Patents

Literature

107results about "Filling tube/pocket electrodes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

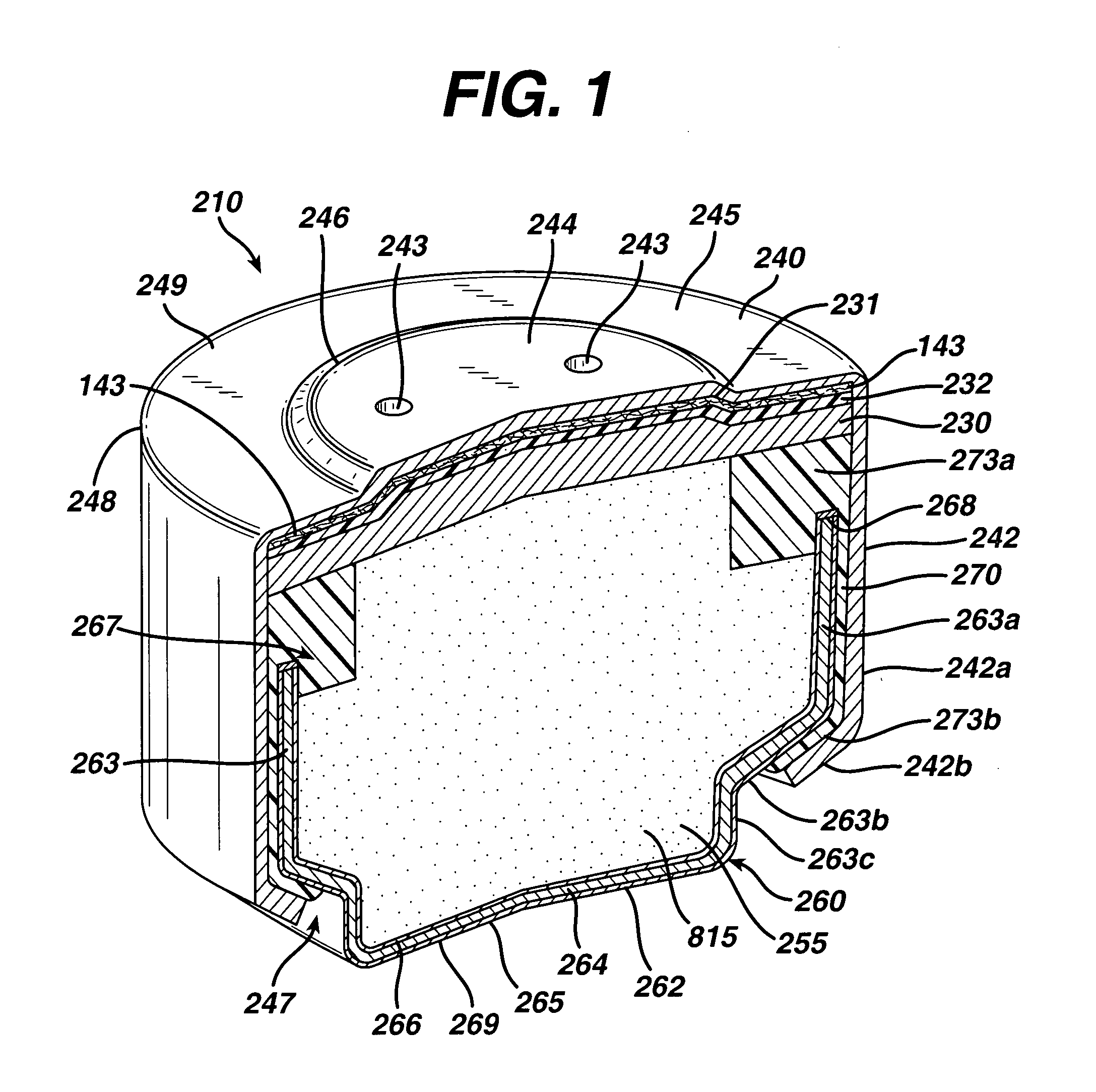

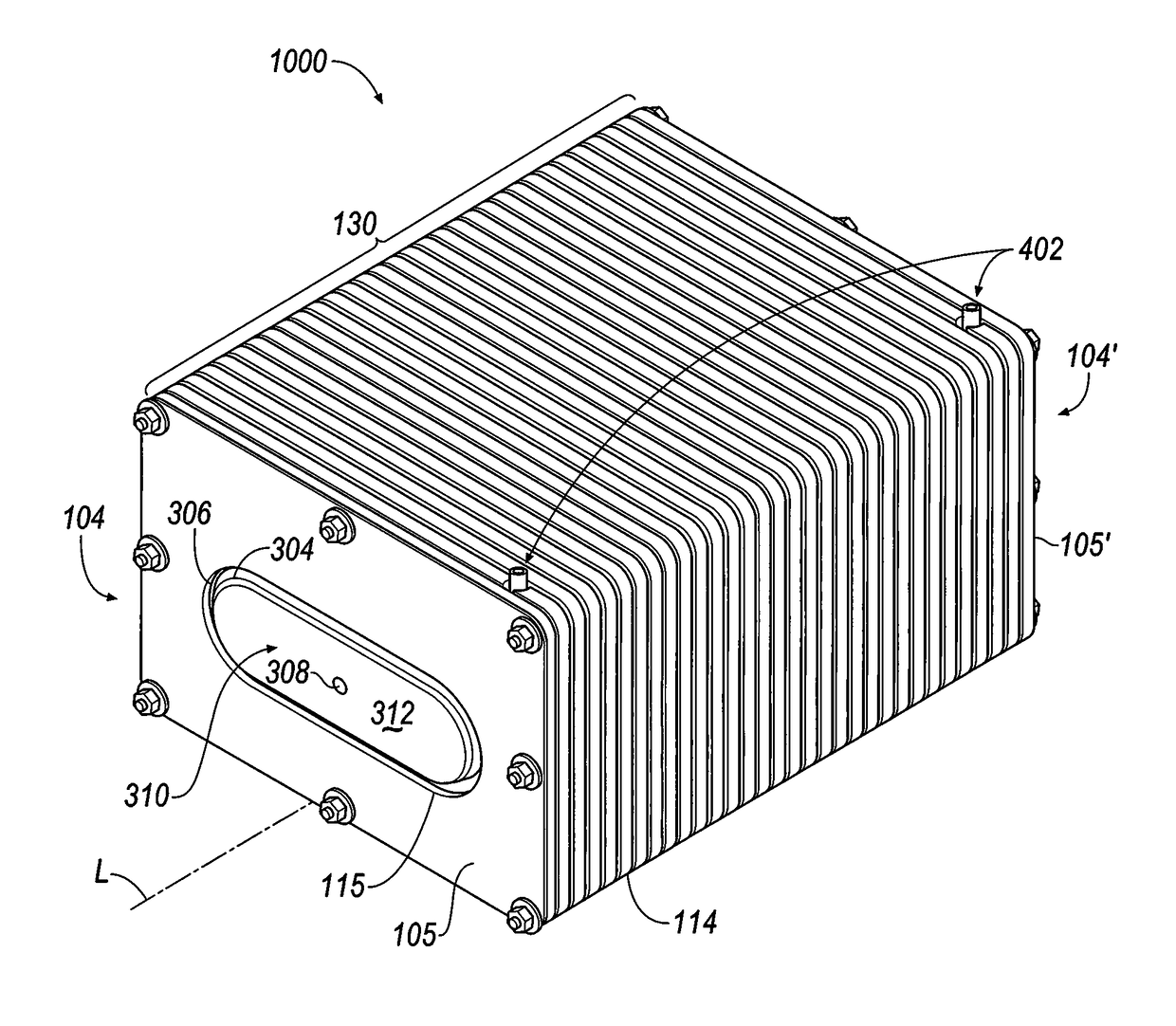

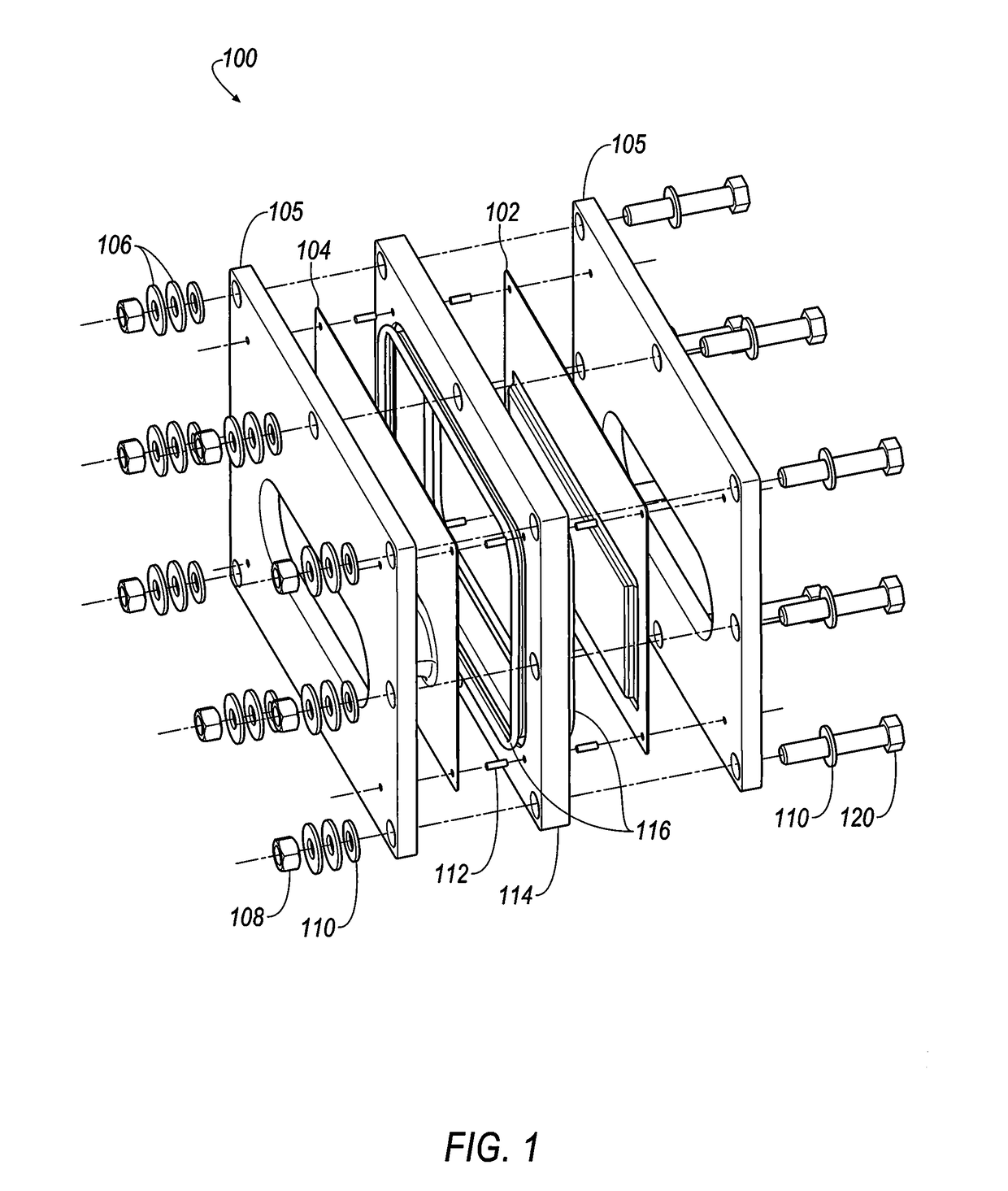

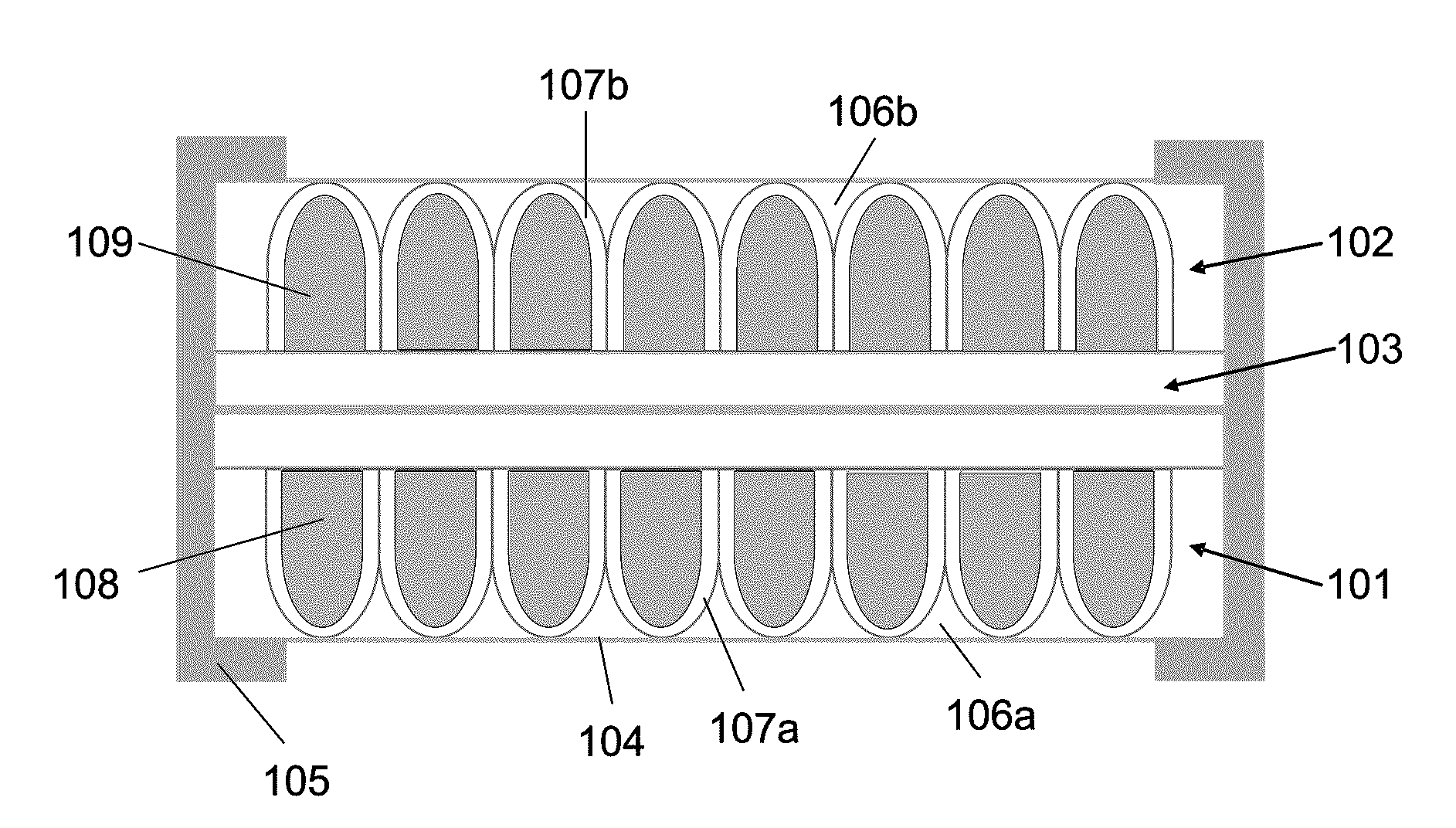

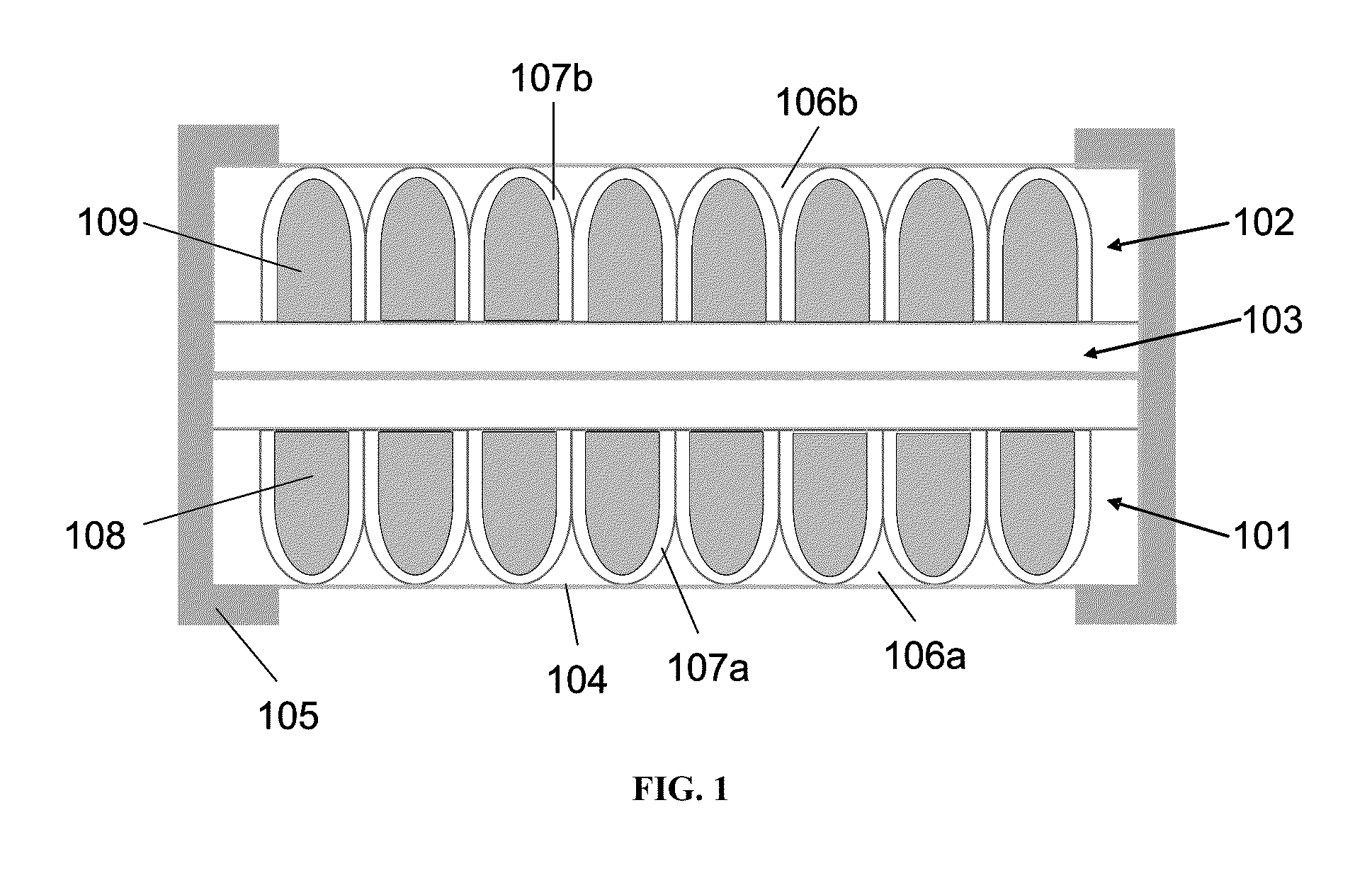

Stationary semi-solid battery module and method of manufacture

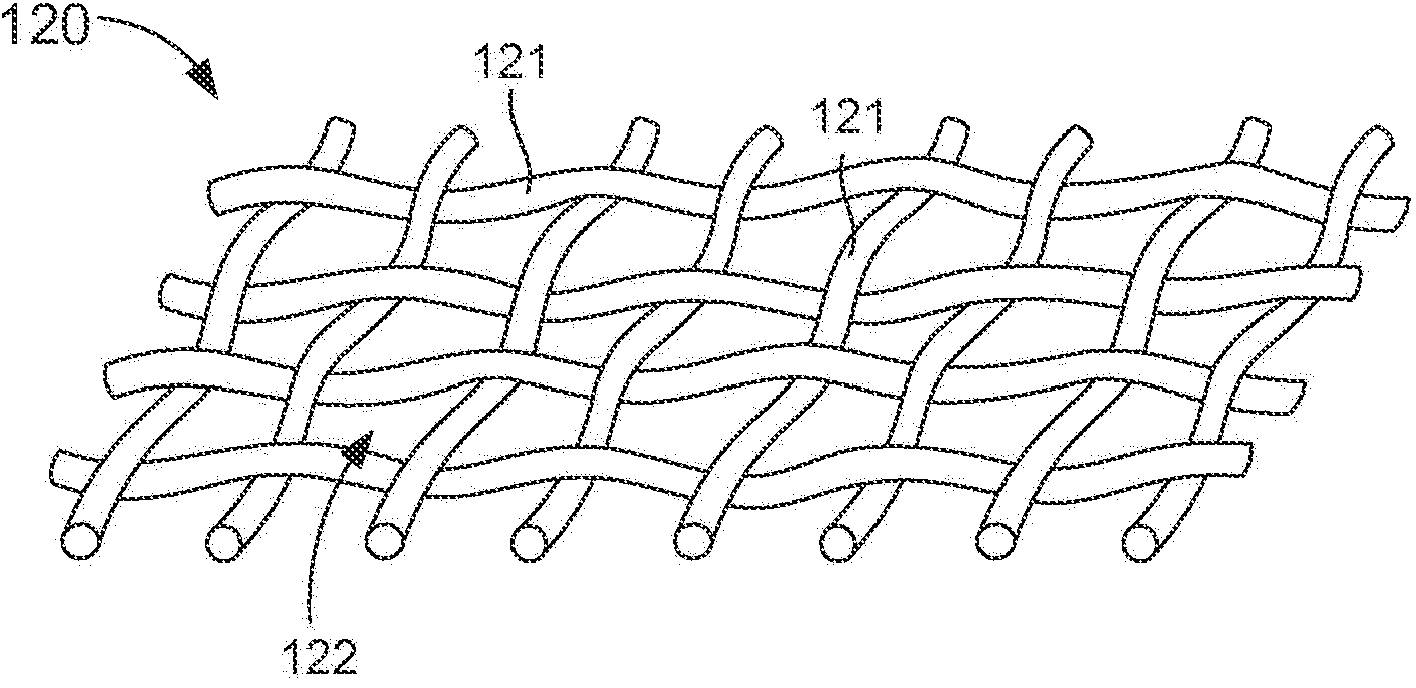

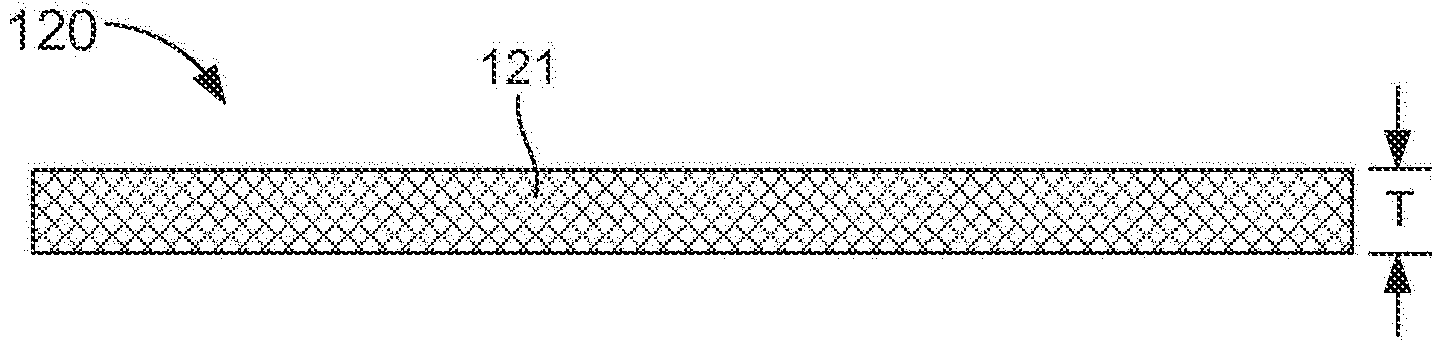

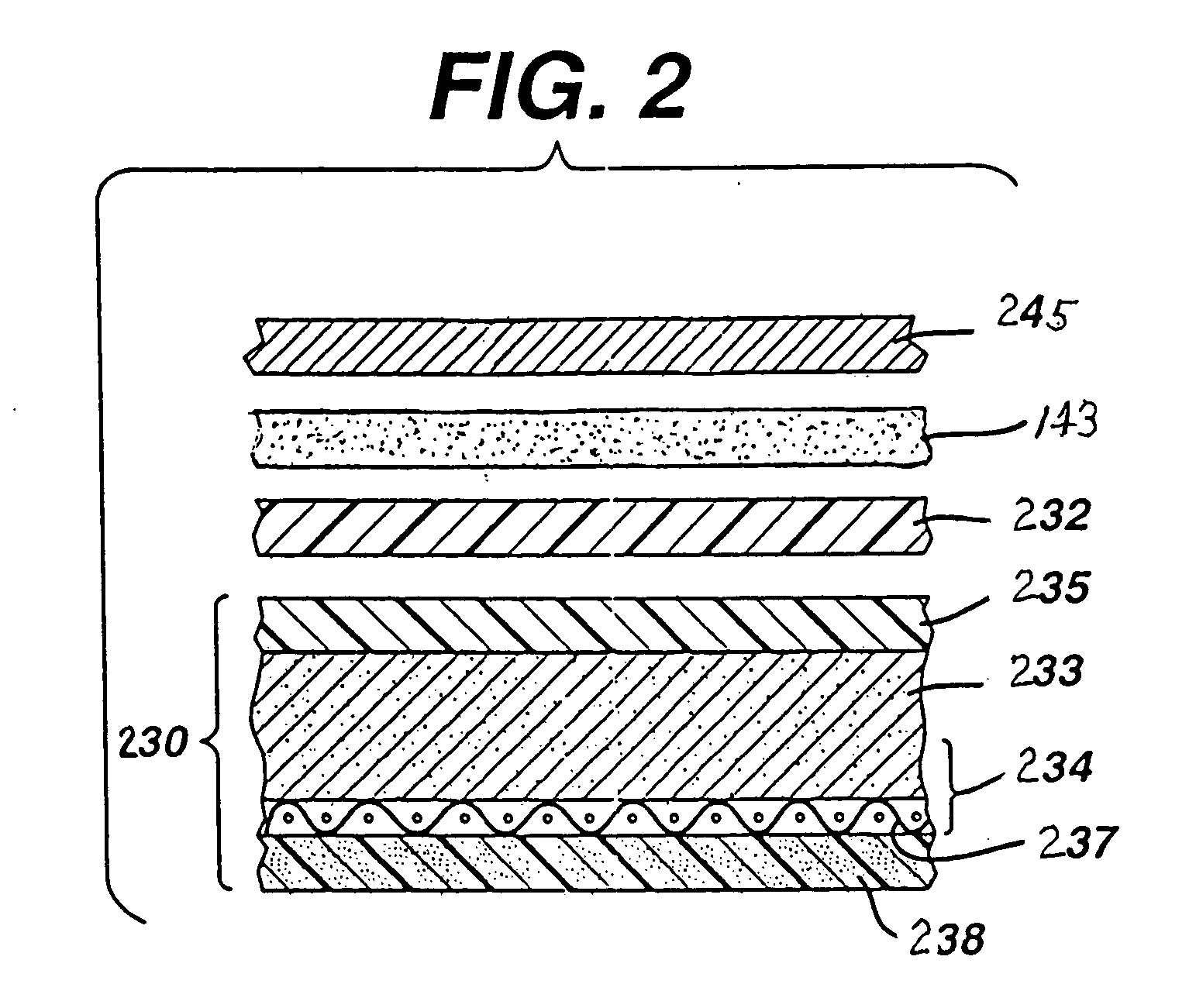

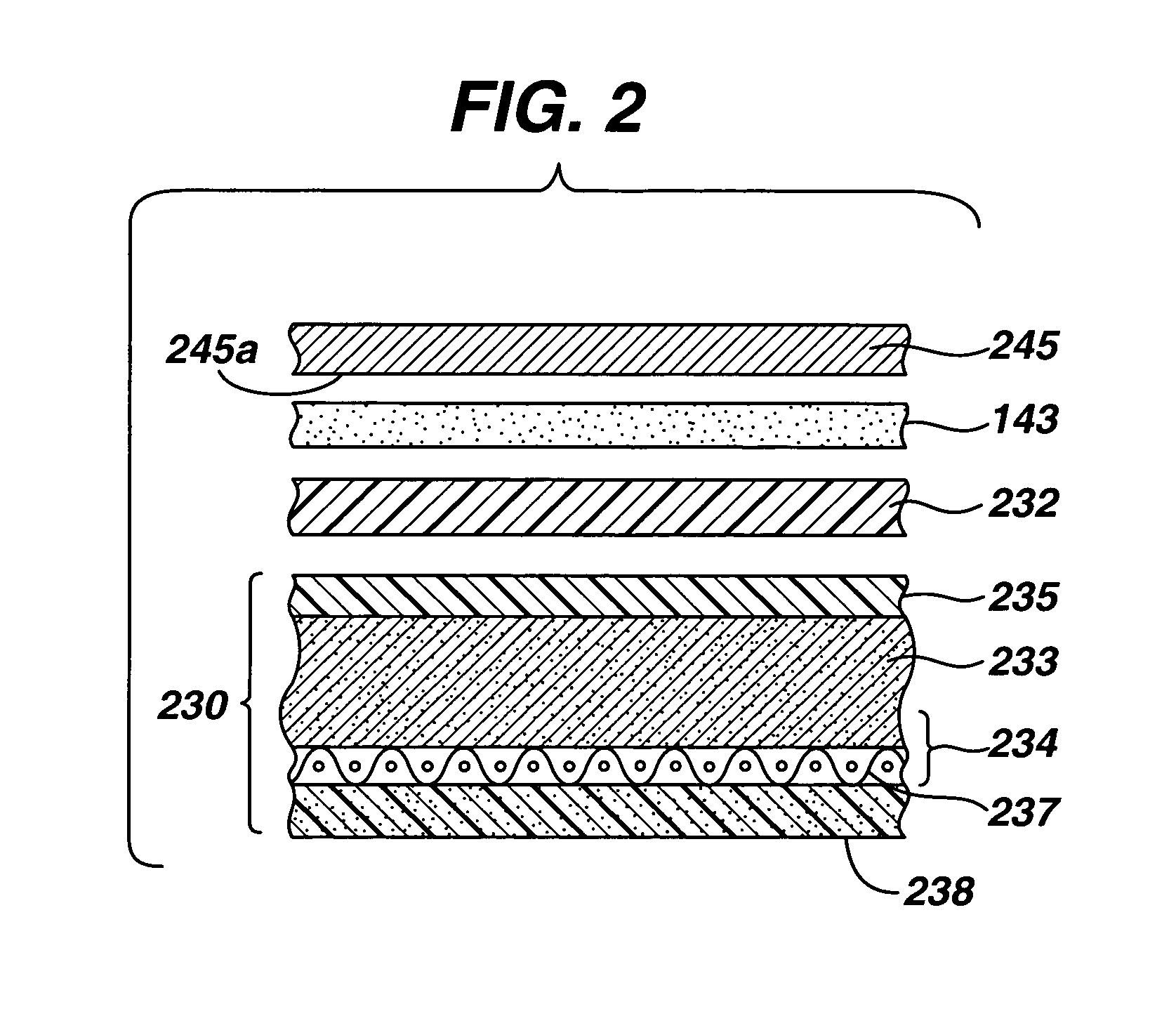

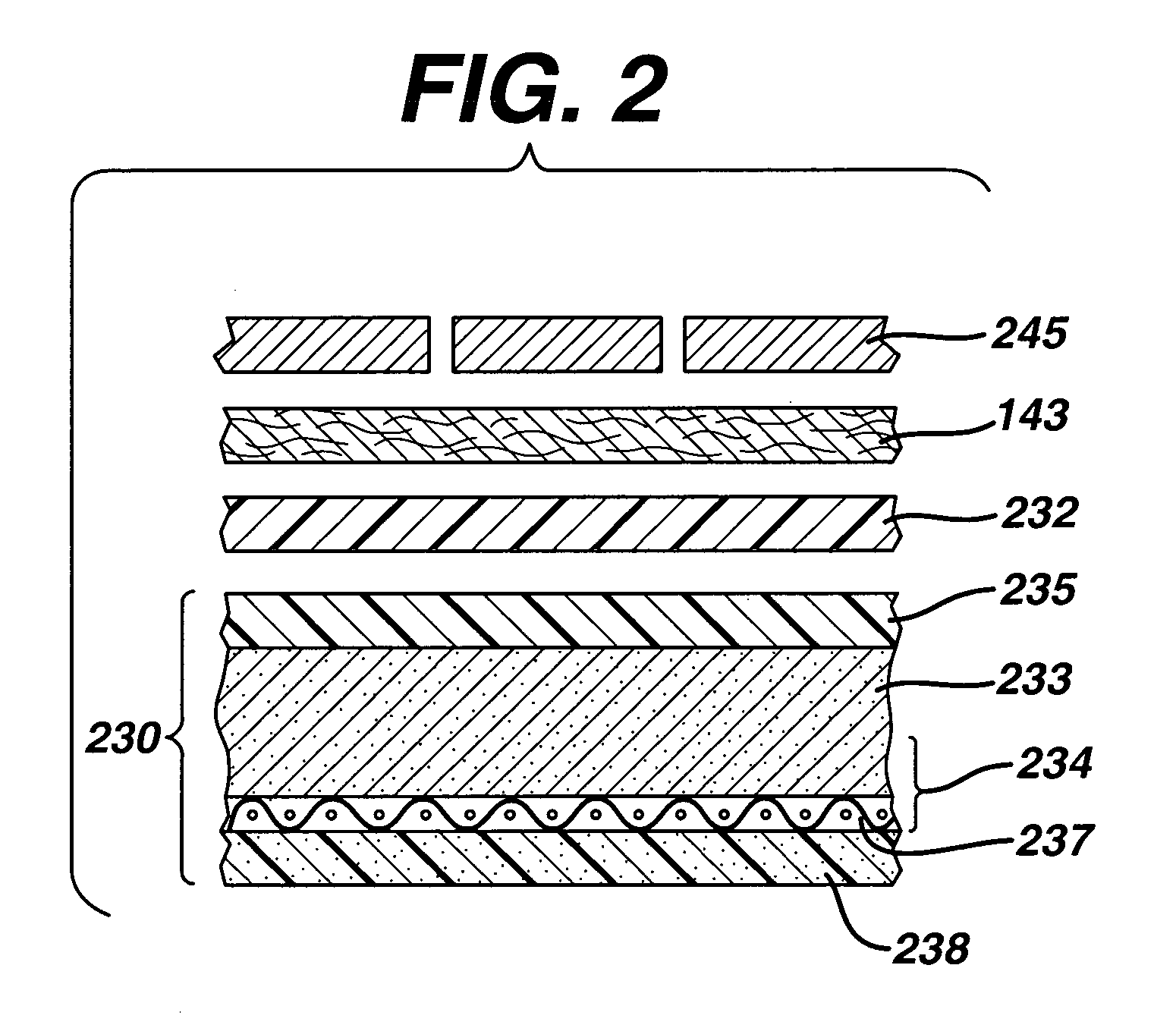

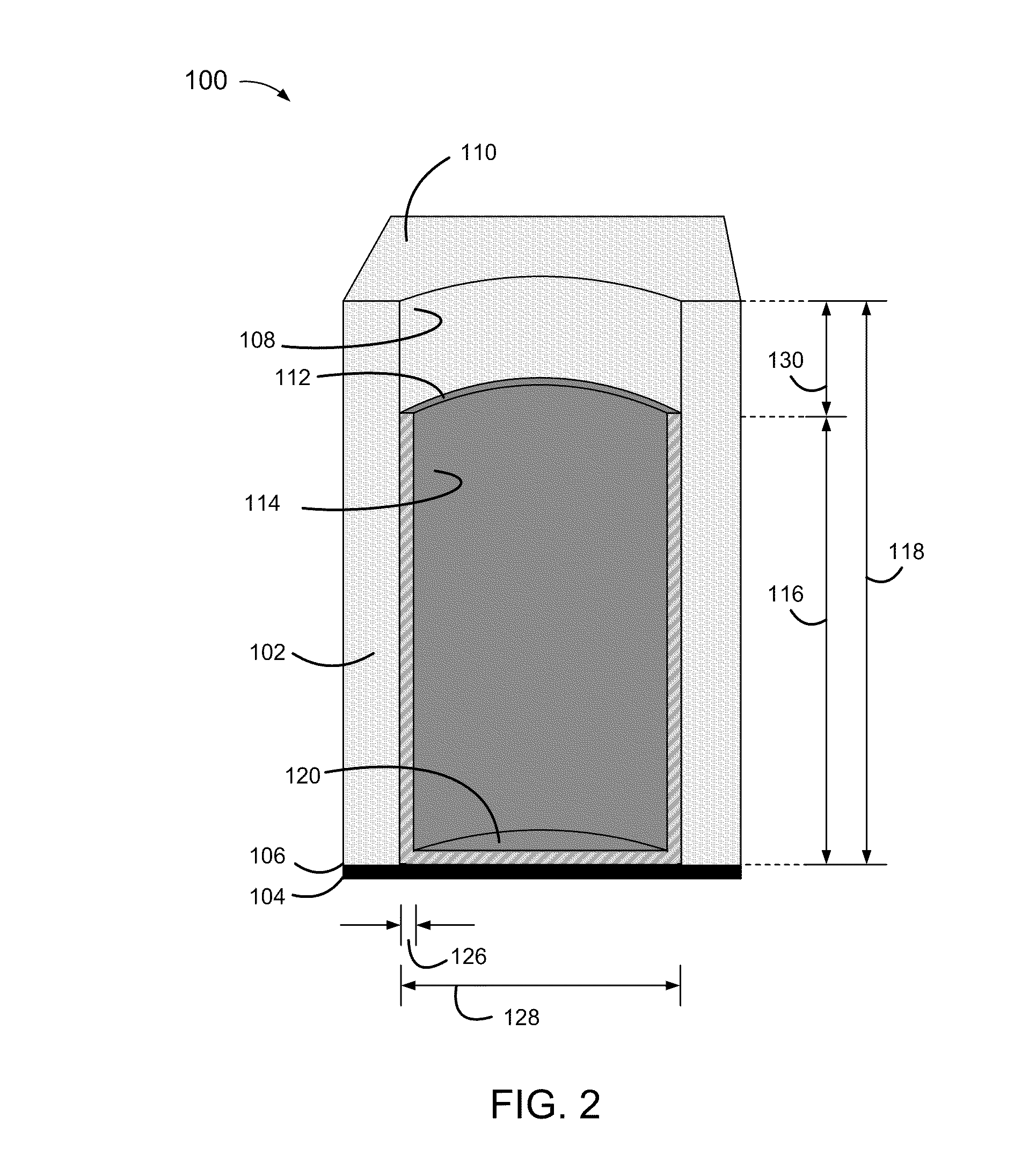

An electrochemical cell includes an anode, a semi-solid cathode, and a separator disposed therebetween. The semi-solid cathode includes a porous current collector and a suspension of an active material and a conductive material disposed in a non-aqueous liquid electrolyte. The porous current collector is at least partially disposed within the suspension such that the suspension substantially encapsulates the porous current collector.

