Preparing device and method of thermoplastic resin matrix prepreg reinforced by continuous carbon fibers

A technology for enhancing thermoplasticity and preparing devices, applied in the direction of coating, etc., can solve the problems of low bearing capacity, poor mechanical properties of carbon fiber composite components, etc., and achieve the effect of improving designability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

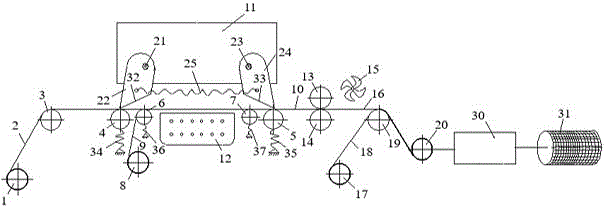

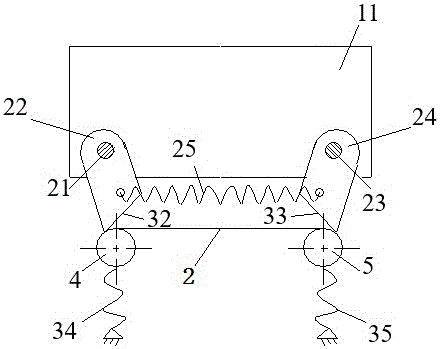

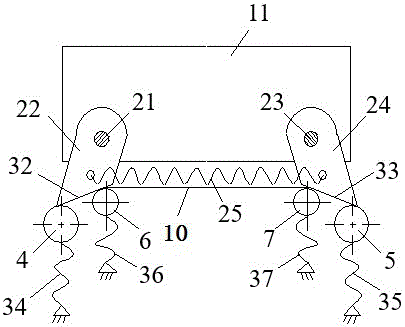

[0021] Such as figure 1 The present invention shows a continuous carbon fiber reinforced thermoplastic resin-based prepreg preparation device, which is a structure arranged horizontally from left to right. From left to right, there are carbon fiber bundle winding rollers 1 and carbon fiber bundle pulling rollers with central axes arranged horizontally. 3. The first left elastic tension roller 4 , the second left elastic tension roller 6 , the second right elastic tension roller 7 and the first right elastic tension roller 5 . The left and right horizontal distance between the two central axes of the first left elastic tension roller 4 and the second left elastic tension roller 6 is equal to the distance between the two central axes of the first right elastic tension roller 5 and the second right elastic tension roller 7 Horizontal distance left and right.

[0022] Carbon fiber bundle roll 1 is wound with carbon fiber bundle 2, and after carbon fiber bundle 2 is drawn out by c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com