Patents

Literature

44results about How to "Accurate connection positioning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

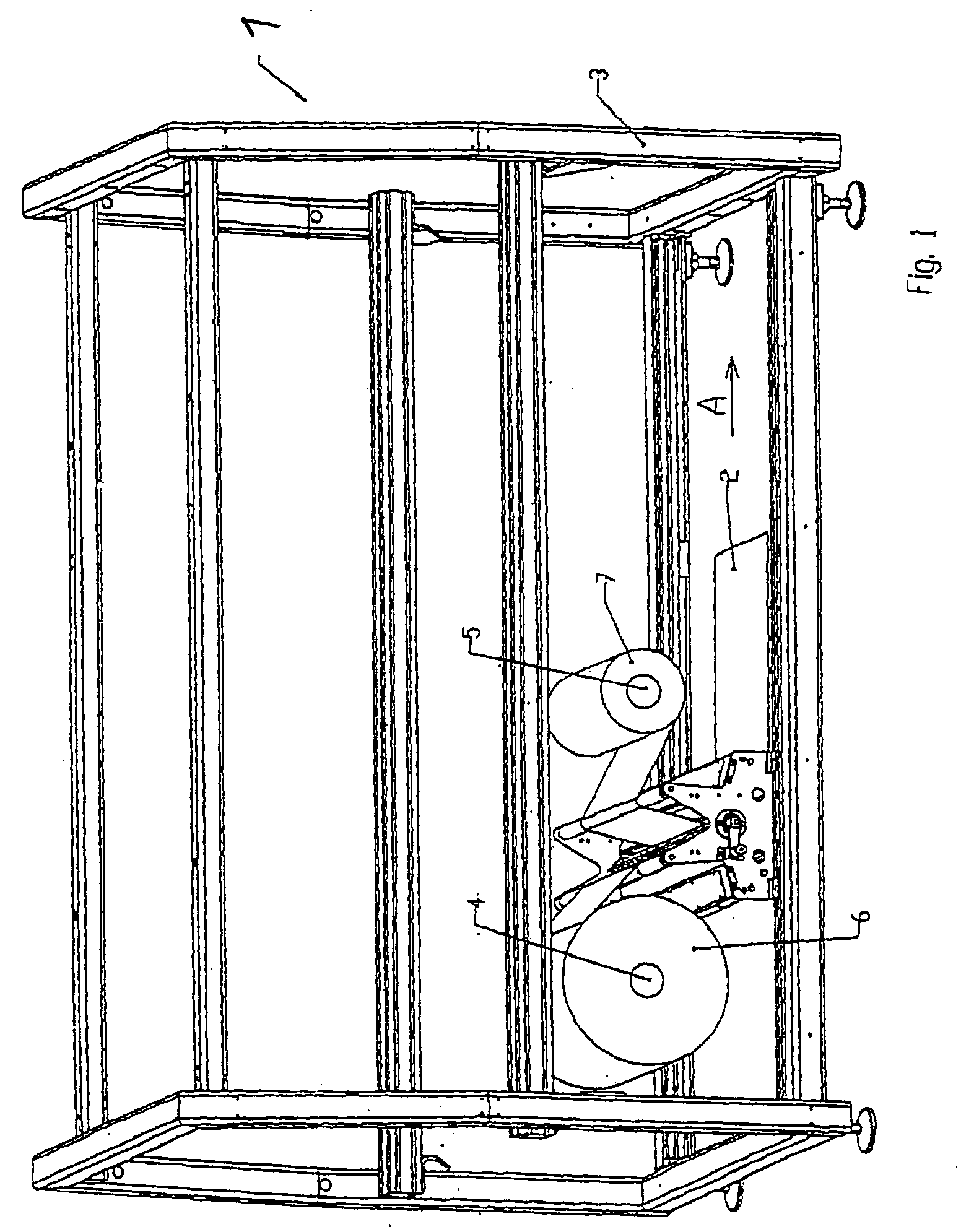

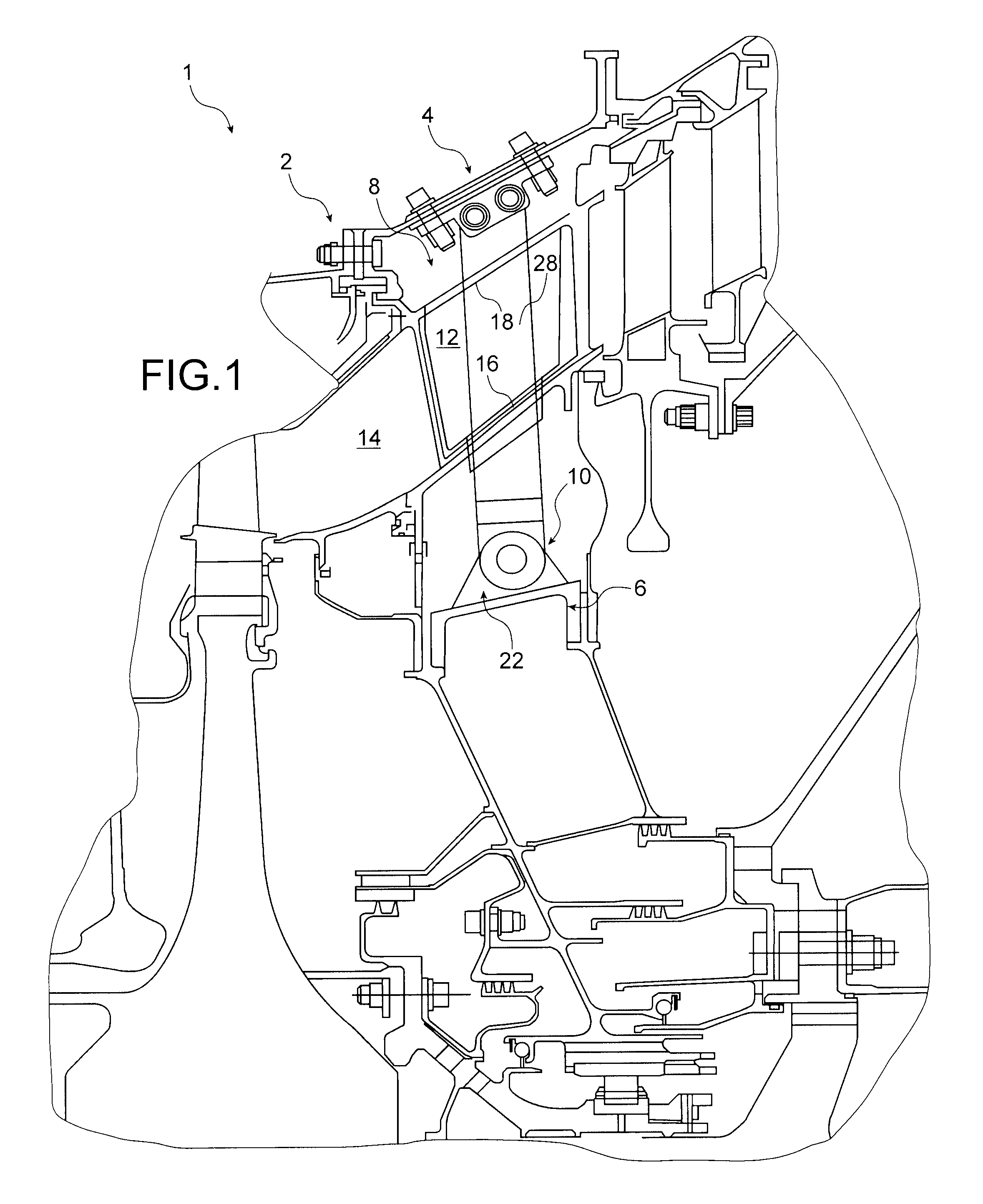

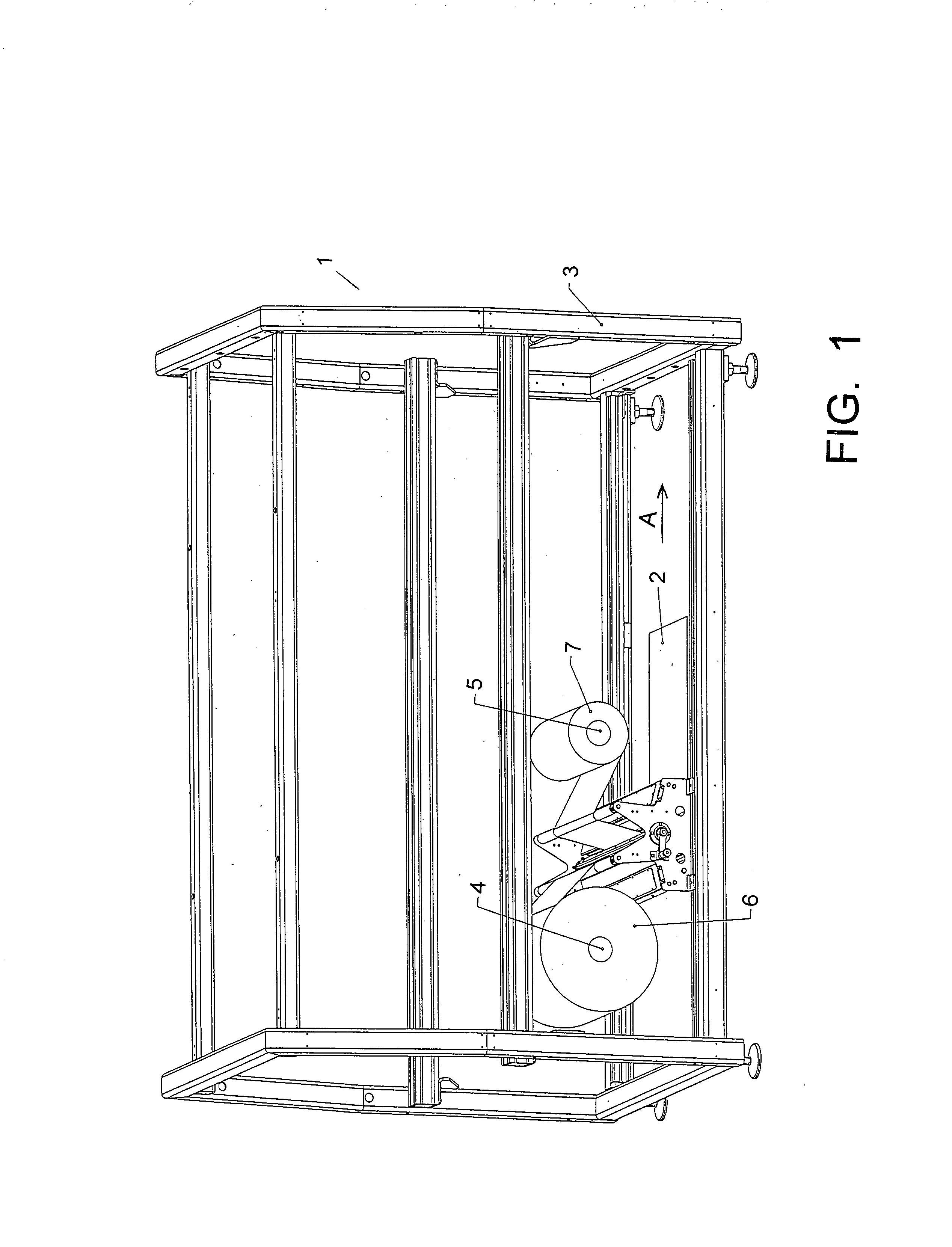

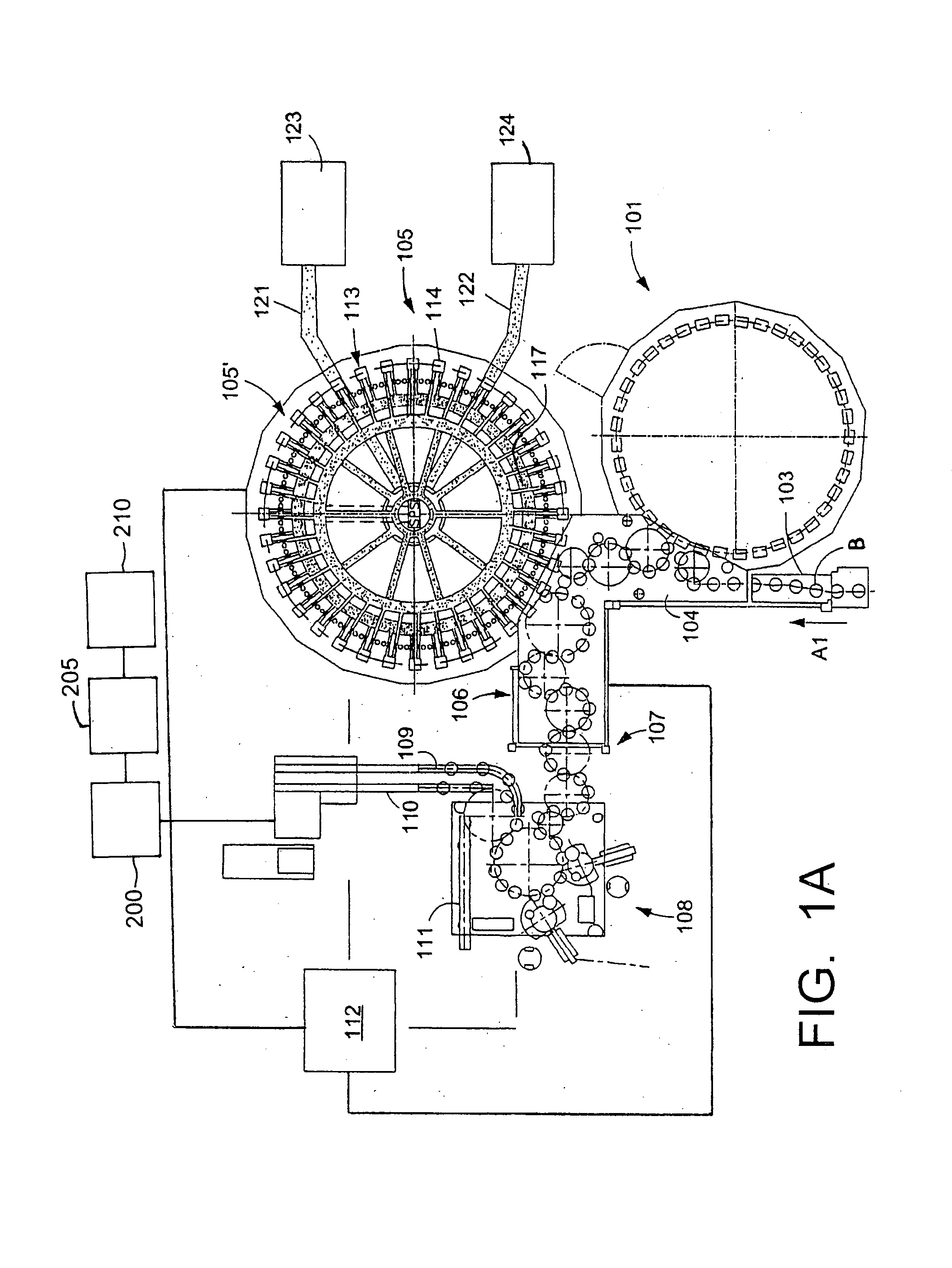

Beverage bottling plant for filling bottles with a liquid beverage material having a machine and method for wrapping filled bottles

InactiveUS20060026926A1Smooth and accurate connectionAccurate connectionMechanical working/deformationWrapping material feeding apparatusTrademarkEngineering

A beverage bottling plant for filling bottles with a liquid beverage material having a machine and method for wrapping filled bottles. The abstract of the disclosure is submitted herewith as required by 37 C.F.R. §1.72(b). As stated in 37 C.F.R. §1.72(b): A brief abstract of the technical disclosure in the specification must commence on a separate sheet, preferably following the claims, under the heading “Abstract of the Disclosure.” The purpose of the abstract is to enable the Patent and Trademark Office and the public generally to determine quickly from a cursory inspection the nature and gist of the technical disclosure. The abstract shall not be used for interpreting the scope of the claims. Therefore, any statements made relating to the abstract are not intended to limit the claims in any manner and should not be interpreted as limiting the claims in any manner.

