Patents

Literature

73results about How to "Fully baked" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

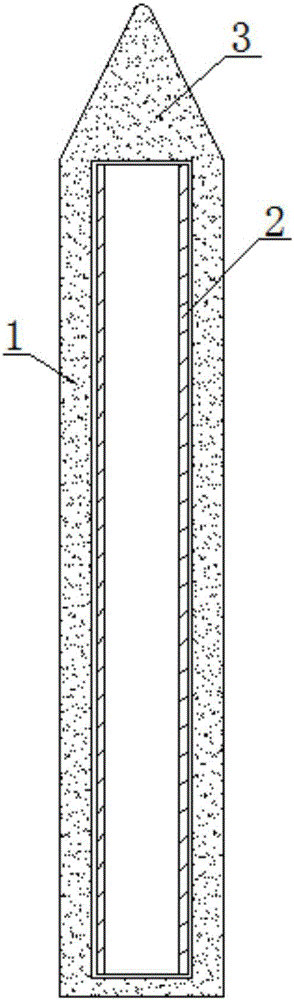

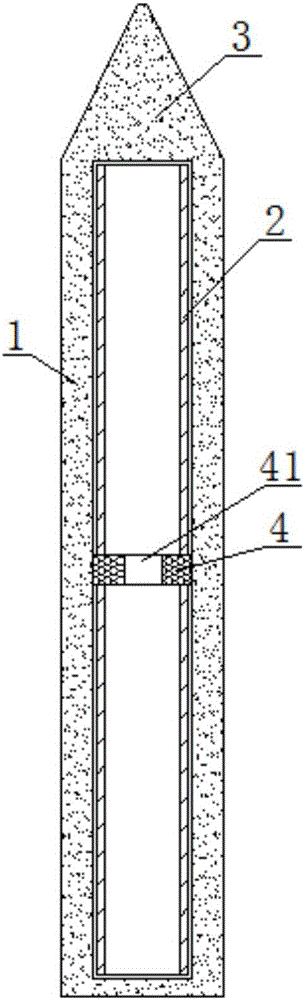

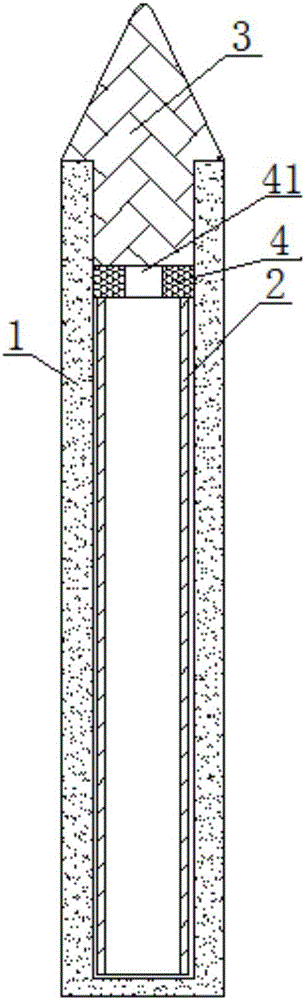

Heating body and curing object matched with heating body, electronic cigarette atomizer and electronic cigarette

PendingCN106617325AImprove yield rateAchieve atomizationTobacco devicesEngineeringAlternating current

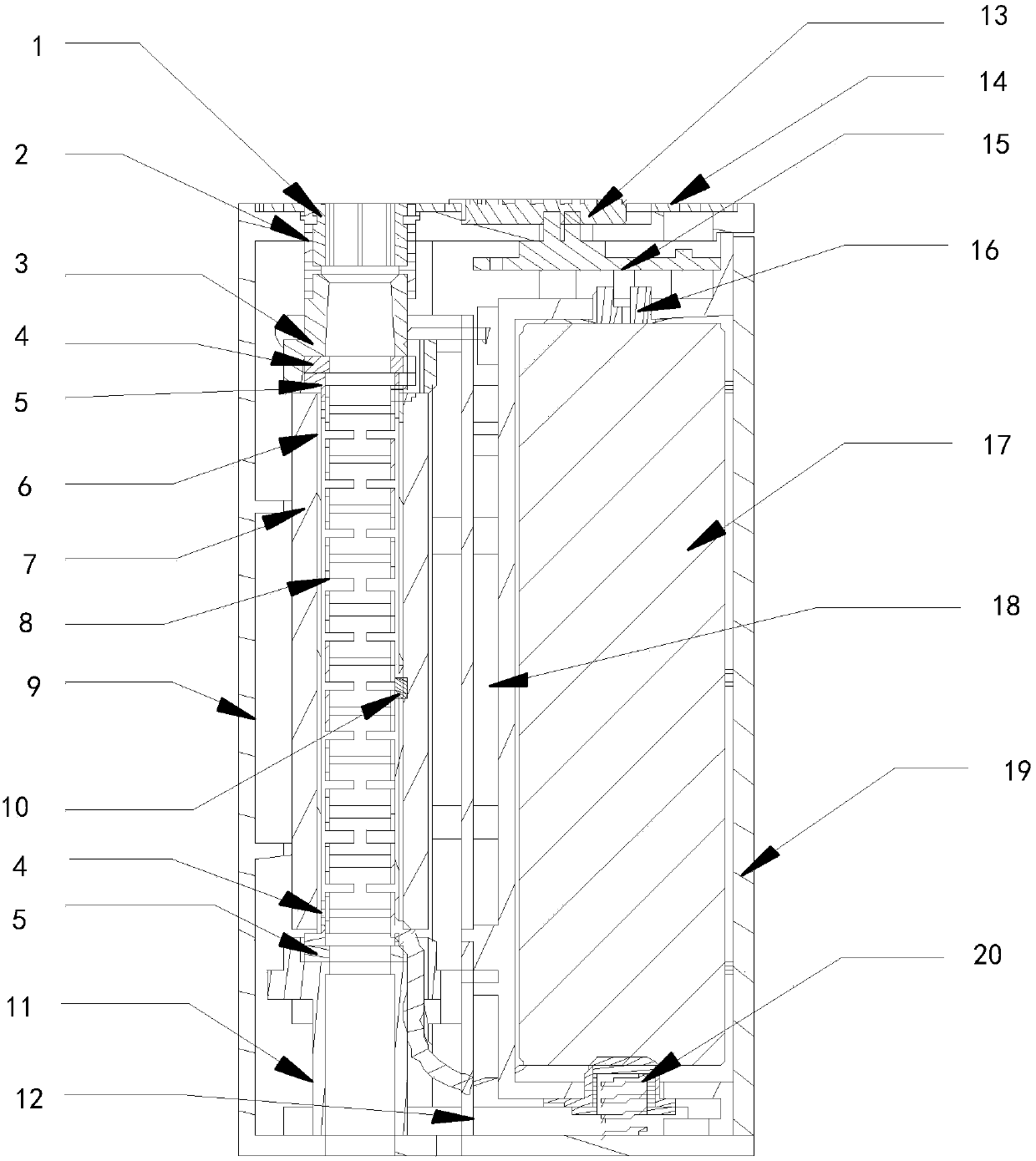

The invention discloses a heating body and a curing object matched with the heating body, an electronic cigarette atomizer and an electronic cigarette. The heating body comprises a glass sleeve and multiple sections of metals which are embedded in the glass sleeve and are capable of generating magnetic induction intensity, a conical body in which the curing object is pierced is arranged at the front end of the glass sleeve; isolating layers for controlling various sections to generate heat independently are arranged between the adjacent metals; and pressure discharge holes are formed in the isolating layers. According to the invention, by conducting self-heating in a mode of electromagnetic induction heating and by generating high-frequency induction current for alternating current through DC conversion, the metals become heated to cure tobacco shreds, so that flavors and fragrances as well as fragrance compounds in the tobacco shreds are volatilized and atomized; by virtue of the glass sleeve, stuffing is prevented from getting oxidized or contaminated by the metals and staged heating is facilitated, so that a heating rate is uniform, curing is conducted fully, a heating rate is moderate and the cured tobacco shreds are pure in fragrance; and in addition, a sachet can be pierced to add relative aromatizing and atomizing aids.

