Patents

Literature

433results about "Honing tools" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultrasonic annular core bit

InactiveUS6948574B2Robust excitation behaviorIncrease amplitudeDrill bitsTransportation and packagingFrequency determinationPower tool

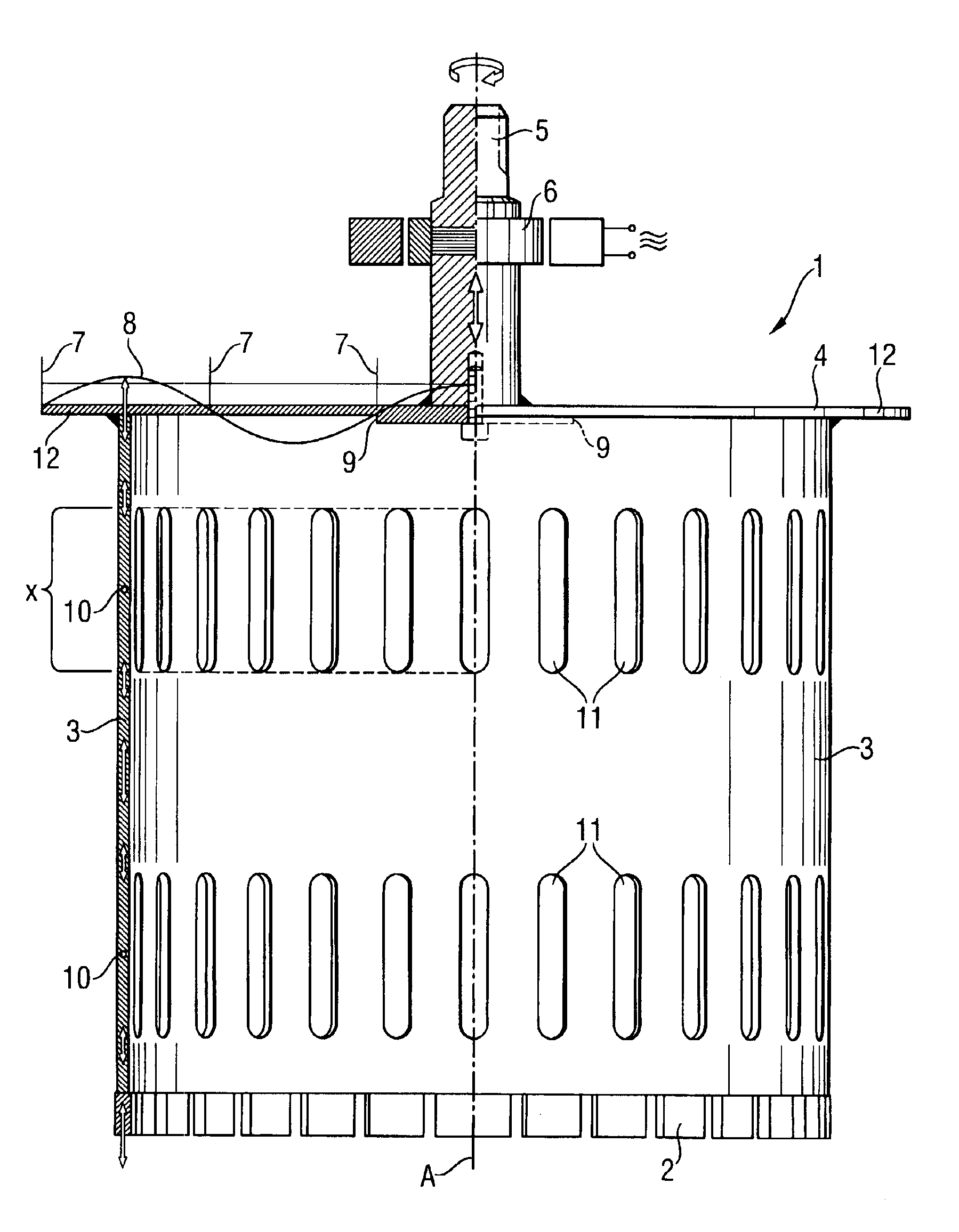

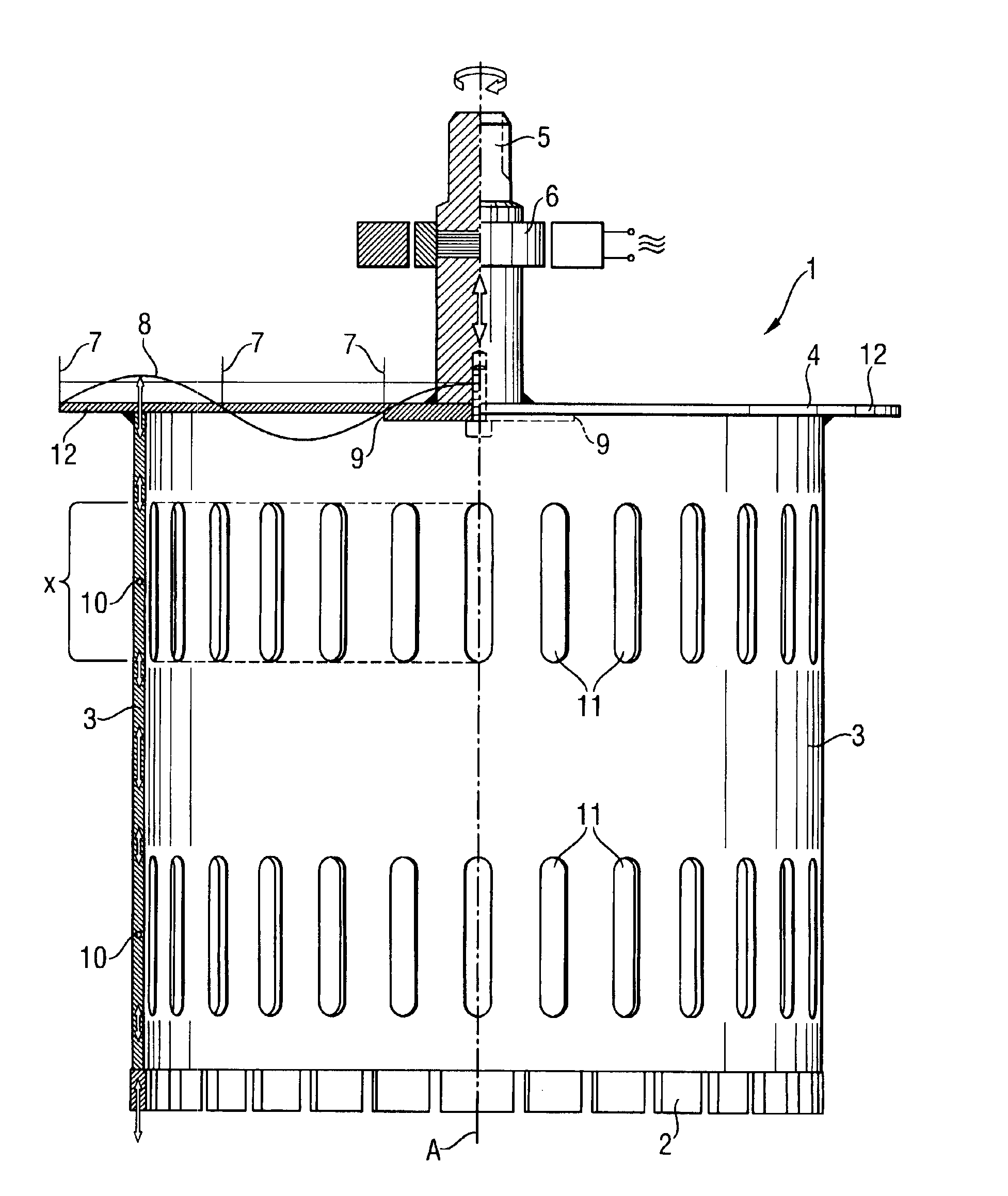

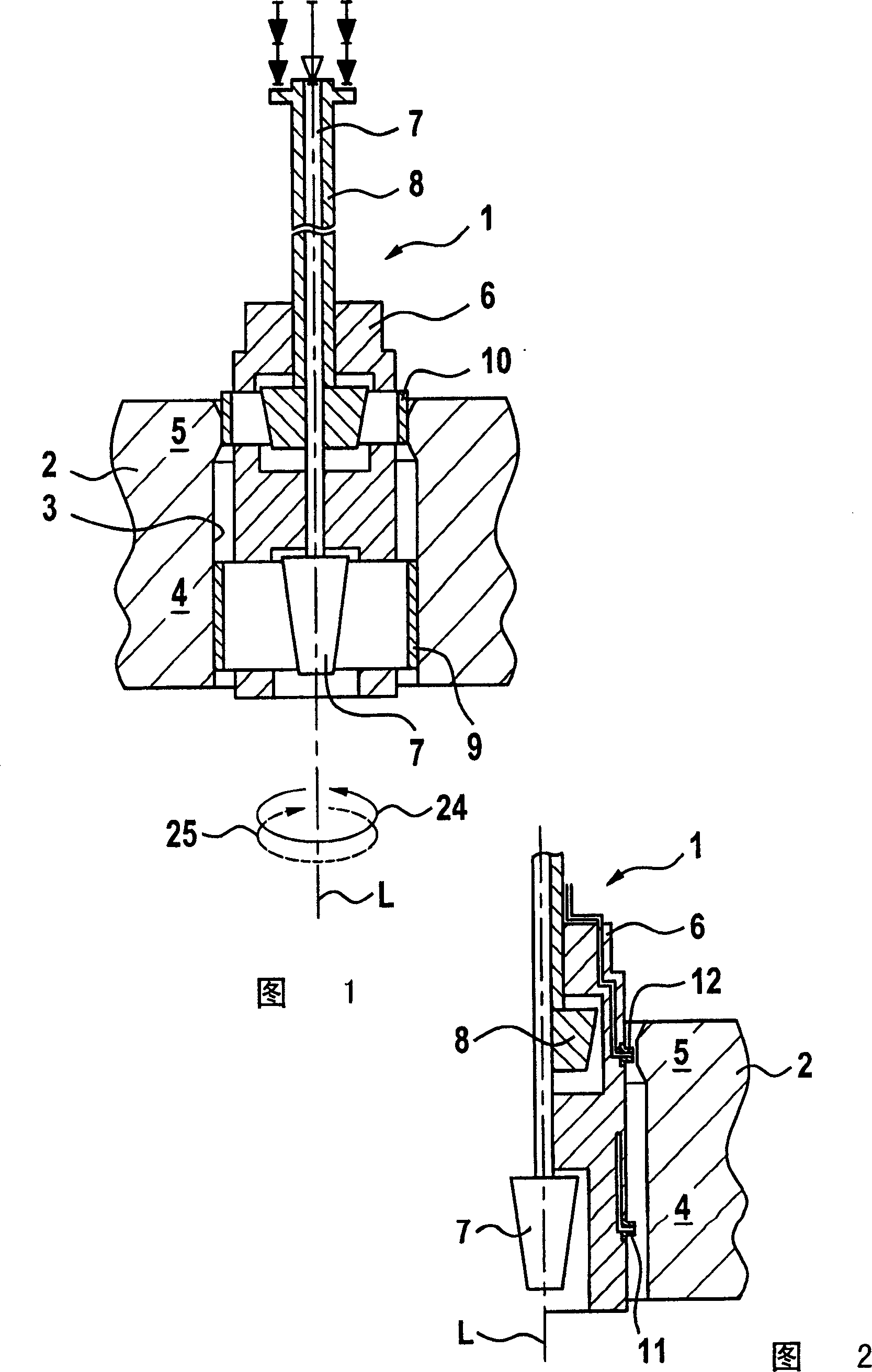

A core bit for abrasive cutting including a cylindrical tube (3) provided at its end surface with cutting or abrasive bodies (2) and a cover (4) provided at an opposite end surface of the cylindrical tube (3) and secured thereto and having, along its central axis (A), a shank (5) to be received in a rotary power tool, with the cover (4) being dimensioned, with respect to a set excitation frequency, for forming a whole number of maximum amplitude oscillations of a concentric flexural oscillation, and the cylindrical tube (3) being dimensioned, with respect to a set excitation frequency, for forming a whole number of maximum amplitude oscillations of axial longitudinal oscillations.

