Patents

Literature

755 results about "Systematic measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

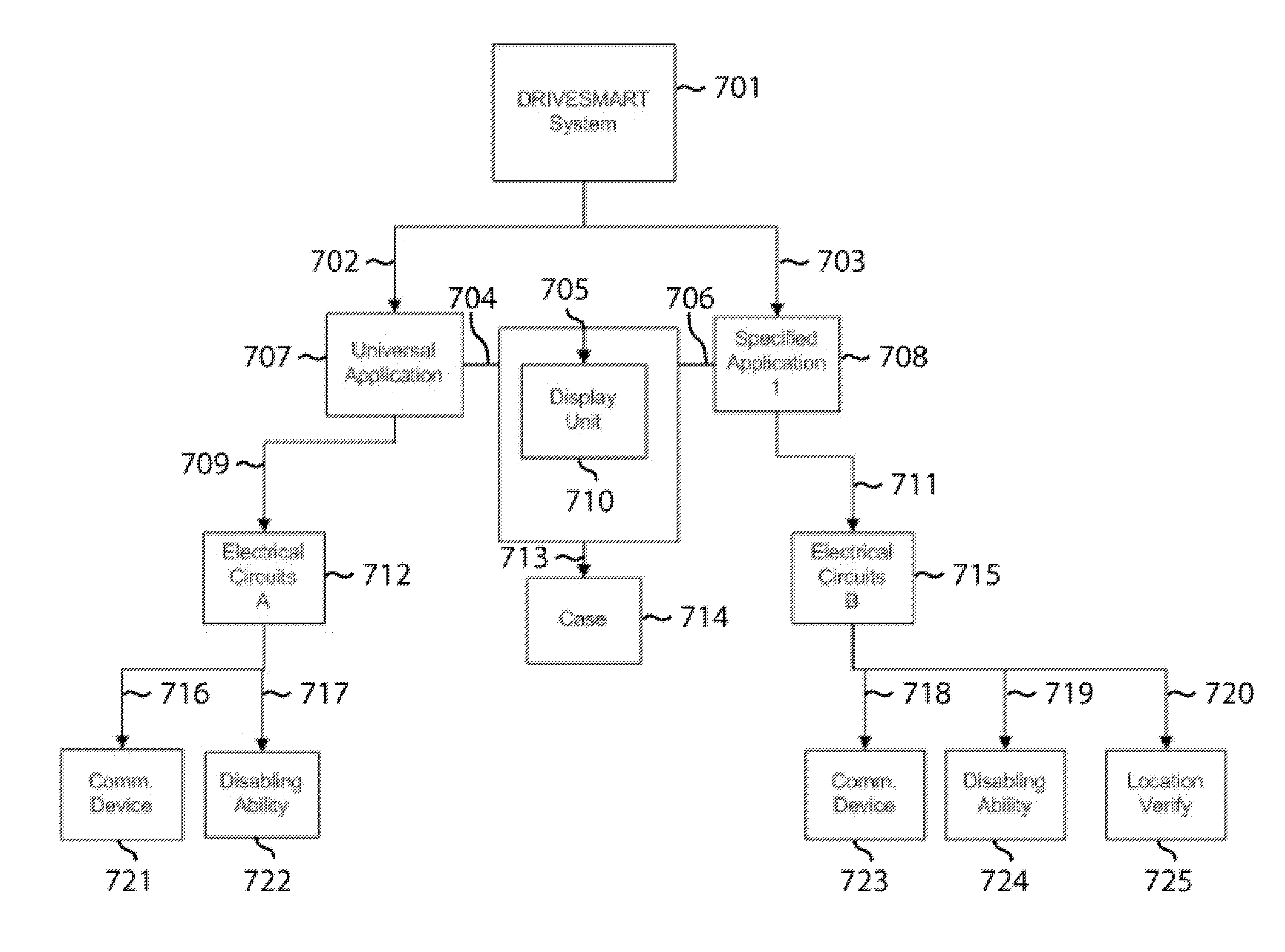

System and method for driver reaction impairment vehicle exclusion via systematic measurement for assurance of reaction time

InactiveUS20110304465A1Prevents DUI without social stigmaAlarmsDriver input parametersDriver/operatorMotor skill

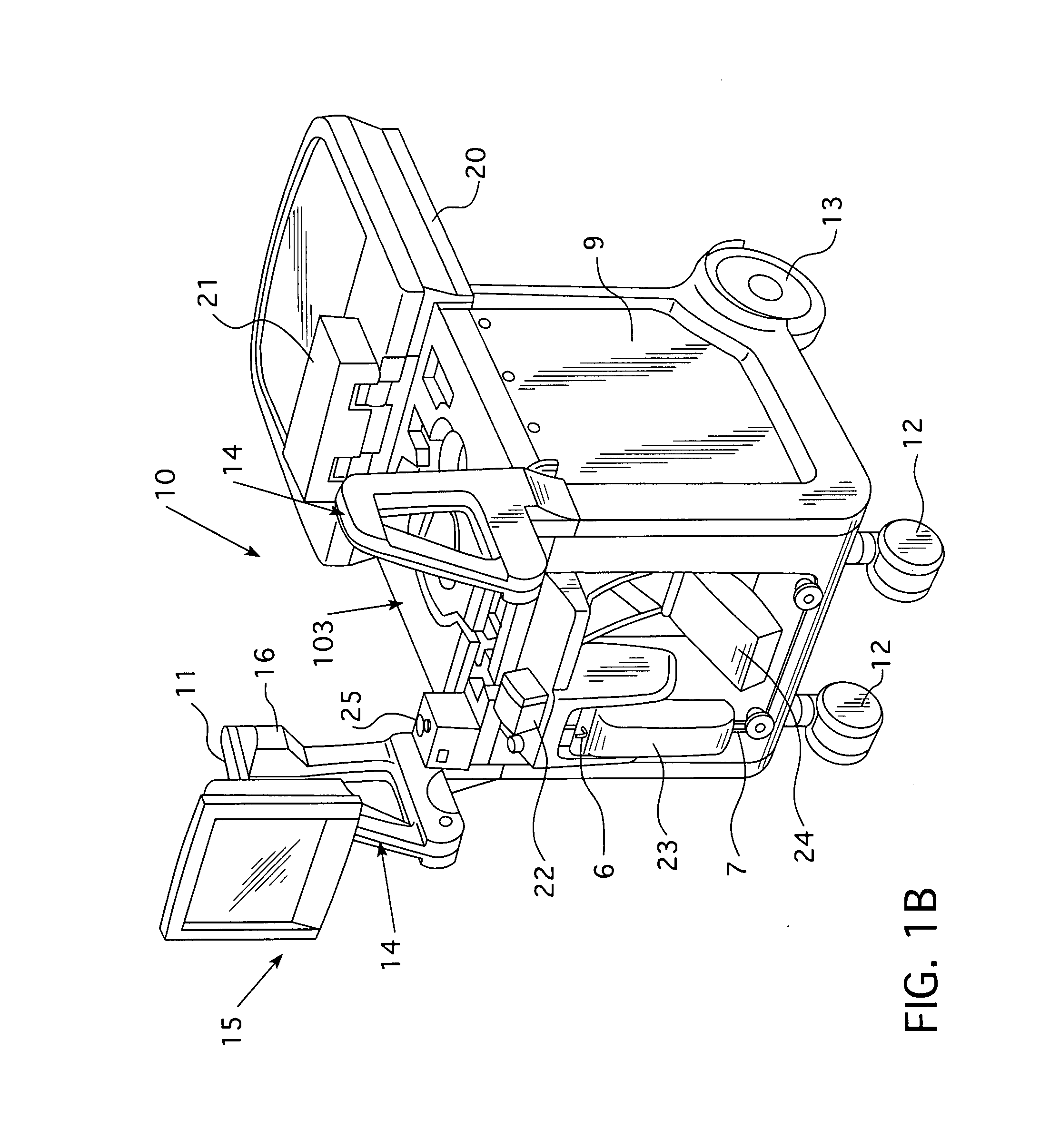

A system and method for measuring impairment in an operator and stopping an impaired operator from operating a vehicle. The method empirically measures an operator's cognitive and motor skills requisite for safely operating a motorized vehicle and verifies the person's identity. The invention includes three interlocking major subsystems. The first subsystem provides generalized impairment measurement unit. The second subsystem interfaces with the impairment measurement unit and a vehicle ignition system and ensures the vehicle does not start if the operator is impaired. The third system determines whether the person blowing into a drug and alcohol analyzer connected to the first system is that person by detecting a various biometric. If the operator is not impaired and their identity is verified the vehicle ignition is enabled. If the operator is indeed impaired beyond a level requisite to safely operate the vehicle the ignition is disabled.

Owner:BOULT TERRANCE E +1

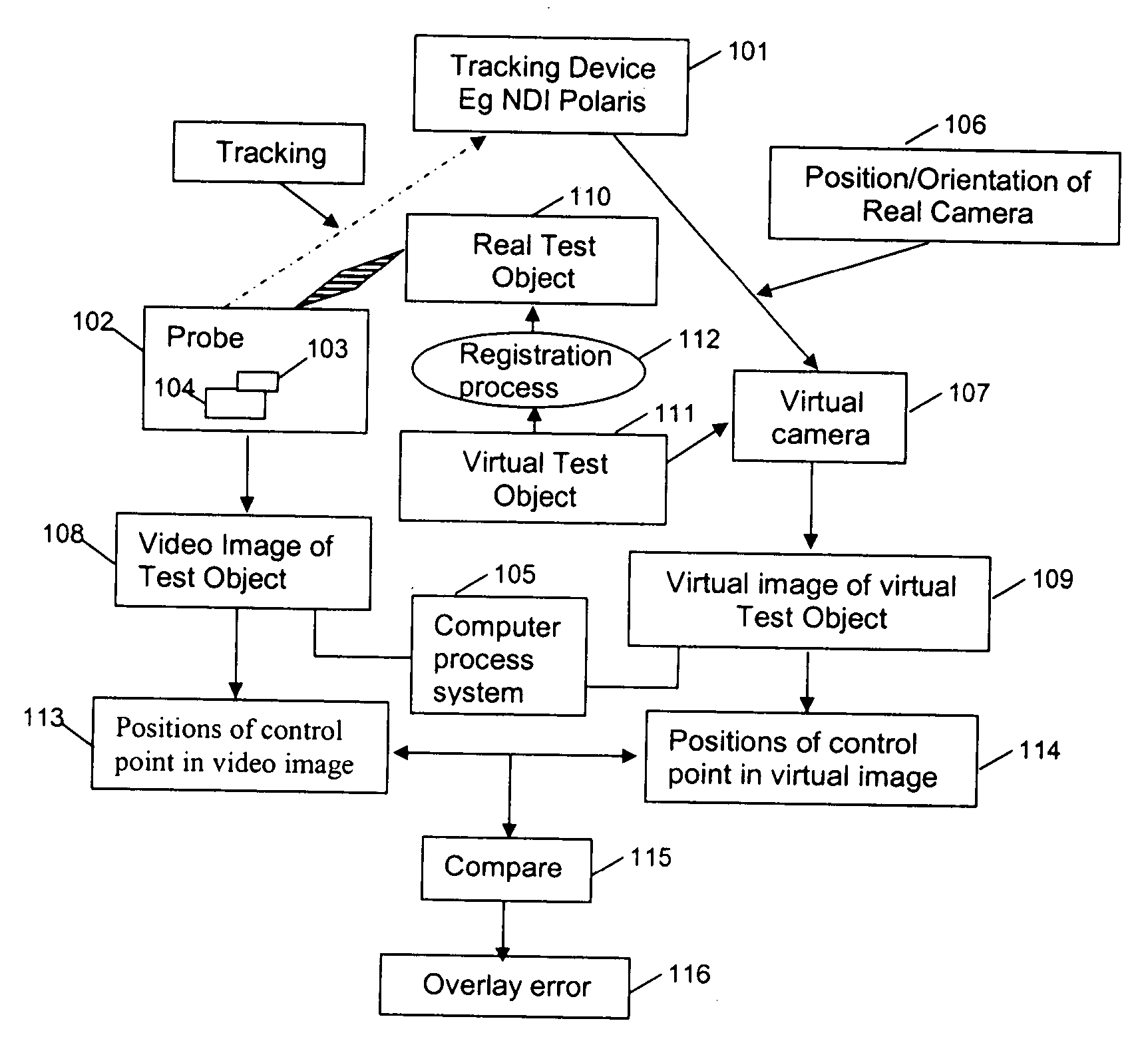

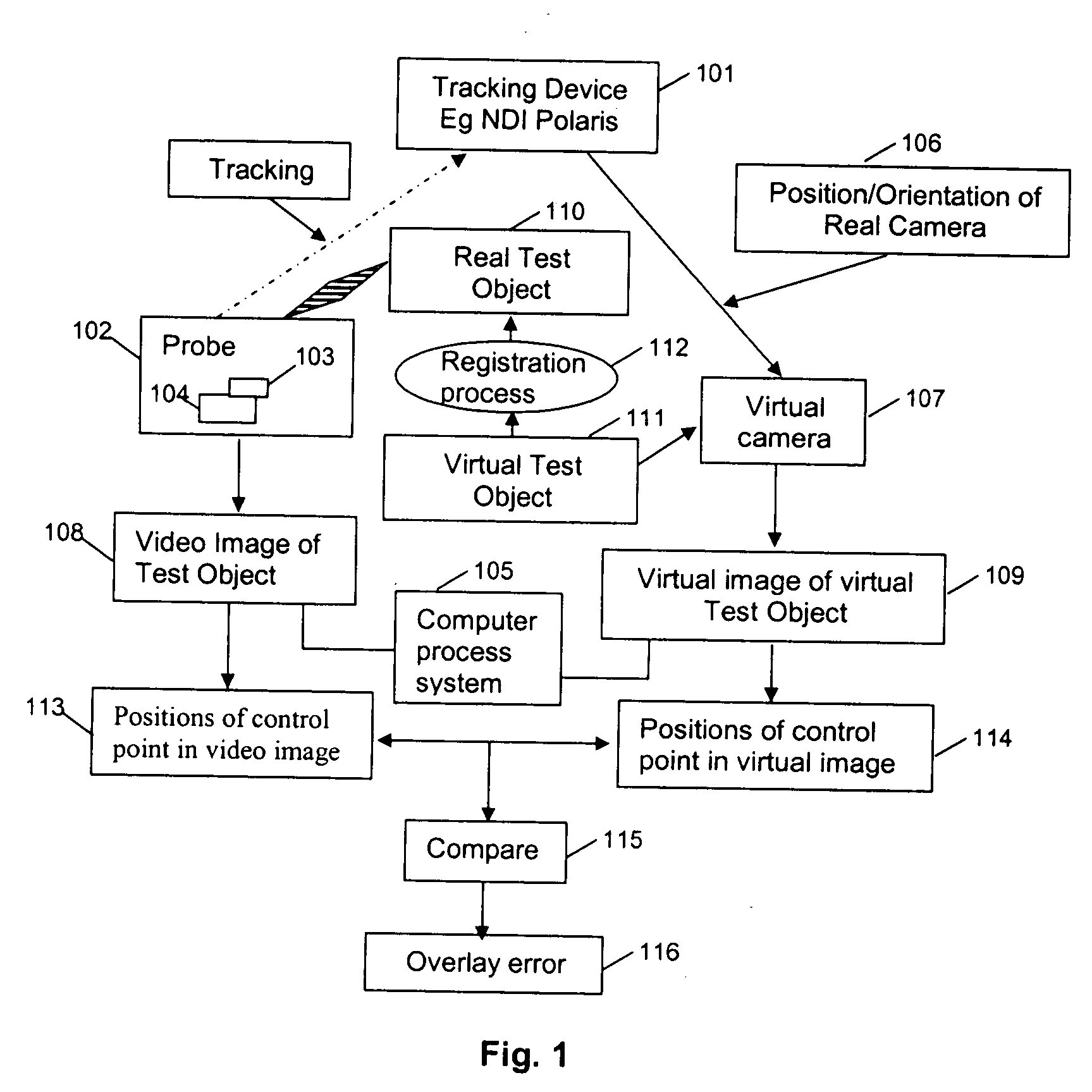

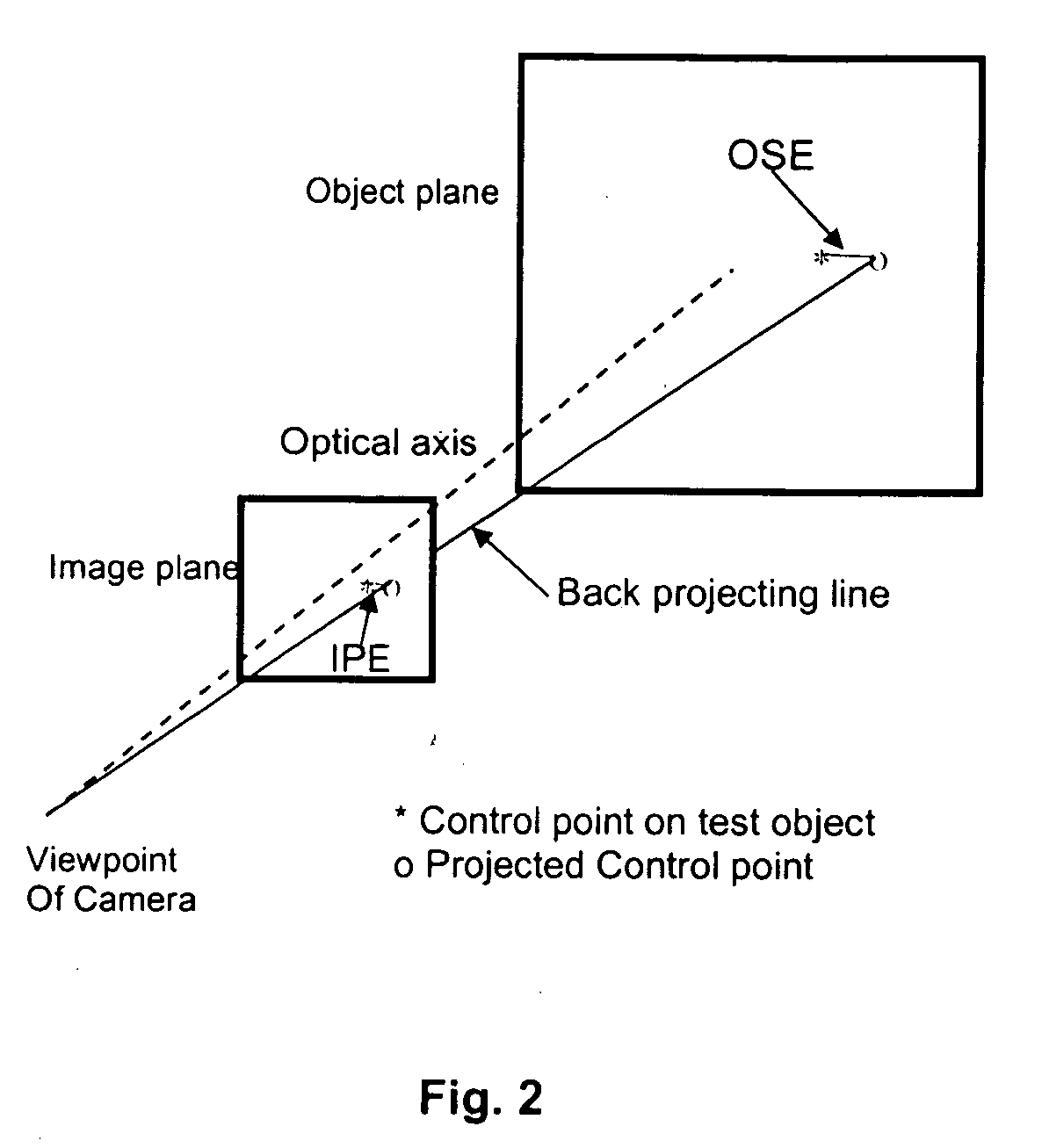

Accuracy evaluation of video-based augmented reality enhanced surgical navigation systems

Systems and methods for measuring overlay error in a video-based augmented reality enhanced surgical navigation system are presented. In exemplary embodiments of the present invention the system and method include providing a test object, creating a virtual object which is a computer model of the test object, registering the test object, capturing images of control points on the test object at various positions within an augmented reality system's measurement space, and extracting positions of control points on the test object from the captured images, calculating the positions of the control points in virtual image, and calculating the positional difference of positions of corresponding control points between the respective video and virtual images of the test object. The method and system can further assess if the overlay accuracy meets an acceptable standard. In exemplary embodiments of the present invention a method and system are provided to identify the various sources of error in such systems and assess their effects on system accuracy. In exemplary embodiments of the present invention, after the accuracy of an AR system is determined, the AR system may be used as a tool to evaluate the accuracy of other processes in a given application, such as registration error.

Owner:BRACCO IMAGINIG SPA

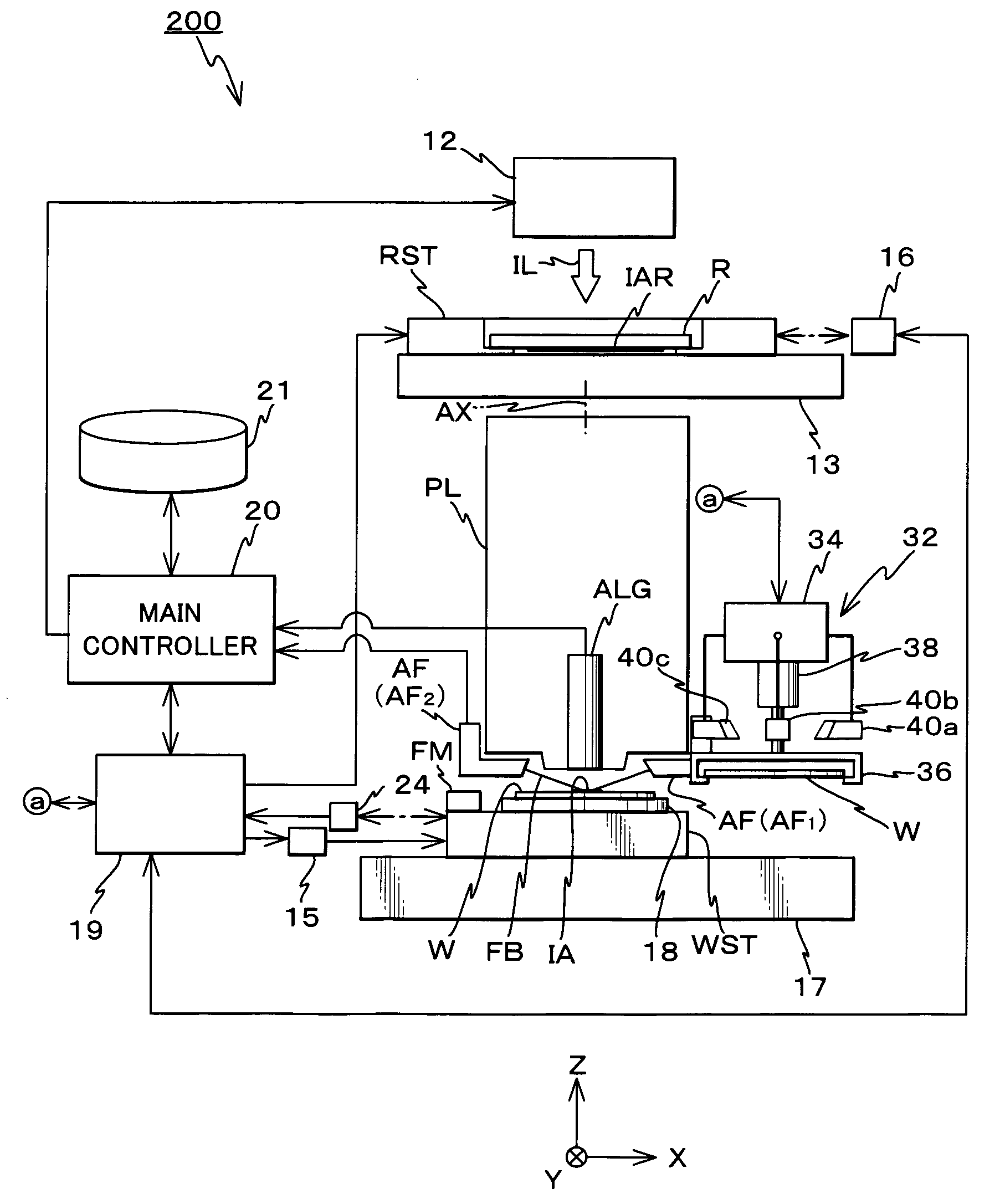

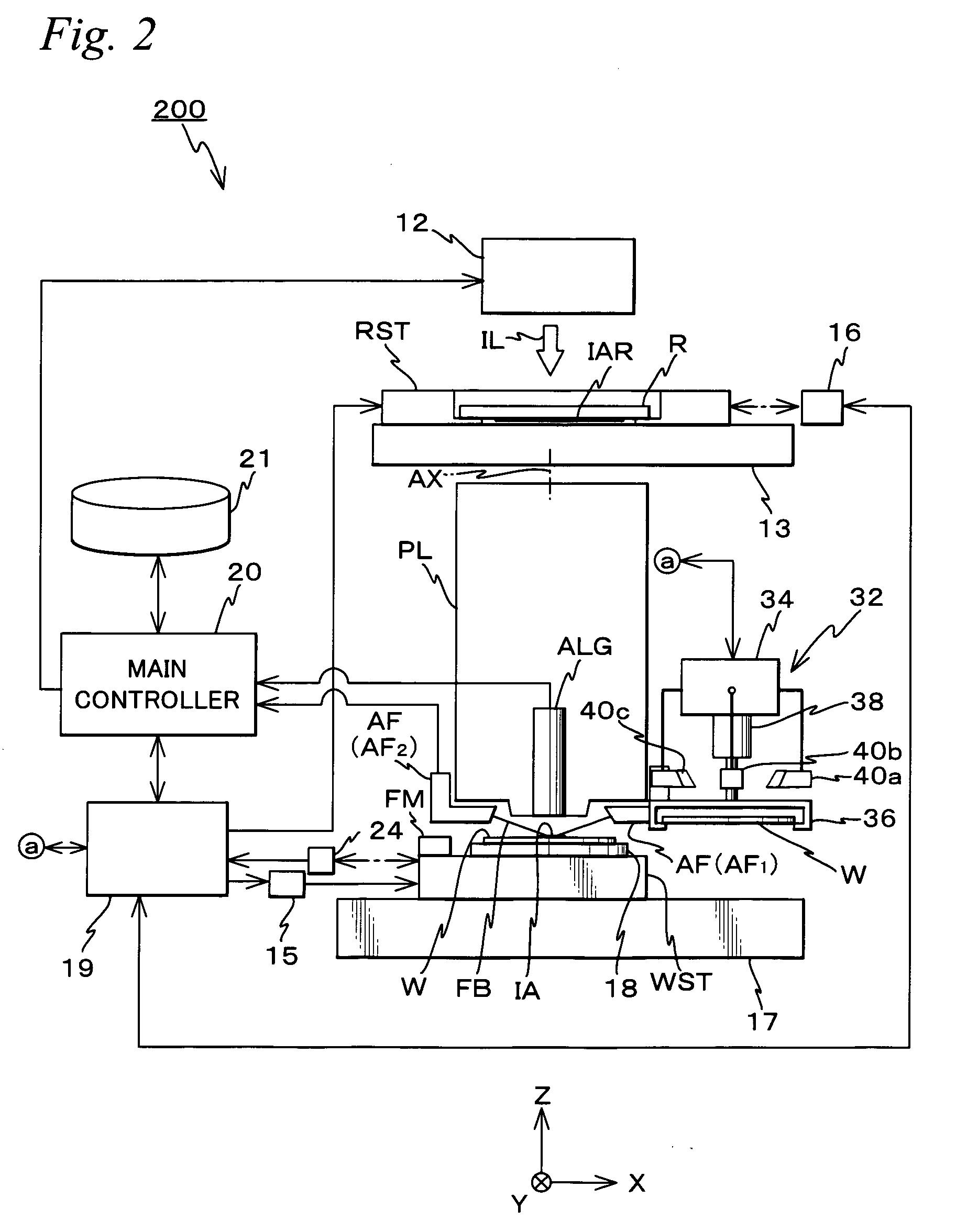

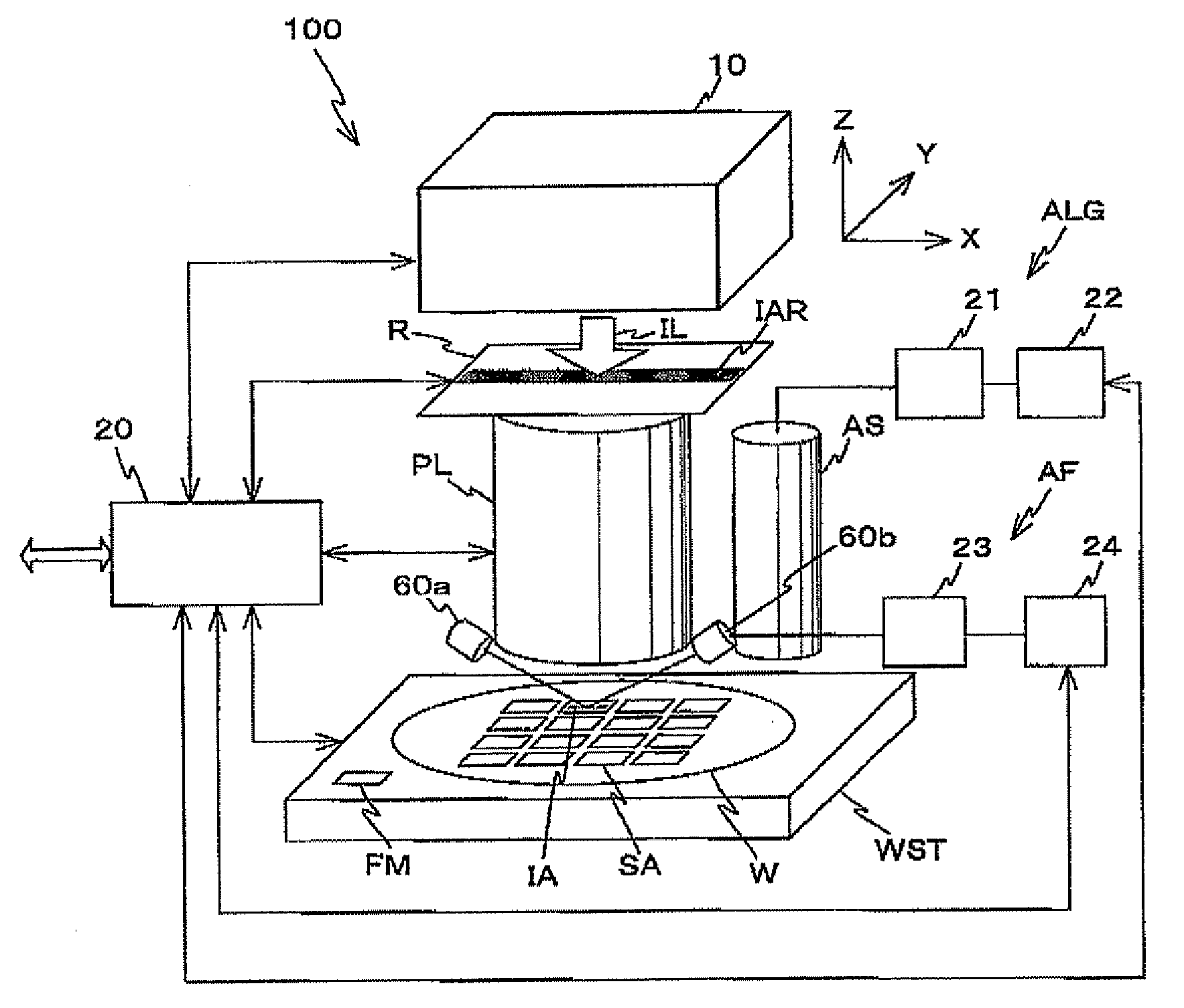

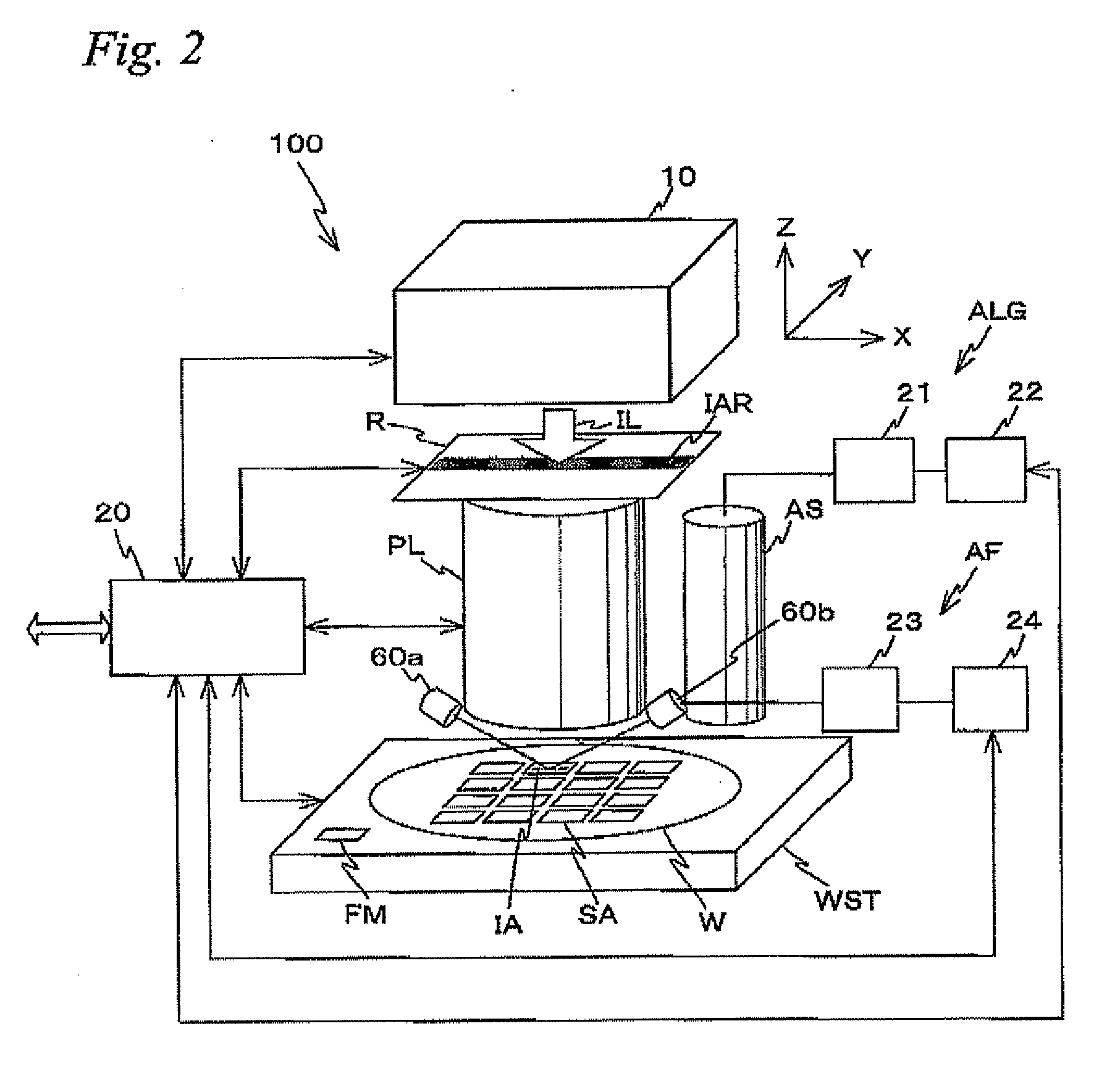

Positioning method, processing system, measurement method of substrate loading repeatability, position measurement method, exposure method, substrate processing apparatus, measurement method, and measurement apparatus

InactiveUS20080013089A1Improve accuracyImprove throughputPhotomechanical apparatusSemiconductor/solid-state device manufacturingMeasurement deviceMeasuring instrument

An edge of a surface to be measured of wafer and each of search alignment marks on the wafer are detected by an inline measurement instrument or the like that operates independently of an exposure apparatus, and position coordinates of the search marks in an X′Y′ coordinate system, which is a two-dimensional coordinate system substantially parallel to the surface to be measured and is set by a position of a notch of the wafer, are measured. Then, in pre-alignment performed when loading the wafer into the exposure apparatus, the edge of the wafer is detected, and from the detection results, position information of the object in the X′Y′ coordinate system is measured. Further, a relative position in the X′Y′ coordinate system of the wafer to be loaded into the exposure apparatus based on measurement results of the pre-alignment with respect to a measurement field of an alignment system that measures positions of the search marks on the wafer is adjusted based on measurement results of the inline measurement instrument or the like.

