Aluminum alloy nanoparticle reinforced composite material and preparation method thereof

A reinforced composite material and nanoparticle technology, which is applied in the field of aluminum alloy nanoparticle reinforced composite material and its preparation, can solve problems such as thermal cracks and mechanical property degradation, and limit the practical application of additive processing, so as to improve thermal cracking and guarantee performance, the effect of avoiding agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] This embodiment provides a method for preparing an aluminum alloy nanoparticle-reinforced composite material. Among them, the chemical composition of the rare earth aluminum alloy powder includes: Zn: 6%, Mg: 5%, Cu: 3%, Mn: 0.3%, Ni: 0.3%, Cr: 0.03%, Ti: 0.03%, Zr: 0.1%, Er: 0.3%, Yb: 0.3%, oxygen content ≤ 1000ppm, the balance is Al. The reinforcement phase adopts ZrB with a mass fraction of 3% 2 Particles: the single impurity amount of P, S or N in the rare earth aluminum alloy powder is not more than 0.05%, and the total amount of impurities is not more than 0.15%.

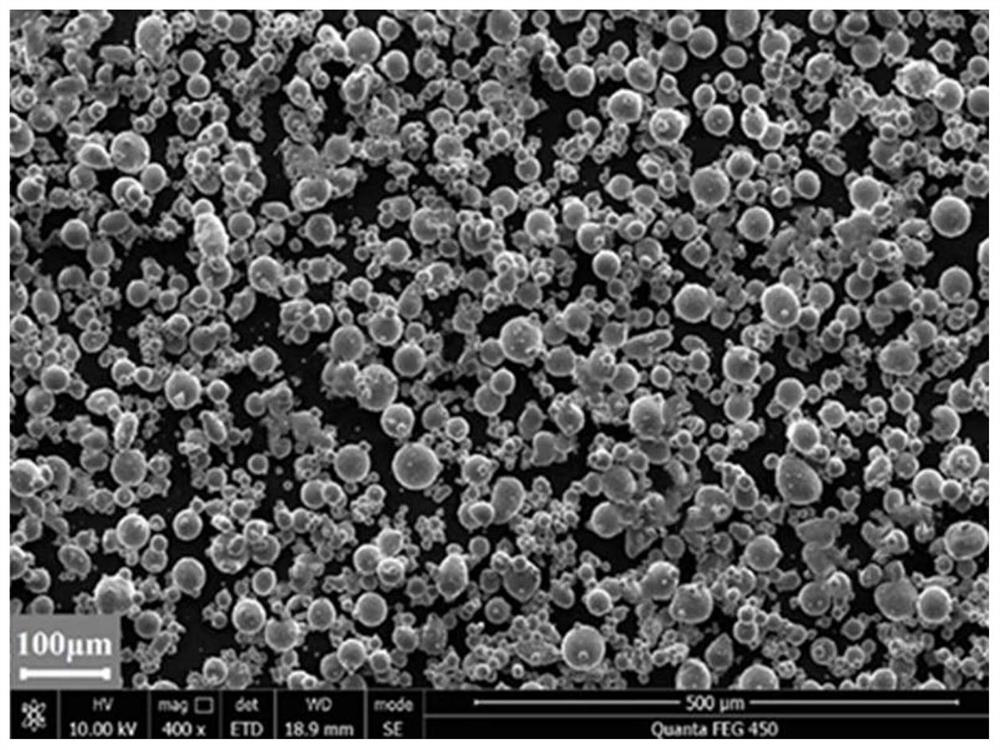

[0048] First, step S1: manufacture spherical powder of nanoparticle-reinforced rare earth aluminum alloy composite material: use vacuum atomization method to prepare rare earth aluminum alloy powder containing the above chemical composition and ZrB 2 Granular powder, after which rare earth aluminum alloy powder and ZrB with a mass fraction of 3% were mixed by homogeneous method 2 The particle powder ...

Embodiment 2

[0055] This embodiment provides a method for preparing an aluminum alloy nanoparticle-reinforced composite material. Among them, the chemical composition of the base aluminum alloy powder is: Zn: 6%, Mg: 3%, Cu: 3%, Mn: 0.2%, Ni: 0.3%, Cr: 0.03%, Ti: 0.03%, Zr: 0.1%, Er: 0.3%, La: 0.3%, oxygen content ≤ 1000ppm, P, S, N and other individual impurities are not more than 0.05%, the total amount of impurities is not more than 0.15%, and the balance is Al. The reinforcement phase uses TiC particles with a mass fraction of 5%.

[0056] First, step S1: manufacture spherical powder of nanoparticle-reinforced rare-earth aluminum-alloy composite material: first, the rare-earth aluminum-alloy powder and TiC particle powder containing the above-mentioned chemical composition are respectively prepared by vacuum atomization method, and then the rare-earth aluminum alloy powder and TiC particle powder are prepared by homogeneous method The aluminum alloy powder and the TiC particle powder ...

Embodiment 3

[0063] This embodiment provides a method for preparing an aluminum alloy nanoparticle-reinforced composite material. Among them, the chemical composition of the base aluminum alloy powder is: Zn: 7%, Mg: 2%, Cu: 2%, Mn: 0.1%, Ni: 0.1%, Cr: 0.03%, Ti: 0.03%, Zr: 0.1%, Sc: 0.3%, La: 0.3%, oxygen content ≤ 1000ppm, P, S, N and other individual impurities are not more than 0.05%, the total amount of impurities is not more than 0.15%, and the balance is Al. The reinforcement phase adopts Al with a mass fraction of 12% 2 o 3 particles.

[0064] First, step S1: manufacture spherical powder of nanoparticle-reinforced rare-earth aluminum-alloy composite material: use vacuum atomization method to prepare rare-earth aluminum-alloy powder and Al 2 o 3 Particle powder, after which the rare earth aluminum alloy powder and the mass fraction of 12% Al were mixed by homogeneous method 2 o 3 The particle powder is mixed evenly, and the specific steps are: (1) Al 2 o 3 Granular powder an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com