Full-automatic continuous lead powder filling machine

A filling machine, fully automatic technology, used in lead-acid battery electrodes, electrode manufacturing, filling tube/bag electrodes, etc., can solve the problems of lead powder scattered on the ground, low efficiency, high noise, etc., to achieve continuous automatic production , High production efficiency, small vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Below in conjunction with embodiment, further illustrate the present invention.

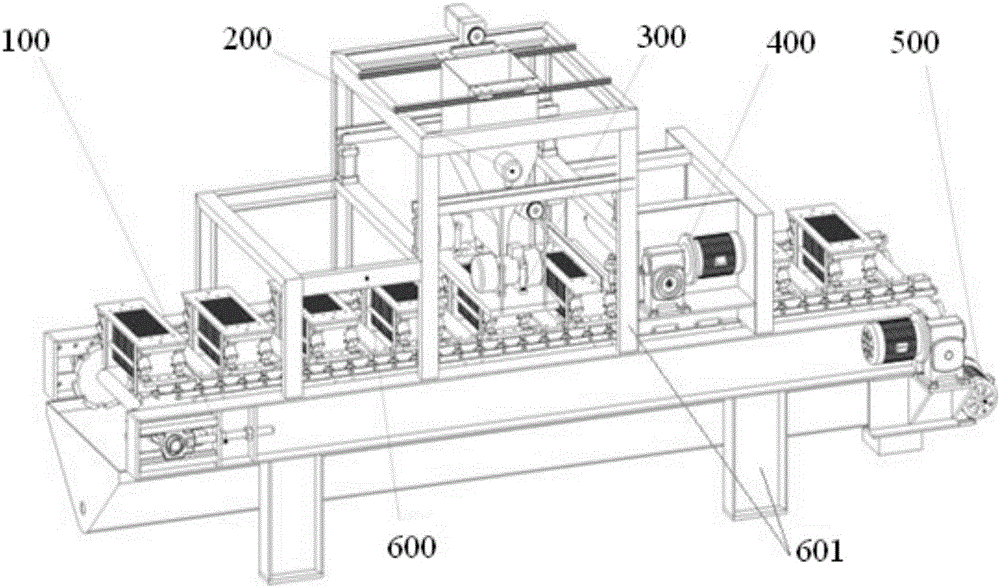

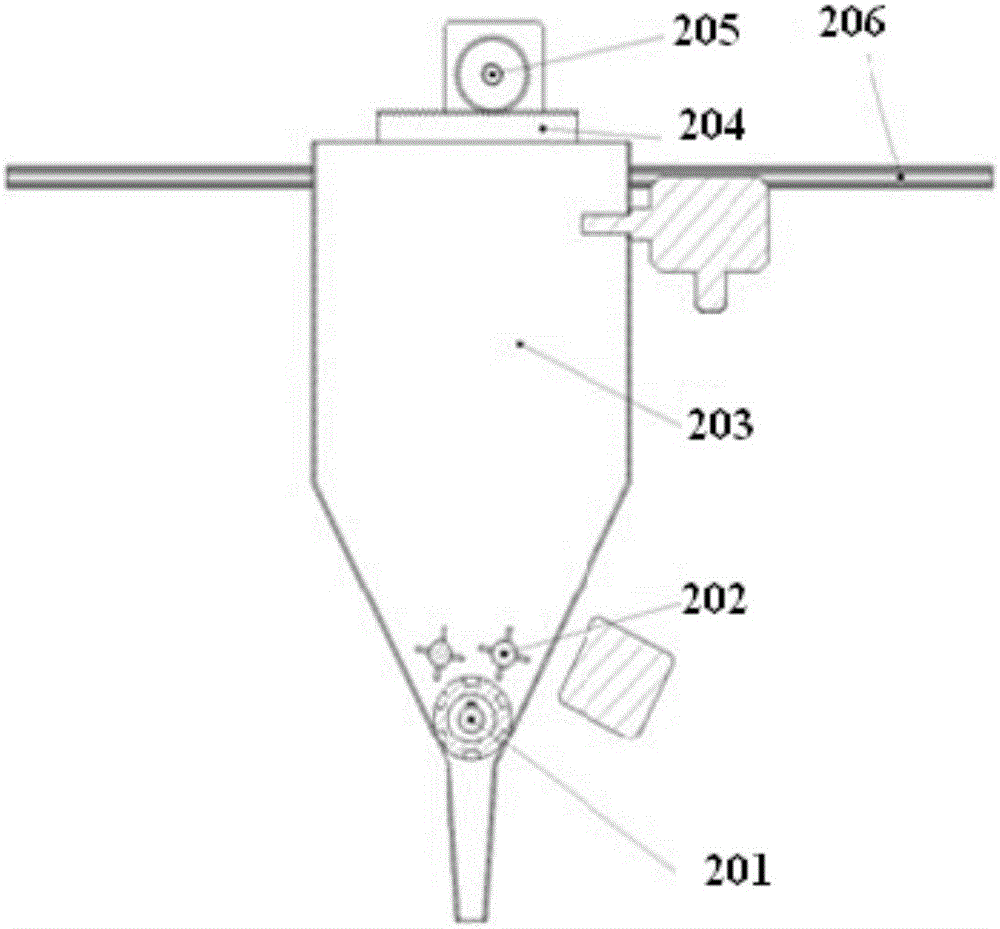

[0046] see figure 1 It can be seen that a kind of full-automatic continuous lead powder filling machine of the present invention is composed of a frame 601 and an automatic rotary device 100 arranged