Owner:NIKON CORP

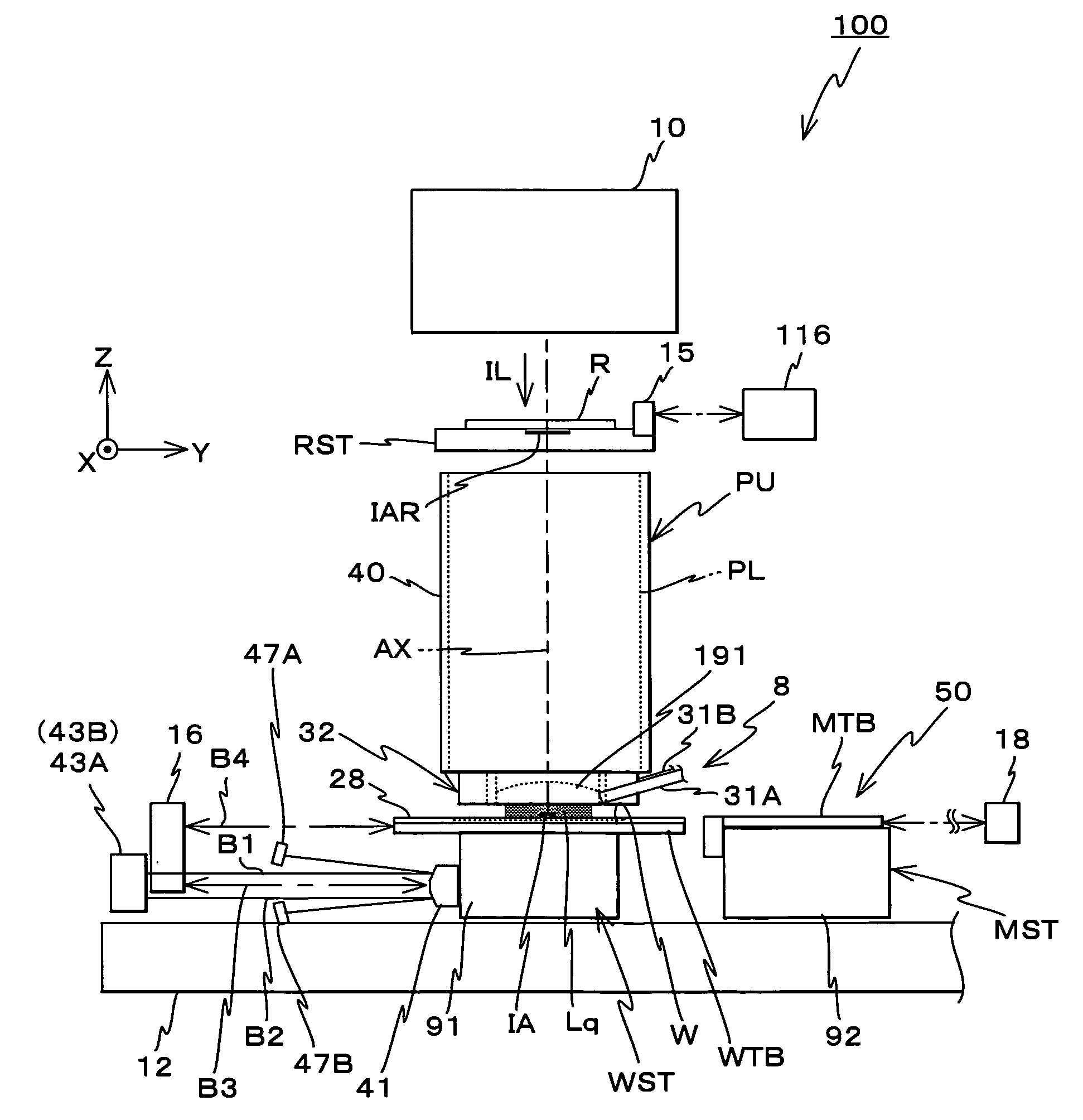

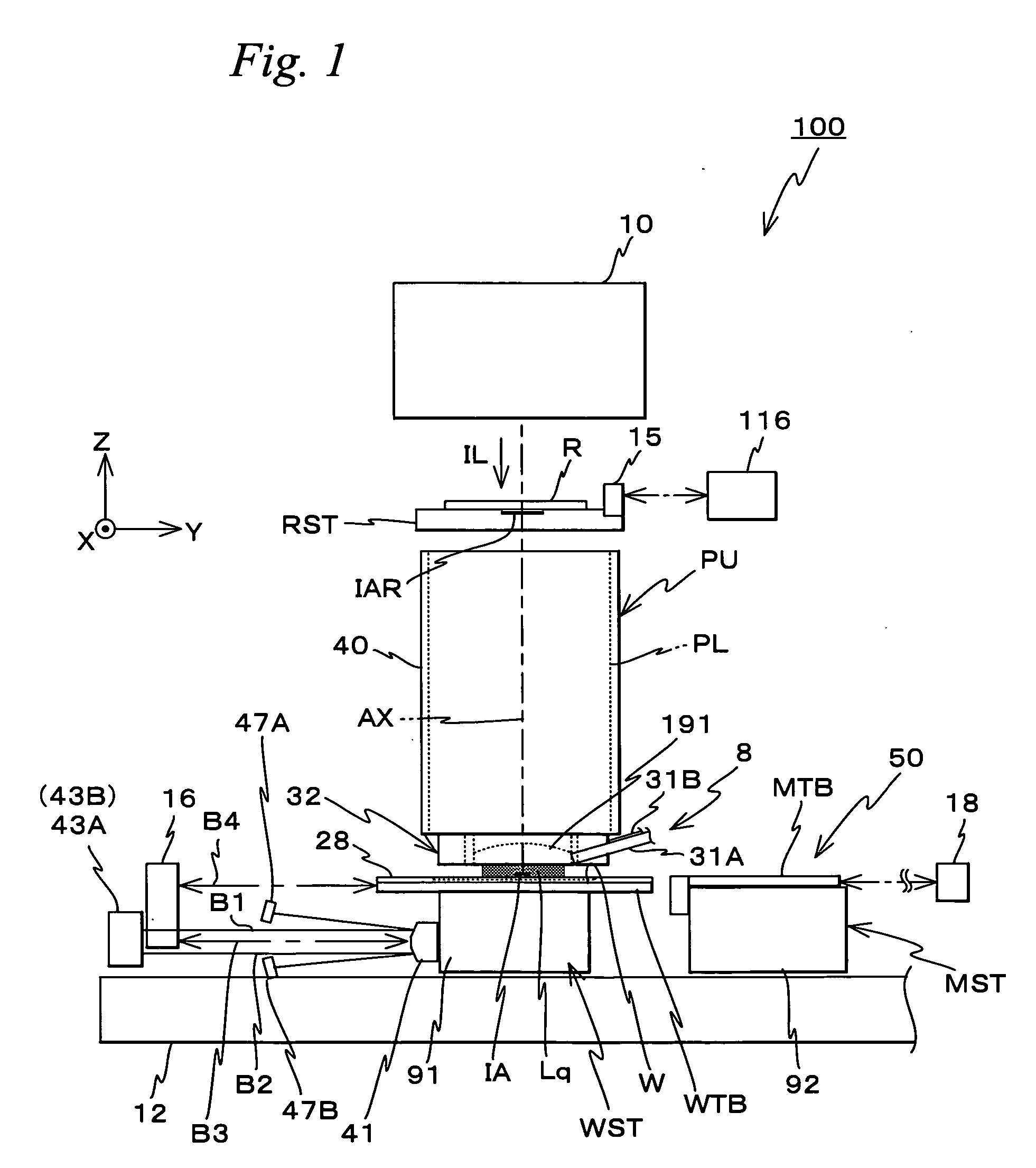

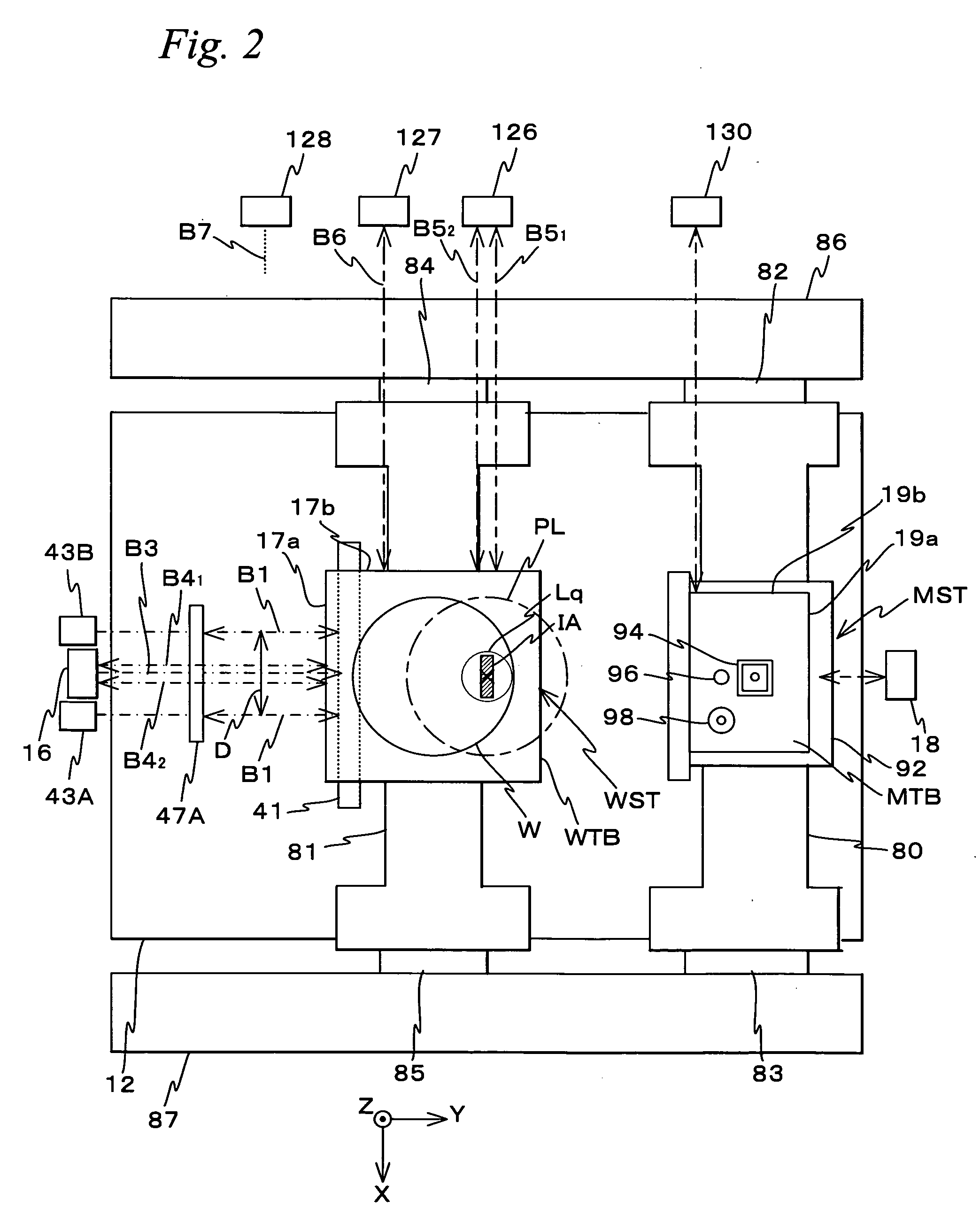

Movable body drive method and movable body drive system, pattern formation method and apparatus, exposure method and apparatus, and device manufacturing method

InactiveUS20080094604A1Good precisionImprove accuracySemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusGratingEngineering

A controller inclines a movable body with respect to an XY plane at an angle α in a periodic direction of a grating, based on a measurement value of an interferometer which measures an angle of inclination of the movable body to the XY plane, and based on a measurement value of an encoder system and information of angle α before and after the inclination, and computes an Abbe offset quantity of the grating surface with respect to a reference surface (e.g., an image plane of a projection optical system) which serves as a reference for position control of the movable body in the XY plane. Then, the controller drives the movable body, based on positional information of the movable body in the XY plane measured by the encoder system and a measurement error of the encoder system corresponding to an angle of inclination of the movable body to the XY plane due to the Abbe offset quantity of the grating surface.

Owner:NIKON CORP

Preparation of a PH sensor, the prepared PH sensor, system comprising the same and measurement using the system

InactiveUS20070095663A1Reduce sheet resistanceImprove conductivityMaterial electrochemical variablesSputteringTitanium nitride

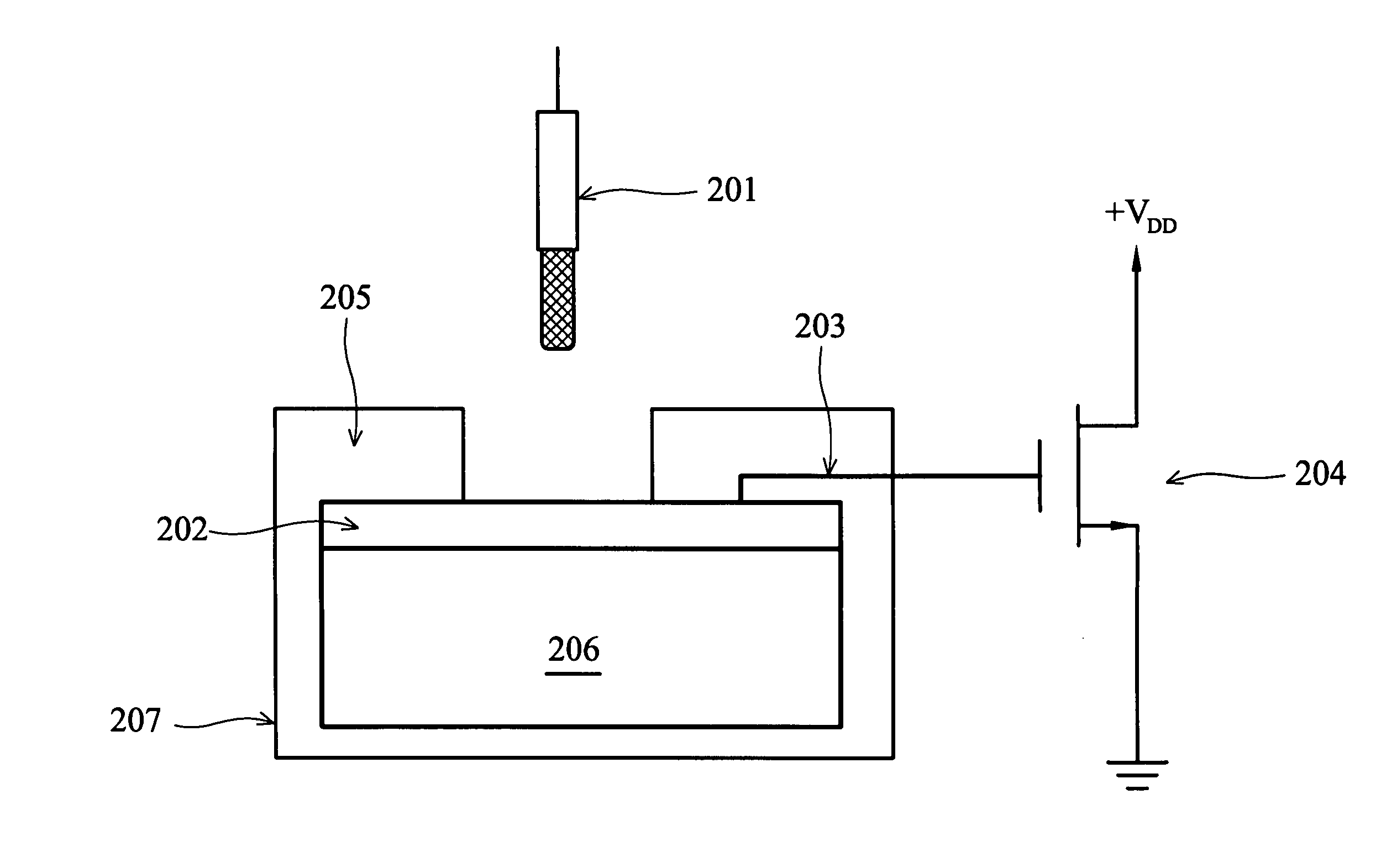

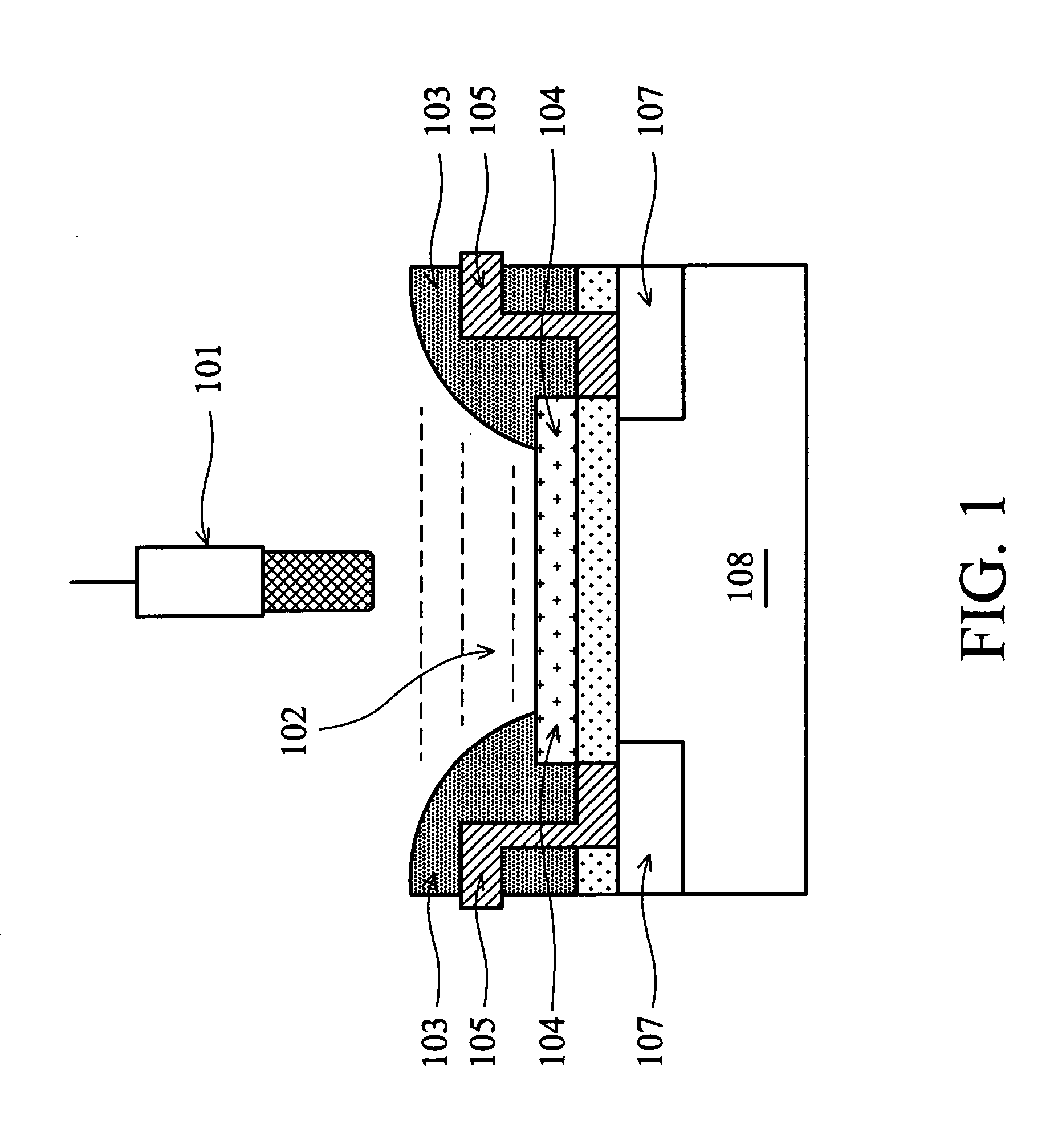

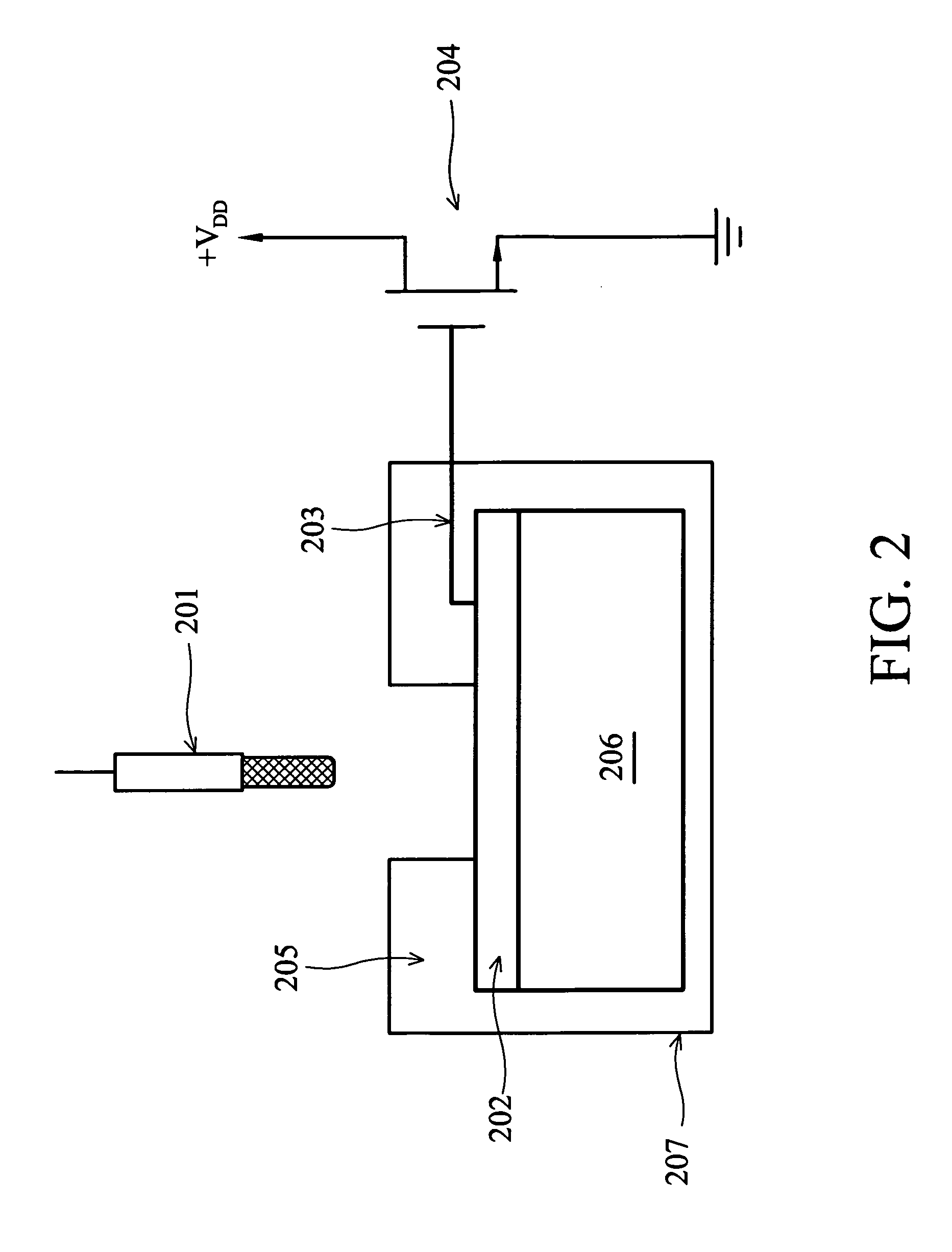

Preparation of a pH sensor, the prepared pH sensor, system comprising the same, and measurement using the system. The pH sensor is an extended gate field effect transistor (EGFET) structure. The preparation includes the steps of providing an extended gate ion sensitive field effect transistor comprising an extended gate region, forming a titanium nitride film on the extended gate region by RF sputtering deposition to obtain a pH sensor.