Owner:KHS GMBH

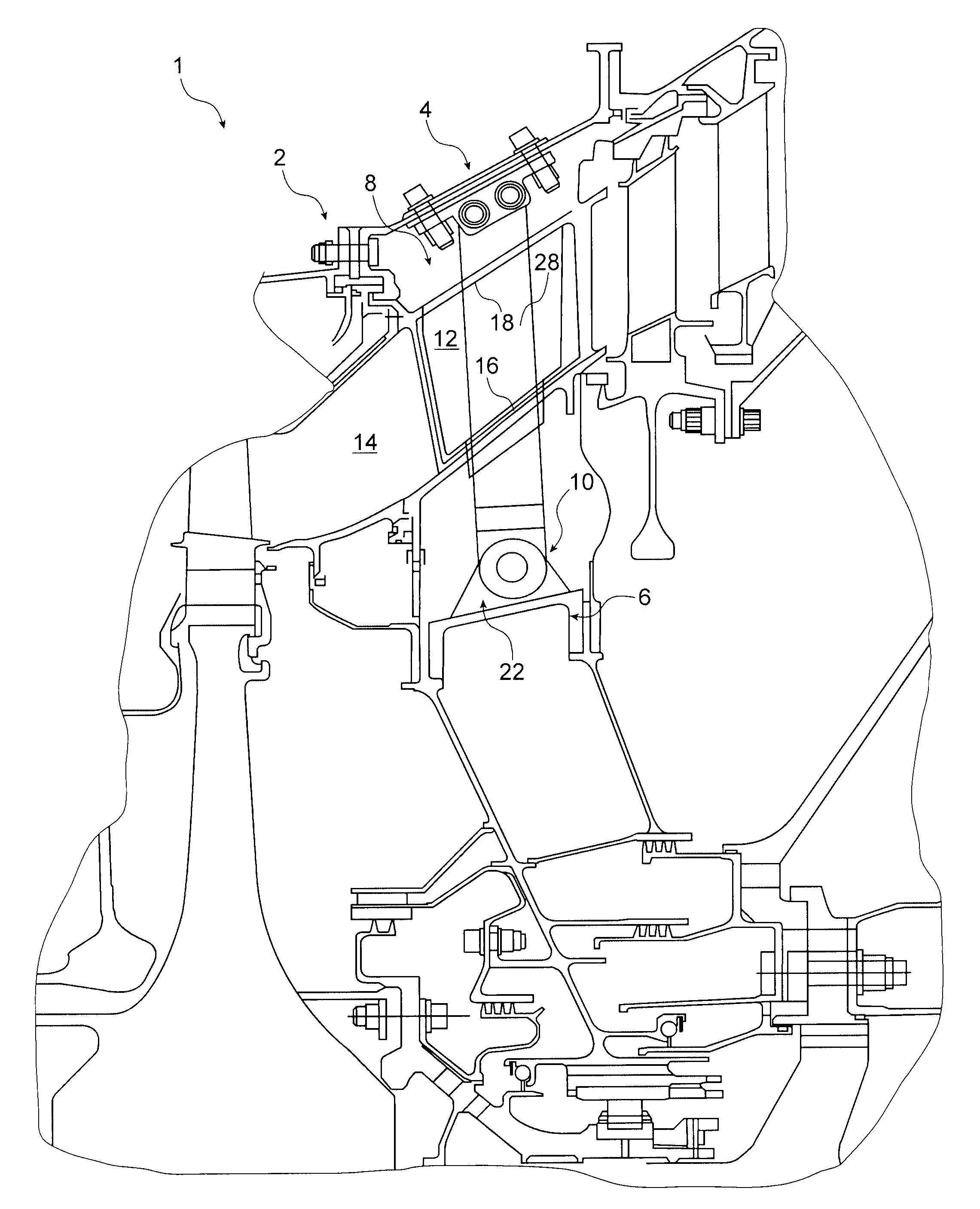

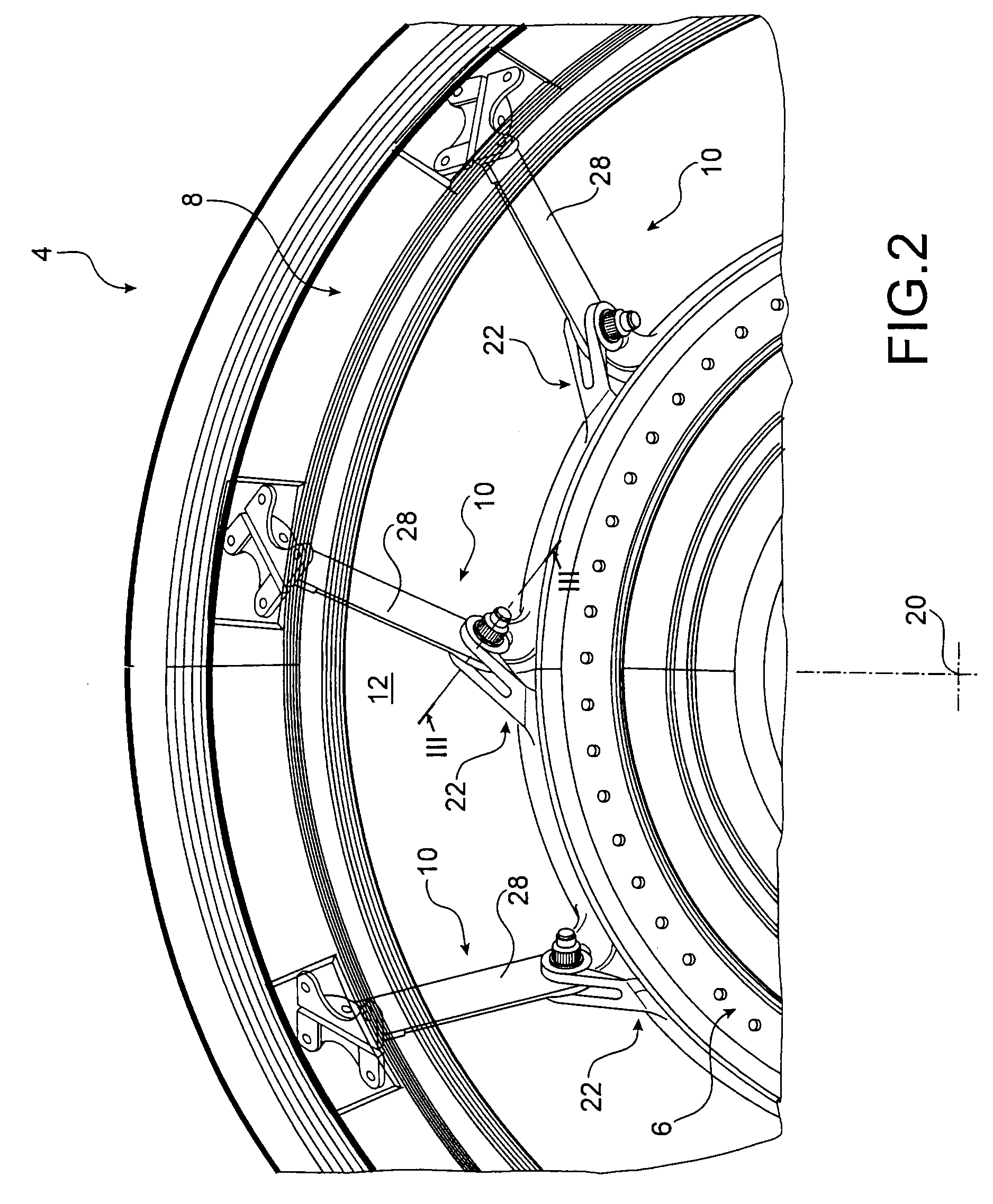

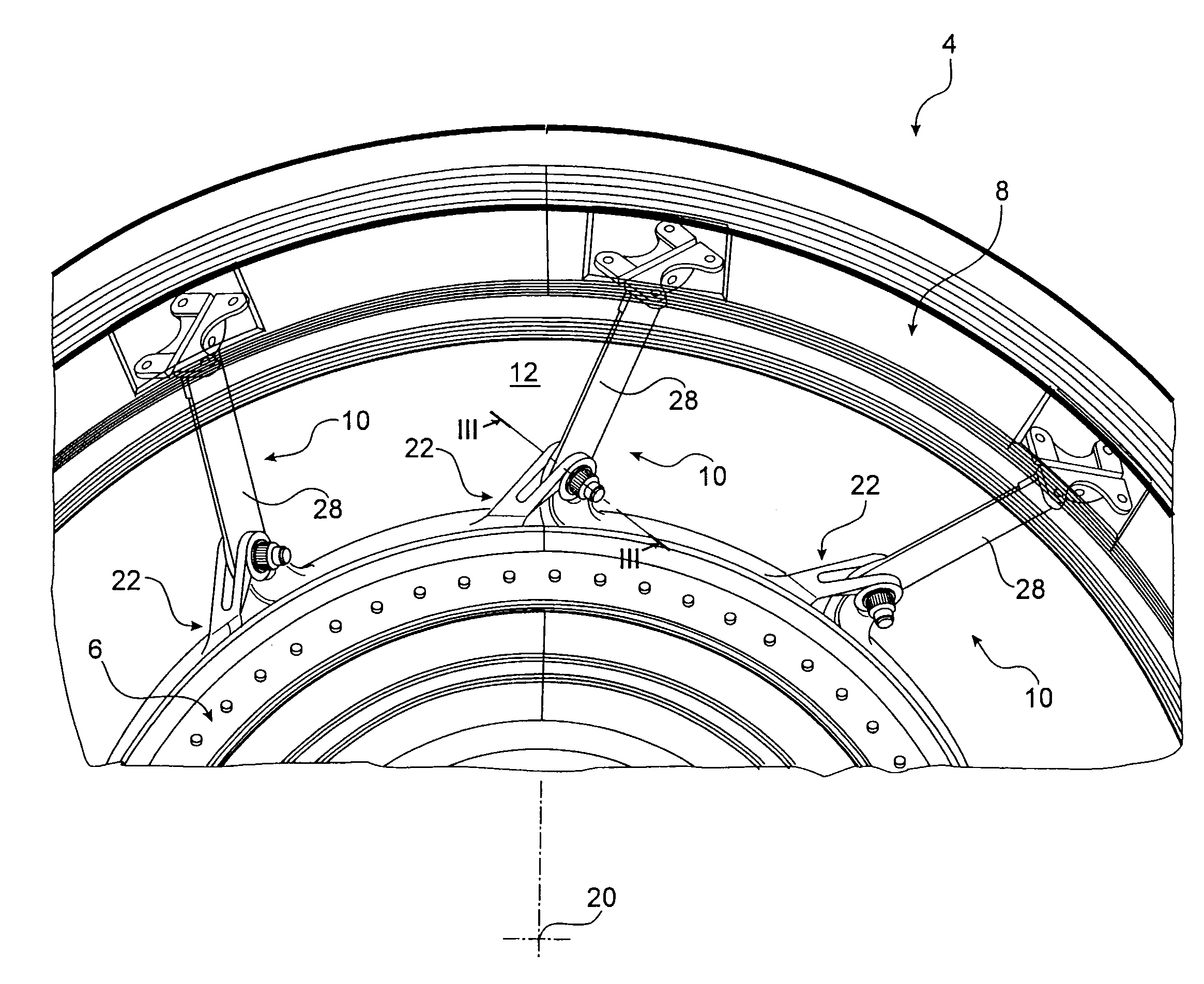

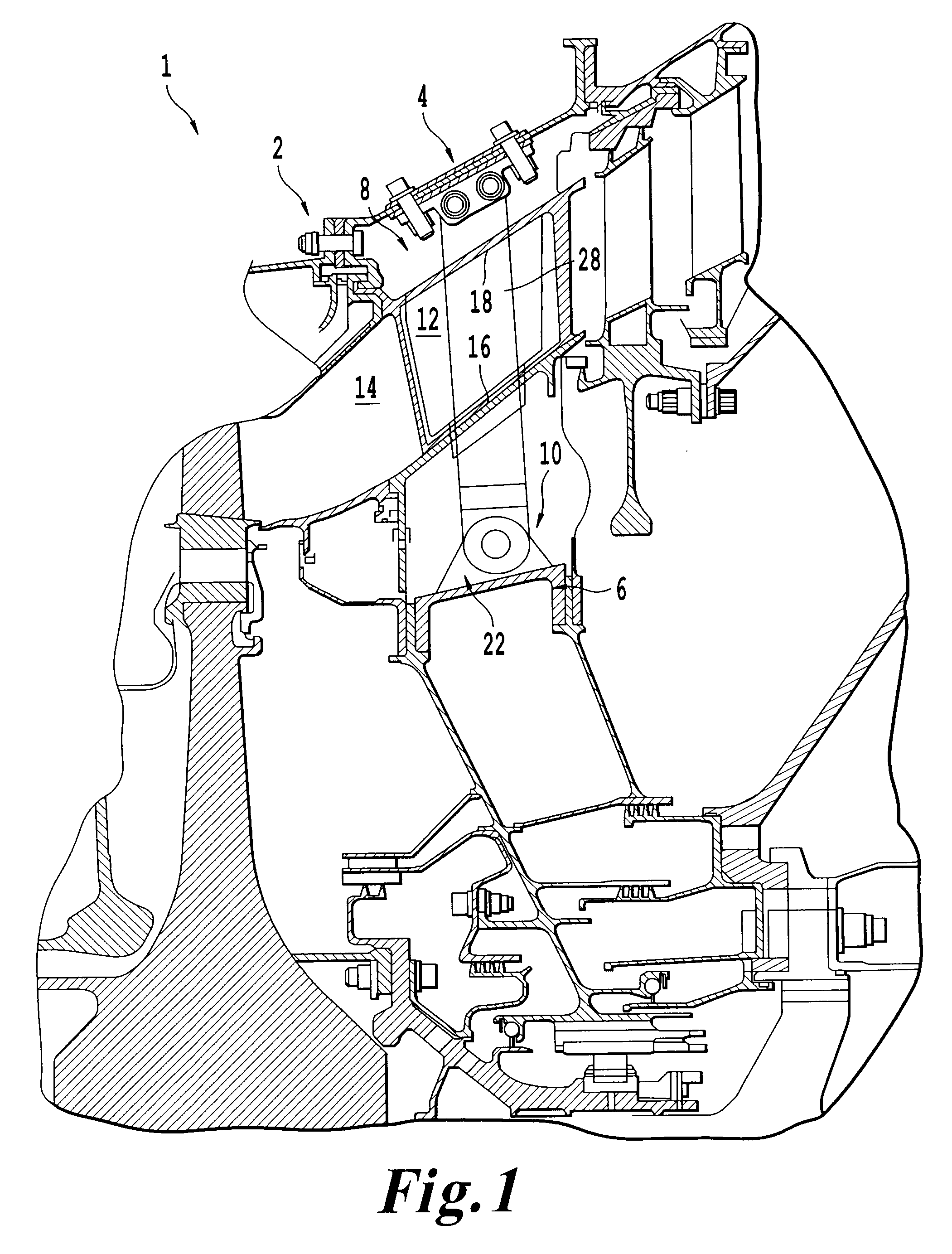

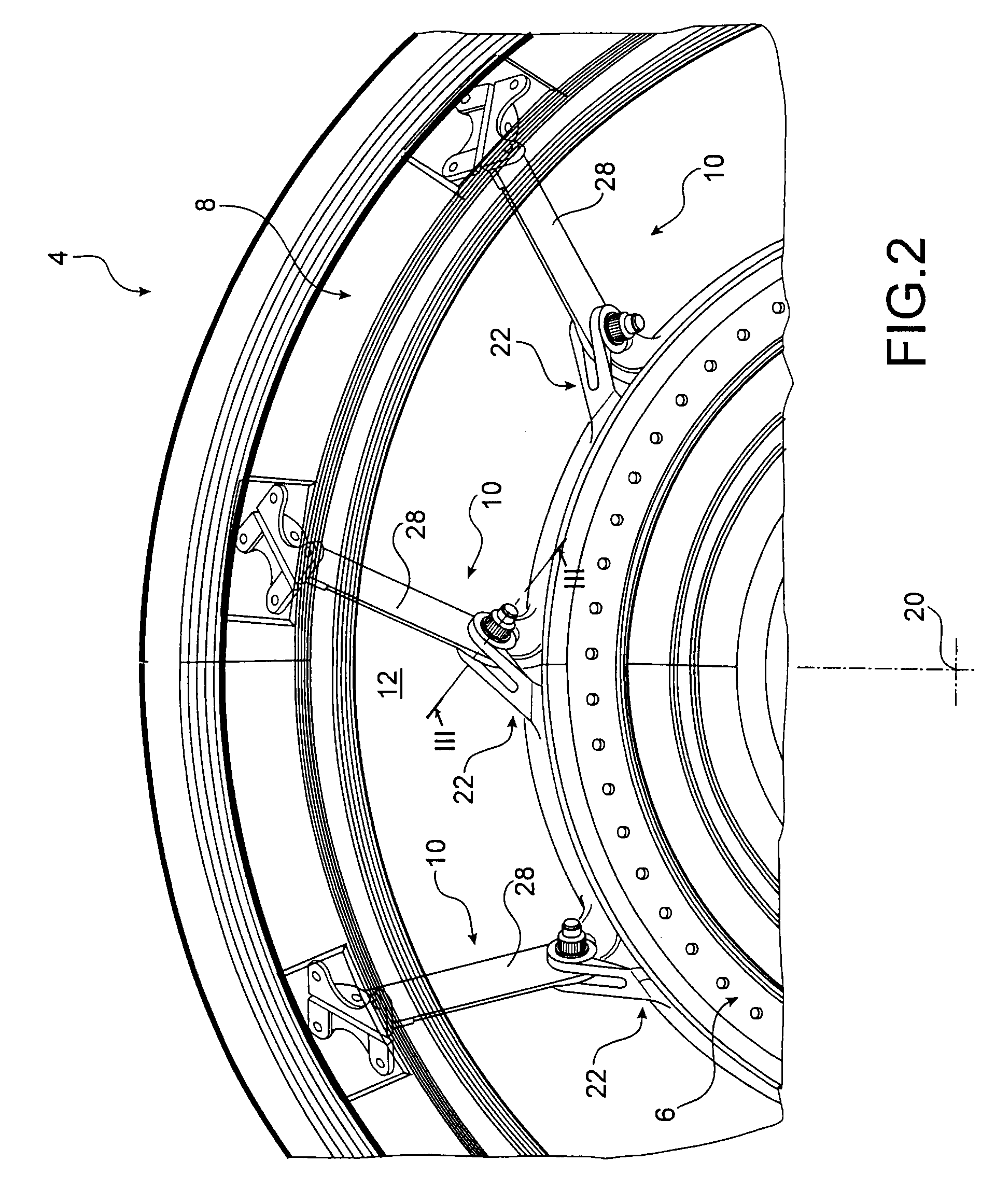

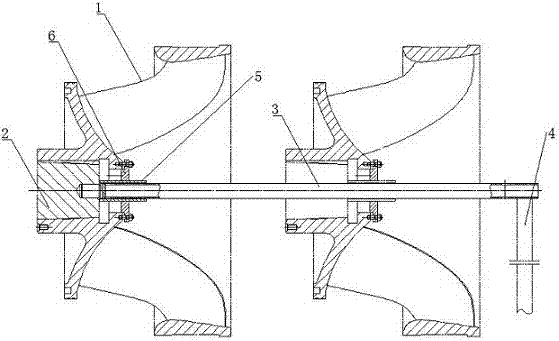

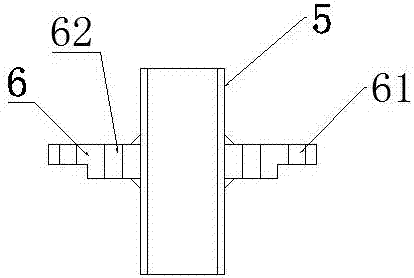

Joining device for joining two assemblies, for example for a stator of a turbomachine

ActiveUS20080240845A1Avoids detrimental bending effectAccurate final positioningPump componentsPlungersEngineeringShear pin

The present invention relates to a joining device (10) comprising a clevis (22) and a connecting member (28), the member (28) pierced with a through hole (30) being housed between a first and a second lug (26a, 26b) of the clevis, these lugs respectively having a first clevis hole (32a) and a second clevis hole (32b), the device further comprising a shear pin system (36) passing through each of said holes (32a, 32b, 30) and comprising a threaded end (46) collaborating with a nut system (44) bearing against the second lug.According to the invention, the shear pin system comprises a widened portion (42) passing through the first hole and forming a shoulder (50) situated between the two lugs, the member situated some distance from the first lug being pressed against the shoulder (50) on the one hand and against the second lug (26b) on the other.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

