Patents

Literature

128results about How to "Good fluidity of powder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

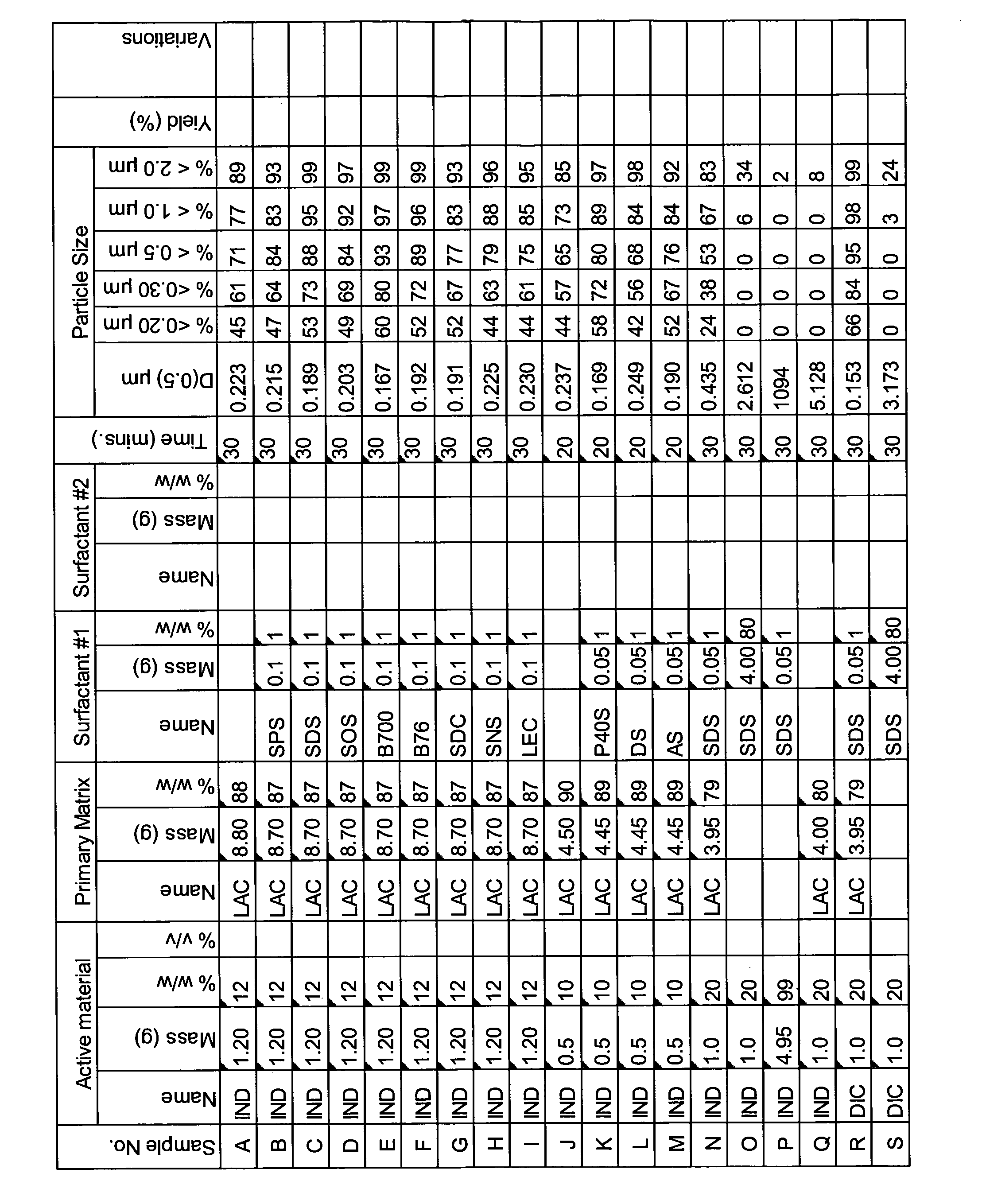

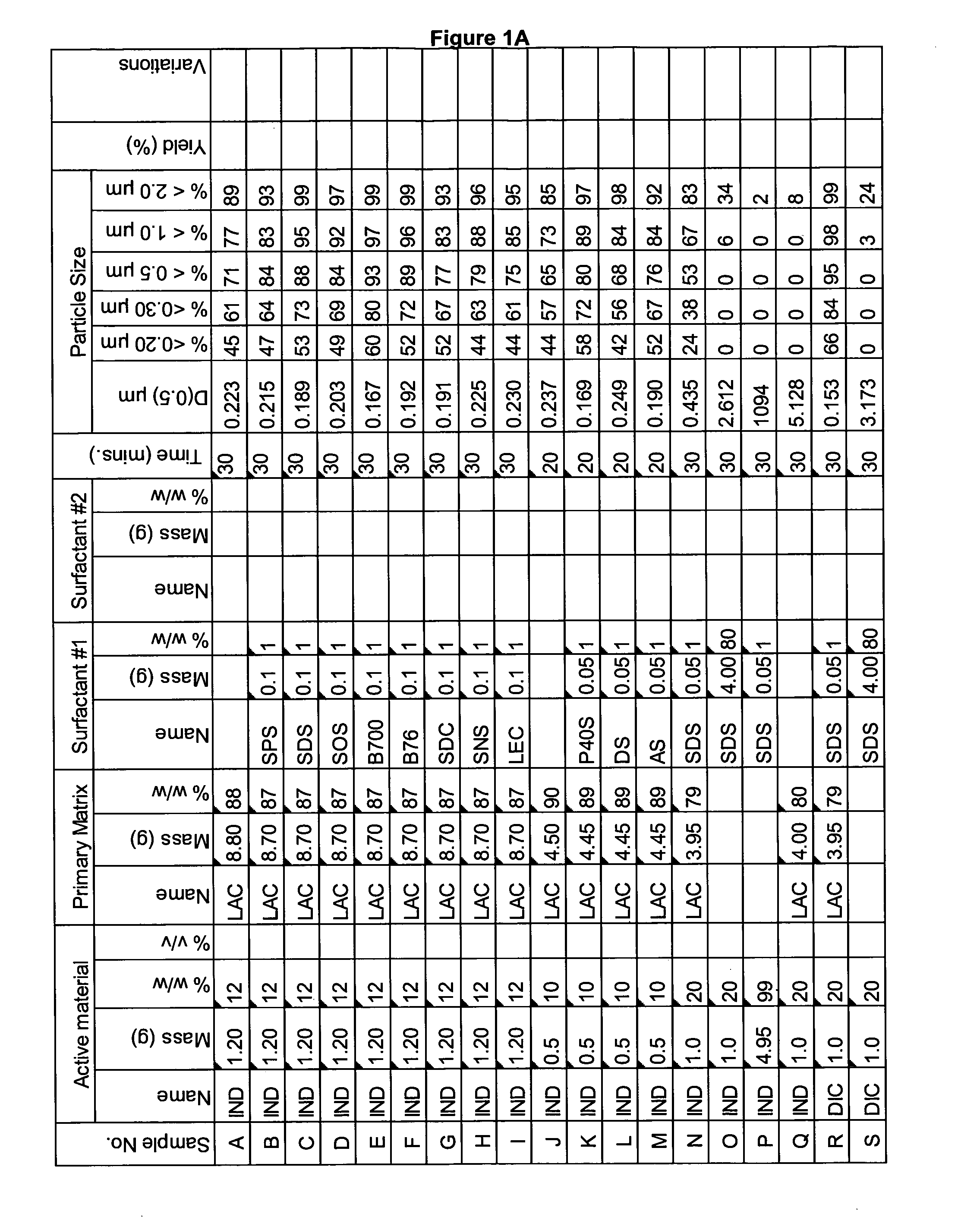

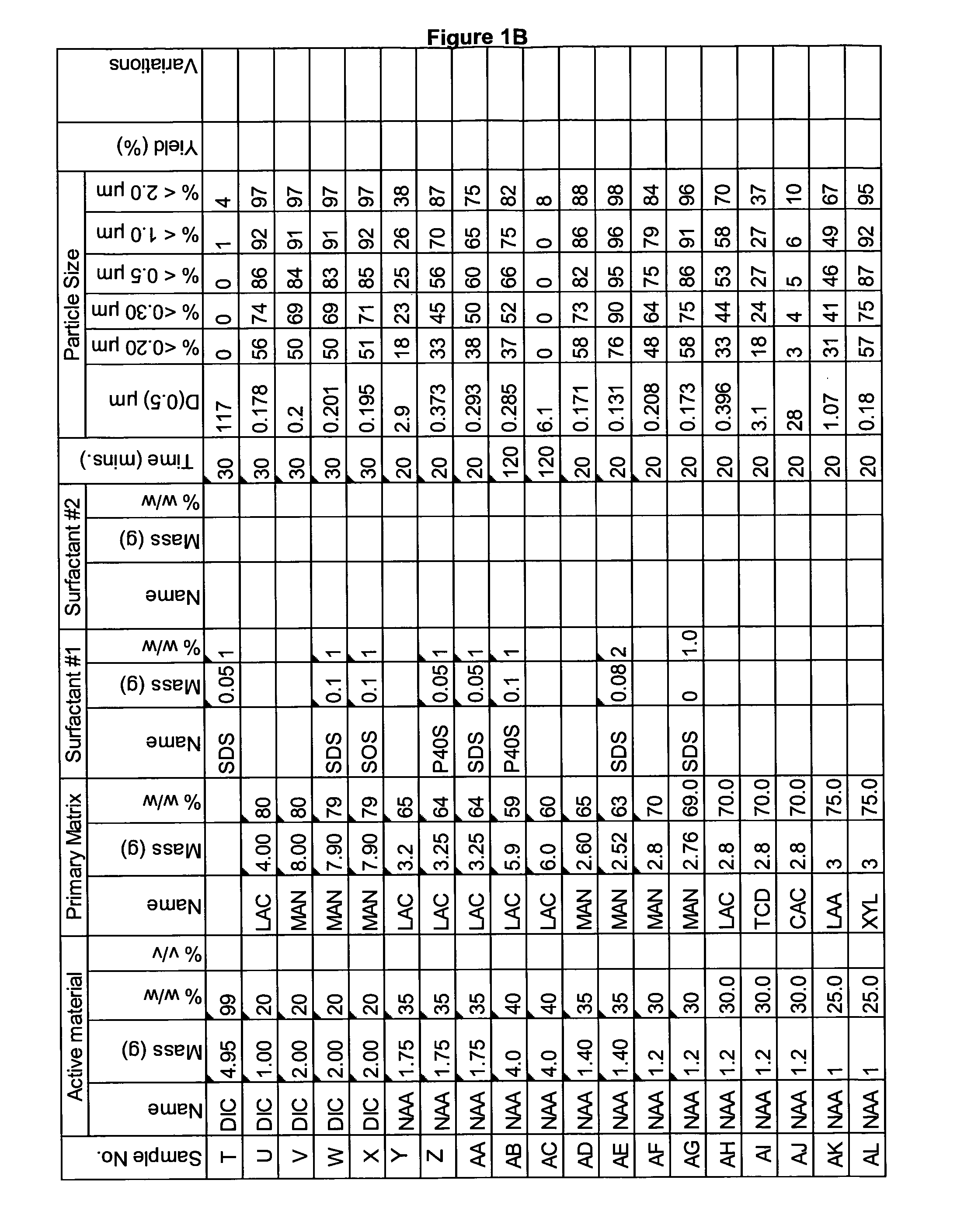

Method for the production of commercial nanoparticle and micro particle powders

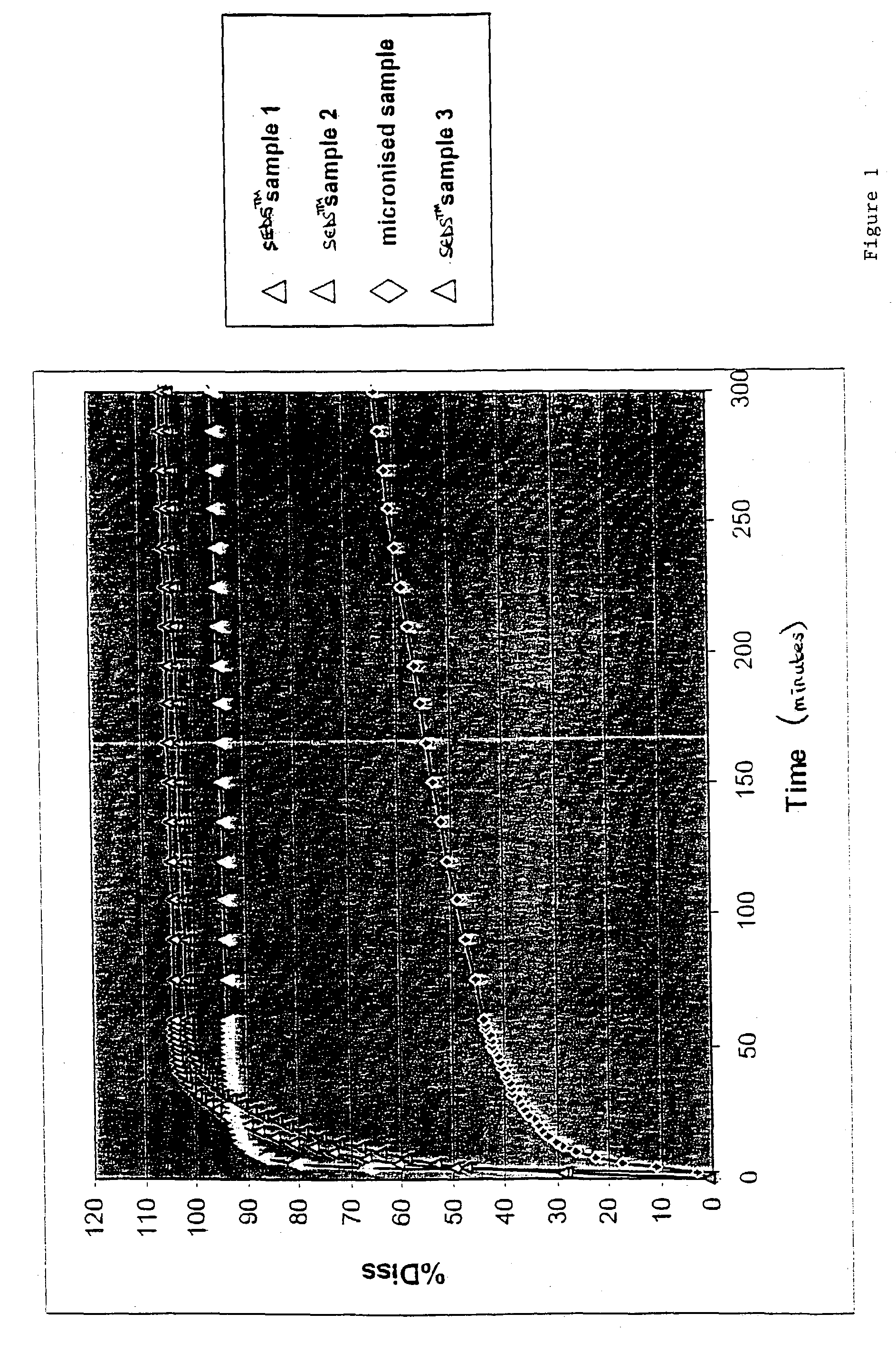

InactiveUS20120160944A1Lower static chargeCohesiveness profileBiocidePowder deliveryParticulatesNanoparticle

The present invention relates to methods for producing nanoparticle and microparticle powders of a biologically active material which have improved powder handling properties making the powders suitable for commercial use using dry milling processes as well as compositions comprising such materials, medicaments produced using said biologically active materials in particulate form and / or compositions, and to methods of treatment of an animal, including man, using a therapeutically effective amount of said biologically active materials administered by way of said medicaments.

Owner:ICEUTICA PTY LTD

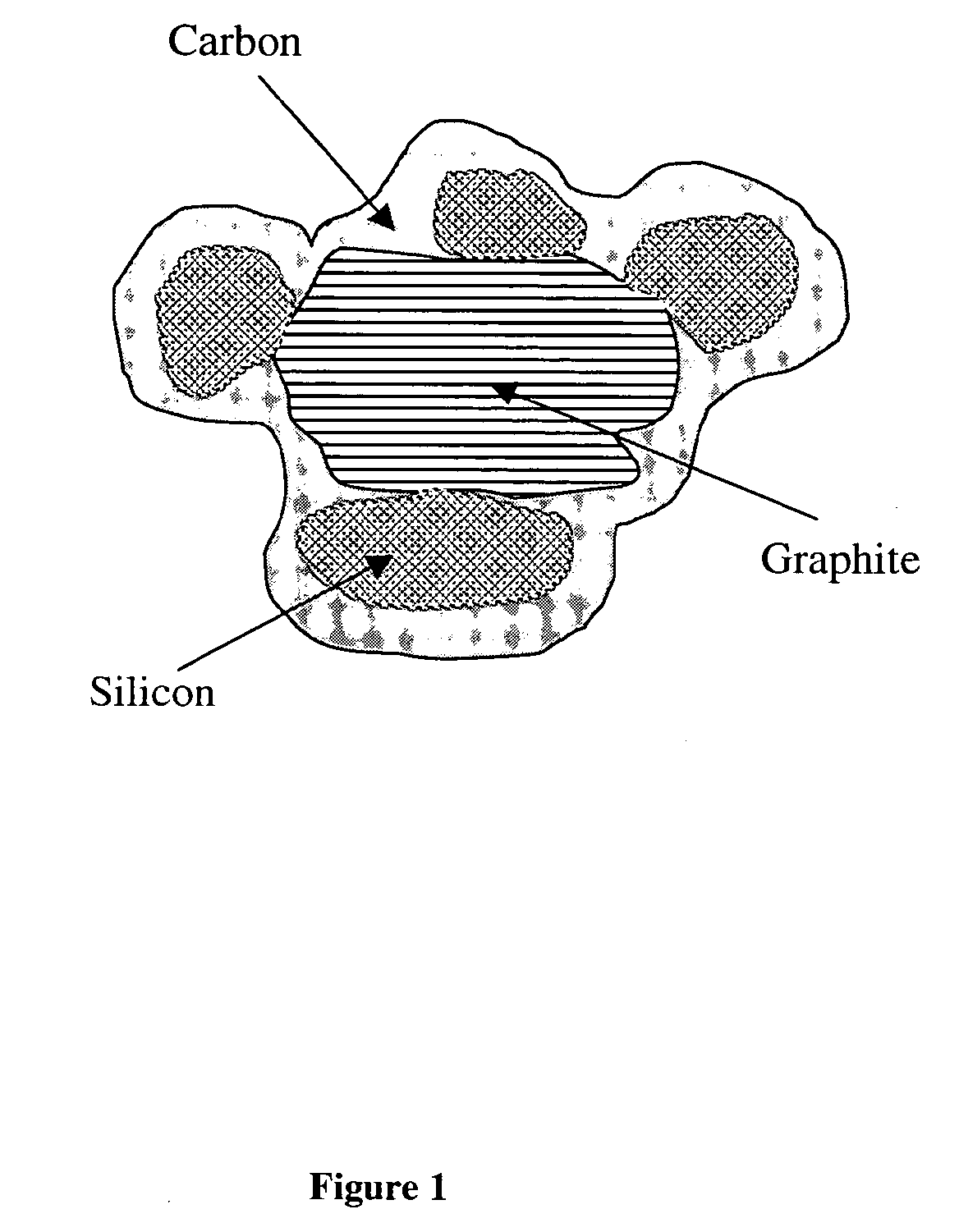

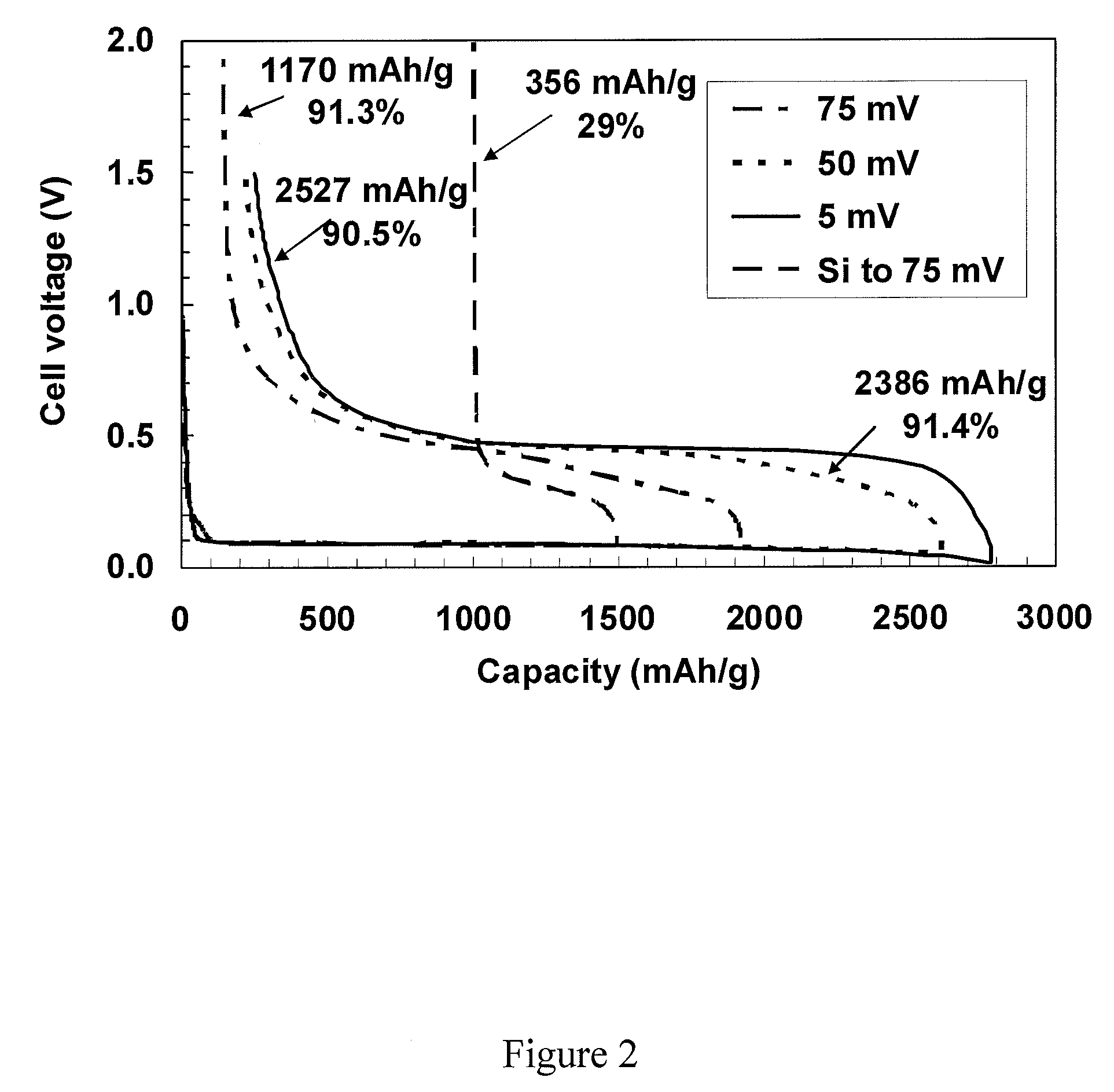

Carbon-Coated Silicon Particle Powder as the Anode Material for Lithium Ion Batteries and Method of Making the Same

InactiveUS20090130562A1Large capacityImprove efficiencyLiquid surface applicatorsElectrode thermal treatmentCarbon compositesSilicon particle