Owner:HILTI AG

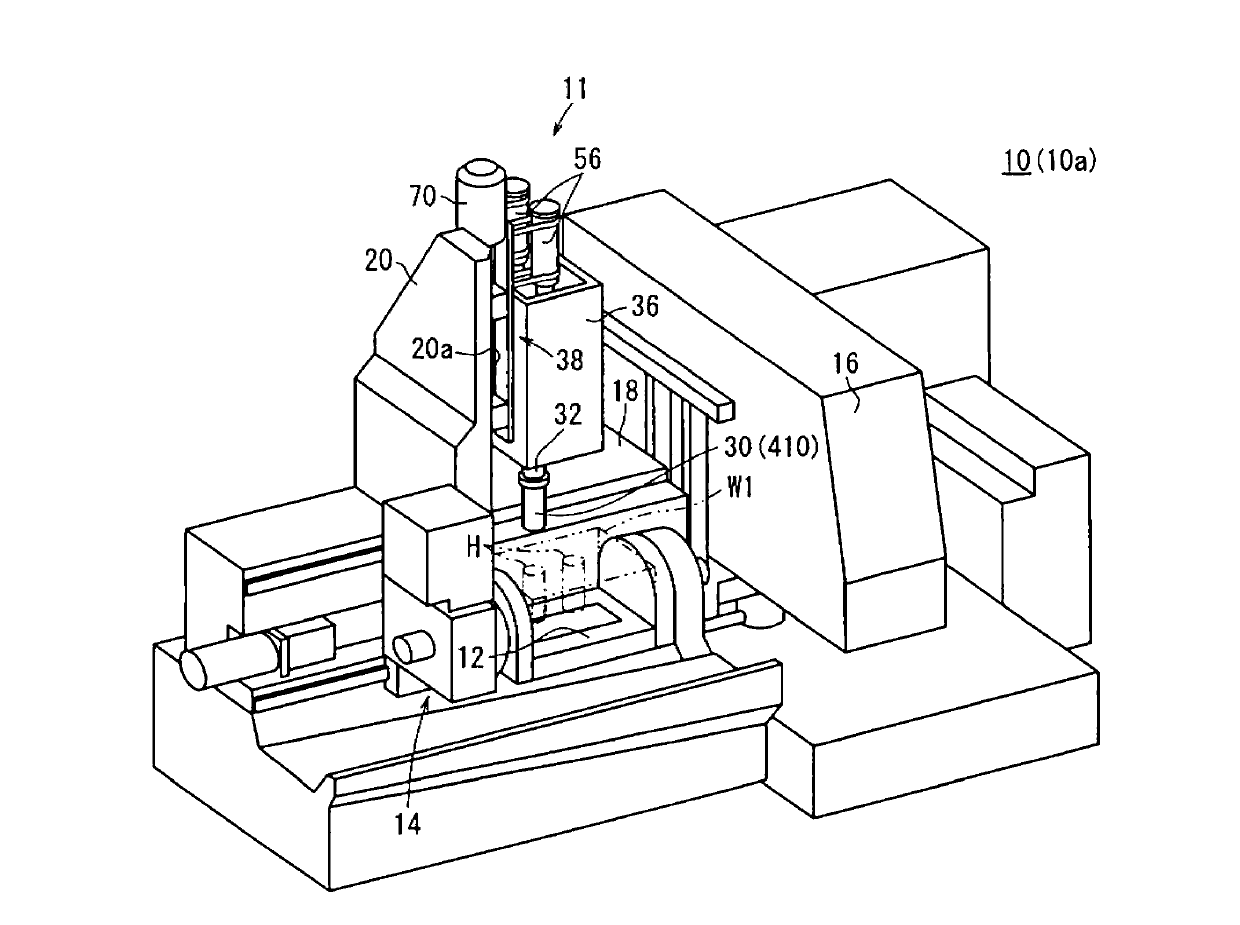

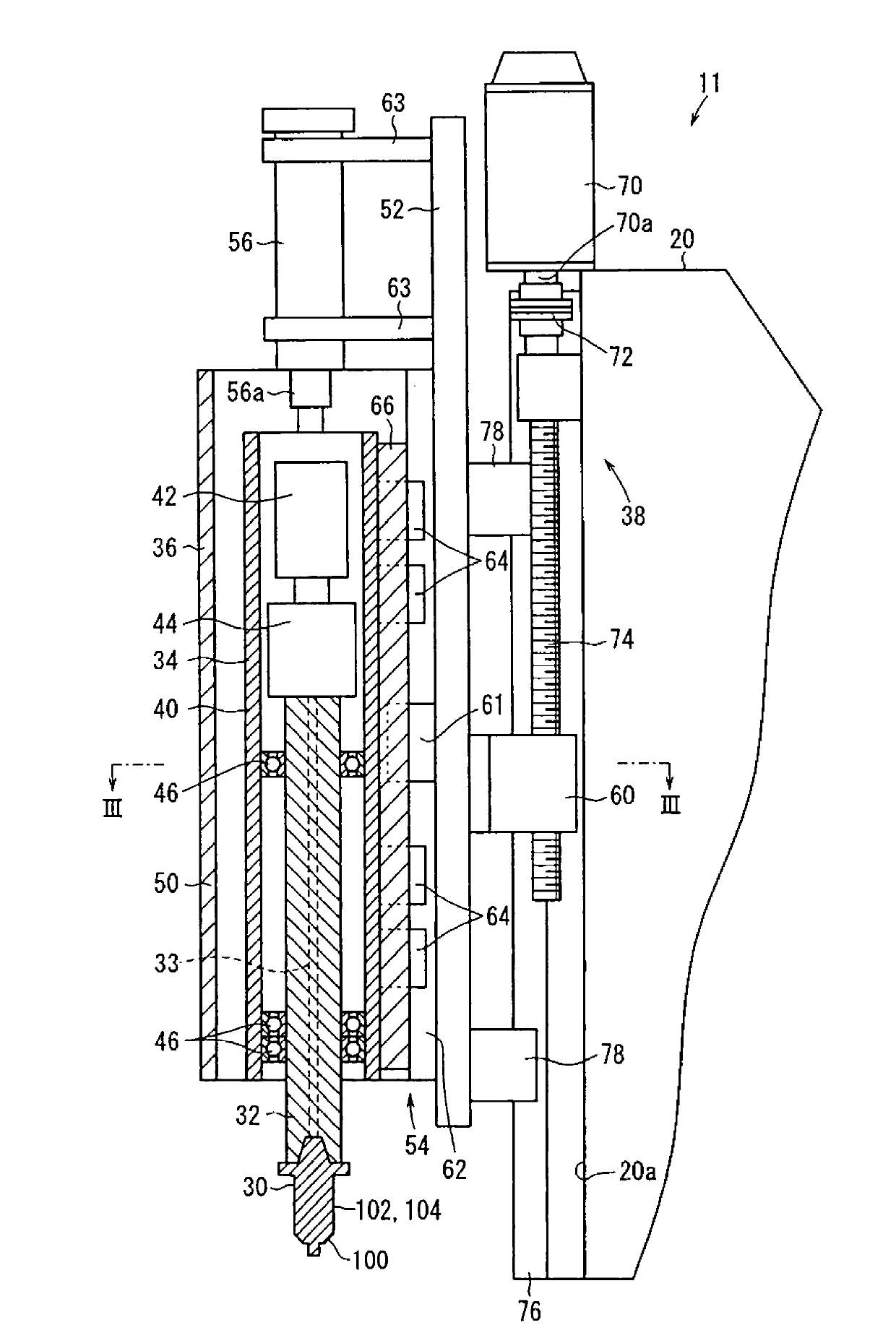

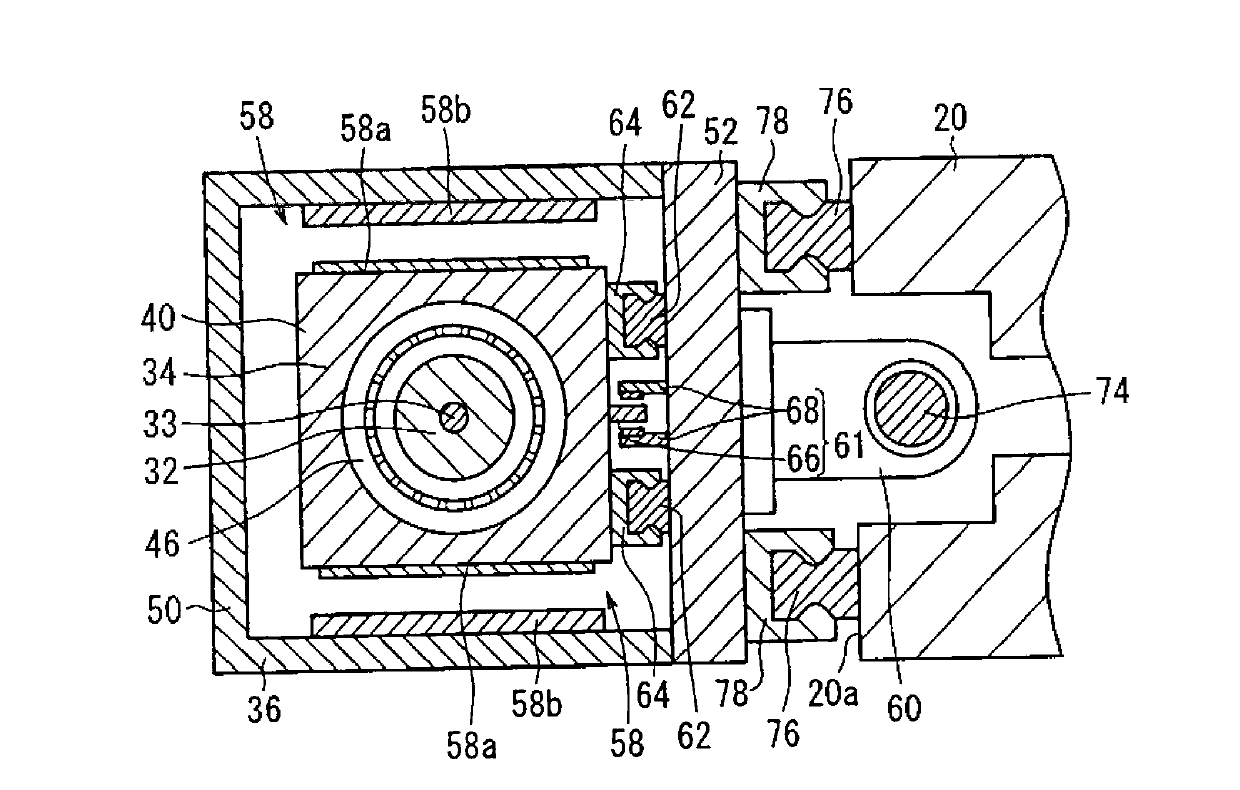

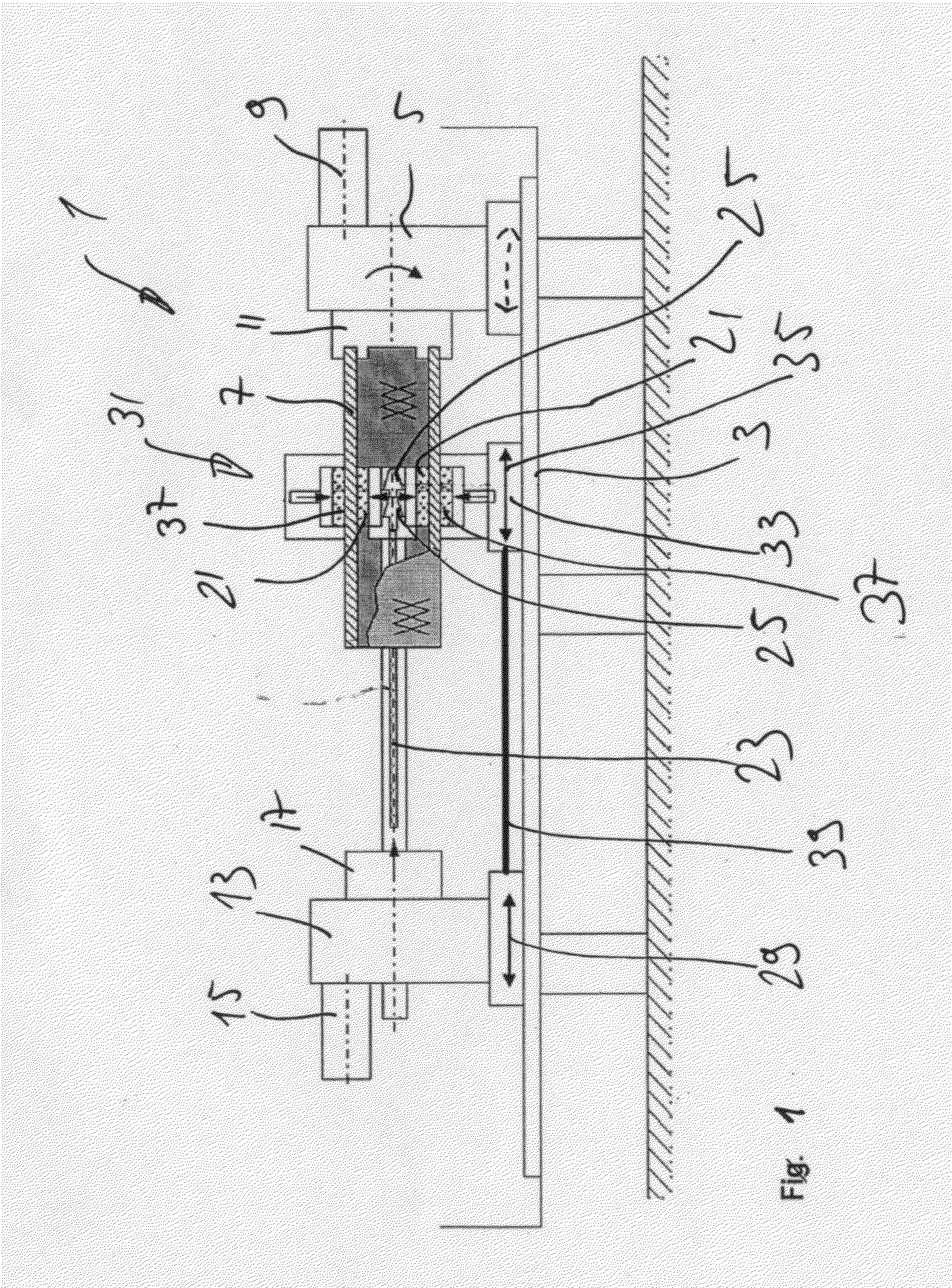

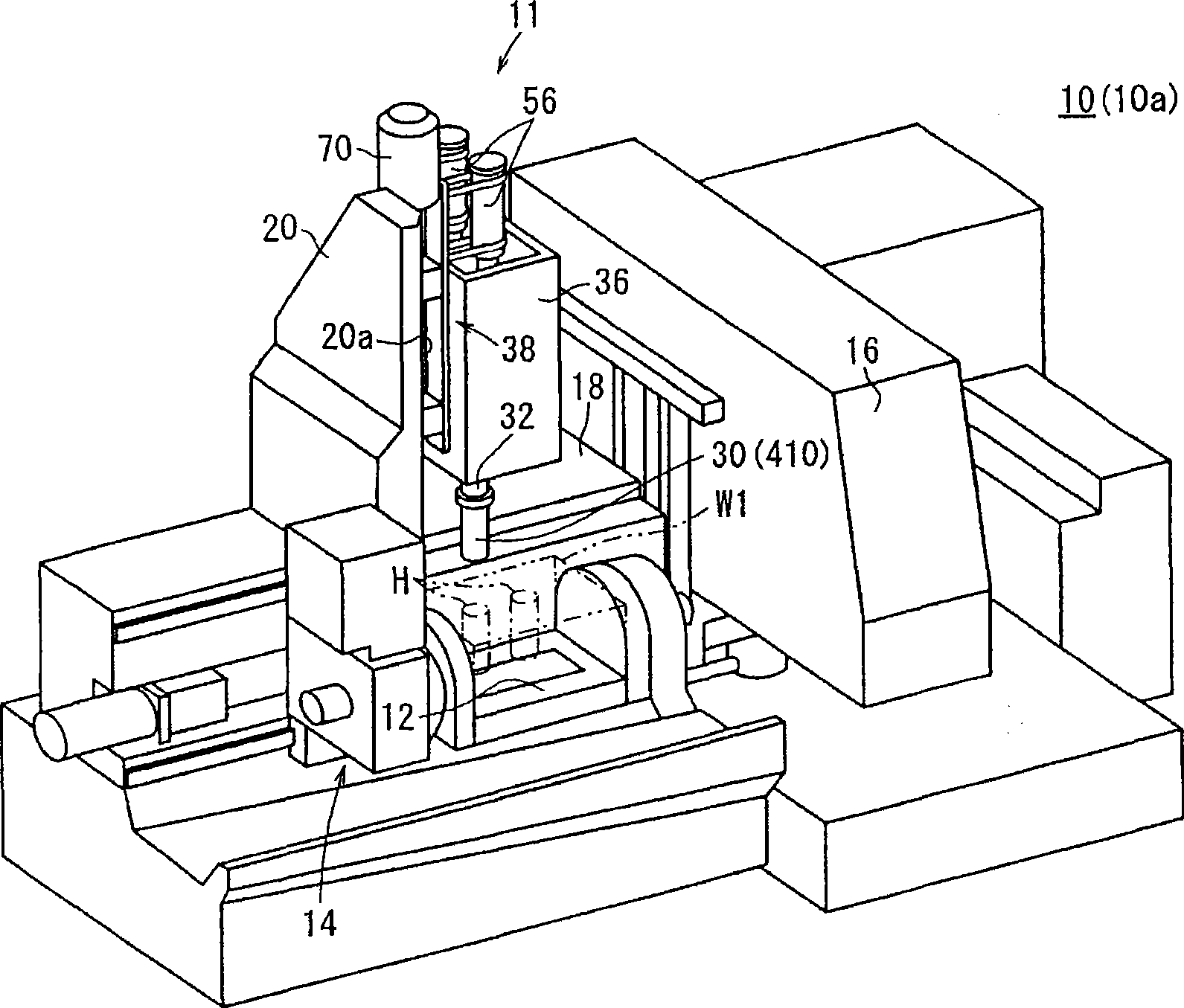

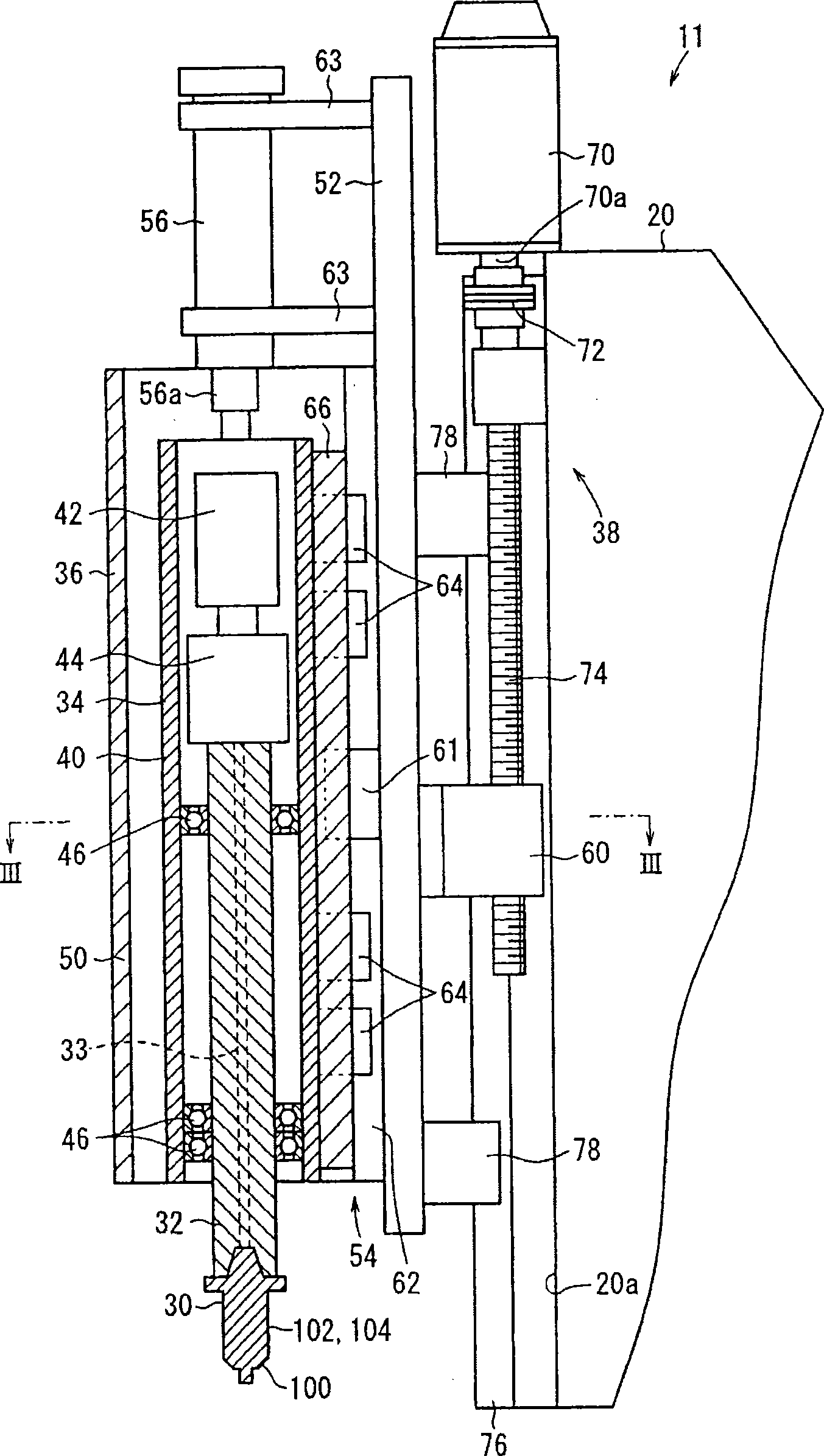

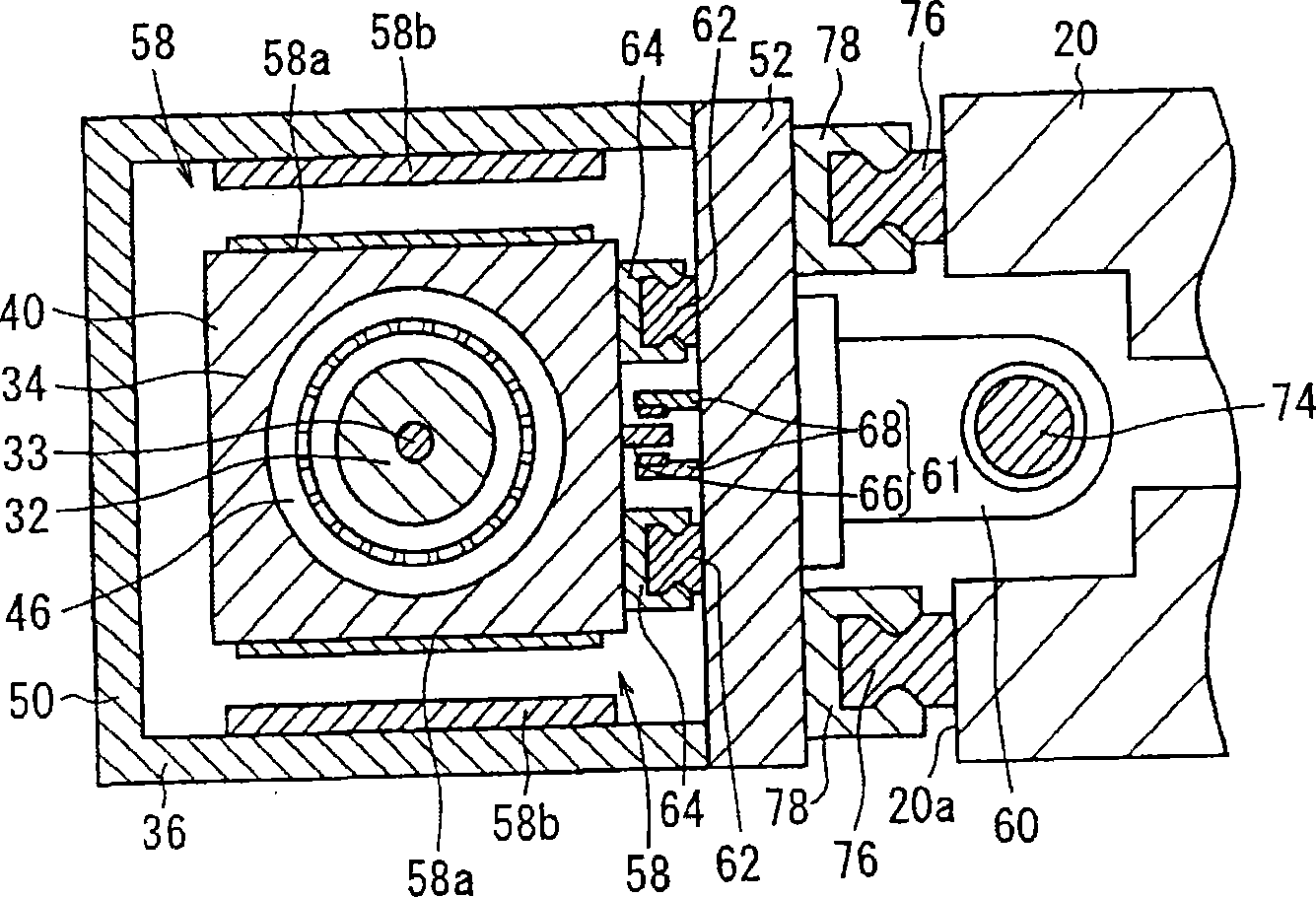

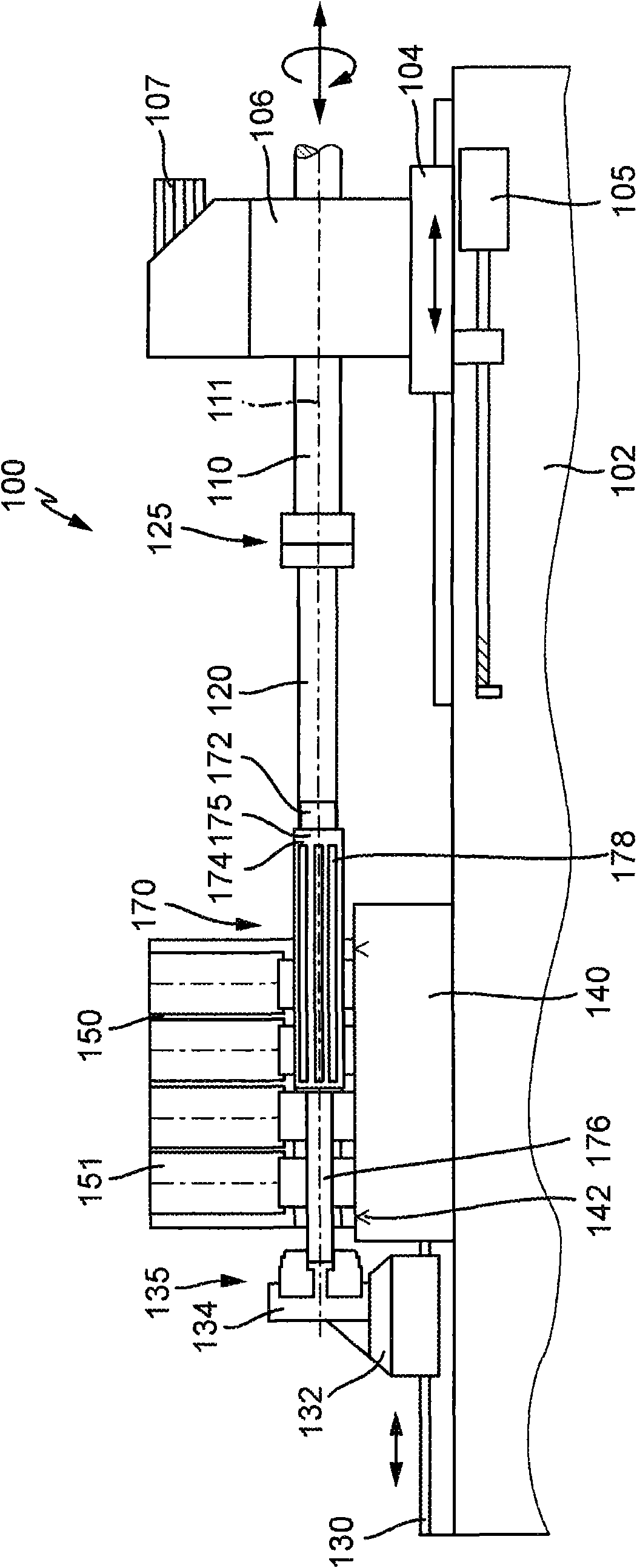

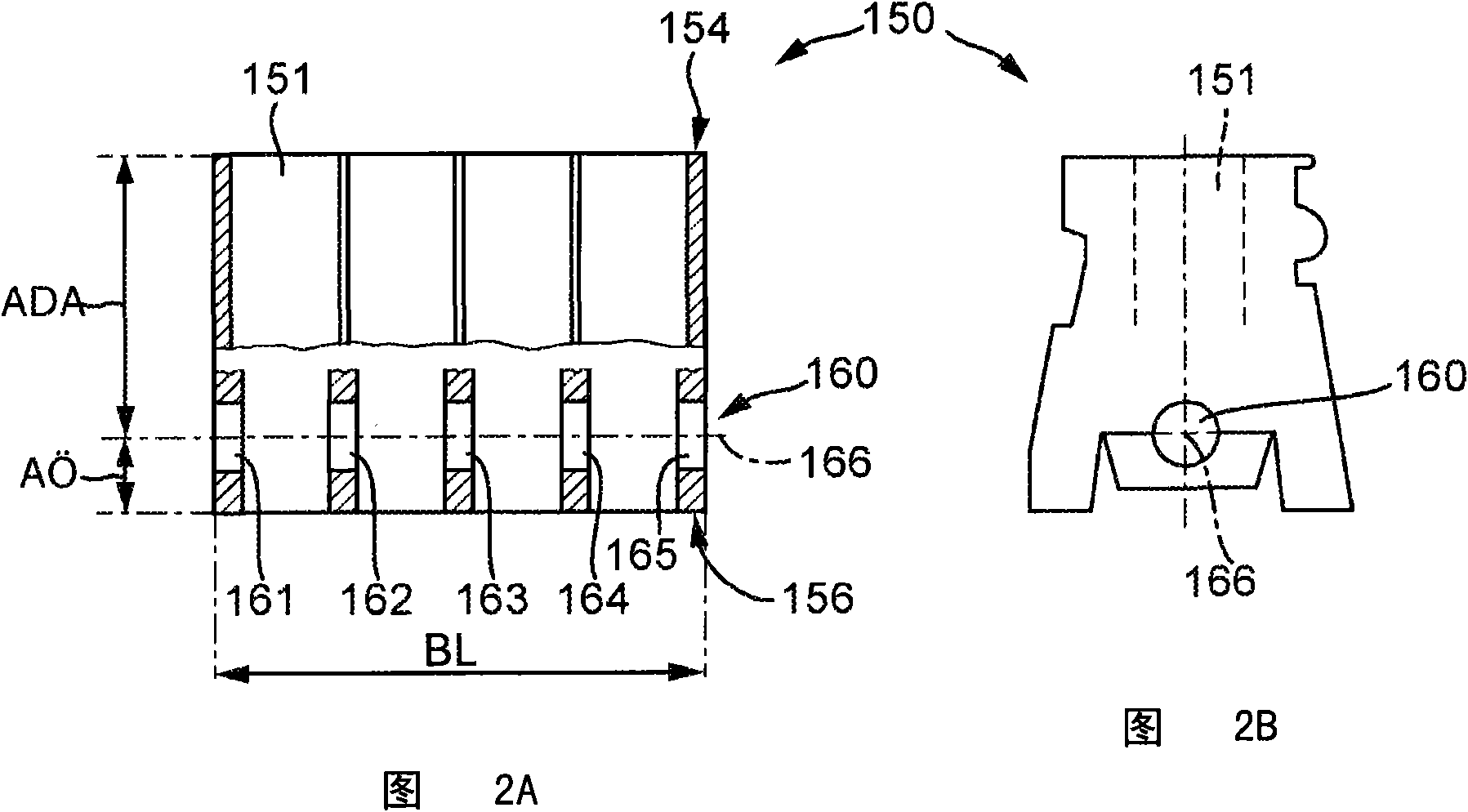

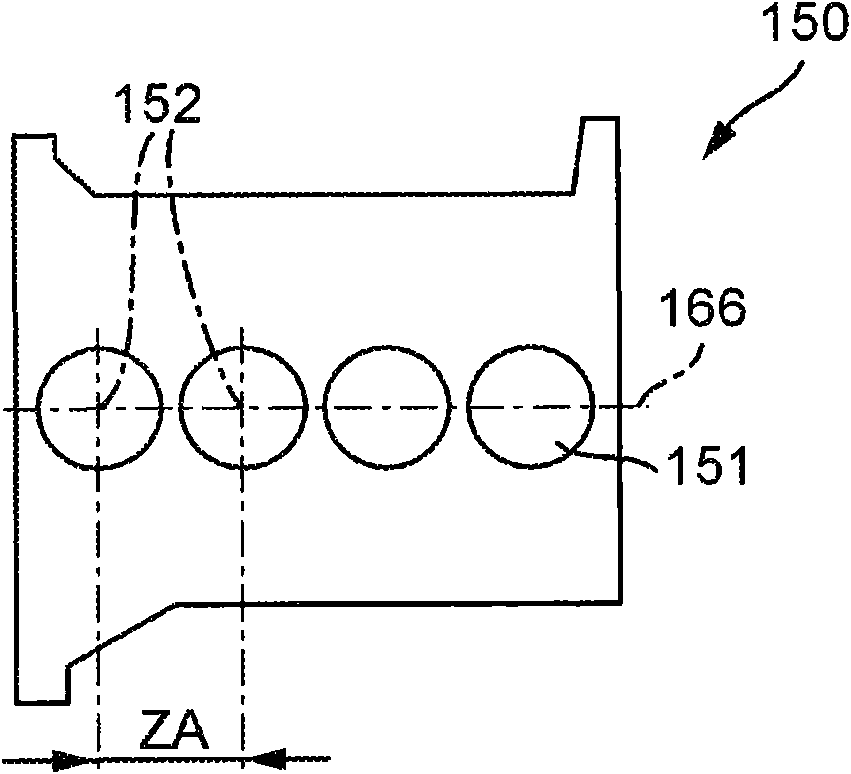

Tool head, machine tool and boring method of bore of cylinder block using the machine tool

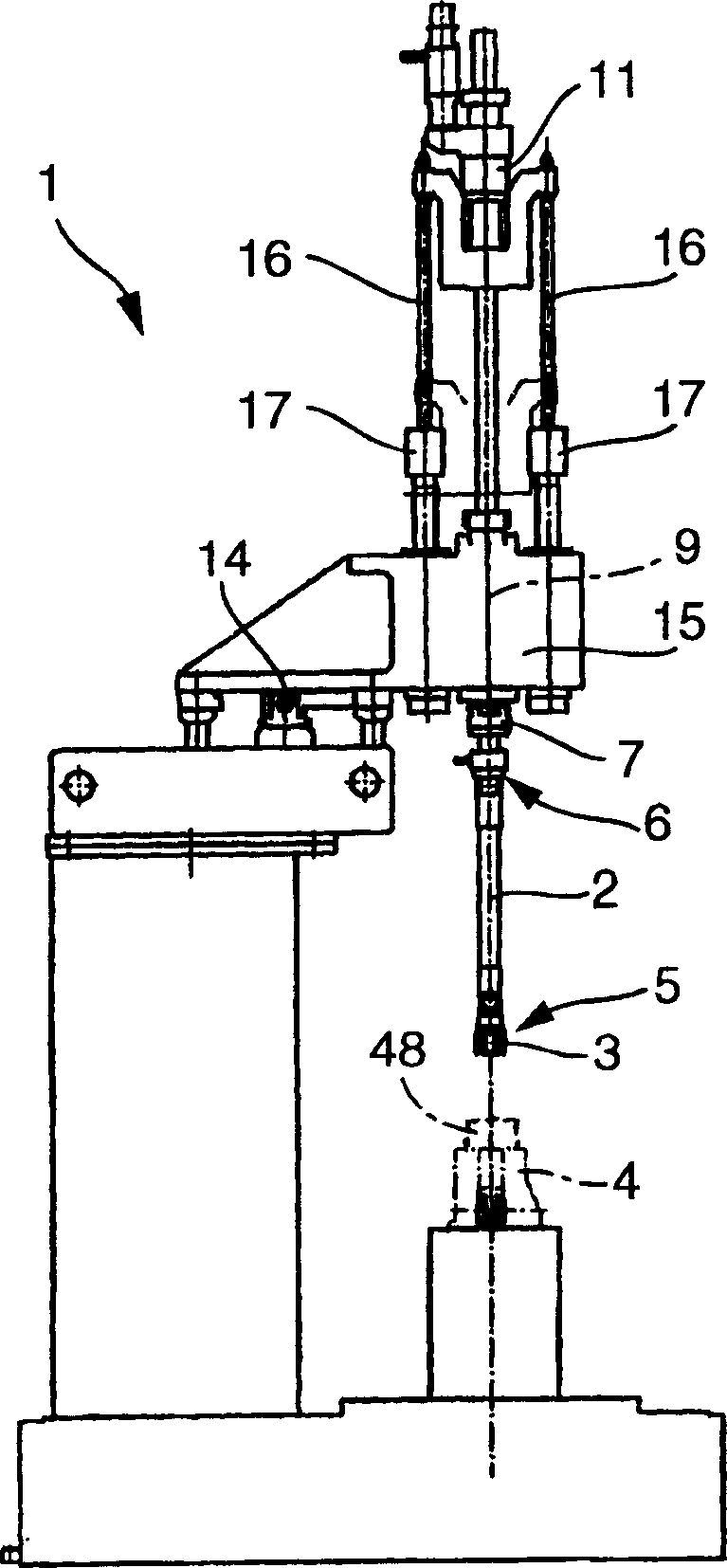

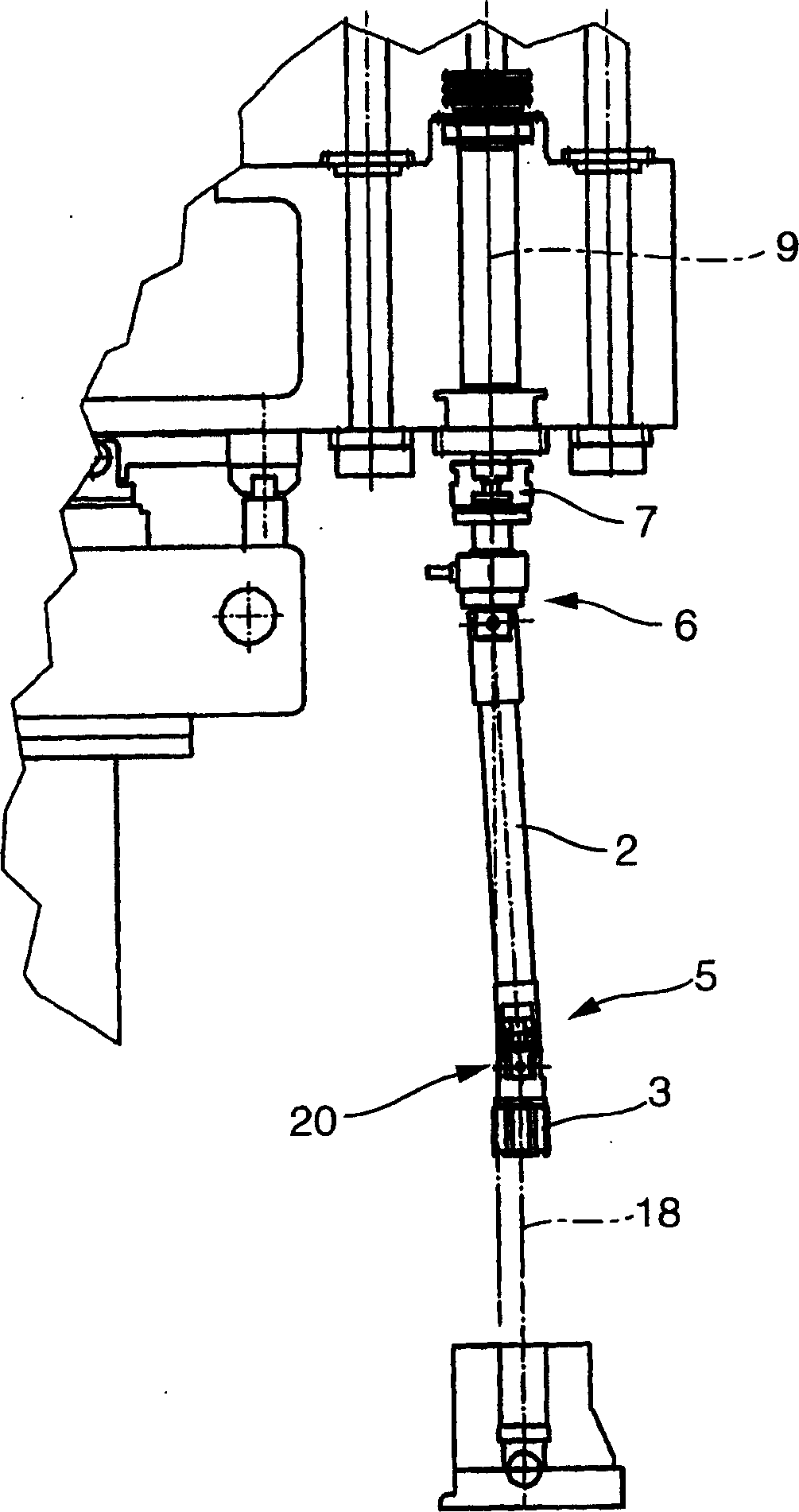

ActiveUS20090129879A1Precise processingEasy to insertThread cutting toolsGrinding machine componentsEngineeringCylinder block

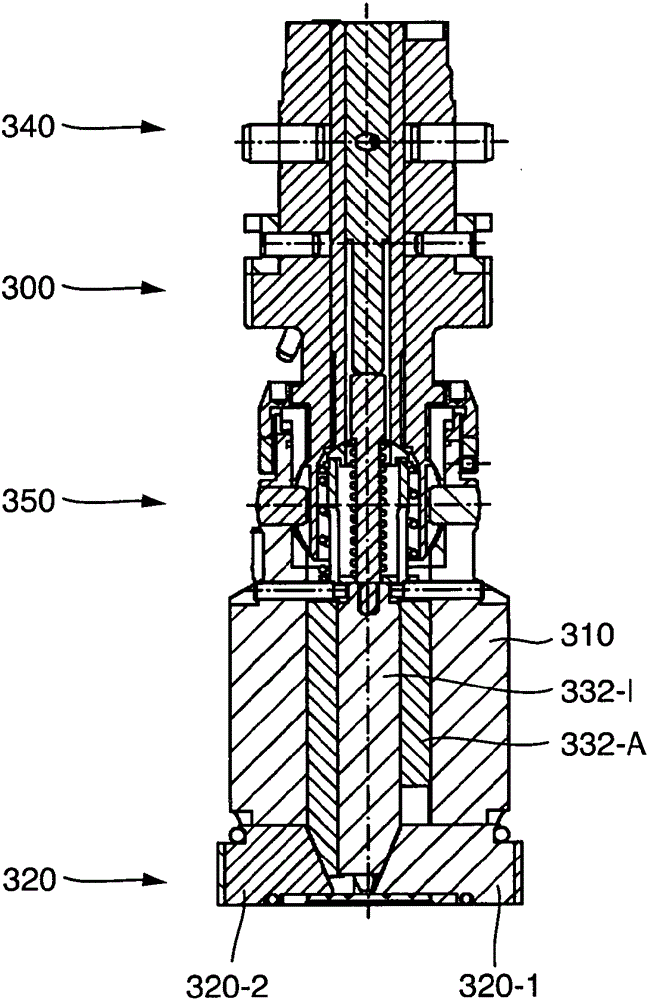

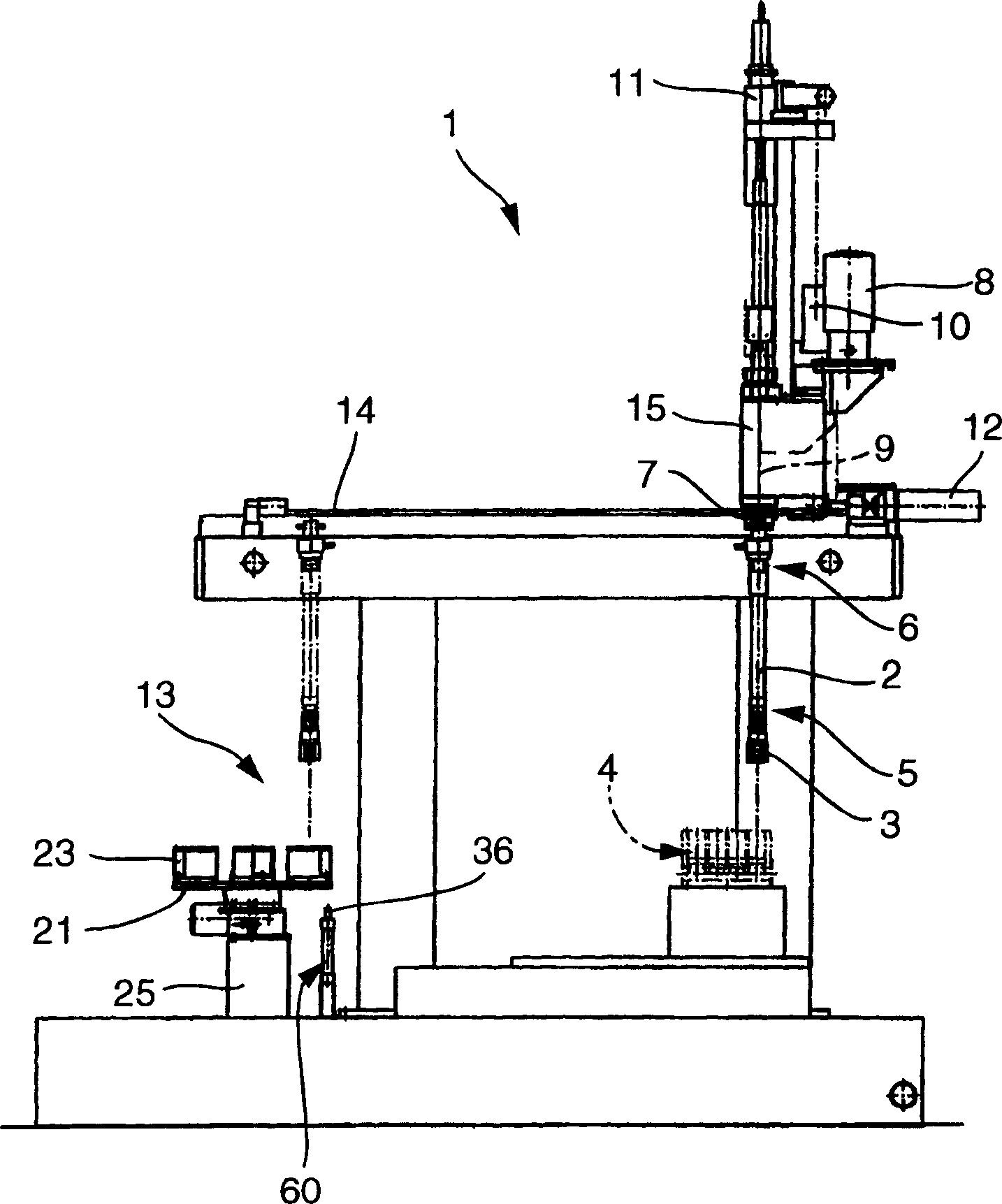

The spindle drive unit of a combined machine tool drives the spindle. The tip end of the spindle is provided with a boring tool and a tool head having a rough grinding stone and a finishing grinding stone. The spindle drive unit has a first support unit and a second support unit capable of receiving the spindle therethrough and supporting it rotatably, a linear motor and a column slide mechanism for moving the first and second support unit in the axis direction of the spindle, and a spindle motor for rotating the spindle.

