Cabin cover support plate for wind generating set

A technology for wind turbines and support plates, which is applied to wind turbines, wind energy power generation, engines, etc., can solve the problems of deformation of the nacelle cover, prone to gaps, structural instability, etc., and achieve accurate connection positioning, not easy to crack, not easy to change. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below according to accompanying drawing and embodiment the present invention will be described in further detail:

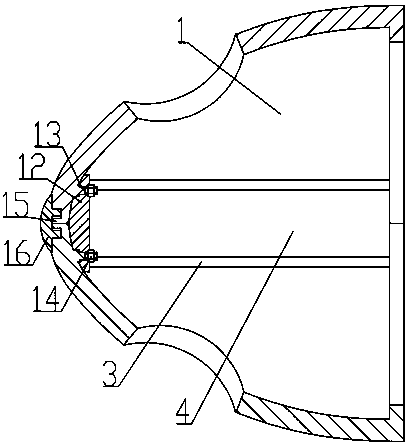

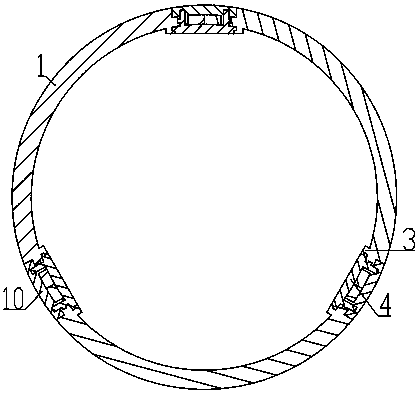

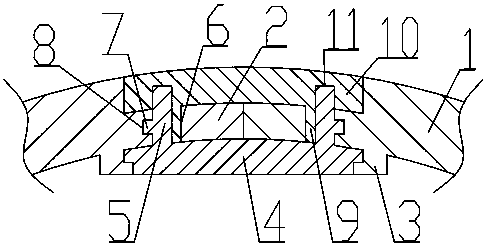

[0018] A support plate for a nacelle cover for a wind power generating set, comprising a nacelle cover plate 1, a support plate 4, a limiting plate 10, a fastening flange 12, and a fixed cover 16. The two ends of the nacelle cover plate 1 have fixed convex plates 2, The lower side of the fixed convex plate 2 has a fixed protrusion 3, the fixed protrusion 3 is adapted to the support plate 4, the support plate 4 is connected to the fixed protrusion 3, and the support plate 4 is stuck in the fixed protrusion 3 , the upper side of the fixed convex plate 2 is connected to the limit plate 10, the limited plate 10 is stuck on the fixed convex plate 2, and the two sides of the support plate 4 have positioning rods 5, and the positioning rods 5 are connected to the fixed convex plate in turn. Plate 2, limit plate 10, the left end of the nacelle cover plate 1 has a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com