Owner:CONOCOPHILLIPS CO

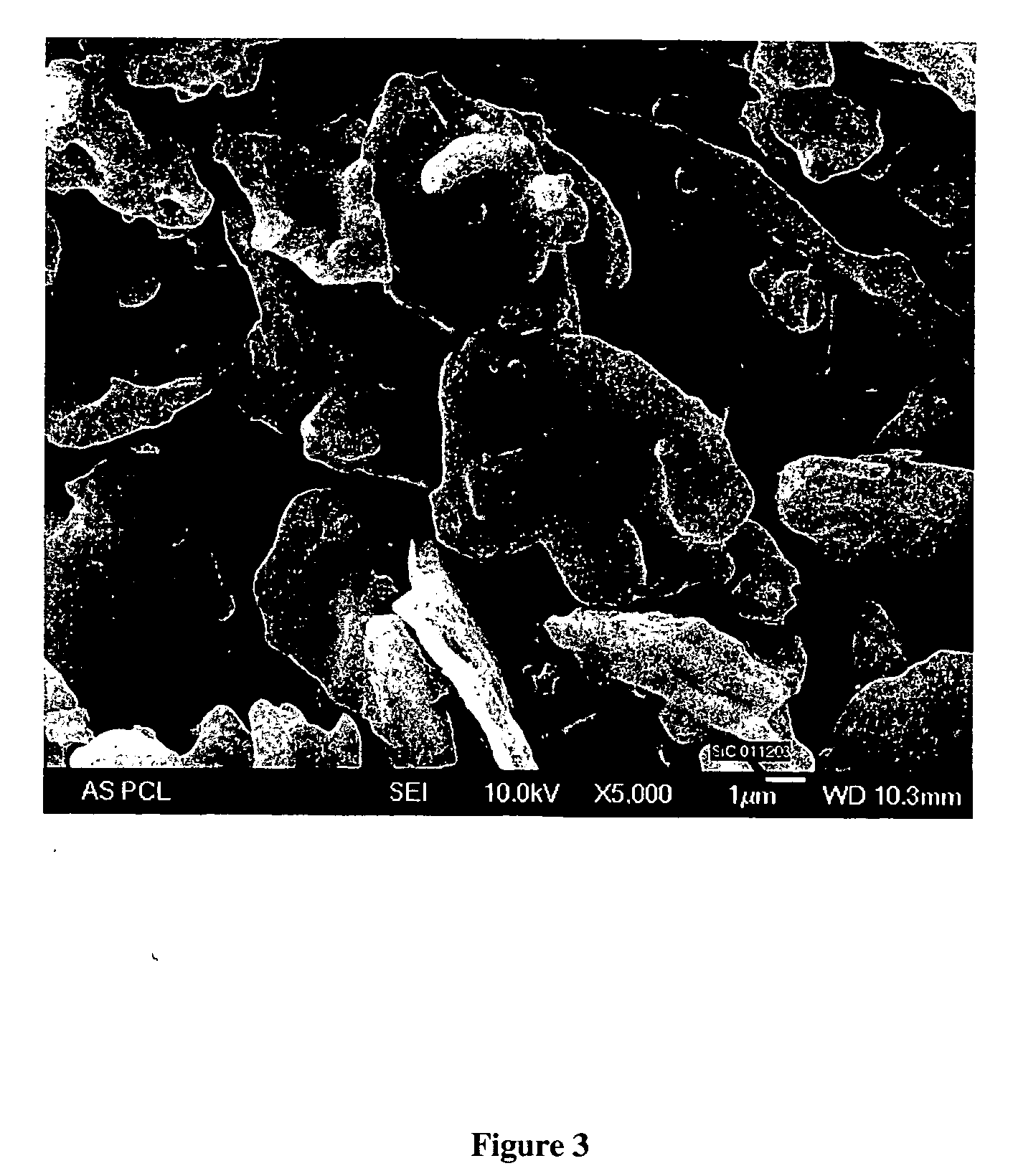

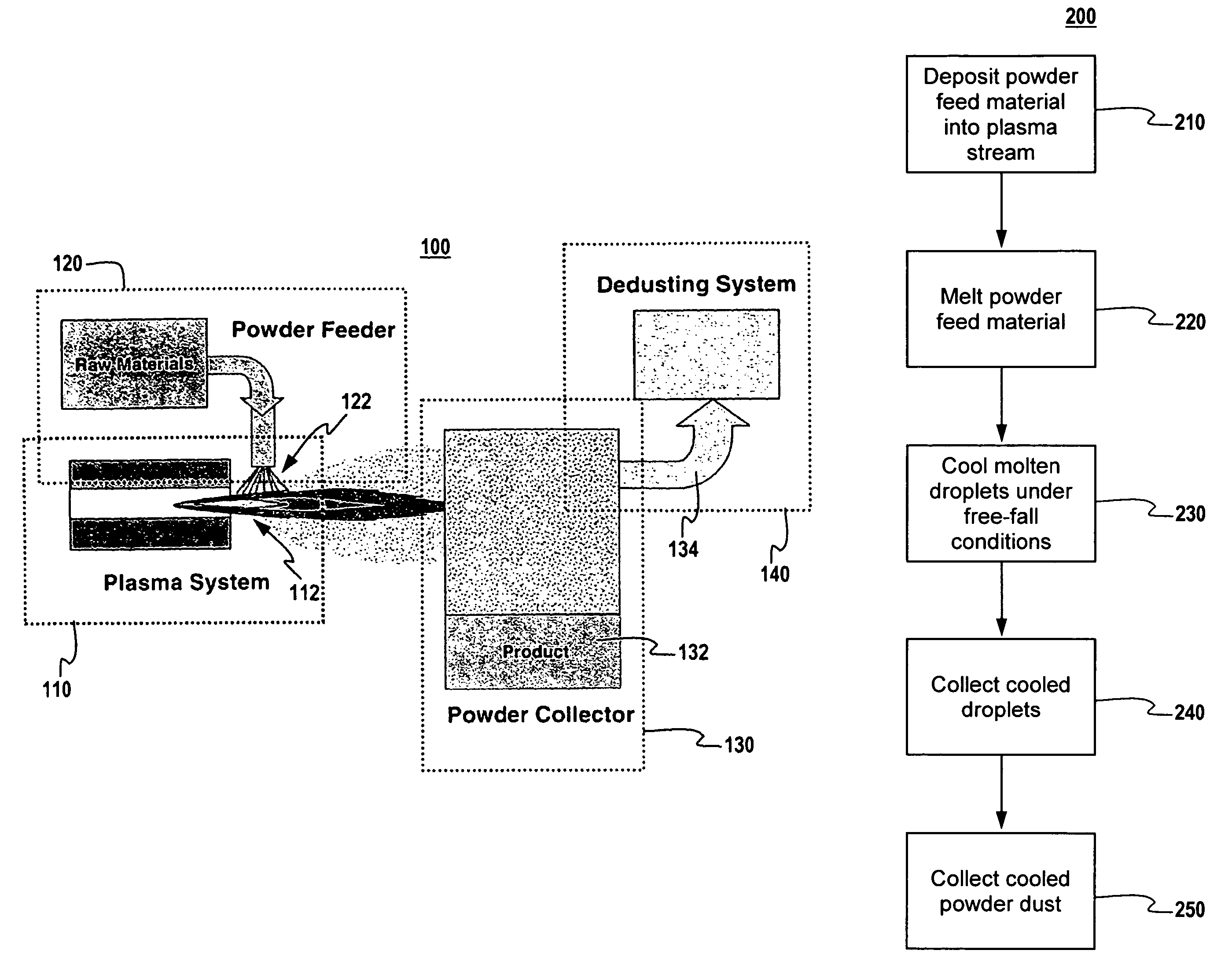

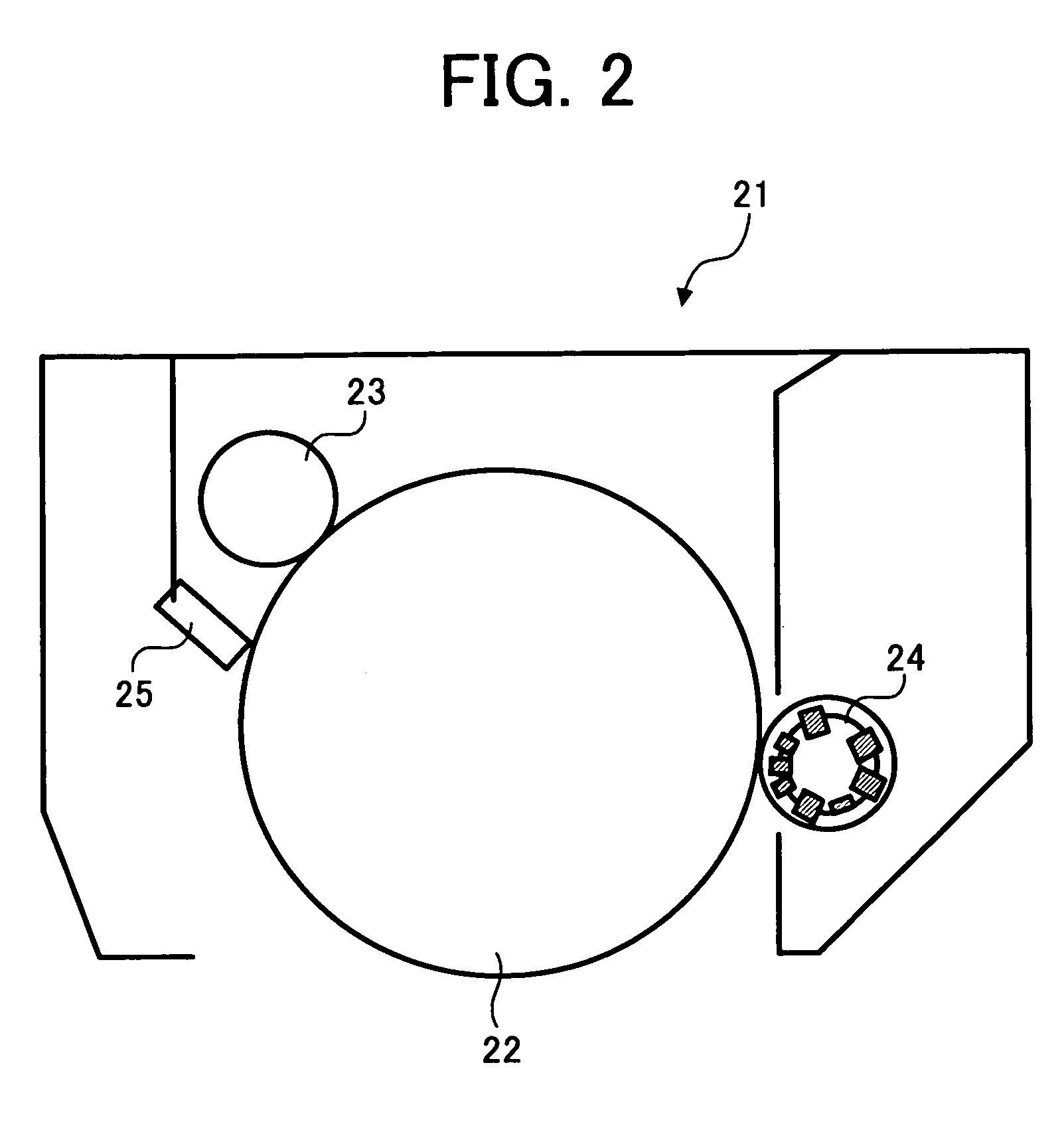

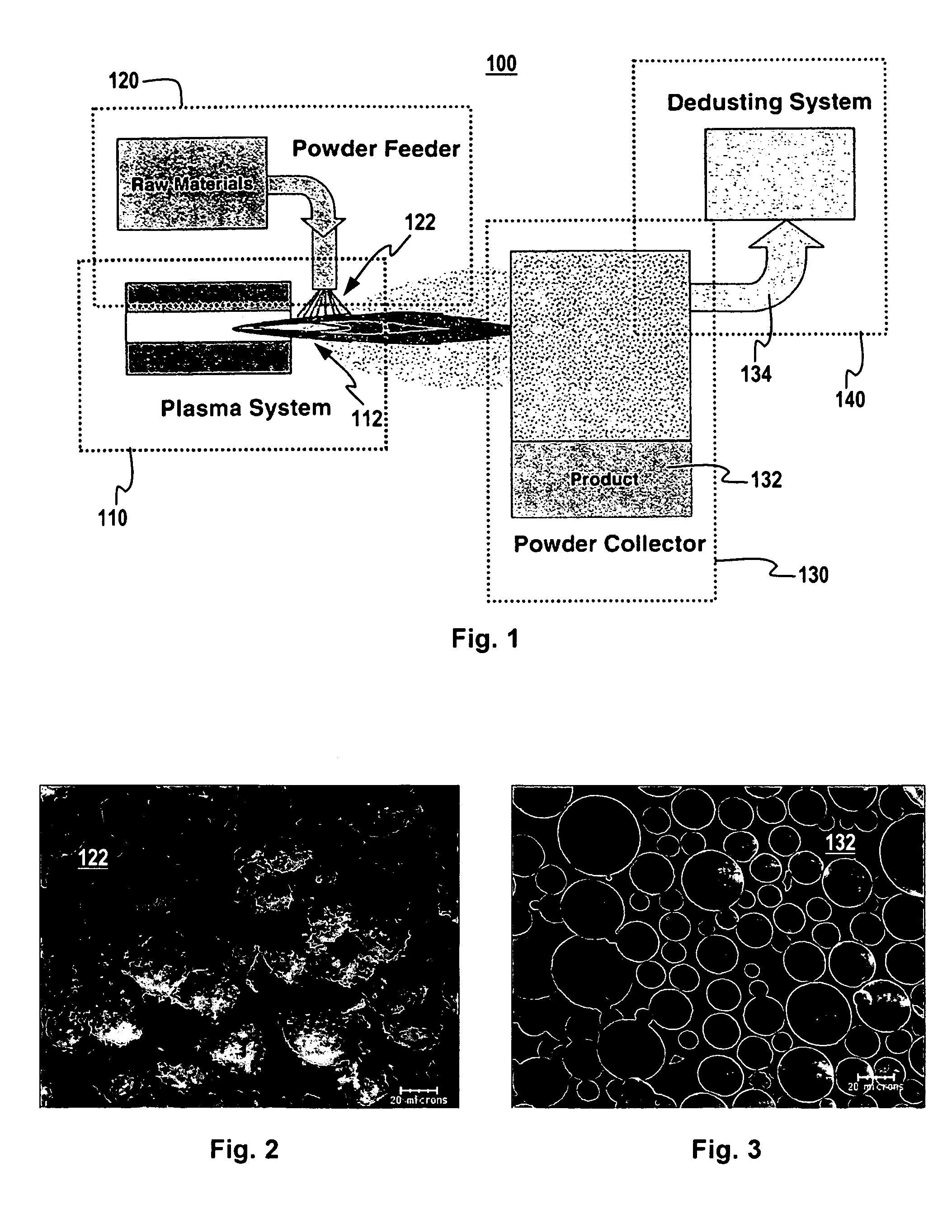

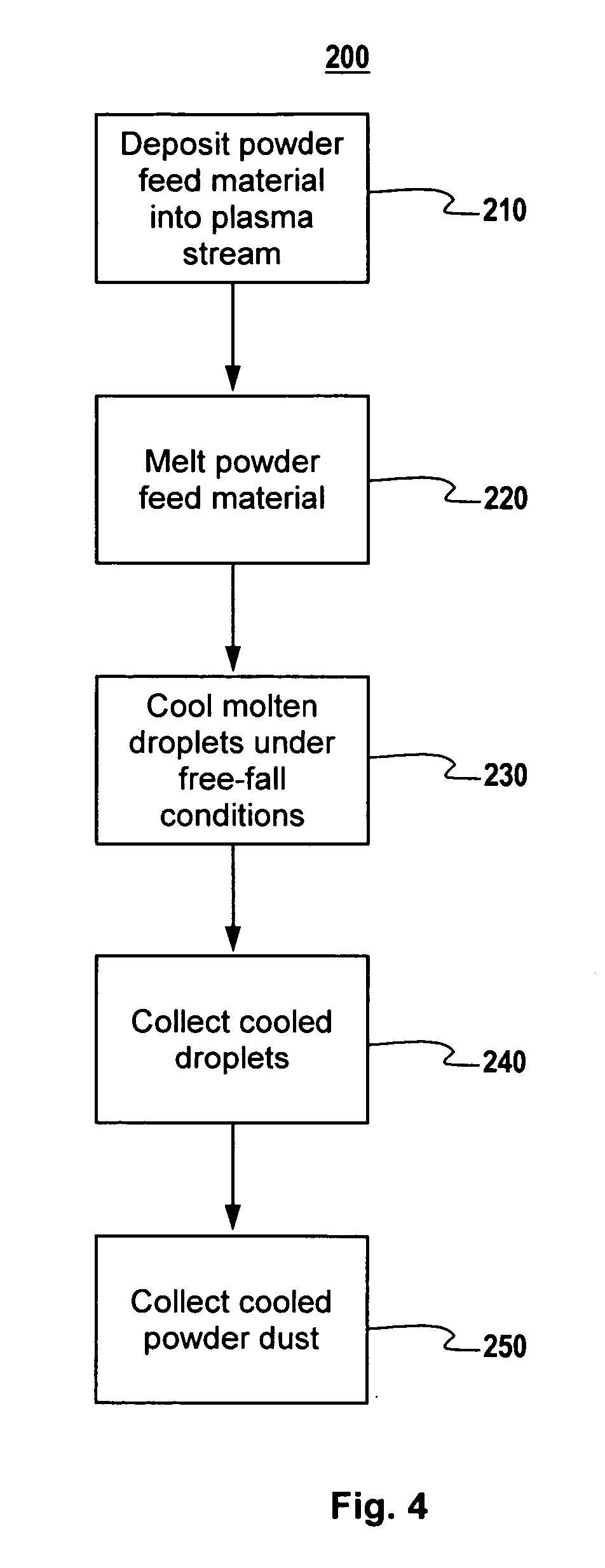

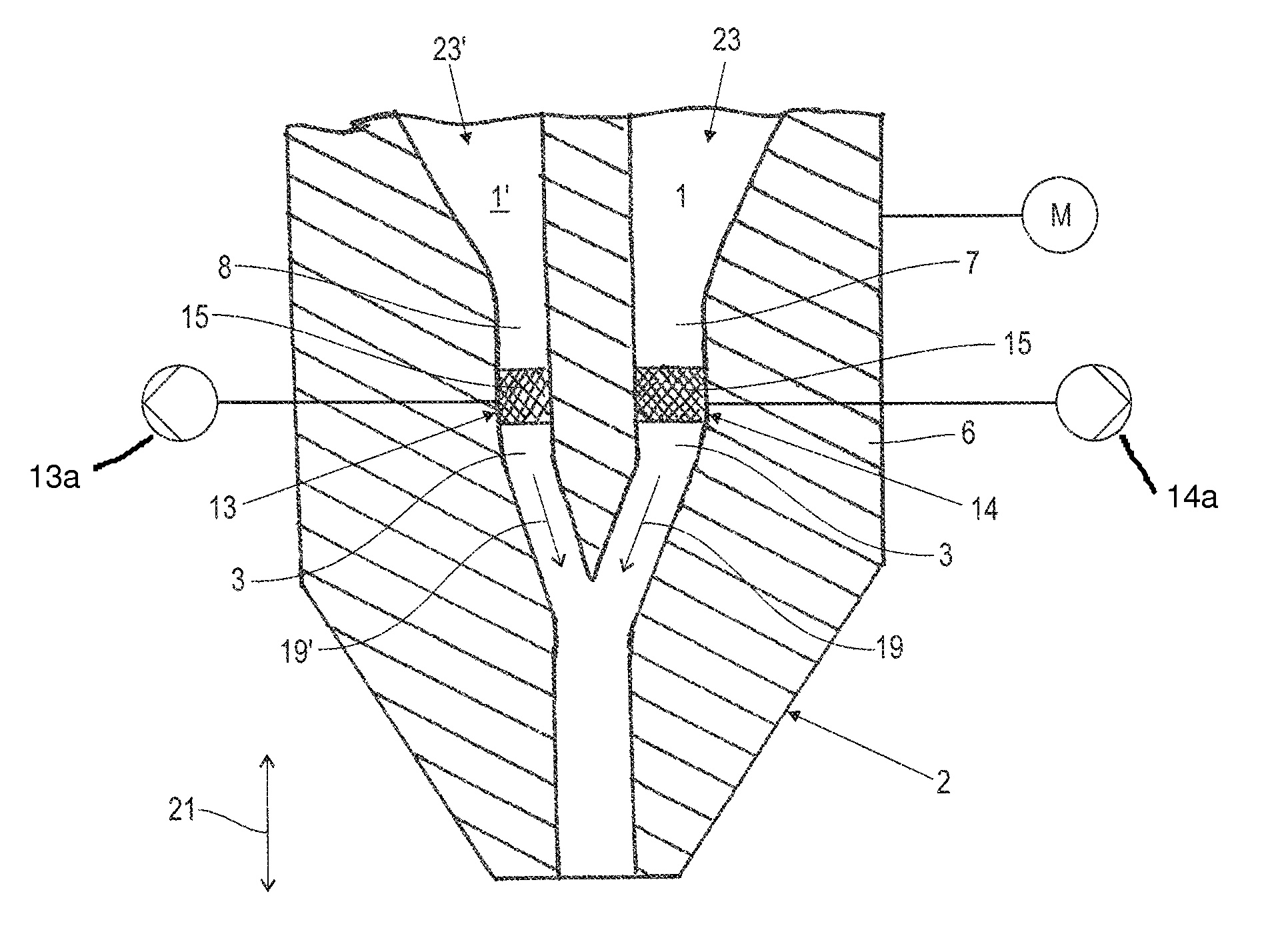

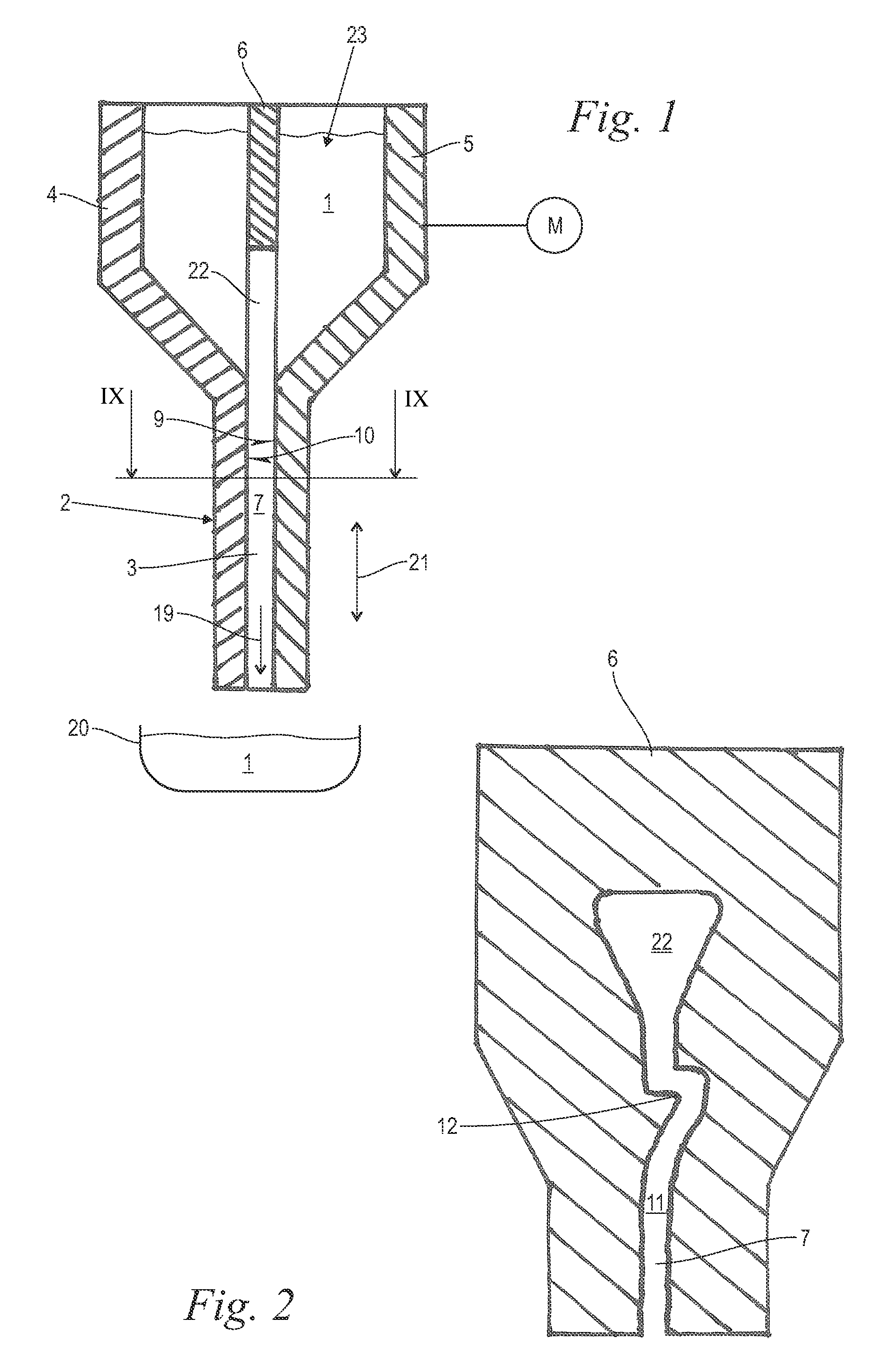

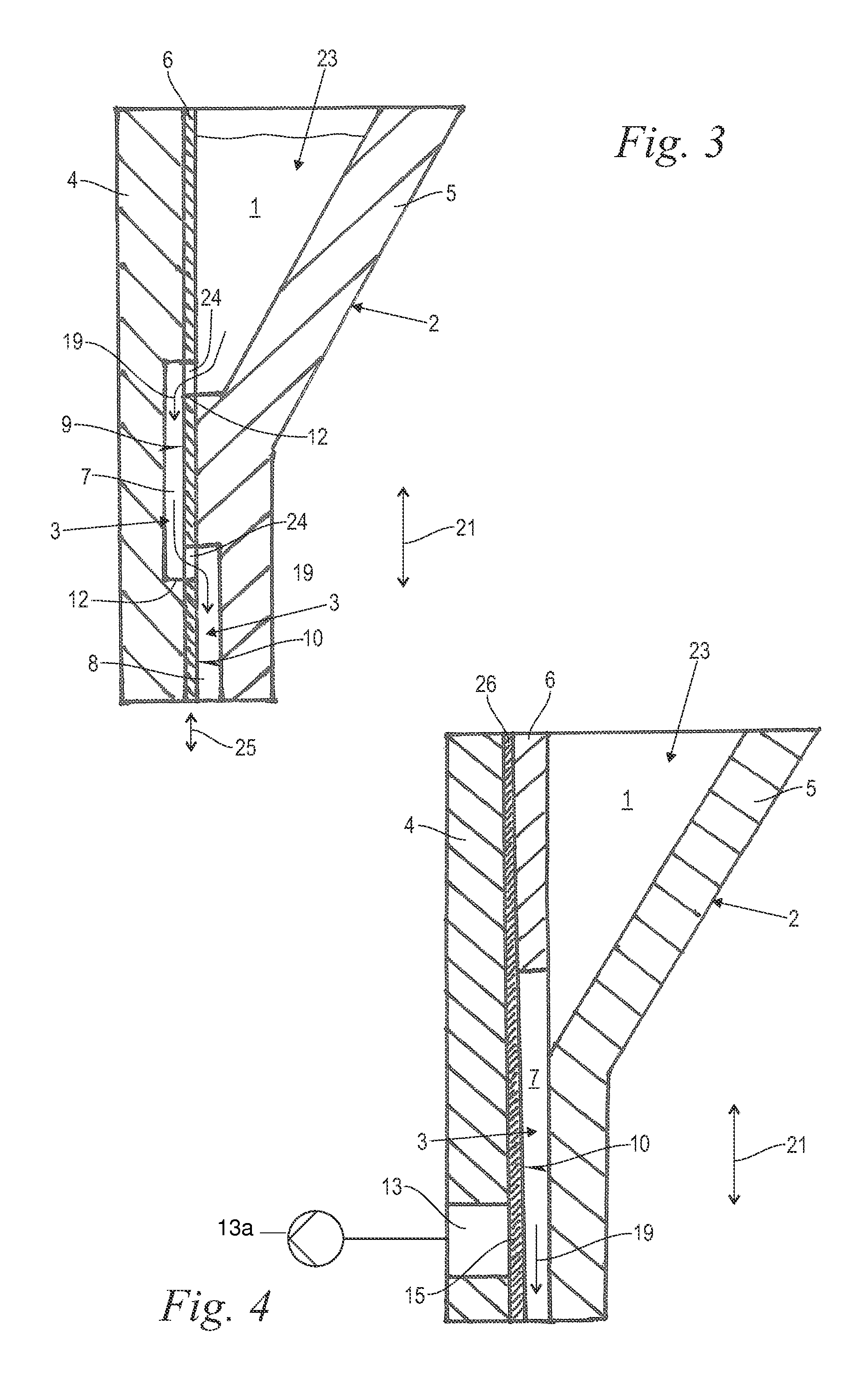

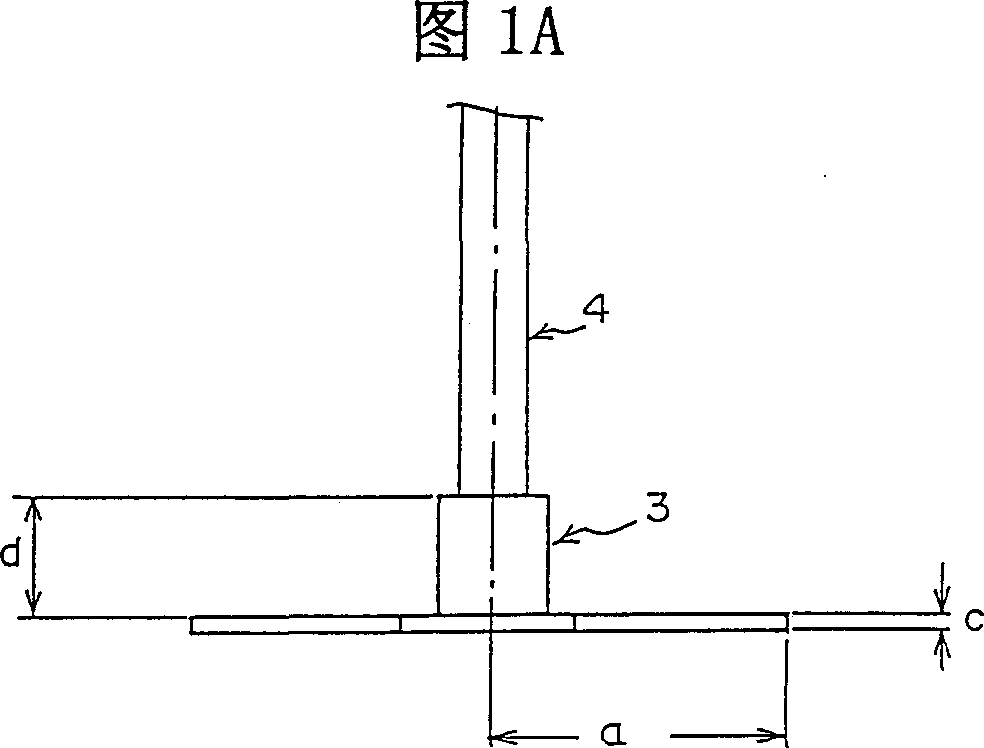

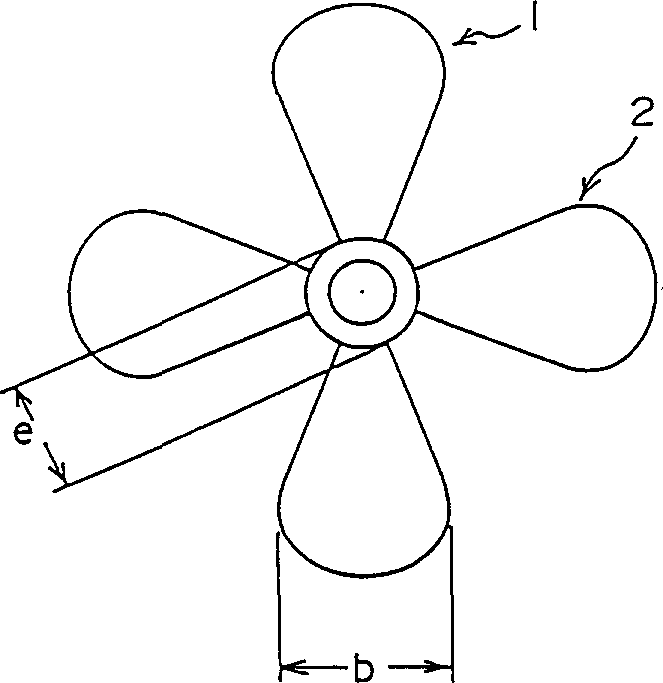

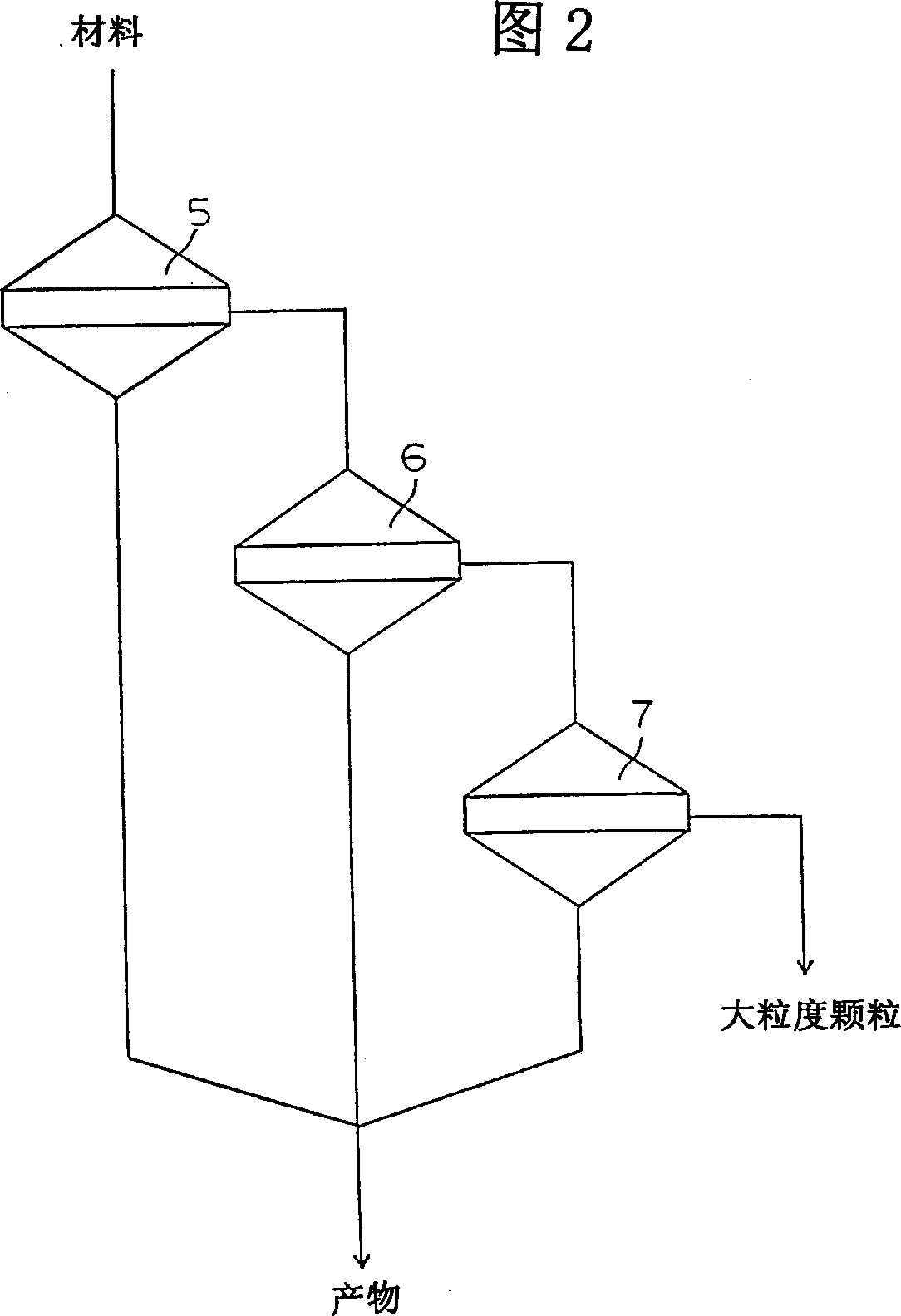

Method for making high purity and free flowing metal oxides powder

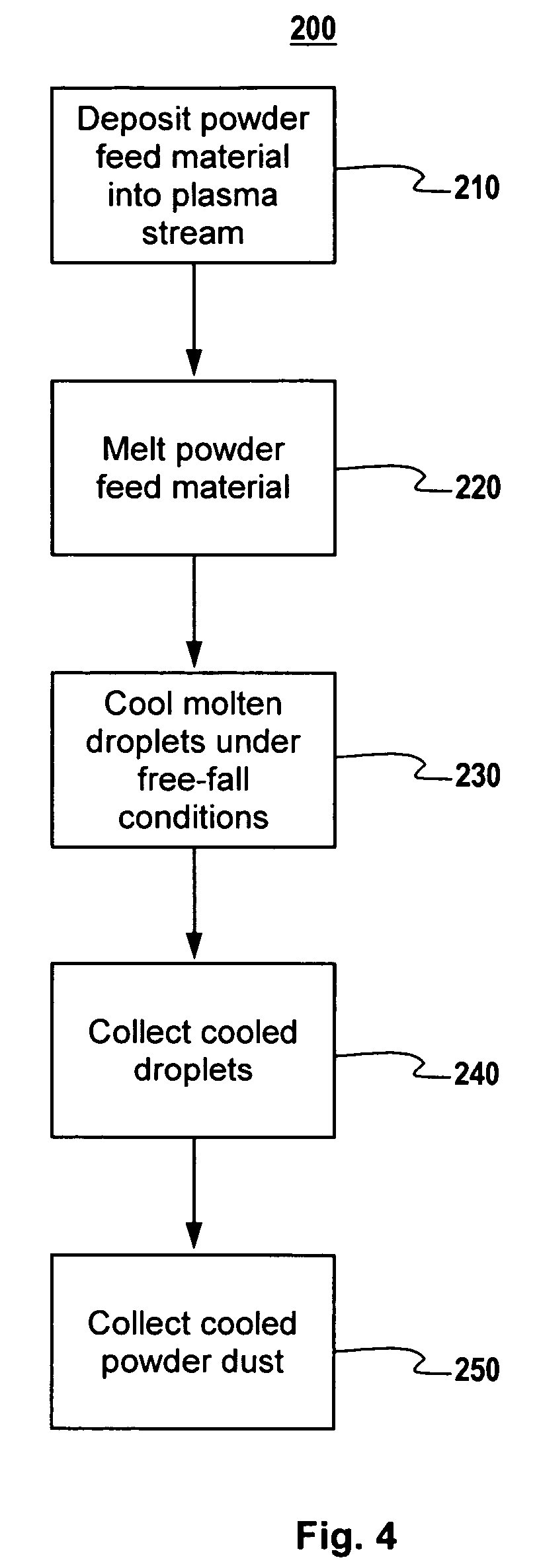

InactiveUS7931836B2Improve physical and chemical propertyImprove purification effectBurnersOxide/hydroxide preparationApparent densityFree falling

According to aspects of the present invention, metal oxide powder, such as yttria and alumina powder (feed material), is processed using a plasma apparatus. The process generally consists of in-flight heating and melting of the feed material by the plasma apparatus. The plasma apparatus contains a plasma torch with required power supply and cooling systems, a powder feeder, a chamber to collect the powder and a dedusting system. The heated powder forms molten spherical droplets that are rapidly cooled under free fall conditions. The plasma densification process removes some impurity oxides, modifies the morphology of the particle and increases the apparent density of the powder.