Owner:HONDA MOTOR CO LTD

Honing strip and manufacturing method thereof

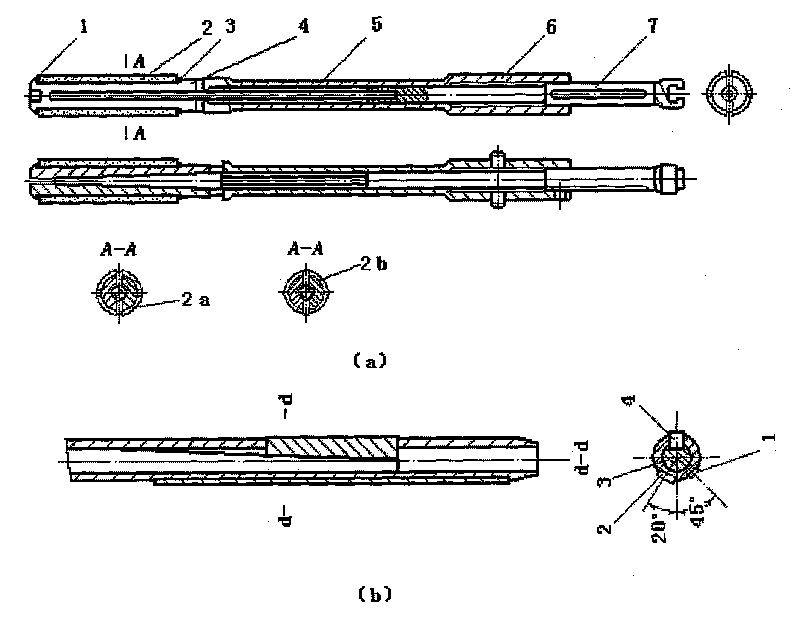

The invention provides a honing strip and a manufacturing method thereof. The method comprises the following steps of: mixing first metal powder prepared from components in a predetermined proportion and nonmetal powder such as graphite, Fe3O4 or MoS2 to form a bonding agent, adding a predetermined amount of abrasive such as diamond or cubic boron nitride (CBN for short) into the bonding agent, and performing granulation to obtain working layer granules; performing granulation on second metal powder to obtain transition layer granules; arranging the working layer granules in a first die to form a working layer of the honing strip, arranging the transition layer granules in the first die and on the working layer to form a transition layer, and pressing the first die to form a preformed honing strip; and charging the preformed honing strip into a second die, and performing hot pressing forming to obtain the honing strip. The honing strip has the characteristics of good exposure effect, low grinding resistance, low heating deformation of a honing head, long durability, high precision of machined workpieces, good finishment and the like.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD +1

Flexible tool for plateauing a surface

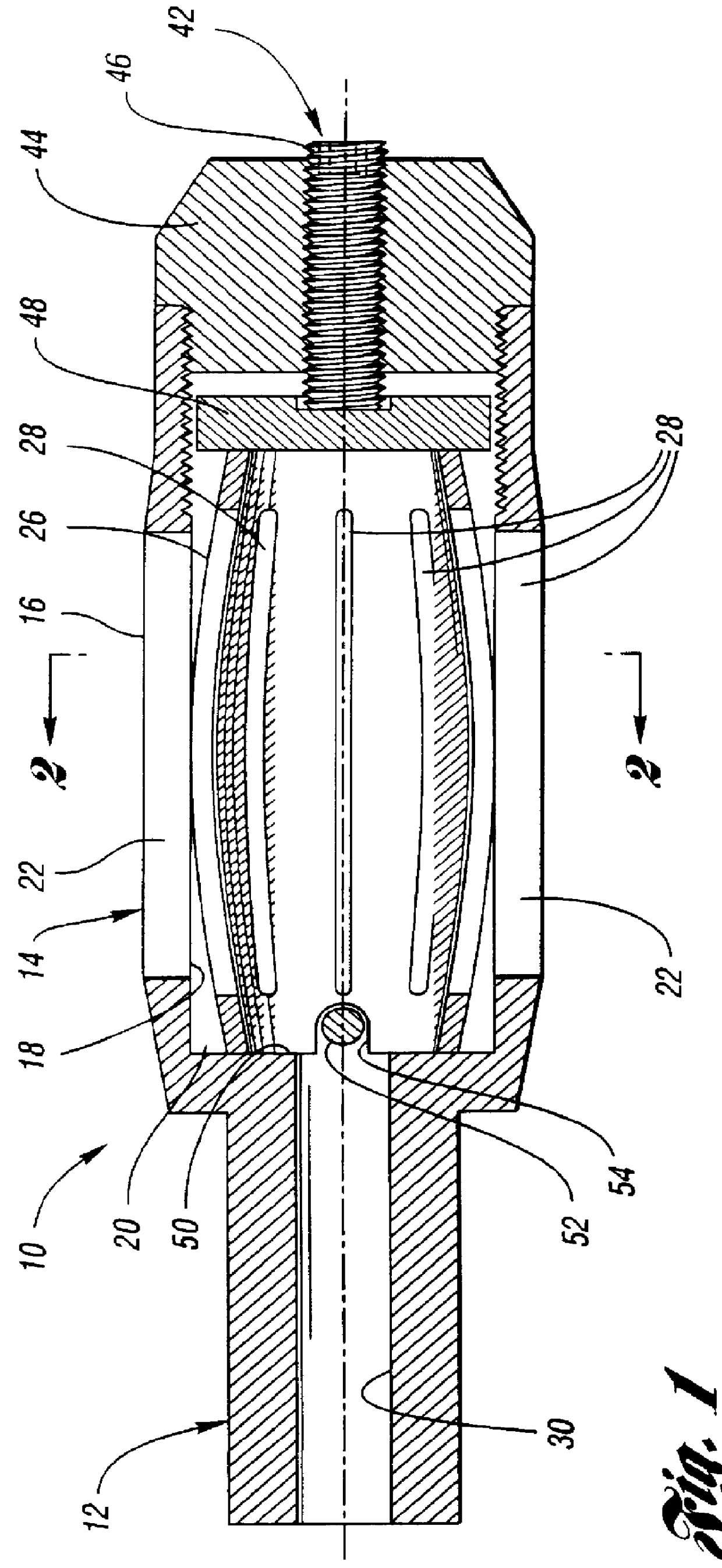

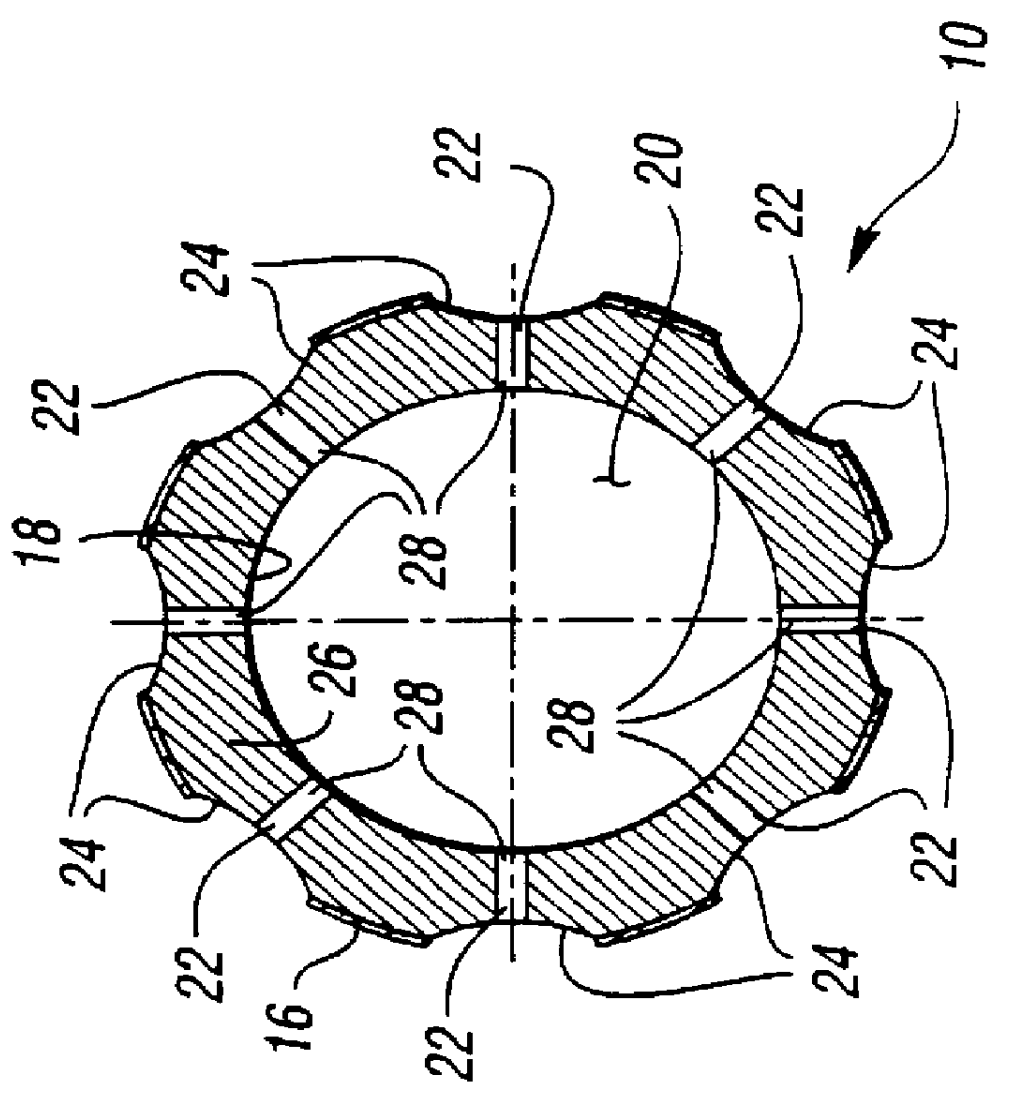

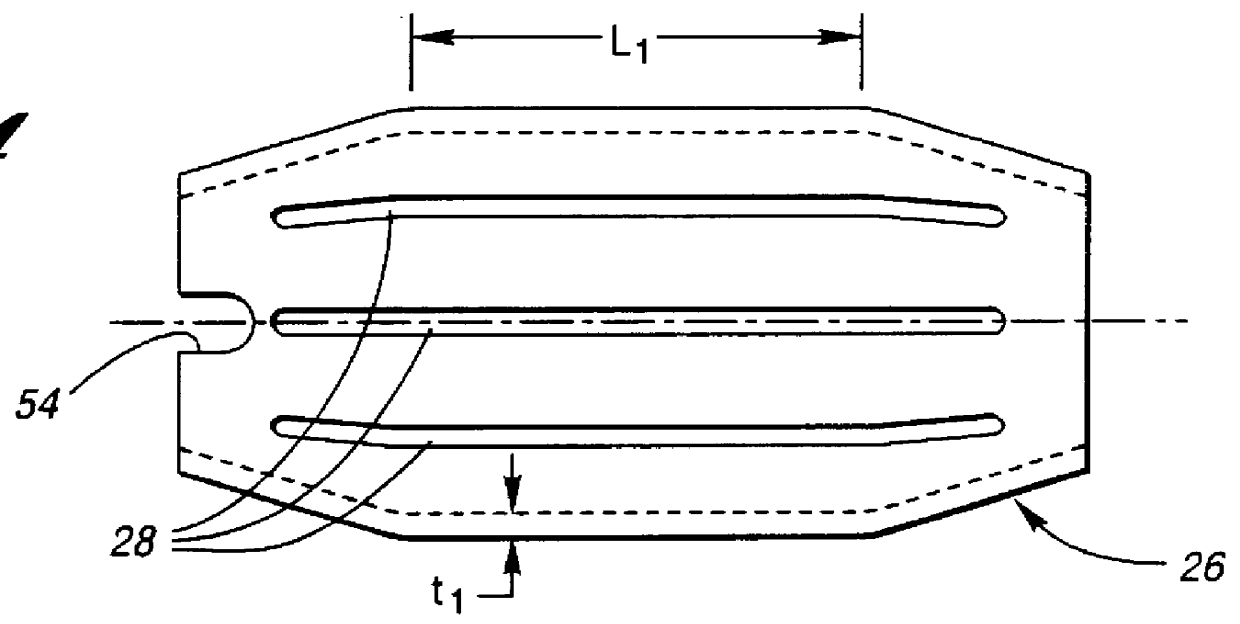

InactiveUS6139414ANabling "plateauing" of the bore surfaceRaise the ratioEdge grinding machinesSupport wheelsCoolant flowEngineering

The present invention provides a radially expandable plateauing tool for finishing bore surfaces. The tool includes a shank for attachment to a means for rotation, and a substantially cylindrical portion including an outer work-engaging surface including abrasive particles secured thereto, and an inner surface defining a bore therethrough with at least one longitudinal split permitting radial expansion and contraction of the cylindrical portion. A metallic spring is disposed within the bore and a threaded bolt assembly or other device is provided for applying an axial compressive force on the spring such that the spring exerts a radial expansive force on the cylindrical portion causing the cylindrical portion to expand to adjust the outer work-engaging surface. The spring is comprised with longitudinal splits aligned with corresponding longitudinal splits on the cylindrical portion to permit coolant flow therethrough.

Owner:ACCU CUT DIAMOND TOOL

Tool head, machine tool and boring method of bore of cylinder block using the machine tool

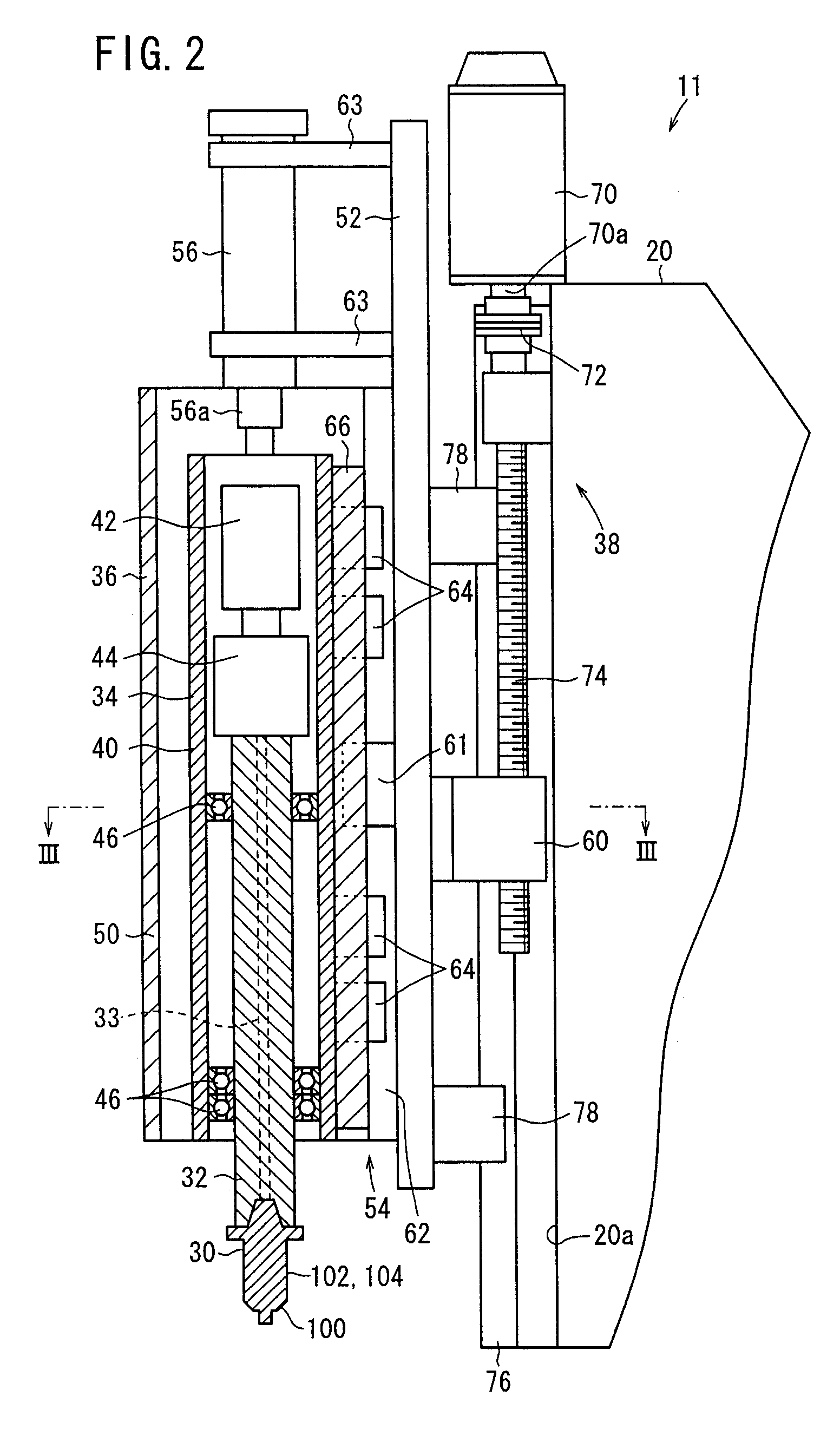

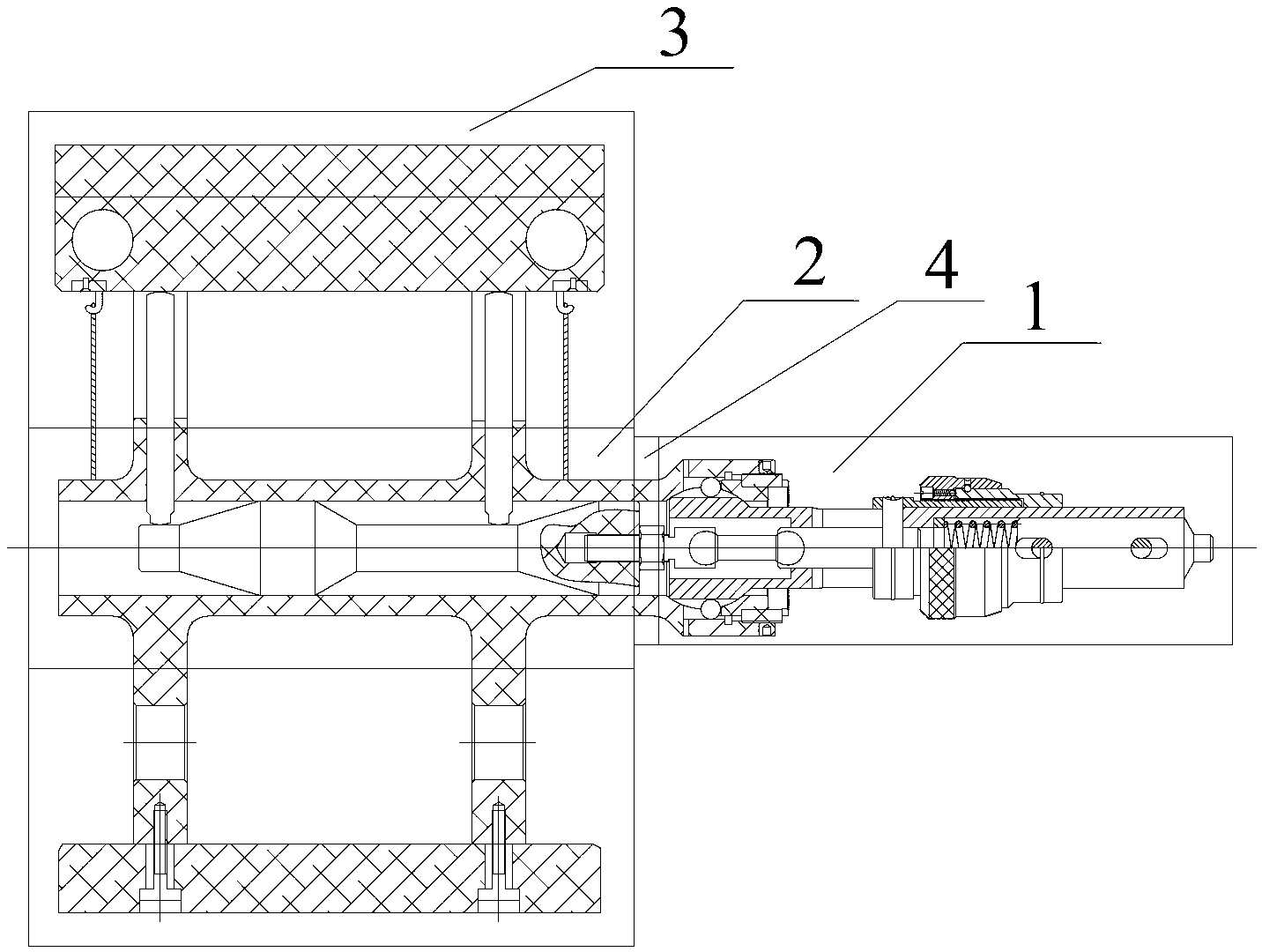

ActiveCN103128554AIncrease productivity in manufacturingLess bendingGrinding machine componentsHoning toolsTool bitLinear motor

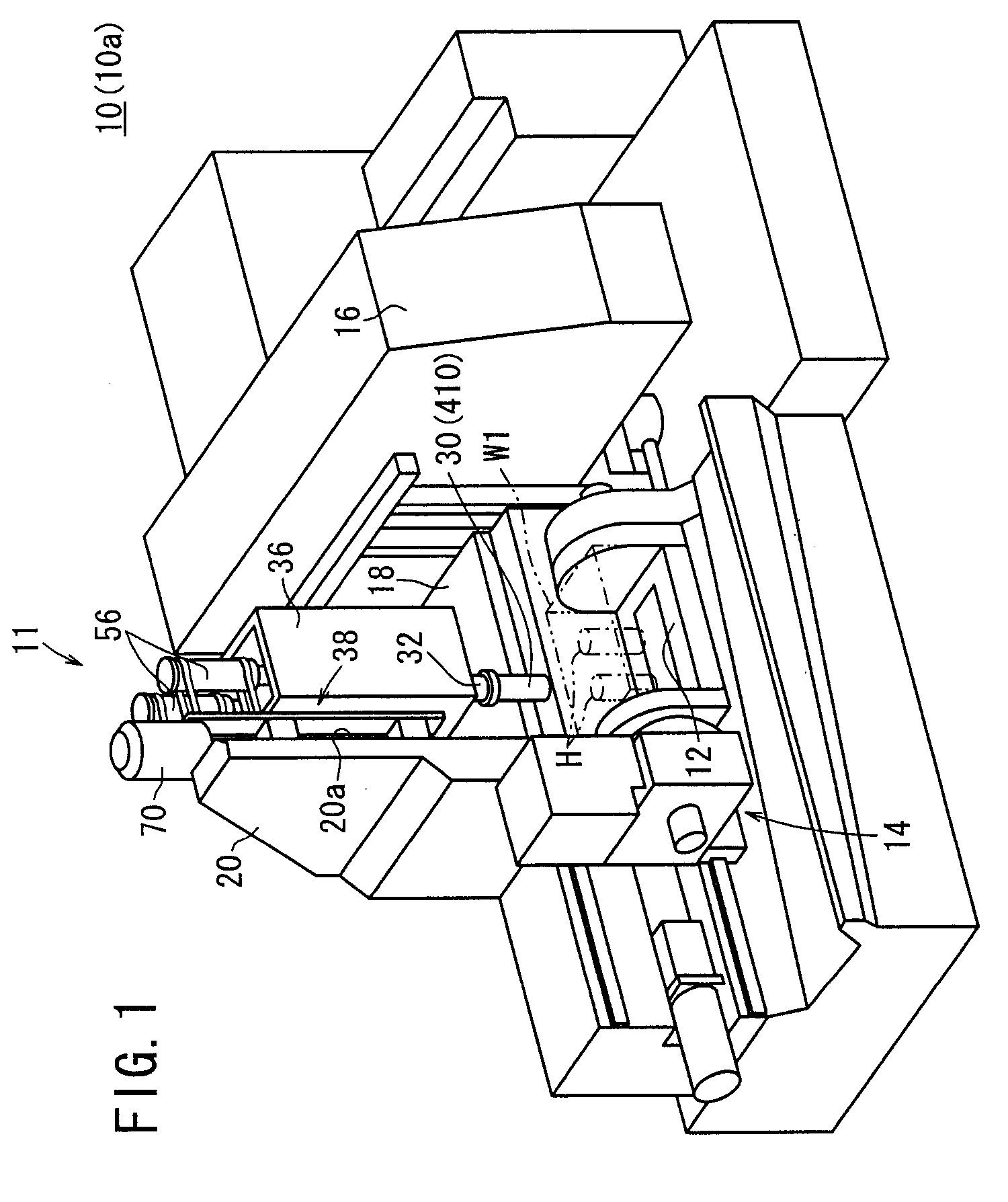

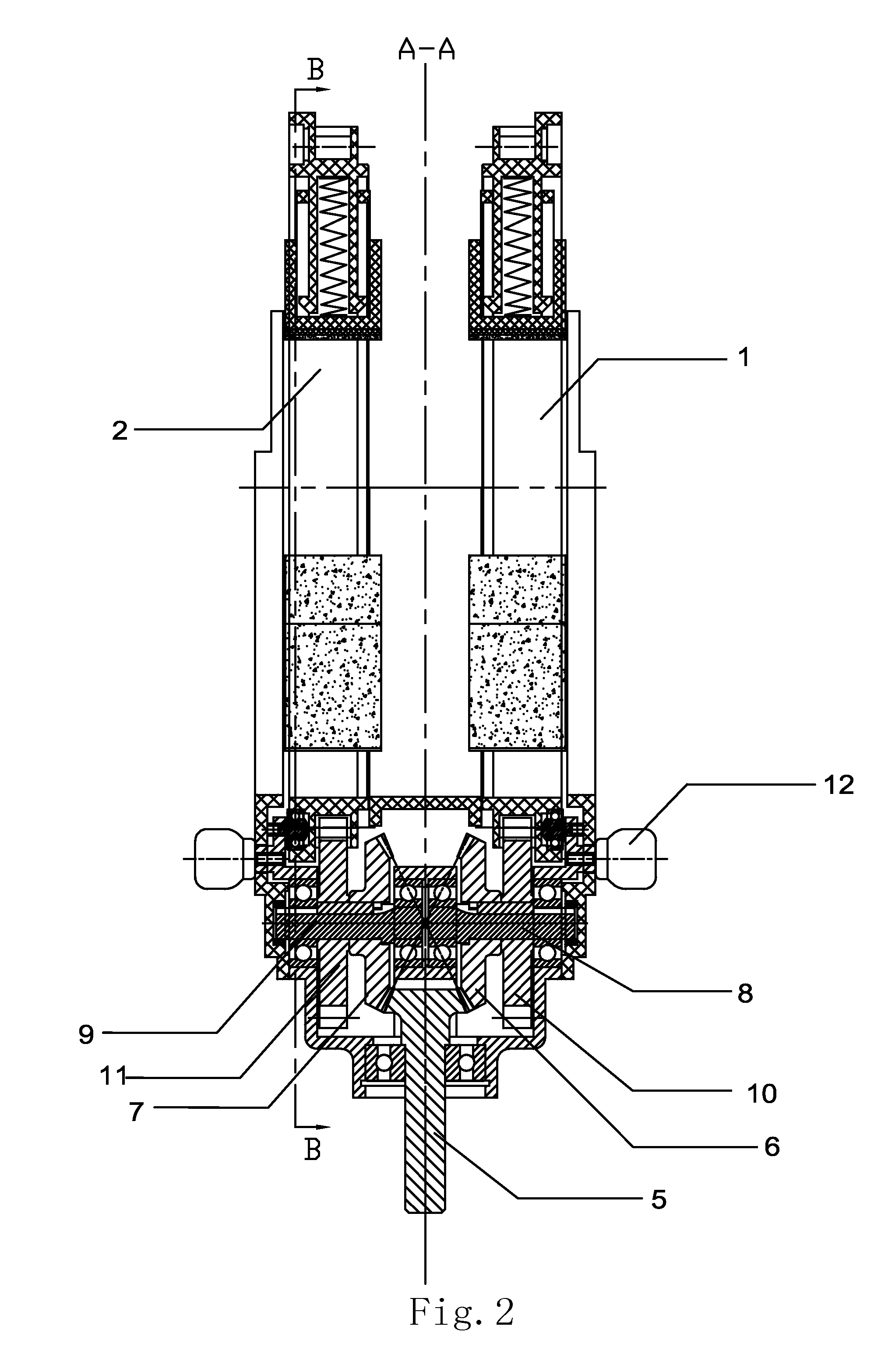

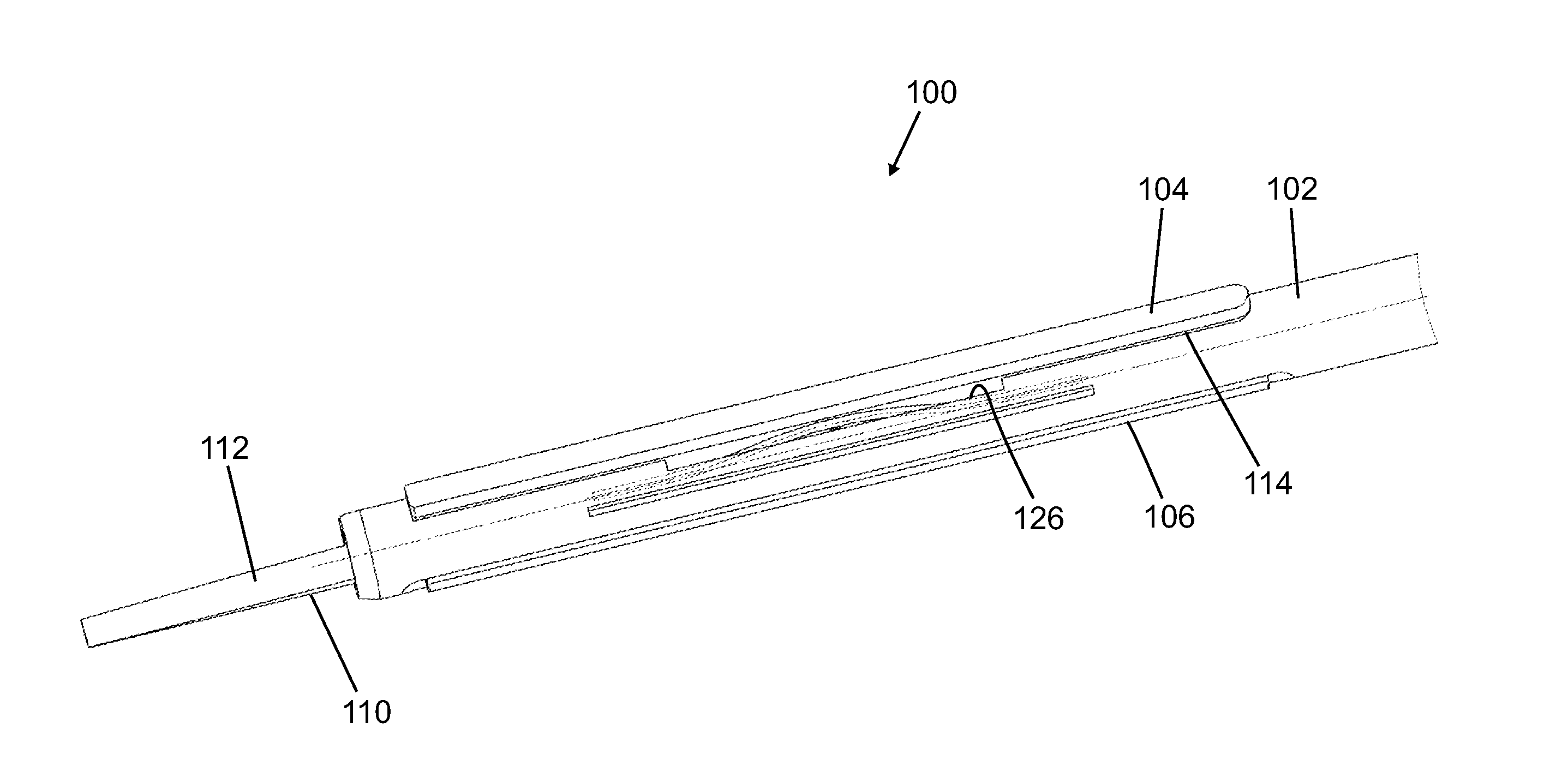

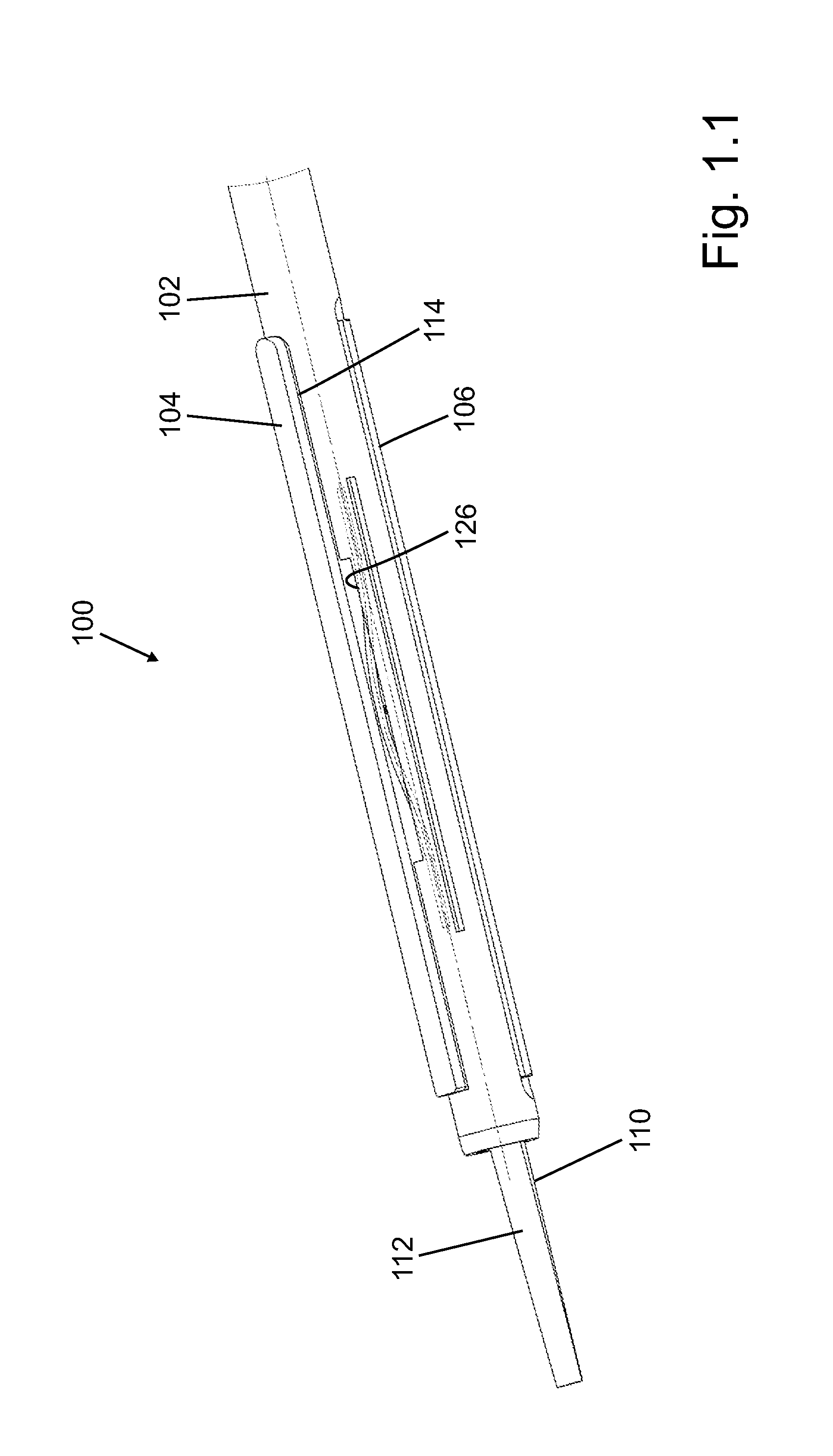

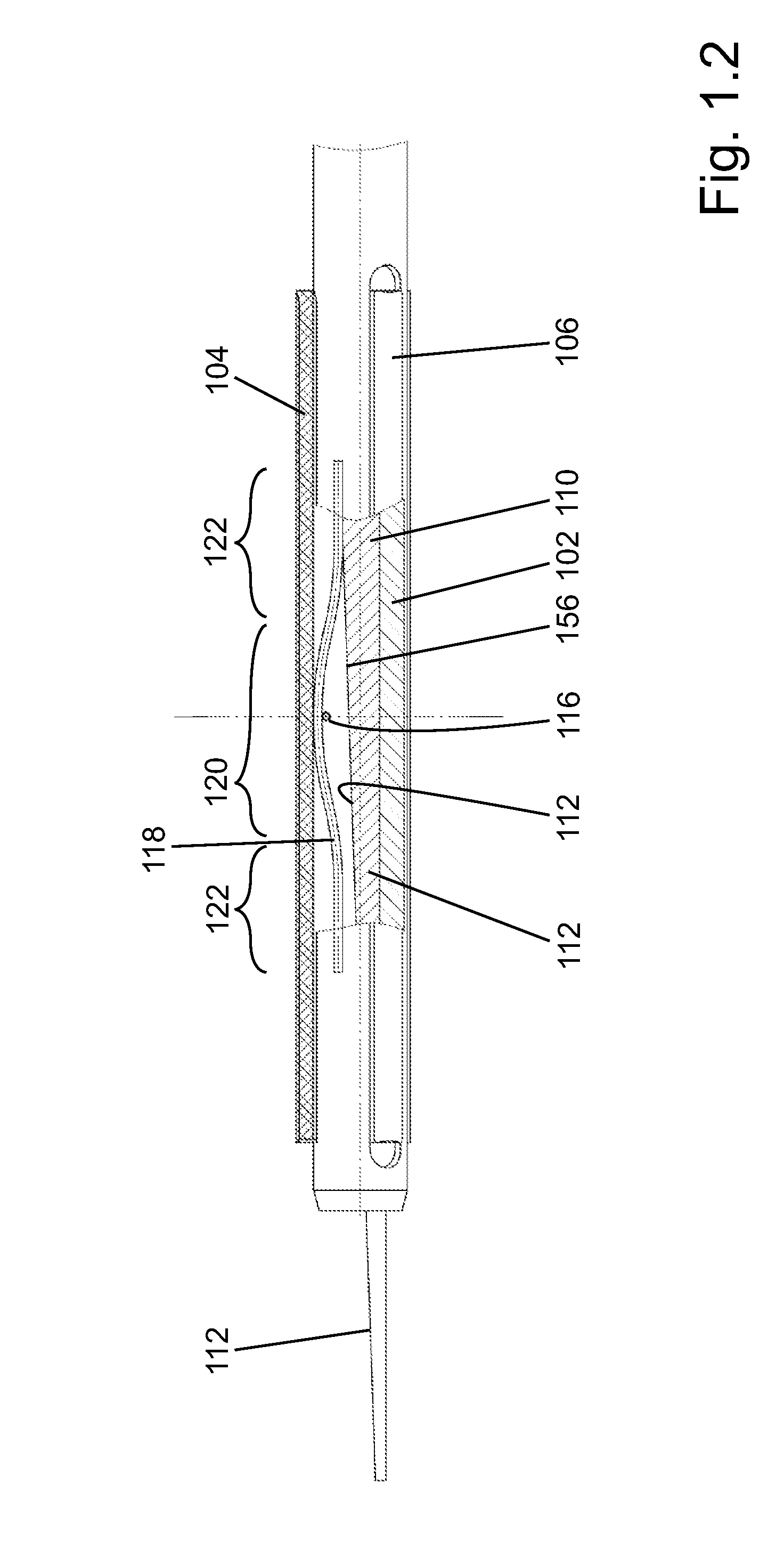

The invention relates to a tool head, a machine tool and a boring method of bore of cylinder block using the machine tool. The spindle drive unit (11) of a combined machine tool (10) drives the spindle (32). The tip end of the spindle (32) is provided with a boring tool (100) and a tool head (30) having a rough grinding stone (102) and a finishing grinding stone (104). The spindle drive unit (11) has a first support unit (34) and a second support unit (36) capable of receiving the spindle (32) therethrough and supporting it rotatably, a linear motor (58) and a column slide mechanism (38) for moving the first and second support unit (34, 36) in the axis direction of the spindle (32), and a spindle motor (44) for rotating the spindle (32).