Owner:湖南酷伯新晶电子科技有限公司

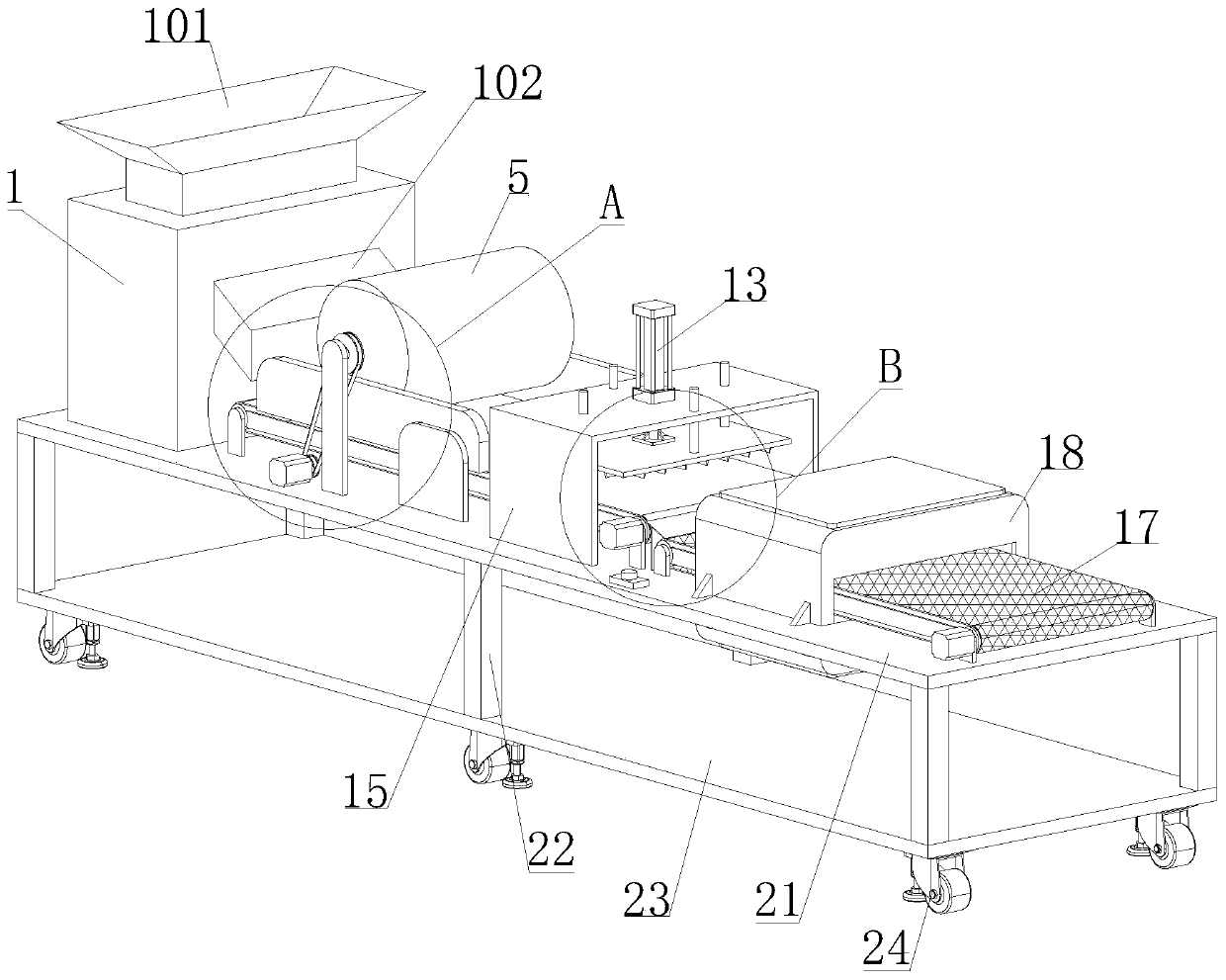

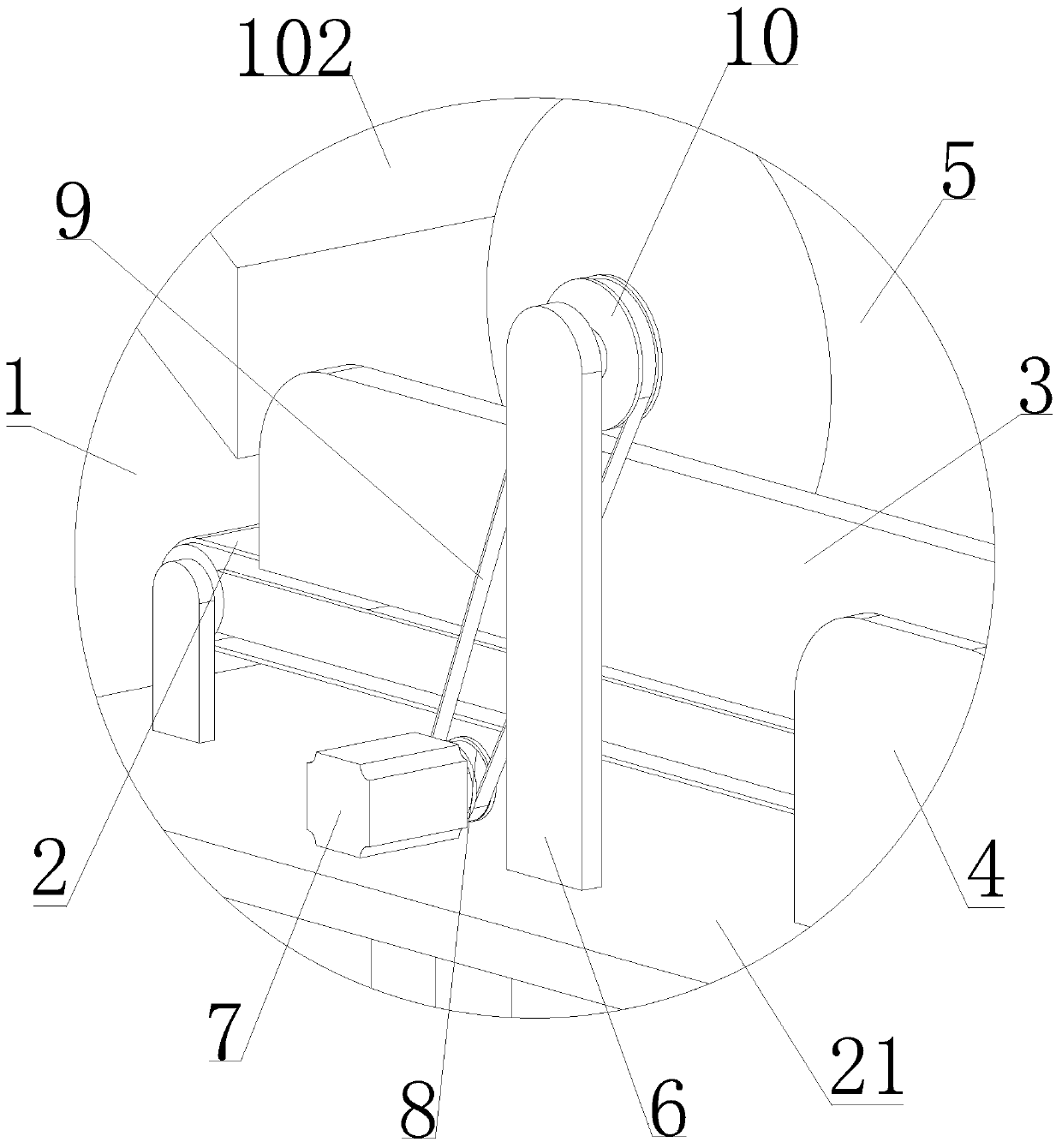

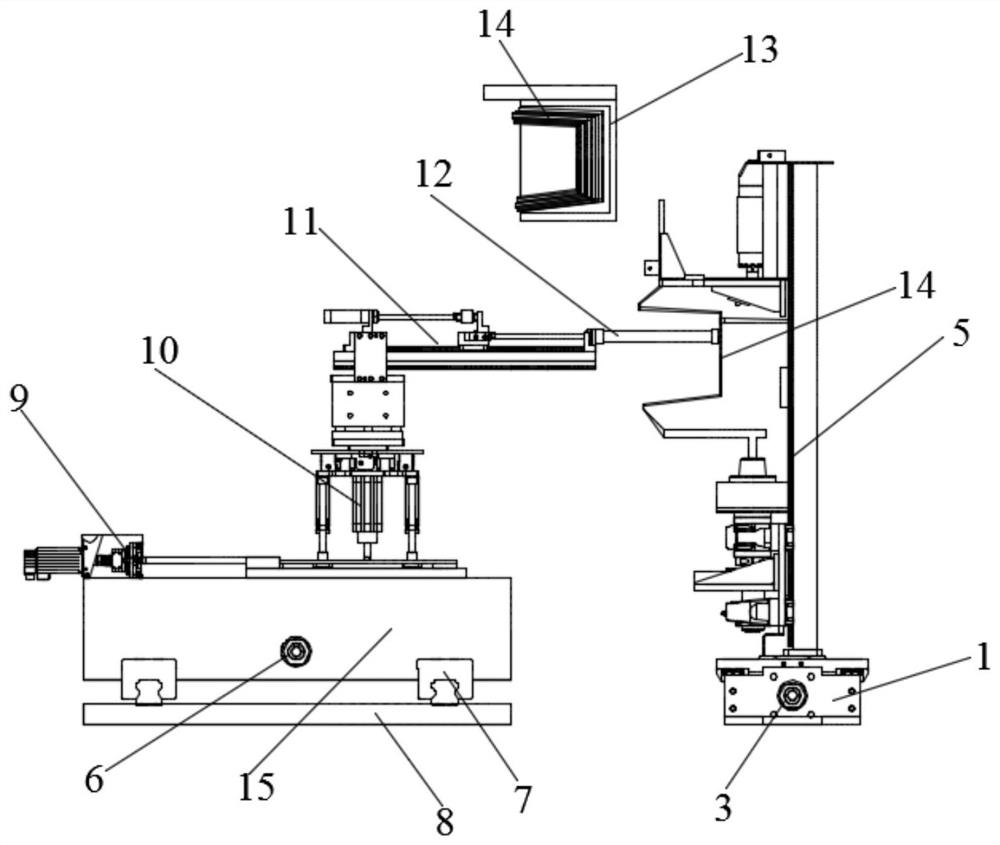

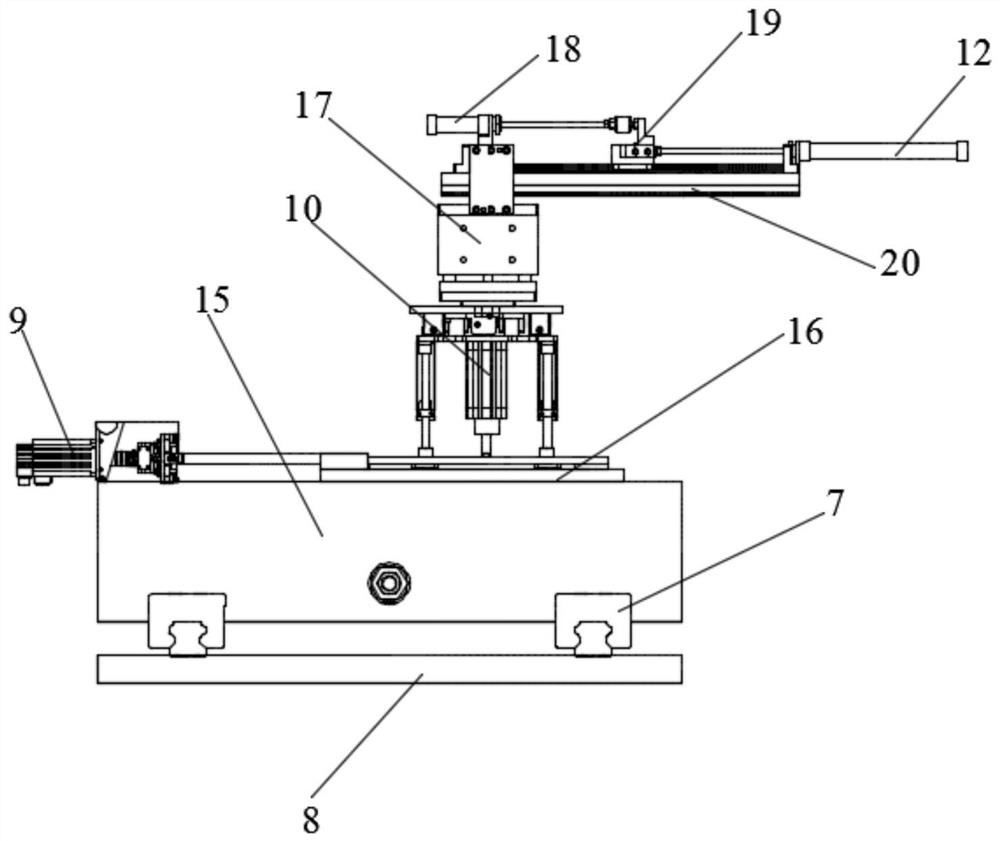

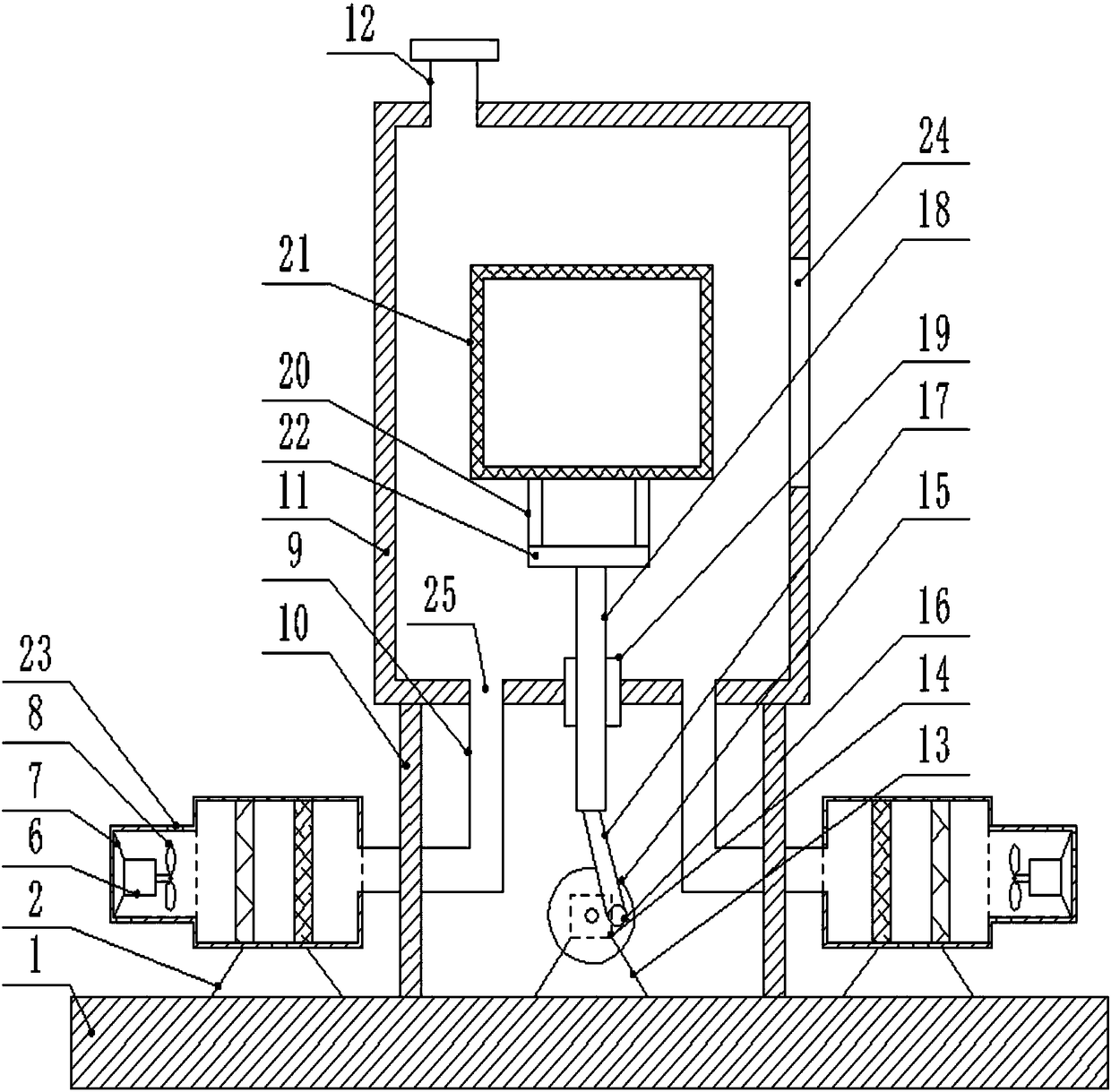

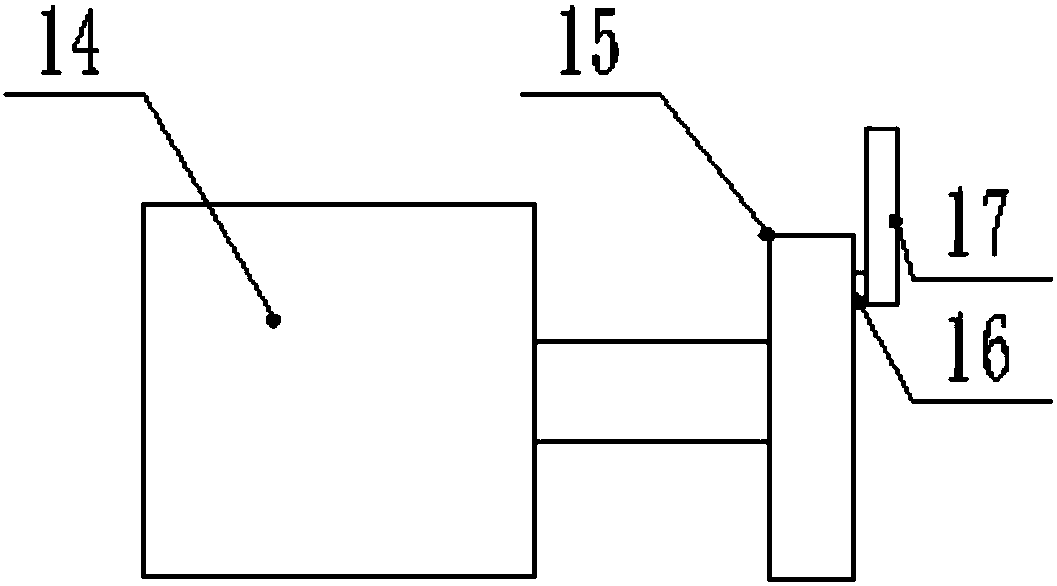

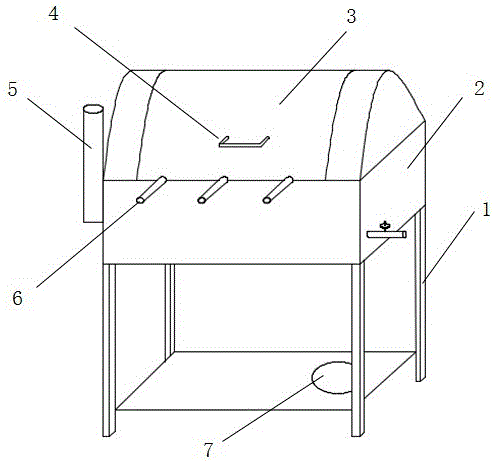

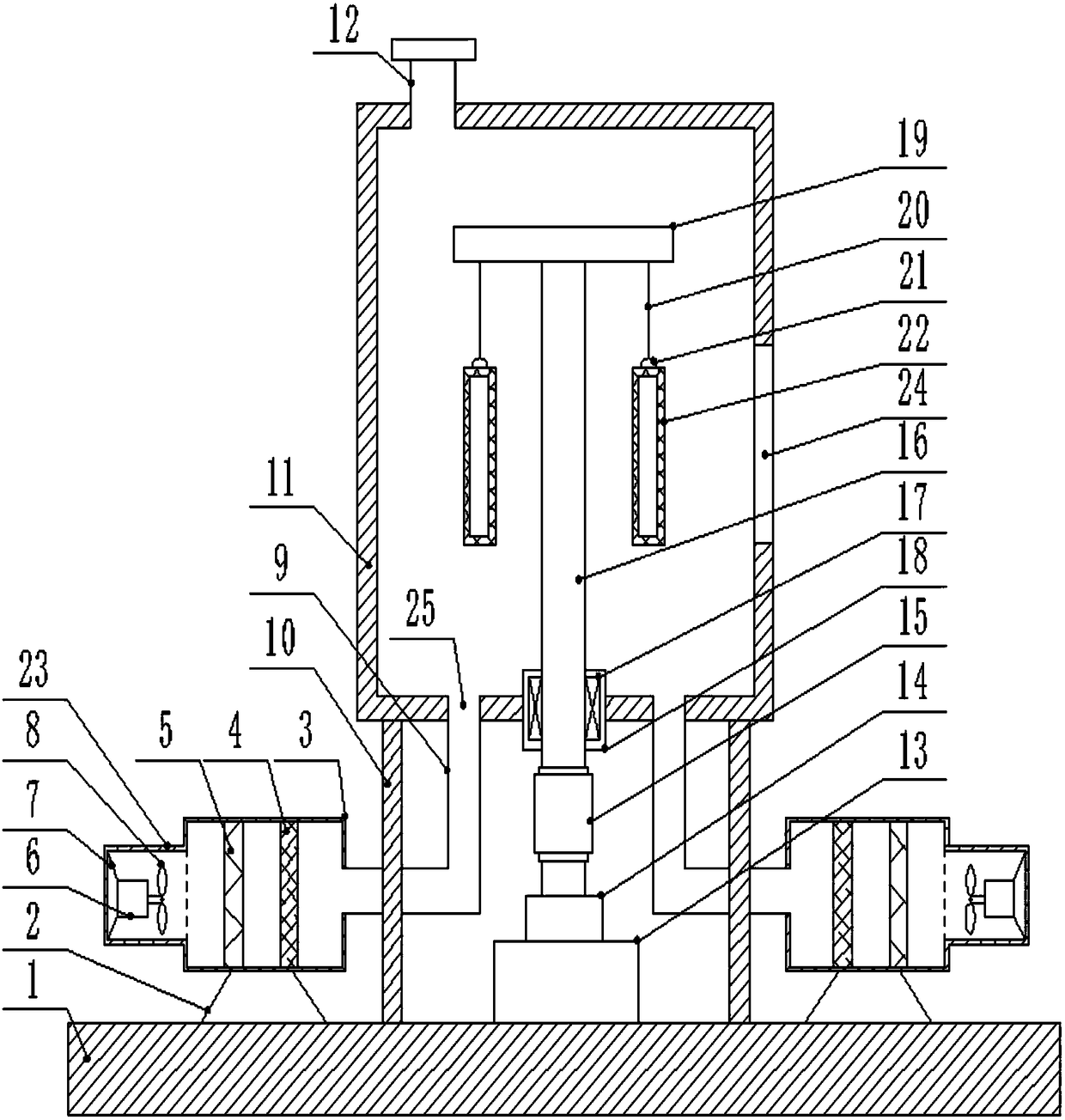

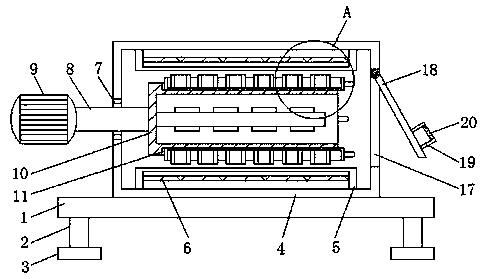

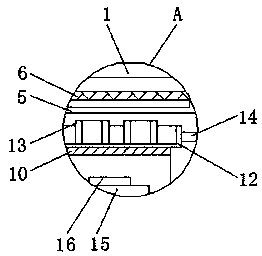

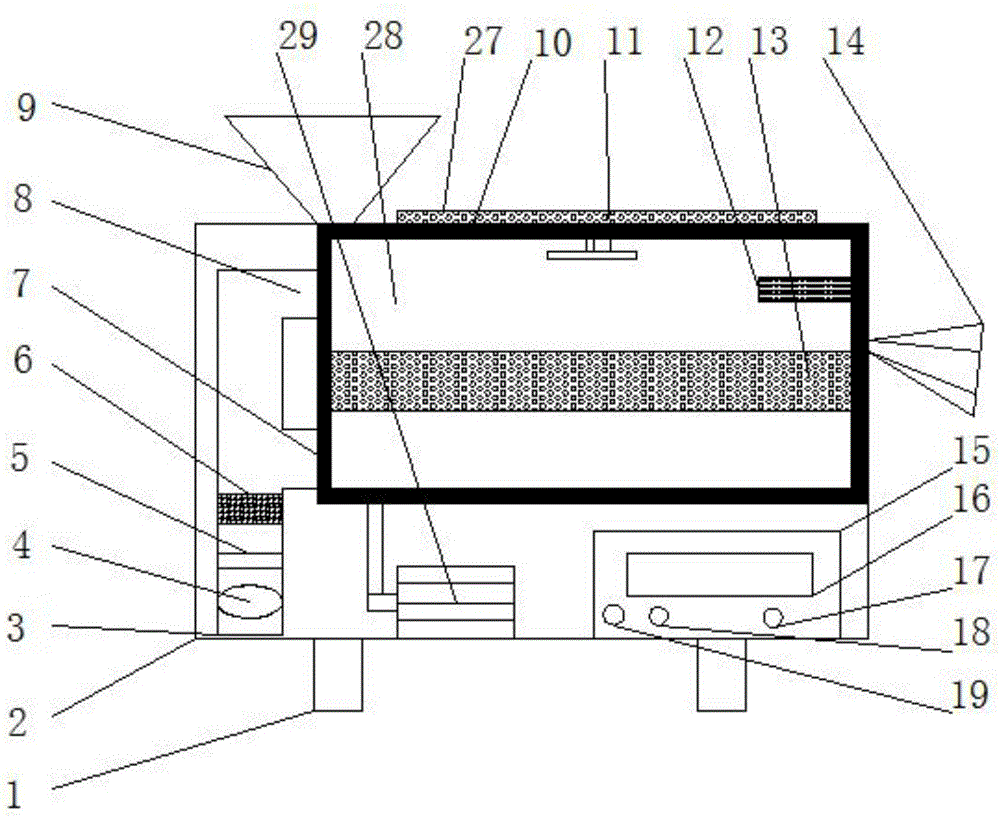

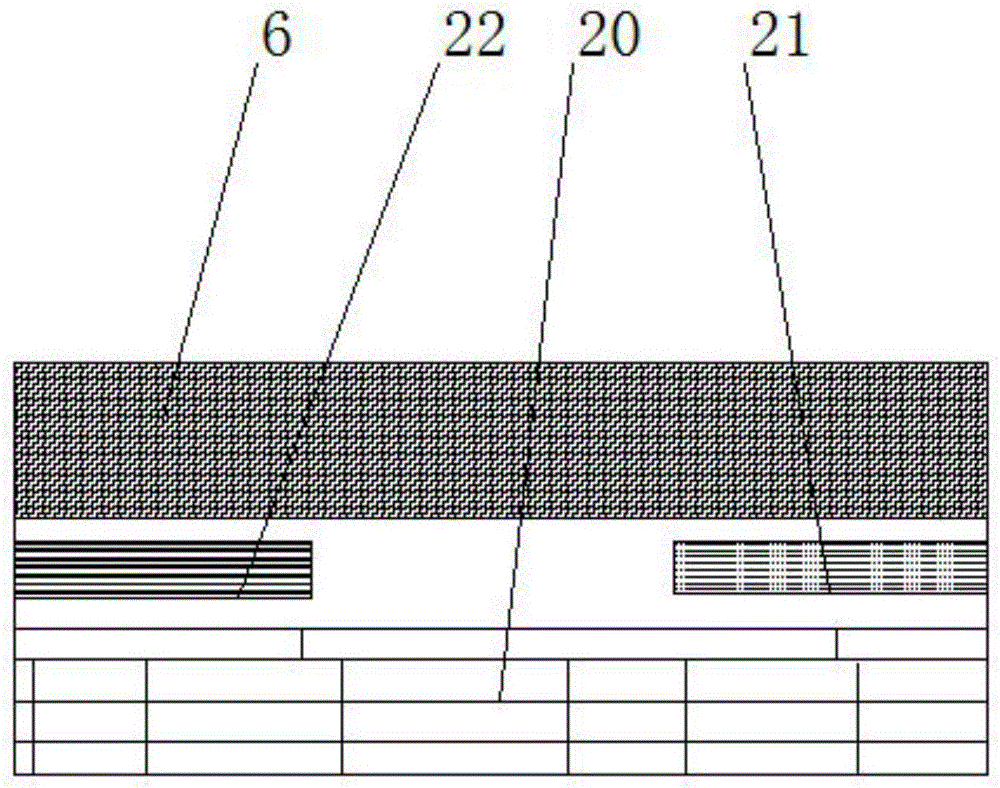

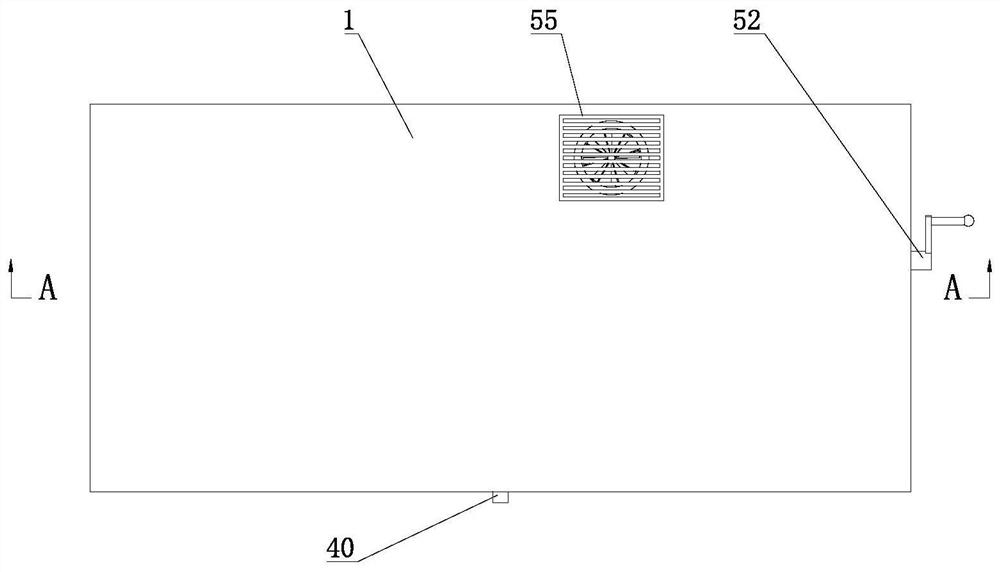

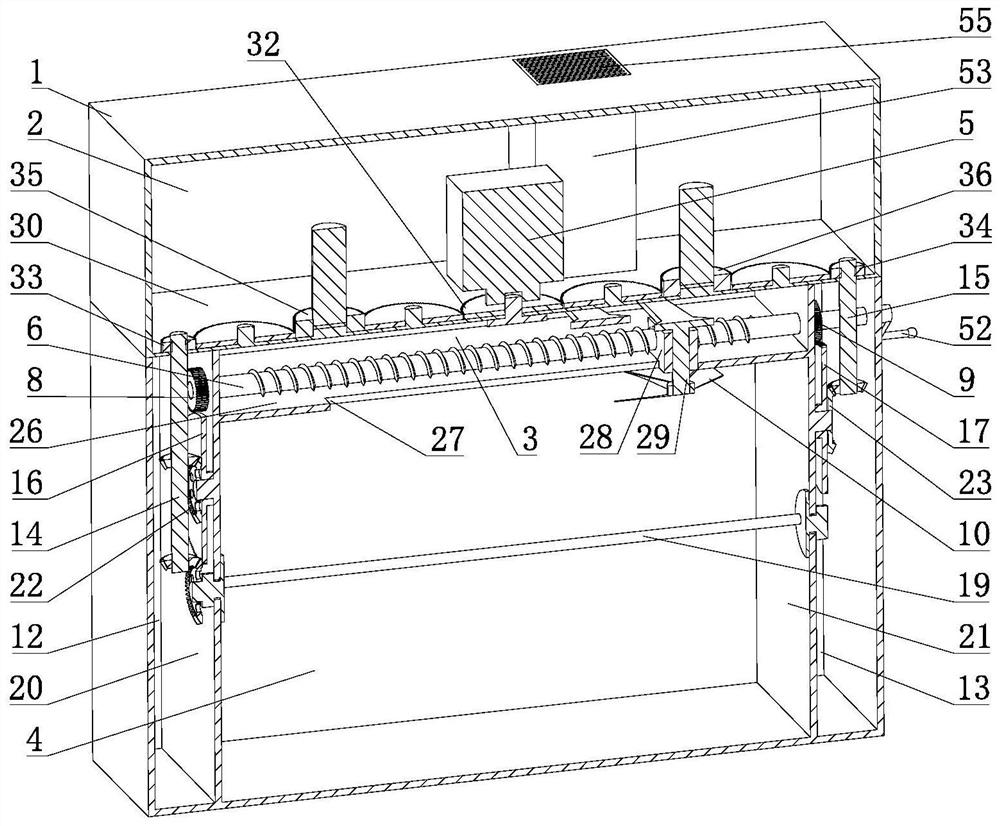

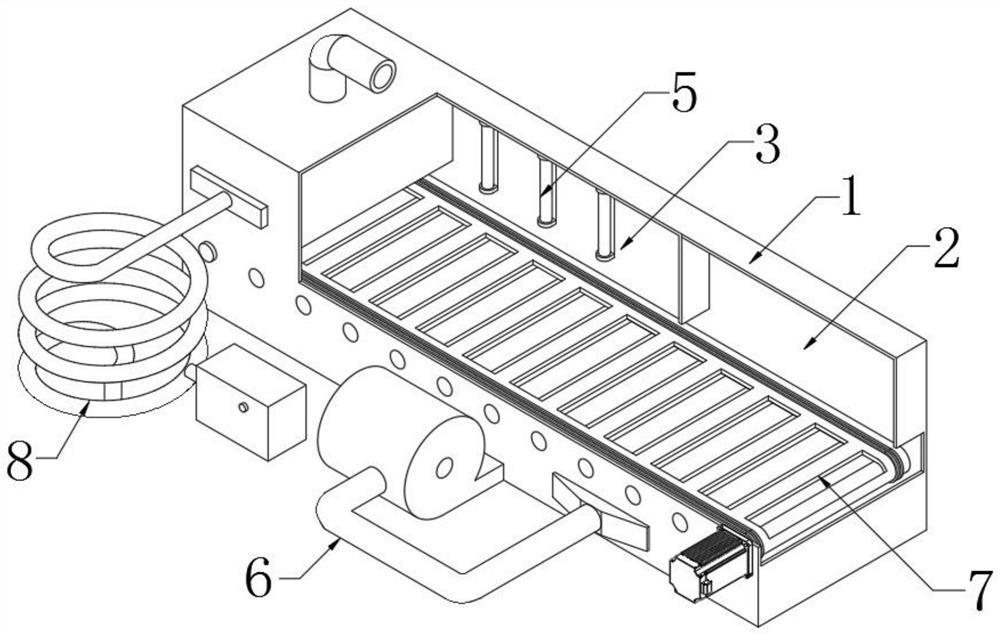

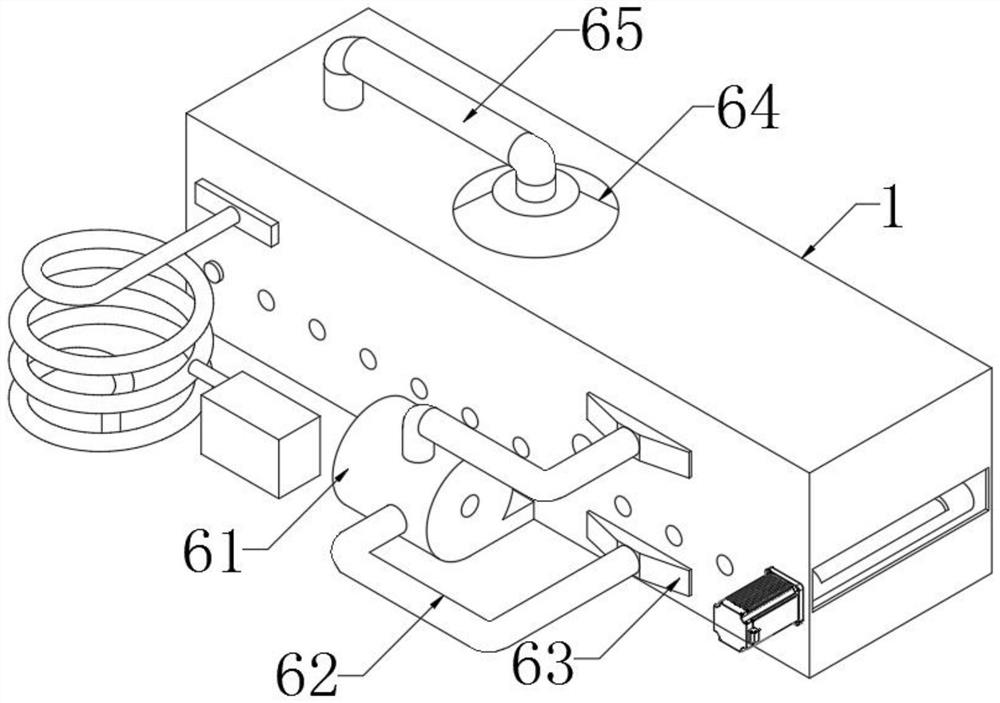

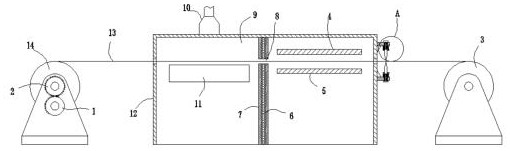

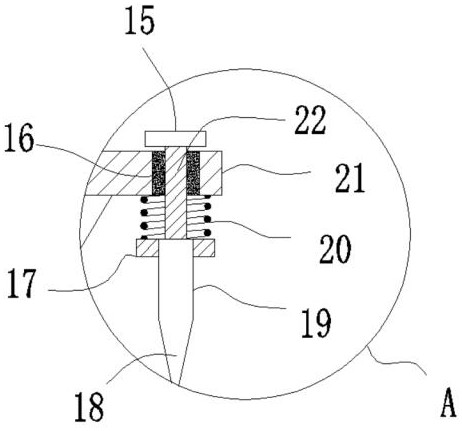

Leavened cake production device and preparation method thereof

InactiveCN110973179AImprove production efficiencyFully bakedDough-sheeters/rolling-machines/rolling-pinsDough dividingEngineeringControl switch

The invention discloses a leavened cake production device and a preparation method thereof. The leavened cake production device comprises a conveying belt conveying mechanism, baffles, a connecting plate, a dough rolling roller, a forming grid plate, a first mounting plate, a supporting frame, a mesh belt conveying mechanism, a baking cover, a baking device, a processing table, supporting legs anda control switch. The two baffles are located at the top of a conveying belt, arranged side by side in the longitudinal direction and connected with the connecting plate. The connecting plate is arranged on the processing table; a driving mechanism for driving the dough rolling roller to rotate is arranged on the processing table; the forming grid plate is arranged at the bottom of the first mounting plate; the supporting frame is arranged on the processing table, and an electric push rod used for driving the first mounting plate to move in the vertical direction is arranged on the supportingframe; the baking cover is arranged on the processing table; the baking device is arranged on the baking cover; the control switch is in respective control connection with the conveying belt conveying mechanism, the mesh belt conveying mechanism, the driving mechanism, the electric push rod and the baking device. According to the invention, automatic production can be achieved, and the leavened cake production efficiency is improved.