Owner:SULZER METCO (US) INC

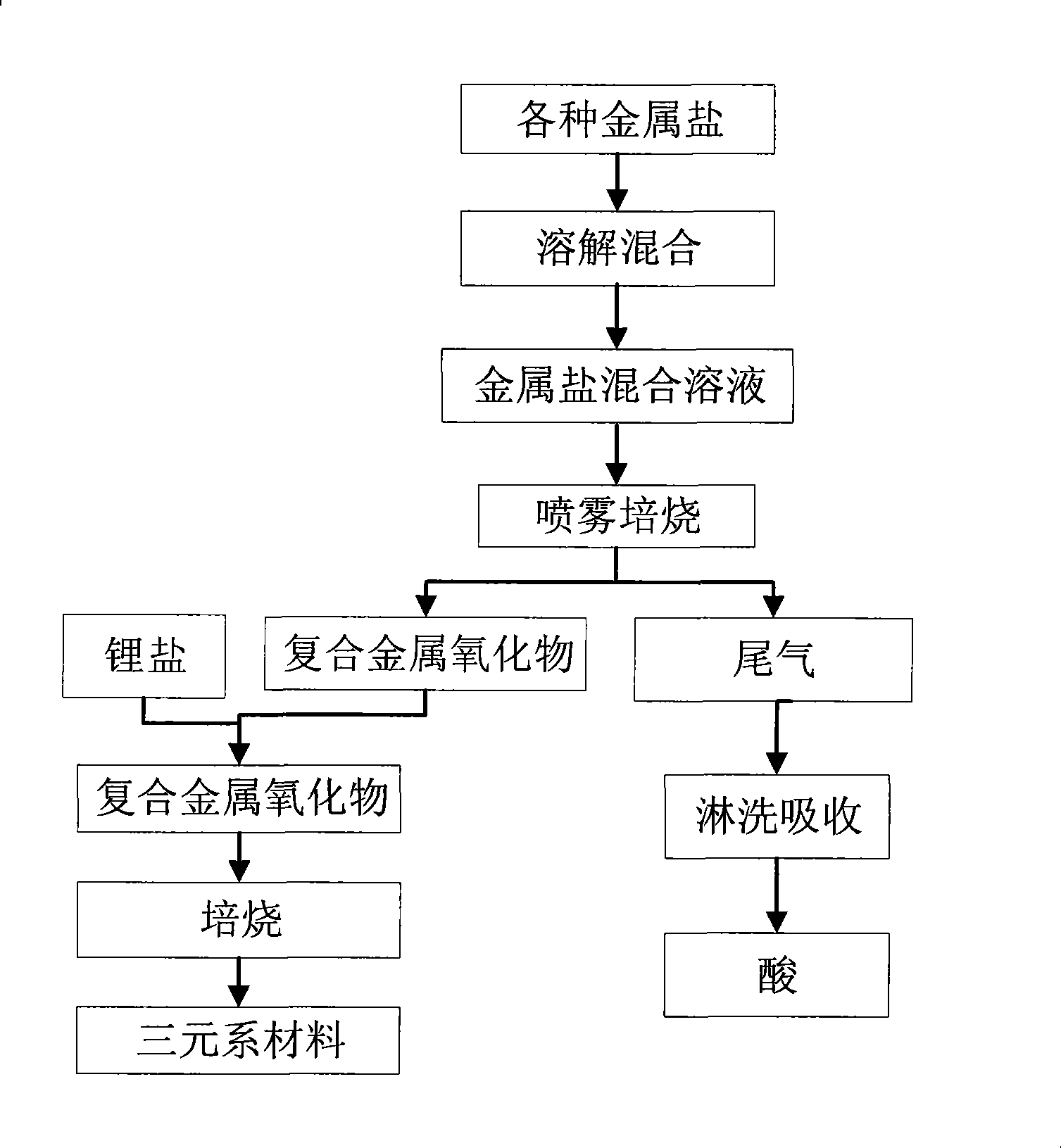

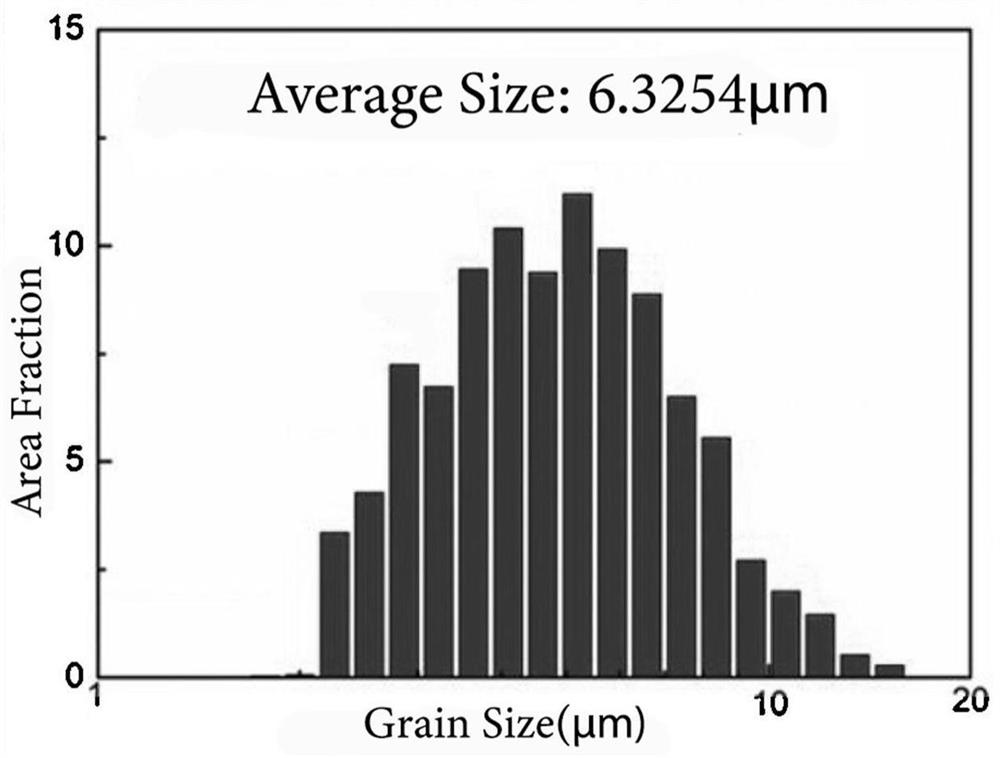

Novel method for preparing lithium ion battery anode ternary material LiCoxNiyMn2O2

InactiveCN101369651AGood fluidity of powderUniform particle sizeElectrode manufacturing processesCrystallinityManganese oxide

The invention relates to a preparation method of ternary system material, in particular to a preparation method of lithium cobalt nickel manganese oxide ternary system material for lithium ion batteries. The invention applies ensured ternary system material salt as raw material. After needed matching weight, by means of eve dissolving and mixing, a composite metal oxide prepared by a spray-roasting method is used as a fore body. The fore body is mixed with a lithium-source compound according to the substance amount of 1:1-1.5, and then roasting is carried out at the temperature of 700 to 1000 degrees centigrade to obtain the ternary system material. The tail gases, such as vapor, acidic gas, generated in the spray-roasting process are absorbed by a washing tower to obtain acid. The invention has the advantages of advanced technique, stable production, low cost, no waste water discharge, environmental protection, high product purity, even granularity, high crystallinity, etc.

