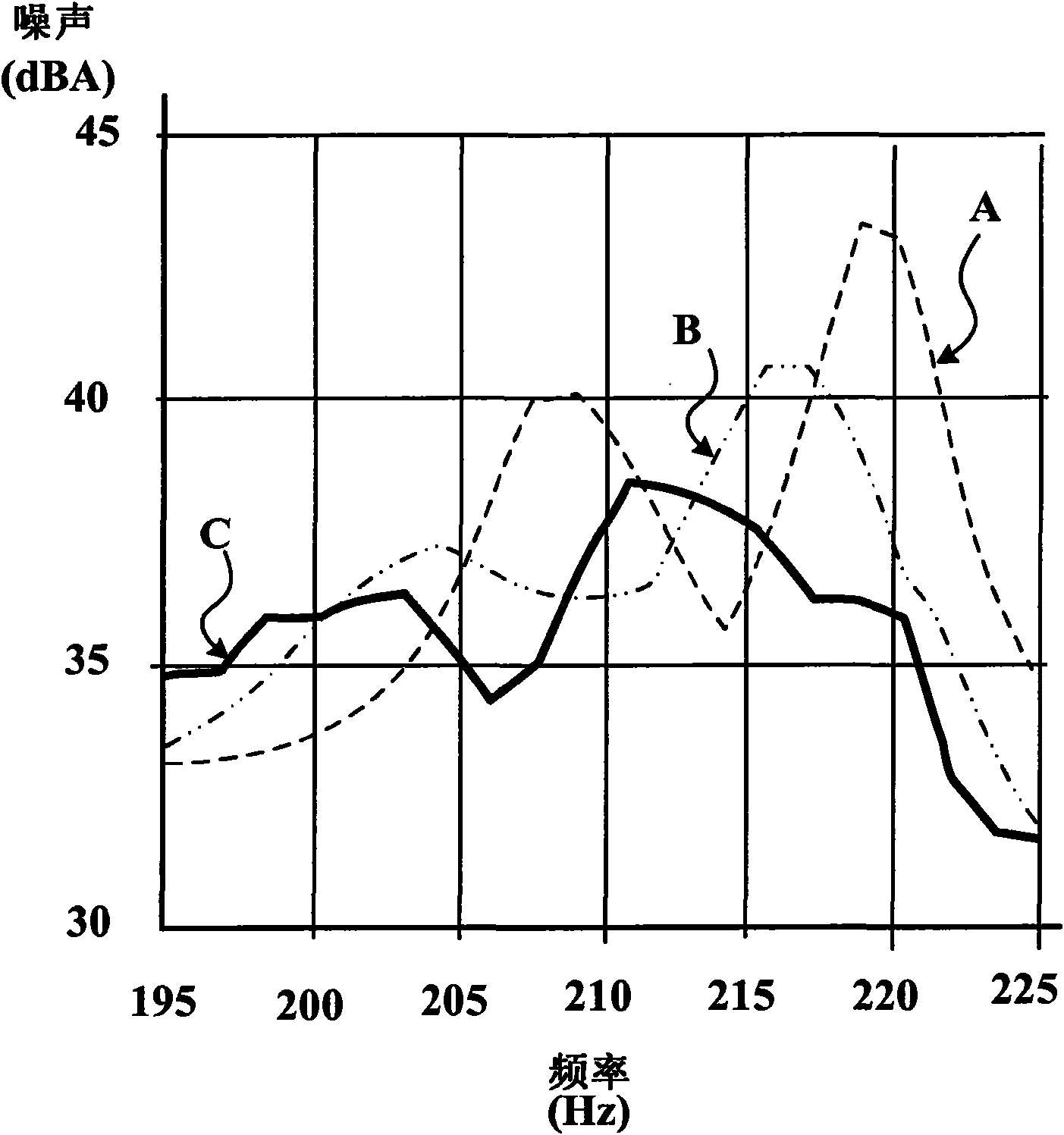

Device inside a tyre for reducing rolling noise.

Tyre (1) comprising a crown (3), sidewalls (4) continuing the crown from each side, these sidewalls being connected to beads (5) designed to be in contact with a tyre-fitting rim (2), and the tyre having an inside wall (10) defining with the fitting rim (2) an internal cavity (100) to enable the tyre to be inflated. This tyre comprises, on at least part of its inside wall (10) defining the internal cavity (100), a plurality of elongated protuberances (6) forming a dense coating, the tyre being characterized in that these elongated protuberances (6) comprise a plurality of supporting fibres 60 and a plurality of branching fibres (61), said branching fibres being attached to said supporting fibres, and each supporting fibre (60) having two ends, at least one of which is attached to the inside wall (10) of the tyre.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

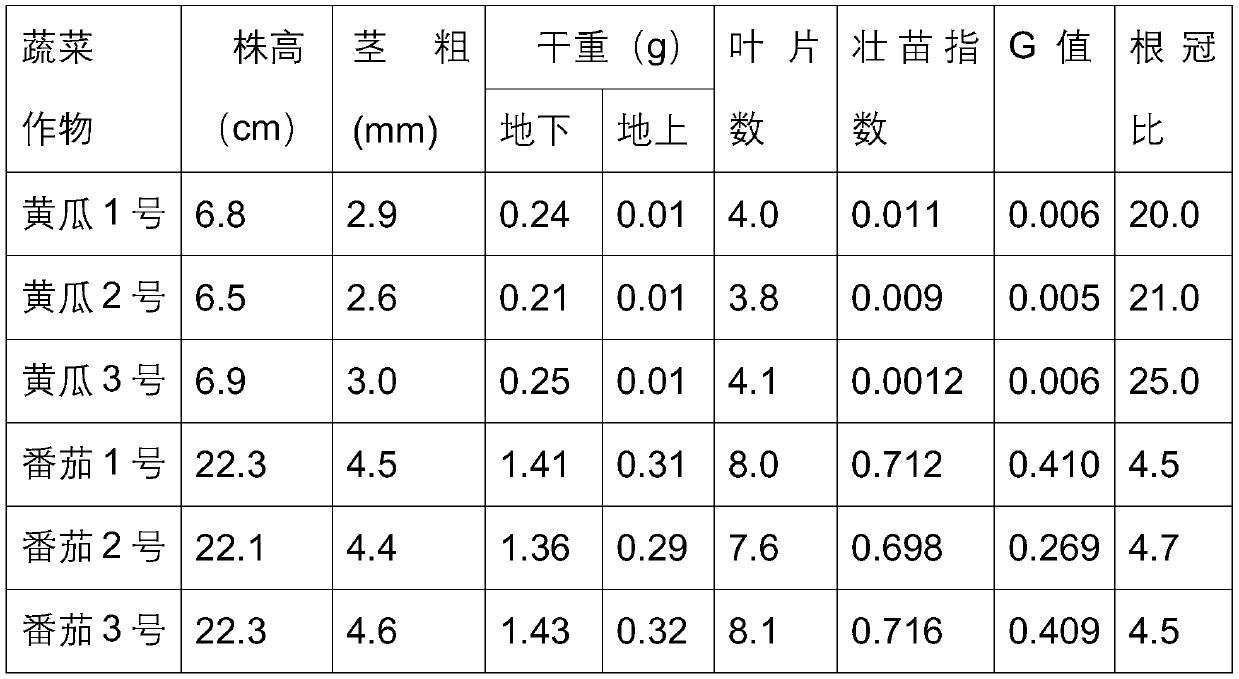

Vegetable seedling culture medium prepared by agriculture and forestry waste

InactiveCN110622824AGood holding effectImprove water retentionExcrement fertilisersBioloigcal waste fertilisersPorosityMicrobial agent

The invention relates to a vegetable seedling culture medium prepared by agriculture and forestry waste. The vegetable seedling culture medium comprises, by mass, 30-40 parts of sawdust, 20-30 parts of straw, 10-20 parts of retted bark, 10-20 parts of thoroughly decomposed cattle manure, 10-20 parts of perlite, 10-20 parts of coconut coir, 5-10 parts of vermiculite, 5-10 parts of mushroom residue,5-10 parts of slag, 5-10 parts of fermentation microbial agent, 3-5 parts of urea, 3-5 parts of distillers' grains, 3-5 parts of calcium magnesium phosphate fertilizer and an appropriate amount of water. The vegetable seedling culture medium is lightweight, easy to transport, low in unit weight, convenient and easy in raw material obtaining, good in total porosity, aeration porosity and water-retaining porosity, beneficial to vegetable immobilization and water-retaining ability, simple in preparation process, cheap and environmentally friendly, beneficial to agriculture and forestry waste resource utilization and promising in application prospect.

