Patents

Literature

127results about How to "Continuous automated production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

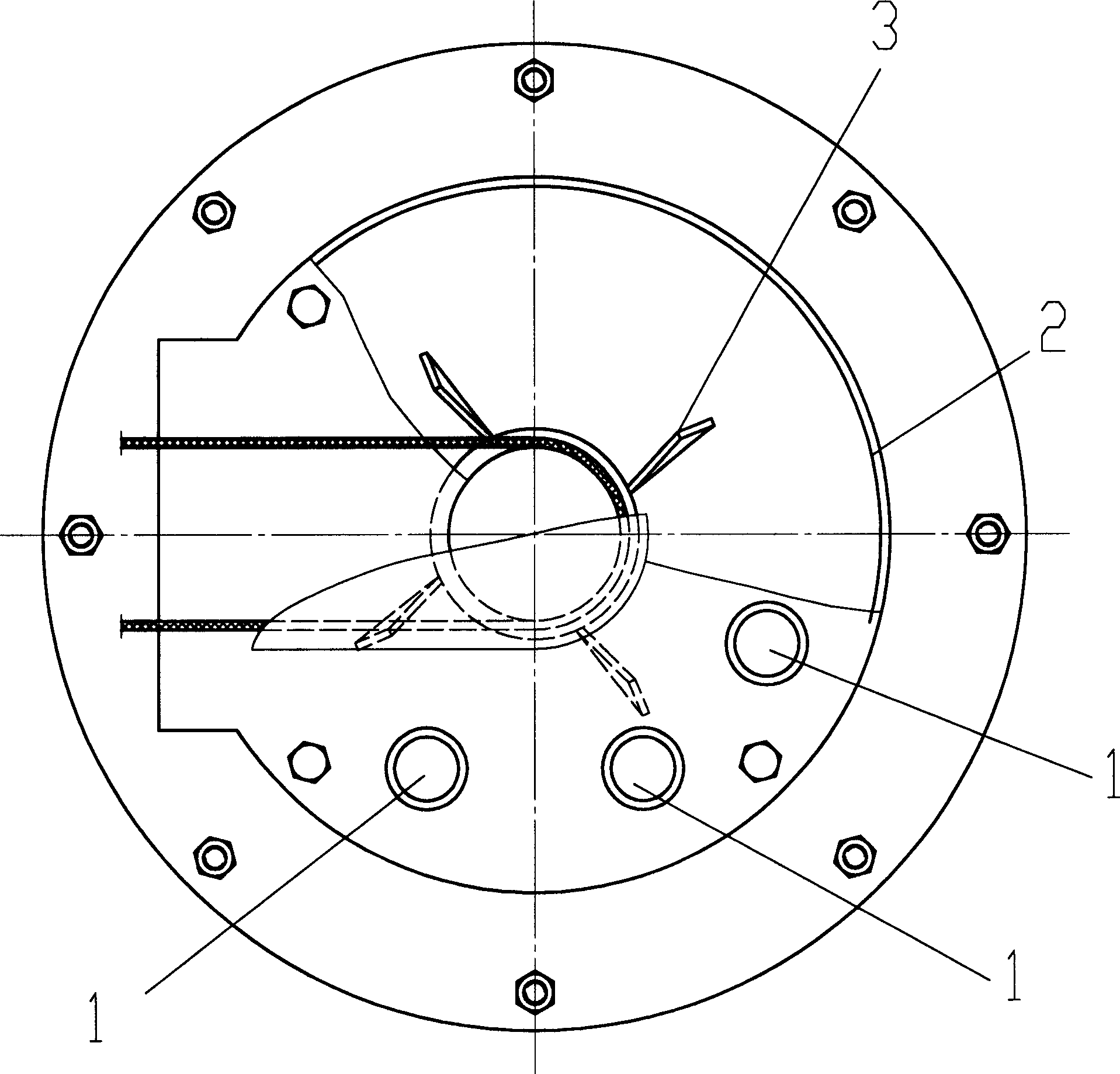

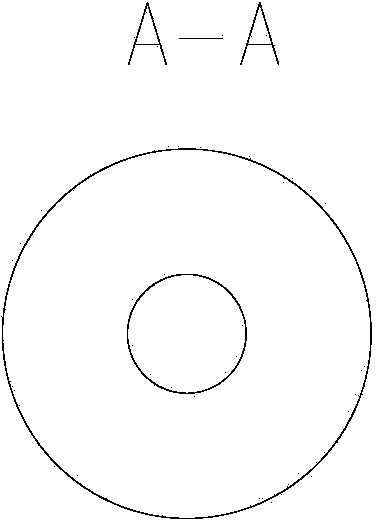

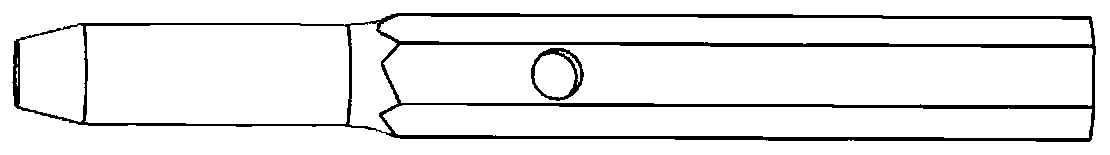

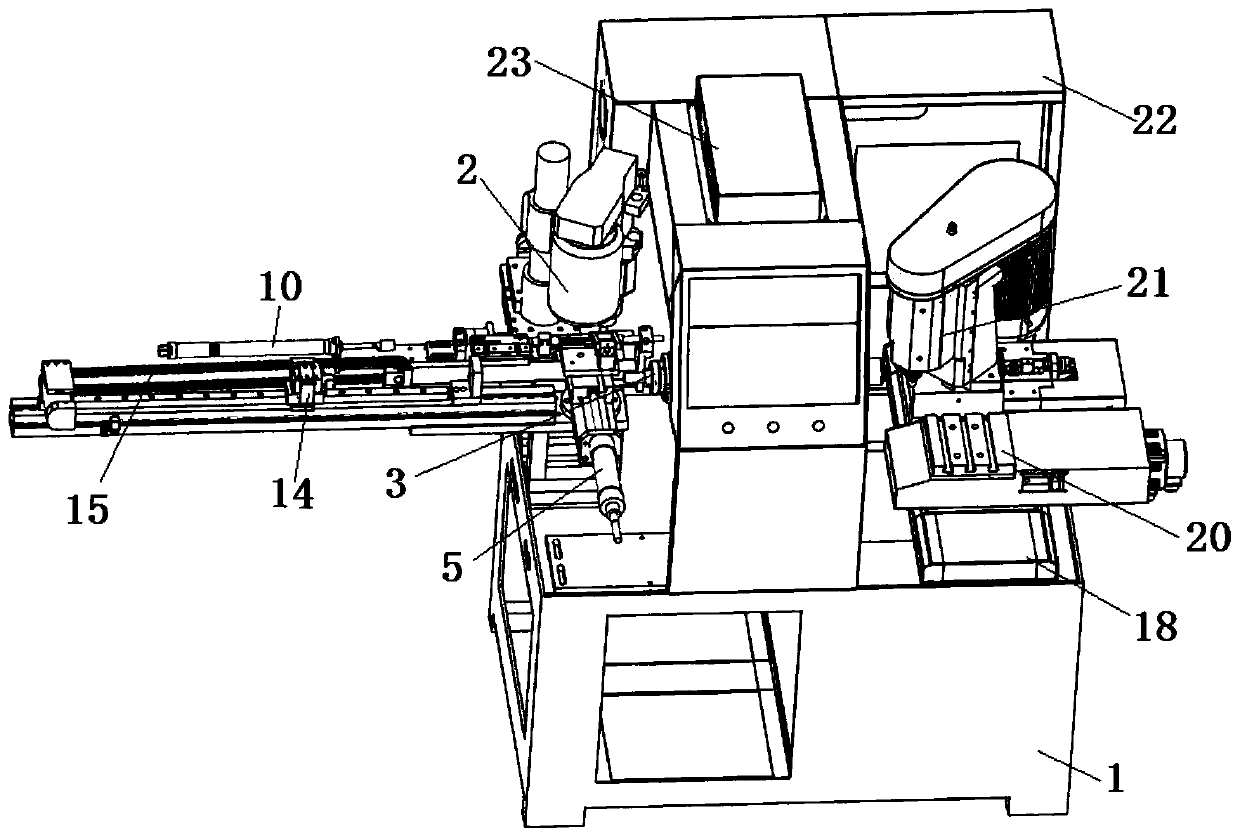

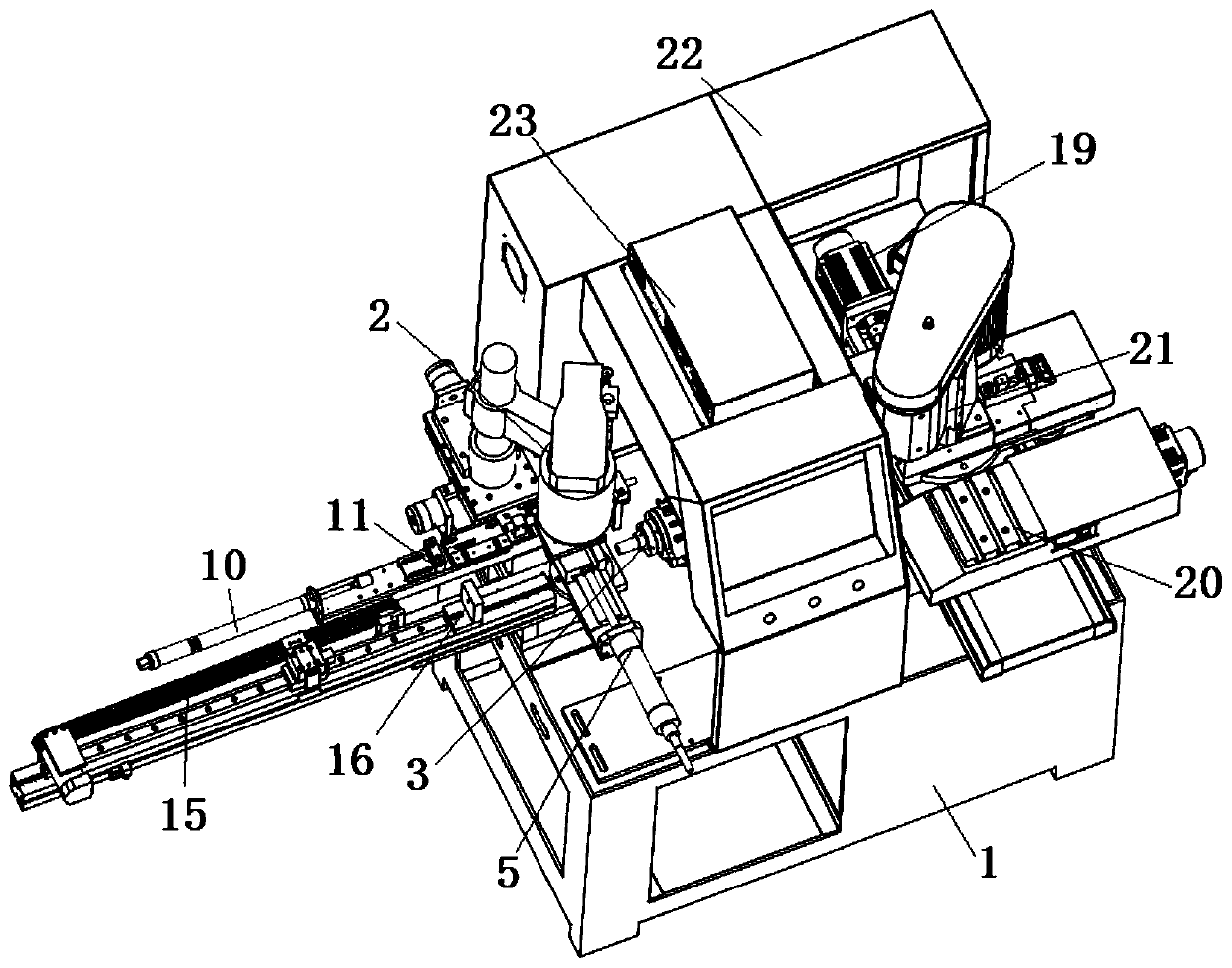

Automatic device for machining two ends of shaft parts

ActiveCN102921968AContinuous automated productionReduce auxiliary timeTurning machinesPositioning apparatusMachine partsIndustrial engineering

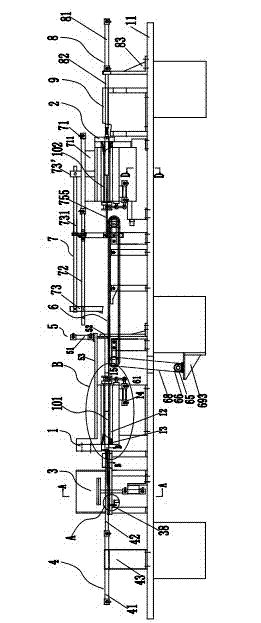

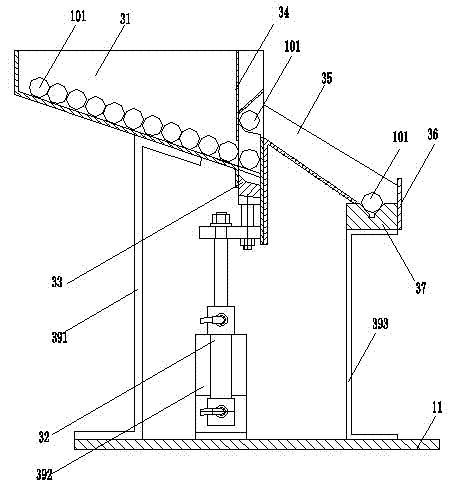

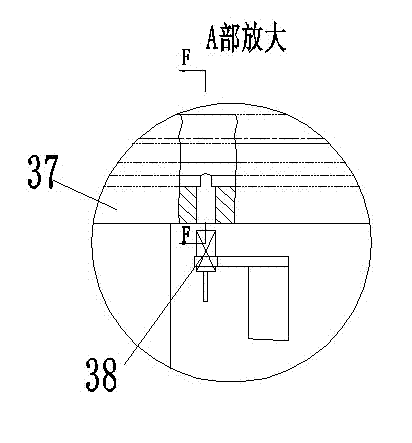

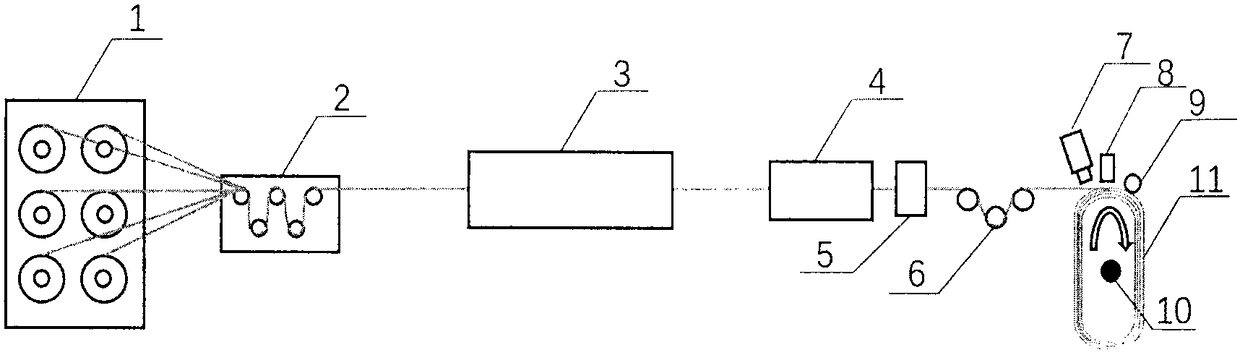

The invention discloses an automatic device for machining two ends of shaft parts. The automatic device comprises two numerically controlled lathes, wherein directions of headstocks of the two numerically controlled lathes are opposite and the two numerically controlled lathes are mounted on the central line on the same horizontal plane; and one numerically controlled lathe is fixedly mounted and the other numerically controlled lathe is mounted in a way of being capable of being movably adjusted. A shaft part semi-finished product conveying mechanism is arranged between the two lathes. The front end of the first lathe is provided with a material cabin of a shaft part blank material and a material conveying mechanism; the rear end of the first lathe is provided with a positioning mechanism; the two mechanisms are matched to place one end of the shaft part blank material at one end of a machining part for machining a work piece of the first lathe; the rear end of the second lathe is provided with a material conveying and positioning mechanism and the front end of the second lathe is provided with an auxiliary positioning mechanism and a shaft part finished product collector; and the two mechanisms are matched to place a machined shaft part semi-finished product on the other end of a machining part for machining the work piece of the second lathe. According to the automatic device disclosed by the invention, the continuous automatic production of the two lathes is realized and two difficulties in the prior art that the labor production rate is low and equipment has no generality are solved.