Owner:24M TECH INC

Zinc/air cell with improved anode

InactiveUS20050003271A1Eliminate disadvantagesSufficient structural integrityFuel and primary cellsAlkaline accumulatorsSolid massPolyvinyl alcohol

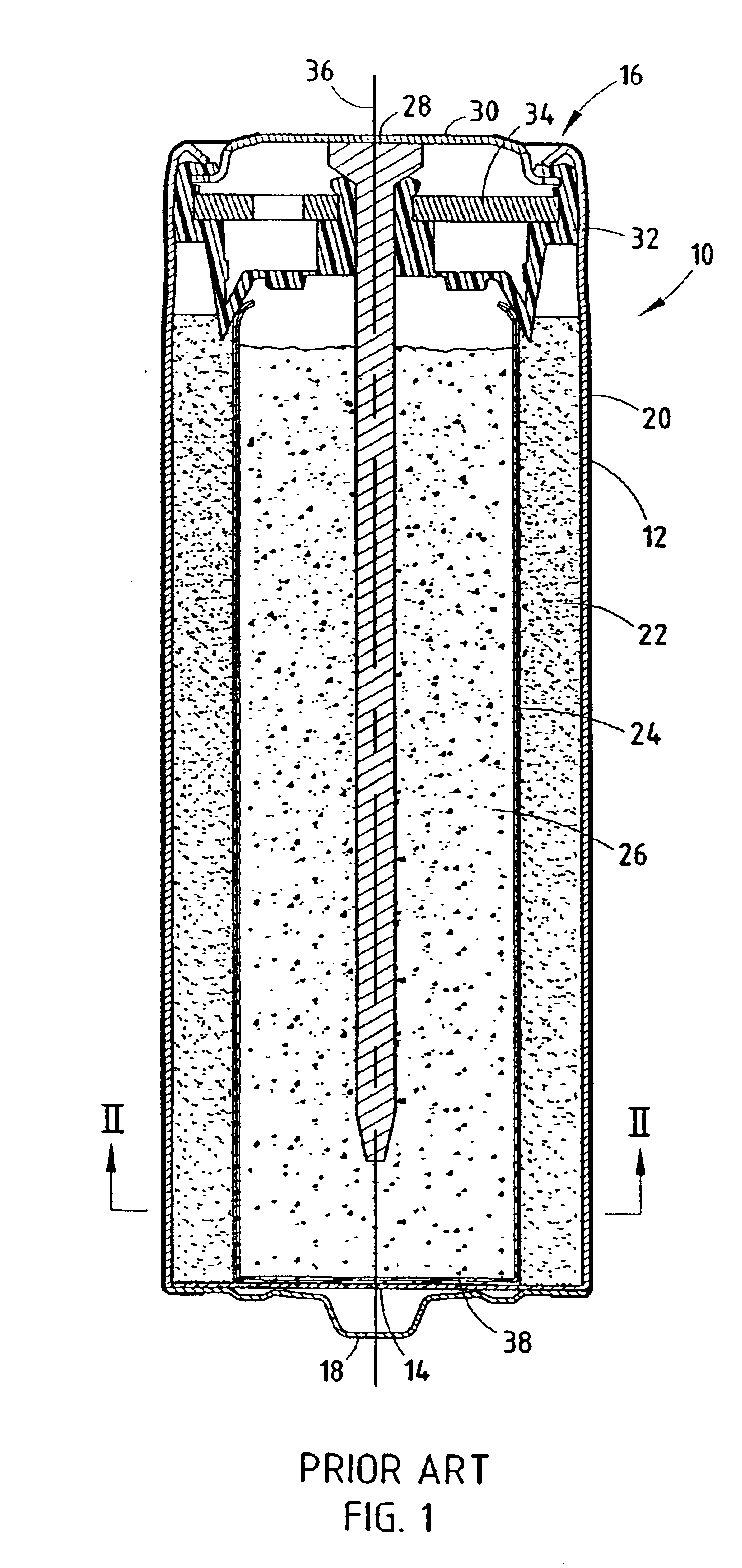

A method of forming an anode comprising zinc for a zinc / air cell. The method involves mixing zinc particles with binders including preferably polyvinylalcohol, surfactant and water to form a wet paste. The wet paste is compacted and molded into the near shape of the cell's anode cavity and then heated to evaporate water. A solid porous zinc mass is formed wherein the zinc particles are held bound within a network with microscopic void spaces between the zinc particles. The solid mass can be inserted into the cell's anode cavity and aqueous alkaline electrolyte, preferably comprising potassium hydroxide, then added. The solid mass absorbs the aqueous electrolyte and expands to fill the anode cavity to form the final fresh anode.

Owner:DURACELL U S OPERATIONS

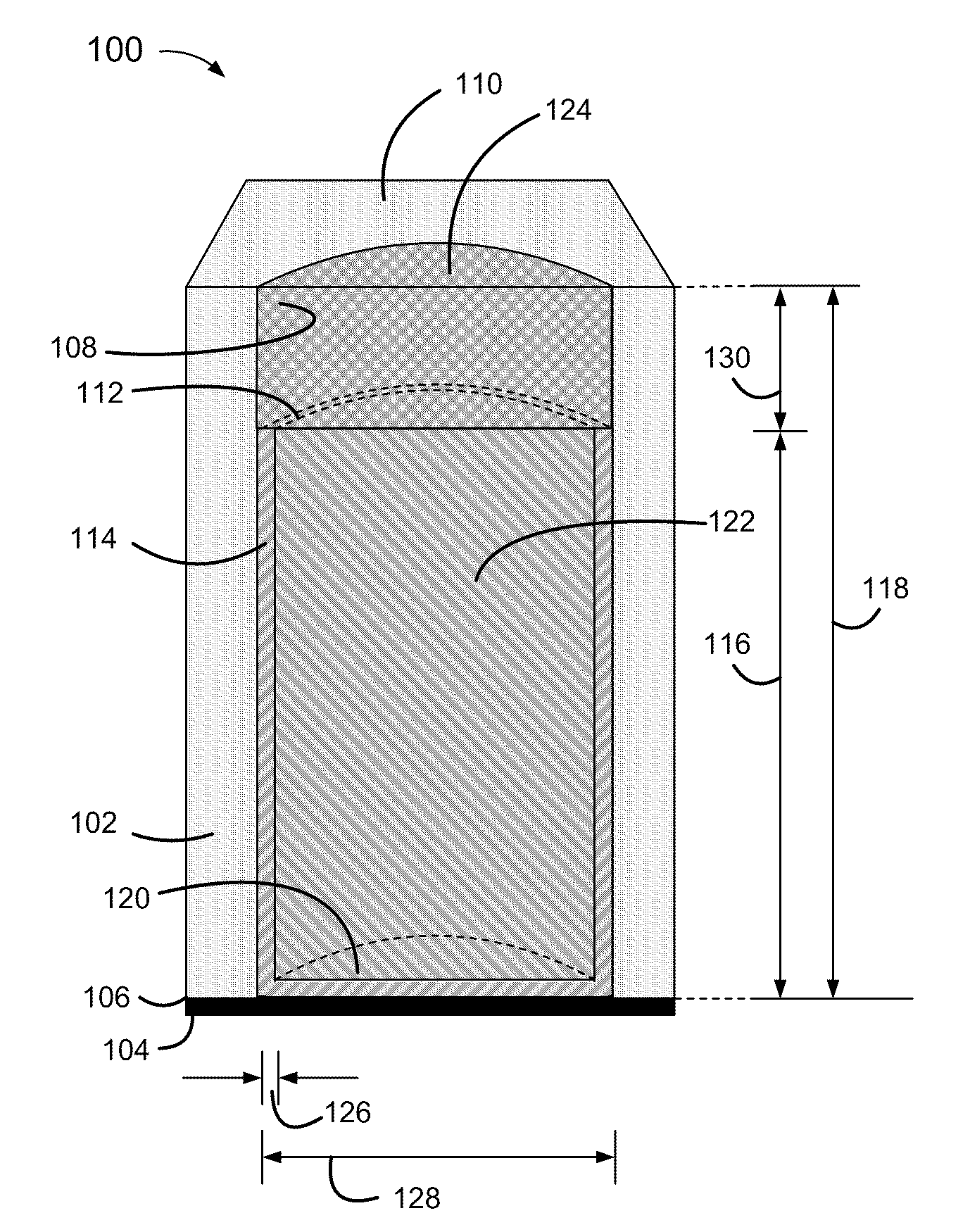

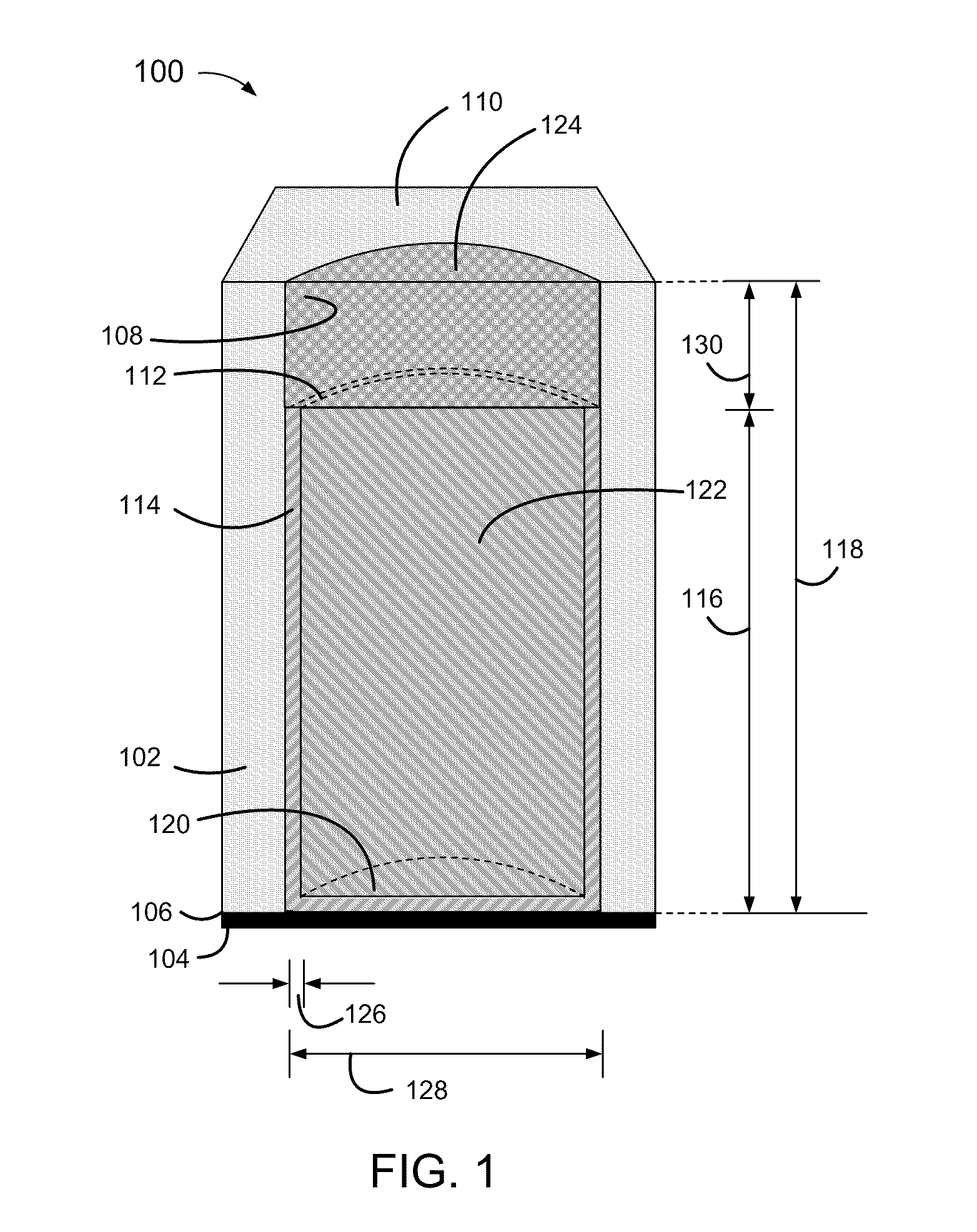

Zinc/air cell

ActiveUS7001689B2Optimized diameterBe consistentFuel and primary cellsFilling tube/pocket electrodesInterference fitButton battery

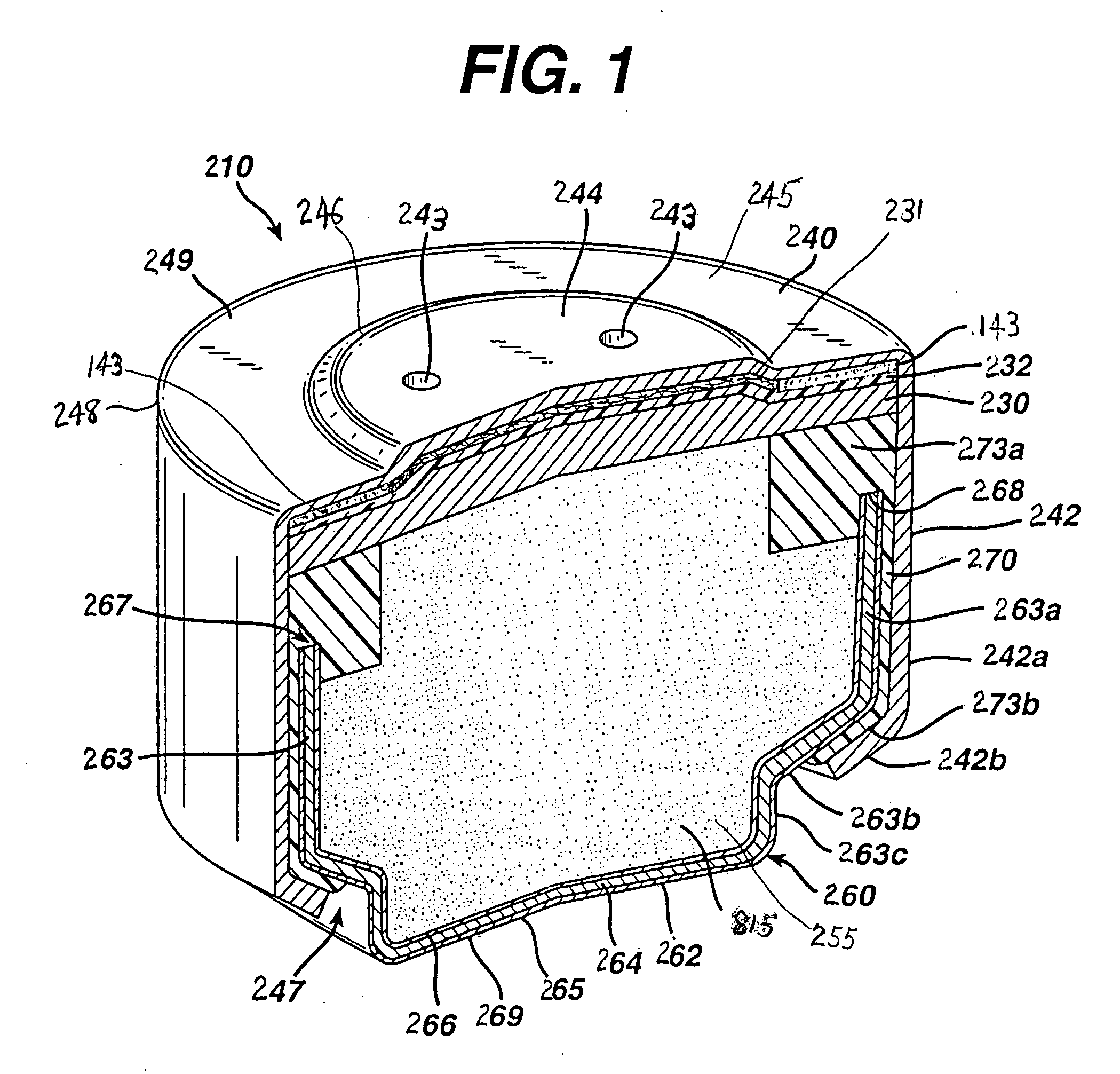

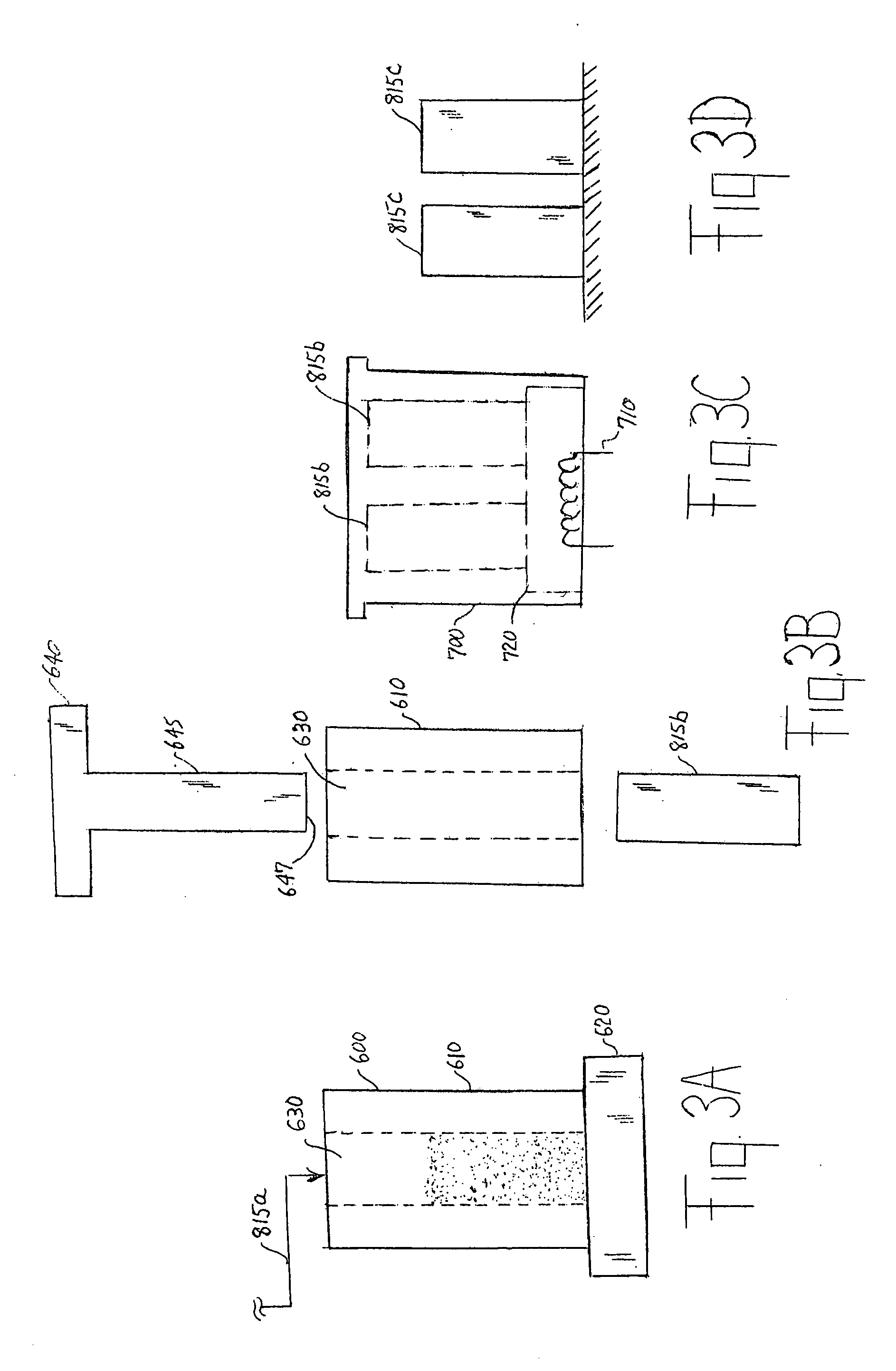

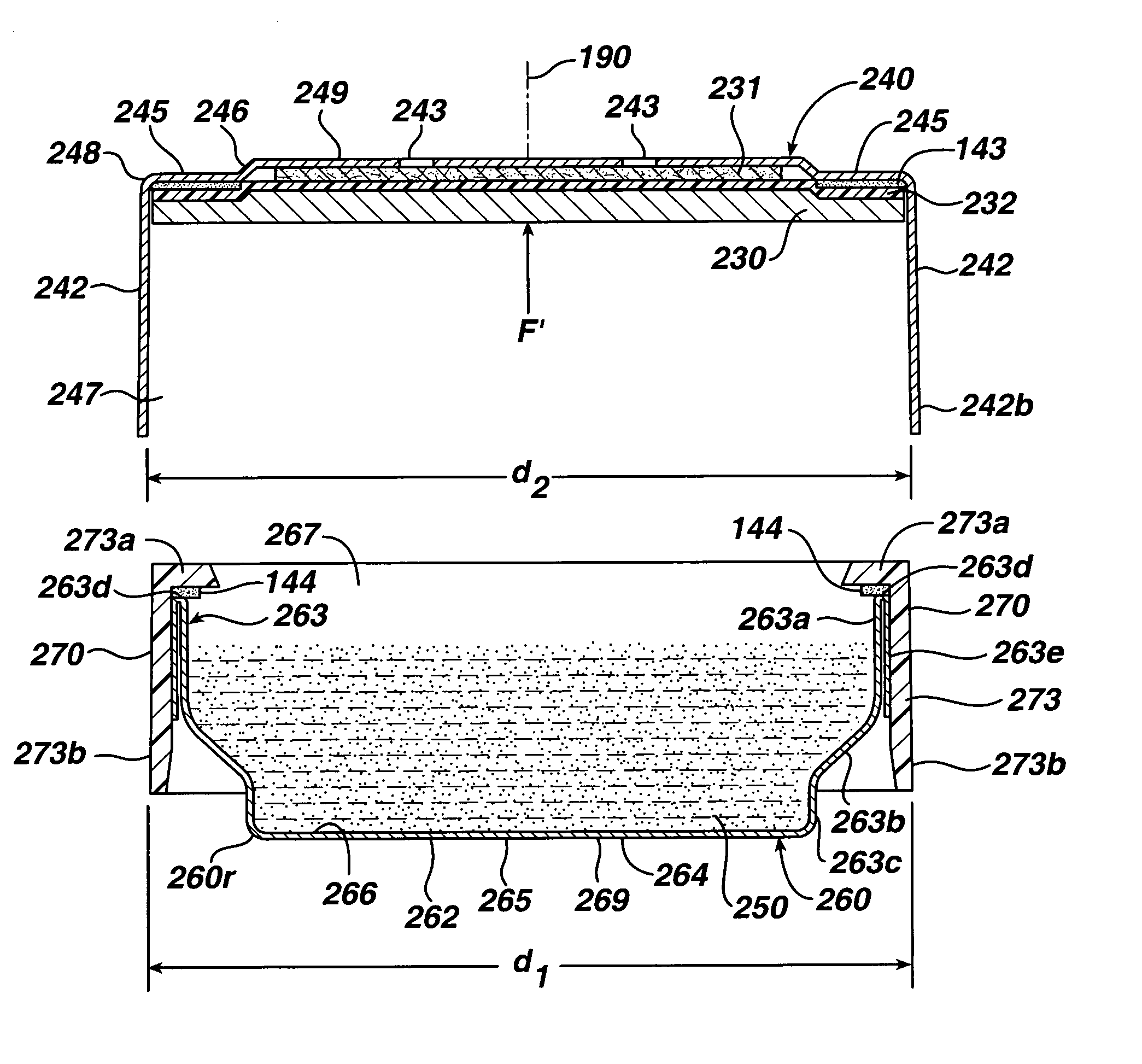

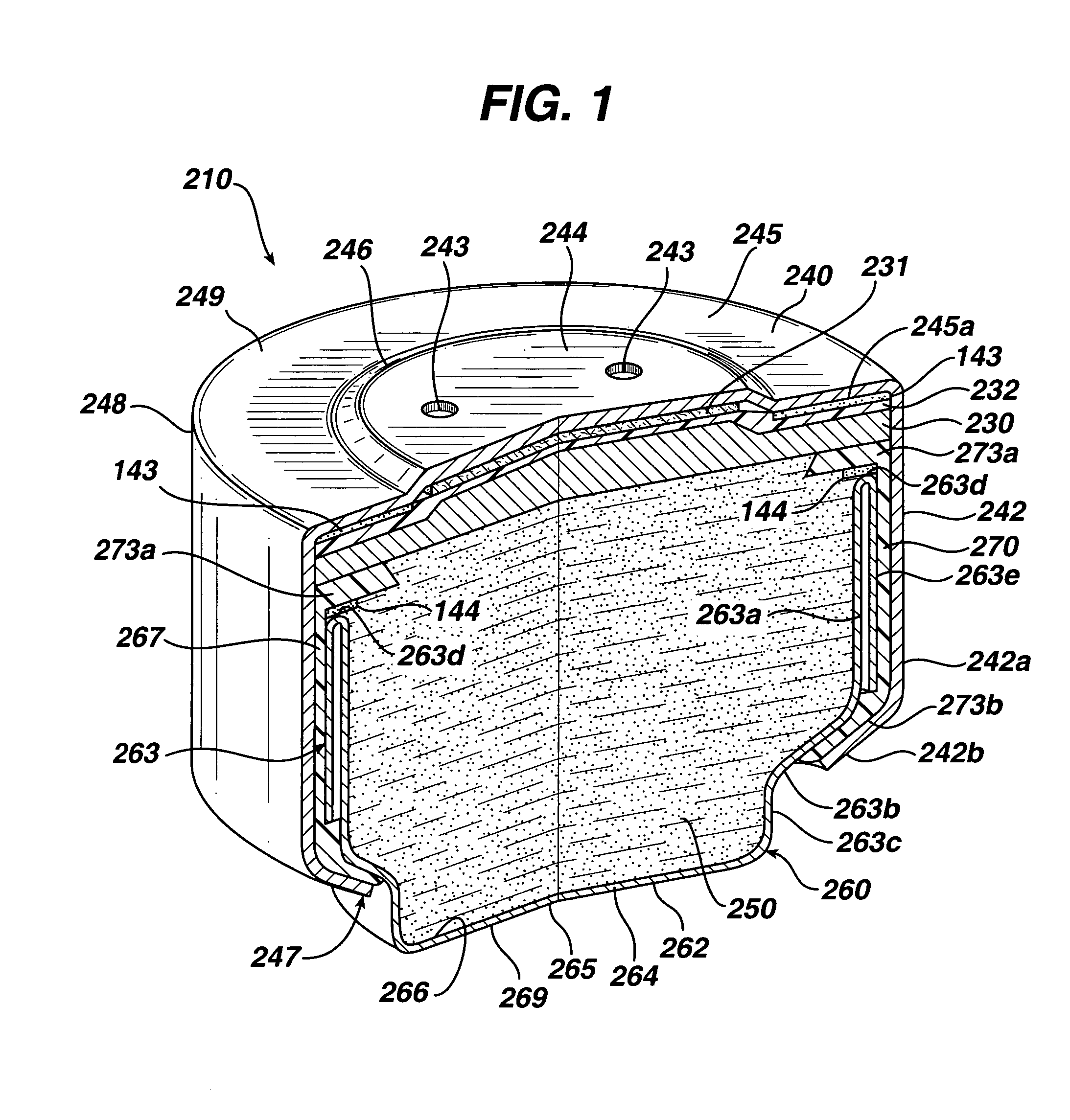

A zinc / air cell having thin walled cup shaped anode casing and cathode casing. The cell may be a button cell having an anode comprising zinc and a cathode, which may be catalytic, comprising manganese dioxide. The anode and cathode casings have small wall thicknesses, preferably between 2 and 5 mil (0.0508 and 0.127 mm), desirably between about 2 and 3 mil (0.0508 and 0.0762 mm). There is an insulating seal ring covering at least a portion of the anode casing side walls. During cell assembly the cathode casing side wall is pushed over at least a portion of the anode casing side wall with insulating sealing disk therebetween. A tight interference fit is achieved with the outside diameter of the anode casing plus insulating seal thereon being preferably between about 2 and 4.5 mil (0.0508 and 0.114 mm) greater than the inside diameter of the cathode casing. This reduces the tendency of the casing side walls to spring back after crimping.

Owner:DURACELL U S OPERATIONS

Composition and energy storage device

In accordance with one aspect of the present invention, a cathode composition is provided that includes at least one transition metal or a transition metal salt, wherein the transition metal is at least one selected from the group consisting of nickel, iron, cobalt, chromium, manganese, molybdenum, and antimony; an alkali metal halide; a salt comprising an alkali metal halide and a metal halide; and a metal polysulfide compound MSn wherein M is a metal and n is an integer equal to or greater than 2. The salt comprising an alkali metal halide and a metal halide has a melting point of less than about 300° C. An energy storage device comprising the electrode composition is also provided.