Owner:TAICANG LVFENG BIOLOGICAL ORGANIC FERTILIZER CO LTD

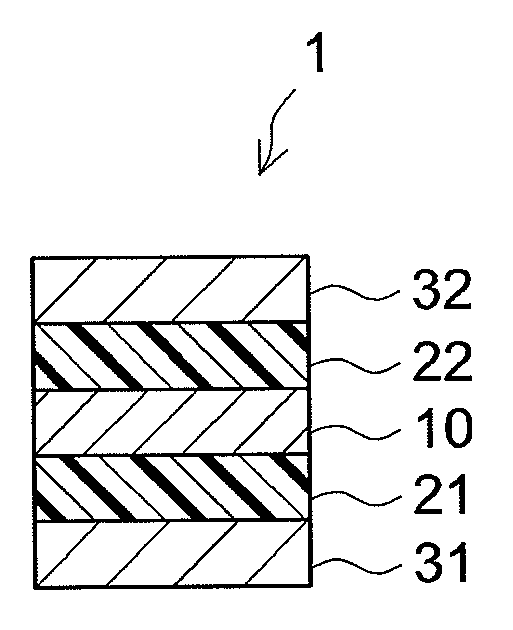

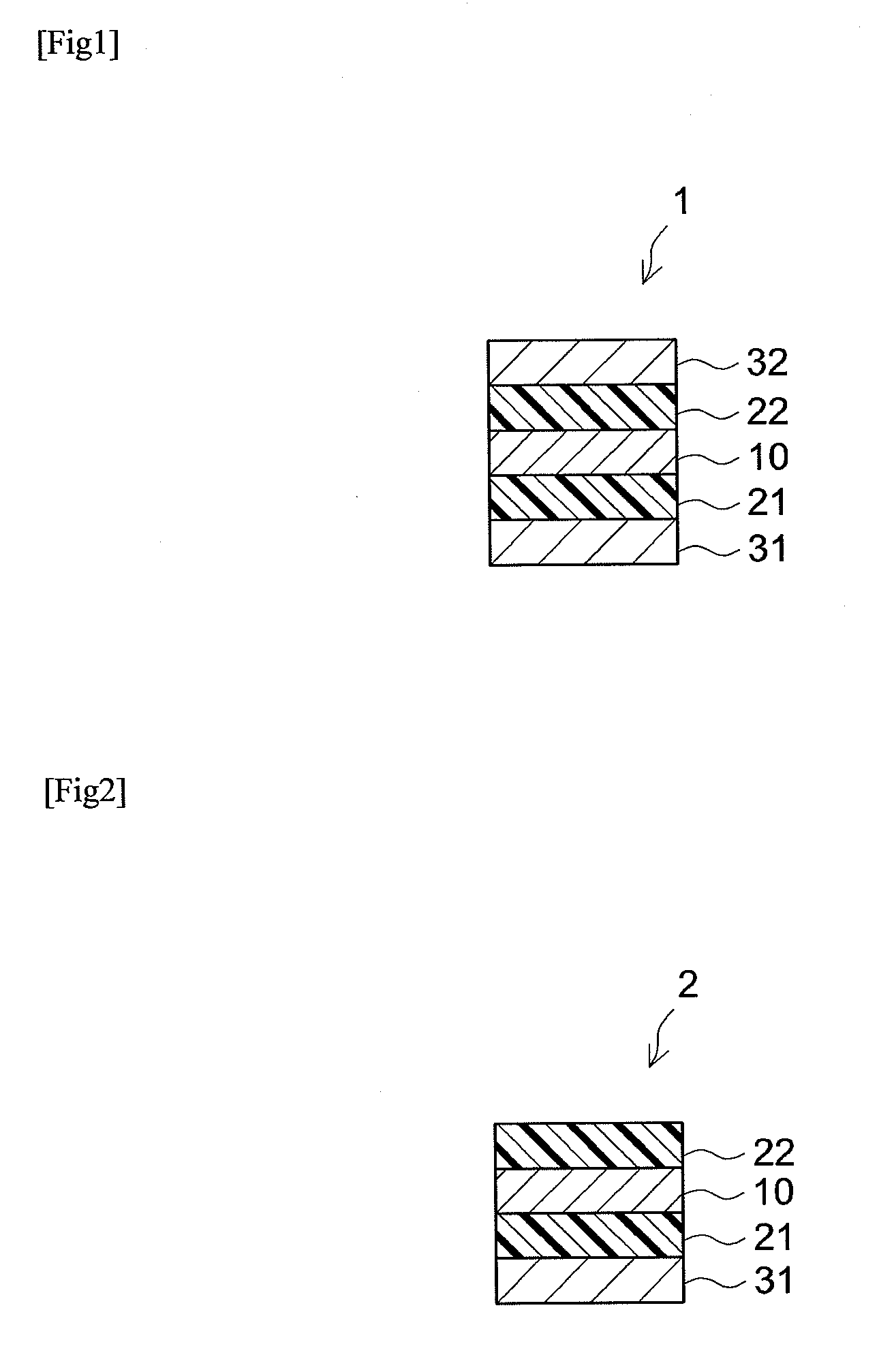

Double-sided adhesive pressure-sensitive adhesive sheet

InactiveUS20110008605A1High strengthPreventing tearing and interlaminar fractureSynthetic resin layered productsWoven fabricsEmulsion polymerizationNonwoven fabric

Provided is a double-sided pressure-sensitive adhesive (PSA) sheet that can be appropriately used in parts to be recycled. A PSA sheet has a hemp-containing nonwoven fabric substrate having a bulk density of 0.35 to 0.60 g / cm3; and PSA layers respectively provided on both faces of the substrate. The PSA layers are formed from an aqueous dispersion containing a polymer obtained through emulsion polymerization of a monomer starting material that contains an alkyl(meth)acrylate having a C4-12 alkyl group, in a proportion not less than 60 wt %. The SUS adhesive strength is not less than 11 N / 20 mm, and the PP adhesive strength is not less than 8.5 N / 20 mm.