Owner:ZHEJIANG HUAYOU COBALT

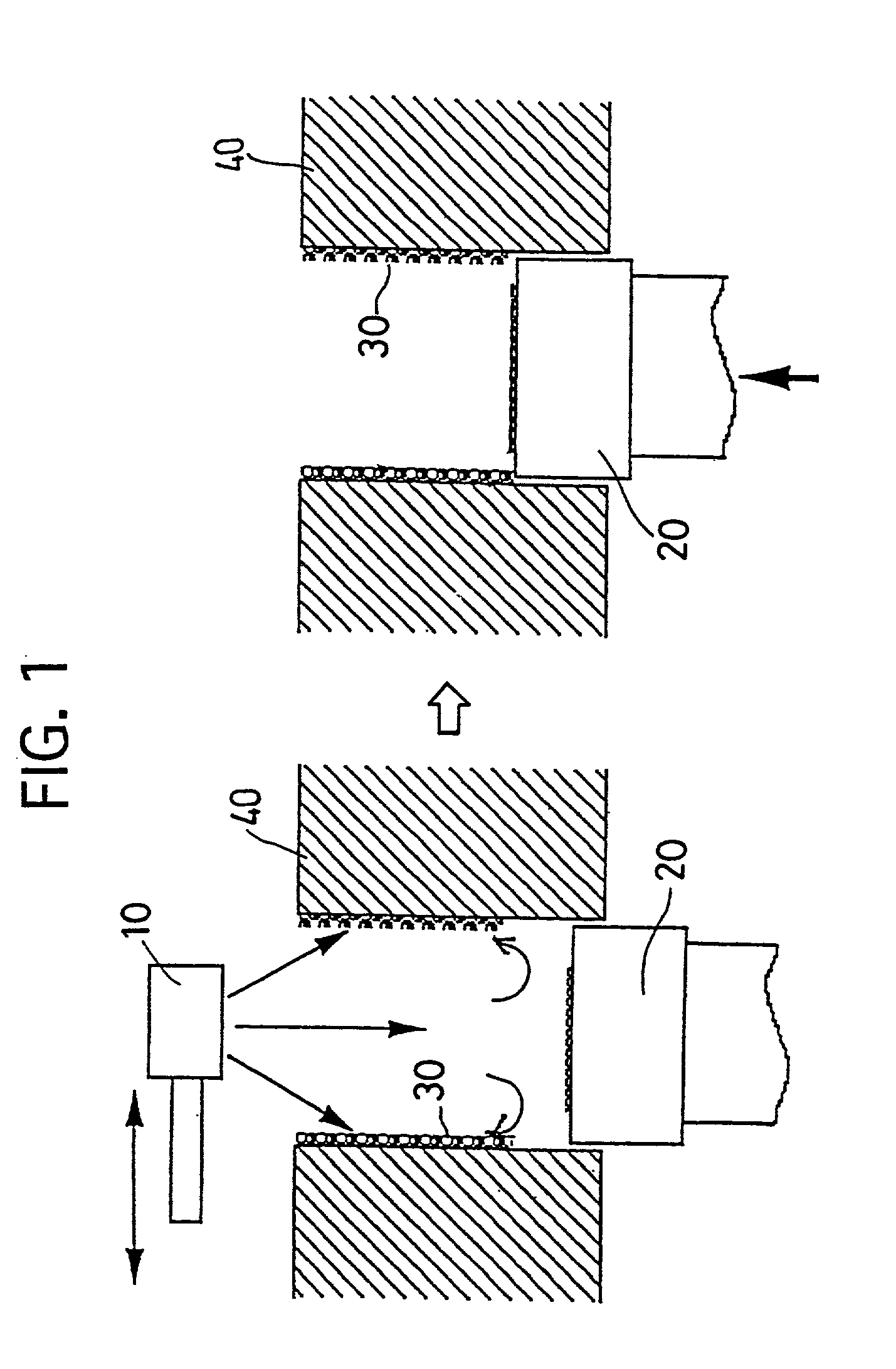

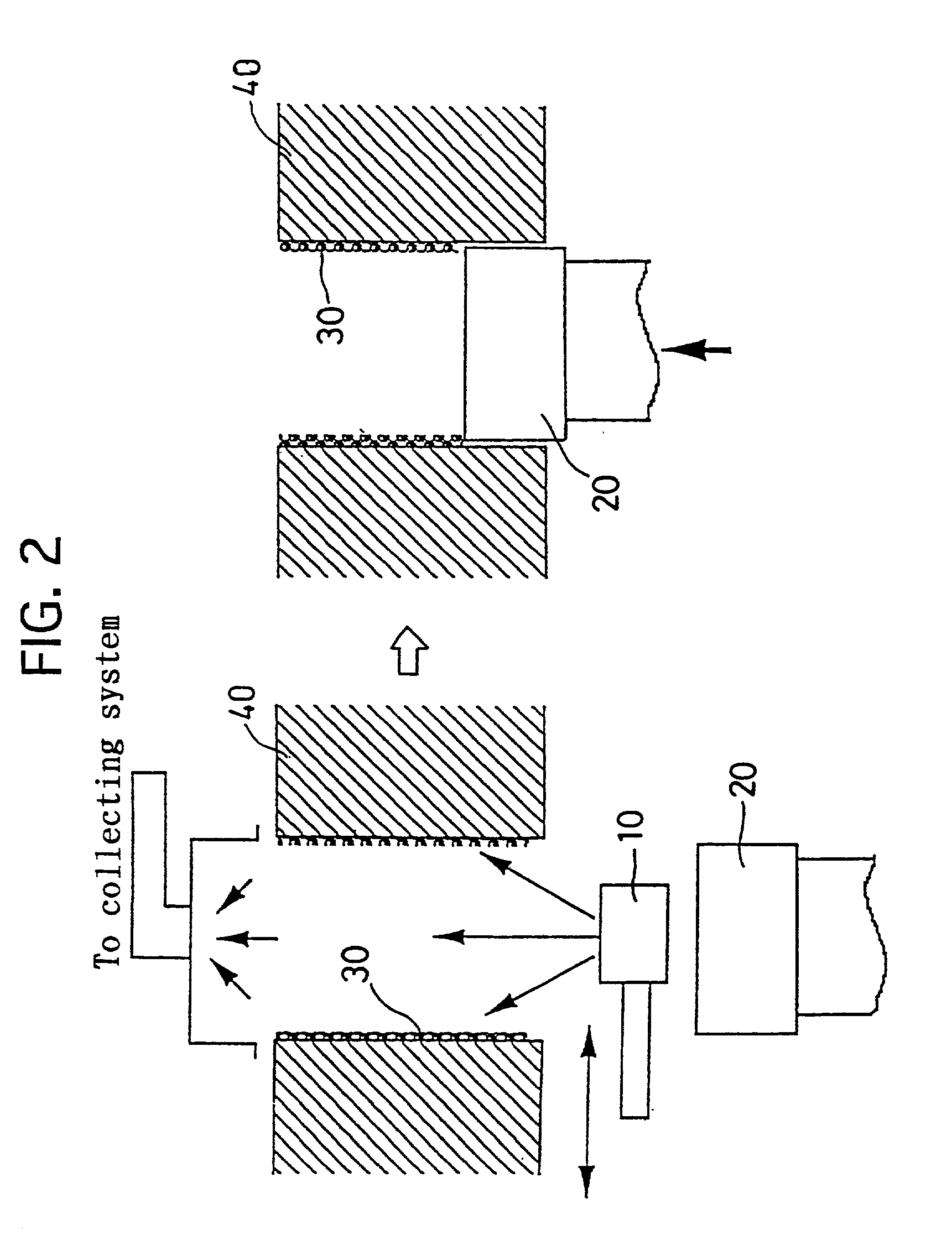

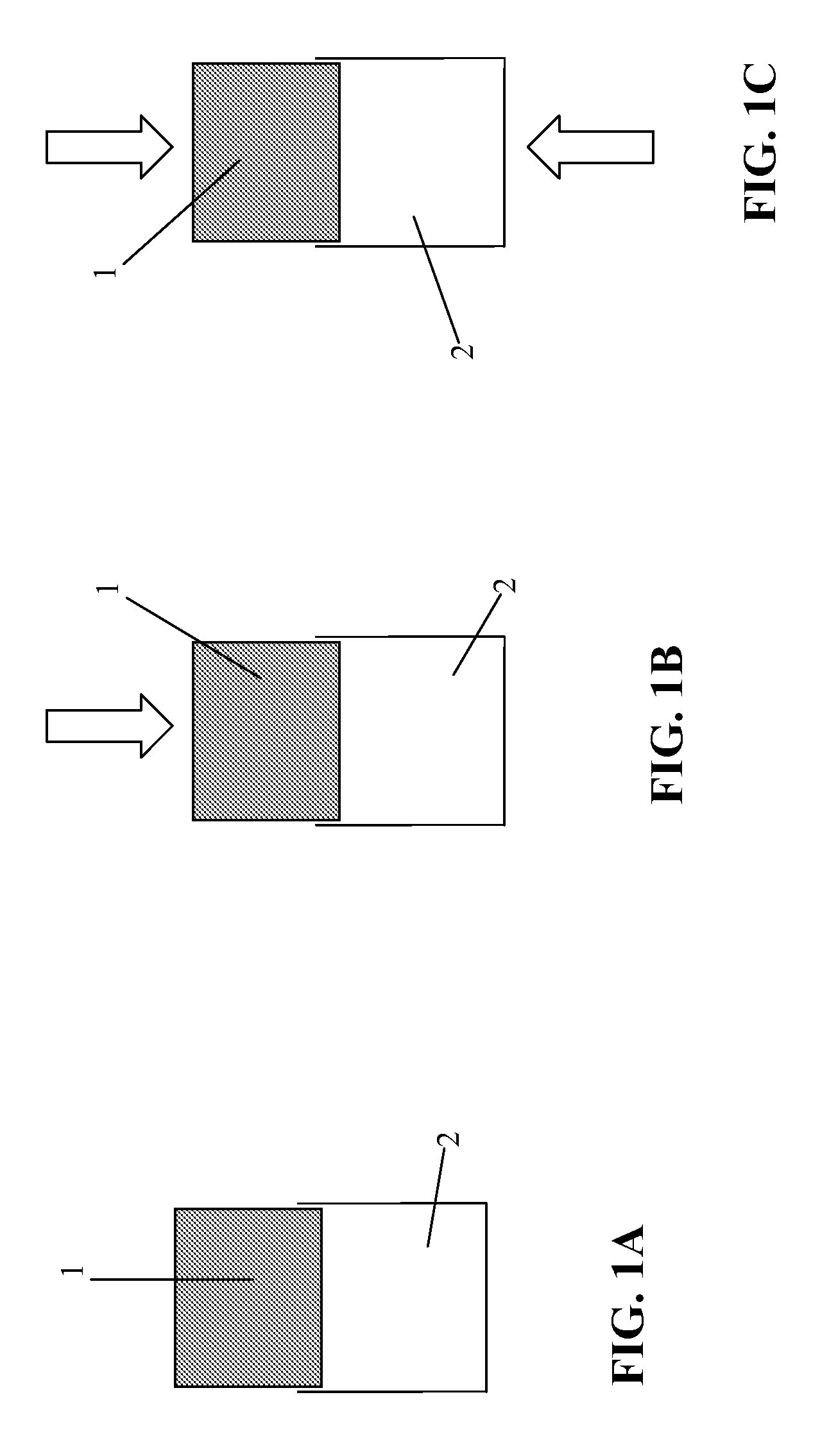

Method of forming a powder compact

This invention provides a method of forming a powder compact which can produce a high density compact under a high pressure and at the same time can reduce pressure for ejecting the compact from a die. This method comprises the application step of applying a higher fatty acid lubricant to an inner surface of a heated die, and the compaction step of filling metal powder into the die and compacting the metal powder under such a pressure as to force the higher fatty acid lubricant to be chemically bonded with the metal powder and form a metallic soap coating. Since the metallic soap coating is formed between the die and a compact, friction force between the die and the compact is decreased and ejecting pressure can be remarkably decreased despite of compaction with high pressure. Besides, a high density compact can be obtained owing to the compaction with high pressure.

Owner:TOYOTA CENT RES & DEV LAB INC +1

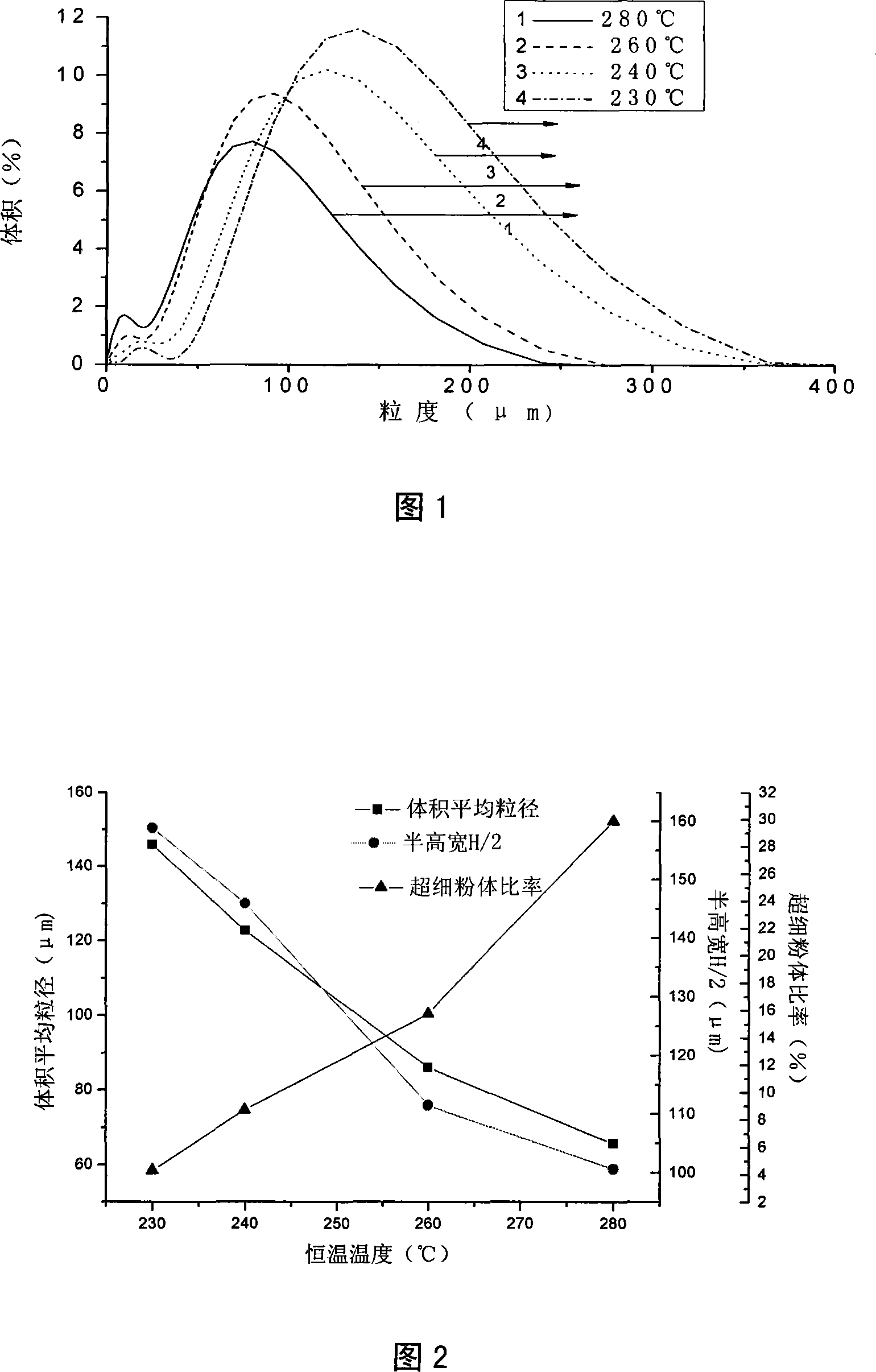

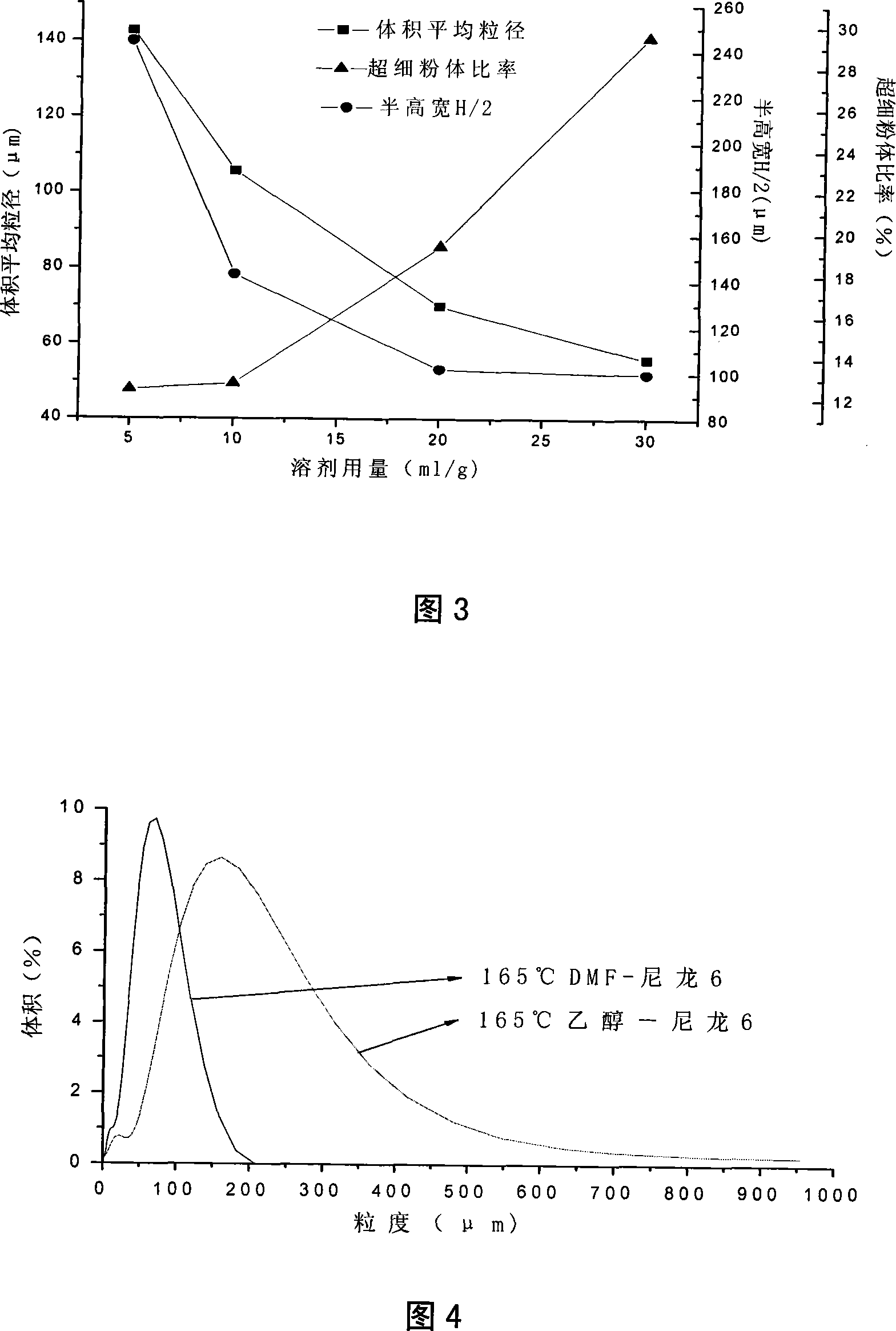

Method for preparing nylon powder by employing DMF

The present invention discloses a preparation method of nylon powder by making use of DMF. The method is that nylon resin is dissolved in the N-dimethylformamide (DMF) solvent, so as to prepare the nylon powder by high temperature, pressure keeping, cooling and drying, the high temperature is controlled at 145DEG C to 290DEG C, the pressure is 0.7 to 1.5MPa; the preparation method of the nylon powder which is provided by the present invention has simple equipment, the preparation process is easy to be operated, the purchase of the solvent is convenient, and the solvent can be recovered and utilized, the particle size of the obtained nylon powder product can be modulated, the granule is spherical approximately, the powder liquidity is good, and the specific surface area is large. The obtained various nylon powders according to the present invention can be used as the nucleating agents of polymer, coating powder of electrostatic spraying technology, powder for magnetic materials and so on.

Owner:ZHENGZHOU UNIV

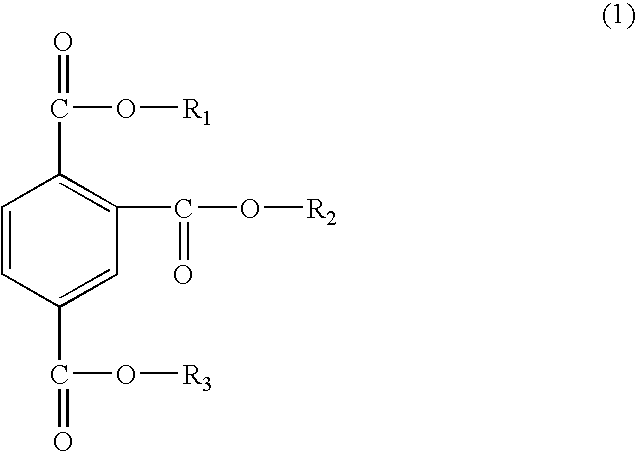

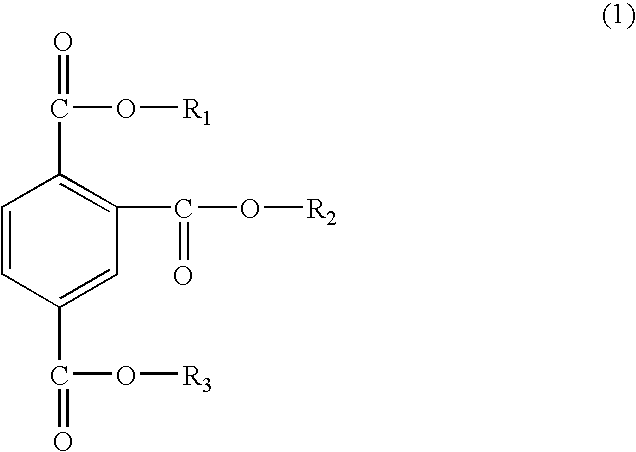

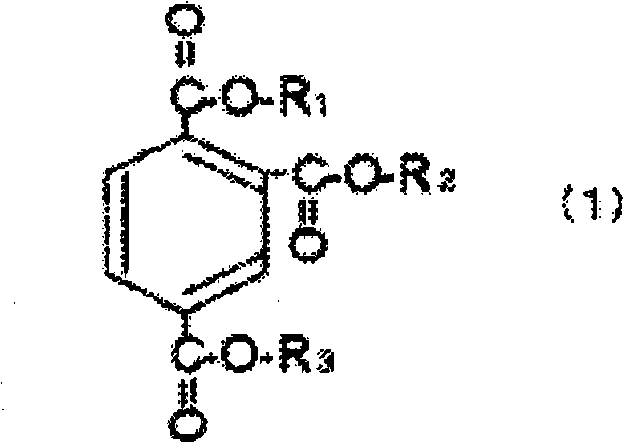

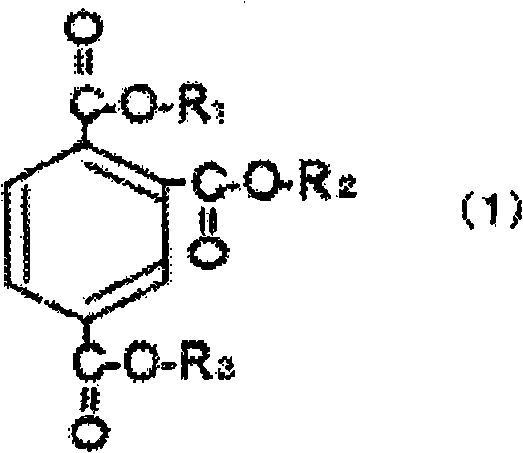

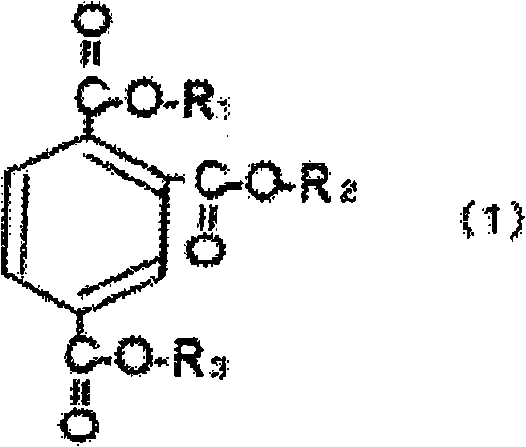

Vinyl chloride resin composition for powder molding, molded object obtained therefrom, laminate, vehicle interior material, and method for producing vinyl chloride resin composition for powder molding

InactiveUS20100272984A1Good fluidity of powderImprove heat aging resistanceSynthetic resin layered productsThin material handlingPlasticizerVinyl chloride

A vinyl chloride resin composition for powder molding of the present invention includes: 100 parts by mass of vinyl chloride resin particles made of vinyl chloride resin whose average degree of polymerization is 1500 or more, the vinyl chloride resin particles having an average particle size ranging from 50 to 500 μm; and 110 to 150 parts by mass of a particular trimellitate plasticizer. The vinyl chloride resin composition has excellent powder flowability and results in a molded object having excellent heat aging resistance and low-temperature resistance.

