A baking device for the production of flame-retardant braided sleeves for cables

A baking device and cable technology, which is applied in the direction of measuring devices, cable/conductor manufacturing, circuits, etc., can solve the problems of high work intensity and low work efficiency, and achieve the effects of improving baking accuracy, preventing burns, and improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

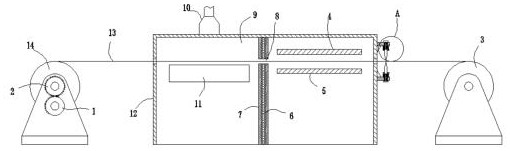

[0021] like Figure 1-2 As shown, a baking device for producing flame-retardant braided sleeves for cables, comprising:

[0022] There are two winding rollers, which are respectively defined as the first winding roller 3 and the second winding roller 14, wherein the first winding roller 3 is used for winding the flame retardant braid for cables Sleeve 13, the second winding roller 14 is driven by the transmission mechanism to rotate intermittently, so that the flame-retardant braided sleeve 13 for cables is wound on the second winding roller 14;

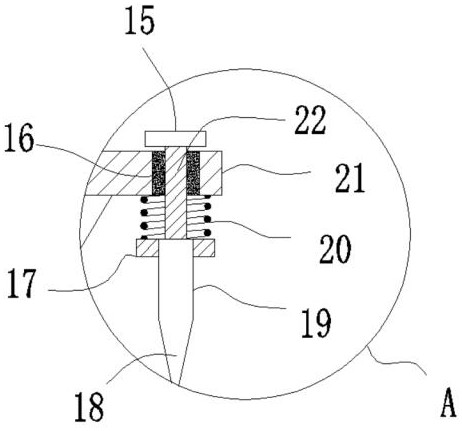

[0023] A baking assembly, the baking assembly includes a baking chamber 12 disposed between the first winding roller 3 and the second winding roller 14 , and the baking chamber 12 is adjacent to the first winding roller 3 on one side up and down Two infrared heating plates are installed opposite to each other, and the two infrared heating plates are respectively defined as the upper infrared heating plate 4 and the lower infrared he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com