Owner:宁波精益微型轴有限公司

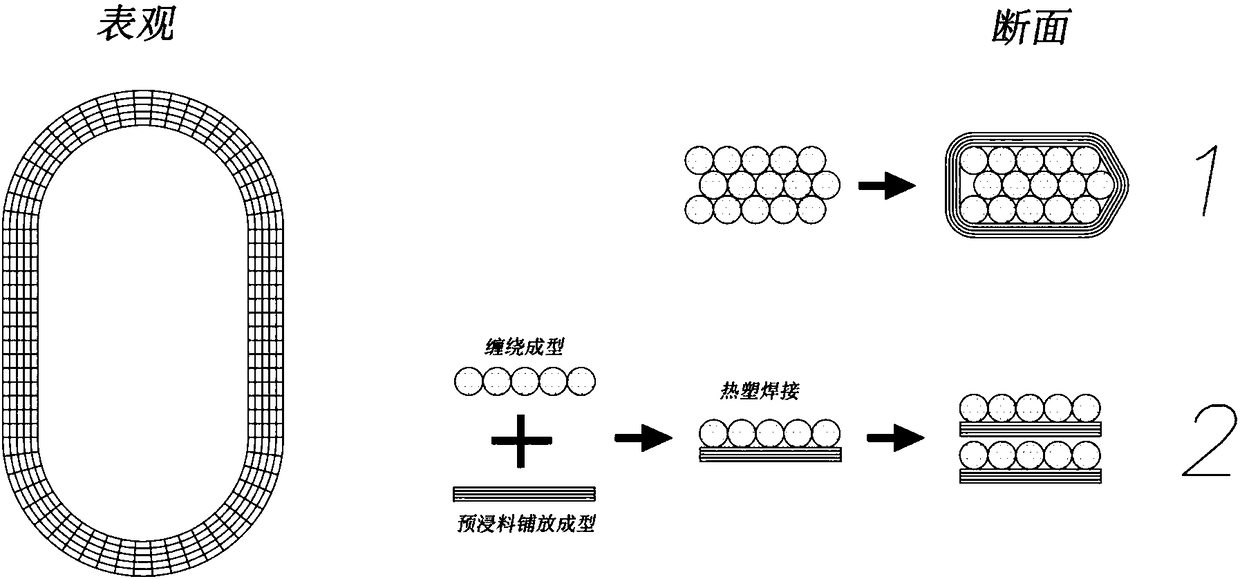

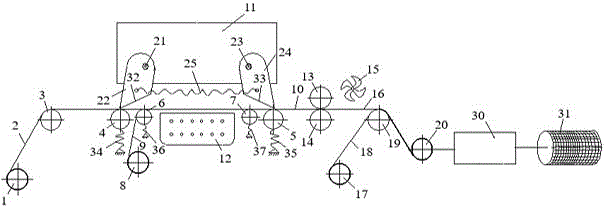

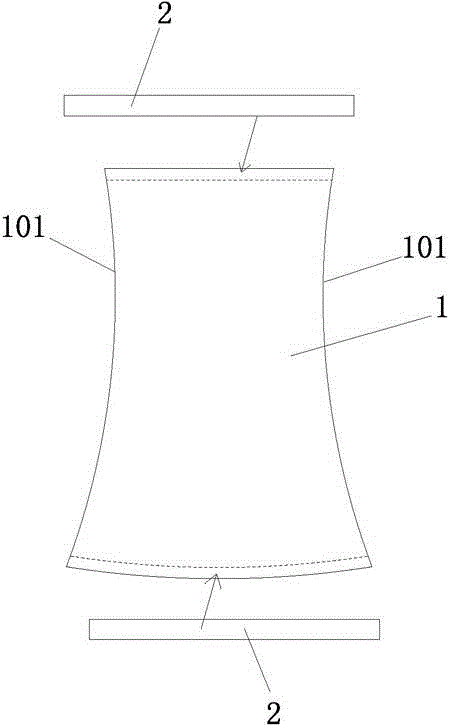

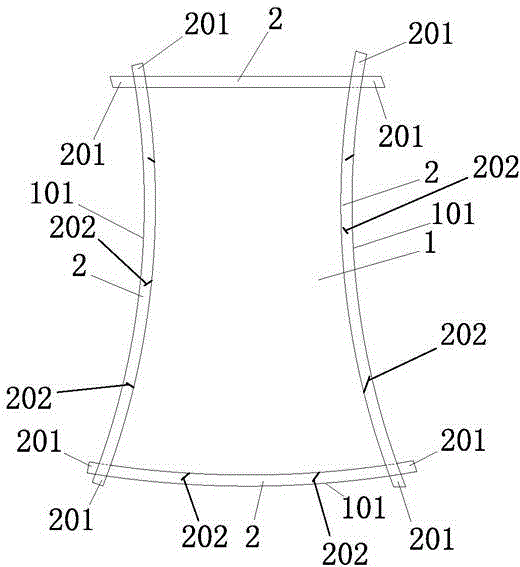

Winding-pressing forming process and device of fiber-reinforced composite material

The invention discloses a winding-pressing forming process and device of a fiber-reinforced composite material. The process comprises the steps: placing filaments, spreading yarns, preheating, dipping, drawing and winding. The forming process comprises the specific steps: fixedly placing a fiber-yarn shaft on a yarn frame, carrying out yarn spreading by a yarn spreading frame, leading the spread fiber yarn to enter a gum-dipping device after preheating, forming a prepreg wire by an outlet of a mold head of the gum-dipping device, then forming a sizing prepreg with smooth surface by a sizing device, drawing the sizing prepreg by a drawing and winding device, winding and sizing by a mold to obtain a pre-formed body, heating the pre-formed body to a needed temperature, pushing into a moldingcavity by a guide rail or a mechanical arm, pressurizing, curing and molding. The winding-pressing forming process and device disclosed by the invention have the beneficial effects that the characteristics of high specific strength and high specific rigidity of the composite material are furthest exerted by a mold-forming process, and the problems of poor mechanical property, weak interlayer connecting property, long manufacturing period and complex manufacture and the like caused by fiber cutting of the traditional fiber-reinforced composite material are solved, so that the application prospect is wide.

Owner:泰安市中研复合材料科技有限公司 +1

Optical diffusing poly carbonate (PC)/ polymethyl methacrylate (PMMA) alloy

InactiveCN102702714AGood compatibilityHigh impact strengthLiquid-crystal displayPolymethyl methacrylate

The invention relates to optical diffusing poly carbonate (PC) / polymethyl methacrylate (PMMA) alloy. The optical diffusing PC / PMMA alloy comprises the following components: 50 to 100 parts of PC, 5 to 20 parts of PMMA, 1 to 8 parts of PC and PMMA compatilizer, 0.01 to 2 parts of optical diffusing agent, and 0.3 to 1 part of other aid; by compounding and using the compatilizer, the compatibility between PC and PMMA is improved, continuous production can be realized, and the alloy material is high in mechanical property; by adding the optical diffusing agent, the light-emitting source and the dazzling light source are shielded, and the whole resin can emit soft, attractive and elegant light, so that the aims of light transmitting and non-transparency can be fulfilled; and the optical diffusing PC / PMMA alloy has the soft light-distributing effect, and can be widely applied to the fields of liquid crystal displays and the like.

Owner:昆山聚威工程塑料有限公司

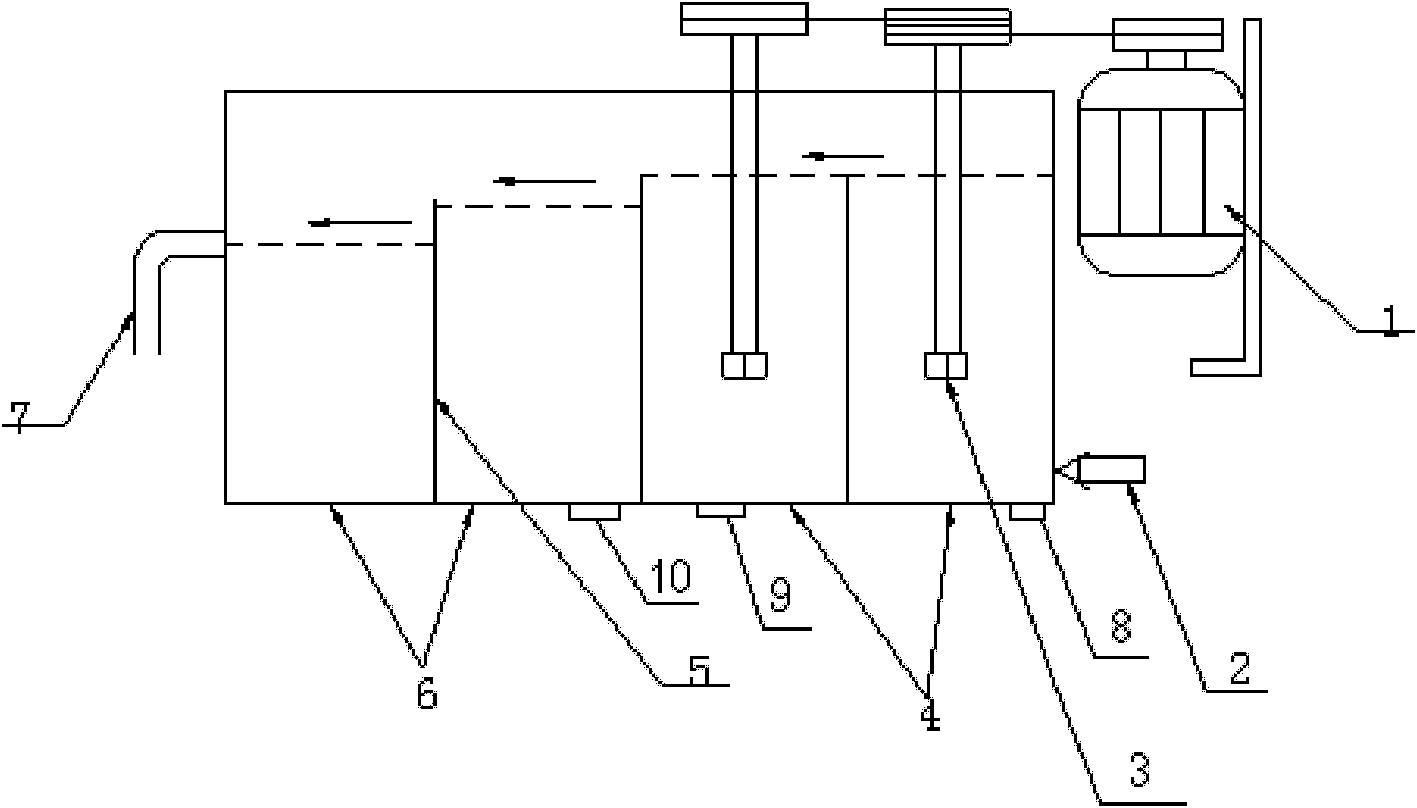

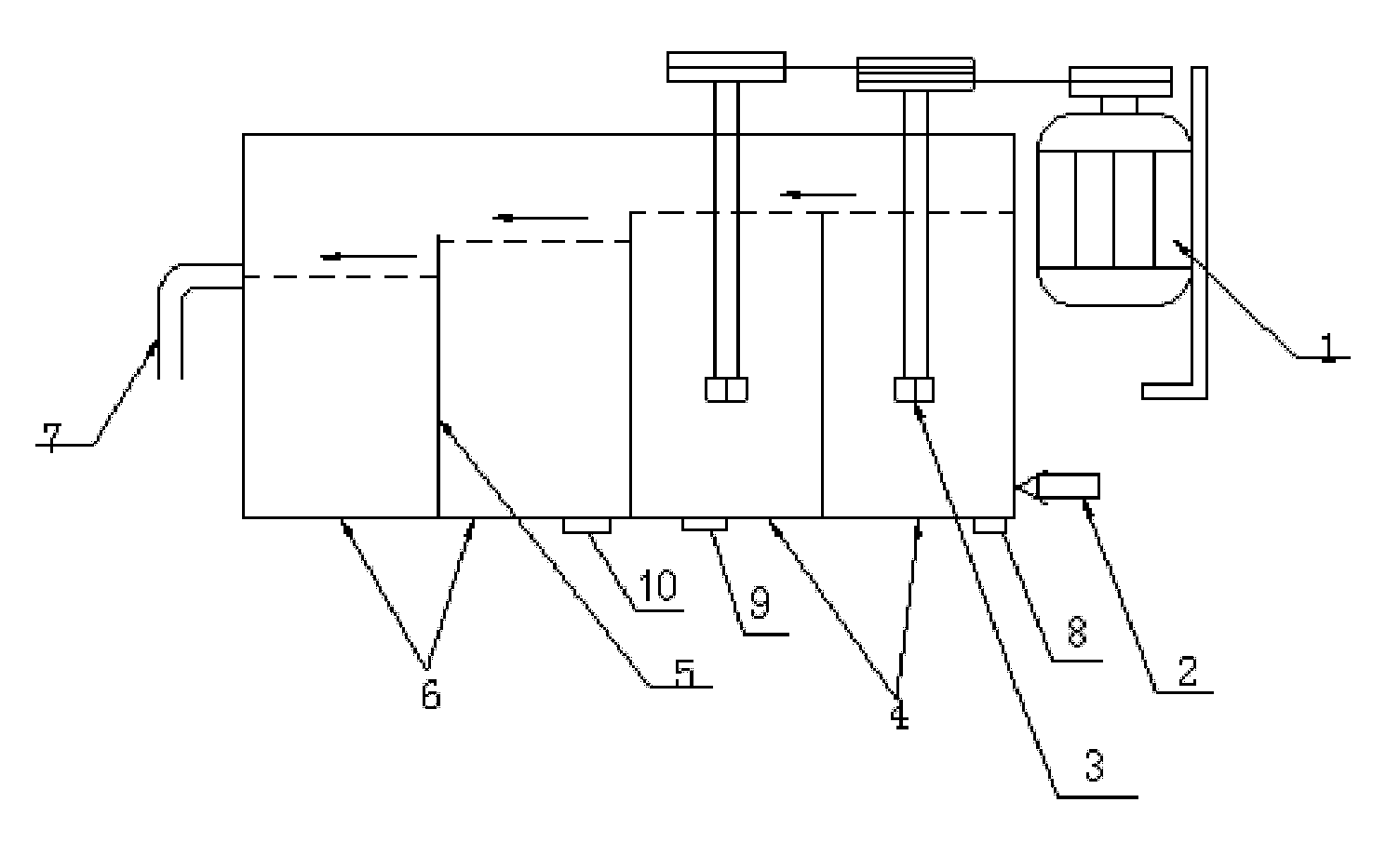

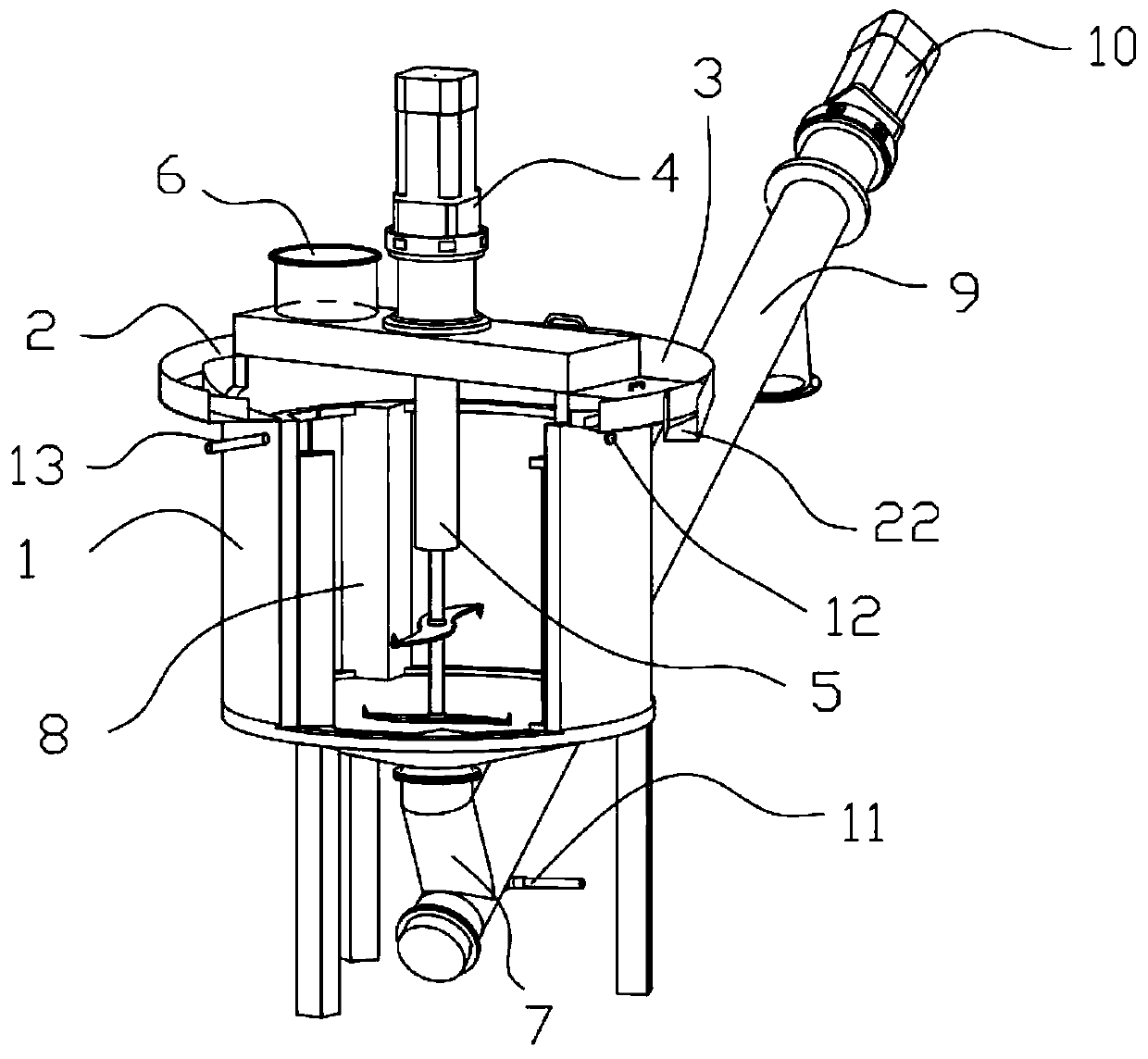

Solid powder continuous mixing machine

InactiveCN1579607AUniform and stable contentImprove mixing uniformityFlow mixersTransportation and packagingContinuous mixingMechanical engineering

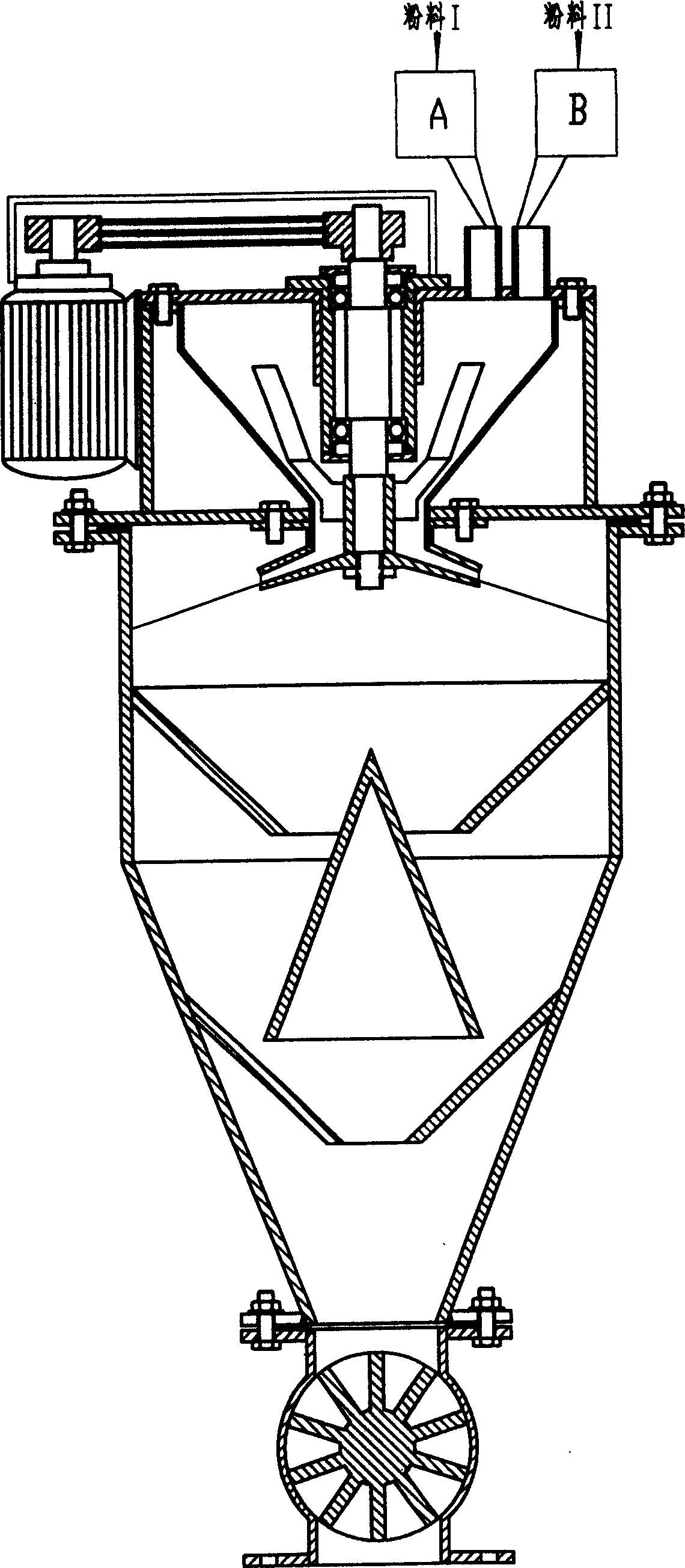

The invention relates to a blending machine for solid fine material. It includes: feed inlet, premixing chamber, premixing palm, sprinkling pan, collector, baffle and discharge lip. Premixing chamber, sprinkling pan and collector are placed in gravity direction. Premixing palm and sprinkling pan are installed in same axis. The blending machine has a simple and novel construction and flexible operation. It can realize fine material blending continually and automatically.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for producing potassium sulphate fertilizer by using phosphogypsum

The invention relates to the technical field of fertilizer production methods, in particular to a method for producing potassium sulphate fertilizer by using phosphogypsum. The method comprises the following steps: fully mixing 20 to 80 percent of the phosphogypsum and 20 to 80 percent of potassium feldspar powder in percentage by weight, and calcining the mixture, wherein the calcination temperature is 800 to 1,800 DEG C, and the calcination time is 2 to 120 minutes. The method has easily-obtained raw materials and low cost; and the whole process flow is smooth, simple, easy and is quite suitable for industrialized production.