Owner:NATIONAL YUNLIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

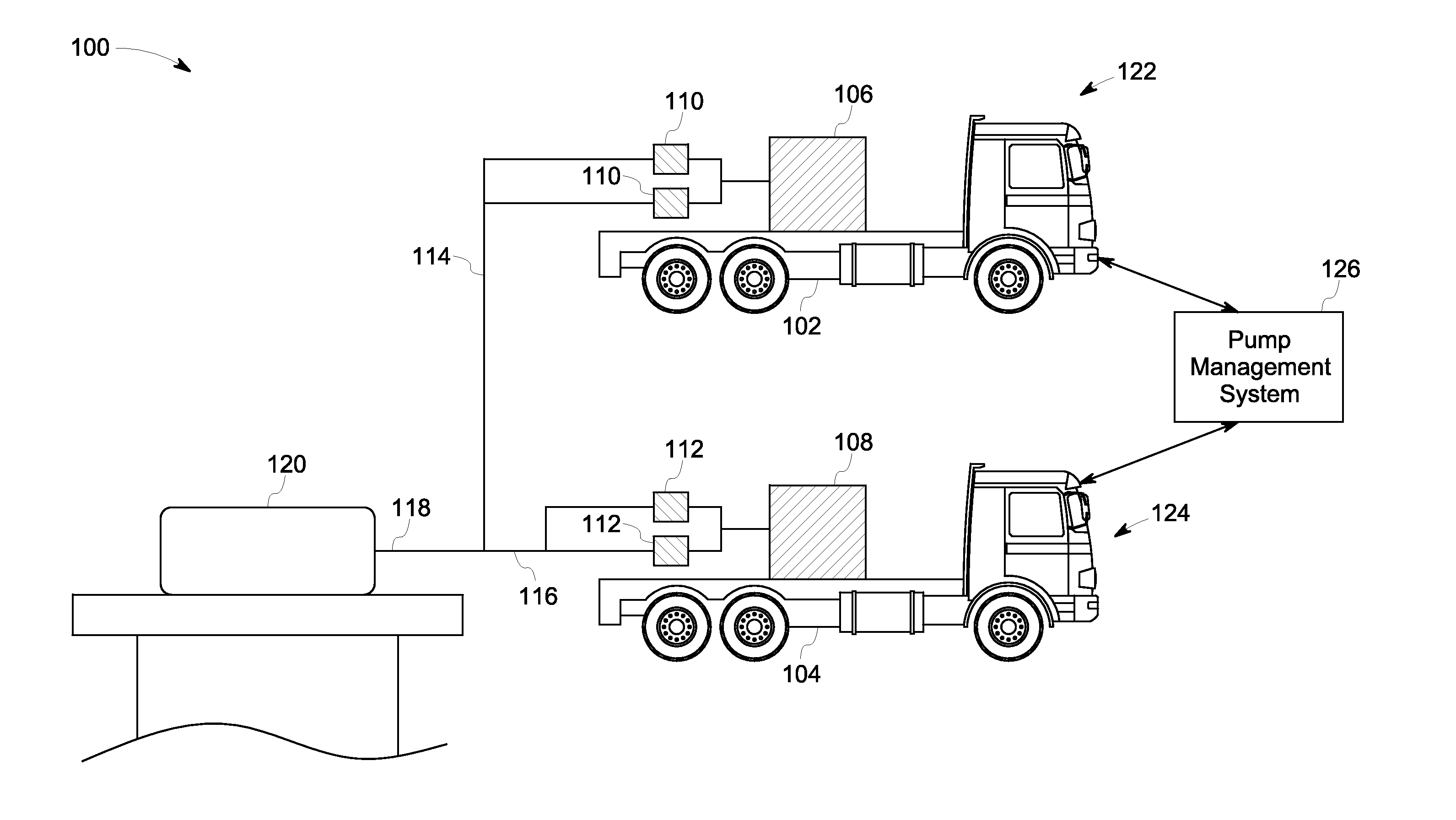

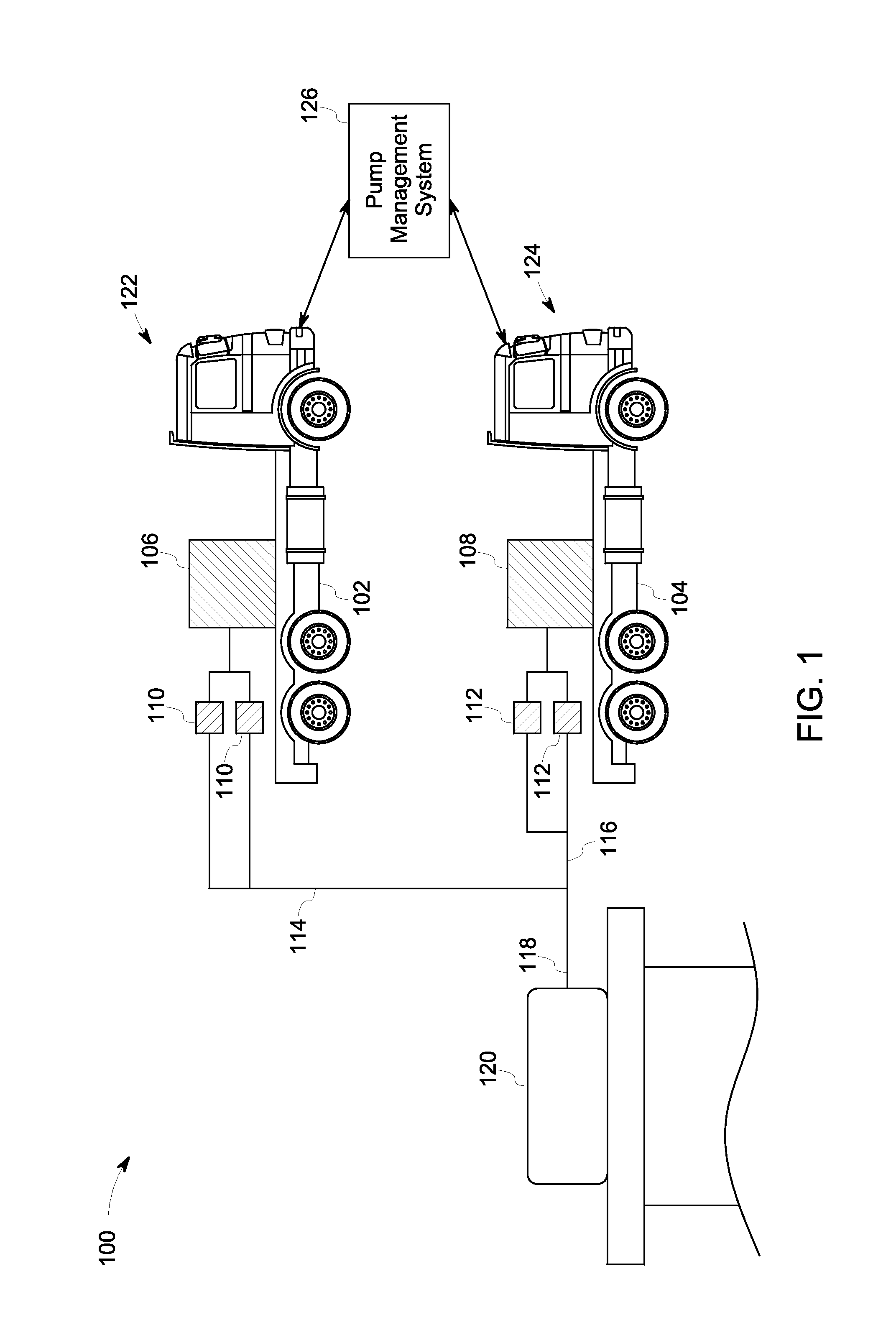

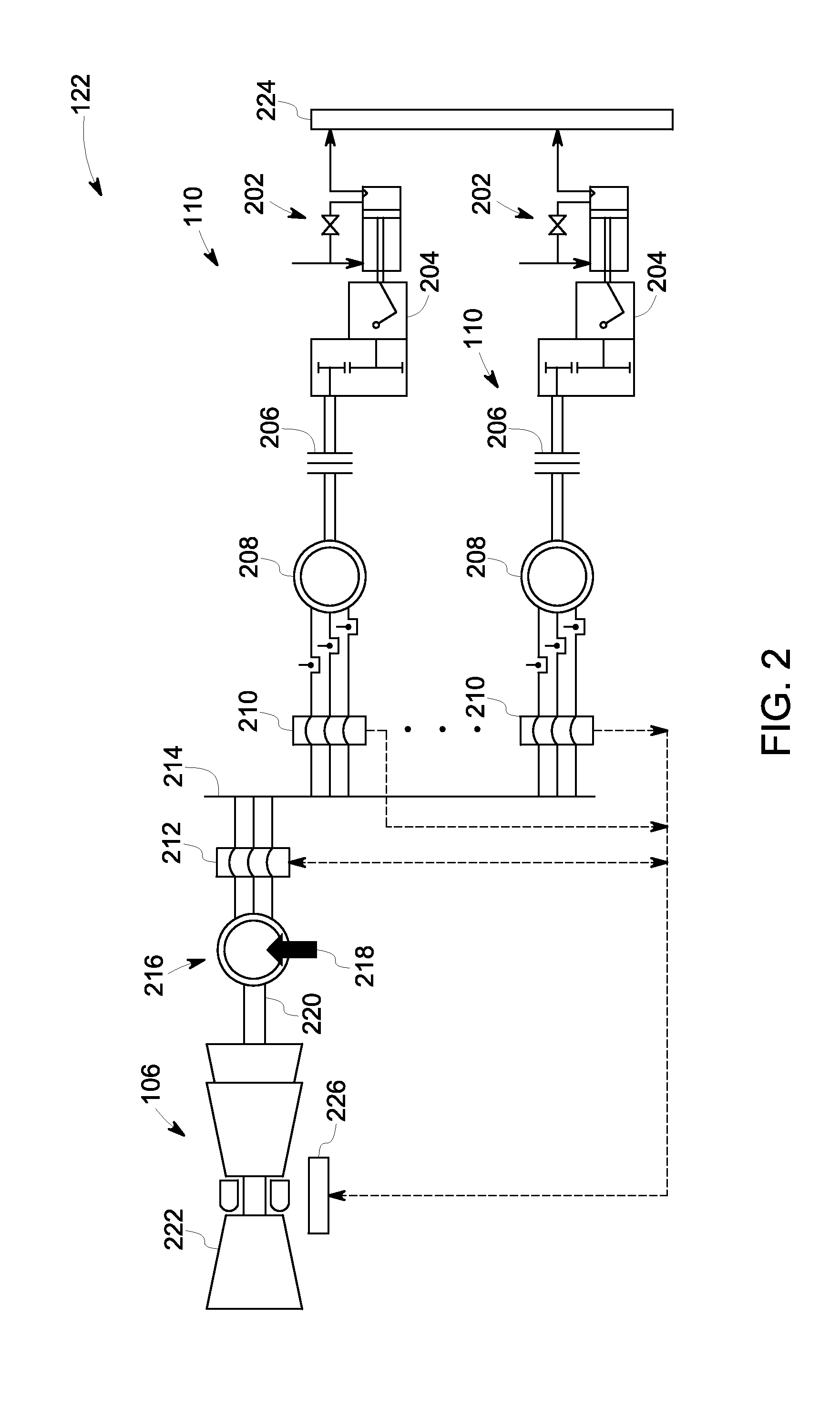

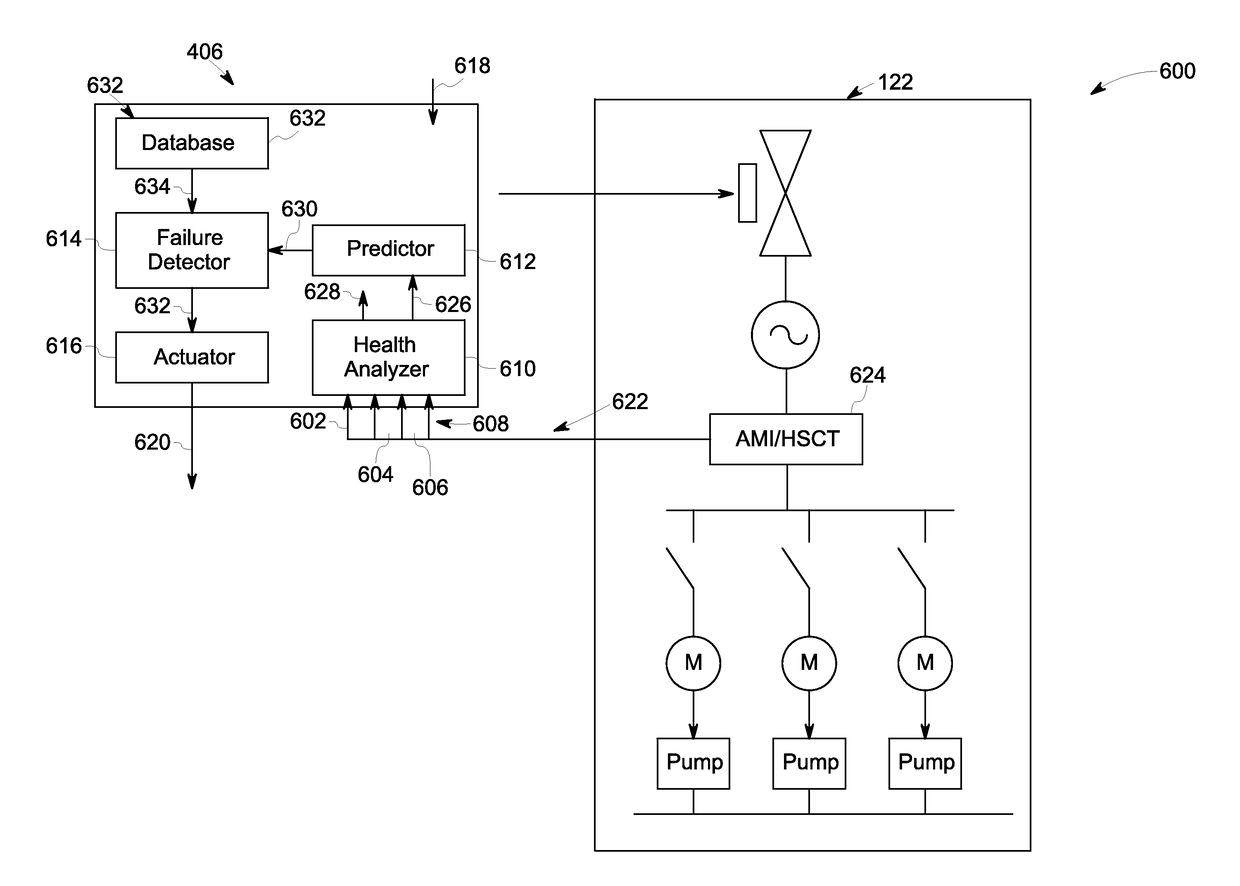

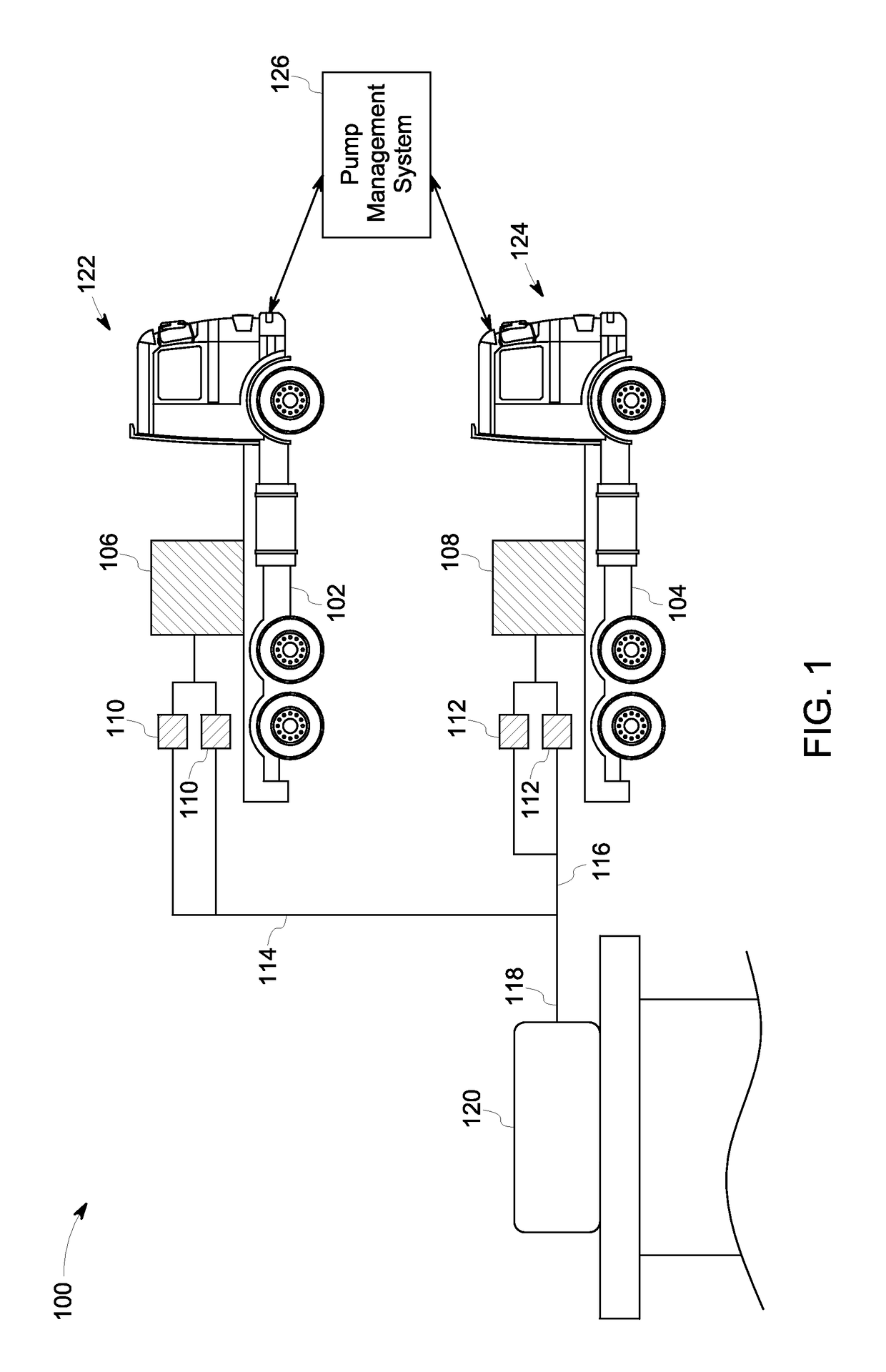

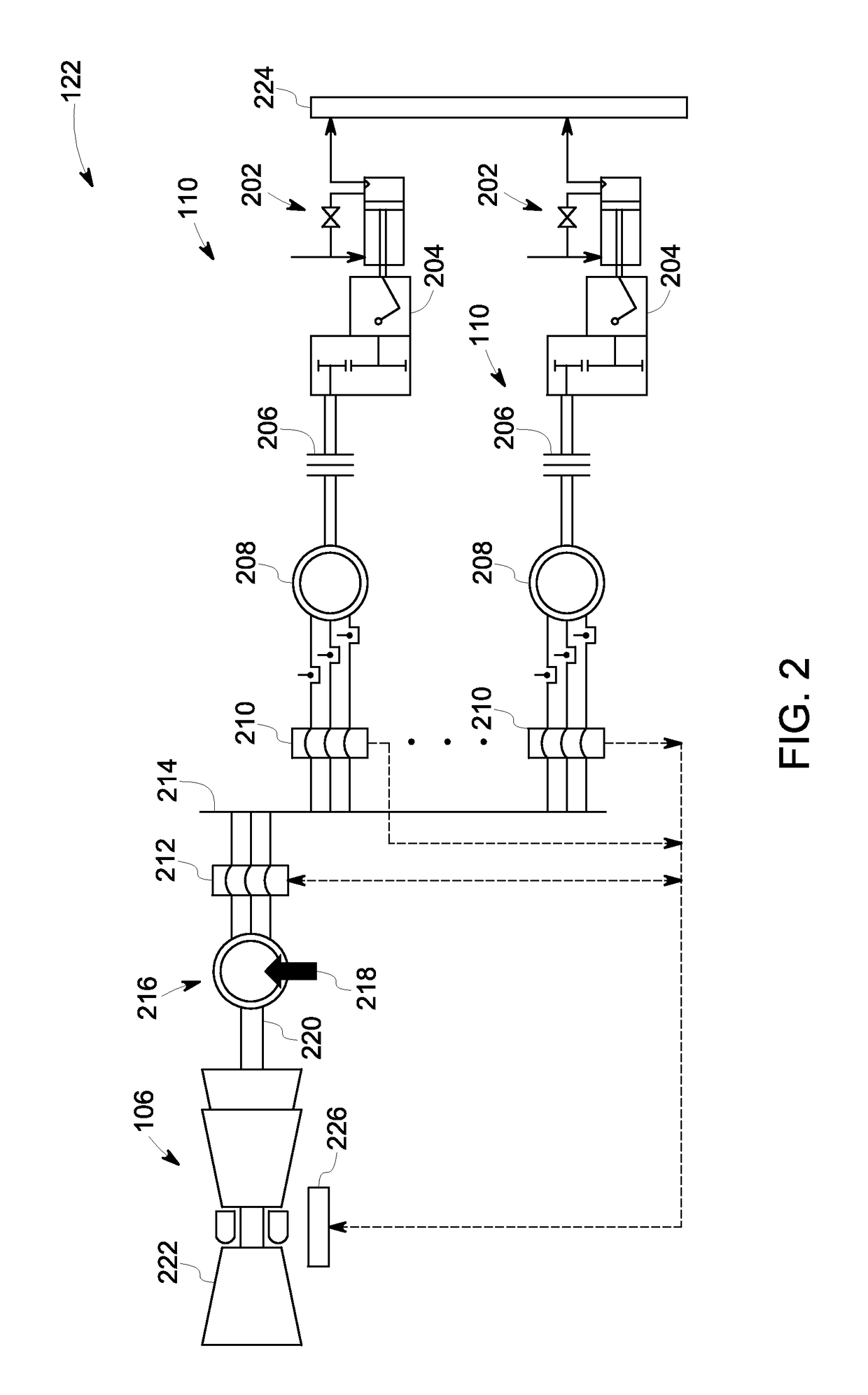

System and method for health management of pumping system

ActiveUS20160195082A1Guaranteed uptimeFluid parameterFlexible member pumpsSimulationManagement system

A method implemented by at least one processor includes receiving a plurality of operating parameters of a pumping system, wherein the pumping system has a plurality of pump-units powered by a generator-unit. The operating parameters include a pump-unit parameter and a generator-unit parameter. The method also includes receiving reference data of the pumping system, wherein the reference data includes measurements from the pumping system representative of performance of the plurality of pump-units. The method also includes determining one or more health parameters corresponding to one or more pump-units based on the plurality of operating parameters and the reference data. The method further includes modifying one or more input parameters of the generator-unit based on the one or more health parameters for continued operation of the pumping system.

Owner:HYDRIL USA DISTRIBUTION LLC

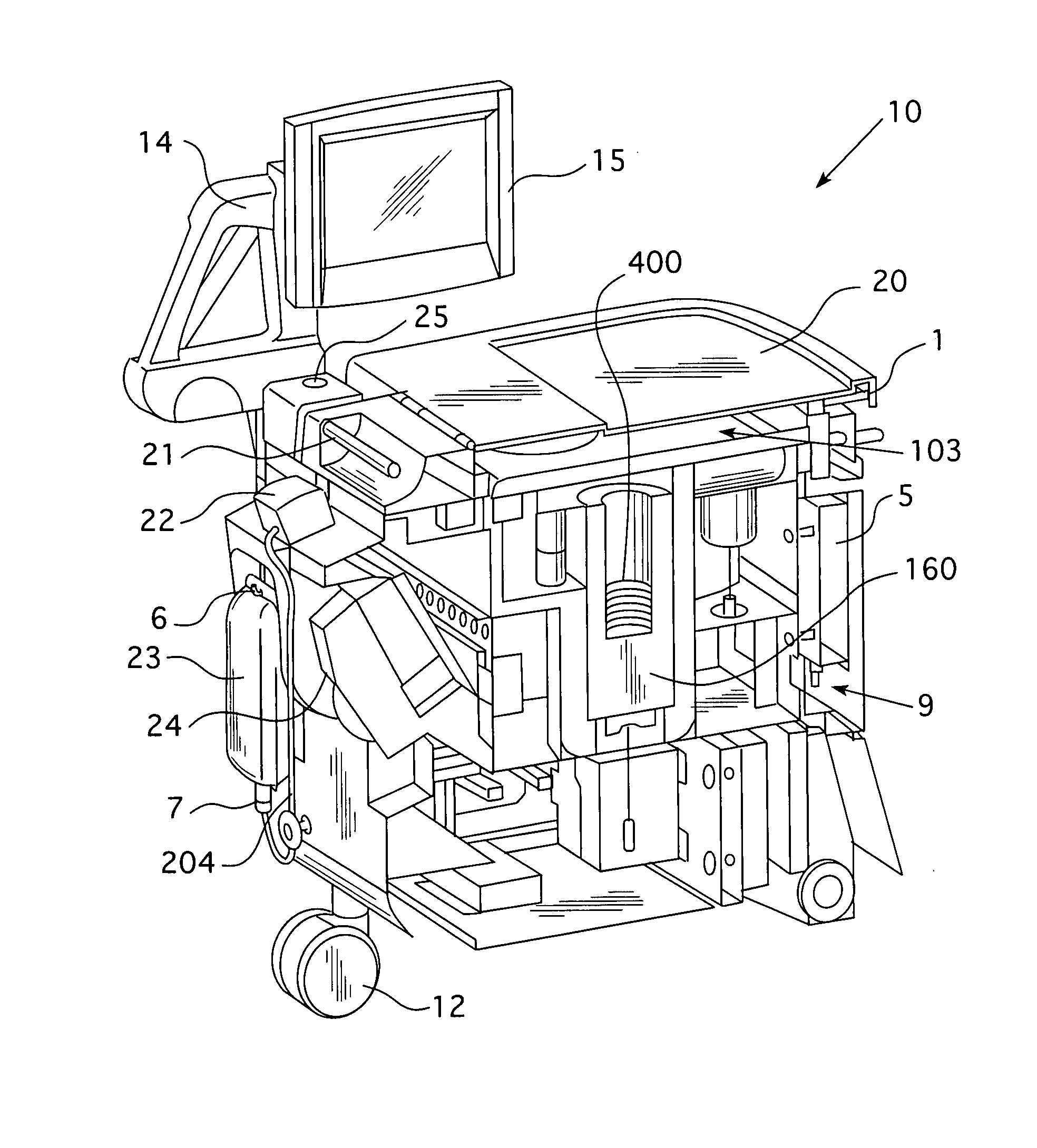

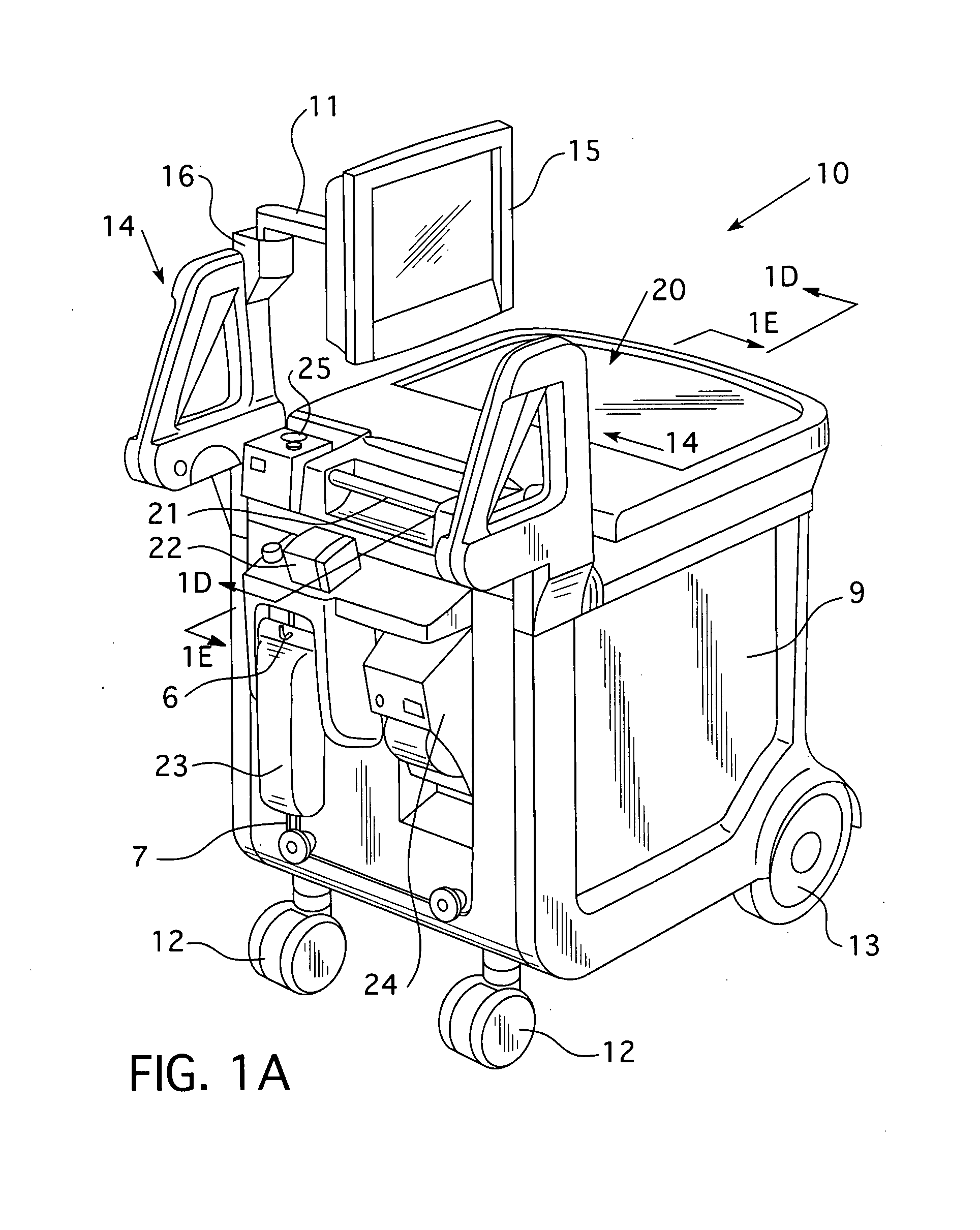

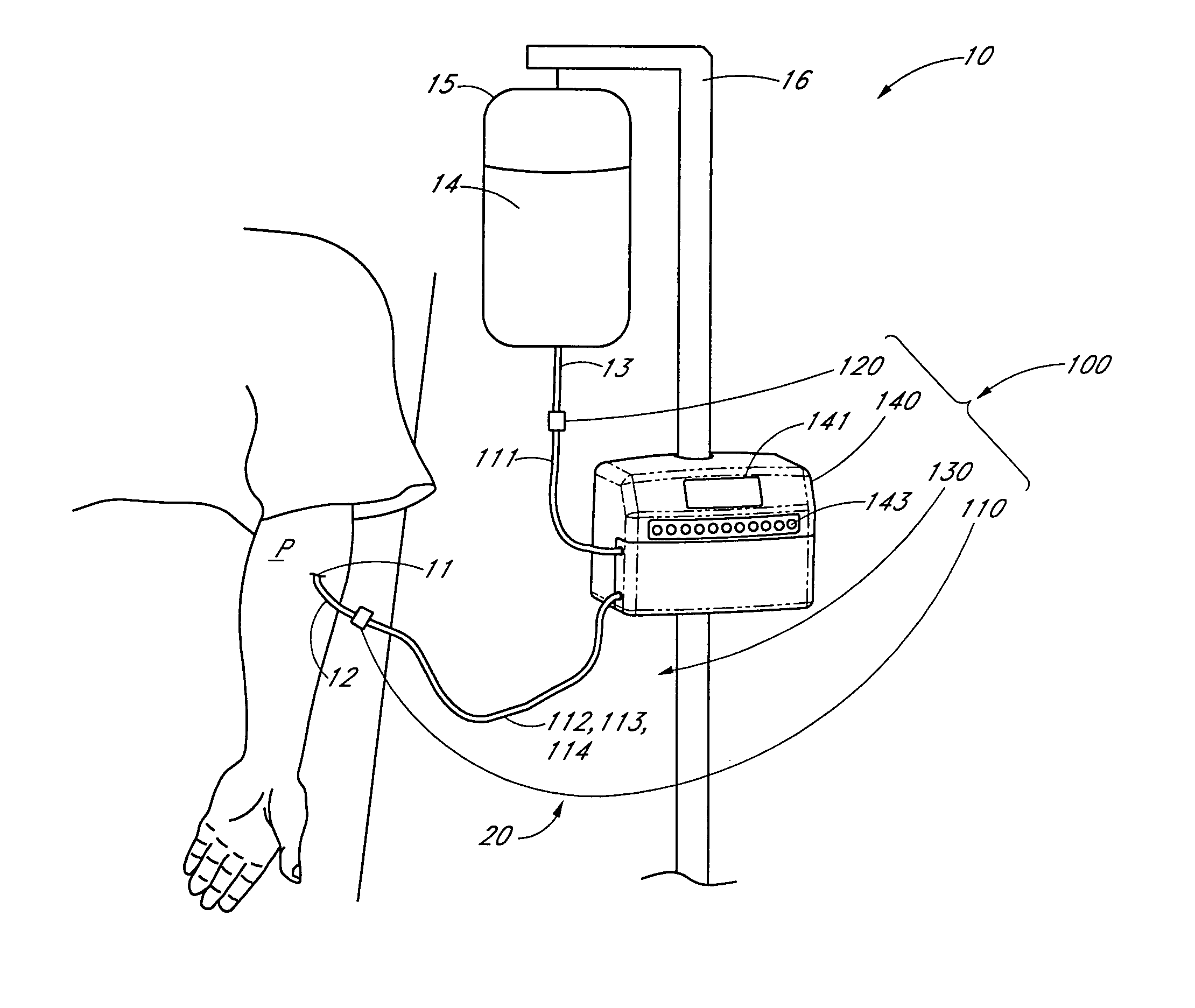

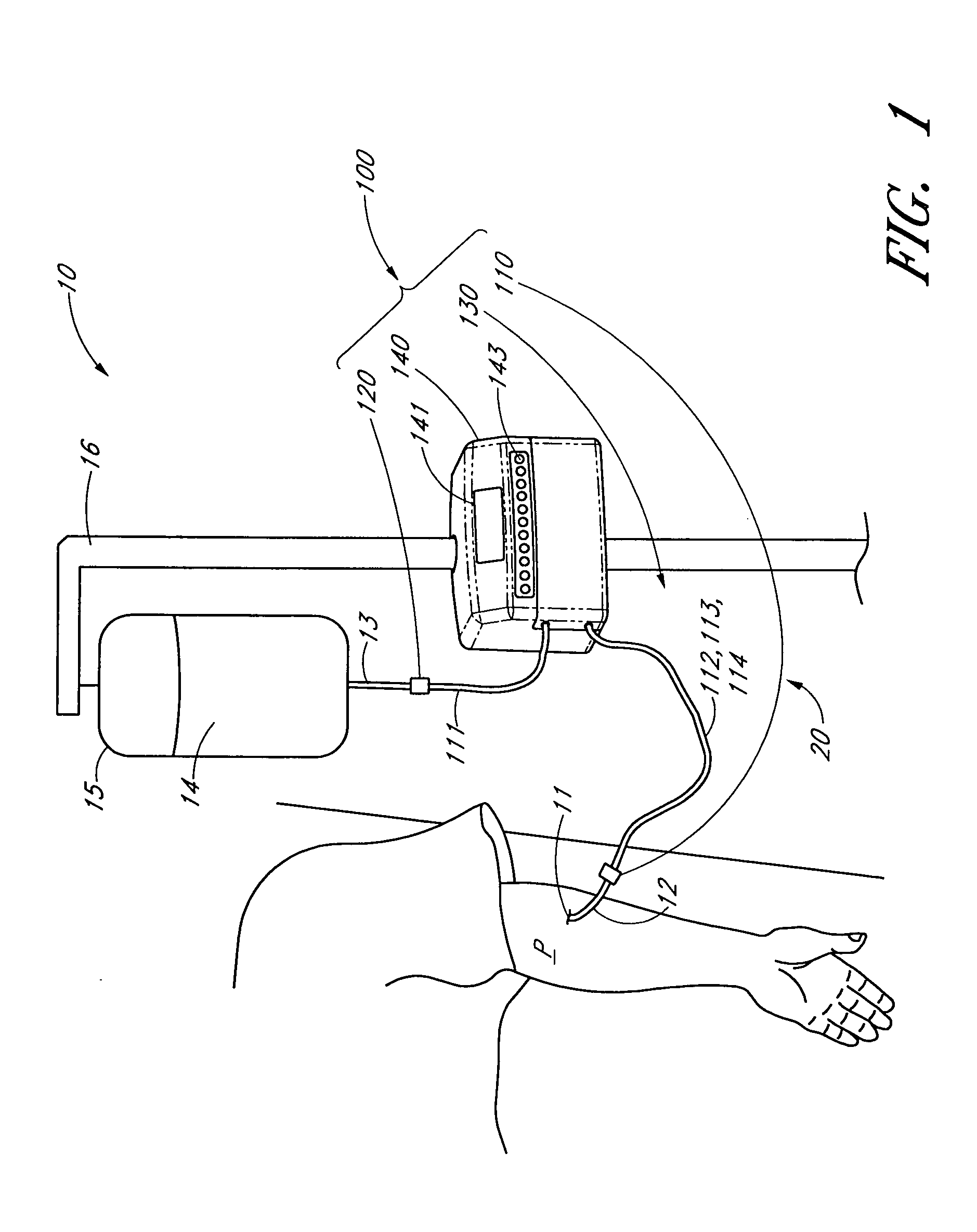

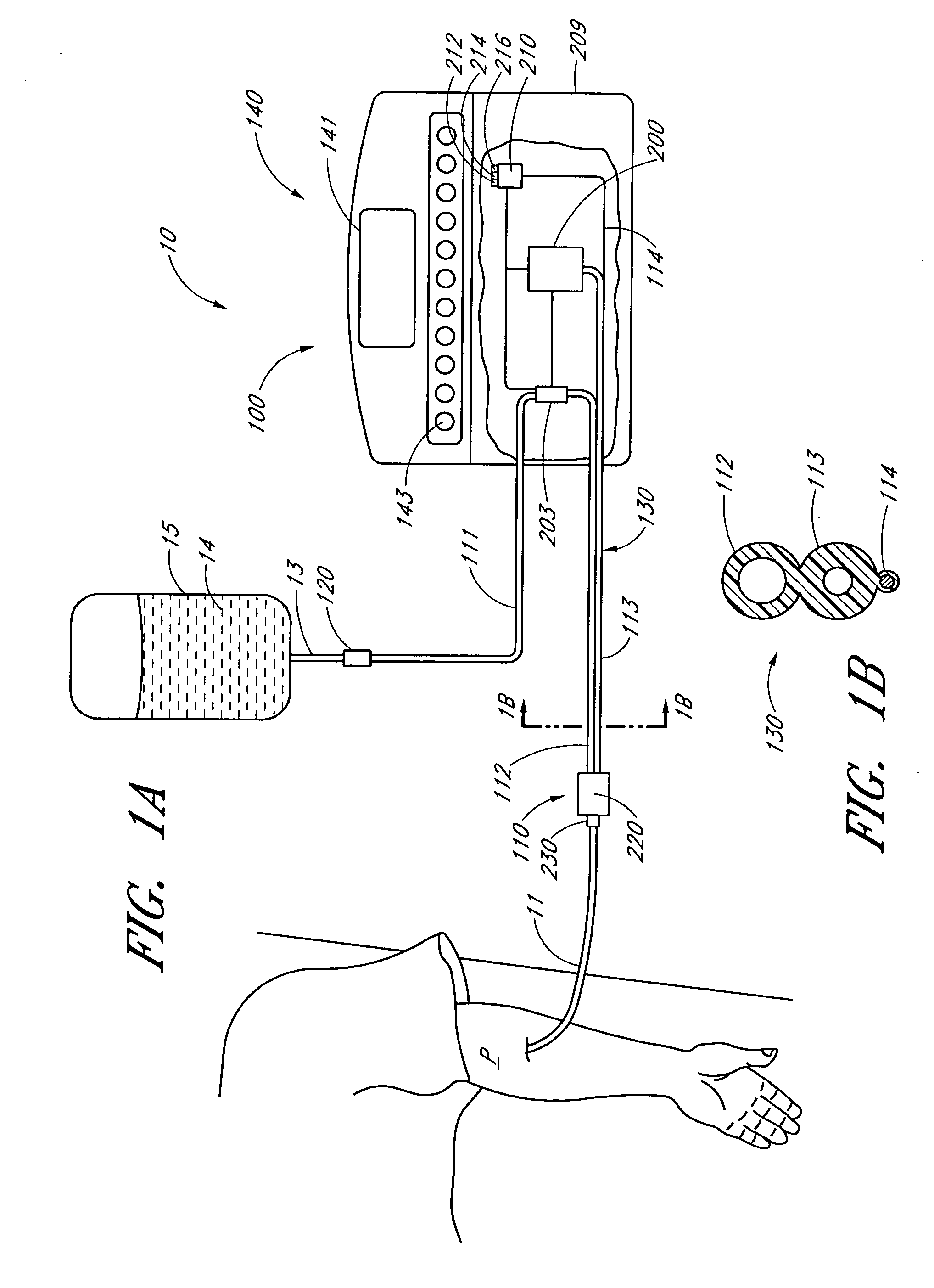

Radiopharmaceutical administration methods, fluid delivery systems and components thereof

ActiveUS20080177126A1Accurately calculating and delivering effective dosEasy extractionIn-vivo radioactive preparationsDrug and medicationsIonization chamberHandling system

A fluid path set for a fluid delivery system includes a tube coil that is designed to optimally position one or more volumes of a pharmaceutical within an ionization chamber to optimally measure and prepare a pharmaceutical dose for administration to a patient. The tube coil may be maintained in a desired dimensional geometry by means of a core structure around which the tube coil is positioned. Novel developments in radiopharmaceutical administration methods and systems include, but are not limited to, the configuration and layout of a fluid path set for use in a fluid delivery system, arrangements for piercing and drawing fluid from a pharmaceutical container (such as a vial), arrangements for optimizing the positioning of a tube coil within an ionization chamber, a handling system for transporting vial shields that maintain an operator's hand and fingers at a safe distance from a pharmaceutical vial, a method for calibrating a radiopharmaceutical delivery system in which the difference between the expected and measured activities of two radioisotopes are used to calculate an estimated error in the measured activity of a third radioisotope and a vial access system that ensures an optimal draw of fluid from a radiopharmaceutical container.

Owner:BAYER HEALTHCARE LLC

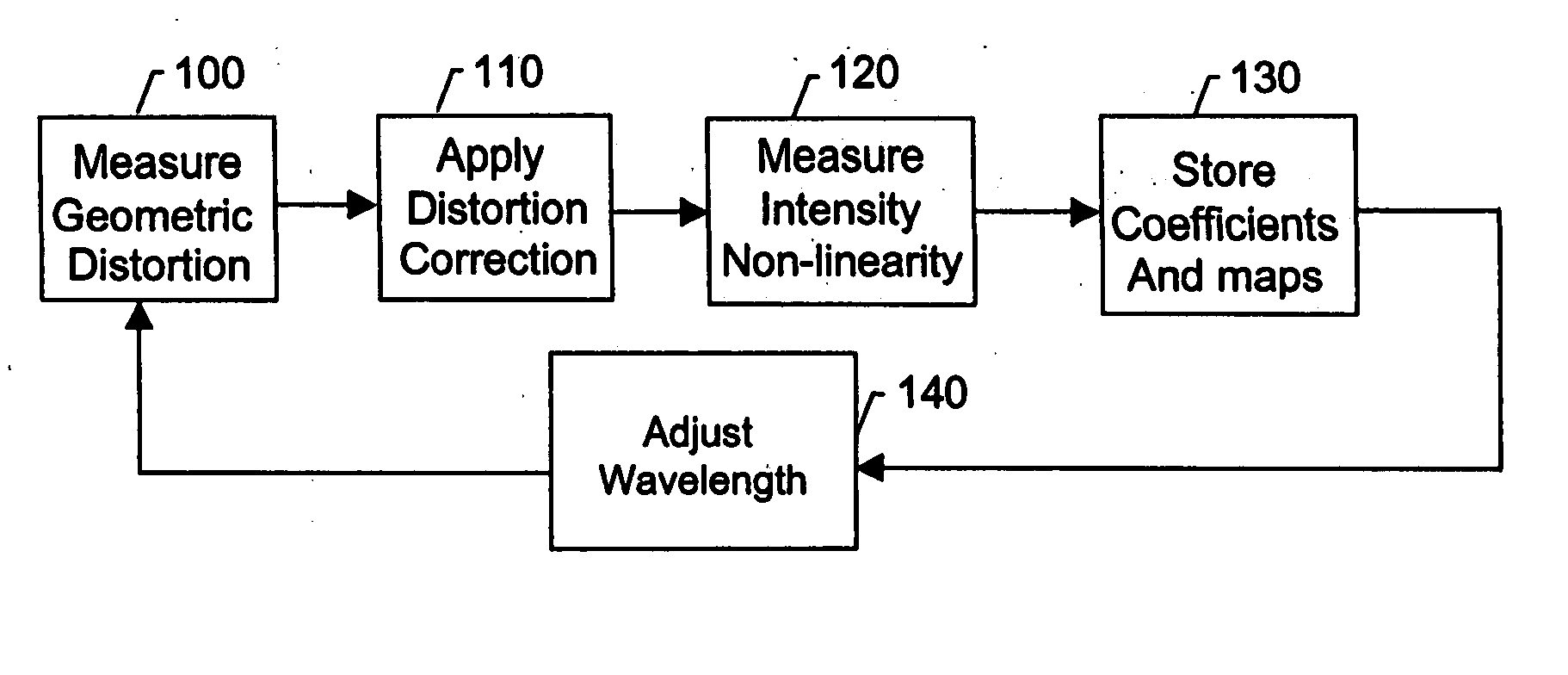

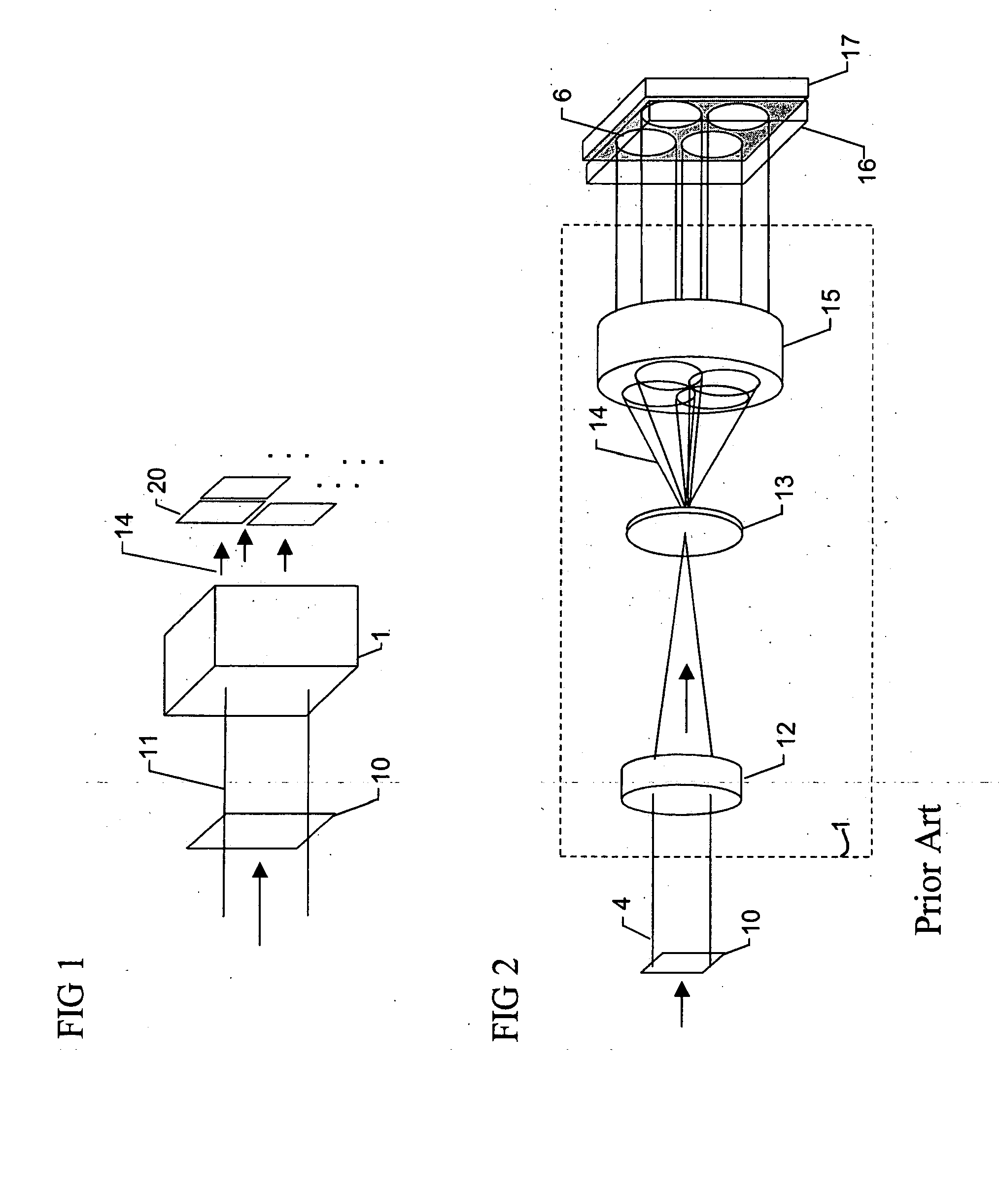

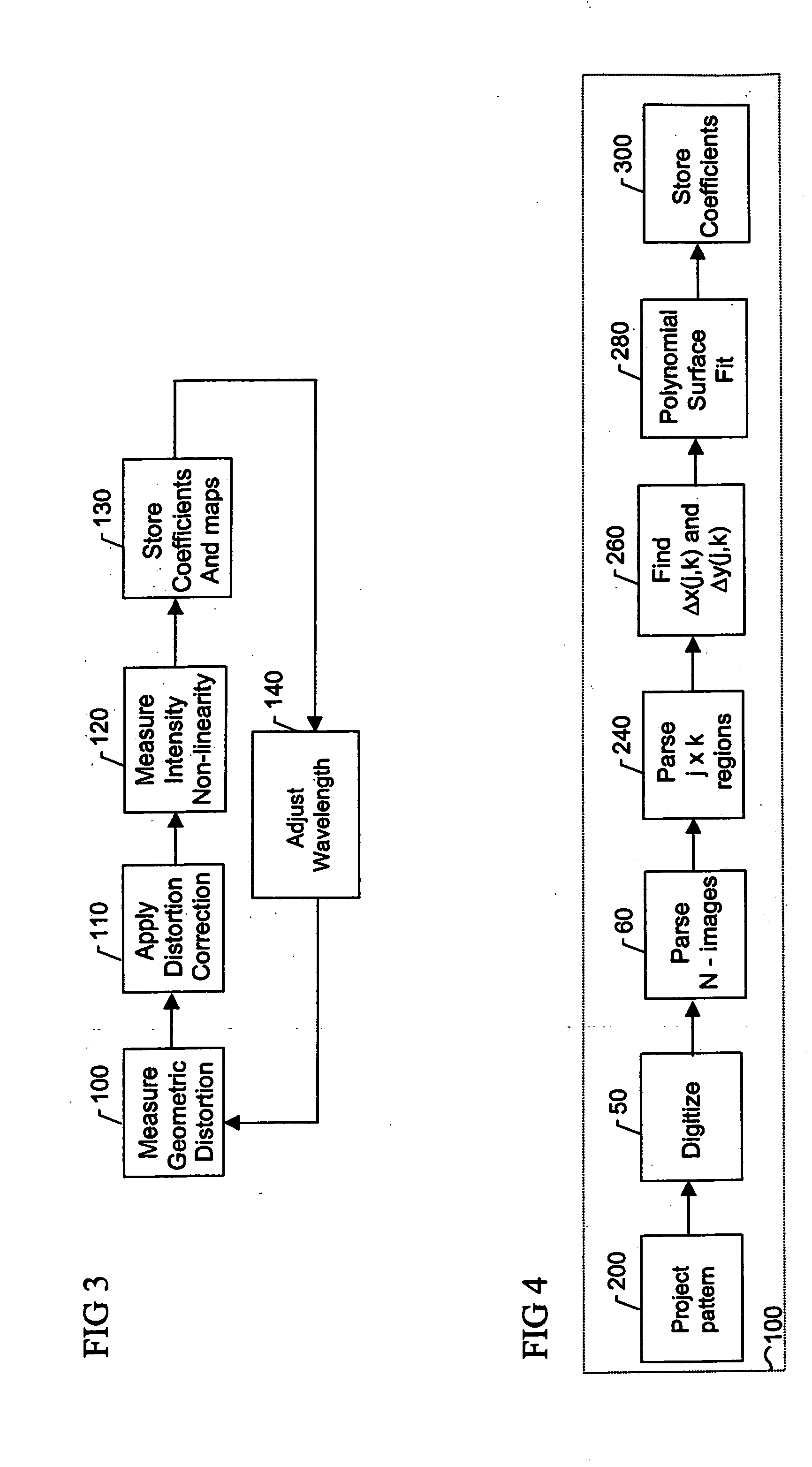

Calibration and error correction in multi-channel imaging

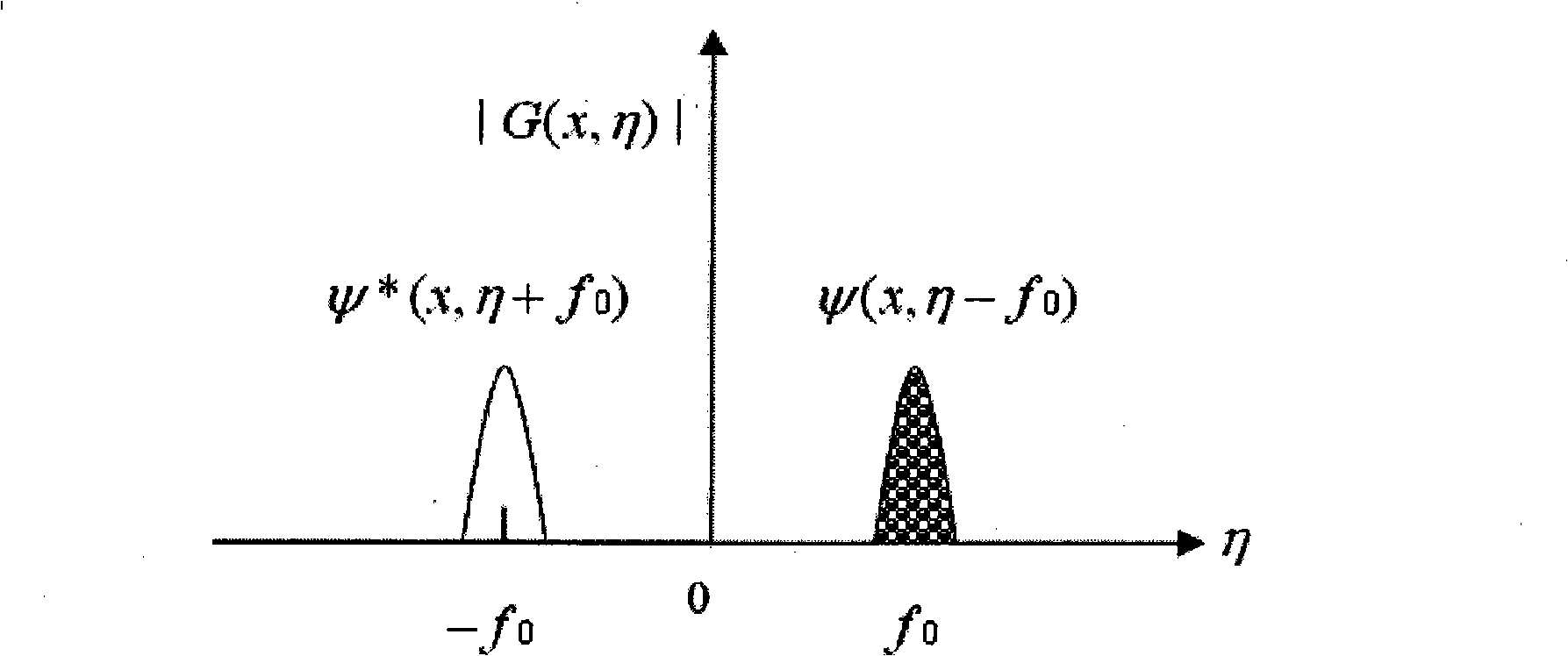

ActiveUS20050083531A1Reducing phase-dependent systematic measurement errorMeasure can be takenImage enhancementOptical measurementsPhase correlationPath length

A multi-channel imaging system is calibrated by measuring the geometric distortion in each sub-image, generating corresponding correction factors, and applying such factors to correct subsequent image data. In addition, intensity transfer-function arrays are measured at each pixel, and further used to correct for system and detector nonlinearities and nonuniformity between images. The procedure is repeated over a range of wavelengths to produce a complete set of correction coefficients and transfer functions. When the system is used for interferometric phase measurements, multiple measurements are preferably taken and a random phase offset in the reference path length is introduced at each measurement. The multiple phase data so derived are then averaged to reduce phase-dependent systematic measurement errors.