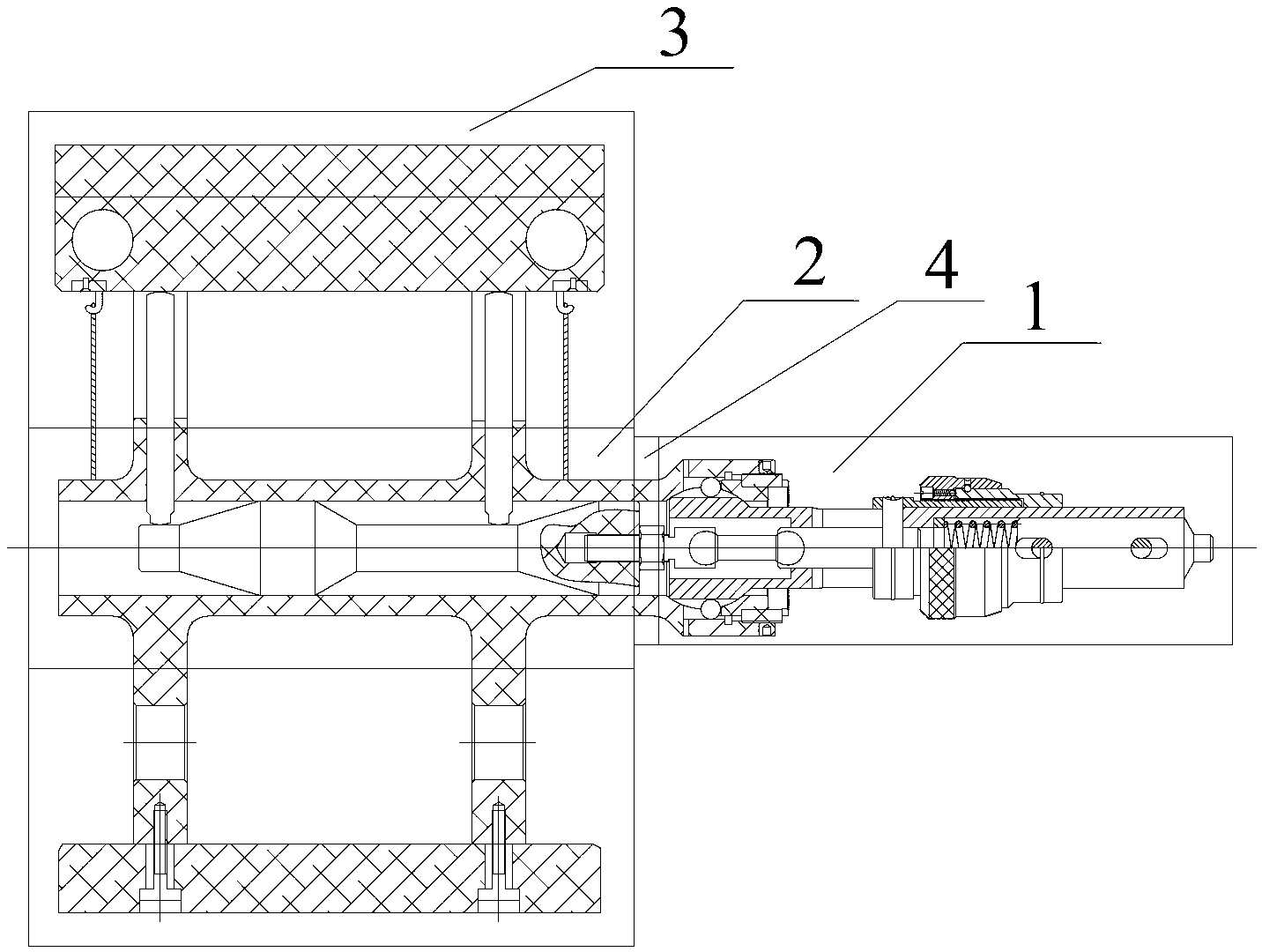

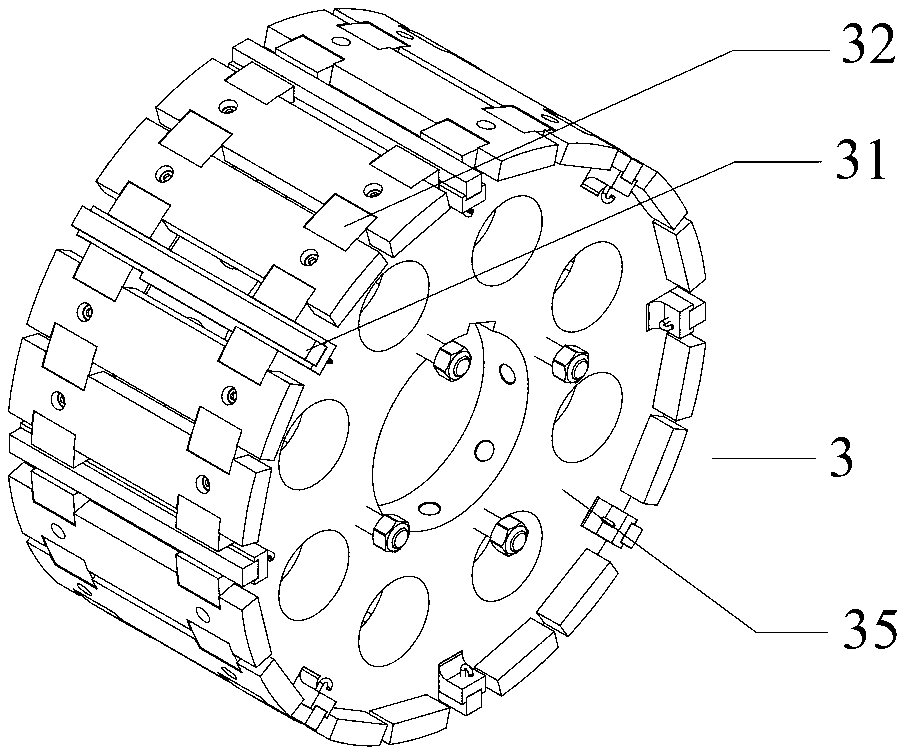

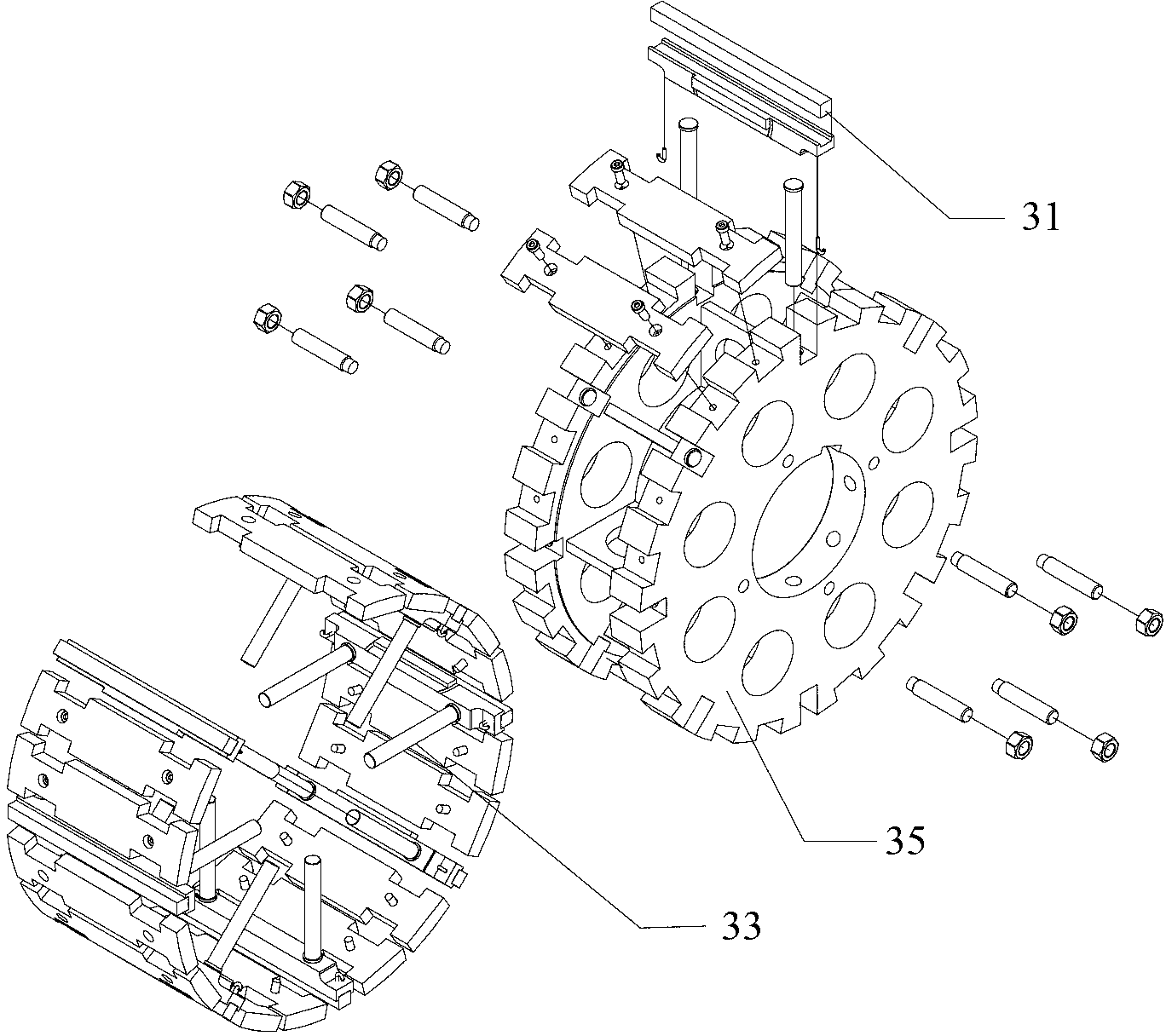

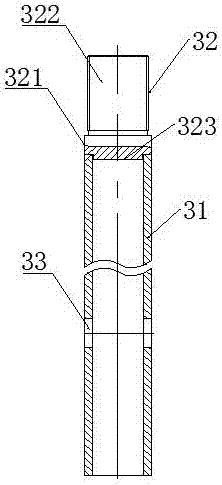

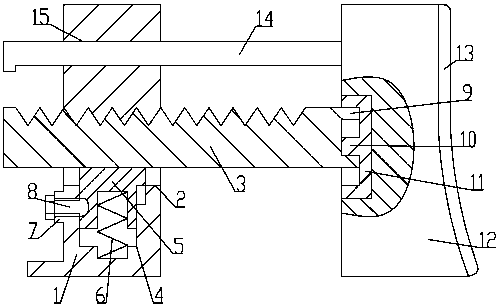

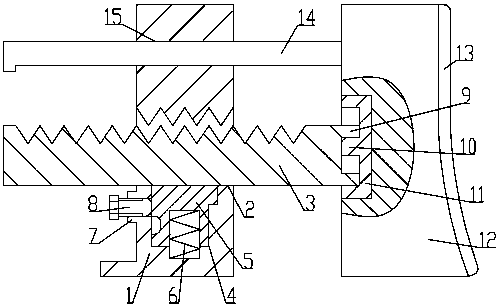

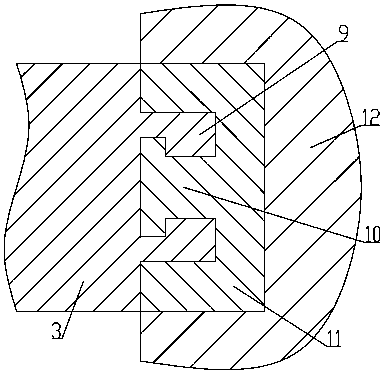

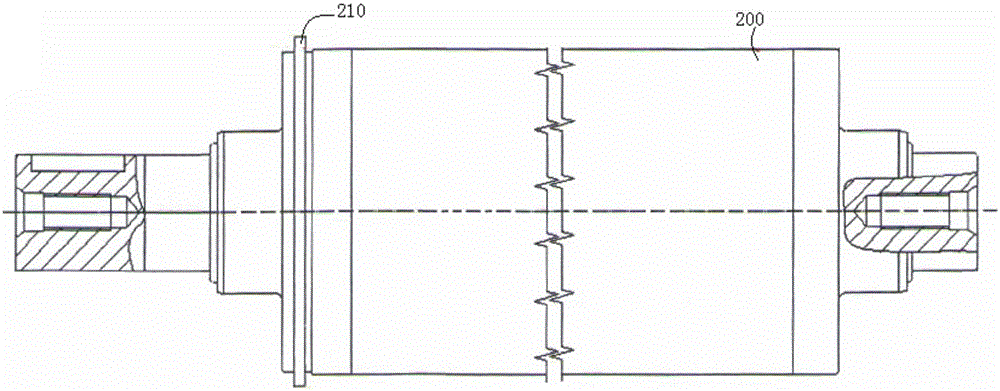

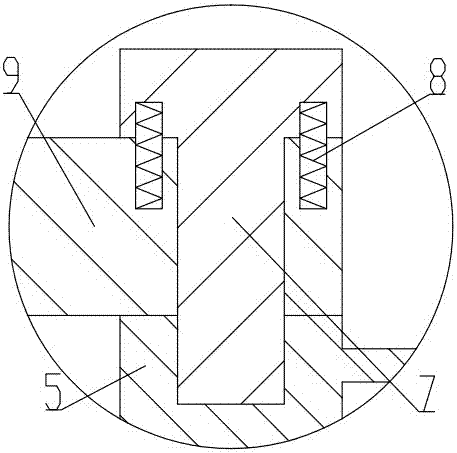

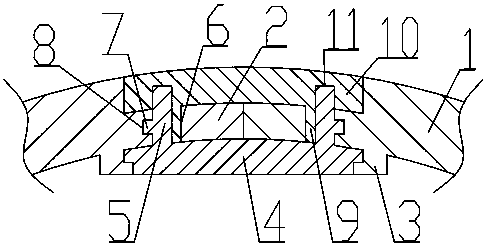

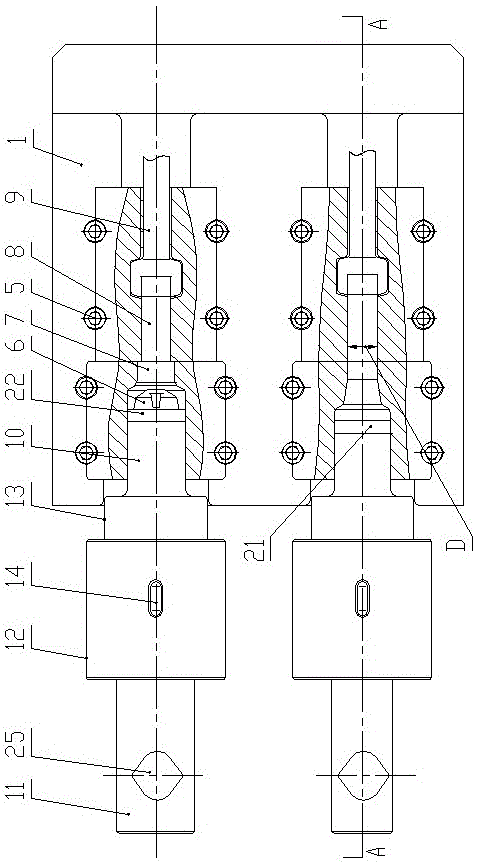

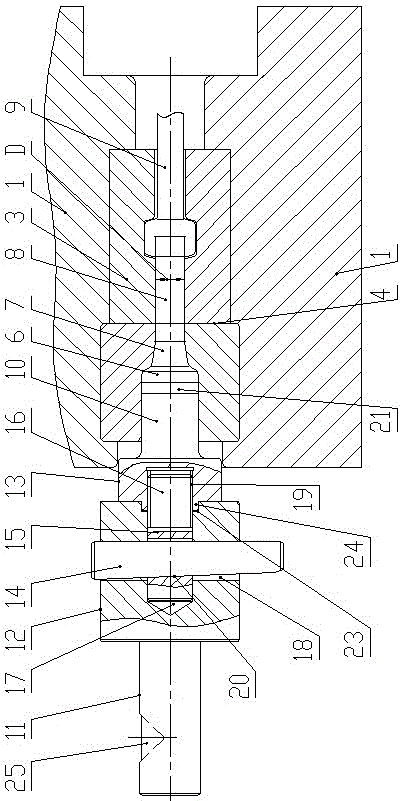

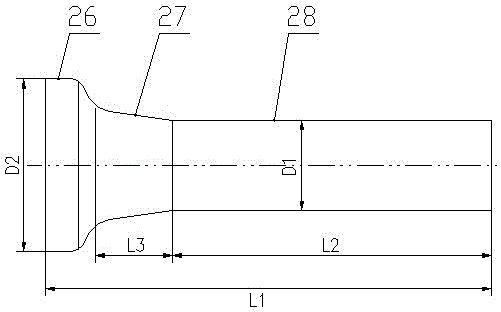

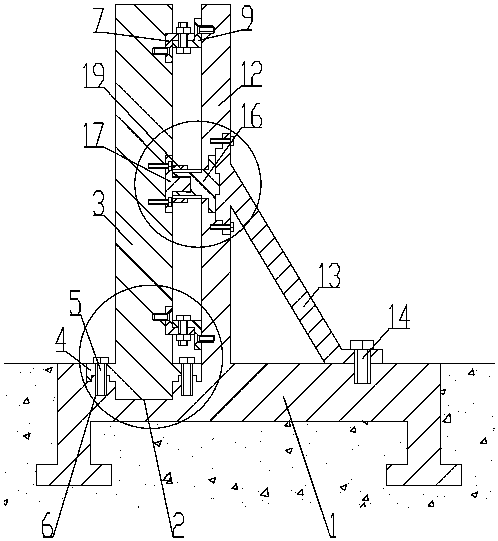

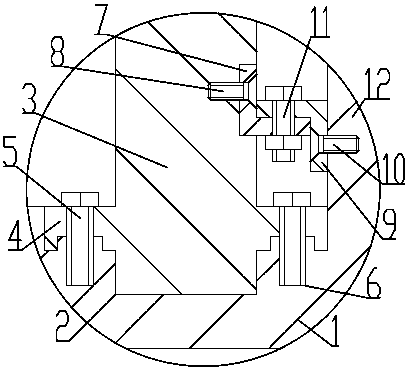

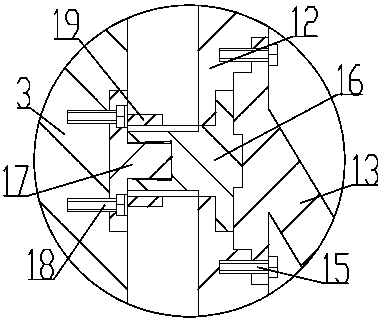

Honing head combination device

ActiveCN103317428APrecise positioningEasy and flexible assembly and disassemblyHoning toolsEngineeringBolt connection

The invention relates to a honing head combination device which can process whole-circle holes and non-whole-circle holes with the diameters ranging from 300mm to 1000mm. The honing head combination device comprises a fine adjustment connection rod part, a pneumatic core shaft part and a honing sleeve part, wherein the fine adjustment connection rod part, the pneumatic core shaft part and the honing sleeve part are of a split type structure, and the fine adjustment connection rod part is connected with the honing sleeve part through a flange plate and a bolt and is located through a key groove. The honing sleeve part is sleeved on the outer side of the pneumatic core shaft part and comprises a sleeve body, a honing strip, a guide board and a regulating bolt, wherein the honing strip and the guide board are arranged on the outer surface of the sleeve body, the regulating bolt is arranged on the lower portion of the honing strip, the pneumatic core shaft part is arranged at the axial center of the honing sleeve part, and the regulating bolt abuts against the pneumatic core shaft part. Compared with prior art, the honing head combination device has the advantages that the split type structure is utilized, using convenience is achieved, manufacturing cost and using cost are greatly lowered, and large-span holes with the diameters ranging from 300mm to 1000mm can be processed.