Owner:GUANGDONG DAZHONG AGRI SCI CO LTD

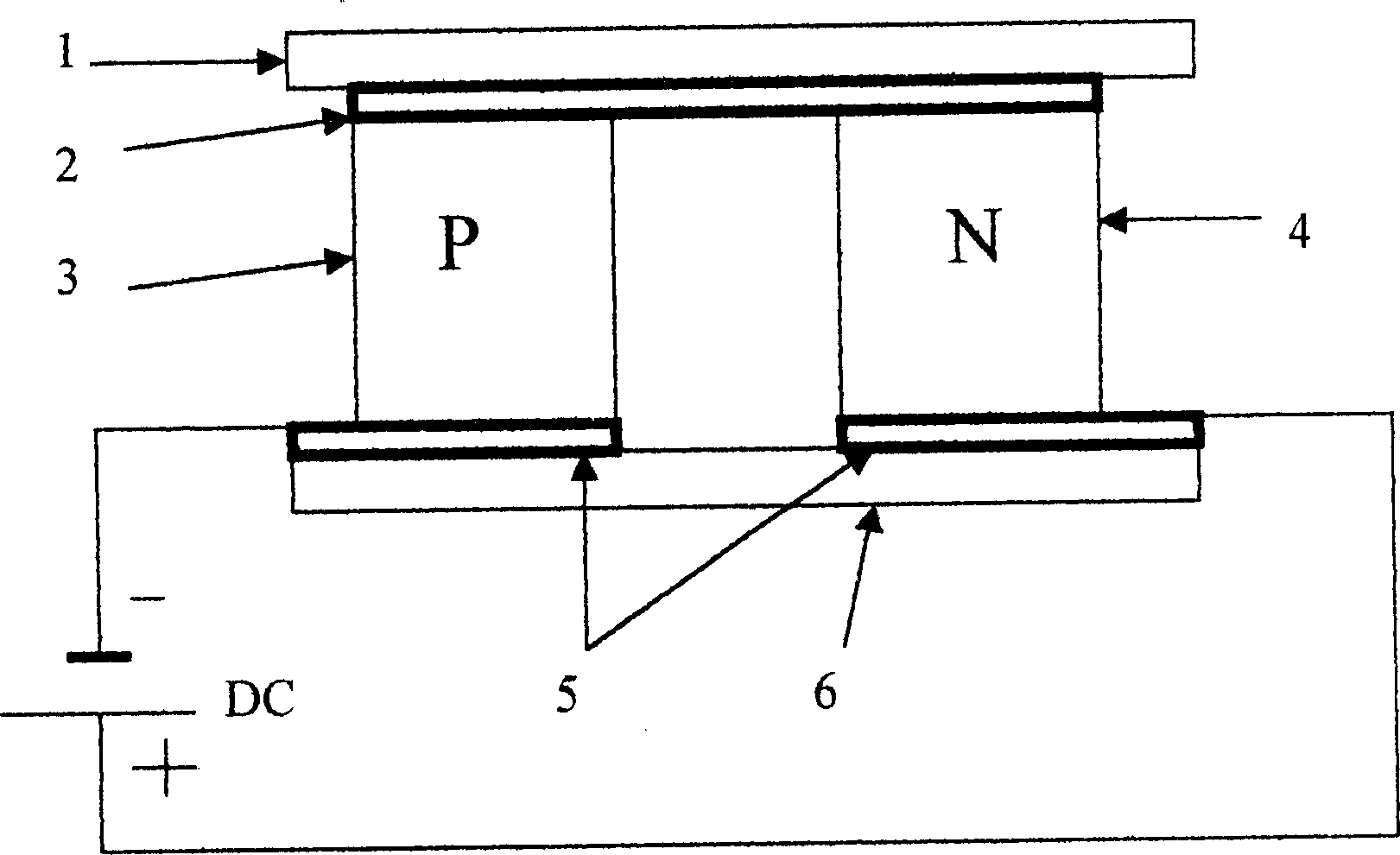

Method and device for producing thermoelectric semiconductor device and its products obtained thereof

InactiveCN1750287ANo mechanical cutting damageCompact structureThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentSemiconductor materialsThermoelectric element

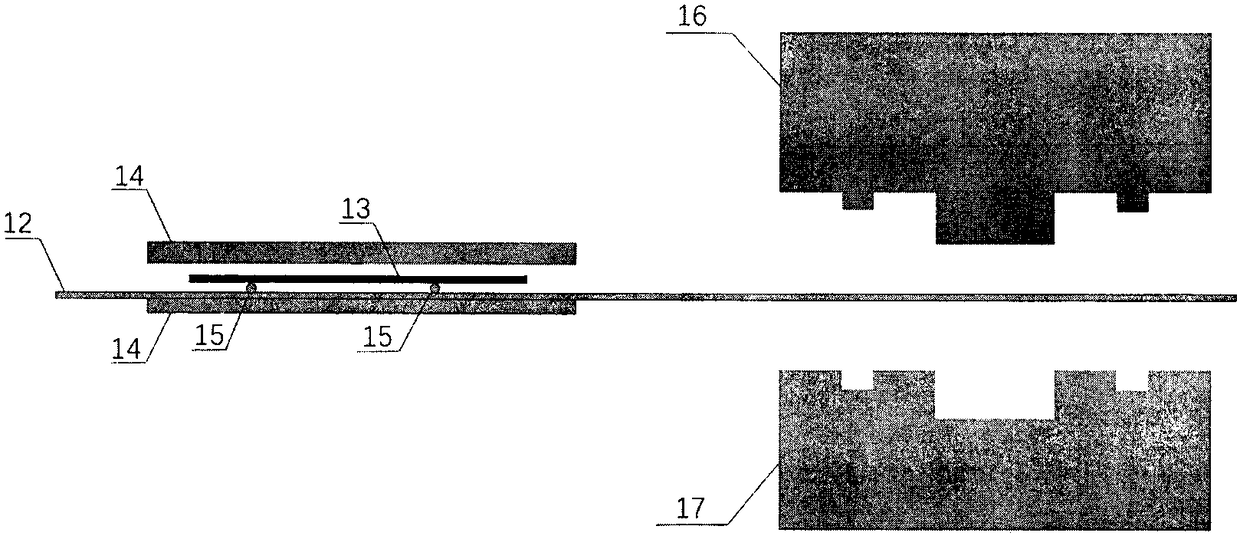

This invention discloses a method for manufacturing a thermal electric semiconductor device, the equipment and its products charactering in applying an accurate casting technology to directly cast the melt type P and type N thermal electric semiconductor materials to preset special models separately by quantitatively controlling the exit unit, which casts the materials onto the models separately by a conduit charactering that the P and N thermal electric elements are set at either side of a baffle, the bending part of the metal connection sheets is inserted into the elements and the plane part are fixed on the upper and the lower base plates.

Owner:杜效中

Method for purifying cobalt solution

ActiveCN101831547AReduce consumptionReduce organic contentProcess efficiency improvementSolventBromine

The invention relates to a method for purifying cobalt solution which can decrease the organic matter content in the cobalt solution to less than 10ppm. The method comprises the step of removing the organic matter from the cobalt solution through solvent extraction, wherein the cobalt solution is obtained by acid leach, extraction and re-extraction; the solvent contains extracting agent; the extracting agent is 1-bromine-3-chloropropane, carbon trichloride, carbon tetrachloride or 1-bromine-2-chloroethane. The improvement in the invention is that the solvent also contains solid cobalt naphthenate, the mass of which is 0.01% to 0.1% of the extracting agent mass. The invention has the following advantages of efficiently decreasing the organic matter content in the cobalt solution, obtaining the cobalt chloride satisfying the lithium battery, lowering the consumption of the solvent which is easy to regenerate, making up the defect of using activated carbon, obviously promoting the recovery in the process of processing cobalt due to no cobalt salt loss in the solvent and promoting the use ratio of cobalt.

Owner:GEM JIANGSU COBALT IND CO LTD

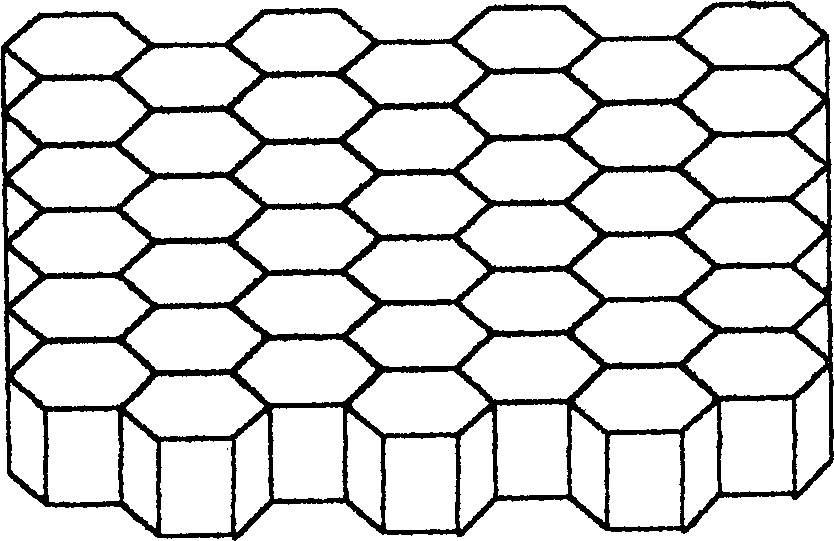

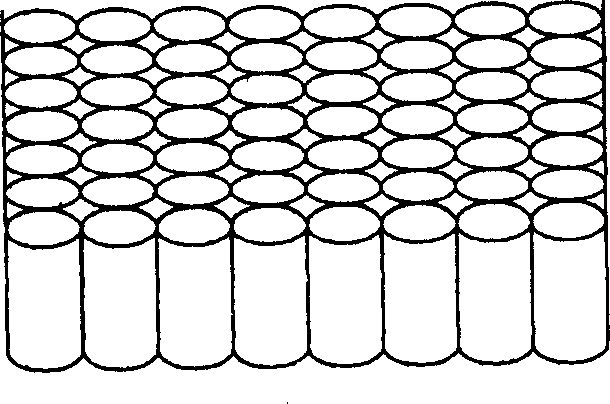

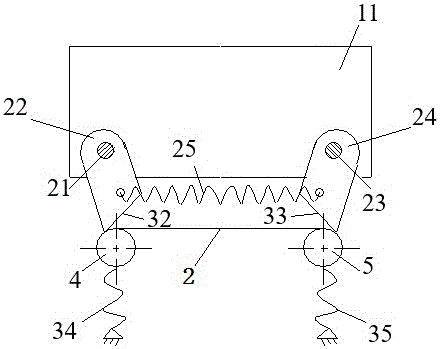

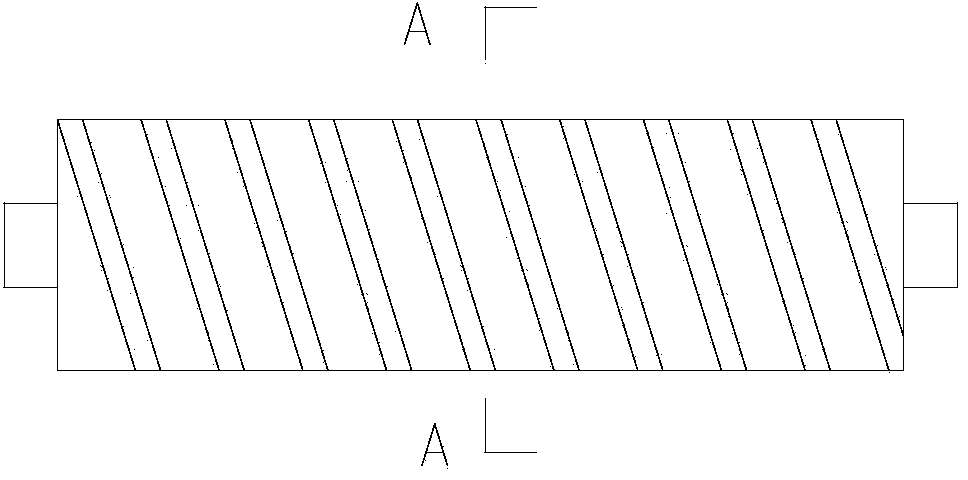

Preparing device and method of thermoplastic resin matrix prepreg reinforced by continuous carbon fibers

The invention discloses preparing device and method of a thermoplastic resin matrix prepreg reinforced by continuous carbon fibers and belongs to the field of composites. Left and right wedge-shaped swaying blocks are separately matched with first left and right elastic tension rollers so as to realize the bundle loosening, splitting and tensioning of the carbon fibers. Through a rapid pressing function which is performed after the left and right wedge-shaped swaying blocks are separately in contact with second left and right elastic tension rollers, tensioned carbon fiber bundles carry out rapid vertical downward cutting on a fused matrix resin film and are buried in the fused matrix resin film, and the embedding and burying of the carbon fiber bundles in the thermoplastic matrix resin are realized. Then, through the following secondary compaction of compression rollers, a thermoplastic pregreg tape with one-directional continuous carbon fibers is prepared. Through secondary spinning or weaving, various kinds of prepreg cloth or fabric reinforced by one-directional, two-directional, diagonal and three-directional continuous carbon fibers are prepared. The problems that the thermoplastic resin matrix has large viscosity and is poor at permeating and infiltrating the carbon fiber bundles, and the content of the resin is hard to precisely control are solved. The preparing device and method are also suitable for the preparation of thermosetting carbon fiber prepreg tapes.

Owner:JIANGSU UNIV

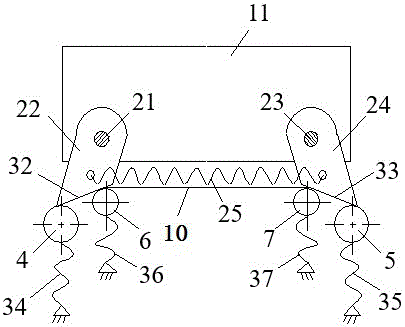

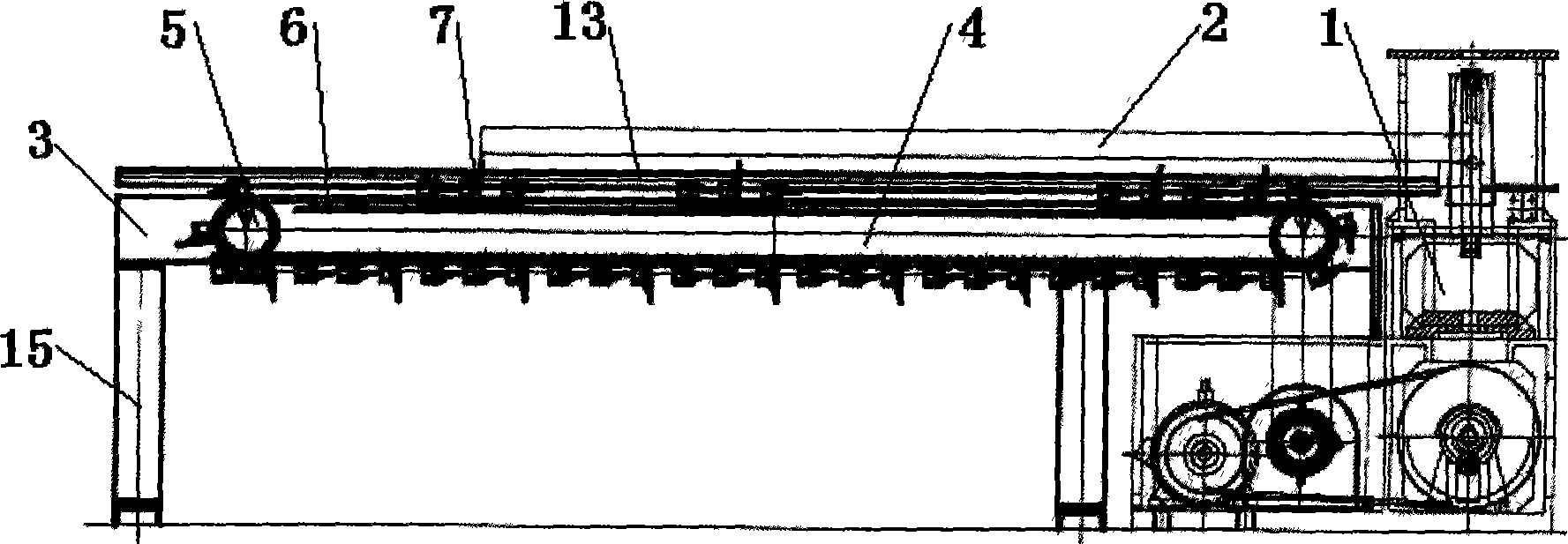

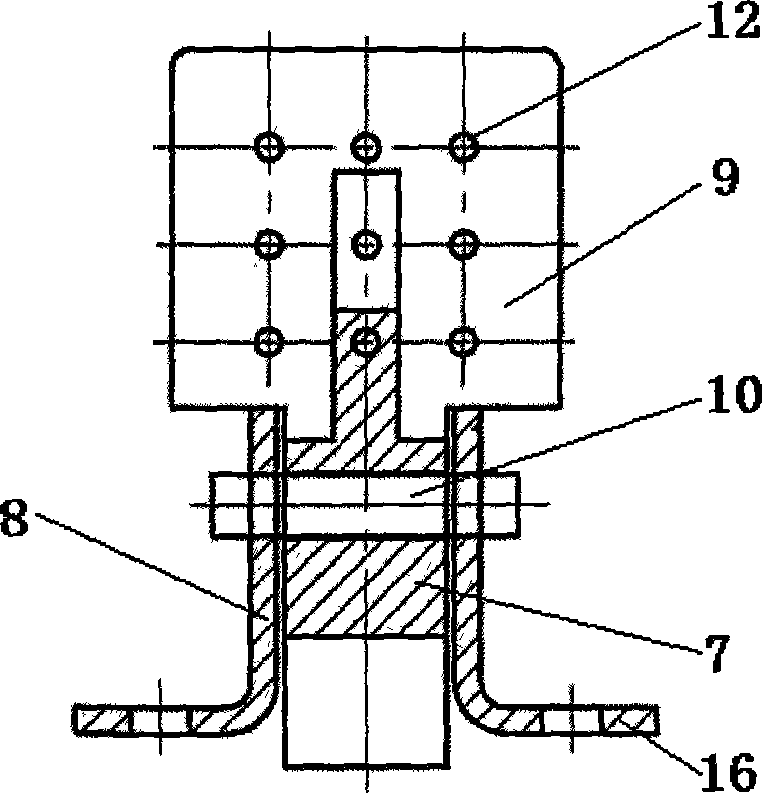

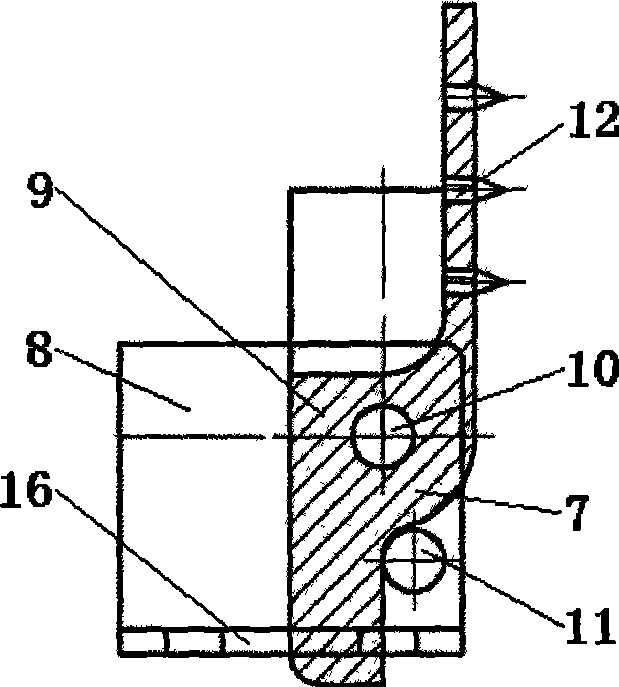

Feeding mechanism and operation method of timber processing machine

The invention discloses a feeding mechanism for wood processing machinery. The feeding mechanism (3) is provided with a chain feeding mechanism (4) which comprises a sprocket wheel (5) and a chain (6), wherein the moving direction of the chain (6) is the feeding direction of wood (2); the feeding mechanism is provided with a rushing board component (7) to be connected with the chain (6); and the rushing board component (7) is pushed from the end part of the wood (2). The invention also discloses an operation method for the feeding mechanism. With the technical proposal, the operation of the feeding mechanism can be more stable and reliable, the production efficiency for wood processing is improved, the continuous automatic production is realized under the condition of no outage and no withdrawal of the feeding mechanism, and the labor intensity for operator is reduced. The structure of the equipment is more reasonable and simpler, and the processing cost is reduced.