Owner:NITTO DENKO CORP

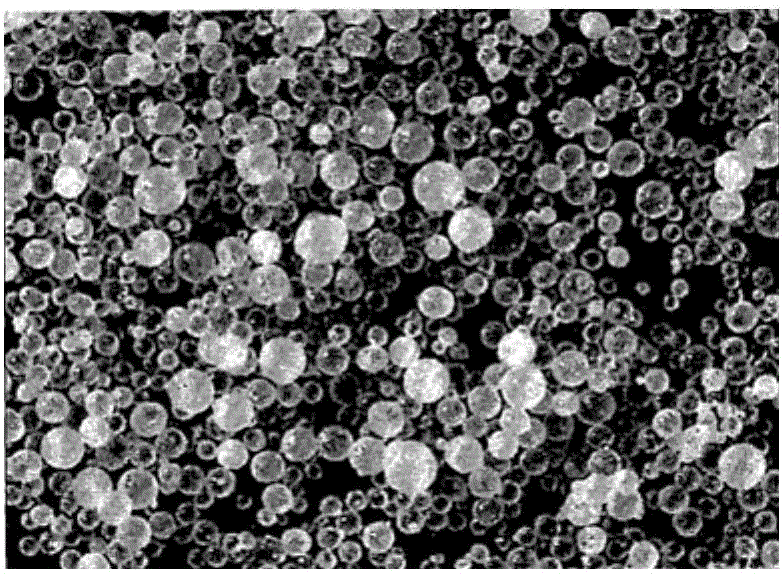

Carrier used for olefin polymerization catalyst and preparation method thereof

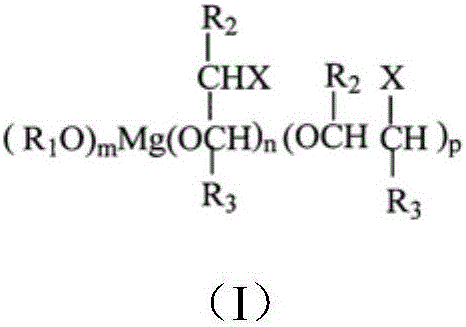

The invention relates to a carrier used for an olefin polymerization catalyst and a preparation method thereof. The carrier is (MgXY)m.[Mg(OR')Z]p.(ROH)n. The preparation method comprises the following steps: mixing magnesium halide as shown in MgXY, a compound as shown in ROH and a first inert medium; carrying out heating at 90 to 150 DEG C for 0.5 to 5 h; then emulsifying a liquid-state mixture obtained in the previous step; introducing an emulsification product to a second inert medium which has been cooled to -40 to 10 DEG C for rapid cooling and forming; carrying out solid-liquid separation so as to obtain a spherical carrier; and carrying out washing and drying so as to obtain the carrier. According to the invention, a forming agent and a grain-shape controlling agent are added during formation of an alcohol adduct of magnesium halide, so the obtained carrier has more concentrated particle size distribution; the catalyst prepared from the carrier has improved activity and hydrogen sensitivity when applied to olefin polymerization, especially to propylene polymerization; and an obtained polymerization product has moderate bulk density and is almost free of special-shaped materials.