Owner:GENERAL ELECTRIC CO

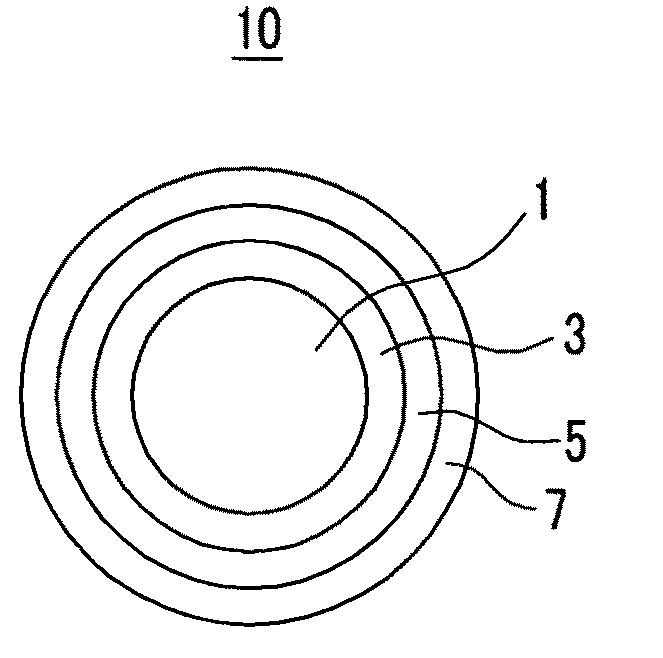

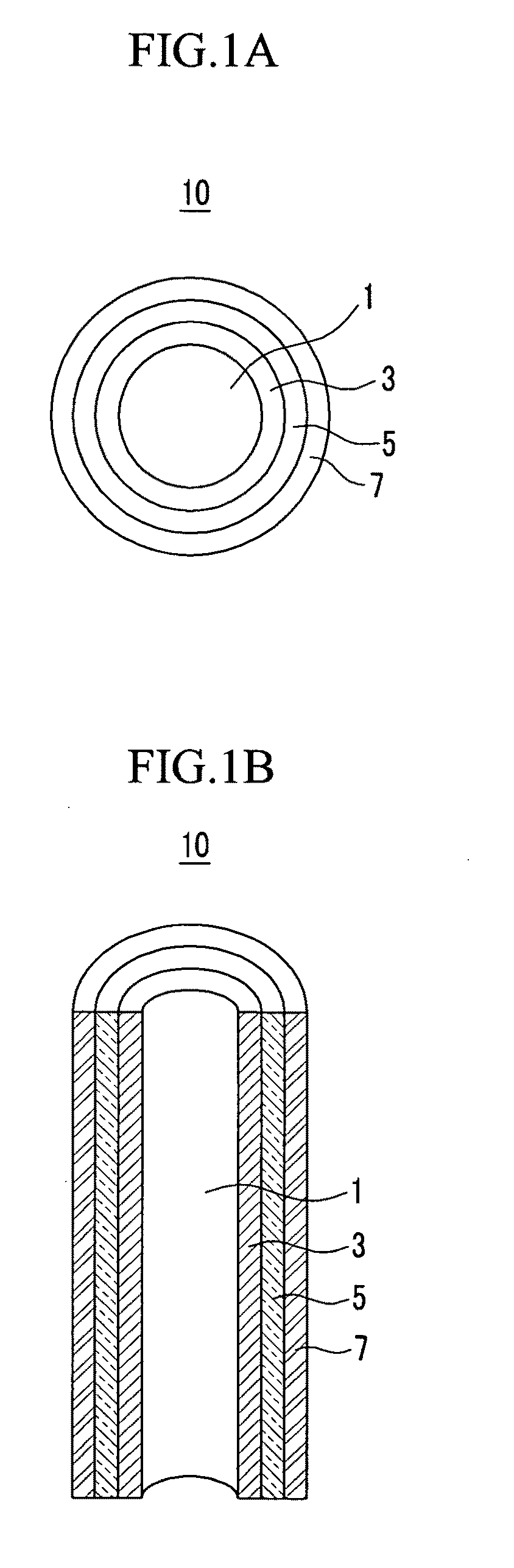

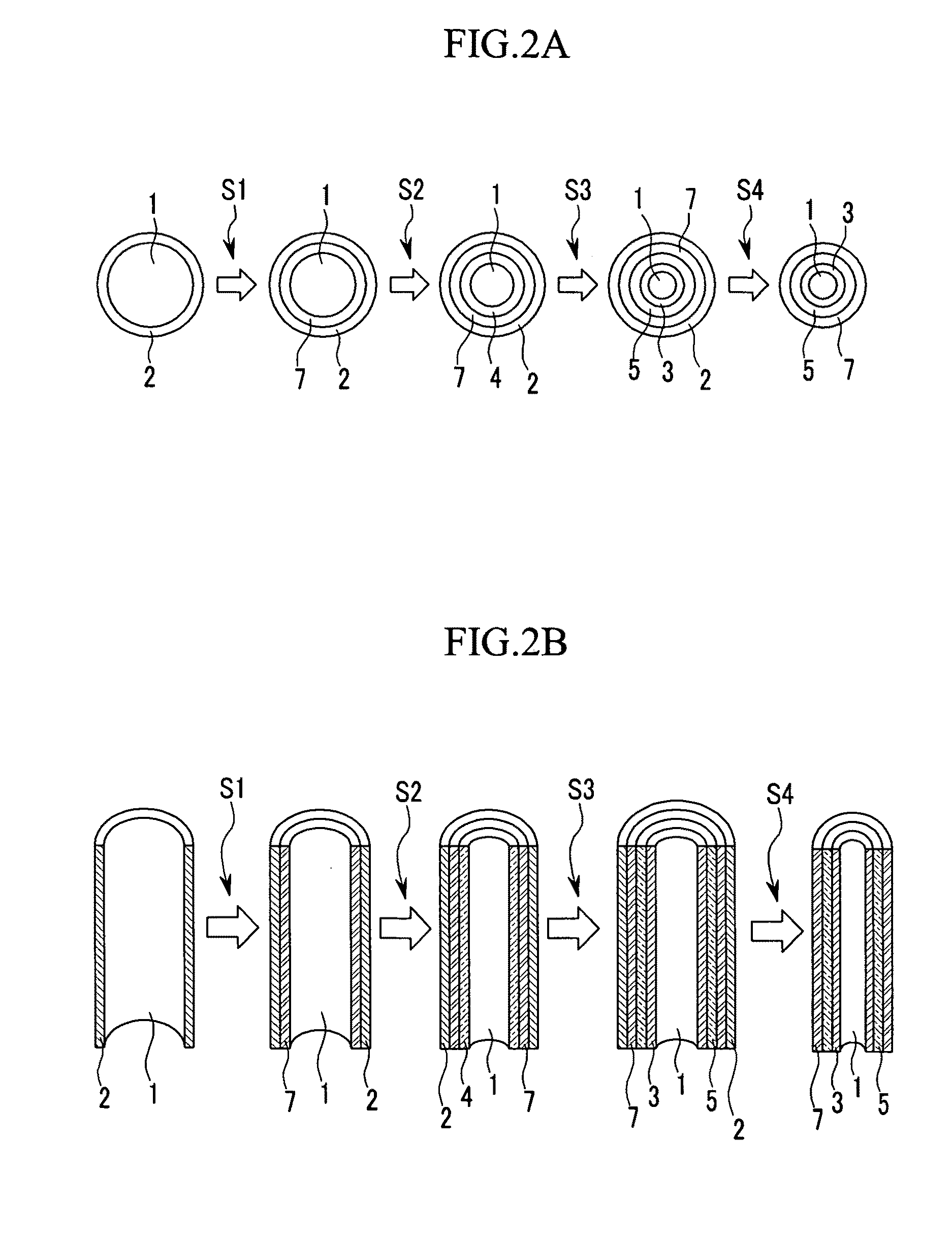

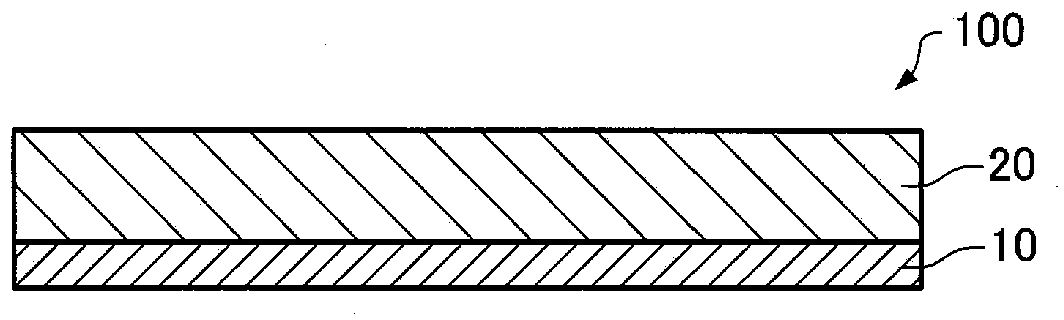

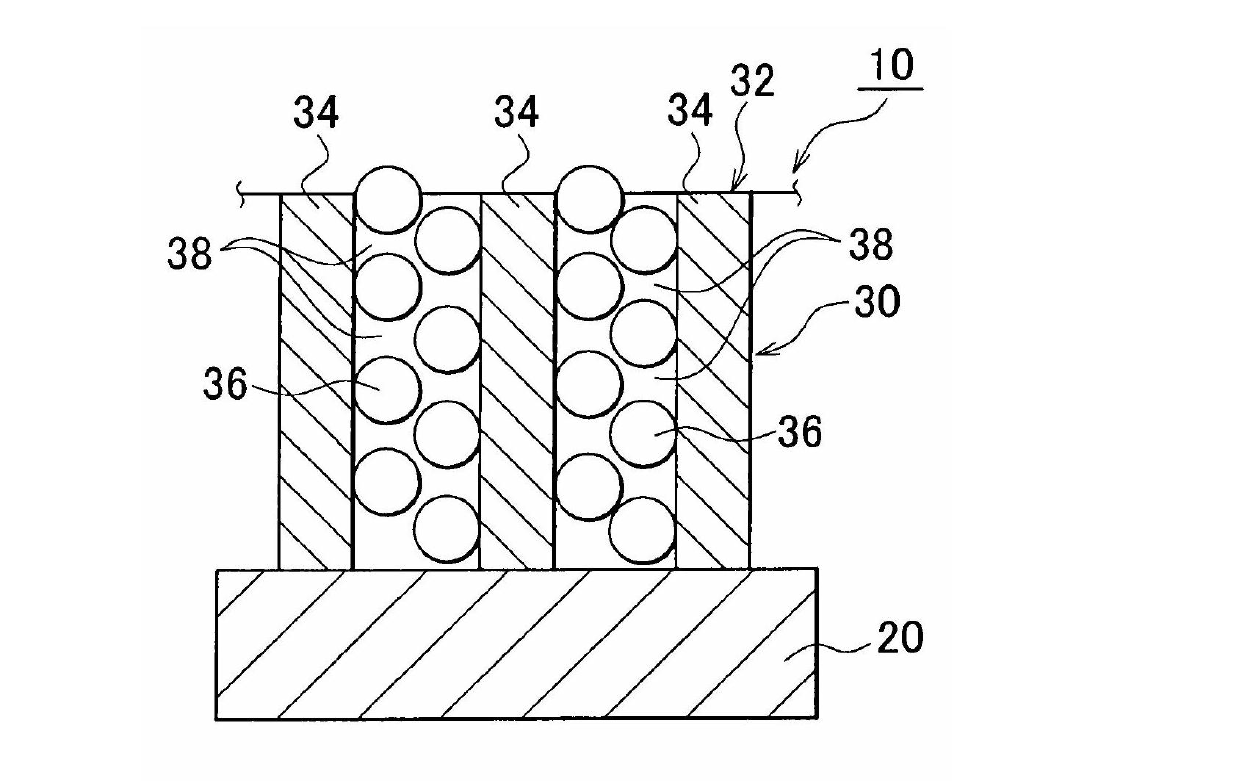

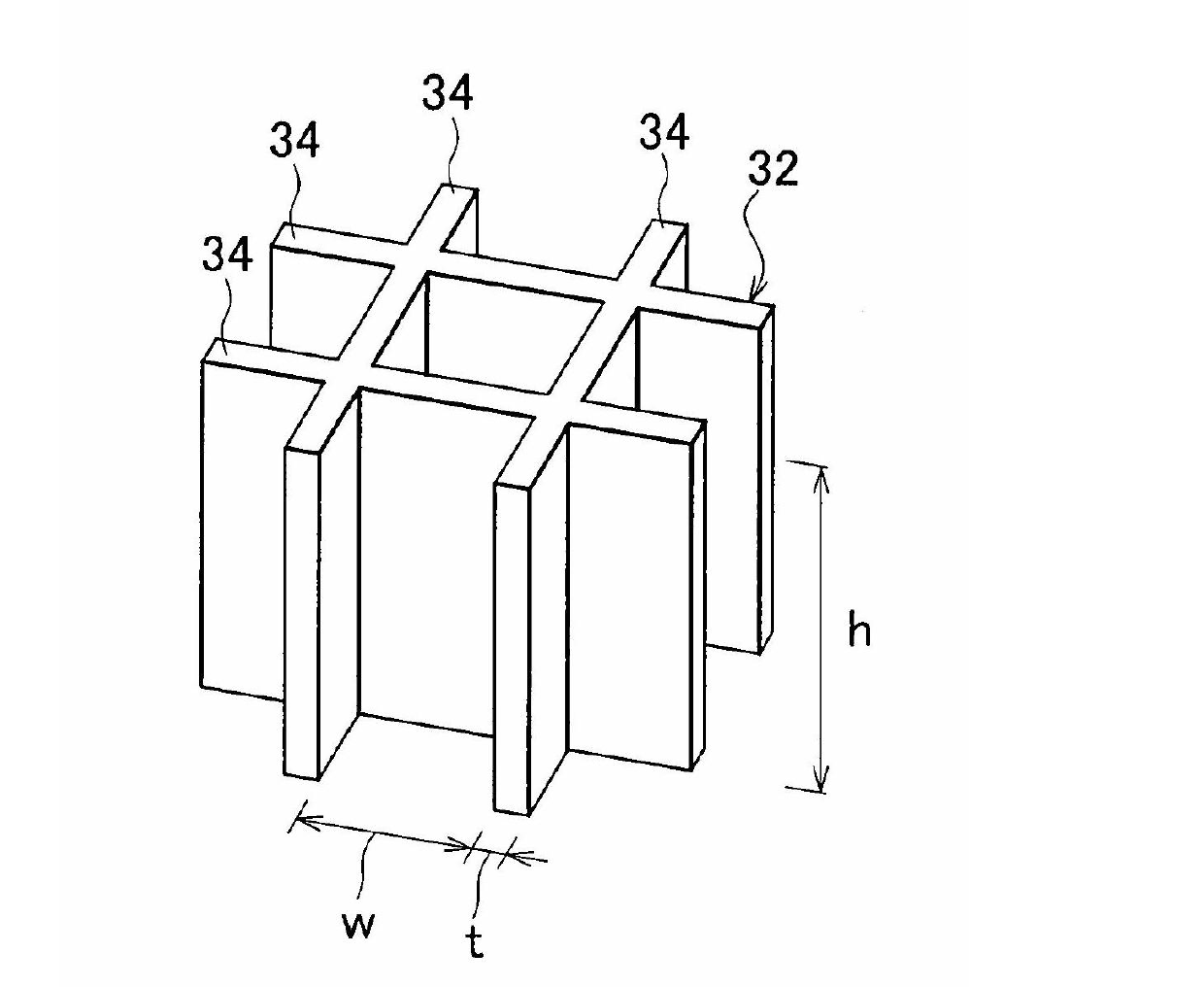

Negative electrode for lithium secondary battery, method for preparing the negative electrode, lithium secondary battery having the negative electrode, and vehicle having the lithium secondary battery

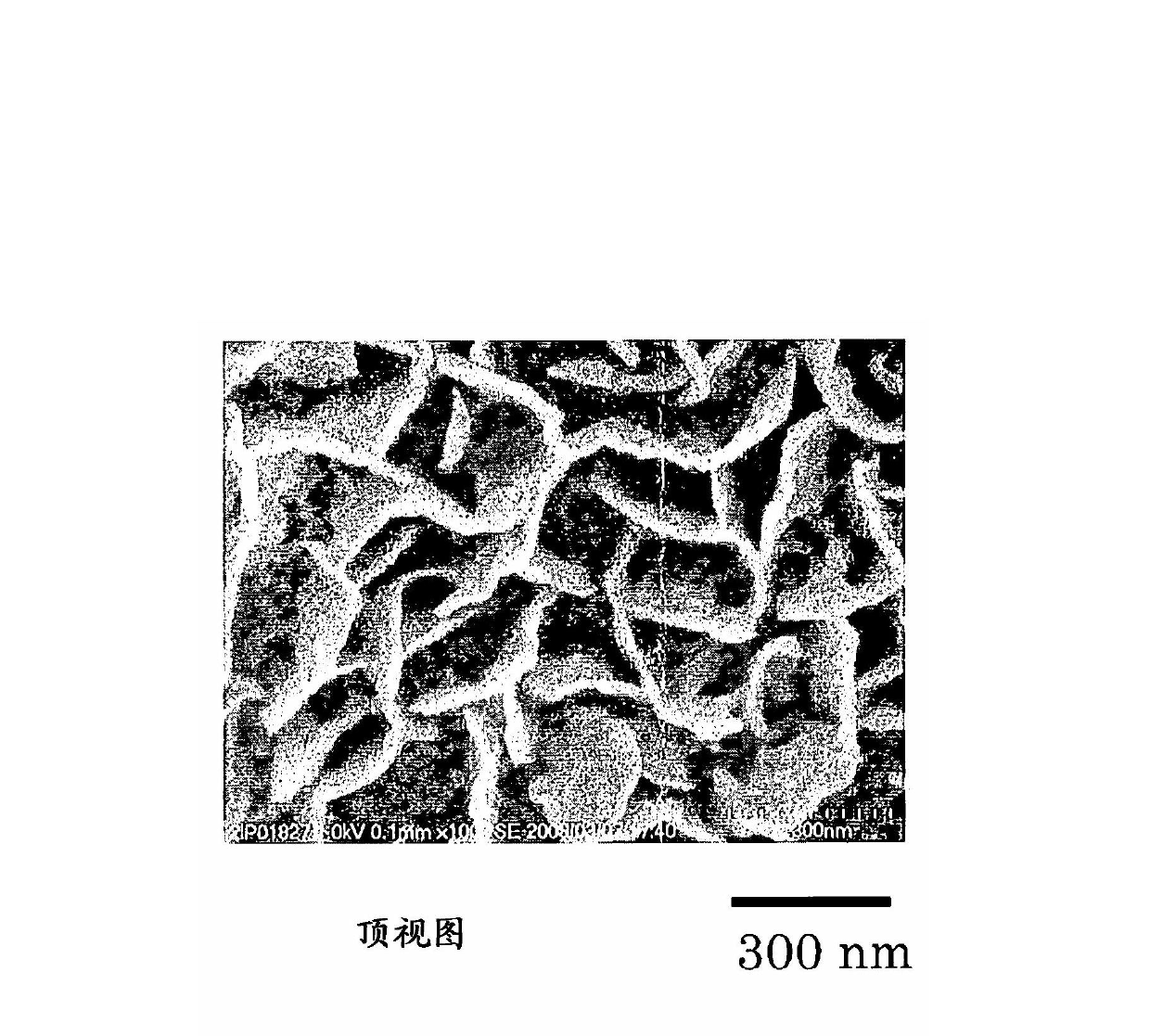

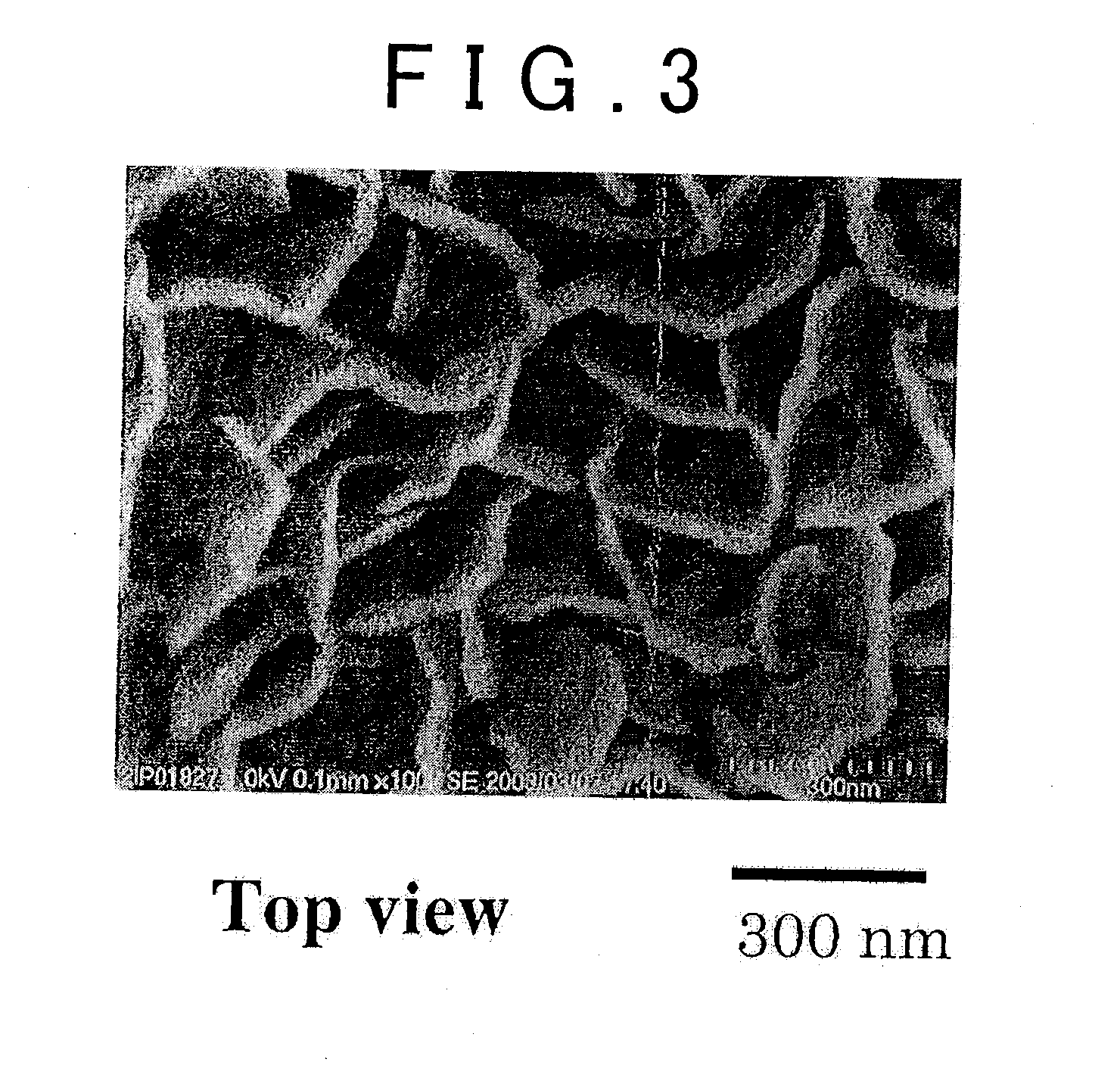

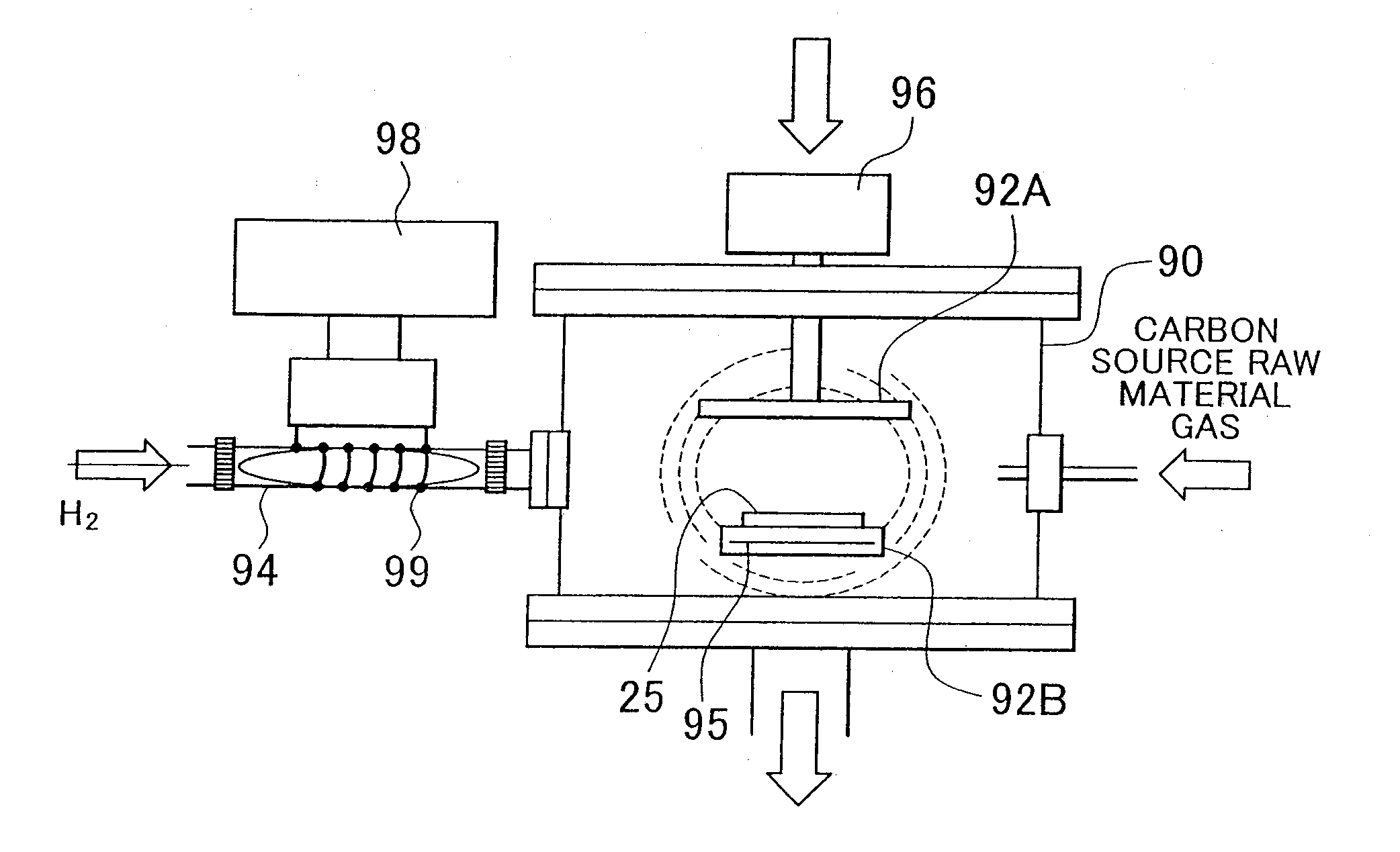

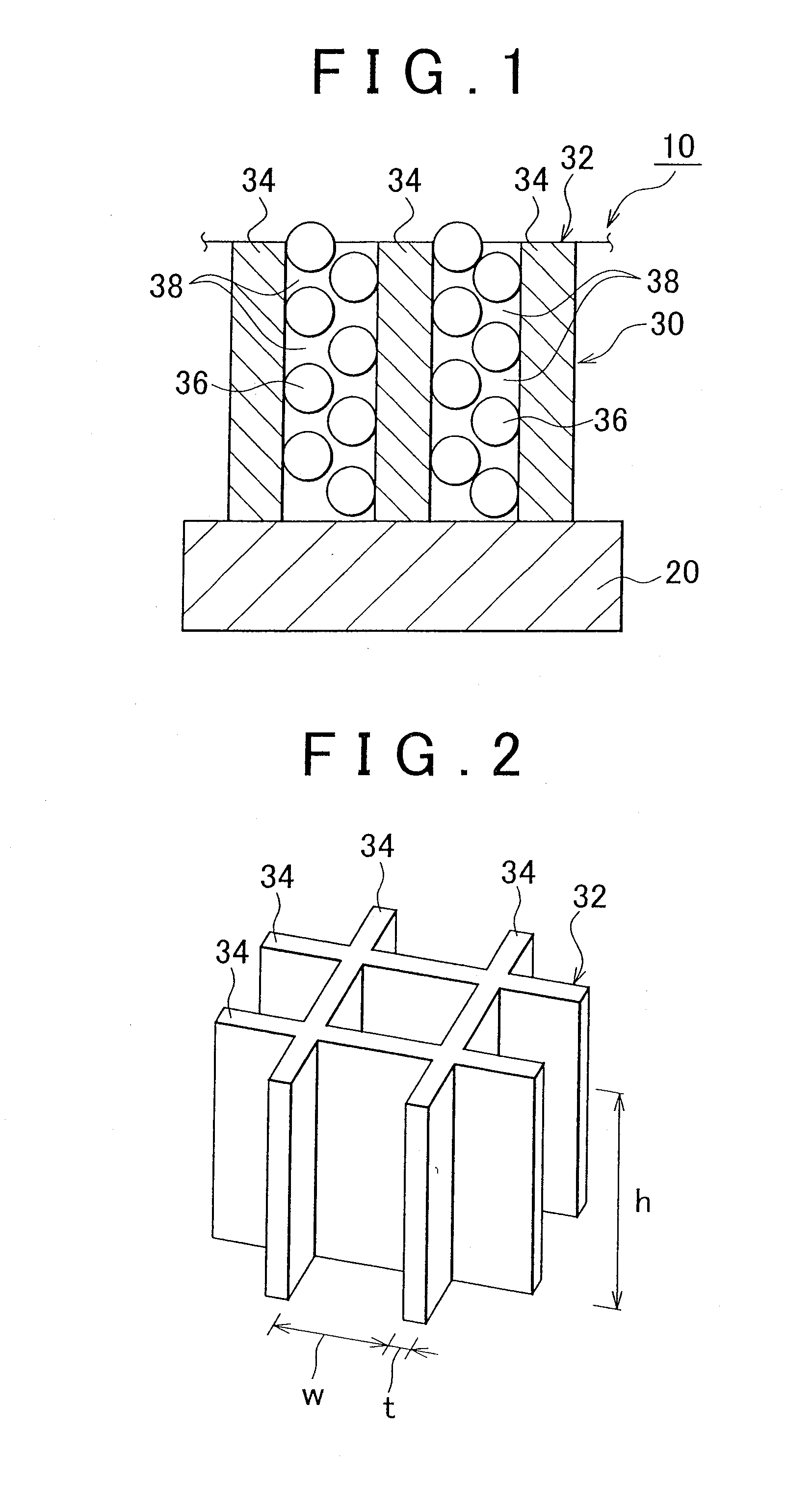

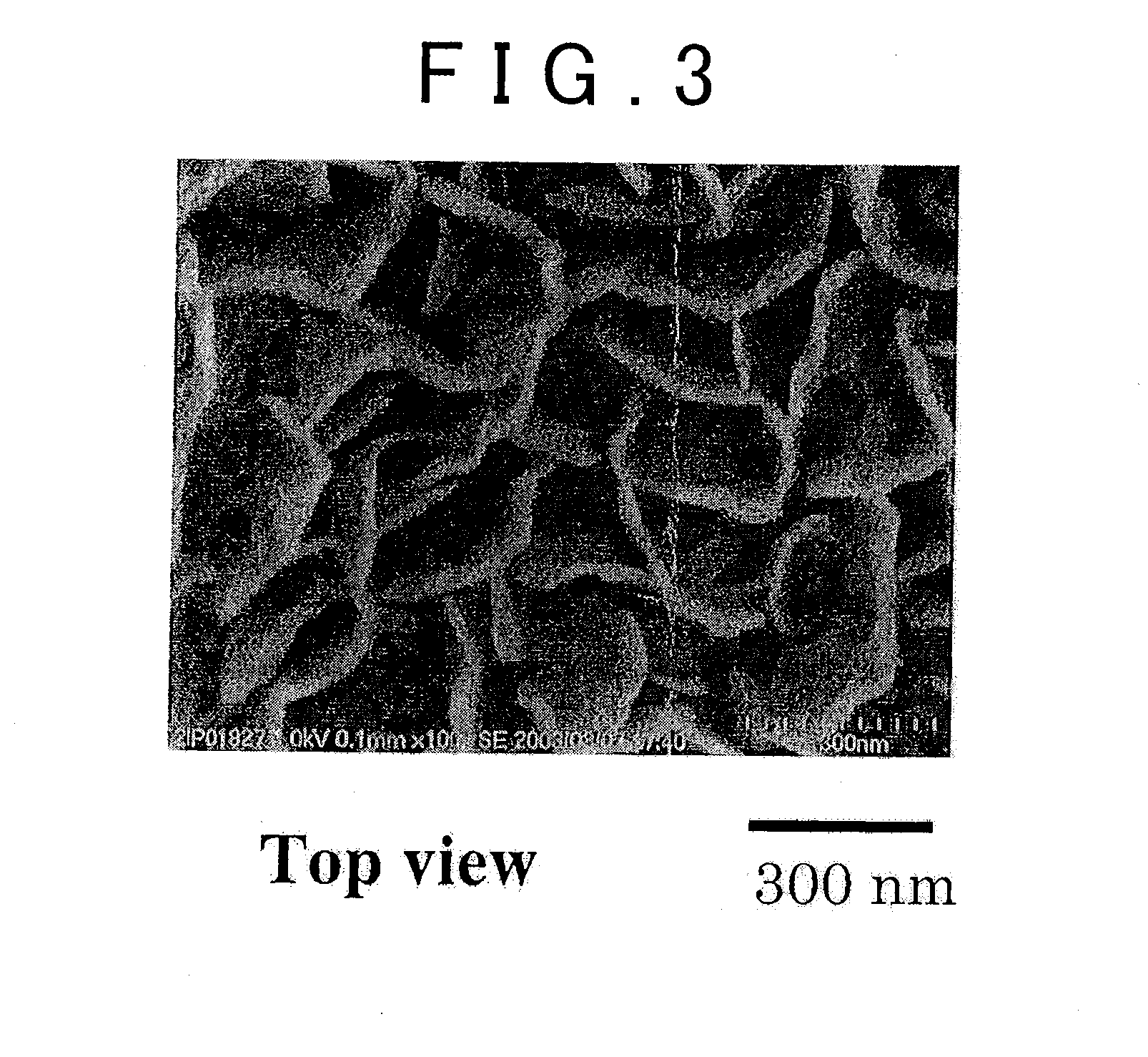

ActiveUS8551657B2Filling tube/pocket electrodesElectrode carriers/collectorsCarbon nanowallsElectrical battery