Owner:ZEON CORP

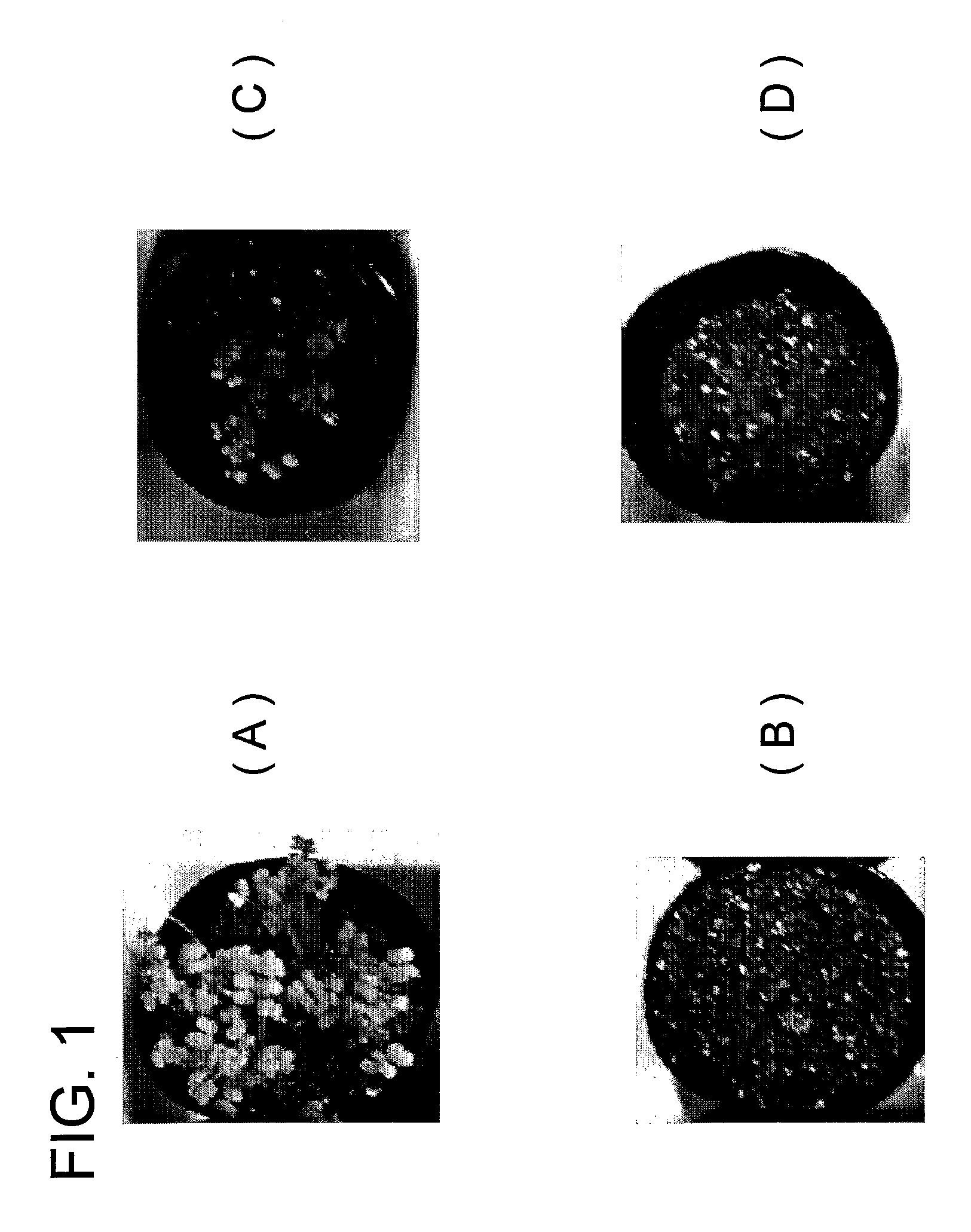

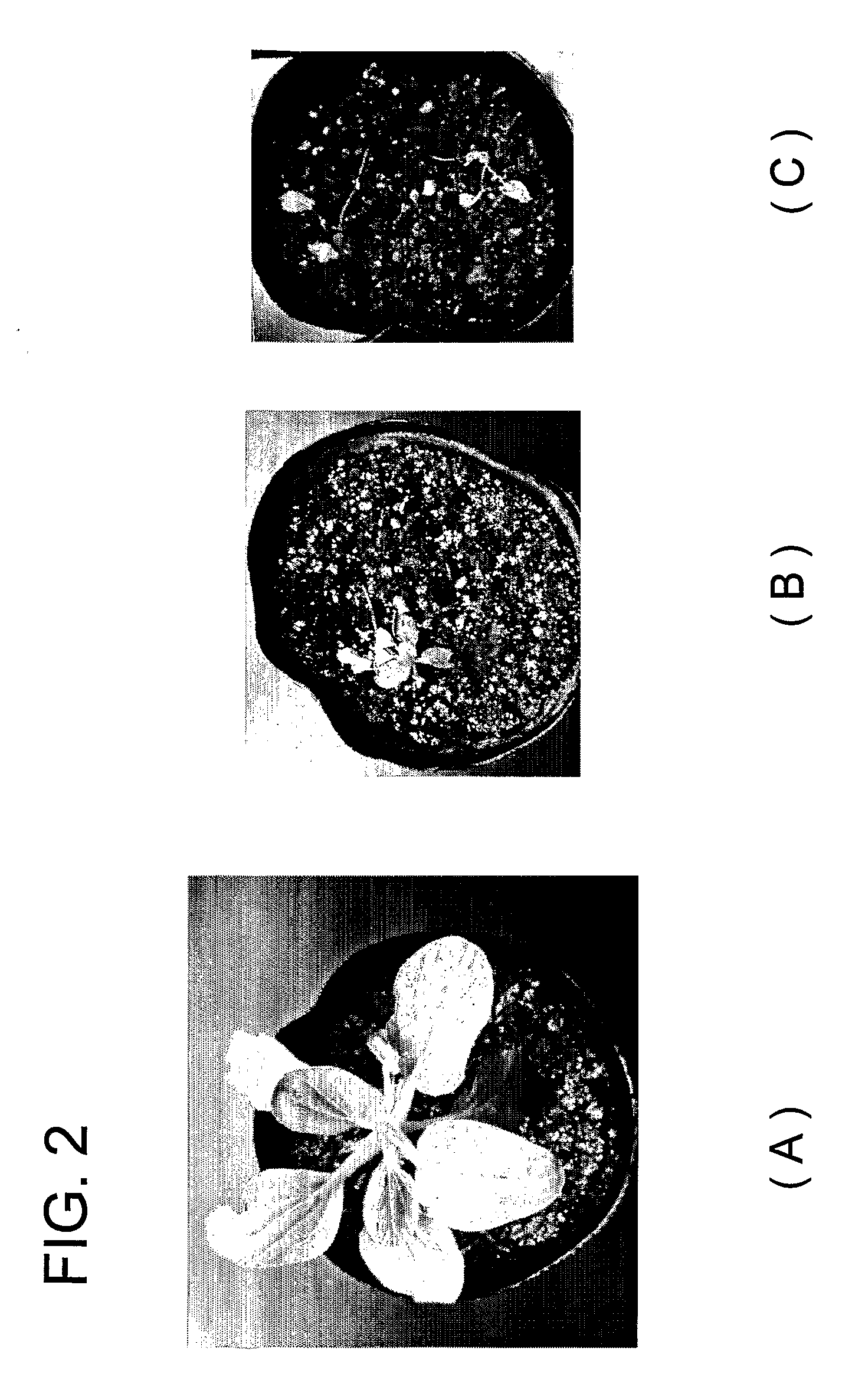

Particulate water retaining material for cultivating plant having water absorbent resin as main component

ActiveUS20070101644A1Promotes rhizogenesisImprove irrigation efficiencyGrowth substratesCulture mediaParticulatesWater insoluble

A particulate water retaining material for cultivating plant comprising (A) a carboxyl group-containing water-insoluble water absorbent resin and (B) a polyvalent metal compound, by having the compound (B) deposited on the the rerin (A), it is made possible to possess an outstanding water absorbing property without impairing the growth of a plant.

Owner:NIPPON SHOKUBAI CO LTD

High-flowability elastic powder for 3D printing and preparation method of high-flowability elastic powder

The invention provides high-flowability elastic powder for 3D printing. The high-flowability elastic powder is characterized in that nano molybdenum disulfide modified elastic powder is adopted, and the high-flowability elastic powder is prepared from materials in parts by weight as follows: 100 parts of polyurethane resin, 10-20 parts of a solid flowable agent, 5-10 parts of inorganic filler, 1-5 parts of a lubricating agent and 0.5-2 parts of a coupling agent. Materials are dried by a vacuum drying box and uniformly mixed by a coulter type mixing machine, molybdenum disulfide is attached to the surface of the elastic powder after the mixture is dried by a spray drier, products have good uniformity and flowability, the particle diameters are uniform, the mechanical performance is excellent, and 3D printing of the elastic powder is realized; the production process is simplified, and operation and control are convenient.

Owner:福建慧思通三维技术有限公司

Vinyl chloride resin composition for powder molding, vinyl chloride resin molded body, laminate, automobile interior material, and method for producing vinyl chloride resin composition for powder molding

InactiveCN101889054AGood fluidity of powderImprove heat aging resistanceThin material handlingPlasticizerCold resistance

Owner:ZEON CORP

Dry toner

InactiveUS7303847B2Small particle sizeHigh temperature resistanceDevelopersElectrographic processes using charge patternPolyesterOrganic solvent

A dry toner is provided that is prepared by a method including the steps of (A) dissolving or dispersing a toner composition in an organic solvent to prepare a toner composition liquid and (B) dispersing the toner composition liquid in an aqueous liquid which contains a binder resin formed of a modified polyester (i) and a colorant containing a carbon black having a pH not greater than 7, wherein the toner has a volume average particle diameter (Dv) is from 3 to 7 μm and a ratio of the volume average particle diameter (Dv) to a number average particle diameter (Dp) is from 1.00 to 1.25.

Owner:RICOH KK

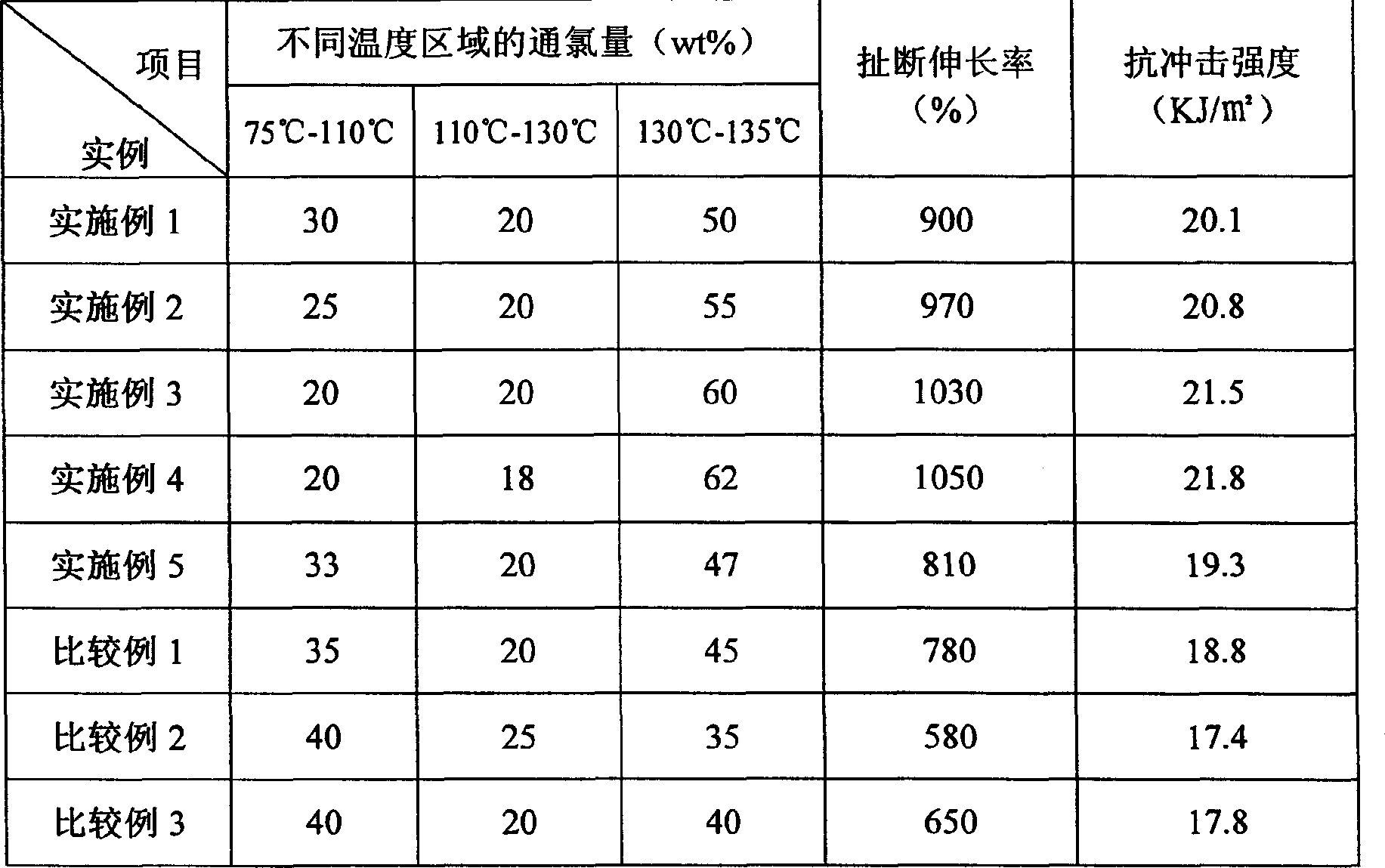

Chlorinated polyethylene with high maximum elongation, and preparation process and application thereof

ActiveCN1827661AImprove the uniformity of chlorinationHigh elongation at breakElastomerPolymer science

A chlorinated polyethylene with high pull-apart elongation percentage and the process for preparing and its application belong to a weatherable snappy rubber and its preparative technological sphere. Obtained by chlorinated polyethylene, it is characterized in that, first, the said chlorinated polyethylene is partially chlorinated below its meltin point, afterwards, it performs chlorination reaction when it is heated up to above its meltin point, and as a result, the chlorinated polyethylene elastomer is obtained with more than 800 % of pull-apart elongation percentage, which can be as polychloroethylene impact modifier. The said chlorinated polyethylene is of high pull-apart elongation percentage and good impact property, can be used in modifying the polychloroethylene resin, and can have impact property function even in a smaller dosage. The dosage ratio is about 2-25 % of polychloroethylene resin weight and its method for using is the same as the present modifier. The dosage of chlorinated polyethylene is small, which eliminates the precipitation problem of polychloroethylene because of excessive chlorinated polyethylene and improves the mechaniclal property and weatherable property of polychloroethylene resin at the same time.

Owner:SHANDONG RIKE CHEM

Method for making high purity and free flowing metal oxides powder

InactiveUS20070110655A1Improved particle surface finishImprove smoothnessBurnersOxide/hydroxide preparationApparent densityFree falling

According to aspects of the present invention, metal oxide powder, such as yttria and alumina powder (feed material), is processed using a plasma apparatus. The process generally consists of in-flight heating and melting of the feed material by the plasma apparatus. The plasma apparatus contains a plasma torch with required power supply and cooling systems, a powder feeder, a chamber to collect the powder and a dedusting system. The heated powder forms molten spherical droplets that are rapidly cooled under free fall conditions. The plasma densification process removes some impurity oxides, modifies the morphology of the particle and increases the apparent density of the powder.

Owner:SULZER METCO (US) INC

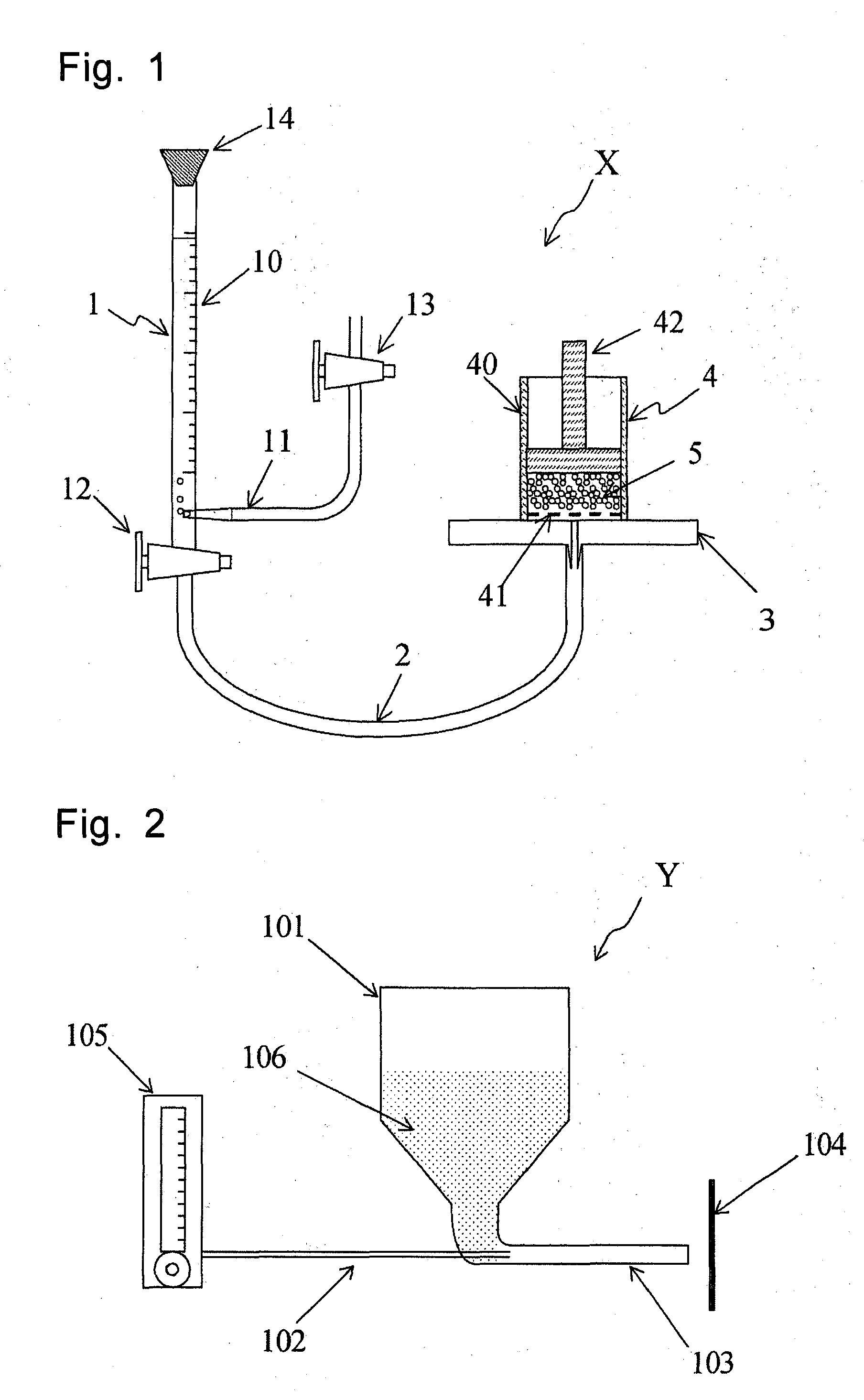

Capillary metering device and method for operating such a capillary metering device

ActiveUS9409699B2Improve precisionImprove reliabilityPowdered material dispensingVolume measurement and fluid deliveryBiomedical engineering

A capillary metering device for a powder product has a vibration body with a capillary formed within the vibration body for receiving and conveying the powder product. The vibration body is formed of at least two adjoining body parts, wherein the capillary is formed as a channel with at least one open side in the demounted state in at least one of the body parts. The open side of the channel in the mounted state is closed off by the adjoining body part. The vibration body is caused to vibrate with such an amplitude and frequency that a powder flow of the powder product passes through the capillary formed in the vibration body into a target container and that upon reaching a target quantity of the powder product in the target container the powder flow to the target container is interrupted.