Owner:ONTO INNOVATION INC

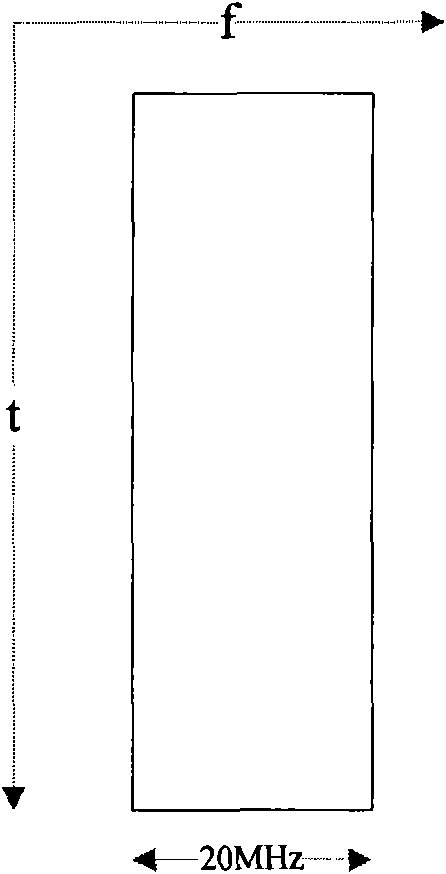

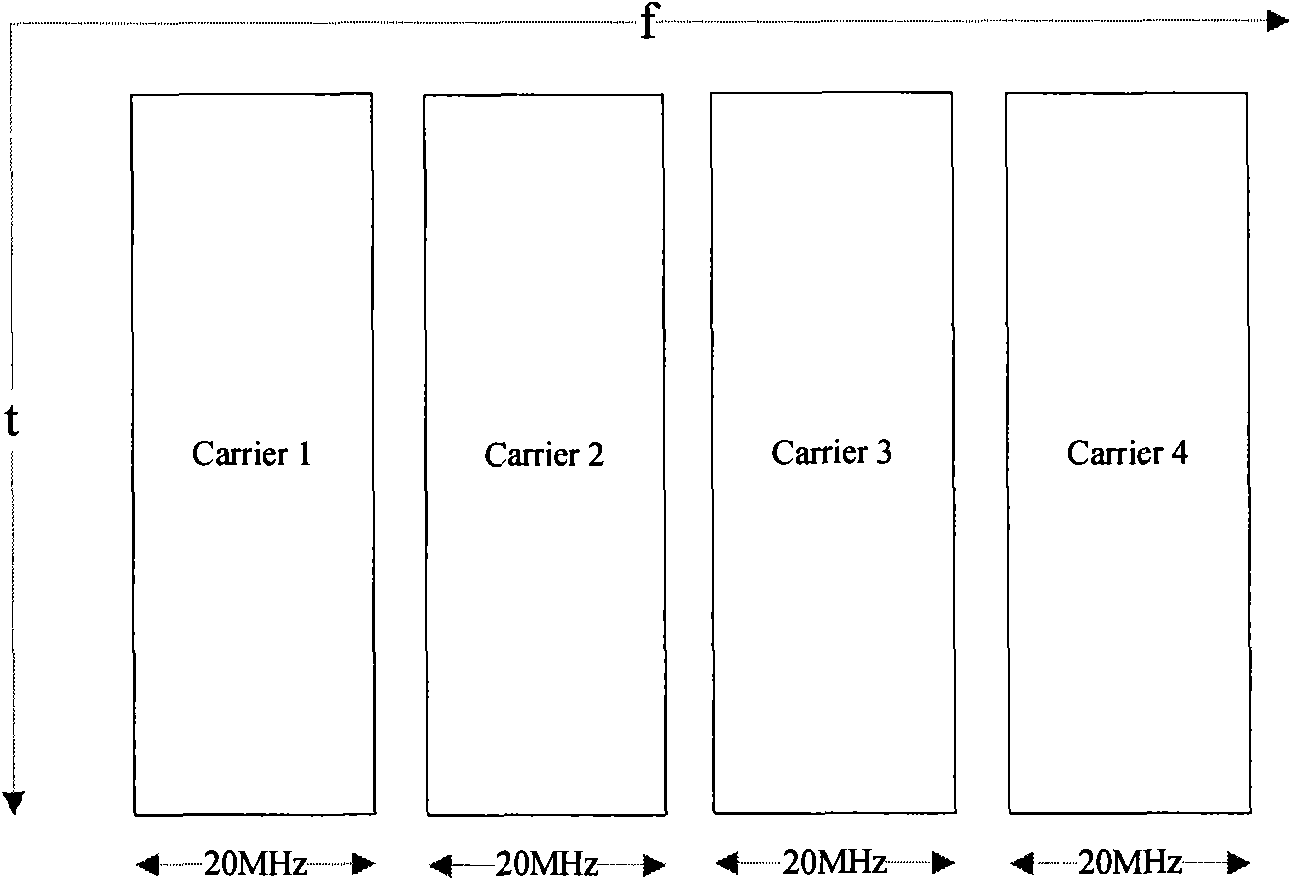

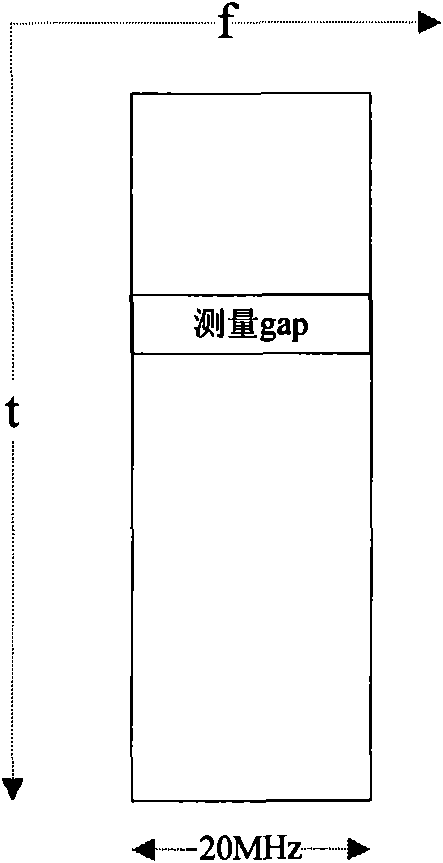

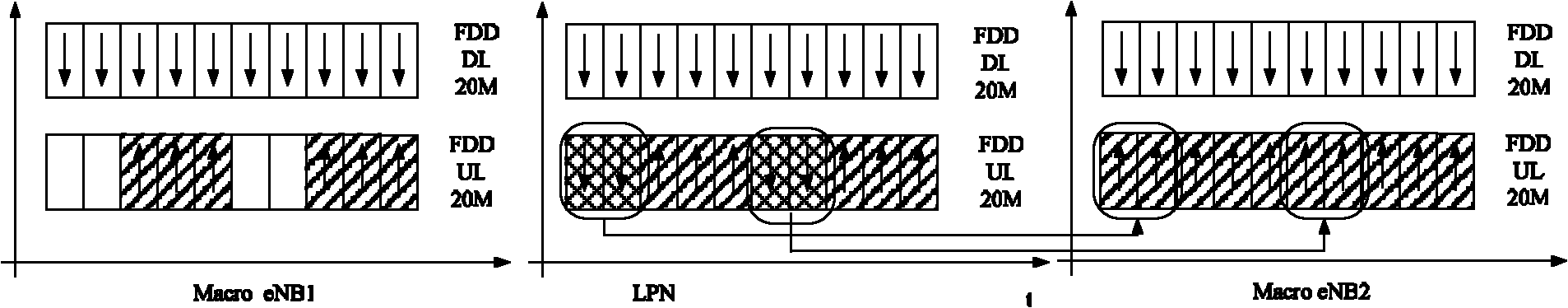

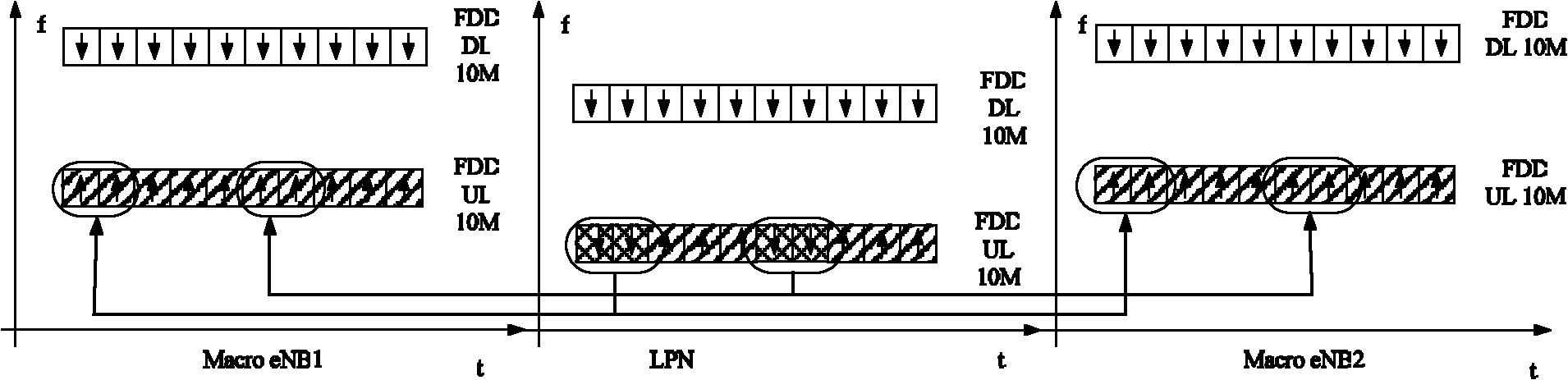

Measurement gap configuration method and device of multi-carrier polymerization system

ActiveCN101873646ARealize measurementImprove data transmission qualityNetwork traffic/resource managementSystem capacityCarrier signal

The invention discloses a measurement gap configuration method and a device of a multi-carrier polymerization system. The method comprises the following steps that: according to the measurement capability of a user terminal reported by the user terminal and the frequency points of a different frequency or a different system to be measured, the measurement gap configuration information of the userterminal is determined, and the measurement gap configuration information instructs to measure the different frequency or the different system to partial or all working member carriers of the user terminal; and the measurement gap configuration information is sent to the user terminal, and the measurement gap configuration information is used for providing the measurement of the different frequency or the different system to the user terminal when in multi-carrier polymerization transmission. The embodiment of the invention respectively configures measurement gaps to partial or all member carriers of the user terminal in a multi-carrier polymerization system, so that the user terminal does not need to stop CA transmission when entering the measurement gaps, thereby improving the data transmission quality and enhancing the transmission performance of the system and the system capacity.

Owner:DATANG MOBILE COMM EQUIP CO LTD

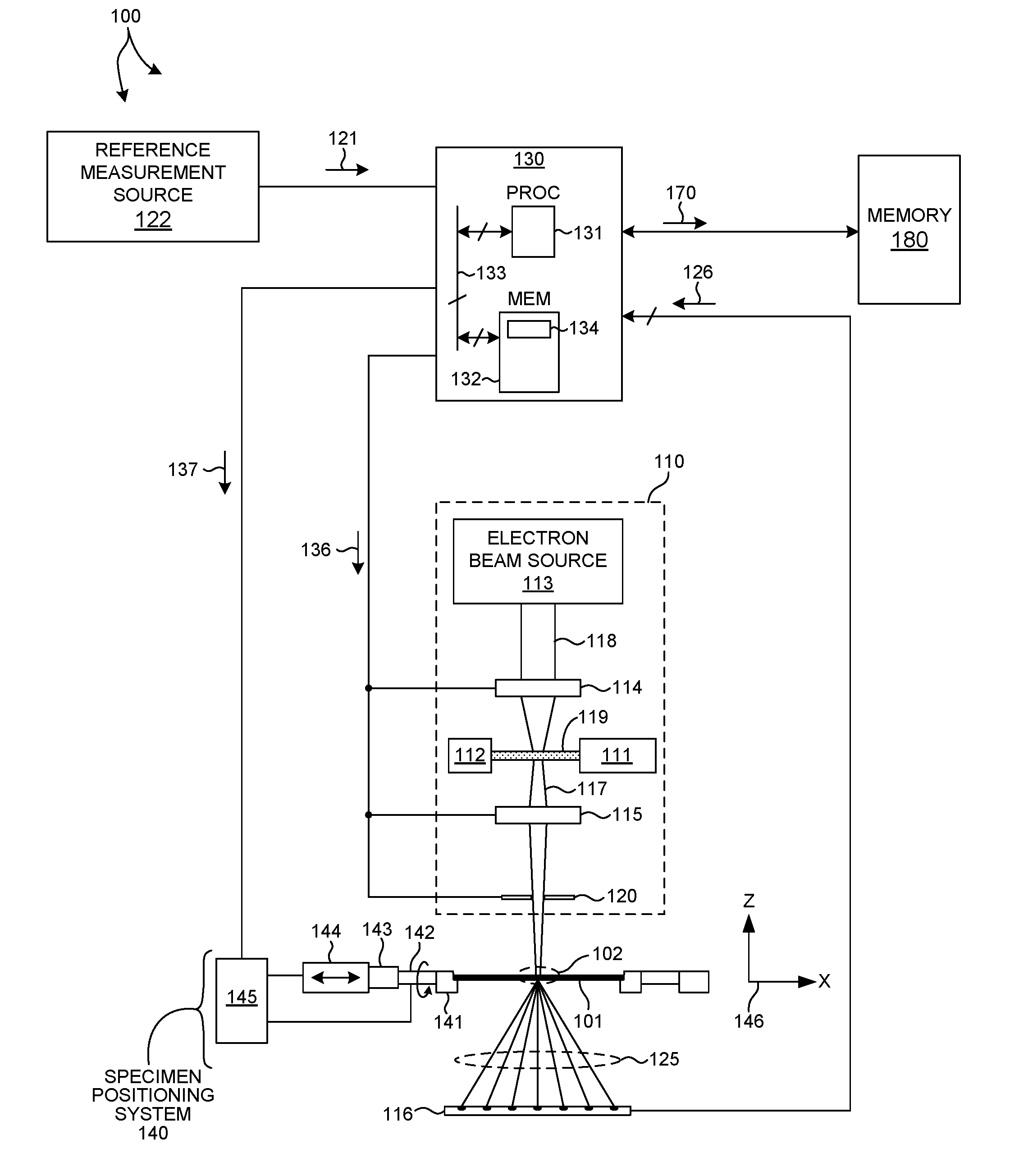

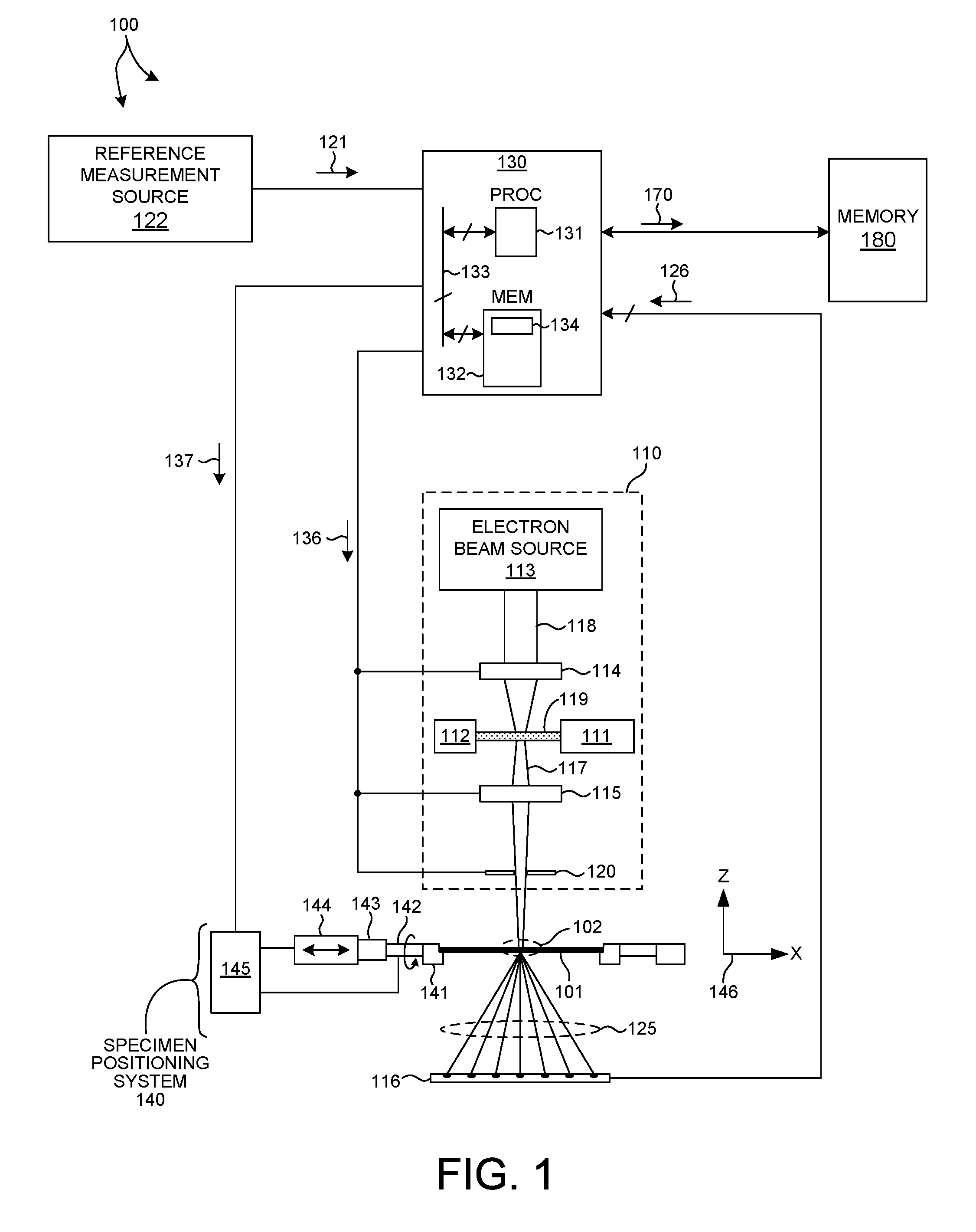

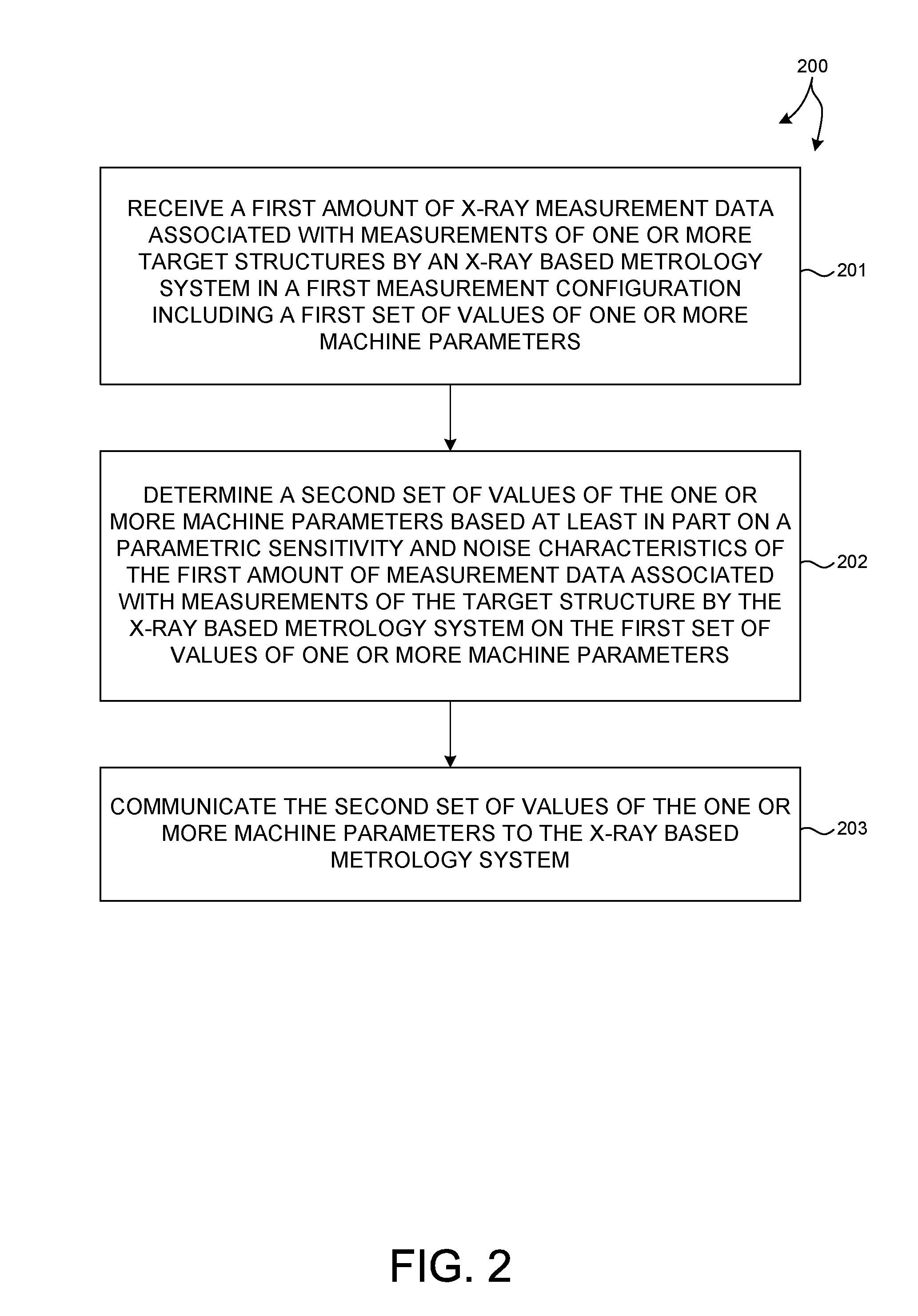

Measurement System Optimization For X-Ray Based Metrology

ActiveUS20160202193A1Maximize precisionMinimize correlationMaterial analysis by optical meansSemiconductor/solid-state device manufacturingSoft x rayMetrology

Methods and systems for optimizing measurement system parameter settings of an x-ray based metrology system are presented. X-ray based metrology systems employing an optimized set of measurement system parameters are used to measure structural, material, and process characteristics associated with different semiconductor fabrication processes with greater precision and accuracy. In one aspect, a set of values of one or more machine parameters that specify a measurement scenario is refined based at least in part on a sensitivity of measurement data to a previous set of values of the one or more machine parameters. The refinement of the values of the machine parameters is performed to maximize precision, maximize accuracy, minimize correlation between parameters of interest, or any combination thereof. Refinement of the machine parameter values that specify a measurement scenario can be used to optimize the measurement recipe to reduce measurement time and increase measurement precision and accuracy.

Owner:KLA TENCOR TECH CORP

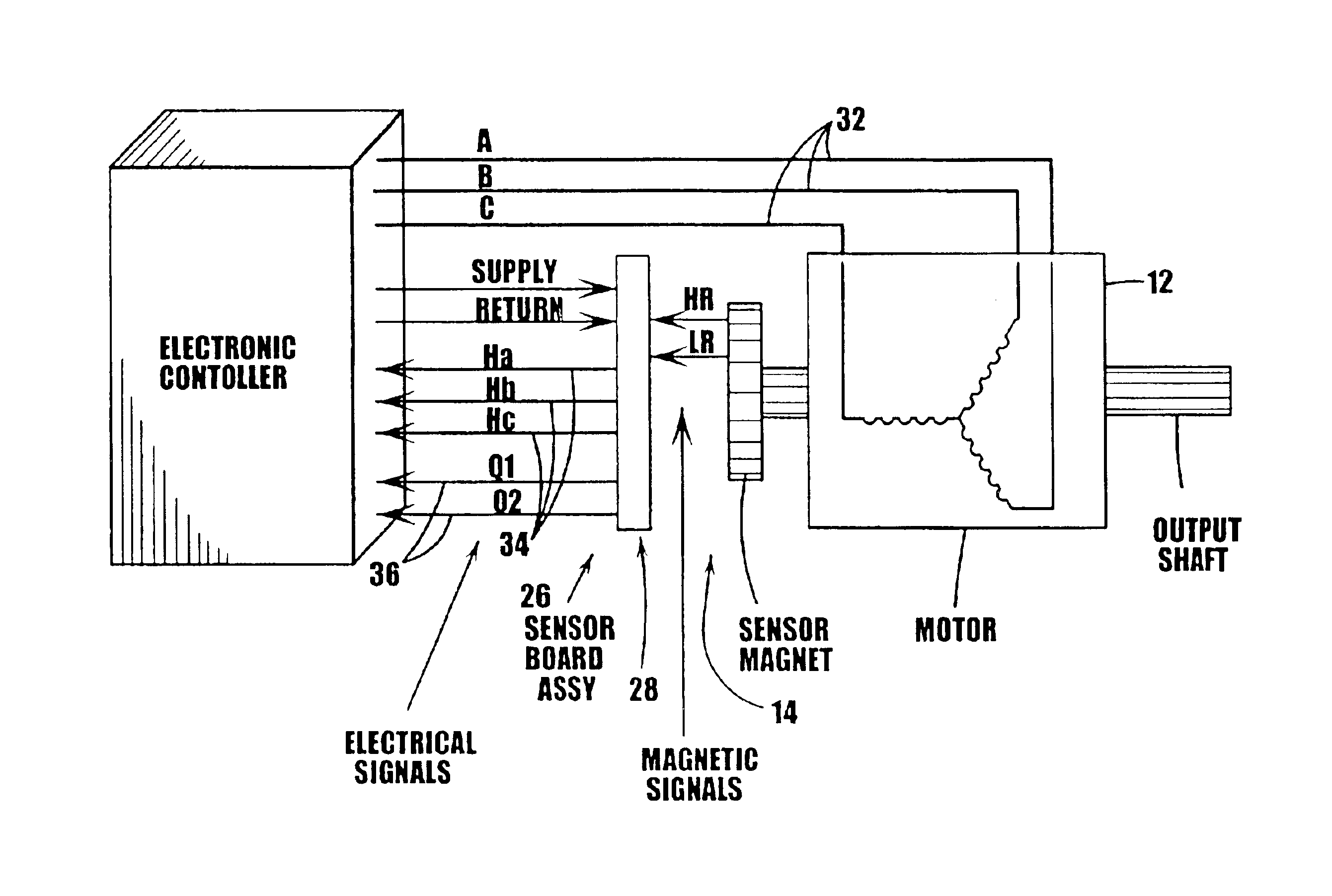

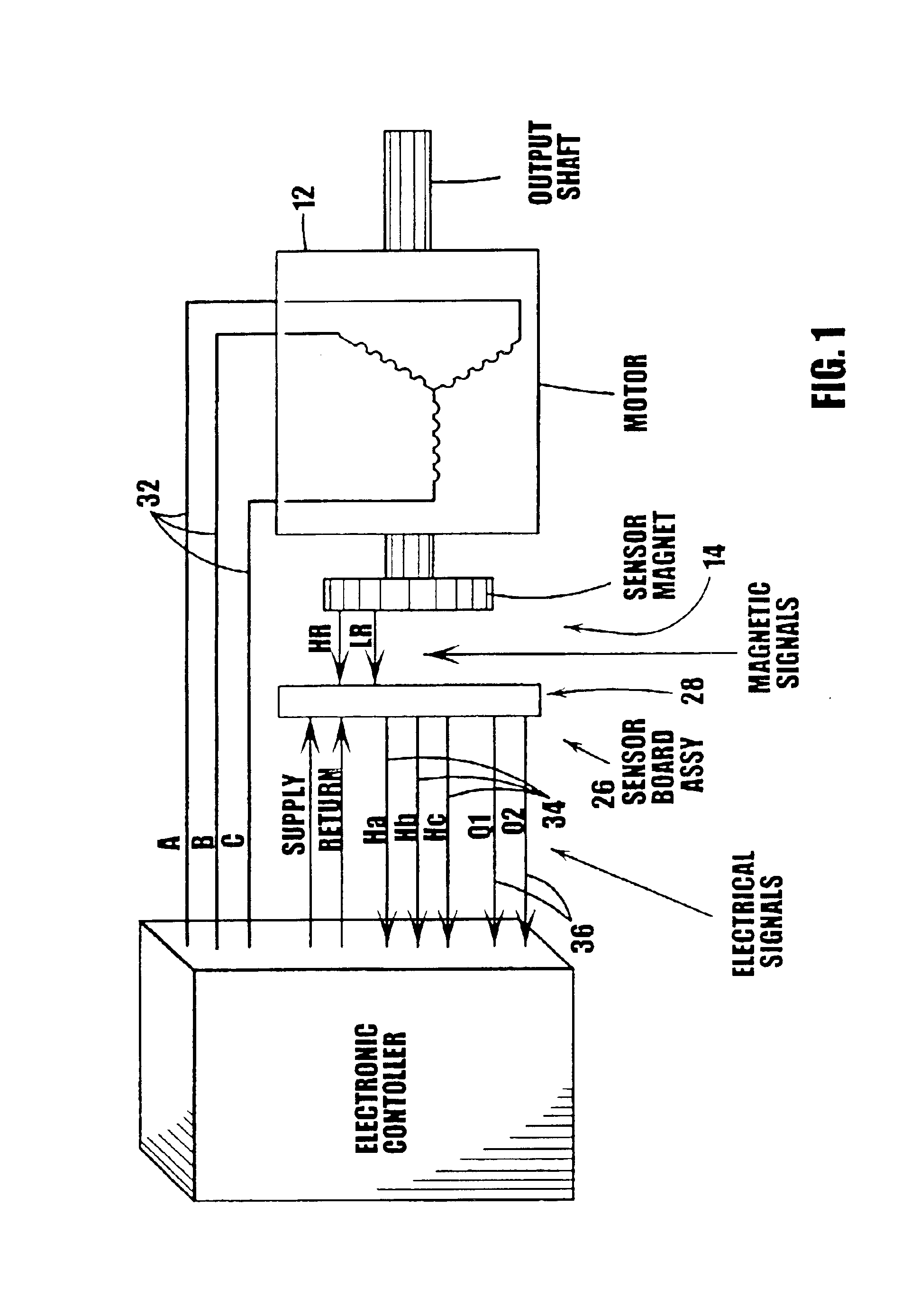

Method and apparatus for calibrating and initializing an electronically commutated motor