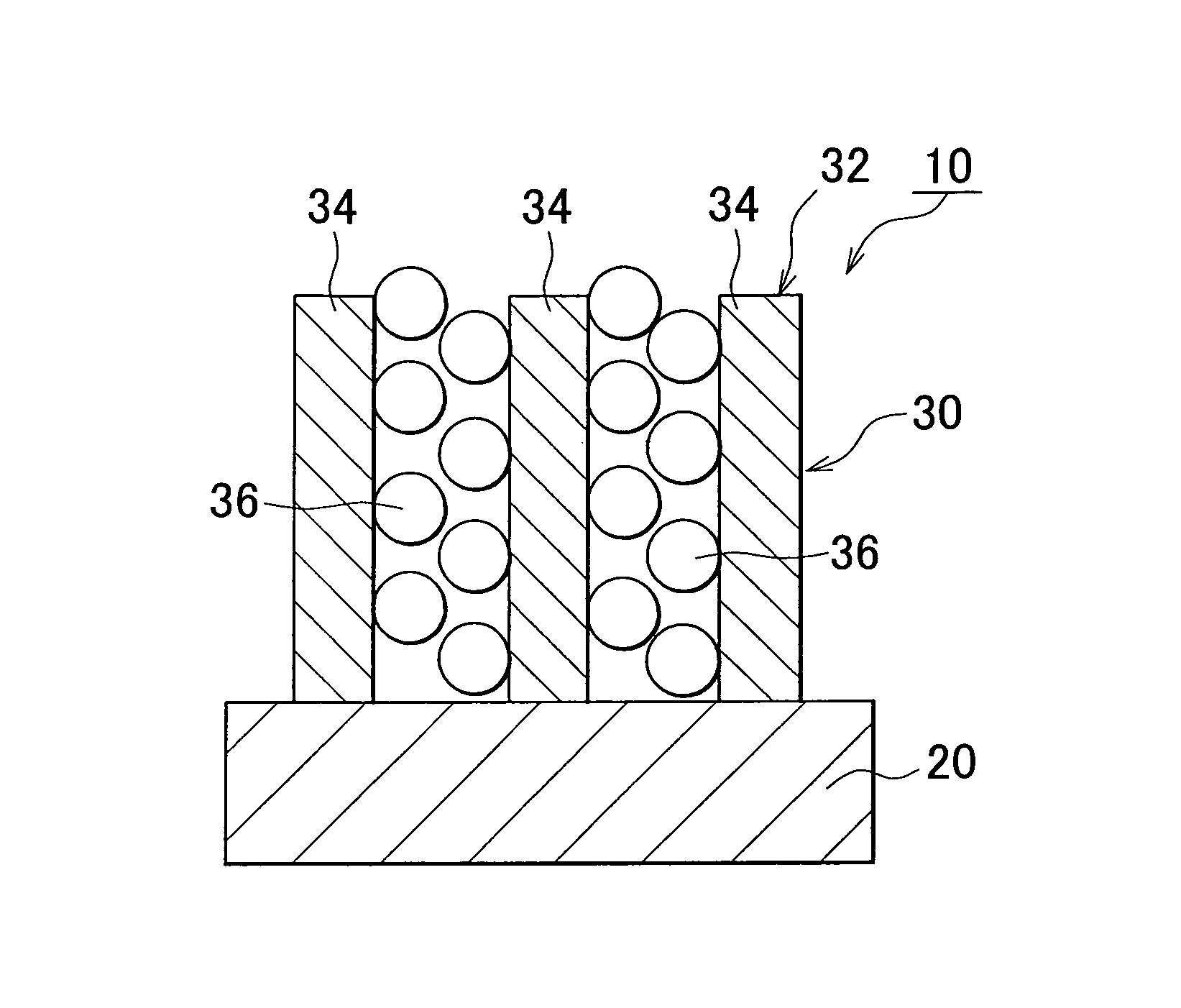

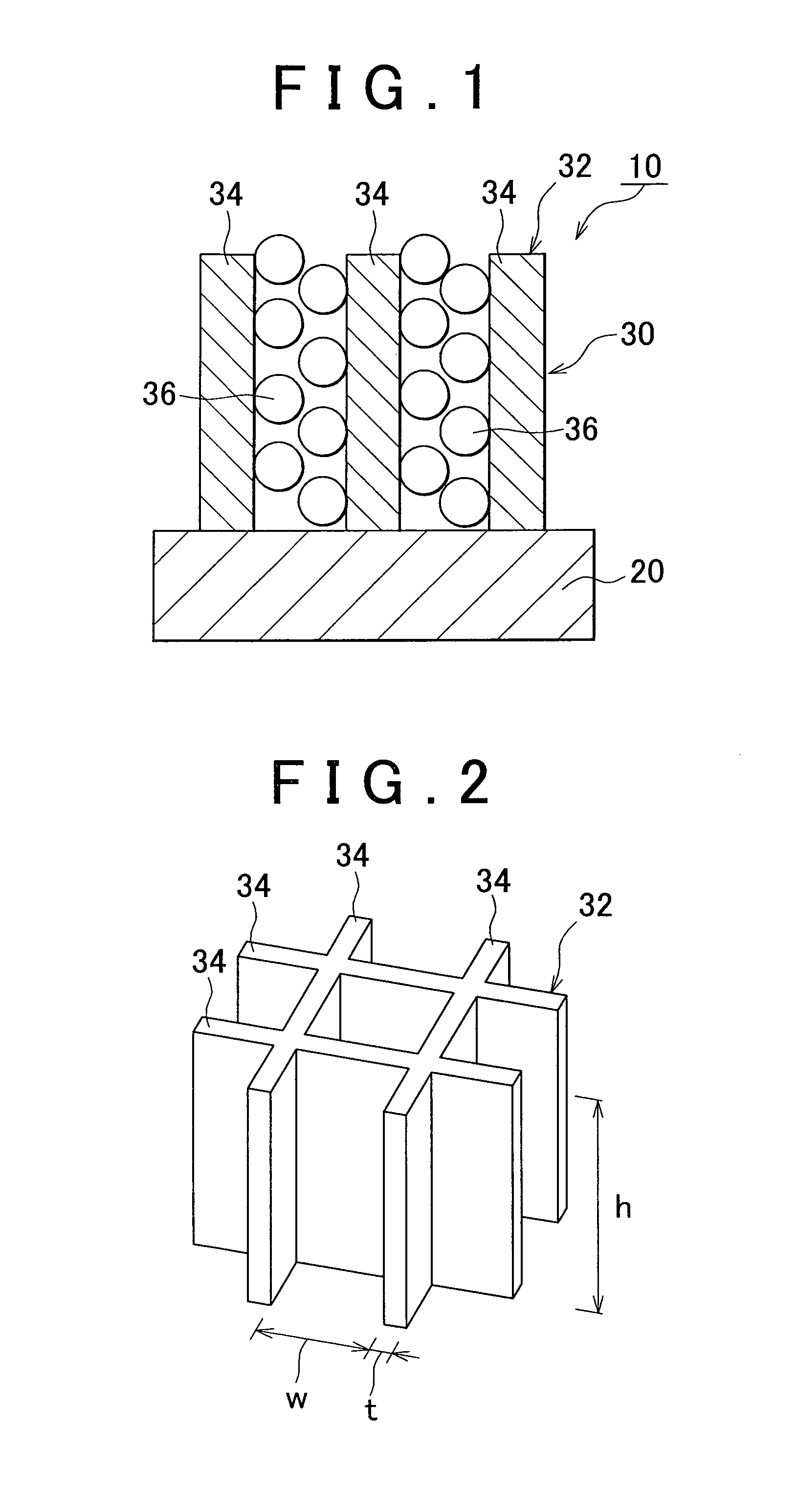

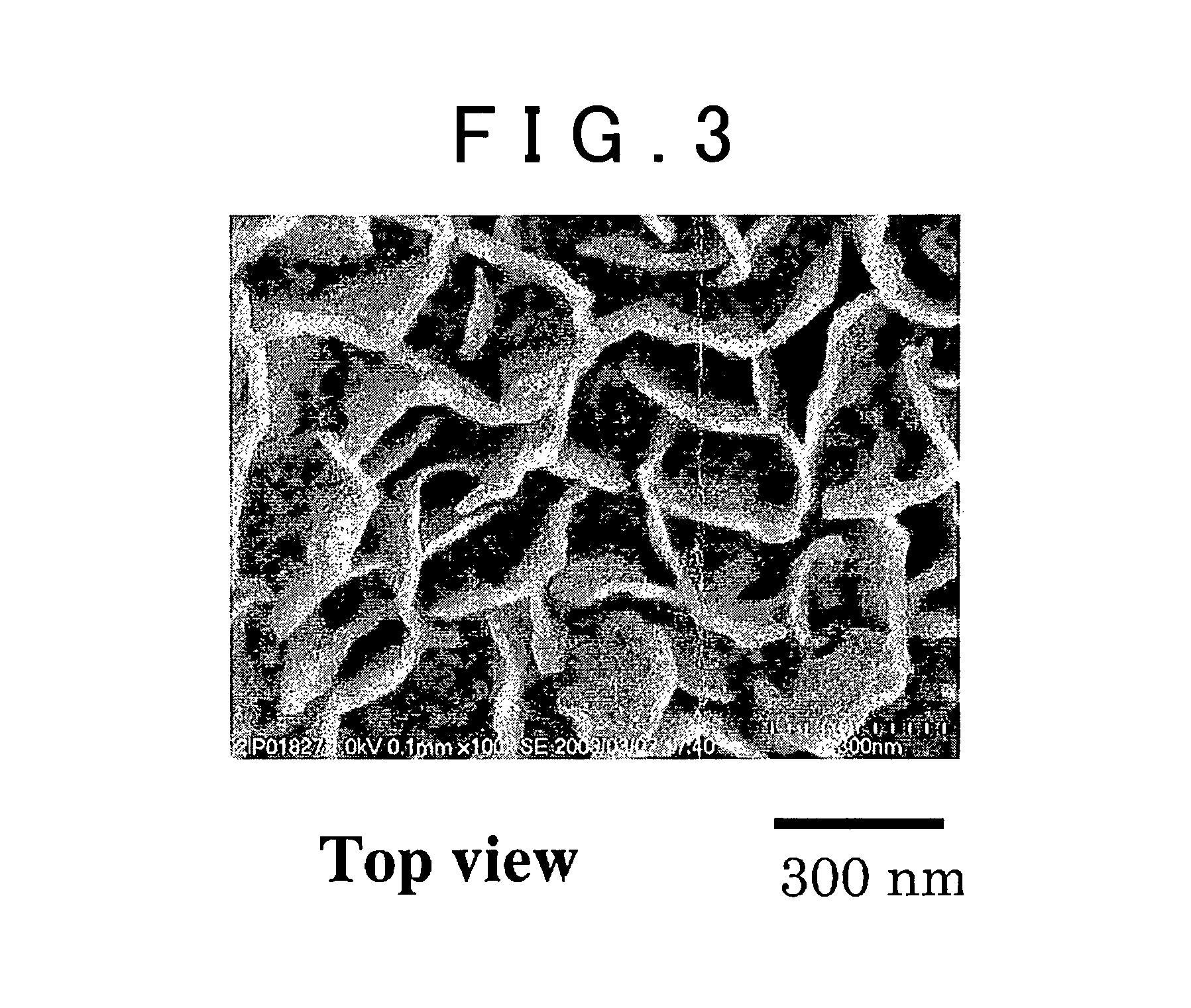

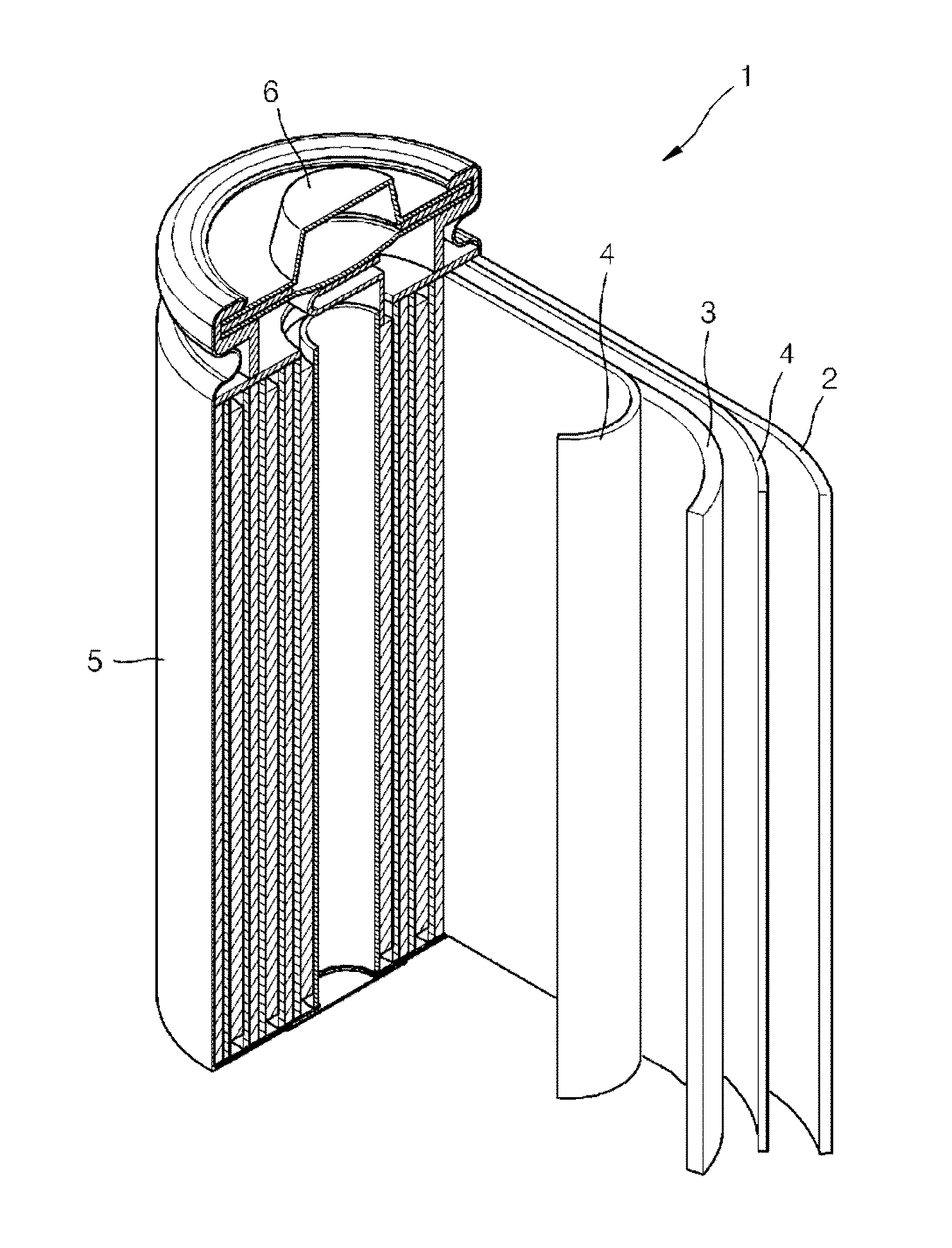

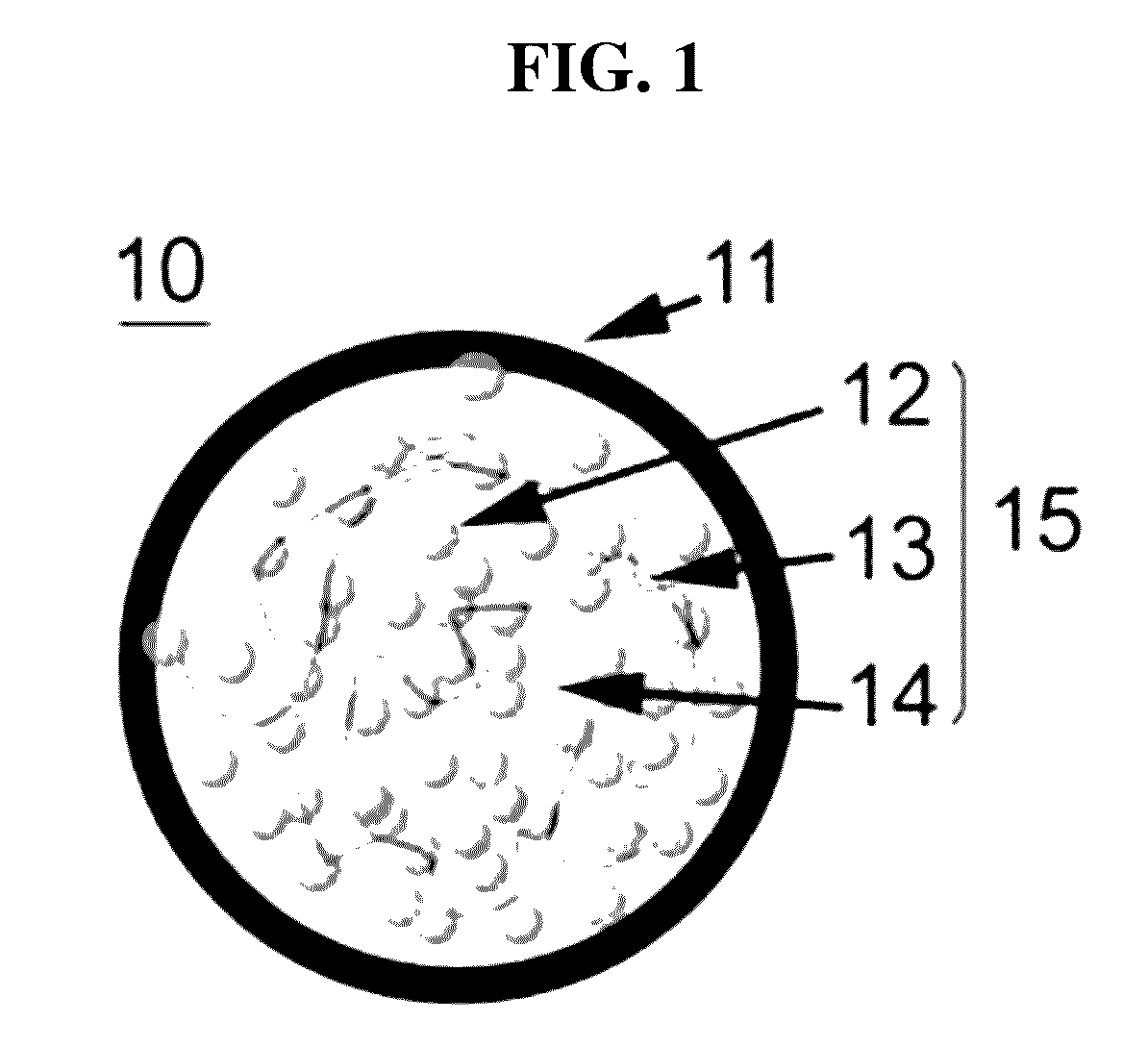

A negative electrode (10) for a lithium secondary battery, including a negative electrode collector (20), and a negative electrode active substance layer (30) that is supported on the negative electrode collector (20) and includes carbon nanowalls (32) which are formed on the negative electrode collector (20), and a negative electrode active substance (36) which is supported on the carbon nanowalls (32).

Owner:TOYOTA JIDOSHA KK

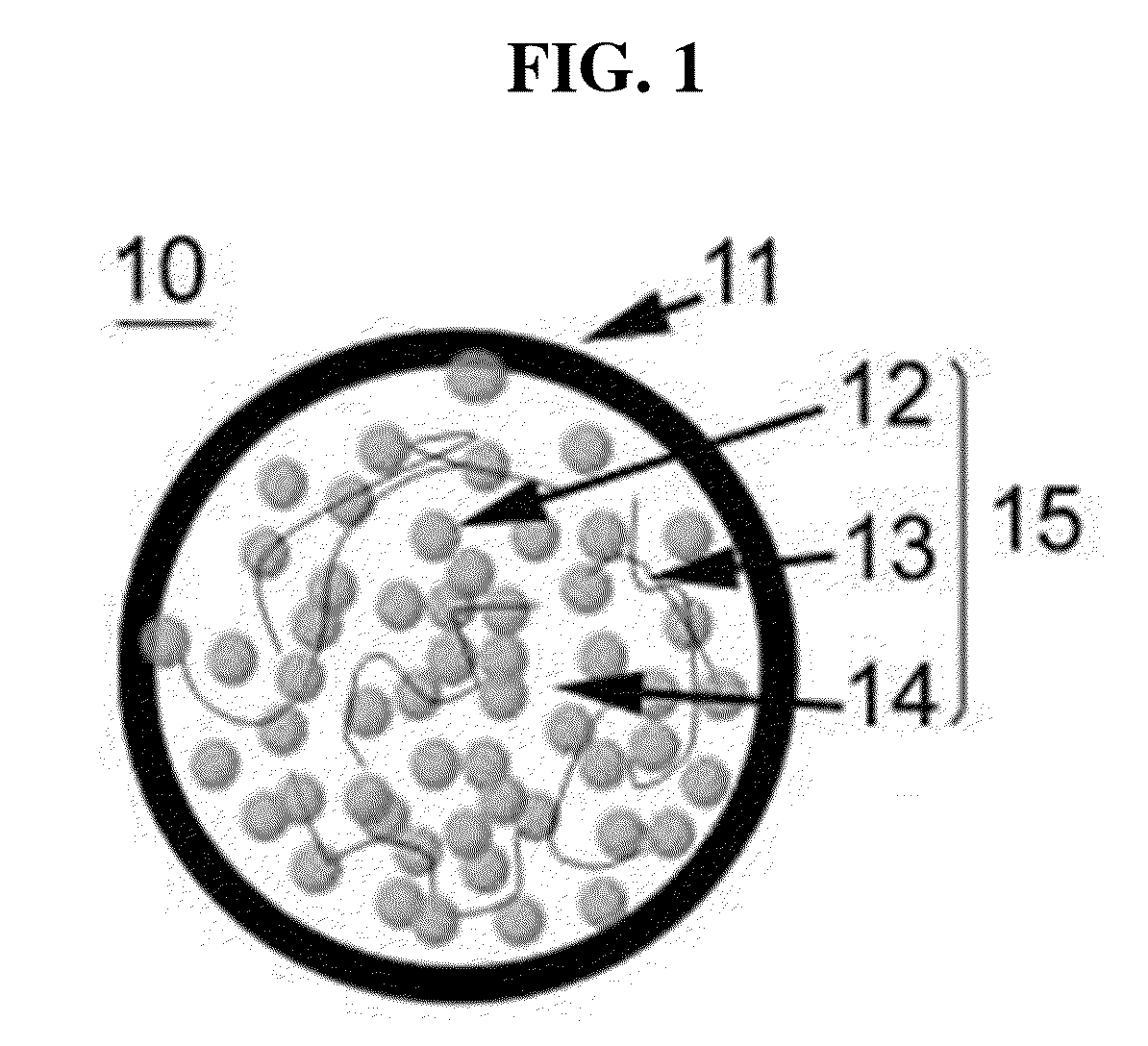

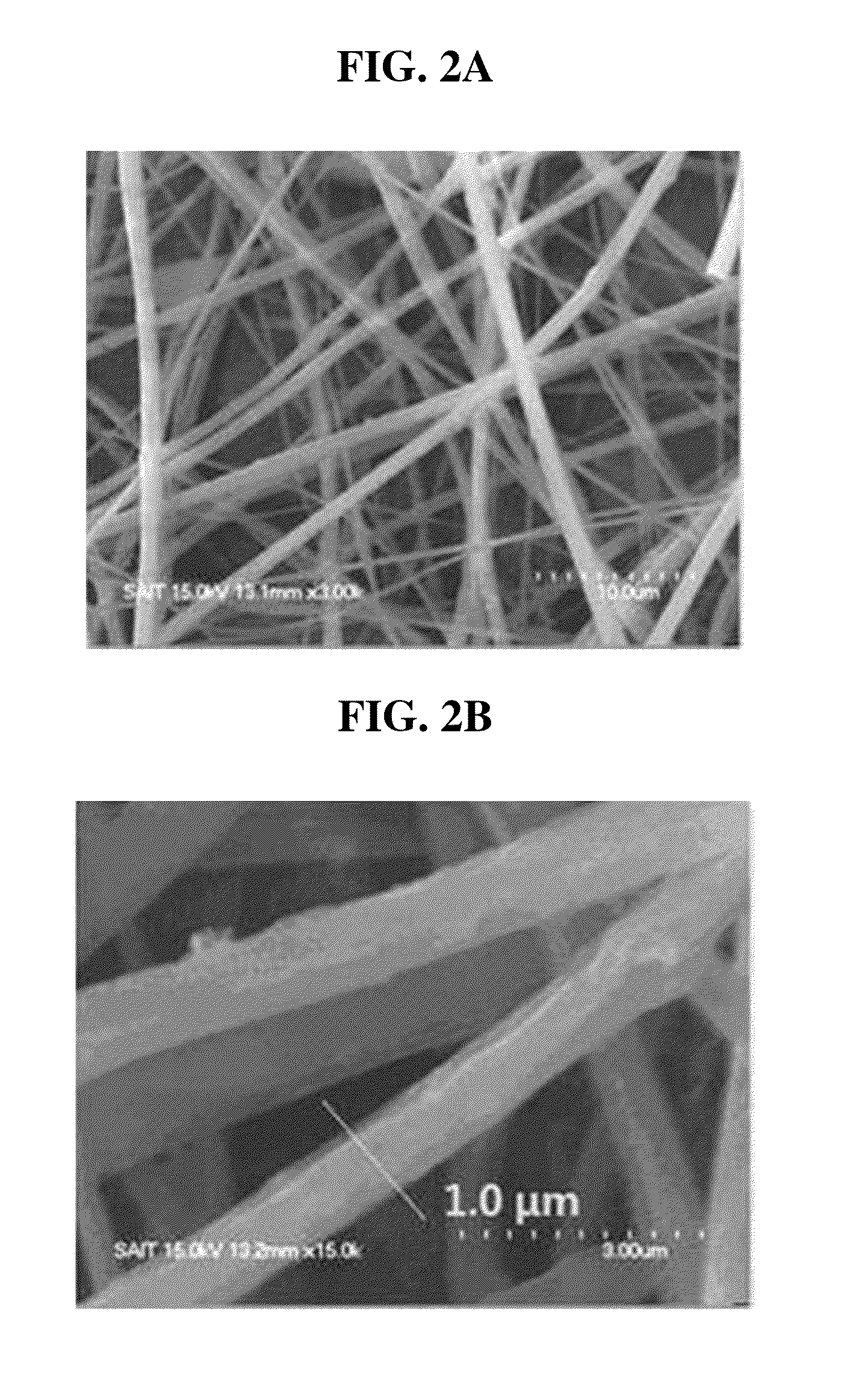

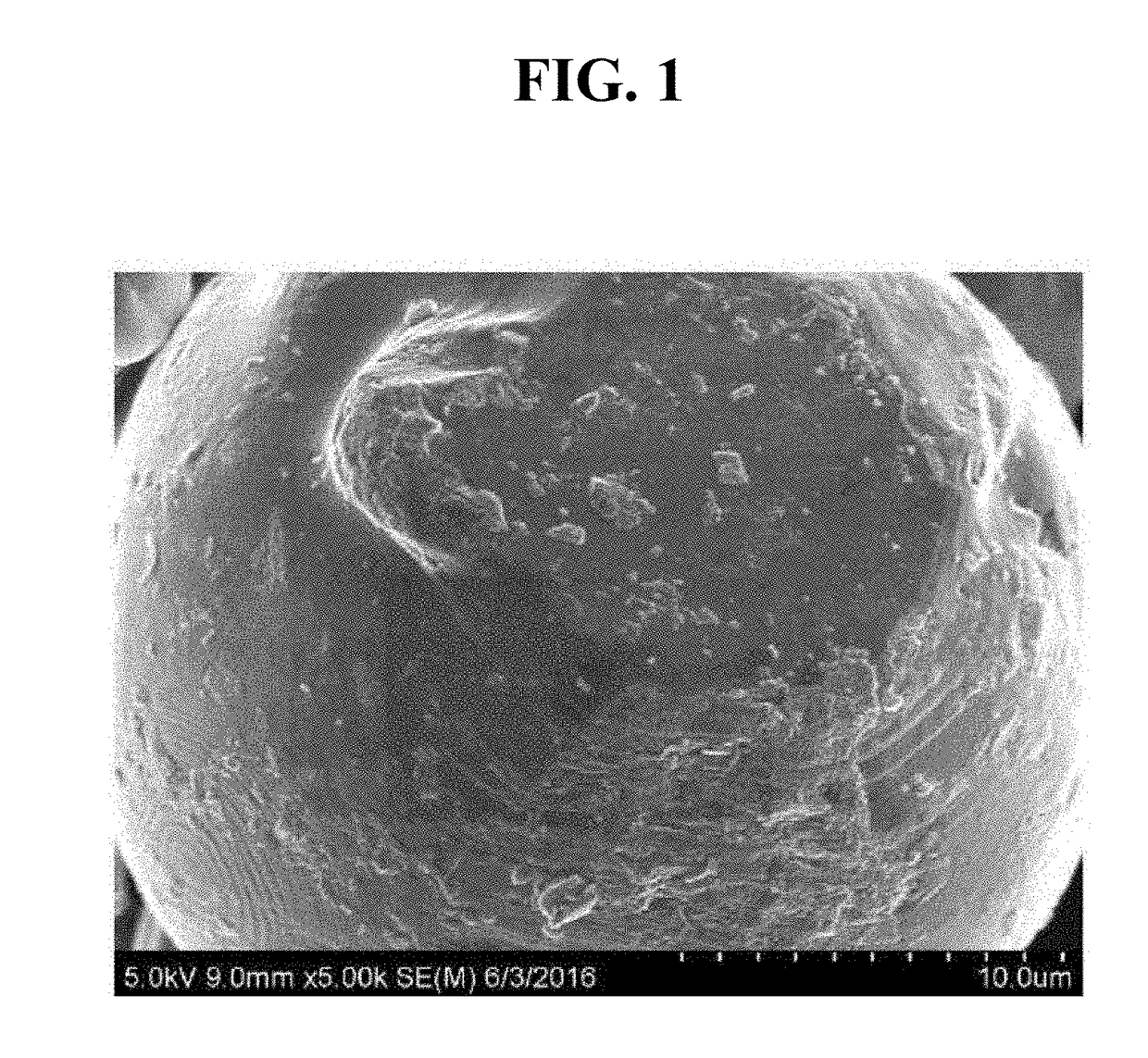

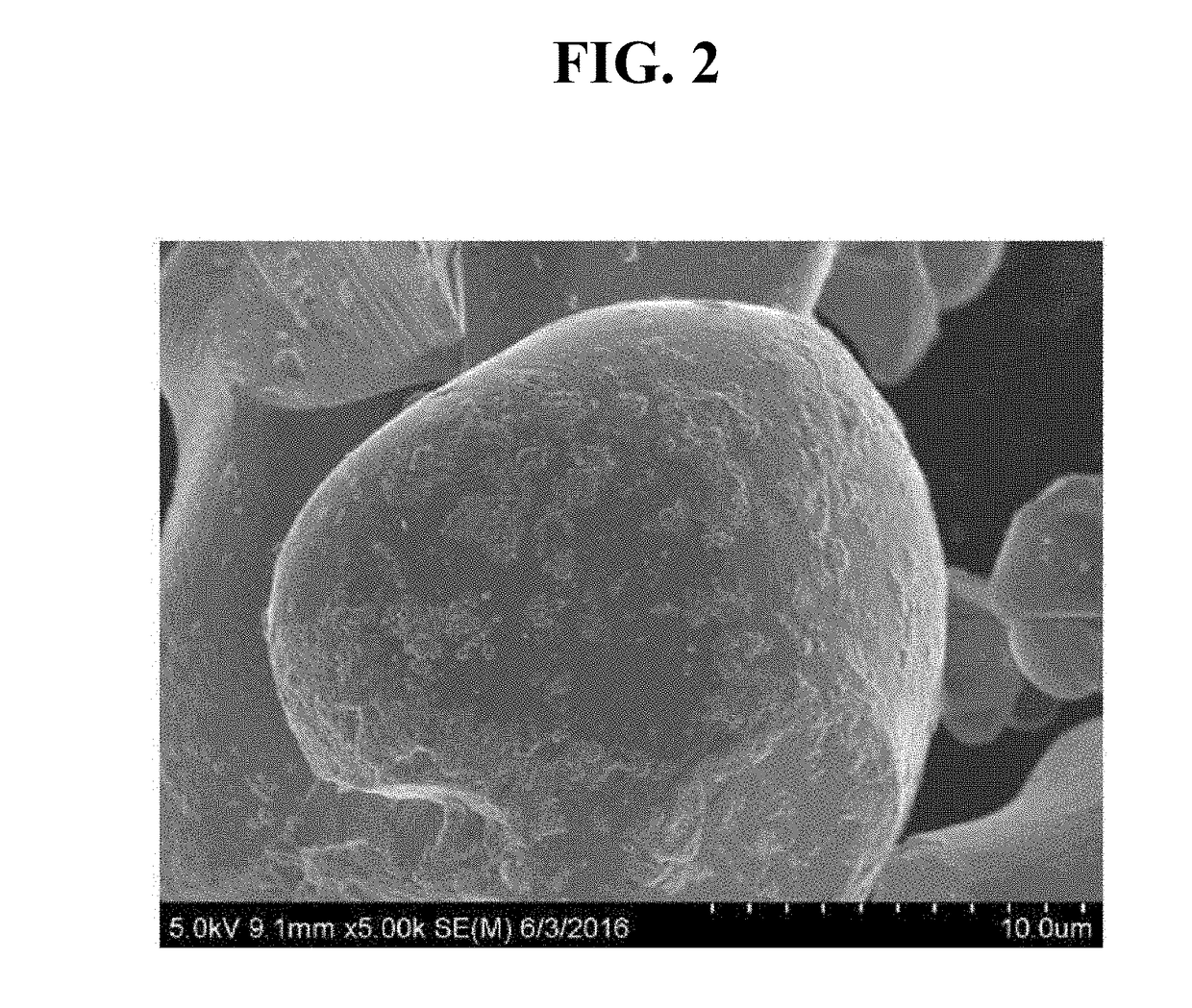

Composite anode active material, anode and lithium battery each including the composite anode active material, method of preparing the composite anode active material

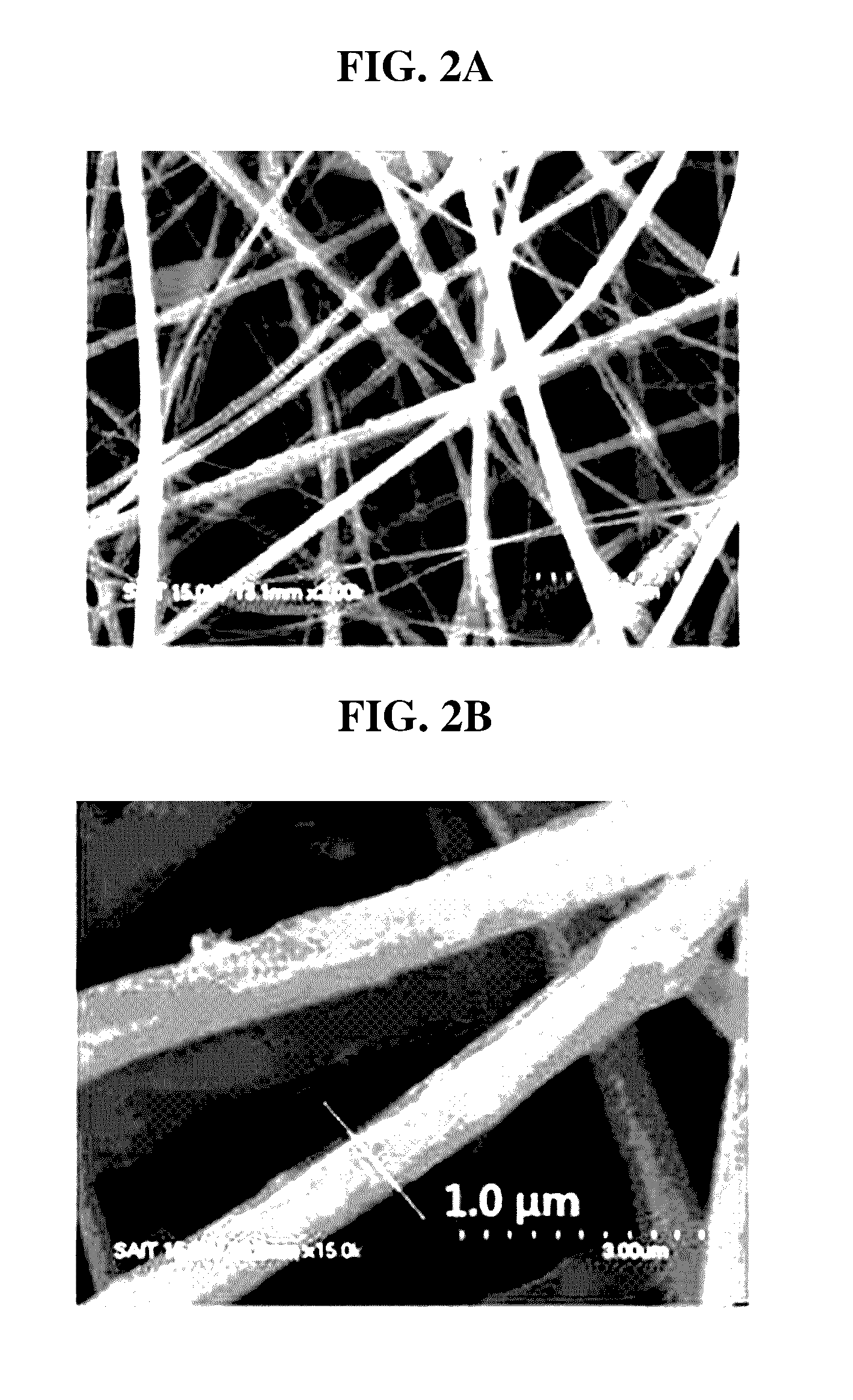

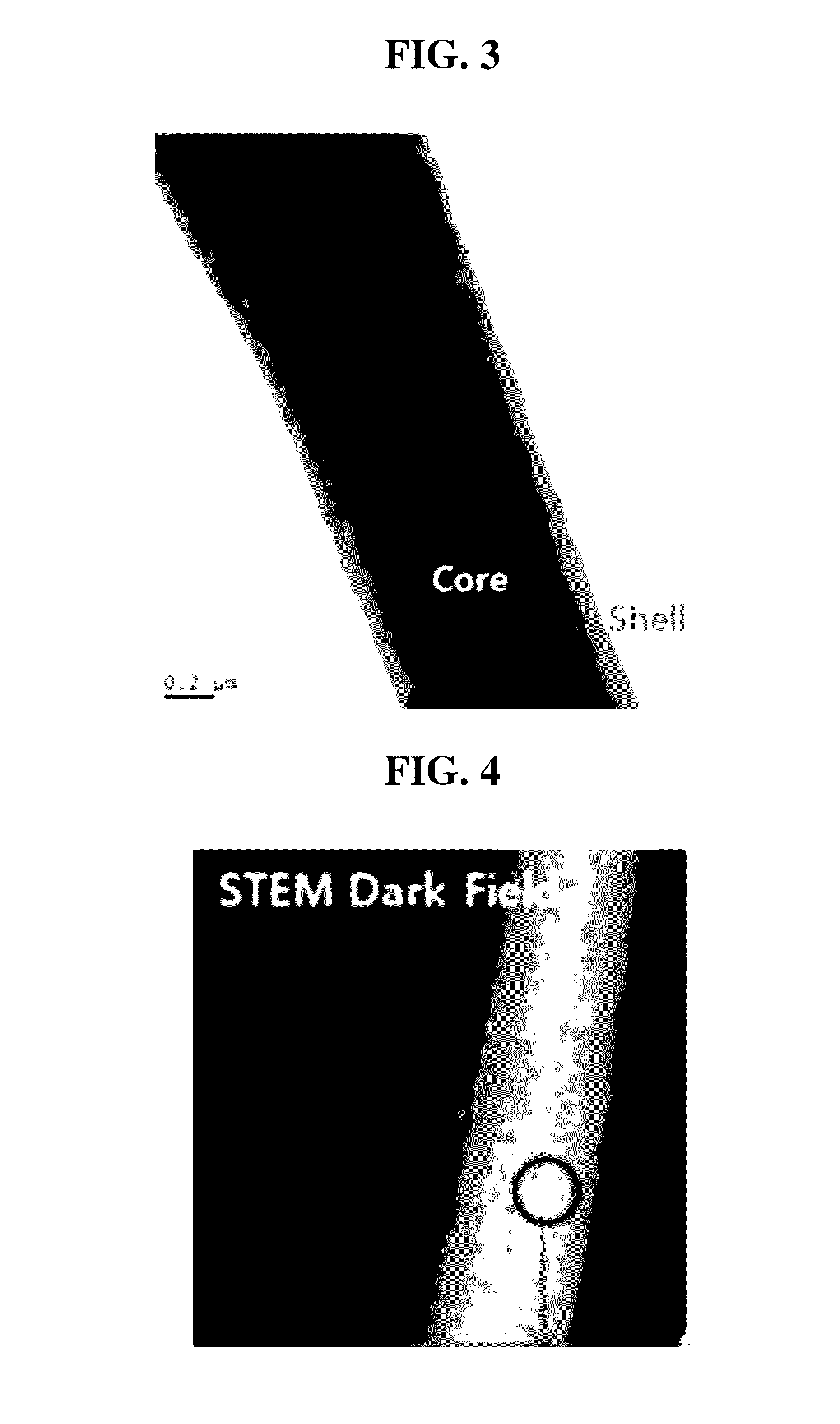

ActiveUS20140087255A1Increase capacityImprove featuresSilver accumulatorsMicroscopic fiber electrodesFiberCarbon fibers

A composite anode active material, an anode including the composite anode active material, a lithium battery including the anode, and a method of preparing the composite anode active material. The composite anode active material includes: a shell including a hollow carbon fiber; and a core disposed in a hollow of the hollow carbon fiber, wherein the core includes a first metal nanostructure and a conducting agent.