Owner:冯士祥

Color-adsorbing laundry sheet and manufacturing method thereof

InactiveCN106281819AImprove adsorption capacityCause secondary pollutionNon-ionic surface-active compoundsDetergent mixture composition preparationLauryl ether sulfatePotassium

The invention discloses a color-adsorbing laundry sheet and a manufacturing method thereof and belongs to the technical field of washing products and manufacturing methods. The color-adsorbing laundry sheet comprises a color-adsorbing cloth body and is characterized in that a clothes-washing substance layer is attached to the color-adsorbing cloth body and comprises, by weight, 50-60 parts of deionized water, 2-8 parts of lauryl sodium sulfate, 1-5 parts of C12-14 alkyl glycoside, 0.05-0.2 part of ethylene diamine tetraacetic acid disodium, 5-15 parts of ammonium lauryl ether sulfate, 5-10 parts of sodium alpha-olefin sulfonate, 1-5 parts of isomeric alcohol ethoxylates, 1-5 parts of coconut fatty acid diethanol amide, 1-5 parts of potassium soap base, 0.5-2.5 parts of sodium polyacrylate, 1-5 parts of penetrating agent, 1-10 parts of cocoamido propyl hydroxy sulfobetaine, 0.05-0.5 part of preservative, 0.1-0.5 part of citric acid, 0.1-0.8 part of essence and 2-10 parts of DFE. The color-adsorbing cloth is used as a carrier, is high in tensile strength and not prone to damage, and can effectively adsorb faded colors in the washing process of clothes.

Owner:冯鲜花

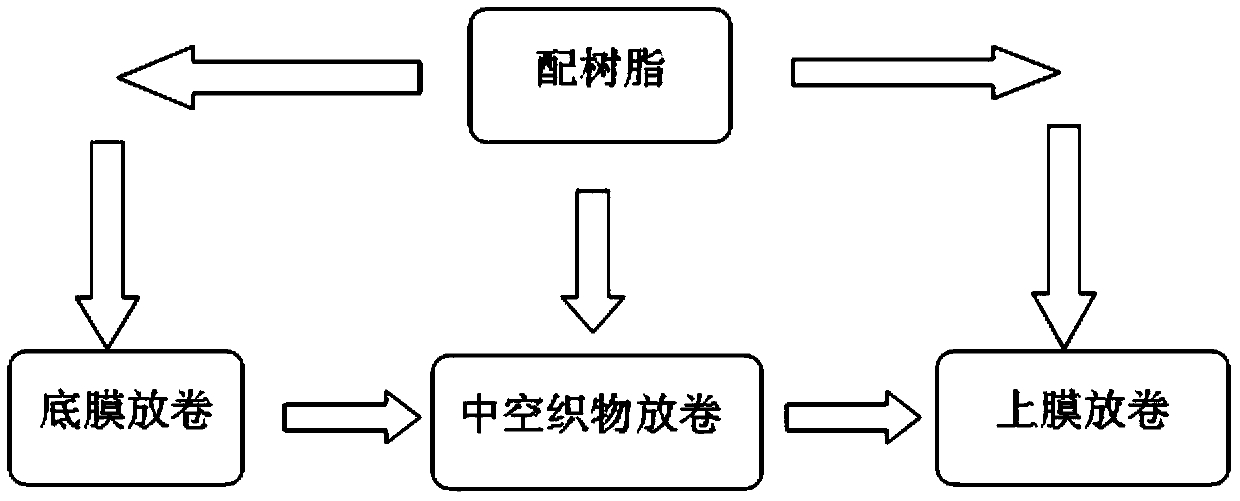

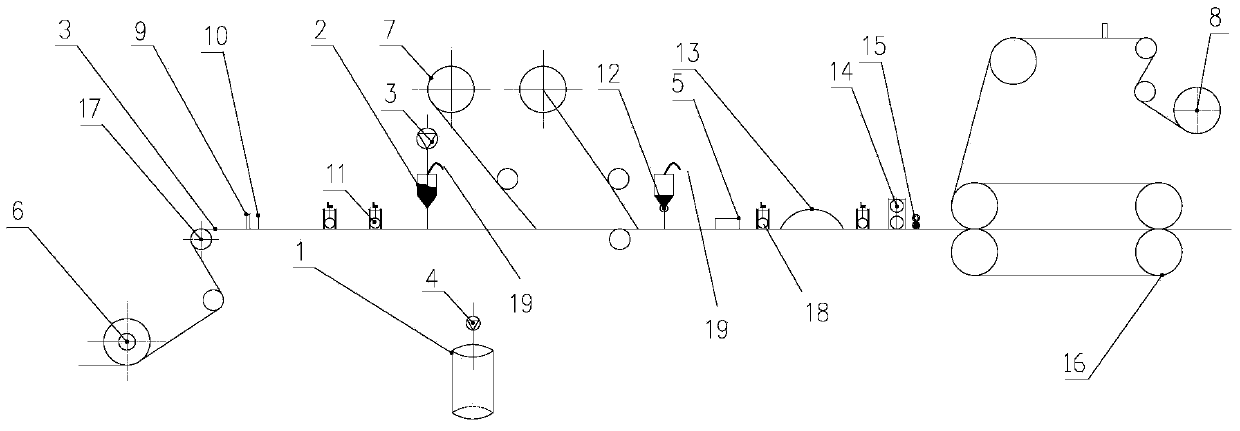

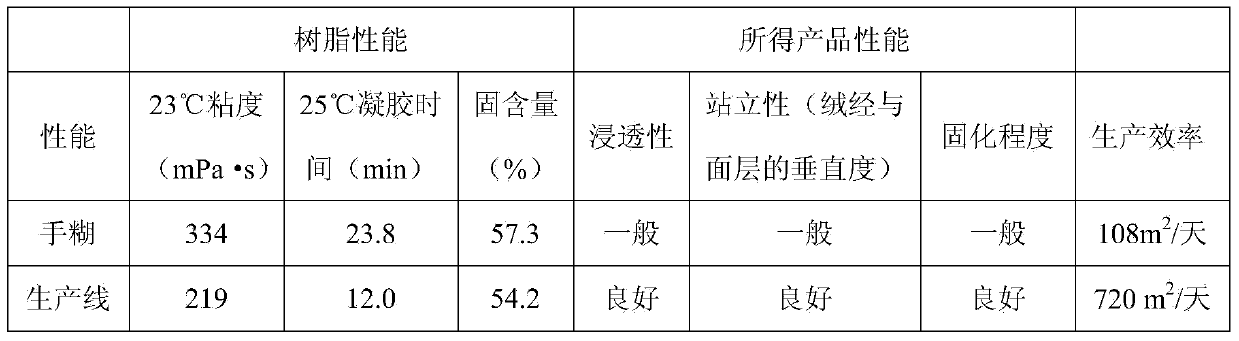

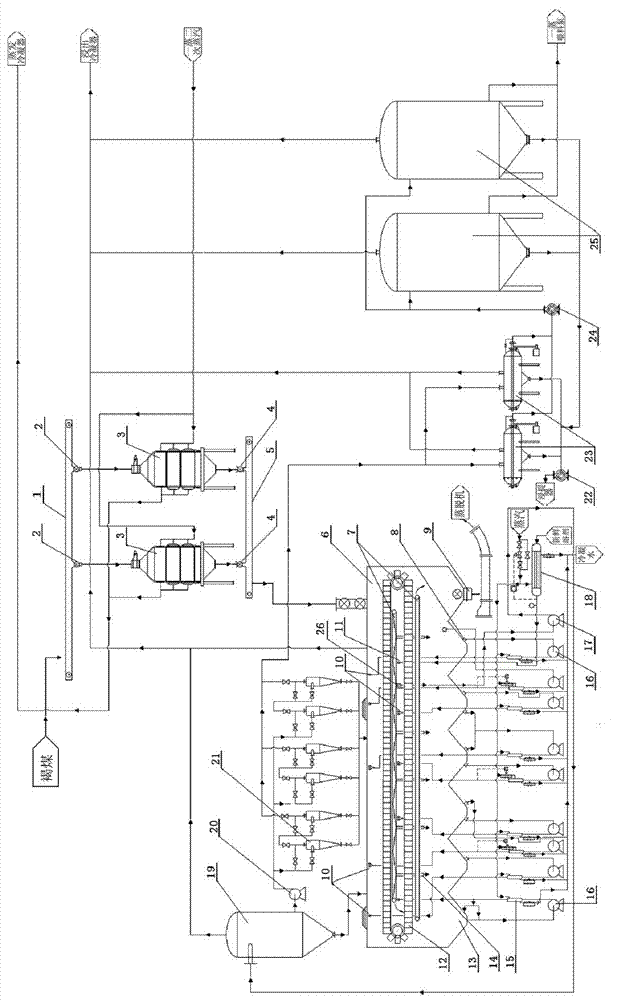

Cloth feeding and dipping device on hollow composite slab production line

The invention discloses a cloth feeding and dipping device on a hollow composite slab production line. The cloth feeding and dipping device comprises a glue preparing device, a frame platform, a lower film unreeling machine, a glue distribution device, a first dipping roller, a hollow cloth unreeling machine, a multi-reel constant tension active unreeling mechanism, an auxiliary standing device, an upper film unreeling machine and a power thickness controller, wherein the lower film unreeling machine, the glue distribution device, the first dipping roller, the hollow cloth unreeling machine, the multi-reel constant tension active unreeling mechanism, the auxiliary standing device, the upper film unreeling machine and the power thickness controller are orderly arranged along the frame platform; a constant tension controller is arranged on the multi-reel constant tension active unreeling mechanism; the glue preparing device is communicated with the glue distribution device through a hose. By adopting the cloth feeding and dipping device on the hollow composite slab production line disclosed by the invention, the resin dosage and the resin temperature can be accurately adjusted; bubbles generated in the mixing process of the resin and a curing agent are removed; the sizing sufficiency of hollow fabric, the glue content uniformity and the hollow fabric standing property are improved; the planeness and the height dimension of the product are accurately controlled; the cloth feeding and dipping device has the advantages of being low in manufacturing cost, high in production efficiency, stable in product quality and the like; continuous automatic production can be achieved; the marketizing requirements can be met.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

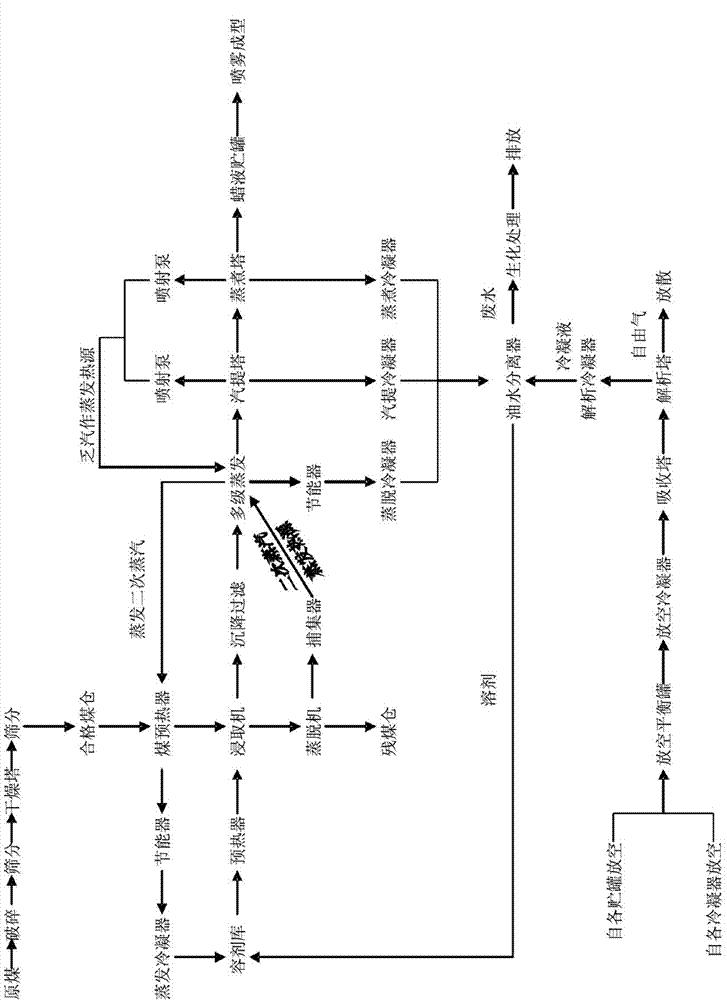

Method for efficiently extracting fossilized plant wax from brown coal and device thereof

ActiveCN102851076AImprove processing powerImprove equipment utilization efficiencyMineral wax recovery/refiningWaxSolvent

The invention discloses a method for efficiently extracting fossilized plant wax from brown coal and a device thereof. The method comprises the steps of pretreating the brown coal, conducting gradient leaching, recovering the solvent to precipitate the wax, desolventing residual coal, and molding and packaging. The device comprises a feeding unit, a leaching unit, an evapo-separated unit, a disolventing unit, and a condensation system. According to the invention, by using a mixed solvent comprising toluene and ethanol or tert-butyl alcohol as the extraction solvent, the toxicity is lower than that of toluene, the latent heat of vaporization is lower than that of toluene, thus the energy consumption of mass transfer process is reduced; by adopting a large liquid-solid ratio cycle work mode to carry out gradient continuous cycle leaching on the brown coal particles, the leaching rate can reach more than 85%, and wax content in the coal dry basis after leaching is less than 0.8%; the technology leaching temperature is lower than the solvent boiling point, thus isopropanol and other insoluble substances in the lignite wax are greatly reduced; the negative desolventing process can effectively prevent wax pyrolysis, raise the acid value and saponification value of the was, so as to raise the quality of the obtained wax; the brown coal throughput per unit reaches 60T / h, and the automation and large scale production can be realized.

Owner:QUJING ZHONGYI FINE CHEMICAL INDUSTRY CO LTD

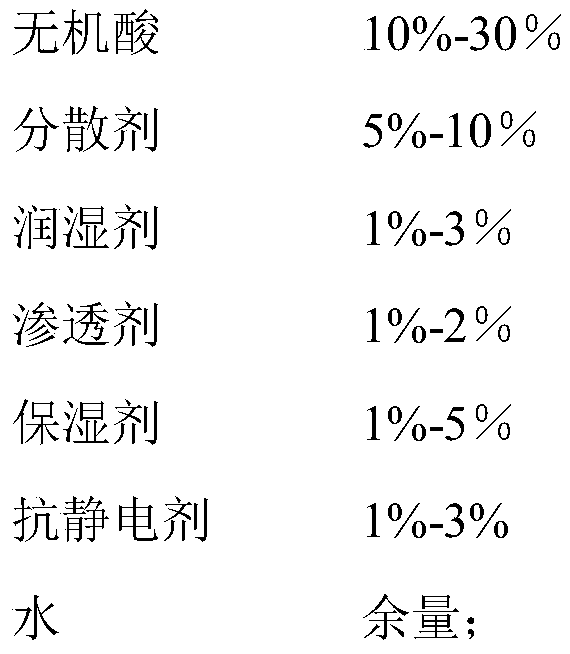

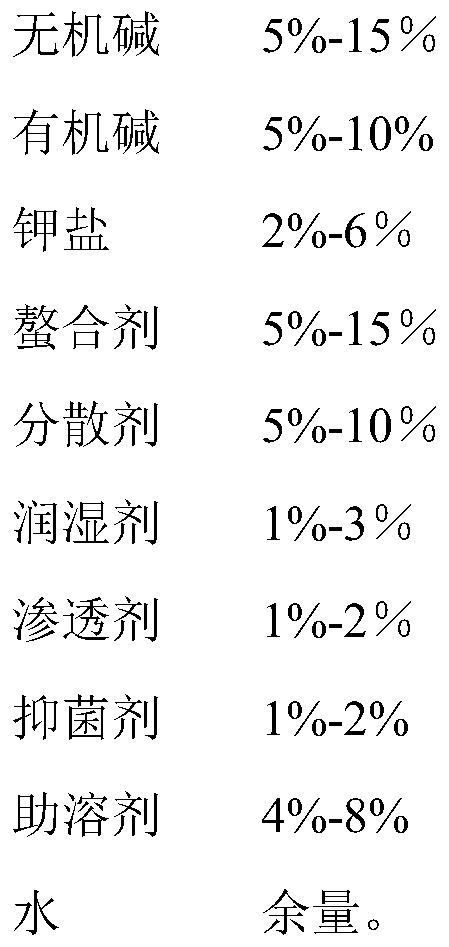

Glass cover plate cleaning agent and cleaning method thereof

InactiveCN111073767AGood cleaning effectTransparent surfaceInorganic/elemental detergent compounding agentsCationic surface-active compoundsMegasonic cleaningOrganic inorganic

The invention relates to the technical field of glass cover plate cleaning, in particular to a glass cover plate cleaning agent and a cleaning method thereof, and the glass cover plate cleaning agentcomprises an acidic cleaning agent and an alkaline cleaning agent; the method comprises the following steps: putting the glass cover plate into an ultrasonic cleaning machine, firstly cleaning the glass cover plate for 2-6 minutes at the temperature of 40-80 DEG C by adopting the acidic cleaning agent, then cleaning the glass cover plate for 5-15 minutes at the temperature of 40-80 DEG C by adopting the alkaline cleaning agent, then washing the glass cover plate with water, and then drying the glass cover plate. According to the cleaning agent, by adopting the dispersing agent, small-particleimpurities adhered to the surface of the glass cover plate can be separated, fingerprints, dust, glass powder, grease and other organic and inorganic solid particles on the surface of the glass coverplate are effectively removed, and the cleaning effect is good. The cleaning method disclosed by the invention is particularly suitable for cleaning polished 2.5 D and 3D glass, can avoid a manual brushing process and use of a strong alkaline cleaning agent, and can improve the cleaning efficiency and the cleaning yield.