Owner:九江市金樱食品发展有限公司

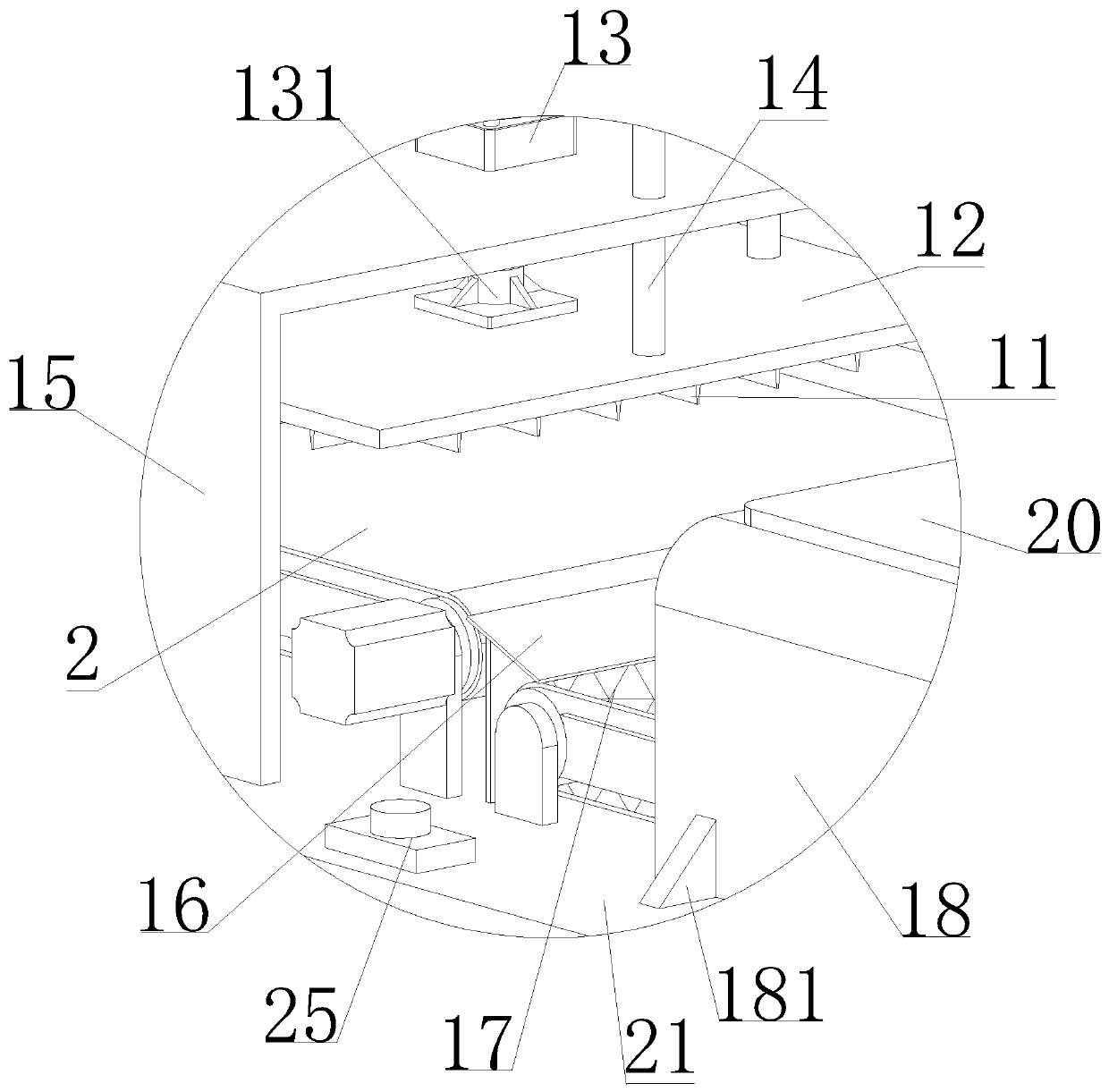

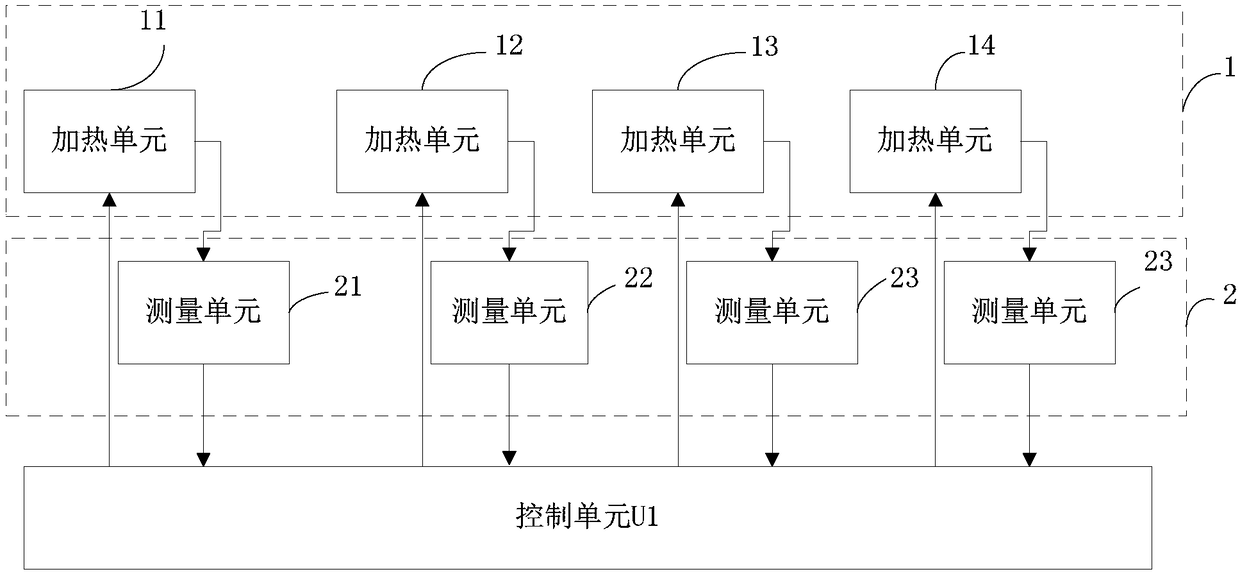

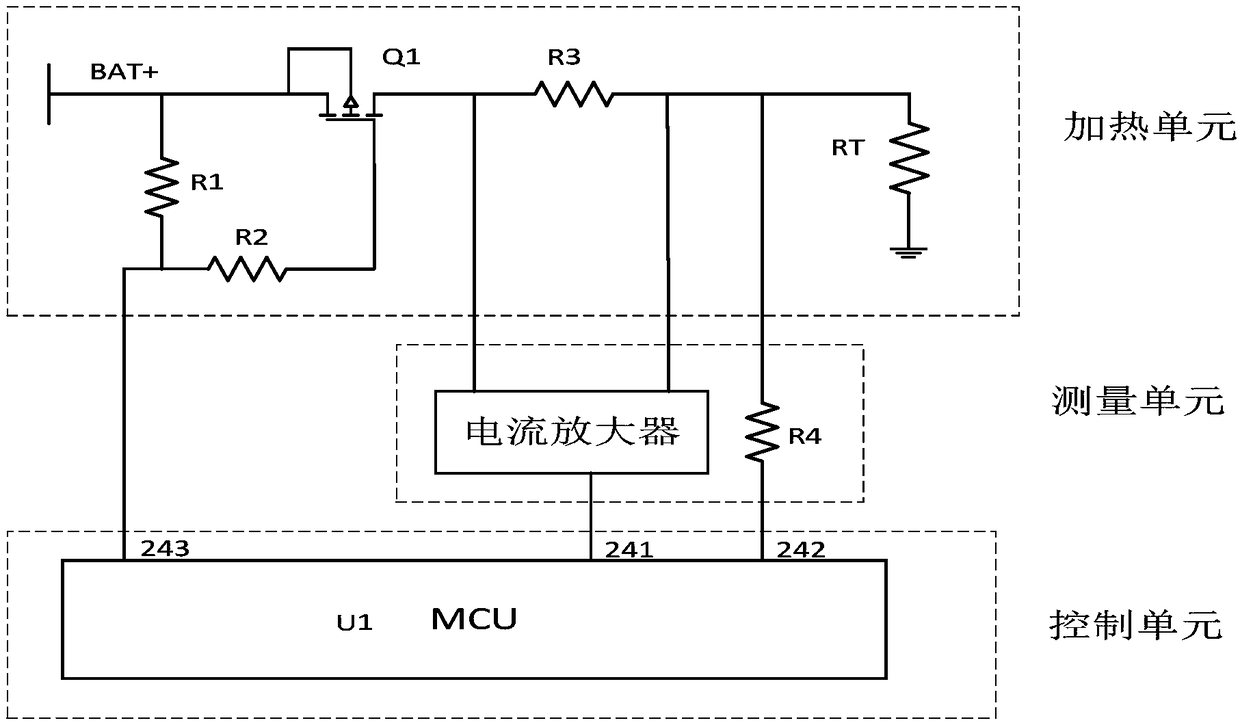

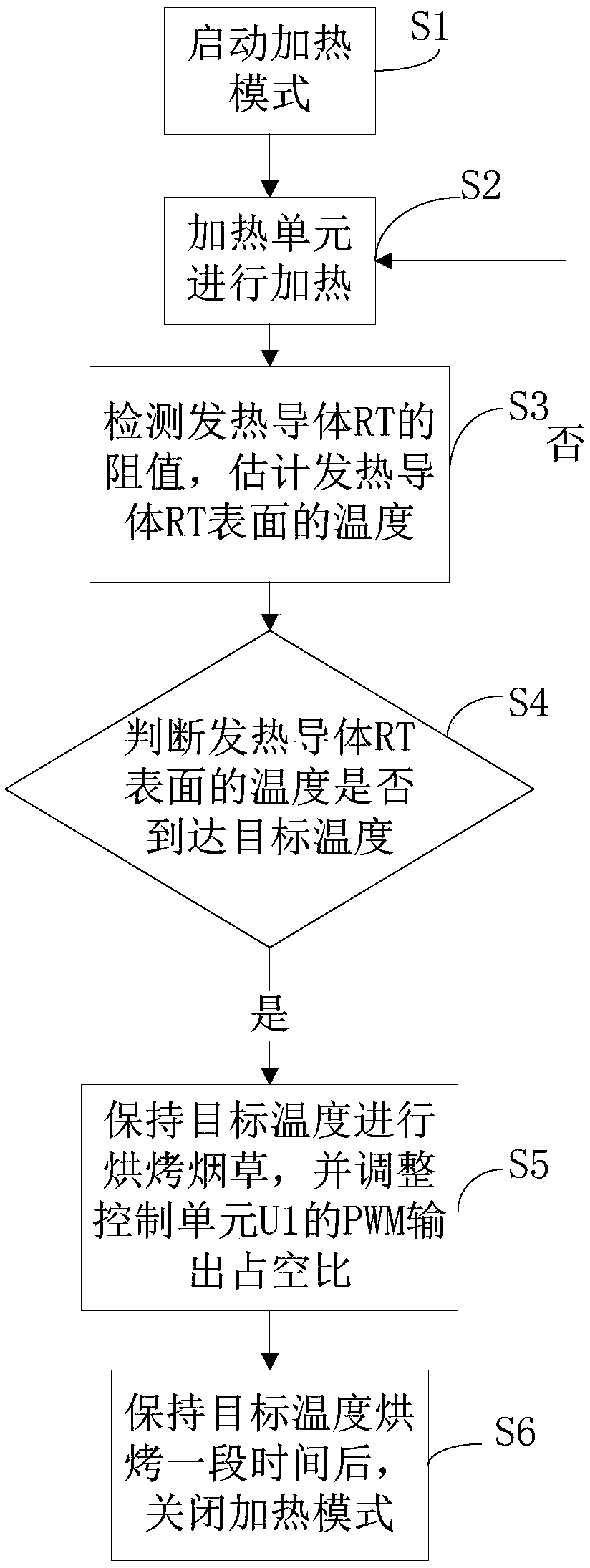

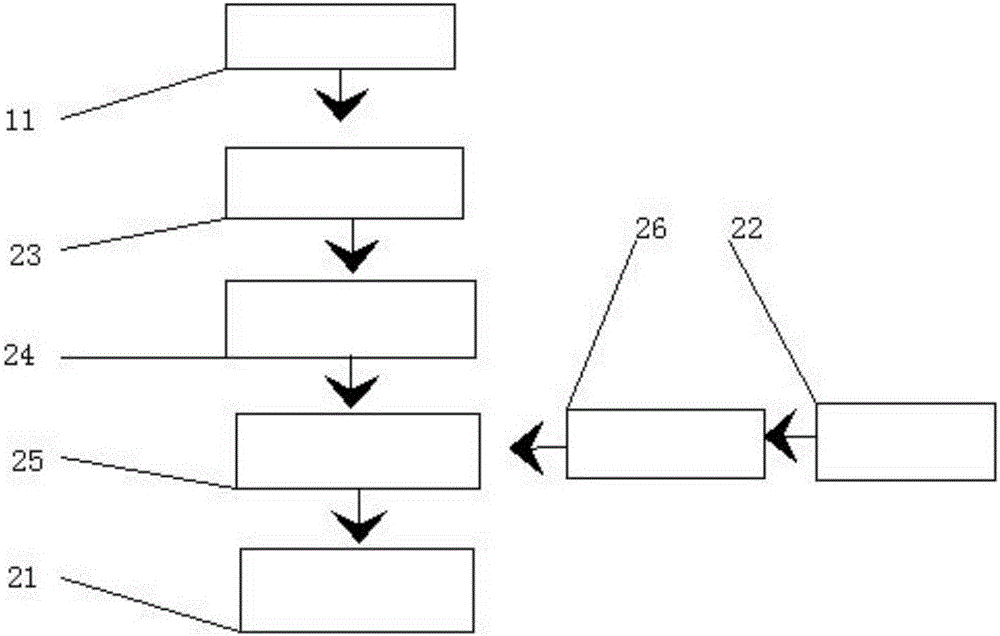

Electronic heating device and heating method

PendingCN108770084ARealize direct baking heatingSmooth releaseTobacco devicesOhmic-resistance heatingCooking & bakingPower flow

The present invention relates to an electronic heating device and a heating method. The device comprises a control unit U1, a plurality of heating modules and a plurality of measuring modules. The control unit U1 is used for outputting control signal(s) to drive the heating modules to work or shut down. The heating modules are used for heating a cigarette. The measuring modules are used for collecting voltage information and current information of the heating modules and converting the voltage(s) and the current(s) into resistance information to transmit into the control unit U1, so that the control unit U1 can adjust the control signal(s) and keep the voltage(s) and the current(s) within an allowable range of the control unit U1 when the heating modules work. According to the device, by providing the heating modules and the measuring modules, the control unit can control the heating temperature of the heating modules to a target temperature according to the data transmitted by the measuring modules, the direct heating and baking on the ordinary cigarette is realized, smoke is uniformly released, the heating modules are arranged at intervals around the cigarette, so that the bakingis more sufficient, the release of the cigarette smoke is more uniform, and the energy is saved.

Owner:SHENZHEN HANGSEN STAR TECH

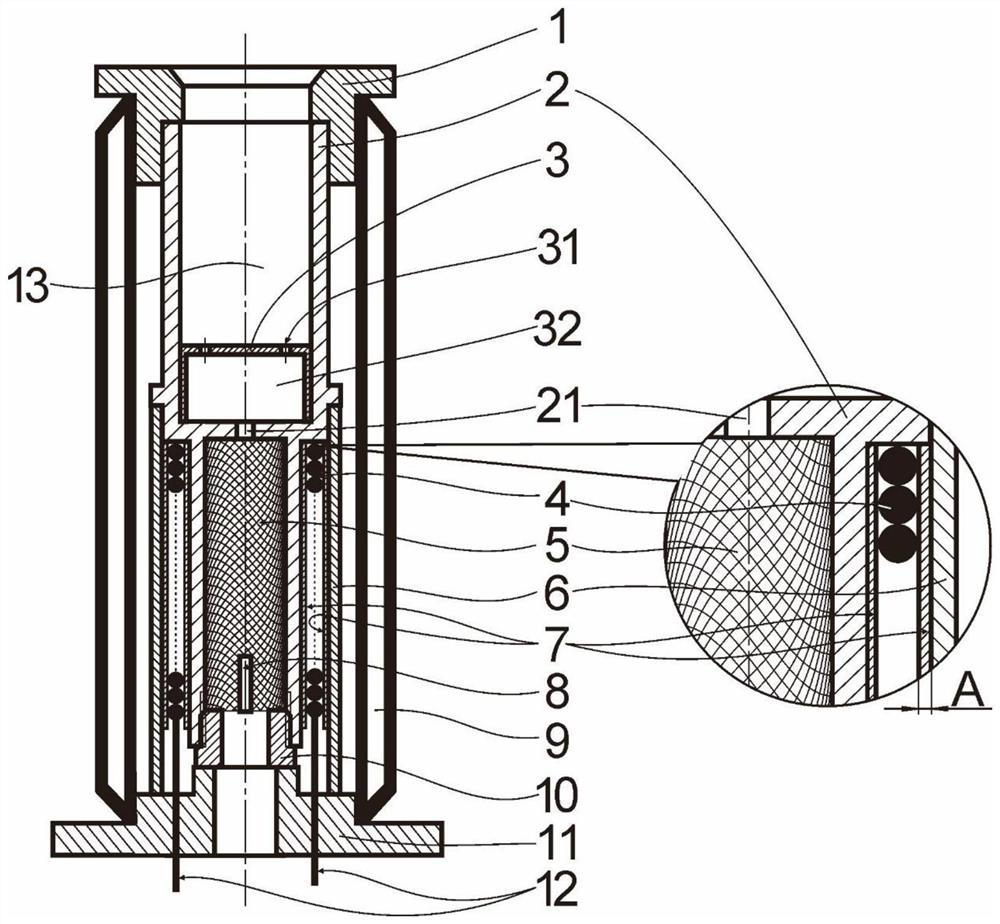

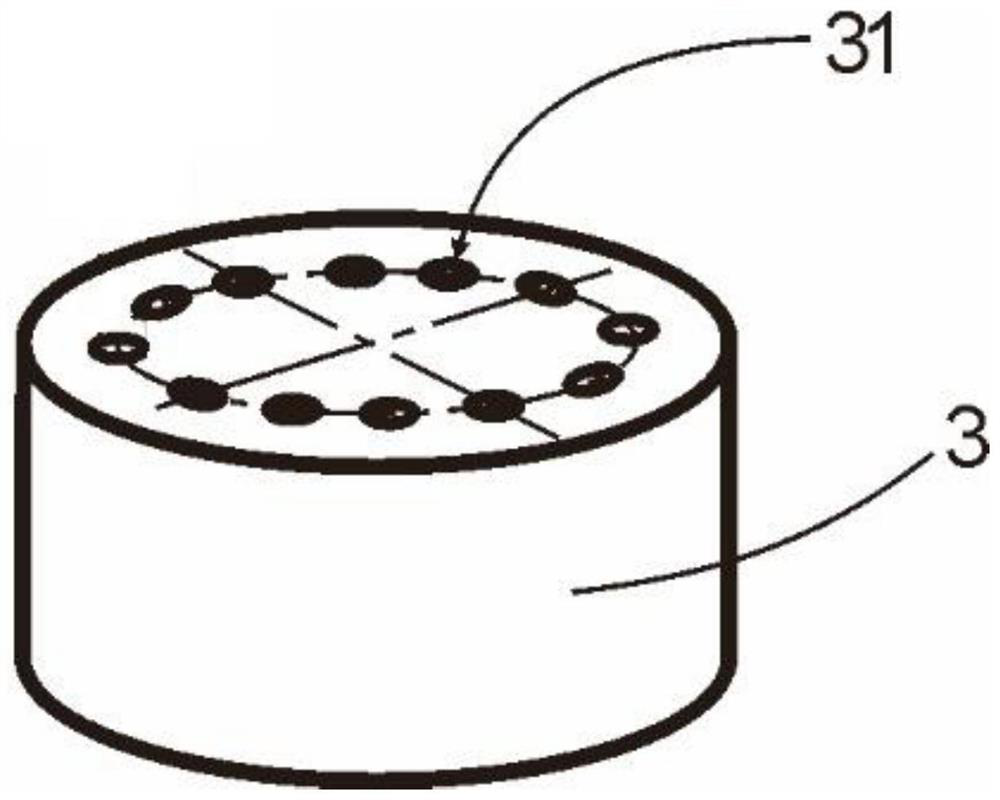

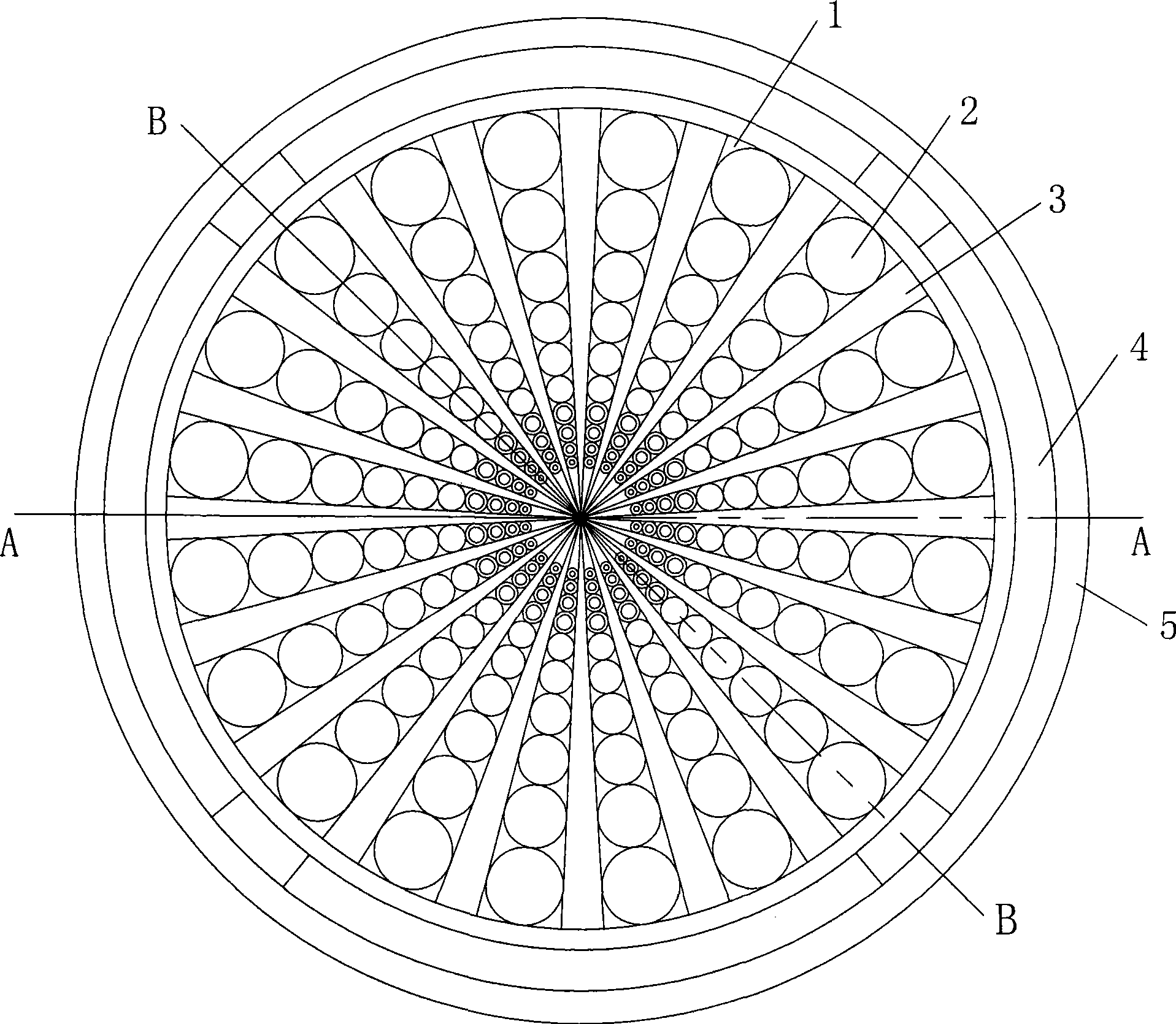

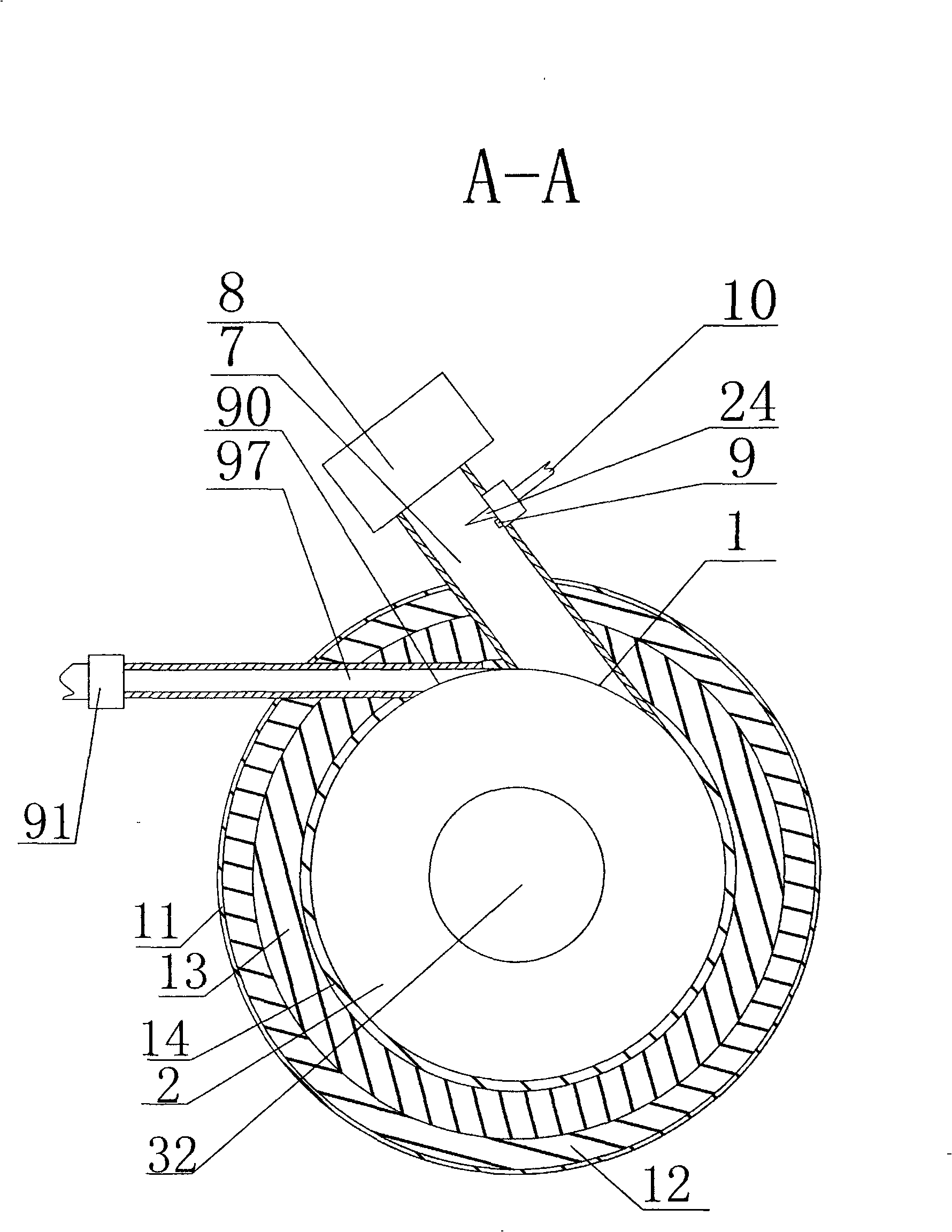

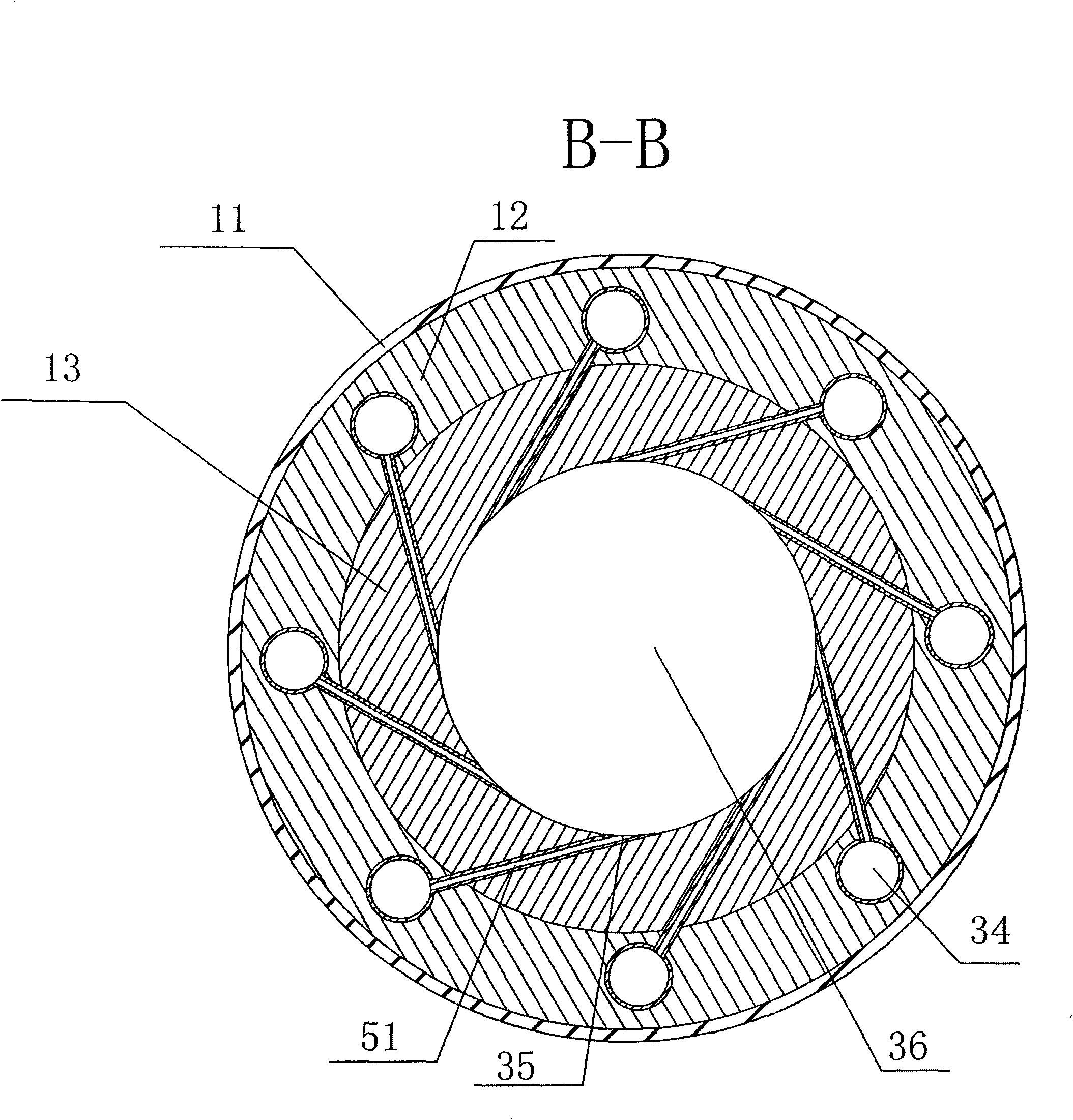

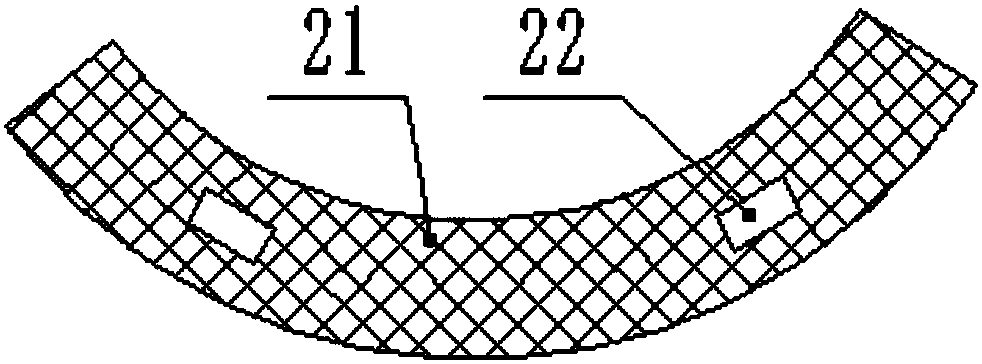

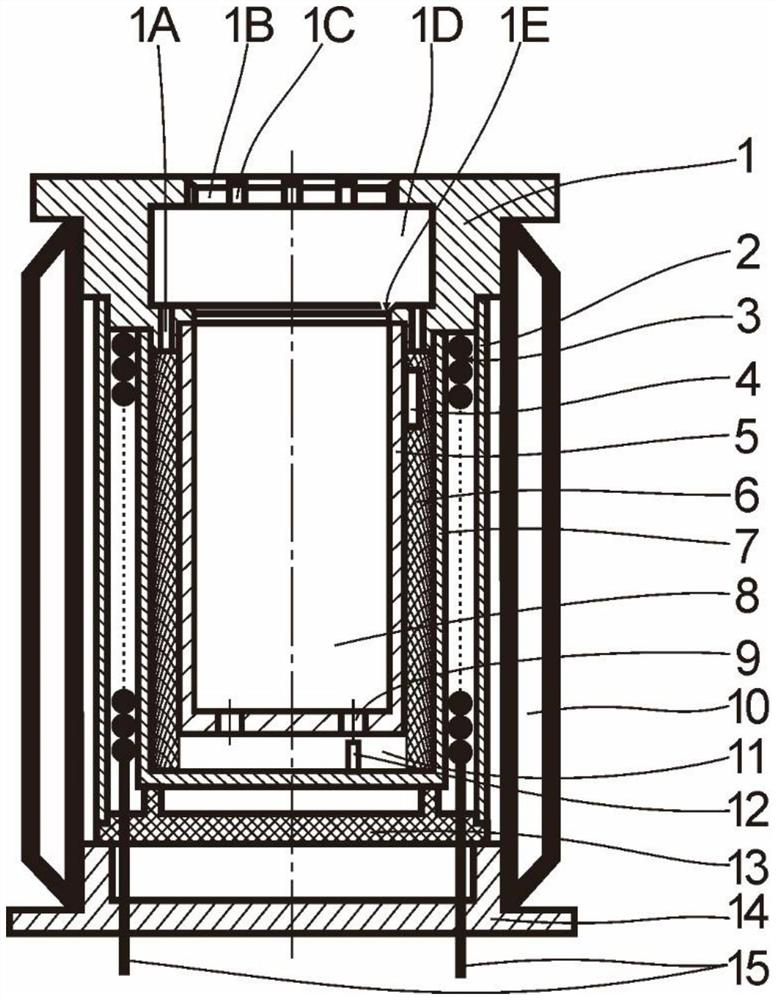

Smoke generating device for induction heating at front end of cigarette

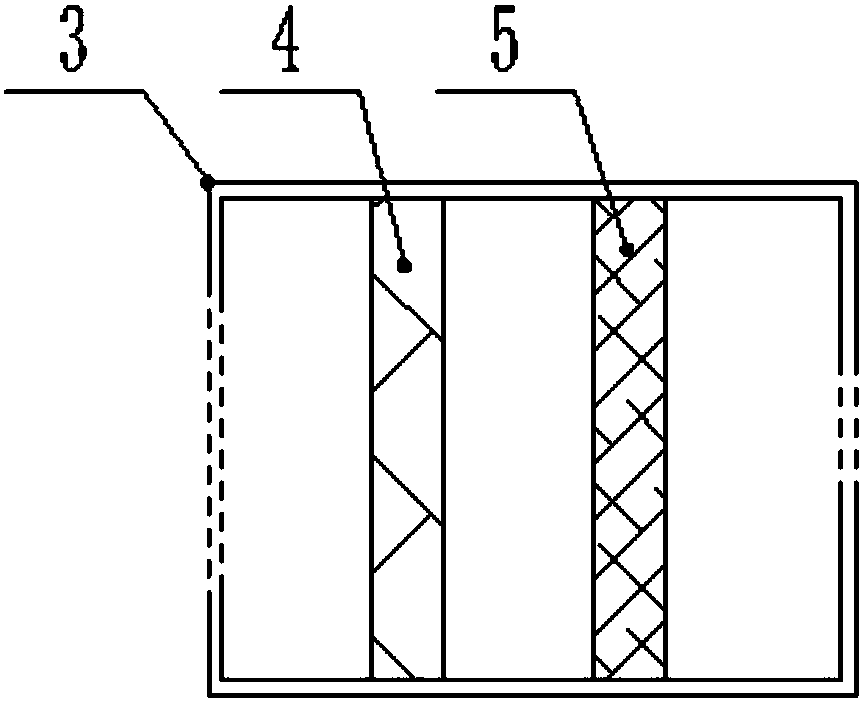

The invention belongs to the field of novel cigarette smoking sets, and particularly relates to a smoke generating device for induction heating at the front end of a cigarette. The smoke generating device comprises a hollow heating cup (2), a heating body (5) and an induction coil (4), A hollow heating cup (2) comprises an upper hollow structure, a lower hollow structure and a baffle between the upper hollow structure and the lower hollow structure; a heating body (5) is arranged in the lower hollow structure, and an induction coil (4) is arranged on the periphery of the heating body (5); andthe heating body (5) is made of ferromagnetic metal and has a structure through which air can pass. According to the invention, the smoke generating device for induction heating at the front end of the cigarette is designed for the first time, and a plurality of airflow channels are formed inside and / or on the surface of the heating body, so that air flowing through the surface of the heating bodycan be quickly and fully heated; the problems that an existing electric heating cigarette is uneven in heating, a carbon heating cigarette is easy to roast and burn and not easy to control, aroma components are insufficient, and smoking feeling is poor are effectively solved.