Owner:HONDA MOTOR CO LTD

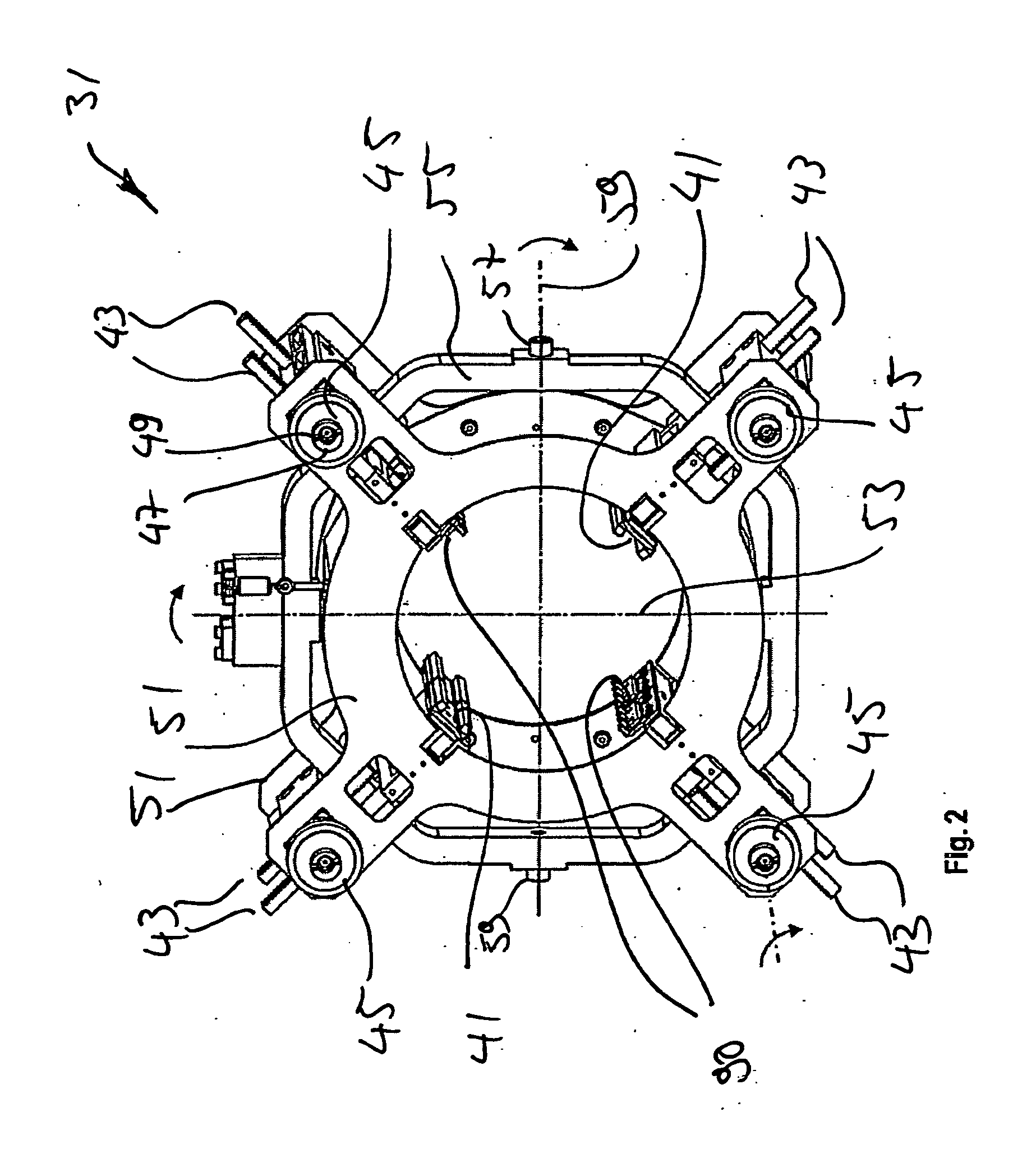

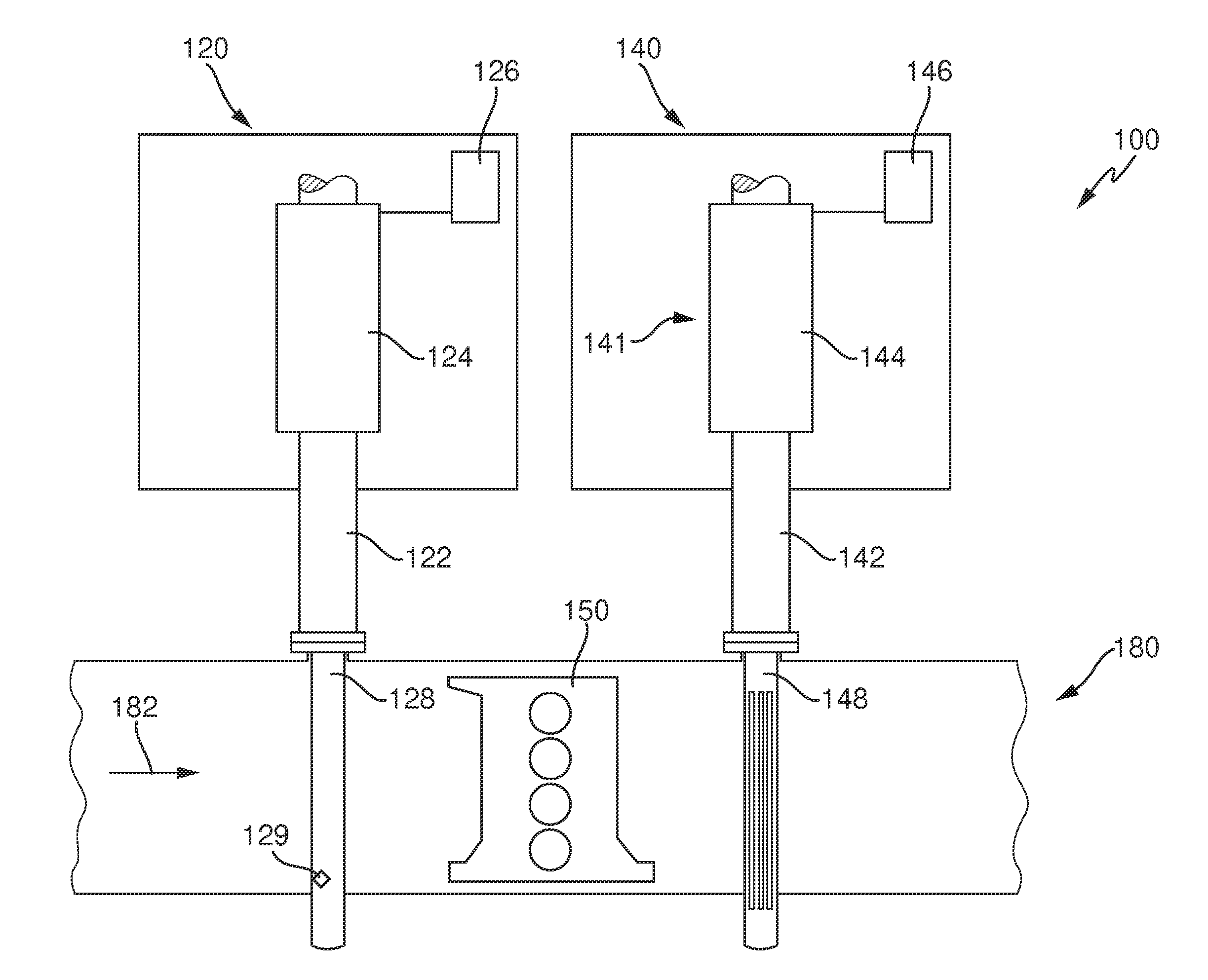

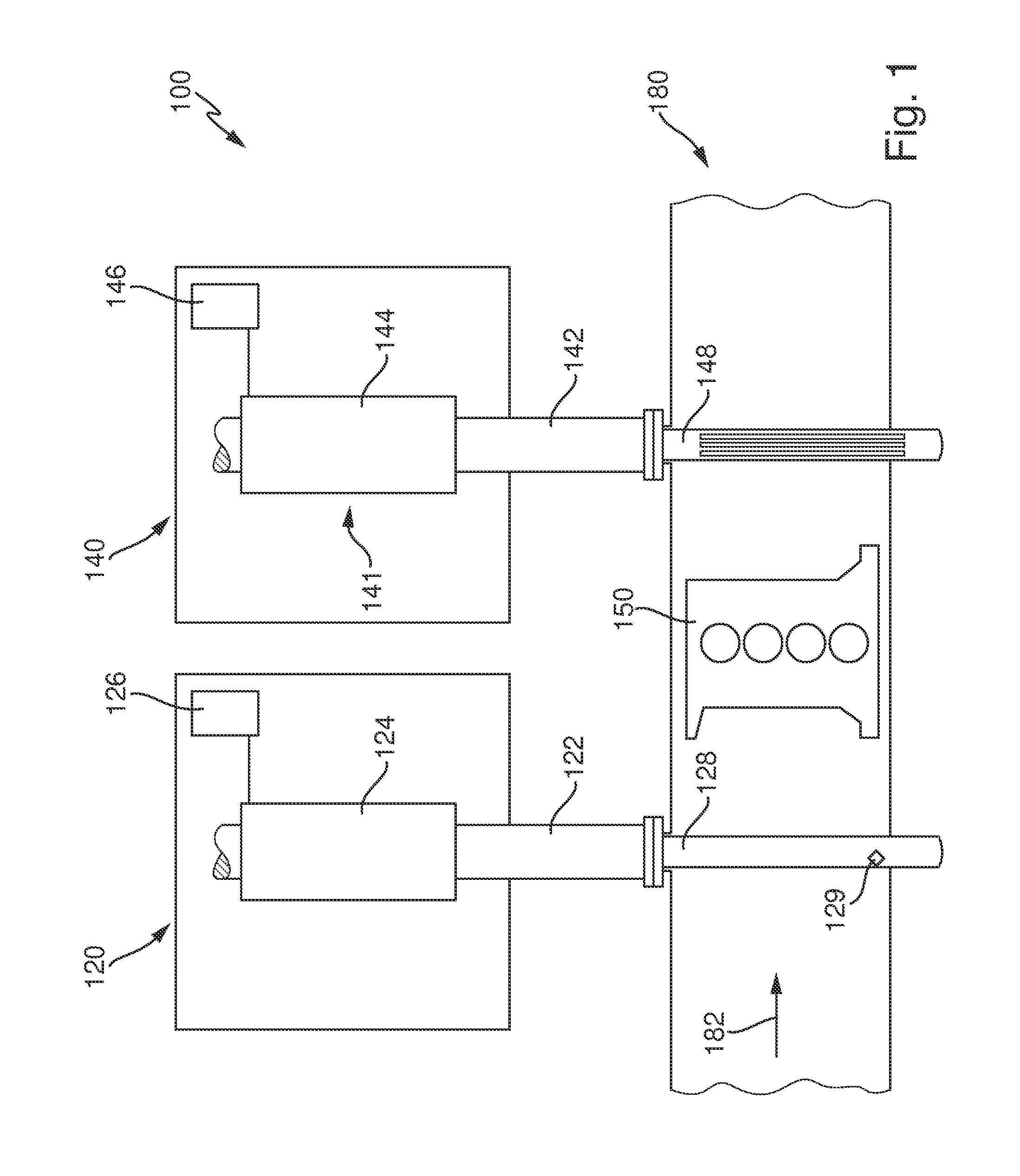

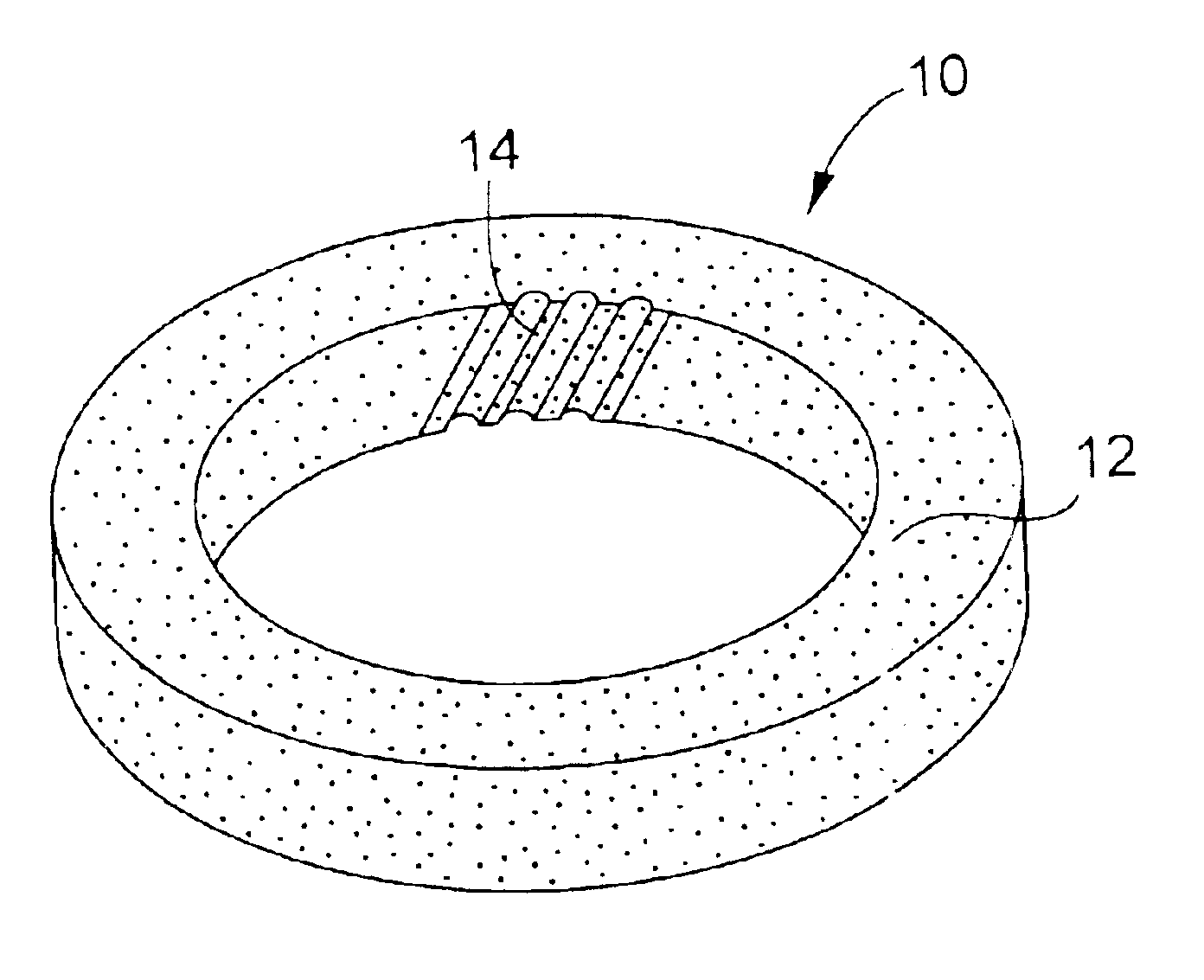

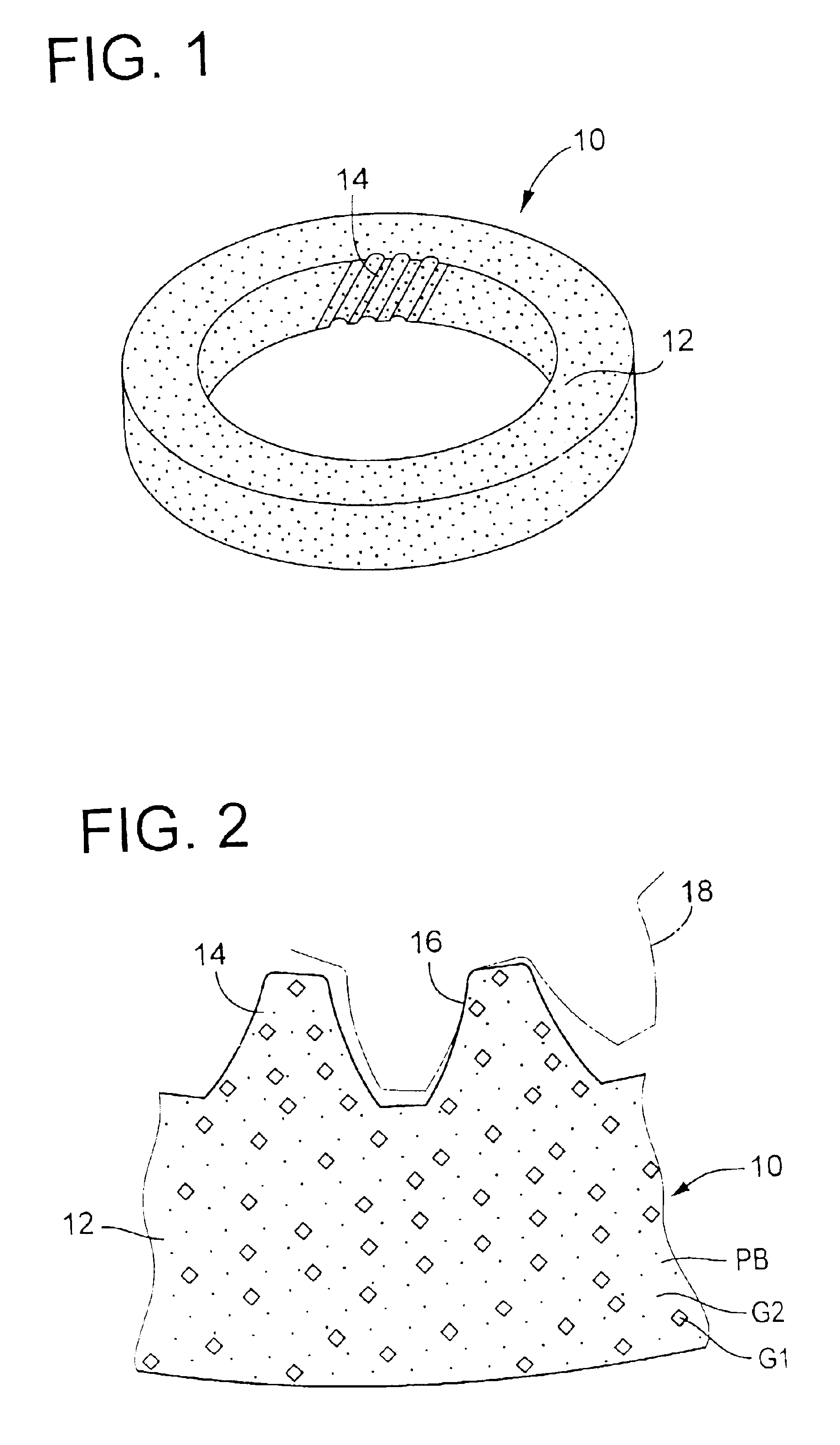

Honing Machine for Inner Honing and Outer Honing

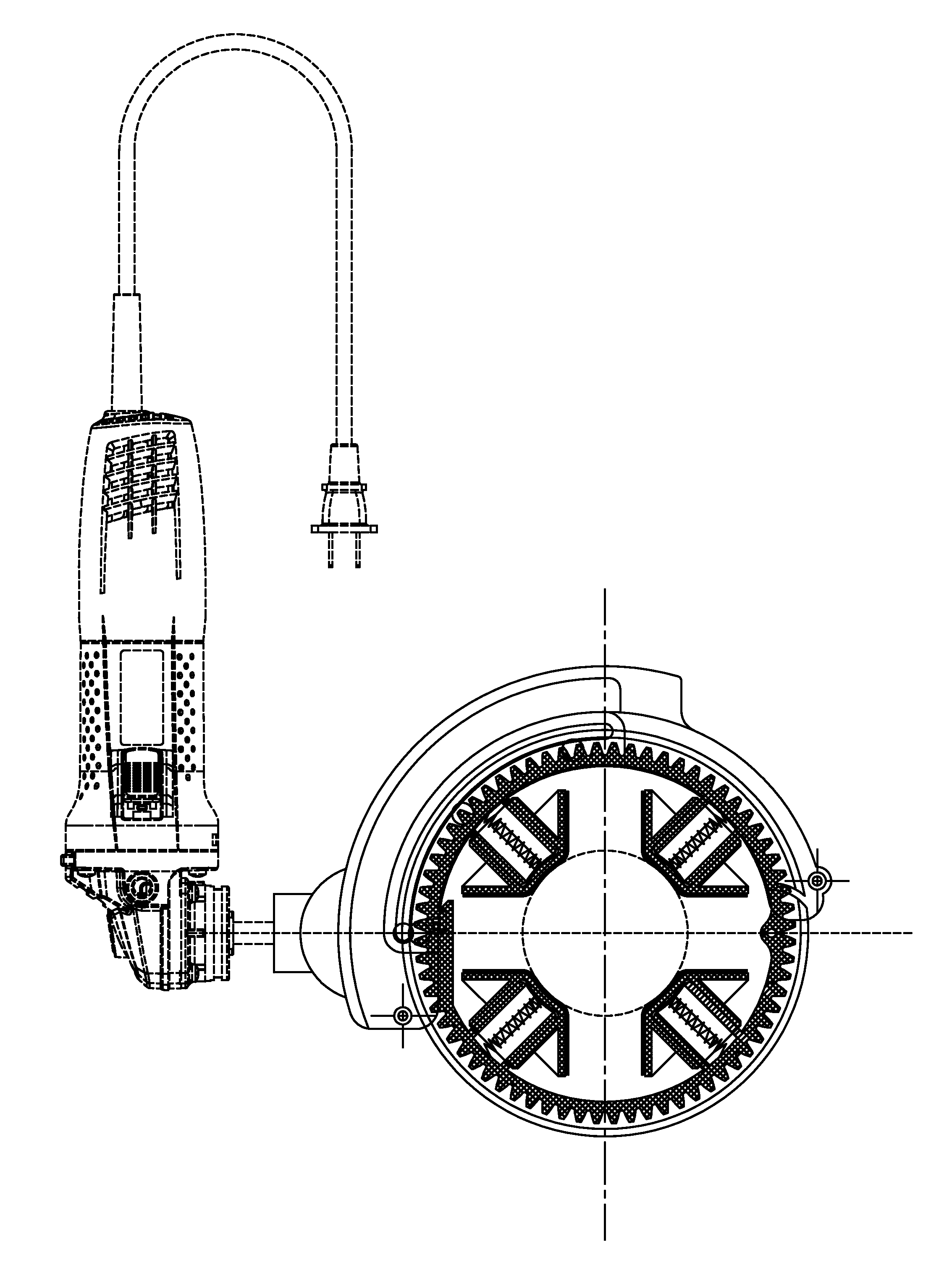

ActiveUS20140057535A1Speed up the processEdge grinding machinesRevolution surface grinding machinesDrive motorLinear drive

A honing machine has at least one clamping unit that clamps a workpiece and has a rotary drive for the workpiece. A spindle unit has a stroke drive for an inner honing tool for inner honing of the workpiece. An outer honing device that is movable relative to the workpiece in an axial direction of the workpiece is provided. The outer honing device has several honing stones and an advancing device acting on the honing stones. The honing stones each are advanced in a radial direction relative to the workpiece. The advancing device has at least one linear drive for each one of the honing stones and a common drive motor for all of the linear drives.