Owner:DONGGUAN JINGBO PHOTOELECTRIC BIT CO

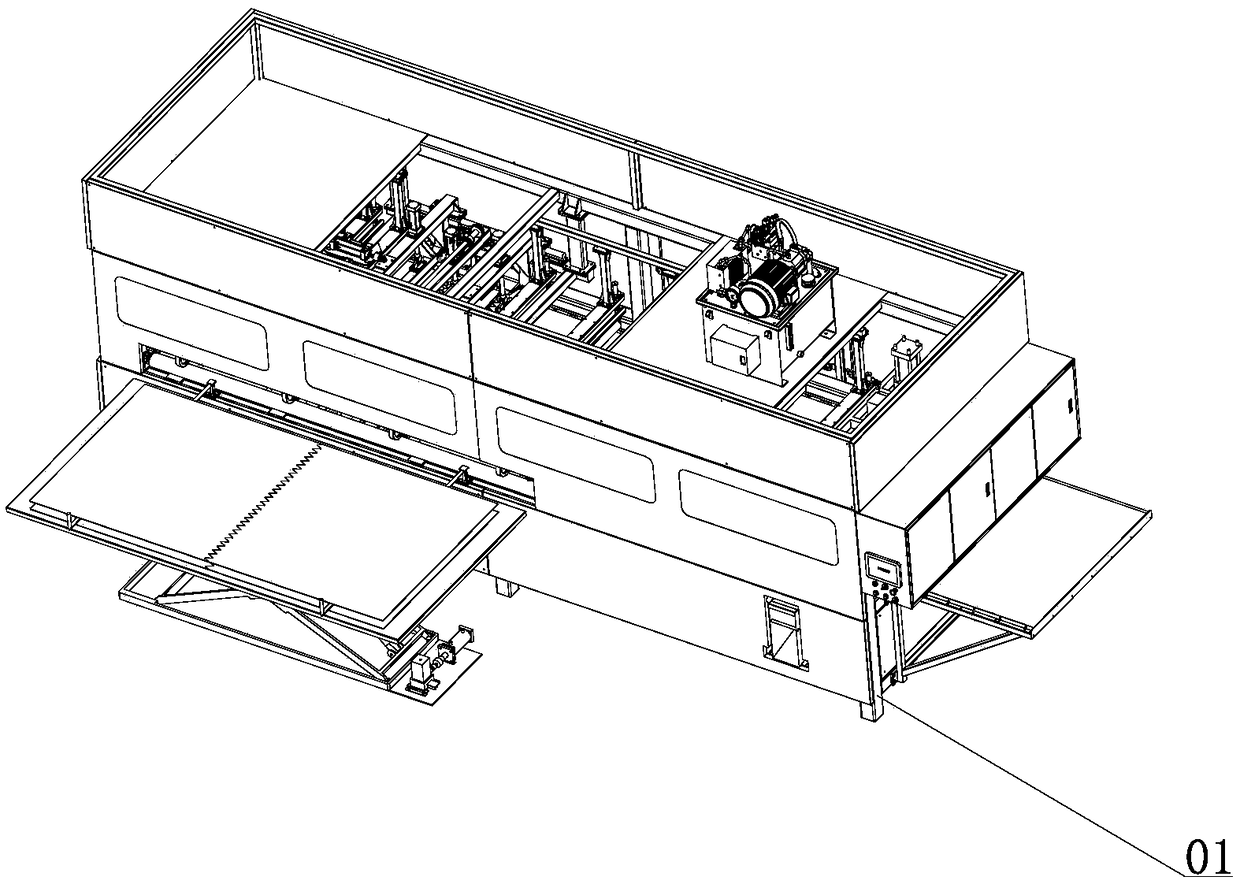

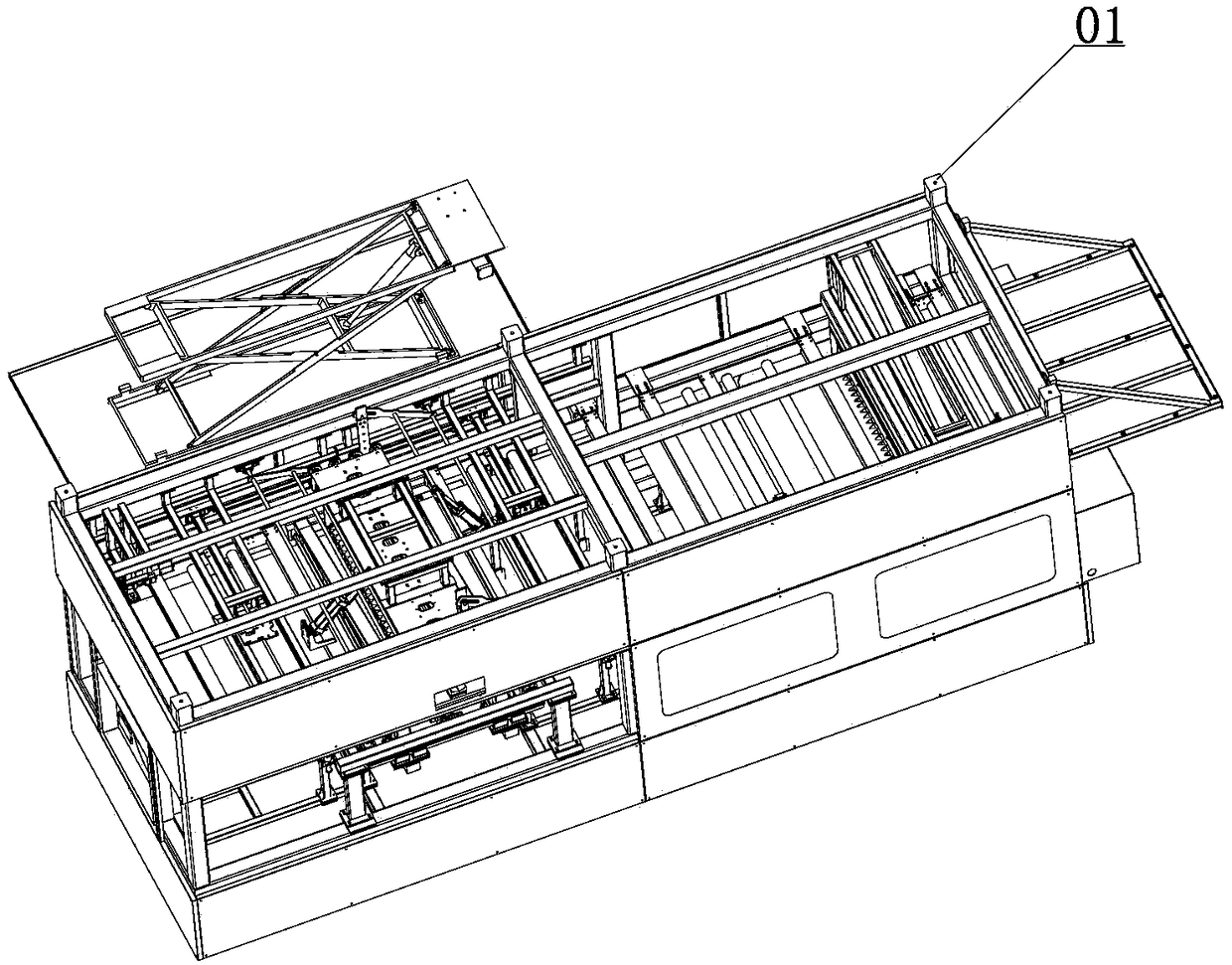

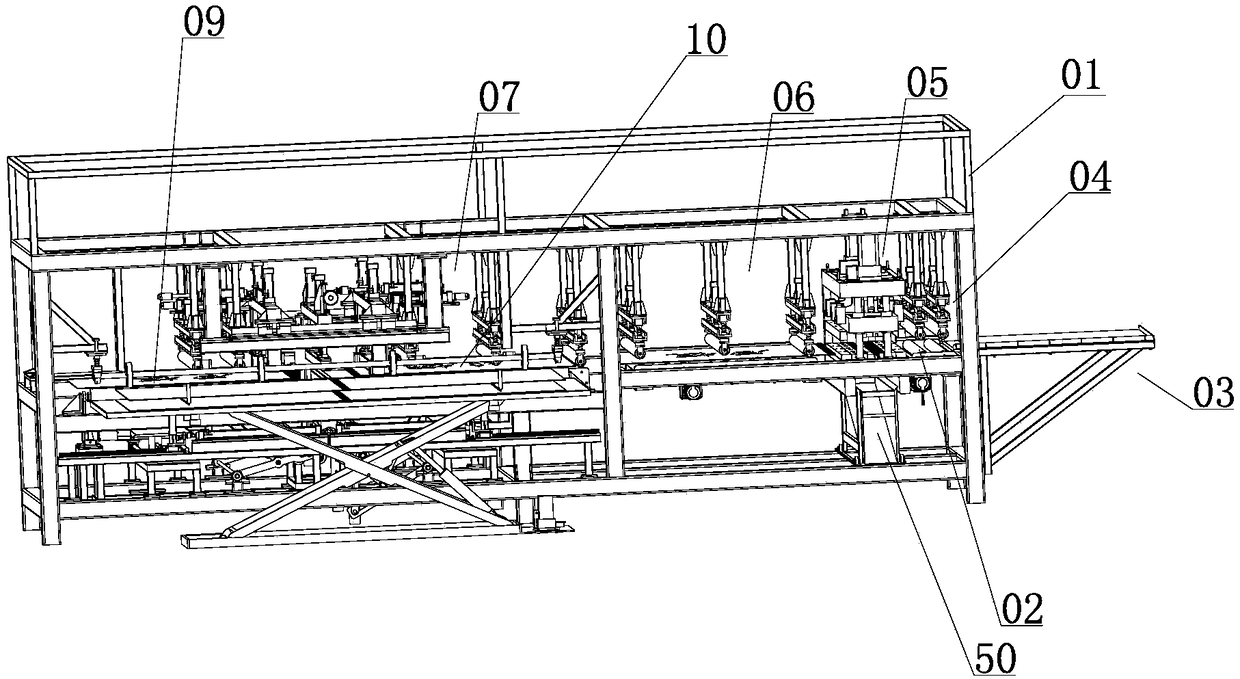

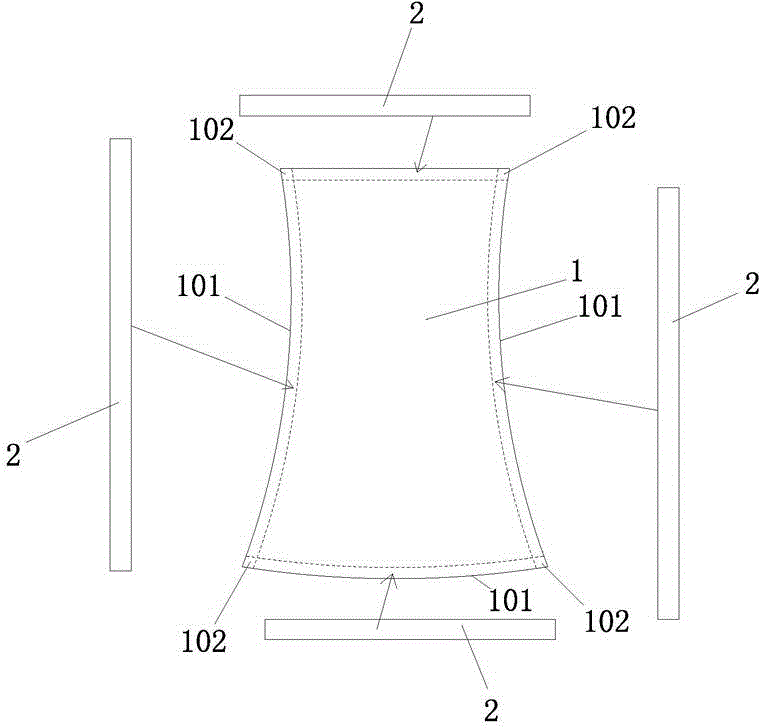

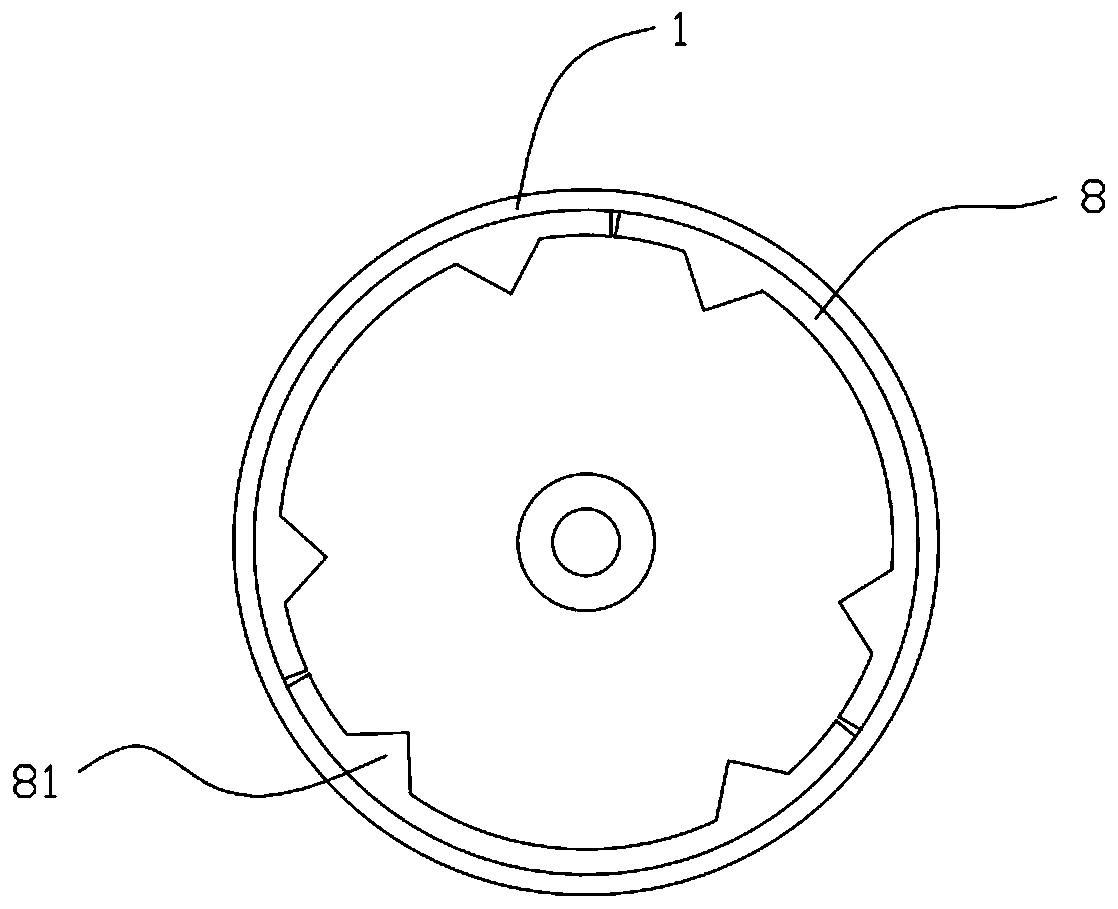

Veneer toothing machine

PendingCN109304774AReduce labor costsContinuous automated productionOther plywood/veneer working apparatusDovetailed workMechanical engineeringEngineering

The invention discloses a veneer toothing machine. The veneer toothing machine comprises a rack, a roller conveying belt, a feeding table, a feed rolling and conveying device, a plate tooth cutting device, a buffer rolling and conveying device and a plate splicing device, wherein the roller conveying belt is arranged on the rack, the feeding table is arranged on one end of the roller conveying belt, and the feed rolling and conveying device, the plate tooth cutting device, the buffer rolling and conveying device and the plate splicing device are arranged above the roller conveying belt in sequence and are matched with the roller conveying belt to convey plates. The veneer toothing machine has the effects that the labor cost is reduced, and the automatic production is continuous.

Owner:GUANGZHOU HENGWEI ELECTROMECHANICAL EQUIP CO LTD

Fireproof aluminum-plastic panel core material

The invention discloses a fireproof aluminum-plastic panel core material comprising the following components: low-density polyethylene, an ethylene-octene copolymer, aluminum hydroxide, anhydrous magnesium carbonate, calcium stearate, silicon dioxide, a coupling agent, a smoke suppressant, a reinforcing toughener and titanium dioxide. The fireproof aluminum-plastic panel core material prepared by the formula has the advantages of being halogen-free, low-smoke, flame-retardant, and drop-resistant; the panel has flexible rolling property; the fireproof aluminum-plastic panel core material is strong in toughness, easy to mold and good in processability and play roles in thermal insulation, oxygen isolation and smoke suppression; a relatively good flame retardant effect is reached; and continuous automatic production can also be achieved.

Owner:RUGAO BINJIANG URBAN CONSTR INVESTMENT

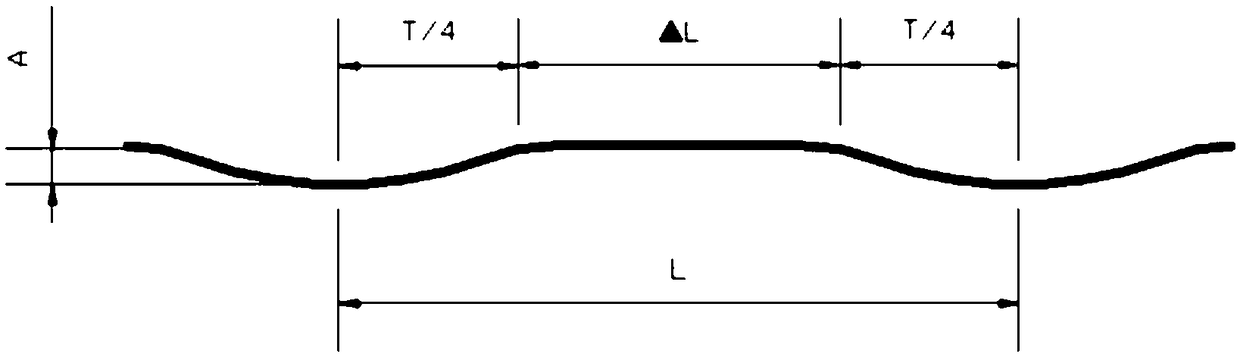

Seamless wave bottom of underpants and technology for compounding wave bottom and hot melting adhesive tape

InactiveCN106263047ANo archingReduce individually cut fabricsLamination ancillary operationsLaminationPhysicsHot pressing

The invention relates to a seamless wave bottom of underpants and a technology for compounding the wave bottom and a hot melting adhesive tape. The seamless wave bottom comprises a wave bottom fixing area arranged on an underpants main body, and the wave bottom is formed on the wave bottom fixing area through seamless pressure pasting; the seamless wave bottom is characterized in that the hot melting adhesive tape with the width being L is arranged on the wave bottom close to the contour edge, the hot melting adhesive tape is arranged in a manner of integrally extending along the contour edge of the wave bottom, and the wave bottom is formed on the wave bottom fixing area through hot-pressing laminating by adopting the hot melting adhesive tape. The technology for compounding the wave bottom and the hot melting adhesive tape comprises the following steps: (1) slitting a hot melting adhesive film and a fabric of the wave bottom; (2) punching a positioning hole and an inner frame hole; (3) carrying out thermal compounding on the hot melting adhesive film and the fabric; and (4) forming the wave bottom finished product through die cutting and integrated blanking. The process is simple and reasonable, the processing efficiency is high, the operation is safe and reliable, the technology is energy-saving and environmentally friendly, and the production cost is greatly reduced.