Owner:SHANGHAI DALONG MACHINE FACTORY CO LTD

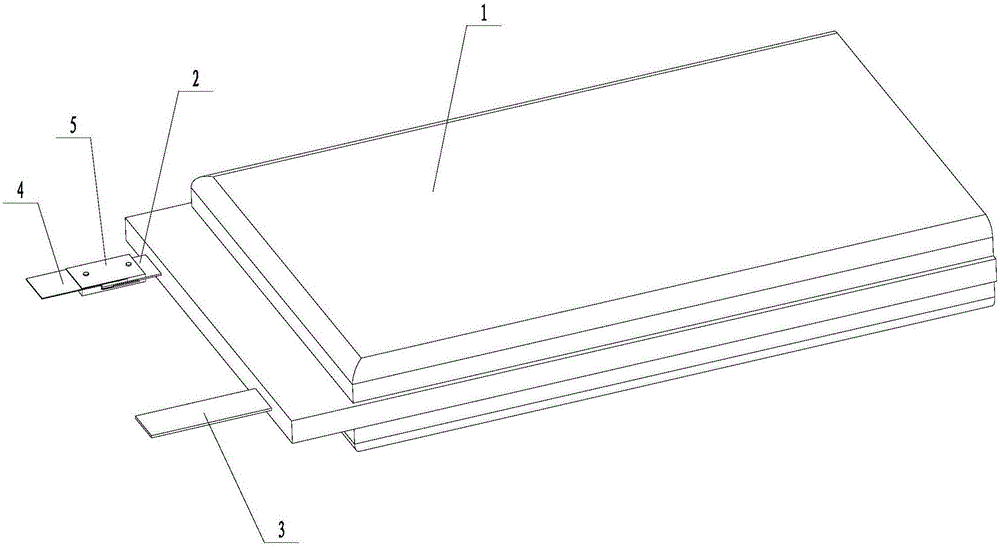

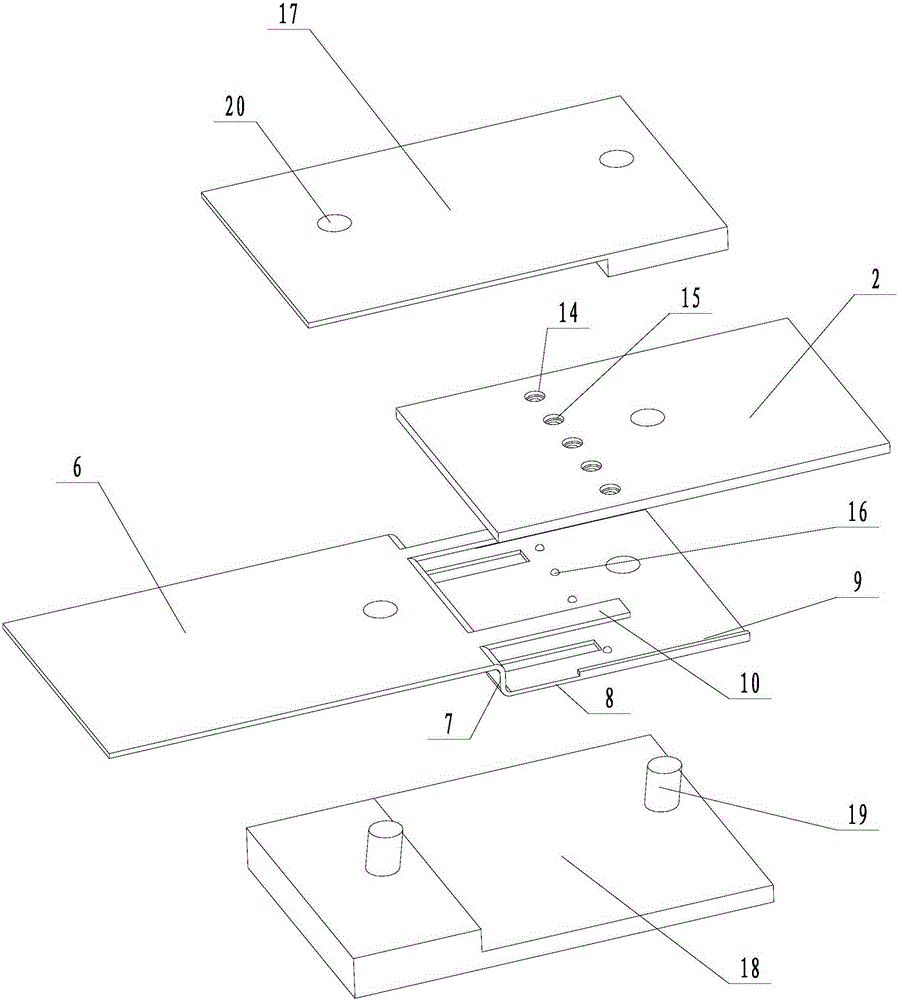

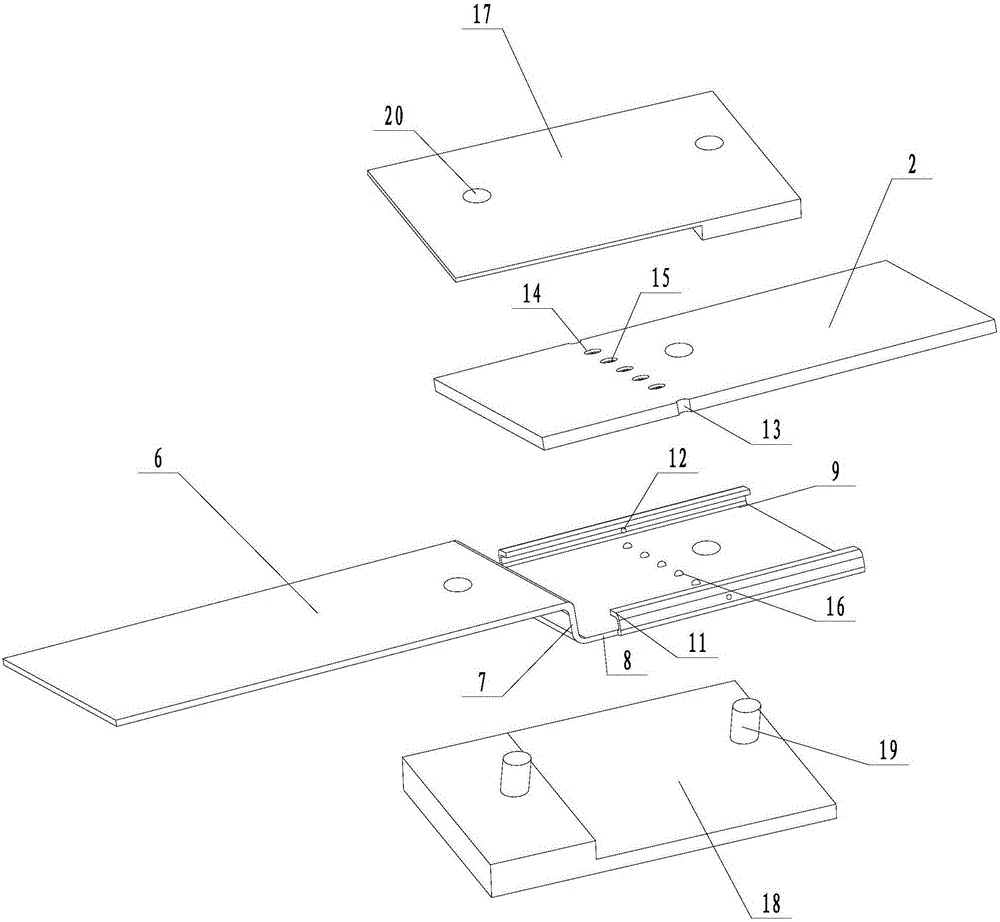

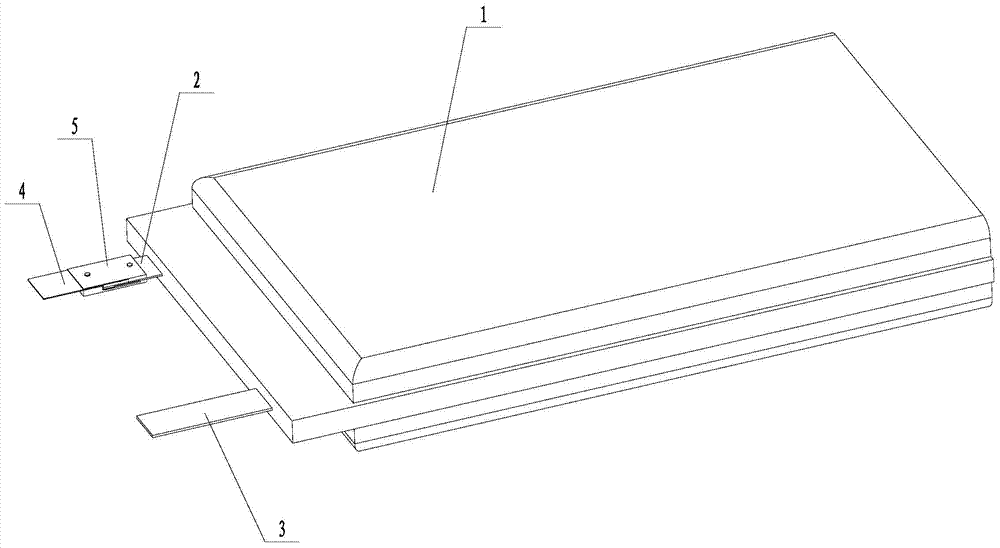

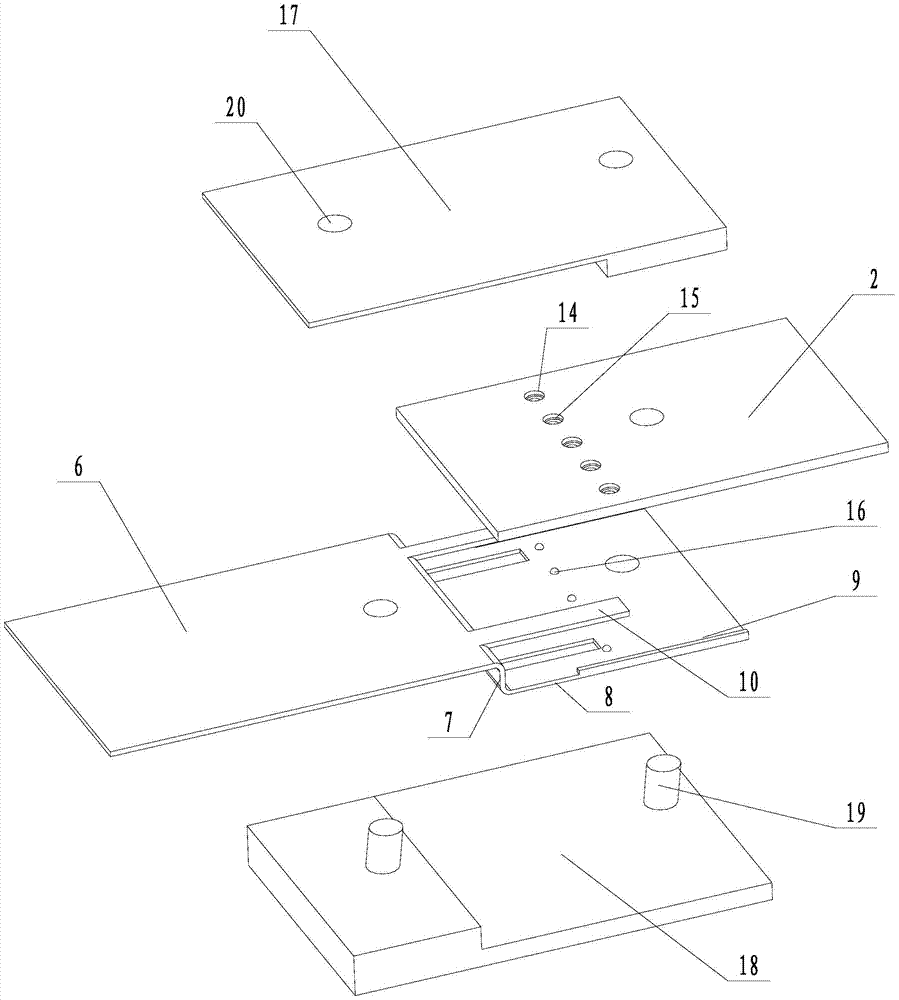

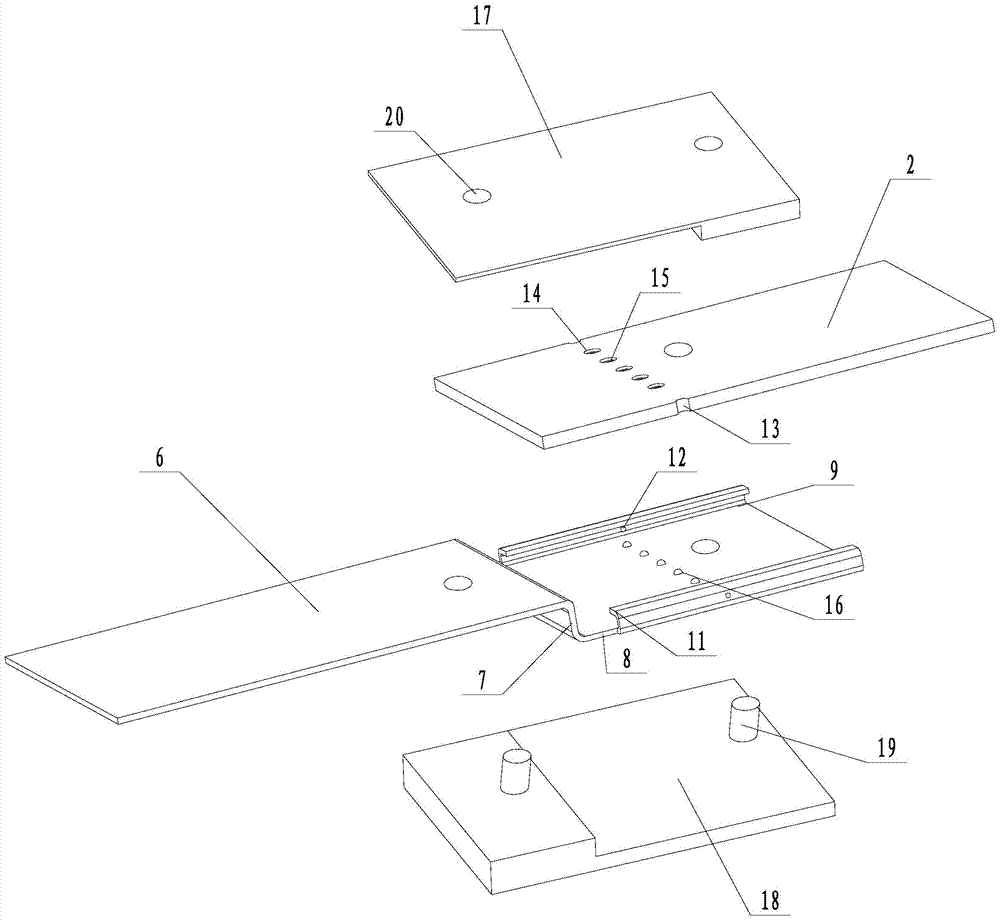

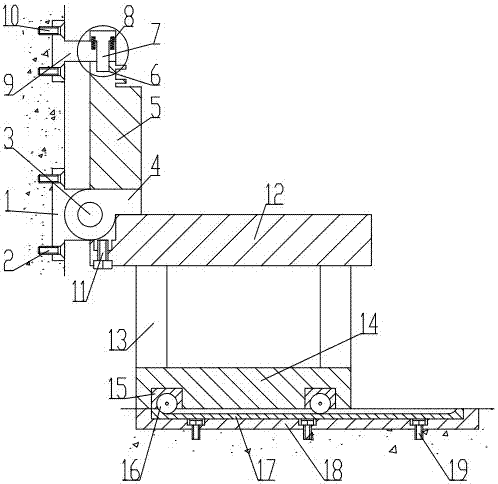

Positive tab connection structure of battery and welding method

ActiveCN105261726AFirmly connectedPrecise positioningSmall-sized cells cases/jacketsLaser beam welding apparatusDip solderingElectrical battery

The invention discloses a positive tab connection structure of a battery and a welding method, and aims at solving the problems that bad phenomena of welding instability, cold soldering, faulty soldering and the like are easily generated when tin soldering and electric resistance welding are utilized by an aluminum tab in an assembly process, the product quality cannot be effectively controlled, the aluminum tab is poor in connection reliability and a connection operation is inconvenient due to the fact that the positive tab of an existing soft package lithium battery is the aluminum tab and the aluminum tab is not easily connected and assembled with a tin bonding pad and a nickel bonding pad in the assembly process. The positive tab connection structure of the battery comprises a battery body, wherein the battery body is provided with the positive tab and the negative tab; a nickel current-carrying plate is welded on the positive tab; and a metal conductive clamp is detachably connected between the nickel current-carrying plate and the positive tab.

Owner:ZHEJIANG CHAOWEI CHUANGYUAN INDUSTRAIAL

Joining device for joining two assemblies, for example for a stator of a turbomachine

ActiveUS7794203B2Avoids detrimental bending effectAccurate connection positioningPump componentsEngine fuctionsEngineeringClevis fastener

A joining device including a clevis and a connecting member is disclosed. The connecting member includes a through hole which is housed between a first and a second lug of the clevis. These lugs respectively have a first clevis hole and a second clevis hole. The device further includes a shear pin system passing through each of the holes and includes a threaded end collaborating with a nut system which abuts against the second lug. The shear pin system includes a widened portion passing through the first hole and forming a shoulder situated between the two lugs. The member is situated away from the first lug. A first side of the member is pressed against the shoulder and a second side of the member is pressed against the second lug.

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

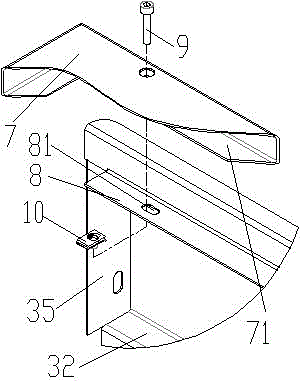

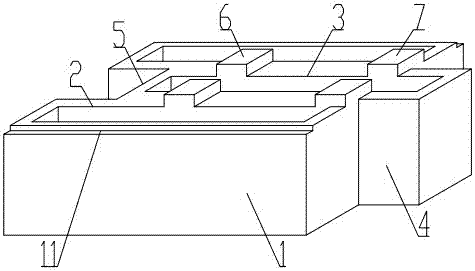

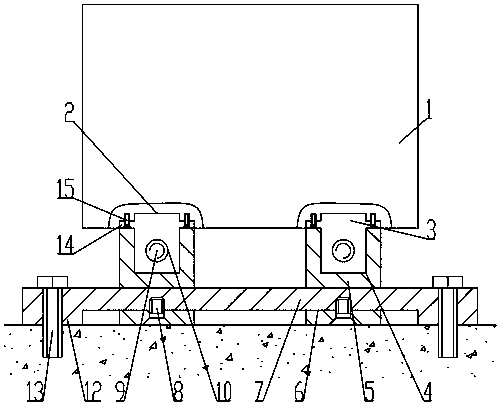

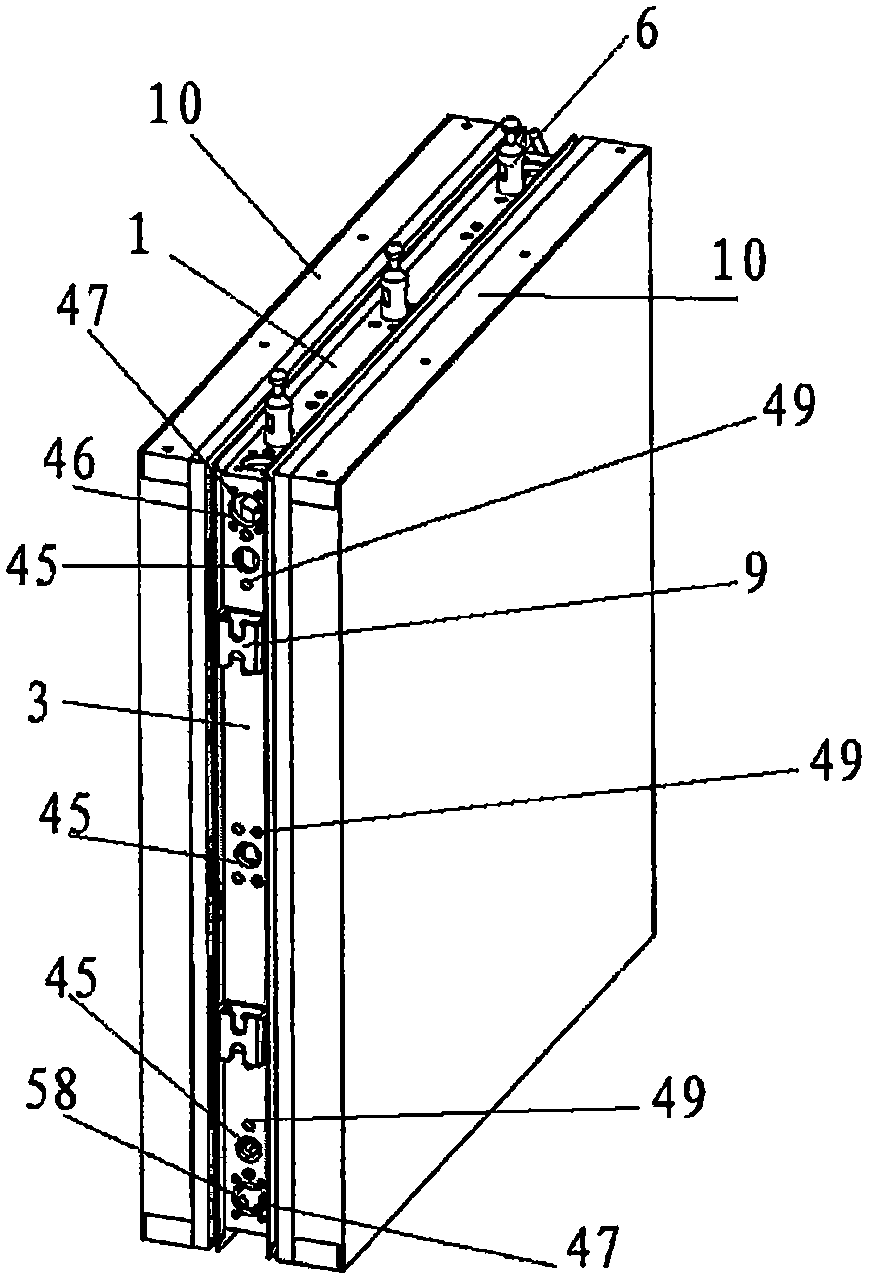

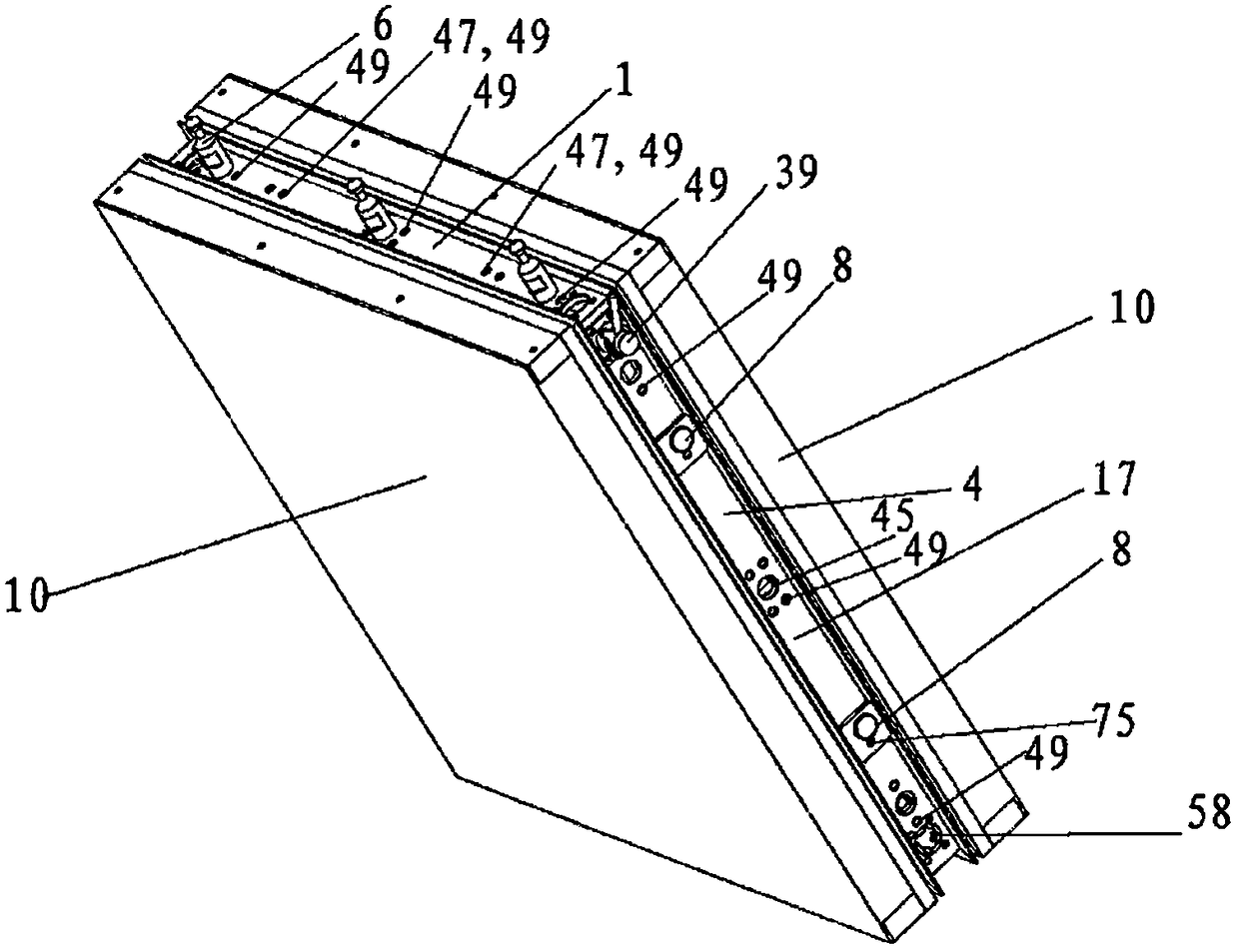

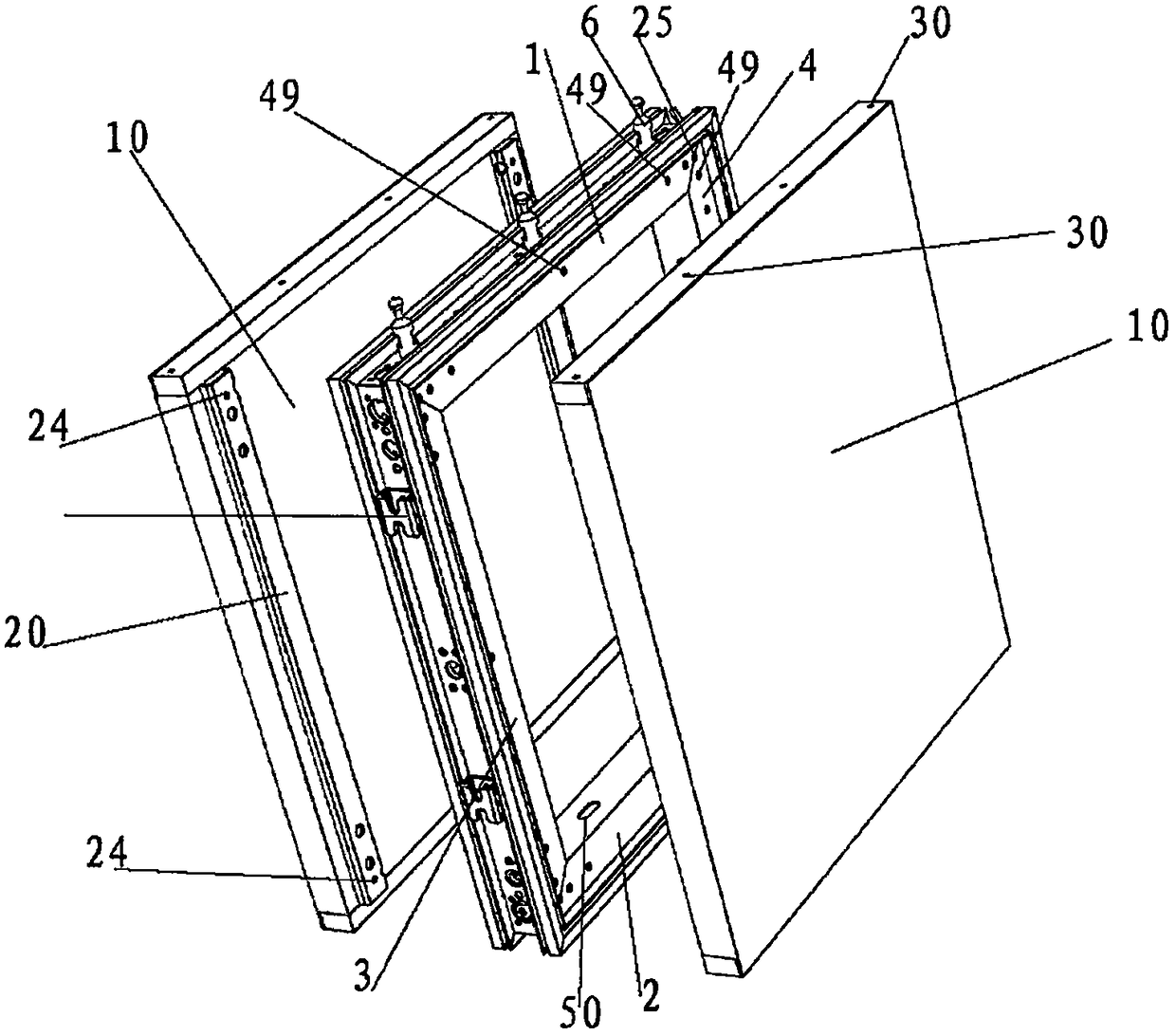

Vortex unit component assembly cabinet and assembly method thereof

ActiveCN104994692ASimple structureImprove cooling effectCasings/cabinets/drawers detailsMechanical engineeringEngineering

The invention relates to a vortex unit component assembly cabinet and an assembly method thereof. The vortex unit component assembly cabinet comprises a rectangular base. The two sides of the rectangular base are respectively connected with a vertical side plate; the upper portion of the front side between the two vertical side plates is provided with a front side plate; a front movable plate is arranged under the front side plate; the upper portion of the back side between the two vertical side plates is provided with a back side plate; a back movable plate is arranged under the back side plate; a sunk step surface formed between the front side plate, the back side plate and the two vertical side plates is provided with a top plate; a side portion of the front side plate is provided with an installation hole for installing a control panel; and the upper and lower portions of one vertical side plate are provide with an air outlet pipe installation hole and a power line wiring hole correspondingly. The assembly cabinet is compact in structure, convenient to assemble and disassemble and simple in assembling method.

Owner:LIDA CHINA MACHINE EQUIP

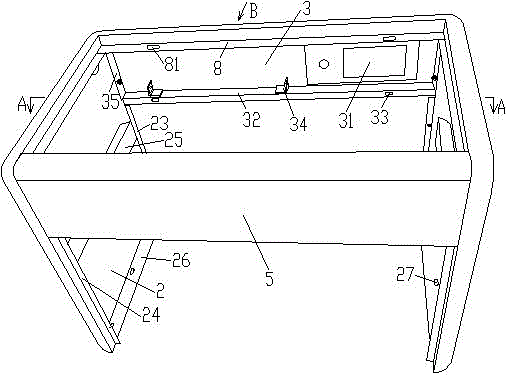

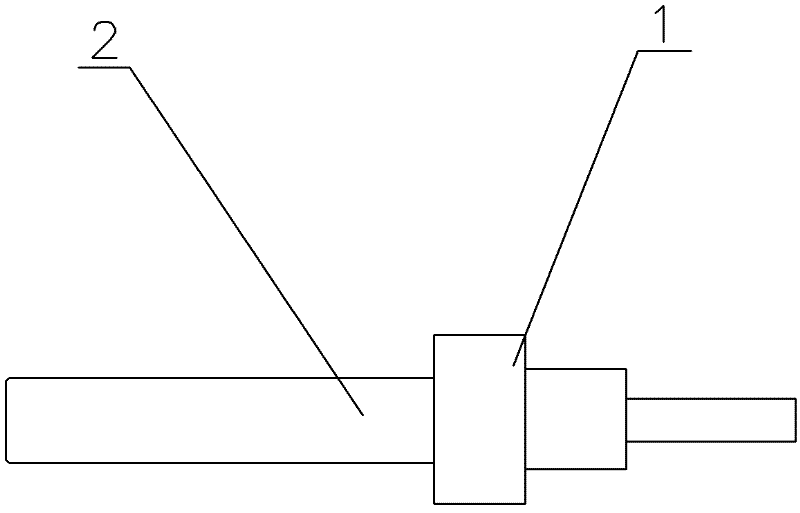

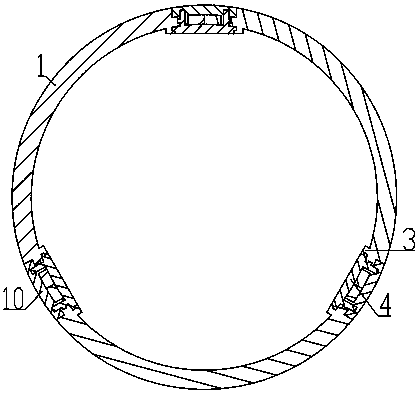

Disassembling and assembling tool for mixed flow horizontal water turbine

InactiveCN107511793AStable alignmentStable correctionMetal-working hand toolsMixed flowWater turbine

The invention discloses a disassembling and assembling tool for a mixed flow horizontal water turbine. The disassembling and assembling tool comprises a spindle and rotary wheels and further comprises a pull rod; the pull rod is sleeved with a bushing, and a flange plate is fixedly connected to the bushing and detachably connected with the rotary wheels; and the pull rod and the spindle are coaxial and are detachably connected. According to the scheme, the rotary wheels can be prevented from shaking or deflecting, so that the rotary wheels always move in the axis direction of the spindle without shaking or deflecting in the process that the rotary wheels are lifted and installed on the spindle, the rotary wheels can be better positioned in the process of being assembled on or disassembled from the spindle, the situation that center holes of the rotary wheels collide with the surface of the spindle and is abraded can be avoided, the assembling or disassembling precision is higher, and the errors are smaller.

