Reaming honing cutter brazed with cubic boron nitride superhard abrasives for processing holes in materials difficult to process

A cubic boron nitride and superabrasive technology, applied in honing tools, etc., can solve problems such as limited application, low service life, and easy shedding of electroplated reamer abrasives, so as to ensure processing quality, reduce tool wear, and reduce possibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

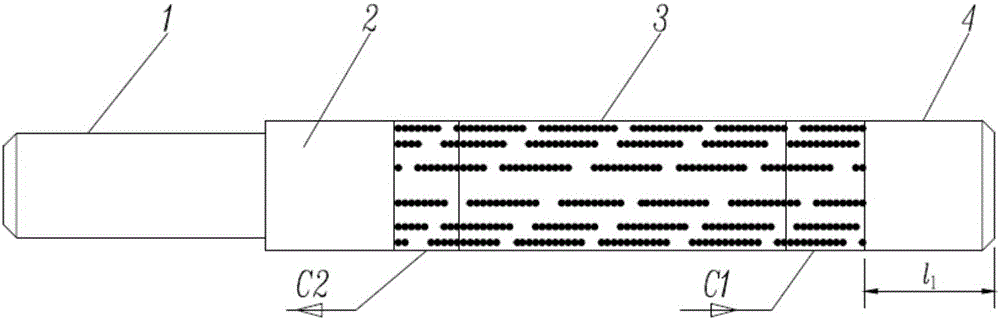

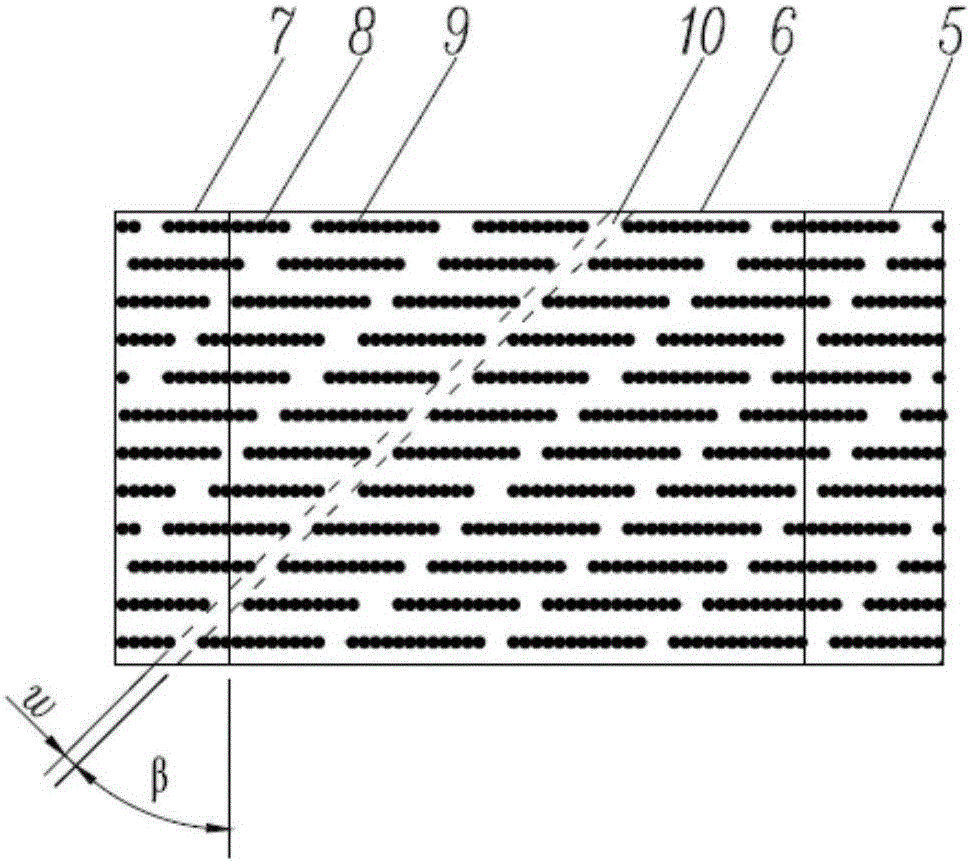

[0016] refer to figure 1 As shown, a brazed cubic boron nitride superhard abrasive reaming and honing tool for hole machining of difficult-to-machine materials of the present invention includes: a cutter bar 1, a cutter base 2, and the two are connected; the cutter base 2 is provided with a processing Part 3 and guide part 4, wherein the processing part 3 is composed of a cutting part 5, a finishing part 6 and a tool retraction part 7.

[0017] The processing part 3 is arranged in the shape of a cubic boron nitride superabrasive and brazed on the cutting edge 9. The cutting edge 9 has an upper / lower linear structure, and the cutting edge 9 is arranged in a left / right-handed helical shape. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com