Owner:GM GLOBAL TECH OPERATIONS LLC +1

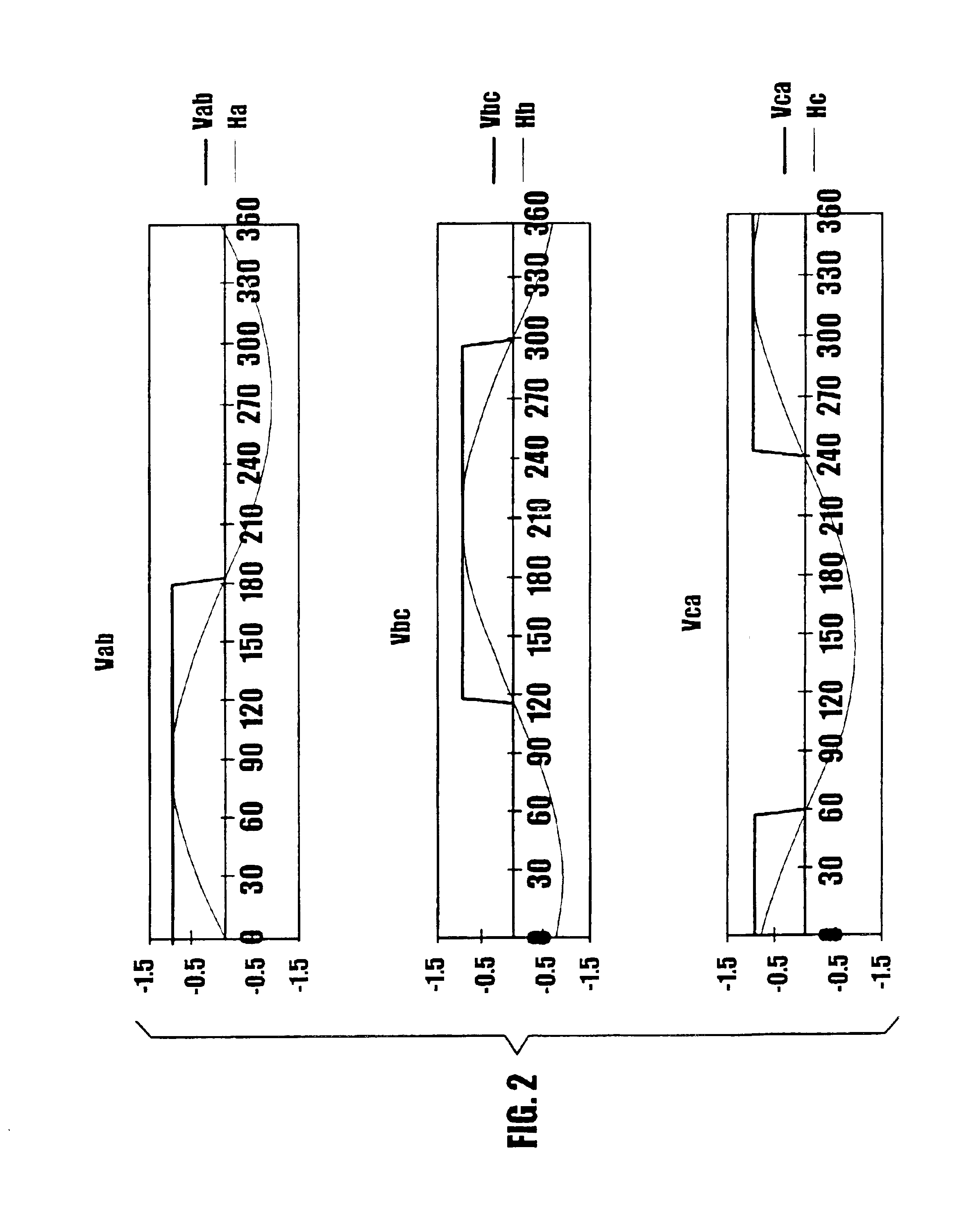

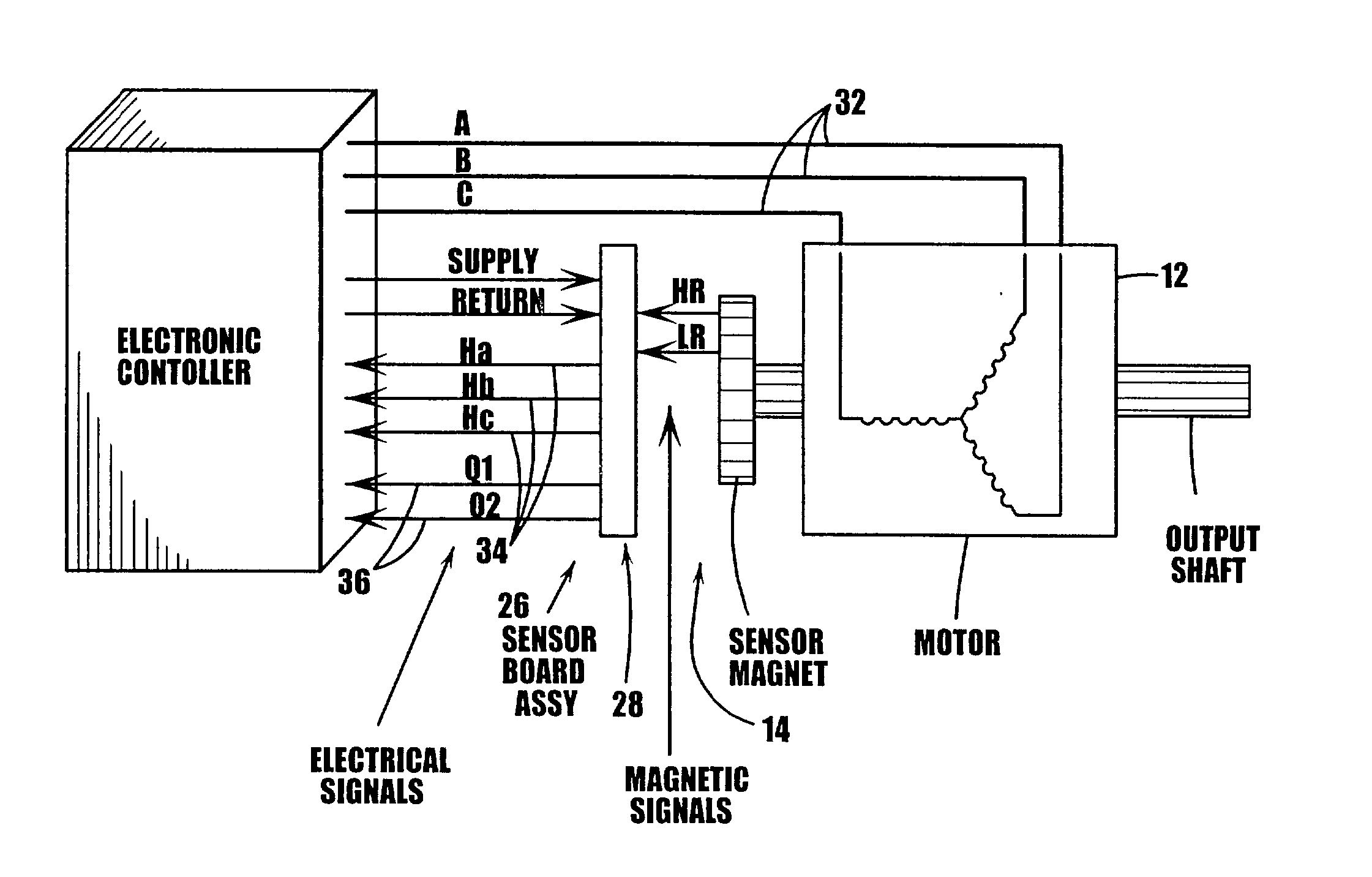

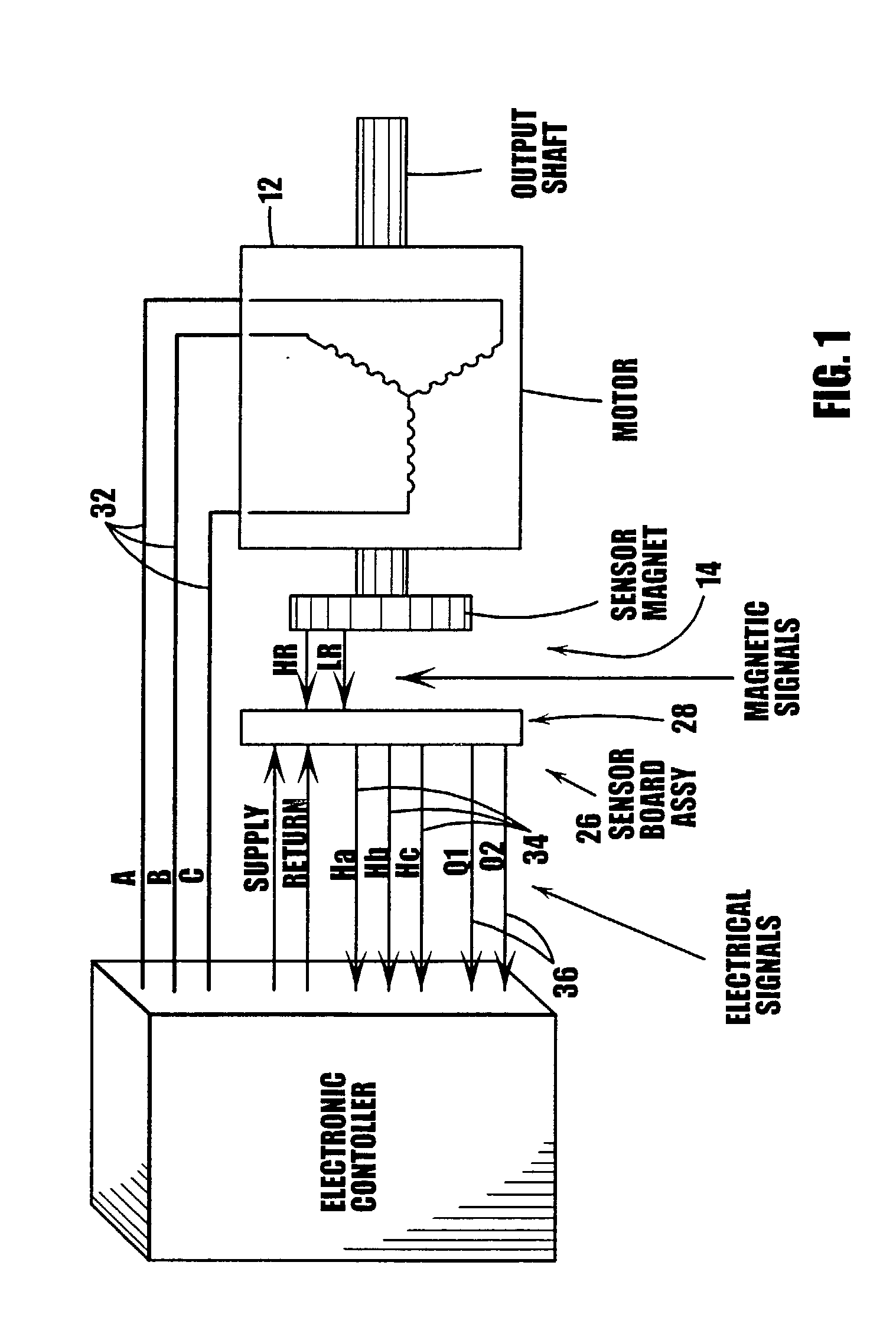

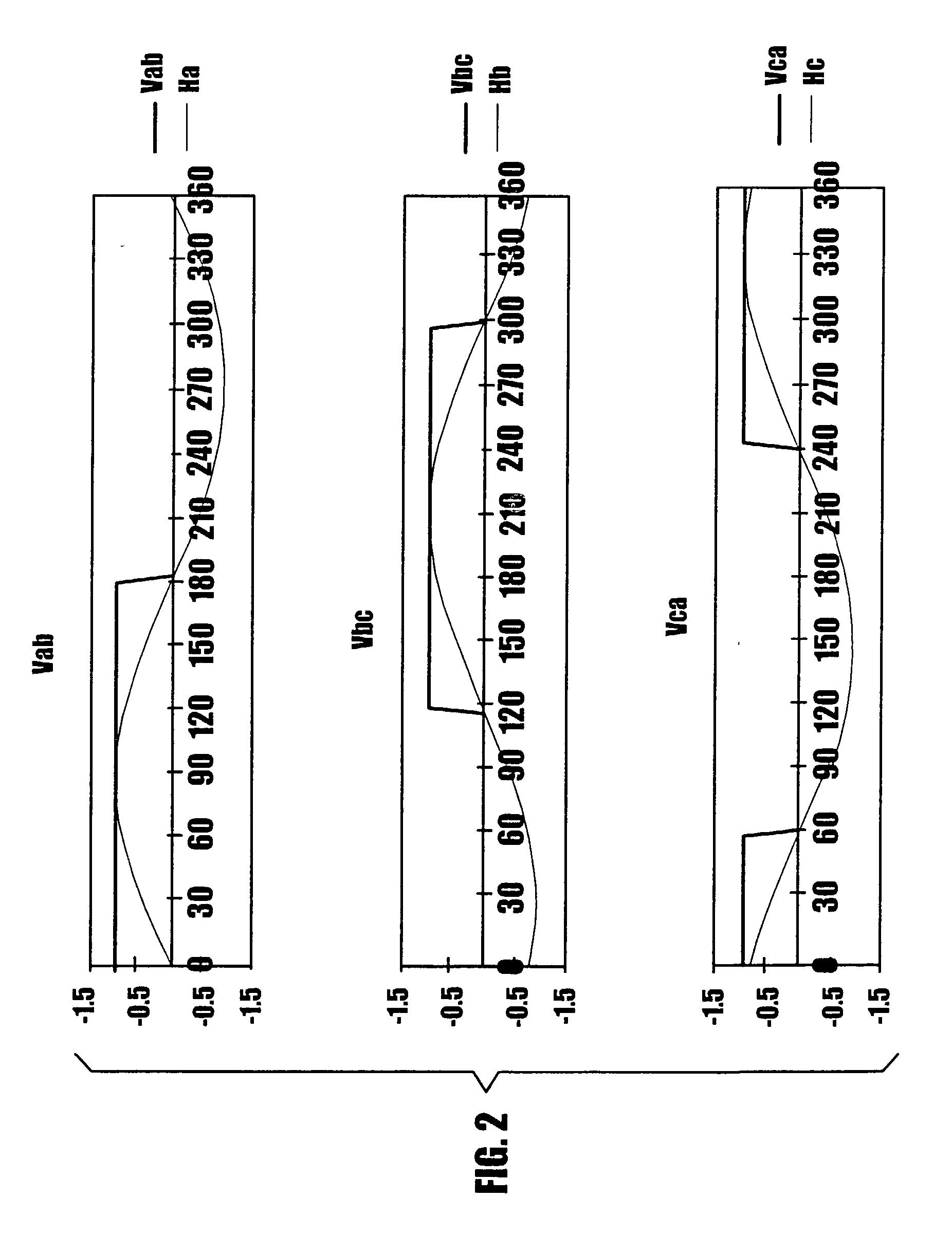

Method and apparatus for calibrating and initializing an electronically commutated motor

Disclosed herein is a method and system for initializing a rotating device such as an electronically commutated electric machine. The system comprises: an electric machine; a position sensor subsystem operatively connected to the electric machine configured to measure a position and transmit a position signal to a controller. The controller executes a method initializing position for the electric machine, the method comprising: establishing a sensor subsystem datum indicative of a measurement reference point for a sensor subsystem; obtaining a calibration value corresponding to a distance to a selected magnetic reference position for the electric machine, relative to the sensor subsystem datum; and measuring a position and calculating a position delta relative to an initial reference. The method also includes: estimating an offset from the sensor subsystem datum to an initial reference; determining an absolute position estimate of the electric machine relative to the magnetic reference position. The absolute position estimate is responsive to the calibration value, the position delta, and the offset from the sensor subsystem datum to the initial reference.

Owner:GM GLOBAL TECH OPERATIONS LLC +1

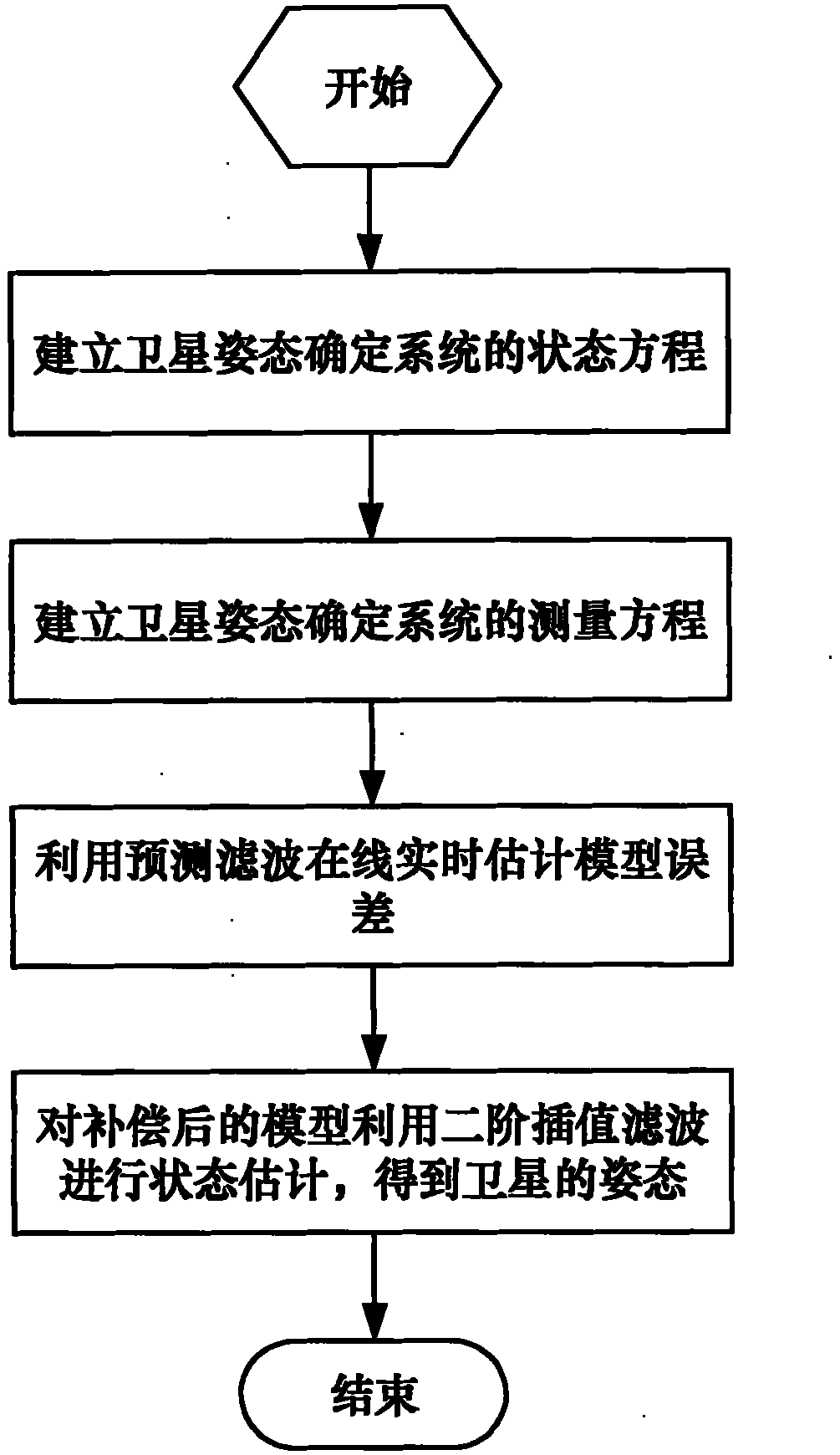

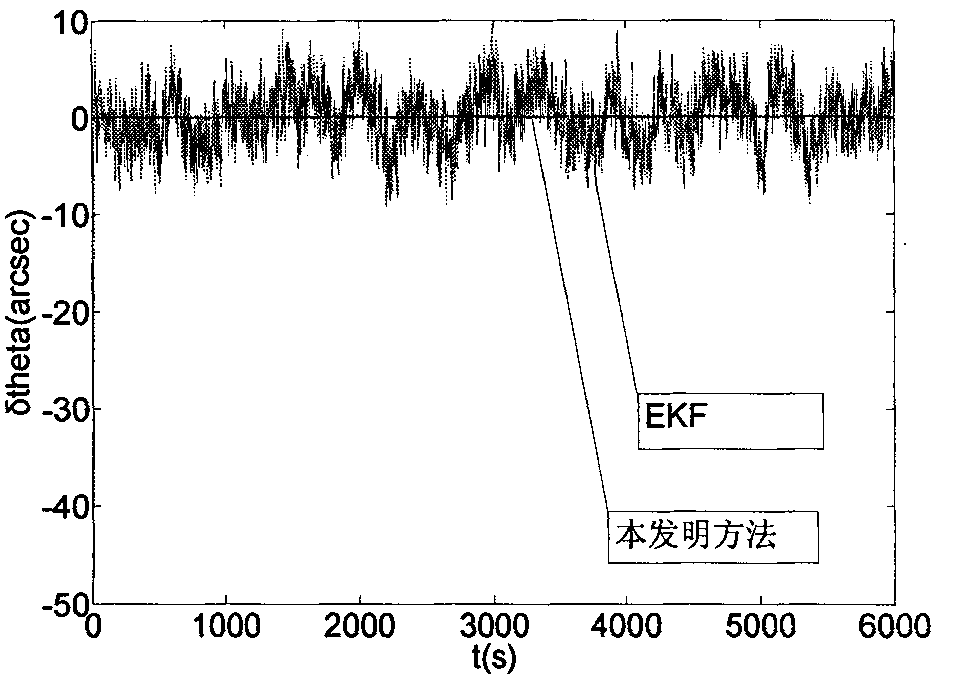

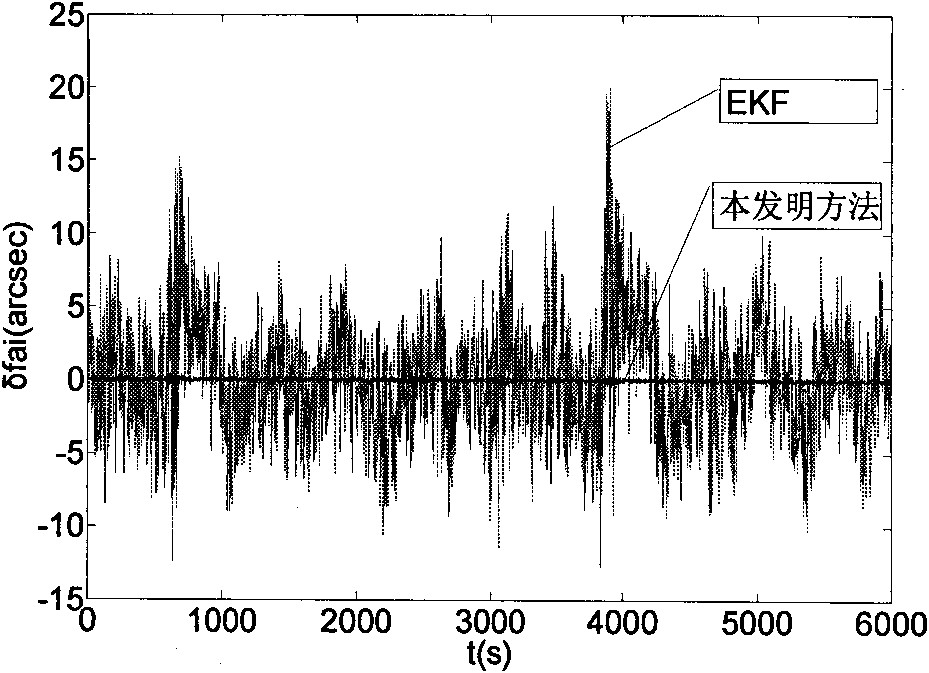

High-precision satellite attitude determination method based on star sensor and gyroscope

InactiveCN101846510AOvercome the disadvantage of error processing as zero-mean white noiseHigh precisionAngle measurementNavigation instrumentsGyroscopeZero mean

The present invention discloses a high-precision satellite attitude determination method based on star sensor and gyroscope, which comprises the following steps: step 1. establishing a status equation of a satellite attitude determination system; step 2. establishing a measurement equation of the satellite attitude determination system; step 3. performing an online real-time model error estimation through predictive filtering; and step 4. performing a status estimation on a compensated model through 2-order interpolation filtering to obtain the attitude of a satellite. By applying predictive filtering to performing an online real-time model error estimation and correcting the system model, the invention overcomes the shortcoming existing in the conventional estimation process that error is processed into zero-mean white noise; and in addition, the invention can process any nonlinear system and noise conditions to obtain an estimation result of higher precision and is applicable to thefield of high-precision attitude determination.

Owner:BEIHANG UNIV

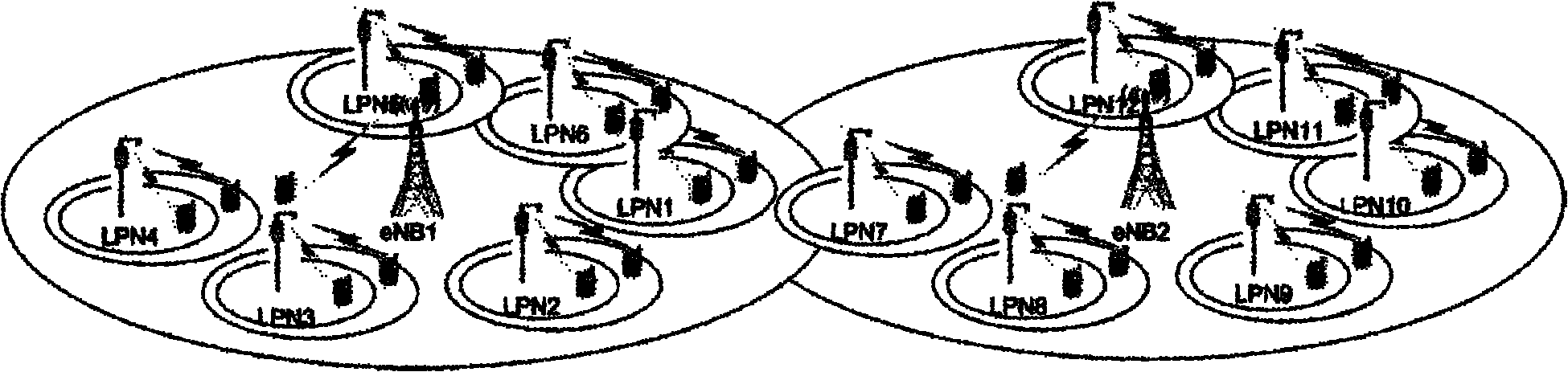

Method, device and system for detecting interference

InactiveCN102595436AFlexible deploymentFlexible interferencePower managementReceivers monitoringDisparate systemComplex network

The embodiment of the invention discloses a method, a device and a system for detecting interference. Taking the implementation of the method embodiment as an example, the method comprises the following steps that: a measuring base station obtains a measuring reference mark of an interference base station, and the configuration information of the measuring reference mark; and the measuring base station detects a measuring reference mark receiving quality valve of the interference base station according to the configuration information. The embodiment of the invention provides the method and the system for the base station to detect the interference, provides long-term steady channel measurement result, and solves the problem of detecting and processing the interference of the downlink transmitting of the interference base station in common frequency, pilot frequency and disparate system on the uplink receiving of the measuring base station in the same system or disparate system on the neighboring frequency band under complex network condition, thus, the networks can be flexibly deployed and coexist with interference.

Owner:HUAWEI TECH CO LTD

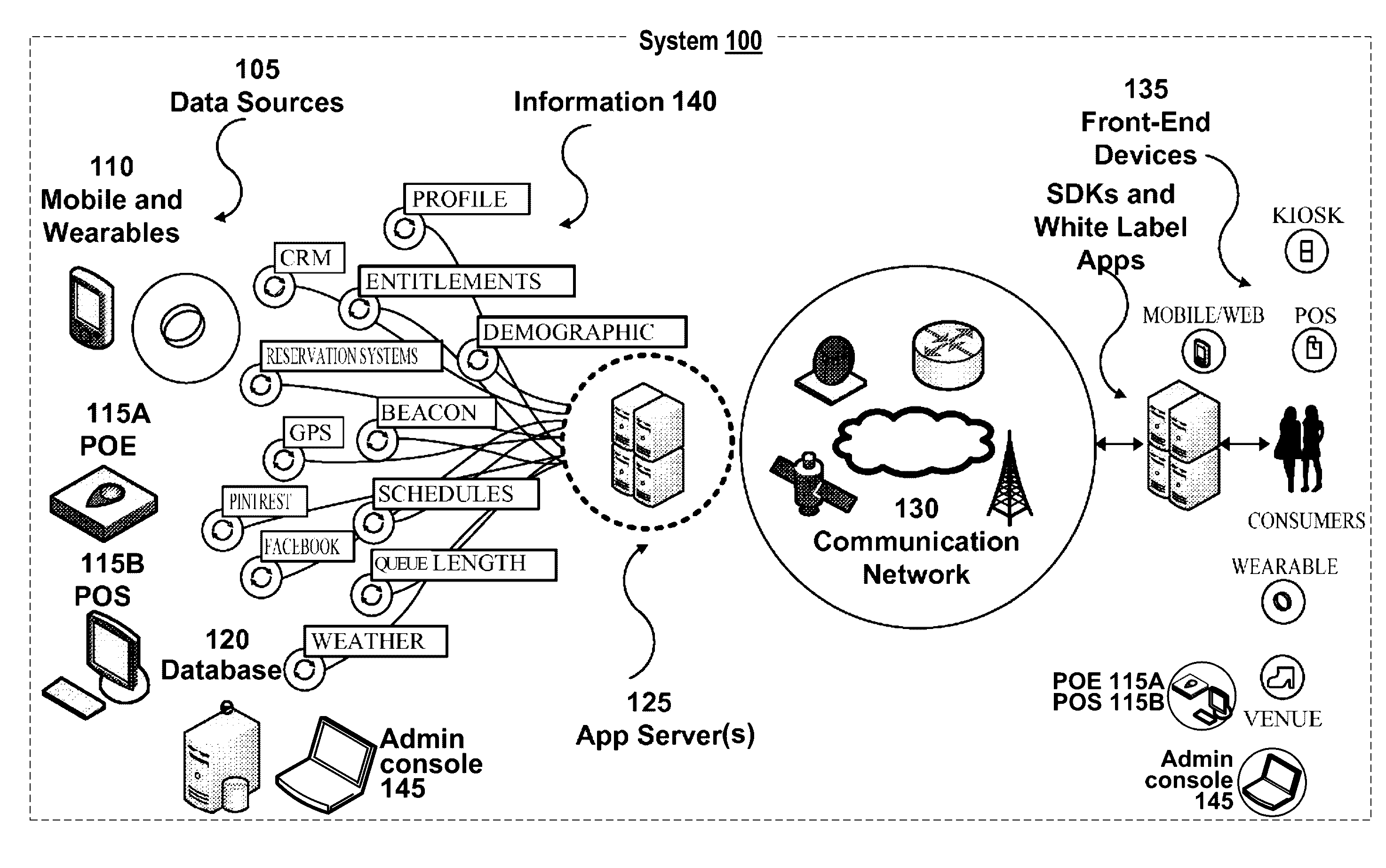

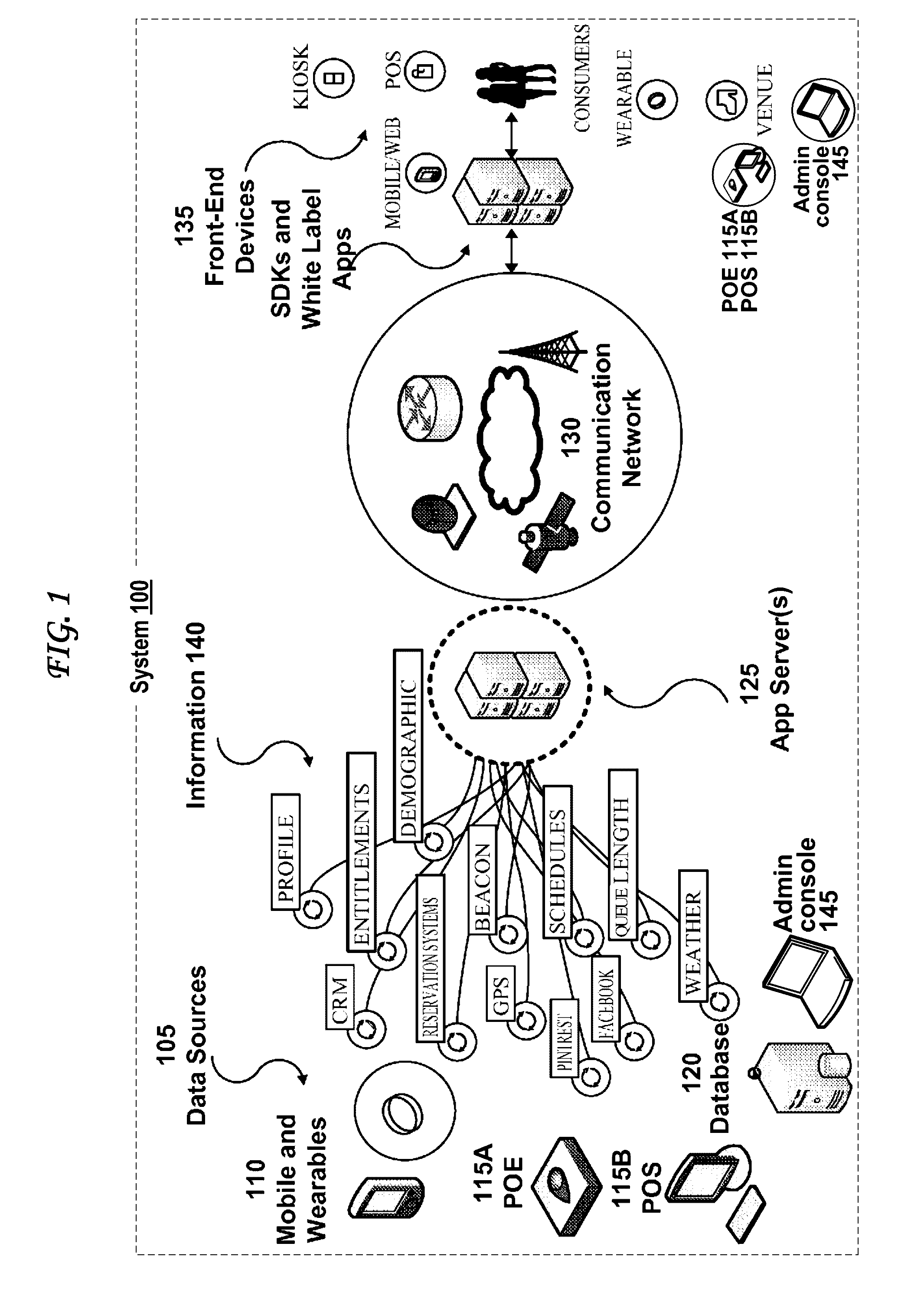

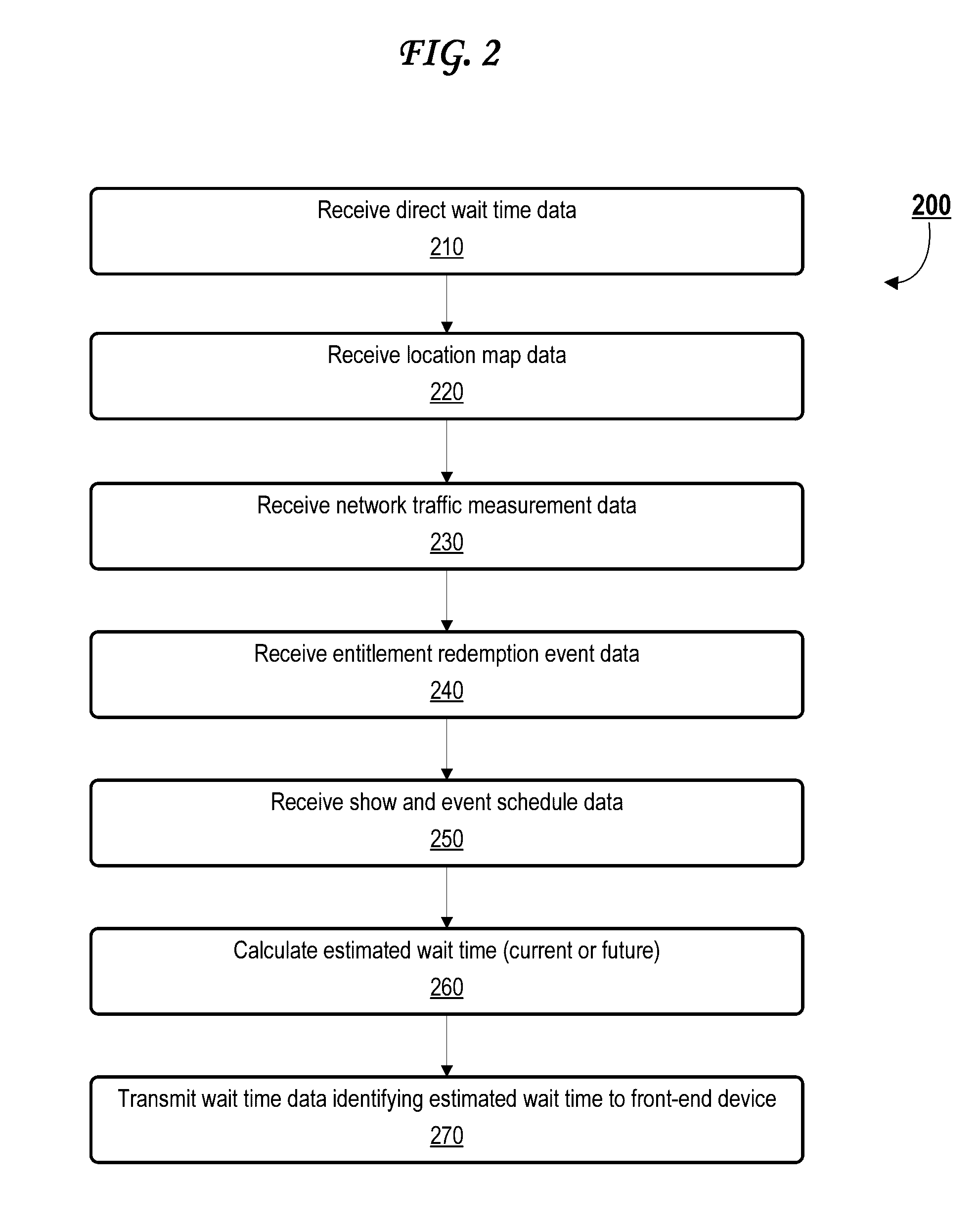

Intelligent prediction of queue wait times

ActiveUS20160321548A1Customer communicationsProbabilistic networksTraffic volumeSystematic measurement

An estimate is provided for how long a guest will have to wait to enter a ride, restaurant, restroom, or other point of interest at a venue. Wait times are computed using one or more algorithms (e.g., Bayesian) that can combine direct measurements around the point of interest, historical measurements around the point of interest, and measurements taken from other systems not directly connected to the point of interest. Supporting systems will vary by venue and may include entry ticketing systems, network traffic, point of sale registers, event schedules, and proximity detectors in other parts of the venue. By comparing probabilities generated from this disparate data, current and future wait times can be estimated and provided to front-end devices corresponding to guests or staff.