Owner:CHONGQING ELECTRIC MACHINE FEDERATION

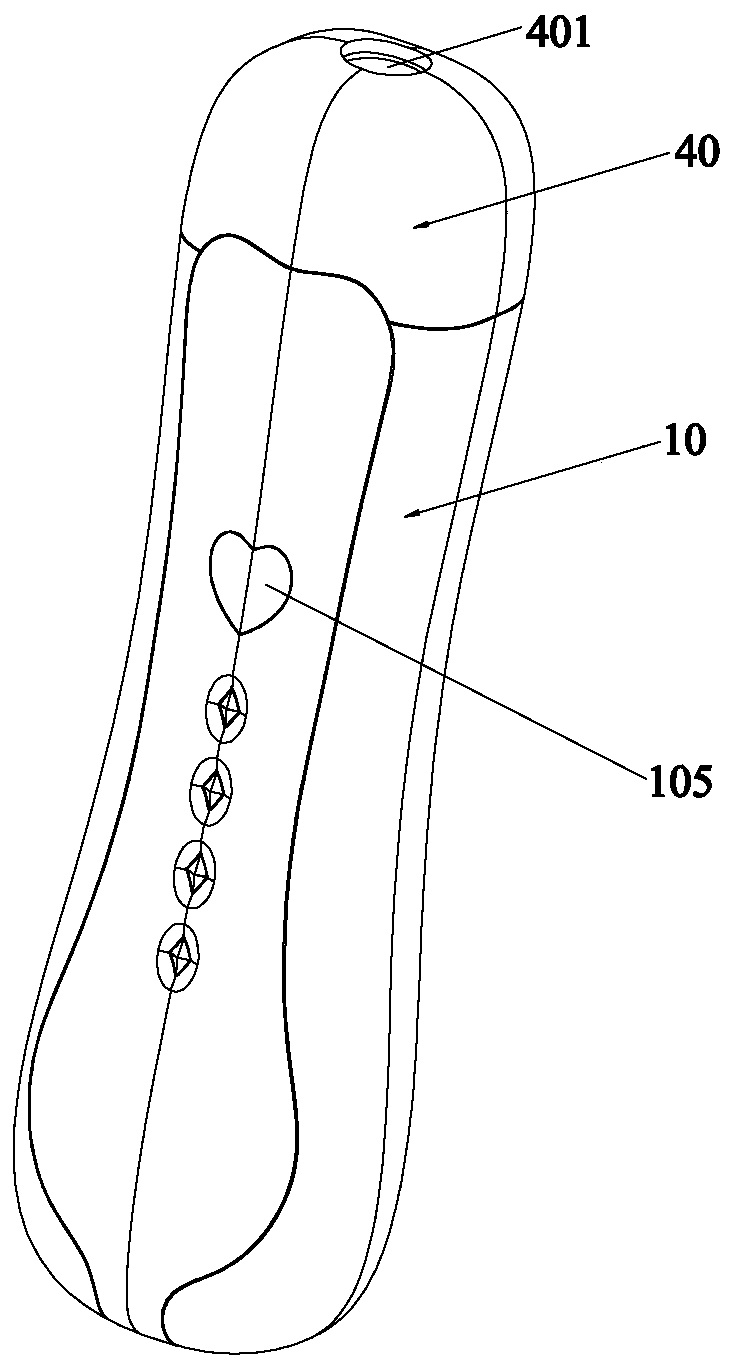

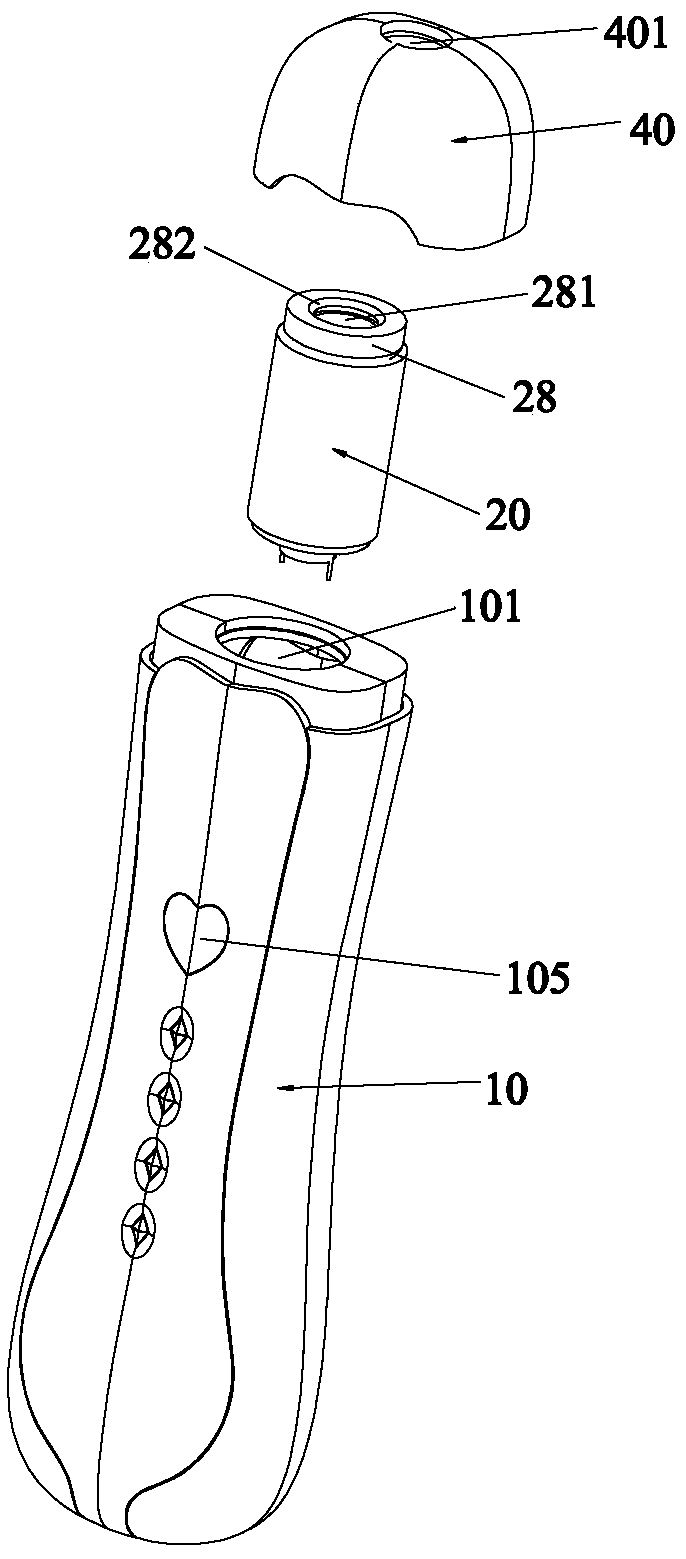

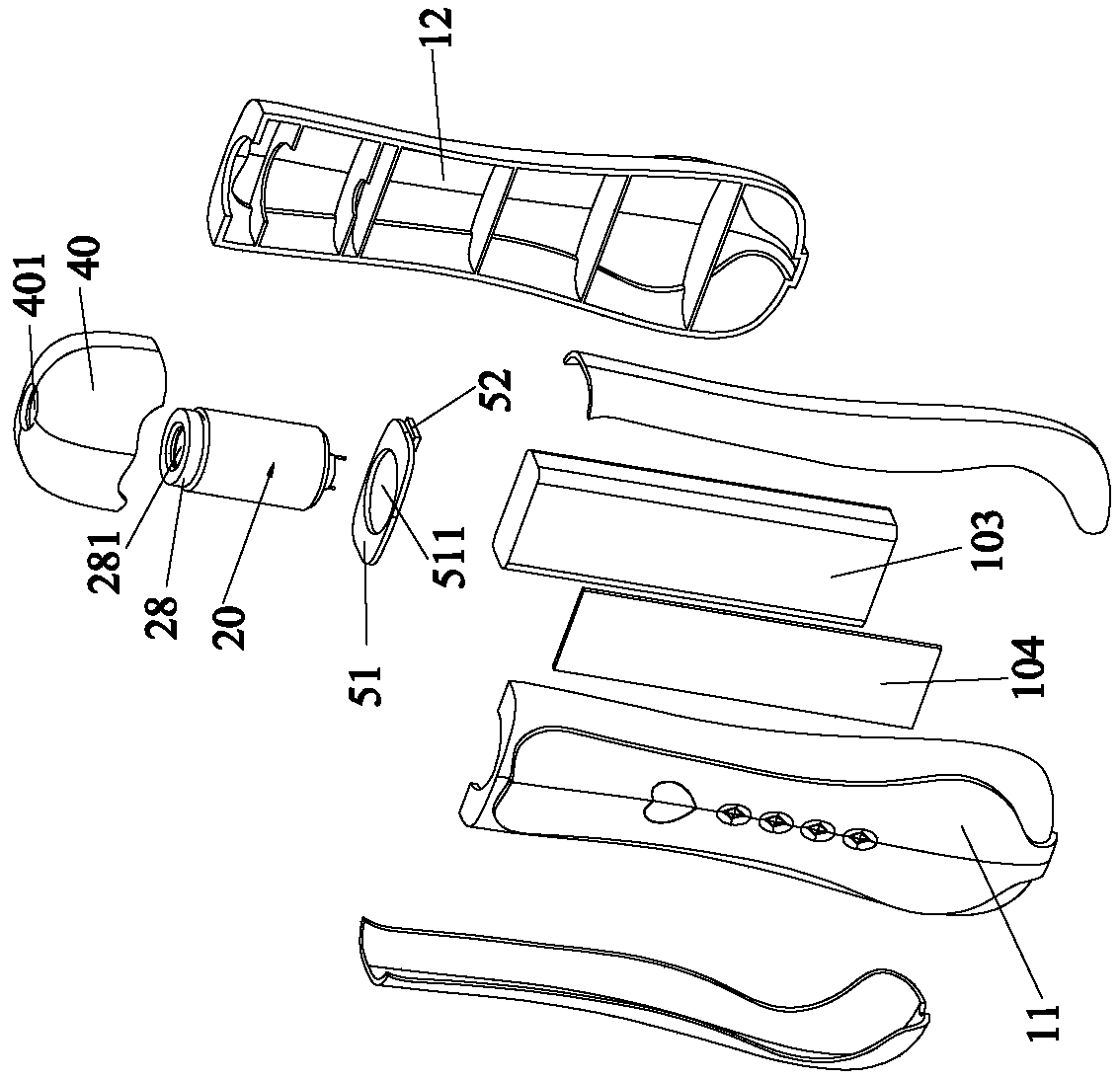

Air heating tobacco curing machine with improved heating performance

PendingCN109156862AIncrease the heating areaImprove heating efficiencyTobacco preparationEngineeringFlue

The invention relates to an air heating tobacco flue-cured machine with improved heating performance. The air heating tobacco curing machine comprises a housing and a heating and heat preservation device. The heating and heat preservation device is arranged in the mounting cavity of the housing. The heating and heat preservation device comprises a heat insulating cup, a smoke containing cup and aheating part. The smoke-containing cup is provided with a smoke-containing main cavity and a contact heat conduction part, and a heating part is arranged below the contact heat conduction part. Between that out side of the smoke cup and the inner side of the heat insulation cup, an air convection gap is maintained. A main chamber body side wall is provided with an air flow radiation heat through hole, that first air inlet of the shell is connected with an air convection gap, the air enters the main chamber body through the first air inlet, the heat element and the air convection gap, and the air flow radiation heating through hole. Therefore, the heat generate by the heating part is transmitted to the smoke body through the combination of the heat contact conduction at the bottom and the convection radiation of the hot side air. The heating area of the smoke body and the heating efficiency of the smoke body are improved, the heat is uniformly heated, the tobacco body is omni-directionally heated, the use taste of the user is improved, the tobacco shred is completely baked, and waste of the tobacco shred is avoided.

Owner:DONGGUAN TELAKANG TECH CO LTD

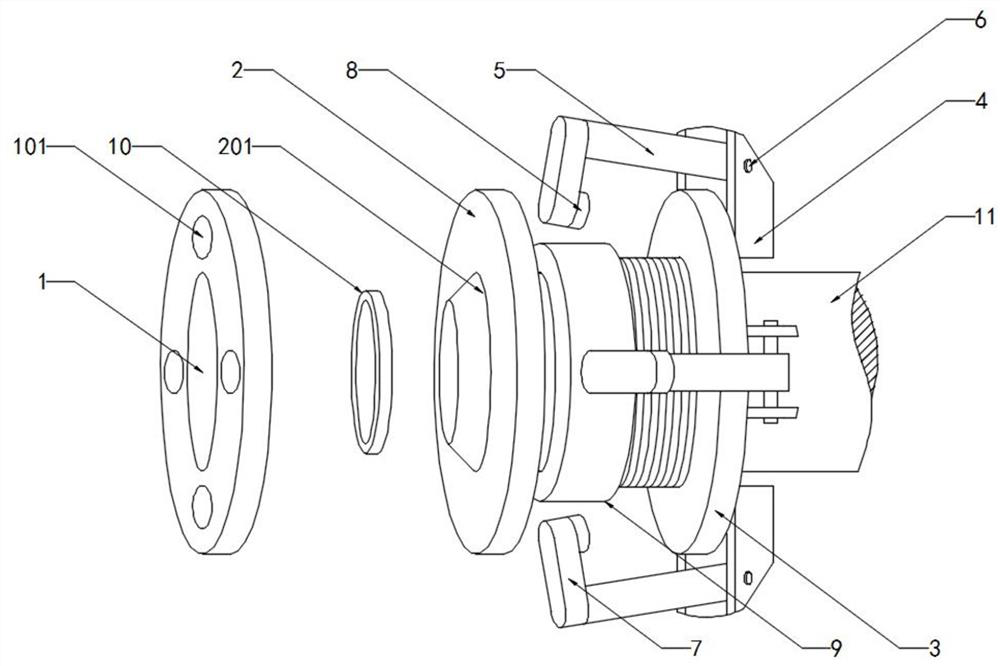

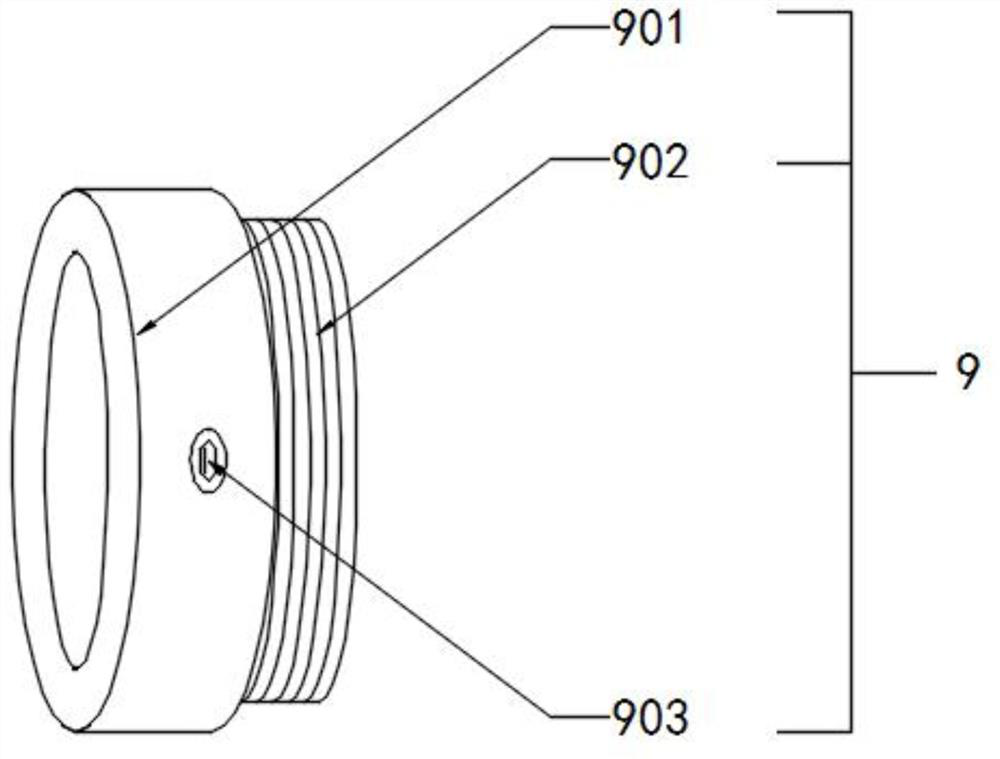

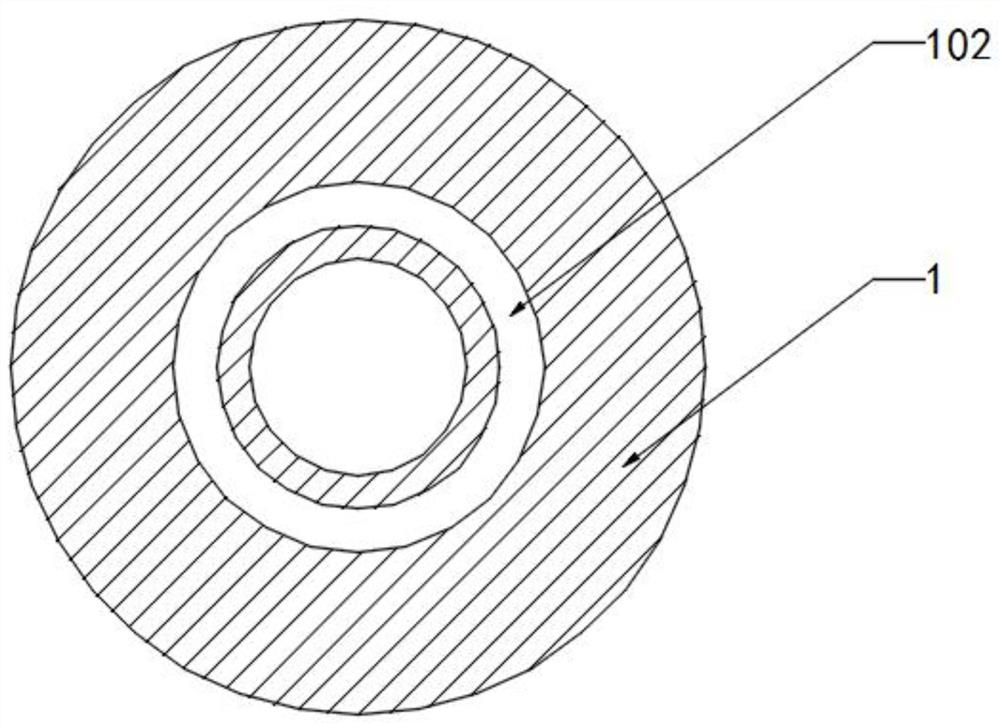

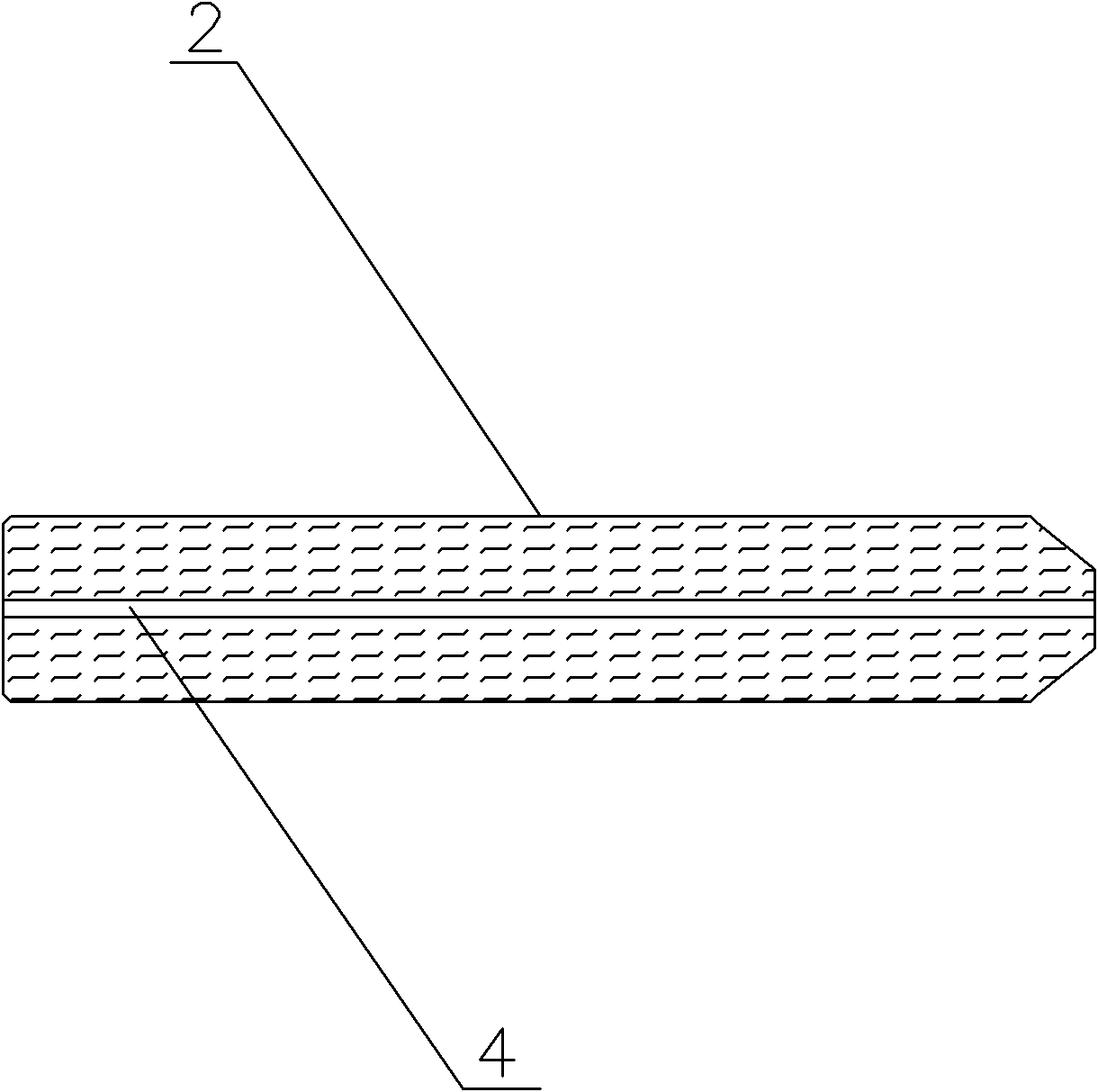

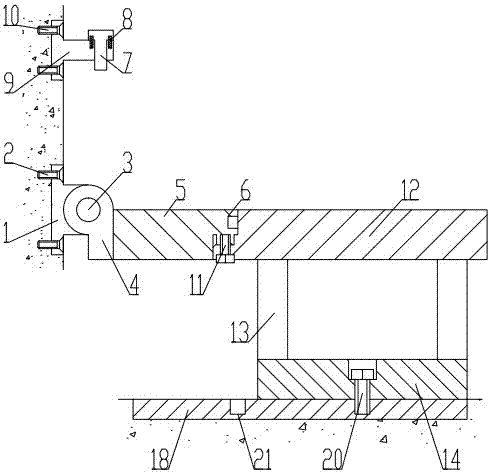

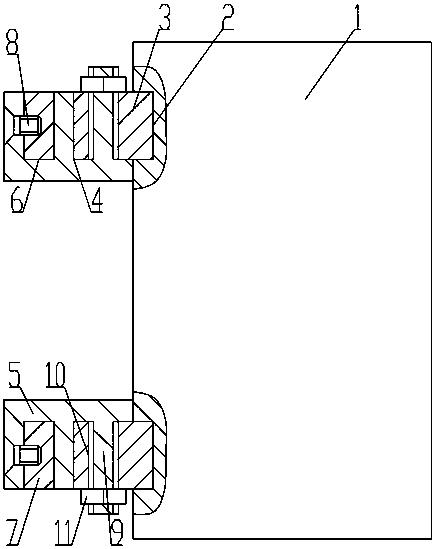

Flange convenient to detach and install

InactiveCN111853393AAccurate connection positioningShorten the timeFlanged jointsScrew threadIndustrial engineering

The invention discloses a flange convenient to detach and install. The flange comprises a first flange sheet, a second flange sheet and a pipeline fixedly connected with the second flange sheet. Cylinder grooves are formed in the side wall, away from the second flange sheet, of the first flange sheet. A fixed ring is arranged on the pipeline in a sleeving manner. Hinged supports are fixedly connected to the side face, away from the second flange sheet, of the fixed ring. A pull rod is hinged to each hinged support through a rotating shaft. The end portion of each pull rod is fixedly connectedwith a connection piece. A positioning pin is fixedly connected to the side face, connected with the corresponding pull rod, of each connection piece. A pressurization mechanism arranged on the pipeline in a sleeving manner is arranged between the fixed ring and the second flange sheet. The pressurization mechanism is mainly composed of a sleeve, a threaded barrel and an insertion hole. In the flange, by means of the pull rods hinged to the fixed ring, the positioning pins can be inserted in the cylinder grooves in the first flange sheet through the connection pieces, the sleeve in the pressurization mechanism is screwed, the first flange sheet is tightly pulled through the pull rods, flange connection positioning can be precise, the installation and detachment time is saved, and efficiency is high.