Owner:营口风光新材料股份有限公司

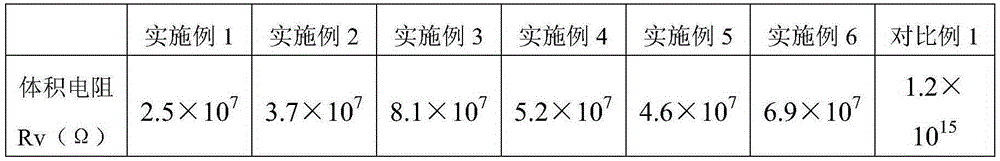

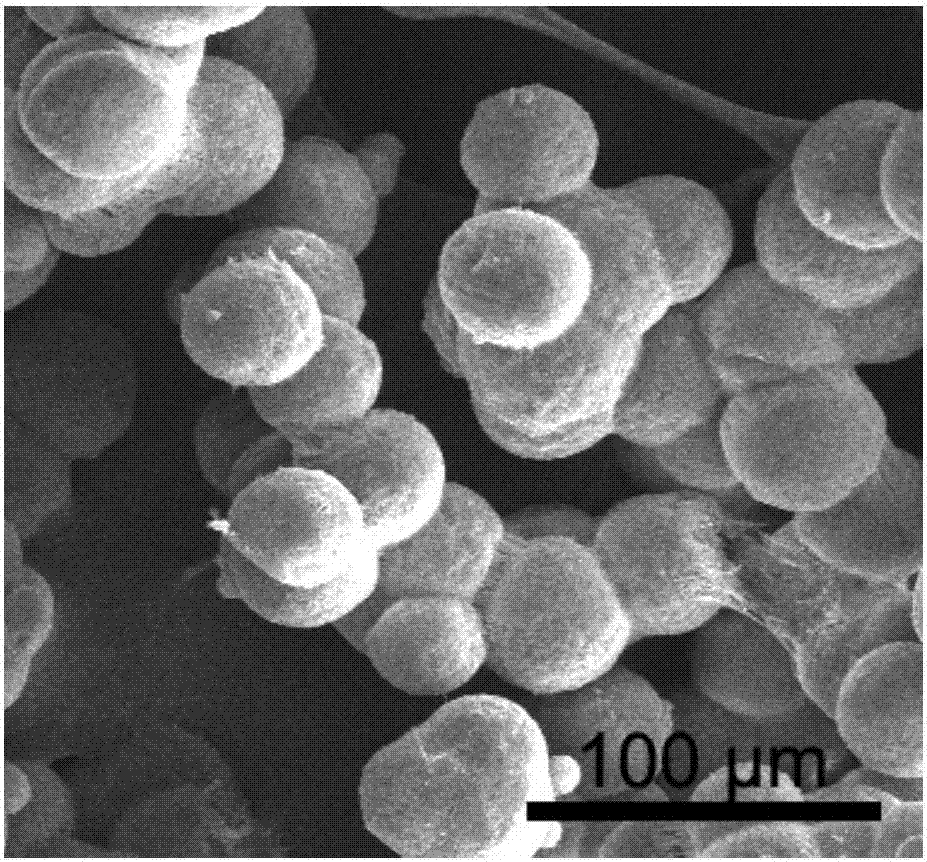

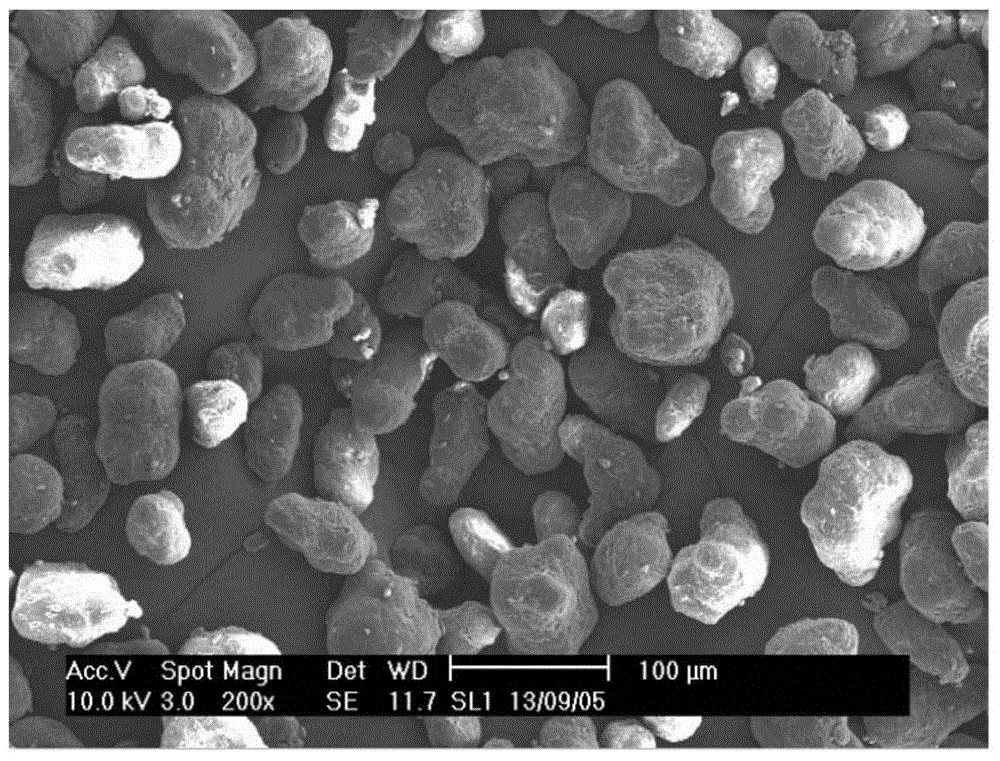

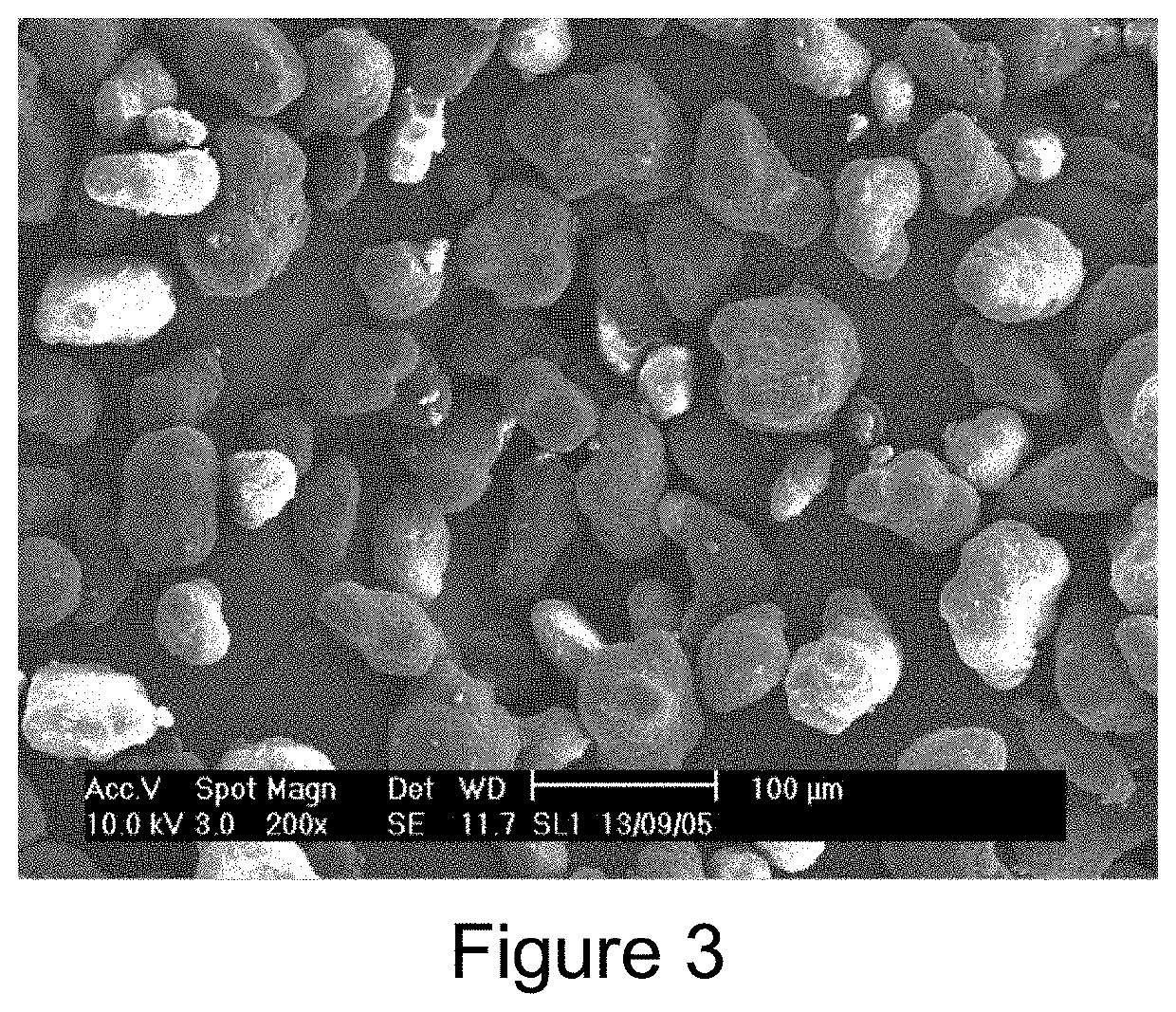

Nylon resin powder for selective laser sintering and preparation method of nylon resin powder

InactiveCN107304292AUniform particle size distributionAppropriate bulk densitySelective laser sinteringAlcohol

The invention provides a method for preparing nylon resin powder for selective laser sintering. The method comprises the following steps: a) dissolving a nylon resin in an amide and / or alcohol organic solvent at a heating temperature so as to obtain a nylon resin solution; b) cooling the nylon resin solution obtained in the step a), and separating out the solid precipitate so as to obtain a solid-liquid mixture; c) adding aids into the solid-liquid mixture obtained in the step b), and uniformly mixing; and d) performing solid-liquid separation, and drying the solids, thereby obtaining the nylon resin powder for laser sintering, wherein the aids comprise functional aids, a powder release agent and an antioxidant. The invention further provides a selective laser sintering method taking the nylon powder as a raw material.

Owner:CHINA PETROLEUM & CHEM CORP +1

Polypropylene resin powder for selective laser sintering as well as preparation method and application thereof

InactiveCN106589418AUniform particle size distributionAppropriate bulk densityAdditive manufacturing apparatusAlkaneDispersity

Owner:CHINA PETROLEUM & CHEM CORP +1

Antistatic polylactic resin powder used for selective laser sintering, and preparation method thereof

The invention provides a preparation method of an antistatic polylactic resin powder used for selective laser sintering. The method comprises the following steps: 1, dissolving polylactic resin in a ketone and / or ether organic solvent at a heating temperature to obtain a polylactic resin solution; 2, cooling the polylactic resin obtained in step 1 to precipitate a solid precipitate; and 3, adding assistants to a solid-liquid mixture obtained in step 2, uniformly mixing the solid-liquid mixture and the assistants, and drying the obtained mixture to obtain the powder, wherein the assistants comprise an antistatic agent, an antioxidant and a powdery isolating agent. The method has the advantages of simplicity in operation, easiness in operation, provision of a sintering raw material with excellent processing properties for the selective laser sintering, and provision of a new direction for processing and application of functional polylactic resin. The invention further provides the antistatic polylactic resin powder prepared through the method, and a selective sintering method adopting the antistatic polylactic resin powder as a sintering powder raw material.

Owner:CHINA PETROLEUM & CHEM CORP +1

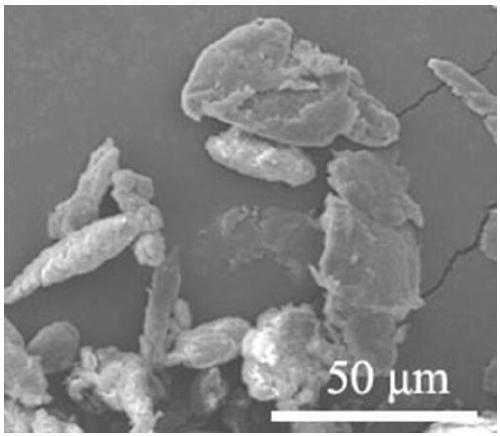

Glass fiber reinforced polylactic acid resin powder for selective laser sintering, and preparation thereof

ActiveCN106589858AEasy to operateEasy to manufactureAdditive manufacturing apparatusAdditive manufacturing with solidsSelective laser sinteringOrganic solvent

The present invention provides a preparation method of glass fiber reinforced polylactic acid resin powder for selective laser sintering. The preparation method comprises: a) dissolving a polylactic acid resin in a ketone and / or ether organic solvent at a heating temperature to obtain a polylactic acid resin solution; b) cooling the polylactic acid resin solution obtained in the step a) to precipitate the solid; and c) adding an auxiliary agent to the solid-liquid mixture obtained in the step b), uniformly mixing, and drying to obtain the powder, wherein the auxiliary agent comprises ultra-short glass fibers, an antioxidant and a powder isolation agent. According to the present invention, the method is simple and easy to operate, the sintering raw material having excellent processing performance is provided for the selective laser sintering, and the new direction is provided for the processing and application of the functional polylactic acid resin. The invention further provides the glass fiber reinforced polylactic acid resin powder prepared according to the method, and a selective laser sintering method using the glass fiber reinforced polylactic acid resin powder as the sintering powder raw material.