Owner:GEHRING NAUMBURG GMBH

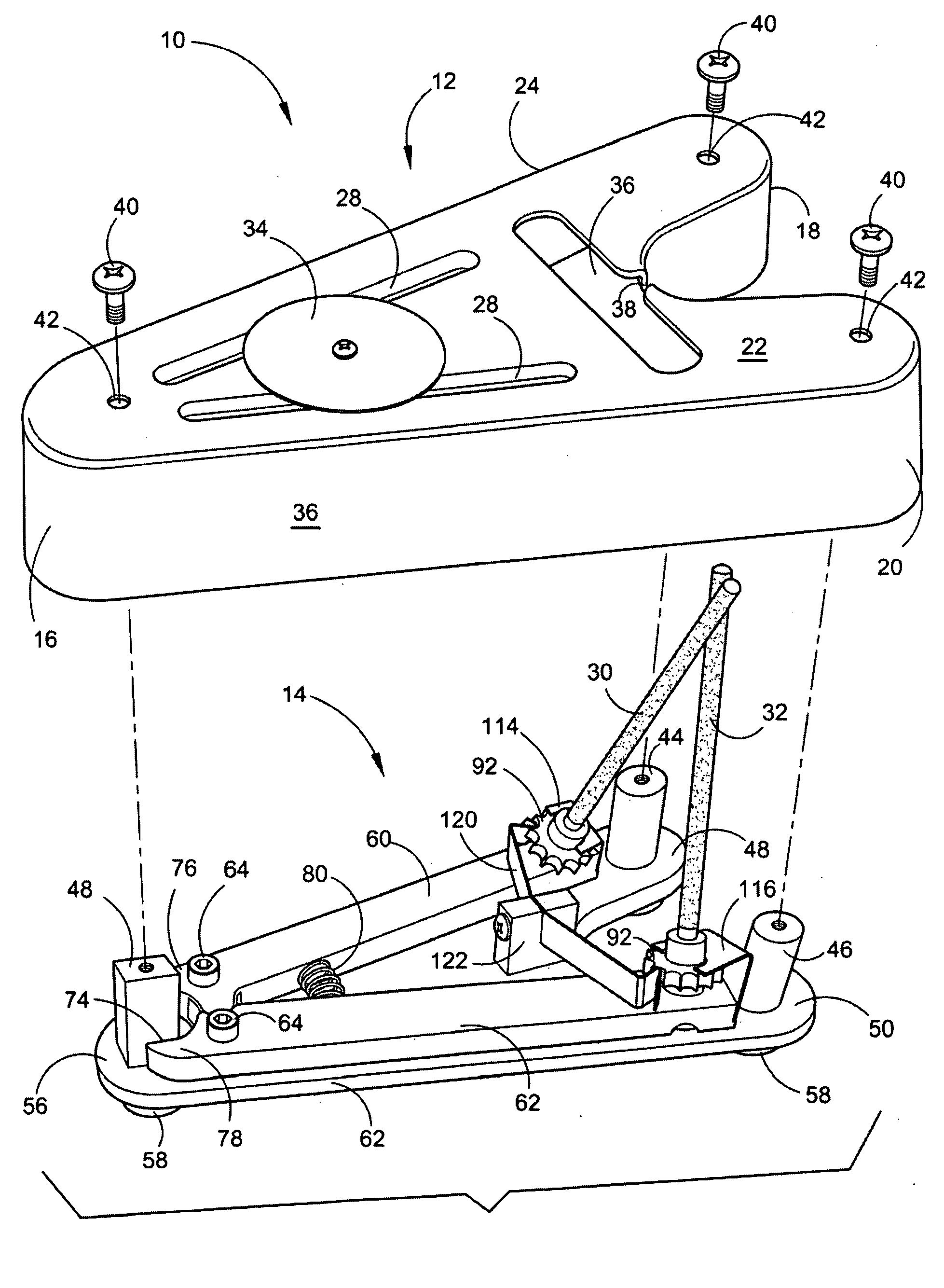

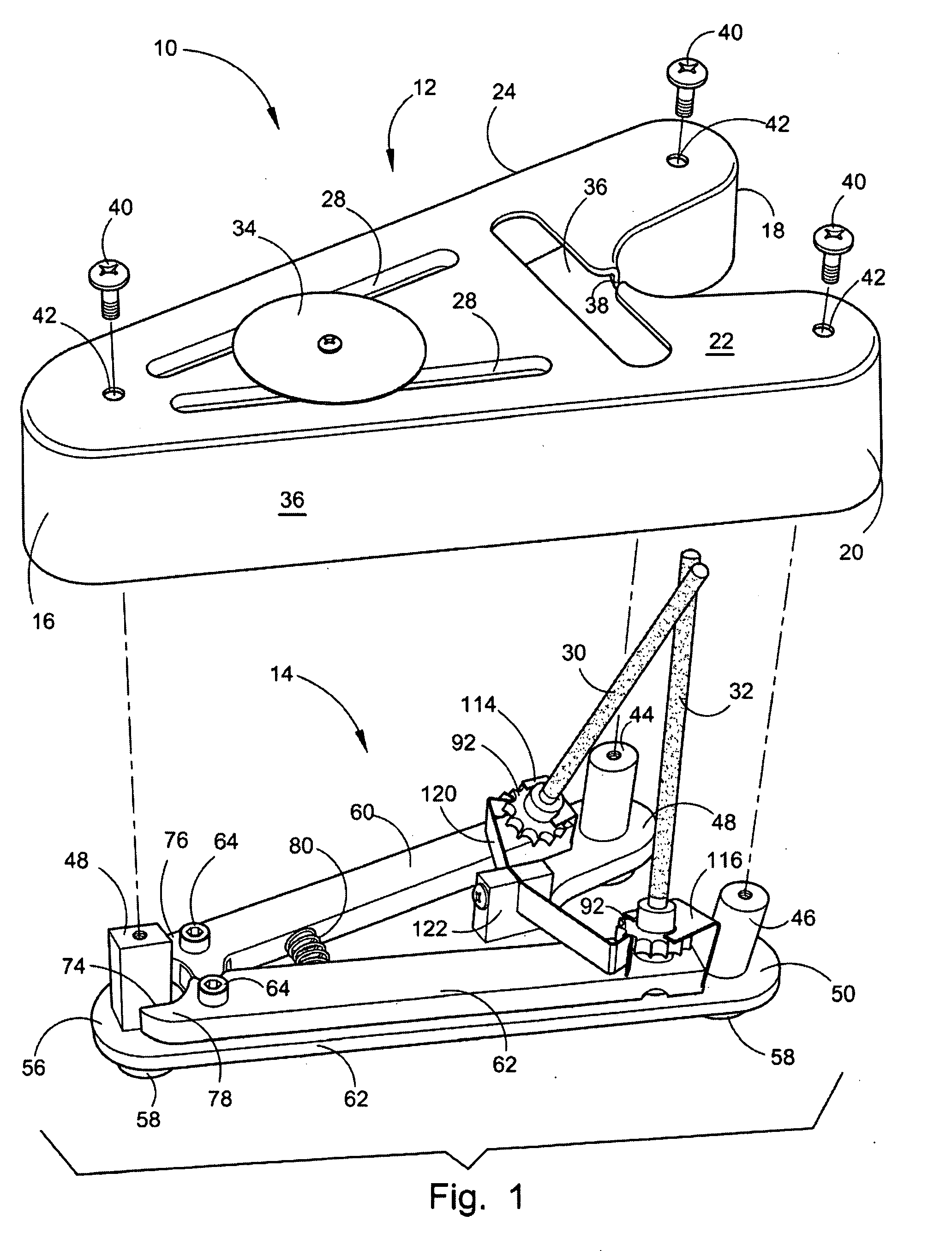

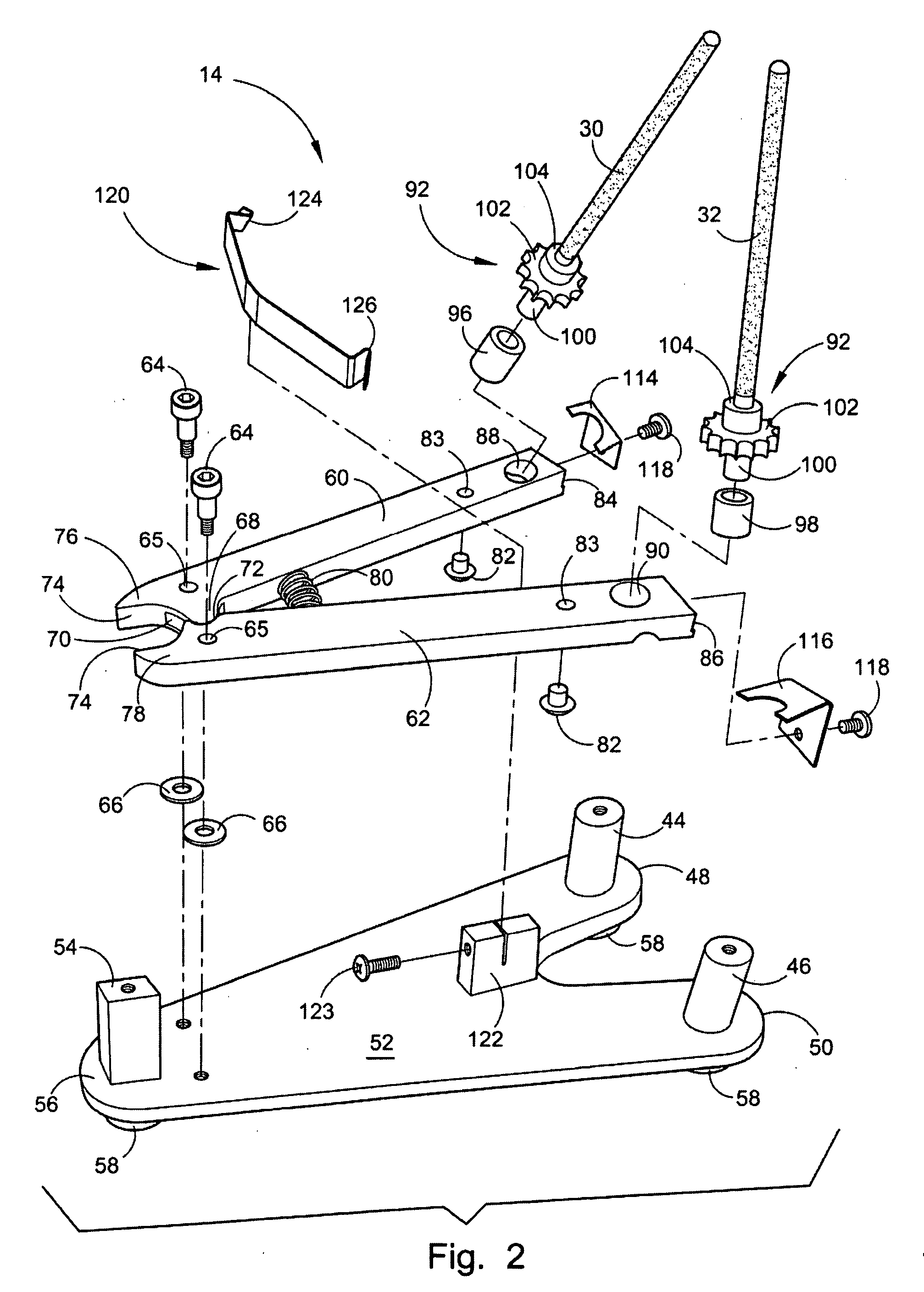

Automatic rotation knife sharpener

InactiveUS20090275272A1Easy to disassembleRevolution surface grinding machinesOther chemical processesKnife sharpenerEngineering

The present invention is directed to an automatic rotation knife sharpener where the crossed sharpening rods are automatically rotated each time a knife is passed down and through the sharpener. The rotation is derived through the means of a spring steel actuator mechanism making contact with the cogwheels of the sharpening rod holders. Magnets retain the sharpening rods in place within the sharpening rod holders. Sharpening rods may be easily removed and stored in troughs on the upper surface of the protective cover. A variety of sharpening rods with different abrasive surfaces can be easily exchanged in the device.

Owner:BONAPACE MARIO J

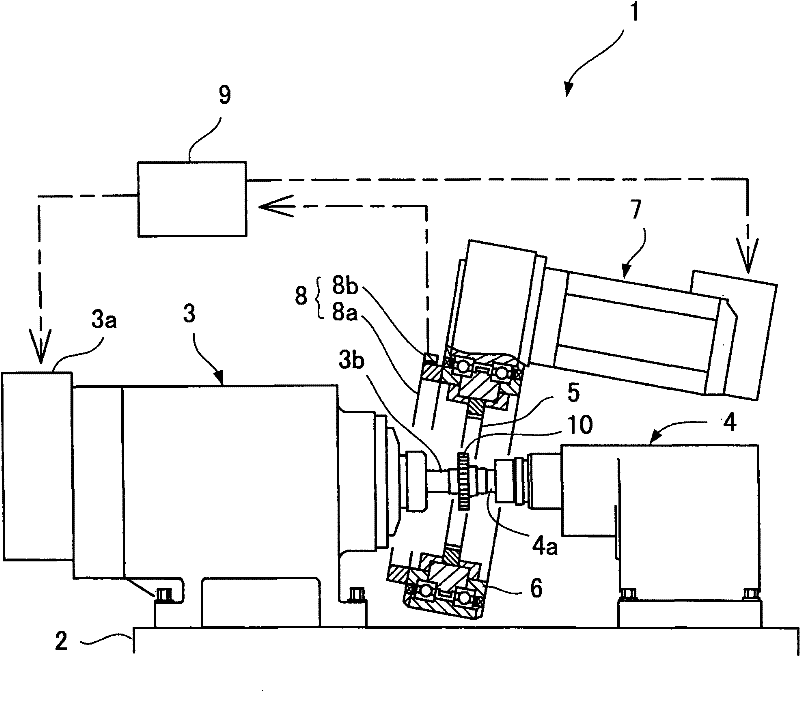

Tool head, machine tool and boring method of bore of cylinder block using the machine tool

InactiveCN101443147AIncrease productivity in manufacturingLess bendingHoning toolsOther manufacturing equipments/toolsEngineeringLinear motor

The invention relates to a tool head, a machine tool and a boring method for boring a cylinder b6lock using the machine tool. A spindle drive unit (11) of the machine tool (10) drives the spindle (32). The tip end of the spindle (32) is provided with a boring tool (100) and a tool head (30) having a rough grinding stone (102) and a finishing grinding stone (104). The spindle drive unit (11) has a first support unit (34) and a second support unit (36) capable of receiving the spindle (32) therethrough and supporting it rotatably, a linear motor (58) and a column slide mechanism (38) for moving the first and second support unit (34, 36) in the axis direction of the spindle (32), and a spindle motor (44) for rotating the spindle (32).

Owner:HONDA MOTOR CO LTD

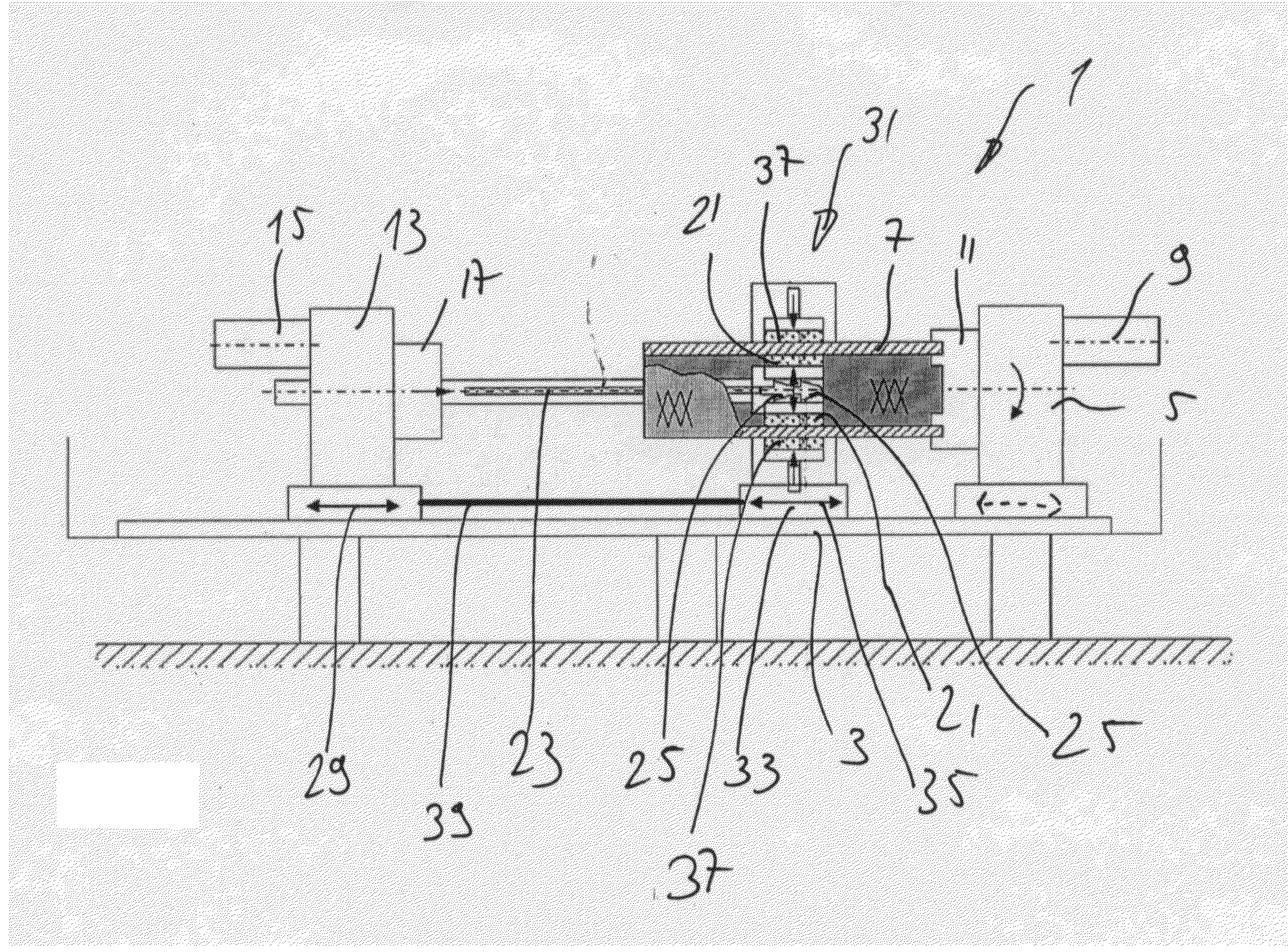

Method of Honing Bores

InactiveUS20050130560A1Great dimensionReduce hardnessEdge grinding machinesRevolution surface grinding machinesEngineeringHardness

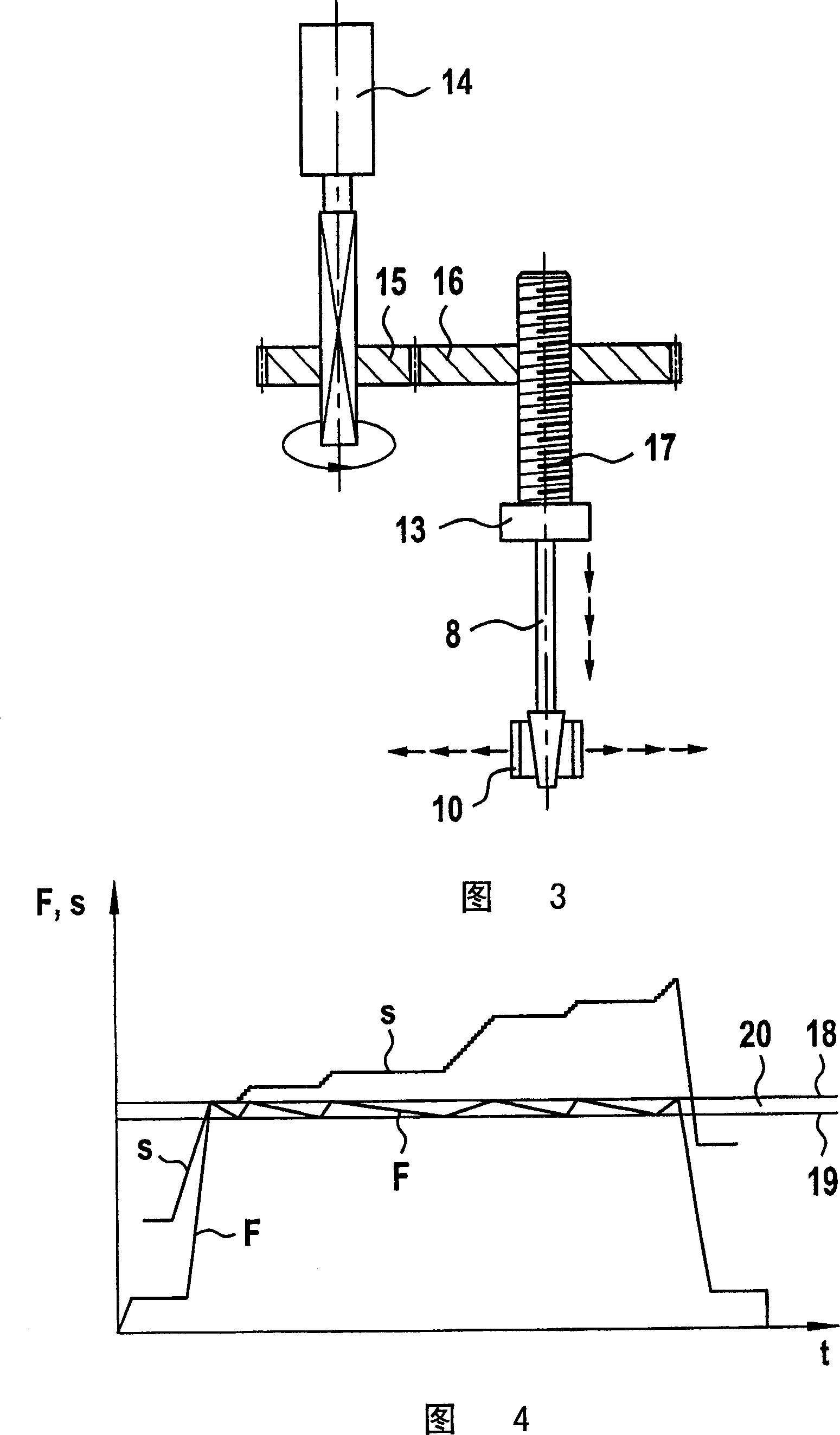

In a method for honing a bore having first and second sections sequentially arranged in an axial direction of the bore, wherein the first section is hardened so that the first and second sections have different hardness, a honing tool is radially supported by positioning guides of the honing tool on the second bore section first section is machined with honing stones arranged on the honing tool to remove material from the first section. During machining of the first section, the honing tool is expanded by feeding the honing stones according to a defined feeding mode against a surface of the first section by a force-guided electro-mechanical advancement. During machining of the first section, the working stroke of the honing tool is adjusted continuously at least toward the end of the honing process. Feeding of the guides is realized independently of feeding of the honing stones.

Owner:GEHRING GMBH & CO KG

External circular polisher with double polishing wheels

InactiveUS20150183075A1Improve working efficiencyGood effectEdge grinding machinesRevolution surface grinding machinesCircular surfaceElectric motor

An external circular polisher with double polishing wheels includes: a first polishing wheel having a first internal circular surface; a second polishing wheel having a second internal circular surface; a plurality of holders mounted on the first internal circular surface and the second internal circular surface; a plurality of polishing units connected to the holders for polishing a target external circular surface; a driving unit for driving the first polishing wheel and the second polishing wheel; and a supporter for supporting the first polishing wheel and the second polishing wheel. With the foregoing structure, a user can polish a target with two polishing wheels at the same time, and the external circular polisher works stably; the present invention can be driven by a motor of a conventional device for further increasing a scope of application of the external circular polisher with double polishing wheels.