Owner:SAMSUNG ELECTRONICS CO LTD

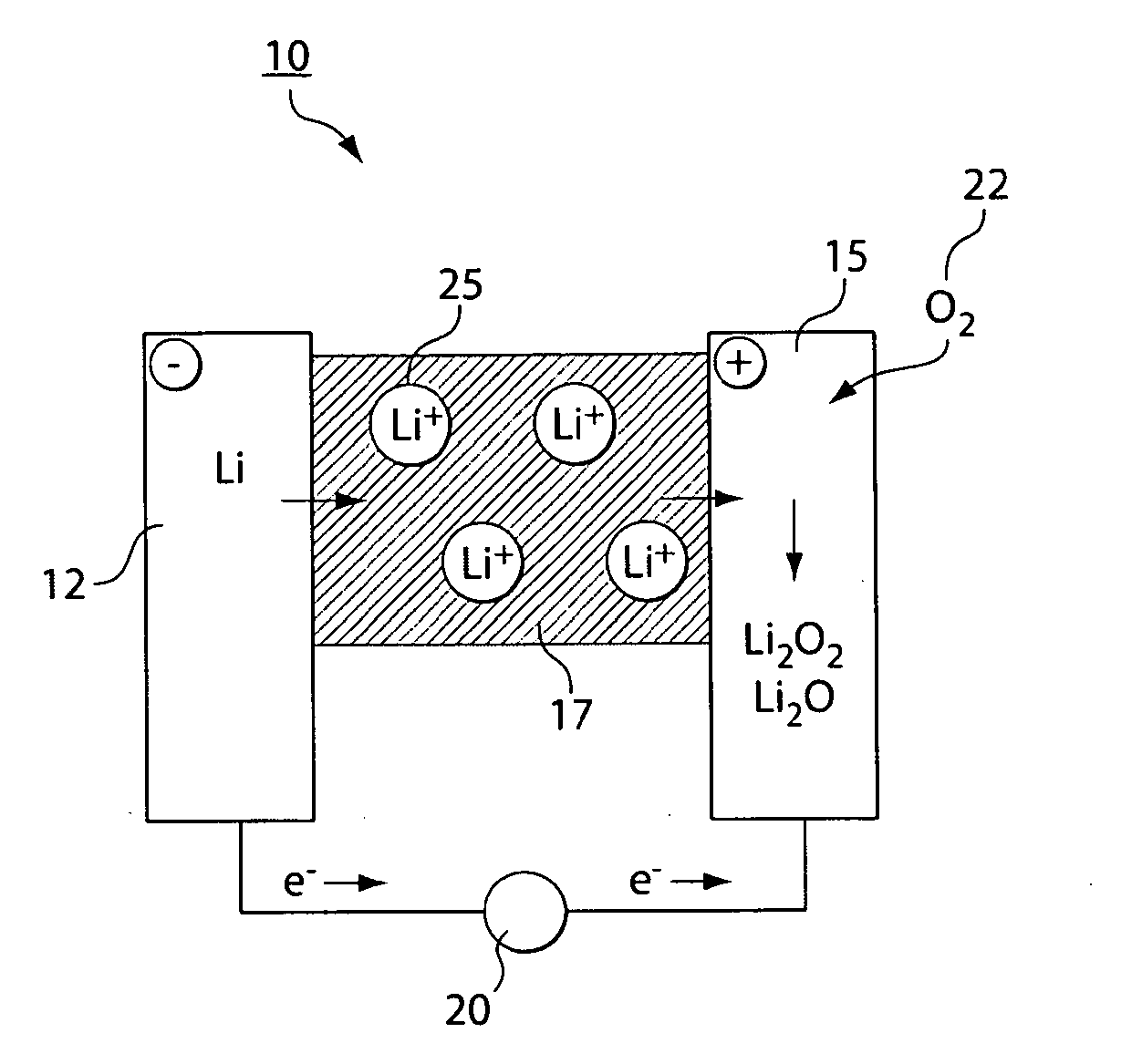

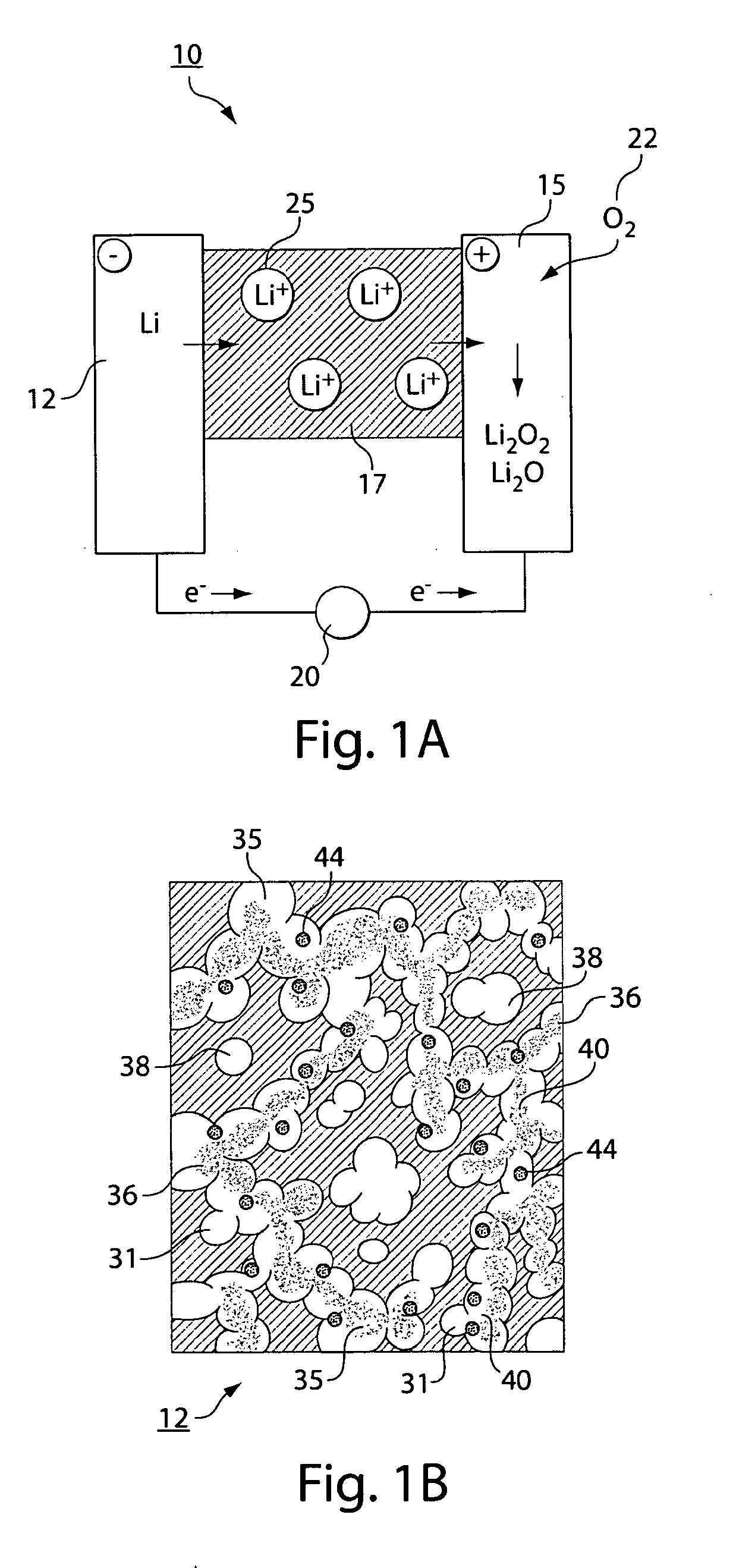

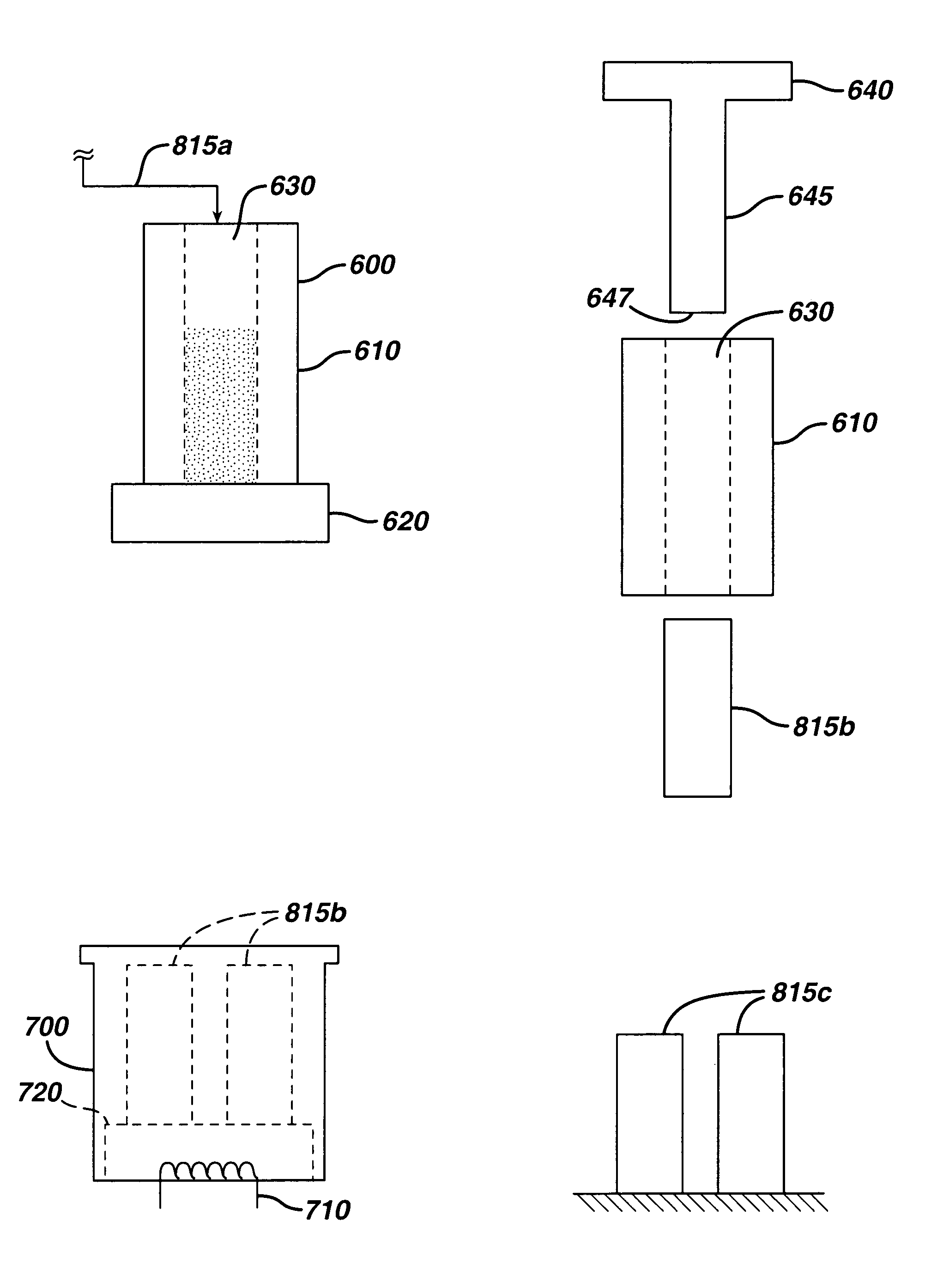

Gas diffusion electrodes for batteries such as metal-air batteries

InactiveUS20130089795A1Fuel and primary cellsFuel and secondary cellsReactive siteLithium–air battery

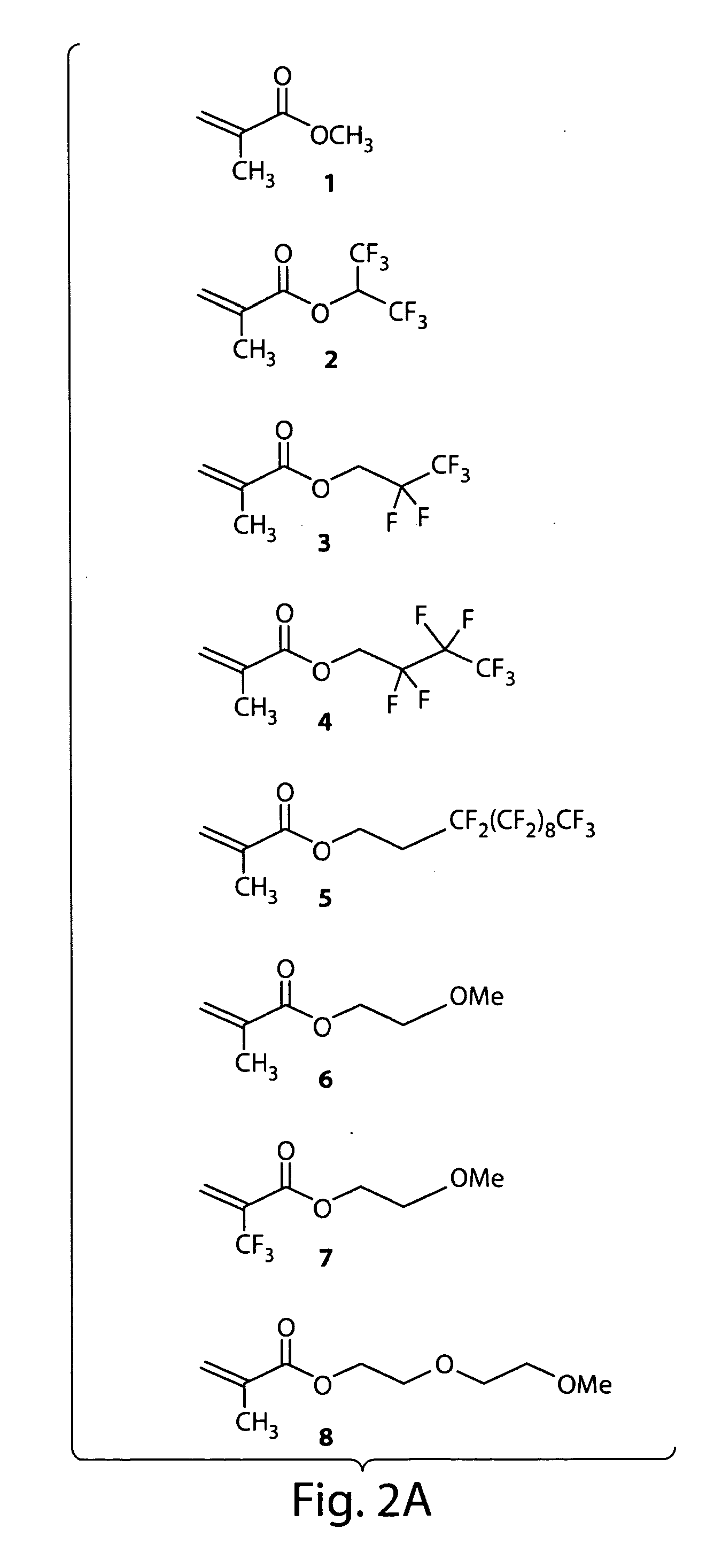

The present invention generally relates to batteries and, in particular, to electrodes for use in batteries such as non-aqueous metal-air batteries, for example, lithium-air batteries, as well as in other electrochemical devices. Such devices may exhibit improved performance characteristics (e.g. power, cycle life, capacity, etc.). One aspect of the present invention is generally directed to electrodes for use in such devices containing one or more pores or channels for transport of gas and / or electrolyte therein, e.g., forming an open porous network. In certain embodiments, the electrolyte may be a gel or a polymer. In some embodiments, there may be network of such channels or pores within the electrode such that no active site within the electrode is greater than about 50 micrometers distant from a gas channel. In some embodiments, such systems may be created using electrodes containing gel or electrolyte polymers, and / or by forming electrodes having different wettabilities such that certain regions preferentially attract the electrolyte compared to other regions, thereby causing self-organization of the electrolyte within the electrode. Other aspects of the invention are generally directed to methods of making such batteries or electrochemical devices, methods of using such batteries or electrochemical devices, kits involving such batteries or electrochemical devices, or the like.

Owner:LIOX POWER

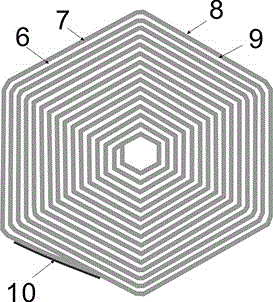

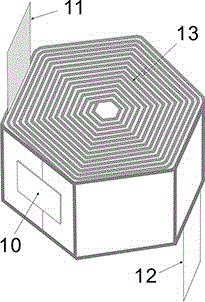

Battery with high electrode interfacial surface area

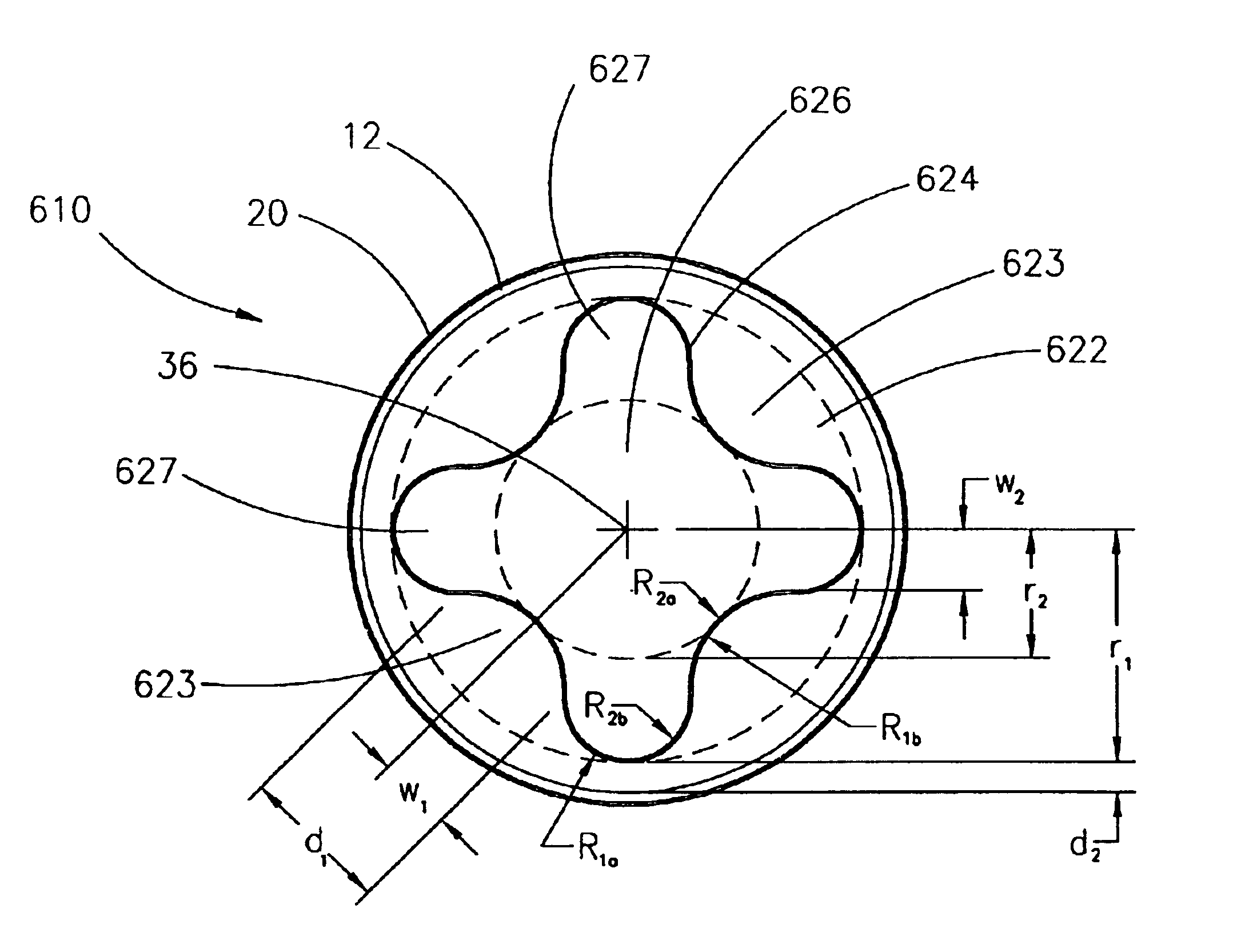

InactiveUS6869727B2Increase speedIncrease internal resistanceAlkaline accumulatorsSmall-sized cells cases/jacketsHigh rateEngineering

An electrochemical battery cell in accordance with the invention has a high electrode interfacial surface area to improve high rate discharge capacity, and the shapes of the electrodes facilitate the manufacture of cells of high quality and reliability at high speeds suitable for large scale production. The interfacial surfaces of the solid body electrodes have radially extending lobes that increase the interfacial surface area. The lobes do not have sharp corners, and the concave areas formed between the lobes are wide open, to facilitate assembly of the separator and insertion of the other electrode into the concave areas without leaving voids between the separator and either electrode.

Owner:EVEREADY BATTERY CO INC

Molybdenum/air battery and cell design

InactiveUS20100255375A1Reduce oxygenFuel and primary cellsFilling tube/pocket electrodesCell designAlloy

A metal-air battery has an anode in which the electrochemically active material is molybdenum. The molybdenum may be in the form of a bulk body of material or it may comprise a particulate material dispersed with or in another material. In some instances, the molybdenum may comprise a member of an alloy or mixture. Also disclosed is a modular battery system which may include the molybdenum-based anode material.

Owner:US SEC THE ARMY THE

Electrolyte for rechargeable electrochemical cell

ActiveUS20170194666A1Increased durabilityImprove stabilityLarge-sized flat cells/batteriesFinal product manufacturePolymer chemistryElectrolytic agent

The present invention provides an aqueous electrolyte for use in rechargeable zinc-halide storage batteries that possesses improved stability and durability and improves zinc-halide battery performance. One aspect of the present invention provides an electrolyte for use in a secondary zinc bromine electrochemical cell comprising from about 30 wt % to about 40 wt % of ZnBr2 by weight of the electrolyte; from about 5 wt % to about 15 wt % of KBr; from about 5 wt % to about 15 wt % of KCl; and one or more quaternary ammonium agents, wherein the electrolyte comprises from about 0.5 wt % to about 10 wt % of the one or more quaternary ammonium agents.

Owner:EOS ENERGY TECH HLDG LLC

Zinc/air cell with improved anode

InactiveUS7179310B2Sufficient structural integrityReadily removable from the dieFuel and primary cellsAlkaline accumulatorsSolid massPolyvinyl alcohol

A method of forming an anode comprising zinc for a zinc / air cell. The method involves mixing zinc particles with binders including preferably polyvinylalcohol, surfactant and water to form a wet paste. The wet paste is compacted and molded into the near shape of the cell's anode cavity and then heated to evaporate water. A solid porous zinc mass is formed wherein the zinc particles are held bound within a network with microscopic void spaces between the zinc particles. The solid mass can be inserted into the cell's anode cavity and aqueous alkaline electrolyte, preferably comprising potassium hydroxide, then added. The solid mass absorbs the aqueous electrolyte and expands to fill the anode cavity to form the final fresh anode.

Owner:DURACELL U S OPERATIONS

Micro-Aluminum Galvanic Cells and Method for Constructing the Same

InactiveUS20070111090A1Mass productionSpeed up preparationSilver accumulatorsFuel and primary cellsAluminum anodeHigh volume manufacturing

The present invention in directed to the fabrication of thin aluminum anode batteries using a highly reproducible process that enables high volume manufacturing of the galvanic cells.

Owner:UNIV OF SOUTH FLORIDA

Negative active material for rechargeable lithium battery, method of preparing the same, and rechargeable lithium battery including the same

InactiveUS20110076565A1Improve rendering capabilitiesImprove efficiencyFilling tube/pocket electrodesLi-accumulatorsCarbon layerPhysical chemistry

The present invention provides a negative active material for a rechargeable lithium battery, including an inner layer including a material being capable of doping and dedoping lithium, a carbon layer outside the inner layer, and an outer layer disposed on the carbon layer and including a material being capable of doping and dedoping lithium. The materials being capable of doping and dedoping lithium included in the inner layer and in the outer layer may be the same or different from each other.

Owner:UNIST ULSAN NAT INST OF SCI & TECH

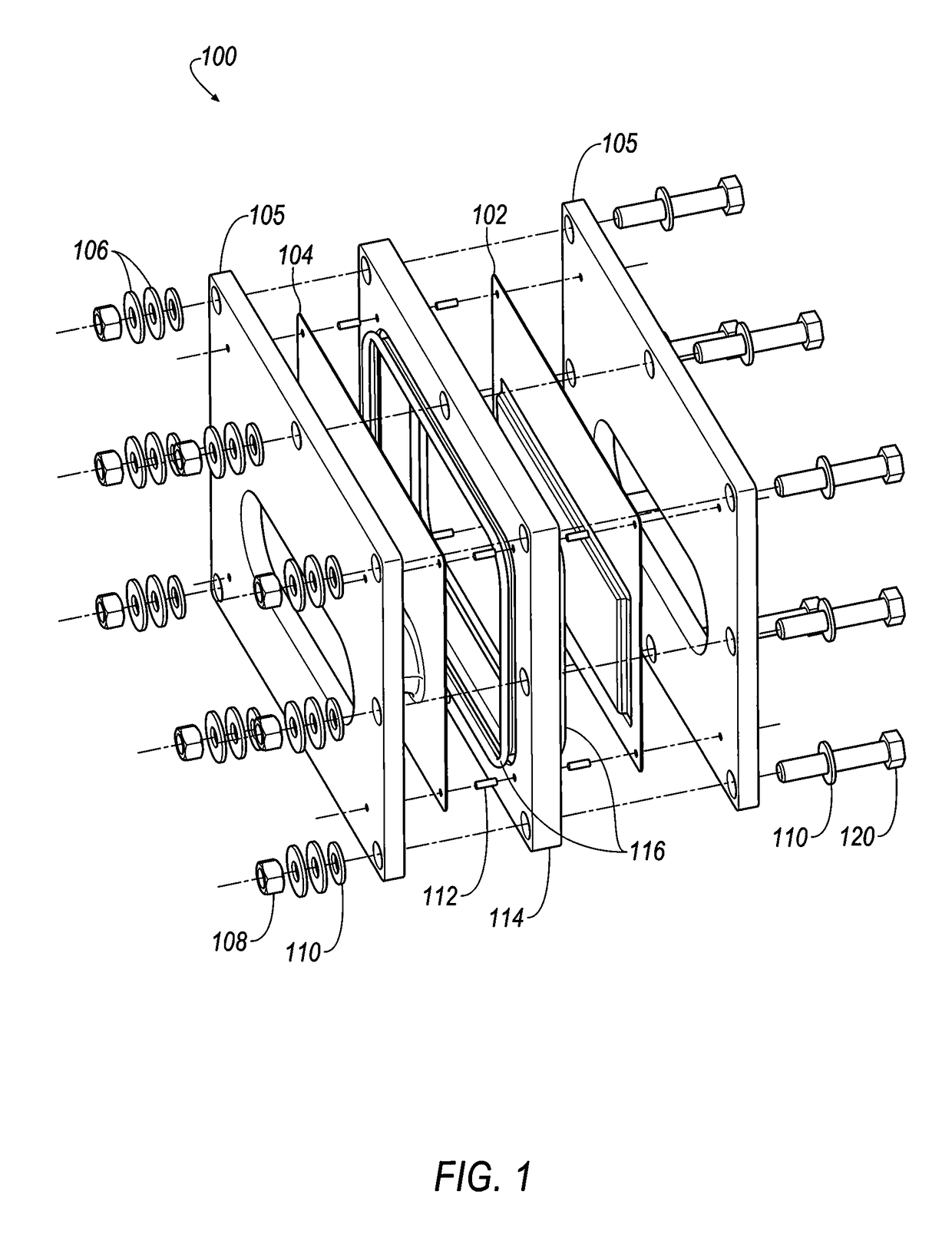

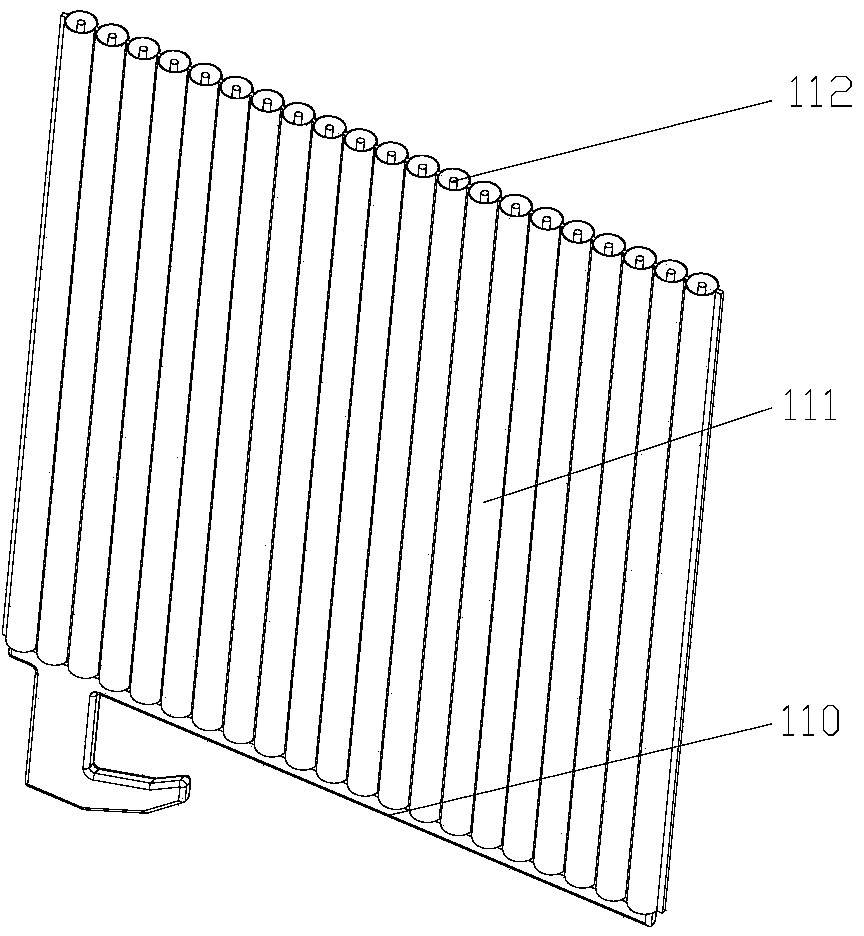

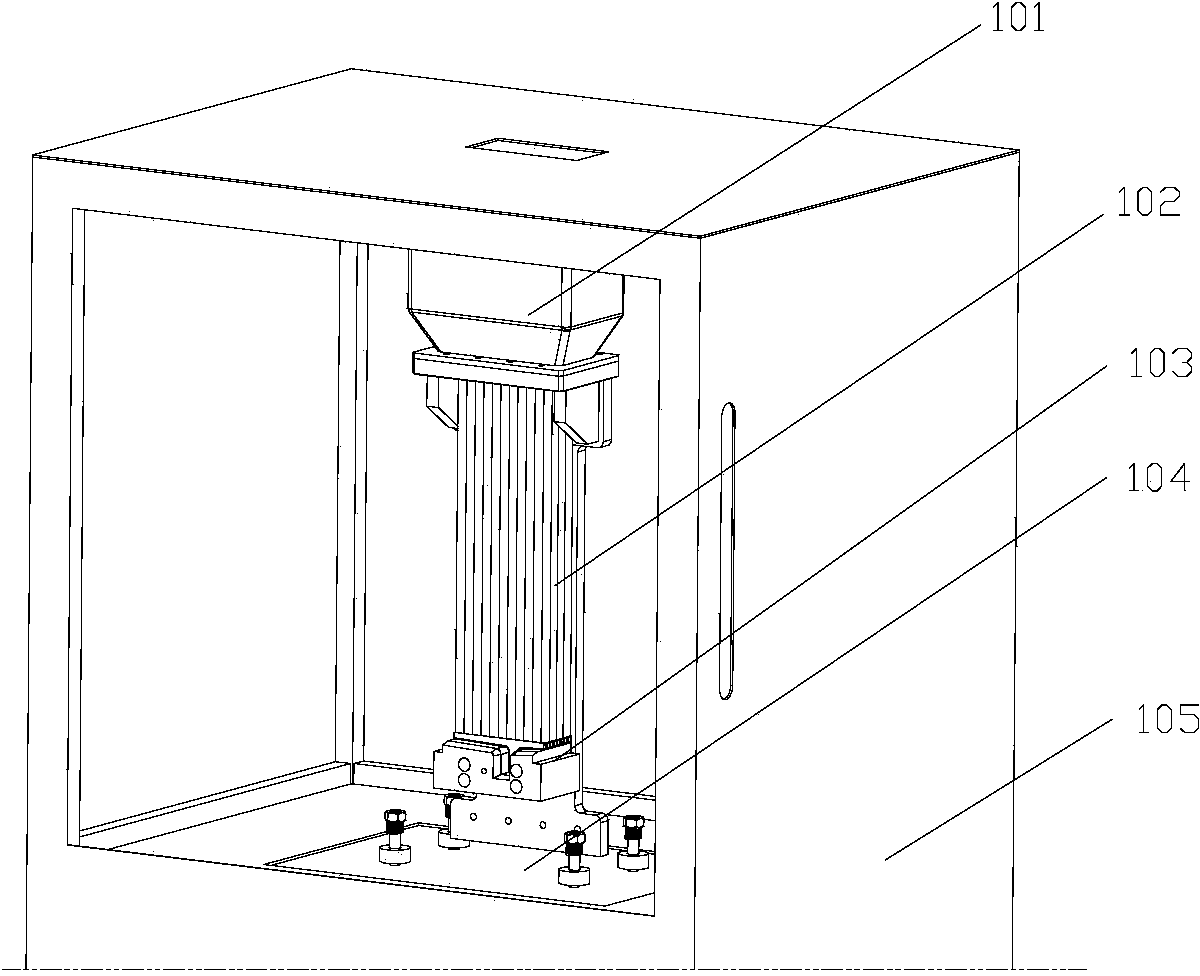

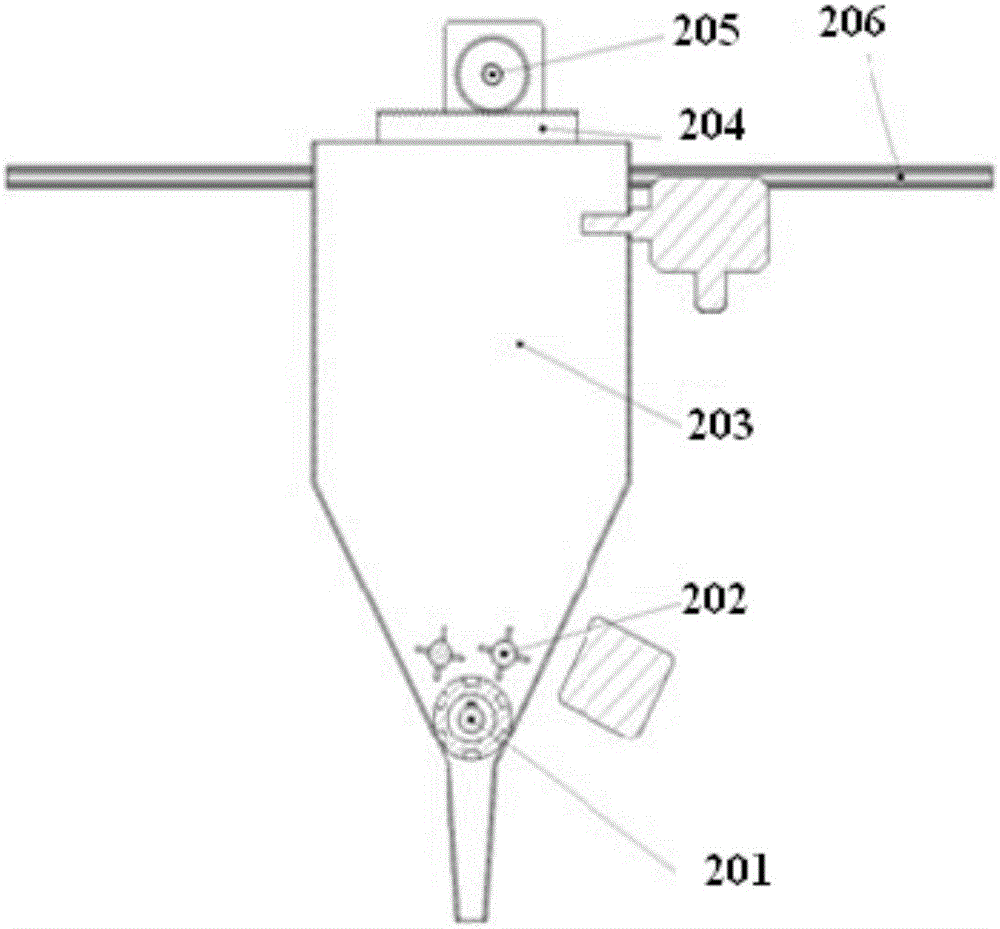

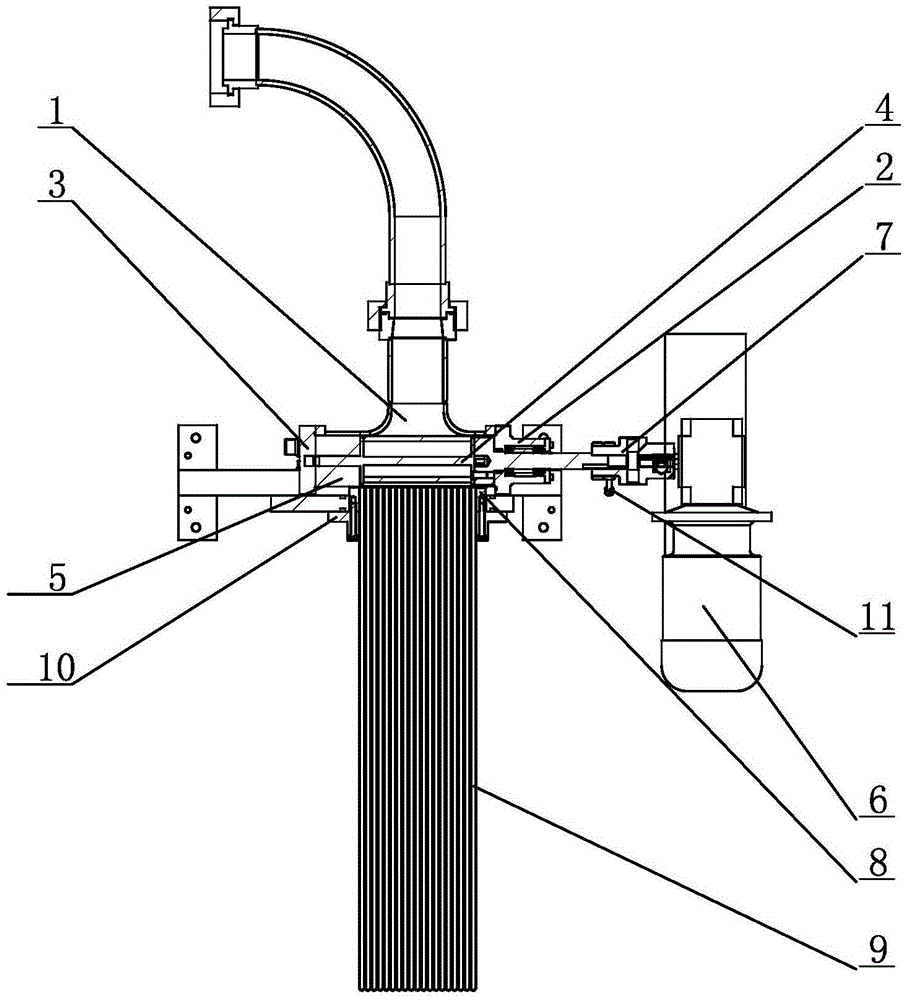

Lead-acid storage battery tubular plate powder filling device

ActiveCN103811724AEasy loading and unloadingA large amountFilling tube/pocket electrodesLead-acid accumulator electrodesEngineeringVibration source

The application discloses a lead-acid storage battery tubular plate powder filling device which comprises a powder filling chamber, a feeding mechanism, a plate fixing mechanism, a vibration seat and a vibration source, wherein the powder filling chamber is provided with a feeding hole and a powder filling chamber door; the feeding mechanism is fixed in the powder filling chamber; the plate fixing mechanism is fixed on the vibration seat; the vibration seat is arranged on the vibration source in the powder filling chamber; the plate fixing mechanism comprises a mould box and a pressing mechanism; the pressing mechanism is used for fixing the mould box; the mould box is used for containing polar plates to be subjected to powder filling. The device can be applied to the field of lead-acid storage battery tubular plate powder filling. By adoption of the lead-acid storage battery tubular plate powder filling device, the polar plates are conveniently loaded and detached, the number of polar plates to be subjected to powder filling each time can be increased, and thus the production efficiency is improved. Moreover, the whole powder filling process is finished when the powder filling chamber door is closed, manual intervention is not needed, and thus dust pollution on an external environment is alleviated.

