A kind of polypropylene powder for selective laser sintering and its preparation method

A technology of laser sintering and polypropylene, which is applied in the field of 3D printing technology and plastic processing, can solve the problems of lack of literature and reports, and achieve the effect of moderate size, simple operation steps and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

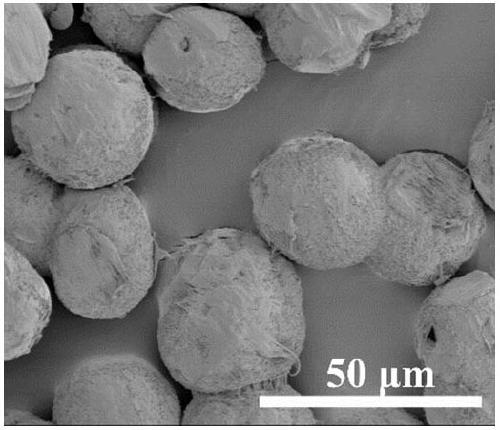

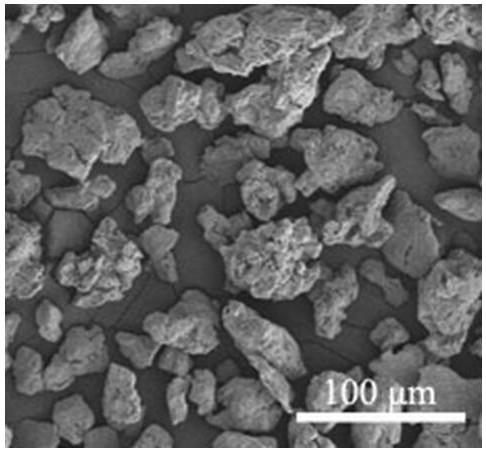

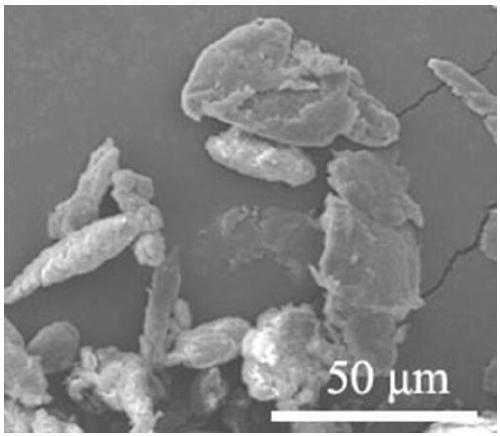

Image

Examples

preparation example Construction

[0030] In the preparation method involved in the present invention, the polypropylene includes a polymer obtained by polymerizing propylene alone or copolymerizing propylene and other olefins, and a blend of the above-mentioned polyolefins.

[0031] In the preparation method involved in the present invention, the polypropylene solvent is a solvent for dissolving polypropylene.

[0032] In the preparation method involved in the present invention, the polypropylene solvent is preferably selected from one or both of toluene, xylene, diphenyl ether, butyl acetate, isoamyl acetate, n-heptane, n-octane, and decahydronaphthalene. A combination of more than one, more preferably one or a combination of two or more selected from xylene, isoamyl acetate, and n-heptane.

[0033] Polypropylene solution refers to the uniform and transparent mixture of polypropylene and polypropylene solvent, and the polypropylene polymer chain is well dispersed in the polypropylene solvent.

[0034] Emulsifi...

Embodiment 1

[0056] The polypropylene powder for selective laser sintering of the present embodiment is made of the following raw materials: 100 grams of polypropylene solvent (xylene), 0.1 to 60 parts of polypropylene (PP1), polar solvent (ethylene glycol) ) 100-400 parts, emulsifier (Tween80) 0.1-4 parts, antioxidant 1010 0.01-0.2 parts, auxiliary agent (silicon dioxide) 0.001-20 parts.

[0057] The preparation method of the polypropylene powder for selective laser sintering of the present embodiment is as follows:

[0058] (1) 15 grams of PP1 and 100 grams of xylene are added to a 500 milliliter flask;

[0059] (2) Stir at a constant temperature of 150°C for 60 minutes, and the stirring rate is 100 rpm, and PP1 is completely dissolved in xylene to form a polypropylene solution;

[0060] (3) Then add Tween80-ethylene triol solution dropwise (Tween80 is 1.5 grams, ethylene glycol is 100 grams), the rate of addition is 30 drops / minute, continue stirring for 10 minutes after the addition i...

Embodiment 2-7

[0074] Embodiment 2-7 adopts the preparation method of polypropylene powder for selective laser sintering provided by the present invention to prepare polypropylene powder, and the following are the basic preparation steps:

[0075] (1) add polypropylene and polypropylene solvent in reaction vessel;

[0076] (2) Heating to 80-180°C under stirring, the polypropylene is completely dissolved in the polypropylene solvent to form a polypropylene solution, and the constant temperature stirring is continued for 10-60 minutes, and the stirring rate is 30-200 rpm;

[0077] (3) Add the solution composed of emulsifier and polar solvent drop by drop under stirring condition, the dropping rate is controlled at 1-60 drops / minute, and continue to stir for 10 minutes after the dropping is completed to form a uniform and transparent solution;

[0078] (4) The solution is cooled to room temperature, and an insoluble precipitate is formed in the solution to obtain a solid-liquid mixture;

[007...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com