Owner:CHINA TOBACCO YUNNAN IND

Rotary food oven

The invention discloses a rotary food oven, which comprises an oven body, wherein a transparent mobile door is formed in the oven body; a rotary grill is arranged in the transparent mobile door; heating pipes are arranged in the oven body above and below the rotary grill; exhaust ducts are arranged at the two ends of the oven body and on the two sides of the rotary grill; exhaust fans are mounted on the exhaust ducts; an oil absorption fan is arranged at the top of the oven body; a constant-temperature box is arranged at the bottom of the oven body. According to the rotary food oven provided by the invention, the rotary grill is arranged, a rotating shaft rotates to drive ducks to rotate, and the ducks are baked gradually with the temperature rise of the oven, so that the duck meat is baked uniformly; heat sources are distributed above and below the rotary grill, so that baking is more complete; in order to keep the color and taste of food, the baked food is put into the constant temperature box, so that the phenomenon of overbaking is avoided.

Owner:江勇汉

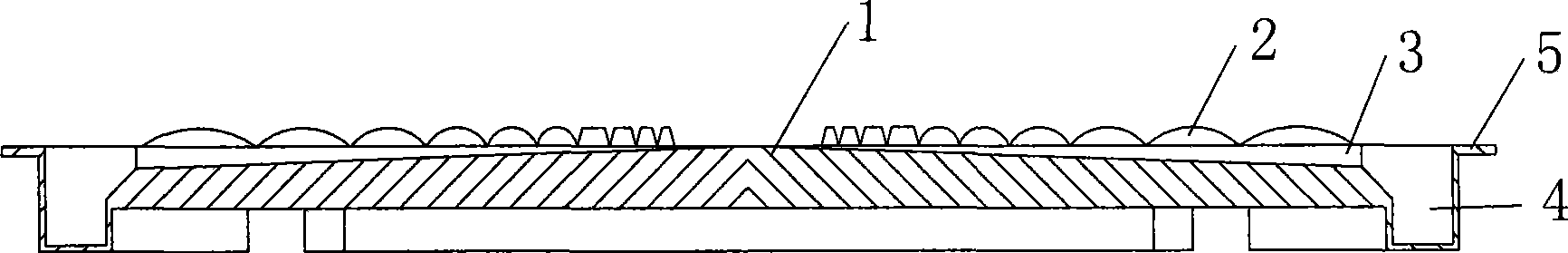

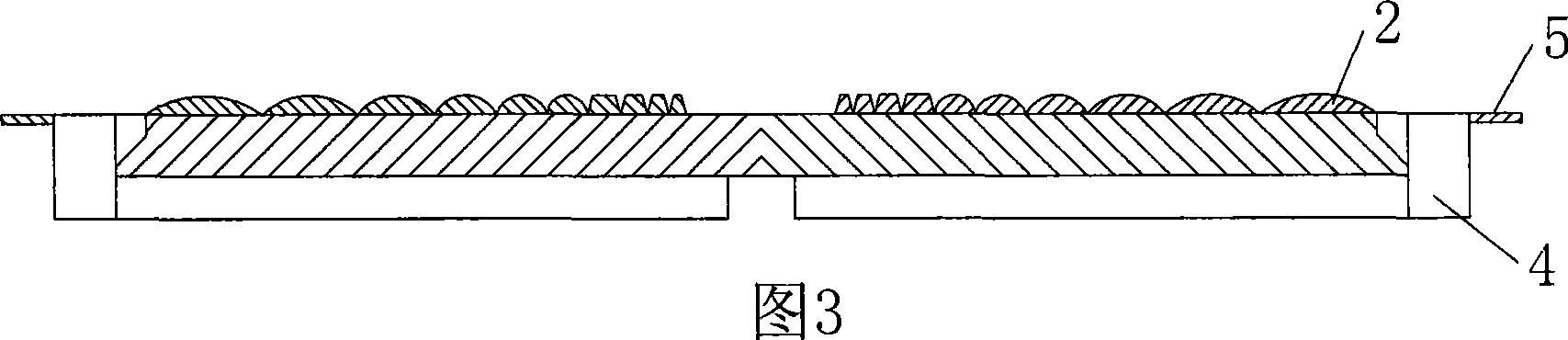

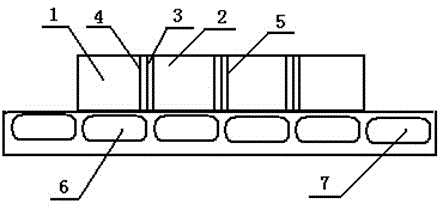

Composite material for producing bakeware and bakeware produced with the material

The invention relates to a composite material for manufacturing a baking tray and the baking tray. The composite material for manufacturing the baking tray is characterized in that the composite material consists of the following compositions in mass percentage: 40 to 65 percent of liquid crystal polymer LCP, 4 to 40 percent of polyether sulphone PES, 1 to 15 percent of poly(tetrafluoroethylene) PTFE, 15 to 45 percent of glass fibre, 0.5 to 5 percent of mica, 2 to 10 percent of calcium carbonate and 1 to 15 percent of talcum powder. The baking tray made from the material is characterized in that the baking tray is made into a tray shape; the upper surface of the baking tray is provided with a plurality of protrusions in radial arrangement; a launder is arranged between the protrusions of the adjacent ranks; the periphery of the baking tray is provided with an oil storage tank; and the launder is communicated with the oil storage tank. The composite material for manufacturing the baking tray has low cost, good rigidity and excellent heat resistance and can fully bake food; and the baking tray made from the material can avoid partial oil from remaining in the food and greatly improve the mouthfeel of the food.

Owner:MIDEA GRP CO LTD

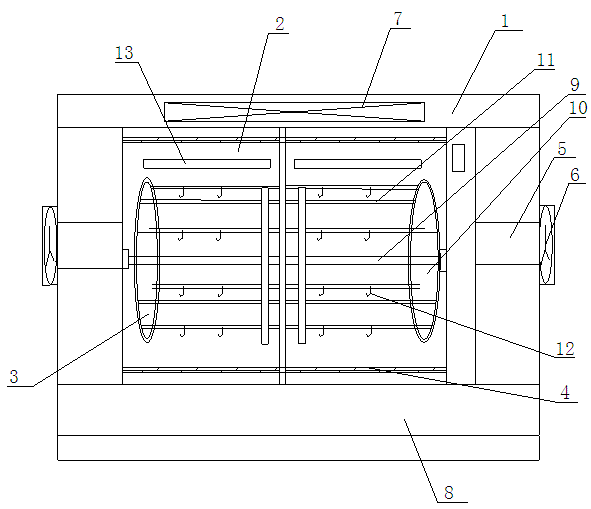

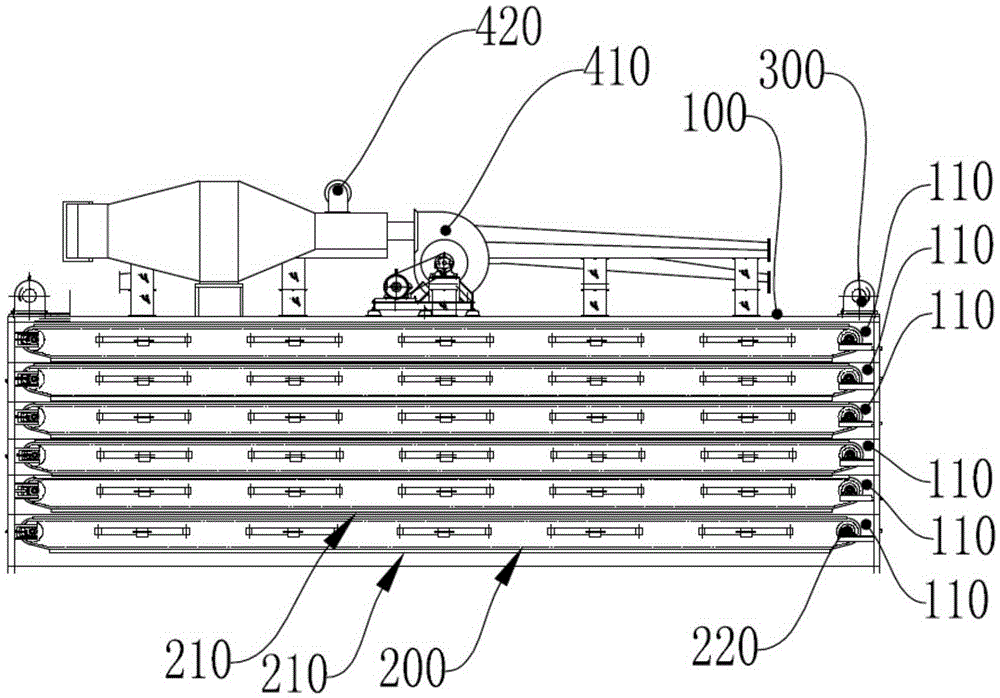

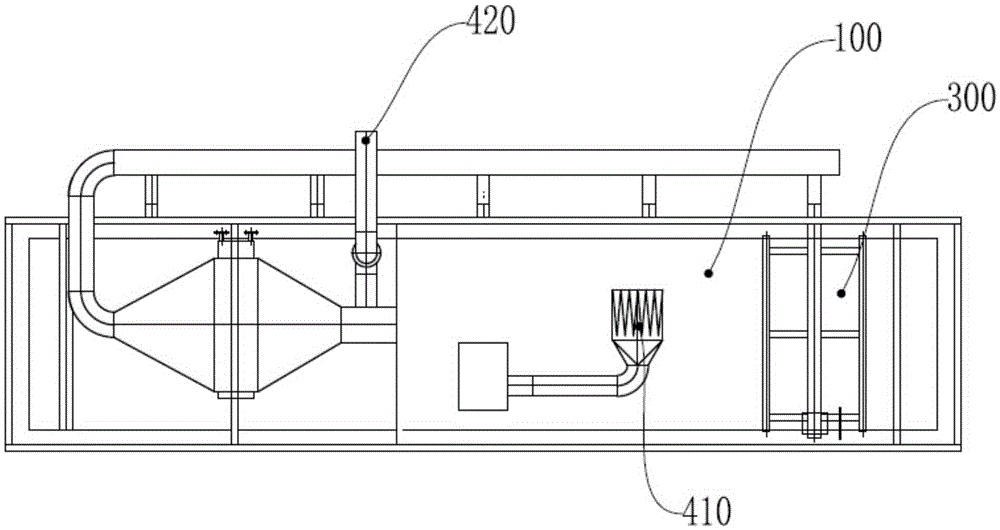

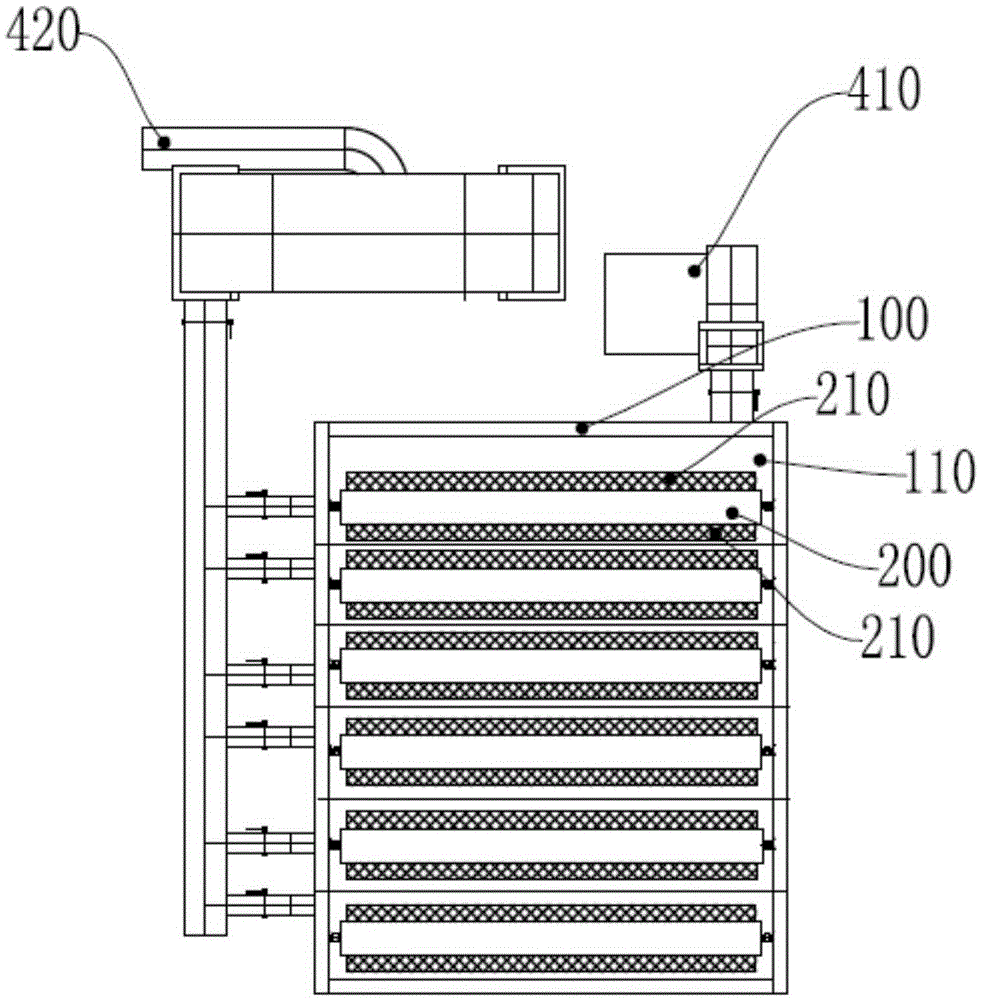

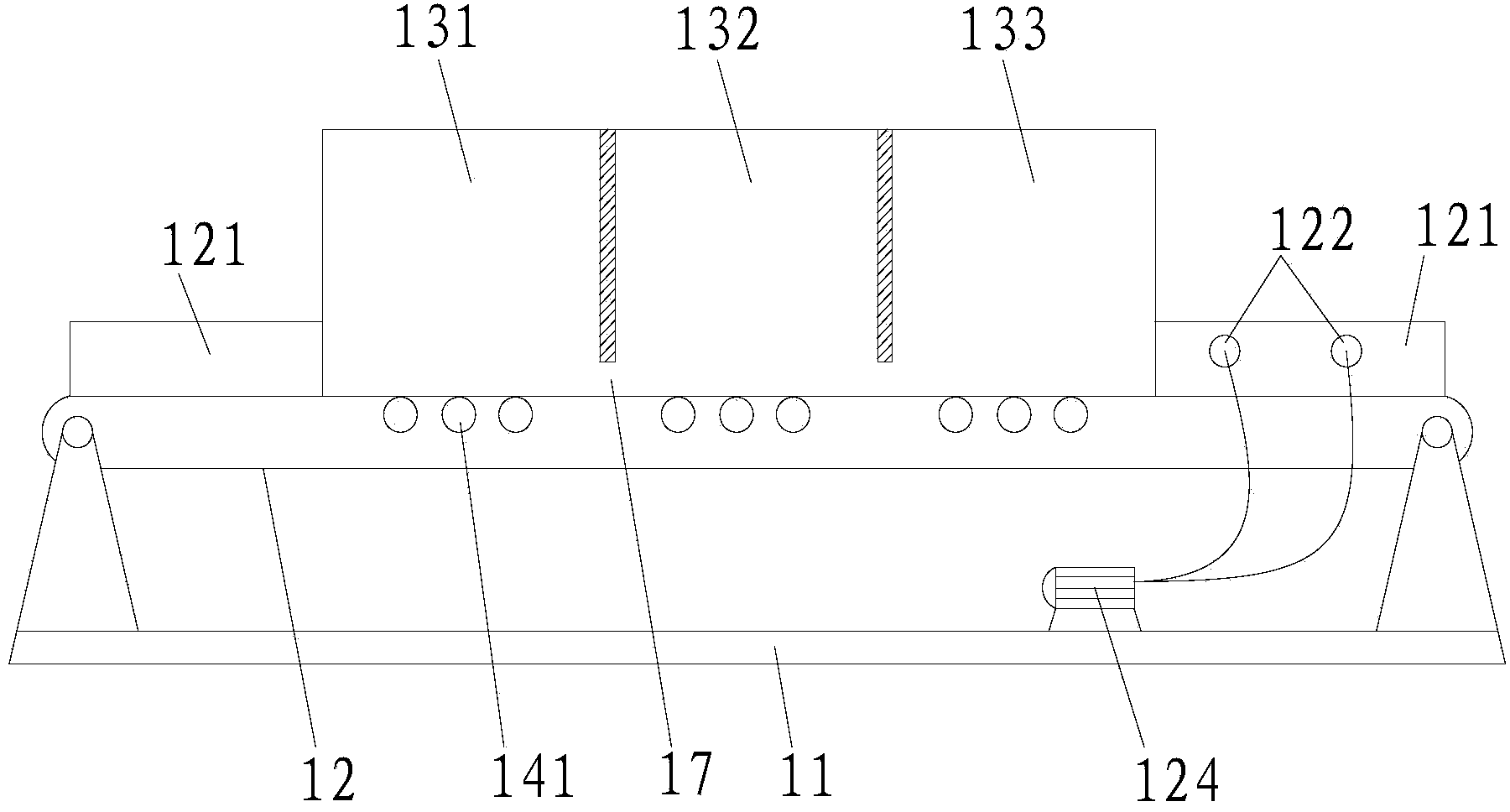

Dryer for high-density fiberboards

ActiveCN105300071AImprove drying efficiencyShorten the lengthDrying gas arrangementsDrying machines with progressive movementsHigh densityEngineering

The invention relates to the technical field of special fiberboards, in particular to a dryer for high-density fiberboards. The dryer comprises a drying room. A plurality of layers of drying chambers are arranged in the drying room. Net bags which can contain the fiberboards are arranged in all the layers of drying chambers. The fiberboards are arranged in the multiple layers of drying chambers respectively and driven by conveying belts to cyclically rotate in the drying room, and therefore overall multidirectional and sufficient braking is achieved, and the drying efficiency of the fiberboards is higher. Compared with an existing drying conveying line, a drying line is stacked to be of the drying room of a multilayer structure in the dryer, the length of the dryer is greatly reduced, and the upper space of a plant is fully utilized.

Owner:GUANGDONG WALKKIND SPECIAL FIBERBOARD TECH

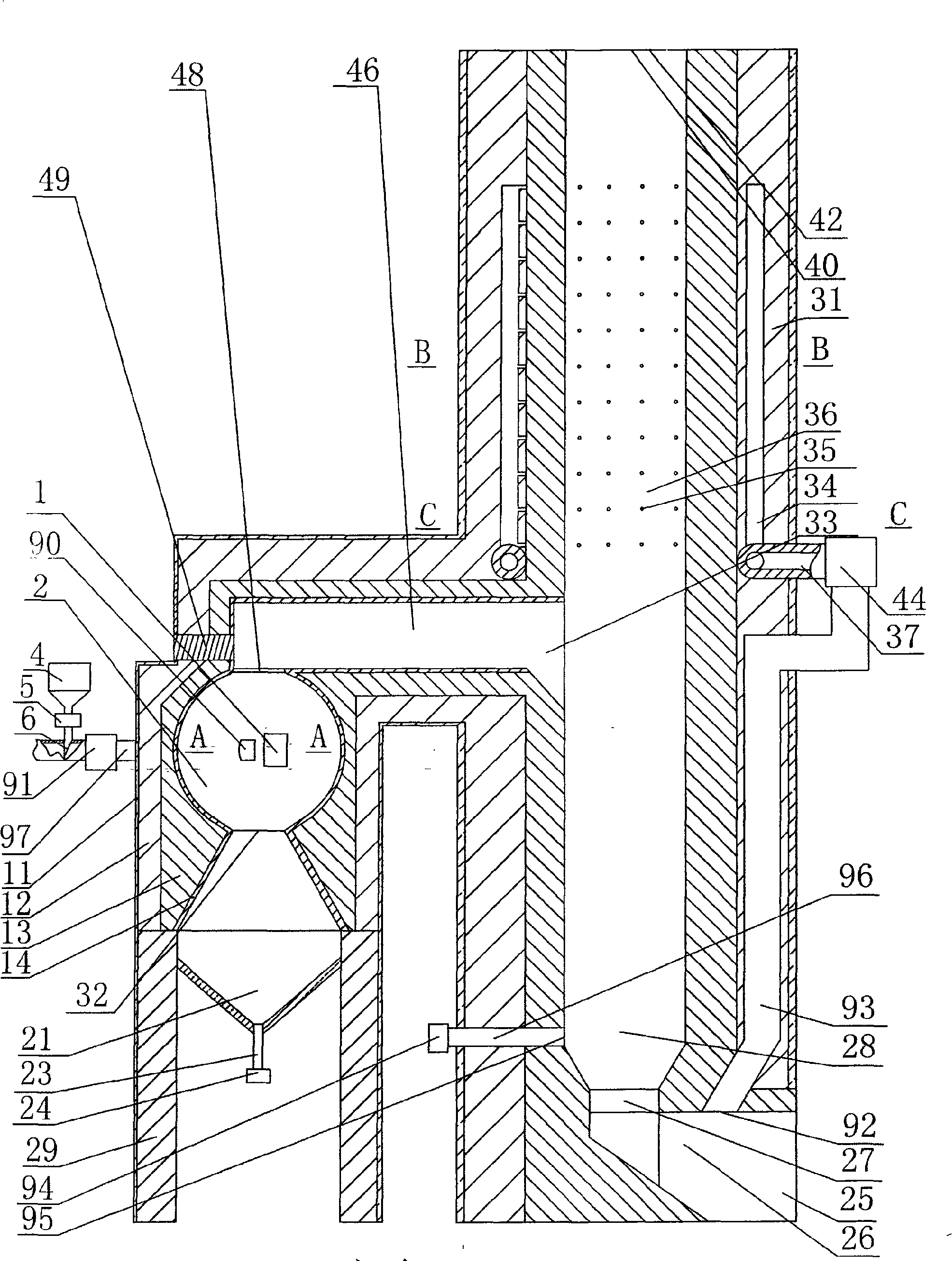

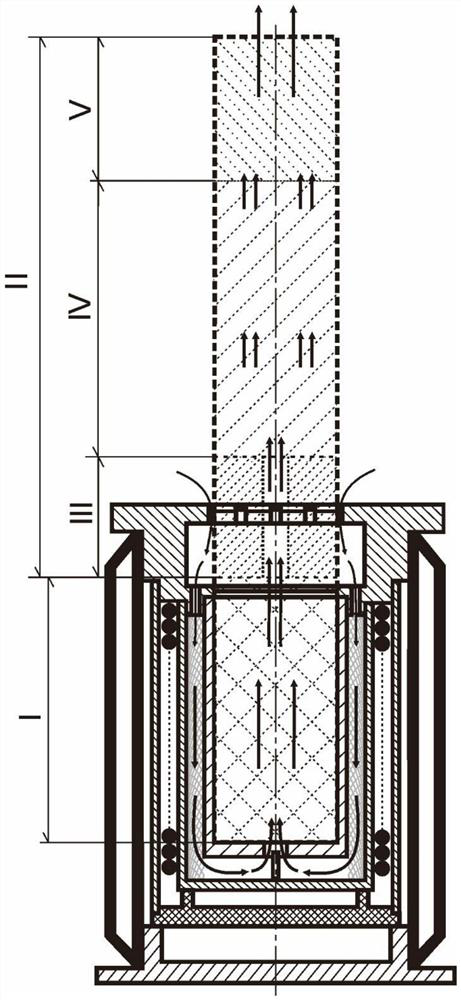

Vertical kiln

InactiveCN101349500AExtended stayExtended burn timeVertical furnacesCombustion chambersFuel supplyCombustion chamber

A shaft kiln is more energy-saving and environment-friendly through utilizing hot convection and vortex burning in the novel burning method and heating method. The shaft kiln can form eddying turbulence in a kiln chamber through utilizing pressurized air flow, and makes the material have even heating. As the movement is mutual, the heating method of rolling material is replaced by the movement of hot air flow around the material, and the material naturally moves to a preheating zone, a heating zone and a cooling zone through utilizing the natural settling, and the shaft kiln is provided with a fuel supply device, a burning chamber, a kiln chamber, a fan, an air pipe, refractory material and heat-insulating material. The shaft kiln is characterized in that an air inlet is arranged on the side walls of the burning chamber, and is connected with an air inlet pipe, and the fan is installed on the air inlet pipe, the burning chamber is connected with the fuel supply device, the kiln chamber is provided with a heating chamber and a cooling chamber, the lower portion of the heating chamber is communicated with the cooling chamber, a feeding inlet is arranged on the upper portion of the heating chamber, and an air outlet is arranged on the upper portion of the heating chamber, a discharge port is arranged on the lower portion of the cooling chamber, a kiln chamber air inlet is arranged between the heating chamber and the cooling chamber, and the burning chamber is provided with an air outlet which is communicated with a kiln air inlet.

