Collapsible honing head

A technology of honing head and expansion and contraction, applied in the direction of honing tools, etc., can solve the problems of low labor productivity, unguaranteed quality, difficult operation, etc., and achieve the effect of saving material resources, improving labor productivity and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings, but the present embodiments are not intended to limit the present invention, and any similar structures and similar changes of the present invention should be included in the protection scope of the present invention.

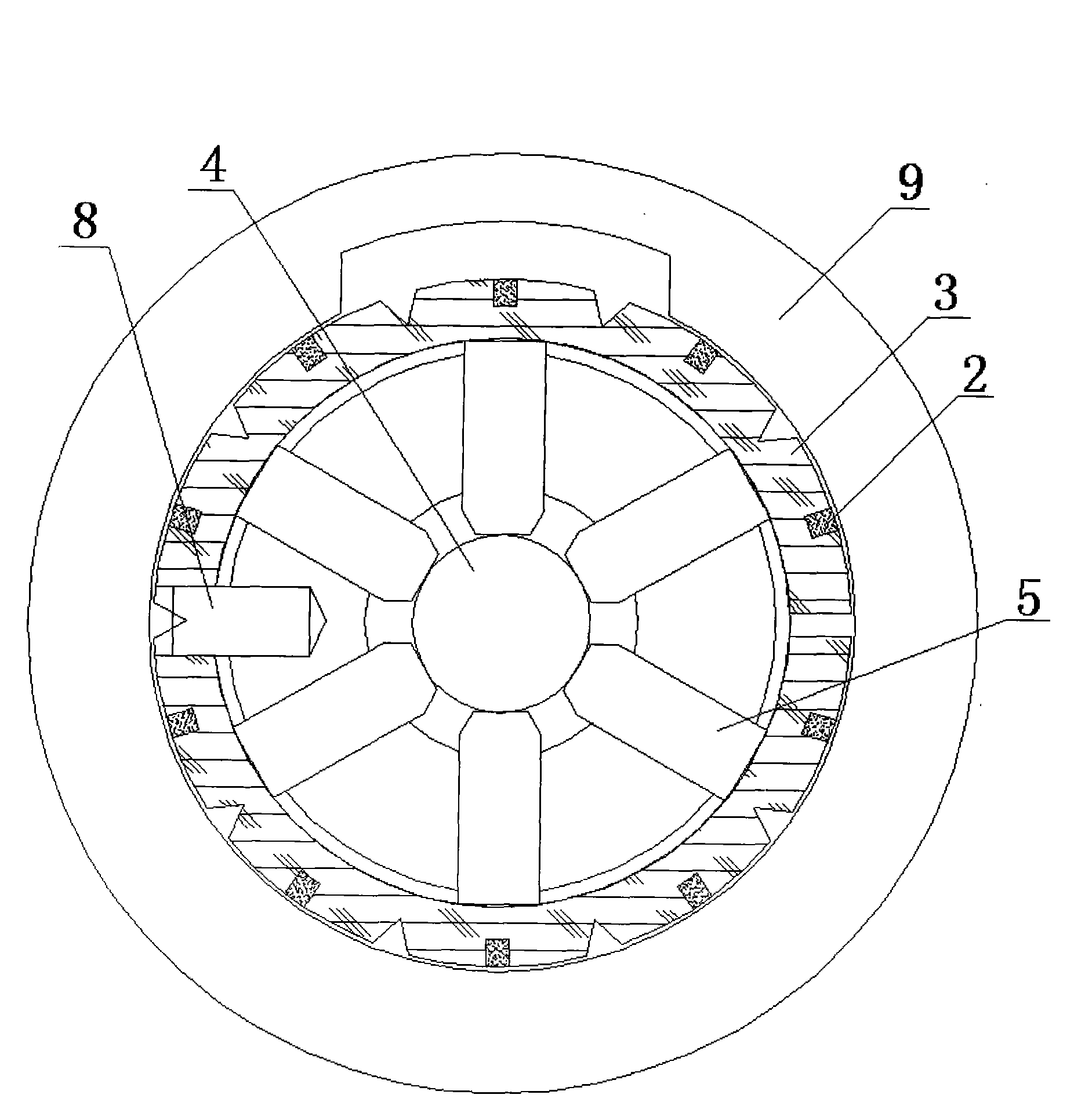

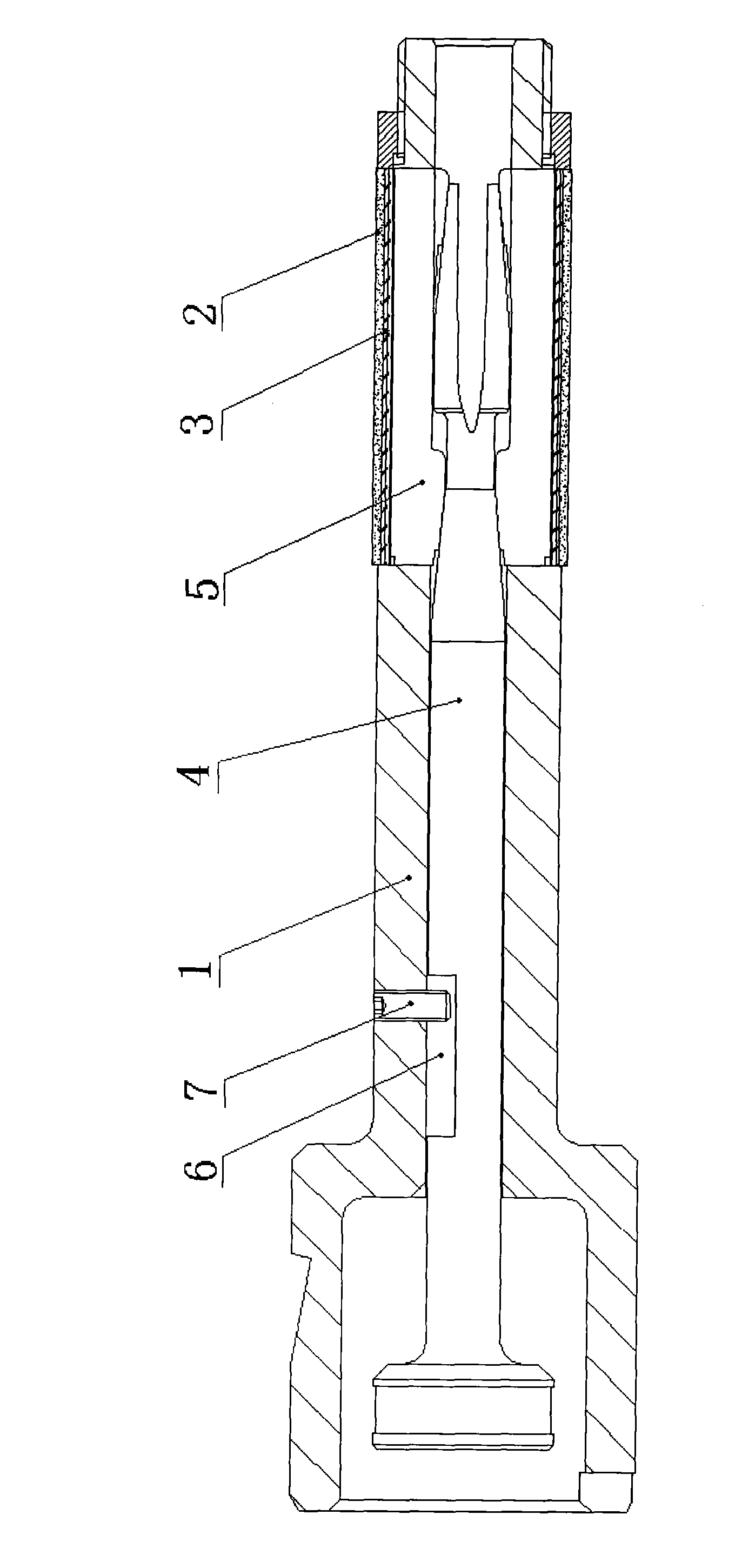

[0012] Such as figure 1 , figure 2 As shown, an expansion-contraction honing head provided by the embodiment of the present invention includes a housing 1, an expansion-contraction member arranged on the housing 1 that can expand and contract radially, an oil stone seat arranged on the expansion-contraction member, The oil stone 2 arranged on the oil stone seat is characterized in that: the oil stone seat is an open collar 3 sleeved on the expansion and contraction member and fixed, and the outer peripheral surface of the open collar 3 is arranged at least parallel to the axial direction. A piece of whetstone 2, the describe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com