Owner:ACCESSO TECH GRP

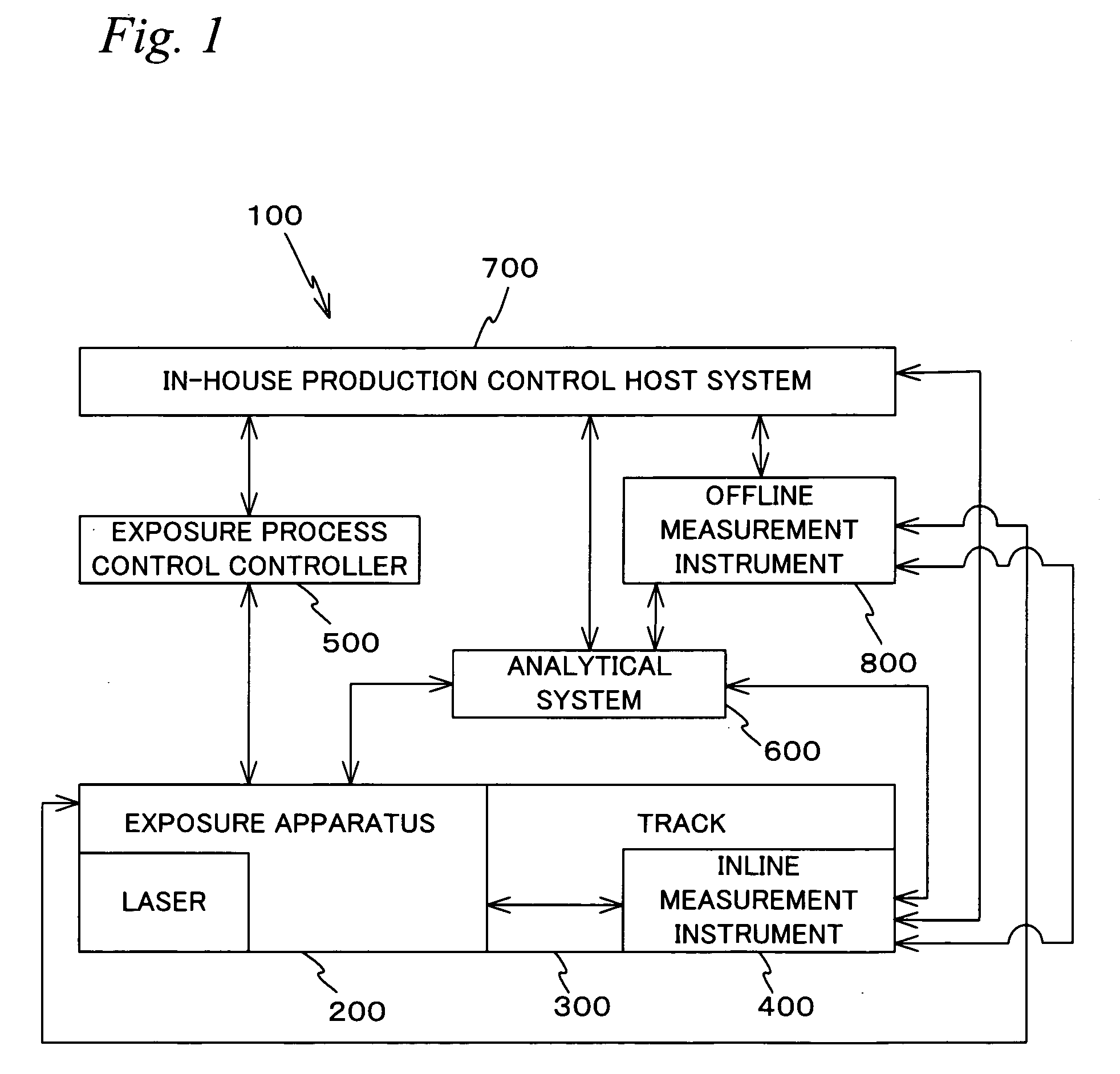

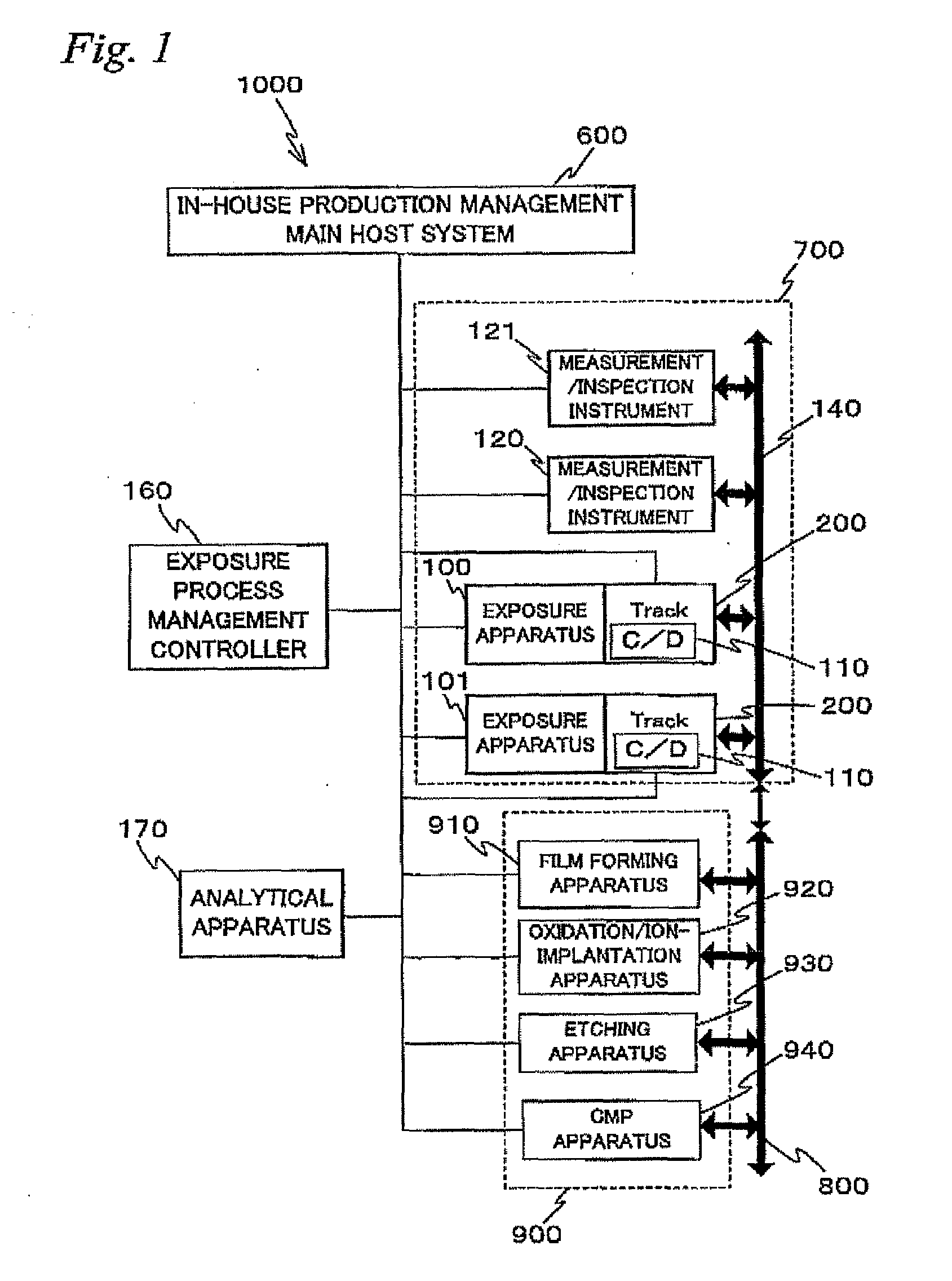

Device manufacturing method, device manufacturing system, and measurement/inspection apparatus

ActiveUS20090009741A1Semiconductor/solid-state device testing/measurementSolid-state devicesMeasurement deviceEngineering

In the case where measurement / inspection of a wafer is performed in a measurement / inspection instrument before and after exposure is performed in an exposure apparatus, various kinds of conditions of the exposure apparatus and the measurement / inspection instrument such as environment in the apparatus / instrument, a measurement condition of an alignment system a measurement condition of an AF measurement device, a wafer grid, and image distortion are made to be matched. In particular, in accordance with a processing state of the exposure apparatus and a coater developer, a measurement result of a film, and the like, exclusion of a mark for overlay error measurement, adjustment of the measurement condition and correction of the measurement result, adjustment of the environment, correction of the measurement result according to the environment, and adjustment of pattern defect inspection are performed. Further, in calibration processing, aberration of a projection optical system of an exposure apparatus that transfers a pattern on a wafer for calibration, and the like are also taken into consideration. Accordingly, the yield of device production can be improved.

Owner:NIKON CORP

Multi-position strapping north-seeking system direction effect calibration method

InactiveCN101187568AImprove measurement accuracyEliminate measurement errorsRotary gyroscopesObservational errorGyroscope

The invention belongs to a calibration method of an error which is measured by a multi-position strapdown north seeking device, in particular to a calibration method of orientation effect of a multi-position strapdown north seeking device. A true north prism, two theodolites and a mechanical dividing rotating platform are used as auxiliary testing tools, the multi-position strapdown north seeking device is fixed on the mechanical dividing rotating platform, and is divided according to one circle equipartition point, an angle of a benchmark prism of a strapdown north seeking system and the true north direction is defined through rotating an equipartition angle value at one time by the mechanical rotating platform and through the true north prism system in an initial rotating position of the north seeking system, and then the angle is compared with a north-oriented value which is measured by the strapdown north seeking system, the error is calculated, and an azimuthal effect of a gyroscope which is simulated according to the characteristic of the error is marked. The invention effectively eliminates measuring error which is caused by the azimuthal effect, thereby improves the measuring accuracy of the multi-position strapdown north seeking system.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

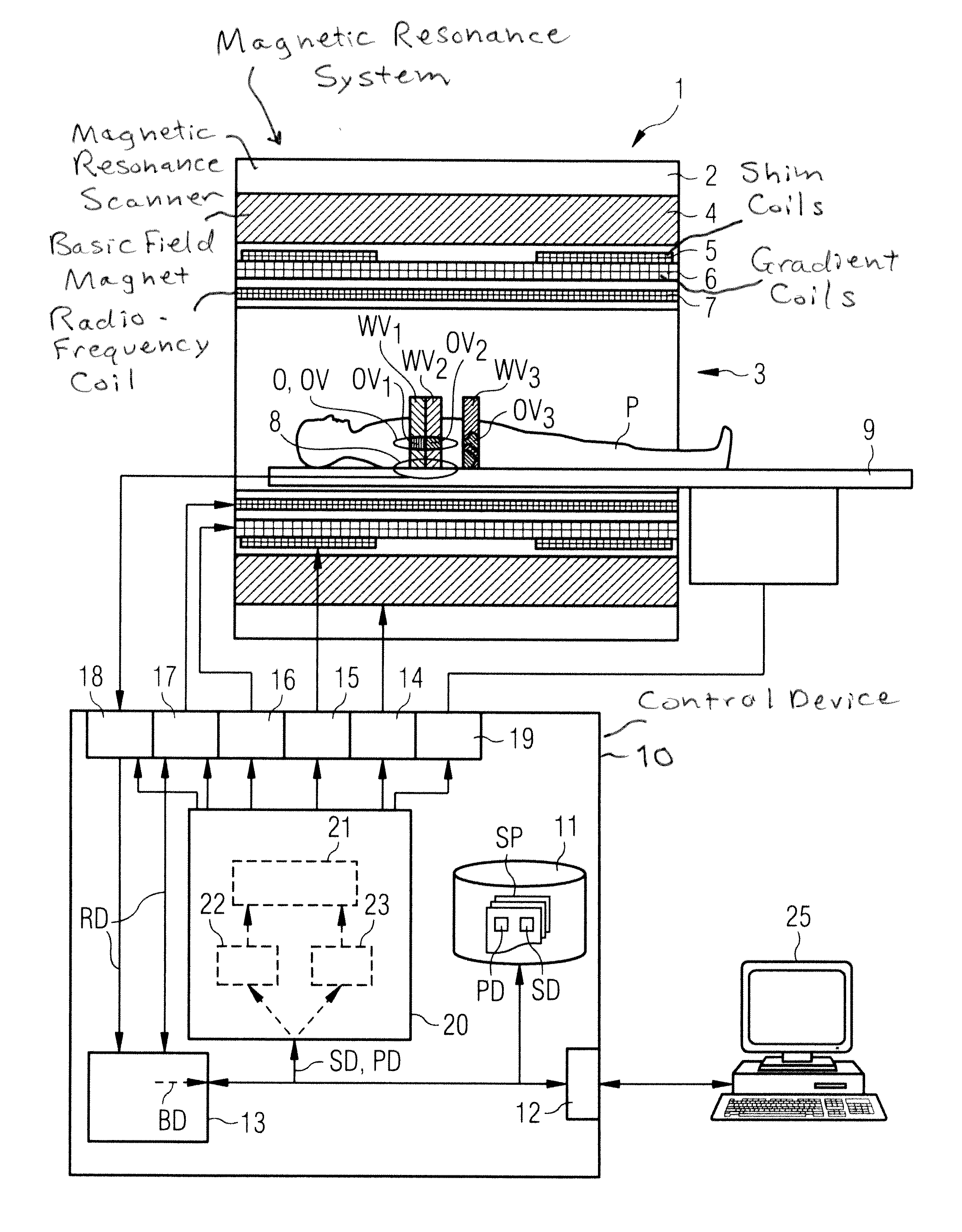

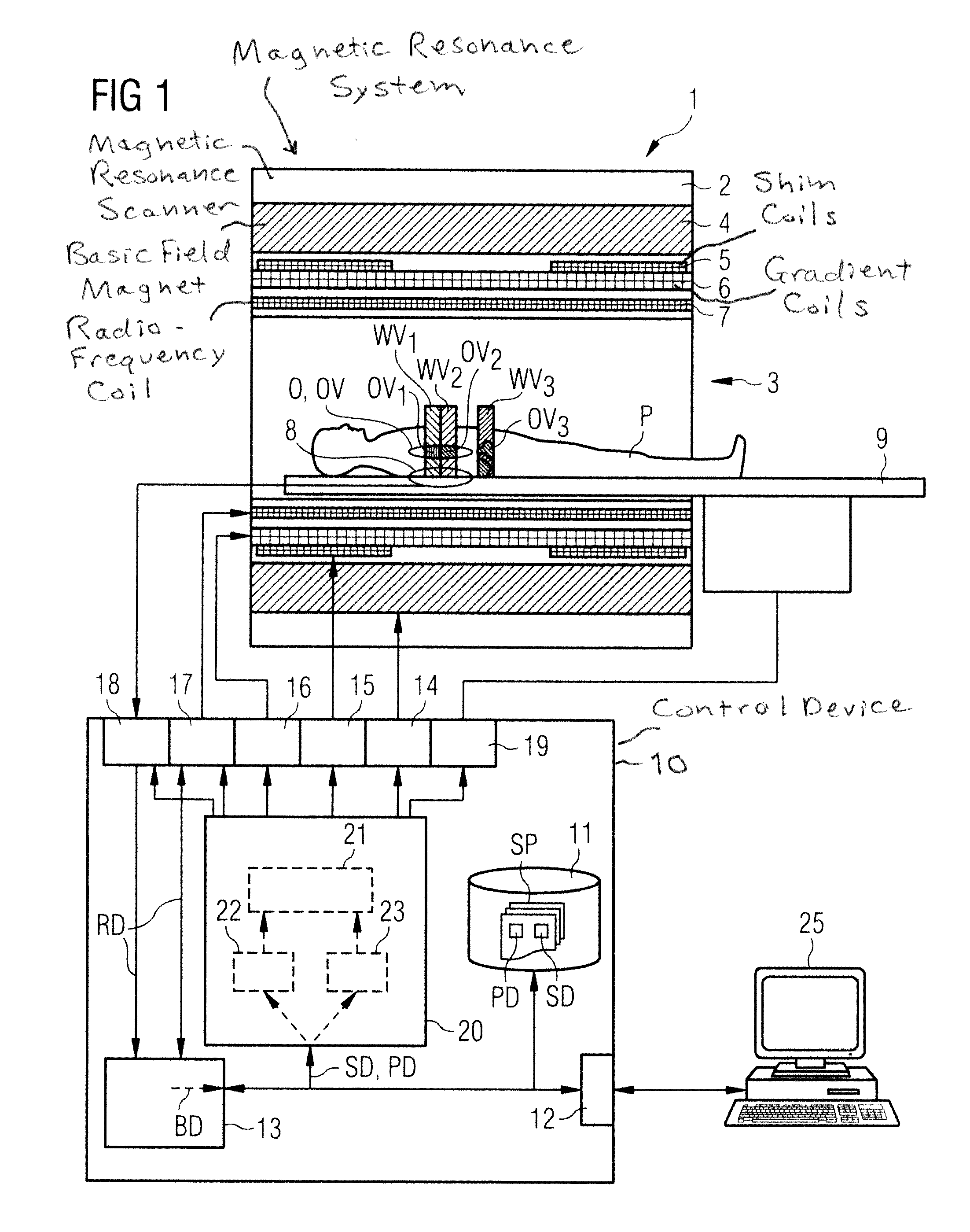

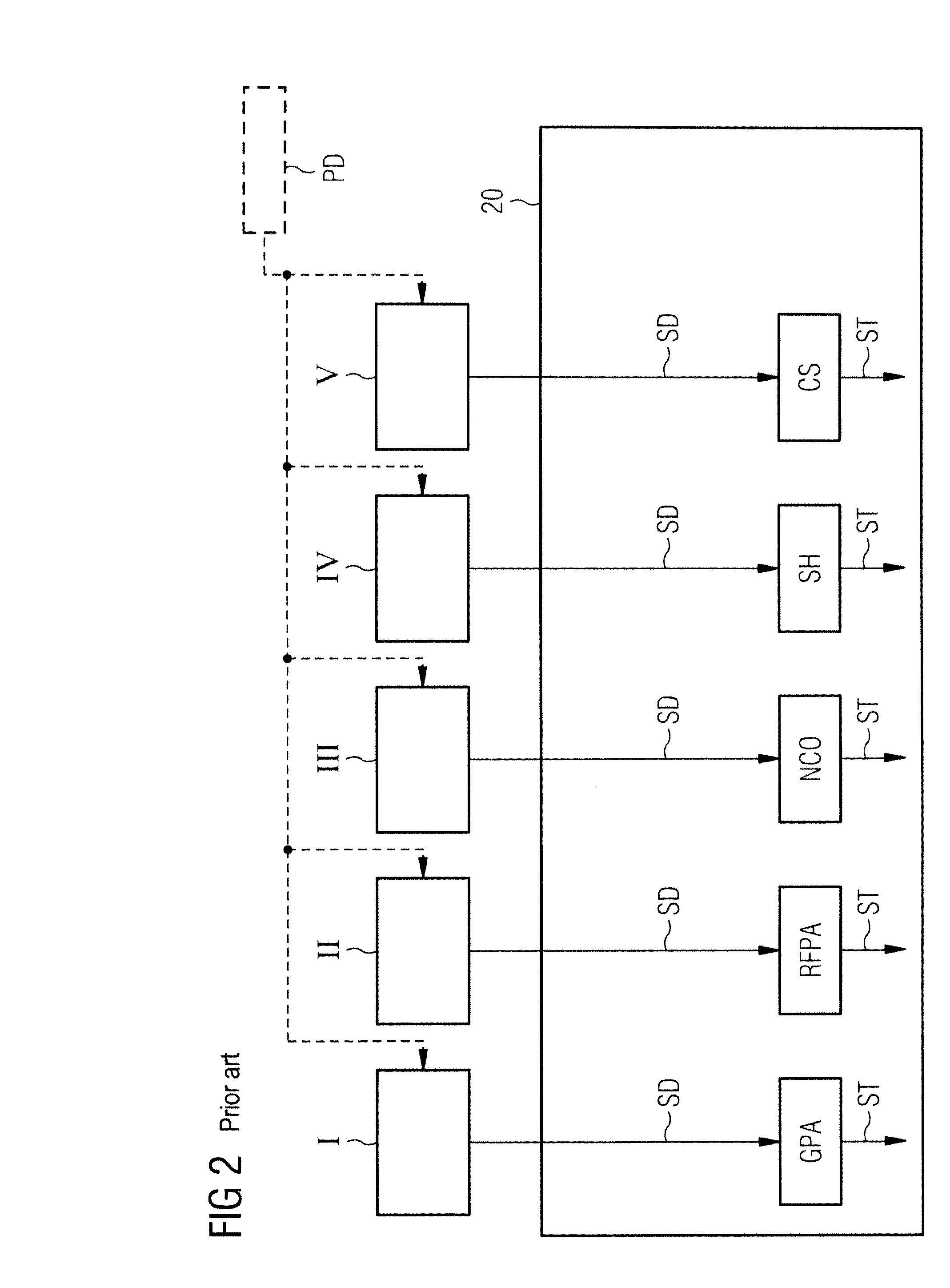

Method to operate an imaging system, and imaging system

ActiveUS20100286802A1Quality improvementImprovement effortsDiagnostic recording/measuringMeasurements using NMR imaging systemsSequence controlControl signal

In an imaging system having a number of subsystems and a control device that controls the subsystems in a coordinated manner to implement a measurement sequence and an operating method therefor, sequence control data that define different functional sub-sequences of the measurement sequence are transmitted to the control device. Different active volumes are associated with the functional sub-sequences. In addition to the sequence control data, active volume position data are provided to the control device that define bearing and extent of the active volumes associated with the different functional sub-sequences. Control signals to implement the measurement sequence for the different subsystems are generated automatically by the control device based on the sequence control data and the active volume position data so that the individual functional sub-sequences are locally optimized at least with regard to a sub-region of their associated active volume.

Owner:SIEMENS HEALTHCARE GMBH

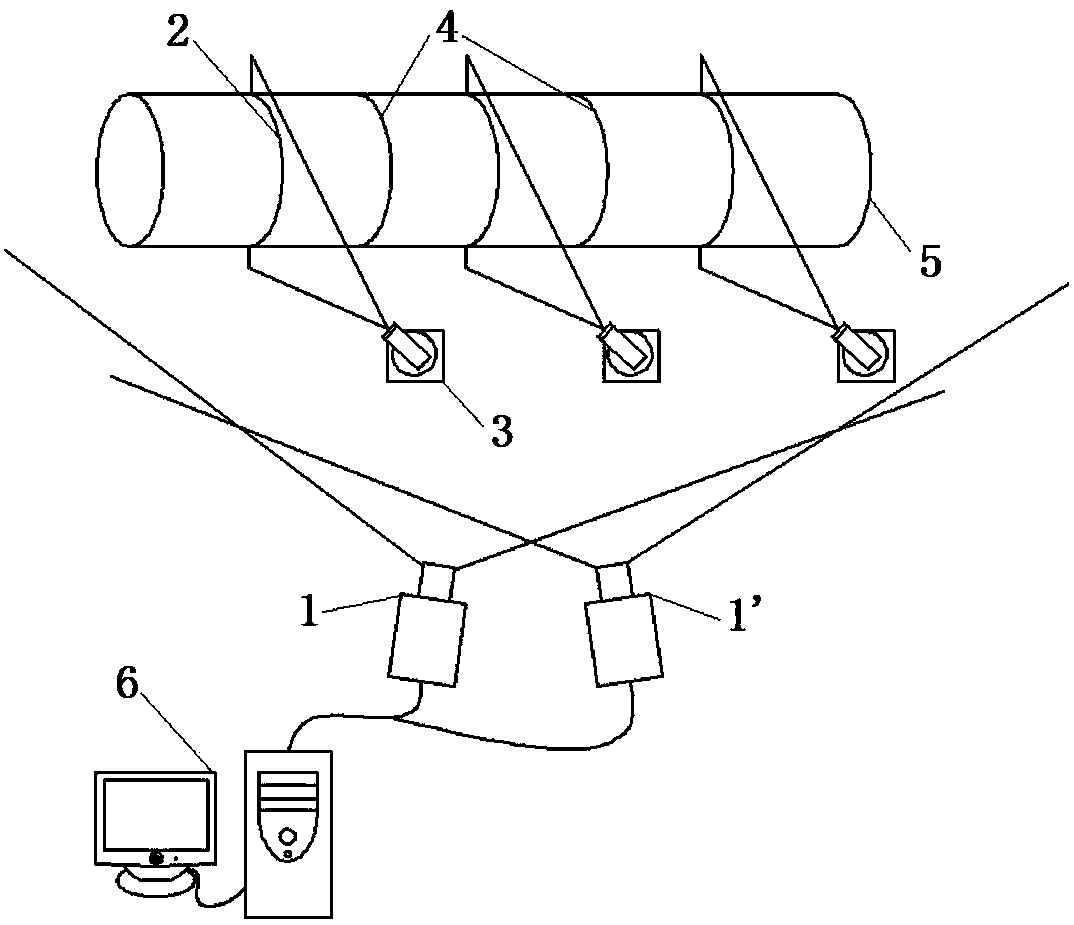

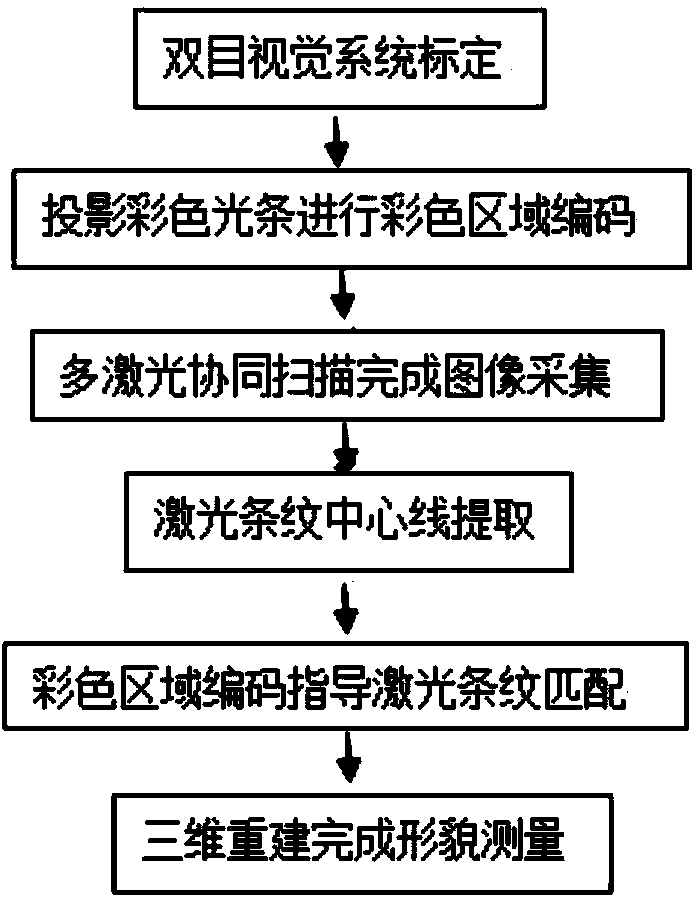

Quick morphology vision measuring method in multi-laser synergic scanning mode

InactiveCN103940369AIncrease brightnessImprove linearityUsing optical meansImage extractionSystematic measurement

The invention discloses a quick morphology vision measuring method in a multi-laser synergic scanning mode, belongs to the technical field of computer vision measurement and relates to a quick big component morphology measuring method in the multi-laser synergic scanning mode. The method comprises the steps that firstly, colorful light bars are projected to the surface of an object to be measured, and then color area coding within a measurement range is conducted; secondly, multiple lasers are projected to the surface of a component to be measured, the multiple lasers are scanned simultaneously by controlling a rotating platform, laser stripes are subjected to image extraction and matching according to the binocular vision measurement theory, and then quick measurement of morphology is achieved finally. By the adoption of the quick morphology vision measuring method in the multi-laser synergic scanning mode, quick and accurate big component morphology measurement without any processing on a target object is achieved, and the image acquisition quality is improved through high brightness and high condensation of the lasers; besides, color area coding is used for assisting in accurate matching of the multiple laser stripes, so that the matching requirement and the calculated amount are greatly lowered, and the measurement efficiency of the whole system is improved.

Owner:DALIAN UNIV OF TECH

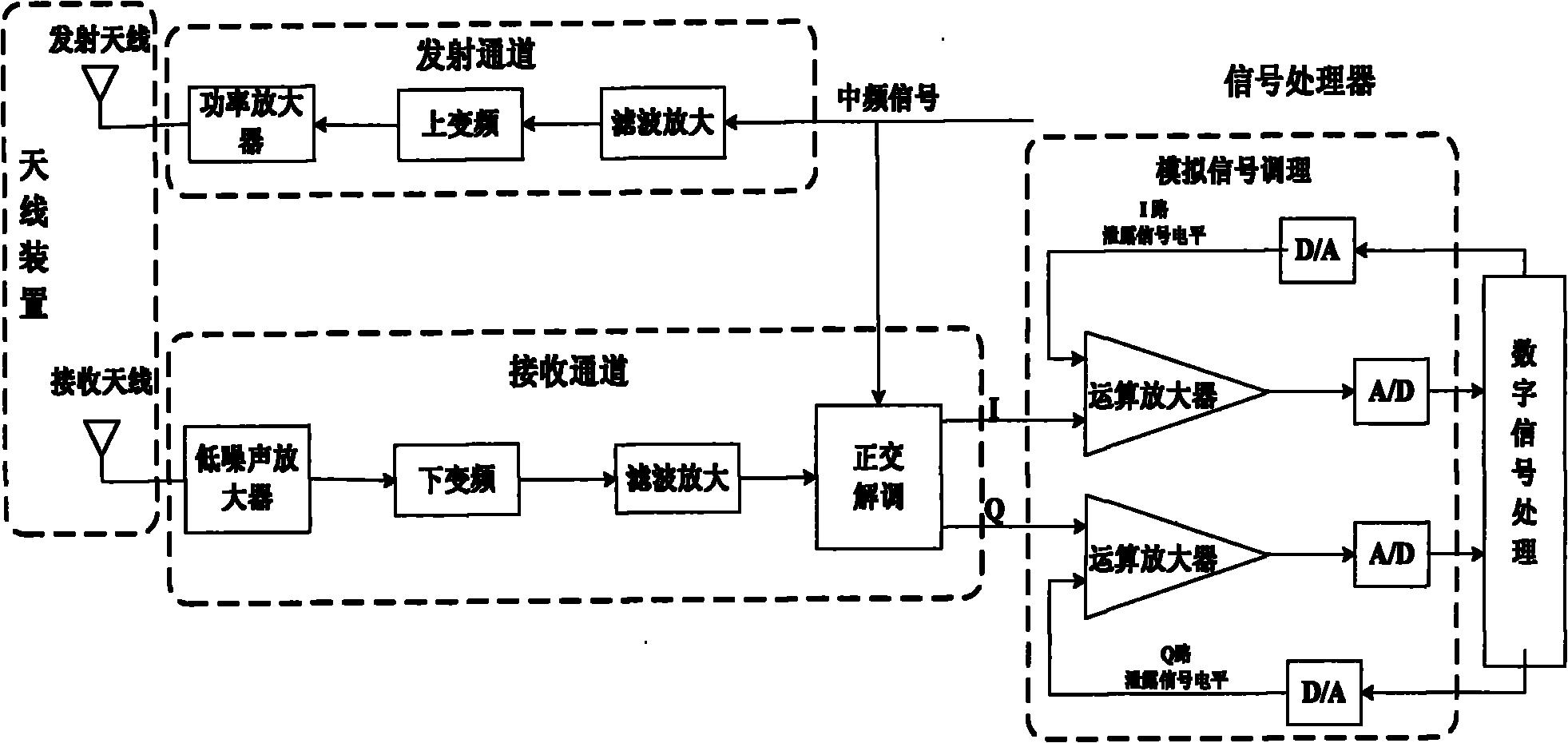

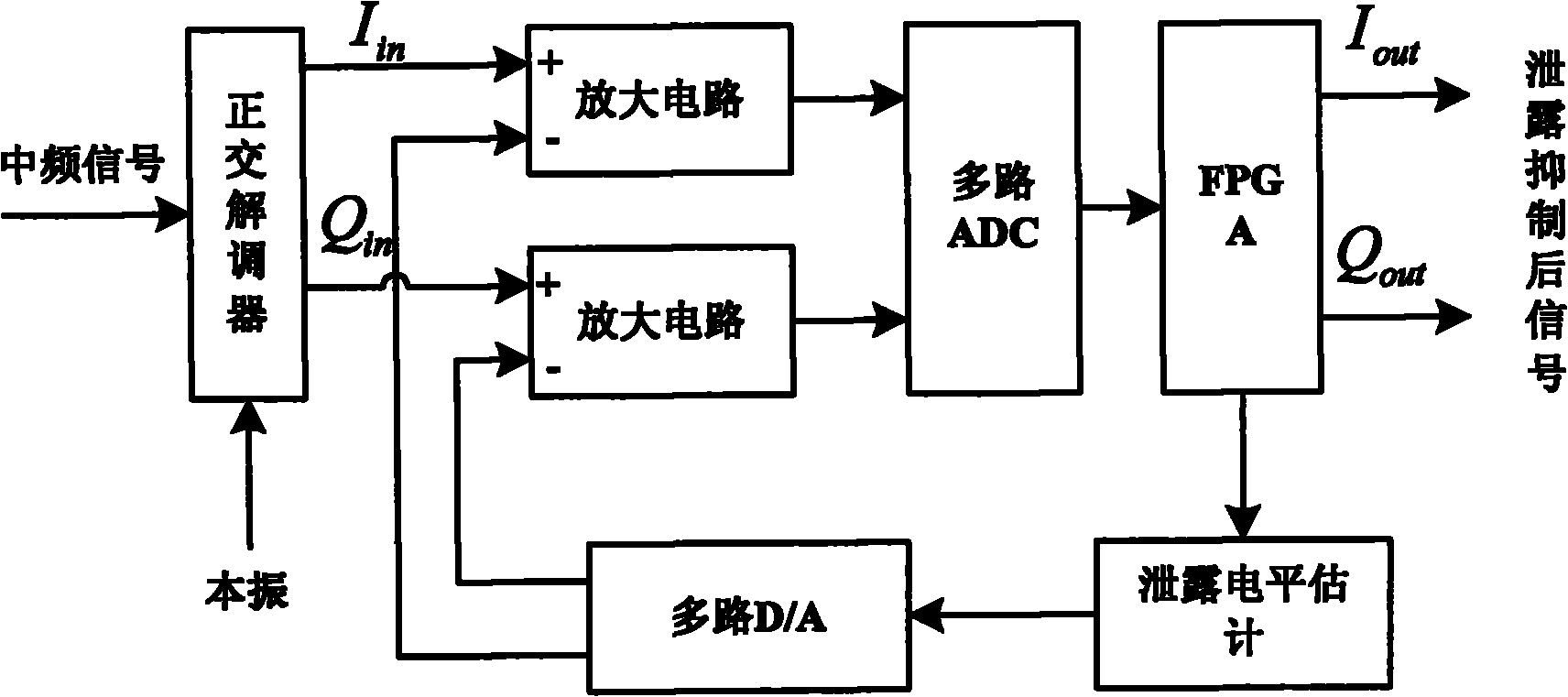

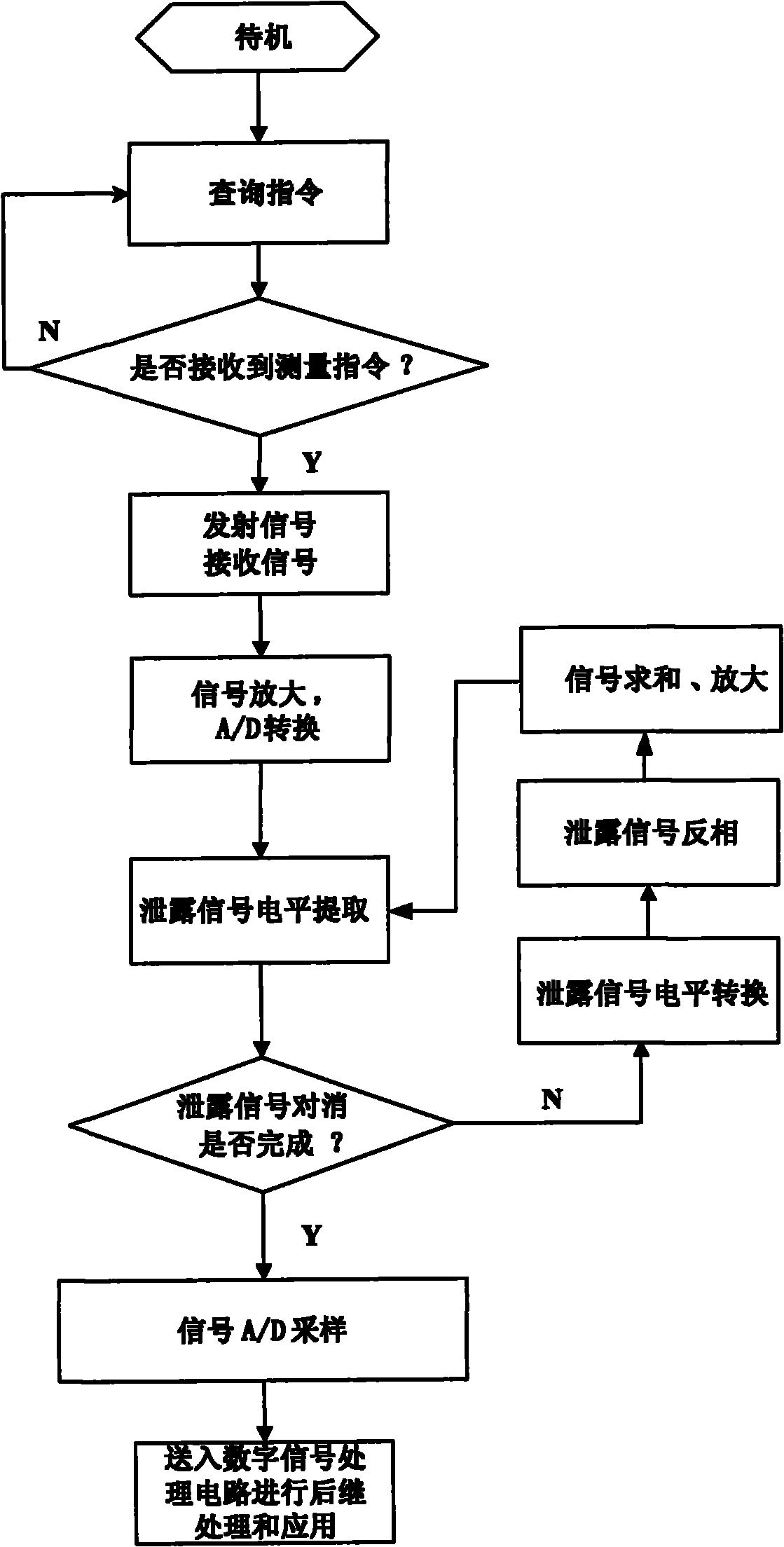

Continuous wave radar feed-through nulling system and method

ActiveCN102023292AHigh rejection ratioReduced isolation requirementsRadio wave reradiation/reflectionDigital signal processingAudio power amplifier

The invention provides a continuous wave radar feed-through nulling system and a continuous wave radar feed-through nulling method. The system comprises an antenna device, a transmitting channel, a receiving channel and a signal processor, wherein the antenna device consists of a transmitting antenna and a receiving antenna; the transmitting channel consists of a filter and amplifier module, an up-conversion module and a power amplifier; the receiving channel consists of a low-noise amplifier, a down-conversion module, a filter and amplifier module and a quadrature dDemodulation module; and the signal processor comprises an analog signal conditioning unit circuit and a digital signal processing unit circuit. In the invention, through the sampling of an orthogonally demodulated signal and the real-time self-adaptive nulling of the signal, feed-through signals are prohibited and the measurement accuracy of the system is improved. Meanwhile, the video nulling system provided by the invention also has the characteristics that: the scheme is simple; the implementation is easy; and the like.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

System and method for determining a treatment dose for a patient

InactiveUS20070083090A1Bioreactor/fermenter combinationsBiological substance pretreatmentsAnalyteSystems analysis

In certain embodiments, a method of maintaining health of a patient uses an analyte detection system. The analyte detection system is coupled to the patient such that a bodily fluid of the patient is accessible to the analyte detection system. The method includes automatically initiating and conducting a measurement of an analyte in the bodily fluid using the analyte detection system. The method further includes determining a treatment dose for the patient based on the measurement using the analyte detection system.

