Honing head combination device

A combined device and honing head technology, which is applied to honing tools and other directions, can solve the problems of inability to realize large-span hole processing and increase in cost, and achieve the effects of ensuring long-term use, low cost and convenient manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

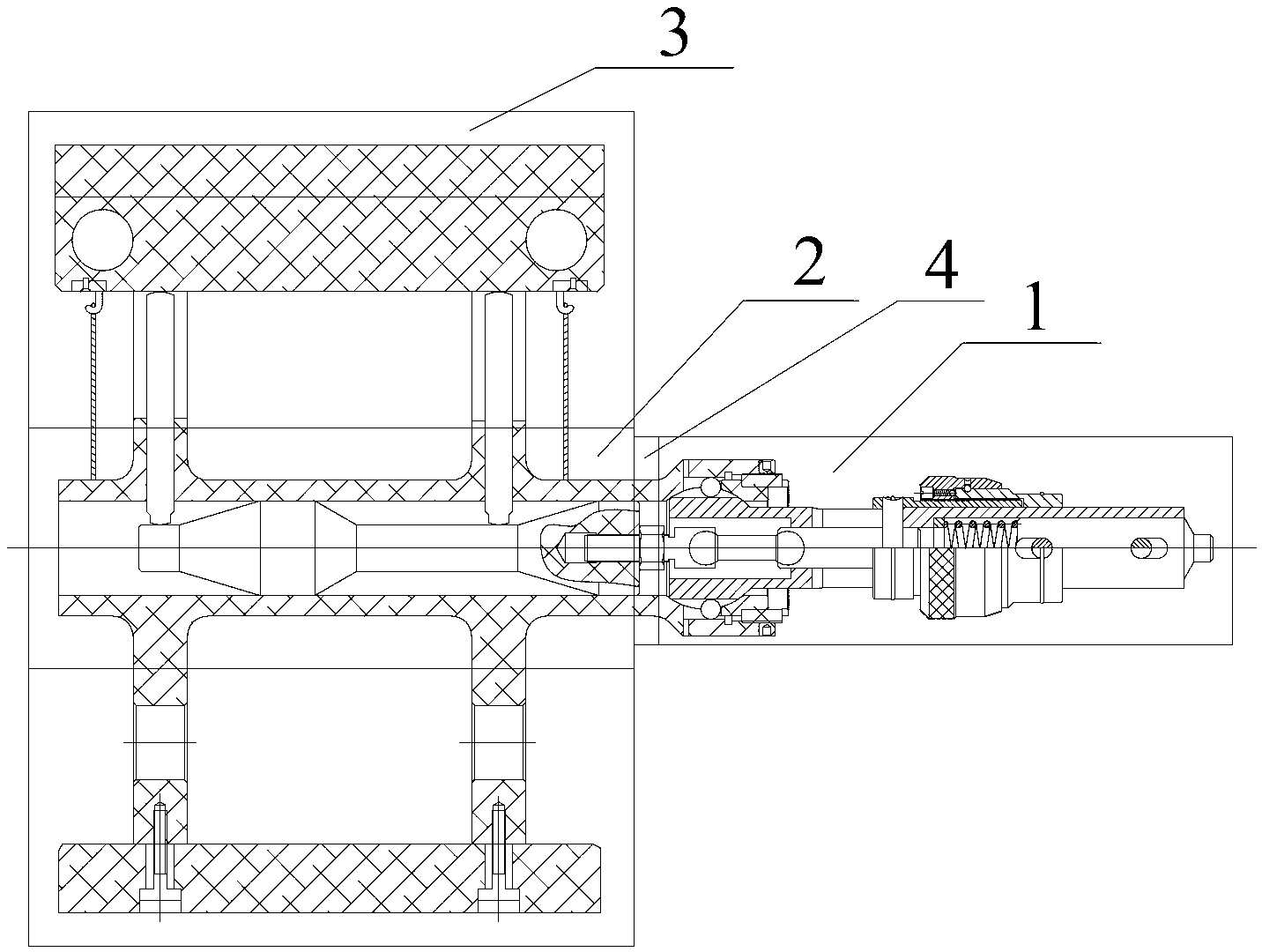

[0041] A kind of honing head combination device, its structure is as figure 1 As shown, it can process full-circle holes and non-full-round holes in the range of 300mm-1000mm. The combined device is composed of a fine-tuning rod part 1 with a split structure, an expanding mandrel part 2 and a honing sleeve part 3. The fine-tuning rod part 1 is connected to the honing sleeve part 3 through the flange plate 4 and bolts to realize the radial positioning with the honing sleeve part 3. In addition, the axial positioning with the honing sleeve part 3 is realized through the key groove, and the fine-tuning joint is fixed by double positioning. The position between the rod part 1 and the honing sleeve part 3.