Owner:浙江至丰法兰科技有限公司

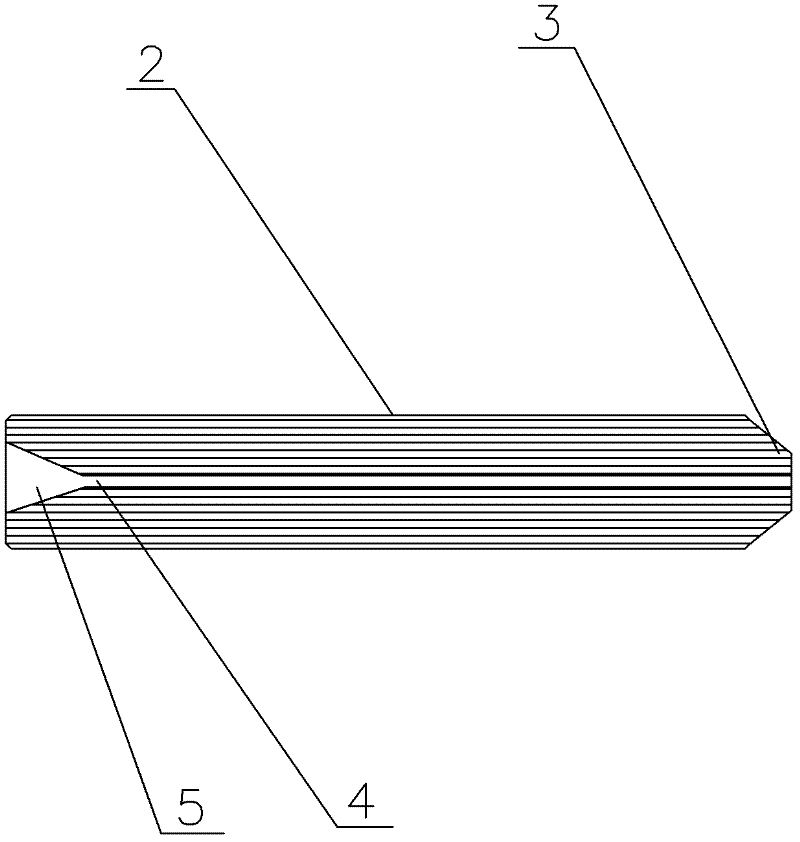

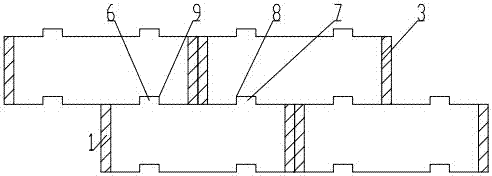

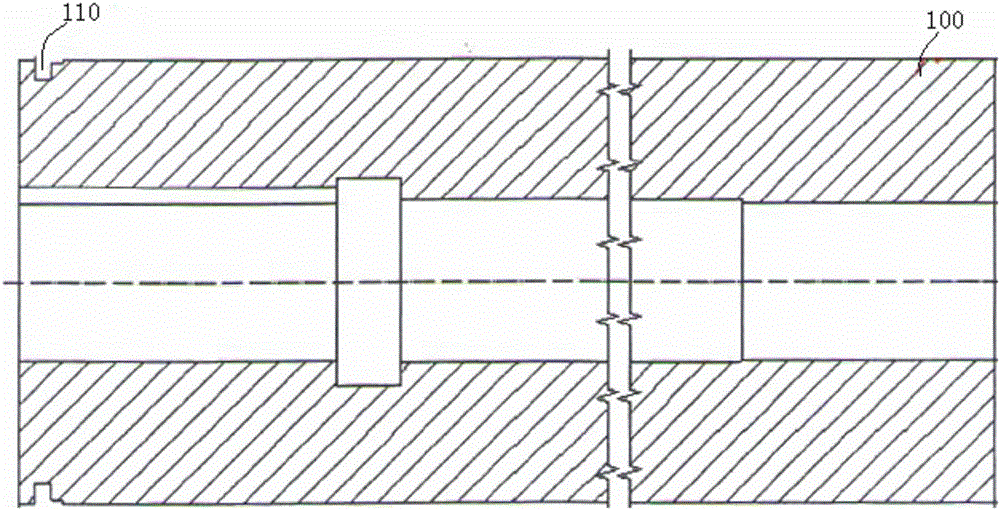

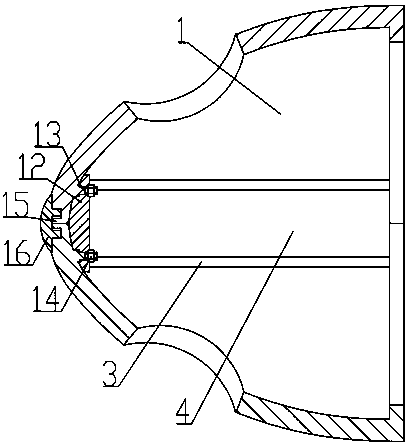

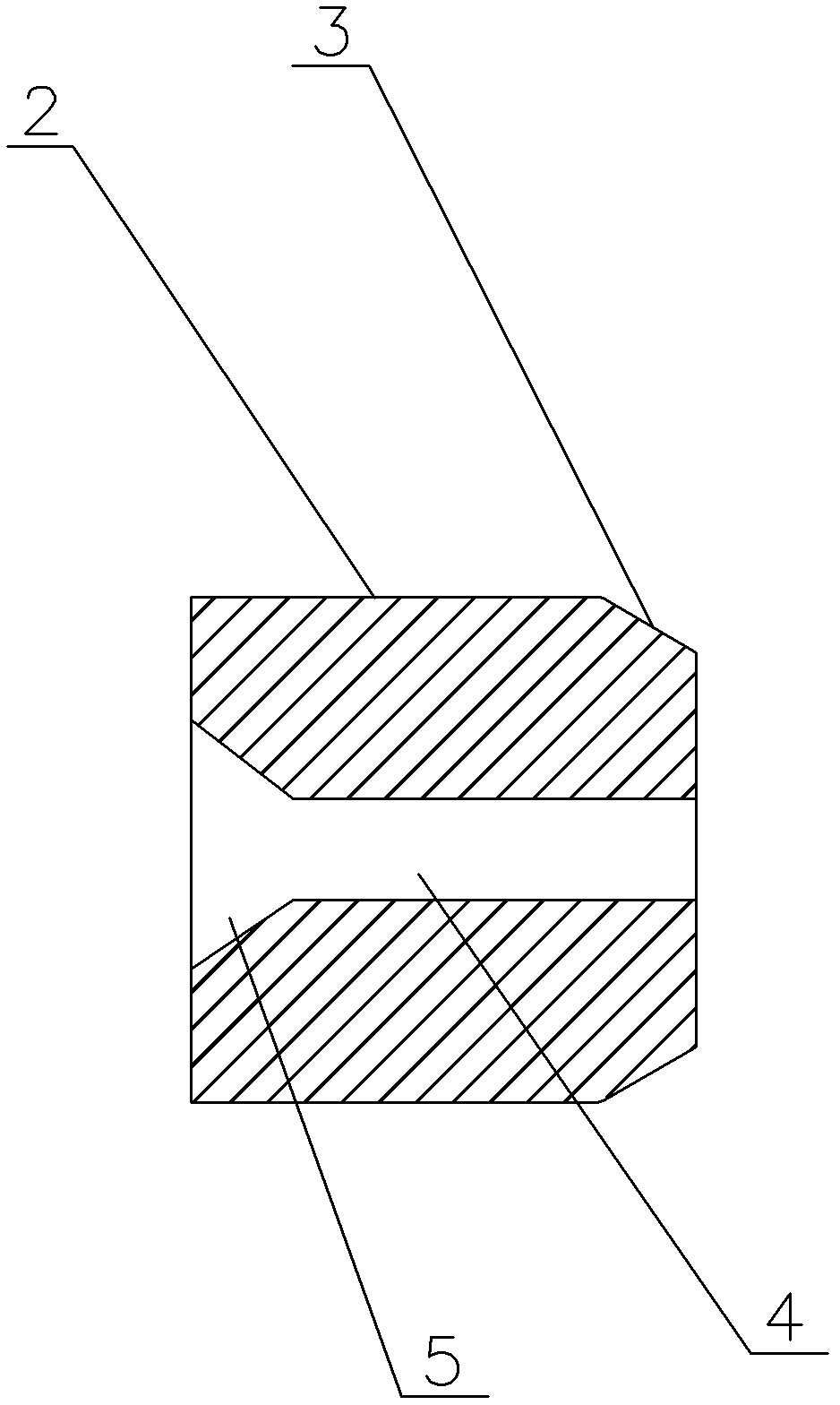

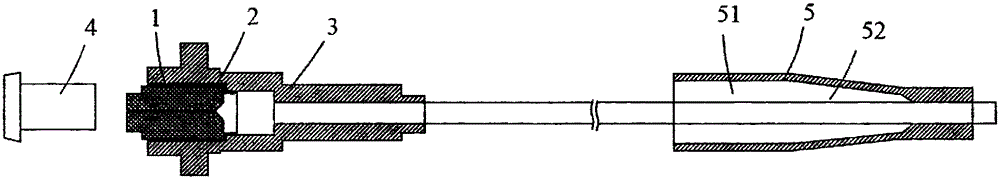

A middle slotted ceramic ferrule

InactiveCN102289041AEasy to insert and installAccurate connection positioningCoupling light guidesOptical fiber connectorCylindrical lens

The invention discloses a ceramic ferrule with a slot in the middle, which is installed in the center of an optical fiber connector and used in conjunction with a metal seat. The main body of the ceramic ferrule is in the shape of a cylinder. Groove; the length of the main body of the ceramic ferrule is 16±0.05mm, and the diameter is 1.599±0.003mm; the length of the semi-cylindrical groove is 7.5±0.05mm; the diameter of the through hole of the main body of the ceramic ferrule is 0.126- 0.127mm; both ends of the ceramic ferrule are provided with conical grooves at the axial through holes, and the diameter of the conical grooves is 0.9±0.05mm. By setting a semi-cylindrical groove in the middle of the main body of the ceramic ferrule, conical grooves are provided at the axial through holes at both ends of the ceramic ferrule, which achieves accurate connection positioning, convenient fiber insertion and installation, and stable performance , and can greatly improve the optical signal transmission speed and facilitate maintenance purposes.

Owner:昆山迎翔光电科技有限公司

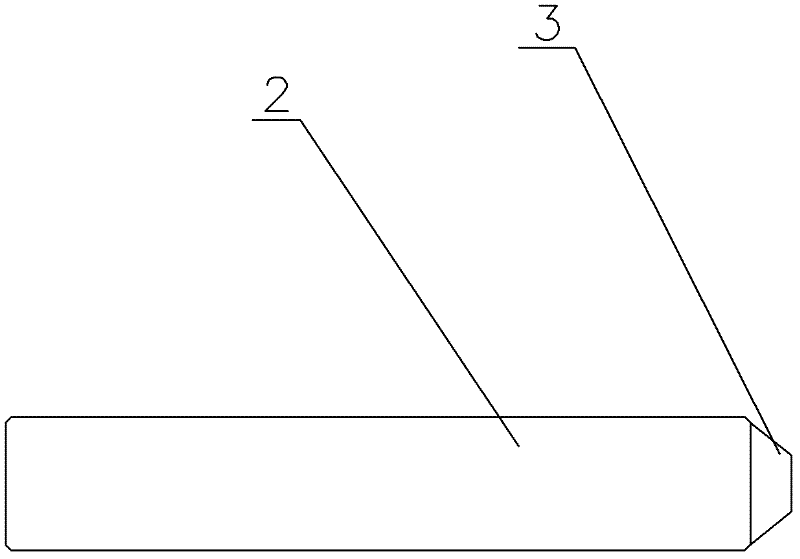

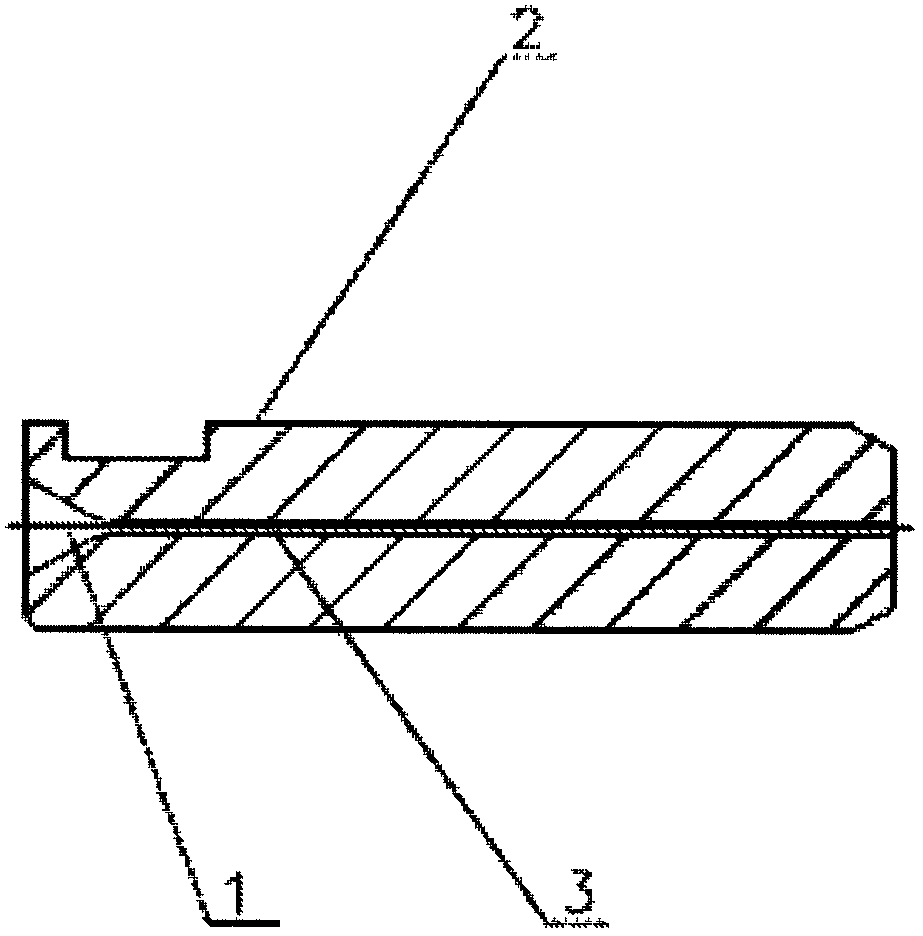

A sc-pc single-mode ceramic ferrule

InactiveCN102298176AReduce coupling lossAccurate connection positioningCoupling light guidesLight signalOptical fiber connector

The invention discloses a SC-PC single-mode ceramic ferrule, which is installed in the center of an optical fiber connector and used in conjunction with a metal seat. The main body of the ceramic ferrule is in the shape of a cylinder; one end of the ceramic ferrule is tapered end; the tapered end is conical; the inner hole of the other end of the ceramic ferrule is provided with a conical groove; the length of the SC-PC single-mode ceramic ferrule is 10.50±0.05mm, and the inner diameter It is 0.125-0.126mm, the outer diameter is 2.4990±0.0005mm, and the concentricity is not less than 1μm. By designing the main body of the ceramic ferrule into a cylindrical shape, one end of the ceramic ferrule is designed as a conical end, the conical end is in the shape of a cone, and the inner hole of the other end is provided with a conical The groove achieves the purpose of small optical coupling loss of the ferrule, accurate connection positioning, convenient use, beautiful appearance, stable performance, and can greatly improve the transmission speed of optical signals and prolong the service life.