on the frame 601; Device 300 , scraping and cleaning device 400 , powder collection and recovery device 500 , protective dust removal device 600 .

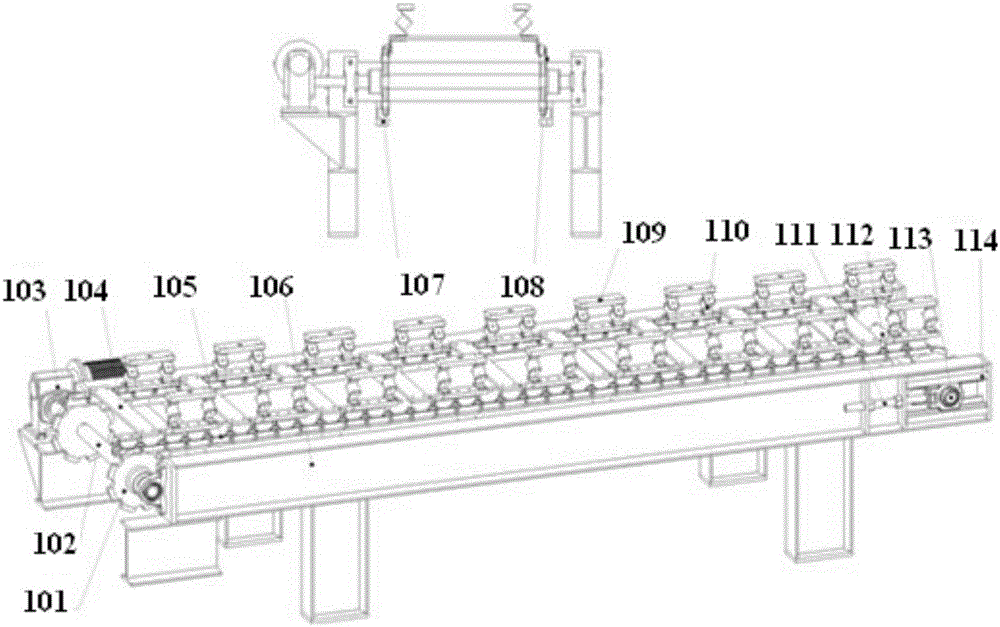

[0047] combine figure 2 It can be seen that the automatic turning device 100 is provided with a chain conveyor, and tooling positioning plates 109 are arranged at equidistant intervals on the chain plate 104 of the chain conveyor.

[0048] Both sides of the chain conveyor are provided with lower guide rails 107 and upper guide rails 108 arranged in pairs. The lower guide rail 107 and the upper guide rail 108 ensure that the chain plate 104 and the chain 105 operate normally along the guide rail to prevent falling and deviation.

[0049] The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com