Owner:CHINA PETROLEUM & CHEM CORP +1

Polyformaldehyde resin powder for selective laser sintering and preparation method thereof

InactiveCN107304249AUniform particle size distributionSuitable for selective laser sintering applicationsAdditive manufacturing apparatusSelective laser sinteringOrganic solvent

The invention provides a method for preparing polyformaldehyde resin powder for selective laser sintering, which comprises the following steps: (1) dissolving polyformaldehyde resin in at least one organic solvent selected from amide, cyclic ether, ketone and chloralkane at a heating temperature to obtain a polyformaldehyde resin solution; (b) cooling the polyformaldehyde resin solution obtained in the step (a) until solid precipitate is separated out to obtain a solid-liquid mixture; (c) adding an additive into the solid-liquid mixtu.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing ceramsite from printing and dyeing sludge and sodium silicate alkaline residues in cooperation

InactiveCN109336638ASimple processAppropriate bulk densityCeramic materials productionCeramicwareSludgeOrganic matter

The invention relates to the technical field of ceramsite preparation, in particular to a method for preparing ceramsite from printing and dyeing sludge and sodium silicate alkaline residues in cooperation. According to the method, the printing and dyeing sludge, the sodium silicate alkaline residues and fly ash are taken as raw materials, organic matter in the printing and dyeing sludge is fullyutilized to provide residual heat and serves as an expansion source of the ceramsite, and the process for preparing the ceramsite from the printing and dyeing sludge is improved by regulating granulation performance of the raw materials with the fly ash and the sodium silicate alkaline residues, so that the industrial waste, namely, the printing and dyeing sludge and the sodium silicate alkaline residues, which are different to utilize, are effectively recycled. Besides, the method for preparing the ceramsite from the printing and dyeing sludge and the sodium silicate alkaline residues in cooperation is simple in process, the ceramsite prepared with the method has no cracks on the surface, and the ceramsite has appropriate bulk density and cylinder compressive strength and is suitable forpopularization and use.

Owner:XUZHOU ZHONGLIAN CONCRETE CO LTD

Water-resisting modified ammonium nitrate fuel oil explosive and preparation method thereof

InactiveCN102351618AStrong explosive performanceGood explosive performanceExplosivesExplosive AgentsANFO

The invention relates to a preparation technology of a water-resisting modified ammonium nitrate fuel oil (ANFO) explosive, and provides a preparation technology of a non-TNT high-performance powdery ANFO explosive with high physical and chemical properties of functional powder. According to the invention, a mechanical force chemical modification technological mode is adopted. Good water resistance is provided for the explosive through the addition of a water-resisting composite oil phase rich in hydrophobic factors. The density of the explosive is reasonably regulated through the addition ofa density regulator. Therefore, good detonation sensitivity and detonating transfer performance are provided for the explosive. Compared to prior arts, the water-resisting modified ANFO explosive prepared with the technology provided by the invention is characterized by reasonable and advanced formulation. The explosive is safe and reliable, and has good damp proofing, agglomeration resisting, water resisting, and explosion performances. Therefore, the explosive is suitable for industrialized productions.

Owner:HUNAN SHINEHOOD GRP NO 169 CHEM IND

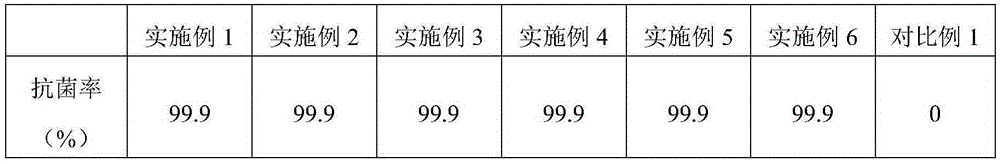

Antibacterial polypropylene resin powder used for selective laser sintering and preparation thereof

InactiveCN106565975AUniform particle size distributionGood fluidity of powderAlkaneSelective laser sintering

A preparing method of antibacterial polypropylene resin powder used for selective laser sintering is provided. The method includes a) dissolving polypropylene resin to an alkane organic solvent at a heating temperature to obtain a polypropylene resin solution, b) cooling the polypropylene resin solution prepared in the step a) to allow a solid precipitate to precipitate out, and c) adding auxiliary agents into a solid liquid mixture obtained in the step b), then fully mixing the mixture, and drying the mixture to obtain the power, wherein the auxiliary agents comprise an antibacterial agent, an antioxidant and a powder separating agent. The method is simple and easy to operate. A sintering raw material having excellent processing performance is provided for selective laser sintering, and a novel direction is provided for processing and application of functional polypropylene resin. The invention further provides the antibacterial polypropylene resin powder prepared by the method and a selective laser sintering method adopting the antibacterial polypropylene resin powder as a sintering powder raw material.

