Measuring unit for measuring drilled holes

A technology of measuring unit and measuring hole, which is applied in the direction of measuring device, using fluid device, instrument, etc., to achieve the effect of reliable operation and simple rough structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

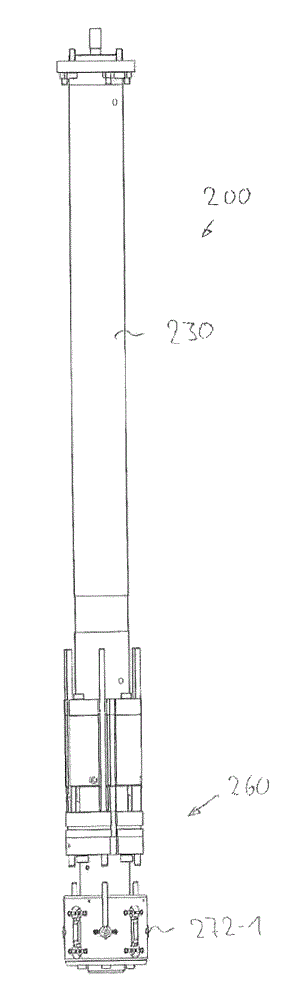

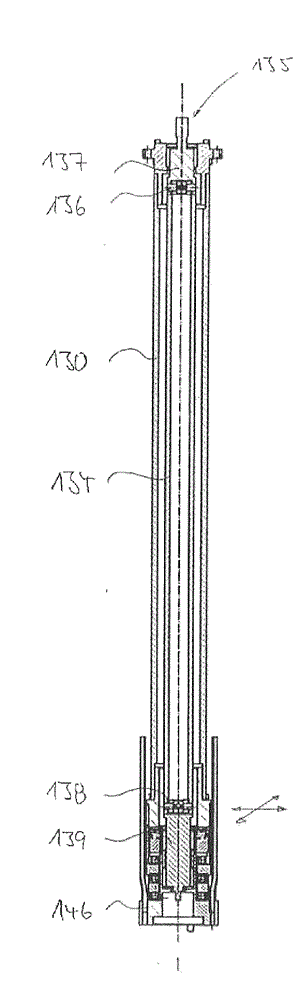

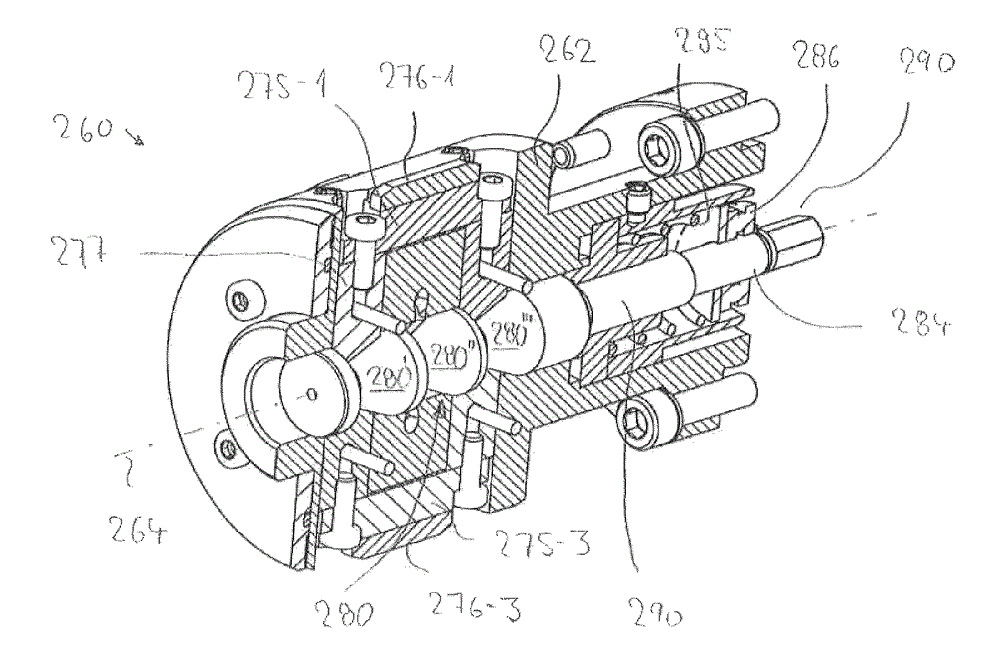

[0050] figure 1 The general illustration of the figure shows a pneumatic measuring unit 100 according to a first embodiment of the invention. The measuring unit can be used to measure the inner diameter in through holes or blind holes. In this example, the measuring unit is designed in conjunction with the honing machining of the hole in the workpiece 190 to perform an accurate inner diameter determination of the honed hole in a re-measurement operation after completion of the honing machining. For this purpose, the measuring unit is a constituent part of a measuring station integrated into the honing machine. Integration into a measuring station independent of the processing machine is also possible.

[0051] The measuring unit is equipped with a pneumatic plug gauge 160 with an adjustable diameter and allows testing the inner diameter of holes of different sizes with very low systematic measurement deviation and high repeatability. By using the same plug gauge, holes in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com