Owner:陈久斌

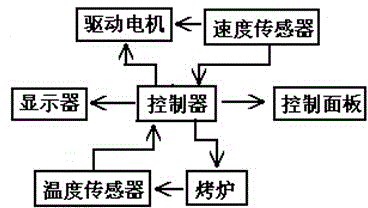

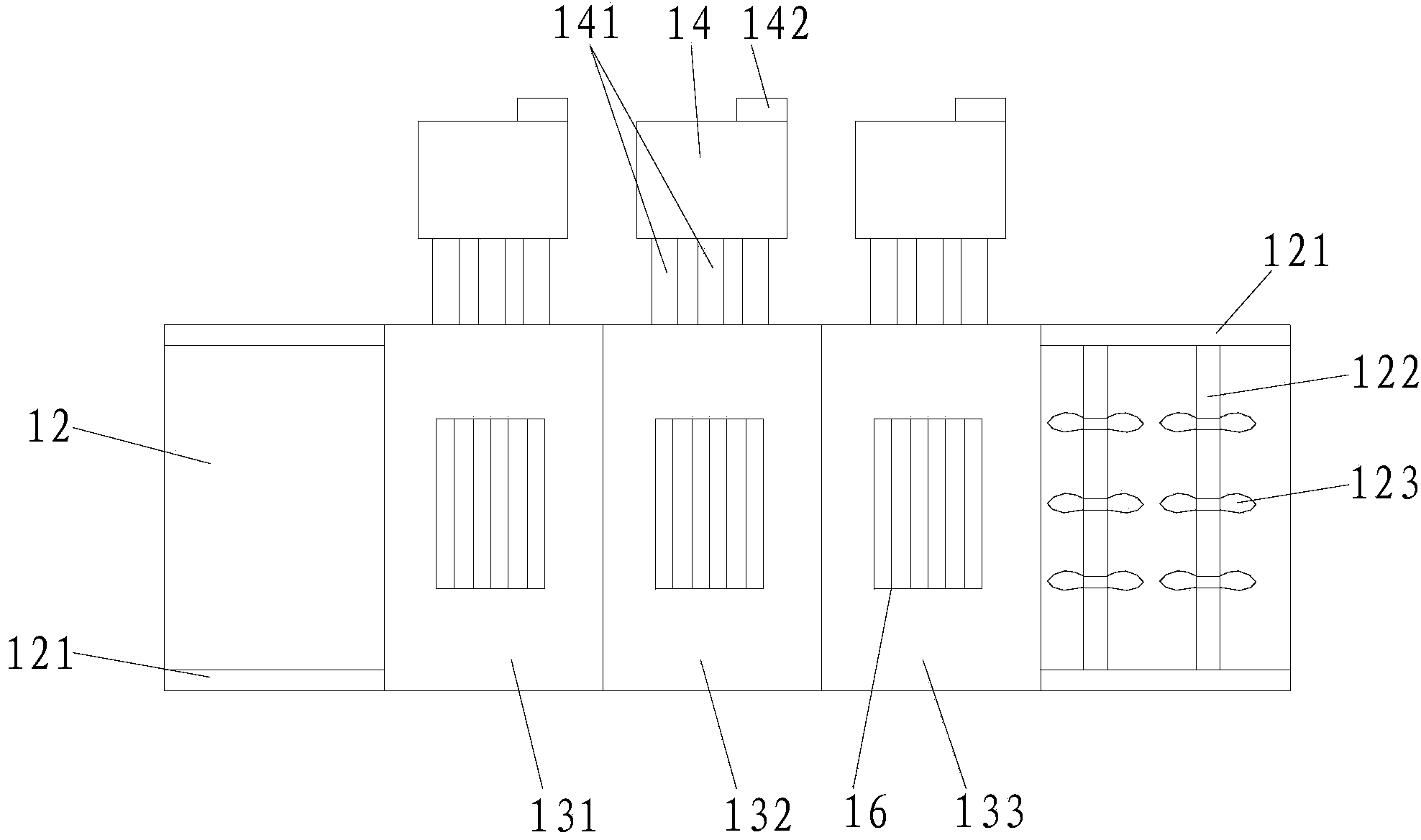

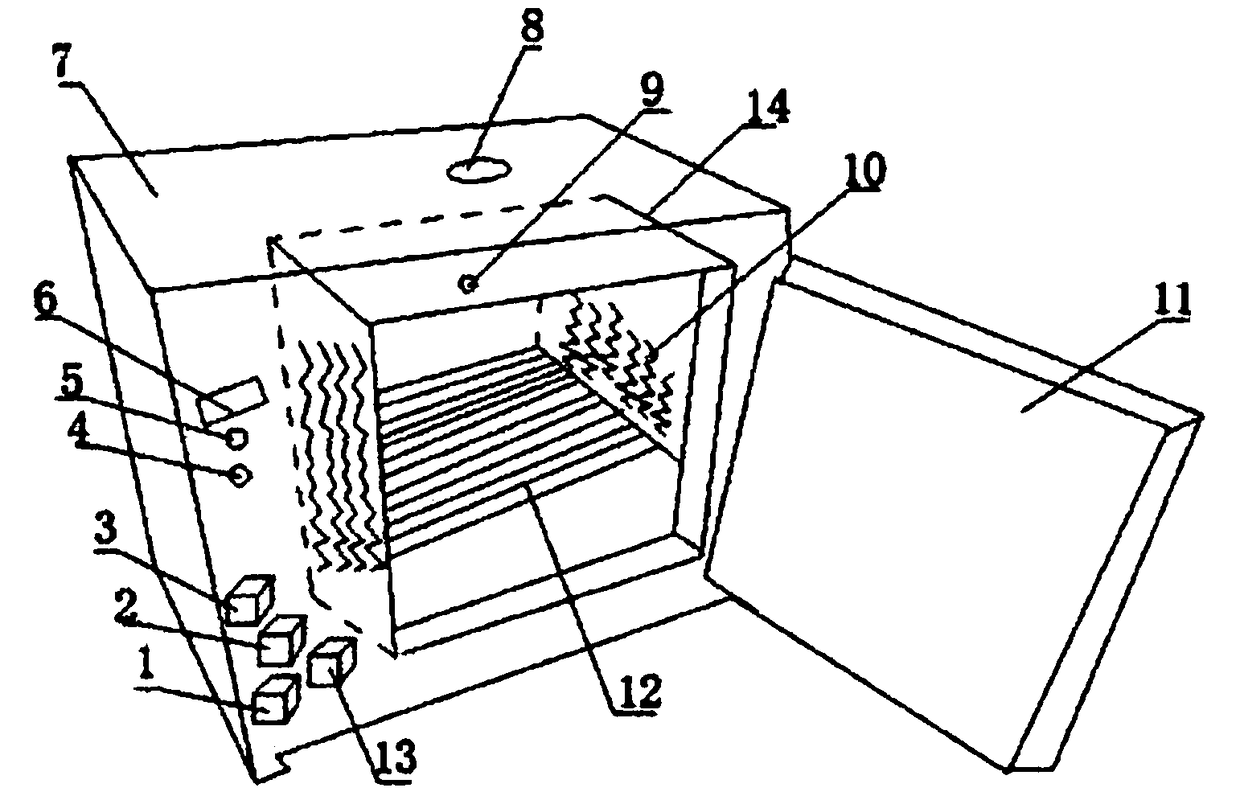

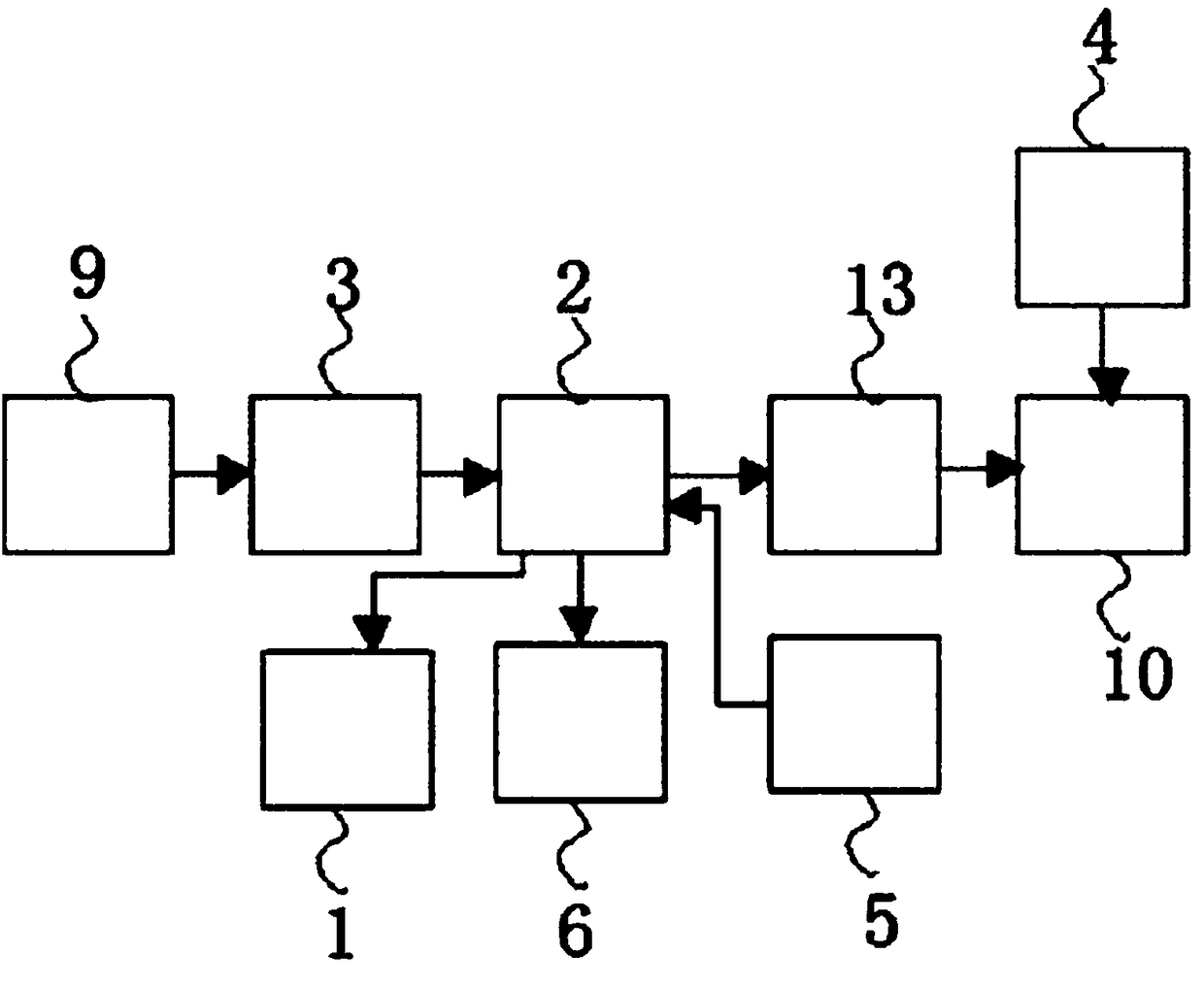

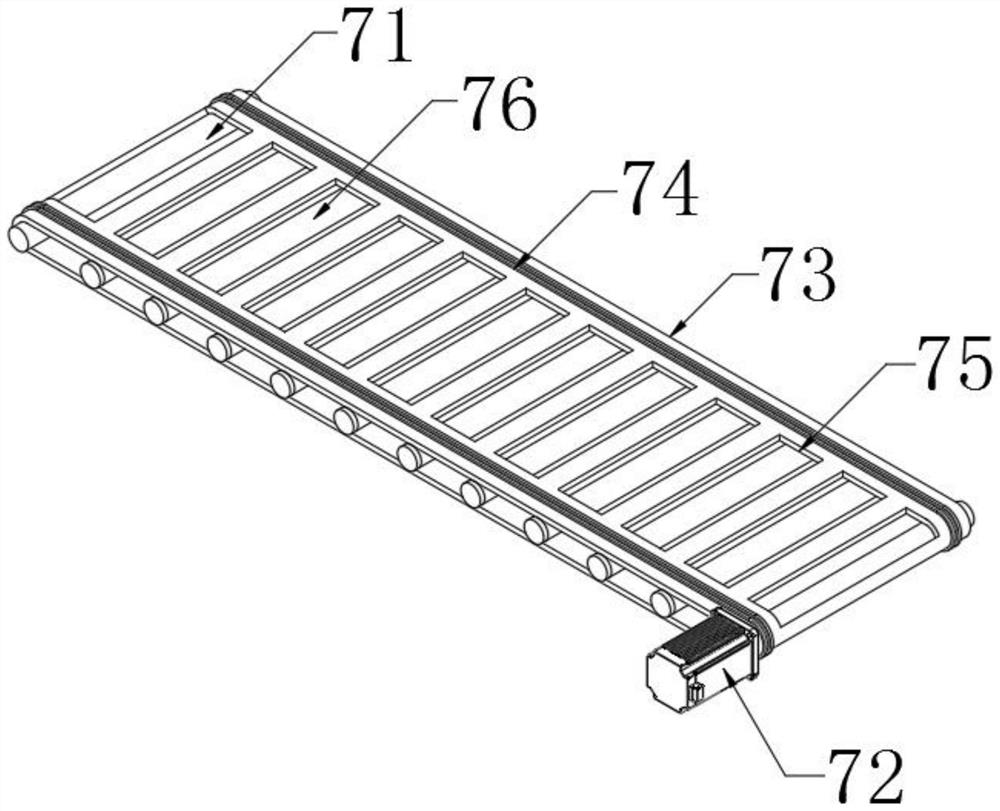

Baking system in LED (Light Emitting Diode) packaging

InactiveCN104393149AUniform temperatureEasy to control speedSemiconductor devicesCooking & bakingThermal insulation

The invention discloses a baking system in LED (Light Emitting Diode) packaging. The baking system in the LED packaging comprises a controller, an oven, a transmission device and a plurality of temperature sensors; the oven comprises a plurality of sections of temperature zones; every temperature zone is provided with the temperature sensor; the controller is respectively connected with the oven, the transmission device and the plurality of temperature sensors; a thermal insulation device is arranged between the adjacent two temperature zones of the oven; bilateral sides of the thermal insulation device are provided with heating plates being identical to the temperature zone. According to the baking system in the LED packaging, the thermal insulation device is arranged between every two adjacent temperature zones, the difference between the actual temperature and the set temperature of every temperature zone is small, and the temperature in every temperature zone is uniform.

Owner:WUXI WISEN INNOVATION TECH

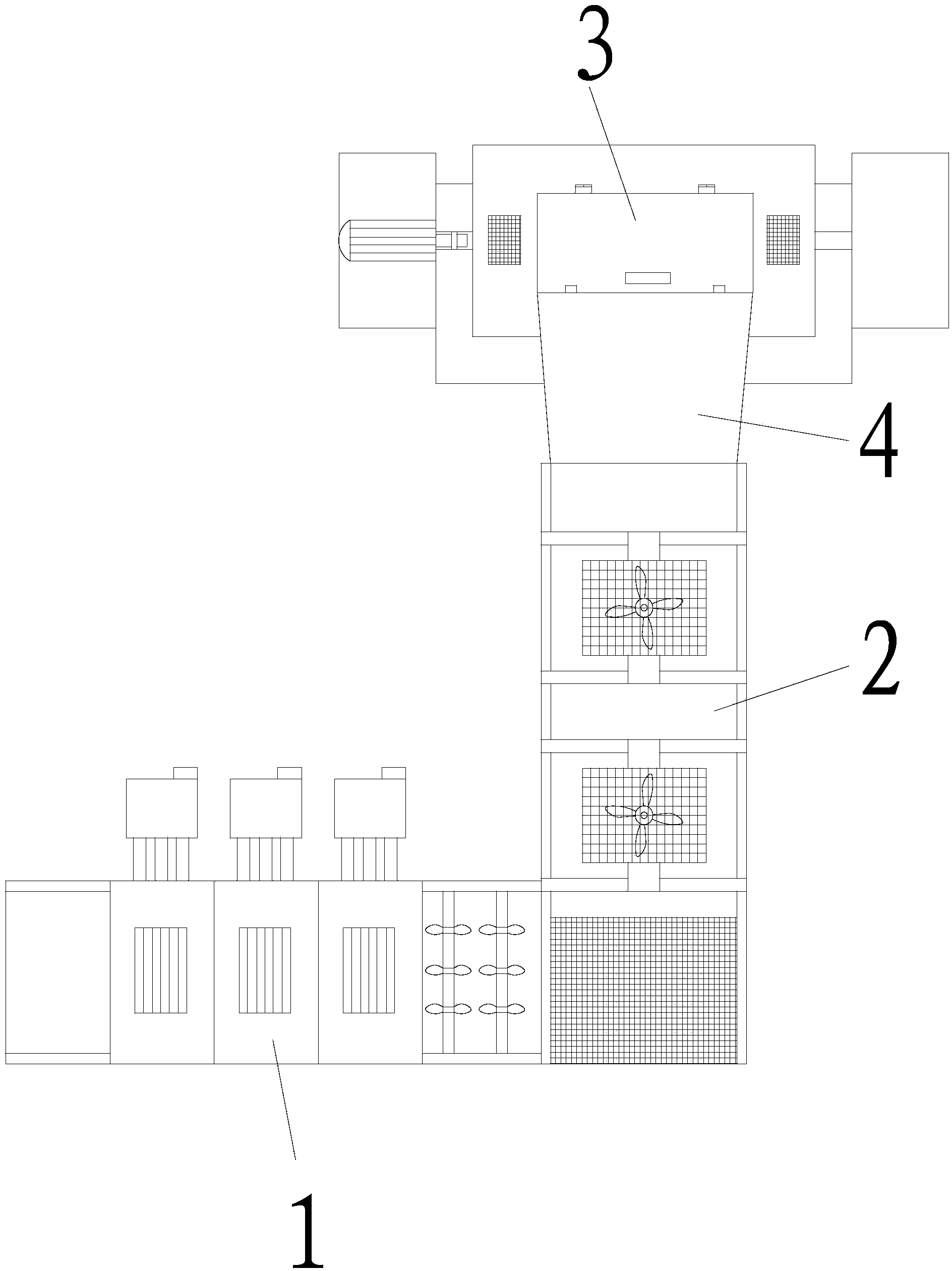

Tea fixation and fragrance-improving system

InactiveCN104068139AImprove tea aromaImprove cooling effectPre-extraction tea treatmentTea flavoringFlavorEngineering

The invention discloses a tea fixation and fragrance-improving system which comprises a temperature-varying fixation machine, a conveying device and a fragrance-improving machine, wherein the temperature-varying fixation machine is connected with one end of the conveying device, a discharging hopper is arranged at the other end of the conveying device, and the discharging hopper is located above the fragrance-improving machine. According to the tea fixation and fragrance-improving system, by adopting multiple fixation chambers, fixation is performed on tea at high temperature and low temperature in sequence, so that the tea fixation and fragrance-improving system can ensure that nutritional ingredients inside the tea leaves can not be damaged in the final fixation stage, and the fragrance of the tea is improved; the conveying device is capable of cooling the tea in a tea conveying process, meanwhile preventing impurities in an environment from falling in the tea, and screening the tea fragments, thereby improving the quality of the tea; the fragrance-improving machine is capable of enabling the tea to roll along with the rotation of a roller, so that the tea can be fully baked, the stale odor and the coarse oiliness of the tea can be well removed, the fragrance of the tea is improved, the green and astringency taste of the tea is reduced, and the flavor of the tea is improved.

Owner:ZHEJIANG ZHUJI SHILIPING TEA IND

Shell spray-coating production line equipment for computer production

ActiveCN111889287ARealize automatic feeding processAchieve sprayingPretreated surfacesCoatingsProduction lineProcess engineering

The invention discloses a shell spray-coating production line equipment for computer production. By arranging spray-coating stations and a feeding station, automatic feeding and spray-coating can be achieved, and comprehensive spray-coating can be achieved without turn-over during spray-coating. A baking lamp set is directly used for baking, and the production efficiency is guaranteed. A feeding robot is movably arranged on the feeding station in the length direction of the feeding station, and the feeding robot can transfer and feed computer production shells stored in a storage bin to clamping and positioning mechanisms corresponding to the spray-coating stations, and the length direction of the feeding station is parallel to the arrangement direction of all the spray-coating stations. Space utilization is effectively guaranteed, and the production efficiency is improved.

Owner:HUZHOU TEACHERS COLLEGE

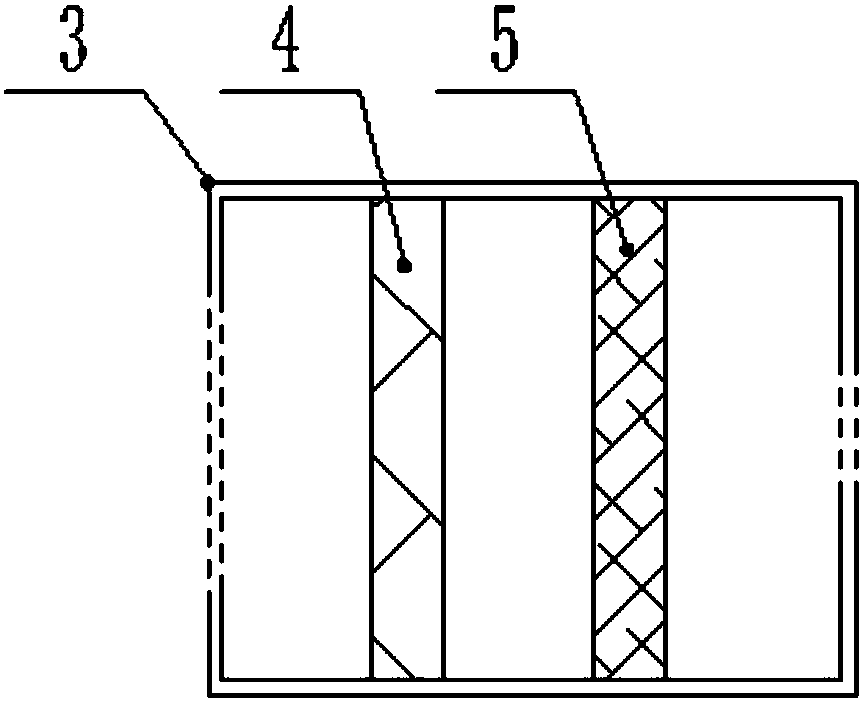

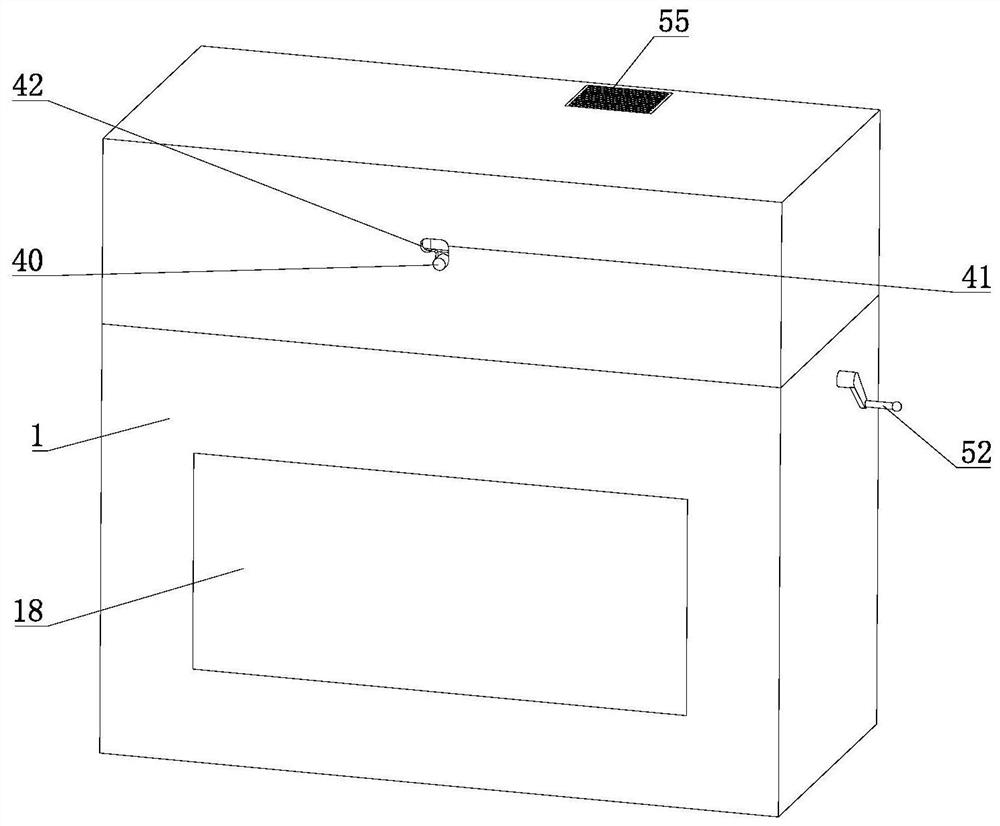

Jolting-type cigarette and tobacco baking device

The invention discloses a jolting-type cigarette and tobacco baking device. The jolting-type cigarette and tobacco baking device comprises a base, supporting pillars are fixedly connected to the leftside and the right side of the upper portion of the base, a baking box is fixedly connected to the upper ends of the supporting pillars, an exhaust cylinder is installed at the left side of the box body above the baking box, a baking box door is formed in the middle of the box body at the right side of the baking box, supports are fixedly connected to the upper portions of the left side and the right side of the base, heating boxes are fixedly connected to the upper ends of the supports, protection nets are arranged at the left sides inside the heating boxes, heating sheets are arranged at theright sides inside the heating boxes, an outer hood is connected to the left side of the heating box at the left side, a first motor support is fixedly connected to the box body at the left side inside the outer hood, a first motor is fixedly connected to the right end of the first motor support, a fan is installed at the right end of the first motor, pipes are connected to middle of the box bodyat the right side of the heating box at the left side, and the upper ends of the pipes are communicated with the left side of the box body below the baking box. By means of the jolting-type cigaretteand tobacco baking device, baking of cigarette and tobacco can be more comprehensive and thorough, the baking efficiency is high, both the time and labor are saved, and the pollution to the environment is reduced in the baking process.

