Air heating tobacco curing machine with improved heating performance

An air heating and flue-curing machine technology, applied in the field of flue-curing machines, can solve the problems of single implementation of flue-curing machines, affecting the user's experience of use, and difficulty in curing all cut tobacco, so as to avoid heat loss, avoid heat loss, Avoid wasting cut tobacco

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

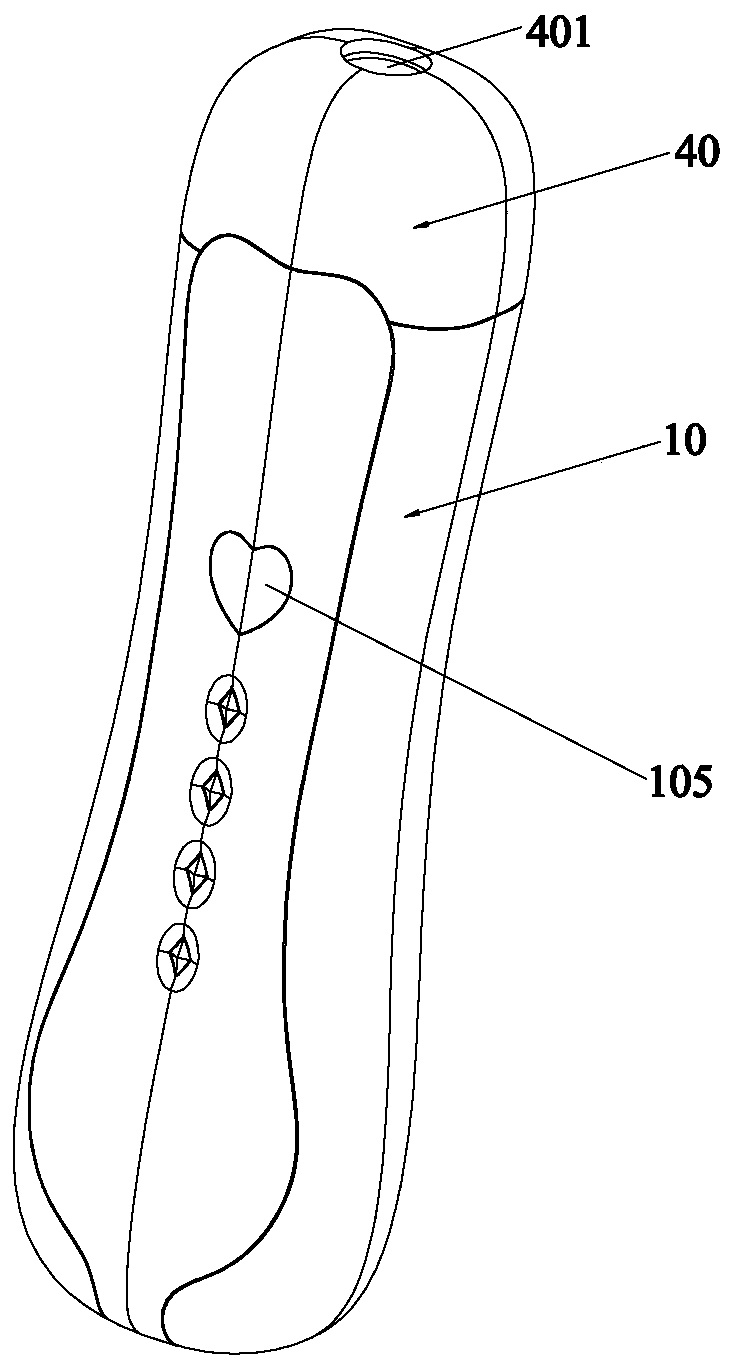