Owner:昆山迎翔光电科技有限公司

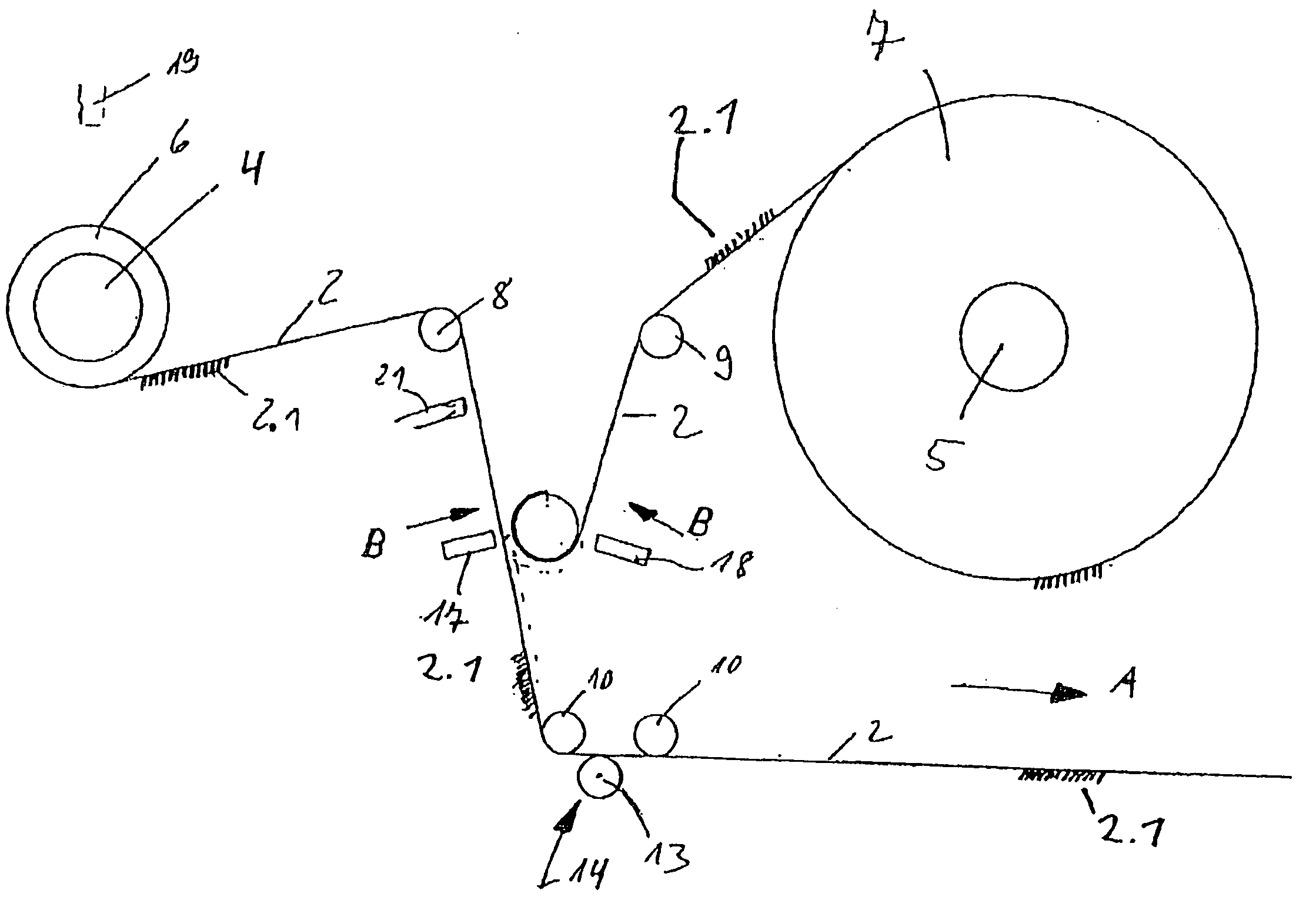

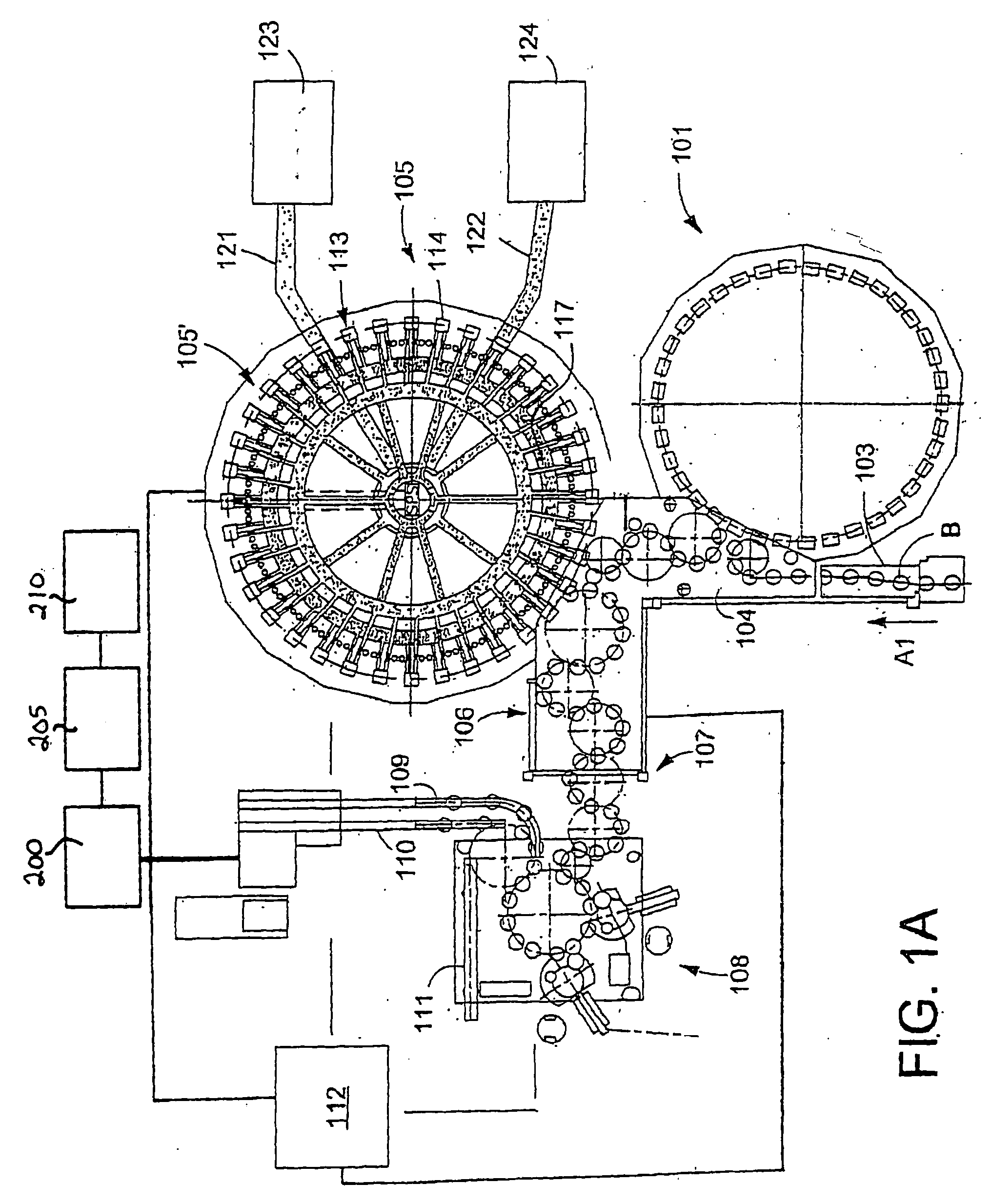

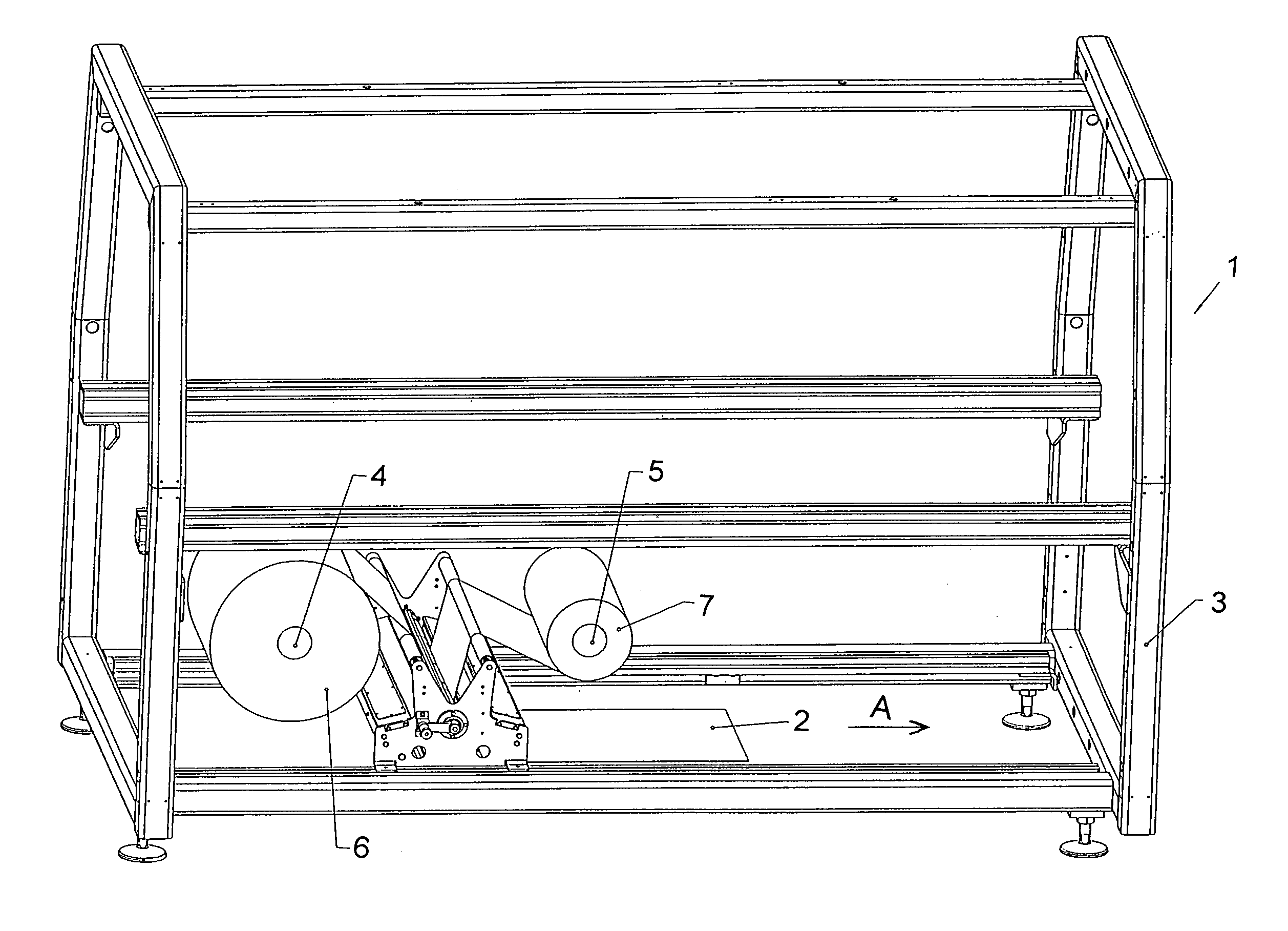

Beverage bottling plant for filling bottles with a liquid beverage material having a machine and method for wrapping filled bottles

InactiveUS7263812B2Performed easily and quicklyAccurate connection positioningMechanical working/deformationWrapping material feeding apparatusEngineeringBottle

A beverage bottling plant for filling bottles with a liquid beverage material having a machine and method for wrapping filled bottles, wherein one roll of wrapping material is replaced with a new roll of wrapping material quickly and accurately to minimize disruptions or interruptions in the bottle wrapping process.

Owner:KHS GMBH

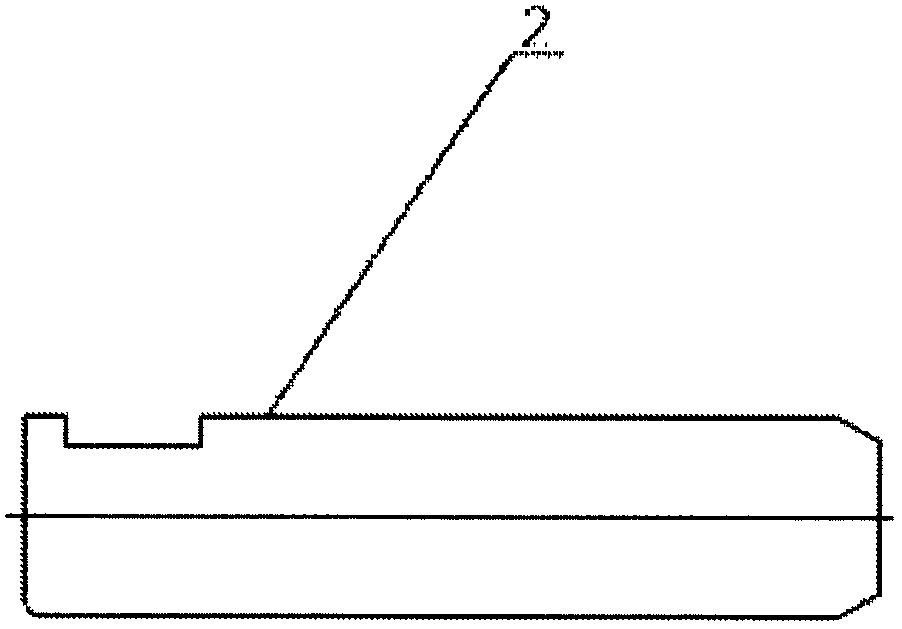

A sc-apc single-mode ceramic ferrule

InactiveCN102298177AReduce coupling lossAccurate connection positioningCoupling light guidesConical formsOblique angle

The invention discloses an SC-APC single-mode ceramic ferrule, which is installed in the center of an optical fiber connector and used in conjunction with a metal seat. The main body of the ceramic ferrule is in the shape of a cylinder; one end of the ceramic ferrule is tapered end; the tapered end is conical; the inner hole of the other end of the ceramic ferrule is provided with a conical groove; the angle between the oblique length of the tapered end and the axis of the ceramic ferrule is 30°±2°; the length of the ceramic ferrule is 10.50±0.05mm, the inner diameter is between 0.125-0.126mm, the outer diameter is 2.4990±0.0005mm, and the concentricity is not greater than 1μm. By designing the main body of the ceramic ferrule into a cylindrical shape, one end of the ceramic ferrule is designed as a conical end, the conical end is in the shape of a cone, and the inner hole of the other end is provided with a conical The groove achieves the purpose of small optical coupling loss of the ferrule, accurate connection positioning, convenient use, beautiful appearance, stable performance, and can greatly improve the transmission speed of optical signals and prolong the service life.

Owner:昆山迎翔光电科技有限公司

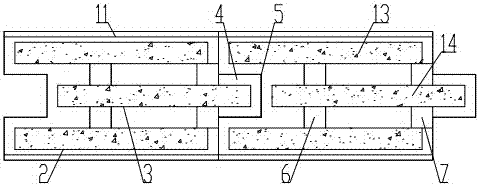

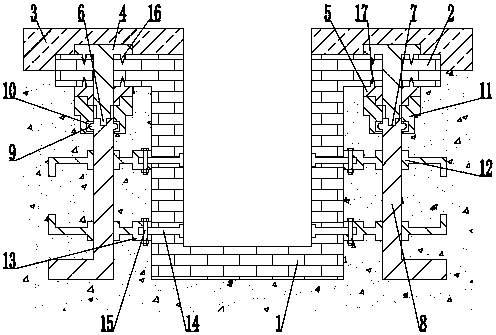

Energy-saving building brick and construction method

PendingCN107447906AAccurate connection positioningImprove stabilityConstruction materialWallsArchitectural engineeringBrick

The invention relates to an energy-saving building brick and a construction method. The energy-saving building brick comprises energy-saving building bricks, a heat-insulating plate and a matched heat-insulating plate, wherein the energy-saving building bricks include a left upper energy-saving building brick, a right upper energy-saving building brick, a left lower energy-saving building brick and a right lower energy-saving building brick; the heat-insulating plate holes are formed on the two sides of the energy-saving building bricks; the heat-insulating plate holes are matched with the heat-insulating plate; the heat-insulating plate is connected with the heat-insulating plate holes; matched heat-insulating plate holes are formed on the middle parts of the energy-saving building bricks; the matched heat-insulating plate holes are matched with the matched heat-insulating plate; the matched heat-insulating plate is connected with the matched heat-insulating plate holes; mounting bulge slots are formed on the left side of the energy-saving building bricks; mounting bulges are arranged on the right side of the energy-saving building bricks; the mounting bulges are matched with the mounting bulge slots; and the mounting bulge on the left upper energy-saving building brick is connected with the mounting bulge slot on the right upper energy-saving building brick.

Owner:TIANJIN XINGCHENG TONGDA TECH DEV CO LTD

SC fast-connecting ceramic ferrule

The invention discloses a SC fast-connecting ceramic ferrule which is assembled in the center of an optical fiber connector. The body of the ceramic ferrule is cylinder-shaped. One section of one end of the ceramic ferrule is shaped as a conical end. The conical end is shaped as a circular truncated cone. A conical groove is arranged at an inner hole of the other end of the ceramic ferrule. The included angle between the inclined length of the conical end and the axis of the ceramic ferrule is 30 degrees. The cylinder has a positioning groove which is 2.0mm wide. The length of the ceramic ferrule is (10.50+ / -0.05)mm, the inner diameter is between 0.1253mm and 0.1263mm, the outer diameter is (2.4990+ / -0.0005)mm, and the concentricity is not larger than 1 micron. The body of the ceramic ferrule is designed into a cylinder, one section of one end of the ceramic ferrule is designed into a conical end, the conical end is shaped as a circular truncated cone, and the conical groove is arranged at the inner hole of the other end, thus achieving the purposes of small optical coupling loss, accurate connection and positioning, convenient use, beautiful appearance, stable performance, greatly-improved light signal transmission speed and longer service life.

Owner:昆山迎翔光电科技有限公司

Magnetic resonance clinical patient head assisted fixation device and operation method thereof

PendingCN109924979AStable structureEasy to adjust connection statusDiagnostic recording/measuringSensorsResonanceMedicine

The invention relates to a magnetic resonance clinical patient head assisted fixation device and an operation method thereof. The device comprises a fixing plate, an adjusting rod, a limiting block, asupporting spring, a limiting rod, a positioning sleeve and a sliding rod, the lower side of the fixing plate has an adjusting rod groove, the adjusting rod groove is adapted to the adjusting rod, the adjusting rod is connected to the adjusting rod groove, the adjusting rod slides in the adjusting rod groove, the upper side of the adjusting rod groove and the upper side of the adjusting rod are connected by a tooth groove, the lower part of the adjusting rod groove has a limiting block groove, the limiting block groove is adapted to the limiting block, the limiting block is connected to the limiting block groove, the limiting block slides in the limiting block groove, and the upper surface of the limiting block is connected with the adjusting rod, and the limiting block is internally connected with the upper end of a supporting spring. The lower end of the support spring is connected to the fixing plate, the outer side of the fixing plate has a limiting protrusion, and the limiting protrusion is internally screwed to the limiting rod, and the inner end of the limiting rod is stuck on the limiting block.

Owner:陈飞

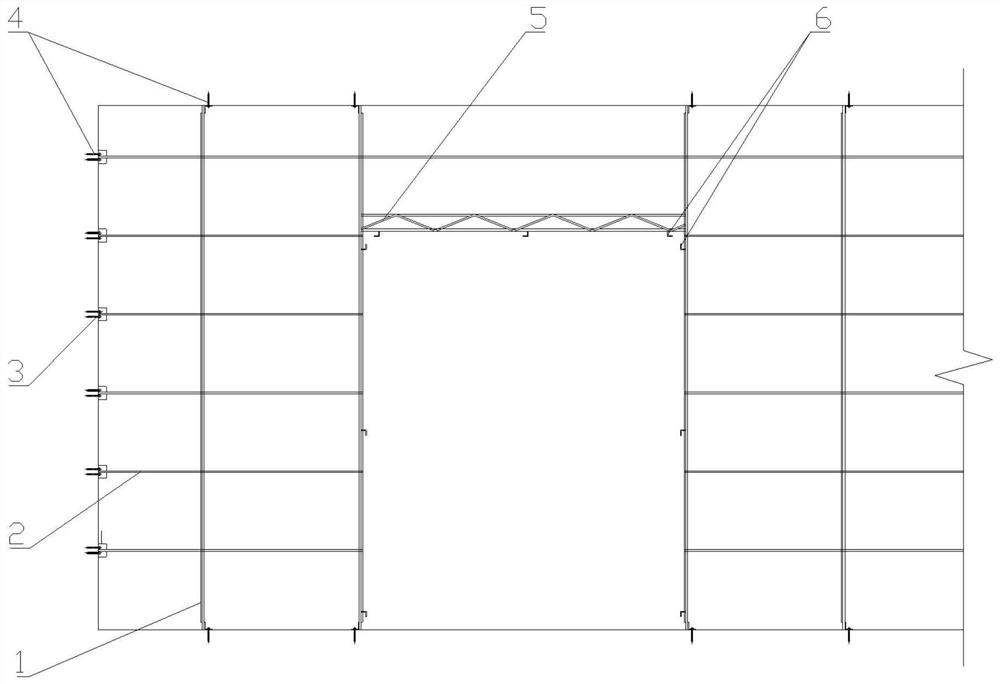

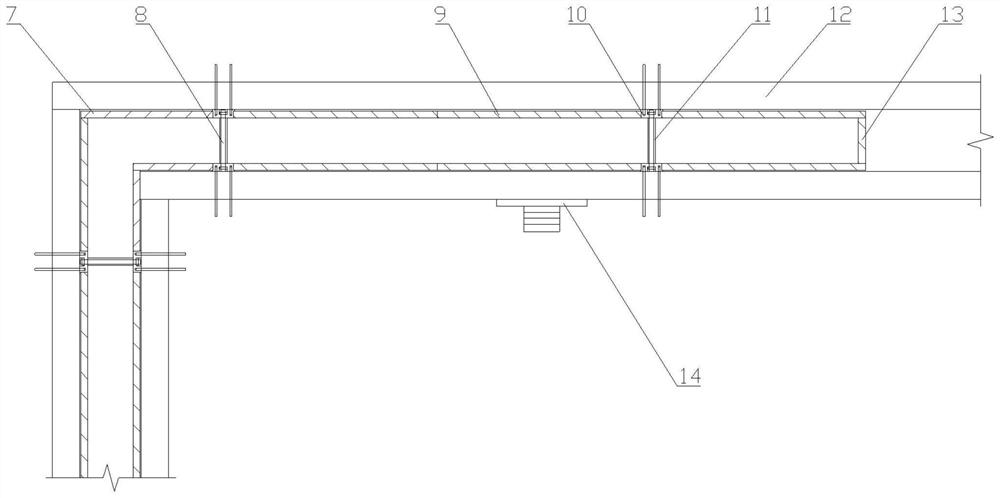

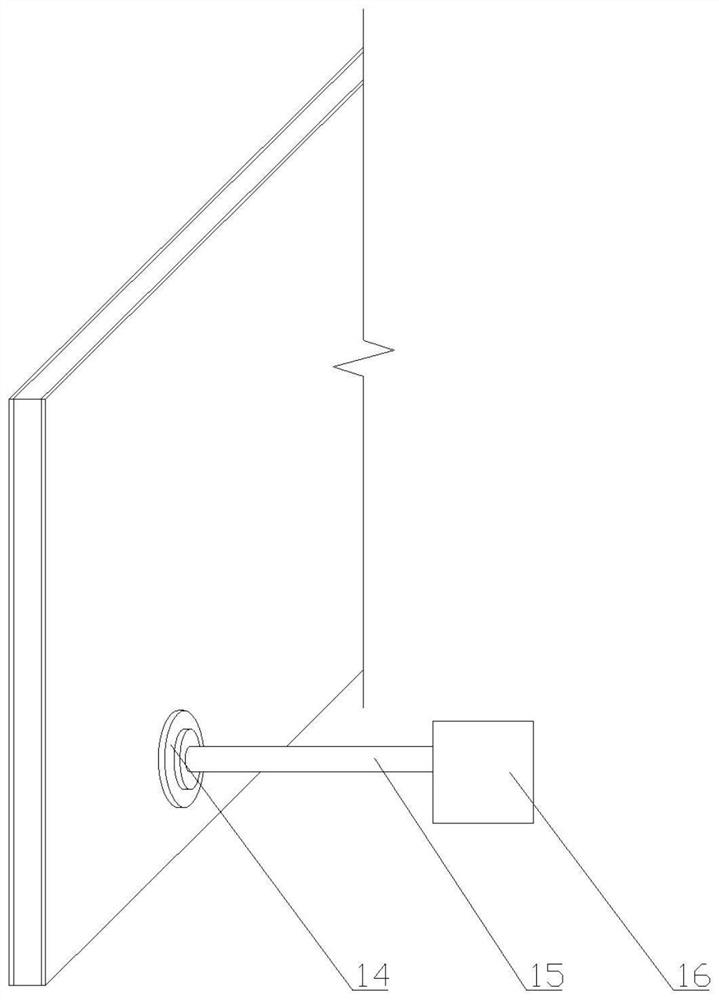

Steel bar truss keel standard formwork cast-in-place light concrete partition wall construction method

InactiveCN111764546AReduce installation processImprove work efficiencyWallsRebarArchitectural engineering

The invention relates to the technical field of building partition wall construction, in particular to a steel bar truss keel standard formwork cast-in-place light concrete partition wall constructionmethod, and aims at solving the problems that according to a concrete pouring construction method in the prior art, many installing procedures are adopted, the work efficiency is low, and cost is high. The steel bar truss keel standard formwork cast-in-place light concrete partition wall construction method comprises the following steps that firstly, a steel bar truss keel system is installed; secondly, a rapid-mounting formwork system is installed on the steel bar truss keel system; and thirdly, a light concrete pouring system is arranged on the rapid-mounting formwork system and used for pouring concrete into the steel bar truss keel system. A plurality of stand columns in the method are connected together through steel bar pull strips, during construction, only the rapid-mounting formwork system needs to be installed on the steel bar truss keel system, the light concrete pouring system is used for pouring concrete into the steel bar truss keel system, accordingly, the installing procedures are fewer, the work efficiency is higher, and cost is lower.

Owner:成都魔筑科技有限公司

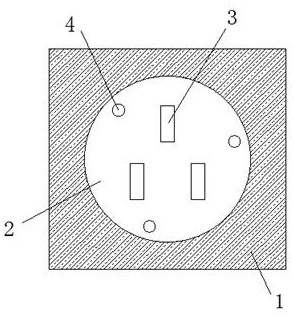

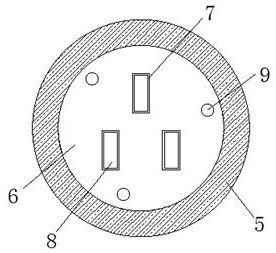

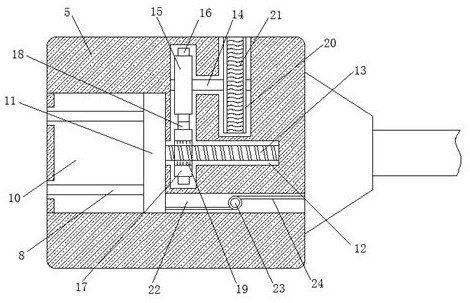

Novel protection device for weak electrical well

InactiveCN108678013AAvoid deformationReduce deformationArtificial islandsUnderwater structuresAgricultural engineeringFlange

The invention discloses a novel protection device for a weak electrical well. The novel protection device for the weak electrical well comprises the weak electrical well, concrete fixing layers, fastening blocks, fastening flanges, pre-embedded rods, rotary sleeves, location sleeves, reinforcing rods and fastening rods, wherein the concrete fixing layers are connected to the upper side of the weakelectrical well; well edges are arranged at the two sides of the weak electrical well; one fastening block is connected to the middle part of each well edge; fixing bulges are arranged at the two sides of each fastening block; the fixing bulges are connected with the upper side of the corresponding well edge; one fastening block is connected to the middle part of each fastening flange; matching fixing bulges are arranged at the two sides of each fastening flange; the matching fixing bulges are connected with the lower side of the corresponding well edge; one fastening bulge is arranged at thelower end of each fastening block; each pre-embedded rod is provided with a fastening bulge groove; each fastening bulge groove is connected with the corresponding fastening bulge; rotary bulges arearranged at the two sides of each pre-embedded rod; one location sleeve is connected to the lower side of each fastening block through a thread; and one rotary sleeve is connected to the lower side of each location sleeve.