Owner:张连军

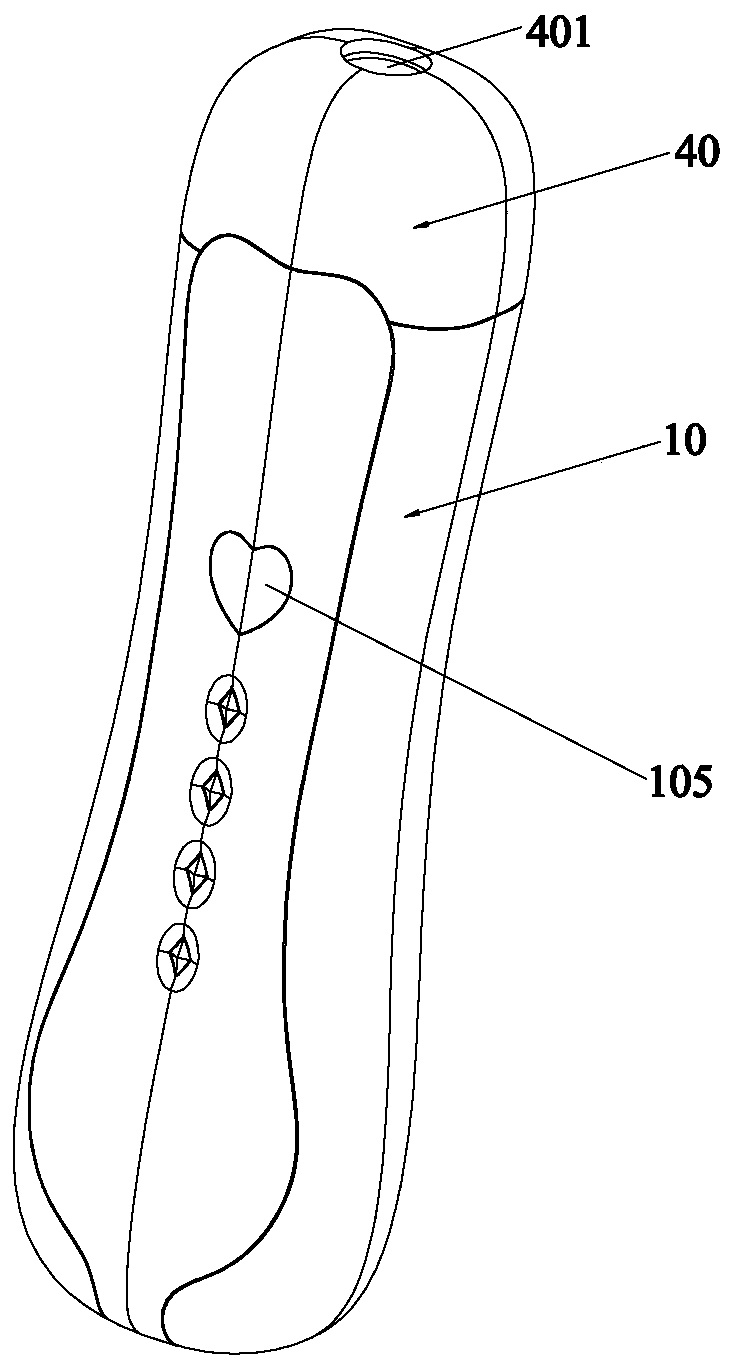

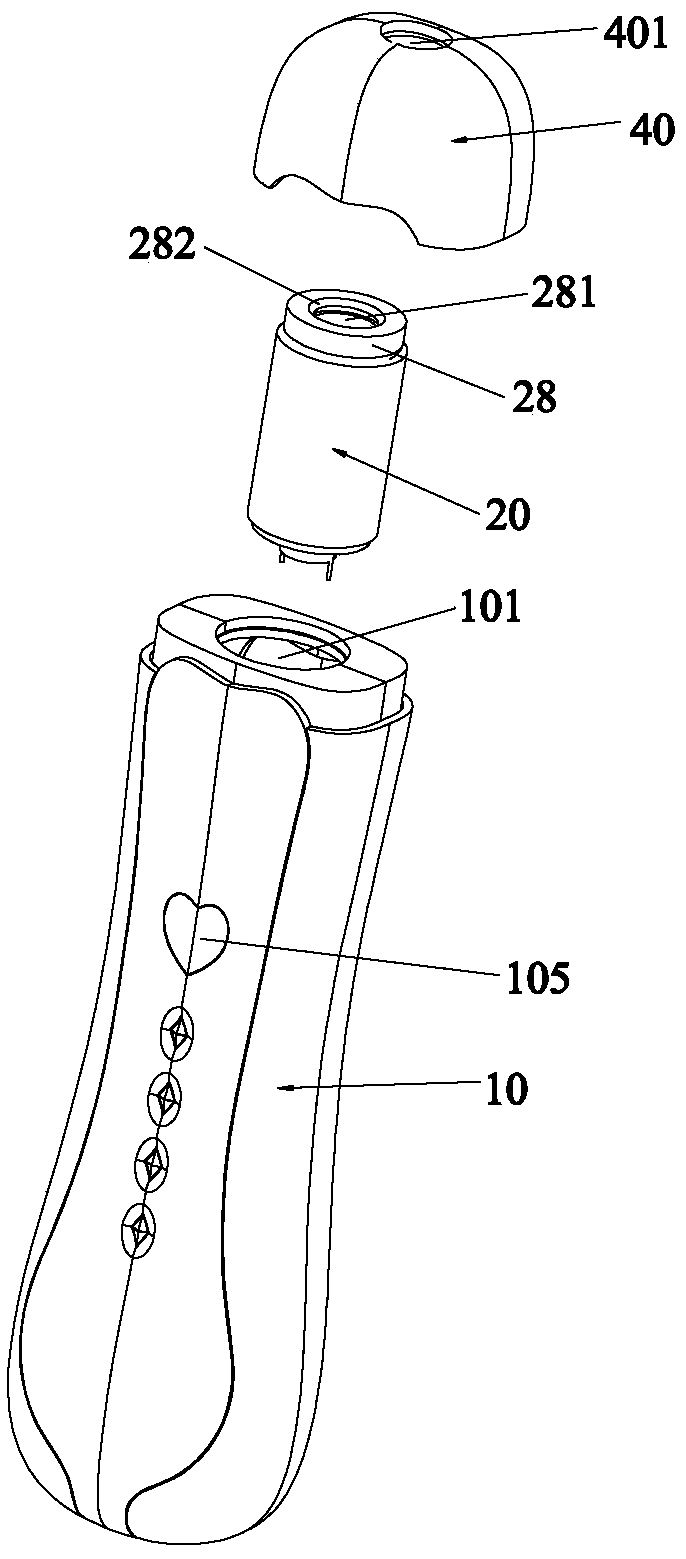

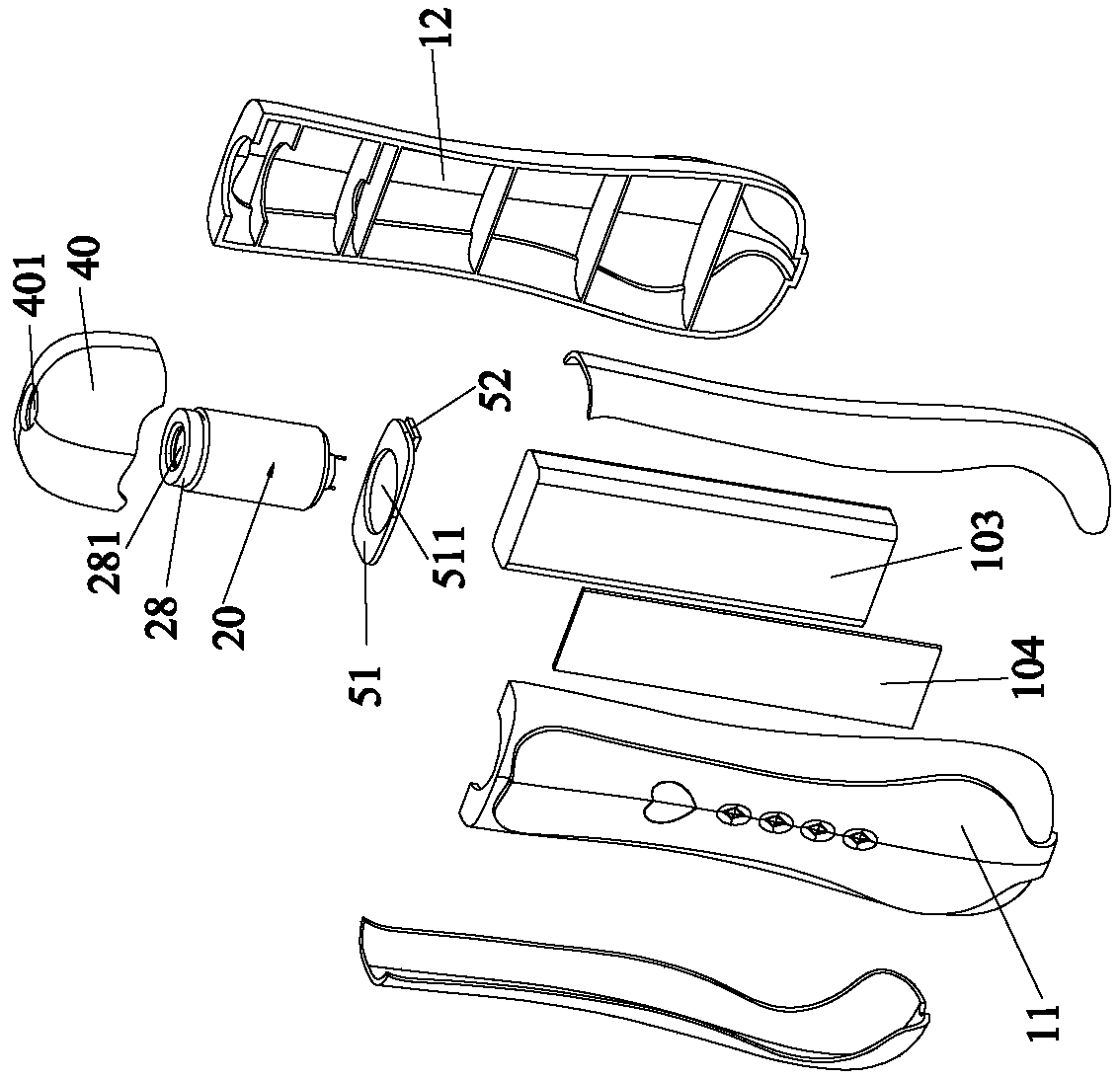

Air heating tobacco curing machine with improved heating performance

PendingCN109156862AIncrease the heating areaImprove heating efficiencyTobacco preparationEngineeringFlue

The invention relates to an air heating tobacco flue-cured machine with improved heating performance. The air heating tobacco curing machine comprises a housing and a heating and heat preservation device. The heating and heat preservation device is arranged in the mounting cavity of the housing. The heating and heat preservation device comprises a heat insulating cup, a smoke containing cup and aheating part. The smoke-containing cup is provided with a smoke-containing main cavity and a contact heat conduction part, and a heating part is arranged below the contact heat conduction part. Between that out side of the smoke cup and the inner side of the heat insulation cup, an air convection gap is maintained. A main chamber body side wall is provided with an air flow radiation heat through hole, that first air inlet of the shell is connected with an air convection gap, the air enters the main chamber body through the first air inlet, the heat element and the air convection gap, and the air flow radiation heating through hole. Therefore, the heat generate by the heating part is transmitted to the smoke body through the combination of the heat contact conduction at the bottom and the convection radiation of the hot side air. The heating area of the smoke body and the heating efficiency of the smoke body are improved, the heat is uniformly heated, the tobacco body is omni-directionally heated, the use taste of the user is improved, the tobacco shred is completely baked, and waste of the tobacco shred is avoided.

Owner:DONGGUAN TELAKANG TECH CO LTD

Intelligent fuel gas barbecue oven

InactiveCN105747897AFully bakedEasy BakingDomestic stoves or rangesLighting and heating apparatusElectricityControl system

The invention discloses an intelligent fuel gas barbecue oven. The intelligent fuel gas barbecue oven comprises a grill, an oven body and an oven lid, the oven body is arranged on the grill, the oven lid is hinged to the oven body, a smoke vent is arranged on the side wall of the oven body, a fuel gas oven head is arranged in the oven body, and an electromagnetic control gas inlet valve is arranged on the fuel gas oven head; a gas tank tray is arranged at the bottom of the grill and used for placing a gas tank; at least one temperature sensor is arranged in the oven body and used for detecting temperature of all portions in the oven body, and an automatic ignition device is arranged on the fuel gas oven head. The fuel gas barbecue oven further comprises a control system, and the temperature sensors, the automatic ignition device and the electromagnetic control gas inlet valve are electrically connected with the control system.

Owner:JIANGSU FEINIDI METAL PROD

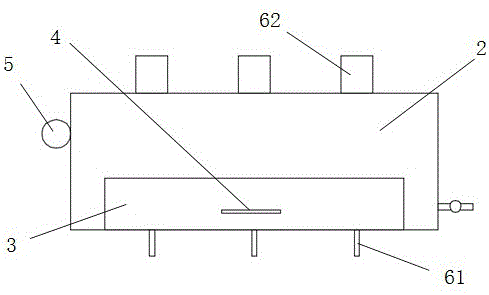

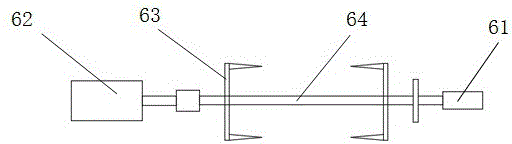

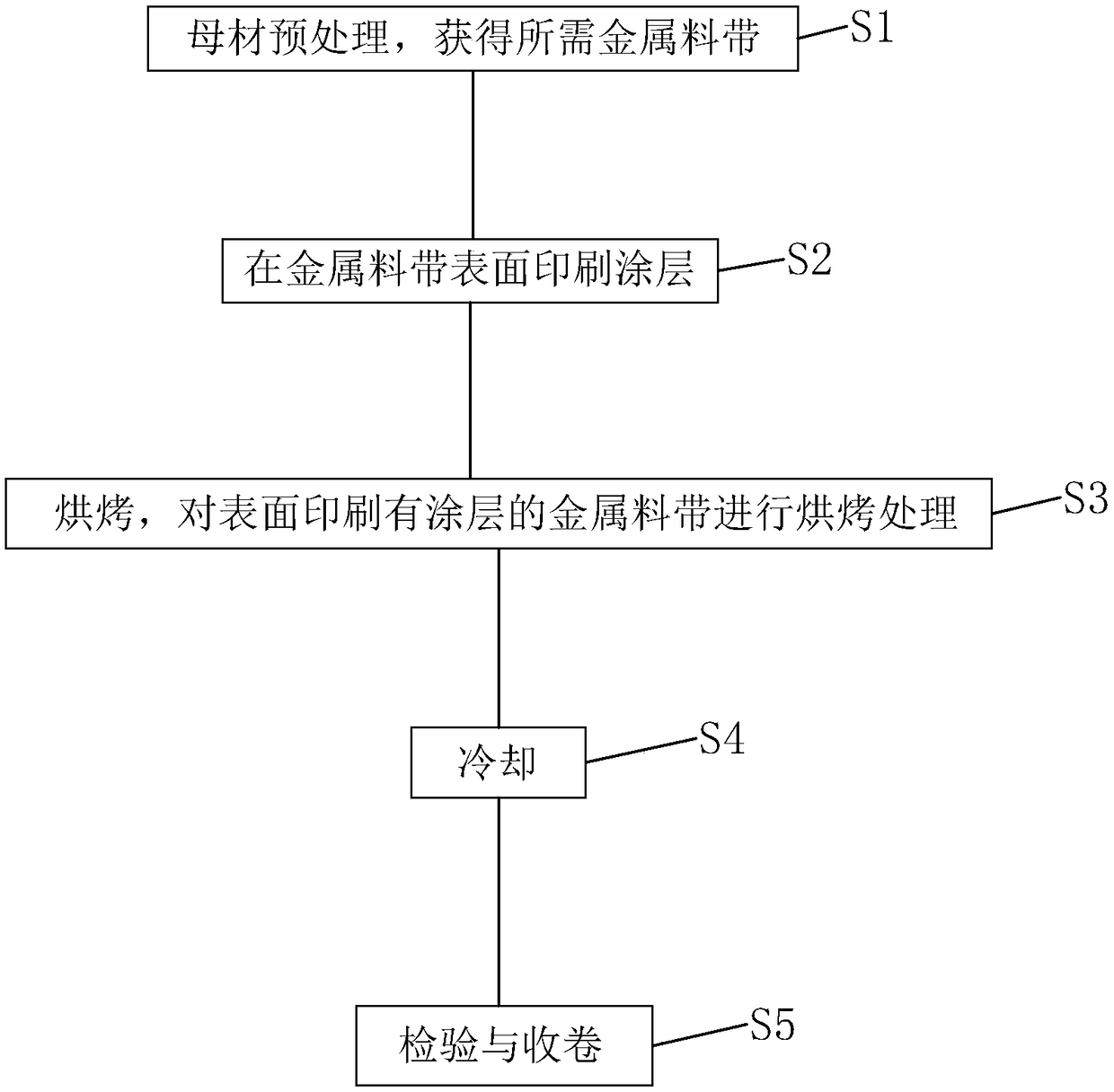

Production process of shielding cover for electronic products

ActiveCN109348697AGuaranteed curing effectReduce the likelihood of disengagementLocalised screeningTemperature differenceElectromagnetic shielding

The invention discloses a production process of a shielding cover for electronic products, and relates to the technical field of electromagnetic shielding. The production process comprises the steps of base metal preprocessing, coating printing, baking, cooling and the like; in the baking process, the baking temperature is 180-220 DEG C and the baking time length is 3-5 min; from the beginning tothe end, the baking process comprises four stages in sequence: a first intermediate temperature stage, a high temperature stage, a second intermediate temperature stage and a secondary high temperature stage; and a baking temperature difference between any two adjacent stages is at least 10 DEG C. The production process of the shielding cover for electronic products is not only capable of improving the using performance of the metal shielding cover and prolonging the service life of the metal shielding cover, but also beneficial for improving the production efficiency and the product outgoingquality.

Owner:上海亿尚金属有限公司 +1

Rotary tobacco baking device

The invention discloses a rotary tobacco baking device which comprises a base. The left side and right side of the upper portion of the base are fixedly connected with struts, and the upper ends of the struts are fixedly connected with a baking box. An exhaust barrel is mounted on the left side of the upper portion of a box body of the baking box, and a baking box door is mounted in the middle ofthe right side of the box body of the baking box. The upper portions of the left side and the right side of the base are fixedly connected with supports, and the upper ends of the supports are fixedlyconnected with heating boxes. Protection nets are arranged on the left sides in the heating boxes, and heating sheets are arranged on the right sides in the heating boxes. The left side of the heating box on the left side is connected with an outer cover, and the left side, in the outer cover, of a box body is fixedly connected with a first motor support. The right end of the first motor supportis fixedly connected with a first motor, and a fan is mounted at the right end of the first motor. The middle of the right side of the box body of the heating box on the left side is connected with apipeline, and the upper end of the pipeline is communicated with the left side of the lower portion of the box body of the baking box. The rotary tobacco baking device can bake tobacco completely andthoroughly, is high in baking efficiency and saves time and labor, and pollution to the environment in the baking process is reduced.

Owner:张连军

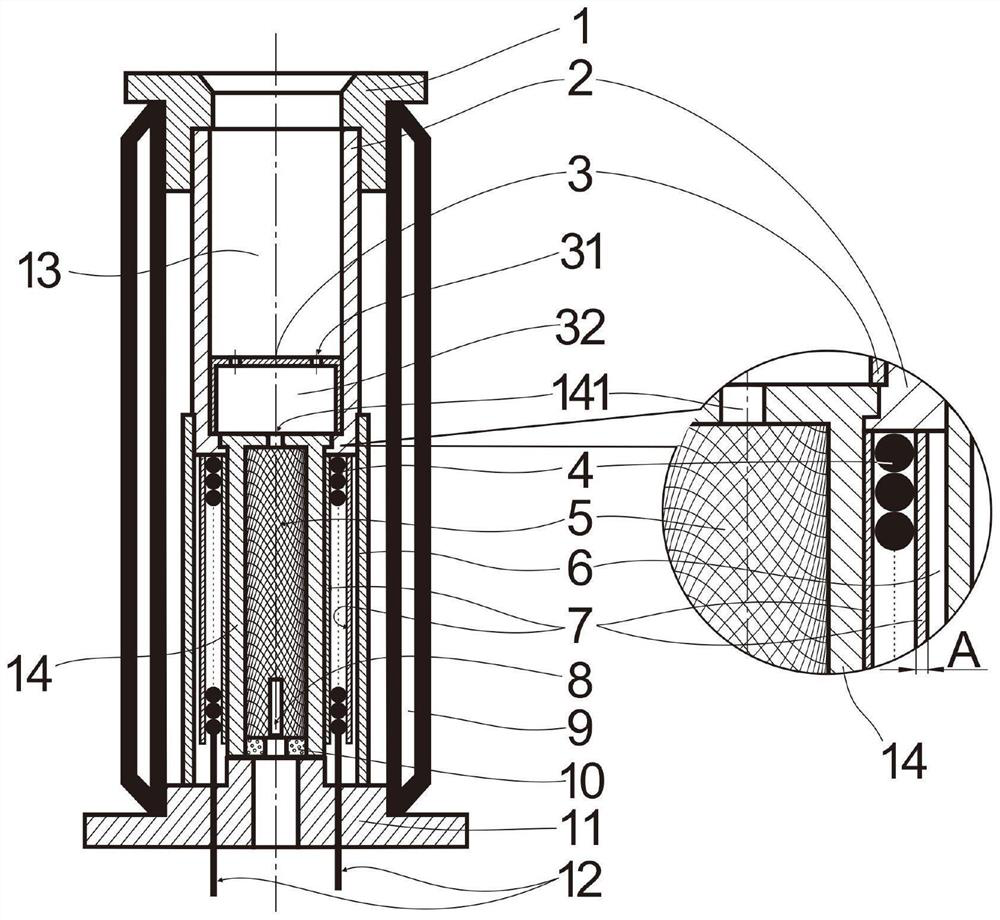

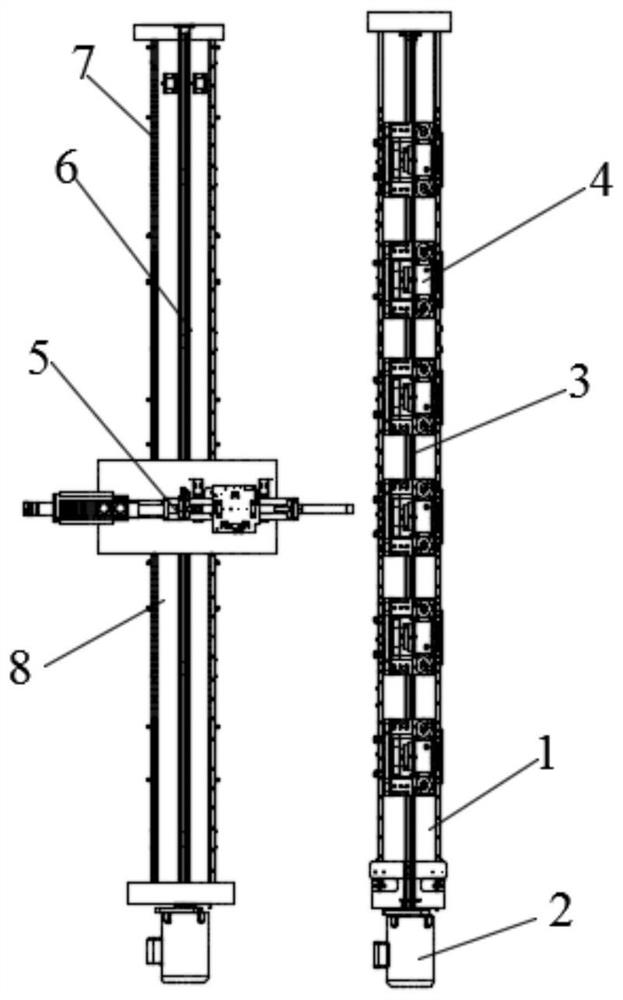

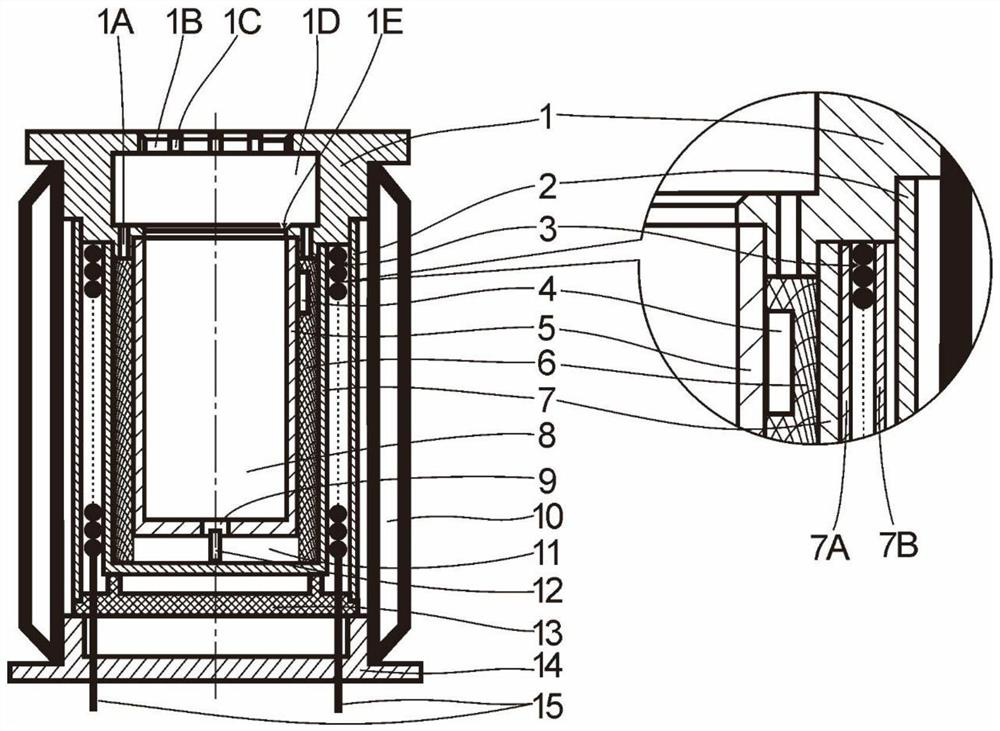

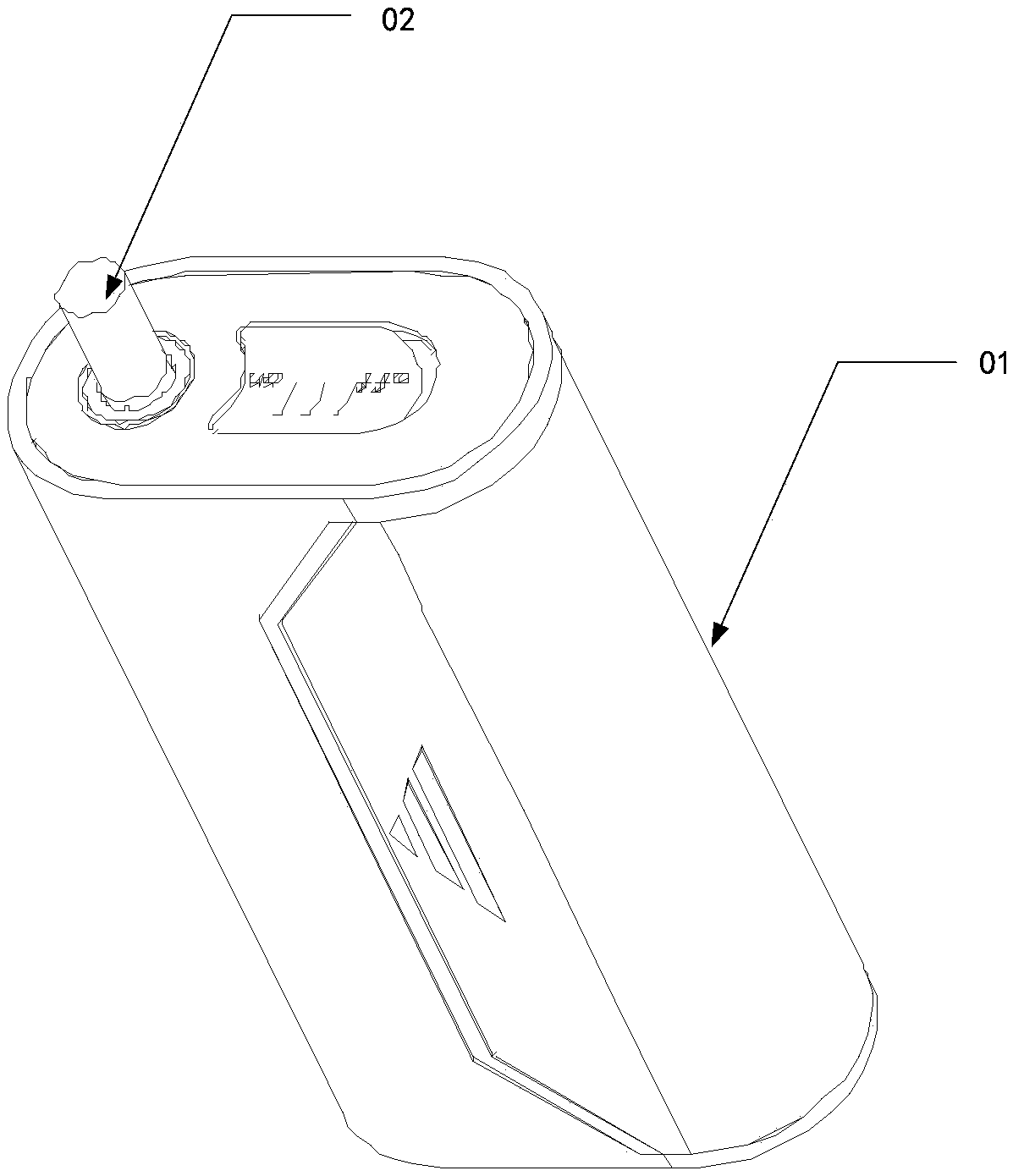

Smoke generating device for induction heating in folding air passage

The invention belongs to the field of novel cigarette smoking sets, and particularly relates to a smoke generating device for induction heating in a folding air passage. The smoke generating device comprises a cigarette leading-in pipe (1), an induction coil (3), a heating cup (5), a heating element (6) and a magnetic conductive sealing body (7). The cigarette leading-in pipe (1) is arranged at the upper end of the smoke generating device and is of a hollow pipe structure, an inner cavity is a gas mixing cavity (1D), the diameter of the gas mixing cavity (1D) is larger than that of the inner cavity of the heating cup (5), and a gap is formed between the inner wall of the cigarette leading-in pipe (1) and the upper end of the heating cup (5) and serves as a gas inlet channel (1A). Space folding with reduced space axial length is carried out on an original "heating body+cigarette", so that the axial length of the heating part of the smoking set is reduced. According to the invention, theheating element (6) is arranged in the air passage, and the air passage is folded back and forth, so that the length of the airflow passage is increased, and the axial length of the smoke generatingdevice is reduced.