Owner:OPTISCAN BIOMEDICAL

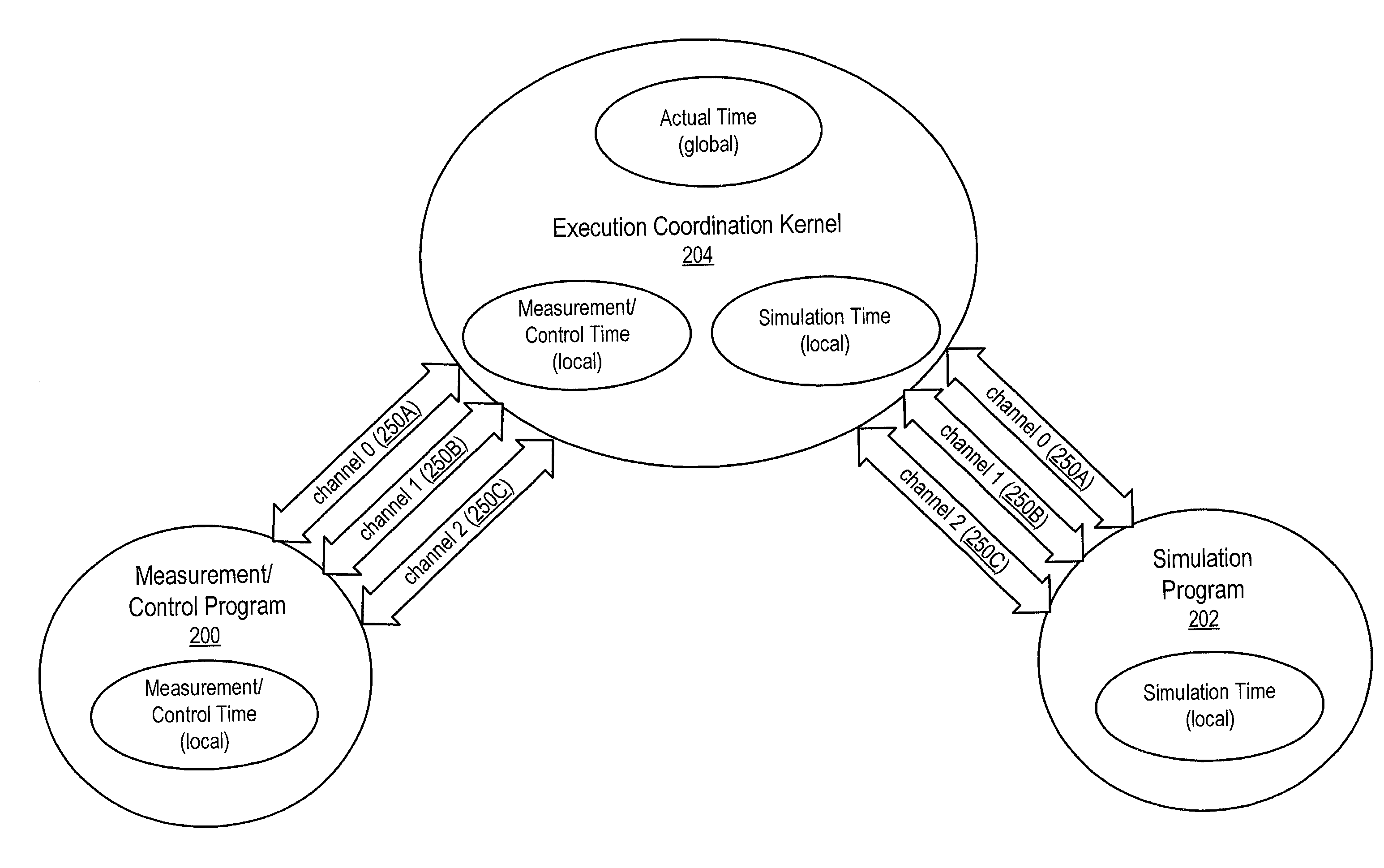

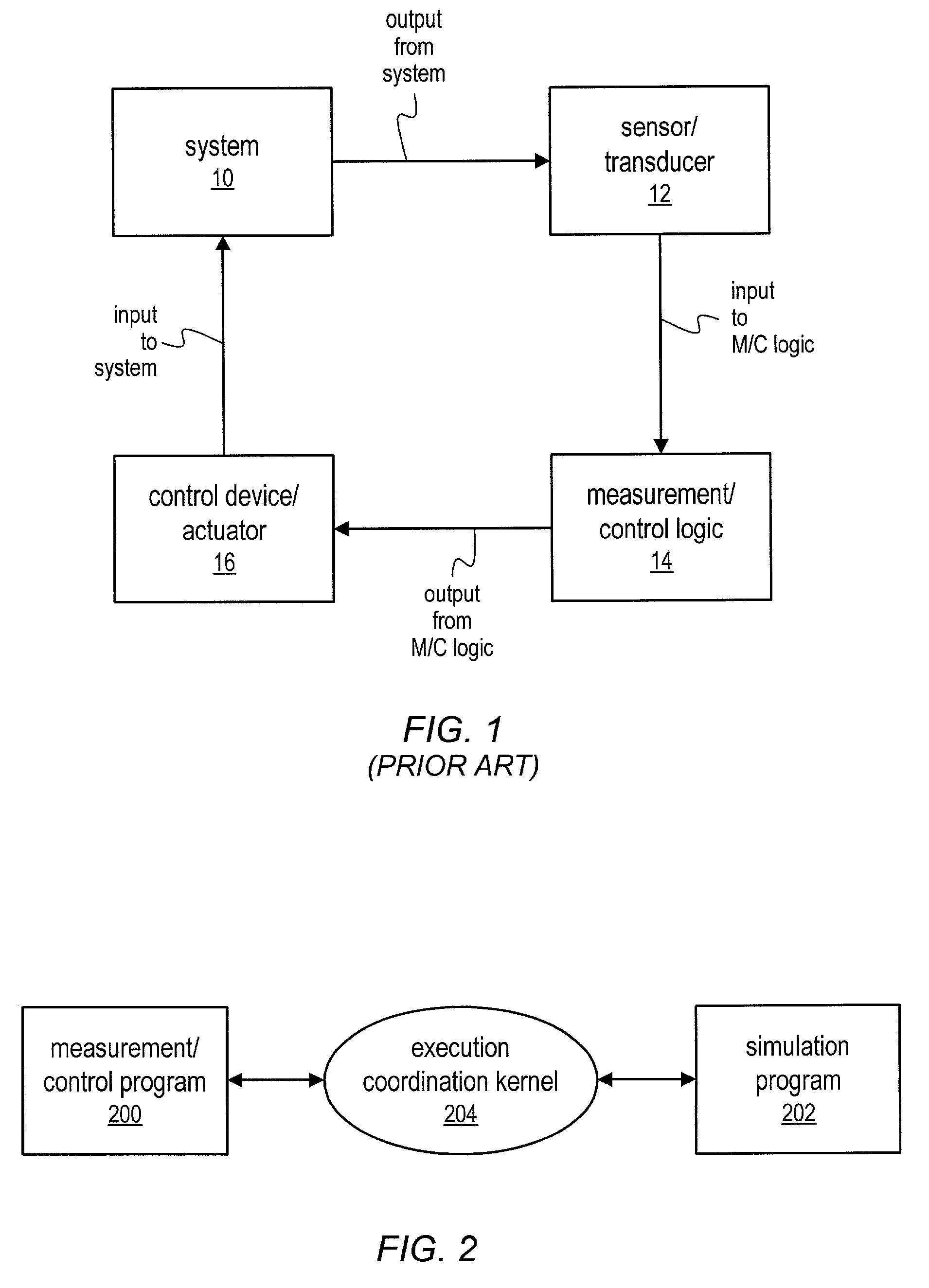

Simulation, measurement and/or control system and method with coordinated timing

ActiveUS7865349B2Simulator controlAnalogue computers for electric apparatusControl systemSystems simulation

A system and method for coordinating timing between simulation of a system and measurement and / or control of the system. A measurement / control loop comprising a measurement / control program, a simulation program, and an execution coordination kernel is described. The simulation program may be operable to simulate any of various types of systems. The measurement / control program may provide measurement / control logic for measuring various variables associated with the simulated system. The execution coordination kernel is responsible for coordinating the execution and time advancement of the measurement / control and simulation programs. The execution coordination kernel may be operable to intercept I / O calls produced by the measurement / control program and the simulation program. If the execution coordination kernel determines that the system is in simulation mode, the calls may be routed to software routines instead of to the I / O hardware.

Owner:NATIONAL INSTRUMENTS

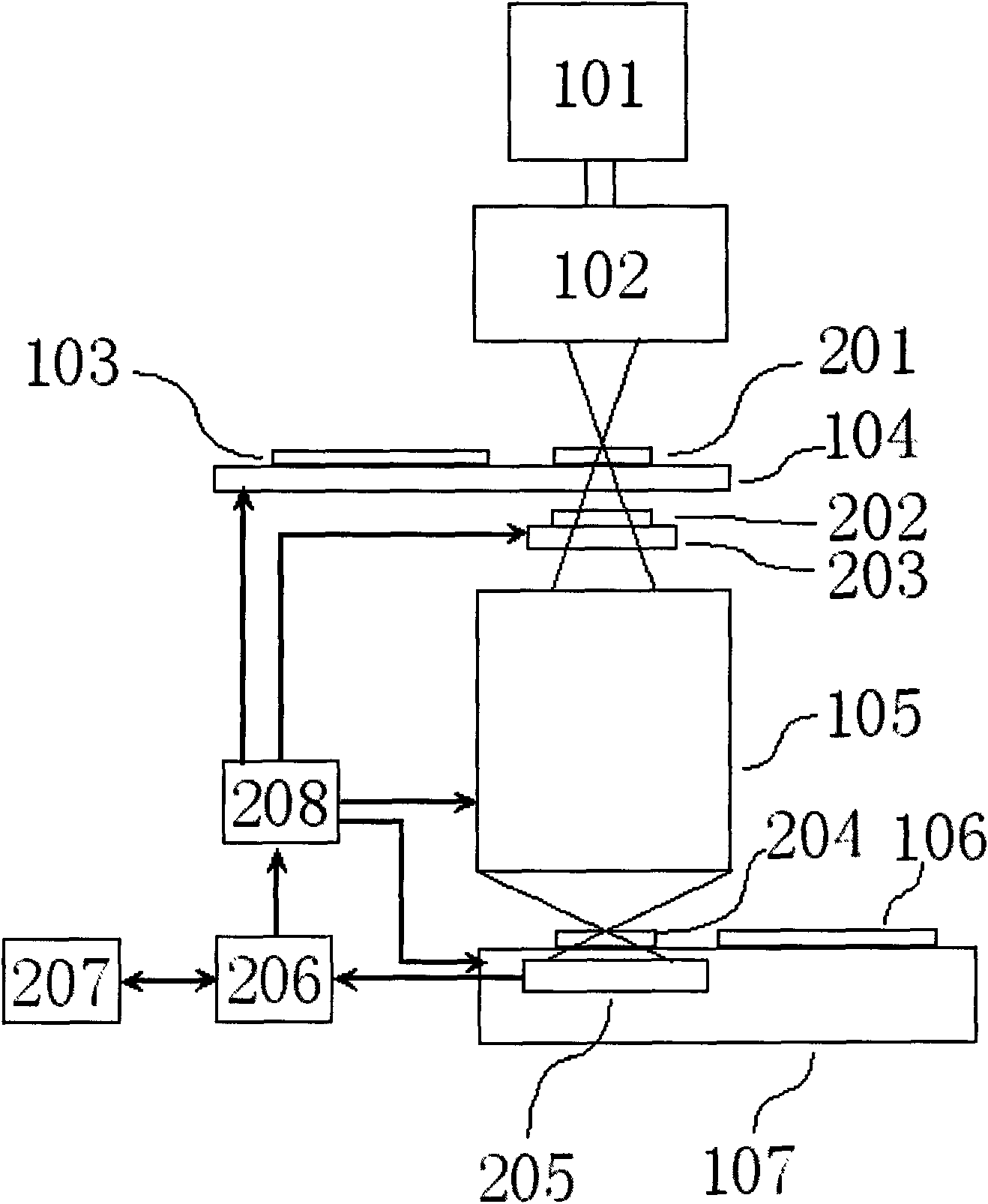

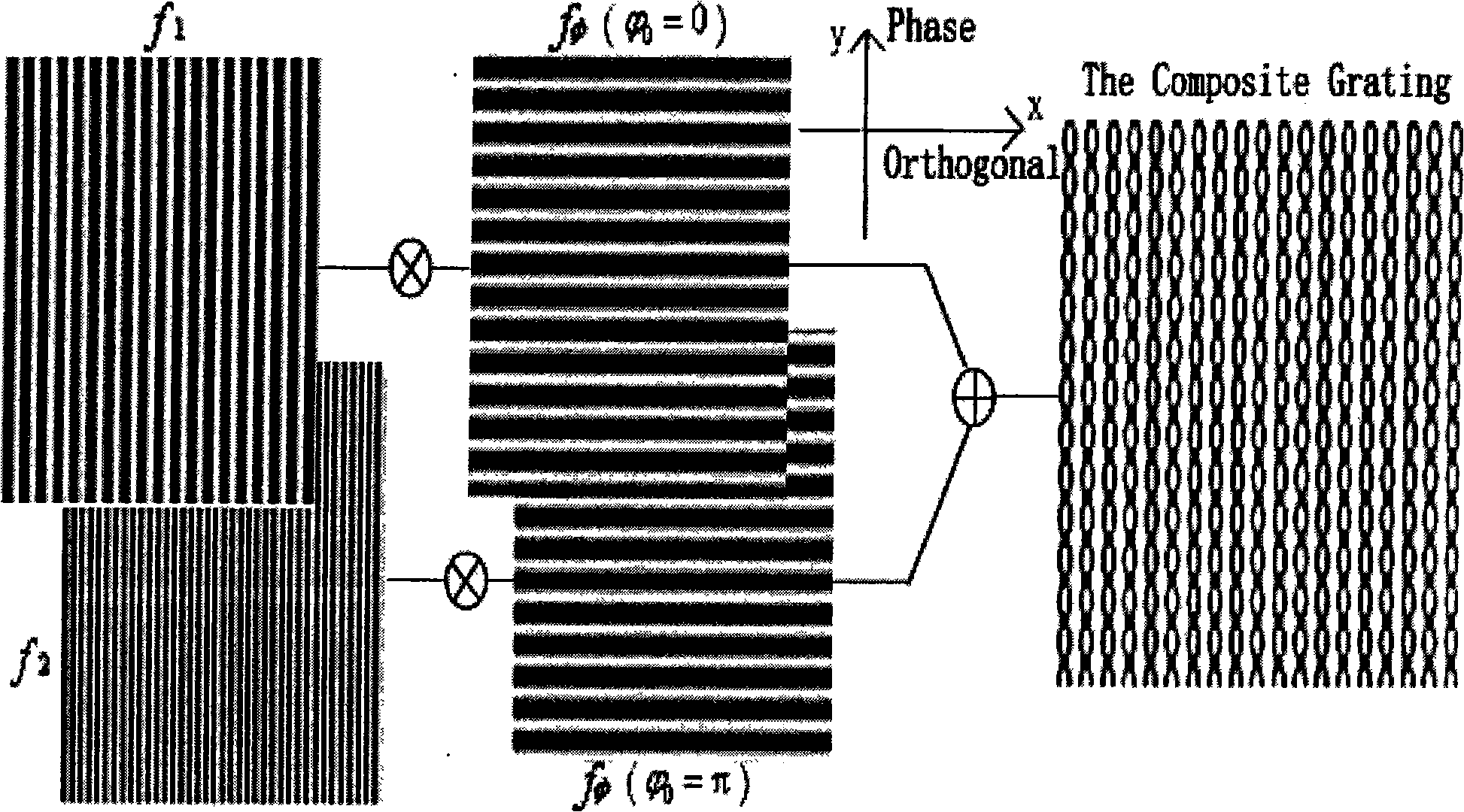

On-line detection device with function of calibrating systematic error for wave aberration of projection objective of photoetching machine

ActiveCN101655670AHigh measurement accuracyPhotomechanical exposure apparatusMicrolithography exposure apparatusBeam splittingWave aberration

The invention discloses an on-line detection device with the function of calibrating a systematic error for wave aberration of a projection objective of a photoetching machine, belonging to the fieldof optical detection. The device comprises an object space mask plate with circular holes, a phase-shifting device, a photoelectric sensor, a memorizer, a controller, an arithmetic unit, a beam splitting device and an image space mask plate, wherein the beam splitting device comprises two binary diffraction gratings: a first grating and a second grating; and the image space mask plate comprises awindow and a first circular hole and a second circular hole with equal diameters. The second grating of the beam splitting device and the second circular hole of the image space mask plate are used aselements for calibrating the systematic error, and the systematic error of the device is calibrated according to the orthogonal property and the odd-even symmetrical property of the Zernike multinomial in a unit circle. The device of the invention is integrated on a masking workpiece platform and a silicon slice workpiece platform of the photoetching machine, and compared with the prior art, thedevice can calibrate the systematic measurement error introduced by a measuring device, thereby increasing the accuracy of measurement.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

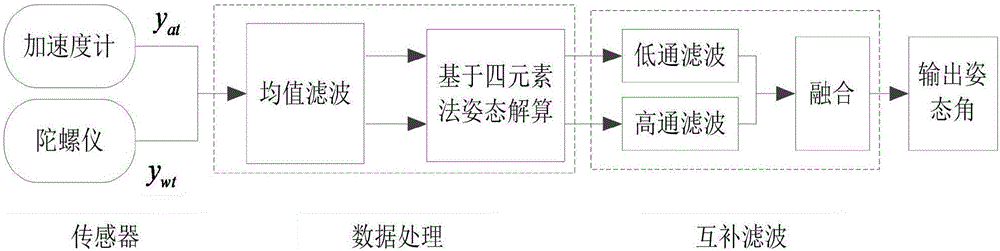

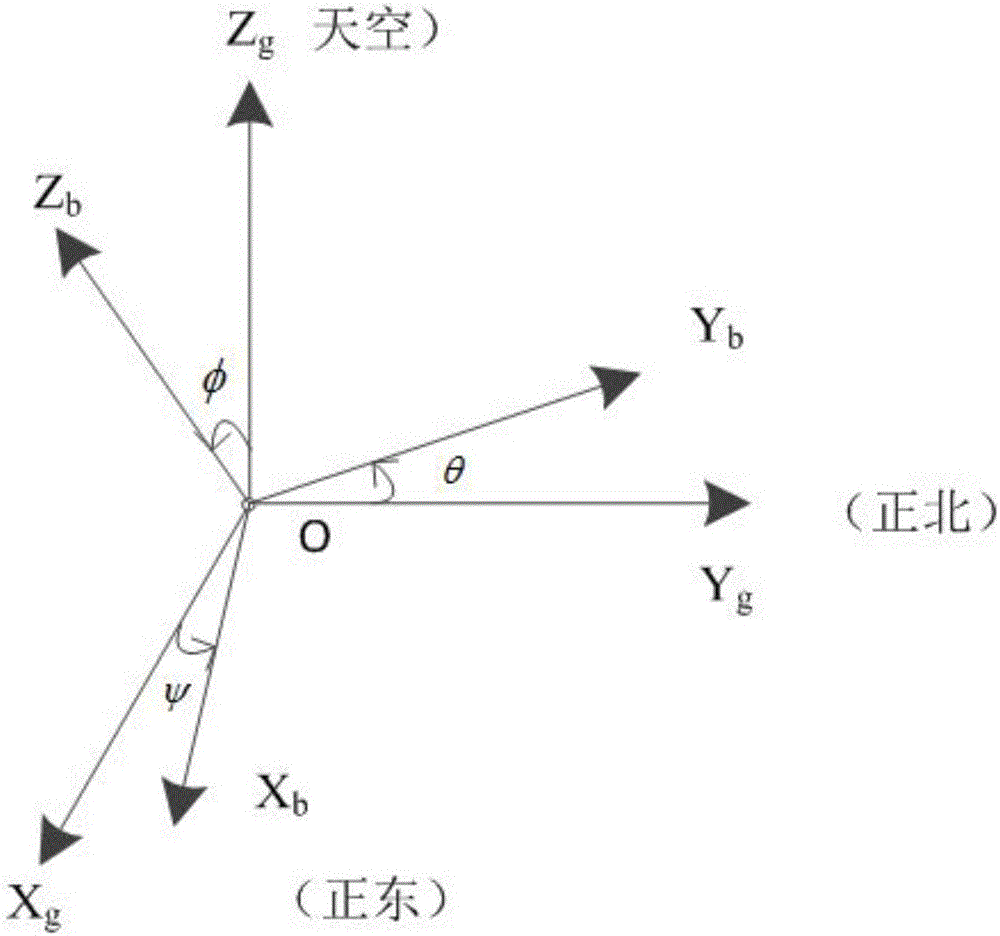

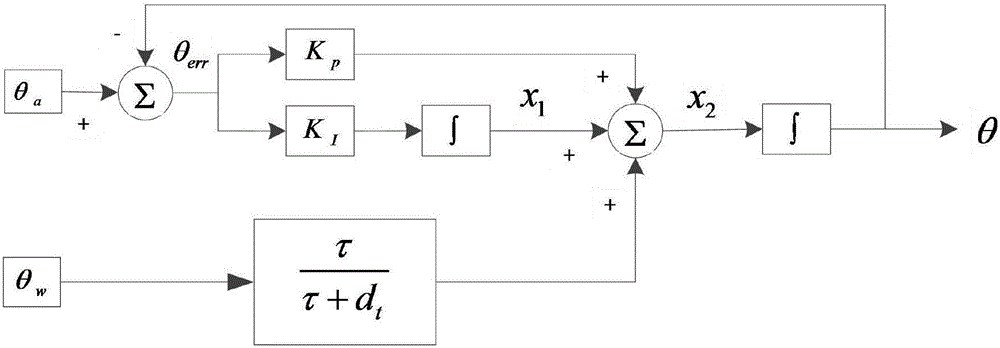

Filtering method for IMU multi sensor data fusion

InactiveCN106482734AHigh measurement accuracyImprove dynamic performanceNavigation by speed/acceleration measurementsMathematical modelComplementary filter

The present invention provides a filtering method for IMU multi sensor data fusion, firstly data is collected, aircraft attitude data can be acquired by an IMU inertial measurement unit comprising a gyroscope, an accelerometer and other multiple sensors, and a sensor output information mathematical model expression formula can be established; output data processing is performed, and the output data processing mainly includes removal of interference information and noises by use of slide average filter and resolution of the rotation angle of each sensor based on a four element method; a high-pass filter and a low-pass filter are combined, PI control parameters are added into a low-pass filtering part, proportionality coefficient variable Kp and integral coefficient variable KI are introduced for design of an error correction negative feedback of a second order complementary filter so as to realize the data fusion of each sensor, and finally attitude angles are outputted. By introduction and setting of the PI control parameters, a negative-feedback-containing second order complementary filter algorithm is designed to fuse the information of each sensor to improve the measurement accuracy and dynamic performance of the system.

Owner:湖南优象科技有限公司

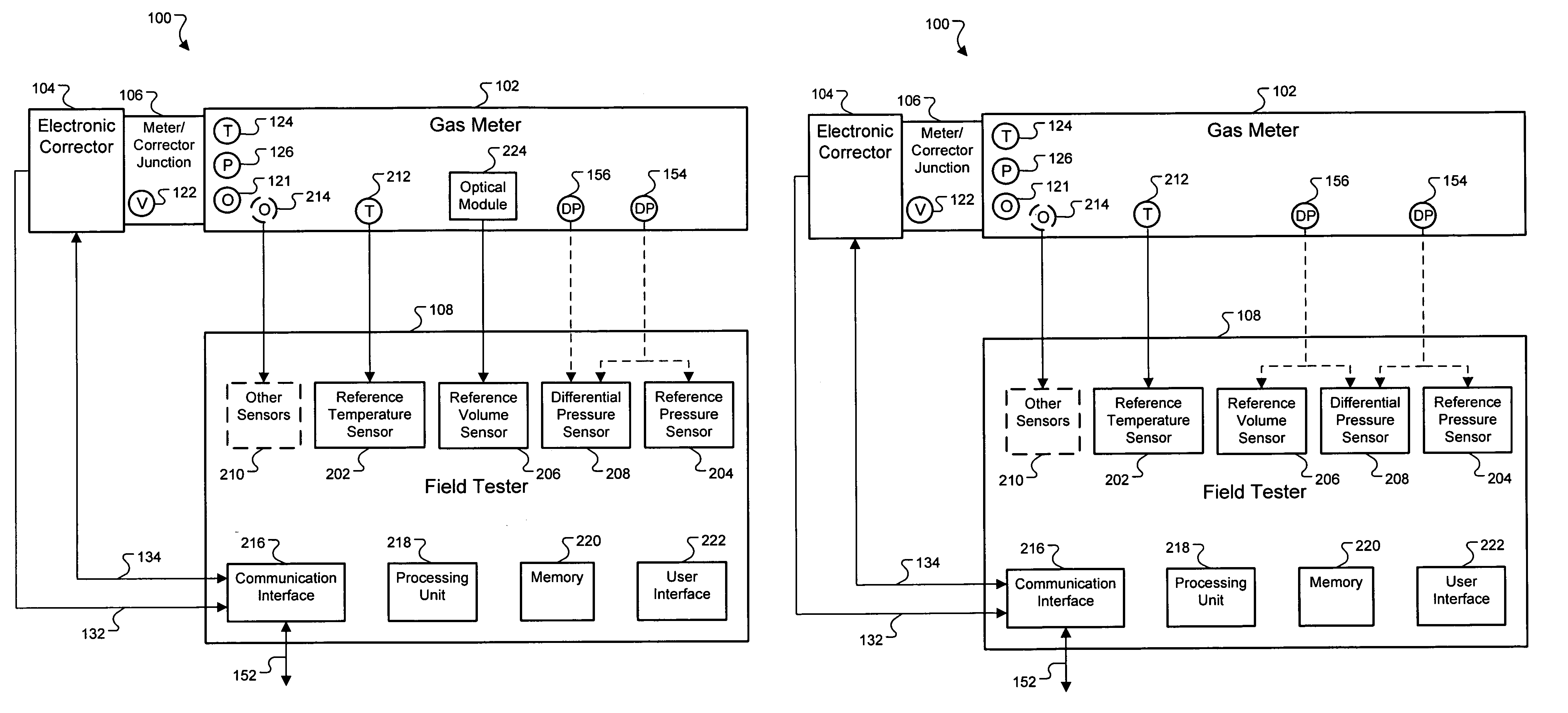

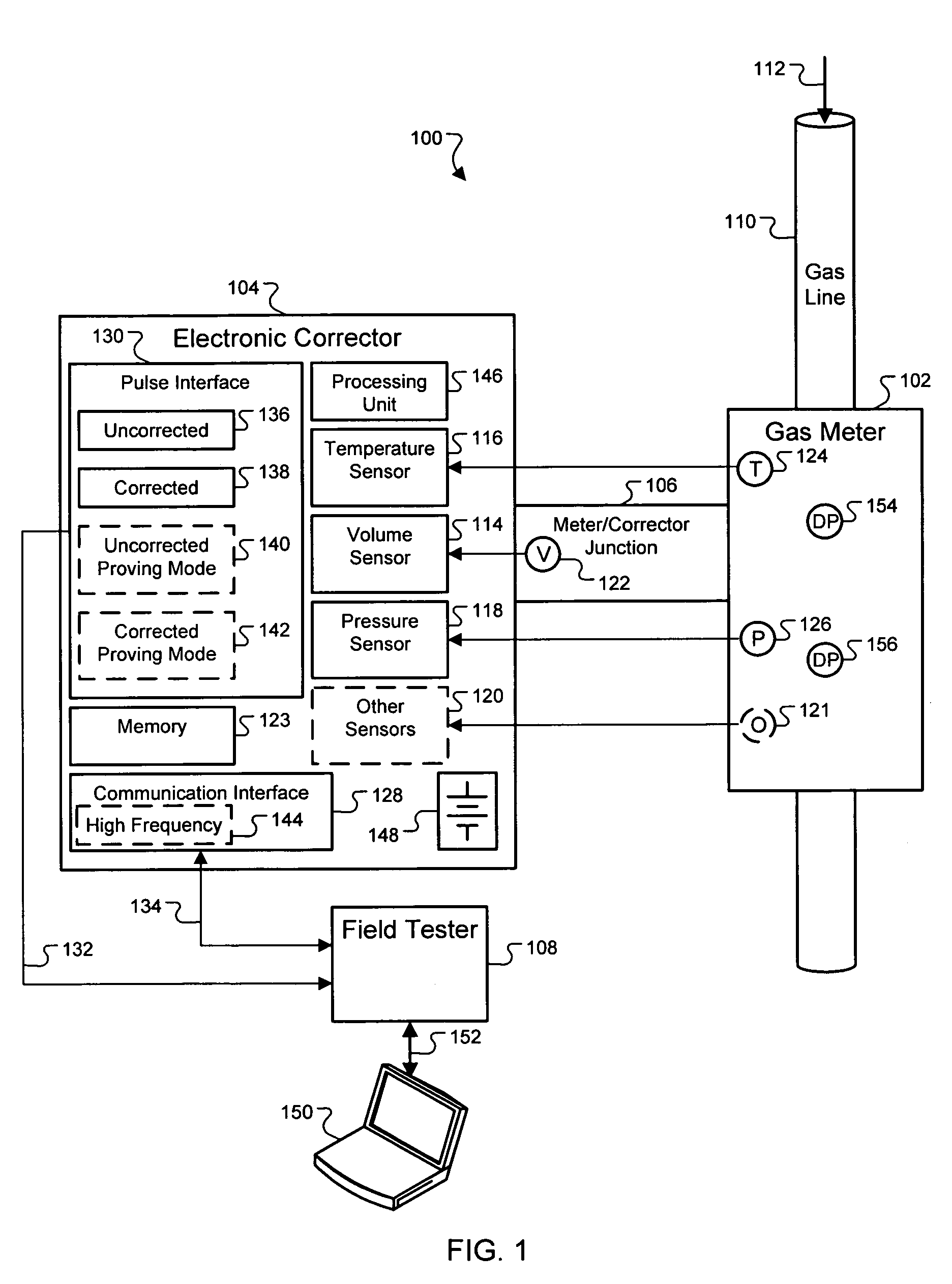

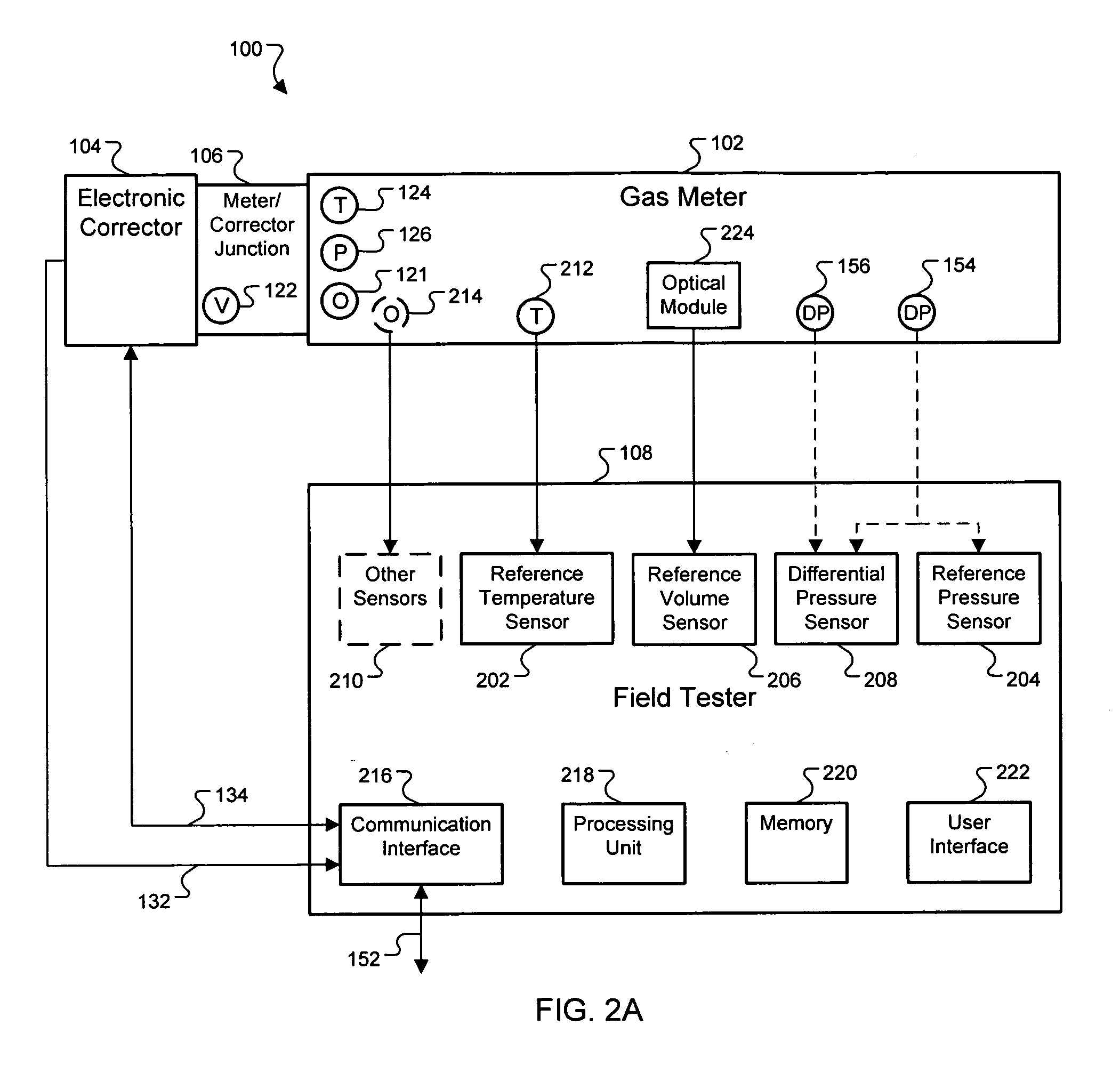

Portable diagnostic analysis of gas meter and electronic corrector

Systems and associated apparatus, methods, and computer program products, relate to a small, portable diagnostic instrument for checking the correct operation of a gas metering system that include a gas meter, an electronic corrector, and a junction there between. Some embodiments may use calibrated sensors to check the operation of a rotary or other positive displacement type gas meter or turbine meter. For example, reference sensors may be temporarily applied to monitor gas temperature and pressure, as well as the motion of a flow-responsive element (e.g., impellers, turbine, or diaphragm) in the gas meter. Measured volume signals from the gas meter system may be compared to reference volume signals determined from the reference sensors to check operation of the junction, and / or the electronic corrector. Some embodiments may detect other failure mechanisms, such as bearing-related problems in the gas meter, for example.