Owner:HARRO HOFLIGER VERPACKUNGSMASCHEN

Metal powders with improved flowability

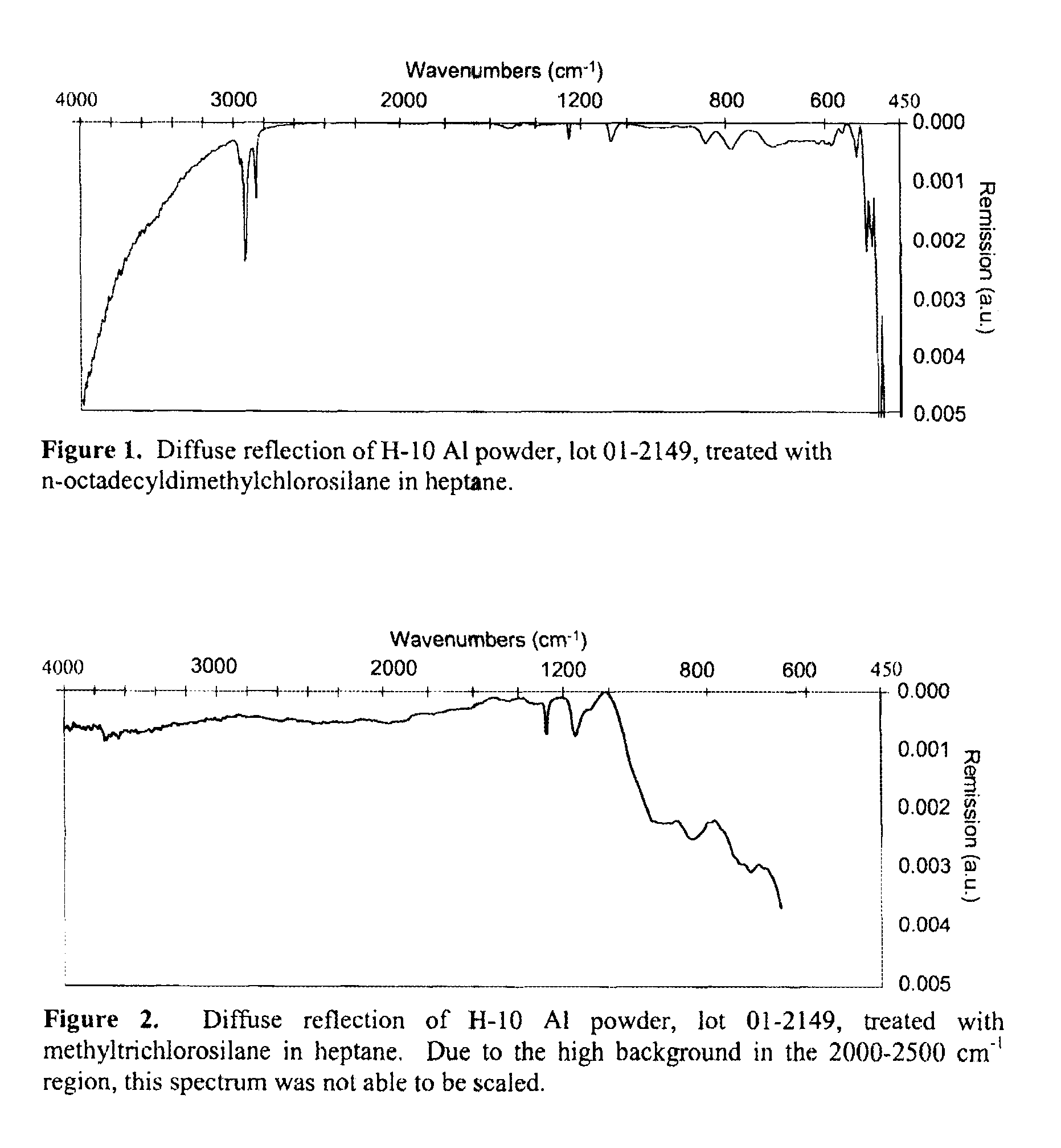

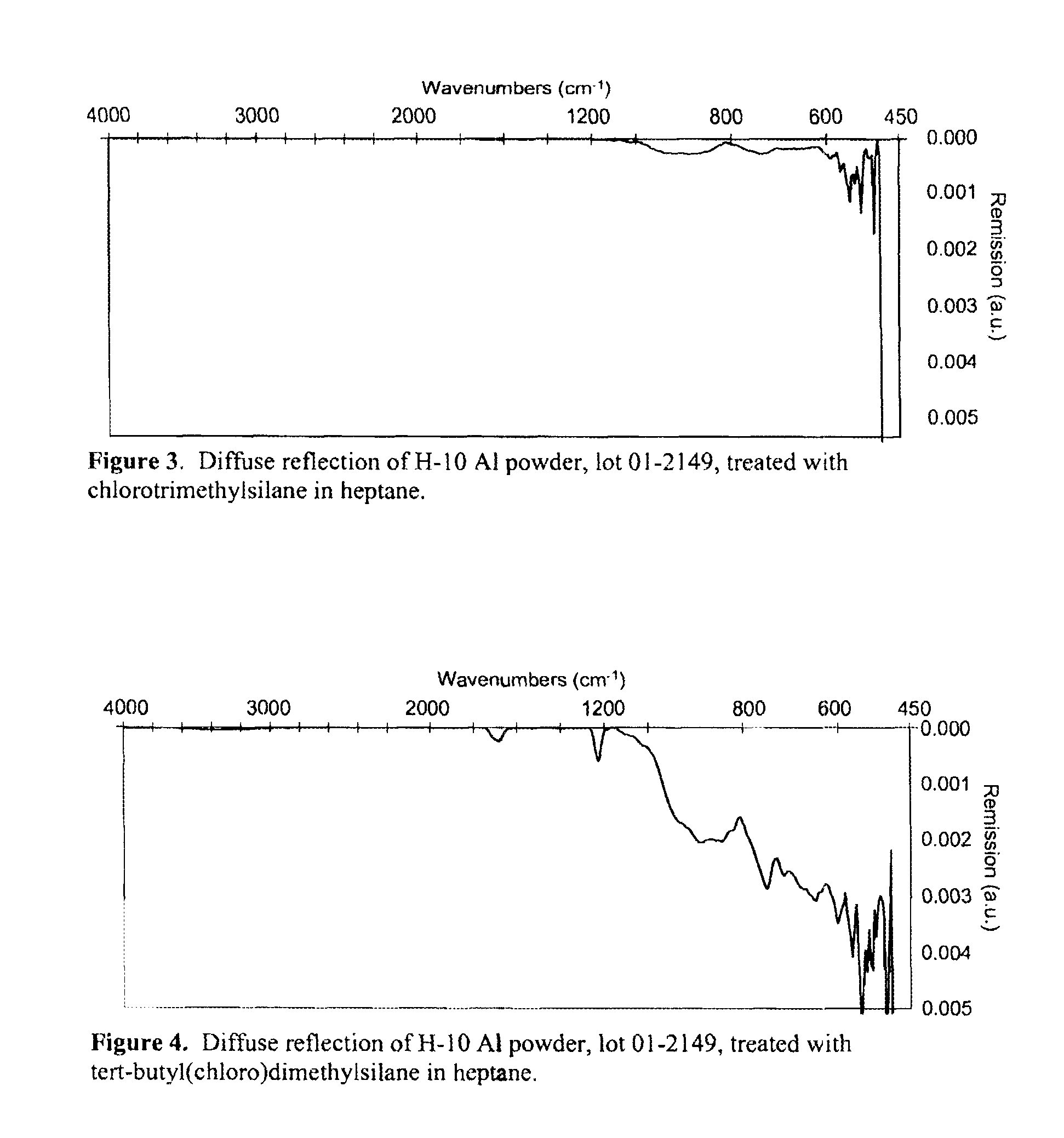

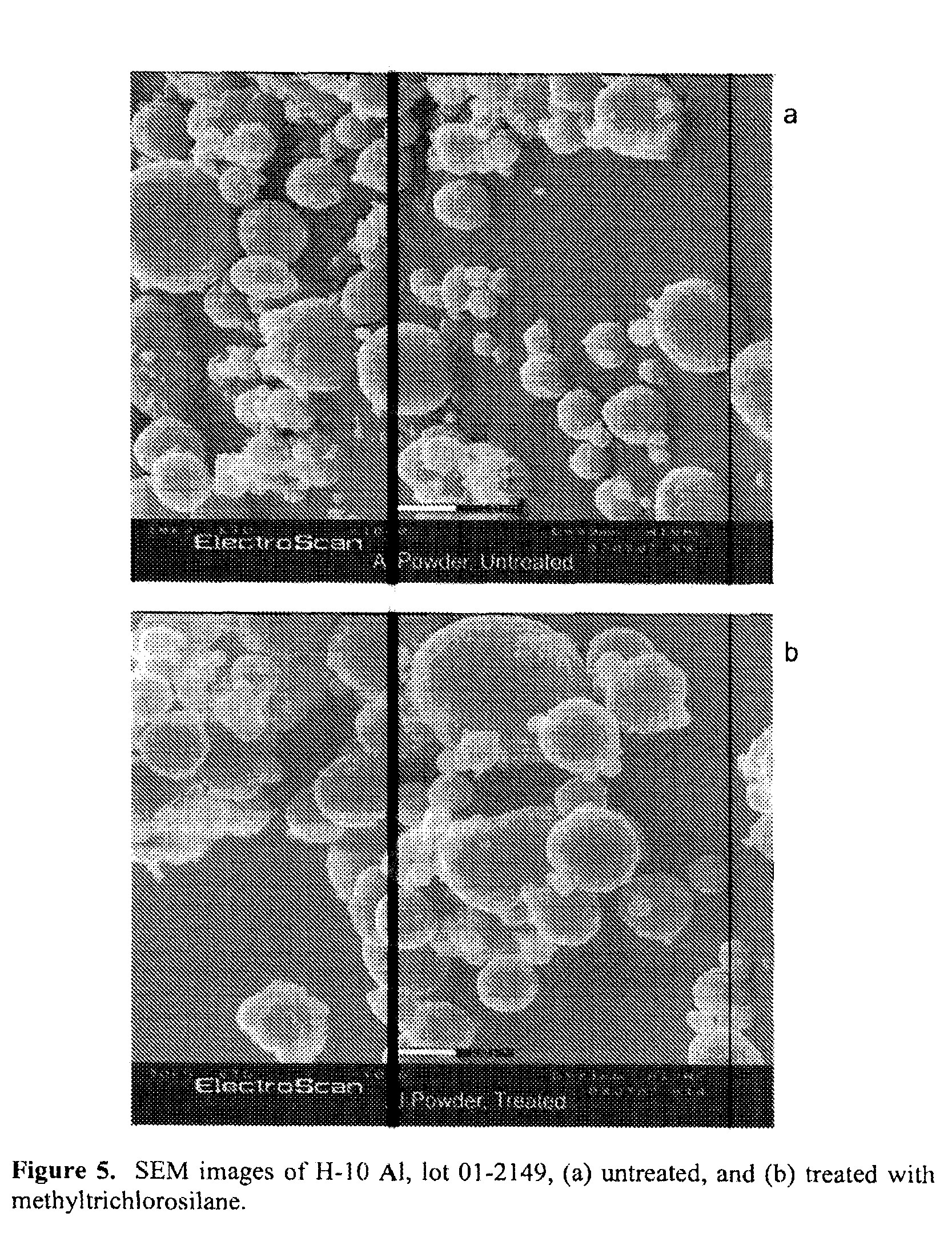

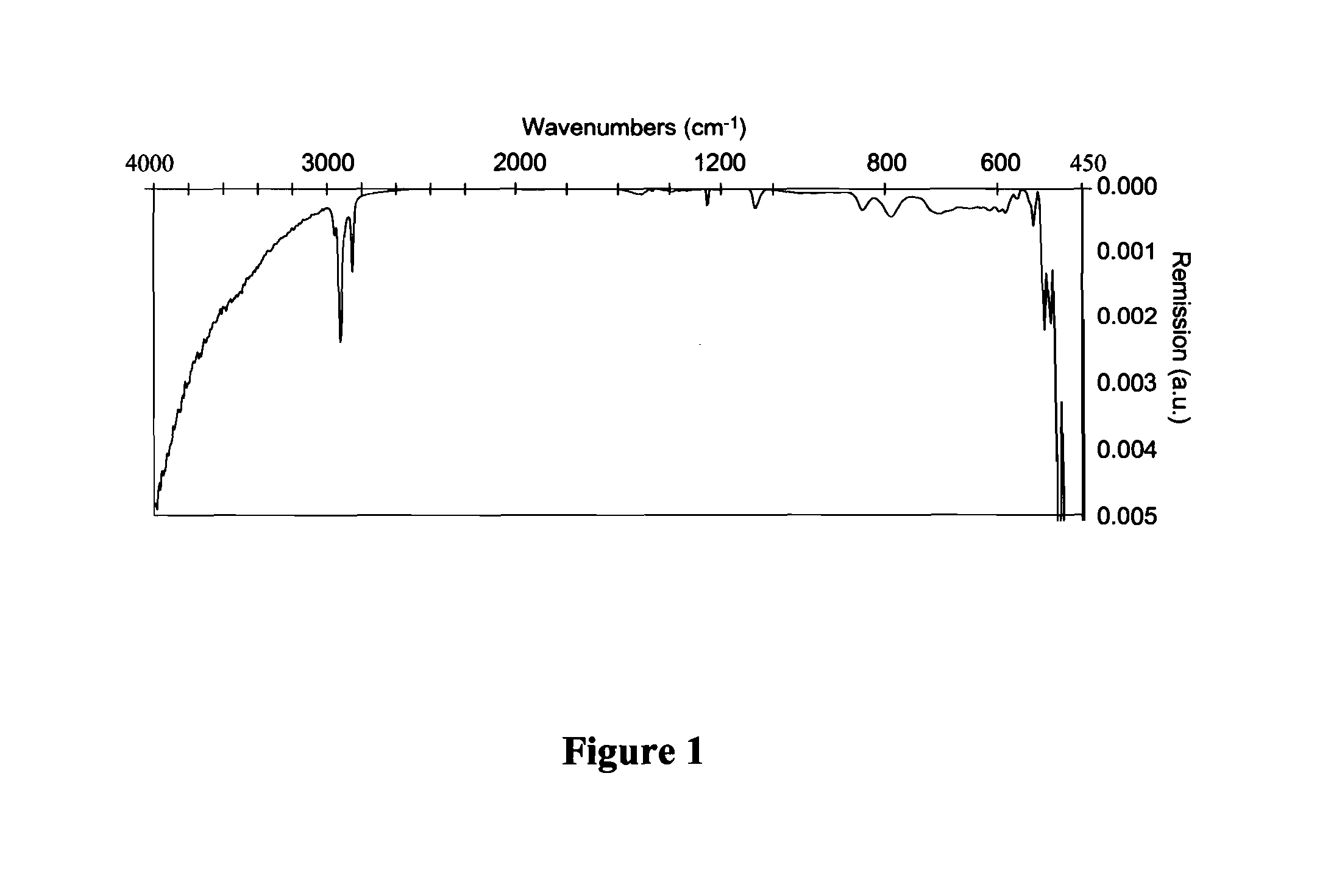

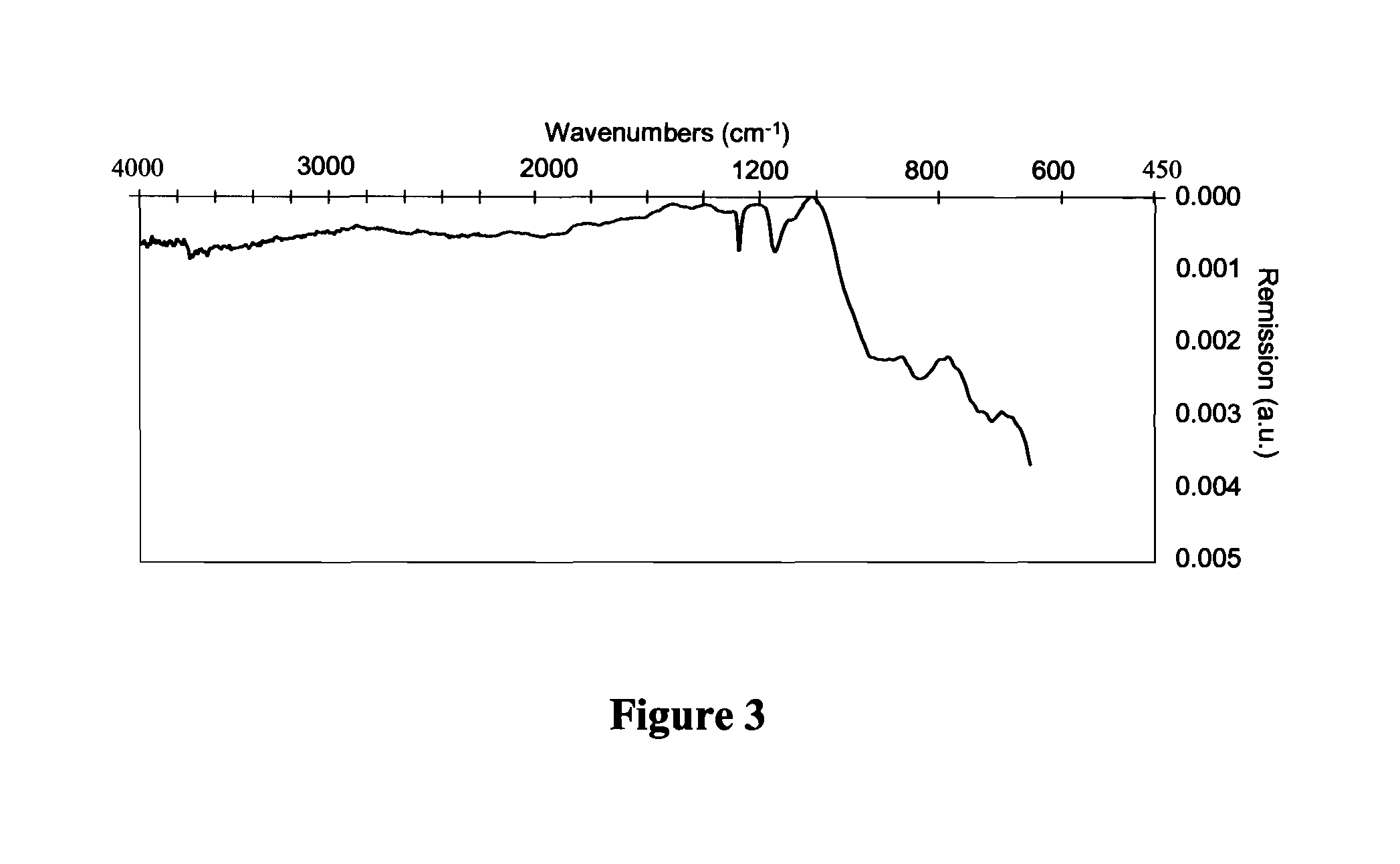

ActiveUS7943084B1Improve flow behaviorNot readily wetted by waterTransportation and packagingMetal-working apparatusMean diameterMethyltrichlorosilane

The present invention demonstrates a superior, more economical, and scalable process to increase the fluidity of metal powders by surface modification with alkylsilane reagents. This invention discloses that the most efficient process results from treatment with methyltrichlorosilane in hexane. In particular, the fluidity of aluminum powders having mean diameters smaller than 10 micrometers was considerably improved by the process of the present invention. It is emphasized that this abstract is provided to comply with the rules requiring an abstract that will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope of the claims.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Particulate materials