Owner:ZHAOQING LEOCH BATTERY TECH

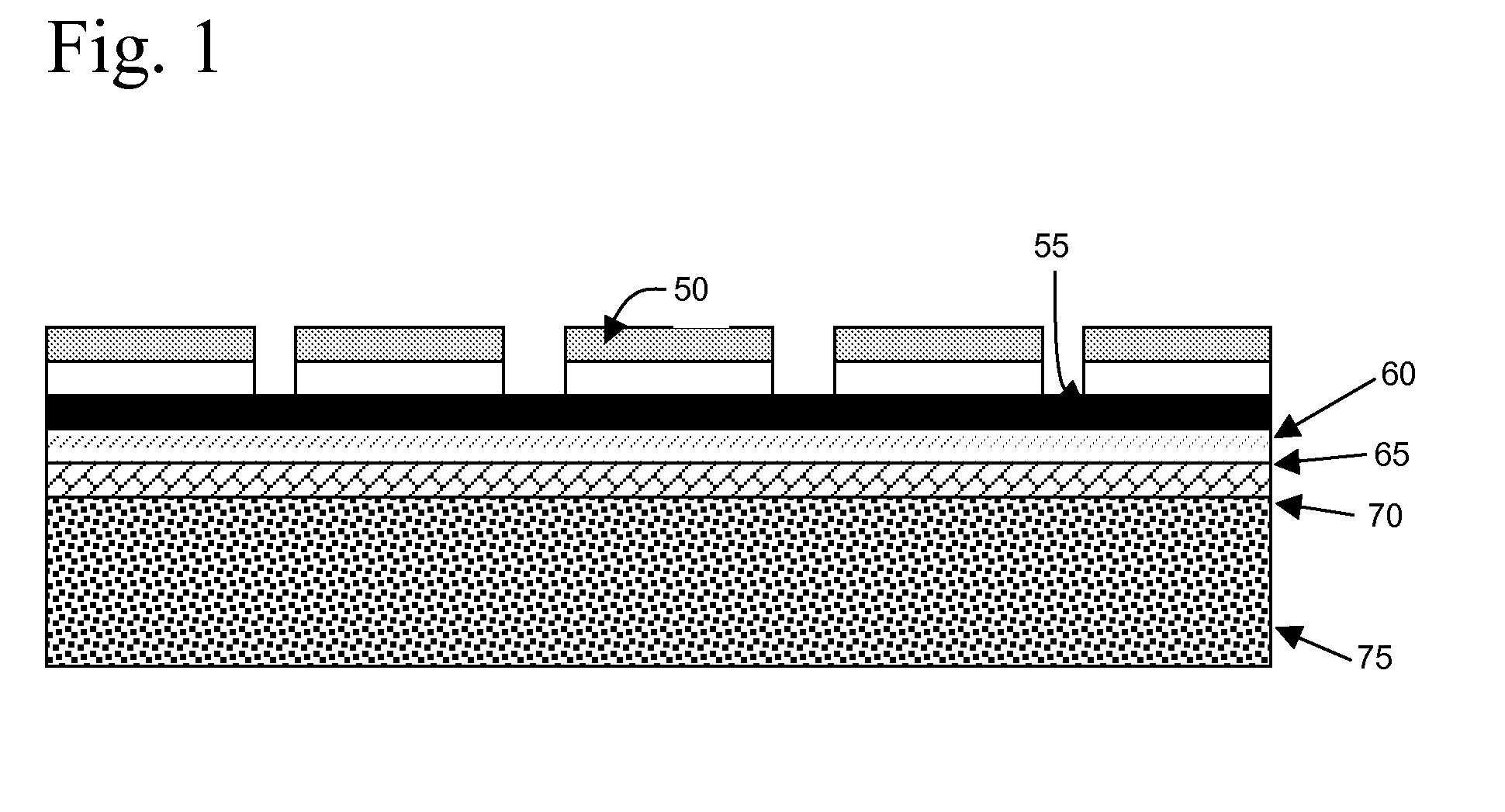

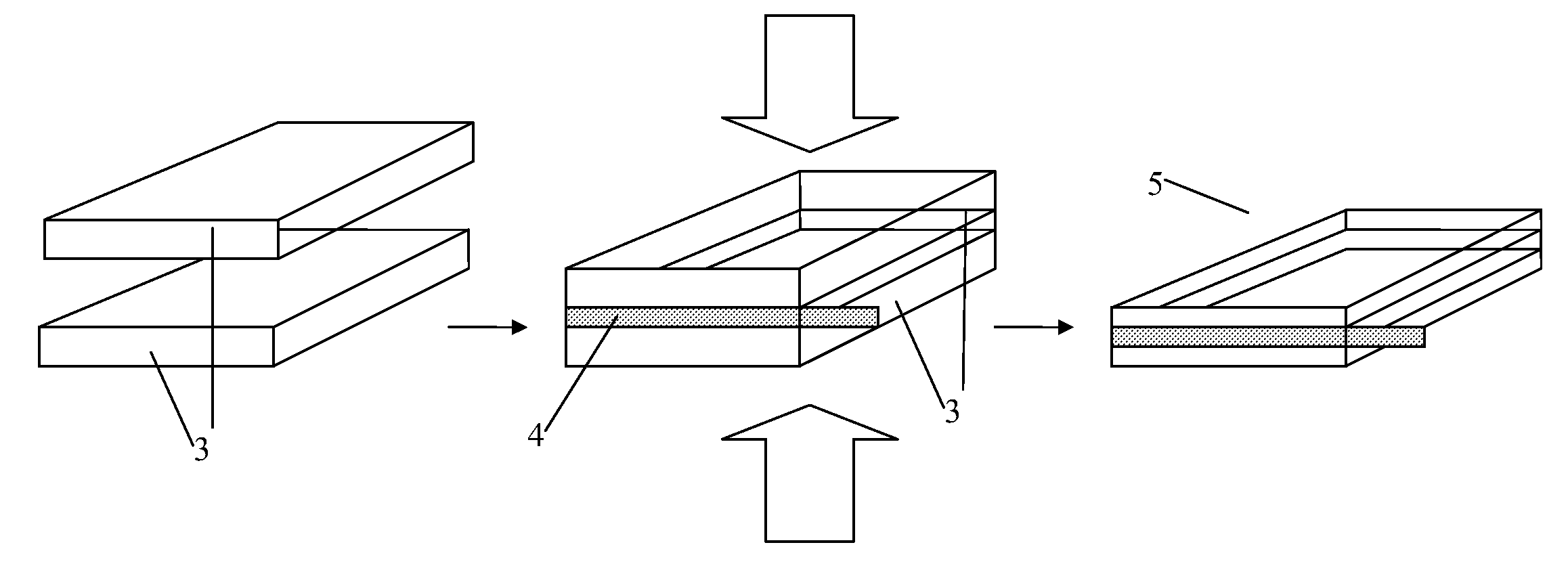

Thin Film Electrodes and Battery Cells, and Methods of Fabrication

ActiveUS20110123852A1Lower internal resistanceReduce the total massFinal product manufactureFilling tube/pocket electrodesThin film electrodeMicrometer

Thin-film electrodes and battery cells, and methods of fabrication. A thin film electrode may be fabricated from a non-metallic, non-conductive porous support structure having pores with micrometer-range diameters. The support may include a polymer film. A first surface of the support is metalized, and the pores are partially metallized to create metal tubes having a thickness within a range of 50 to 150 nanometers, in contact with the metal layer. An active material is disposed within metalized portions of the pores. An electrolyte is disposed within non-metalized portions of the pores. Active materials may be selected to create an anode and a cathode. Non-metalized surfaces of the anode and cathode may be contacted to one another to form a battery cell, with the non-metalized electrolyte-containing portions of the anode facing the electrolyte-containing portions of the cathode pores. A battery cell may be fabricated as, for example, a nickel-zinc battery cell.

Owner:THE JOHN HOPKINS UNIV SCHOOL OF MEDICINE

Powder mixture for manufacture of a battery electrode, a respective battery electrode and a method for manufacturing same

ActiveUS20100330432A1Outstanding shapingImprove mechanical stabilityElectrode rolling/calenderingFilling tube/pocket electrodesPowder mixtureMetallurgy

A method for manufacturing of a powder mixture for a battery electrode that includes suspending of particles of at least one binder within an inert solvent producing a first suspension, slowly suspending of particles of an active material within the first suspension producing a second suspension, drying of the second suspension producing a granulate material. Further relates to a respective powder mixture, an electrode and a method of manufacturing the electrode.

Owner:LITRONIK BATTERIETECHNOLOGIE GMBH

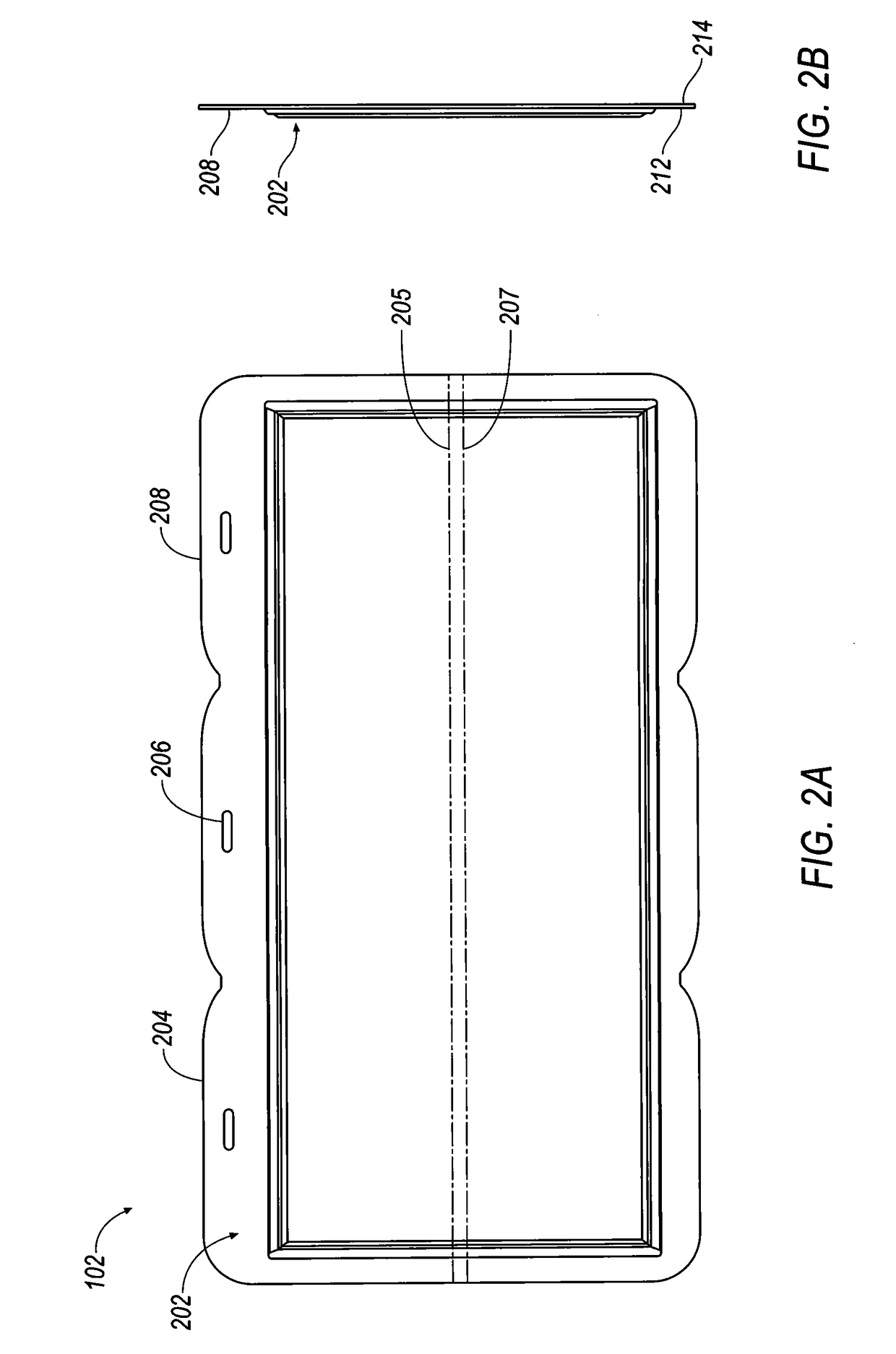

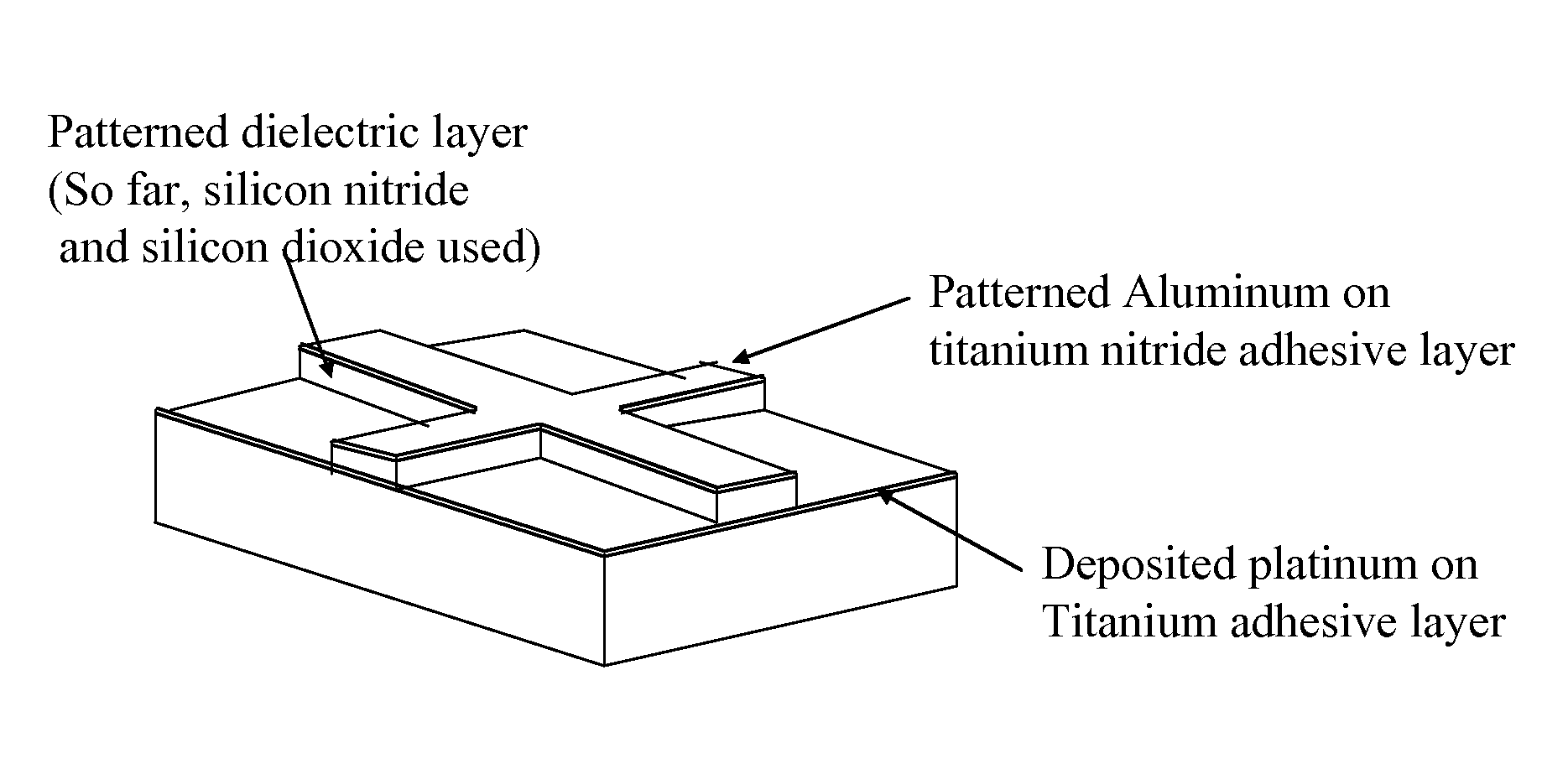

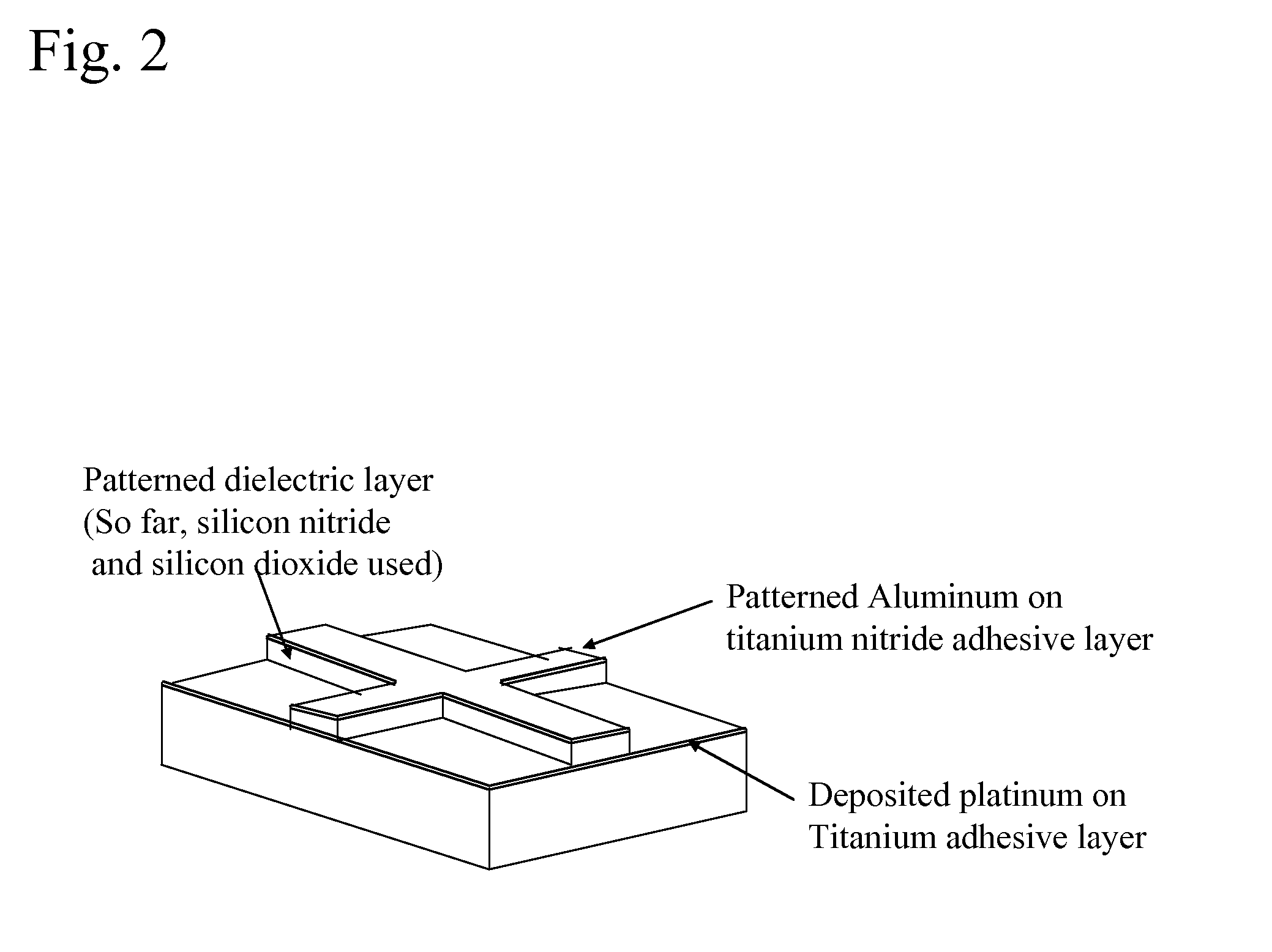

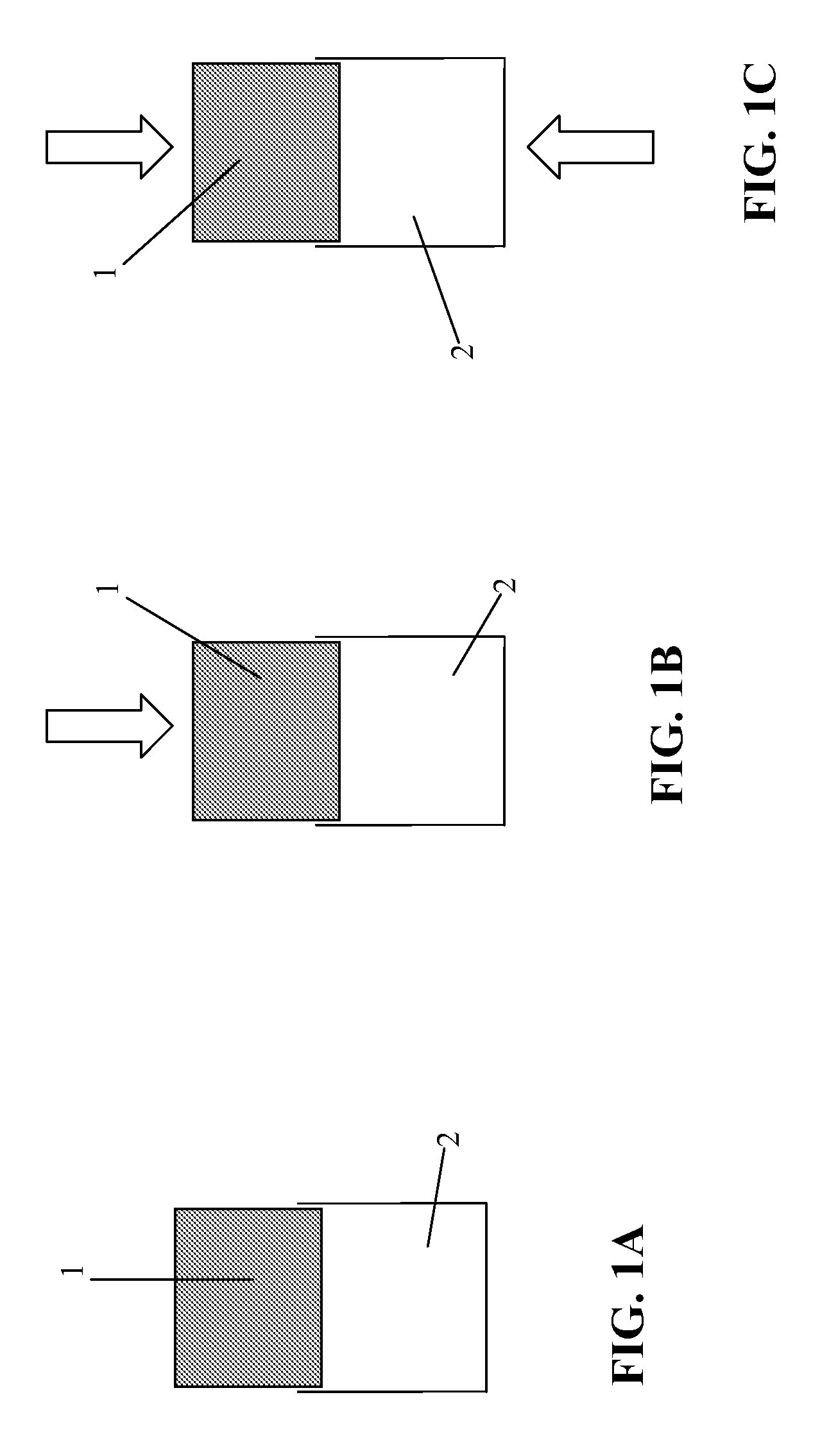

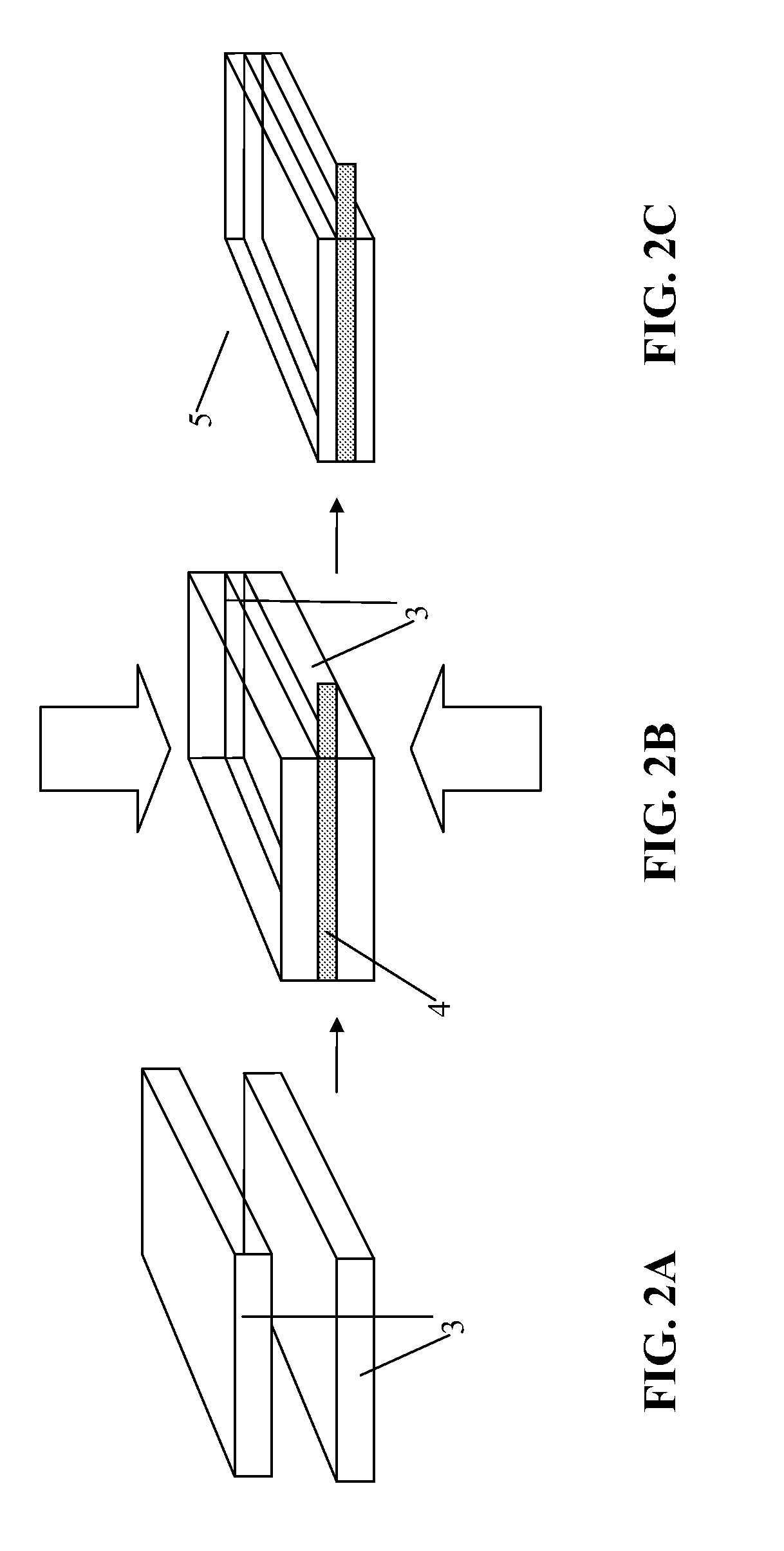

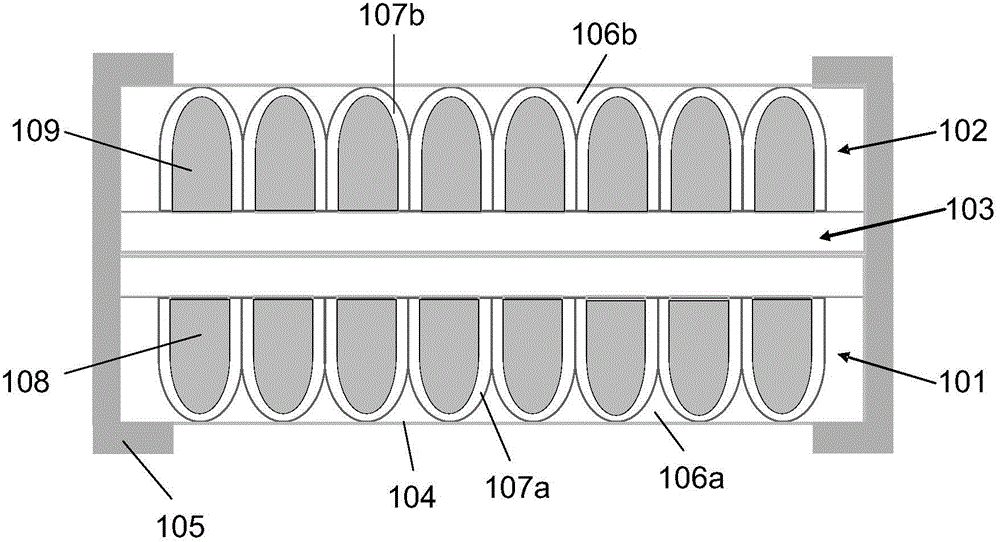

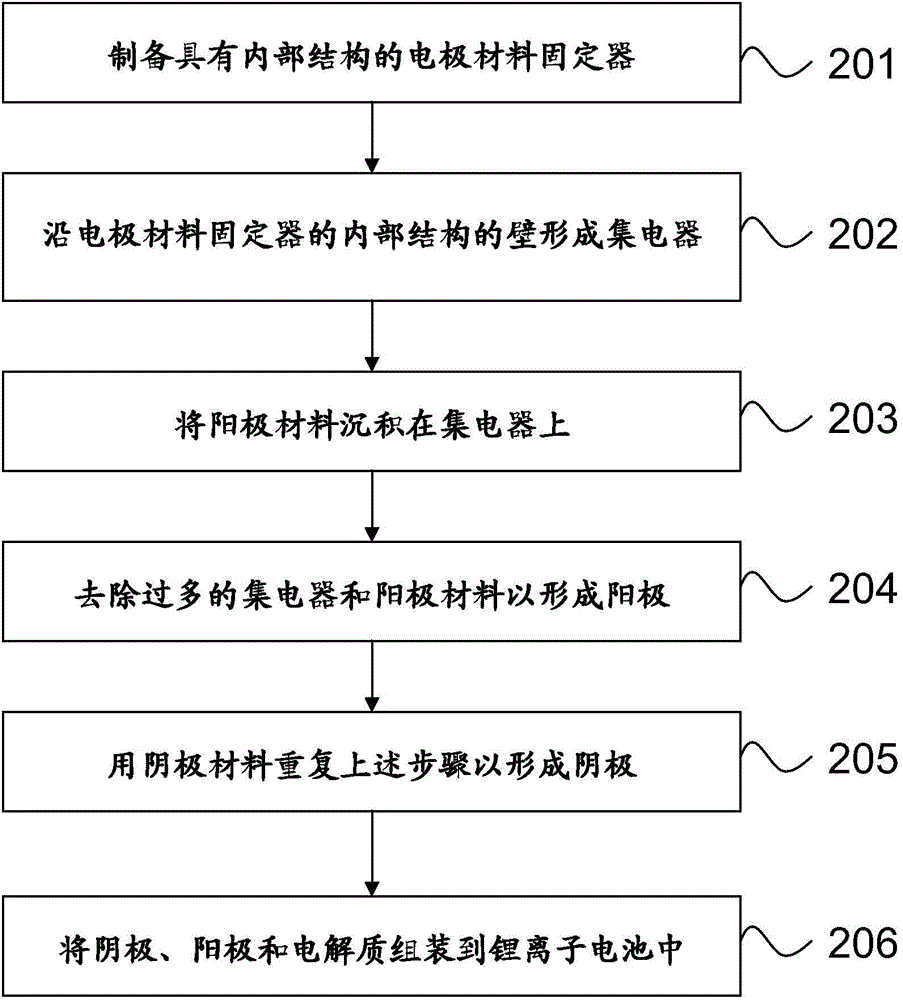

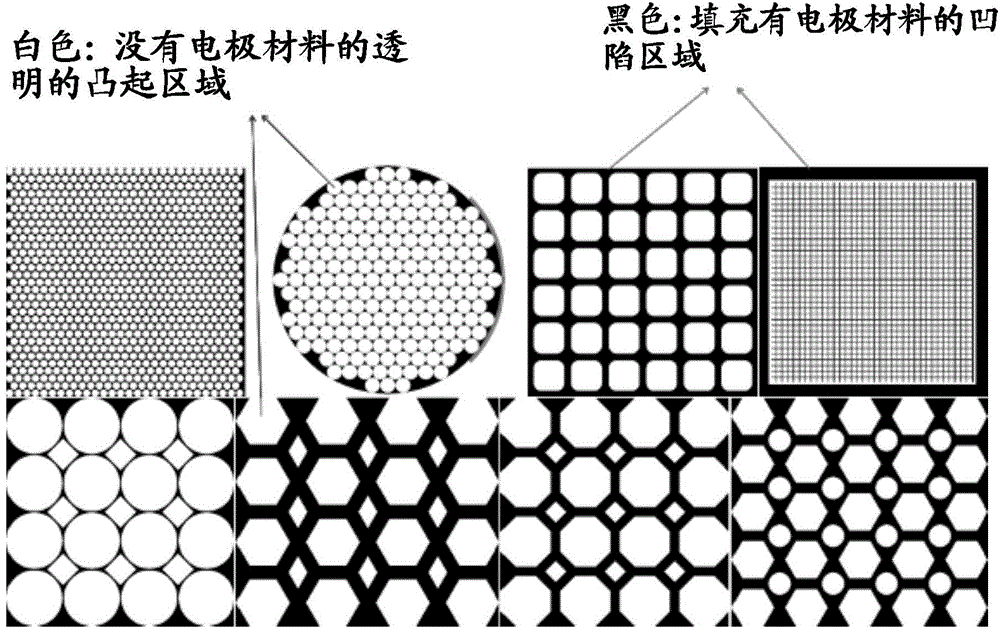

Transparent or translucent lithium ion battery and electrodes thereof

ActiveCN104037388AHigh transparencyHigh energy storage capacityFilling tube/pocket electrodesElectrode carriers/collectorsLithium-ion batteryMaterials science