Owner:NATURAL GAS SOLUTIONS NORTH AMERICA LLC

System and method for health management of pumping system

A method implemented by at least one processor includes receiving a plurality of operating parameters of a pumping system, wherein the pumping system has a plurality of pump-units powered by a generator-unit. The operating parameters include a pump-unit parameter and a generator-unit parameter. The method also includes receiving reference data of the pumping system, wherein the reference data includes measurements from the pumping system representative of performance of the plurality of pump-units. The method also includes determining one or more health parameters corresponding to one or more pump-units based on the plurality of operating parameters and the reference data. The method further includes modifying one or more input parameters of the generator-unit based on the one or more health parameters for continued operation of the pumping system.

Owner:HYDRIL USA DISTRIBUTION LLC

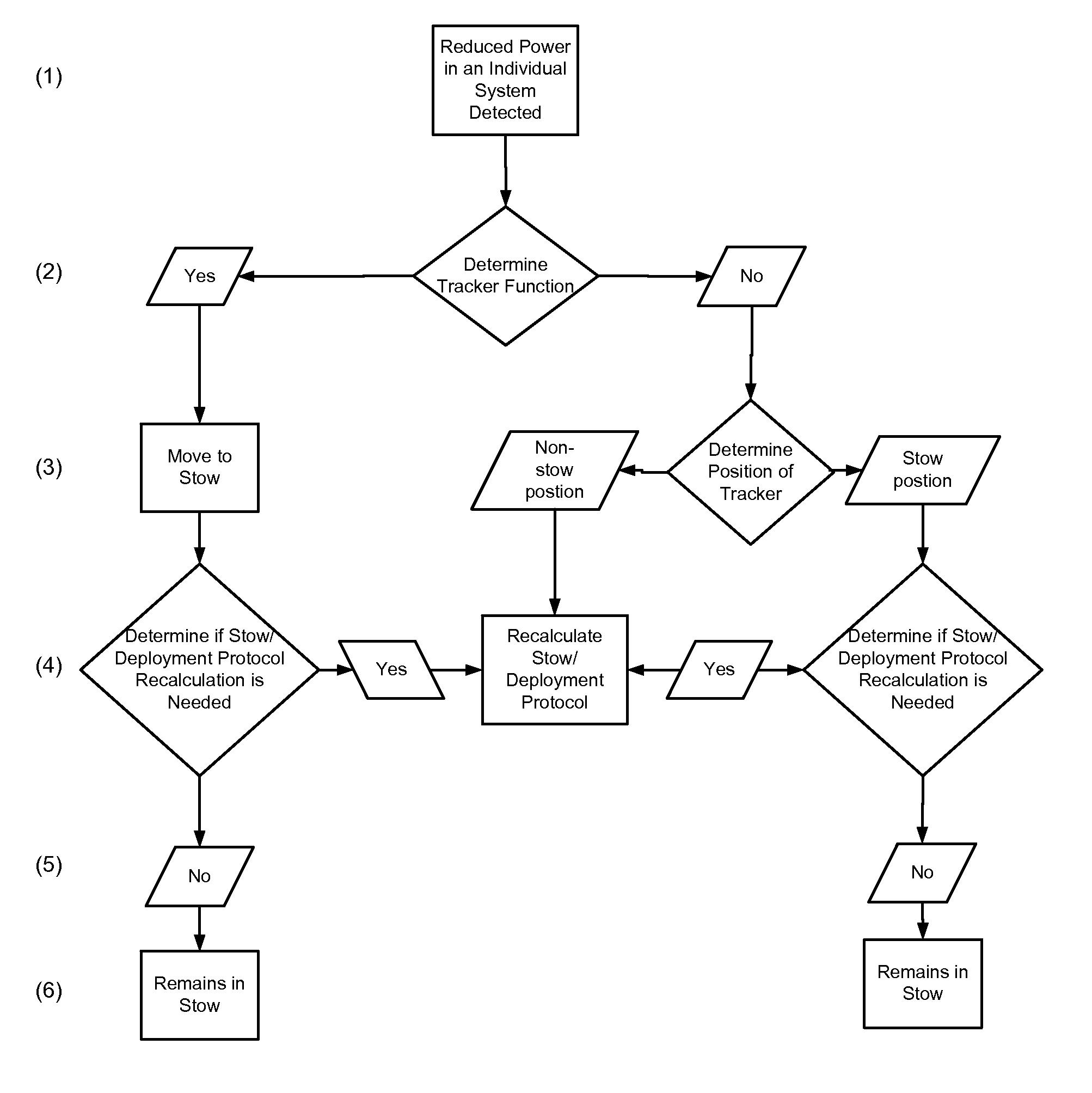

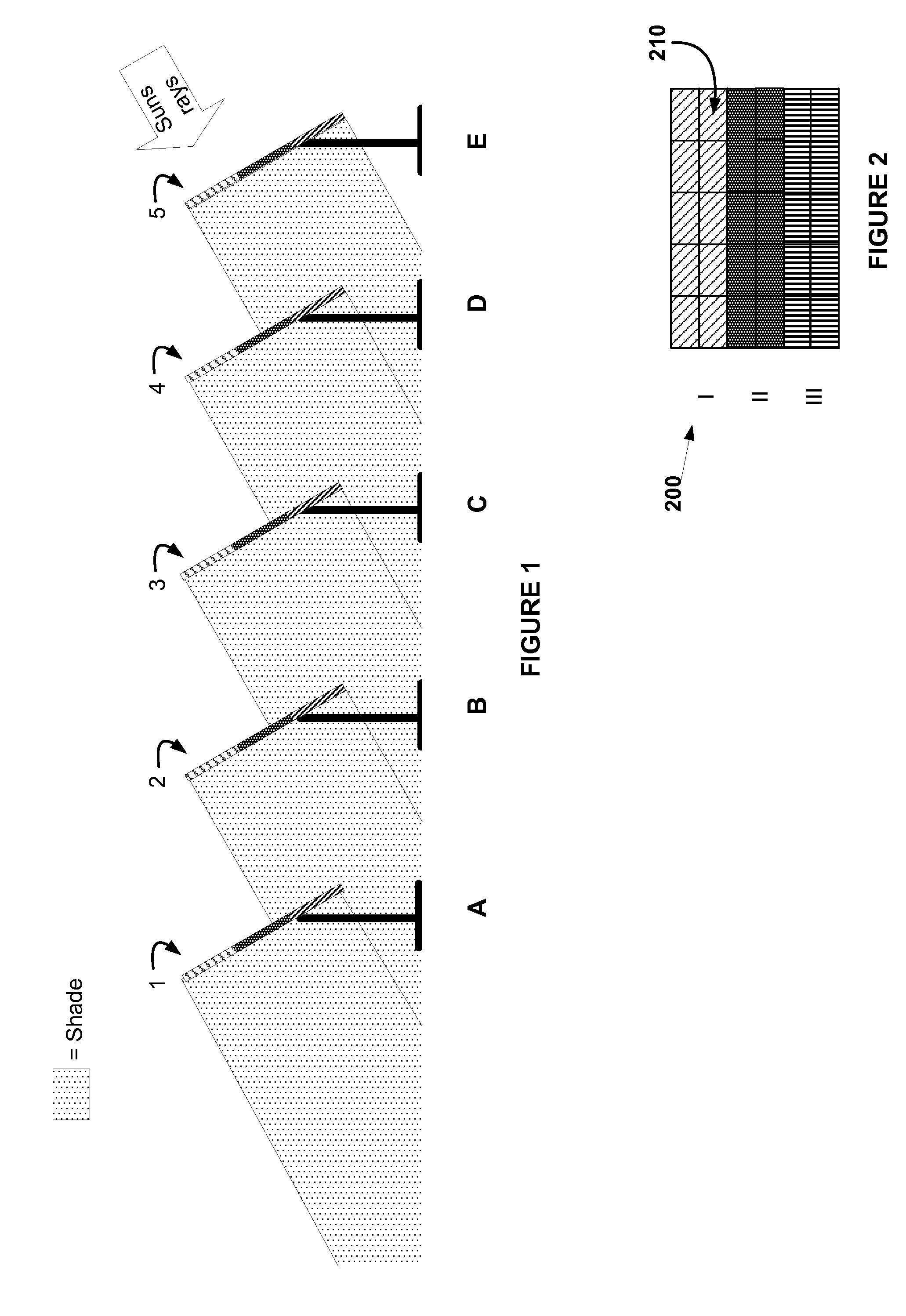

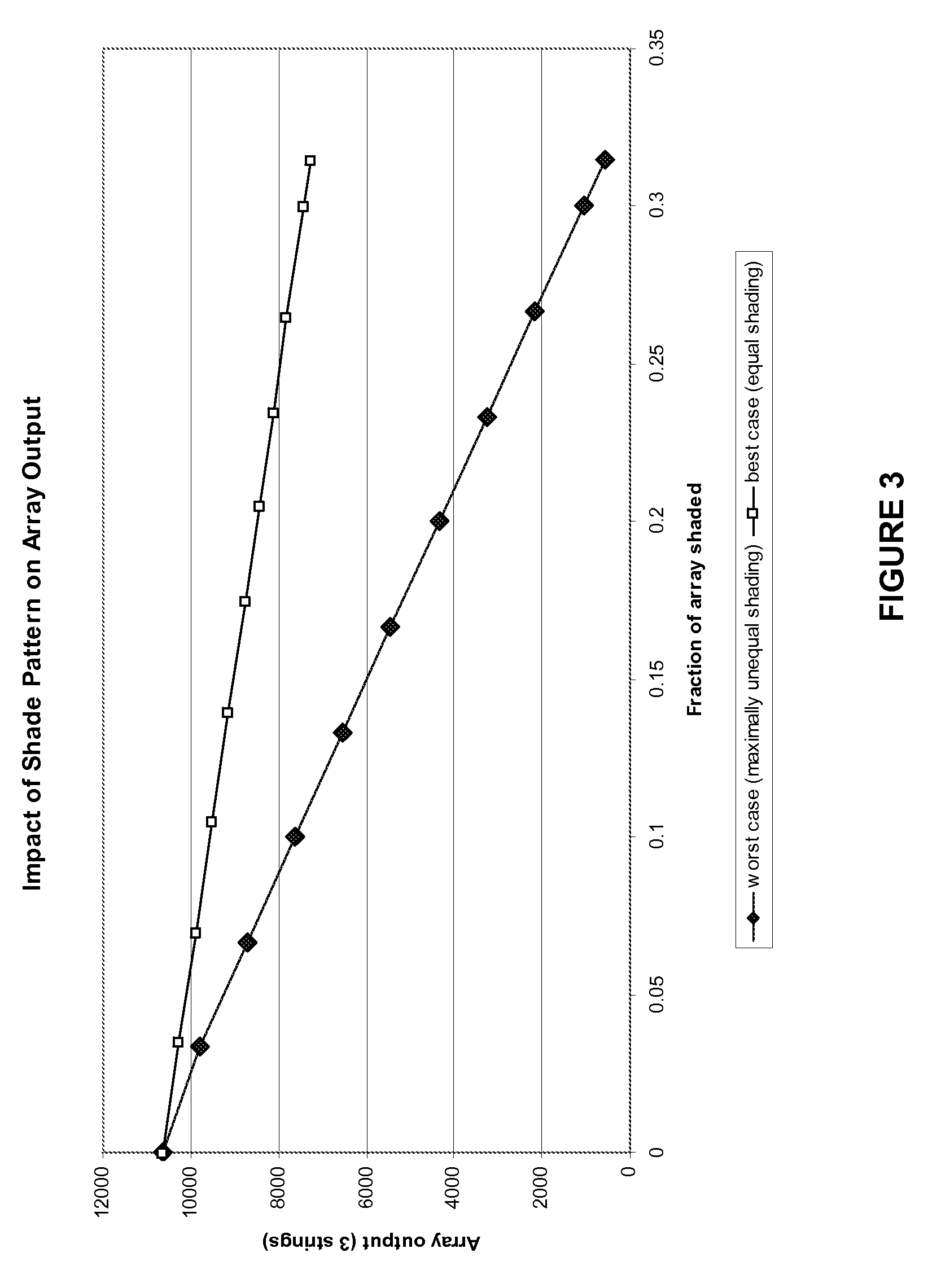

Field Level Tracker Controller

InactiveUS20100212653A1Maximize power outputOptimizationPhotovoltaic supportsSolar heating energyMeasuring outputEnergy system

The present invention is directed to an apparatus and method for improving the total power output from a field of solar energy systems. The invention provides a field level tracker controller which calculates an improved positioning of individual solar energy systems and communicates those configurations to trackers in the field. An algorithm stored in the controller calculates the improved configuration for the solar energy systems based on factors such as solar movement, shade patterns generated by surrounding structures, and measured output of the energy systems. Improved positioning may include individual energy systems being directed to a stowed position to maximize the power output of the field as a whole.

Owner:SUMITOMO ELECTRIC IND LTD

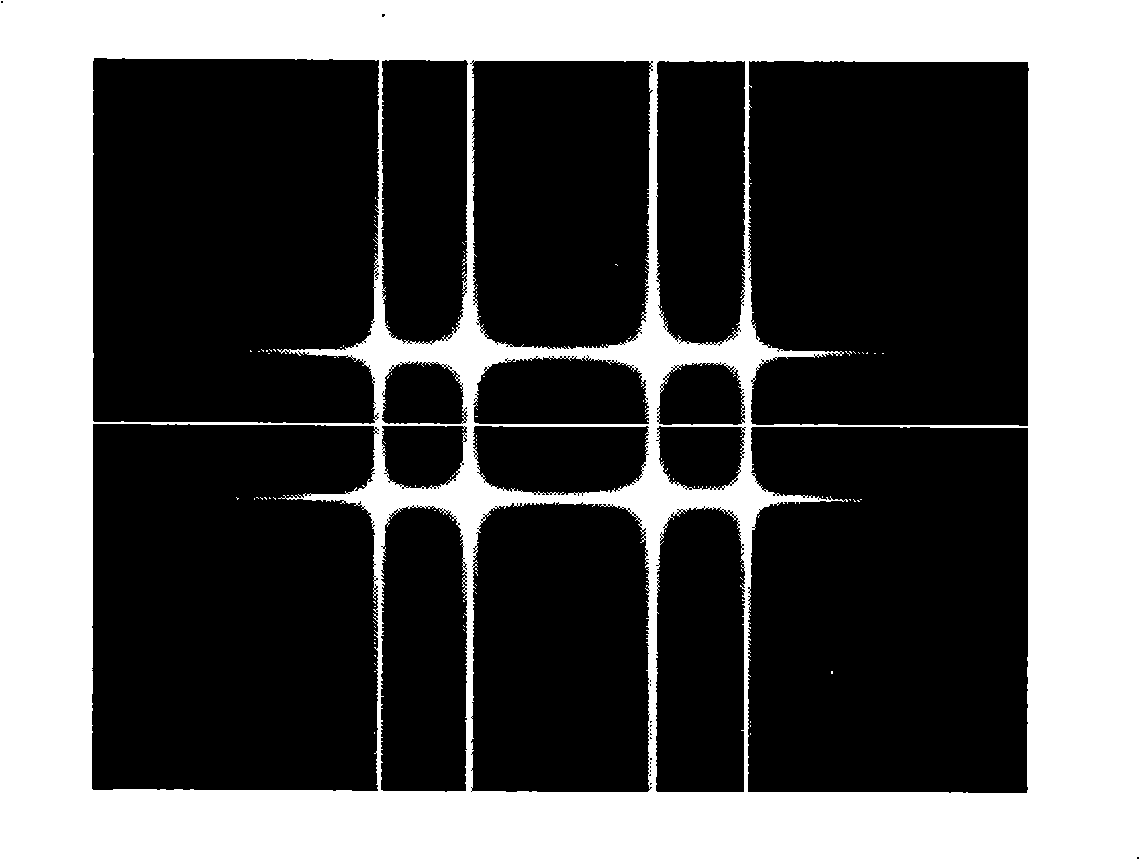

Measurement method and equipment of digitized measurement system of human face three-dimensional surface shape

InactiveCN101347332AFacilitate the process of digitizationDiagnostic recording/measuringSensorsBandpass filteringGrating

The invention discloses a human face three-dimensional shape digital measuring system and a method thereof. The method is based on a composite structure light projection technology. Composite structure light striation consists of a plurality of carrier frequencies of different frequencies which are modulated respectively to be piled with a plurality of frames of sine striations with phase difference at the direction vertical to the carrier frequencies; only one frame of human face modulated composite structure light striation raster image is required to be collected, and a plurality of frames of simple sine striations with phase shift can be taken out from one frame of composite striation by two-dimensional Fourier transformation, frequency domain two-dimensional bandpass filtering and inverse Fourier transformation; then a target human face three-dimensional shape is rebuilt by the traditional phase shifting technology in the phase measuring figure technology. The method can conveniently obtain the exact digital three-dimensional figure of human face, provides the novel measuring method and evaluating measure for human face plastic surgery and promotes the digital development of medical cosmetology.

Owner:SHENZHEN INST OF ADVANCED TECH

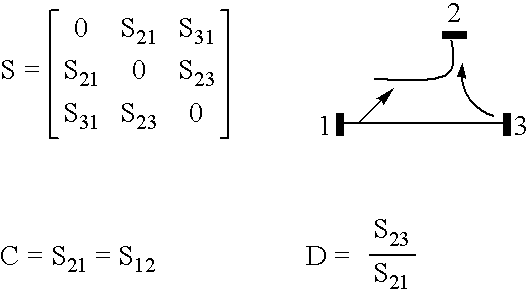

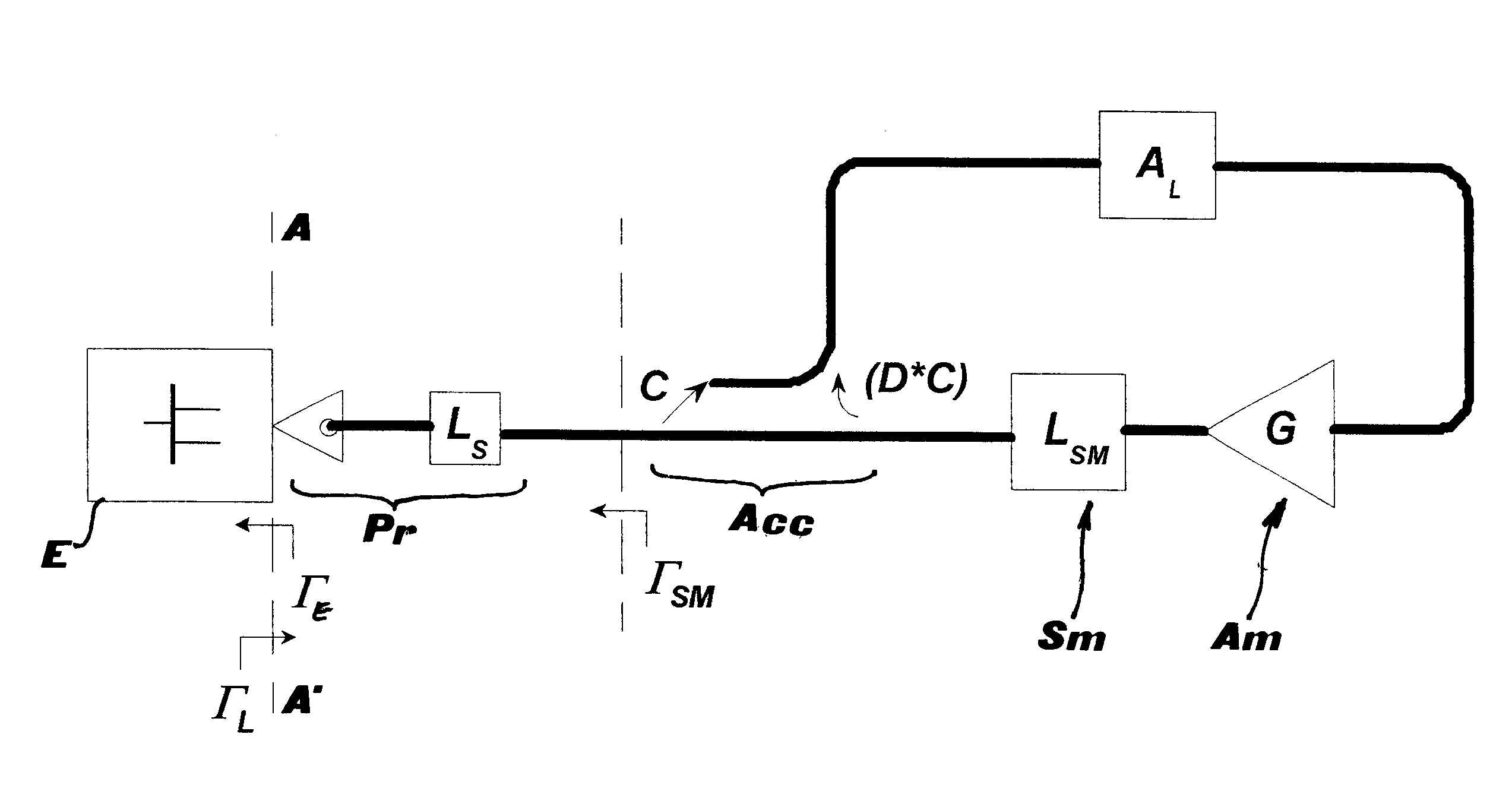

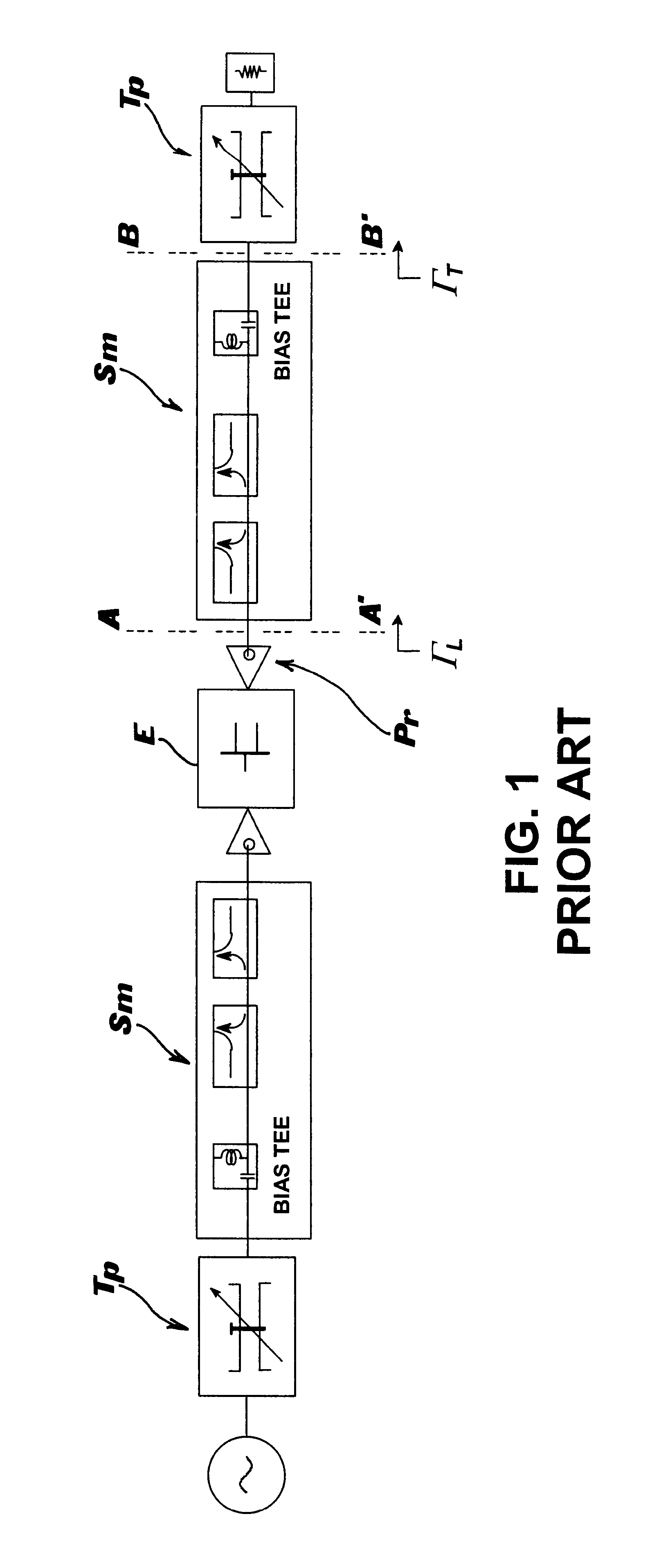

Active load or source impedance synthesis apparatus for measurement test set of microwave components and systems

InactiveUS6509743B1Resistance/reactance/impedenceCurrent/voltage measurementMeasurement testMicrowave

An active load or source impedance synthesis apparatus for experimental characterization of electronic components (E) working in the range from 500 MHz to 110 GHz, includes an active loop with at least one amplifier (Am), one magnitude and phase control system (Ra, Rs, one directional coupler (Acc) and a measurement system connected to a device under test (E), where the directional coupler (Acc) is connected after the most significant losses of the measurement system.

Owner:FERRERO ANDREA

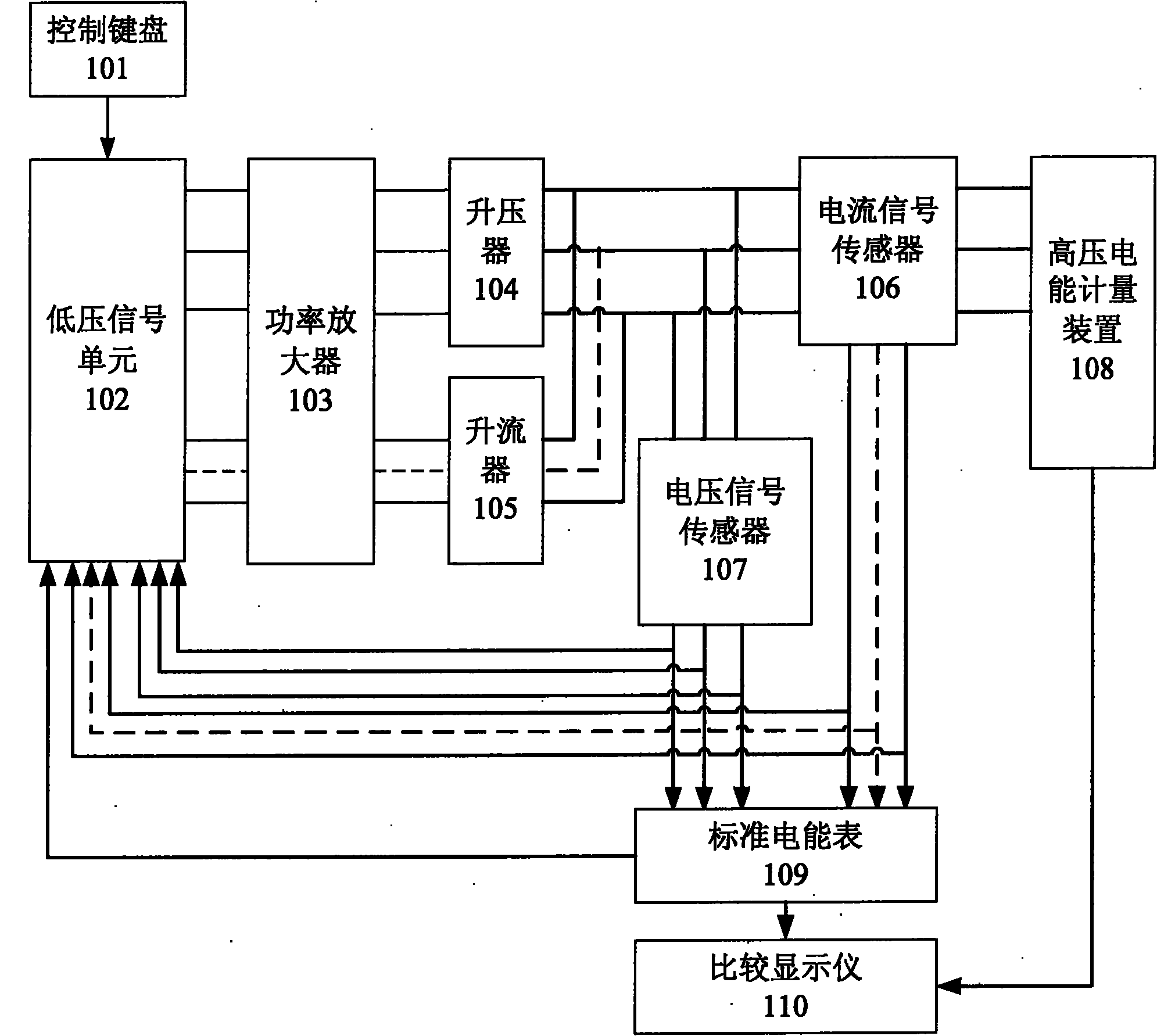

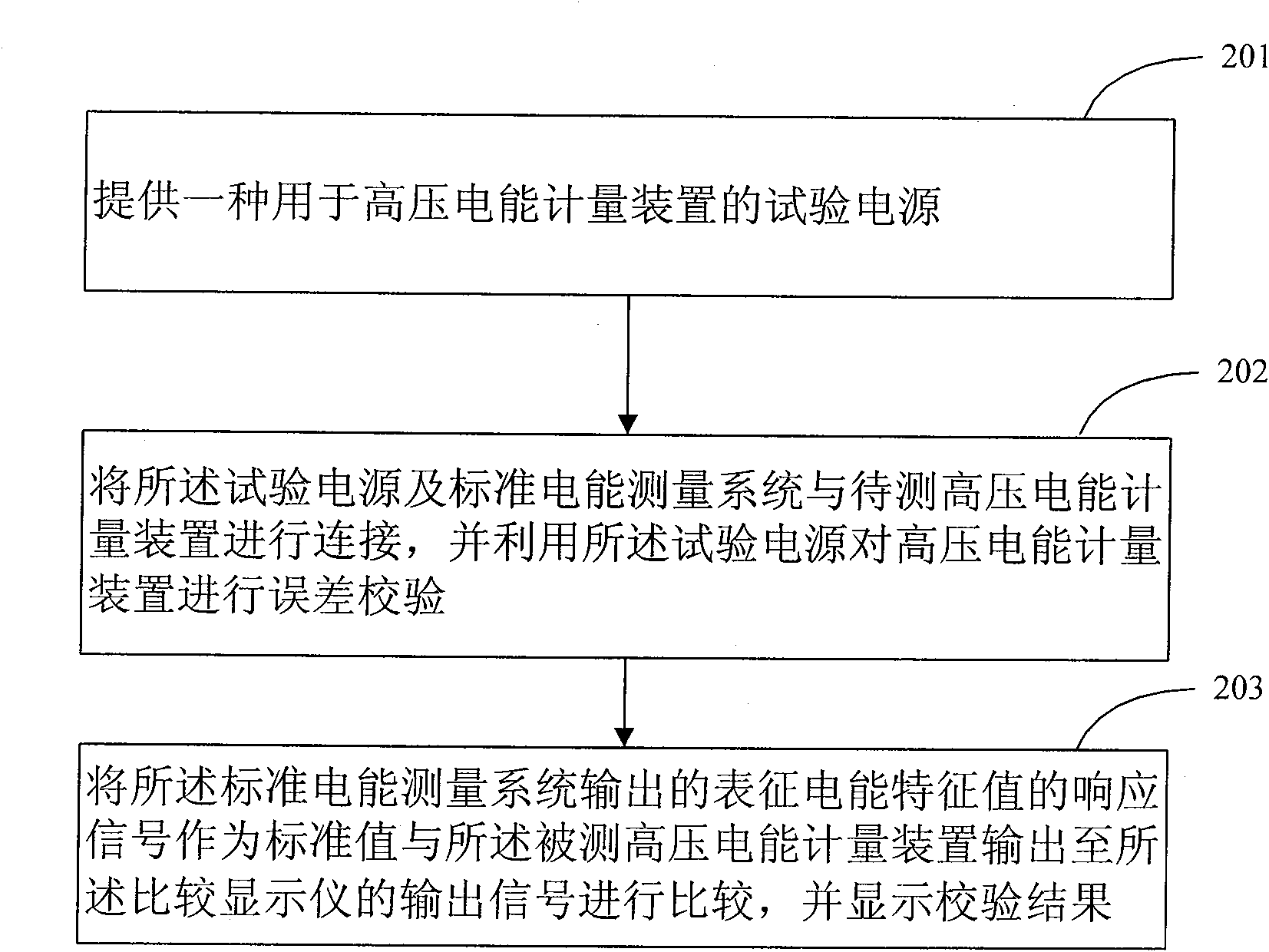

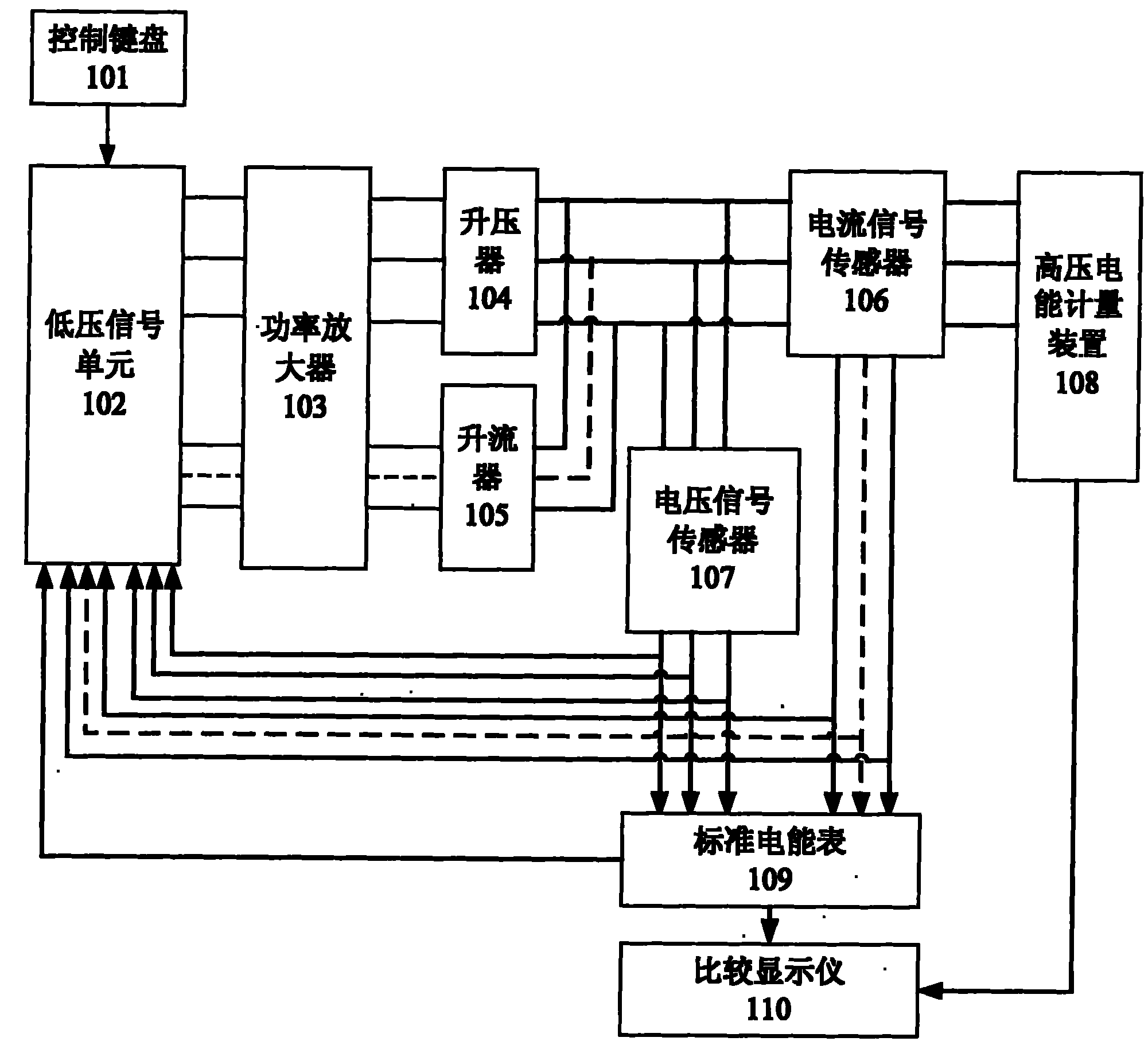

System and method for checking error of high-voltage electric energy measurement device

InactiveCN101865986AWith measurement accuracyAvoid cumbersomeElectrical measurementsTest powerMeasurement device

The invention discloses a system and a method for checking the error of a high-voltage electric energy measurement device. The system comprises a test power source, a standard electric energy measurement system and a comparison display, wherein the error of the high-voltage electric energy measurement device is checked in the field by using the high-voltage current of the test power source, whichis generated by using three-phase high voltage as the test voltage of the test power source to carry out the high-potential clamping process on two / three groups of test current respectively, to excite the measurement device to be checked, and comparing the response output of the measurement device to be checked with that of the standard electric energy measurement system. The measurement system comprises a voltage sensor, a current sensor and a standard electric energy meter. The method comprises the following steps: determining the error of the system in measurement accuracy by the standard electric energy measurement system; and calculating the overall error according to the limit of the error, so as to control the requirements for the lowest accuracy level. The system of the invention is capable of determining the overall measurement accuracy (0.1) of the high-voltage electric energy measurement device to be checked.

Owner:WUHAN GUOCE HENGTONG INTELLIGENT INSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com