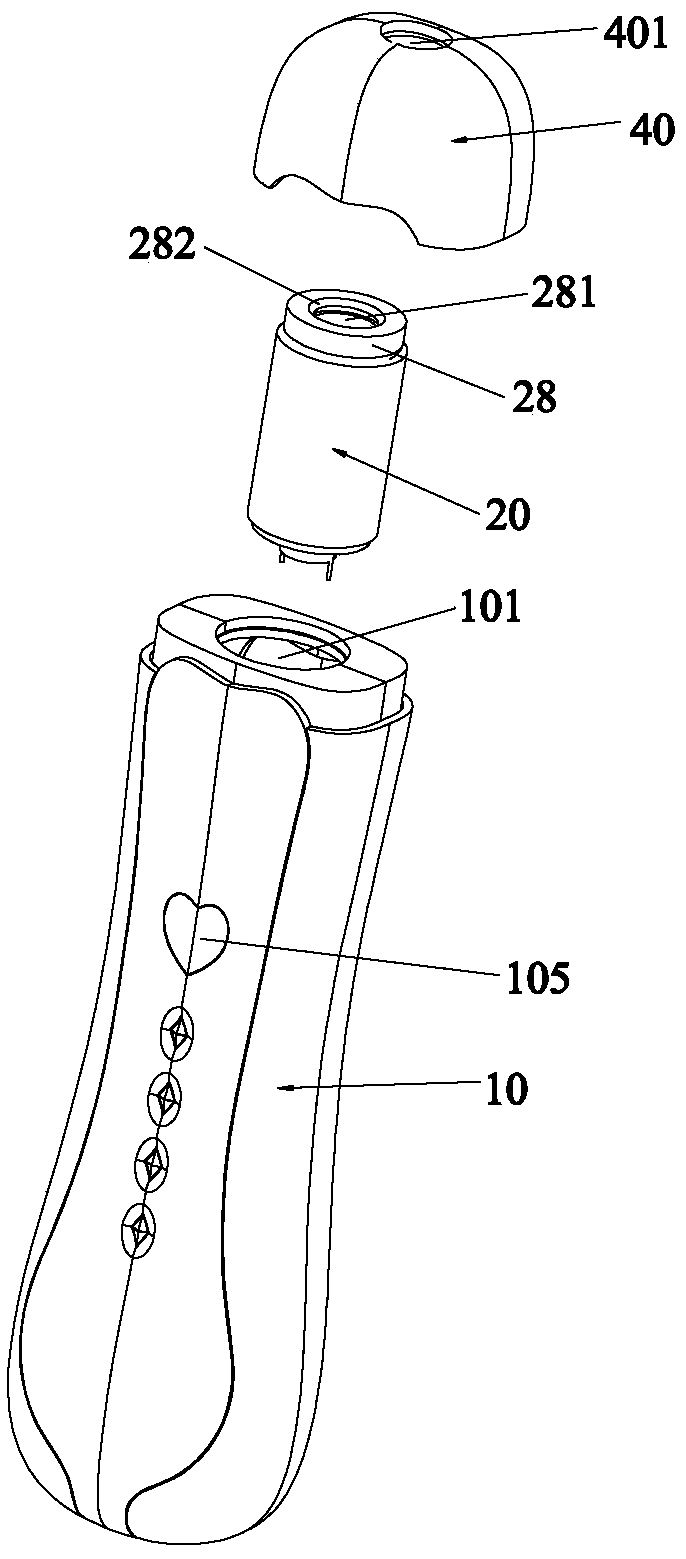

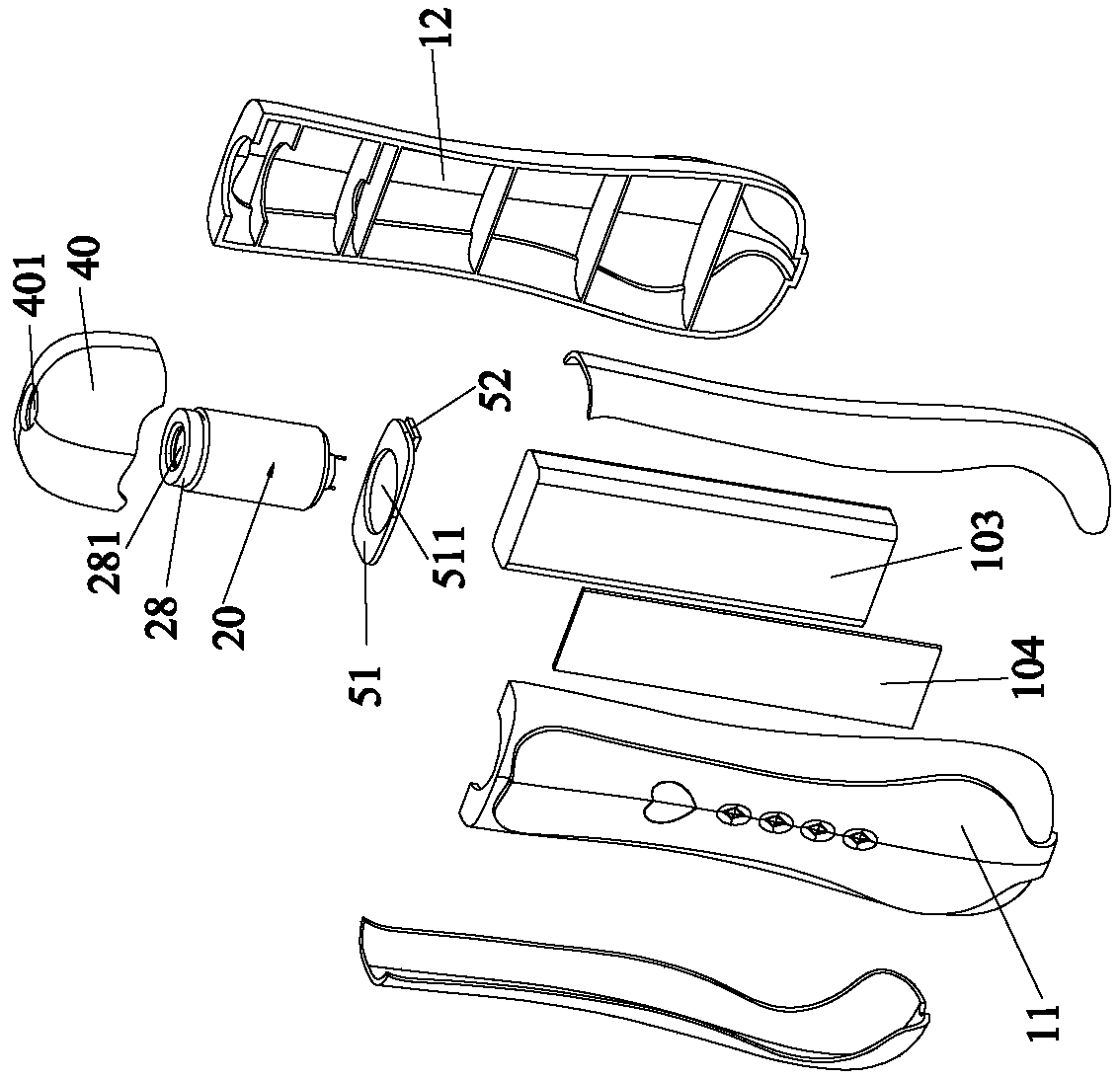

[0075] like Figure 1 to Figure 11 As shown, an air heating tobacco flue-curing machine with improved heating performance includes a casing 10 and a heating and heat preservation device 20 installed on the casing 10, the casing 10 includes a front casing 11 and a rear casing 12, the front casing 11 and the rear casing 12 The rear case 12 encloses the following installation cavity 101, wherein:

[0076] The left side and the right side of the housing 10 are connected with a left side bar and a right side side bar through buckles 211 . The housing 10 has an installation cavity 101 and a first air inlet 102 , and the heating and heat preservation device 20 is installed in the installation cavity 101 . A battery is installed in the installation cavity 101 of the housing 10. In Embodiment 1 and Embodiment 2, the battery is a rechargeable battery 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com