Owner:天津企鸿科技有限公司

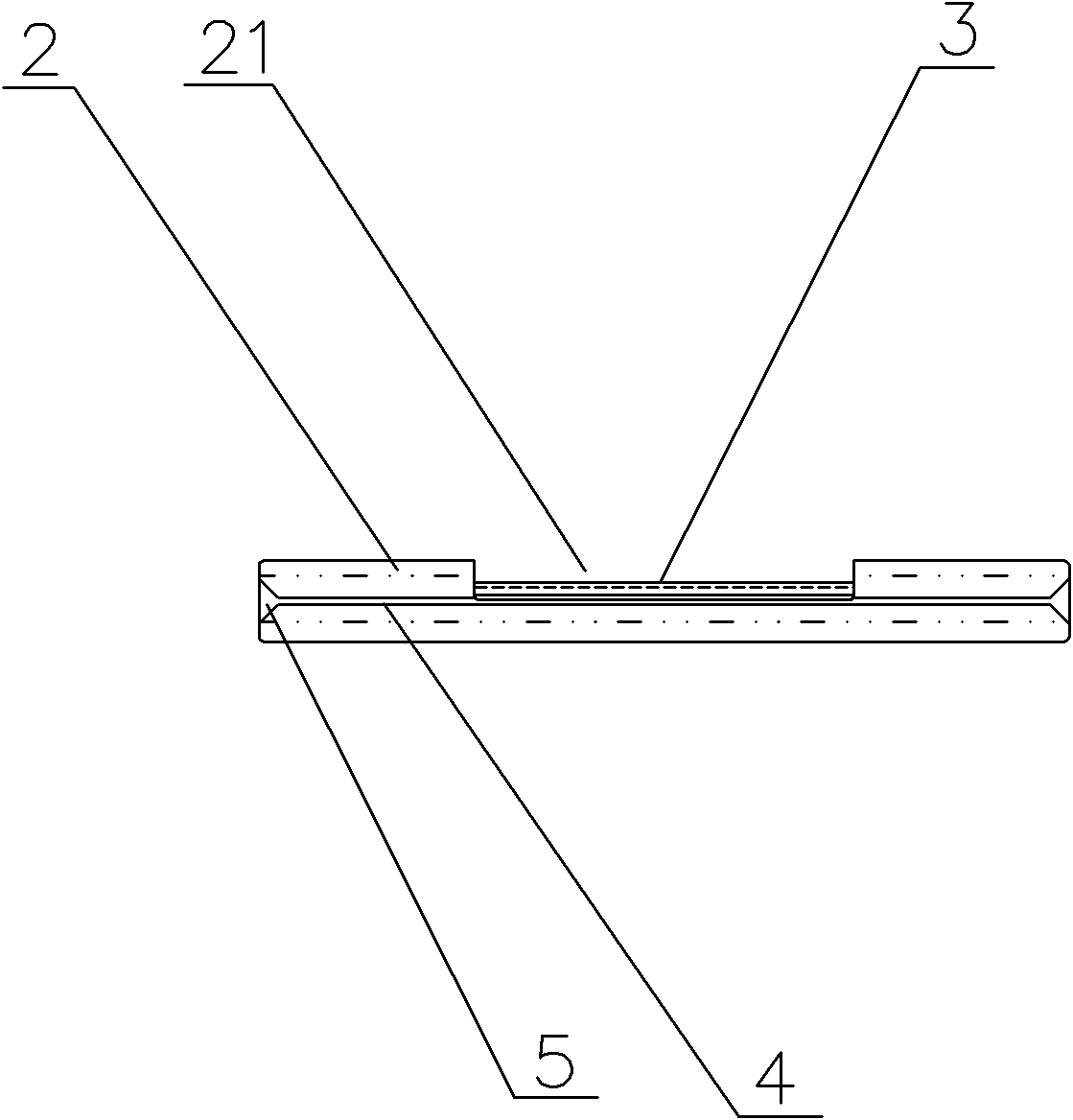

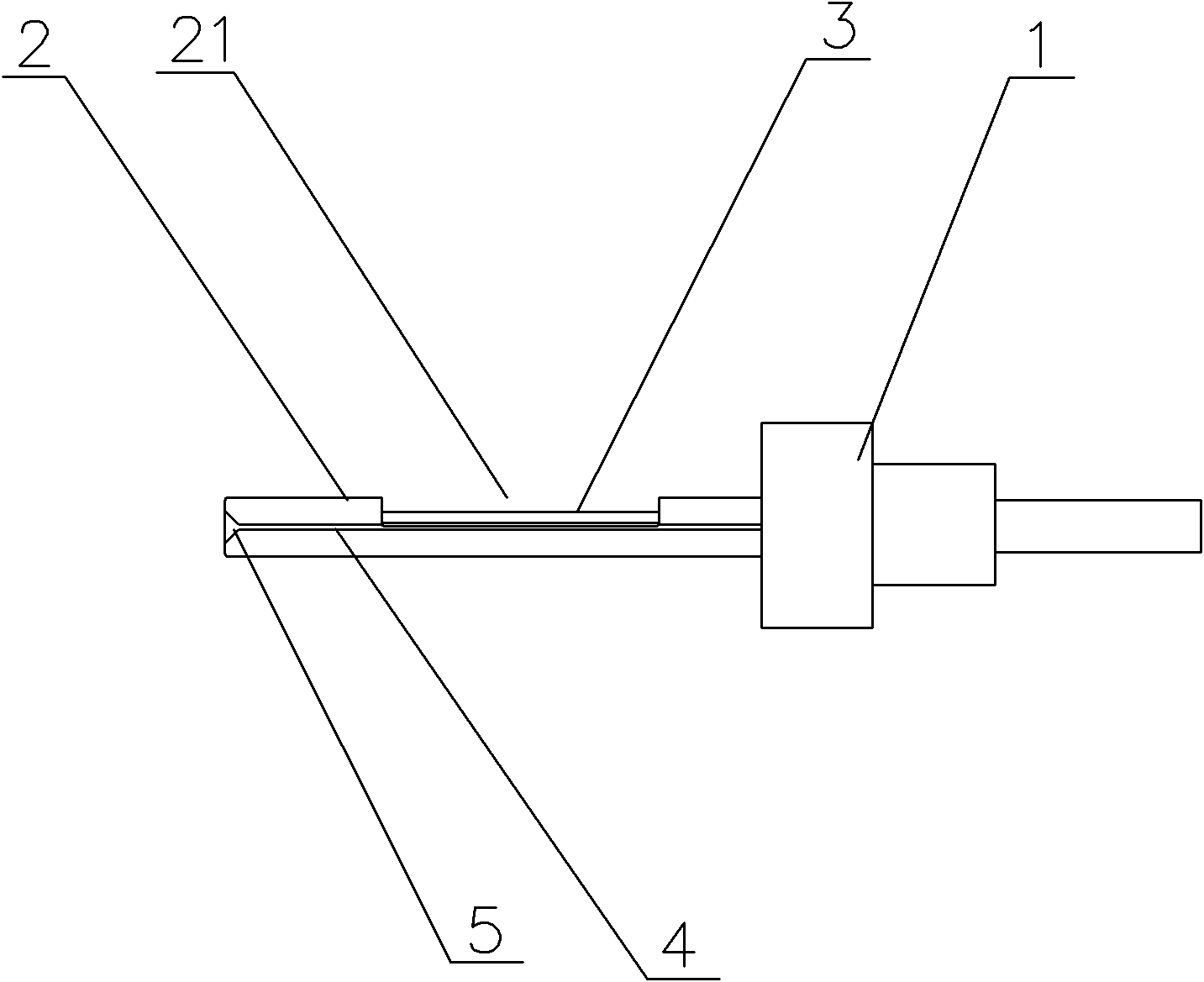

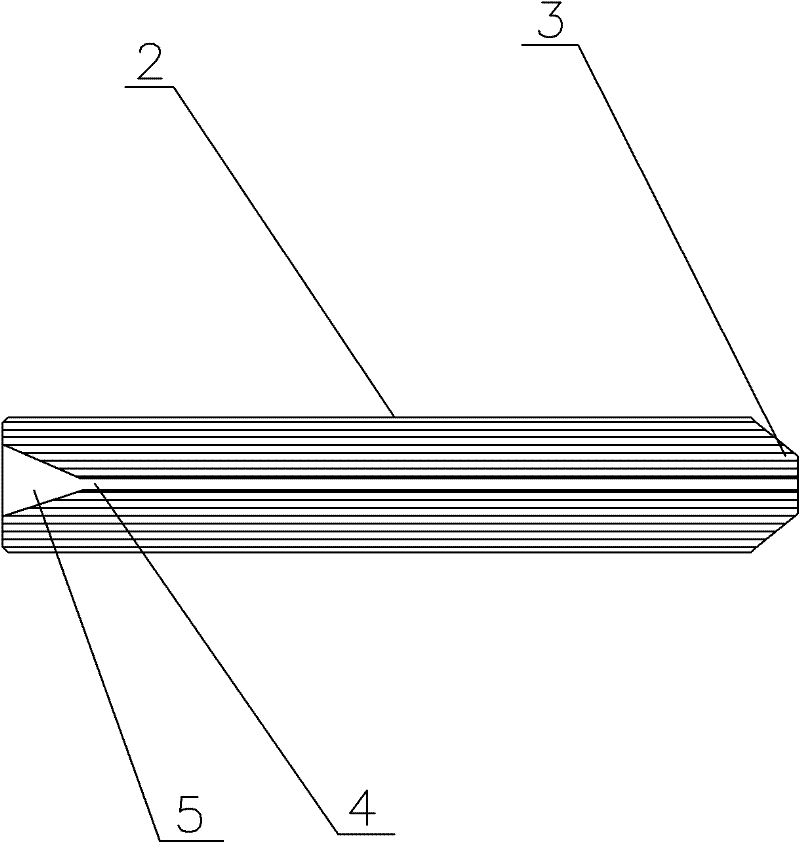

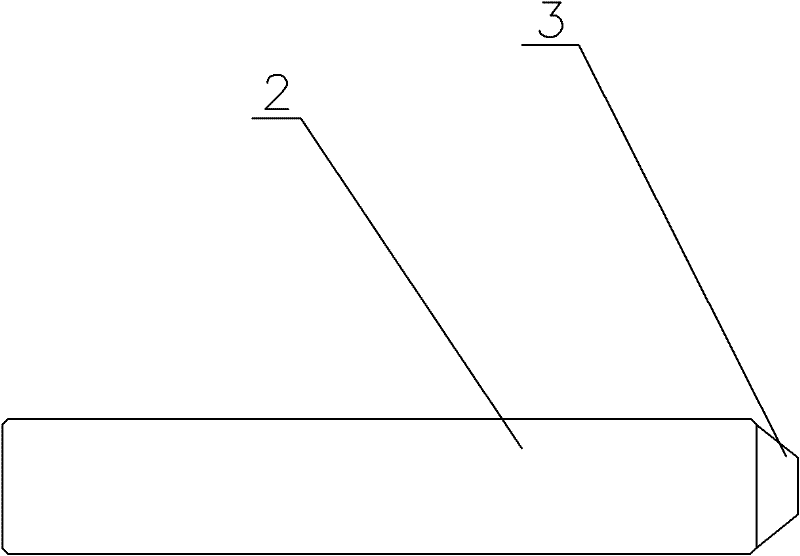

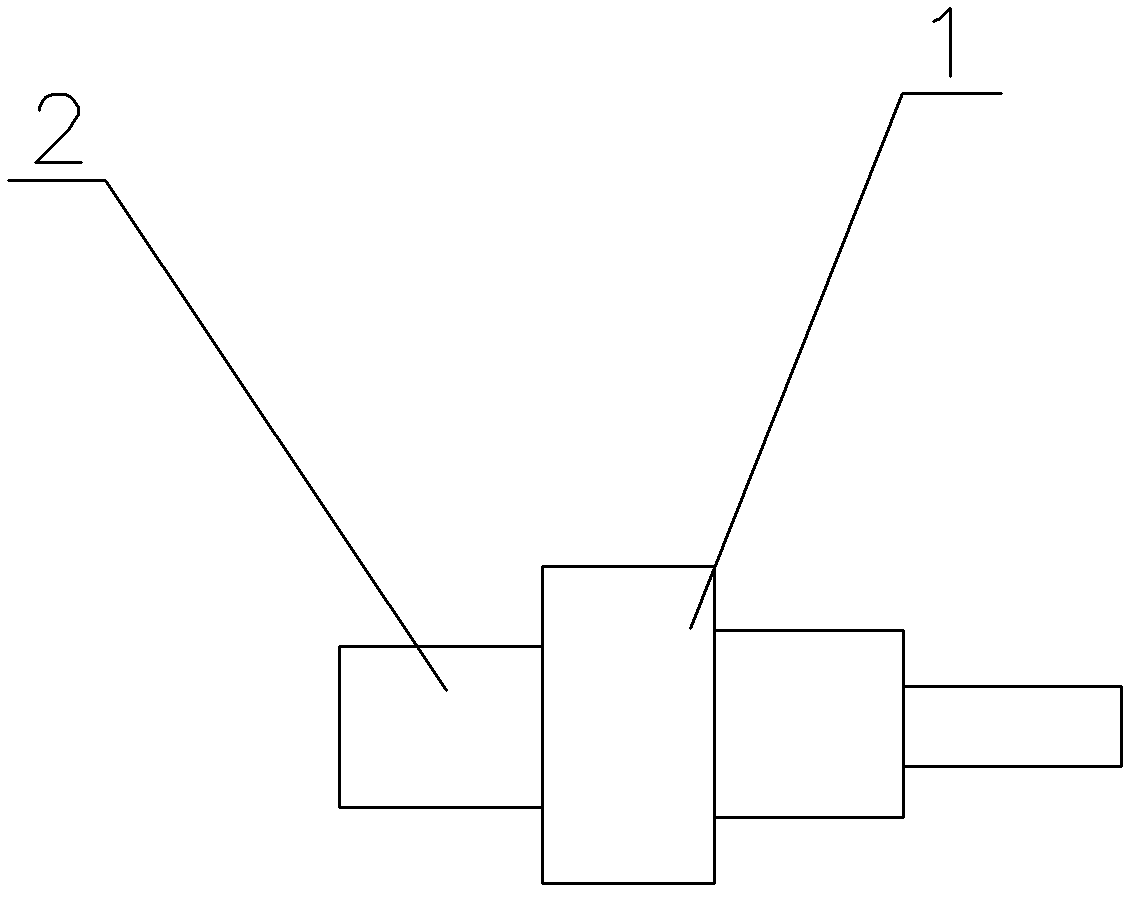

Improved FX2 embossing roller for packaging machine

InactiveCN105775255AAccurate connection positioningReduce frictionPackaging cigaretteGear drivePulp and paper industry

The invention discloses an improved FX2 embossing roller for a packaging machine. The improved FX2 embossing roller for the packaging machine comprises a roller A and a roller B, wherein the roller A is in transmission connection with the roller B through a gear pair, concave positioning patterns are processed at one end of the roller cylinder of the roller A, convex positioning patterns are processed at one end of the roller cylinder of the roller B, the concave positioning patterns on the roller A are engaged with the convex positioning patterns on the roller B, and the roller A and the roller B are axially positioned. The roller A and the roller B in the FX2 embossing roller for the packaging machine are very accurately connected and positioned, so that decorative patterns embossed on aluminum-foil paper or recycled paper are very clear and consistent. As the transmission between the roller A and the roller B depends on gears, the friction force of the roller A and the roller B is reduced, and the service life is prolonged.

Owner:SHANGHAI QINCHANG RIBBON FACTORY

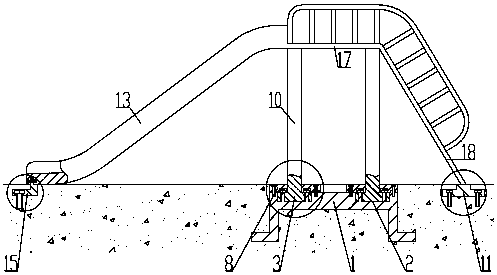

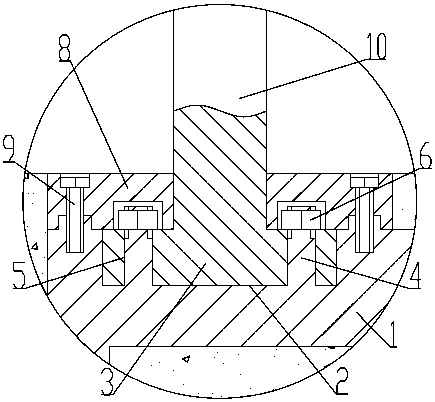

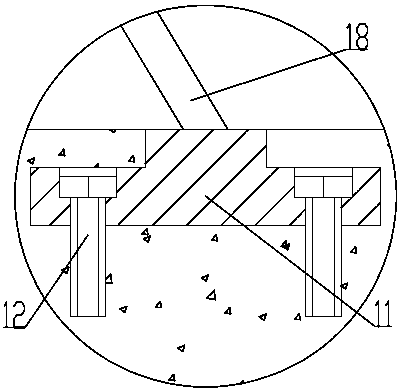

Novel children's slide convenient to fix

The invention discloses a novel children's slide convenient to fix. The novel children's slide comprises a middle mounting base, a fastening flange, a plurality of support rods, a right mounting base,a left mounting base and a children's slide. The multiple support rods are connected with the middle of the children's slide, positioning flanges are arranged on the lower portions of the support rods, the middle mounting base is connected with the ground, positioning flange grooves are formed in two sides of the middle mounting base and are matched with the positioning flanges, the positioning flanges are connected with the positioning flange grooves and are inserted in the positioning flange grooves, positioning rods are arranged on two sides of each positioning flange groove, positioning rod grooves are formed in two sides of each positioning flange and are matched with the corresponding positioning rods, the positioning rods are connected with the positioning rod grooves and are inserted in the positioning rod grooves, and positioning nuts are connected with the upper portions of the positioning rods and mesh with the positioning rods.

Owner:FAIRHILL TECH TIANJIN CO LTD

Battery positive tab transfer structure and welding method

ActiveCN105261726BFirmly connectedPrecise positioningSmall-sized cells cases/jacketsLaser beam welding apparatusElectrical resistance and conductanceElectric resistance welding

Owner:ZHEJIANG CHAOWEI CHUANGYUAN INDUSTRAIAL

Water purifier inspection and maintenance table

PendingCN107971057AStable structureAccurate connection positioningMeasurement devicesLaboratory benches/tablesAgricultural engineering

Owner:天津东研润泽科技股份有限公司

Cabin cover support plate for wind generating set

InactiveCN110566416AEasy to changeAccurate connection positioningMachines/enginesWind energy generationArchitectural engineeringFlange

The invention relates a cabin cover support plate for a wind generating set. A cabin cover plate, a support plate, limit plates, a fastening flange and a fixed cover are included, the two ends of thecabin cover plate are provided with fixed convex plates, fixed protrusions are arranged on the lower sides of the fixed convex plates, the fixed protrusions are matched with the support plate, the support plate is connected to the fixed protrusions, the support plate is clamped in the fixed protrusions, the upper sides of the fixed convex plates are connected to the limit plates, the limit platesare clamped on the fixed convex plates, the two sides of the support plate are provided with positioning rods, the positioning rods are sequentially connected to the fixed convex plates and the limitplates, the left end of the cabin cover plate is provided with a fixed convex rod, the middle of the fixed cover is in threaded connection with the fixed convex rod, the inner side of the cabin coverplate is connected with the fastening flange, the cabin cover plate is provided with a fastening rod, and the fastening rod passes through the fastening flange to be connected with a fastening nut.

Owner:天津市盛佳怡电子有限公司

Novel electric energy meter box fixing device

PendingCN108120860ARelatively structurally stableImprove stabilityTime integral measurementEngineeringElectric energy

A novel electric energy meter box fixing device comprises an electric energy meter box, mounting fixing blocks, mounting fixing sleeves, fixing rods and fixing nuts. Two sides of the electric energy meter box are provided with mounting fixing block troughs. The mounting fixing block troughs are adapted with the mounting fixing blocks. The mounting fixing blocks are connected with the mounting fixing block troughs. Two sides of the mounting fixing block are provided with fastening projections. The fastening projections are connected with the electric meter box through a fastening nut. The mounting fixing sleeve is internally provided with a fixing trough. The outer end of the mounting fixing block is adapted with the fixing trough. The mounting fixing sleeve slides on the mounting fixing block. The mounting fixing block is inserted into the fixing trough. The outside of the mounting fixing sleeve is provided with a fixing rod trough. The fixing rod trough is adapted with the fixing rod.The fixing rod is connected with a fixing rod trough through a mounting nail. The mounting tail is successively connected with the fixing sleeve and the fixing rod. The fixing rod is inserted into the fixing rod trough.

Owner:TIANJIN TIANHUITONG TECH

A large aperture ceramic ferrule

InactiveCN102289043AReduce coupling lossAccurate connection positioningCoupling light guidesLight signalOptical fiber connector

The invention discloses a large-aperture ceramic ferrule, which is installed in the center of an optical fiber connector and used in conjunction with a metal seat. The main body of the ceramic ferrule is in the shape of a cylinder; one end of the ceramic ferrule has a tapered end; The tapered end is conical; the length of the ceramic ferrule is 2.5±0.05mm, the inner diameter is 0.5±0.02mm, the outer diameter is 2.499±0.0005mm, and the concentricity is not greater than 1μm; the other end of the ceramic ferrule A conical groove is provided at the inner hole of the head. By designing one section of one end of the ceramic ferrule as a tapered end, the tapered end is in the shape of a truncated cone, and the inner hole of the other end is provided with a conical groove, so that the optical coupling loss of the ferrule is small, The connection and positioning are accurate, easy to use, beautiful in appearance, stable in performance, and can greatly improve the transmission speed of optical signals and prolong the service life.

Owner:昆山迎翔光电科技有限公司

Optical fiber connector

InactiveCN106707420AImprove performanceReduce coupling lossCoupling light guidesCoupling lossInstability

The invention discloses an optical fiber connector comprising a ceramic inserting core, a ceramic bushing and an integrally formed bushing shell. An installing cavity is formed along the axial direction of the bushing shell. The installing cavity comprises a first cavity having the first diameter and a second cavity having the second diameter. The first cavity is close to the end of opening. The first diameter is greater than the second diameter. One end of the ceramic inserting core is installed in the first cavity. The ceramic bushing is installed in the installing cavity and arranged between the ceramic inserting core and the bushing shell. According to the structure of the optical fiber connector, the problem of matching instability of metal pieces caused by the fact that the stability of the electrical isolation mode is influenced by the error of structural assembling clearance and influenced by the stress of welding can be solved; and the structure achieves the objectives that the inserting core optical coupling loss is low, connection and positioning are accurate, use is convenient, the appearance is beautiful and the performance is stable and the optical signal transmission speed can be greatly enhanced and the service life can be prolonged.

Owner:KUNSHAN XINYUTONG OPTOELECTRONICS TECH CO LTD

Constructing module component

PendingCN108590247AHigh strengthAccurate connection positioningShow shelvesShow hangersComputer moduleEngineering

Owner:YEEDAA ENVIRONMENTAL TECH SHANGHAI CO LTD

Spline Shaft Forging Process of Drive Shaft

ActiveCN103537595BReduce manufacturing difficultyReduce manufacturing costForging/hammering/pressing machinesDrive shaftMedium frequency

Owner:XUCHANG ZHONGXING FORGING +1

Novel children climbing wall device

PendingCN107648824ANot easy to shakeAccurate connection positioningGymnastic climbingMovement coordination devicesArchitectural engineeringIliac screw

Owner:FAIRHILL TECH TIANJIN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com