Owner:CHINA PETROLEUM & CHEM CORP +1

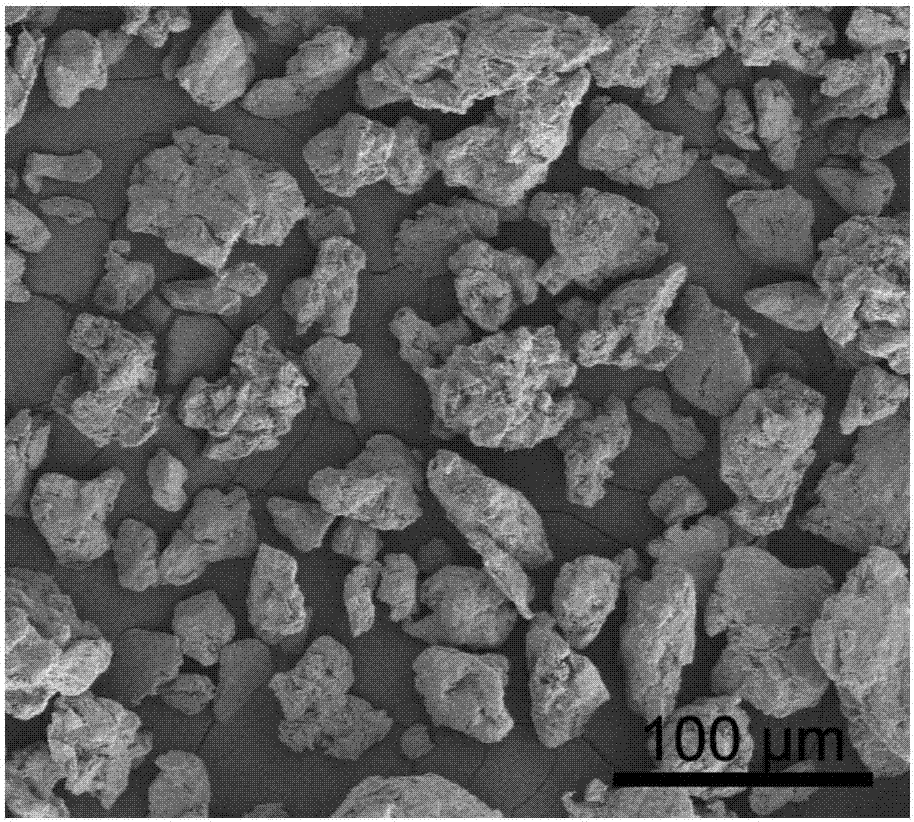

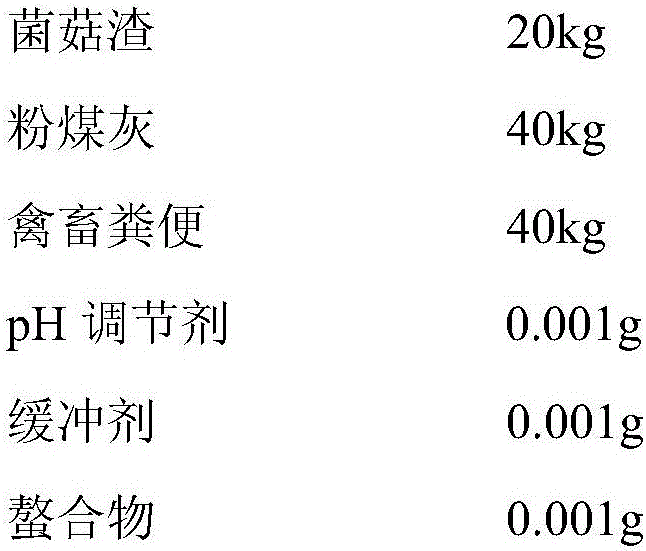

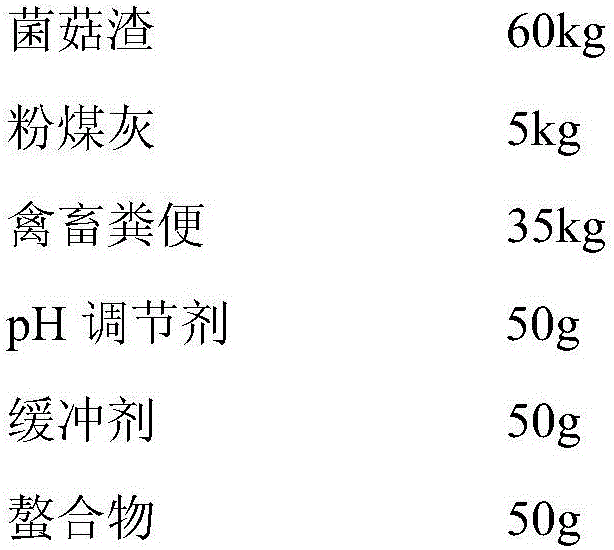

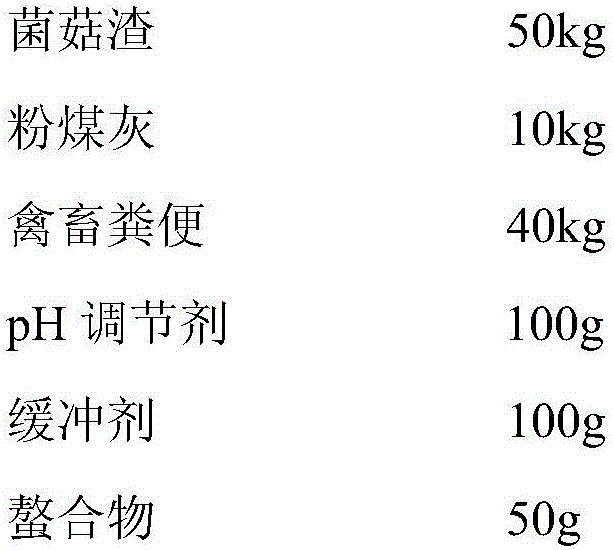

Mushroom residue-based artificial soil and synthesis method thereof

InactiveCN105948903AGuaranteed water retention and breathabilityLight textureExcrement fertilisersGrowth substratesPlant rootsFeces

The invention discloses a mushroom residue-based artificial soil. The mushroom residue-based artificial soil comprises mushroom residues, fly ash, animal dung, a pH regulator, a buffering agent and a chelate, wherein a mushroom residue, fly ash and animal dung mixture contains 20-60wt% of mushroom residues, 5-40wt% of fly ash and 15-40wt% of animal dung, and every ton of the mushroom residue, fly ash and animal dung mixture contains 0.01-1000g of the pH regulator, 0.01-1000g of the buffering agent and 0.01-500g of the chelate. The mushroom residues have light weight, the unit weights of the fly ash and the animal dung are large, and a ratio of the mushroom residues to the fly ash to the animal dung is controlled to make the unit weight of the artificial soil be similar to the unit weight of manure soil, so plant roots can be well fixed, the water holding permeability of soil is increased, water, fertilizers, air and other environment factors needed in the growth process of the plants are well coordinated, and a large amount of beneficial microorganisms in the mushroom residues increase the diversity of microorganisms in soil. The artificial soil has stable performances, is not affected by batches, seasons or regions, and keeps excellent application effects.

Owner:灌南县畜牧兽医站

Glass fiber reinforced polypropylene resin powder for selective laser sintering and preparation thereof

InactiveCN106589419ASmall sizeImprove mechanical propertiesAdditive manufacturing apparatusSelective laser sinteringOrganic solvent

The invention provides a preparation method of a glass fiber reinforced polypropylene resin powder for selective laser sintering. The method includes the steps of: a) at a heating temperature, dissolving polypropylene resin in an alkane organic solvent to obtain a polypropylene resin solution; b) cooling the polypropylene resin solution obtained by step a) to make solid precipitate out; c) adding assistants into the solid-liquid mixture obtained by step b), mixing the substances evenly, and performing drying so as to obtain the powder, wherein the assistants include ultra-short glass fiber, an antioxidant and a powder separant. The method has the characteristics of simple operation and easy operation, not only provides the sintering raw material with excellent processing properties for selective laser sintering, but also provides a new direction for processing and application of functional polypropylene resin. The invention further provides the glass fiber reinforced polypropylene resin powder prepared according to the method and a selective laser sintering method adopting the glass fiber reinforced polypropylene resin powder as the sintering powder raw material.

Owner:CHINA PETROLEUM & CHEM CORP +1

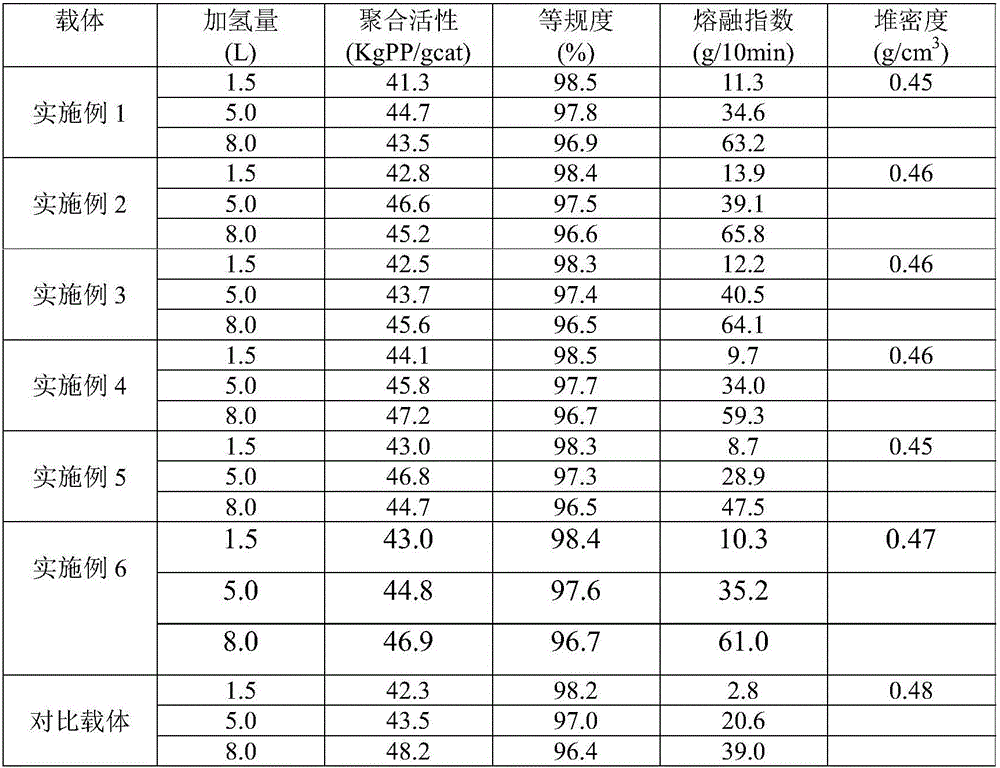

Olefin polymerization method

The invention relates to an olefin polymerization method. The method comprises steps as follows: a hexane solution of triethyl aluminum, a hexane solution of cyclohexyldimethoxymethylsilane and a catalyst are sequentially added to a high-pressure reactor under the protection of nitrogen, the high-pressure reactor is closed, 1.5-8.0 L of hydrogen and liquid olefin are added, the components are heated to 60-80 DEG C to react for 1-2 h, cooled, subjected to pressure release, discharged and dried, and polymers are obtained. According to the olefin polymerization method, a supporter and the catalyst are improved, so that when the catalyst prepared from the supporter is used for polymerization of olefin, especially, polymerization of propylene, activity and hydrogen regulation sensitivity of the catalyst can be improved, particle morphology of obtained polymers is good, bulk density of the polymers can be reduced, and no special-shaped materials are produced basically.