Owner:佛山市真北工业技术材料有限公司

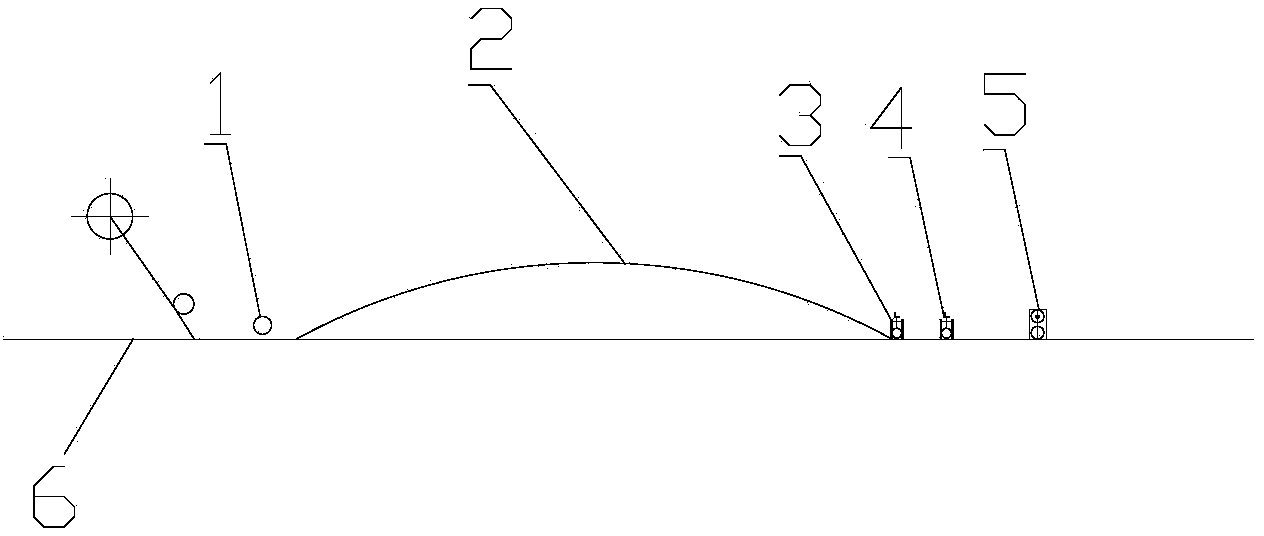

Auxiliary standing device on hollow composite flat plate production line

The invention discloses an auxiliary standing device on a hollow composite flat plate production line. The auxiliary standing device on the hollow composite flat plate production line comprises a frame platform, wherein a soaking roller, an arched soaking platform, a longitudinal drawing roller, a transverse drawing roller and a height controlling roller are sequentially arranged along the horizontal direction on the frame platform. The auxiliary standing device on the hollow composite flat plate production line is capable of controlling resin content and soaking effect of hollow fabric, improving the standing property and height evenness of pile warp of the hollow fabric and precisely controlling surface flatness and height size of product; the auxiliary standing device on the hollow composite flat plate production line has the advantages of low manufacture cost, high production efficiency and the like and the products have stable quality; through the auxiliary standing device on the hollow composite flat plate production line, continuous automatic production can be realized; and market requirements can be met.

Owner:NANJING FIBERGLASS RES & DESIGN INST CO LTD

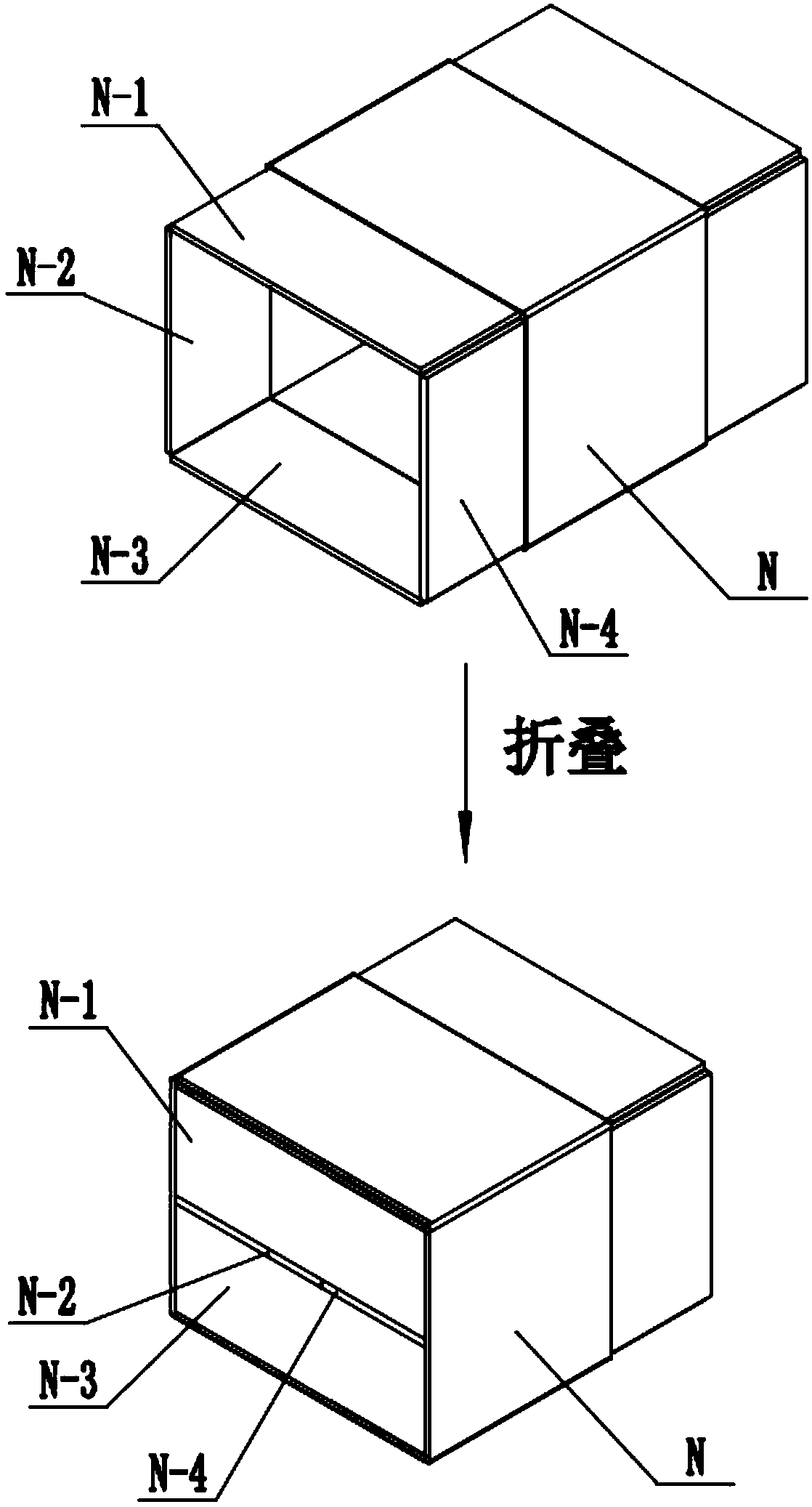

Carton automatic folding device and carton sticking machine

InactiveCN109514916ASafe and reliable workOperational securityBox making operationsPaper-makingEngineeringFront edge

The invention discloses a carton automatic folding device. The carton automatic folding device is characterized by comprising a left edge folding mechanism, a rear edge folding mechanism, a front edgefolding mechanism and a right edge folding mechanism. The left edge folding mechanism comprises a first support, a first horizontal air cylinder, a first sucker, a first turn-over air cylinder and afirst turn-over pressing plate. The rear edge folding mechanism comprises a second support, a second horizontal air cylinder, a second sucker, a second turn-over air cylinder and a second turn-over pressing plate. The front edge folding mechanism comprises a third support, a third turn-over air cylinder and a third turn-over pressing plate. The right edge folding mechanism comprises a fourth support, a fourth turn-over air cylinder and a fourth turn-over pressing plate. Automatic folding of four edges at the bottom of a carton can be achieved, and production efficiency can be improved. In addition, the invention further discloses a carton sticking machine.

Owner:重庆仨睿包装印务有限公司

Multi-strain co-immobilized fermented papaya vinegar and preparation method thereof

InactiveCN106222055AIncrease profitIncrease economic incomeMicroorganism based processesOn/in organic carrierAlcoholUltrafiltration

The invention discloses novel multi-strain co-immobilized fermented papaya vinegar and a preparation method thereof. The preparation method comprises the steps of papayas selection, cleaning, blanching, peeling, seed removal, cutting, pulping, enzymolysis, centrifugation, component adjustment, pasteurization, cooling, co-immobilized alcohol fermentation, immobilized acetic bacteria fermentation, clarification, filtration, sterilization, ultrafiltration membrane purification, filling and product finishing. According to the novel multi-strain co-immobilized fermented papaya vinegar and the preparation method thereof, the problems that multiple papayas in the mature season are difficult to store, the traditional fruit vinegar fermentation is complicated to operate and the strains are liable to be deactivated can be solved effectively; the papayas can be used for batched fruit vinegar production, the production cycle is reduced and the production capacity is improved; the prepared papaya vinegar is clear and transparent, has stable color, is orange-yellow, has the prominent fragrance of the papayas, is faint scent, has mellow taste and soft mouthfeel, is good for a human body to digest and absorb food, and has the characteristics of invigorating spleen to promote digestion, prolonging life and the like.

Owner:AGRI PROD PROCESSING INST GUANGXI ACADEMY OF AGRI SCI

Method for preparing p-hydroxybenzonitrile

InactiveCN105418455AContinuous automated productionThe reaction steps are simplePreparation by ammonia-carboxylic acid reactionOrganic solventReaction temperature

The invention discloses a method for preparing p-hydroxybenzonitrile. The method comprises the following steps: adding filler and a catalyst into a fixed-bed reactor, dissolving feed, i.e., methyl p-hydroxybenzoate in an organic solvent, then, adding the solution into the fixed-bed reactor together with water, controlling the reaction temperature of the reactor to 300-480 DEG C and the reaction pressure of the reactor to 0-0.1KPa, carrying out continuous discharging, and carrying out rectification, thereby preparing p-hydroxybenzonitrile. The method is energy-saving and environment-friendly, continuous automated production can be achieved, reaction steps are simplified, process flows are reduced, and the problem in former p-hydroxybenzonitrile production that waste gases, waste water and waste residues are severe and the continuous automated production cannot be achieved is solved.

Owner:JIANGSU RUIDA TECH CO LTD

Method for resolving metoprolol enantiomers by using simulated moving bed chromatography

InactiveCN103787901ASimple processProduction Continuous AutomationOrganic compound preparationAmino-hyroxy compound preparationChemistrySimulated moving bed

The invention discloses a method for resolving metoprolol enantiomers by using simulated moving bed chromatography. The method is characterized in that the simulated moving bed chromatography is adopted, an amylose-tris(3,5-dimethylphenylcarbamate) is used as a filler and n-hexane and an alcohol organic modifier are used as a mobile phase, to resolve the metoprolol enantiomers under a positive phase condition, thus obtaining high-pure R-metoprolol and S-metoprolol. The simulated moving bed chromatography is continuous production, has high automatic degree and high production efficiency.

Owner:江苏汉邦科技股份有限公司

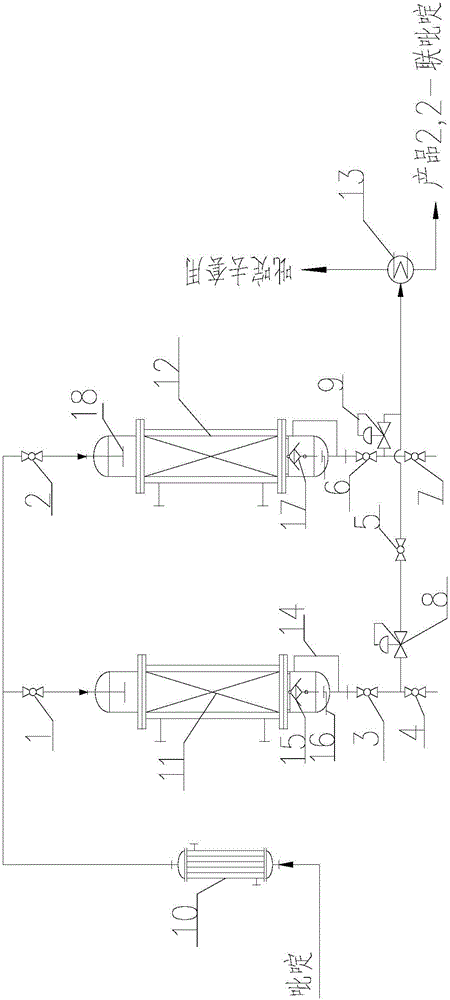

Device and method for synthesizing 2,2-bipyridyl

InactiveCN106117121AEasy loading and unloadingReaction conditions are easy to controlOrganic chemistryPyridineDistributor

The invention discloses a device and method for synthesizing 2,2-bipyridyl, and belongs to the field of fine chemical engineering. The device comprises a preheater, reactors and discharge devices, each reactor is internally provided with a liquid distributor, a catalyst bed layer, a catalyst support plate and catalyst unloading device and a gas distributor in sequence from top to bottom, each discharge device comprises a regulating valve, and an aftertreatment device is an evaporator. According to the process, pyridine enters the reactors through the preheater and passes through the liquid distributors to be uniformly scattered on the catalyst bed layers, discharging is conducted through the regulating valve after a reaction is completed, unreacted pyridine is distilled and recycled through the evaporator for reuse, and the residue obtained after pyridine is distilled is 2,2-bipyridyl.