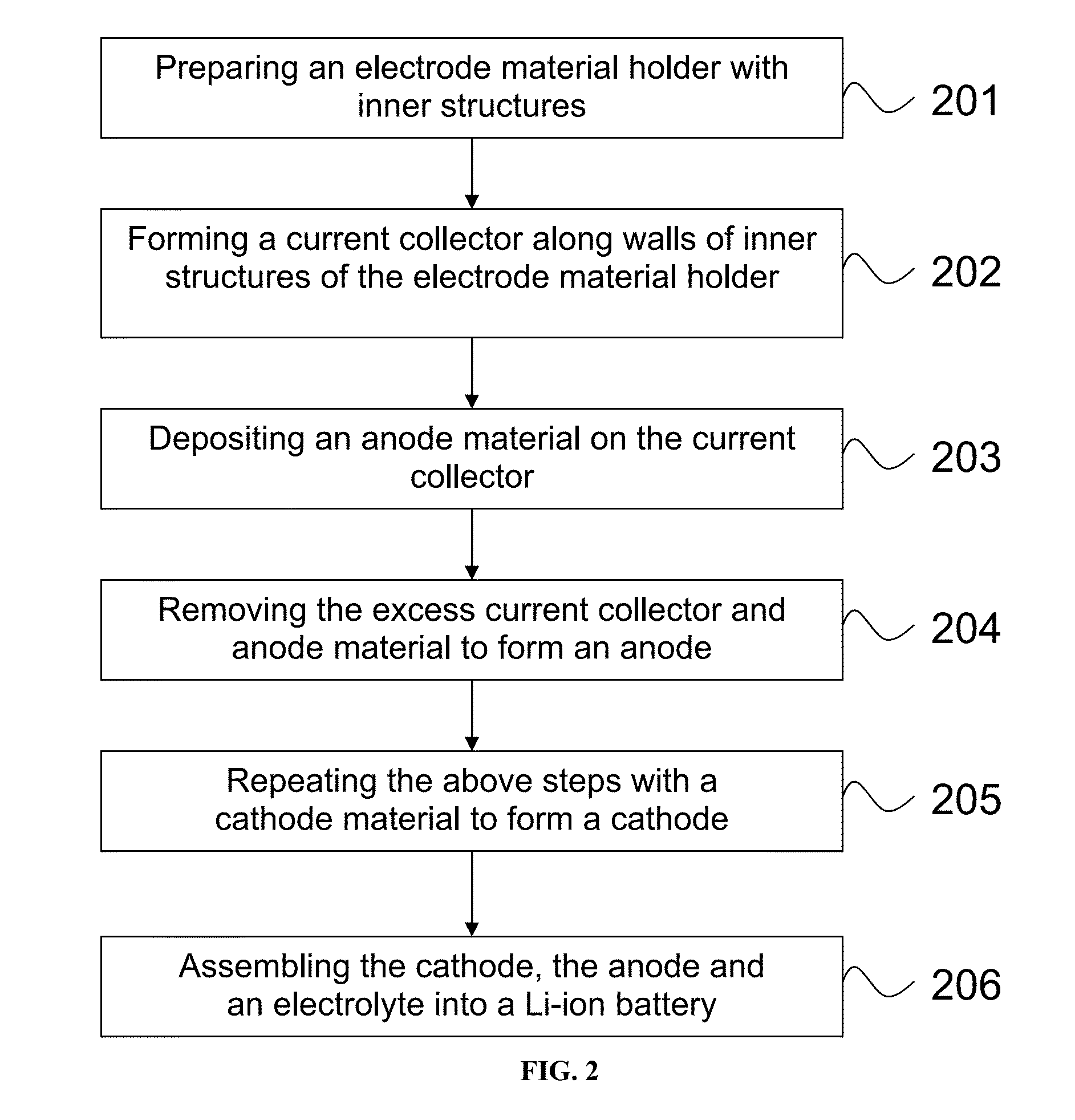

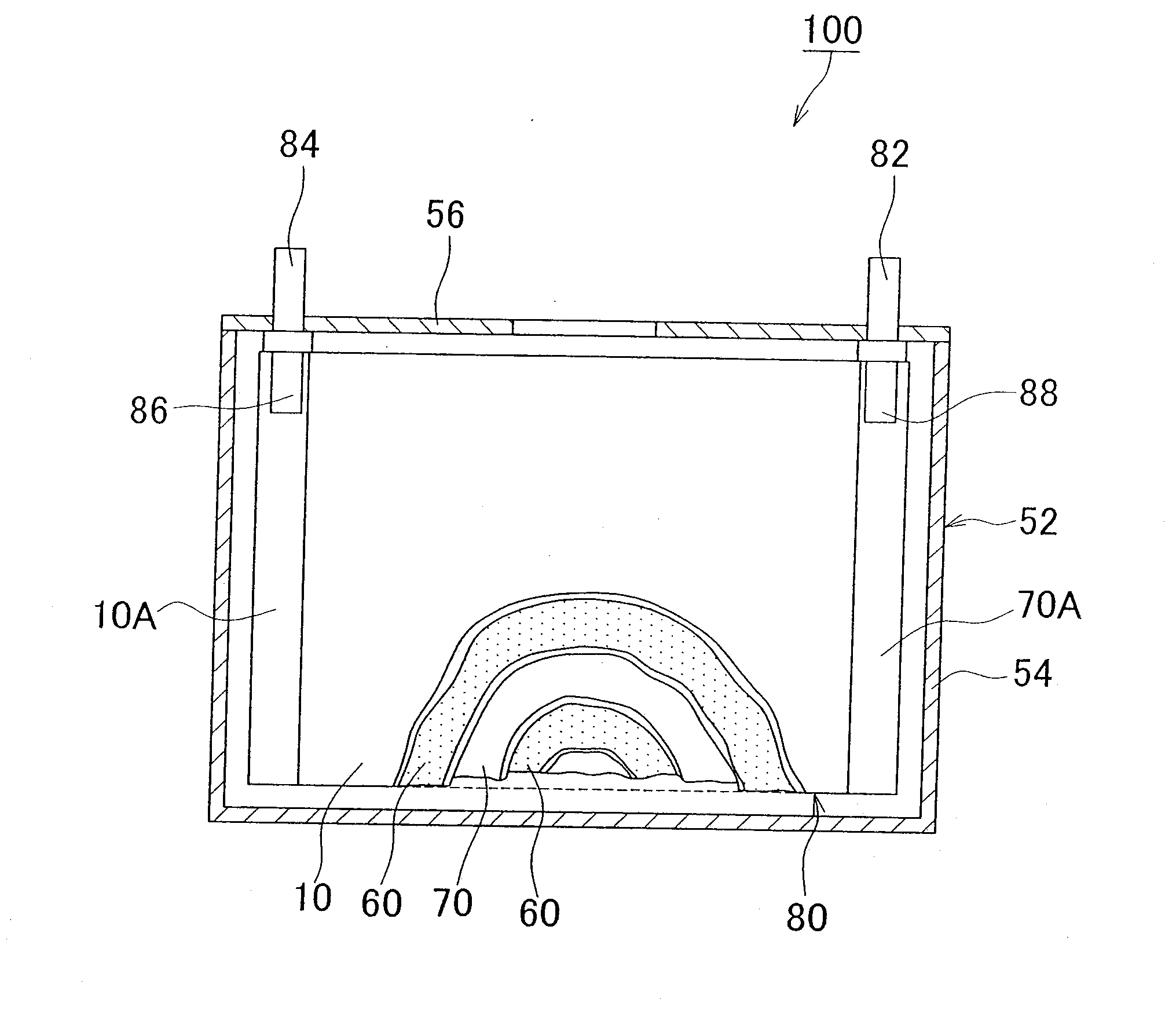

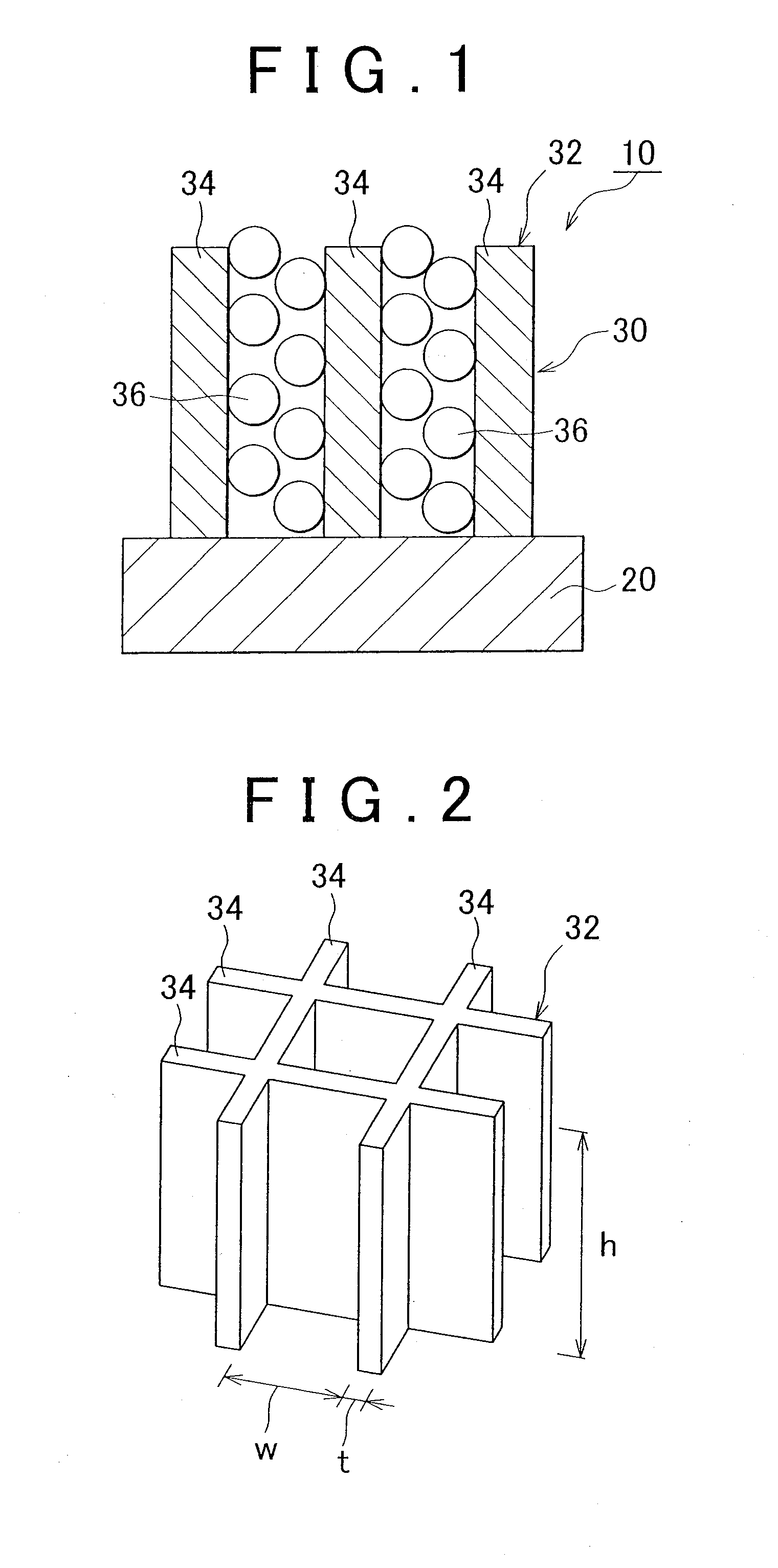

The present invention is to provide a transparent / translucent Li-ion battery and electrodes thereof. The transparent / translucent Li-ion battery comprises an anode, a cathode, and an electrolyte. The anode comprises an electrode material holder with inner structures, a current collector, and an anode material. The current collector is formed along the wall of the inner structures of the electrode material holder, and the anode material is deposited on the current collector, and filled within the inner structures. The cathode is fabricated with the similar method as the anode by using a cathode material. The electrode material holder with the inner structures can be a patterned glass or quartz slice with concave parts, or an anodized aluminum oxide film with channels. The transparent / translucent Li-ion battery of the present invention provides high transparency and electrical storage capacity.

Owner:NANO & ADVANCED MATERIALS INST

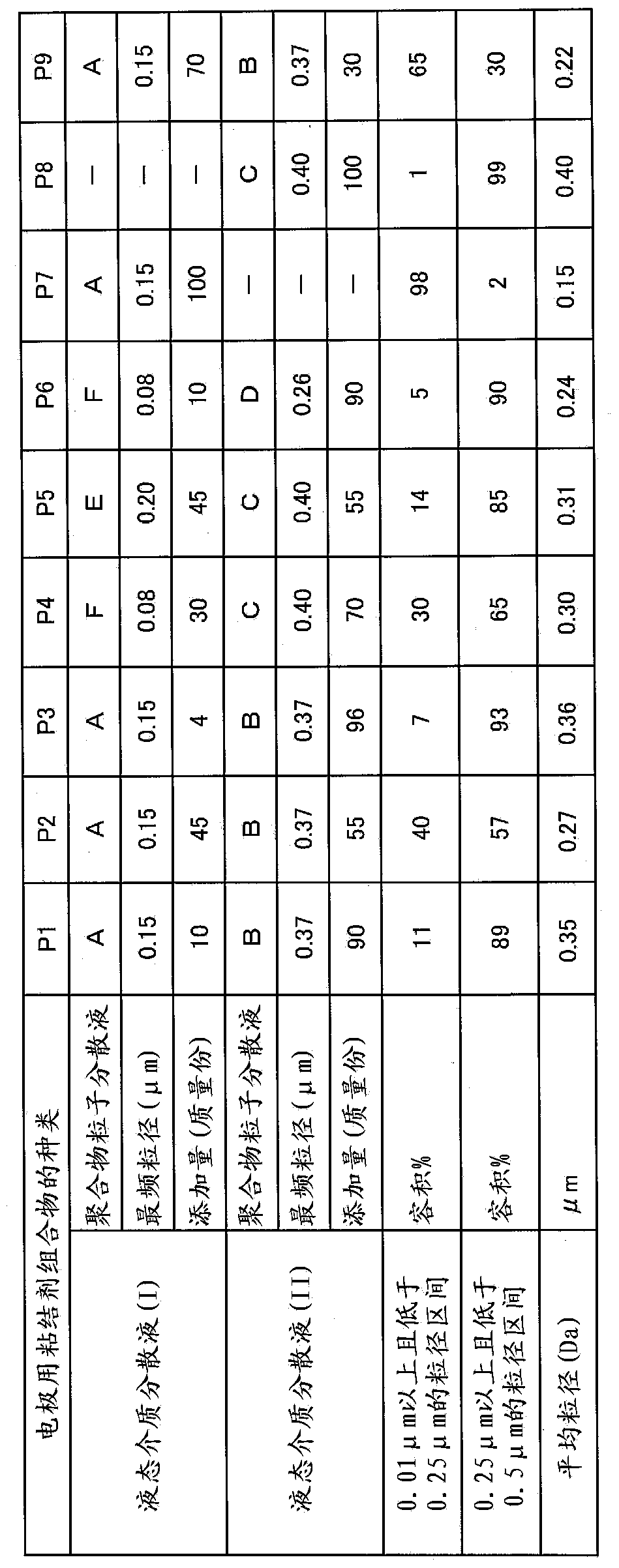

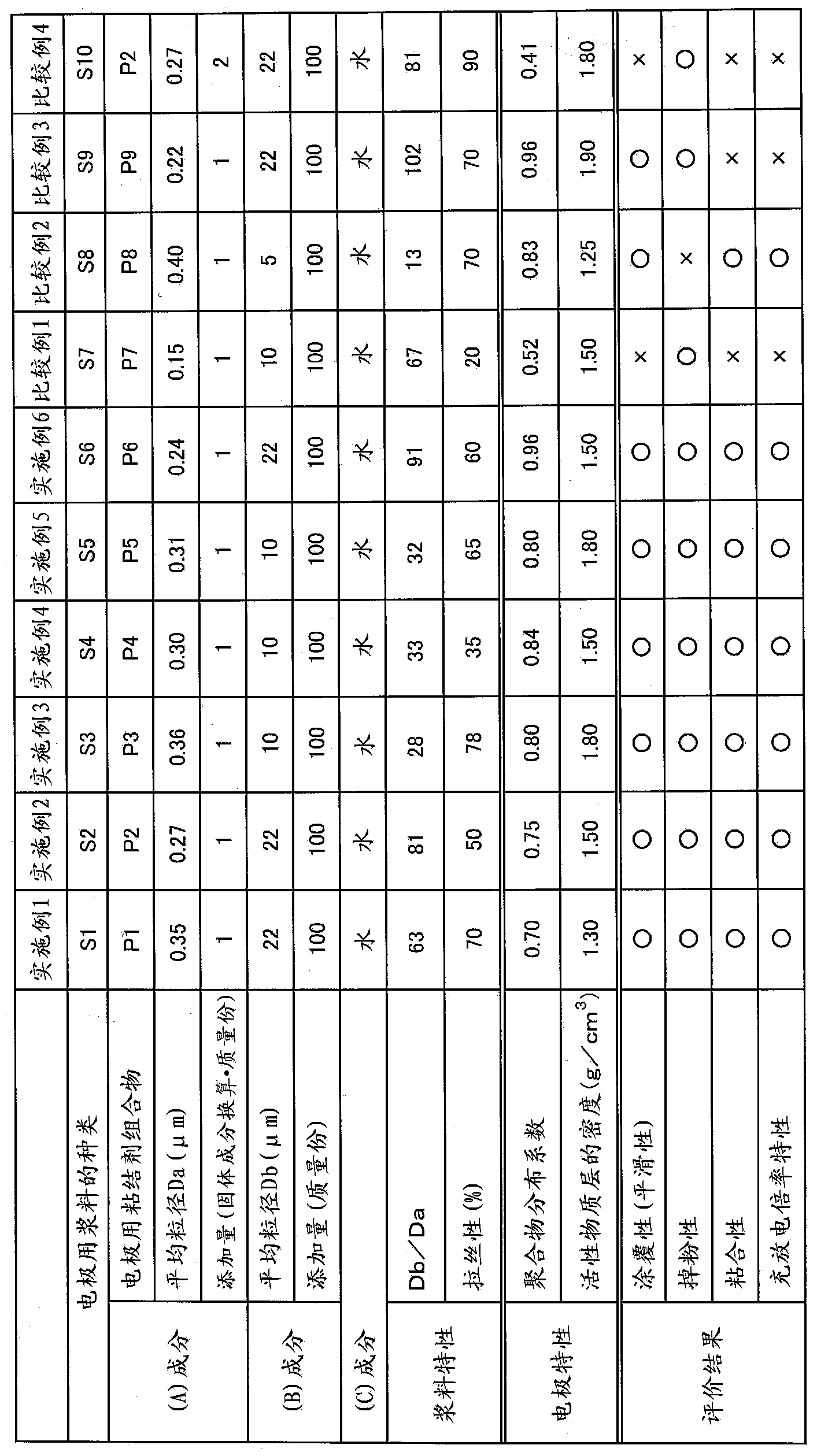

Electrode for electricity storage device, slurry for electrode, binder composition for electrode, and electricity storage device

InactiveCN103460453AImprove adhesionExcellent powder sheddingNon-aqueous electrolyte accumulatorsElectrolytic capacitorsElectricitySlurry