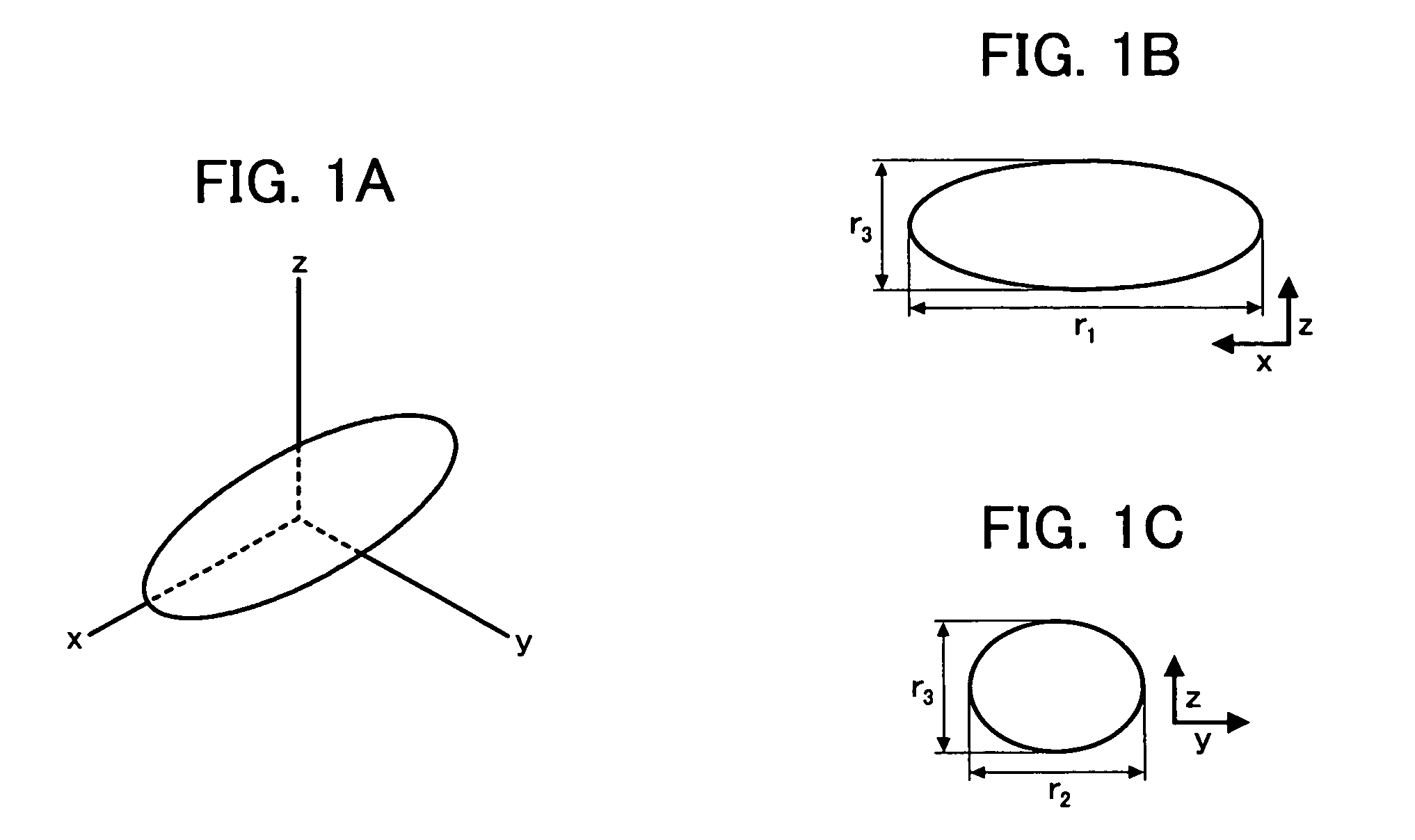

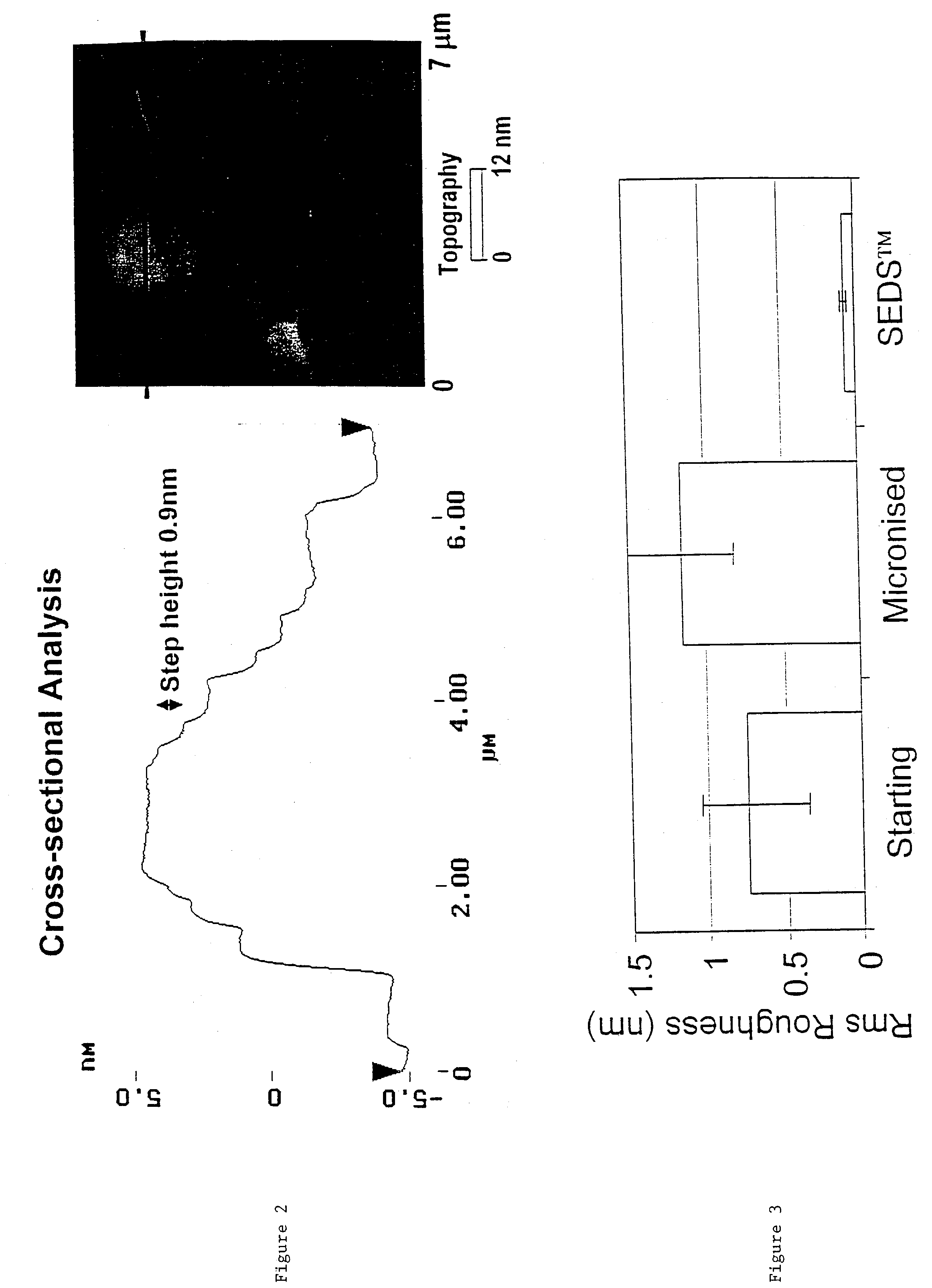

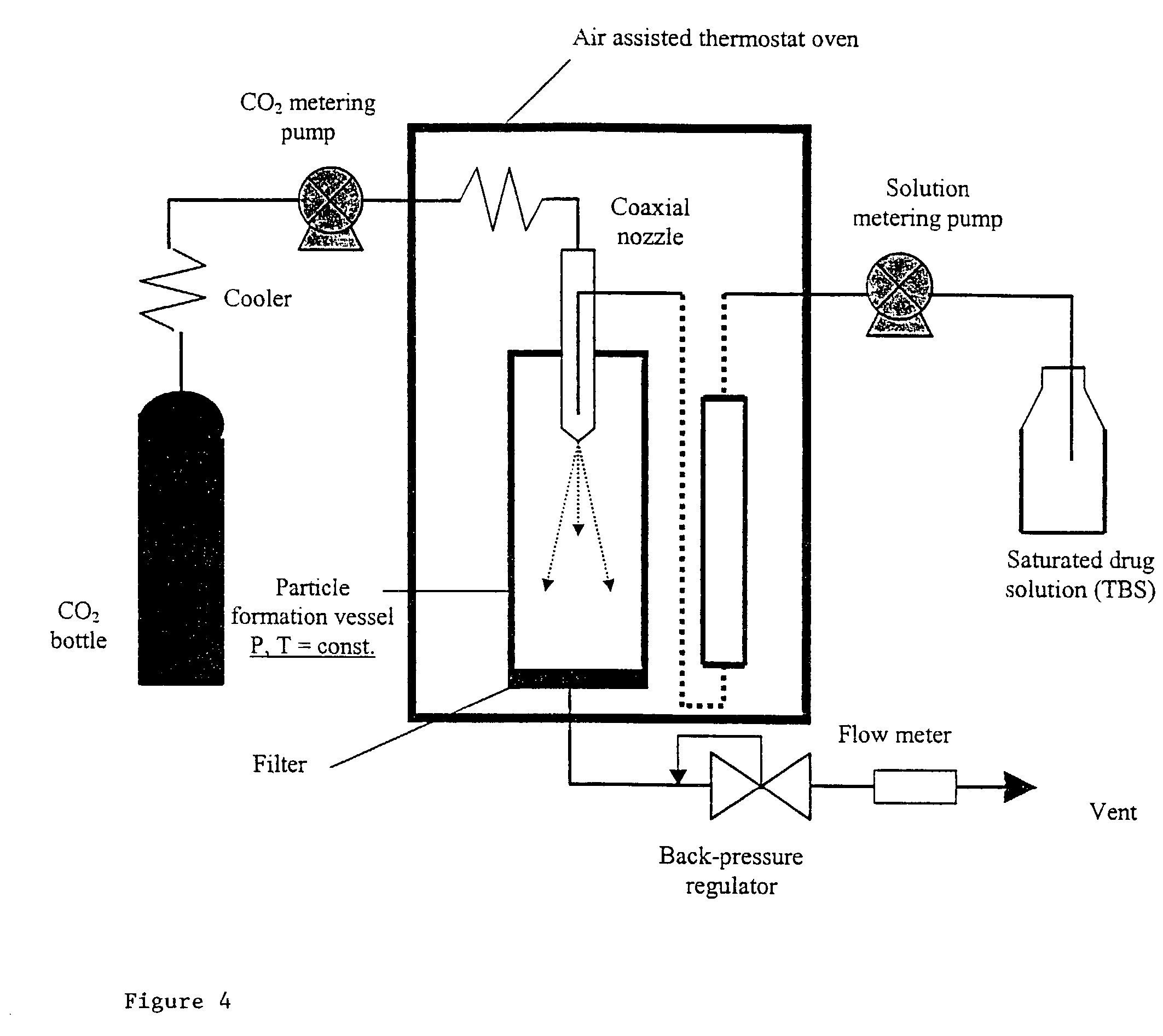

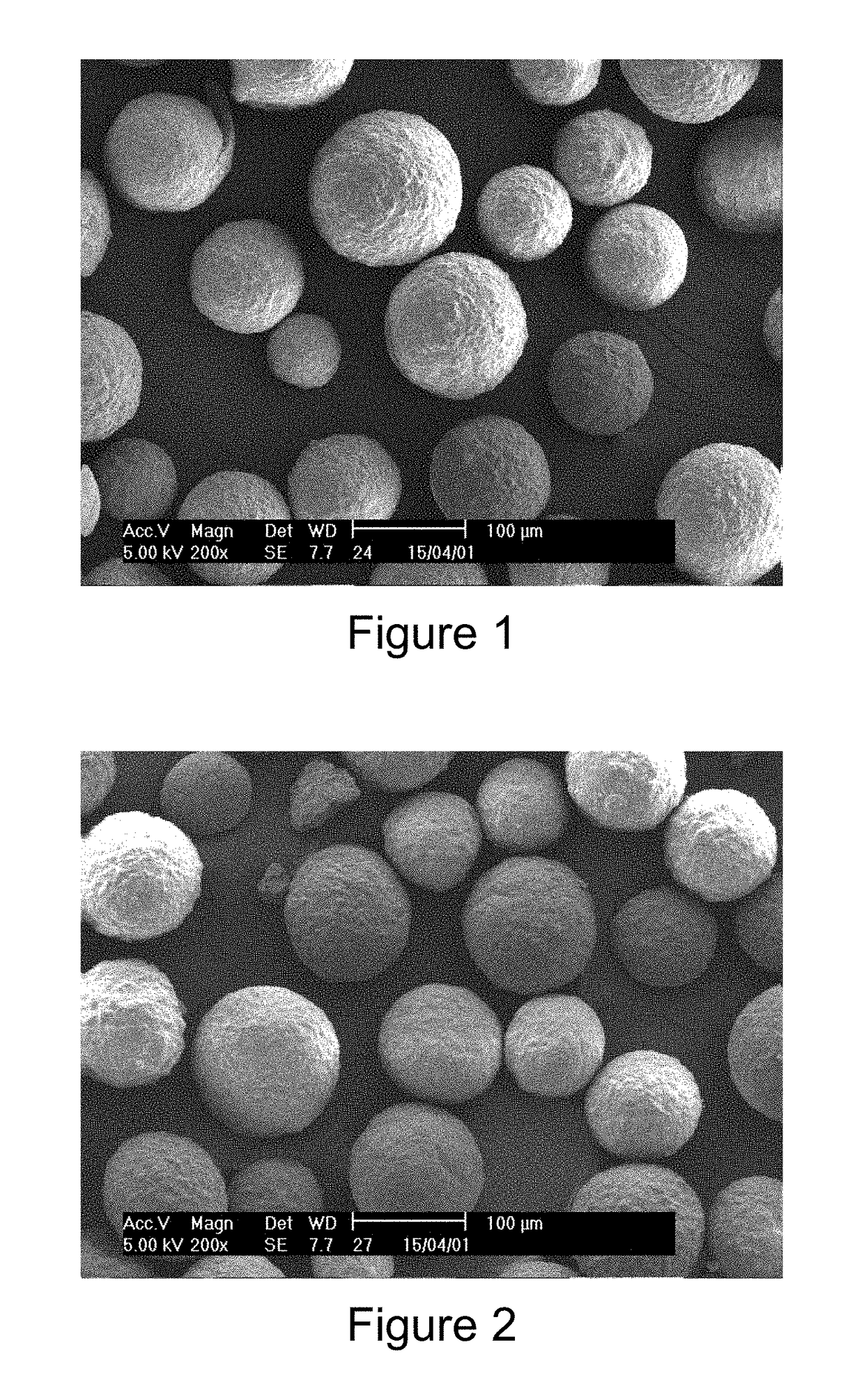

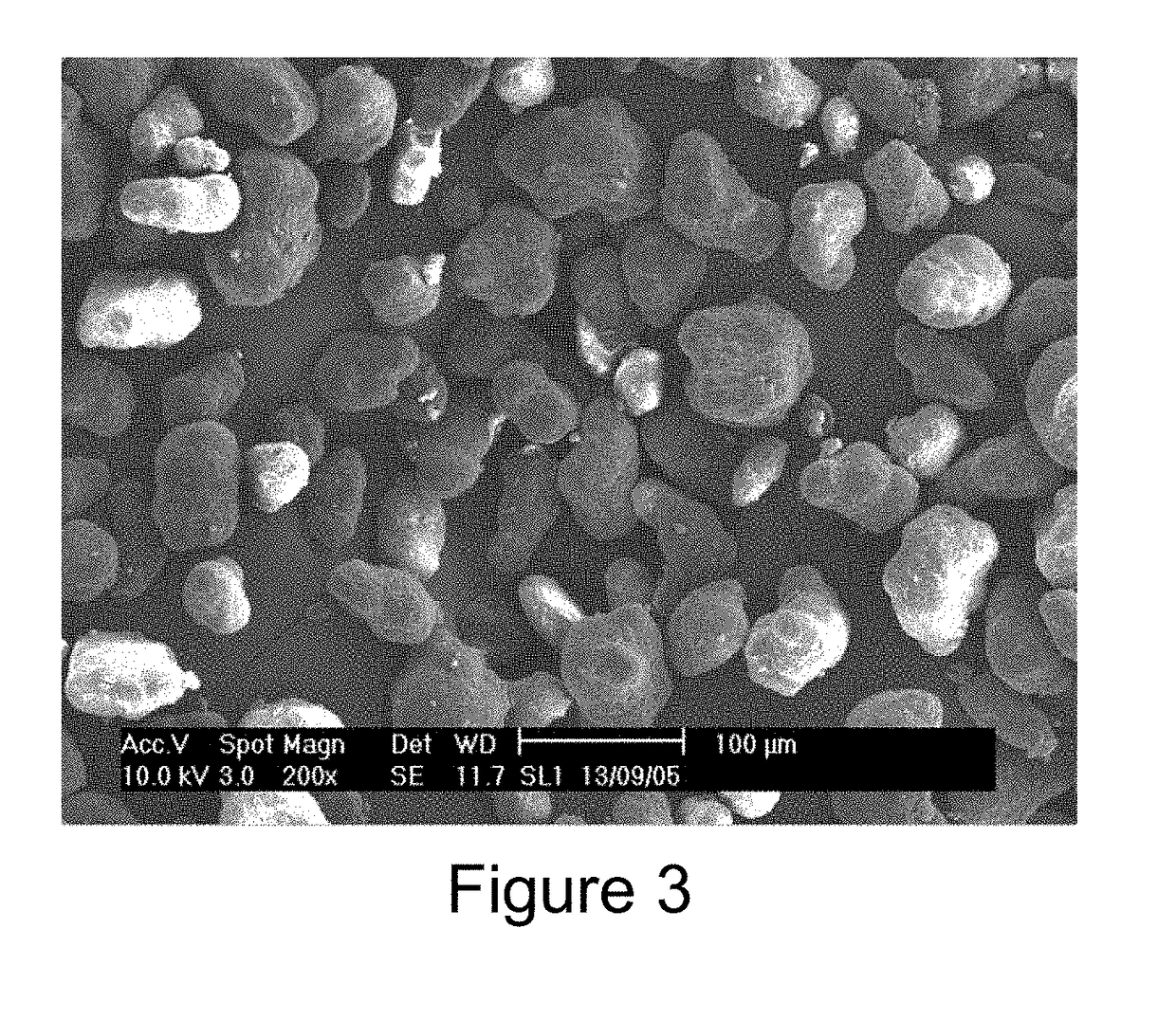

ActiveUS8273330B2Reduce surface roughnessReduced crystal lattice imperfectionPowder deliveryPeptide/protein ingredientsParticulatesMedicine

The present invention relates to active substances in particulate form, to methods for preparing them and to their uses. The present invention provides particulate powders, such as might be of use for delivery using a dry powder inhaler (DPI) or similar delivery device, having properties which may be beneficial to the DPI delivery process.

Owner:NEKTAR THERAPEUTICS INC

Polyolefin resin powder suitable for selective laser sintering and its preparation method

ActiveUS20180355122A1Improve the immunityReduce sizeAdditive manufacturing apparatusTransportation and packagingSolubilitySelective laser sintering

A method for preparing a polyolefin resin powder has the steps ofa) heat dissolving a polyolefin resin in an organic solvent having a solubility parameter less than or equal to the solubility parameter of the polyolefin resin to obtain a polyolefin resin solution;b) cooling the polyolefin resin solution to precipitate a solid, thereby obtaining a solid-liquid mixture;c) optionally adding an adjuvant to the solid-liquid mixture and mixing; andd) conducting solid-liquid separation and drying to obtain a polyolefin resin powder suitable for selective laser sintering.The difference between the solubility parameters of the organic solvent and of the polyolefin resin is within 0-20% of the solubility parameter of the polyolefin resin. The polyolefin resin powder obtained according to this method has good antioxidant property, good powder flowability, moderate size, smooth surface, suitable bulk density, and suitable dispersibility and particle size distribution.

Owner:CHINA PETROCHEMICAL CORP +1

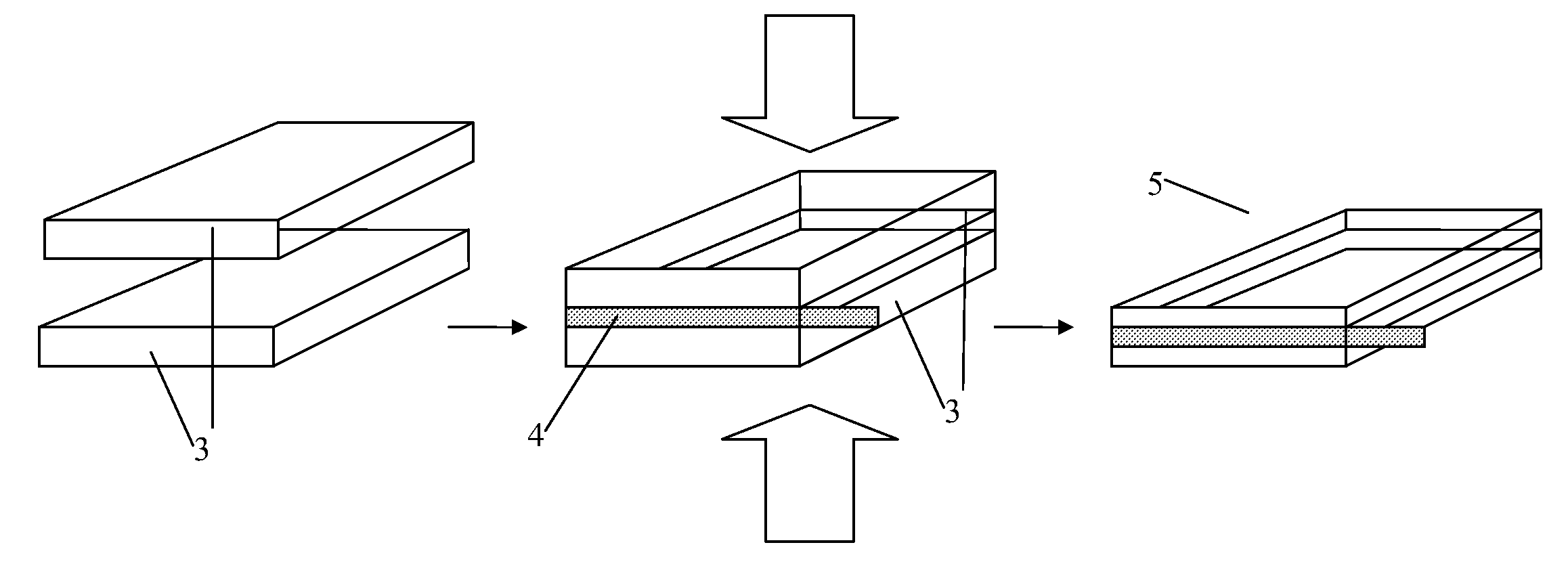

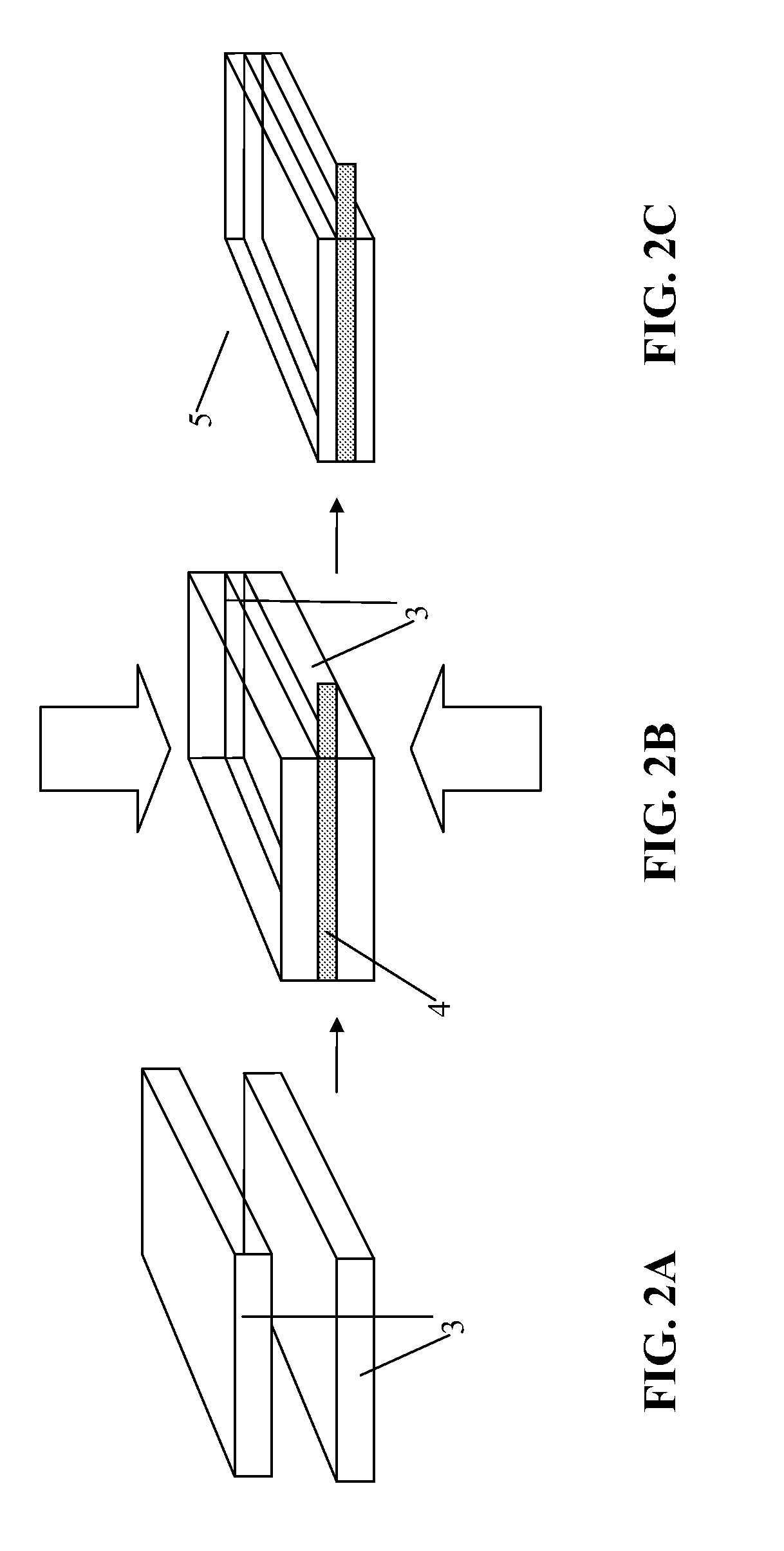

Powder mixture for manufacture of a battery electrode, a respective battery electrode and a method for manufacturing same

ActiveUS20100330432A1Outstanding shapingImprove mechanical stabilityElectrode rolling/calenderingFilling tube/pocket electrodesPowder mixtureMetallurgy

A method for manufacturing of a powder mixture for a battery electrode that includes suspending of particles of at least one binder within an inert solvent producing a first suspension, slowly suspending of particles of an active material within the first suspension producing a second suspension, drying of the second suspension producing a granulate material. Further relates to a respective powder mixture, an electrode and a method of manufacturing the electrode.

Owner:LITRONIK BATTERIETECHNOLOGIE GMBH

Surface treated toner

InactiveUS20120308923A1Low photoconductor filming propertyGood fluidity of powderDevelopersSquare meterCore Particle

A toner composition includes resin core particles having outer surfaces, and surface treatment, wherein the surface treatment includes at least first metal oxide particles having a surface area equivalent average particle diameter of greater than 25 nm and a surface energy of less than 28 erg / cm2, as determined by methanol wettability midpoint at 22° C., tacked to the outer surfaces of the resin core particles, at a concentration to provide a total projected area of the first metal oxide particles sufficient to cover at least 10% of the resin core particle outer surfaces area, and wherein the toner composition comprises less than 0.013 g non-tacked surface treatment per square meter of resin core particles outer surface. A developer for developing electrostatic images includes magnetic carrier particles and toner as described above, wherein the developer comprises less than 0.013 g non-tacked surface treatment per square meter of resin core particles outer surface, that is free to transfer between the outer surface of the resin core particles and outer surfaces of the magnetic carrier particles.

Owner:EASTMAN KODAK CO

Water-absorbent resin particle, method for production thereof, and absorbent material using the same

InactiveUS20120298913A1Good fluidity of powderIncrease moisture contentMedical scienceWoven fabricsSilica particleAbsorption capacity

A method for production of a water-absorbent resin particle which is excellent in a particle strength, and in which even after mechanical impact, a particle diameter retaining rate and a retaining rate of water absorption capacity under pressure are high, and an absorbent material using the same particle. The method includes the steps of polymerizing a water-soluble ethylenic unsaturated monomer using a water-soluble radical polymerization initiator, optionally in the presence of a crosslinking agent, to obtain a water-absorbent resin particle precursor, adding a post-crosslinking agent to crosslink a surface of the particle, adding an amorphous silica particle and adjusting the resulting particle to a moisture content of less than 10%, and subsequently adding moisture to adjust a final moisture content of the resulting particle to 10 to 20%.

Owner:SUMITOMO SEIKA CHEM CO LTD

Method for producing coenzyme q10 particle

ActiveUS20100004473A1Uniform particle sizeGood fluidity of powderOrganic active ingredientsPowder deliveryOrganic solventSolid particle

The present invention aims to provide a production method capable of industrially and producing coenzyme Q10 particles having a high content and superior powder flowability characteristics by simple facility and convenient operations. The present invention provides a method of producing coenzyme Q10 particles, including mixing coenzyme Q10 and a poor solvent by stirring at a temperature not less than the melting point of coenzyme Q10, dispersing coenzyme Q10 into the form of oil droplets, and cooling them to a solidification temperature of coenzyme Q10 or below while stirring the dispersion to give solid particles, wherein the poor solvent is an aqueous solution comprising an organic solvent and / or a surfactant having an HLB of 6 or above. According to the production method of the present invention, coenzyme Q10 particles markedly superior in powder characteristics, and having, for example, a powder flowability index of not less than 80 can be obtained.

Owner:KANEKA CORP

Amorphous alloy coating with advantages of wear resistance, corrosion resistance and slip resistance, and preparation method thereof

InactiveCN107794484APrevent oxidationAvoid overall overheatingMolten spray coatingPorosityCombustion

The invention discloses an amorphous alloy coating with advantages of wear resistance, corrosion resistance and slip resistance, and a preparation method thereof, and belongs to the technical field ofamorphous alloy coatings. According to the present invention, the coating is prepared by using a HVAF supersonic flame spraying method, wherein the HVAF supersonic flame spraying uses gas fuels suchas propane, propylene and the like, and uses compressed air as a combustion aid, such that the low-temperature high-speed process is achieved while the use of a large amount of oxygen is avoided; thecoating obtained through the method comprises the following components by mass: 13-25% of Cr, 10-30% of Mo, 0-8% of W, 0-5% of Mn, 1-4% of B, 0-4% of Si, 0-4% of C, 40-65% of Fe, 0-5% of Y, 0-1% of Ca, and less than or equal to 3% of other impurities; and the coating obtained through the method is uniform, and has advantages of low porosity, high hardness, excellent corrosion resistance and excellent slip resistance.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

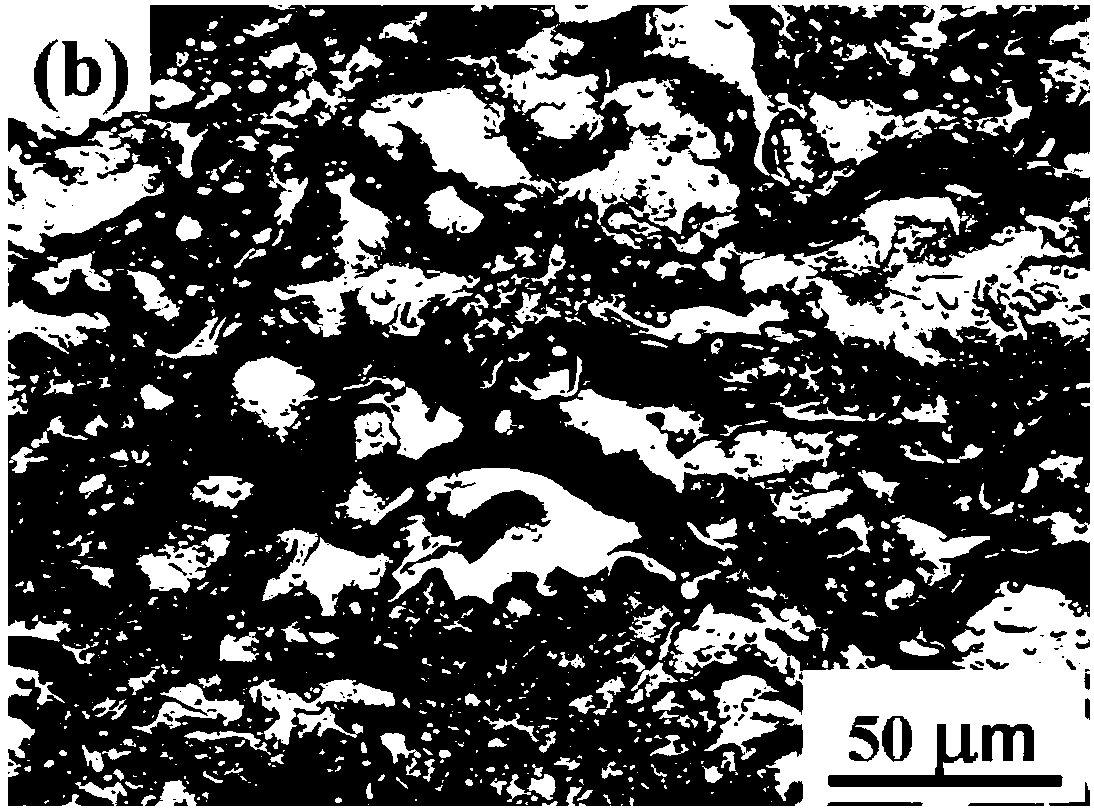

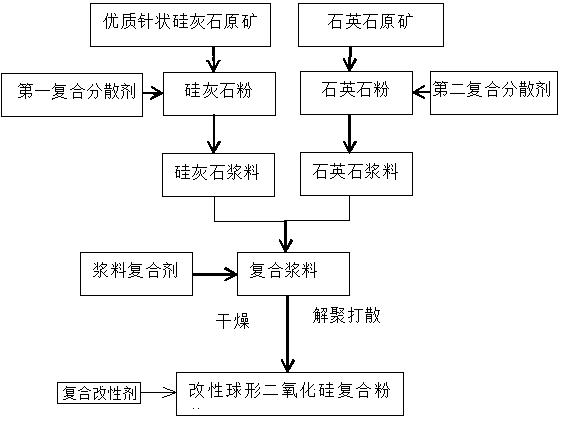

Preparation method of ultrafine needle-like wollastonite modified spherical silicon dioxide composite powder

InactiveCN110951279AInhibition dispersionAvoid intensityPigment physical treatmentPigment treatment with non-polymer organic compoundsWollastoniteSlurry

The invention relates to a preparation method of ultrafine needle-like wollastonite modified spherical silicon dioxide composite powder, wherein the method comprises the steps: treating high-quality needle-like wollastonite raw ore and quartzite raw ore to obtain needle-like wollastonite powder and spherical quartzite powder; adding a composite dispersing agent into the needle-like wollastonite powder and the spherical quartzite powder to prepare wollastonite powder slurry and quartzite powder slurry; and making the two slurries into a composite slurry, drying, depolymerizing and scattering, and carrying out surface modification by a composite modifier to obtain the special ultrafine needle-like wollastonite modified spherical silicon dioxide composite powder for an epoxy pouring sealant.The needle-like wollastonite powder and spherical silicon dioxide are subjected to superfine wet grinding, and then slurry compounding is carried out, so the problems of poor dispersity, low bonding strength, low adhesive strength and the like caused by single use of one kind of powder in the epoxy pouring sealant are avoided, the needle-like wollastonite powder and the spherical silicon dioxide are interspersed and accumulated in the pouring sealant, the dispersity and the suspension property of the powder are improved, the pouring sealant is compact in pouring, and the heat-conducting property of the sealant is improved.