Owner:CHINA TOBACCO YUNNAN IND

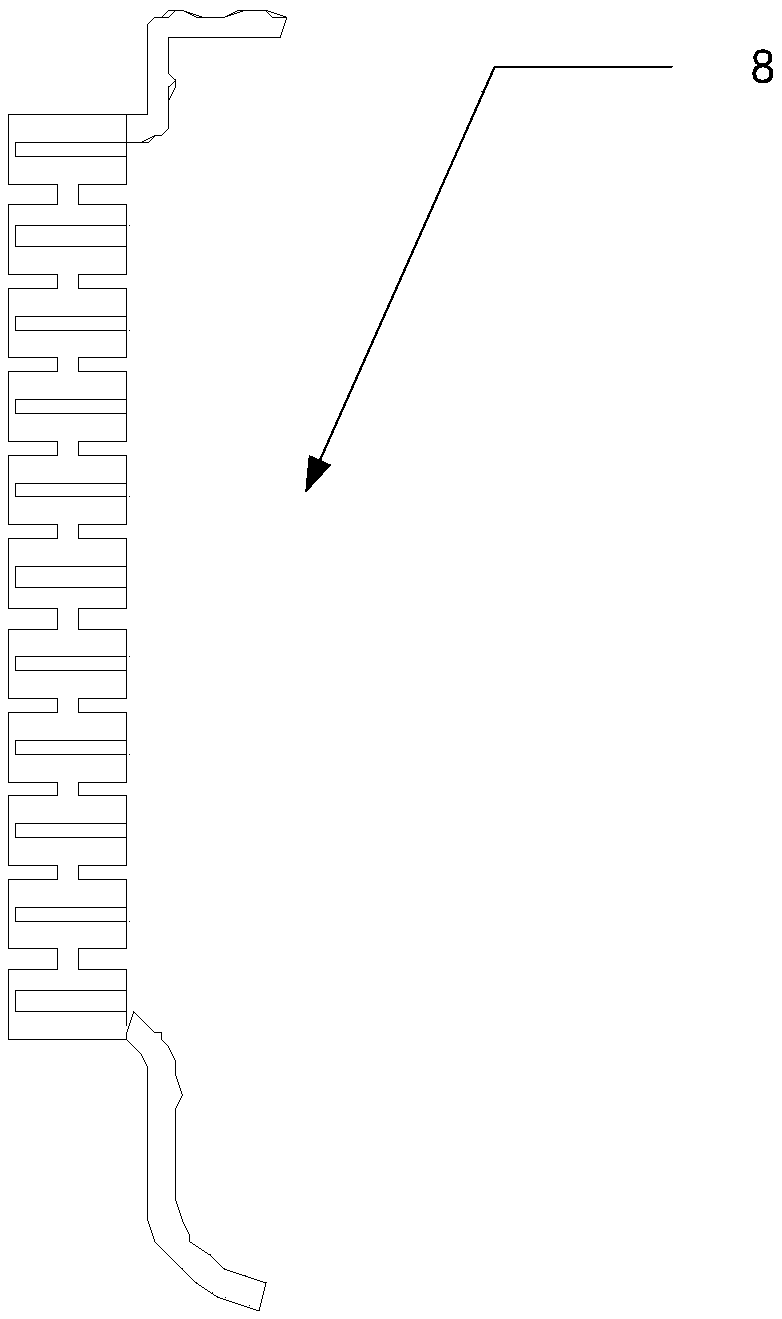

Electronic cigarette heating element comprising electronic heating film

The invention provides an electronic cigarette heating element comprising an electronic heating film, belonging to the field of electronic cigarettes. The electronic cigarette heating element comprises a heating cup manufacturing by adopting a non-conducting material and the electronic heating film wrapping the outer wall of the heating cup, wherein electrodes electrically connected with the electronic heating film are arranged at the parts, positioned at two end parts of the heating cup, of the electronic heating film, the electronic heating film is composed of chromium powder, rhenium powder, nickel powder, tungsten powder and rare earth powder at the weight percentage of 10-18 %, 15-25 %, 20-30 %, 20-30 % and 10-20 %, and the particle sizes of the chromium powder, rhenium powder, nickel powder, tungsten powder and rare earth powder are not greater than 80nm. Compared with the prior art, the electronic cigarette heating element comprising the electronic heating film has the advantages that tobacco shreds in the heating cup are rapidly and comprehensively heated by adopting the electronic heating film, so that the tobacco shreds are baked completely, and the harm to the human body is reduced.

Owner:晏华琅

Cigarette roaster box

The invention relates to a cigarette roaster box, comprising a box body. A heating device for heating a body of a cigarette is mounted in the box body and comprises a heating tube that is of hollowed-out structure; the heating tube that is of hollowed-out structure is provided with a holding cavity for holding the cigarette body; after the cigarette body is inserted into the heating tube, the inner wall of the heating tube contacts the cigarette body to heat the same. The cigarette body is directly heated through the contact between the heating tube of hollowed-out structure and the cigarettebody; compared with the prior art, the cigarette roaster box has higher heat utilization rate can provide full roasting and high smoke quantity.

Owner:SHENZHEN DORTEAM TECH LTD

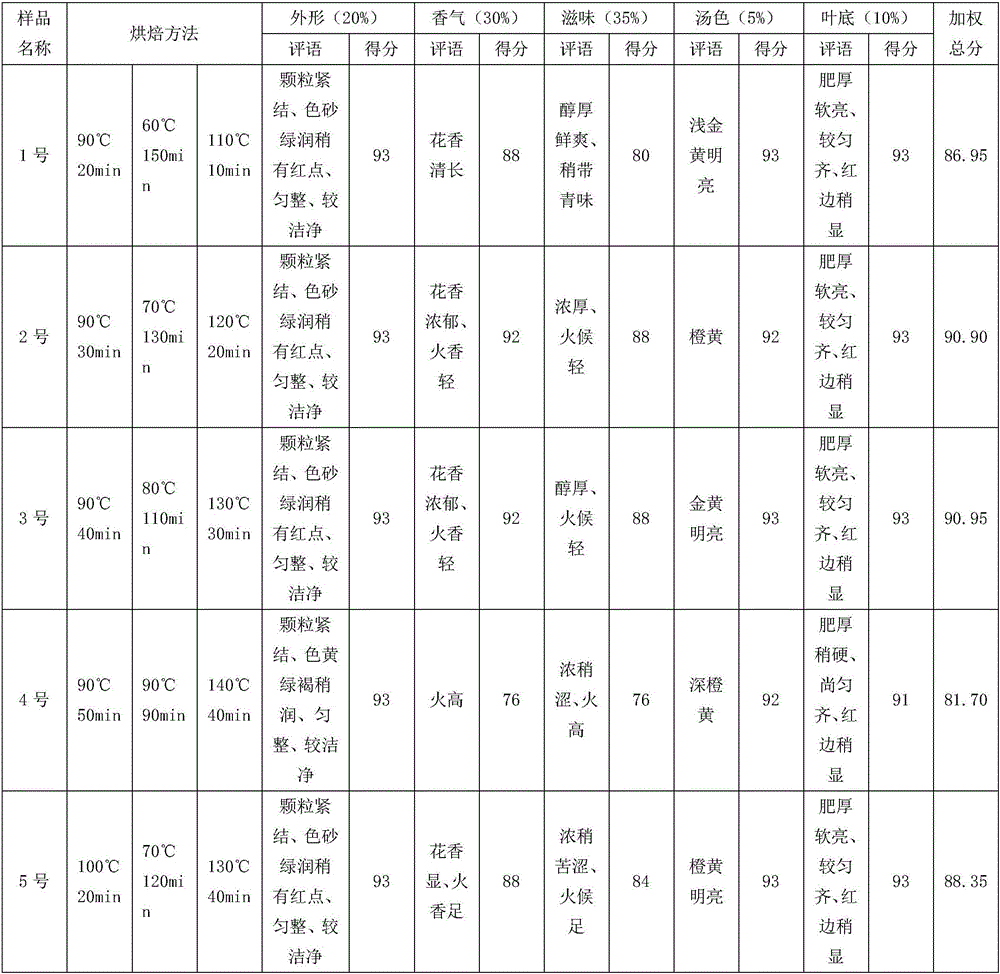

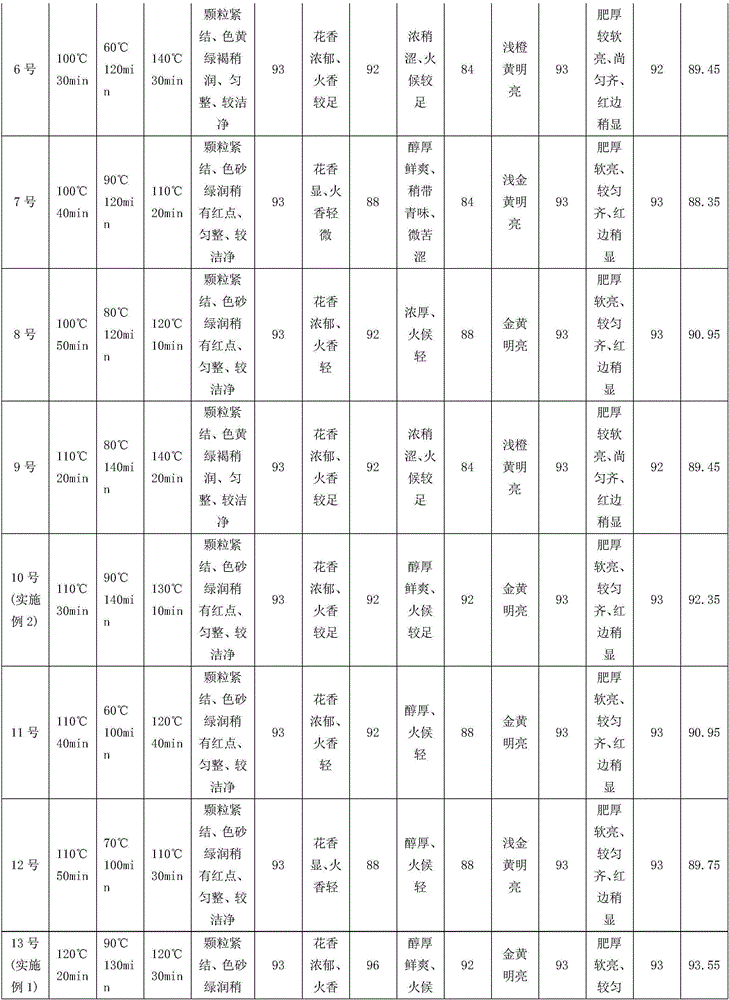

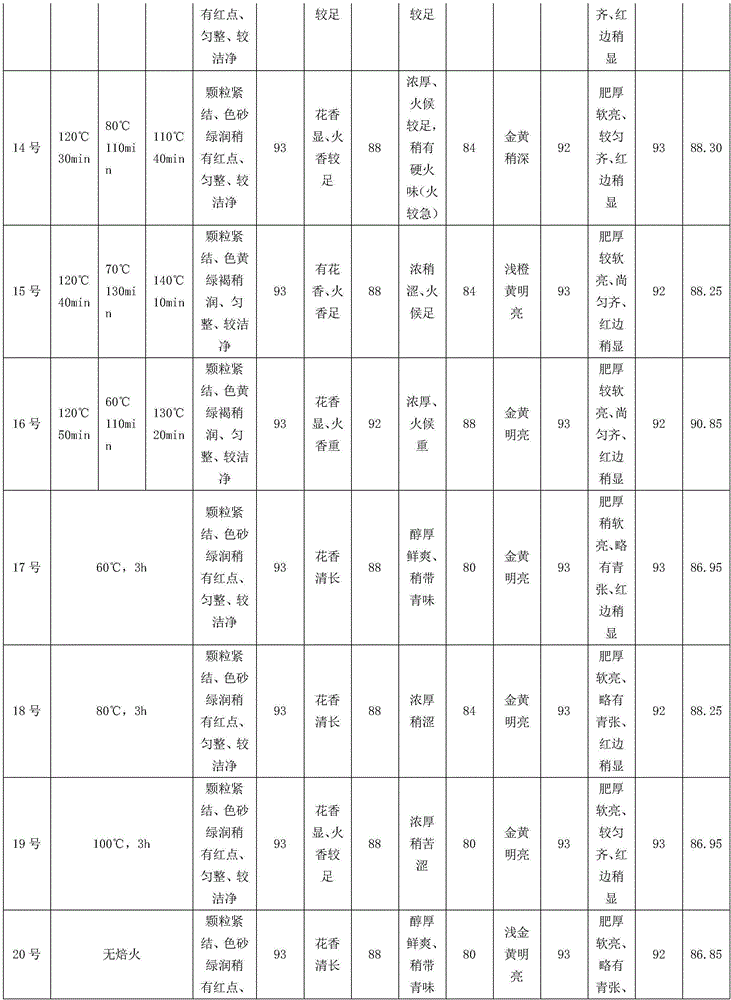

Temperature-changeable baking method of orange osmanthus oolong tea

The invention provides a temperature-changeable baking method of orange osmanthus oolong tea, and belongs to the technical field of tea leaf baking. The orange osmanthus oolong tea is granular orange osmanthus oolong tea which is obtained by removing stems and bracts after refining; the temperature-changeable baking method of the orange osmanthus oolong tea comprises the following steps: (1) removing impurities at high temperature, wherein the temperature is 110 DEG C to 120 DEG C and the lasting time is 20min to 30min; turning and stirring for one time during the process; (2) slowly baking at low temperature, wherein the temperature is 90 DEG C and the lasting time is 130min to 140min; turning and stirring for 1 to 2 times during the process; (3) improving the aroma at high temperature, wherein the temperature is 120 DEG C to 130 DEG C and the lasting time is 10min to 30min; turning and stirring for one time during the process. The method provided by the invention has the advantages that (1) the baked orange osmanthus oolong tea has relatively low water content, the aroma of tea leaves is improved, and the bitter and green tastes of the tea leaves are reduced; (2) baked tea grains are tight, have rich flower aroma, have mellow and fresh taste and have thick, soft and bright leaves after being brewed.

Owner:TEA RES INST OF FUJIAN ACADEMY OF AGRI SCI

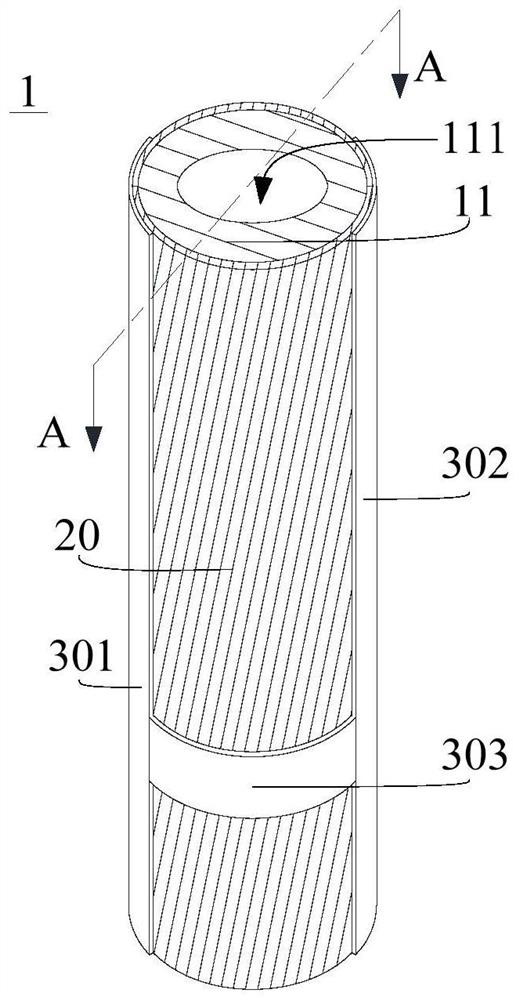

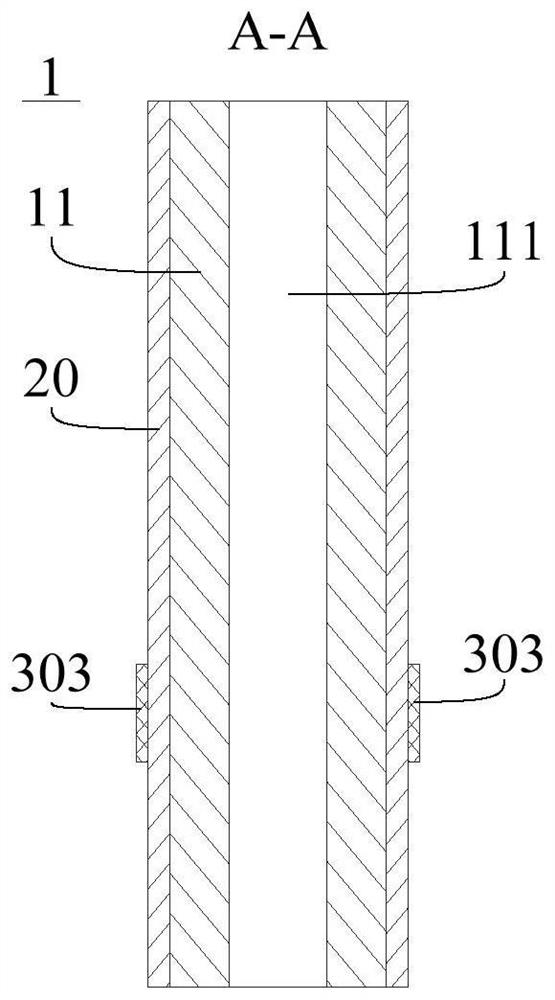

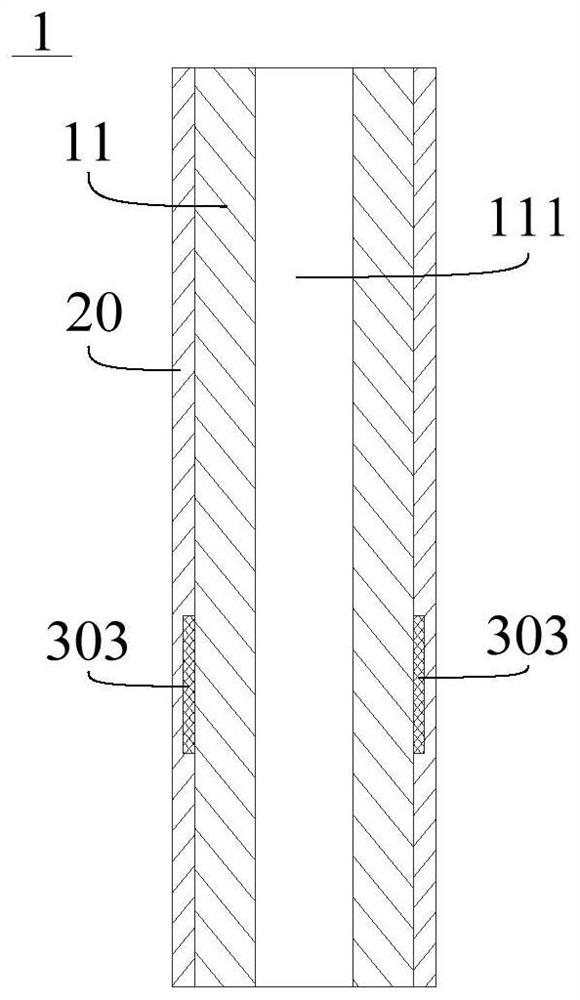

Heating assembly and aerosol generating device

PendingCN114788585AAvoiding the Burning ProblemImprove heating uniformityTobaccoInfraredMaterials science

The invention provides a heating assembly and an aerosol generating device. The heating assembly comprises a base body, an infrared heating layer, a first electrode, a second electrode and a first conductive module. Wherein the base body is used for inserting or accommodating an aerosol generating product; the infrared heating layer is arranged on the base body and is used for radiating infrared rays to heat the aerosol generating product when being electrified; the first electrode and the second electrode are arranged on the surface of the substrate at an interval, are respectively connected with the infrared heating layer, and are respectively used for being connected with a power supply assembly so as to supply power to the infrared heating layer; the first conductive module is arranged on the surface of the base body, the first conductive module is electrically connected with the first electrode and the second electrode, and at least part of the first conductive module makes contact with the infrared heating layer. The heating assembly is simple in structure, and the manufacturing process is effectively simplified.

Owner:SHENZHEN MERIT TECH CO LTD

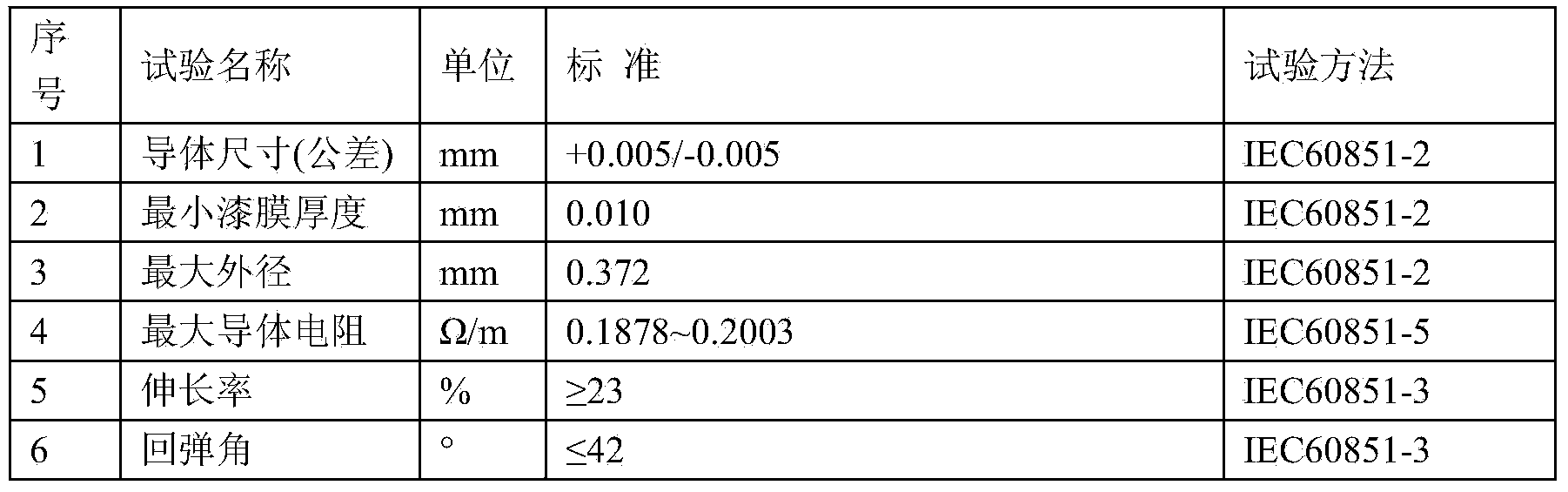

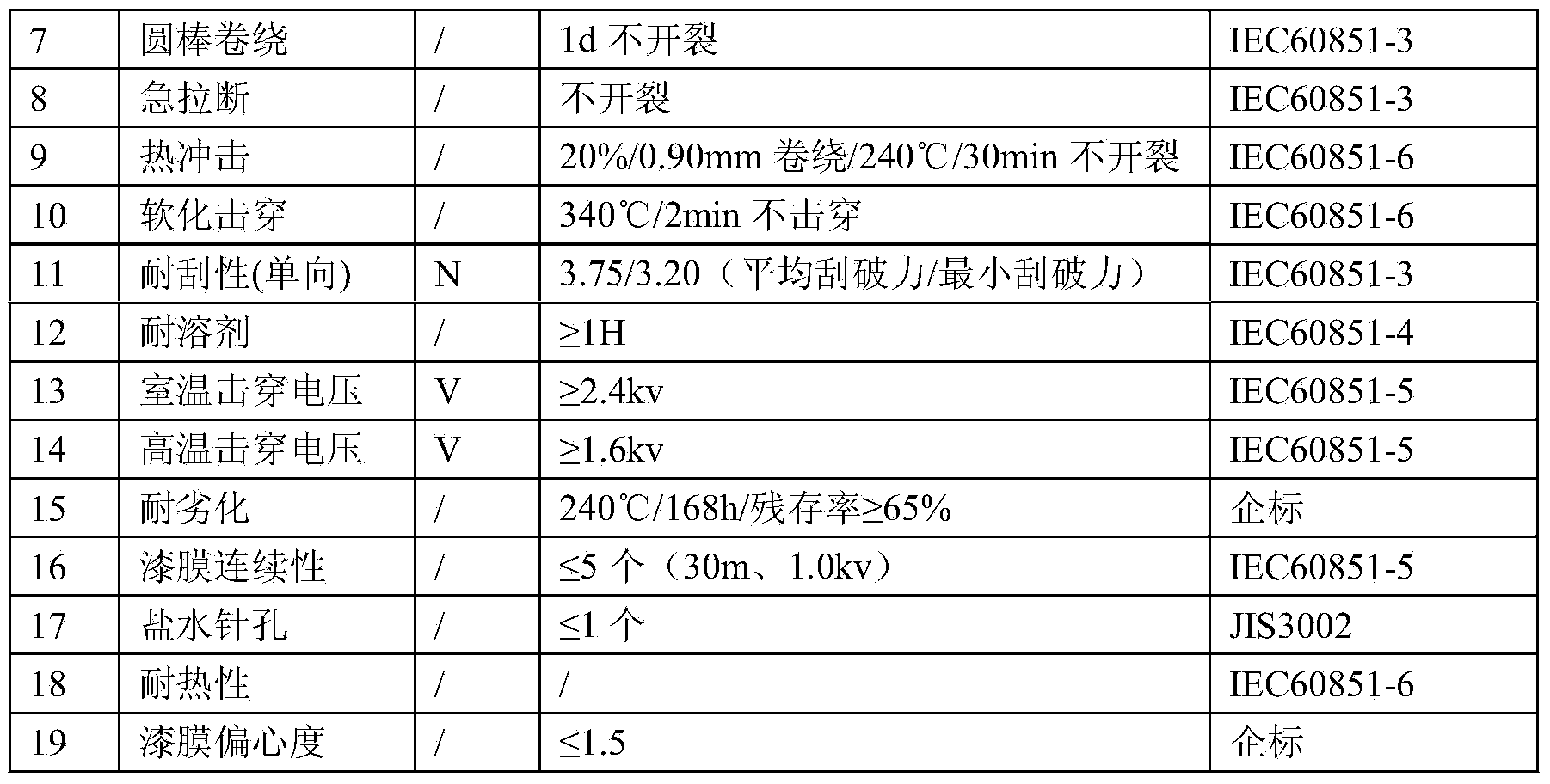

Production method of single-coating enamelled wire

ActiveCN102592752BOvercome weaknessStrong adhesionInsulating conductors/cablesCopper wirePolyamide-imide

The invention discloses a production method of a single-coating enamelled wire, which includes the following steps: 1 drawing: a copper bar is led to be drawn on drawing equipment to be a bare copper wire with the size required by a user; 2 annealing: the bare copper wire which has been drawn is annealed in an enamelling machine, the annealing comprises first-section annealing and second-section annealing, velocity is 260-270 m / min, curing temperature is 560-580 DEG C, the first-section annealing temperature is 480-500 DEG C, the second-section annealing temperature is 460-480 DEG C, circulation wind speed is 3,800-4,000rpm, and waste discharge wind speed is 1,800-2,000rpm; and 3 painting: 220-level polyamide-imide (PAI) wire enamel is adopted for painting, painting passes: 14-24, and the thickness of the insulated paint layer coated for each pass is 0.003-0.004MM. When the method is used, due to the fact that the method adopts the thin-paint multi-painting mode, each pass of paint is led to be even in thickness, baking is most sufficient, the defect of a single coating is overcome, and excellent paint film adhesion is achieved.