Owner:黑龙江省龙油石油化工股份有限公司

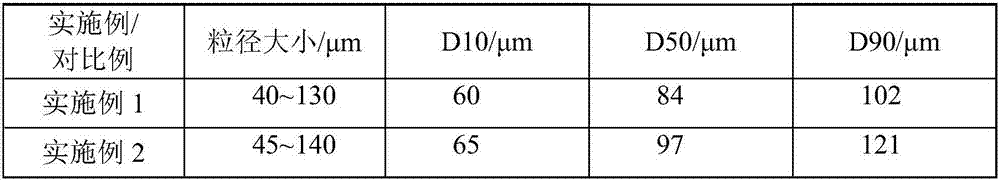

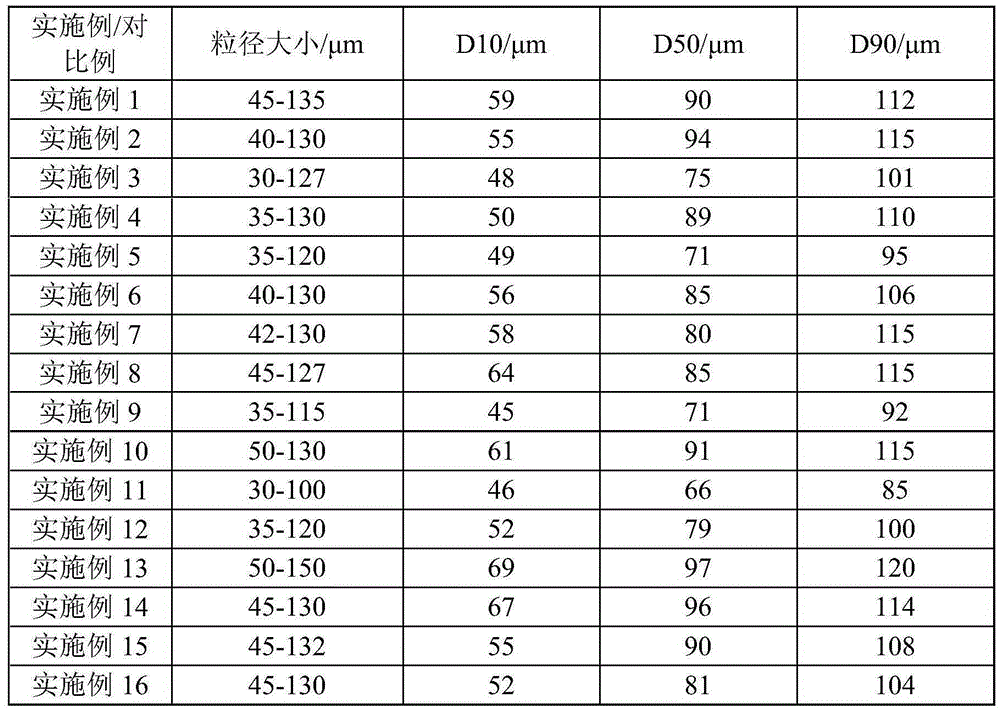

Directly pressed starch and production method thereof

PendingCN112076166ALarge particle sizeImprove liquidityPill deliveryPharmaceutical non-active ingredientsPolymer scienceSpray dried

The invention belongs to the technical field of synthesis of pharmaceutic adjuvants, and particularly relates to directly pressed starch and a production method thereof. According to the invention, astarch material and an adhesive solution are mixed and then subjected to extrusion molding, drying and crushing or direct spray drying, so that the effect of producing improved starch capable of beingdirectly pressed into sheets is achieved. The invention has the advantages that the production method is simple, effective, efficient and convenient, the produced starch is good in flowability, relatively small in hygroscopicity and sufficient in adhesive force, the performance is outstanding after the directly pressed sheets are prepared, and the starch is suitable for a powder direct pressing process when being used as a filling agent and a diluent.

Owner:HUZHOU ZHANWANG PHARMA

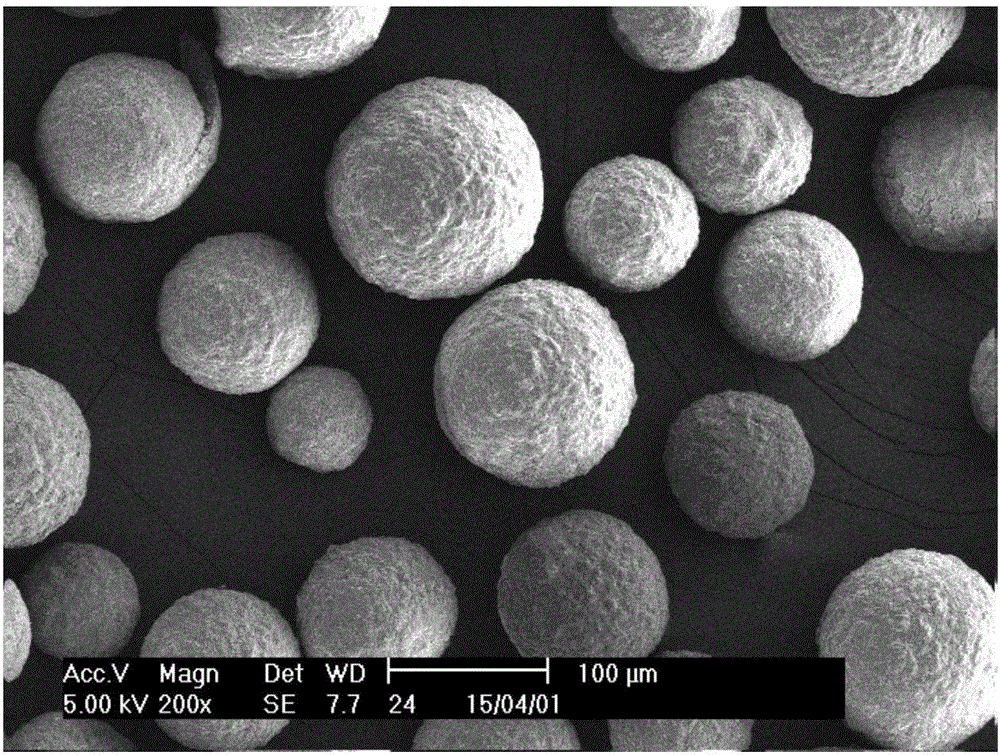

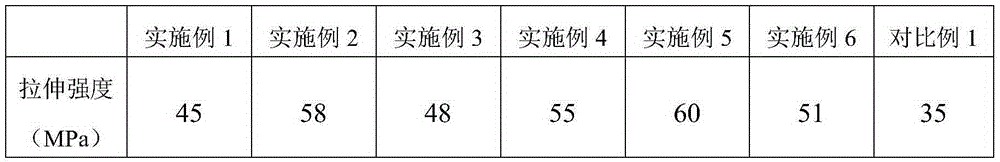

Polyolefin resin powder suitable for selective laser sintering and its preparation method

ActiveUS10920025B2Improve the immunityReduce sizeAdditive manufacturing apparatusTransportation and packagingPolymer scienceSelective laser sintering

A method for preparing a polyolefin resin powder has the steps ofa) heat dissolving a polyolefin resin in an organic solvent having a solubility parameter less than or equal to the solubility parameter of the polyolefin resin to obtain a polyolefin resin solution;b) cooling the polyolefin resin solution to precipitate a solid, thereby obtaining a solid-liquid mixture;c) optionally adding an adjuvant to the solid-liquid mixture and mixing; andd) conducting solid-liquid separation and drying to obtain a polyolefin resin powder suitable for selective laser sintering.The difference between the solubility parameters of the organic solvent and of the polyolefin resin is within 0-20% of the solubility parameter of the polyolefin resin.The polyolefin resin powder obtained according to this method has good antioxidant property, good powder flowability, moderate size, smooth surface, suitable bulk density, and suitable dispersibility and particle size distribution.