Owner:JIANGXI GUANGYUAN CHEM

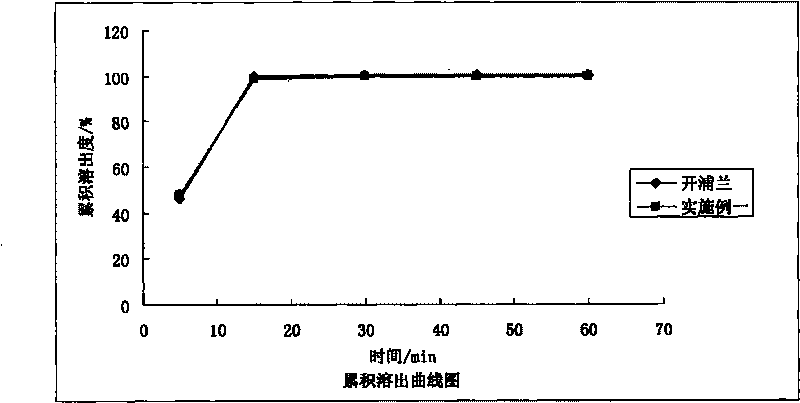

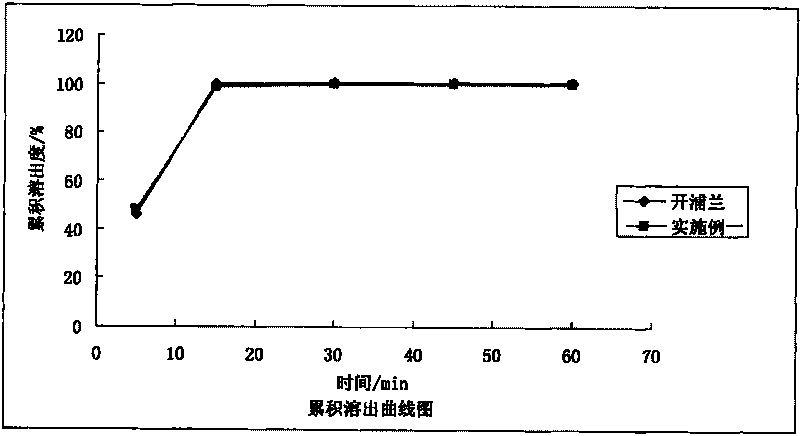

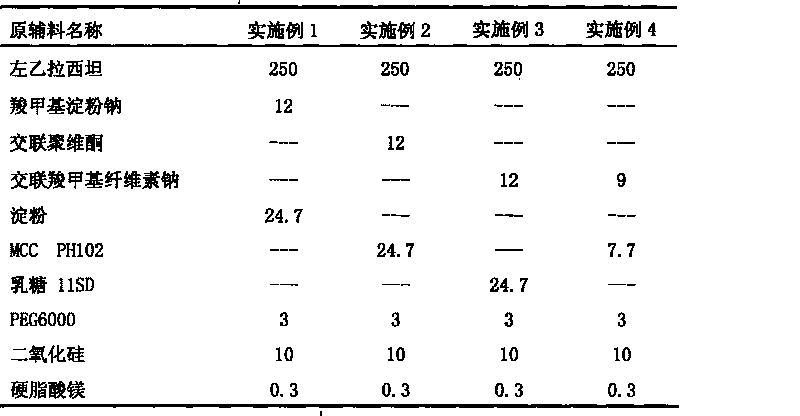

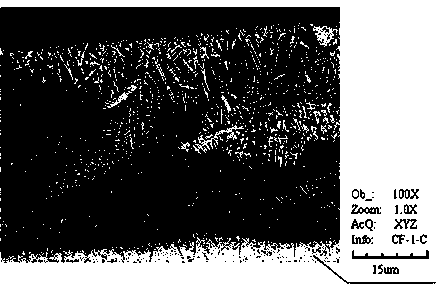

Medicament composition of levetiracetam and preparation process

ActiveCN101693017AEasy to makeImprove stabilityOrganic active ingredientsNervous disorderActive componentLevetiracetam

The invention provides a medicament composition containing active component of levetiracetam and a preparation process thereof. The preparation process does not need producing pallets, and directly presses powder into tablets or fills powder into capsules.

Owner:CHINA RESOURCES SAIKE PHARMA

Repairing composite layer of amorphous/nanocrystalline cooling roller and preparation method of repairing composite layer

ActiveCN103895280AGood workmanshipInhibit sheddingElectrolytic coatingsMetallic material coating processesHigh power lasersHigh energy

The invention belongs to the technical field of material science, and particularly relates to a repairing composite layer of an amorphous / nanocrystalline cooling roller and a preparation method of the repairing composite layer. The composite layer consists of two layers, namely a copper-based alloy layer connected with base materials and a nickel-based alloy layer, wherein the copper-based alloy layer comprises the following components by weight percent: 7-9% of Ni, 8-12% of Sn, 5-15% of Co, 0.8-2% of Si and the balance being Cu; the nickel-based alloy layer comprises one of Ni-Co alloy, Ni-P alloy, Ni-Fe alloy and Ni-Cr alloy, and the weight content of Ni in alloy is 60-75%. The preparation method comprises the following steps of pretreating the surface of the cooling roller, electroplating the copper-based alloy layer and performing wide-strip cladding on the nickel-based alloy layer by a high-power laser. The prepared composite coating is uniform and compact, and excellent in wear resistance and heat resistance, and has the characteristics of high cladding efficiency and high energy absorptivity of the cooling roller to the laser beam.

Owner:QINGDAO YUNLU ADVANCED MATERIALS TECH CO LTD

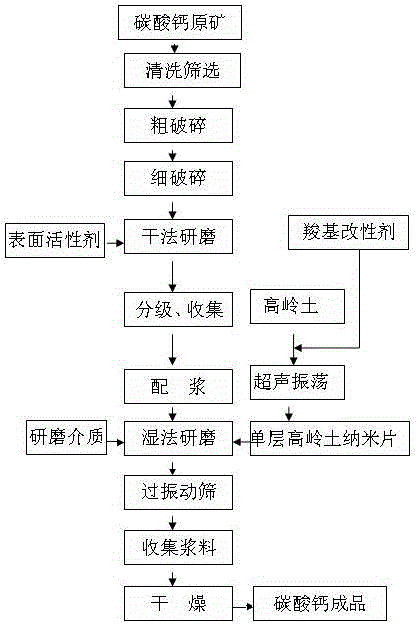

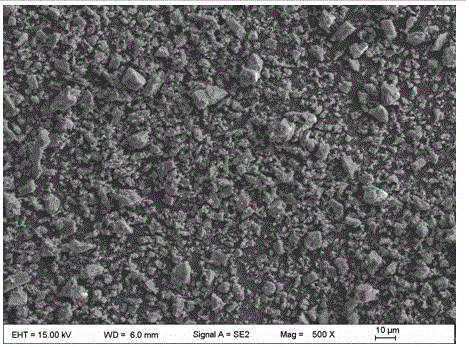

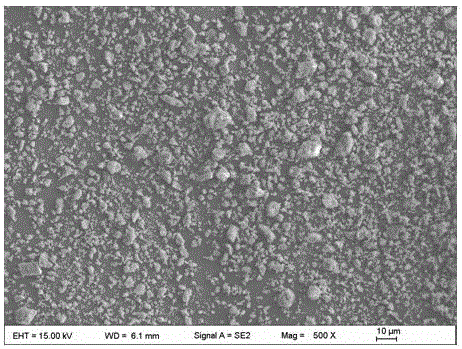

Single-layer kaolin modified ultrafine heavy calcium carbonate and preparation method thereof

ActiveCN106084893AReduce reunionReduce overlapPigment physical treatmentPigment treatment with non-polymer organic compoundsDispersityMicrometer

Single-layer kaolin modified ultrafine heavy calcium carbonate and a preparation method thereof. The method comprises the following steps: firstly preparing carboxyl-modified single-layer kaolin nanosheet by a polymer-assisted liquid-phase stripping method; grinding calcium carbonate coarse powder into 5-10 micrometers of fine powder in the presence of a surfactant; adding the carboxyl-modified single-layer kaolin nanosheet dispersion liquid to prepare slurry with solid content being 70-80%; and stir-grinding by a wet method to obtain the modified ultrafine heavy calcium carbonate with the particle size being 0.1-1 micrometer. The design is scientific and reasonable; the operation process is simple; the production cost is low; and the product is easy for large-scale production. In addition, agglomeration and overlapping of particles can be reduced, powder fluidity of particles can be enhanced, and dispersity of particles in a polymer matrix can be improved. The invention is of great significance for improving comprehensive performance of the polymer matrix and expanding application fields of heavy calcium carbonate.

Owner:JIANGXI GUANGYUAN CHEM

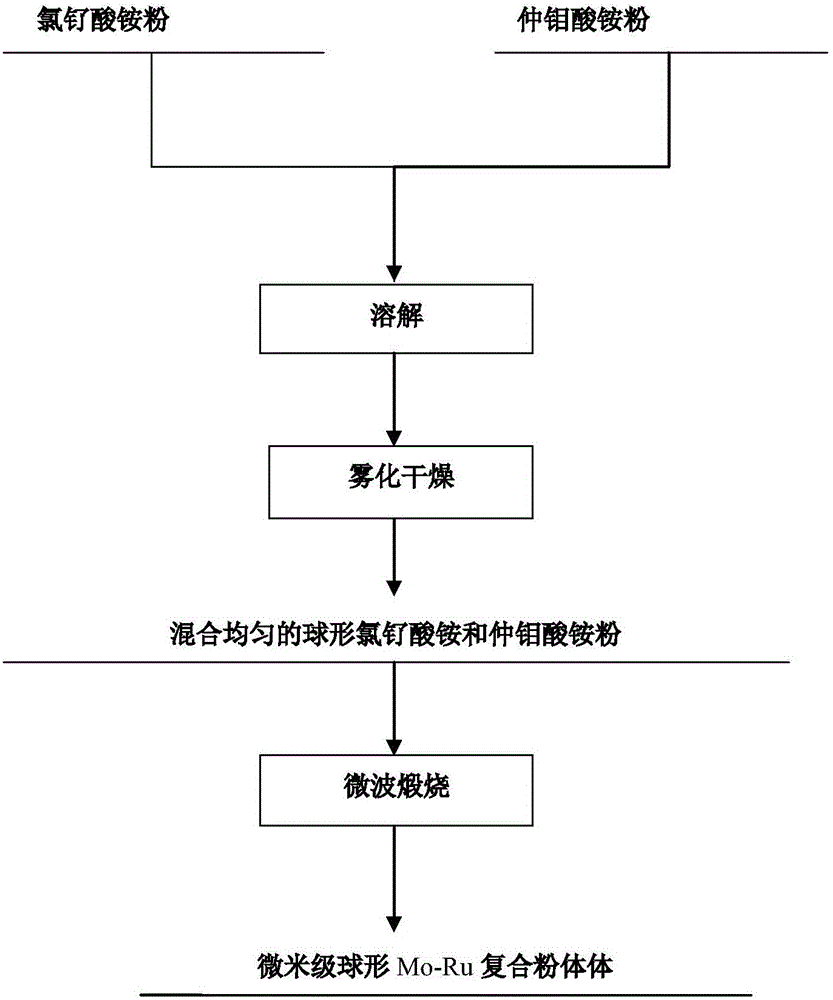

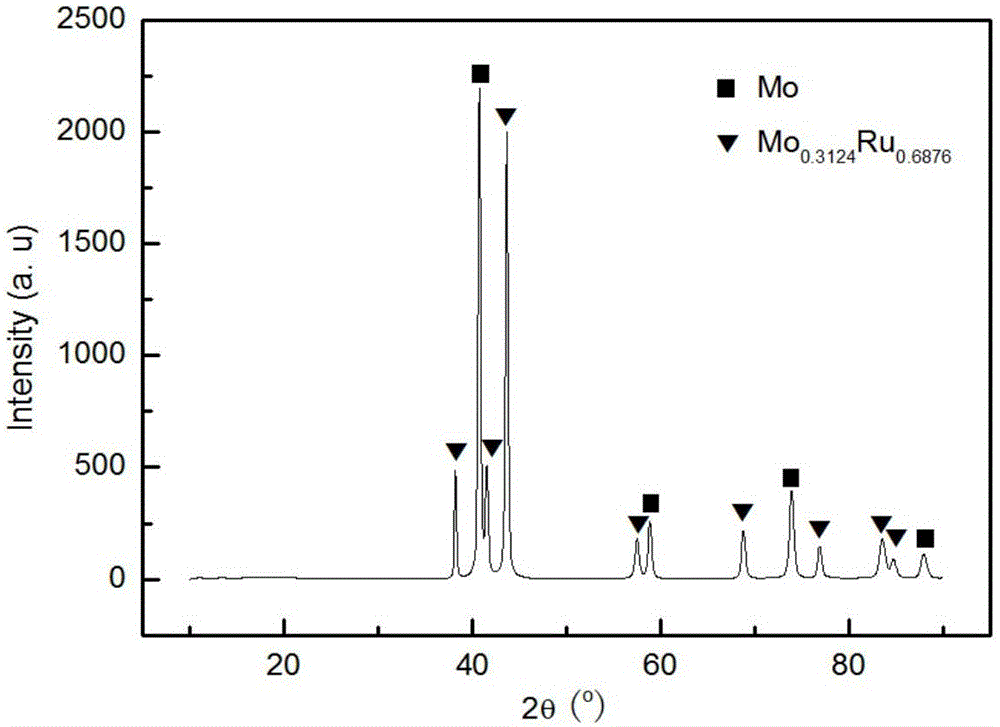

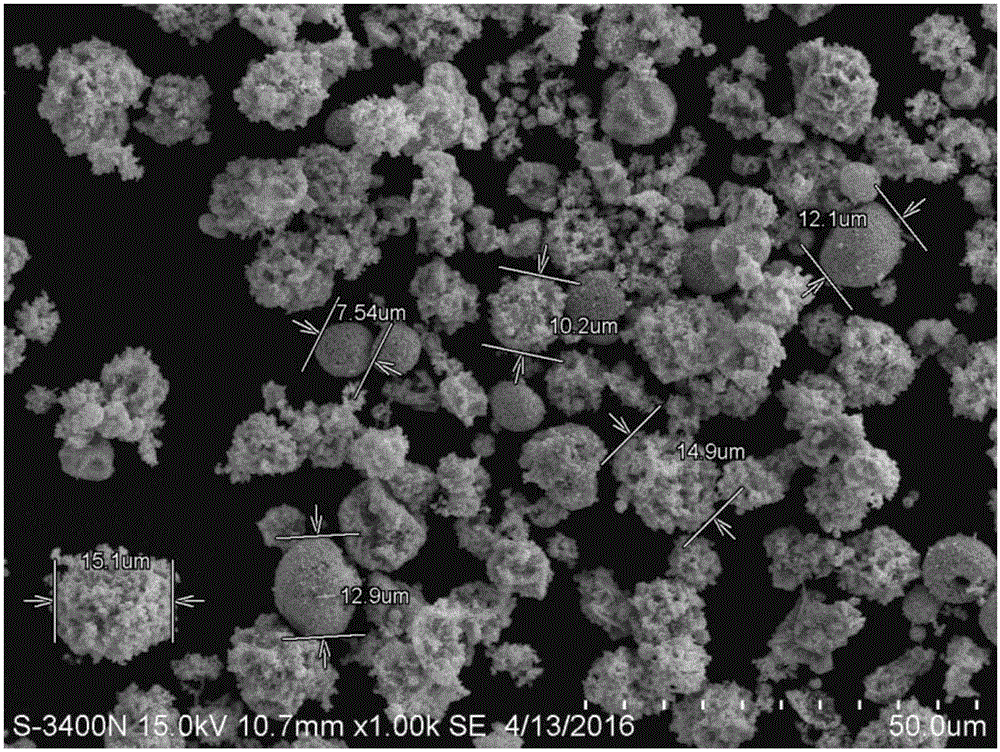

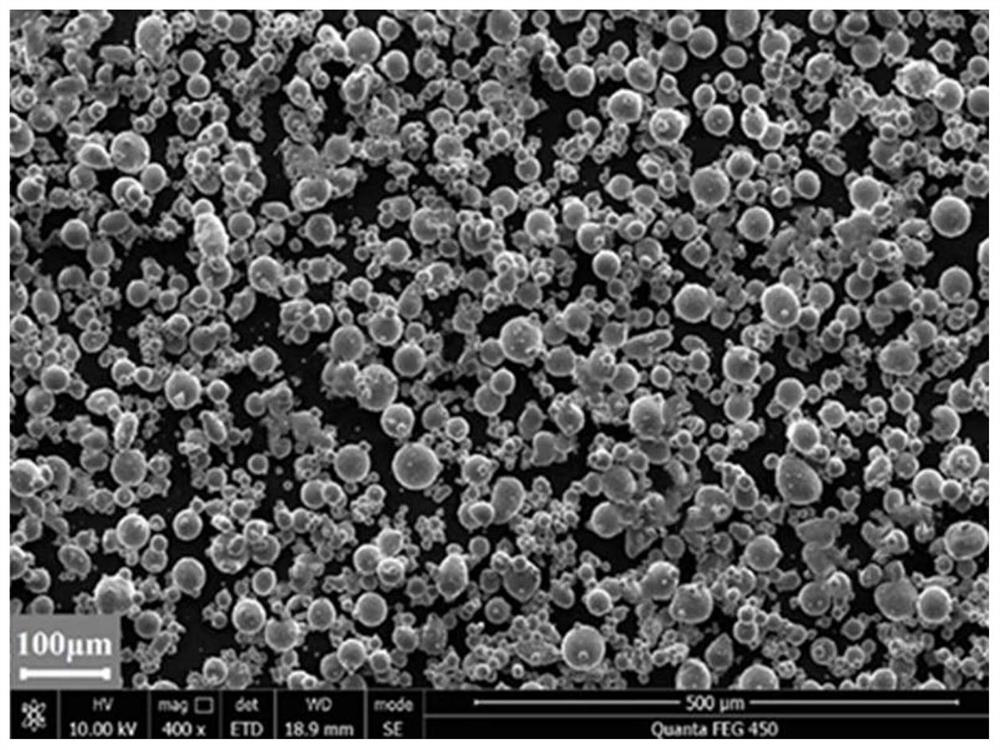

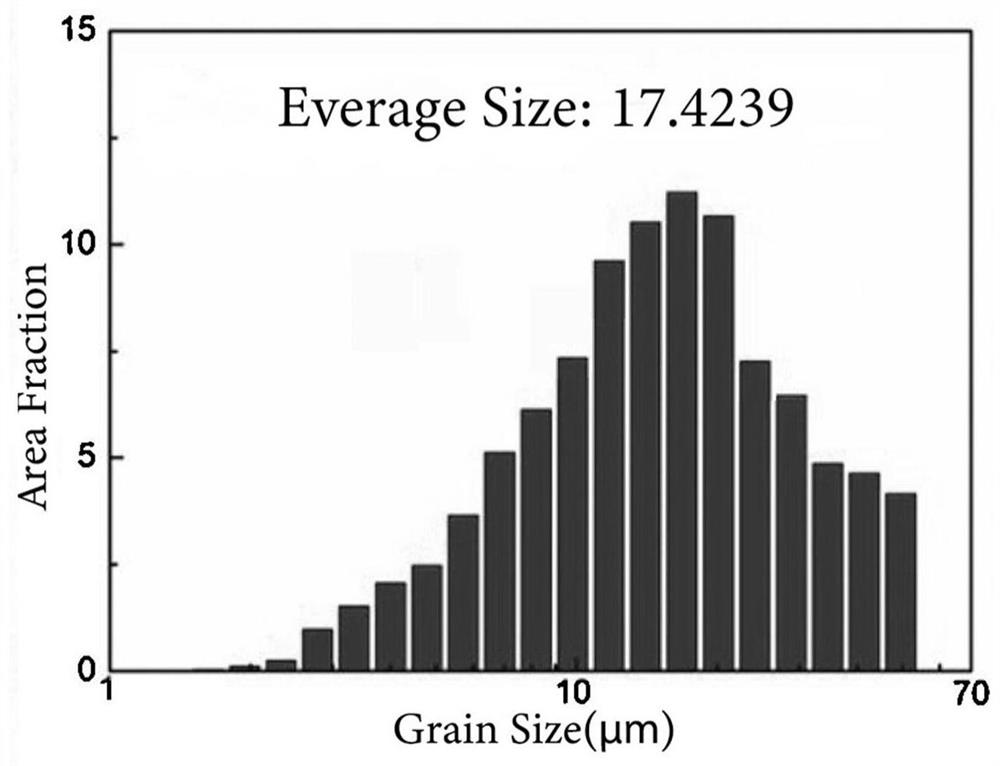

Preparation method for micro-grade spherical Mo-Ru brazing filler powder

The invention discloses a preparation method for micro-grade spherical Mo-Ru brazing filler powder, wherein prepared micro-grade Mo-Ru composite powder contains 35wt%-45wt% of ruthenium, has a particle size being 5-15 mum, and has an average particle size being about 10 mum. According to the preparation method, ammonium paramolybdate [NH4]6Mo7O24.4H2O] and diammonium hexachlororuthenate [(NH4)2RuCl6] are taken as raw materials, and the micro-grade spherical Mo-Ru composite powder is prepared by combining spray drying with a microwave calcination technology. The micro-grade spherical Mo-Ru brazing filler powder with ruthenium content being 35wt%-45wt%, particle size being 5-15 mum and average particle size being 10 mum is prepared by spray drying and the microwave calcinations process, and the liquidity of the powder is good. The molybdenum-ruthenium composite powder can be applied to special part welding flux of the high-temperature field.

Owner:SINO PLATINUM METALS CO LTD

Aluminum alloy nanoparticle reinforced composite material and preparation method thereof

InactiveCN114107778AHigh densityImprove the phenomenon of easy thermal crackingTransportation and packagingMetal-working apparatusUltimate tensile strengthAdditive layer manufacturing

The invention discloses an aluminum alloy nano-particle reinforced composite material and a preparation method thereof.The aluminum alloy nano-particle reinforced composite material comprises rare earth aluminum alloy and reinforced phase nano-particles, the nano-particles account for 0.2%-30% of the total mass, the reinforced nano-particles and aluminum alloy matrix powder are mixed, deionized water is adopted to avoid agglomeration of the reinforced particles, and the rare earth aluminum alloy matrix powder is prepared; by means of the method, the interface bonding degree and wettability of a reinforcing body and a base body can be higher, the powder fluidity is better, and the performance of the powder used for additive manufacturing of formed parts is guaranteed, the modification effect of rare earth elements added into the base body aluminum alloy is combined with the reinforcing effect of nano particles, and the performance of the formed parts is improved. The aluminum alloy nano-particle reinforced composite material can effectively improve the phenomenon that the Al-Zn-Mg-Cu series aluminum alloy is prone to hot cracking in the additive manufacturing process, meanwhile, grains can be refined, the strength of the aluminum alloy formed through additive manufacturing is further improved, the density of the aluminum alloy nano-particle reinforced composite material reaches up to 99.7%, and the volume fraction of a reinforced phase can reach 5.0% or above.

Owner:XI AN JIAOTONG UNIV

Granular vinyl chloride resin for paste processing and process for producing same

InactiveCN1292000AGood fluidity of powderGood dispersionSievingScreeningEmulsion polymerizationPolyvinyl chloride

A granular vinyl chloride resin for paste processing which has a content of particles having a diameter of 10 um or smaller of 10 wt.% or lower, a content of particles not passing through a 149 um standard sieve of below 0.5 wt.%, and a bulk density of 0.45 to 0.58 g / cm<3> and which, when mixed in an amount of 100 g with 50 g of dioctyl phthalate, gives a plastic sol in which the content of particles not passing through a 62 um standard sieve of below 0.3 wt.%; and a process for producing the granular vinyl chloride resin for paste processing, characterized by polymerizing vinyl chloride or a mixture thereof with a copolymerizable monomer by emulsion polymerization or microsuspension polymerization to give an aqueous dispersion of a vinyl chloride polymer, spray-drying the dispersion to obtain particles, and treating the particles with an ultrasonic oscillating sieve having an opening size of 149 um or smaller to remove the particles remaining on the sieve.

Owner:新第一氯乙烯株式会社

Metal powders with improved flowability

ActiveUS8894739B1Improve liquidityImprove flow behaviorSynthetic resin layered productsMetal-working apparatusMean diameterMethyltrichlorosilane

A process to increase the fluidity of metal powders by surface modification with alkylsilane reagents. This invention generally discloses that the most efficient process results from treatment with methyltrichlorosilane in hexane. In particular, the fluidity of aluminum powders having mean diameters smaller than 10 micrometers was considerably improved by the process of embodiments of the invention.

Owner:USA REPRESENTED BY THE SEC OF THE NAVY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com