Owner:HAMMER ELECTRIC POWER TOOLS

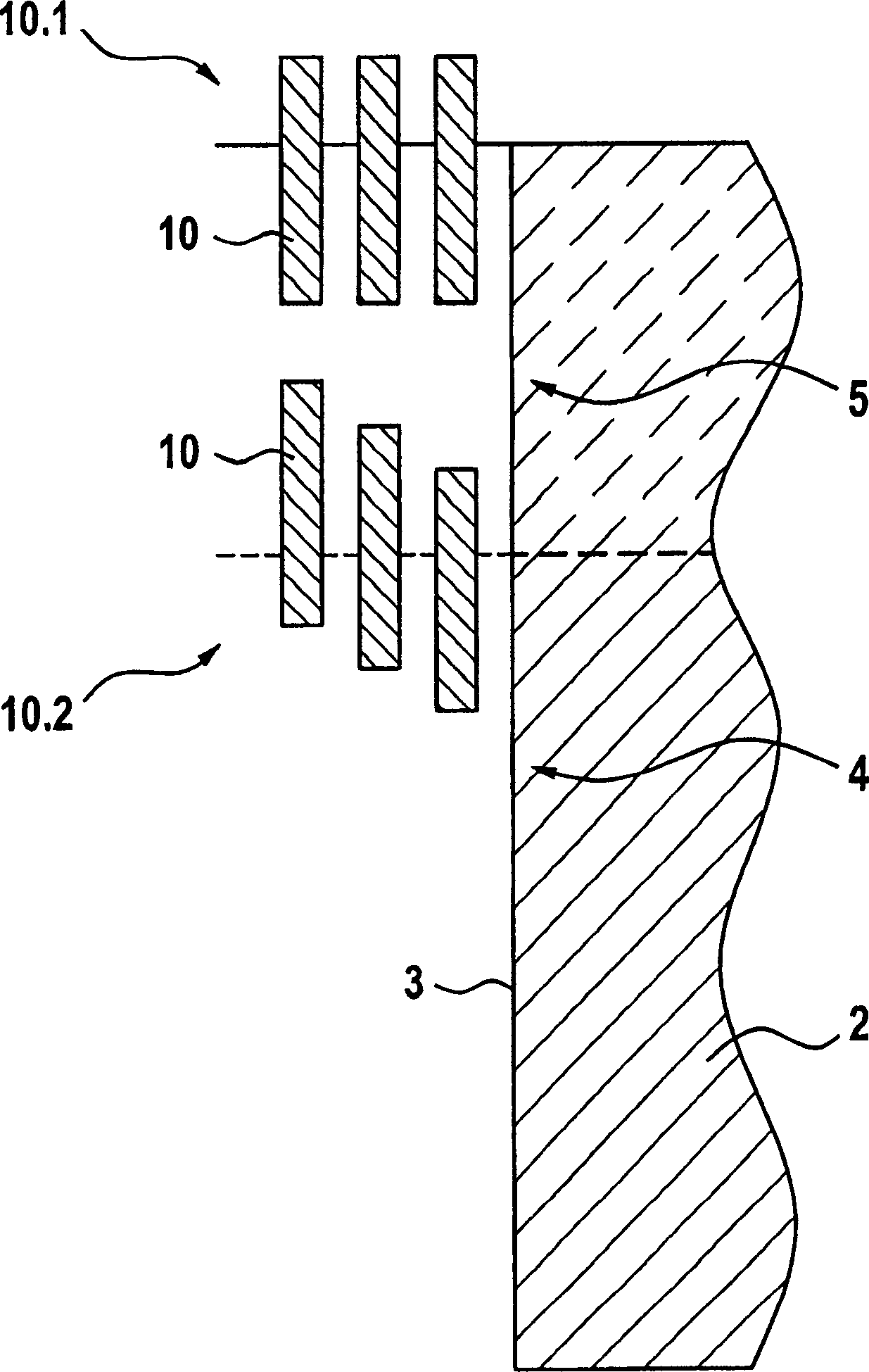

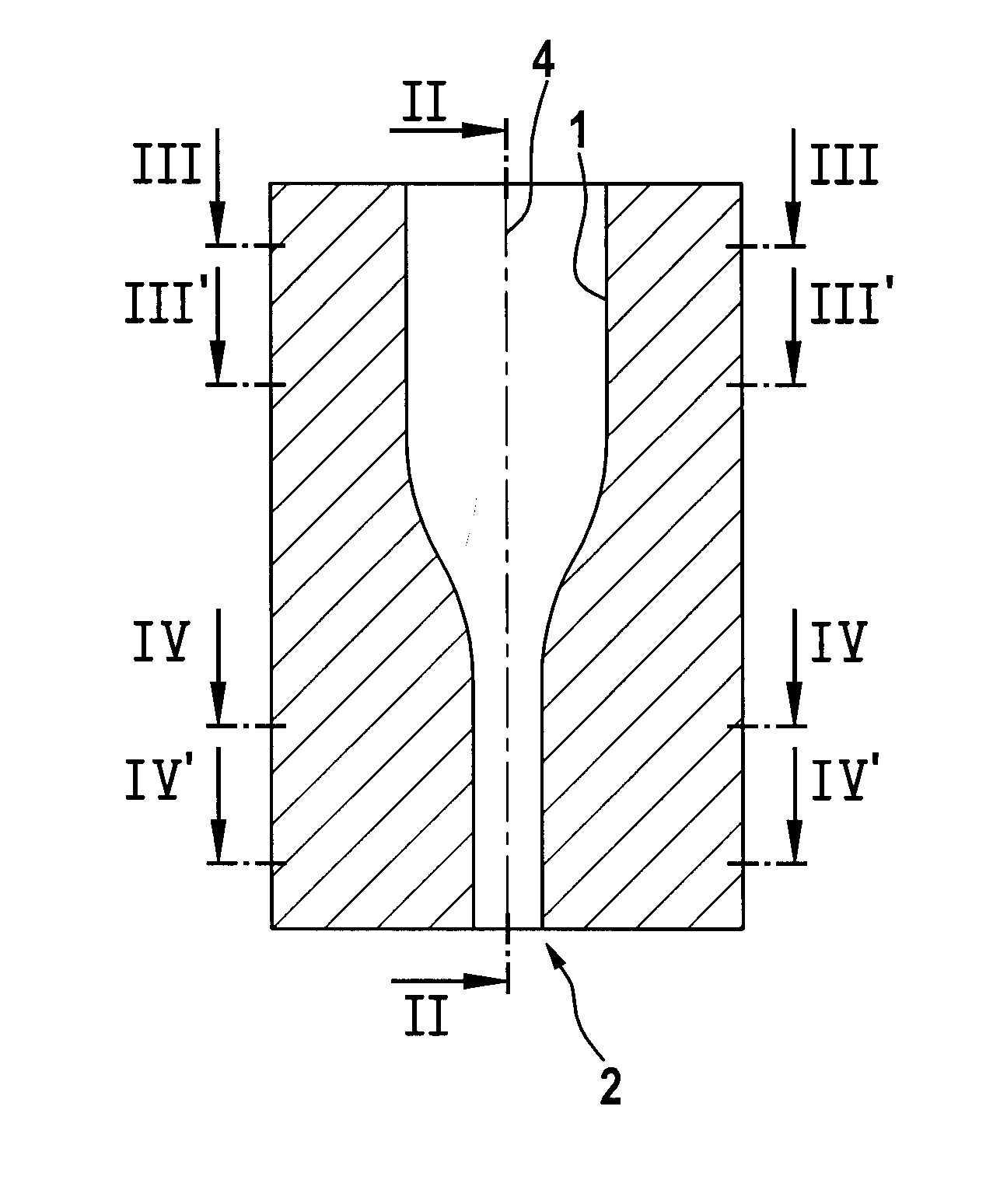

Method of honing bores

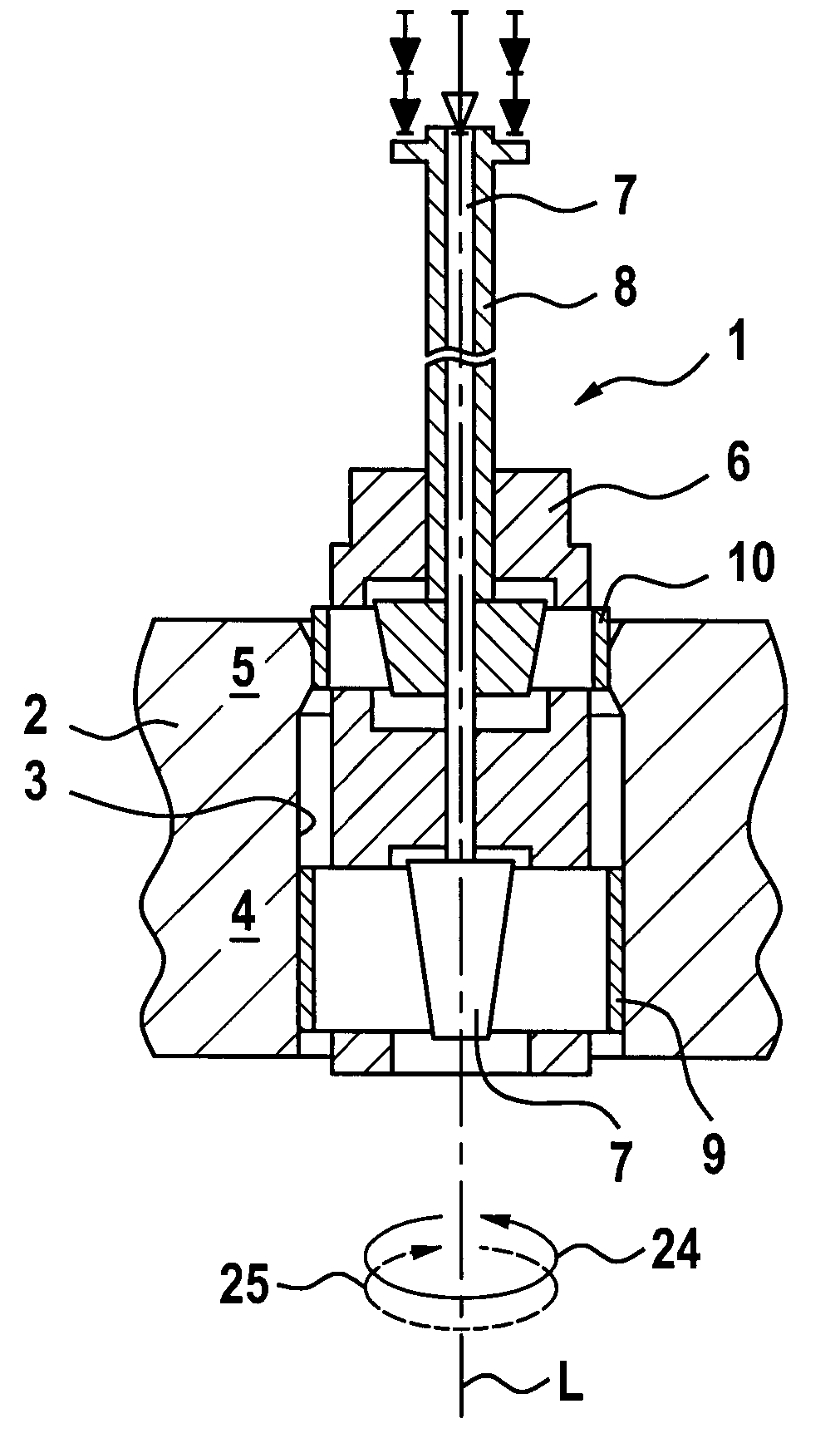

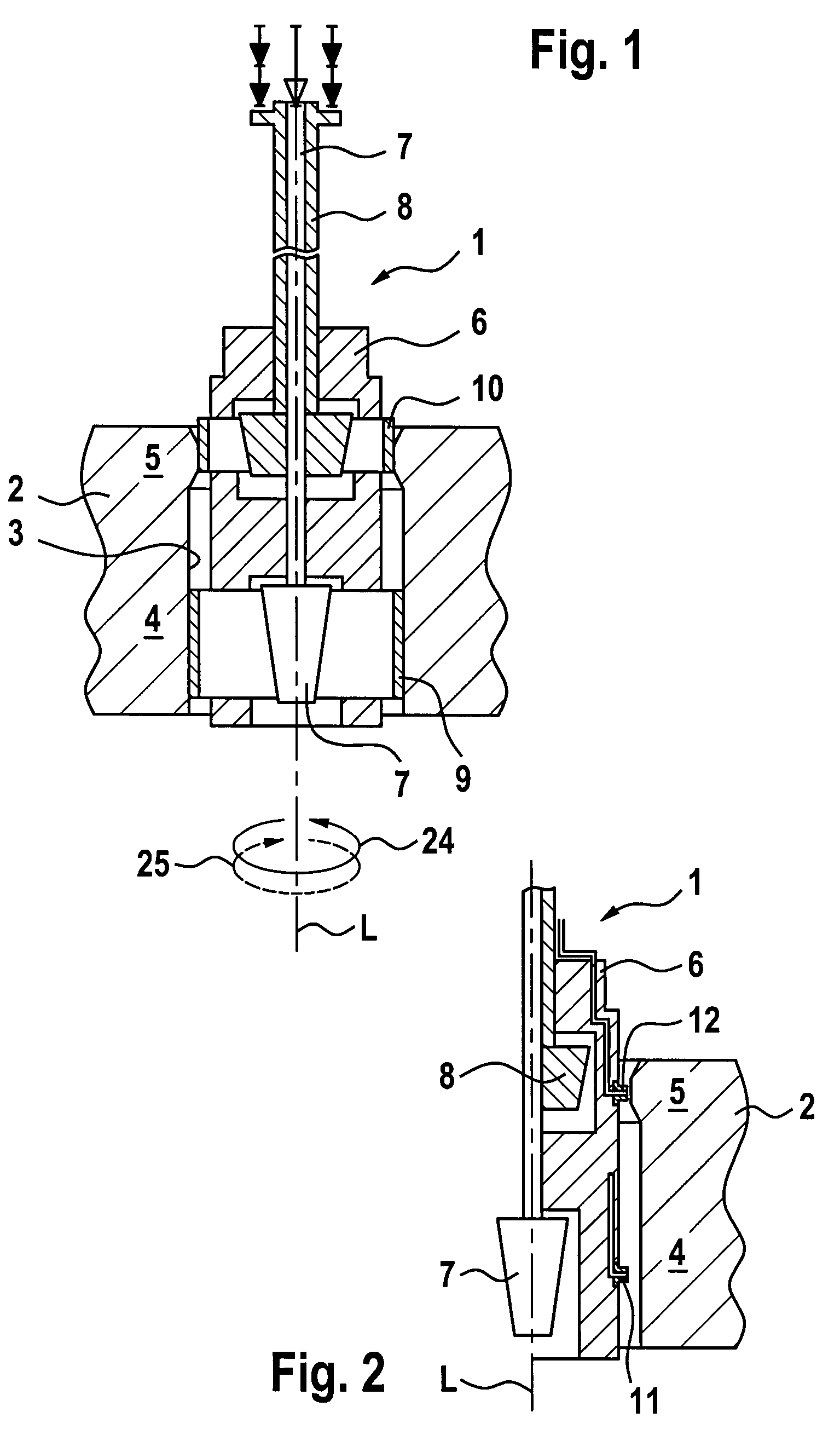

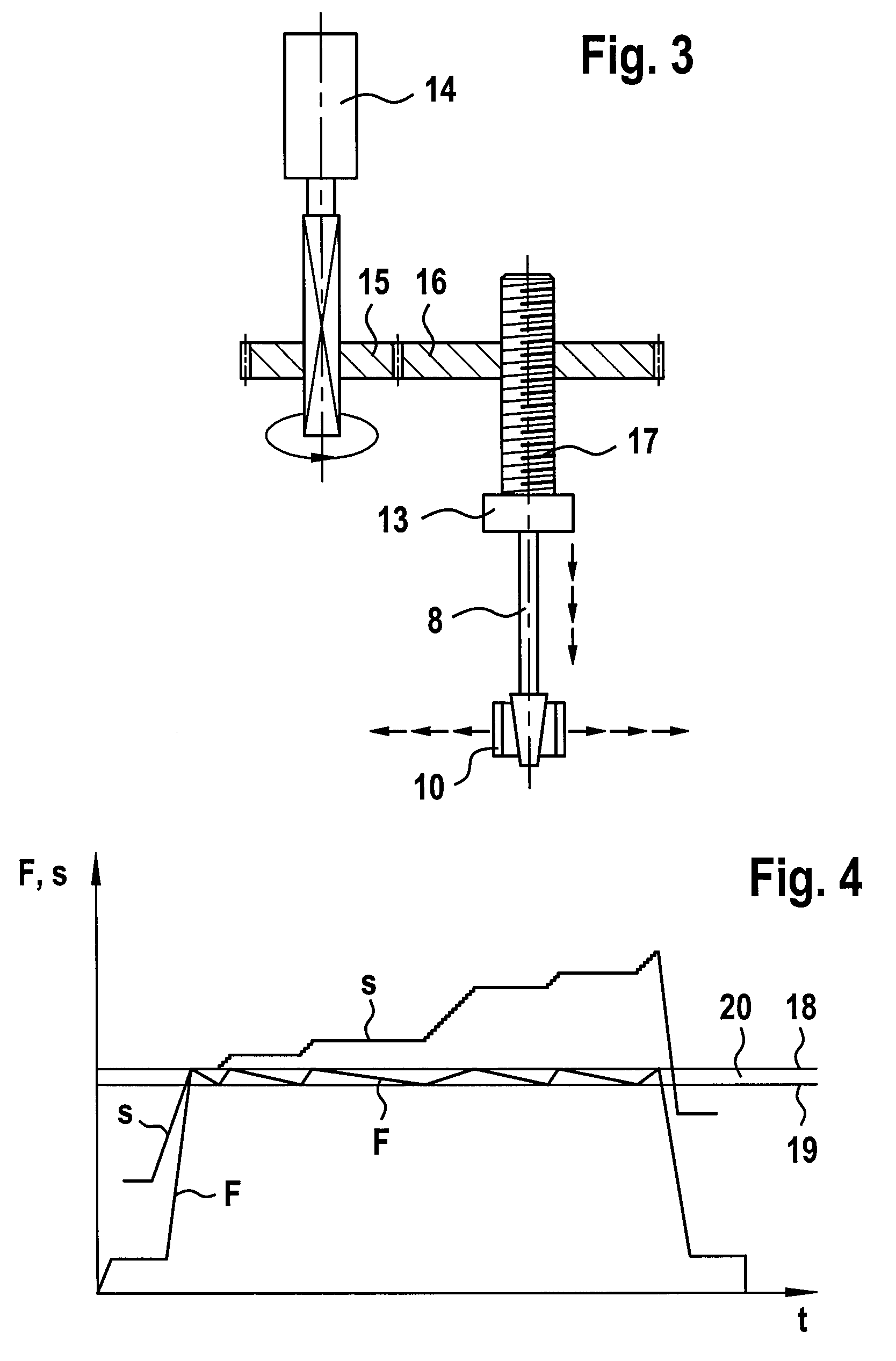

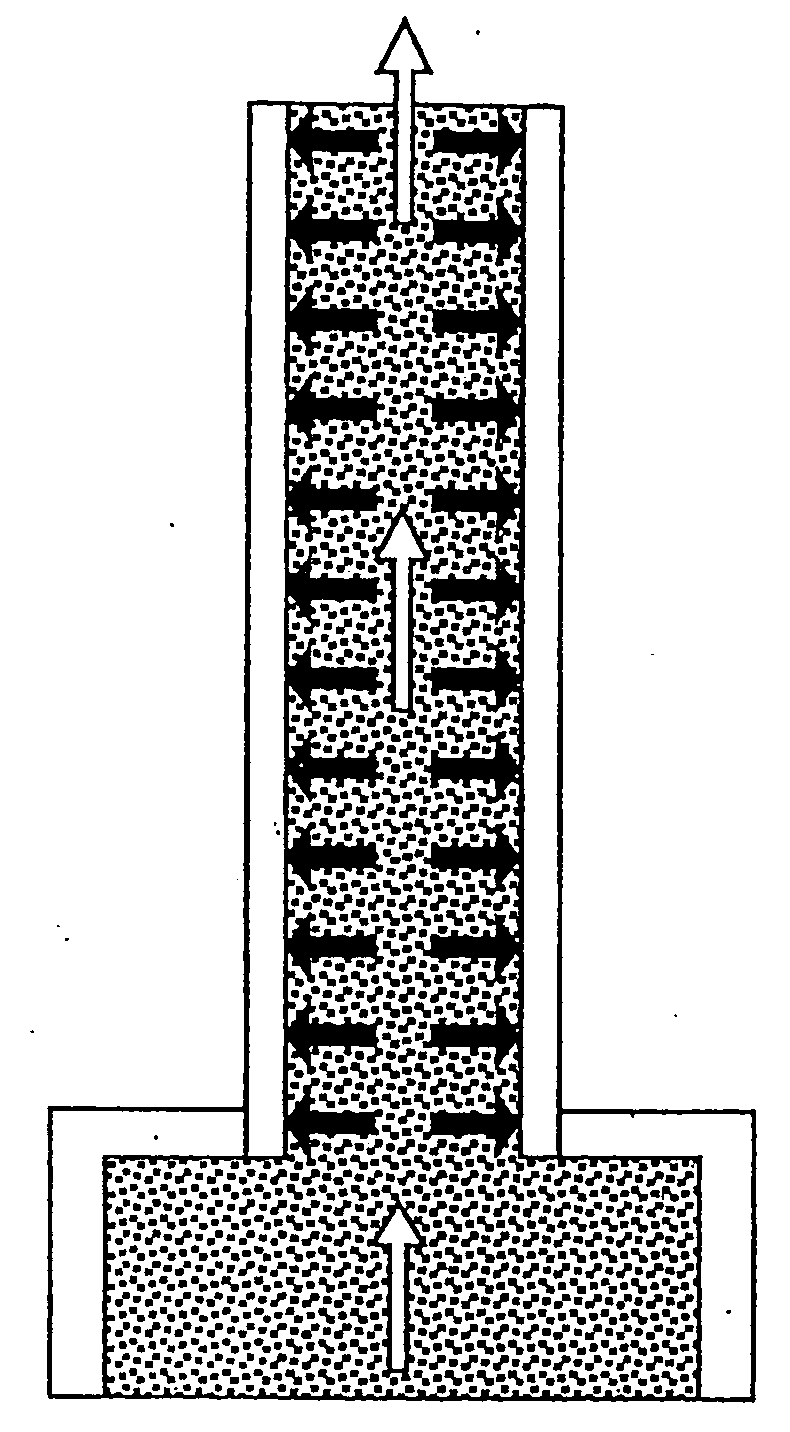

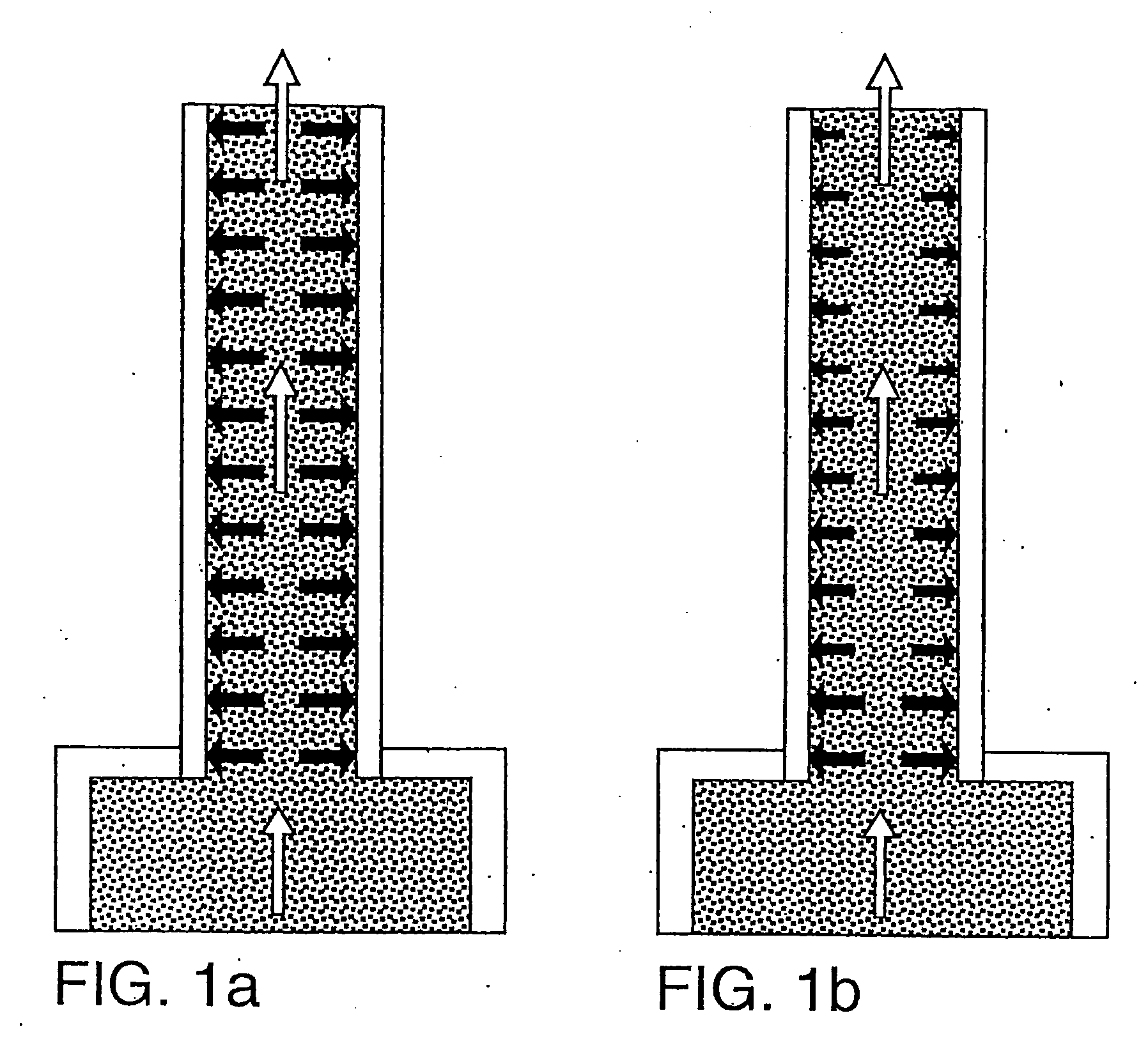

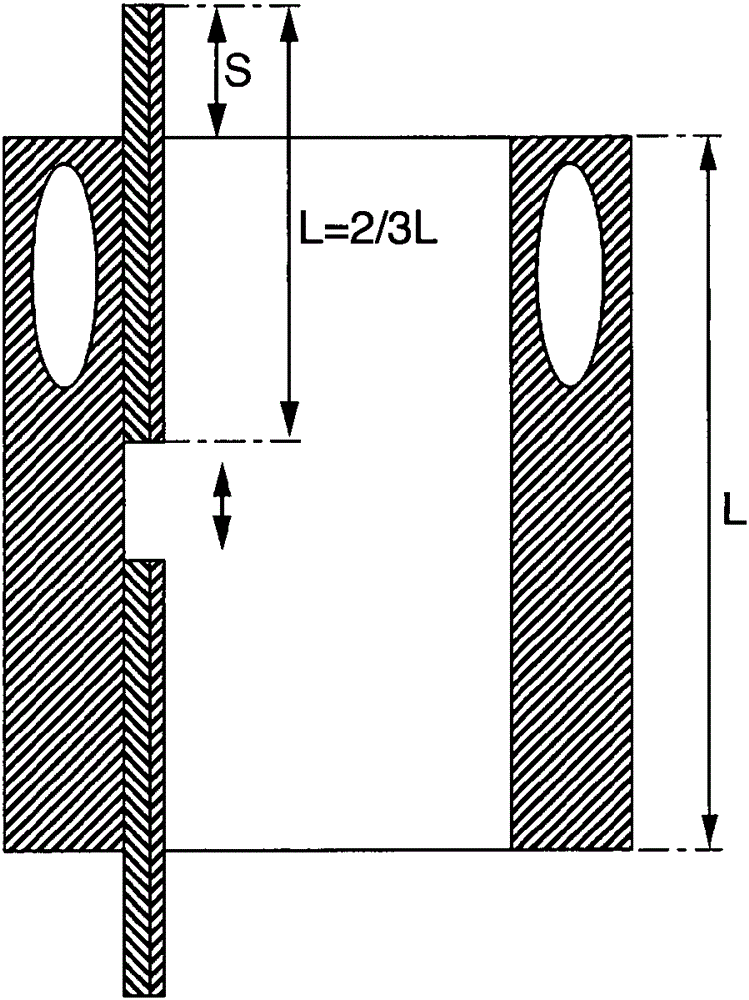

The invention describes a method for honing a hole (3) having two hole sections (4, 5) connected one behind the other in the axial direction of the hole (3), the surfaces to be machined of the hole sections having different hardnesses. The honing tool (1) is supported radially in the unhardened bore section (4), while the hardened bore section (5) is machined and thus ground with the honing stick (10) mounted on the honing tool (1). drop material. The feed adjustment of the honing stick (10) takes place in a force-controlled electromechanical feed and the working stroke of the honing tool is continuously varied at least towards the end of the honing process.

Owner:GEHRING GMBH & CO KG

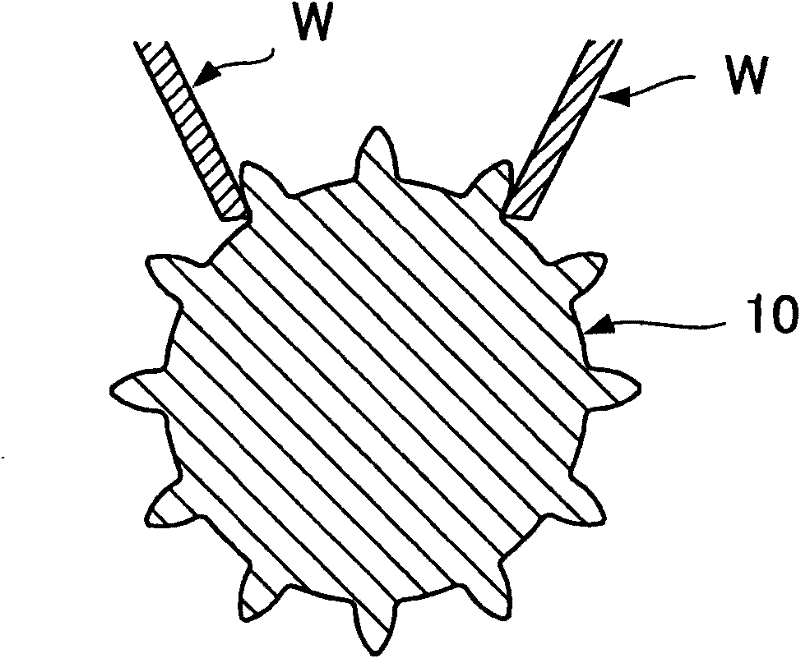

Dressing gear and method for dressing a gear-shaped grinding wheel

InactiveCN101745872ATrimming continuousUniform dressingHoning toolsAbrasive surface conditioning devicesGear wheelMissing tooth

The present invention provides a dressing gear which facilitates fine dressing and grinding with small modulus and a method for dressing with the dressing gear. The dressing gear is characterized in that: diamond fine particles or CBN fine particles are coated on the surface of each tooth for forming a tooth-shortage structure which has an even number of total tooth number and has one missed tooth alternatively for each half of the total teeth; and fine dressing and grinding are performed through a diamond grinding wheel. A synchronization system which causes a main shaft of the tool and a main shaft of a workpiece to match and interlock at a state that the dressing gear is engaged with a gear-shaped grinding wheel, thereby dressing all teeth of the gear-shaped grinding wheel.

Owner:KANZAKI KOKYUKOKI MFG +1

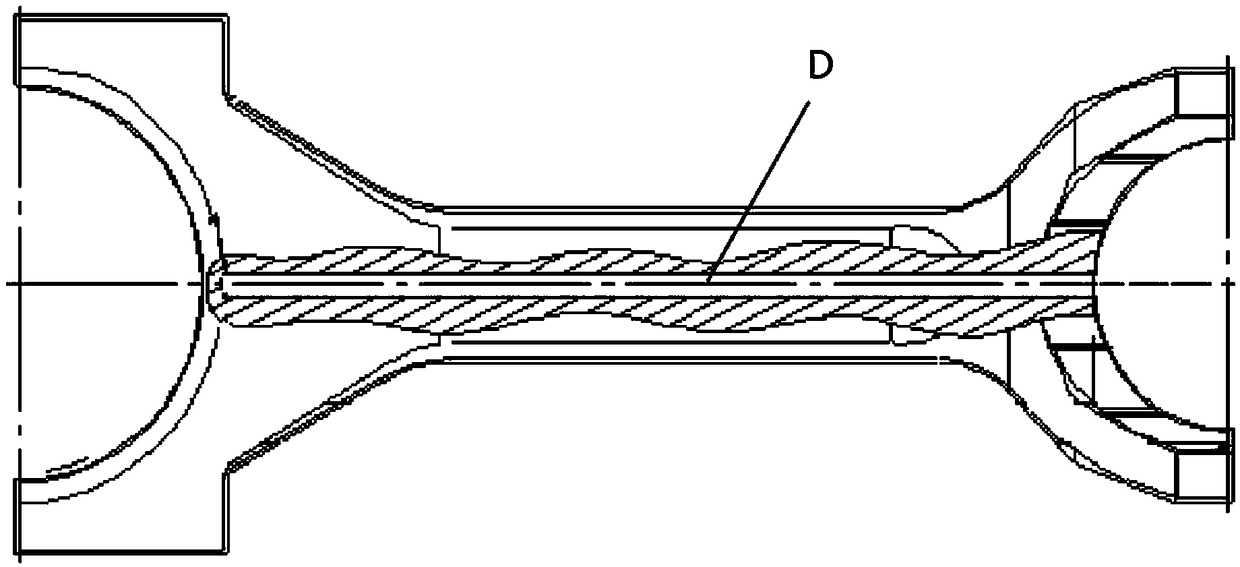

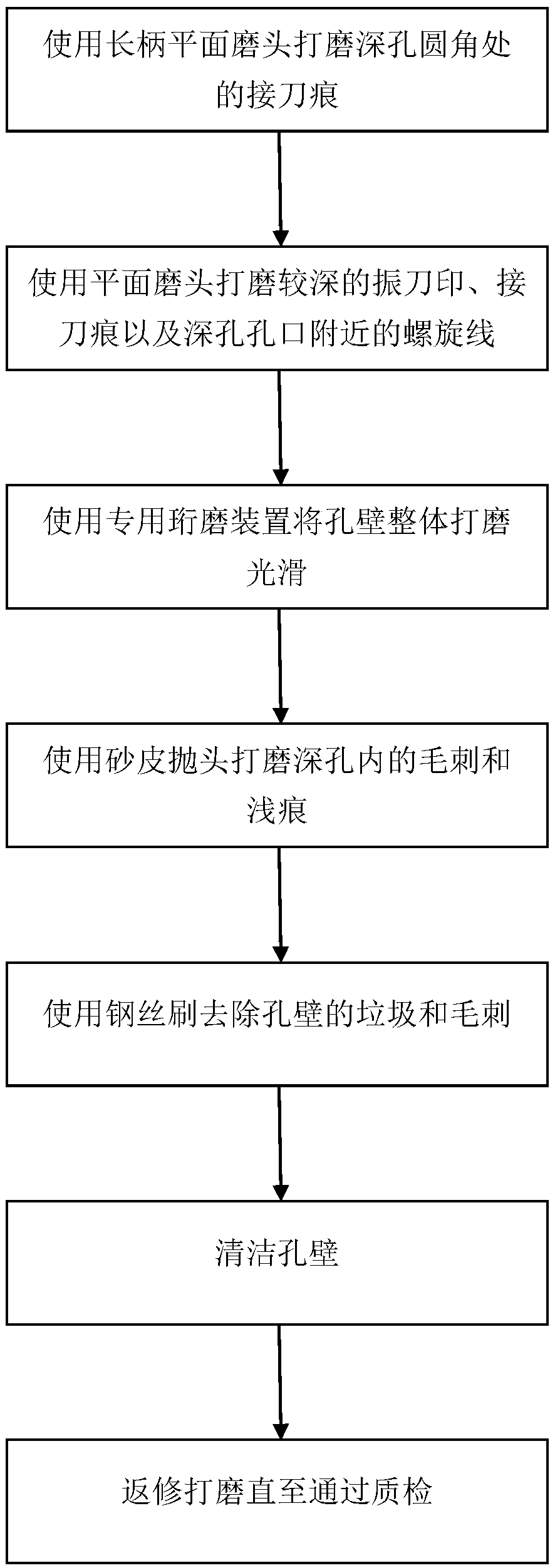

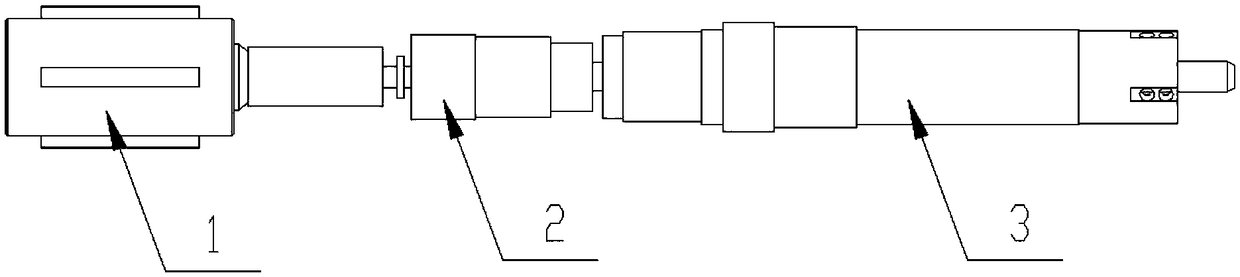

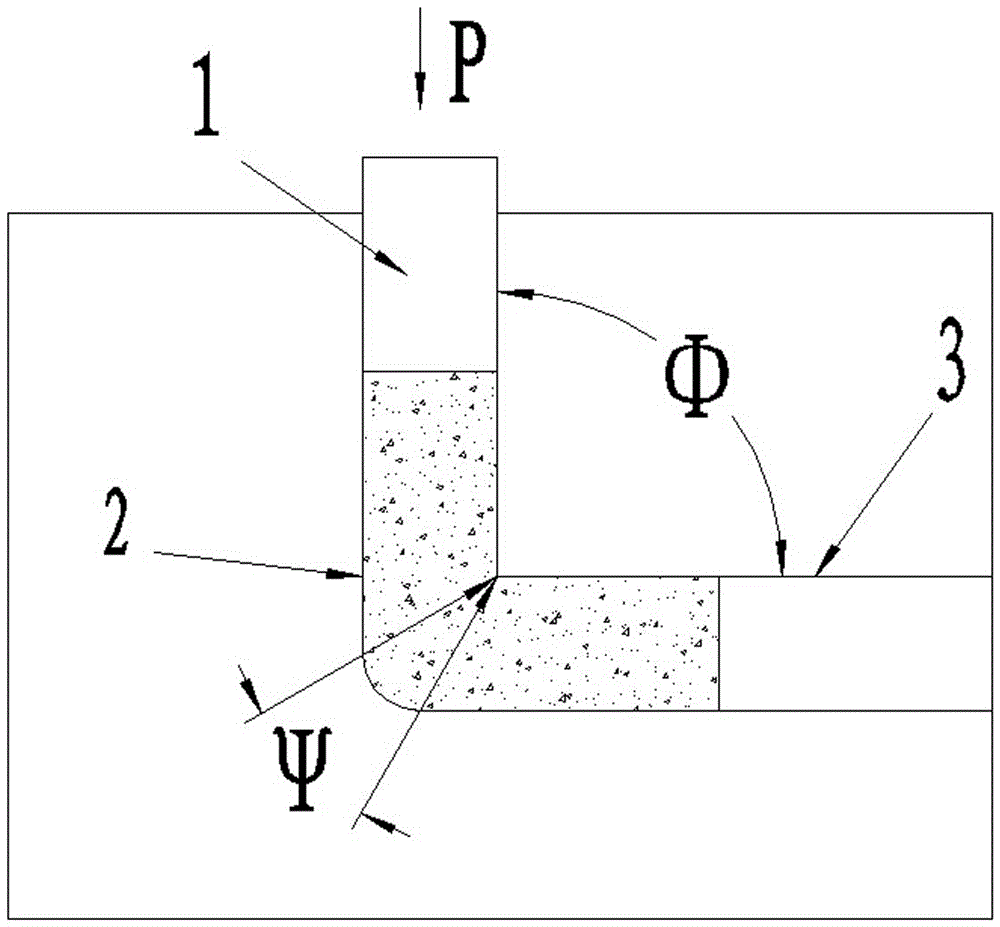

Connecting-rod deep hole grinding method for marine low-speed diesel engine and special honing device

ActiveCN108747608AImprove sanding qualityUniform sanding effectHoning toolsHoning machinesImpellerLow speed

The invention provides a connecting-rod deep hole grinding method for a marine low-speed diesel engine and a special honing device. The connecting-rod deep hole grinding method comprises the followingsteps: 1, grinding machined traces at a rounded corner of a deep hole by using a long-handle plane grinding head; 2, grinding relatively deep vibration knife marks and machined traces as well as spiral lines near an orifice of the deep hole by using a plane grinding head; 3, grinding and smoothening the entire hole wall by using the special honing device, wherein the special honing device comprises a honing head, a universal quick-change adapter and a pneumatic motor and is mounted on an extension rod, the hole wall of the deep hole is tightly supported through an elastic structure, the special honing device is driven by a pneumatic grinder to rotate, the rotating speed of the special honing device is adjusted by using a speed reducer, and then the uniform and efficient deep hole grindingoperation is achieved; 4, grinding burrs and shallow traces in the deep hole by using a sand impeller head; 5, removing waste and burrs on the hole wall by using a steel wire brush; 6, cleaning the hole wall; and 7, carrying out repairing and grinding till quality testing is passed. According to the connecting-rod deep hole grinding method provided by the invention, the grinding effect is uniform, the operation is simple, both the time and the effort are saved, and the entire grinding effect on the deep hole in a connecting rod is improved.

Owner:CSSC MES DIESEL

Honing oilstone

The invention discloses a honing oilstone. The honing oilstone, by weight, comprises 3-10% of silver, 15-30% of cobalt powder, 3-20% of tin, and the balance is copper-tin alloy powder. The volume ratio of diamond is 50-100%. The invention further discloses a method for preparing the honing oilstone. The honing oilstone is sharp in grinding, good in self-sharpening, long in service life, low in cost, and easy to prepare.

Owner:上海鸿宁珩磨机械有限公司

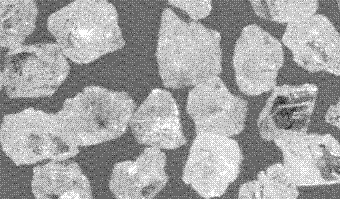

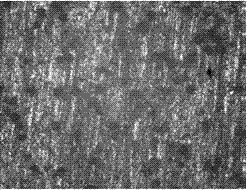

Diamond honing oilstone and preparation method thereof

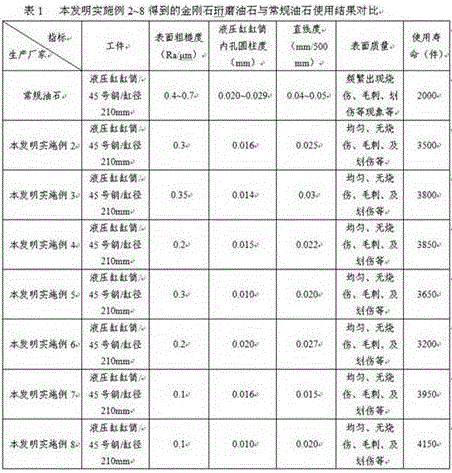

ActiveCN106217273AImprove cooling effectImprove plasticityAbrasion apparatusGrinding devicesHydraulic cylinderGranularity

The invention provides a diamond honing oilstone and a preparation method thereof. The diamond honing oilstone is prepared from, by weight percent, 5%-10% of diamond micro-powder with the granularity ranging from 400 meshes to 1000 meshes and 90%-95% of a metal bond. The metal bond is composed of 45%-55% of copper-tin pre-alloyed powder, 12%-20% of silver powder, 30%-33% of magnesium powder and 2%-5% of talcum powder with the granularity ranging from 200 meshes to 800 meshes. The specific preparation method includes the steps that an oilstone blank is prepared through the procedures such as material mixing, mold forming, sintering and equal channel angular extrusion; and finally, machining is conducted on the oilstone blank, and a finished product with the qualified size precision is obtained. The oilstone manufactured through the method solves the problems that at present, a hydraulic cylinder barrel honing oilstone machining hydraulic cylinder barrel is low in cylindricity and poor in straightness accuracy, the surface roughness does not reach the standard, and burns, burrs and hydraulic cylinder barrel inner hole surface scratches exist, meanwhile, hardness of the oilstone is improved, the shape retention is improved, and the service life is prolonged.

Owner:ZHENGZHOU RES INST FOR ABRASIVES & GRINDING CO LTD

Abrasive machining media containing thermoplastic polymer

ActiveUS20100144247A1Good elastic propertiesIncrease relaxation timeEdge grinding machinesPolishing machinesElastomerThermoplastic elastomer

The present invention incorporates at least one thermoplastic or elastomeric polymer in abrasive flow machining media either as the sole or as one of the polymeric constituents. The presence of thermoplastic polymer imparts a greater elastomer characteristic (elasticity, compression resistance, increased relaxation times) as contrasted with traditional media. Enhanced elastomeric characteristics enable more uniform abrasive machining. In a particularly preferred embodiment, silicone- or polyorganosiloxane-based medium contains elastic silicone rubber particles dispersed therethrough to achieve increased relaxation times comparable to those attainable with the inclusion of a thermoplastic polymer.

Owner:KENNAMETAL INC +1

Multi-functional honing head

The invention relates to a multiwheel (more than or equal to 2 honing wheels) multi-functional honing head through which manufacturing pieces can be directly processed into high accuracy (0.0005-0.005mm) and high surface roughness (Ra0.01-0.04) inner circle and excircle, transverse plane, circular conical surface, circular curved surface after being subjected to lathe work on a lathe by a single honing head. Processing diameter ranges from phi100mm to phi10m, processing length ranges from 10mm to 10m (depending on equipment constraints), detailed information can be seen in chart 6, 7, 8 and 9.