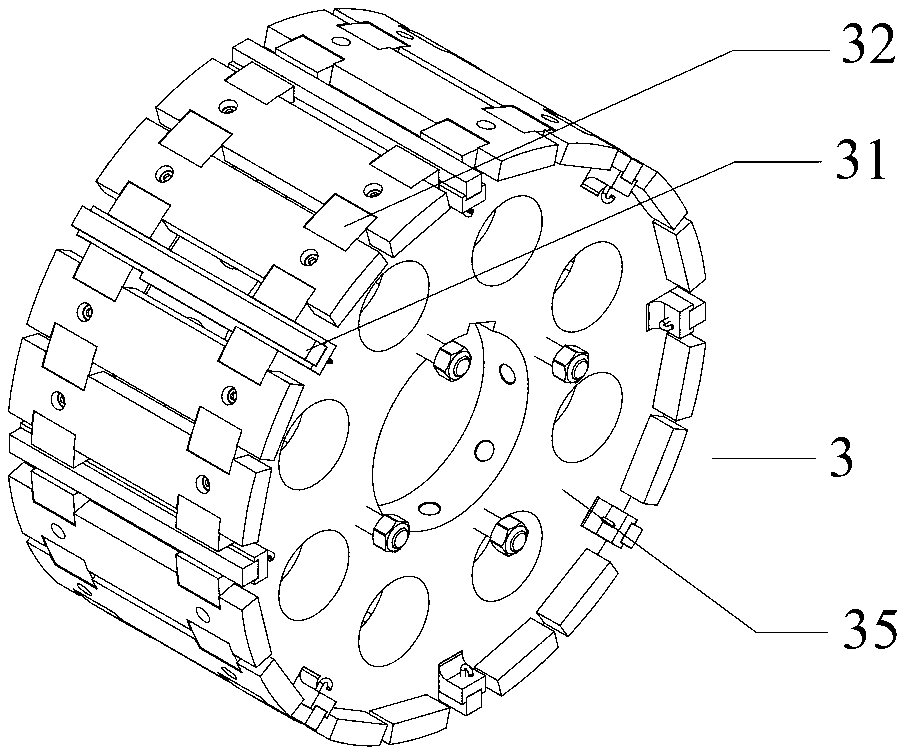

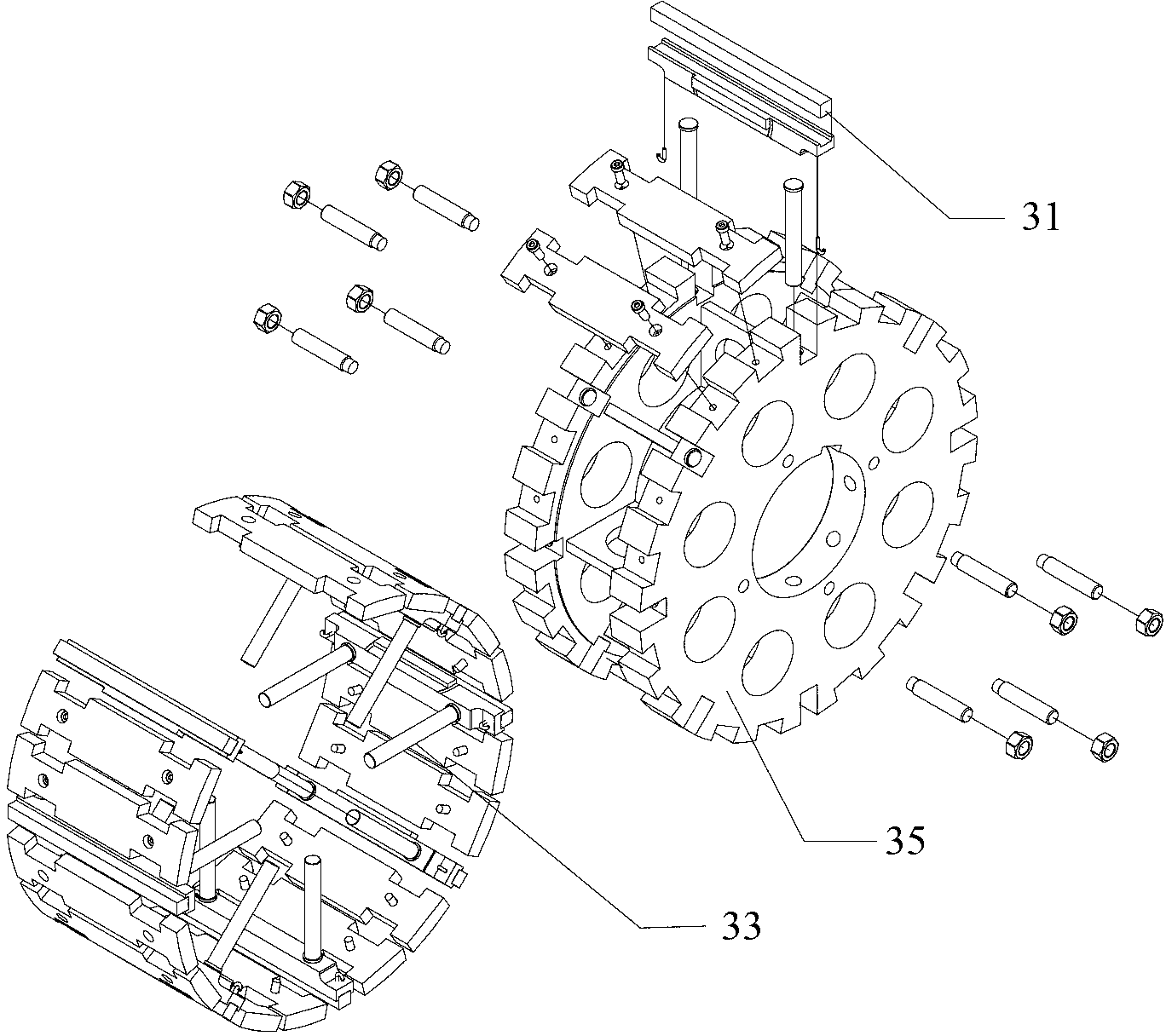

[0042] The structure of the honing sleeve part 3 is as follows Figure 2-4 As shown, the honing sleeve part 3 is sleeved on the outside of the expander mandrel part 2. The honing sleeve part 3 includes a sleeve body 35, a grinding bar 31 and a guide plate 32 arranged on the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com