Owner:CHINA PETROCHEMICAL CORP +1

Camellia mycorrhizal seedling substrate and use method thereof

InactiveCN108849388AImprove disease and insect resistanceHigh degree of decompositionGrowth substratesCulture mediaDiseasePeat

The invention provides a camellia mycorrhizal seedling substrate and a use method thereof. The seedling substrate is prepared from vermiculite, peat, coal cinder, mycorrhiza fungi, coco coir and a water-retaining agent; the seedling substrate is divided into two layers, the vermiculite, the peat, the coal cinder and the mycorrhiza fungi are mixed to be uniform to serve as a lower layer substrate body, and the coco coir and the water-retaining agent are mixed to be uniform to serve as an upper layer substrate body. When the substrate is used, the lower layer substrate body is laid first, camellia seedlings are planted in the lower layer substrate body, then the upper layer substrate body is laid, watering is conducted thoroughly, and water is supplemented in time. The substrate is good in physical and chemical property and low in cost, the substrate preparation and use steps are few, the cultivated camellia seedlings are high in survival rate and less in disease and pest damage, plantsgrow strongly, and the requirements of commercial camellia seedlings are met.

Owner:天柱县佳源科技开发有限公司

A kind of polypropylene powder for selective laser sintering and its preparation method

ActiveCN107383593BEasy to operateHigh sphericityAdditive manufacturing apparatusSelective laser sinteringAntioxidant

Owner:HENAN INST OF ENG

Polypropylene resin powder for selective laser sintering and preparation method thereof

InactiveCN105585719AUniform particle size distributionSuitable for selective laser sintering applicationsSelective laser sinteringPolymer science

The invention provides a preparation method of a polypropylene resin powder for selective laser sintering. The preparation method includes the following steps: a) at a heating temperature, dissolving polypropylene resin in an organic solvent composed of at least one of acetone, butanone, 2-pentanone, 3-pentanone, cyclopentanone, methyl isopropyl ketone, tetrahydrofuran and dioxane to obtain a polypropylene resin solution; and b) decreasing the temperature of the polypropylene resin solution to separate out a solid precipitate. In the method, a proper solvent is firstly selected, and then proper temperature increasing and decreasing methods are designed at certain temperature and under certain pressure, thereby preparing the polypropylene resin powder raw material which is very suitable for the selective laser sintering in shape, characters and the like. The method is free of other additives and can be used for producing the polypropylene resin powder, which is moderate in size, has a smooth surface, is good in dispersibility, is small in particle size distribution and has proper bulk density, for the selective laser sintering.

Owner:CHINA PETROLEUM & CHEM CORP +1

Polyethylene resin powder used for selective laser sintering and preparation method and application thereof

InactiveCN106674550AUniform particle size distributionSuitable for selective laser sintering applicationsAlkaneSelective laser sintering

The invention provides a polyethylene resin powder used for selective laser sintering and a preparation method and an application thereof. The method comprises the following steps: under heating temperature, dissolving polyethylene in at least one of organic solvents of C5-C9 alkanes to obtain a polyethylene resin solution; precipitating the solid precipitate to obtain a solid-liquid mixture; adding an auxiliary agent in the obtained solid-liquid mixture, removing the solvent, and drying the material to obtain the polyethylene resin powder used for laser sintering; wherein the auxiliary agent comprises an antioxidant and / or a powder parting agent. The polyethylen resin powder has the advantages of appropriate size, smooth surface, good dispersibility, small size distribution, good oxidation resistance and flowability, and is suitable for various molded products used for selective laser sintering. The invention provides the selective laser sintering method by taking polyethylen resin powder as a raw material.

Owner:CHINA PETROLEUM & CHEM CORP +1

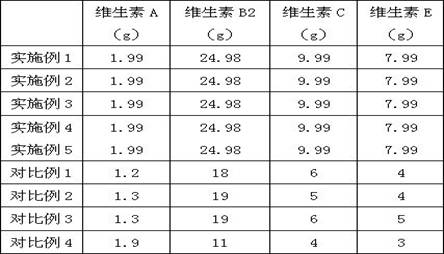

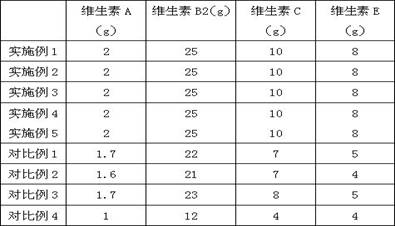

A kind of feed vitamin carrier and preparation method thereof

ActiveCN107535692BGood dispersionImprove adsorption capacityAccessory food factorsBiotechnologyVitamin

The invention provides a vitamin carrier for feed and a preparation method thereof. The first complex and the second complex are firstly prepared respectively, and then the two are extracted through a dimethyl sulfoxide-ethanol mixture, which can promote the production of each component. Good dispersion and improved surface properties. The particle size of the final microbial carrier for feed is controlled at 50-60 mesh. The surface is porous and has strong adsorption. After mixing with vitamins, it will help vitamins evenly adsorb on the surface of the carrier. , to avoid unbalanced product quality, the angle of repose of the carrier is in the range of 42-46°, the vitamins and the carrier are evenly mixed, and there will be no grading caused by vibration during transportation.

Owner:JIANGSU RUIMU BIOLOGICAL TECH CO LTD

Antistatic polylactic acid resin powder for selective laser sintering and its preparation

The invention provides a preparation method of an antistatic polylactic resin powder used for selective laser sintering. The method comprises the following steps: 1, dissolving polylactic resin in a ketone and / or ether organic solvent at a heating temperature to obtain a polylactic resin solution; 2, cooling the polylactic resin obtained in step 1 to precipitate a solid precipitate; and 3, adding assistants to a solid-liquid mixture obtained in step 2, uniformly mixing the solid-liquid mixture and the assistants, and drying the obtained mixture to obtain the powder, wherein the assistants comprise an antistatic agent, an antioxidant and a powdery isolating agent. The method has the advantages of simplicity in operation, easiness in operation, provision of a sintering raw material with excellent processing properties for the selective laser sintering, and provision of a new direction for processing and application of functional polylactic resin. The invention further provides the antistatic polylactic resin powder prepared through the method, and a selective sintering method adopting the antistatic polylactic resin powder as a sintering powder raw material.

Owner:CHINA PETROLEUM & CHEM CORP +1

Aliphatic polyester resin powder suitable for selective laser sintering and its preparation method

ActiveUS10787546B2Promote degradationReduce sizeAdditive manufacturing apparatusAdditive manufacturing with solidsPolymer scienceSelective laser sintering

A method for preparing an aliphatic polyester resin powder includes the steps ofa) heat dissolving a crystalline aliphatic polyester resin in an organic solvent to obtain an aliphatic polyester resin solution;b) cooling the aliphatic polyester resin solution to precipitate a solid, thereby obtaining a solid-liquid mixture;c) optionally adding an adjuvant to the solid-liquid mixture and mixing; andd) conducting solid-liquid separation and drying to obtain an aliphatic polyester resin powder suitable for selective laser sintering.The crystalline aliphatic polyester resin powder obtained has good antioxidant property, good powder flowability, moderate size, smooth surface, suitable bulk density, and suitable dispersibility and particle size distribution. The aliphatic polyester resin powder is particularly suitable for selective laser sintering method.

Owner:CHINA PETROCHEMICAL CORP +1

A kind of spinach cultivation medium and its preparation method and application

InactiveCN104045379BSuitable for growthIncrease dry and fresh weightClimate change adaptationBioloigcal waste fertilisersOrganic acidNitrite

The invention discloses a spinach culture medium as well as a preparation method and an application thereof. The spinach culture medium comprises vinegar residues and seaweed slags. The spinach culture medium disclosed by the invention has the advantages that by using industrial and agricultural wastes, a soilless culture medium is produced through high-temperature fermentation, thereby turning waste into wealth and turning the harm into benefits. The spinach culture medium has the characteristics of sufficient nutrition, good water absorption and ventilation property, moisture and fertilizer conservation and moderate volume-weight, and pH and EC (Electrical Conductivity) values suitable for growth of spinach, and can be used for effectively improving the dry and fresh weight of the overground part of spinach, remarkably reducing the contents of nitrate and nitrite in blades, improving the contents of soluble proteins and organic acids and improving the quality of spinach.

Owner:NANJING AGRICULTURAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com