Owner:BEIJING JINZI TIANCHENG HYDRAULIC TECH

Collapsible honing head

The invention discloses a collapsible honing head, relates to the technical field of honing and aims at solving the technical problem that the prior collapsible honing head is incapable of directly honing a workpiece with a groove or gap wider than a single oilstone. The honing head comprises a shell, a collapsible element which is arranged on the shell and is collapsible in the radial direction, an oilstone seat arranged on the collapsible element and an oilstone arranged on the oilstone seat. The honing head is characterized in that the oilstone seat is an open lantern ring sleeved and fixed on the collapsible element; the peripheral surface of the open lantern ring is provided with at least one oilstone in parallel along the axial direction; and the open lantern ring and the oilstone can swell and shrink along with the collapsible element. Due to the utilization of the collapsible honing head, the labor productivity and the product quality can be improved.

Owner:上海鸿宁精密机械有限公司

Method and apparatus for finish machining crankshaft bearing borehole

In a method for finishing a borehole in a workpiece, particularly for finishing a crankshaft bearing borehole in a cylinder crankcase of an internal combustion engine, a machined borehole is generated based on a prepared borehole, the machined hole has a settable theoretical size, a settable theoretical structure of the inner surface of the borehole and a settable theoretical position of the borehole axis. The method is characterized in at least one high efficient honing operation. A degradation of 0.5 millimeter is generated under the use of a honing tool by the honing of the borehole relative to the diameter of the borehole during the high efficient honing operation. The high efficient honing operation is executed as honing operation such that a shifting of the borehole axis takes place in the direction of the target position by the engine power honing operation.

Owner:NAGEL MASCHEN UND WERKZEUGFAB

Method and Machining Installation for the Finishing of a Crankshaft Bearing Bore

In a method for the finishing of a crankshaft bearing bore in a cylinder crankcase of an internal combustion engine, starting from a prepared crankshaft bearing bore, a finished crankshaft bearing bore is produced with a prescribable desired size, a prescribable desired structure of the bore inner surface and a prescribable desired position of the bore axis. The prepared crankshaft bearing bore is first finished with at least one finishing tool with a geometrically defined cutting edge and then the honing of the crankshaft bearing bore is carried out. In a final finishing operation with a geometrically defined cutting edge immediately preceding the honing, an allowance of at least 0.4 mm is removed, and the honing tool is introduced into the bore coaxially in relation to the desired position of the bore axis and moved within the bore, an allowance of at least 0.08 mm being removed during the honing.

Owner:NAGEL MASCHEN UND WERKZEUGFAB +1

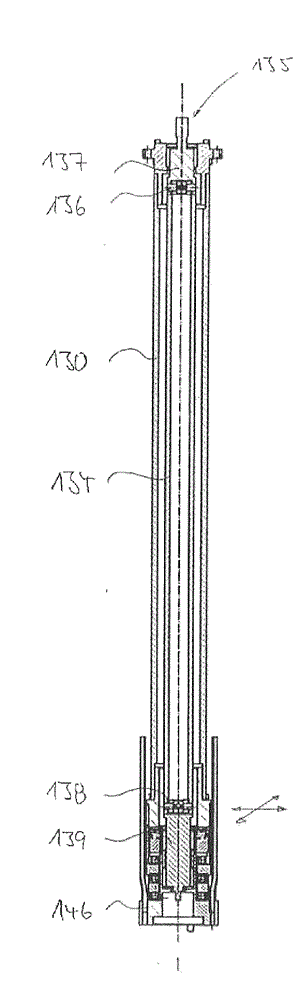

Measuring unit for measuring drilled holes

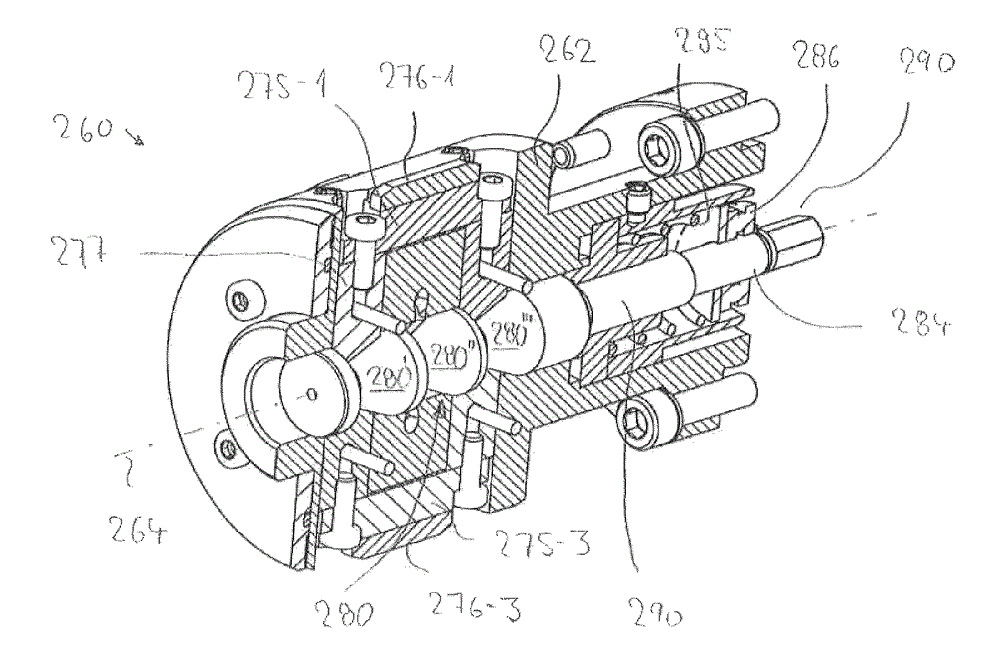

InactiveCN104655061AEasy to operateConvenient radial movementHoning toolsHoning machinesEngineeringDrill hole

A measuring unit for measuring the geometry of a bore, in particular for measuring the internal diameter of a bore after a honing treatment, has a pneumatic measuring mandrel (160) being insertable in the bore and having a pair of measuring nozzles (172-1, 172-3), which are arranged at diagonal distance (175) to each other relative to the longitudinal central axis (164) of the measuring mandrel, and an adjusting drive adjusting diagonal distance between the measurement nozzles when actuated by the adjusting drive. Each of the measuring nozzle is on a separate measuring nozzle carrier (170-1, 170-3) which is arranged in a base body (162) of the measuring mandrel to allow radial movement relative to the longitudinal central axis (164). The adjusting drive moves radially through the adjusting means. The adjusting device has an axially adjustable adjusting cone (180) with at least one conical portion, and an inclined surface cooperating with the conical portion in the manner of a wedge drive is arranged on a measuring nozzle support facing the inner side of adjusting cone. The adjusting device has a screw drive with threaded mandrel (184) drivable by the adjusting drive and mandrel nut (186) running on the threaded mandrel.

Owner:NAGEL MASCHEN UND WERKZEUGFAB

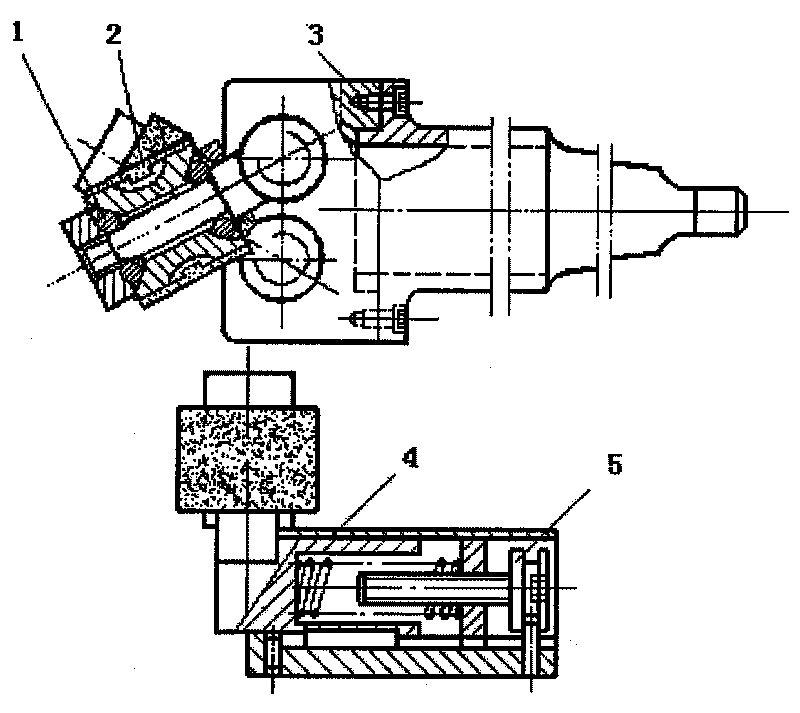

Honing head combination device

ActiveCN103317428APrecise positioningEasy and flexible assembly and disassemblyHoning toolsEngineeringBolt connection

The invention relates to a honing head combination device which can process whole-circle holes and non-whole-circle holes with the diameters ranging from 300mm to 1000mm. The honing head combination device comprises a fine adjustment connection rod part, a pneumatic core shaft part and a honing sleeve part, wherein the fine adjustment connection rod part, the pneumatic core shaft part and the honing sleeve part are of a split type structure, and the fine adjustment connection rod part is connected with the honing sleeve part through a flange plate and a bolt and is located through a key groove. The honing sleeve part is sleeved on the outer side of the pneumatic core shaft part and comprises a sleeve body, a honing strip, a guide board and a regulating bolt, wherein the honing strip and the guide board are arranged on the outer surface of the sleeve body, the regulating bolt is arranged on the lower portion of the honing strip, the pneumatic core shaft part is arranged at the axial center of the honing sleeve part, and the regulating bolt abuts against the pneumatic core shaft part. Compared with prior art, the honing head combination device has the advantages that the split type structure is utilized, using convenience is achieved, manufacturing cost and using cost are greatly lowered, and large-span holes with the diameters ranging from 300mm to 1000mm can be processed.

Owner:SHANGHAI DALONG MACHINE FACTORY CO LTD

Method for Producing a Bore

InactiveUS20030120374A1Minimal expenditureIdeal shapeHoning toolsHoning machinesEngineeringMechanical engineering

Abstract of Disclosure In a method for producing a bore, wherein the bore in an unloaded state has an initial shape and in an operational state has a nominal shape deviating from the initial shape, first a deformation of the bore to a nominal shape present in an operational state is determined. Based on the nominal shape and the deformation determined in the first step, the initial shape is determined. The bore is then transformed by a processing method to the initial shape.

Owner:MASCHFAB GEHRING

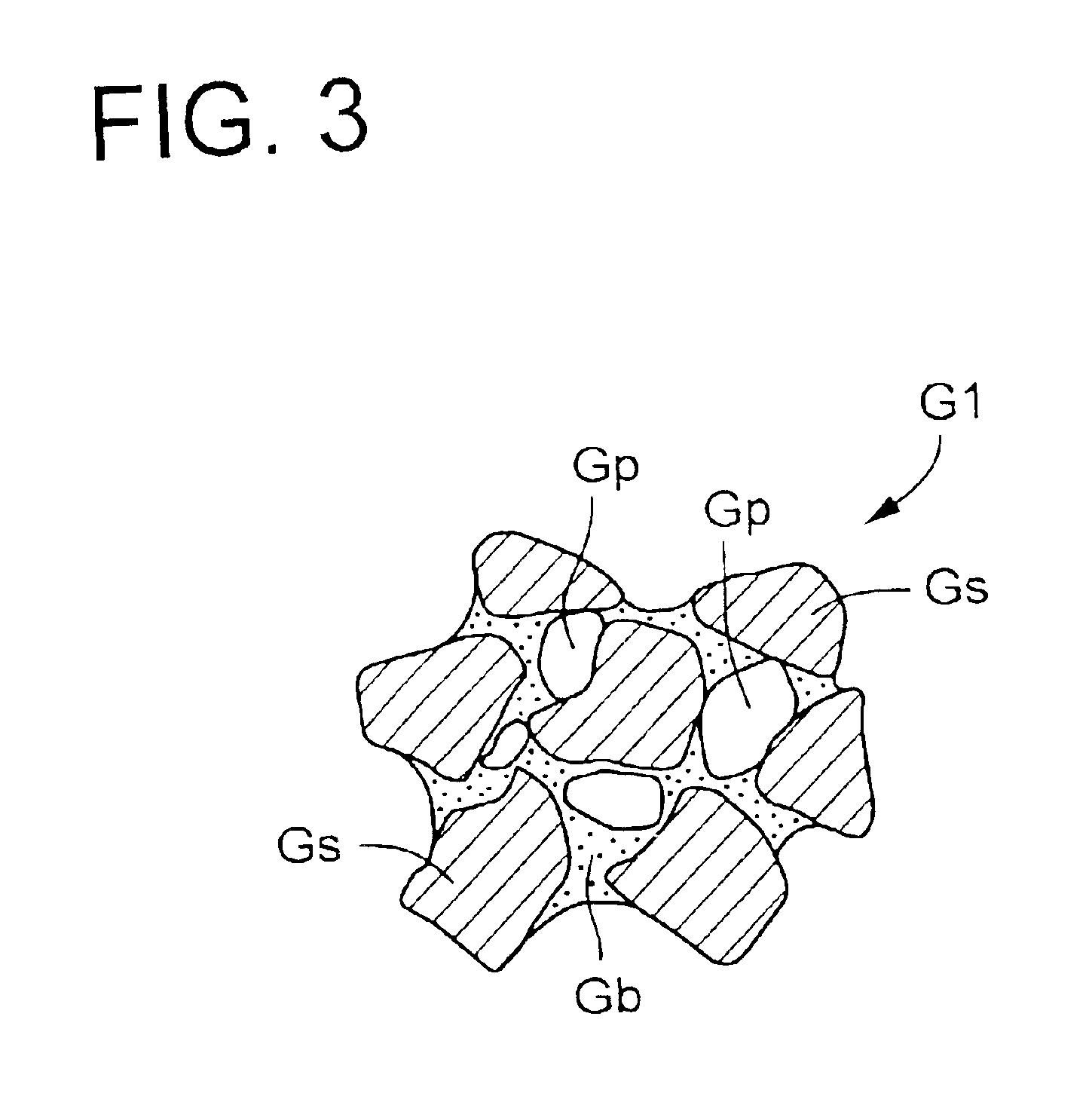

Grindstone having resinoid abrasive structure including abrasive agglomerates each provided by vitrified abrasive structure

InactiveUS6805620B2Improve rigidityReduce removalRevolution surface grinding machinesAbrasion apparatusMaterials scienceGrindstone

A resinoid grindstone including a main body having an abrasive structure in which abrasive agglomerates are held together by a resin bond. Each of the abrasive agglomerates includes abrasive grains which are held together by an inorganic bond. The resin bond includes a filler such that a ratio of a strength of the abrasive agglomerates to a strength of the resin bond is not higher than 1.5. A ratio of a total weight of the abrasive agglomerates included in the abrasive structure, to a weight of the abrasive structure is not lower than 10% and is not higher than 40%.

Owner:NORITAKE CO LTD

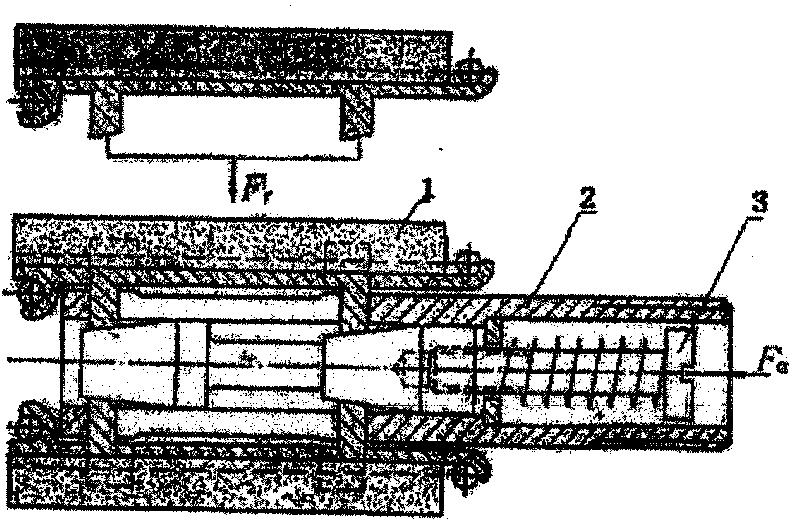

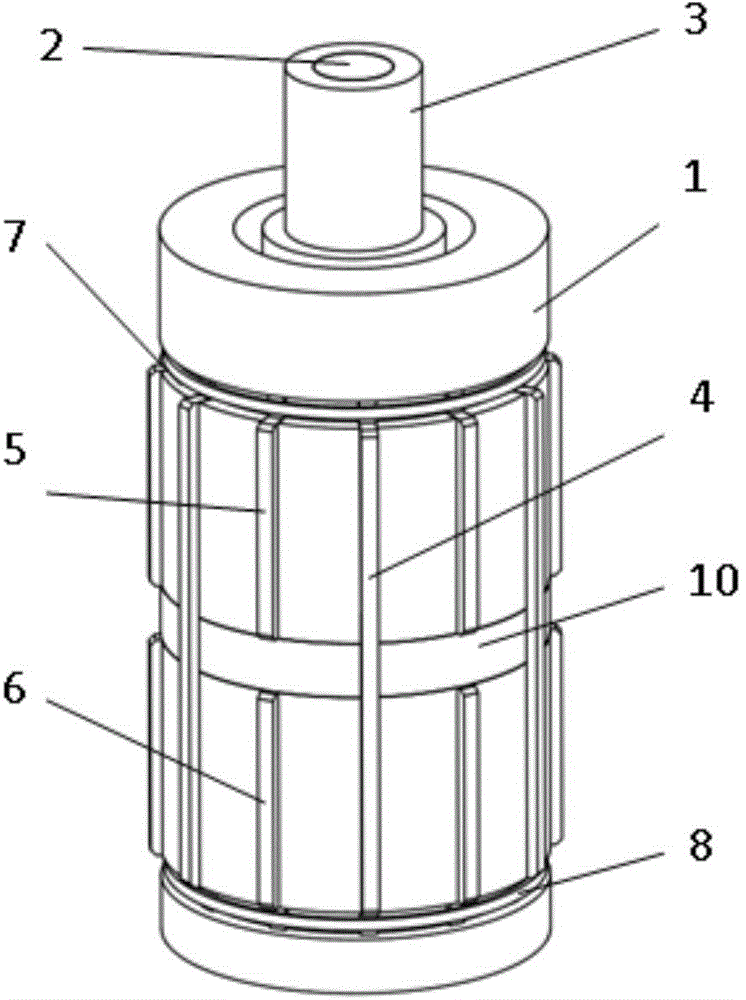

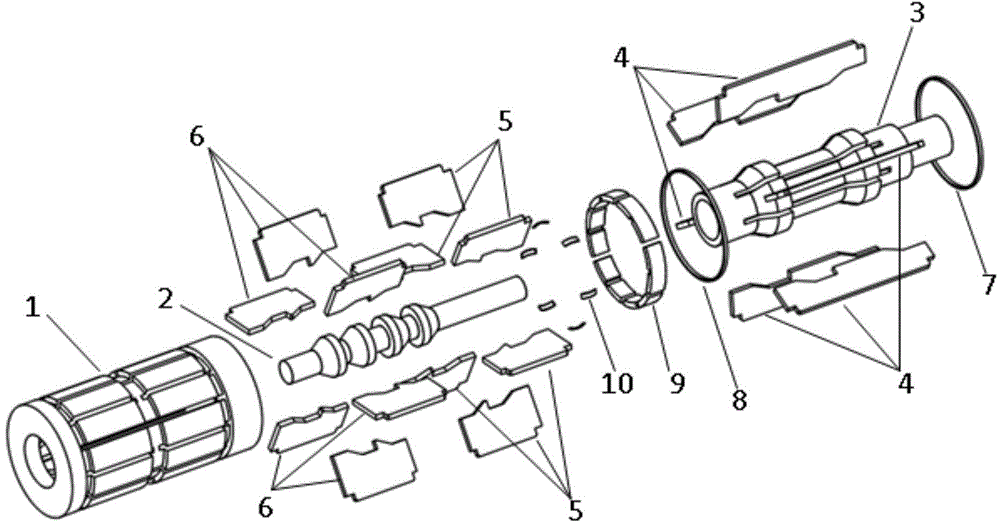

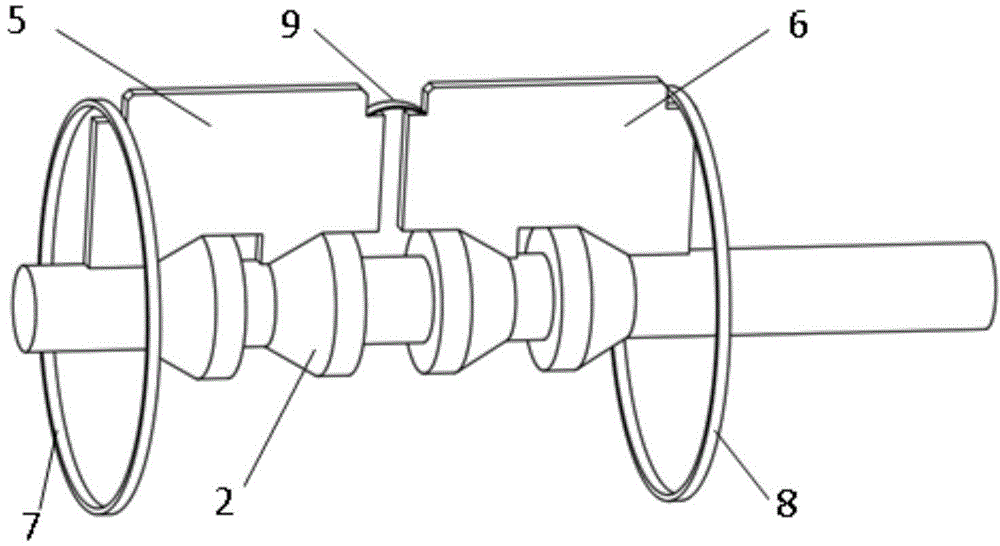

Sectional feeding honing head device with shape deviation compensation function

ActiveCN104400613ANo need to change the running trackSimplify movementGrinding drivesHoning toolsReciprocating motionShape deviation

The invention relates to a sectional feeding honing head device with a shape deviation compensation function. The sectional feeding honing head device with the shape deviation compensation function comprises a main body, an inner spindle, an outer spindle, a main oilstone seat, an upper compensation oilstone seat and a lower compensation oilstone seat, wherein the inner spindle is installed in a hole of the outer spindle, the outer spindle is installed in a center hole of the main body, the main oilstone seat is installed in a main oilstone groove of the main body, the upper compensation oilstone seat and the lower compensation oilstone seat are installed in compensation oilstone grooves of the main body, the edges of the two ends of the main oilstone seat are respectively pressed by a retraction spring ring, the edges of the outer sides of the upper compensation oilstone seat and the lower compensation oilstone seat are respectively pressed by a retraction spring ring, the edges of the inner sides of the upper compensation oilstone seat and the lower compensation oilstone seat are pressed by retraction leaf springs, the upper compensation oilstone seat and the lower compensation oilstone seat are fixed by compensation oilstone fixing blocks, and a main oilstone and compensation oil stones are respectively installed on the corresponding oilstone seats. The sectional feeding honing head device with the shape deviation compensation function has the advantages that since the device itself has the shape deviation compensation function, under the situation that the back-and-forth movement trajectory of the honing head is unchanged, the shape deviation which occurs during machining can be compensated in real time and the shape accuracy of the honed inner bore can be guaranteed.