Owner:江苏中惠电工材料有限公司

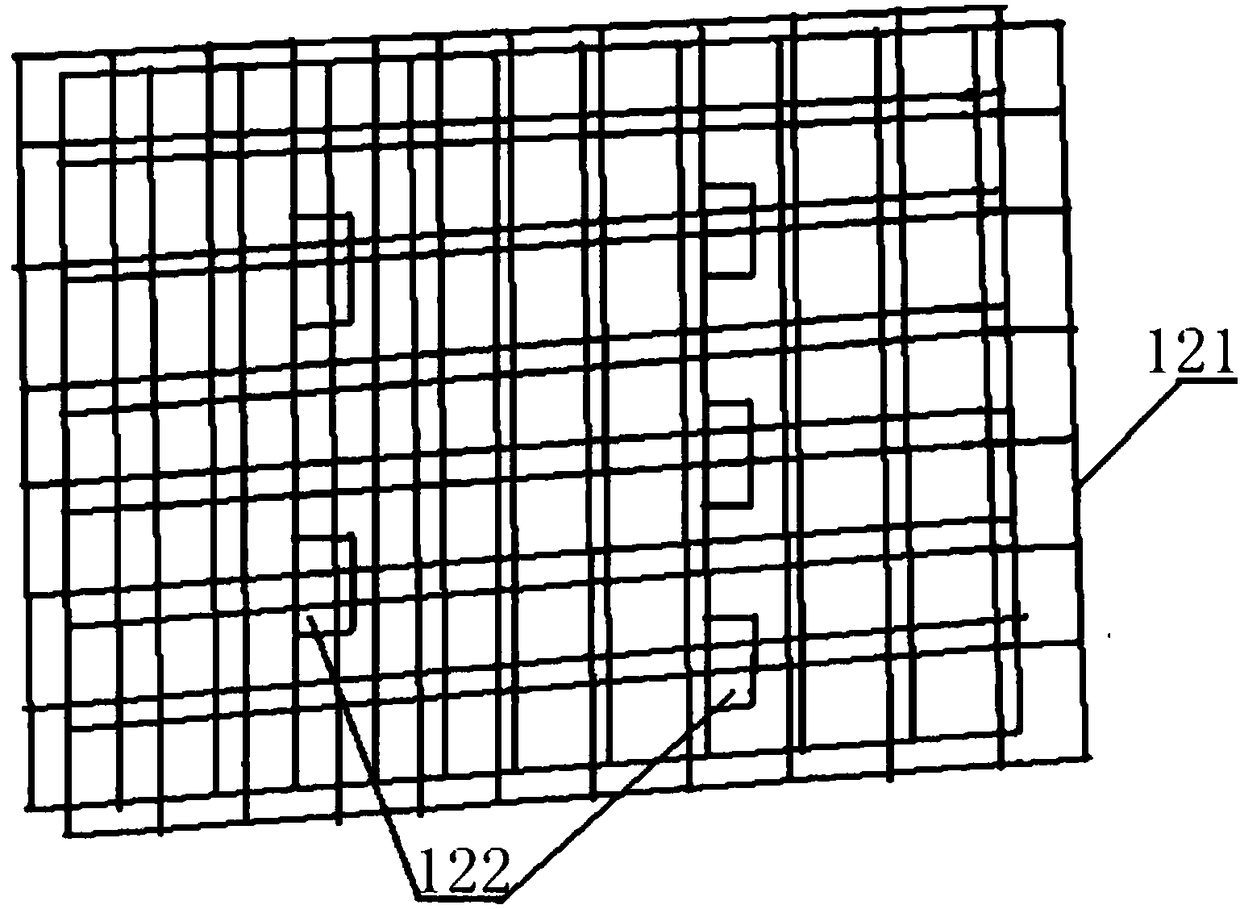

Automated lemon slice roasting equipment

The invention relates to automated lemon slice roasting equipment. The automated lemon slice roasting equipment comprises an alarm, a central processing unit, an information processor, a timing switch, a temperature adjusting controller, a display screen, a steam outlet, a temperature sensor, electric heating wires, a roasting tank door, a lemon placing rack, an electromagnetic switch and an ovenbody, wherein the lemon placing rack comprises single-layer stainless steel nets which are respectively formed by the staggered arrangement of four or more stainless steel wires; two or more bulges are arranged on each single-layer stainless steel net; two or more single-layer stainless steel nets are clamped and fixed together through the bulges; the lemon placing rack is clamped in the oven body; and the electric heating wires are embedded on the left side wall and the right side wall of the oven body. According to the automated lemon slice roasting equipment disclosed by the invention, an intelligent control system for members including the temperature sensor, the electromagnetic switch, the timing switch and the like is additionally arranged, so that the temperature and the roasting time of the roasting device can be intelligently controlled, and the lemon slices are sufficiently roasted; and the automated lemon slice roasting equipment is simple in structure and easy to popularize.

Owner:XIHUA UNIV

Rose cake baking device

InactiveCN108770892AEasy BakingFully bakedOven doors/gatesHollow article bakingEngineeringDrive motor

The invention discloses a rose cake baking device. The rose cake baking device comprises an operating board body, wherein support columns are fixedly connected with the bottom of the operating board body; an oven is fixedly connected with the upper surface of the operating board body; a heating box is fixedly connected with the inner side surface of the oven; a heating pipe is arranged in the heating box; a bearing is fixedly inlaid in the left side surface of the oven; an inner ring of the bearing is fixedly connected with a shaft lever; one end, close to the bearing, of the shaft lever penetrates through the baring and extends to the outside of the oven; one end, extending to the outside of the oven, of the shaft lever is fixedly connected with a drive motor; one end, away from the drivemotor, of the shaft lever is fixedly connected with an overturning box which is located in the oven, sliding chutes are formed in the symmetric outer side surfaces of the overturning box, a tray matched with the sliding chutes is clamped in the sliding chutes, and a plurality of fixed molds are fixedly connected with the inner bottom wall of the tray. The rose cake baking device has the advantages of being conveniently overturned by a user and high in baking speed and facilitating market promotion.

Owner:无锡市鹅湖玫瑰园艺文化有限公司

Uniform baking barbecue rack

Owner:昊鸿电气科技(湖北)有限公司

Automatic temperature control coffee bean baking machine

InactiveCN105686021AGuaranteed baking qualityEvenly bakedFood treatmentTemperature controlPower switching

The invention discloses an automatic temperature-controlled coffee bean roaster, which comprises a housing, an air inlet, a heating net, a detection probe, a control box, a power switch, a temperature signal transmission module and a baking box; fan, and a heating net is installed on the upper side of the intake fan, a motor is installed in the housing, a temperature sensor is installed in the heating net, a feed inlet is provided on the upper side of the baking box, and a feeding port is installed on the lower side of the baking box. A discharge port is installed, a compound gas shuttle plate is installed in the baking box, and a temperature detector is installed on the upper side of the compound gas shuttle plate, a motor is installed in the housing, and a heat exchange hole is installed on the upper side of the baking box , a control display screen is installed on the surface of the control box, and a power switch is installed on the lower side of the control display screen. In the present invention, a detection probe is installed in the roasting box, which can transmit more than 250 times in 1 second, so as to identify the temperature and heat and ensure the uniform roasting of coffee beans.

Owner:SHENZHEN DELONG ELECTRICAL APPLIANCE CO LTD

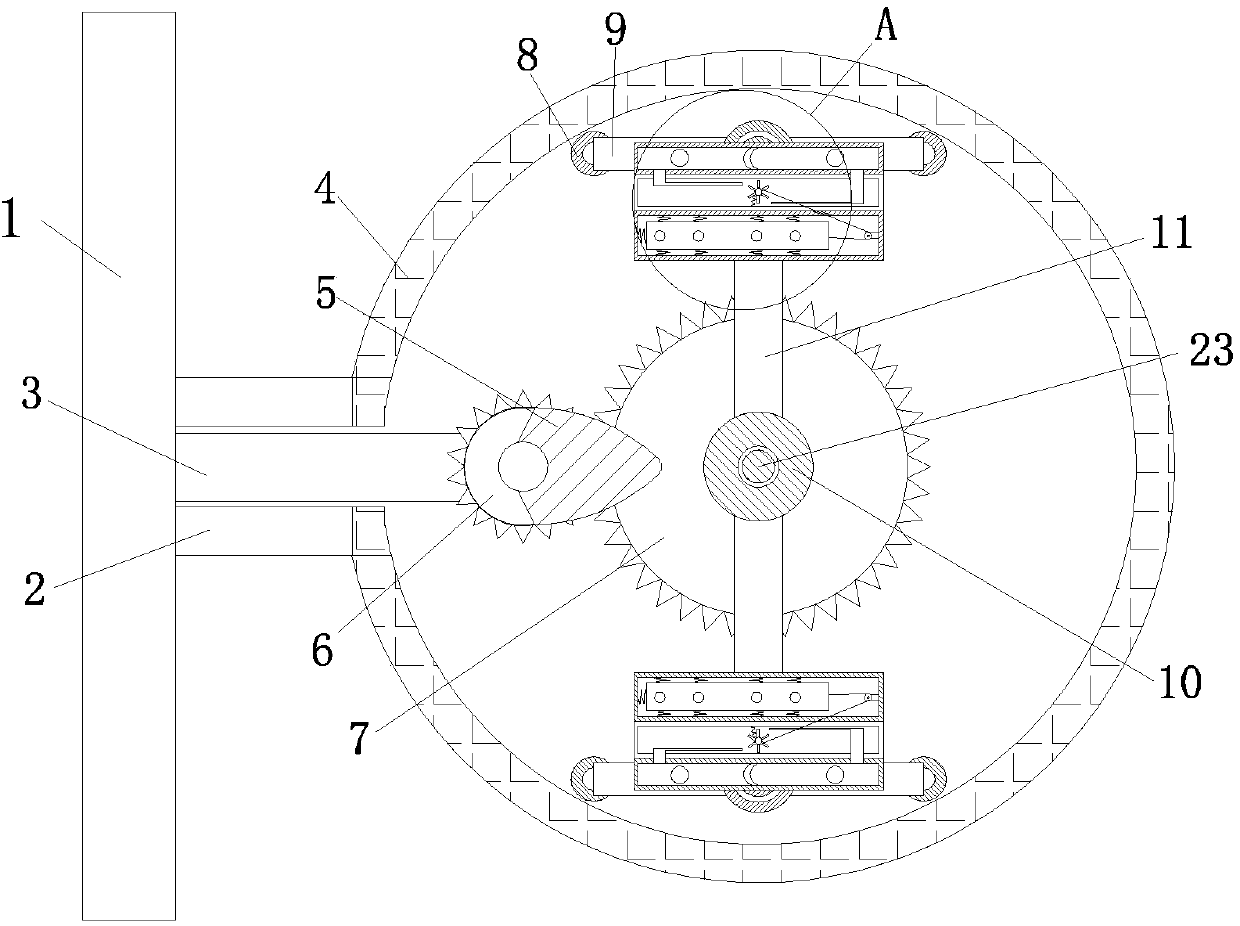

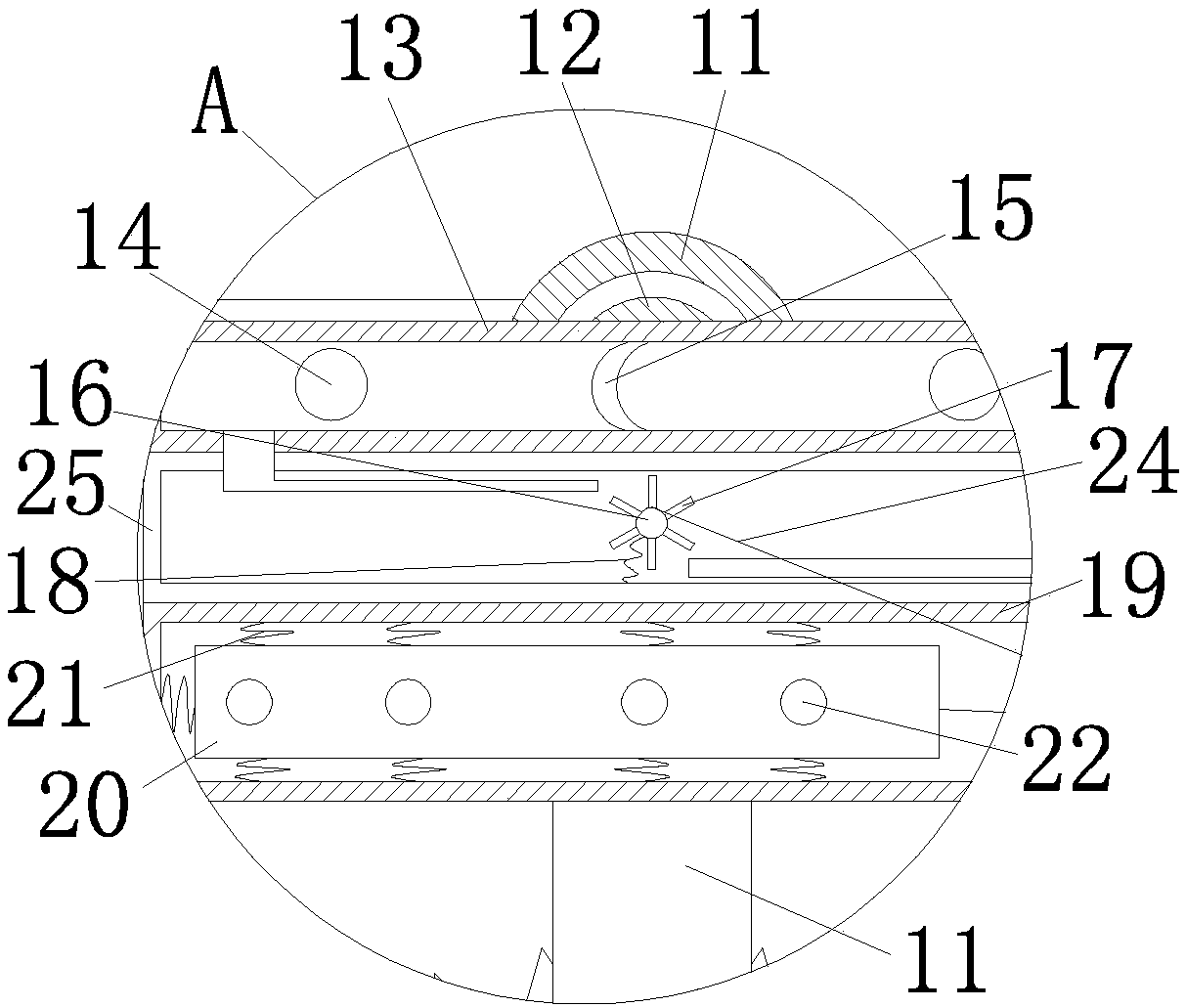

Baking device for food processing

ActiveCN112790200AFully bakedImprove roast qualityOven air-treatment devicesGear wheelElectric machinery

The invention discloses a baking device for food processing, which comprises a box body, a power cavity and a baking cavity are arranged in the box body from top to bottom, a motor is arranged in the power cavity, a fan and a baking pipe are arranged in the baking cavity, the fan is in power connection with the motor, a screw cavity is arranged between the baking cavity and the power cavity, and a screw is rotatably connected in the screw cavity. A screw sleeve is connected to the screw, a left screw gear and a right screw gear are fixed to the left end and the right end of the screw respectively, the fan is connected to the screw sleeve, a left transmission shaft and a right transmission shaft are arranged in the left transmission cavity and the right transmission cavity respectively, and a left incomplete gear and a right incomplete gear are in transmission connection to the left transmission shaft and the right transmission shaft respectively. When the left incomplete gear is meshed with the screw left gear, the right incomplete gear is not meshed with the screw right gear, when the left incomplete gear is not meshed with the screw left gear, the right incomplete gear is meshed with the screw right gear, the screw is alternately driven to rotate forwards and backwards, and the fan can move left and right on the screw in a reciprocating mode along with the screw sleeve. All parts of food can be fully baked, and the baking quality of the food is improved.

Owner:海南佳宁娜食品有限公司

Varnish stoving device for new energy automobile spare part machining and varnish stoving method of varnish stoving device

InactiveCN113634462AImprove adhesionAvoid polluting the air and working environmentPretreated surfacesCoatingsSpare partNew energy

The invention discloses a varnish stoving device for new energy automobile spare part machining and a varnish stoving method of the varnish stoving device. The varnish stoving device comprises a varnish stoving device body; the front side, the rear side and the middle of the interior of the varnish stoving device body are provided with a cooling bin, a dehumidification bin and a varnish stoving bin respectively; varnish stoving lamps are arranged on the left side and the right side of the inner wall of the varnish stoving bin correspondingly; and the outer surface of the varnish stoving device body is fixedly connected with a waste heat utilization mechanism. Primary dehumidification and drying can be carried out in advance through waste heat flowing out of the interior of the varnish stoving bin, the adhesion of varnish surfaces is improved, the situation that the varnish surfaces of spare parts sag, reworking is carried out, and the production qualification rate of the spare parts is affected is avoided, water vapor generated in the varnish stoving bin flows out along with air flow, redundant water vapor is condensed out for centralized collection, air and working environment pollution is avoided, the internal humidity of the varnish stoving bin can be greatly reduced, and the spare parts are comprehensively baked, so that the varnish surface stoving efficiency is improved, and the productivity of the spare parts is prevented from being influenced.

Owner:重庆铂陵机械有限公司

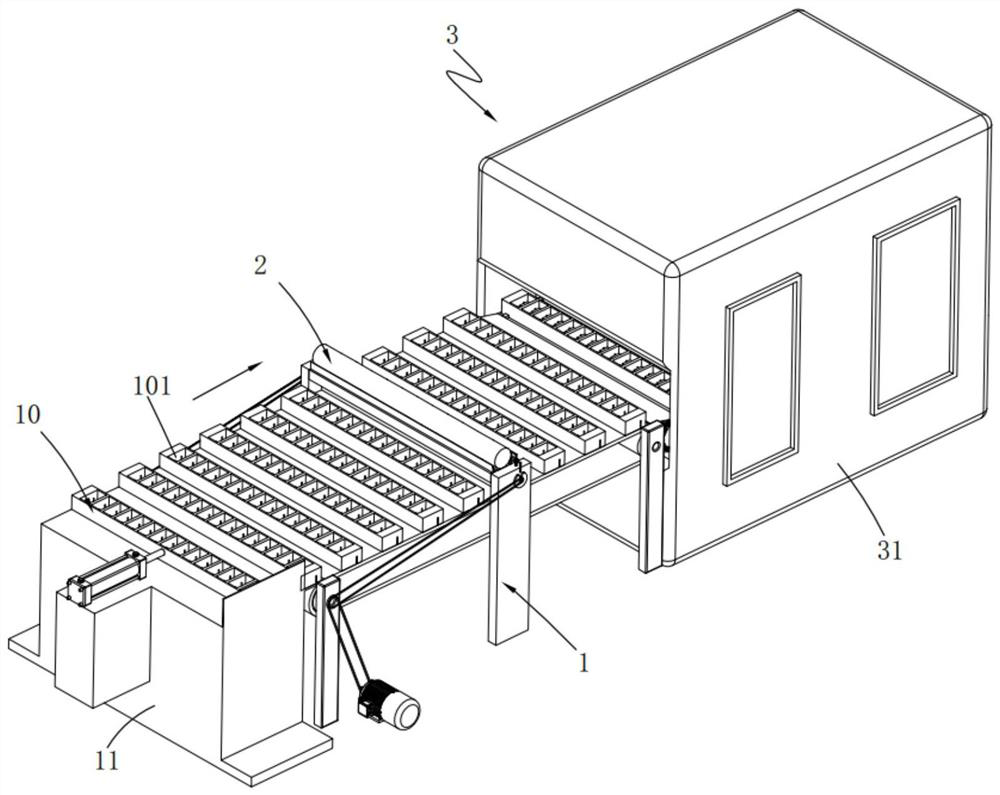

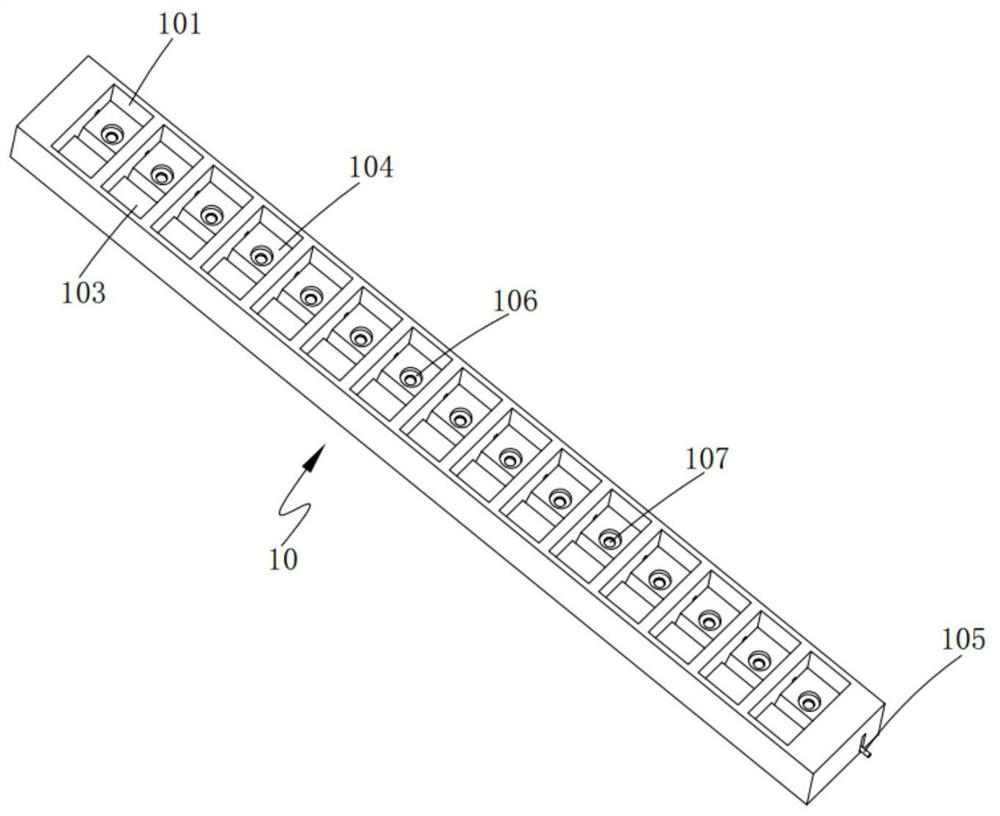

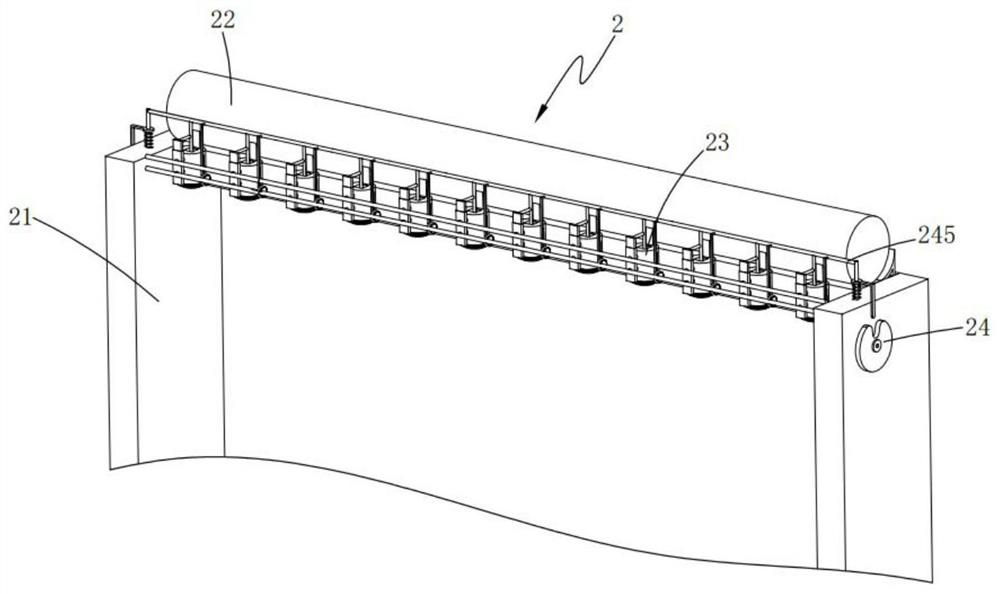

Bread production line

ActiveCN112514932AReduce wasteReduce adhesionBaking surface cleaning/greasingPulp (paper)Manufacturing line

The invention relates to the technical field of food processing equipment, in particular to a bread production line which comprises a conveying mechanism, an operation platform is arranged at the input end of the conveying mechanism, the conveying mechanism conveys bearing parts, and the bearing parts are provided with bearing intervals in an array mode in the length direction of the bearing parts. A material scattering mechanism comprises a base, a material storage barrel, an oiling assembly and a linkage assembly; the conveying mechanism drives the oiling assembly through the linkage assembly to apply slurry to the bearing interval; the baking mechanism is arranged at the output end of the conveying mechanism in the conveying direction of the conveying mechanism. The baking mechanism comprises a drying oven, a conveying assembly, a pressing assembly and a jacking assembly. Bread is conveyed at intervals through the conveying mechanism, auxiliary materials are blown to the surface ofpulp while the pulp falls down through cooperation of the oiling assembly and the linkage assembly, during bread baking, the bread is discontinuously jacked up through cooperation of the pressing assembly and the jacking assembly, complete baking of the bottom of the bread is achieved, and the adhesion between the bread and the bread paper is reduced.

Owner:云南连宸食品有限公司

A baking device for the production of flame-retardant braided sleeves for cables

ActiveCN112151224BImprove cooling effectImprove detection efficiencyMaterial thermal analysisCable/conductor manufactureEngineeringElectric cables

The invention discloses a baking device for producing flame-retardant braided sleeves for cables, which includes a first winding roller, a second winding roller, a transmission mechanism, a baking component, and a cleaning component. The baking component includes a baking chamber, Upper infrared heating plate, lower infrared heating plate, through slot. The beneficial effect achieved by the present invention is that the flame-retardant braided sleeve for the cable passes between the two infrared heating plates through the winding of the flame-retardant braided sleeve by the second winding roller, and is passed by the upper infrared heating plate. and the lower heating plate to simultaneously bake the upper and lower sides of the flame-retardant braided casing for cables, which improves the detection efficiency and detection accuracy. Since the transmission mechanism is set to drive the second winding roller to rotate intermittently, the flame-retardant braided cables for cables The casing moves intermittently, so that the flame-retardant braided casing can stop moving for a short time, so that the upper infrared heating plate and the lower infrared heating plate can fully bake the flame-retardant braided casing for cables, and the baking accuracy is improved.

Owner:衡阳凌云特种材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com