Owner:JSR CORPORATIOON

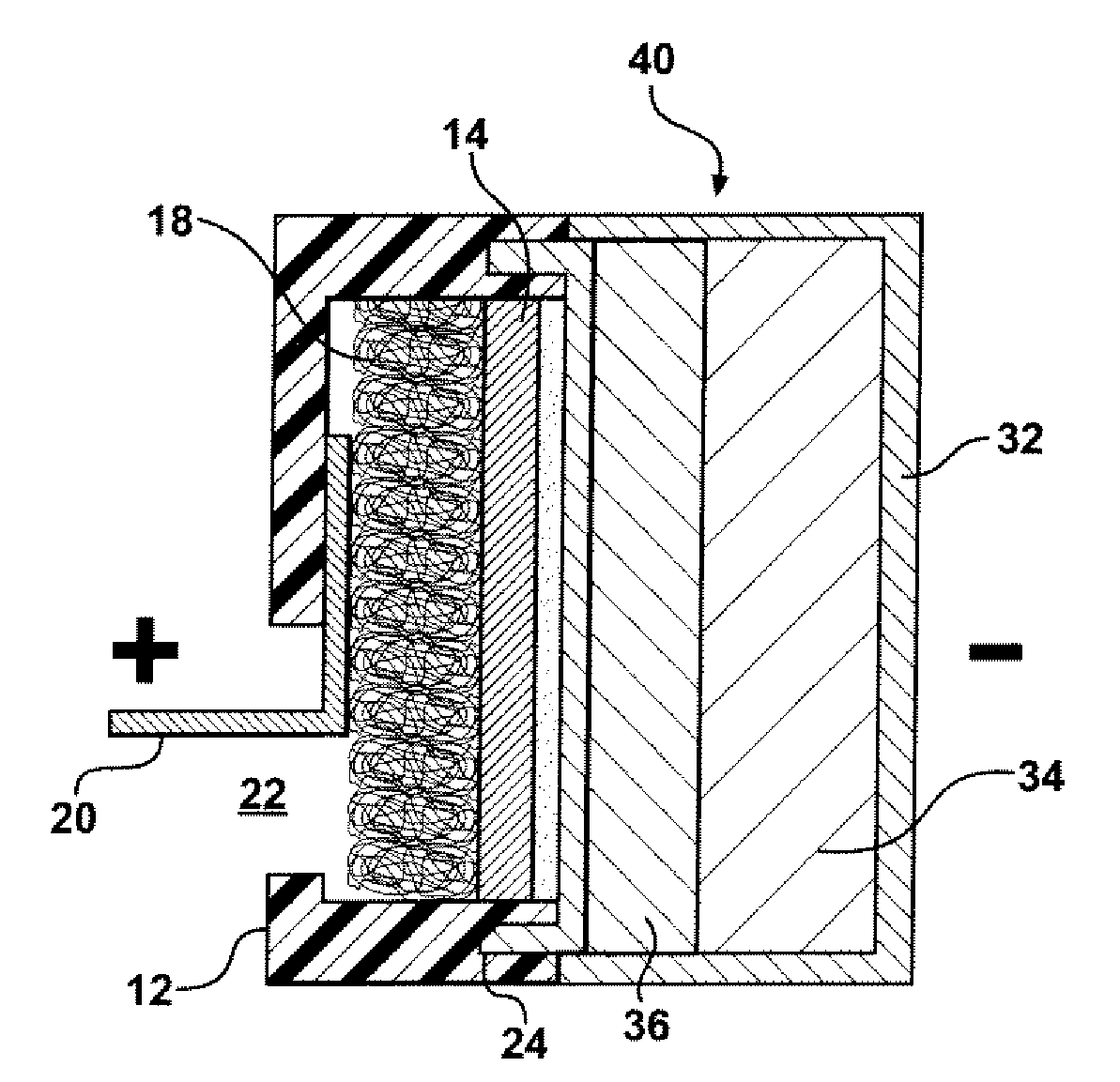

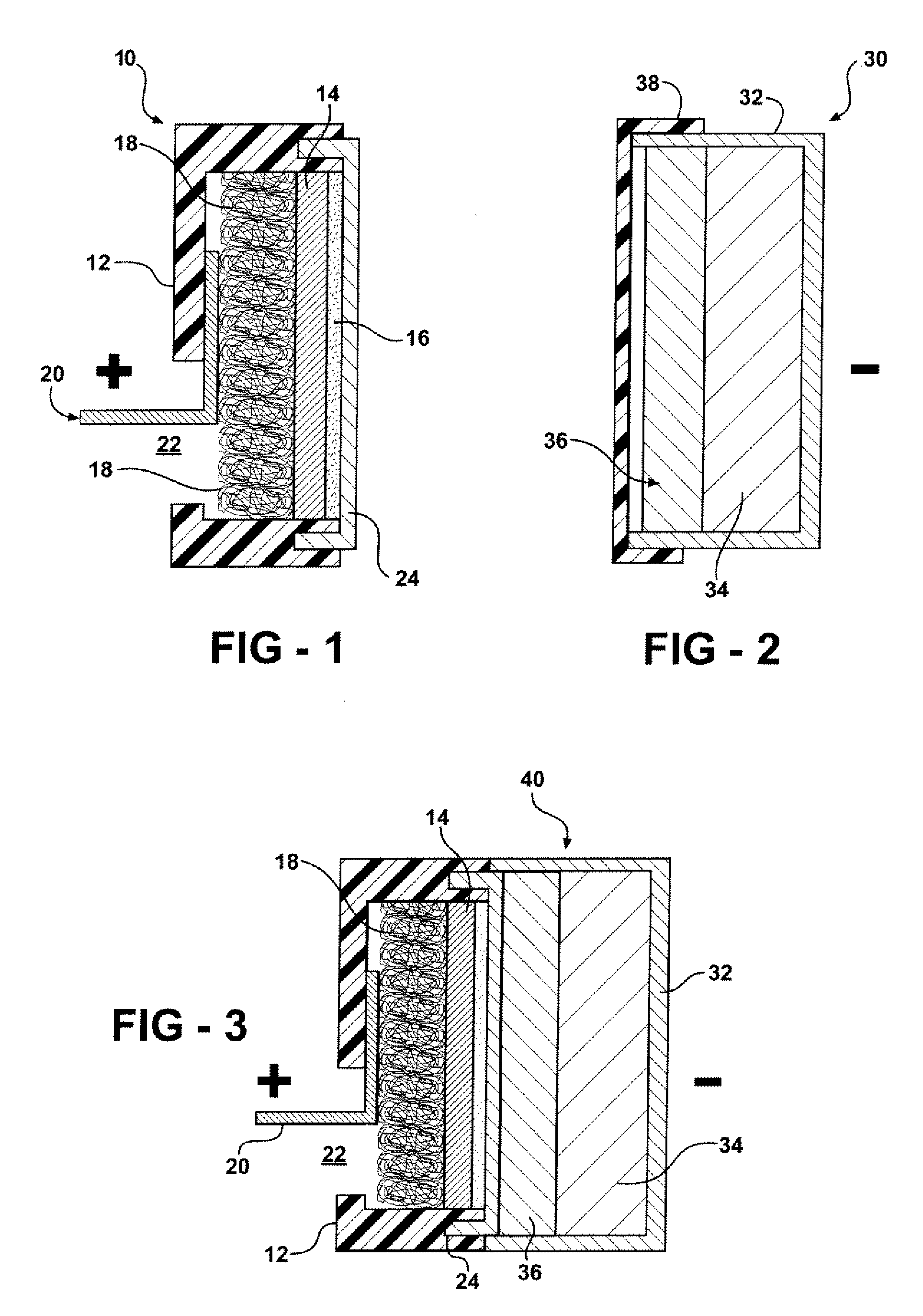

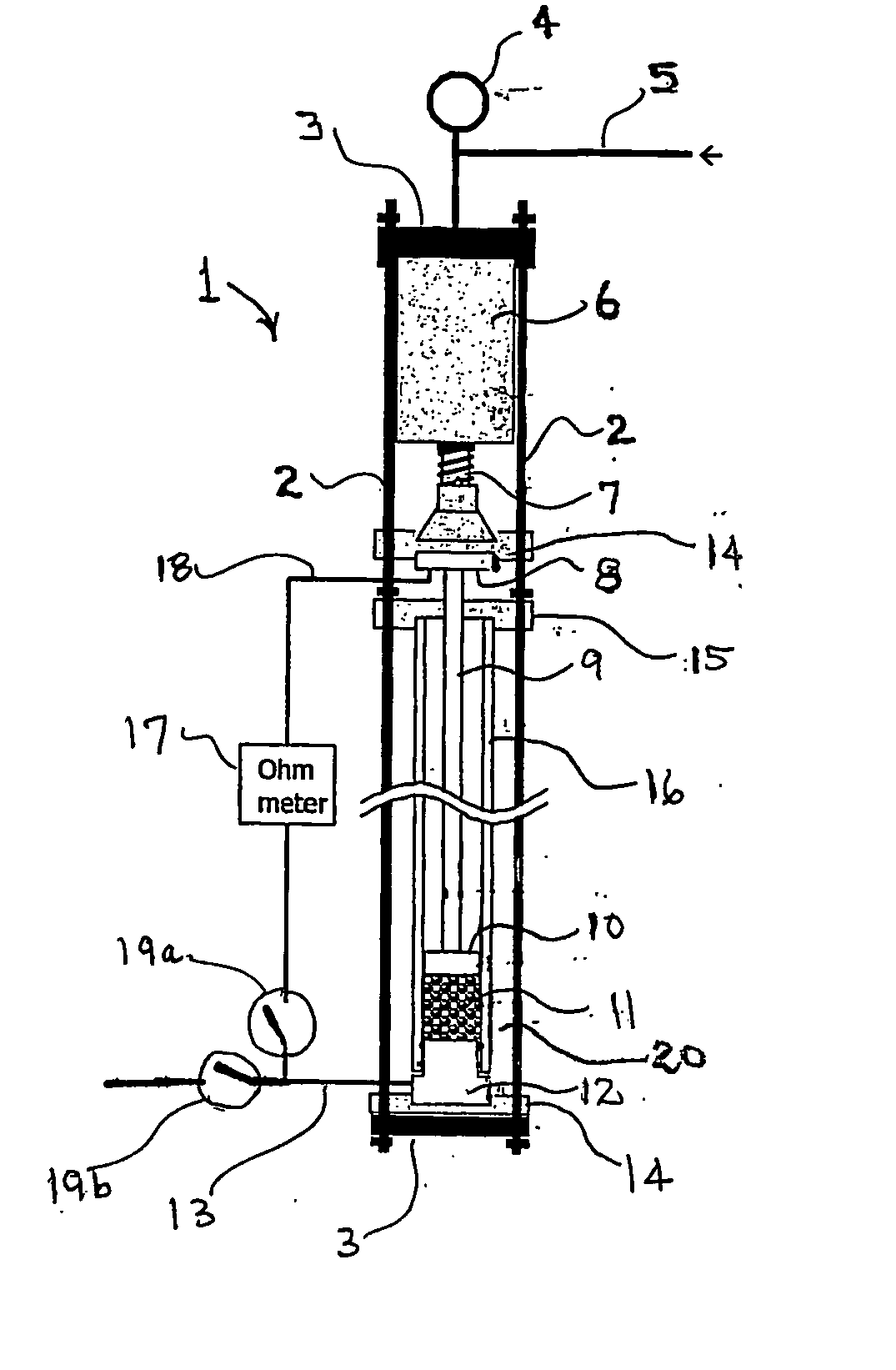

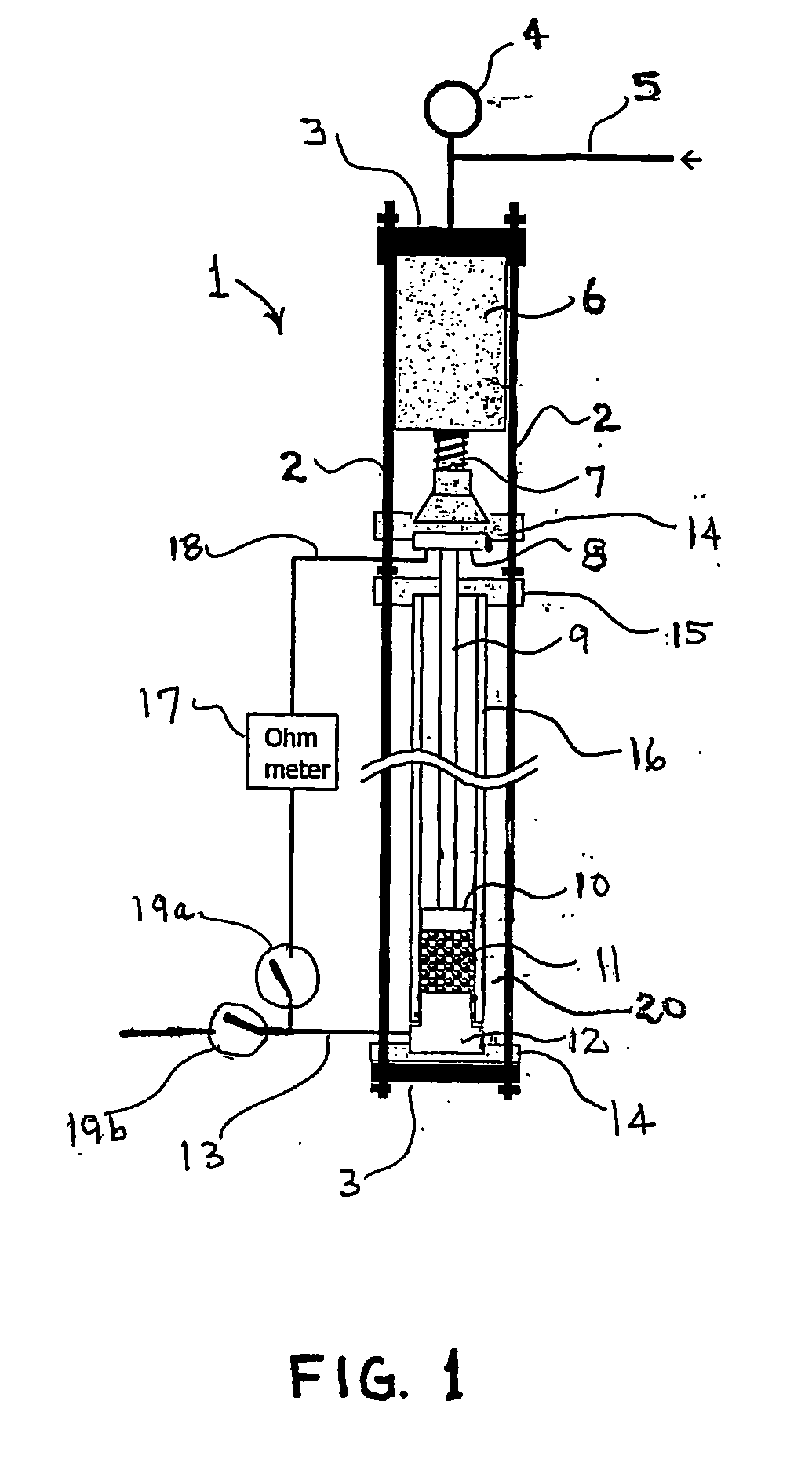

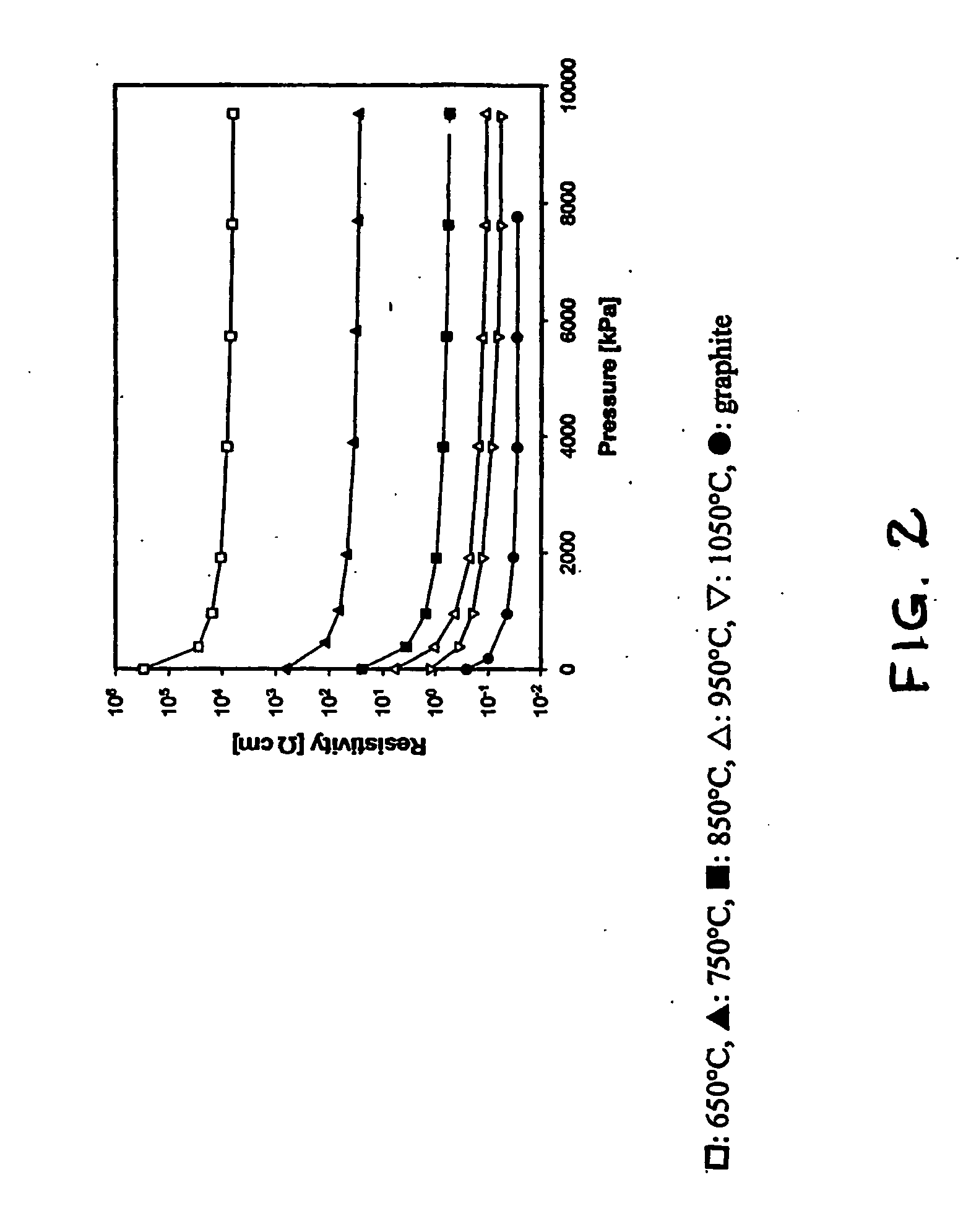

Carbonized charcoal electrode

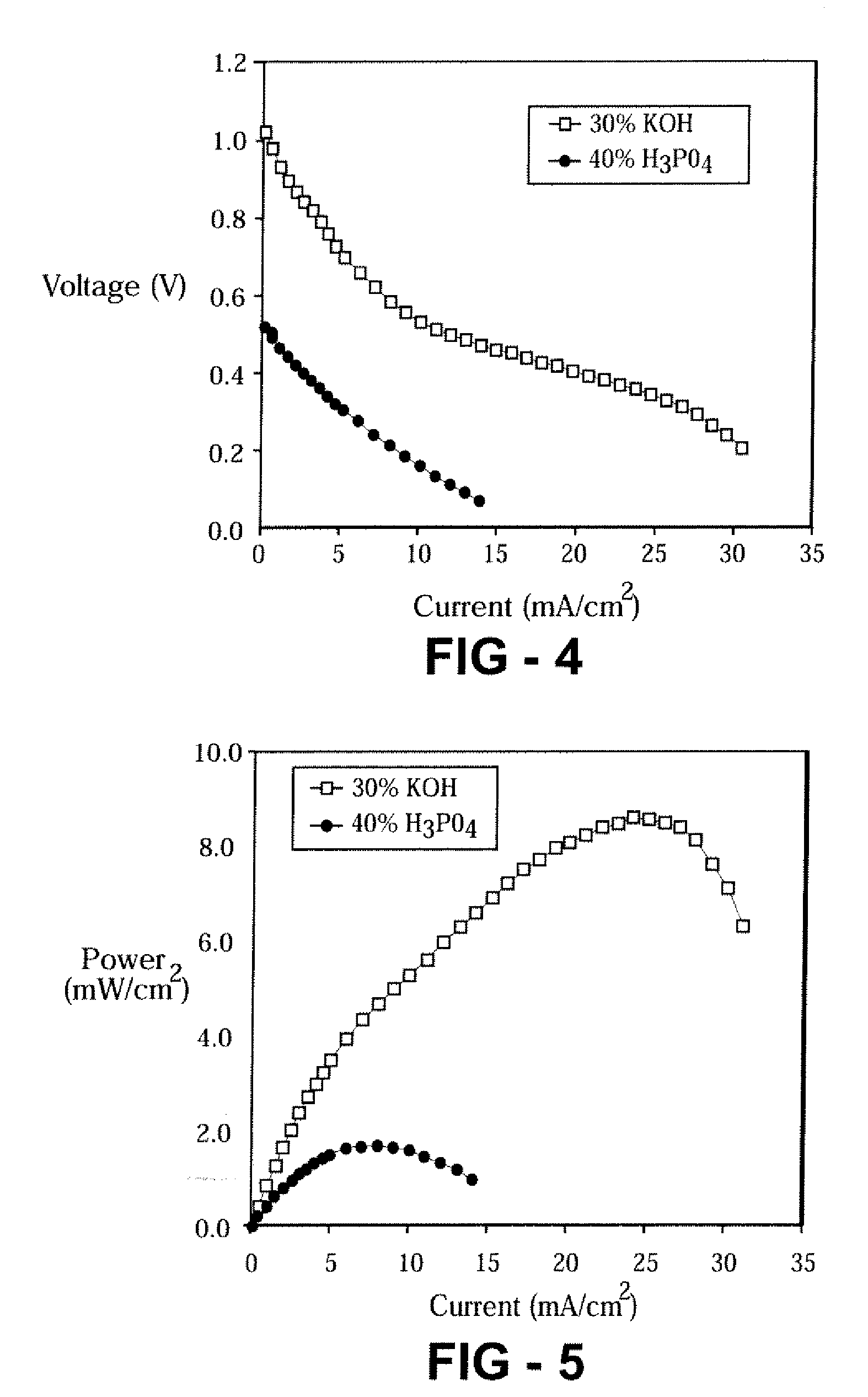

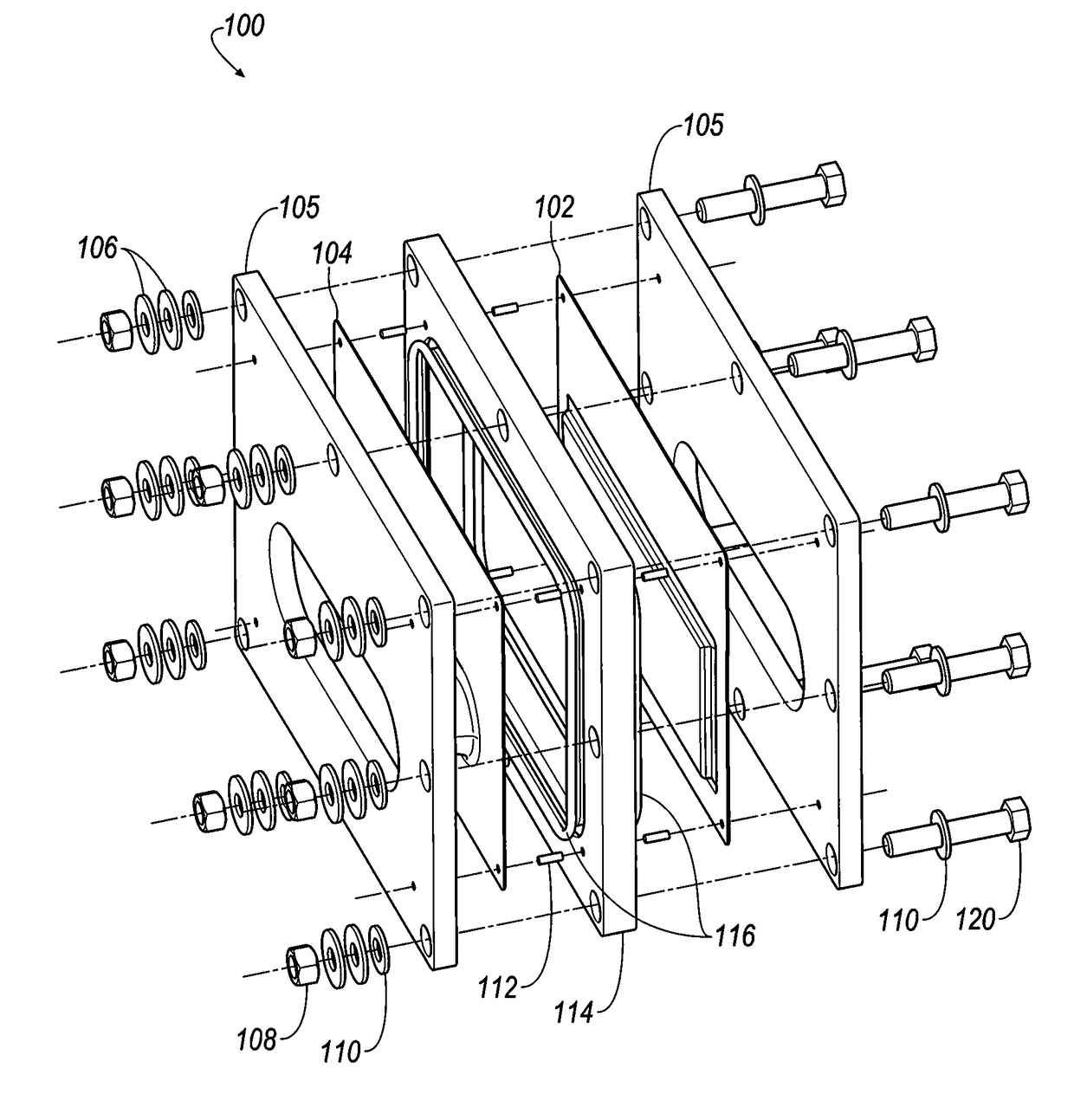

An apparatus (1) for use of carbonized charcoal powder as an electrode is provided. Charcoal is provided as a powder, carbonized, and placed in a container (16) by which compressive pressure is applied to the carbonized-charcoal powder via one or more sides of the container (16). As a result of the compressive pressure the packed-bed (11) of carbonized-charcoal powder manifests a resistivity of less than about 1 ohm-cm and is suitable for use as an electrode in a fuel cell, battery or electrolyzer. The apparatus is adapted with electrical contacts (8, 9, 10) to conduct electric flow to or from the electrode and adapted for communication of an electrolyte with the electrode.

Owner:UNIV OF HAWAII

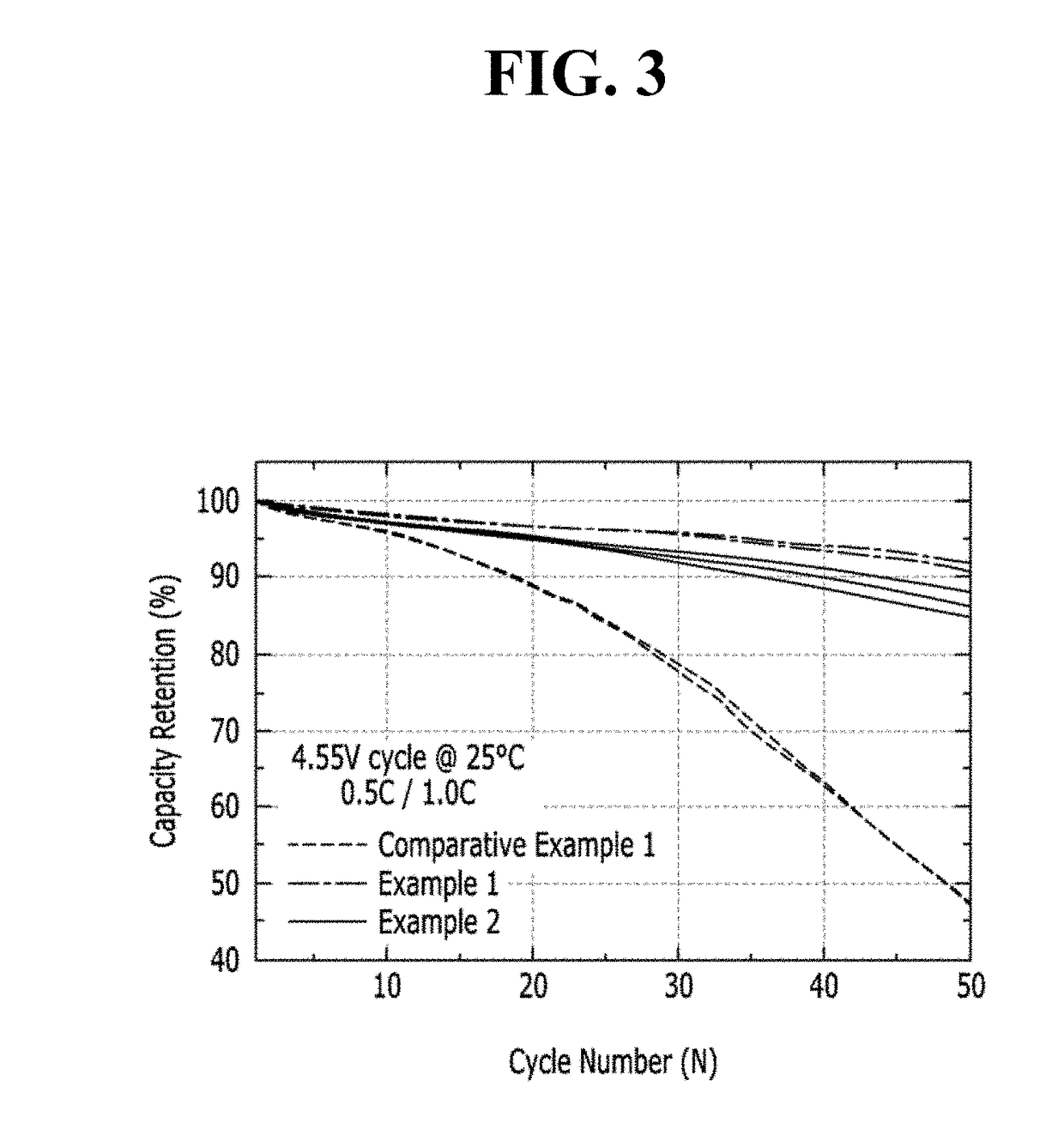

Positive electrode active material particle including core containing lithium cobalt oxide and shell containing composite metal oxide and preparation method thereof

A positive electrode active material particle includes a core that contains lithium cobalt oxide represented by the following Chemical Formula LiaCo(1-x)MxO2-yAy and a shell that is coated on the surface of the core and contains composite metal oxide of a metal with an oxidation number of +2 and a metal with an oxidation number of +3. In particular, M is at least one selected from the group consisting of Ti, Mg, Zn, Si, Al, Zr, V, Mn, Nb and Ni. A is oxygen-substitutional halogen and 1.00≤a≤1.05, 0≤x≤0.05, and 0≤y≤0.001.

Owner:LG ENERGY SOLUTION LTD

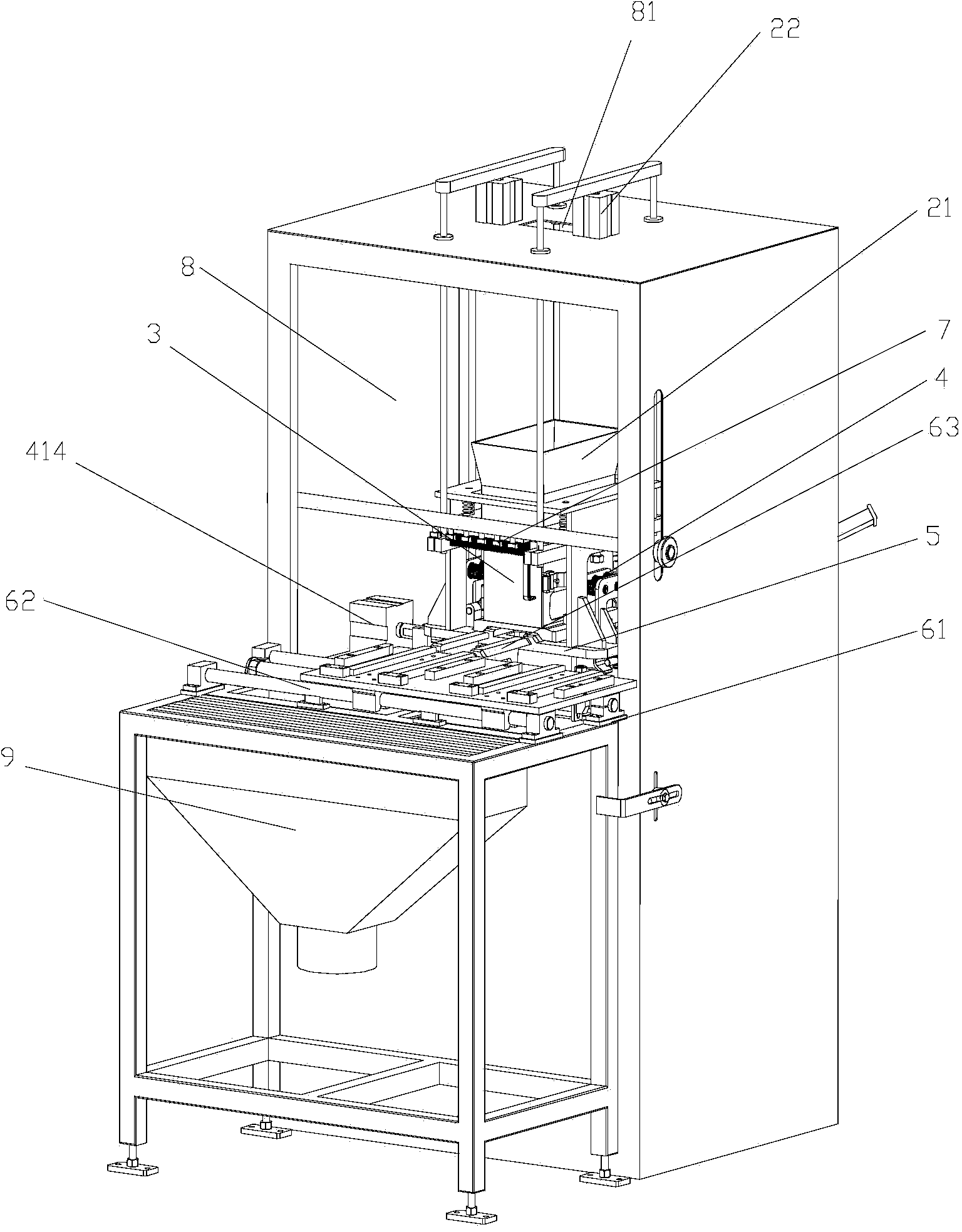

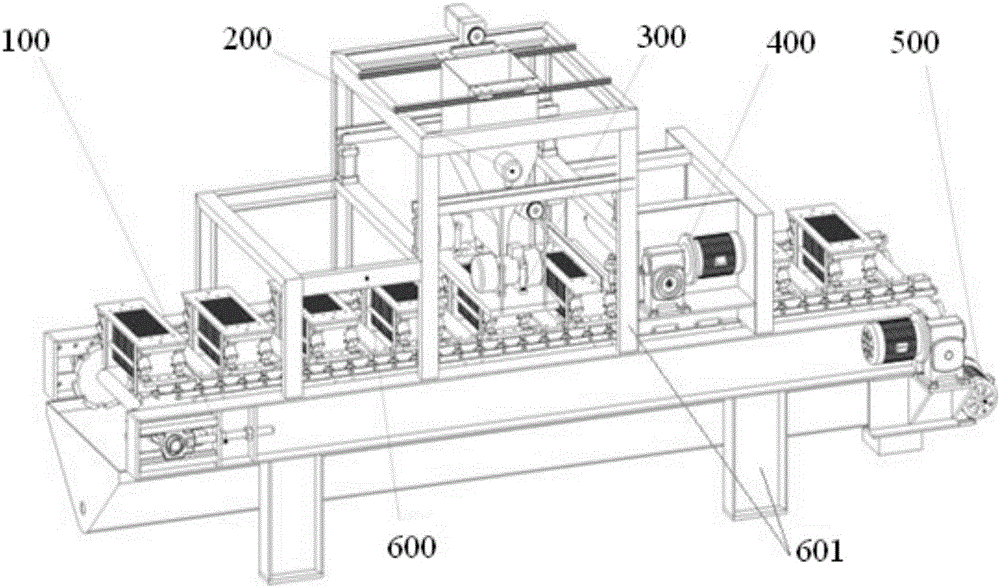

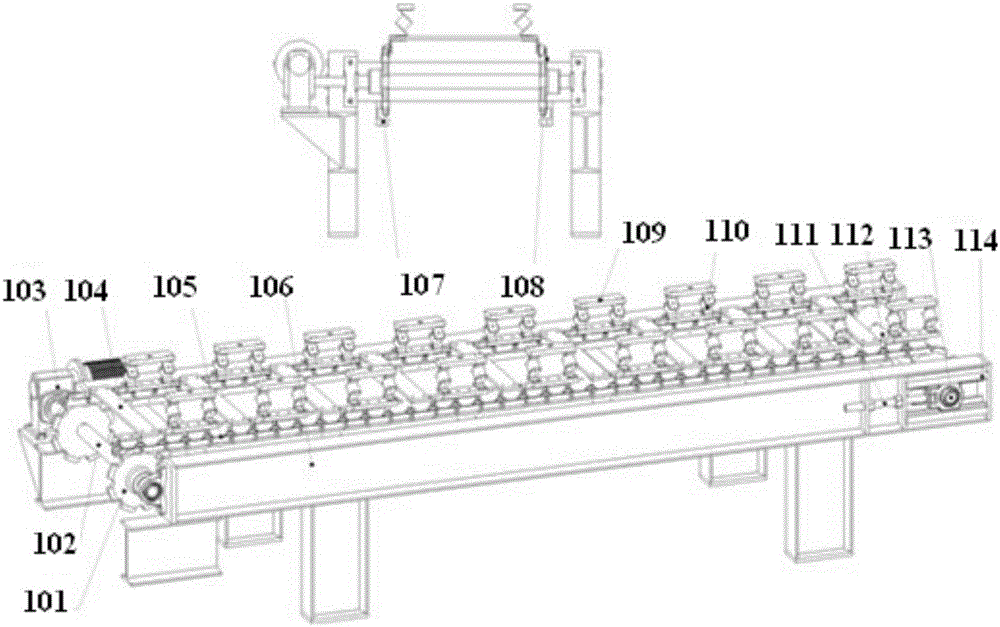

Full-automatic continuous lead powder filling machine

PendingCN106356506AContinuous automated productionIncrease productivityFilling tube/pocket electrodesLead-acid accumulator electrodesEngineeringElectromagnetic vibration

The invention discloses a full-automatic continuous lead powder filling machine. The full-automatic continuous lead powder filling machine comprises a frame and an automatic rotating device, an automatic quantitative powder-blanking device, an electromagnetic vibration filling device, a scraping cleaning device, a powder-collecting recycling device and a protecting dust-removing device which are arranged on the frame. The full-automatic continuous lead powder filling machine has the advantages that the continuous automatic production can be realized; the production efficiency is high and can reach up to 30 tablets per minute; a unique lifting electromagnetic vibration device and a powder filling assembling device are arranged; the vibration component in a filling production process is limited in a powder filling assembly panel 311; the frame 601 is low in vibration and low in noise; the protecting dust-removing device 600 is arranged, so that the closed filling can be performed, without waste or pollution; the scraping cleaning device 400 is arranged for recycling the spilled lead powder; the outer side of the draining pipe is clean and free from lead powder; the lifting electromagnetic vibration device and the powder filling assembling device are arranged, so that uniform powder filling can be realized.

Owner:谭振辉

Electrolyte for rechargeable electrochemical cell

InactiveUS20180013185A1Increased durabilityImprove stabilityFuel and secondary cellsLarge-sized flat cells/batteriesElectrolytic agentZinc bromide

The present invention provides an aqueous electrolyte for use in rechargeable zinc-halide storage batteries that possesses improved stability and durability and improves zinc-halide battery performance. One aspect of the present invention provides an electrolyte for use in a secondary zinc bromine electrochemical cell comprising from about 30 wt % to about 40 wt % of ZnBr2 by weight of the electrolyte; from about 5 wt % to about 15 wt % of KBr; from about 5 wt % to about 15 wt % of KCl; and one or more quaternary ammonium agents, wherein the electrolyte comprises from about 0.5 wt % to about 10 wt % of the one or more quaternary ammonium agents.

Owner:EOS ENERGY TECH HLDG LLC

Positive electrode for lithium secondary battery, method for preparing the positive electrode, lithium secondary battery having the positive electrode, and vehicle having the lithium secondary battery

InactiveCN102668181AFilling tube/pocket electrodesElectrode carriers/collectorsCarbon nanowallsEngineering

A positive electrode (10) for a lithium secondary battery, including a positive electrode collector (20), and a positive electrode active substance layer (30) that is supported on the positive electrode collector (20) and includes carbon nanowalls (32) which are formed on the positive electrode collector (20), and a positive electrode active substance (36) which is supported on the carbon nanowalls (32).

Owner:TOYOTA JIDOSHA KK

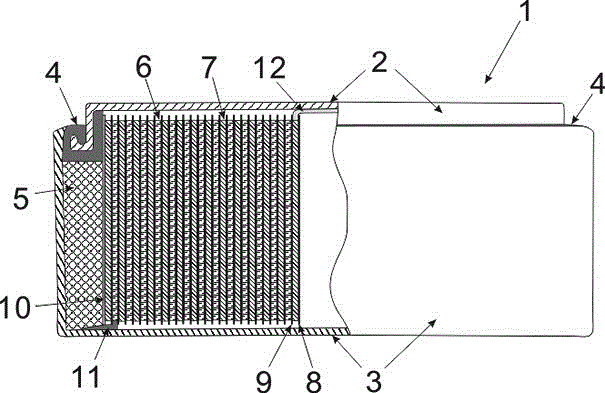

Lithium ion button battery

InactiveCN106025366ARespond to and solve problems caused by cell changesIncrease capacityFinal product manufactureFilling tube/pocket electrodesElastomerEngineering

The invention discloses a lithium ion button battery with the height and diameter being 1 or smaller. Anode and cathode shells and insulation sealing rings are sealed through hemming and tight-pressing, a battery core with the winding axis perpendicular to circular flat planes of the anode and cathode shells of the battery is a multi-polygon regular prism, at least one material is adopted in a diaphragm in battery core pole piece set, a columnar sleeve piece is embedded between the cylindrical side wall of the battery core and the cylindrical side wall of an inner cavity of the anode shell and made of elastomer plastics or metal, and the sleeve contains the battery core so as to effectively adapt to changes of the size of the battery core during charging and discharging.

Owner:SHENZHEN JERAMIC MATERIALS TECH CO LTD

Composite anode active material, anode and lithium battery each including the composite anode active material, method of preparing the composite anode active material

ActiveUS9564631B2Increase capacityImprove featuresMicroscopic fiber electrodesElectrode thermal treatmentFiberCarbon fibers

A composite anode active material, an anode including the composite anode active material, a lithium battery including the anode, and a method of preparing the composite anode active material. The composite anode active material includes: a shell including a hollow carbon fiber; and a core disposed in a hollow of the hollow carbon fiber, wherein the core includes a first metal nanostructure and a conducting agent.

Owner:SAMSUNG ELECTRONICS CO LTD

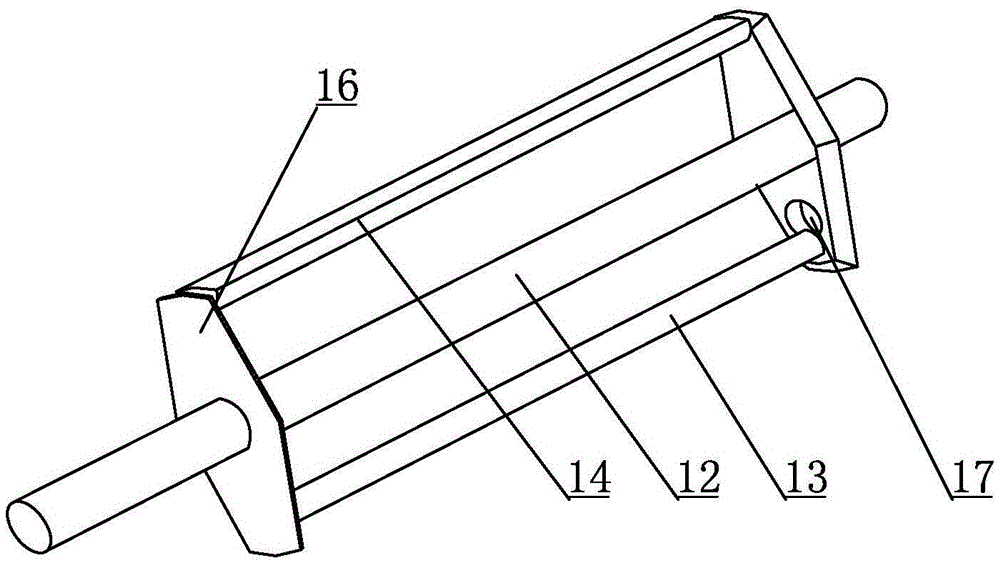

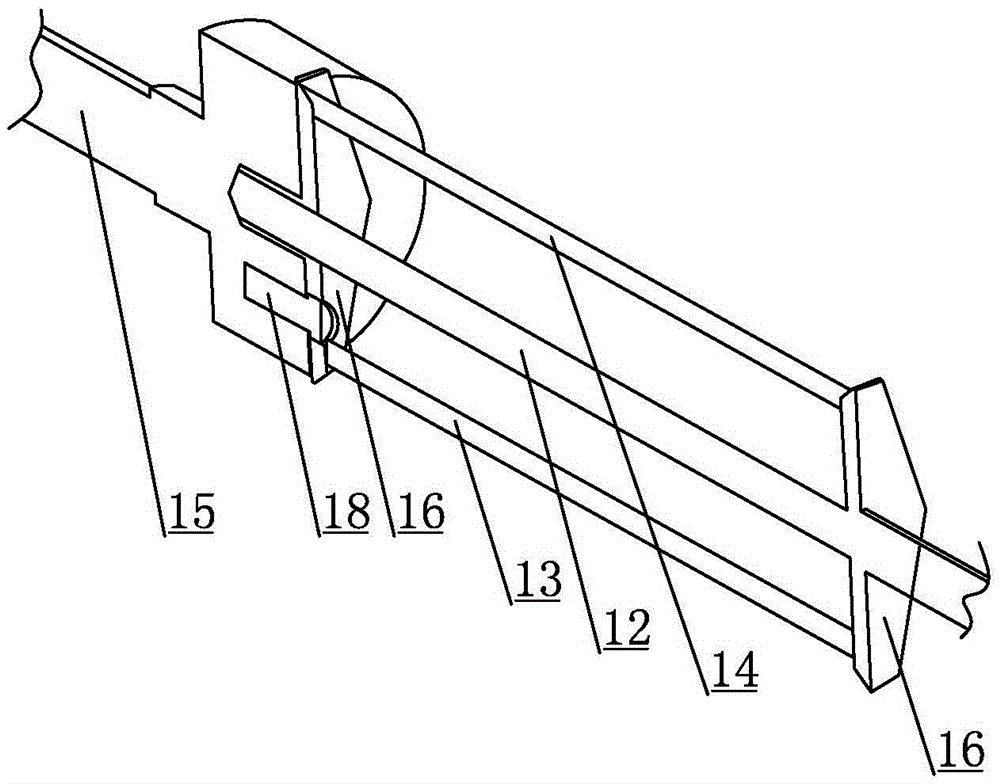

Tubular grid stirring type paste extruding apparatus

ActiveCN105489850AUniform pressureFast blockFilling tube/pocket electrodesLead-acid accumulator electrodesFailure ratePulp and paper industry

The invention belongs to the manufacturing field of a lead-acid storage battery, and specifically relates to a tubular grid stirring type paste extruding apparatus. The tubular grid stirring type paste extruding apparatus comprises a paste extruding head, wherein the paste extruding head is communicated with a paste extruding pipe; a stirring blade is arranged in the paste extruding head; the stirring blade comprises a central shaft, a mixing blade and a mixing barrier blade; the mixing blade and the mixing barrier blade are arranged on the two sides of the central shaft separately; the central shaft is connected with a motor rotating shaft; one side, in contact with the lead paste inlet of the paste extruding head, of the mixing barrier blade is a plane; and an in-place detection part is arranged on the exterior, corresponding to the mixing barrier blade, of the paste extruding head. The tubular grid stirring type paste extruding apparatus is high in extruded paste weight control precision, low in failure rate and convenient to detach and clean.

Owner:ZIBO XINXU POWER SUPPLY TECH

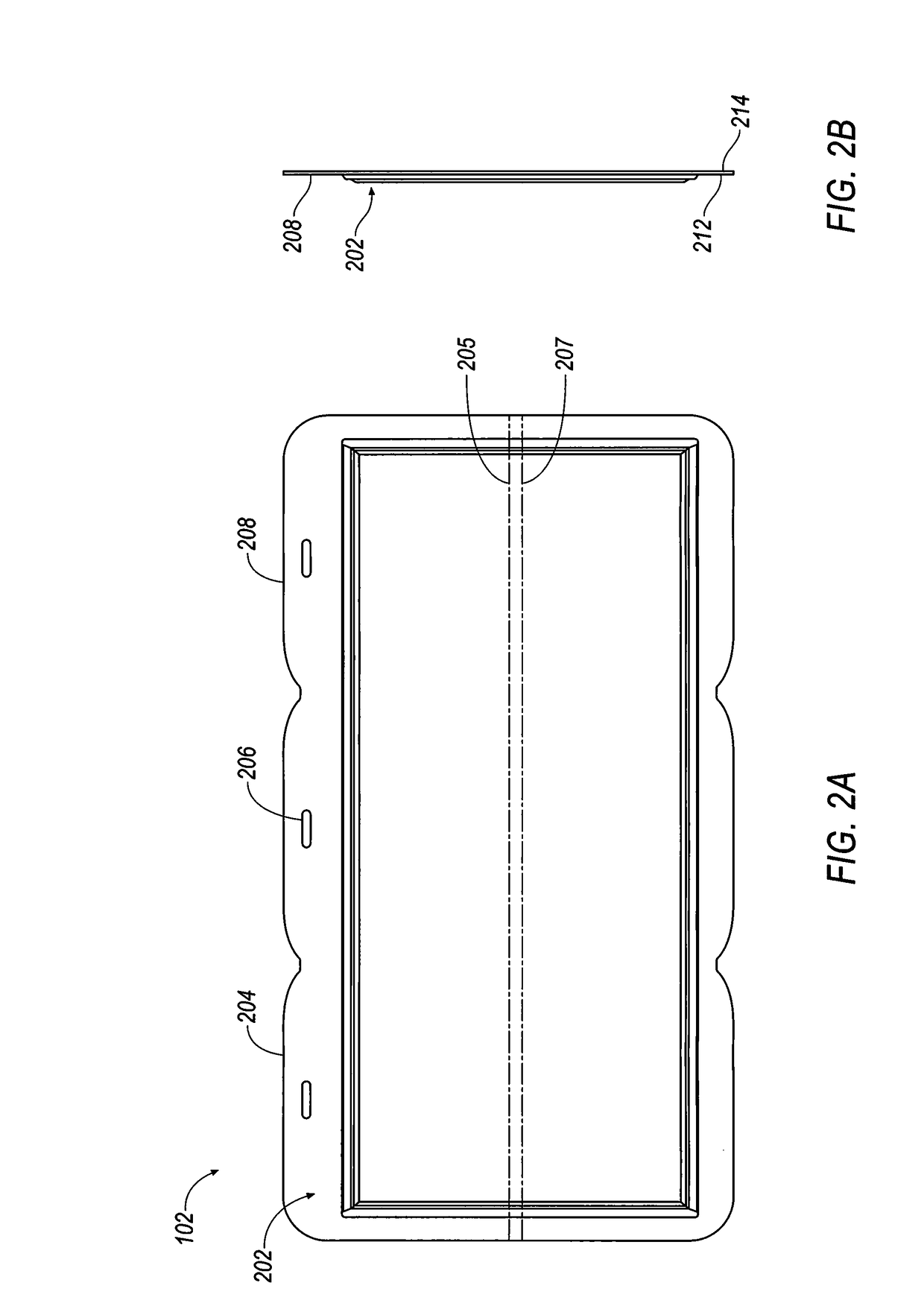

Transparent or Translucent Lithium Ion Battery

InactiveUS20140255791A1Increase capacityHigh transparencyNon-aqueous electrolyte cellsFilling tube/pocket electrodesLithium-ion batteryMaterials science

The present invention is to provide a transparent / translucent Li-ion battery. The transparent / translucent Li-ion battery comprises an anode, a cathode, and an electrolyte. The anode comprises an electrode material holder with inner structures, a current collector, and an anode material. The current collector is formed along the wall of the inner structures of the electrode material holder, and the anode material is deposited on the current collector, and filled within the inner structures. The cathode is fabricated with the similar method as the anode by using a cathode material. The electrode material holder with the inner structures can be a patterned glass or quartz slice with concave parts, or an anodized aluminum oxide film with channels. The transparent / translucent Li-ion battery of the present invention provides high transparency and electrical storage capacity.

Owner:NANO & ADVANCED MATERIALS INST

Electrode slurry precursor, electrode slurry and preparation method of electrode slurry, electrode and lithium ion battery

ActiveCN106159214AImprove uniformityGood mechanical adhesionFilling tube/pocket electrodesSecondary cellsOrganic solventDissolution

The invention relates to the battery filed and particularly provides an electrode slurry precursor which comprises a packaging film bag and an electrode material, and the electrode material is sealed in the packaging film bag which can be dissolved in an organic solvent. The invention provides an electrode slurry and a preparation method of the electrode slurry, the method comprises the steps that (1) polymer materials containing polyvinylidene fluoride are dissolved with an organic solvent to obtain a solution, and the solution is subjected to film forming to obtain the packaging film bag; (2) the electrode material is sealed with the packaging film bag, and the electrode slurry precursor is obtained; (3) the electrode slurry precursor is added to the organic solvent for dissolution to obtain the electrode slurry. The invention provides an electrode and a lithium ion battery. The electrode slurry is high in uniformity and good in mechanical adhesion force.

Owner:BYD CO LTD

Negative electrode for lithium secondary battery, method for preparing the negative electrode, lithium secondary battery having the negative electrode, and vehicle having the lithium secondary battery

ActiveUS20120225353A1Material nanotechnologyFilling tube/pocket electrodesCarbon nanowallsLithium-ion battery

A negative electrode (10) for a lithium secondary battery, including a negative electrode collector (20), and a negative electrode active substance layer (30) that is supported on the negative electrode collector (20) and includes carbon nanowalls (32) which are formed on the negative electrode collector (20), and a negative electrode active substance (36) which is supported on the carbon nanowalls (32).

Owner:TOYOTA JIDOSHA KK

Positive electrode for lithium secondary battery, method for preparing the positive electrode, lithium secondary battery having the positive electrode, and vehicle having the lithium secondary battery

InactiveUS20120214065A1Avoid breakingMaterial nanotechnologyFilling tube/pocket electrodesCarbon nanowallsEngineering

A positive electrode (10) for a lithium secondary battery, including a positive electrode collector (20), and a positive electrode active substance layer (30) that is supported on the positive electrode collector (20) and includes carbon nanowalls (32) which are formed on the positive electrode collector (20), and a positive electrode active substance (36) which is supported on the carbon nanowalls (32).

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com