Owner:NANJING REDSUN BIOCHEM CO LTD +1

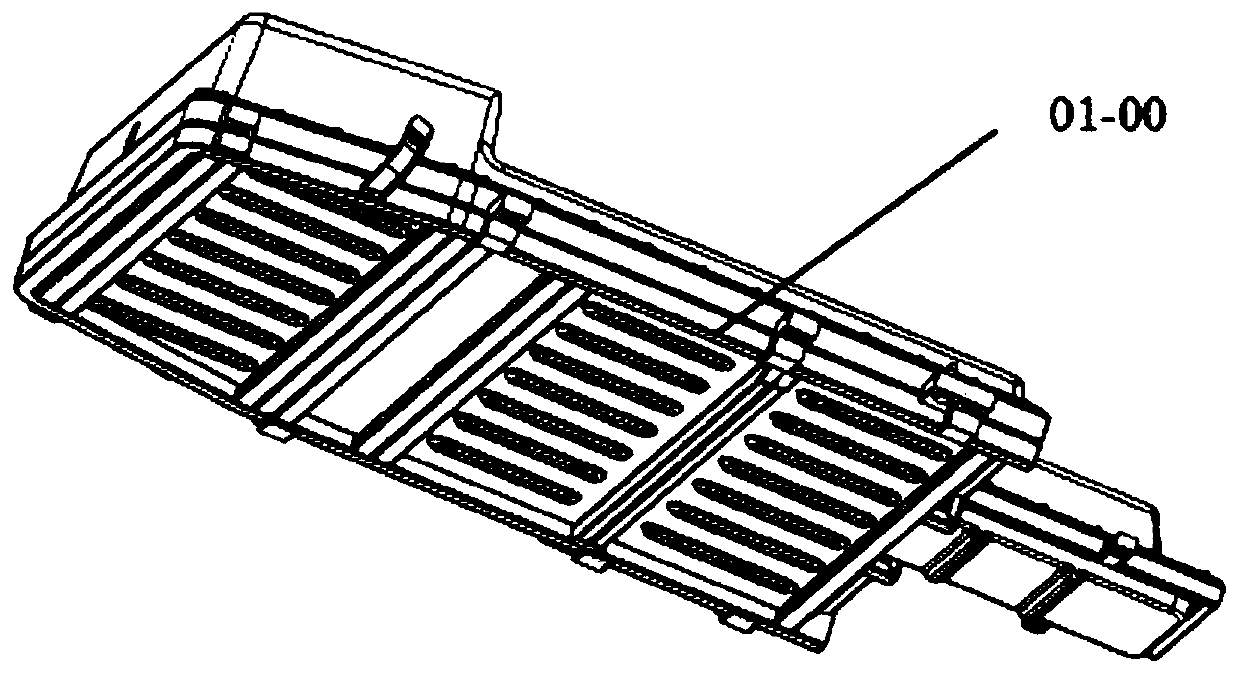

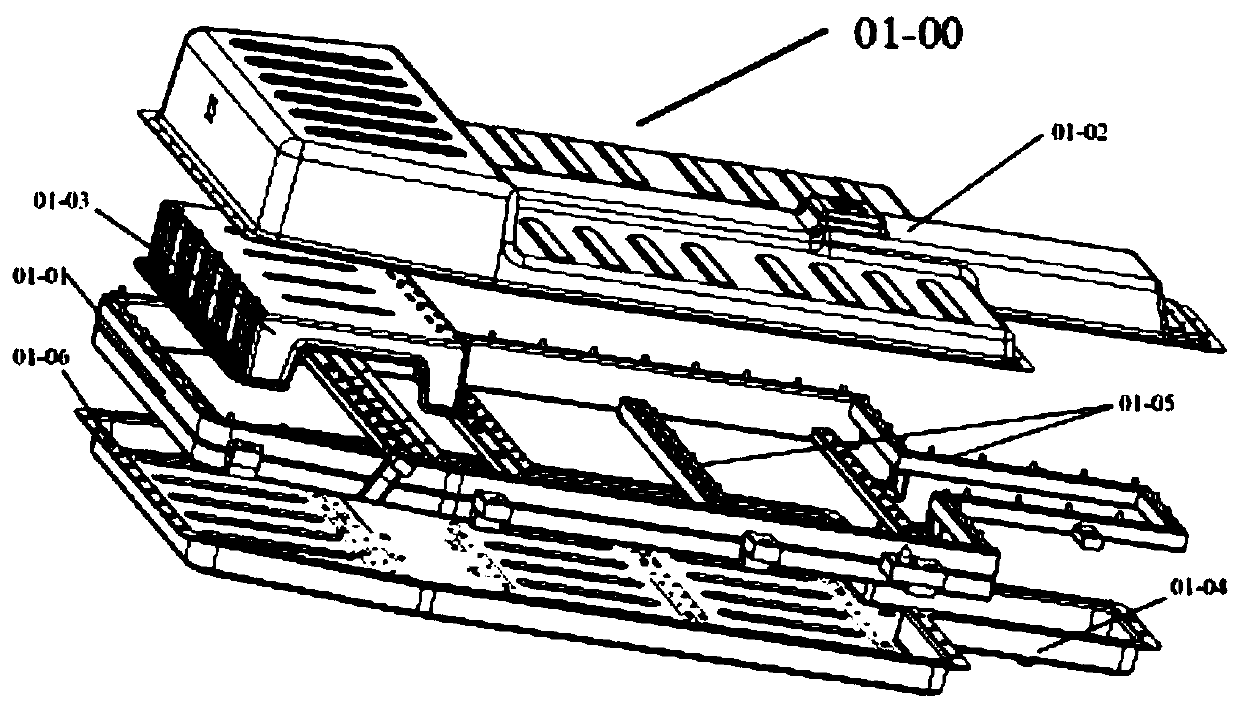

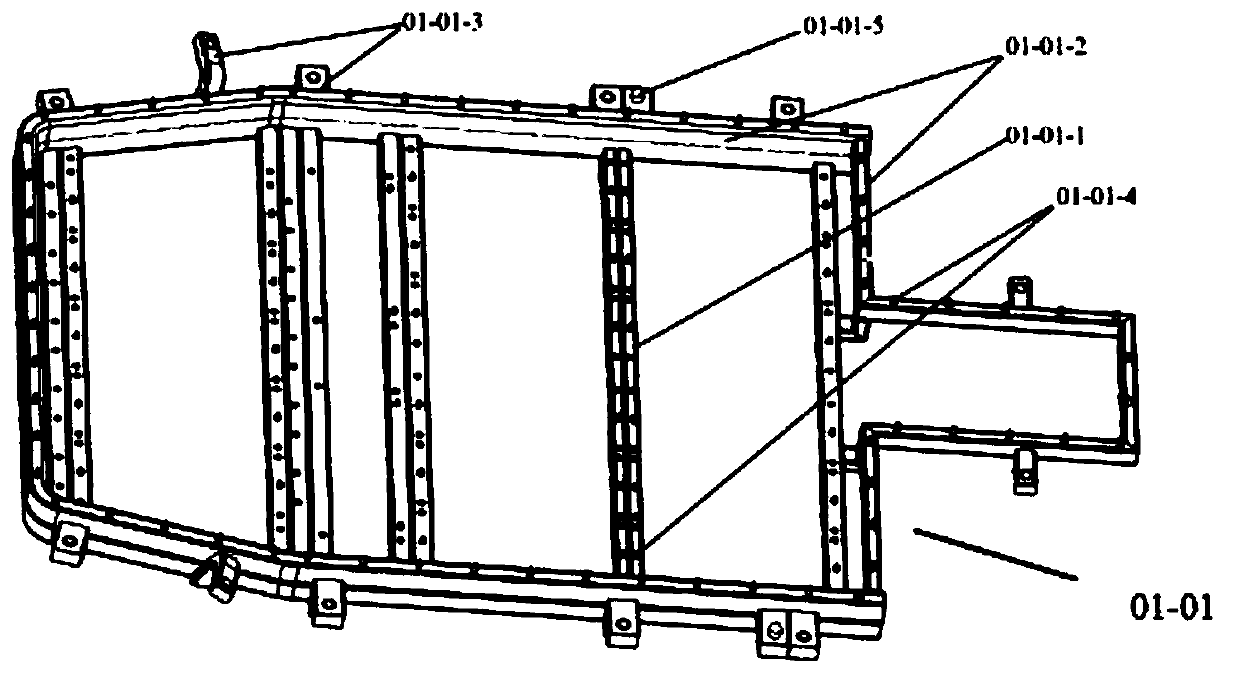

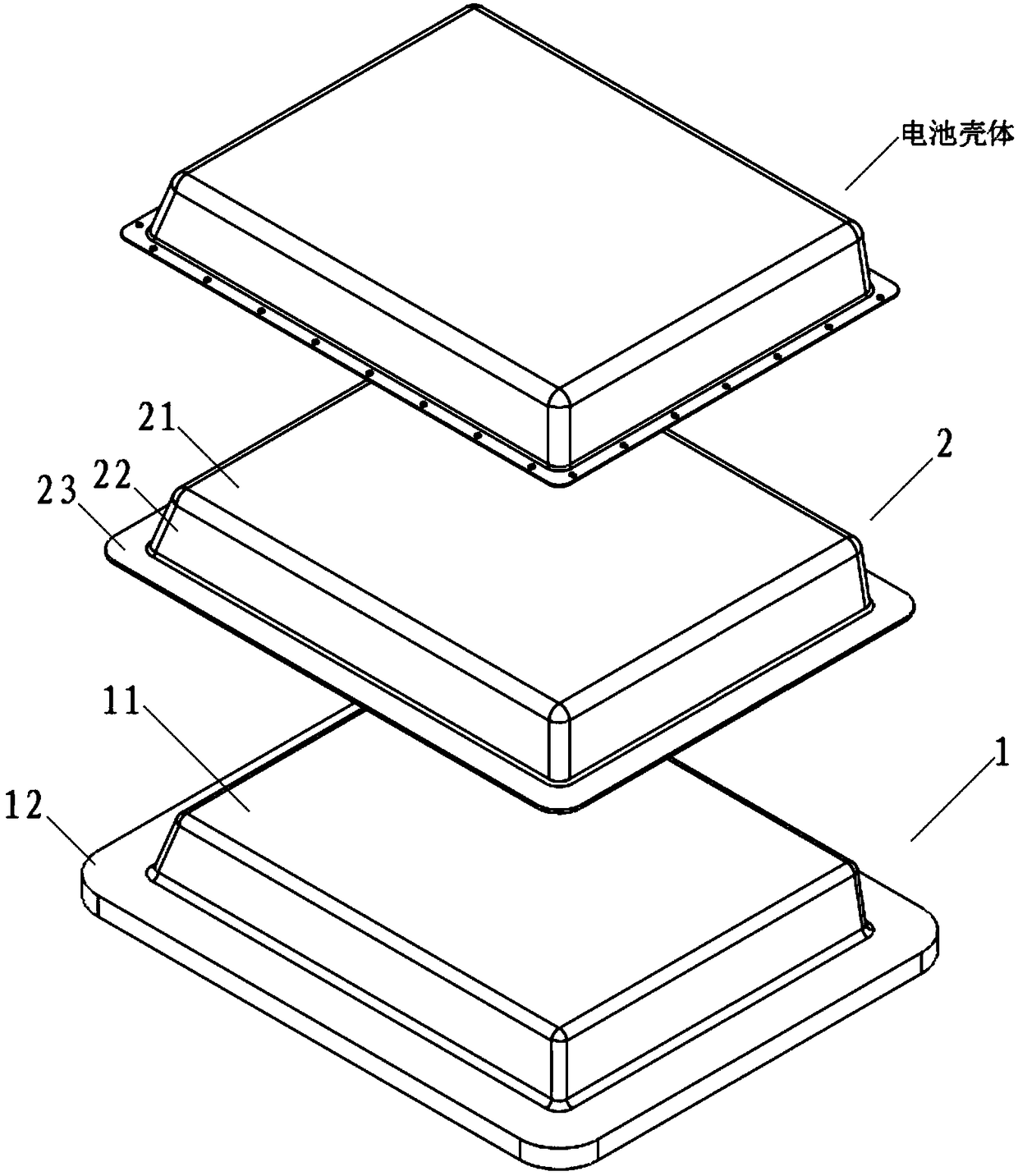

Metal and composite material combined battery box

PendingCN111439106ALow costContinuous/automated productionEngine sealsNon-rotating vibration suppressionMechanical engineeringBattery cell

The invention discloses a metal and composite material combined battery box in the technical field of automobile parts. The battery box is composed of a high-strength metal frame, an upper shell madeof a composite material, a middle shell made of a composite material, a lower shell made of a composite material, a sealing rubber layer and a sealing rubber strip. According to the structural characteristics and technical requirements of the battery box, different materials are applied to different positions of the battery box, and the advantages of the materials are brought into full play, so the production cost is reduced, the rigidity requirement of the battery box is met, meanwhile, the frame weight is reduced to the maximum extent, the local stress is dispersed, and the connection reliability is improved.

Owner:上海瓴荣材料科技有限公司 +1

Battery shell male mould and hot-pressing process

ActiveCN109352875AImprove heat transfer efficiencyReduce weightDomestic articlesHeat transfer efficiencyThermal efficiency

The invention provides a battery shell male mould and a hot-pressing process. The battery shell male mould comprises a core mould and a plurality of metal linings which are matched with the core mould, wherein any metal lining is provided with a bottom wall and side walls which extend out in the same direction from the peripheral edges of the bottom wall, the bottom wall and the side walls are enclosed to form a cavity which communicates with the outer part; the edges of the side walls are further connected with lining flanges which extend outwards; the core mould is provided with a lug boss which is matched with the cavity in shape; and the lug boss is positioned on a bottom plate; and the part, bulged and extended to the peripheral edge of the lug boss, of the bottom plate defines a coremould flange of the core mould. According to the battery shell male mould provided by the invention, an existing male mould is designed into a structure with the core mould and the plurality of the metal linings, so that heat transfer efficiency, in a hot-pressing process of the male mould, is improved, weight of the male mould is relieved, transfer is convenient, continuous and automatic production for a prepreg mould-pressing battery shell is realized, and production efficiency is greatly improved.

Owner:宁德康本科技有限公司

Method for preparing enzyme by using honeysuckle and curcuma longa as main raw materials

InactiveCN106235318AIncrease profitReduce the risk of slow salesMicroorganism based processesVinegar preparationRoom temperatureMusa basjoo

The invention relates to a method for preparing an enzyme by using honeysuckle and curcuma longa as main raw materials. The method specifically comprises: (1) selecting 35-45 parts by weight of honeysuckle, 10-15 parts by weight of musa basjoo siebold, 10-15 parts by weight of pineapple, and 10-15 parts by weight of clausena lansium, and washing with clear water so as to be spare; (2) peeling the clausena lansium to expose the flesh, cutting the pineapple with the peel and the musa basjoo siebold with the peel into pineapple slices with the thickness of 1-2 cm and musa basjoo siebold slices with the thickness of 1-2 cm, and uniformly mixing the slices to obtain a mixture; (3) placing the mixture into a sealed container, adding honey and water, uniformly mixing, placing into a room, carrying out sealed fermentation at a room temperature, and maintain for 1 month, wherein stirring is performed everyday at the starting 5-7 days and stirring is performed every 7 days at the later days; and (4) washing fresh curcuma longa picked before and after winter solstice, cutting into curcuma longa slices with the thickness of 0.3-2 cm, taking 15-25 parts by weight of the curcuma longa slices, adding to the sealed container, and carrying out sealed fermentation for more than 3 months so as to obtain the product. According to the present invention, the enzyme prepared through the method has advantages of original food function maintaining, rich probiotics, rich nutrition, good taste, and long shelf life.

Owner:唐妙红

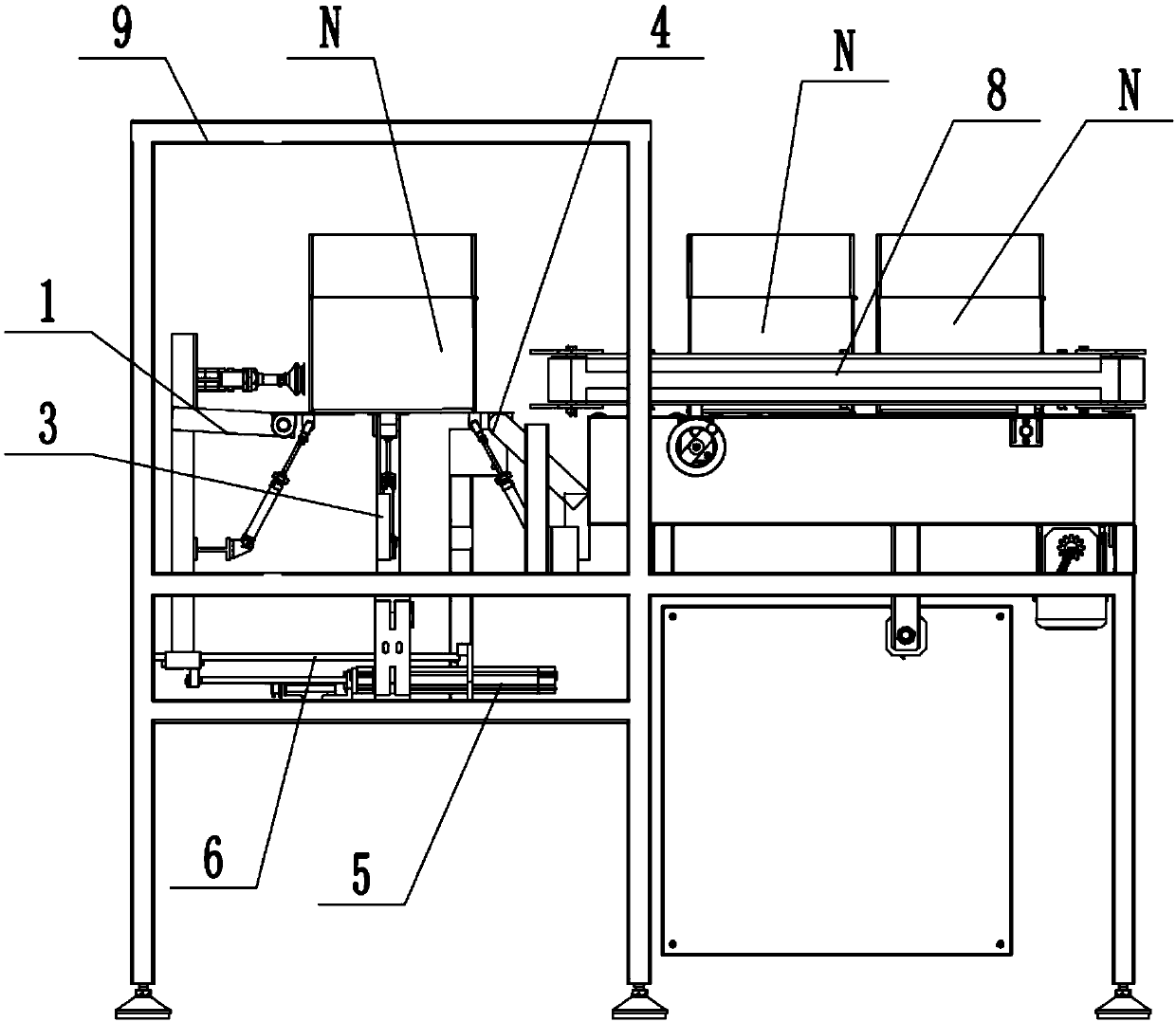

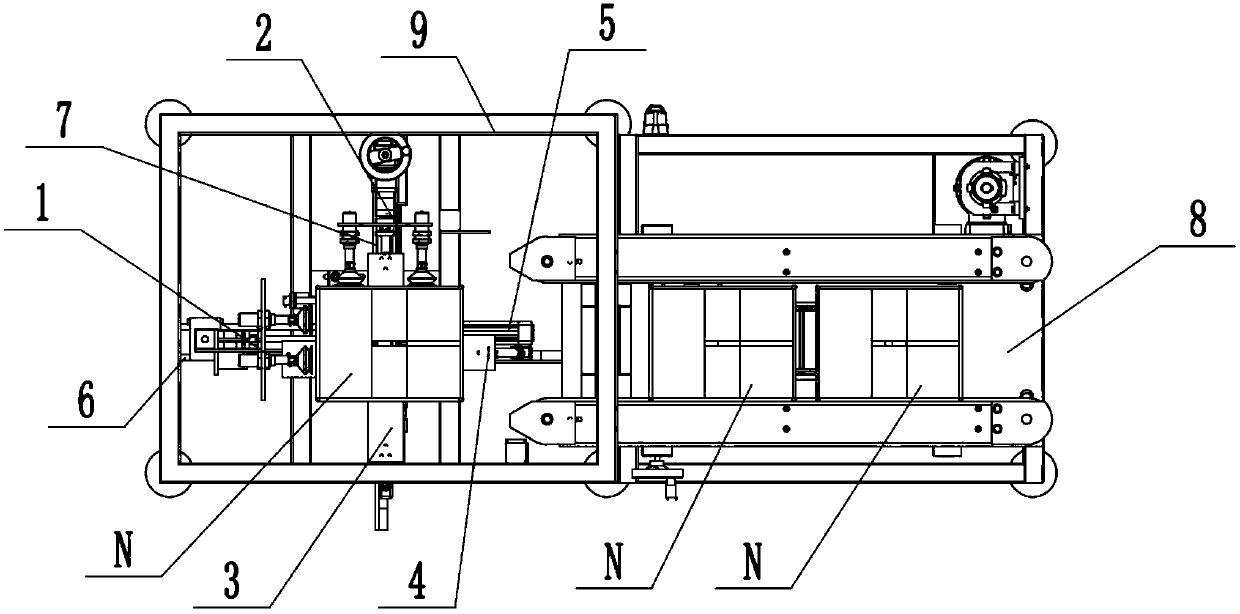

Workpiece punching and turning-milling integrated machine

ActiveCN111300054AContinuous automated productionImprove processing efficiencyWork clamping meansOther manufacturing equipments/toolsTransfer mechanismEngineering

The invention discloses a workpiece punching and turning-milling integrated machine. The workpiece punching and turning-milling integrated machine comprises a worktable, a punching mechanism and a spindle are fixedly arranged on the worktable, a feeding channel is formed in the spindle, and a turning-milling mechanism is arranged at the discharging end of the feeding channel; a pushing mechanism is arranged on the extension line of the feeding channel, a shifting station is arranged between the pushing mechanism and a feeding port of the feeding channel, a punching station is arranged on one side of the shifting station, the punching mechanism is cooperatively arranged in the punching station, a transferring mechanism is slidably arranged between the shifting station and the punching station, and a feeding mechanism is arranged on one side of the punching station; and the transferring mechanism moves a workpiece punched in the punching station into the shifting station, the pushing mechanism pushes the workpiece in the shifting station to a discharging port of the feeding channel from the feeding port of the feeding channel, and the spindle rotates to perform two-stage turning-milling operation on two ends of the workpiece through the turning-milling mechanism. Compared with the prior art, the workpiece punching and turning-milling integrated machine realizes automatic workpiece machining and improves the workpiece machining efficiency and machining quality.

Owner:WENLING KEYU AUTOMATION EQUIP CO LTD

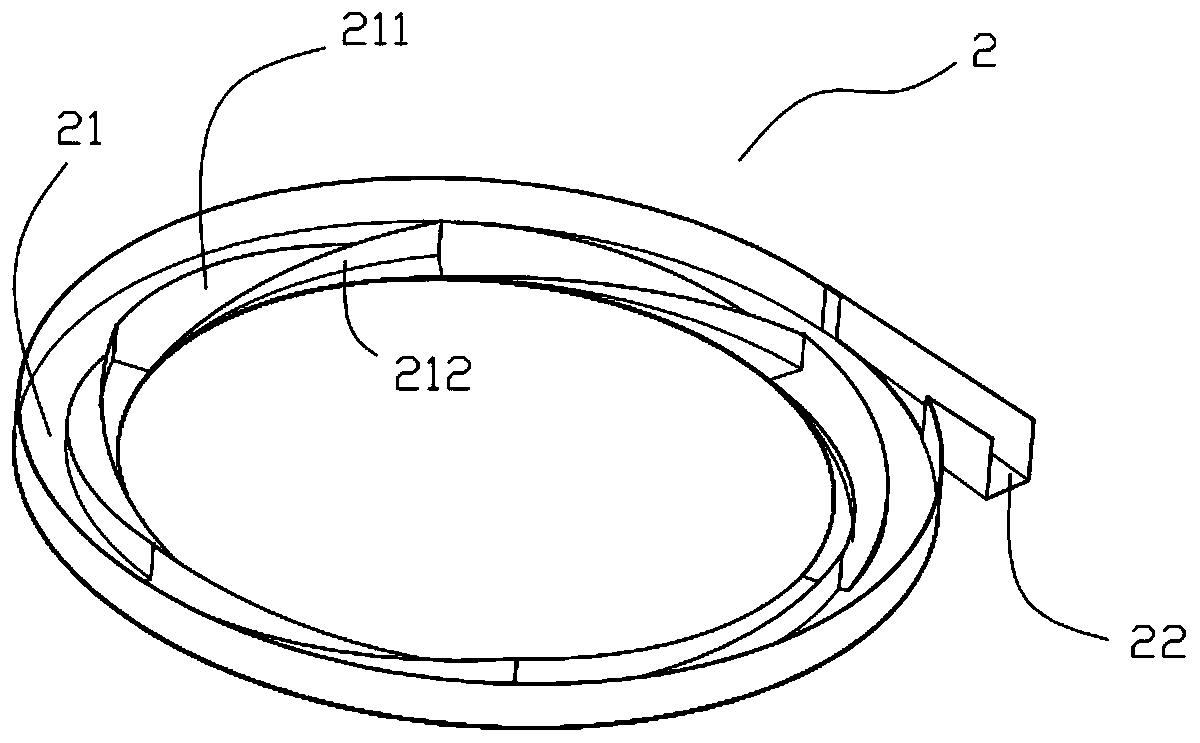

Eggshell membrane separation device, method and production line

The invention discloses an eggshell membrane separation device, method and production line. The eggshell membrane separation device includes a shell, a drainage plate, an upper cover plate and a mixing motor. The drainage plate is provided with a diversion groove and a collecting groove, the diversion groove communicates with the collecting groove, the output end of the mixing motor is connected with a mixing paddle, and the mixing paddle is provided with a first large blade and a second small blade; and the shell is further internally provided with a plurality of arc baffles, the baffles aremovably attached to the inner wall of the shell, and each baffle is provided with one or more bulges. Under the combined action of mechanical agitation, shear breaking and physical water separation ofthe device, the cleaning of eggshell membranes and the high-efficiency continuous automatic separation discharging are realized simultaneously. By using the separation method, device and production line, the purity of the eggshell membranes obtained by separation can reach up to 97% or more, and moreover, by additionally arranging a recovery and purification water pool behind an egg membrane collection device, production water can be recycled. The separation method has the significant advantages of convenient operation, high separation efficiency, high purity of the separated egg membranes, continuous and automatic operation and cost saving.