Owner:SHANGHAI JIAO TONG UNIV

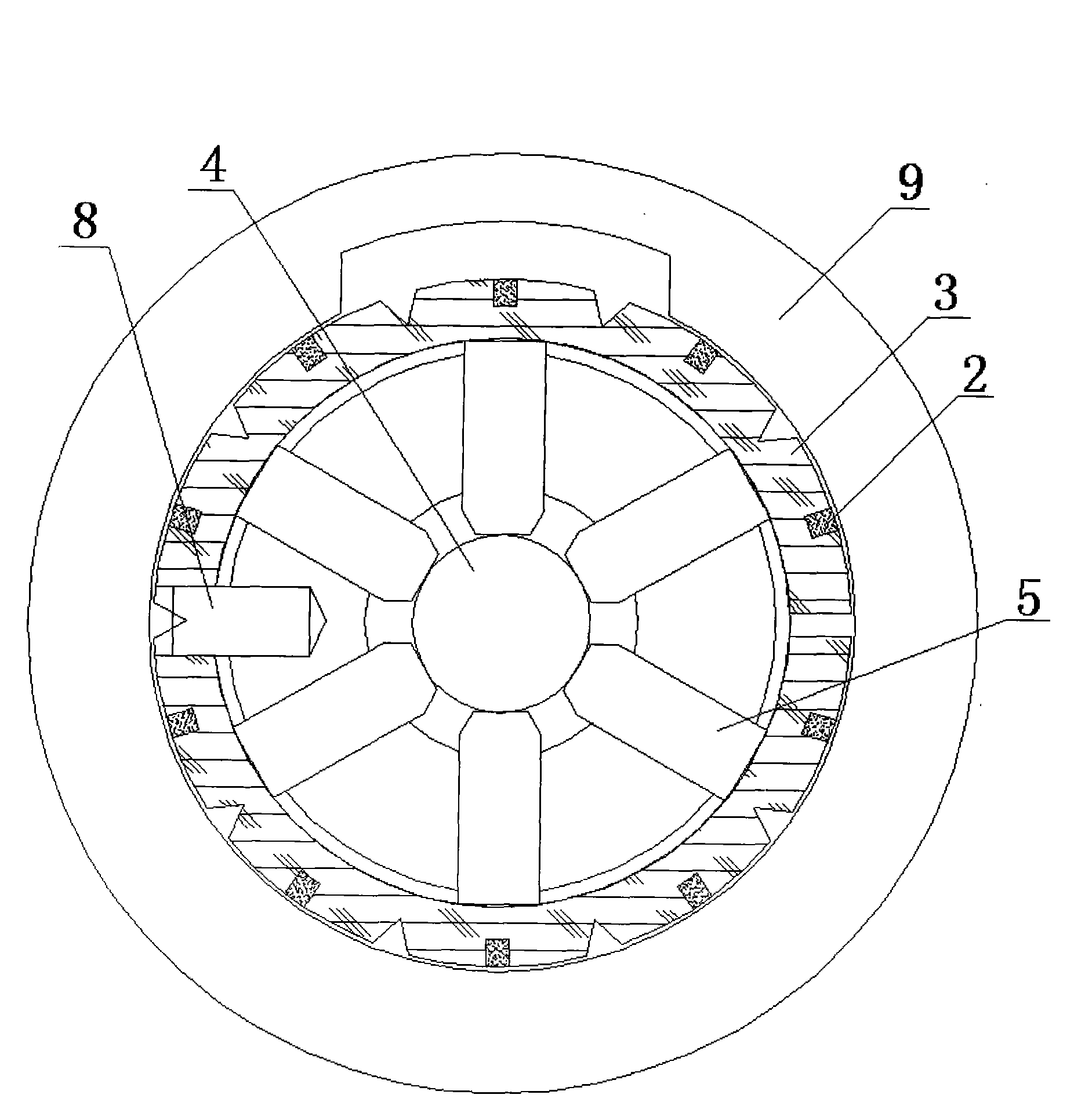

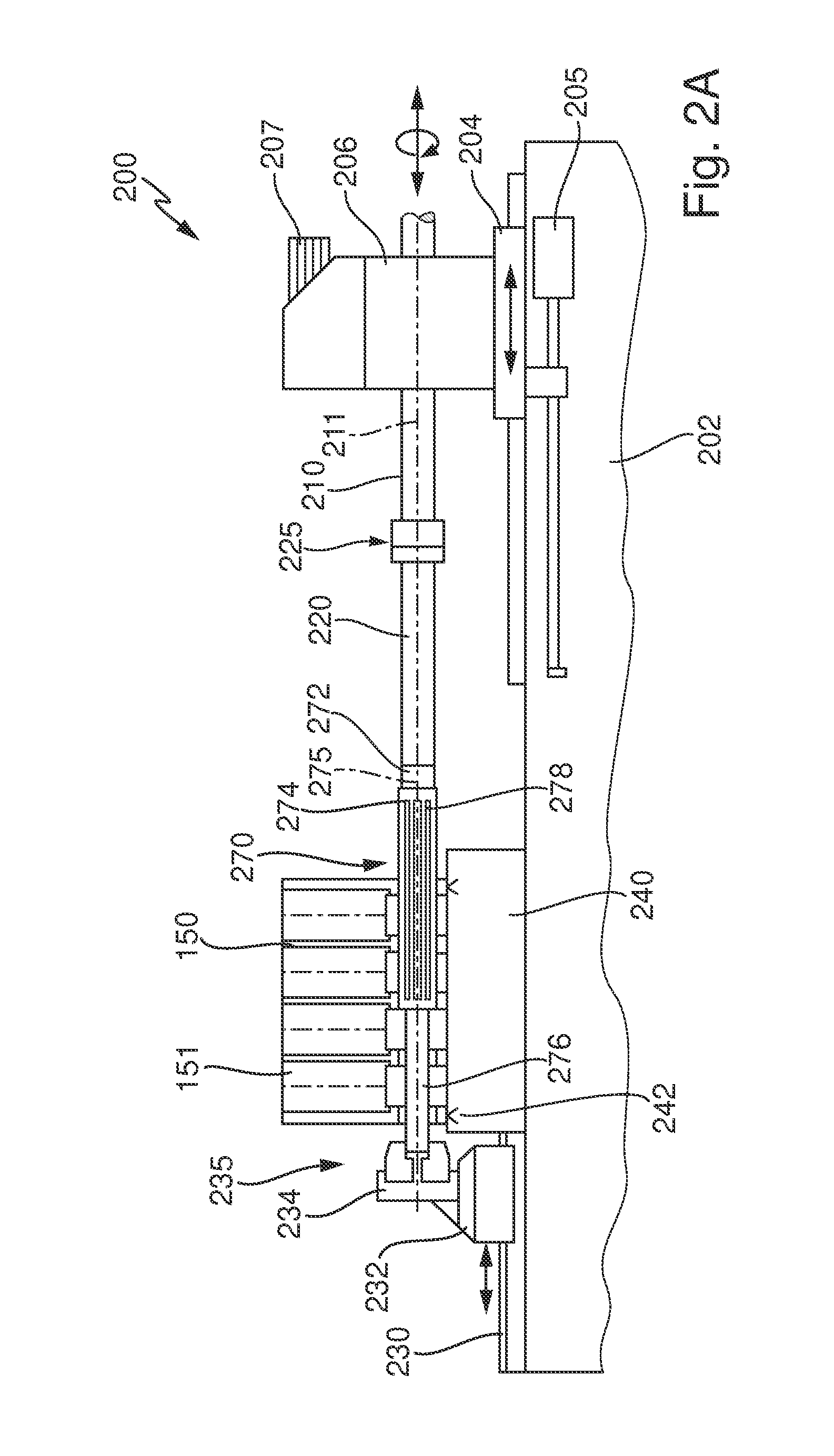

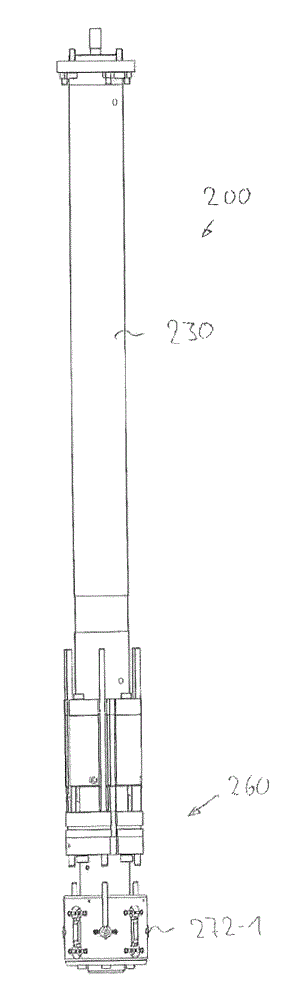

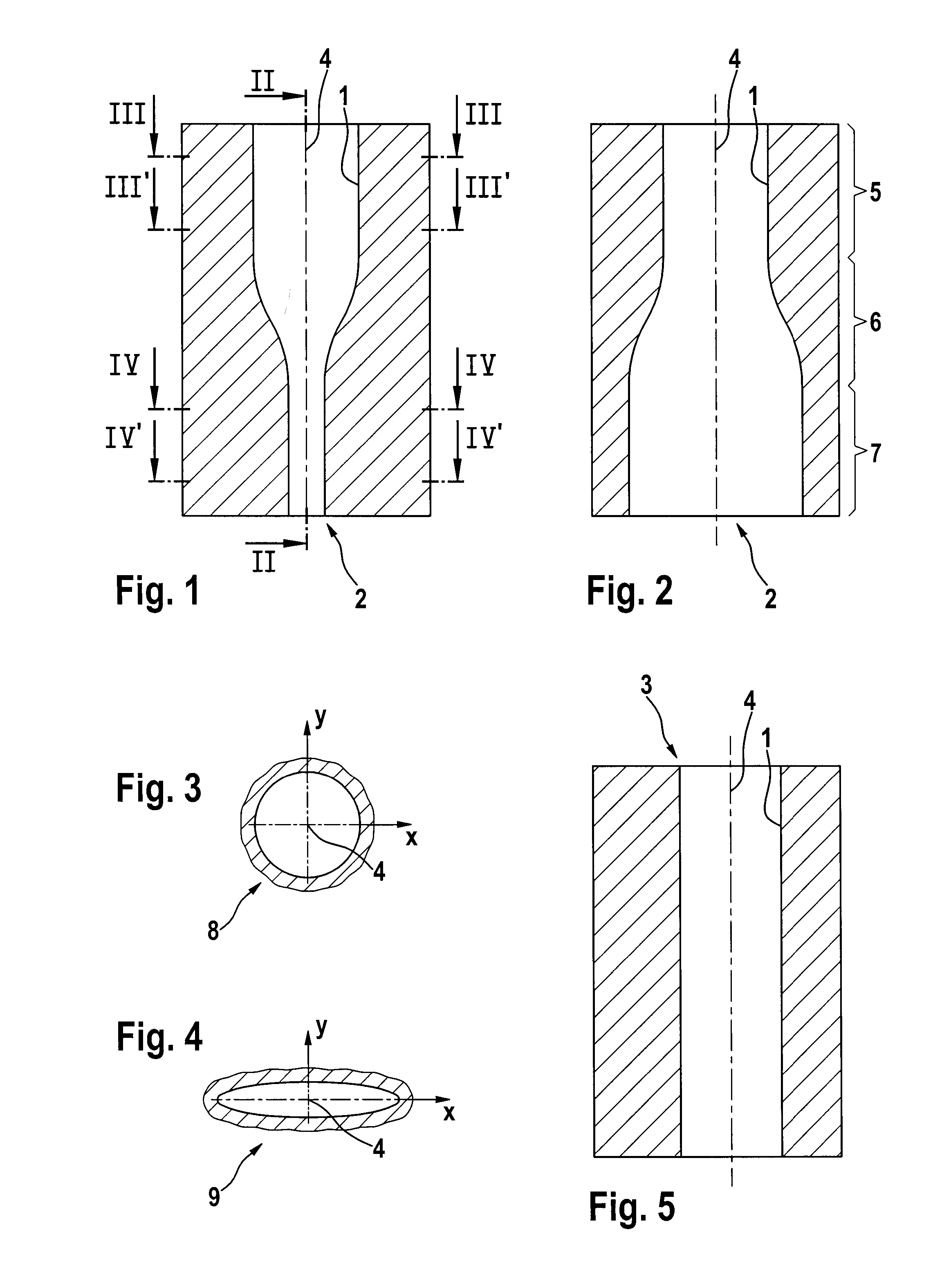

Honing method and honing tool

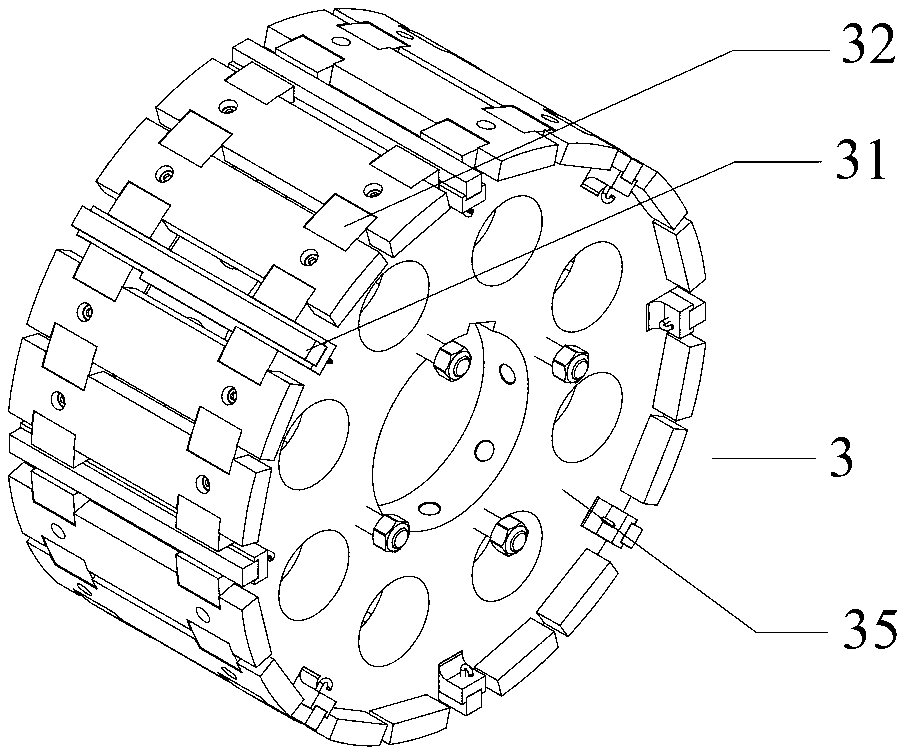

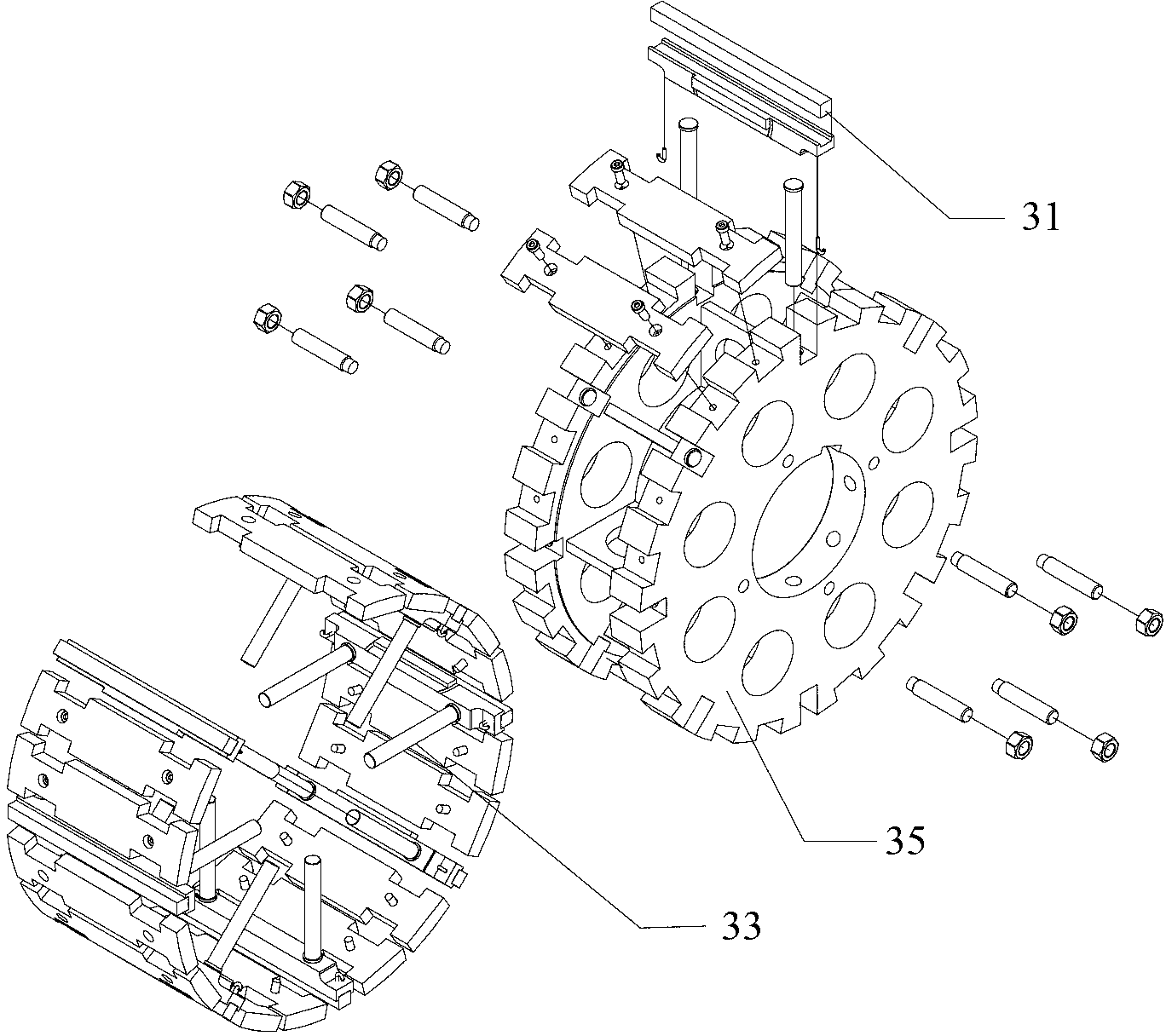

ActiveCN105246649AAvoid leaningAvoid uneven wearHoning toolsHoning machinesReciprocating motionEngineering

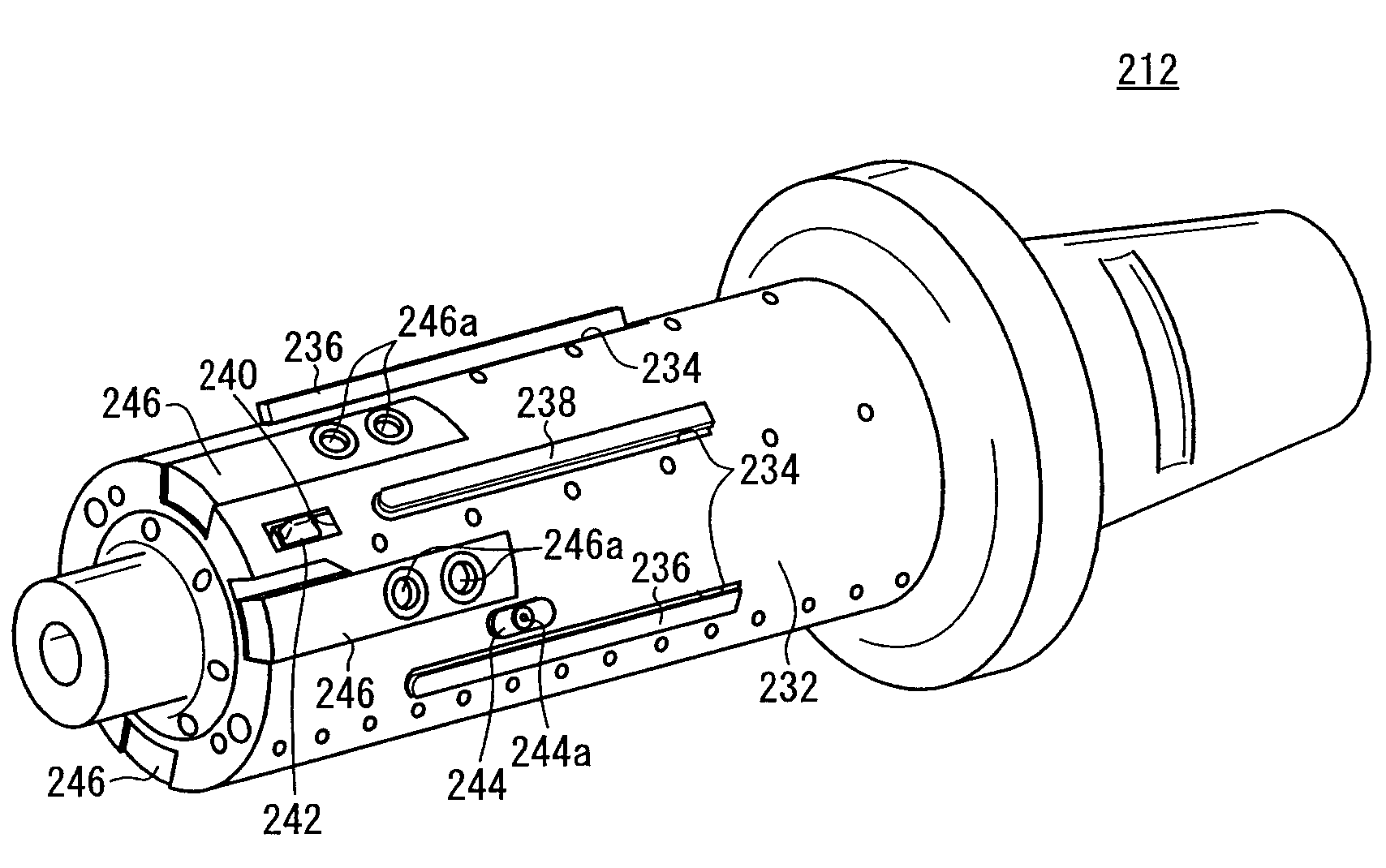

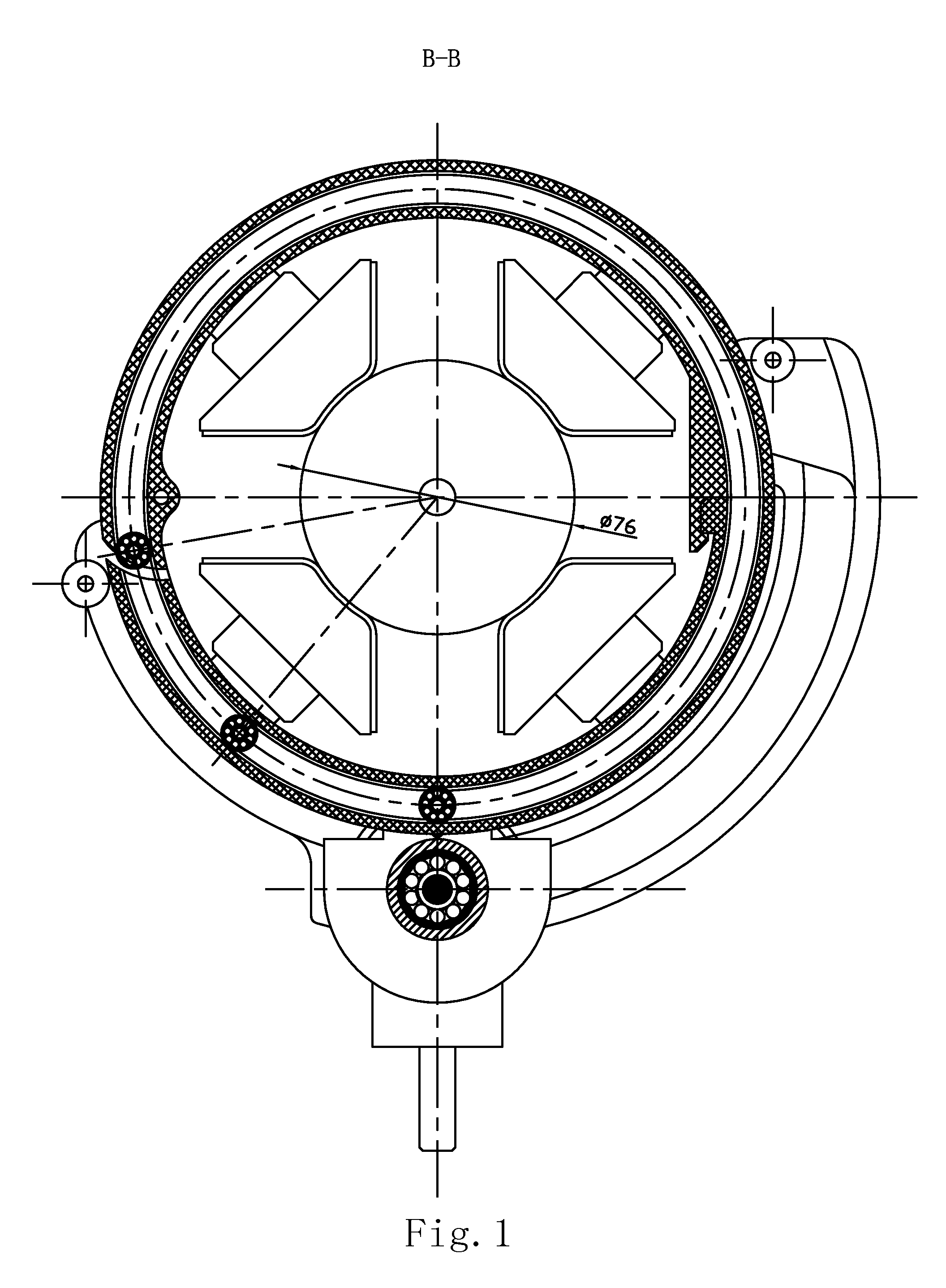

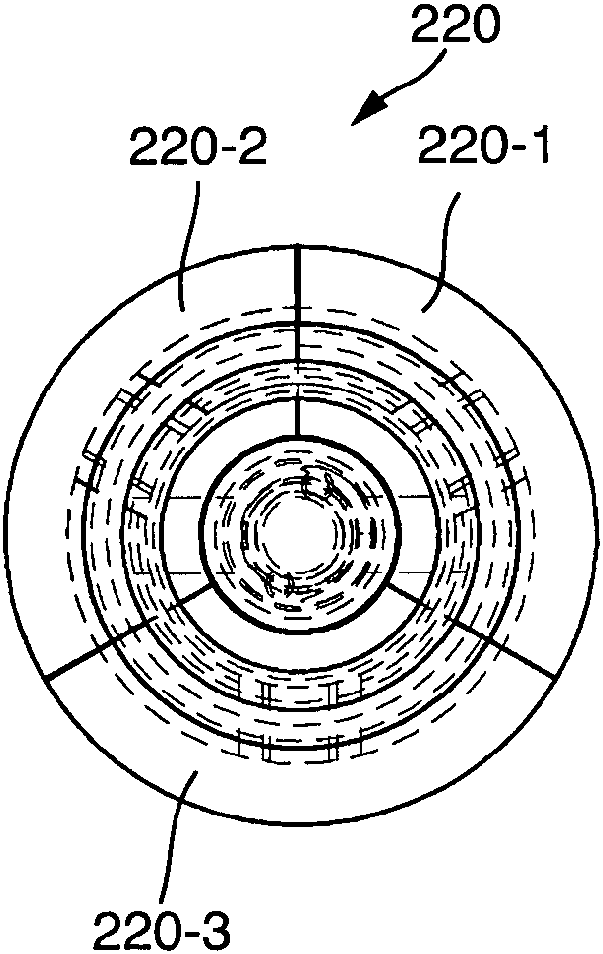

In a honing method for machining the internal surface of a bore in a workpiece with the aid of at least one honing operation, during a honing operation an expandable honing tool is moved up and down within the bore in order to produce a reciprocating movement in the axial direction of the bore and at the same time is rotated in order to produce a rotary movement superimposed on the reciprocating movement. In the process, a bottle-shaped bore is produced, said bore having a first bore section with a first diameter after a bore inlet, a second bore section with a second diameter greater than the first diameter away from the bore inlet, and a transition section having a continuous transition from the first diameter to the second between the first and the second bore section. In this case, during at least one honing operation use is made of an annular tool (200) which has at least one annular cutting unit (220) with a plurality of radially adjustable cutting-material bodies that are distributed around the circumference of a tool body and are formed as honing segments that are wide in the circumferential direction and narrow in the axial direction, wherein an axial length, measured in the axial direction, of the honing segments is less than the width measured in the circumferential direction and the axial length of the cutting region equipped with cutting-material bodies is less than the effective outside diameter of the honing tool. The method is particularly suitable for honing cylinder running surfaces in the production of cylinder blocks or cylinder liners for reciprocating piston machines.

Owner:ELGAN DIAMANTWERKZEUGE

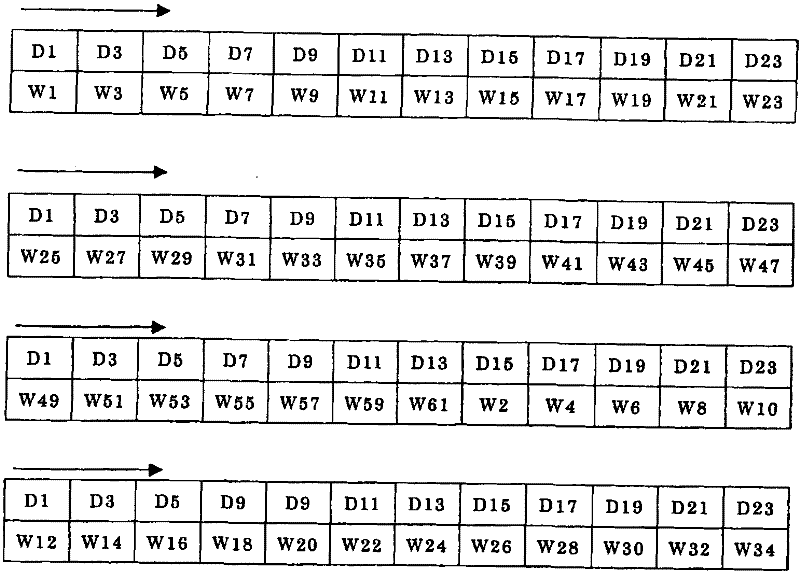

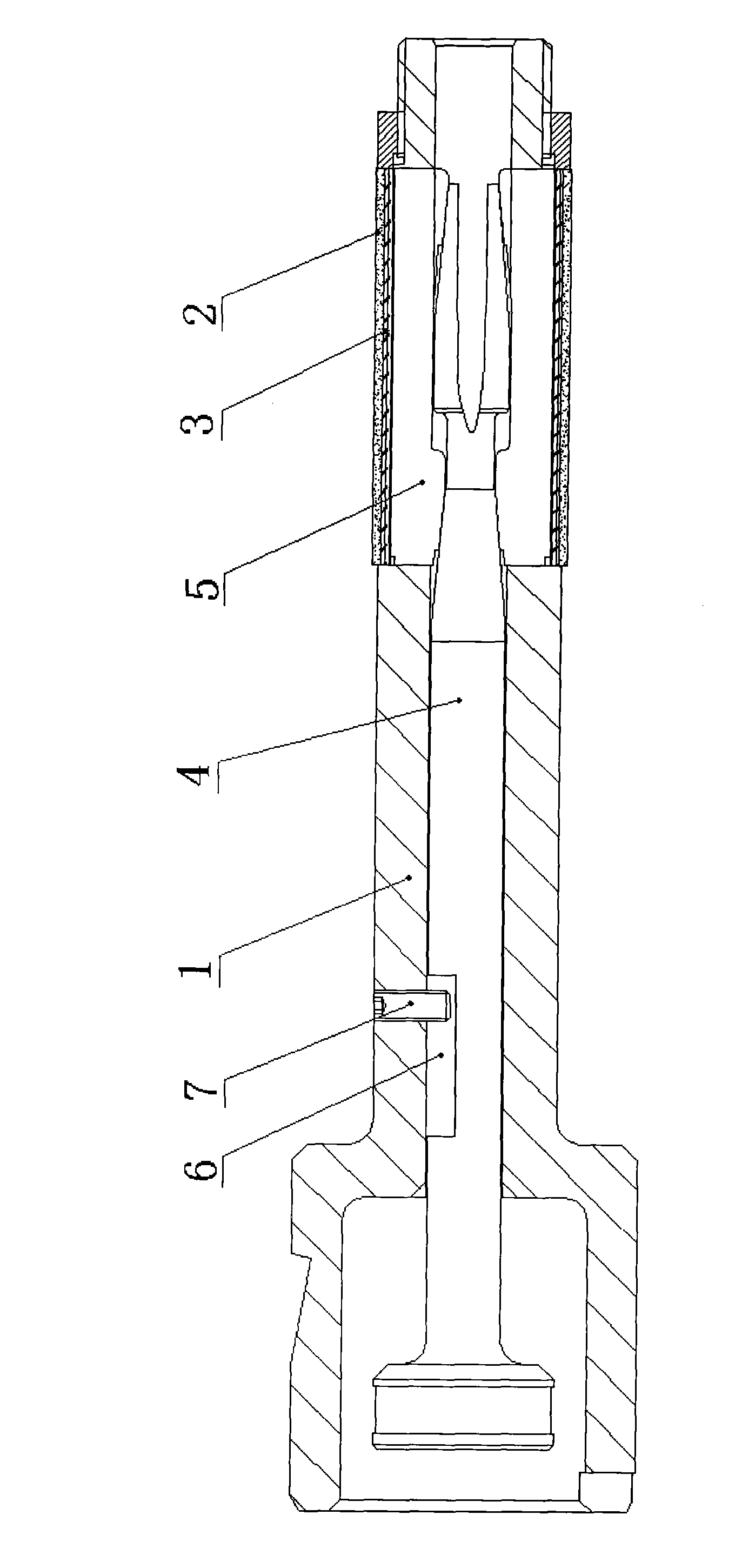

Method and apparatus for automatically changing of honing tools

InactiveCN1712188AEasy to installEasy to disassembleGrinding wheel securing apparatusHoning toolsEngineeringChange positions

The invention relates to a method for exchanging a honing tool on a honing rod, wherein a honing rod is provided for transmitting machining forces from the honing machine spindle to the honing tool and the honing rod has a function for controlling the honing tool that can be compared to the honing tool. An operating device for rod movement, and a corresponding connecting structure of a connecting device on the honing tool and the honing rod, for releasably connecting the honing tool to the honing rod, the connecting device includes at least one relatively movable locking member, used For releasably locking the honing tool to the honing rod, it is characterized in that the locking element is actuated and the honing tool is fixed in the exchange position by applying an external external force to the connecting device by means of the fixing device.

Owner:NAGEL MASCHEN UND WERKZEUGFAB

Honing abrasive belt

The invention relates to a honing abrasive belt which is made of an adhesive and a grinding material, wherein the adhesive consists of the following raw materials in percentage by volume: 5-15 percent of zinc powder, 30-60 percent of cobalt powder, 10-35 percent of copper powder and 15-30 percent of silver powder; the grinding material is self-sharpening artificial diamond particles on which Ni coatings are plated; the particles have particle diameters of D76-D181; and the grinding material content is 3-15 percent of the adhesive in volume. In the abrasive belt, the adhesive belt with a reasonable proportion is selected and used; the hardness of the manufactured honing abrasive belt reaches HB40-60; and the honing abrasive belt has a good application effect. The geometric dimensions of the abrasive belt are as follows: the length is 100-200mm, the width is 1.5-6mm and the height is 6mm; and a reticulated pattern of a cylinder liner which meets the European VI emission standard can be processed.

Owner:GKN ZHONGYUAN CYLINDER LINER CO LTD

Honing Tool

InactiveUS20140113535A1Reduce manufacturing costSpace minimizationRevolution surface grinding machinesHoning toolsMechanical engineering

A honing tool for machining cylindrical bores has a tool body provided with a guide bore and a feed rod disposed in the guide bore. The tool body has a honing stone receptacle extending from the guide bore in a radial direction of the tool body outwardly through the tool body. A honing stone is arranged in the honing stone receptacle. A pin is disposed in the honing stone and projects laterally from the honing stone. An elongate spring is disposed in the tool body parallel to the honing stone, wherein the elongate spring element has a first end section, a central section, and a second end section opposite the first end section. The central section is guided across the pin and the first end section is secured in the radial direction in the tool body.

Owner:GEHRING TECH

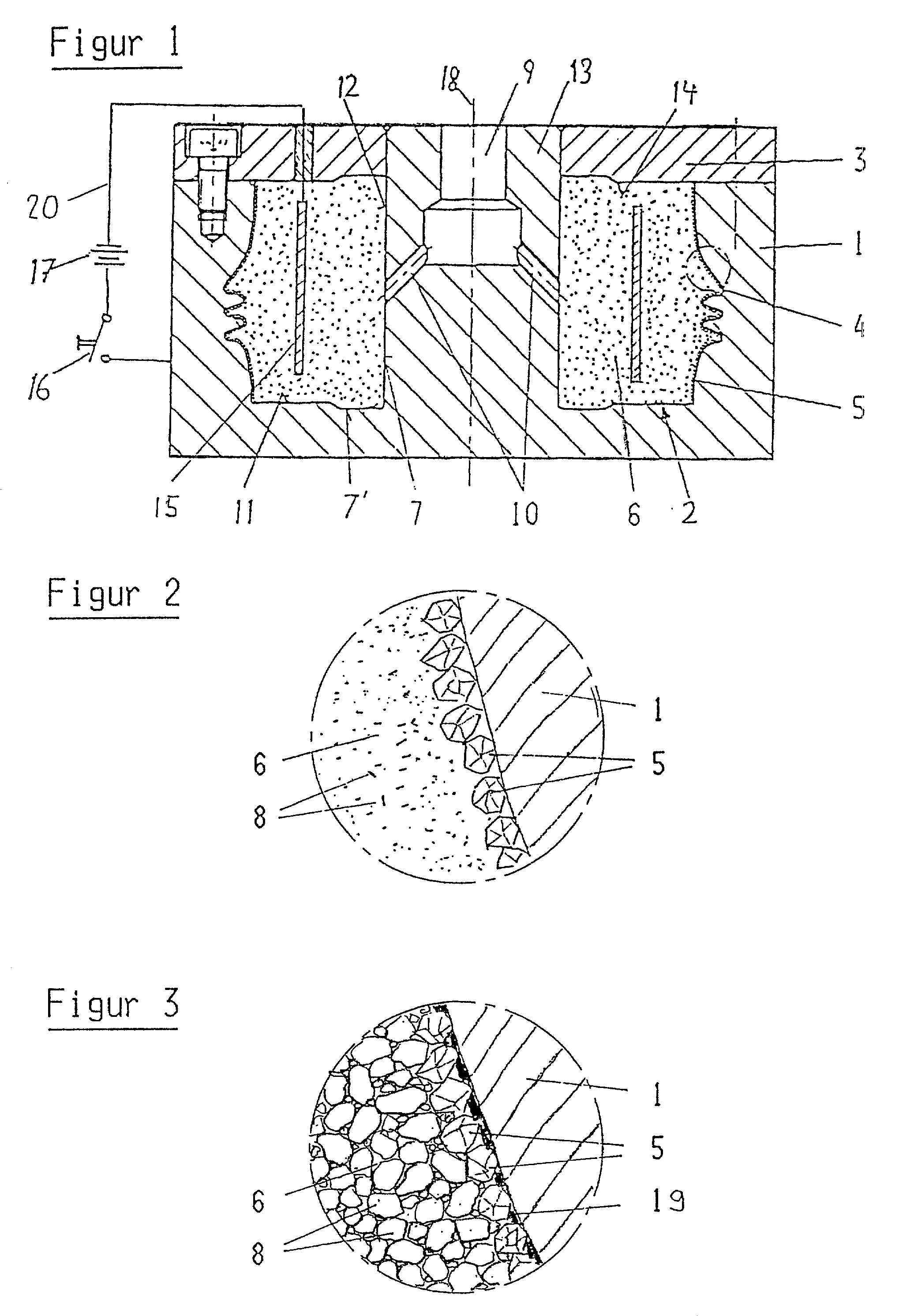

Dressing, honing and grinding tool

InactiveUS20010004581A1Revolution surface grinding machinesBonded abrasive wheelsInterior spaceSolid particle

In a negative mould (1) closed by a lid (3), hard material abrasive grains (5) are nickel-attached to the peripheral inside surface. The negative mould (1) contains, in addition to the outside contour (4) of the tool to be manufactured, also the surfaces for the location bore (7) and the end face locations (7') of the said tool. Subsequently the inner space of the negative mould (1) is completely filled with a casting mass (6) interspersed with solid particles (8) and the said mass allowed to harden. The mould (1) is removed by machining or etching. This process permits the inexpensive and economic manufacture of tools coated with hard material abrasive grains.

Owner:REISHAUER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com