Owner:湖北神地农业科贸有限公司 +2

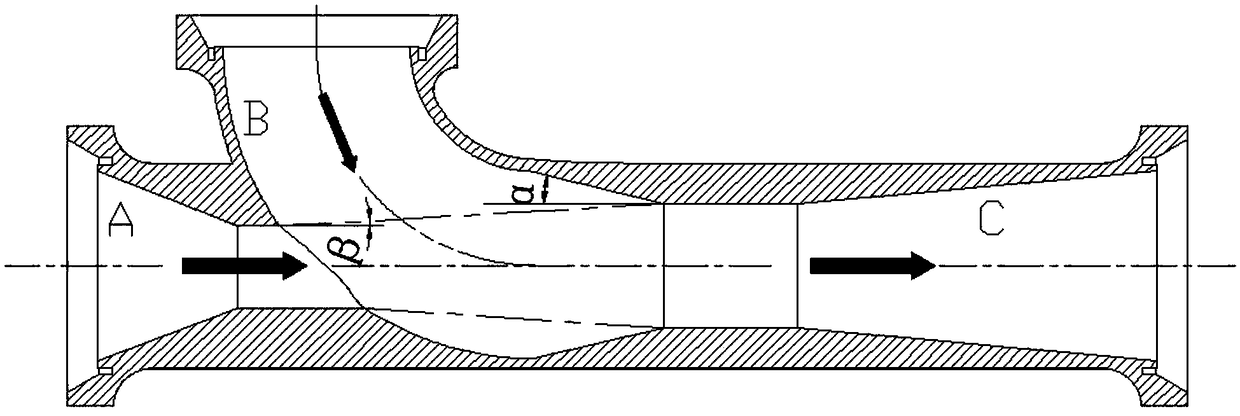

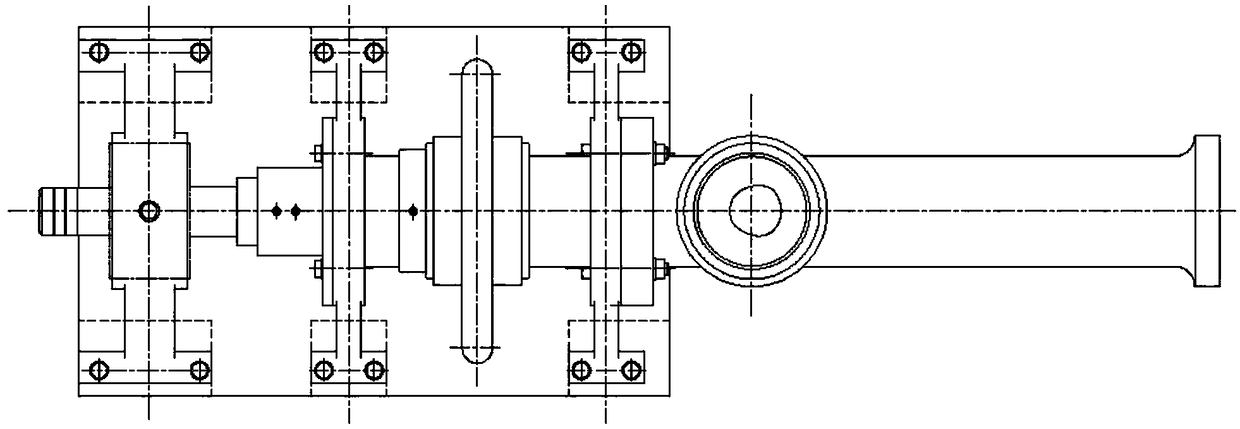

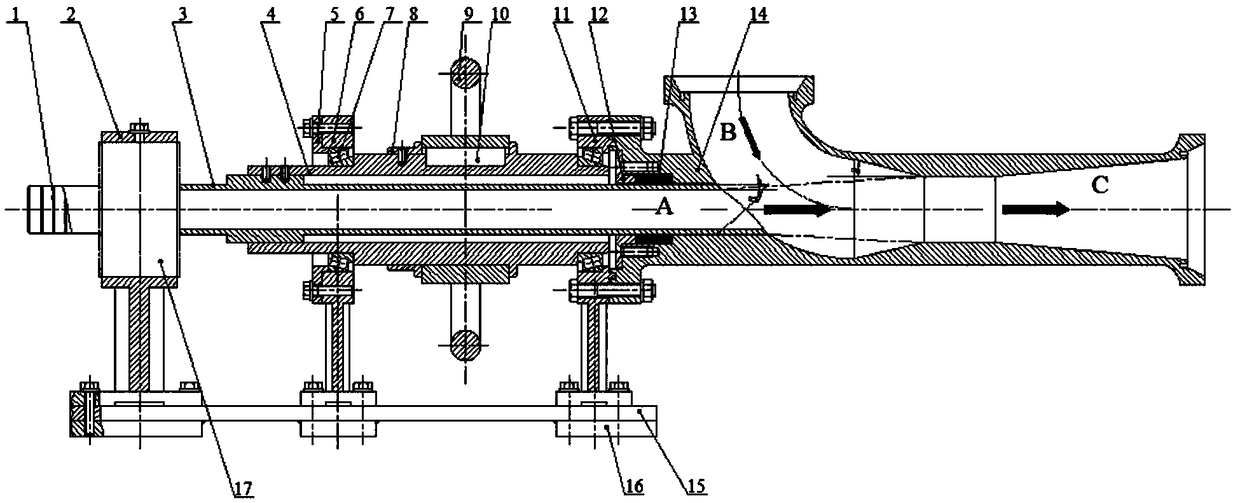

Automatic rotating powder distribution device for nozzle of pulsating vacuum jet pump

ActiveCN109382009AStructuredEvenly distributedFlow mixersTransportation and packagingSpray nozzleVacuum pump

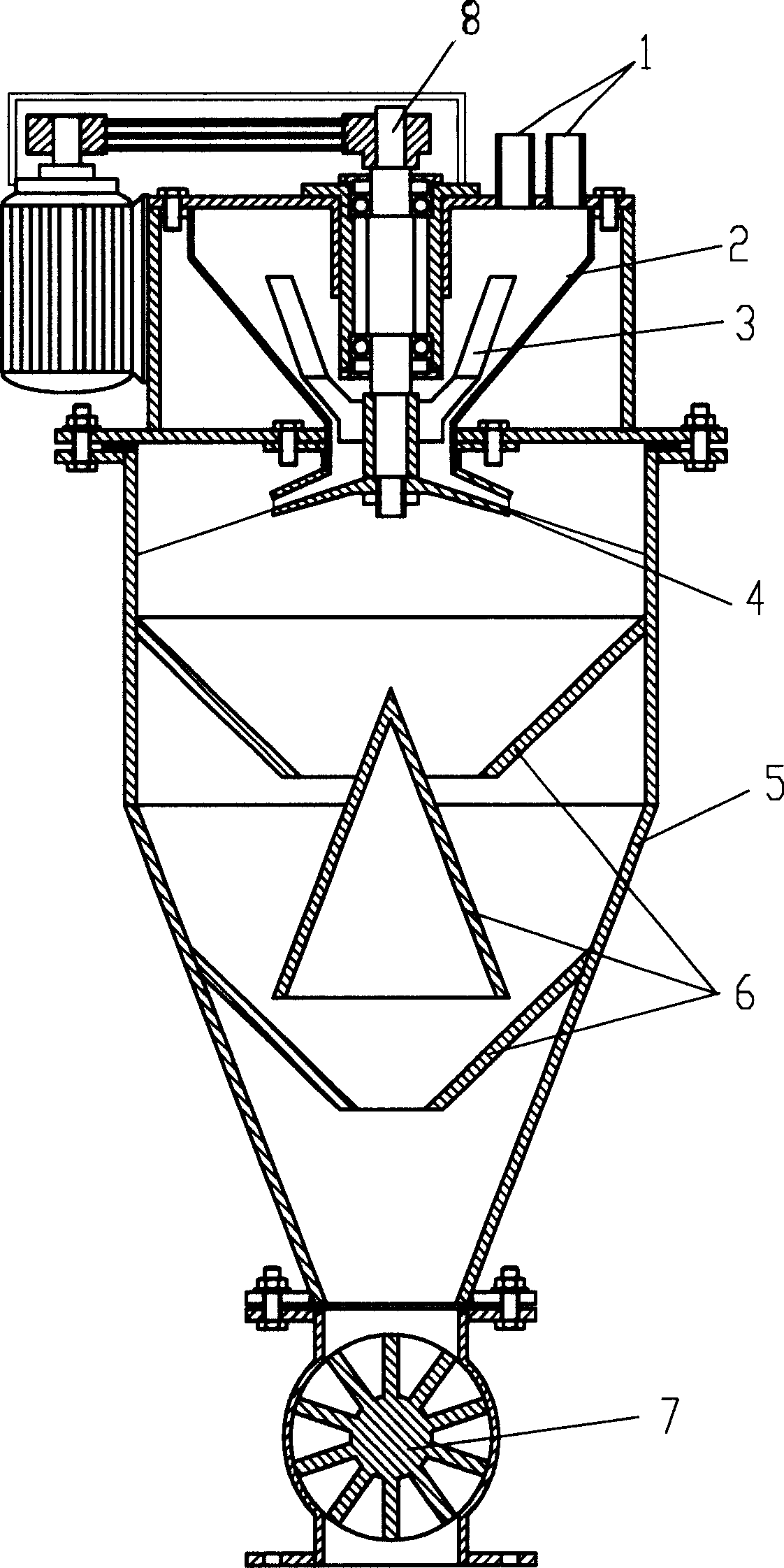

The invention relates to an automatic rotating powder distribution device for a nozzle of a pulsating vacuum jet pump; a left bearing support frame and a right bearing support tube are fixed at the upper end of a fixed plate at intervals; the upper parts of the left bearing support frame and the right bearing support tube are coaxially sleeved and supported with a revolving hollow shaft; the middle part of the revolving hollow shaft is provided with a revolving wheel in a limit manner through a flat key, and the right end of the revolving hollow shaft is coaxially connected with an inlet of apressurization chamber of the nozzle of the jet pump; a jet tube is fixed in the revolving hollow shaft in a coaxially sleeved manner, the right end of the jet tube is inserted in the pressurization chamber connected with the nozzle of the jet pump, and the end port of the right end of the jet tube is of an asymmetrical structure. The jet nozzle of the device has the characteristics of rotatability and asymmetric structure, and can produce pulsating vacuum with periodical change, so that powder can be uniformly distributed before entering a jet area, is not accumulated into blocks, has good fluidity, prevents material heaping and prevents empty operation of the jet pump system.

Owner:TIANJIN UNIV OF SCI & TECH

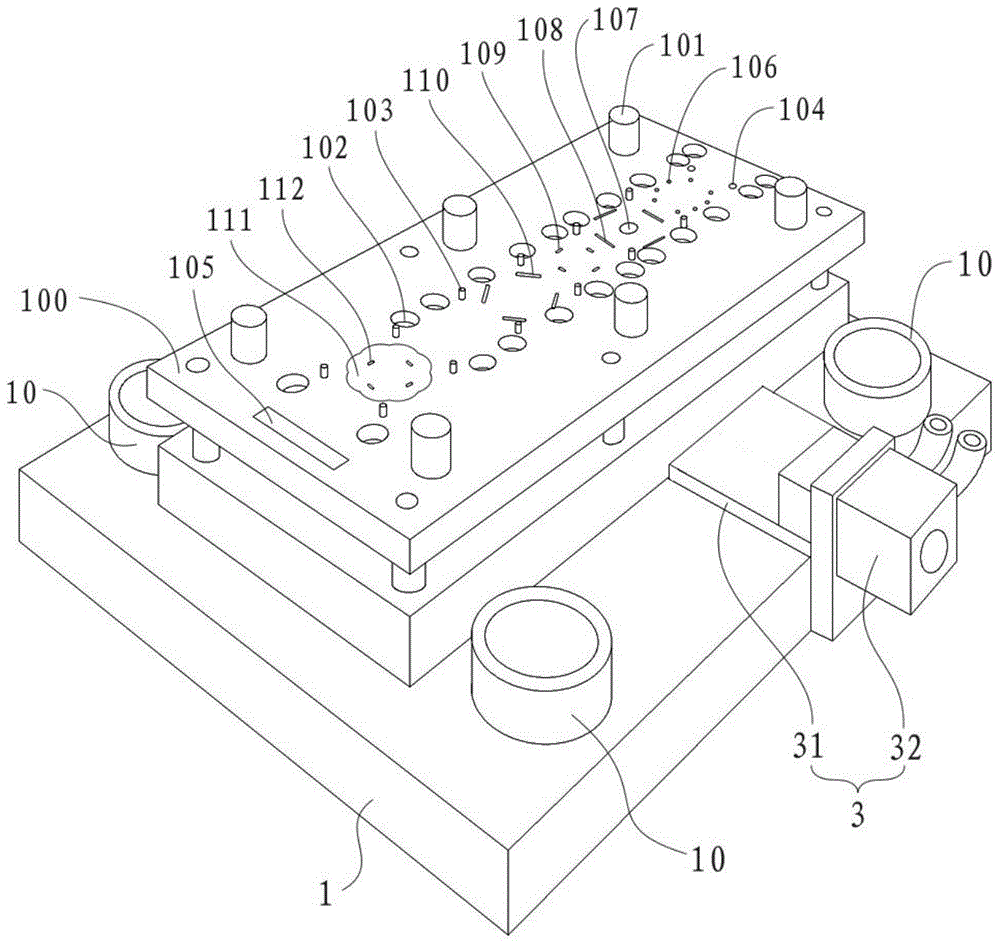

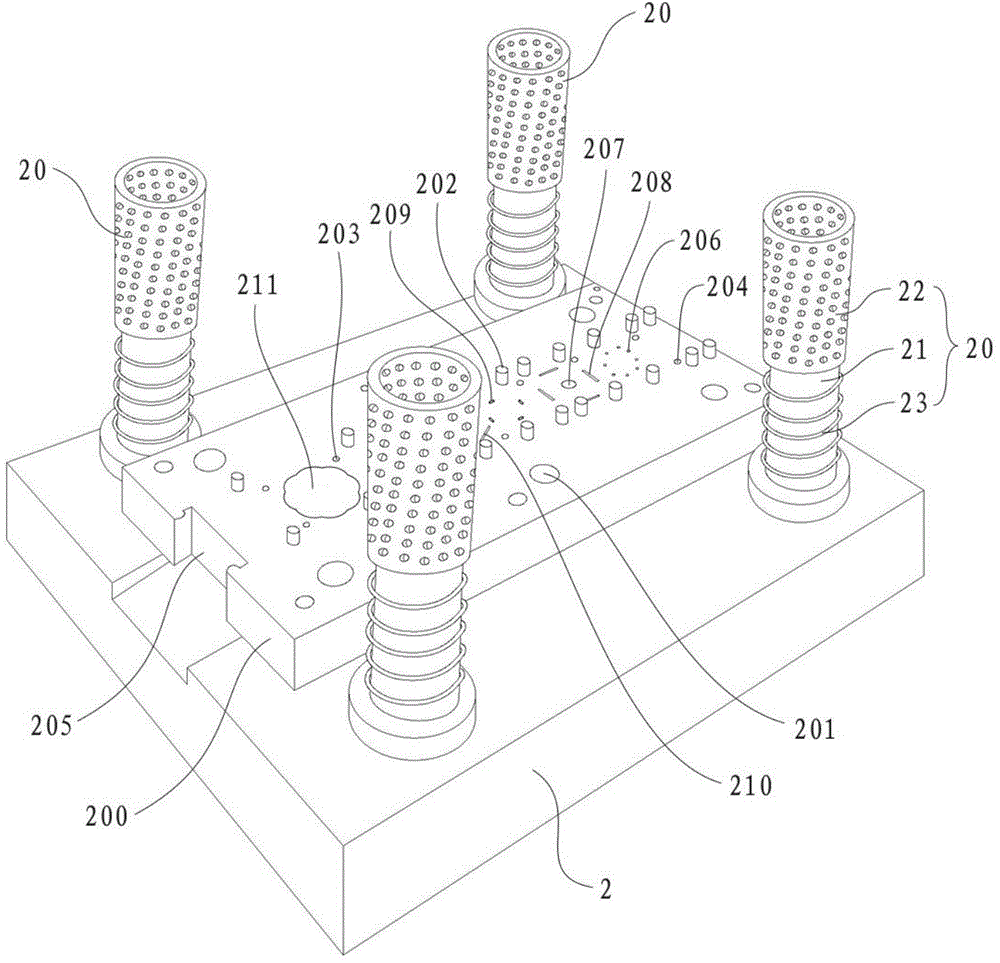

Machining die and method for rotor of brushless motor

The invention discloses a machining die for a rotor of a brushless motor. The machining die comprises an upper die holder and a lower die holder, wherein an upper die plate is arranged on the upper die holder, a lower die plate is arranged on the lower die holder, and machining areas are formed on the upper die plate and the lower die plate respectively; two rows of locating columns are arranged on the portions, close to the edges on the two sides, of the upper die plate respectively, a row of first concave holes are formed between each row of locating columns and the machining area of the upper die plate, two rows of locating nails are arranged in the machining area of the upper die plate, and locating hole plunger chips are arranged between the machining area of the upper die plate and the feeding end; second concave holes, guide columns, third concave holes and locating hole feeding inlets are formed in the corresponding positions of the lower die plate. The machining die can achieve the purpose that the punching working procedure and the laminating working procedure are accomplished through a set of dies, production efficiency is improved, damage caused to semi-finished products in the process of movement among multiple working procedures is avoided, and product quality and machining accuracy of the rotor are guaranteed.

Owner:ZHANGPU HONGQUN ELECTRONICS

Method for preparing enzyme by using lemons and galangal as main materials

InactiveCN106418498AIncrease profitReduce the risk of slow salesFood ingredient as flavour affecting agentVinegar preparationRoom temperatureMusa basjoo

The invention discloses a method for preparing enzyme by using lemons and galangal as main materials. The method comprises the specific steps that 1, 35-45 parts of lemons, 15-20 parts of galangal, 2-5 parts of turmeric, 8-15 parts of rhizoma zedoariae, 8-15 parts of grapefruit and 8-15 parts of musa basjoo are selected and cleaned for usage; 2, the lemons are firstly extruded to make peels broken and expose pulp, then the galangal, the turmeric, the rhizoma zedoariae, the grapefruit and the musa basjoo are cut into galangal slices, turmeric slices, rhizoma zedoariae slices, grapefruit slices and musa basjoo slices which are 0.3-2 cm in thickness, and then the materials are mixed evenly to obtain a mixture; 3, the mixture is put in a sealed container, honey and water are added for even mixing, then the mixture is put in a room, sealed fermentation is performed under room temperature condition, one time of stirring is performed every day in previous 5-7 days, later one time of stirring is performed every 7 days, the cycle is kept for one month, then sealing is performed, and fermentation continues for 6 months. The enzyme prepared by adopting the method retains the effects of original foods, is rich in probiotics and nutrition and long in shelf life and has a good taste.

Owner:唐妙红

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com